Casella CEL Microtherm WBGT heat stress monitor User Manual

WinHSM Application Software - User Manual

MICROTHERM

Heat Stress WBGT

And WinHSM

Application Software

User Manual

HB3279-01

March 2001MICROTHERM Heat Stress WBGT &

COPYRIGHT

The copyright in this document which contains proprietary information is vested in

CASELLA CEL LIMITED. The contents of this document must not be used for purposes

other than that for which it has been supplied or reproduced or disclosed wholly or in

part without the prior written permission of

CASELLA CEL LIMITED

CASELLA CEL LIMITED

Regent House

Wolseley Road

Kempston

Bedford

MK42 7JY

United Kingdom

Telephone: +44 (0) 1234 844 100

Fax: +44 (0) 1234 841 490

E-mail info@casella.co.uk

Web: www.casella.co.uk

.

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Page 2 of 44

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Warnings

WARNINGS !

Any attempt to charge non-rechargeable cells is

hazardous and can result in damage.

This instrument incorporates an internal fast-charger

circuit suitable for recharging nickel-cadmium cells. The

charger is enabled/disabled via a switch in the battery

compartment. (See Figure 9 in Section 2.1.1.)

This instrument is delivered with re-chargeable nickelcadmium cells and with the CHARGER circuit ENABLED.

DISABLE the charger circuit before fitting and using

non-rechargeable cells.

DISPOSAL OF NiCd BATTERIES

Rechargeable batteries contain CADMIUM

and must be disposed of in a safe manner. In

some countries, this may involve specialist

licensed waste disposal companies.

Used batteries MUST NEVER be disposed of

by placing in a fire or incinerator, nor must

they be punctured, crushed or otherwise

mutilated or opened up in anyway.

MICROTHERM instruments contain no user serviceable

components. If an electrical fault is suspected the

instrument must be returned to Casella CEL Ltd for repair.

The instrument and sensors contain delicate components.

They should not be dropped or subjected to mechanical

shock. Failure to comply will render the warranty invalid.

Cd

Page 3 of 44

Getting Started

WinHSM Application Software - User Manual

MICROTHERM Heat Stress WBGT &

GETTING STARTED

It is suggested that you prepare and operate your

Microtherm following the sequence of sections in the

Operations Chapter:

Preparation,

Measurement,

Logging.

Page 4 of 44

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Contents

TABLE OF CONTENTS

1. DESCRIPTION OF THE MICROTHERM ......... 7

1.1 Background . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 The Sensor Array . . . . . . . . . . . . . . . . . . . . . 9

1.4 The Microtherm Menu Structure . . . . . . . . . . . . . 10

1.5 Alarm Output / RS 232 Socket . . . . . . . . . . . . . . 11

1.6 Schedule of Parts . . . . . . . . . . . . . . . . . . . . . 11

2. OPERATION ..................... 13

2.1 Preparation for Use . . . . . . . . . . . . . . . . . . . . 13

2.1.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.2 Temperature Sensor Array . . . . . . . . . . . . . . . . 14

2.2 Preliminary Operations . . . . . . . . . . . . . . . . . . 15

2.2.1 Switching ON and OFF . . . . . . . . . . . . . . . . . . 15

2.2.2 Checking Battery Status & Firmware Version . . . . . . . 16

2.2.3 Configuring for the Current Measurement . . . . . . . . 17

2.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Measurement . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Data Logging . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.1 Configuring the Logger . . . . . . . . . . . . . . . . . . 22

2.5.2 Clearing the Logger Memory . . . . . . . . . . . . . . . 23

2.5.3 Start Logging . . . . . . . . . . . . . . . . . . . . . . . . 23

3. WinHSM APPLICATION SOFTWARE ......... 27

3.1 Installation on Windows 95, 98 & Windows NT . . 27

3.2 Starting WinHSM Application Software . . . . . . . . . . 28

3.3 Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.1 Creating/Editing a Profile . . . . . . . . . . . . . . . . . 28

3.3.2 Sending a Profile to the Instrument . . . . . . . . . . . . 29

3.4 Downloading Data from the Logger . . . . . . . . . . . . 30

3.5 Presentation of Data . . . . . . . . . . . . . . . . . . . . 30

3.5.1 Displaying the Data Summary . . . . . . . . . . . . . . . 30

3.5.2 Displaying Data as a Table . . . . . . . . . . . . . . . . . 34

3.5.3 Displaying Data as a Graph . . . . . . . . . . . . . . . . 35

3.5.4 Exporting Data to Other Applications . . . . . . . . . . . 35

3.6 Real-Time Display Mode . . . . . . . . . . . . . . . . . . 36

Page 5 of 44

Contents

WinHSM Application Software - User Manual

MICROTHERM Heat Stress WBGT &

TABLE OF CONTENTS (Continued)

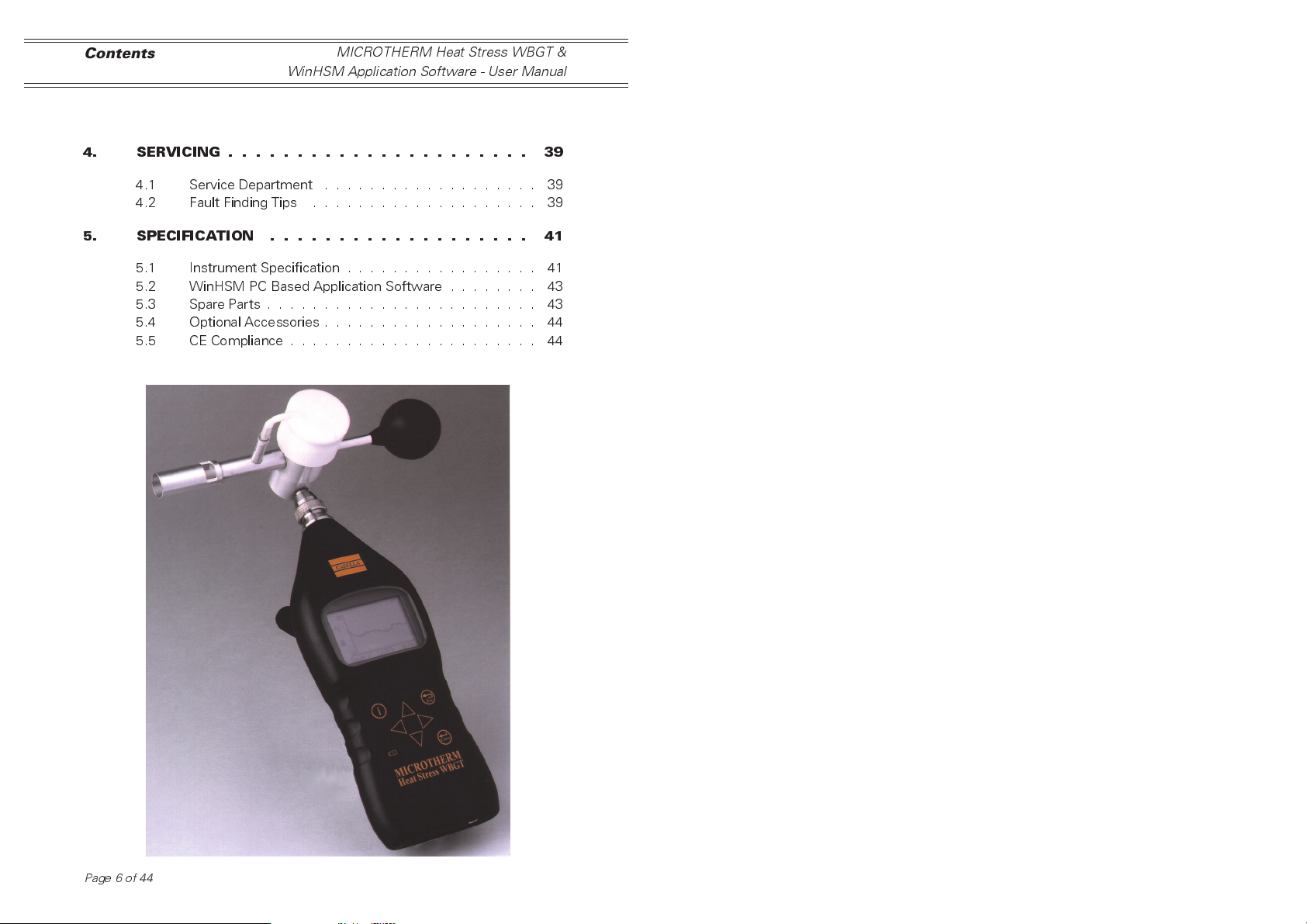

4. SERVICING ...................... 39

4.1 Service Department . . . . . . . . . . . . . . . . . . . 39

4.2 Fault Finding Tips . . . . . . . . . . . . . . . . . . . . 39

5. SPECIFICATION ................... 41

5.1 Instrument Specification . . . . . . . . . . . . . . . . . 41

5.2 WinHSM PC Based Application Software . . . . . . . . 43

5.3 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 Optional Accessories . . . . . . . . . . . . . . . . . . . 44

5.5 CE Compliance . . . . . . . . . . . . . . . . . . . . . . 44

Page 6 of 44

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Description

1. DESCRIPTION OF THE MICROTHERM

1.1 Background

A person's thermal comfort is mainly related to the thermal balance of their

body as a whole. This balance is influenced by their physical activity and

clothing, as well as the environmental parameters of, air temperature, mean

radiant temperature, air velocity and air humidity.

Problems of heat stress are common in workplaces such as foundries, steel

mills, brick glass and ceramic factories, power generation plants, coke ovens,

laundries, modern glass buildings with inadequate air conditioning, mines and

many other types of outdoor work in hot climates.

Whenever heat stress is imposed on the human body, there is a resulting

strain which may result in physiological reactions such as sweat production,

increased heart rate and higher core temperature. The greater the heat

stress, the greater heat strain and under certain conditions, the latter may

attain such magnitude as to cause damage to health.

Several indices have been designed to integrate the environmental factors

contributing to heat stress and one such index is the Wet Bulb Globe

Temperature Index. The WBGT index was initially developed to provide a

simple method for assessment of heat stress among military personnel. The

Microtherm Heat Stress WBGT determines two WBGT values.

For inside applications and outside measurements with no solar load, the

WBGT inside value is used.

WBGTin = 0.7tnw + 0.3ta

For outside measurements with solar load, the WBGT outside value is used.

WBGTout = 0.7tnw + 0.2tg + 0.1ta

Higher exposures to heat than those shown in Table 1 are permissible if the

workers have been undergoing medical surveillance and it has been

established that they are more tolerant to work in heat than the average

worker. Workers should not be permitted to continue their work when their

deep body temperature exceeds 38oC.

Page 7 of 44

Heat Stress WBGT

Description

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

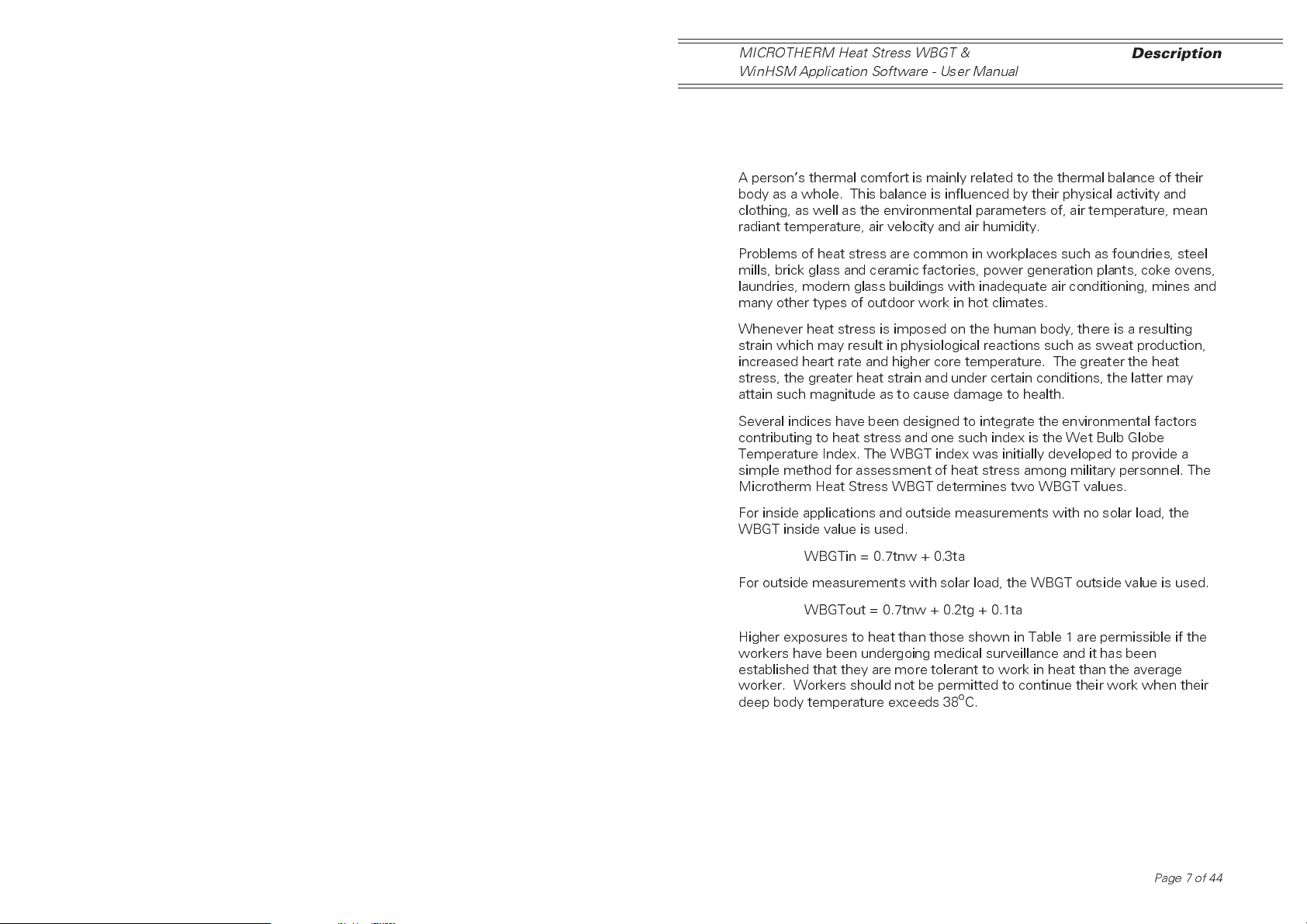

Table 1: Permissible Heat Exposure Threshold Limit Values

(values are given in

o

C WBGT)

Work Regimen Work Load

Light Moderate Heavy

Continuous Work 30.0 27.7 25.0

75% Work 30.6 28.0 25.9

25% Rest, Each Hour

50% Work 31.4 29.4 27.9

50% Rest, Each Hour

25% Work 32.2 31.1 30.0

75% Rest, Each Hour

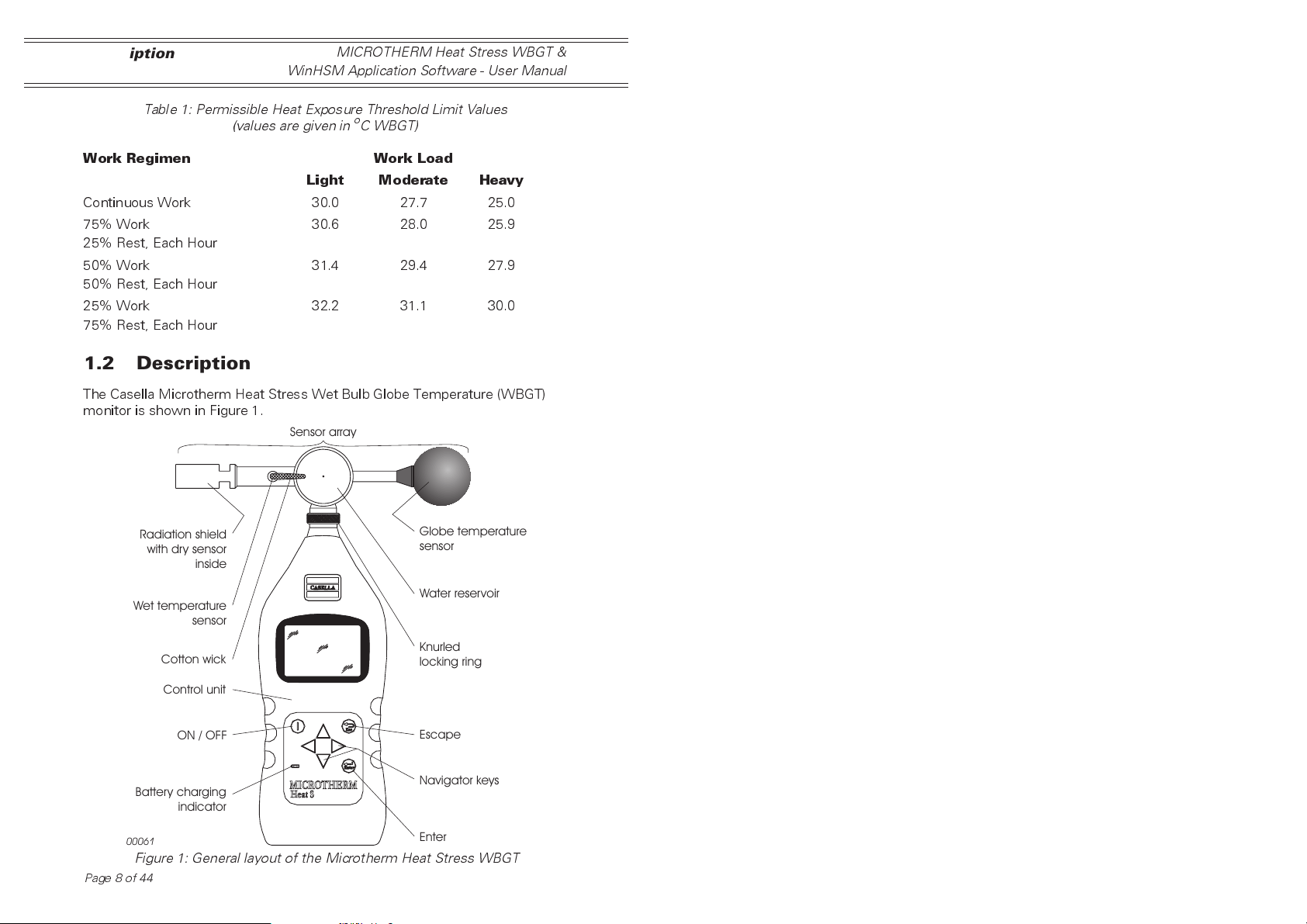

1.2 Description

The Casella Microtherm Heat Stress Wet Bulb Globe Temperature (WBGT)

monitor is shown in Figure 1.

Sensor array

Radiation shield

with dry sensor

inside

Globe temperature

sensor

Wet temperature

Battery charging

00061

Figure 1: General layout of the Microtherm Heat Stress WBGT

Page 8 of 44

sensor

Cotton wick

Control unit

ON / OFF

indicator

MICROTHERM

Heat Stress WBGT

Water reservoir

Knurled

locking ring

Escape

Navigator keys

Enter

0006

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

It is a compact, site monitoring instrument intended primarily for tripod

mounting but may also be handheld; it has the following main features.

¤

LCD graphics display

¤

Real-time display

¤

Full datalogging facilities as standard

¤

Low water level warning

¤

Built-in alarm for WBGT levels

¤

RH% and dewpoint calculation

¤

Automatic calculation of work / rest regimes via PC Software

¤

Optional tripod mounting and extension cable

¤

Meets the requirements of ISO 7234/ DIN

¤

Ergonomic design

The sensor array can be mounted directly on the instrument case, or

detached and mounted on a tripod with an extension cable to provide remote

sensing. Accuracy is achieved by using Platinum Resistance Temperature

Detectors manufactured to high standards of accuracy, stability, and

sensitivity. These sensors conform to the requirements of IEC 751 class A

and EN 60751 class A. On the sensor array, a radiation shield is provided for

the dry temperature sensor.

The instrument will operate from rechargeable batteries, primary cells, or

mains power supply while the high definition liquid crystal display is capable

of showing both text and graphical information. It also shows instrument

configuration details, temperature levels, logger information and battery

condition.

Description

The instrument uses a membrane keypad for all control functions, while a

serial (RS 232) socket is provided for data transfer to a PC for data

manipulation and presentation using Casella WinHSM application software.

Calibration modules can be provided to check the instrument's zero and span

setting.

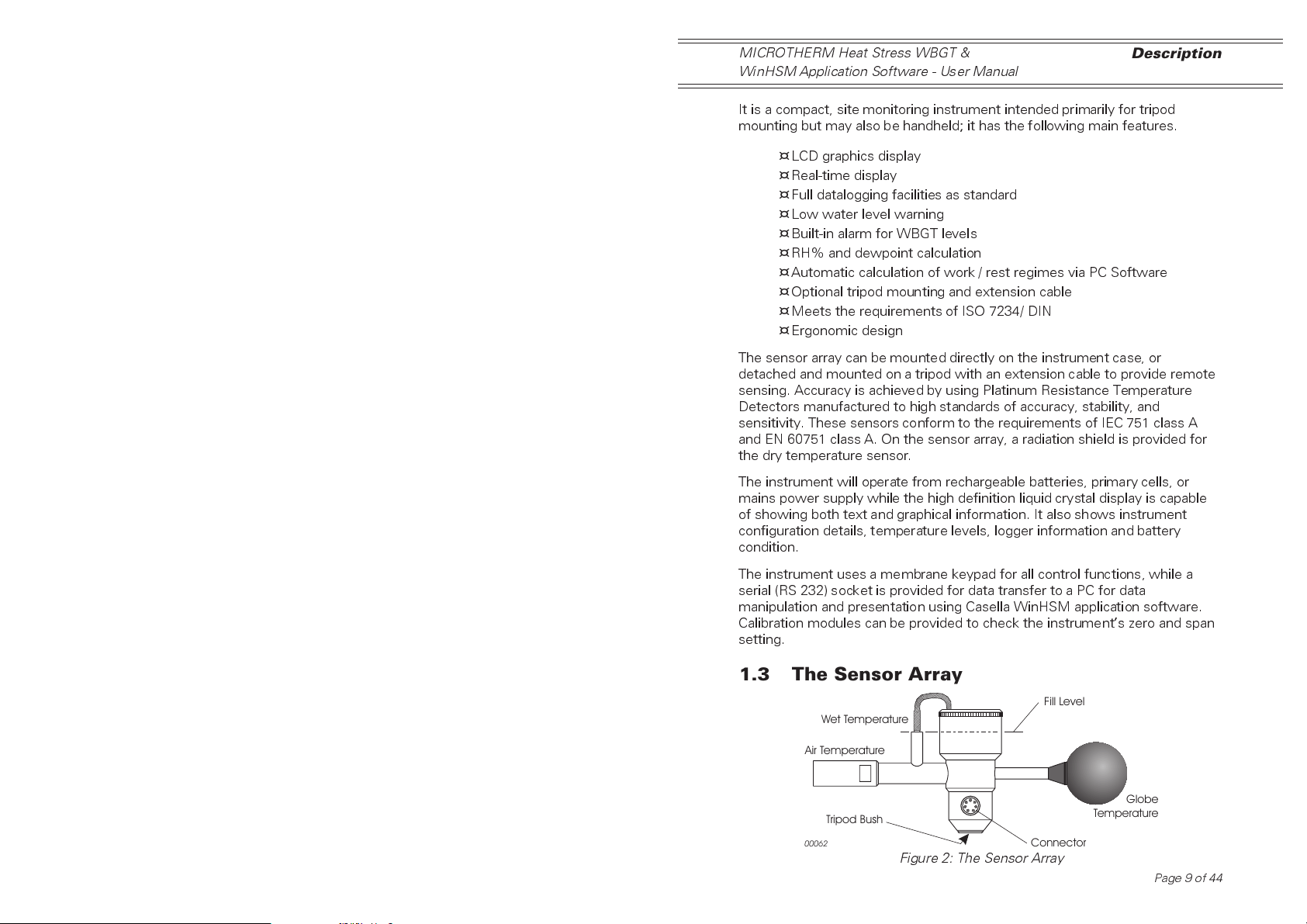

1.3 The Sensor Array

Fill Level

Wet Temperature

Air Temperature

Globe

Tripod Bush

2

Connector

Figure 2: The Sensor Array

Temperature

Page 9 of 44

Description

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

The sensor array is illustrated in Figure 2. It consists of three platinum

resistance temperature detectors (PRTD) to measure three ambient

temperatures as follows.

Wet Temperature Sensor

Mounted vertically with a tubular cotton wick over its length and the end of

the cotton extending into a water reservoir. (Always use distilled water.)

Dry Temperature Sensor

Oriented at 90

o

from the wet temperature sensor and fitted with a radiation

shield.

Globe Temperature Sensor

A sensor within a black globe monitors temperature increase due to incident

heat radiation.

The complete sensor array can be removed from the control unit and

mounted on a tripod for remote operation via extension leads up to 50 m long.

1.4 The Microtherm Menu Structure

The operator interface is based upon a series of menu options organised as

shown on the fold-out sheet at the back of this book.

A combination of function keys and navigator keys on the front panel of the

instrument are used to move around the menu system and change setup

parameters.

Their functions are as follows.

and

and

Enter

Esc

Navigator keys used to move around the

current menu options.

Navigator keys used to change the

contents of the selected field, such as

the indicated date, time, logging interval,

etc.

Enter key that accepts the current menu

option or highlighted option.

Esc (Escape) key that steps back to a

previous menu.

Press this key several times at any point

to obtain a short cut back to the Main

menu.

The Main menu contains all parameters and options relevant to operation and

gives access to the two sub-menus.

Configuration menu Allows the instrument parameters to be

specified.

Page10of44

4

MICROTHERM Heat Stress WBGT &

Description

WinHSM Application Software - User Manual

Logger Allows the logger to be configured and

data storage to be started and stopped.

1.5 Alarm Output / RS 232 Socket

An alarm output is available which switches from a logic 0 to 5 V DC

whenever the on-screen alarm is active.

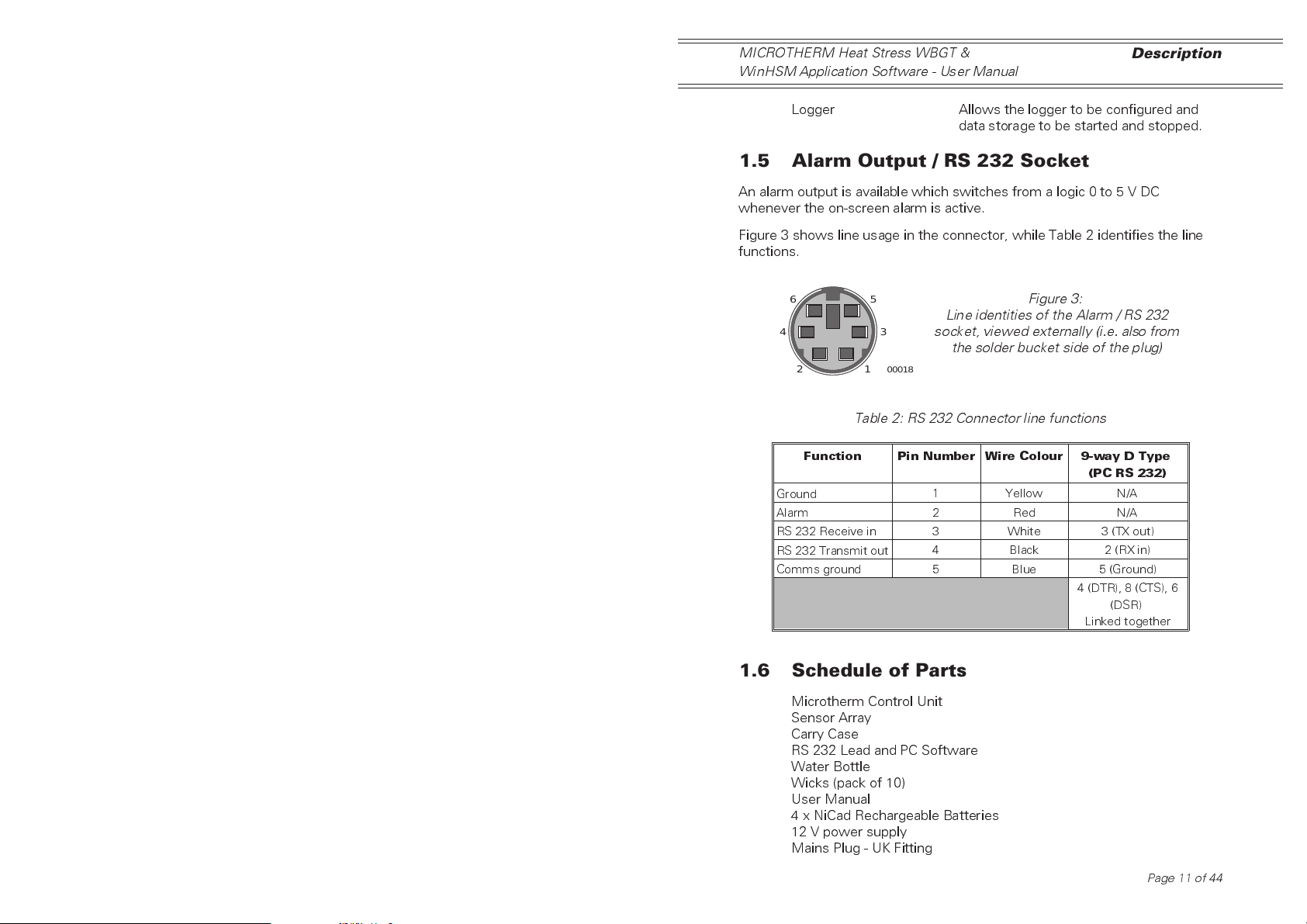

Figure 3 shows line usage in the connector, while Table 2 identifies the line

functions.

6

5

Figure 3:

Line identities of the Alarm / RS 232

3

socket, viewed externally (i.e. also from

the solder bucket side of the plug)

2

00018

1

Table 2: RS 232 Connector line functions

Function Pin Number Wire Colour 9-way D Type

(PC RS 232)

Ground

Alarm

RS 232 Receive in

RS 232 Transmit out

Comms ground

1 Yellow N/A

2 Red N/A

3 White 3 (TX out)

4 Black 2 (RX in)

5 Blue 5 (Ground)

4 (DTR), 8 (CTS), 6

(DSR)

Linked together

1.6 Schedule of Parts

Microtherm Control Unit

Sensor Array

Carry Case

RS 232 Lead and PC Software

Water Bottle

Wicks (pack of 10)

User Manual

4 x NiCad Rechargeable Batteries

12 V power supply

Mains Plug - UK Fitting

Page 11 of 44

0100

Description

WinHSM Application Software - User Manual

Mains Plug - European Fitting

Mains Plug - USA Fitting.

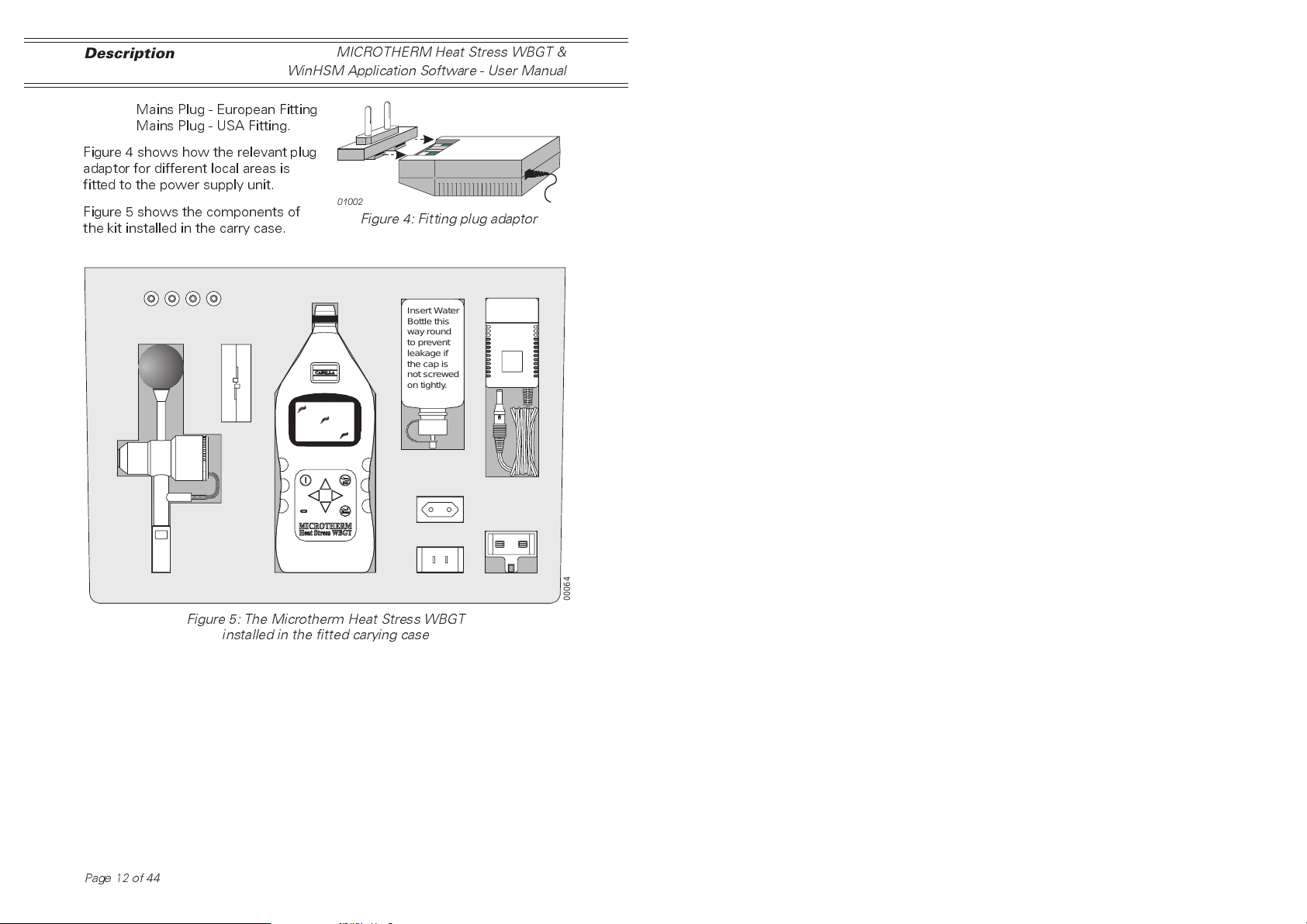

Figure 4 shows how the relevant plug

adaptor for different local areas is

fitted to the power supply unit.

Figure 5 shows the components of

the kit installed in the carry case.

MICROTHERM Heat Stress WBGT &

2

Figure 4: Fitting plug adaptor

Insert Water

Bottle this

way round

to prevent

leakage if

the cap is

not screwed

on tightly.

00064

Figure 5: The Microtherm Heat Stress WBGT

installed in the fitted carying case

Page12of44

L

R

C

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Operation

2. OPERATION

The Microtherm Heat Stress WBGT is a sensitive scientific instrument which

should not be exposed to excessive moisture, vibration, or physical shocks.

The following steps must be performed before your Microtherm can be used

under operating conditions. It is suggested that you follow the sequence of

sections in this chapter.

2.1 Preparation for Use

2.1.1 Power Supply

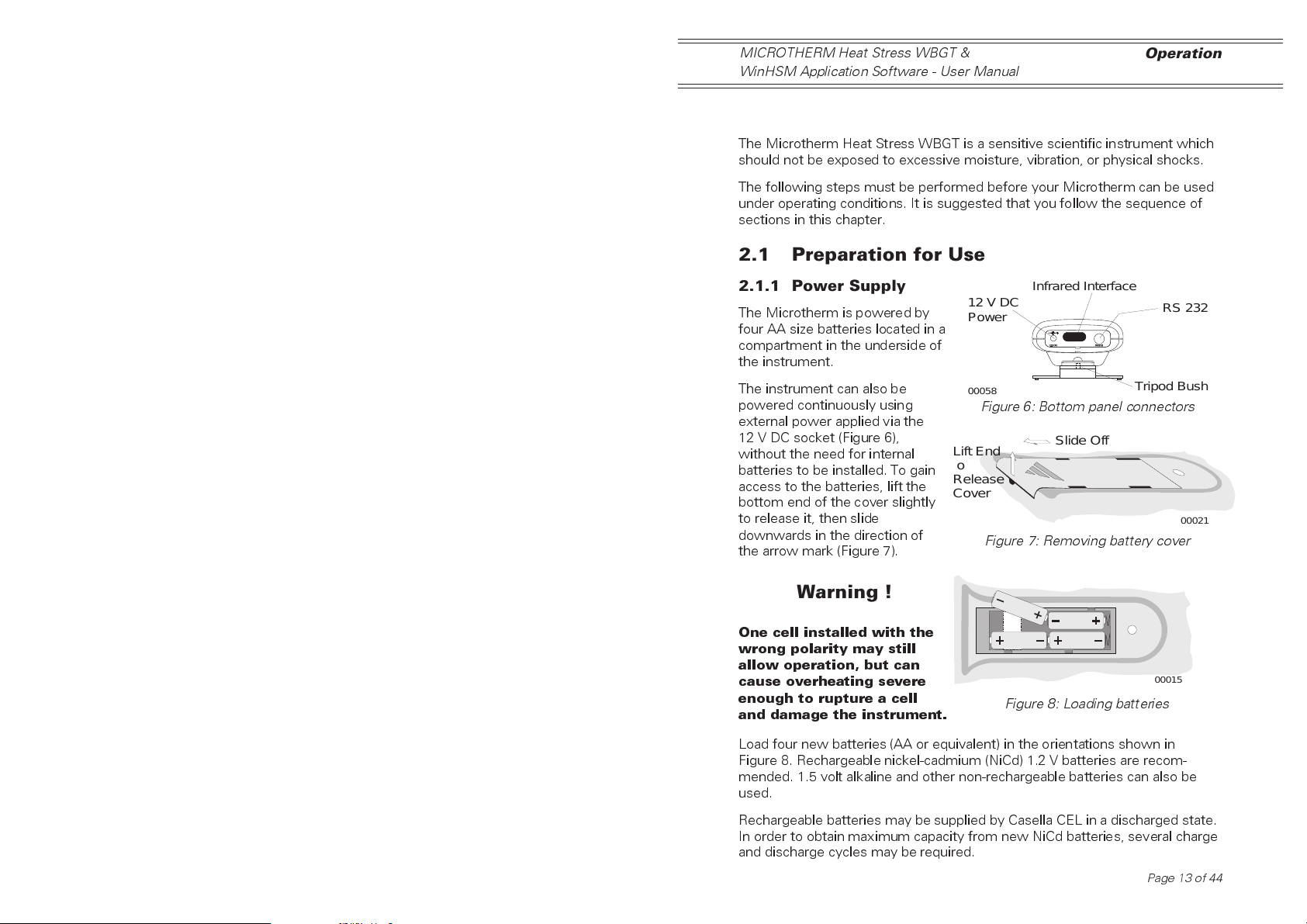

The Microtherm is powered by

four AA size batteries located in a

compartment in the underside of

the instrument.

The instrument can also be

powered continuously using

external power applied via the

12 V DC socket (Figure 6),

without the need for internal

batteries to be installed. To gain

access to the batteries, lift the

bottom end of the cover slightly

to release it, then slide

downwards in the direction of

the arrow mark (Figure 7).

Warning !

One cell installed with the

wrong polarity may still

allow operation, but can

cause overheating severe

enough to rupture a cell

and damage the instrument.

Infrared Interface

12 V DC

Power

00058

Figure 6: Bottom panel connectors

ift End

o

elease

over

Figure 7: Removing battery cover

Figure 8: Loading batteries

Slide Off

RS 232

Tripod Bush

00021

00015

Load four new batteries (AA or equivalent) in the orientations shown in

Figure 8. Rechargeable nickel-cadmium (NiCd) 1.2 V batteries are recom-

mended. 1.5 volt alkaline and other non-rechargeable batteries can also be

used.

Rechargeable batteries may be supplied by Casella CEL in a discharged state.

In order to obtain maximum capacity from new NiCd batteries, several charge

and discharge cycles may be required.

Page 13 of 44

Operation

MICROTHERM Heat Stress WBGT &

WinHSM Application Software - User Manual

Warning !

DO NOT enable the charger circuit while non-rechargeable

batteries are installed.

Factory

The instrument has a built in

fast-charging circuit that uses

Serial Number Label

power applied via the 12 V DC

socket shown in Figure 6. This

allows rechargeable batteries to be

recharged in-situ.

When rechargeable batteries are to

be charged in situ, set the Charger

Enable DIP switch to ON as shown

in Figure 9.

Figure 9: Location of DIP switches

Charging will terminate automatically once the batteries are fully charged,

which takes approxi- mately 3 hours for fully discharged batteries.

2.1.2 Temperature Sensor Array

The detachable sensor array houses three platinum resistance temperature

detectors to measure three associated ambient temperatures (see Figure 2).

use only.

ON

1

DO NOT

2

ADJUST

Charger

Enable

00060

1. The wet temperature sensor is mounted vertically and has a tubular

cotton wick sheathing its length.

2. The dry temperature sensor has a radiation shield.

3. The globe temperature sensor is mounted at the other end of the

crossbar from the dry sensor.

Connect the sensor array by inserting the cable connector into the socket in

the top end of the instrument case, with the red dot facing the front of the

instrument to ensure correct pin location, then turn the large knurled ring to

tighten the security collet. (Remember to free the collet before attempting to

remove the sensor array.)

In use, the sensor array must be maintained with the crossbar horizontal to

prevent spillage from the water container during the duration of a typical

measurement (which should take at least 20 minutes on each station).

This is best achieved by standing the instrument on its foot on a horizontal

surface as shown in Figure 10, mounting the instrument on a tripod (available

from Casella CEL), or by using an extension cable to allow the sensor array to

be installed on a tripod. Extension cables are available with a standard length

of 10 m. The maximum distance between sensors and instrument is 50 m.

Page14of44

Loading...

Loading...