MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

MICROTHERM

indoor air quality

WinIaq Application Software

User Manual

HB3264-06

November 2002

&

COPYRIGHT

The copyright in this document which contains proprietary information is vested in

CASELLA CEL LIMITED. The contents of this document must not be used for

purposes other than for which it has been supplied or reproduced or disclosed wholly

or in part without the prior written permission of

CASELLA CEL LIMITED

CASELLA CEL

Regent House

Wolseley Road

Kempston

Bedford

MK42 7JY, U.K.

Phone: +44 (0)1234 844100

Fax: +44 (0)1234 841490

E-Mail: info@casellacel.com

Web: www.casellacel.com

CASELLA USA

17 Old Nashua Road #15

Amherst

NH 03031,

U.S.A.

Toll Free: +1 800 366 2966

Fax: +1 603 672 8053

E-mail: info@casellausa.com

Web: www.casellausa.com

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Page 2 of 42

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Table of Contents

Chapter . . . . . . . . . . . . . . . . . . . . . . Page

1. INTRODUCTION TO THE MICROTHERM . . . .......... 5

2. ASSEMBLING THE MICROTHERM ................ 6

2.1 Assembly ....................... 6

2.2 Sensors........................ 6

2.3 MainsPower...................... 7

2.4 Communications .................... 7

2.5 Disassembly ...................... 7

3. MICROTHERM CONTROL UNIT . ................ 8

3.1 Indicators . ...................... 8

3.2 Liquid Crystal Display . ................ 8

3.3 Control keys ...................... 8

3.4 Internal Battery .................... 9

Contents

4. WinIaq ...........................10

®

4.1 Installation on Windows 3.1

4.2 Installation on Windows 95

4.3 Starting Win

5. MICROTHERM PROFILES - BASIC ................11

5.1 Creating a New Profile . ................11

5.2 Defining the Serial Interface ..............11

5.3 ChoosingSensors ...................12

5.4 Parameters ......................12

5.5 Transferring Profiles . . ................13

6. DATA RECOVERY . ......................15

7. DISPLAYING DATA ......................16

7.1 Displaying Data as a Graph ...............16

7.1.1 Selecting the Time Base ................16

7.1.2 Selecting a Different Trace ...............17

7.1.3 Changing the Vertical Scale ..............17

7.2 Displaying Data as a Table ...............18

7.2.1 Table Font Size ....................18

7.3 Creating a Summary . . ................18

Iaq ....................10

.............10

®

..............10

8. PRINTING & EXPORTING DATA . ................20

8.1 Printing Data .....................20

8.2 Exporting Data ....................20

Page 3 of 42

Contents

WinIaq Application Software - User Manual

MICROTHERM indoor air quality &

Table of Contents

Chapter . . . . . . . . . . . . . . . . . . . . . . Page

9. MICROTHERM PROFILES - ADVANCED . . . ..........21

9.1 Changing the Recording Interval . . ..........21

9.2 Setting an Alarm . . . ................21

9.3 Changing the Recording Method . . ..........22

9.4 Changing the Calculation Constants . ..........22

9.5 Enabling Real Time Data Output . . ..........23

9.6 ModemOperation ...................24

10. EXTERNALCONNECTIONS ................. 25

10.1 Alarm Connector ....................25

11. USING PCMCIA MEMORY CARDS . . . . . . . . . . . . . . 26

11.1 Dedicated Card Reader . ................26

11.1.1 Clearing a Card ................... 26

11.1.2 Extracting Data From a Card ............. 26

11.2 Existing PCMCIA Card Sockets (CardWizard) . . ....27

11.2.1 DeCopy . . ......................27

11.2.2 De

12. SENSOR SPECIFICATIONS . . . . . . . . . . . . . . . . . 29

12.1 Black Globe Thermometer ...............29

12.2 Air Velocity Probe . . . ................30

12.3 Solid State Temperature and Humidity Probe . . ....31

12.4 Natural Wet Bulb Thermometer . . . ..........32

12.5 CO

12.6 Airborne Particulate Monitor ..............35

12.7 CO Gas Detector ....................36

12.8 O

12.9 CEL-254 Sound Level Meter ..............38

Appendix 1 ...........................39

A1.1 Introduction ......................41

A1.2 Installation ......................41

A1.3 Operation . ......................42

Image .......................28

Monitor ......................33

2

Gas Detector ....................37

2

Page 4 of 42

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Introduction

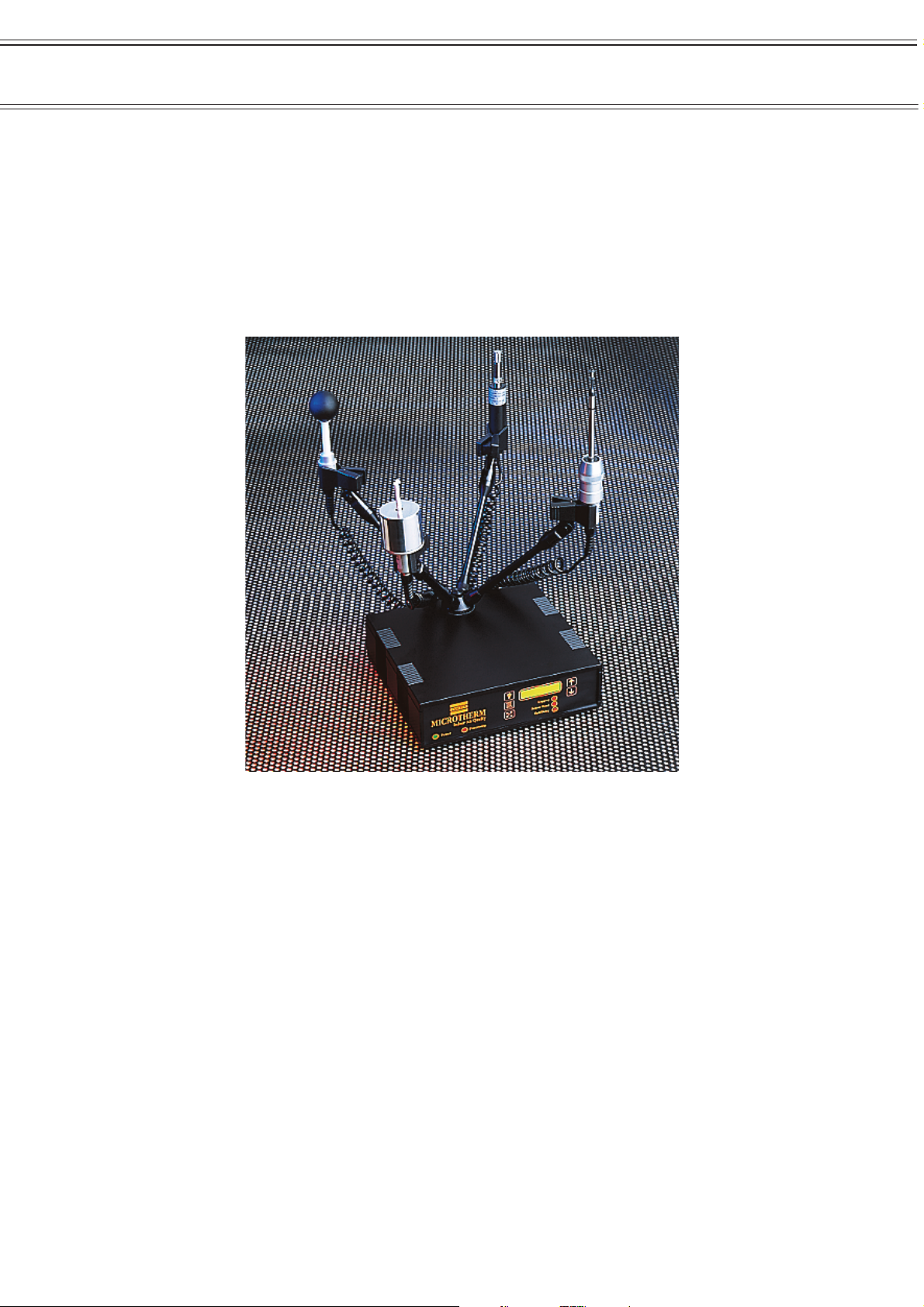

1. INTRODUCTION TO THE MICROTHERM

Increasing our knowledge of the indoor environment is essential in assessing the

welfare of buildings and their occupants. This is of particular importance to

workplaces, where maintaining the best possible working conditions ensures

optimum levels of workforce efficiency.

The MICROTHERM indoor air quality is the product of CASELLA CEL’s many years

of research, development and production of leading edge environmental

monitoring products.

The MICROTHERM system is designed to monitor, record, calculate and display

valuable data relating to the indoor environment of enclosed or partially

enclosed spaces. These environments usually relate to buildings in which:

¤ Human work activity occurs.

¤ Industrial processes are undertaken.

¤ Materials and goods are stored or exhibited.

¤ Animals or plants are housed.

The MICROTHERM is totally portable and is ideal for both fixed site and portable

general survey applications. Supplied in a robust carrying case, the complete

system is easily transported by a single operator.

The overall sensor design and data generation complies with the general

guidelines of the European ISO recommendations.

The accompanying Windows software has been developed to make programming

of the MICROTHERM, together with the collection and presentation of data as

simple as possible.

Page 5 of 42

Assembly

WinIaq Application Software - User Manual

MICROTHERM indoor air quality &

2. ASSEMBLING THE MICROTHERM

The MICROTHERM control unit is supplied in a hard wearing carry case with

sufficient room to house the basic complement of sensors. Prior to use the

MICROTHERM must be assembled and programmed.

2.1 Assembly

To assemble the MICROTHERM prior to use, remove the control unit from the

carrying case and place on a secure level surface.

If fitted, remove the blanking plug from the hub mounting hole located on the

top cover of the control unit.

Locate the small hub over the mounting hole and secure using the hub retaining

screw.

Screw a sensor retaining arm into each of the four holes located in the small hub

making sure the sensor clip on each arm ends up in a vertical position. Lock

each arm in position using the ‘locking collar’ at the base of each arm.

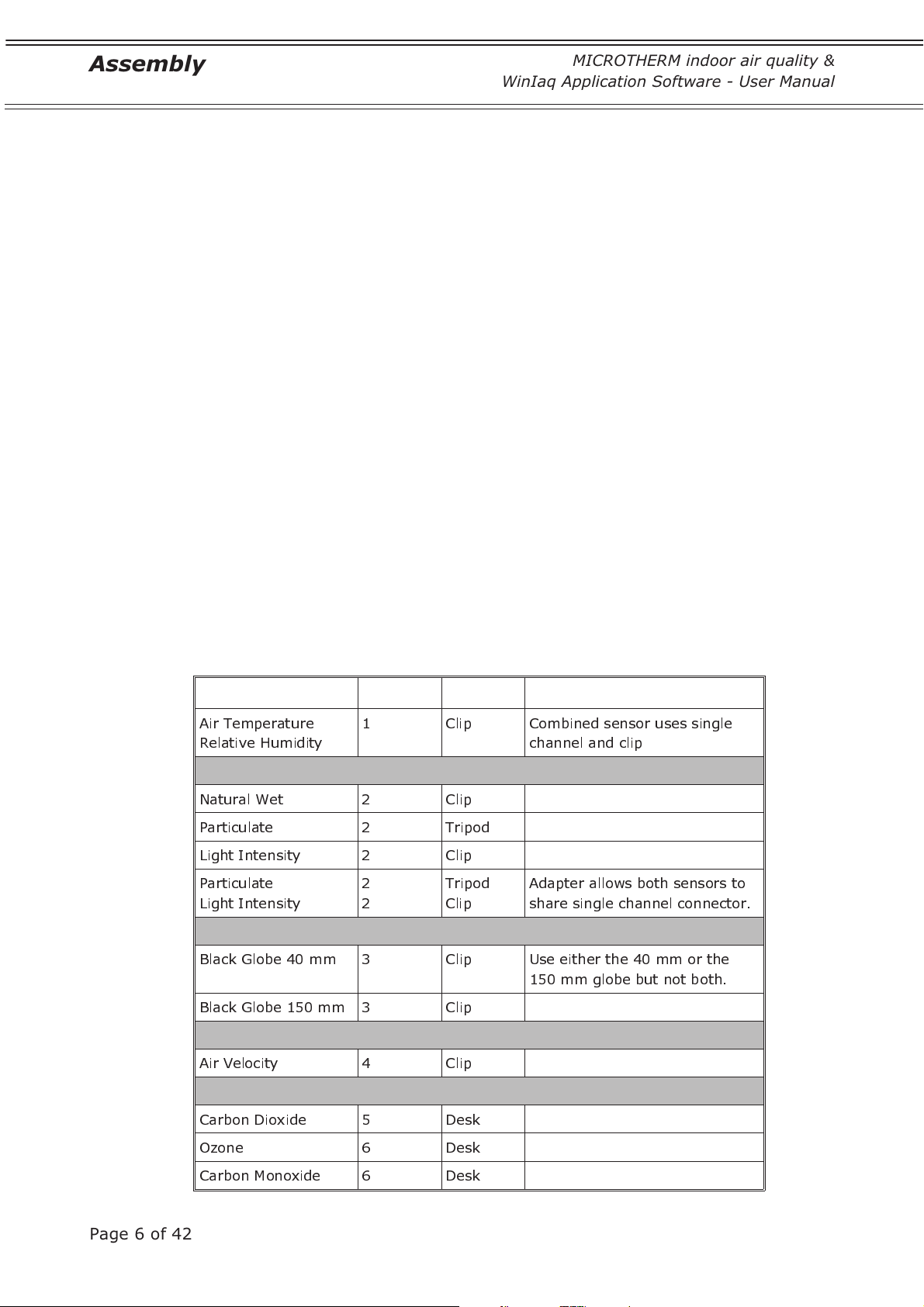

2.2 Sensors

Arrange the required sensors using the available “sensor clips” and insert the

connector in the associated socket located on the back panel. Note that not all

the sensors can be mounted using the “sensor clips” and that some

combinations of sensors are not permissible as they use the same sockets.

The following table outlines possible sensor allocations.

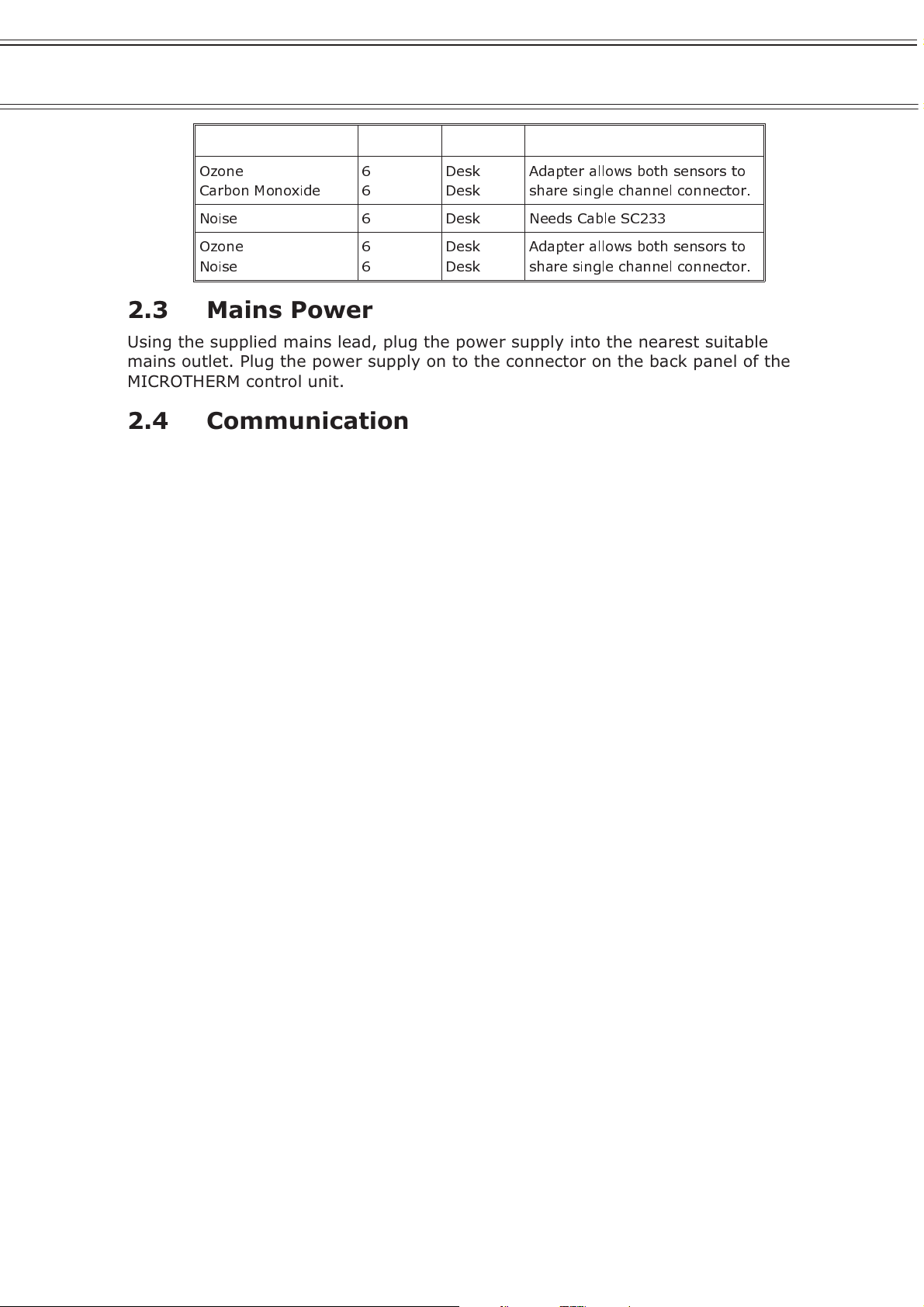

Sensor Channel Mount Combination

Air Temperature

Relative Humidity

Natural Wet 2 Clip

Particulate 2 Tripod

Light Intensity 2 Clip

Particulate

Light Intensity

Black Globe 40 mm 3 Clip Use either the 40 mm or the

1 Clip Combined sensor uses single

channel and clip

2

2

Tripod

Clip

Adapter allows both sensors to

share single channel connector.

150 mm globe but not both.

Page 6 of 42

Black Globe 150 mm 3 Clip

Air Velocity 4 Clip

Carbon Dioxide 5 Desk

Ozone 6 Desk

Carbon Monoxide 6 Desk

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Sensor Channel Mount Combination

Assembly

Ozone

Carbon Monoxide

Noise 6 Desk Needs Cable SC233

Ozone

Noise

6

6

6

6

Desk

Desk

Desk

Desk

Adapter allows both sensors to

share single channel connector.

Adapter allows both sensors to

share single channel connector.

2.3 Mains Power

Using the supplied mains lead, plug the power supply into the nearest suitable

mains outlet. Plug the power supply on to the connector on the back panel of the

MICROTHERM control unit.

2.4 Communications

Using the supplied serial communication cable, connect the RS232 connector

located on the rear panel of the MICROTHERM control unit to a free RS232 port

on your computer.

Switch the MICROTHERM control unit ON by moving the switch on the back

panel to the down position.

2.5 Disassembly

Disassembly of the control unit ready for storage or transportation is a matter of

following the same procedure as for assembly, except in the reverse order.

At this point you are ready to program and record data using the combination of

MICROTHERM control unit and Win

Iaq application software.

Page 7 of 42

Control Unit

WinIaq Application Software - User Manual

MICROTHERM indoor air quality &

3. MICROTHERM CONTROL UNIT

A number of indicators and control keys are accessible on the front panel of the

instrument. The indicators give visual feedback about the current state of the

MICROTHERM while the control keys allow you to view current readings and stop

and start the unit.

3.1 Indicators

There are two light emitting diodes (LEDs) situated at the left end of the front

panel.

Power, green LED lit when mains power is available and the unit is ON.

Processing, red LED flashes when the unit is processing data internally.

There are three LEDs situated below the display at the right end of the front

panel.

Logging, red LED flashes when a data set is committed to memory.

Sensor read, red LED flashes when attached sensors are scanned.

Halt/delay, will flash during the initial delay period then remain off

until the MICROTHERM stops logging were upon it will remain lit.

3.2 Liquid Crystal Display

A two line by 16-character liquid crystal display (LCD) allows you to scroll

through the current values read from the sensors, together with any calculated

values. The display has an integral back light to enhance visibility in low light

conditions.

3.3 Control Keys

The MICROTHERM has five keys positioned around the liquid crystal display.

F

The function key modifies the operation of the other four keys, when

pressed it changes the display to show the alternate function

associated with each key.

The back light key toggles the liquid crystal display back light on and

off. Normally, this key has no alternate function associated with it,

except when memory cards for data retrieval are in use (see Appendix

1).

Page 8 of 42

The scroll key has no function currently associated with it. This key

has no alternate function associated with it.

The up key scrolls up through the list of current readings. Holding the

key down for 3 seconds causes the display to scroll automatically in

this direction. The scrolling action will continue until the key is pressed

again.

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

The alternate function associated with this key is the start function.

Pressing this key in combination with the function key will cause the

MICROTHERM to initialise itself and begin logging. This does not affect

any data currently held within the MICROTHERM as this can be erased

only by reprogramming via the Win

The down key scrolls down through the list of current readings.

Holding the key down for 3 seconds causes the display to scroll

automatically in this direction. The scrolling action will continue until

the key is pressed again.

The alternate function associated with this key is the stop function.

Pressing this key in combination with the function key will cause the

MICROTHERM to stop logging. To resume logging use the alternate up

key function. This does not affect any data currently held within the

MICROTHERM as this can be erased only by reprogramming via the

Iaq application.

Win

Control Unit

Iaq application.

3.4 Internal Battery

Although the MICROTHERM is primarily a mains powered instrument, it uses an

internal lead-acid battery to retain the program, clock and data while the

instrument is in storage. This internal battery has sufficient capacity to retain

the MICROTHERM’s internal state for a period of 2 months, in the absence of

mains power.

Therefore it is advisable to connect the MICROTHERM to a suitable mains power

supply at intervals shorter than 2 months, in order to recharge the internal

battery and maintain the internal configuration. The charge state of the internal

battery can be inspected from the LCD display of the MICROTHERM, use the up

or down key to bring the “battery” display into view where the battery capacity

is expressed as a percentage with 100% indicating fully charged.

When the MICROTHERM has been programmed and is actively collecting data on

site, it continually monitors the mains power supply and if it detects that the

mains power supply is absent, it will stop data collection until the mains power is

re-established.

During this period of power loss the MICROTHERM only checks for the mains

supply every 15 minutes, in order to conserve battery power. Therefore any

period of mains power loss will cause the MICROTHERM to shut down for at least

15 minutes. Once mains power is detected the MICROTHERM will automatically

resume collecting data as before.

Page 9 of 42

WinIaq Software

WinIaq Application Software - User Manual

MICROTHERM indoor air quality &

4. WinIaq

WinIaq is a Windows application specifically written by CASELLA CEL to simplify

the process of programming the MICROTHERM and presenting data collected

with the unit. The current application was designed to operate under Windows

3.1 but will also run under Windows 95.

4.1 Installation on Windows 3.1

1. Insert the WinIaq disk in your floppy disk drive, and close the drive door.

2. From the Program Manager, select File / Run…

3. Type a:\setup, where “a” is the identity of the floppy disk drive.

4. Press Enter.

5. Follow the instructions on the screen.

4.2 Installation on Windows 95

1. Insert the WinIaq disk in your floppy disk drive, and close the drive door.

2. From the Task Bar, select Start / Run…

3. Type a:\setup, where “a” is the identity of the floppy disk drive.

4. Press Enter.

5 Follow the instructions on the screen.

®

®

4.3 Starting WinIaq

Start the WinIaq application by double clicking on the icon (Windows 3.1) or

selecting it from the Start Menu (Windows 95).

WinIaq

Once the application has been loaded you are ready to create your first

MICROTHERM profile.

Page 10 of 42

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Profiles - Basic

5. MICROTHERM PROFILES - BASIC

All aspects of the operation of an MICROTHERM are determined by the settings

maintained in profiles. Profiles are stored on disk and can be recalled at any

time to allow repetition of previous measuring schemes.

5.1 Creating a New Profile

To create a new profile select File / New from the menu or click on the icon

in the toolbar.

As this is a new profile you will be presented with a series of dialog boxes which

will enable you to define the basic features of this profile.

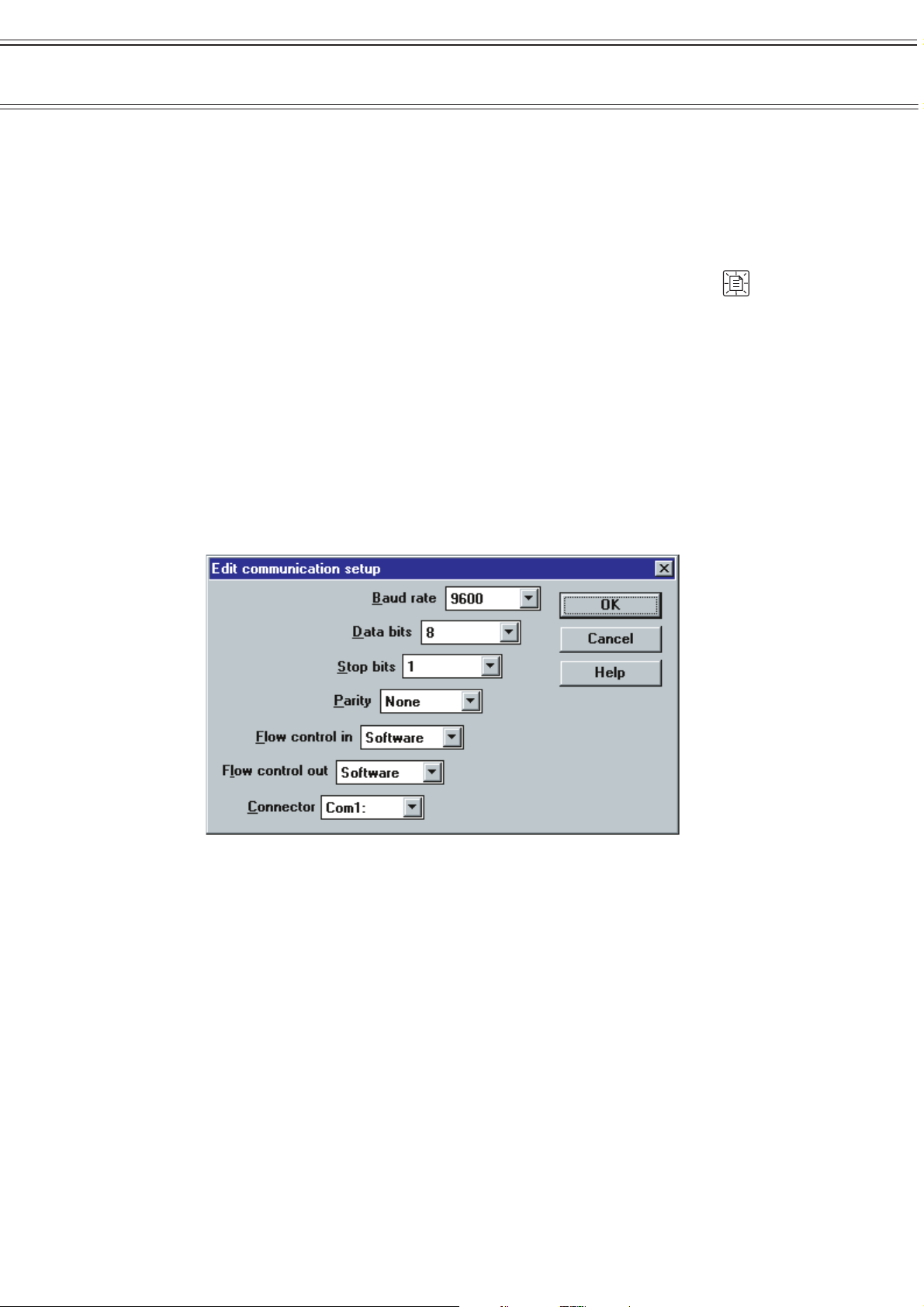

5.2 Defining the Serial Interface

Communication with the MICROTHERM is accomplished using one of the serial

ports available on your computer. In order for this communication to function

correctly both the computer and the MICROTHERM must be set to use the same

protocol. This dialog box enables you to set them.

The default settings in the dialog box match those of a standard MICROTHERM.

The only setting you may need to change is that of the Connector. If a mouse or

other device is already installed on Com1, you will need to change this setting to

another free port.

Note that MICROTHERM control units fitted with internal firmware of V3.30 and

above can be configured to communicate at 9600 baud, all other control units

are limited to a maximum communication speed of 4800 baud.

To determine the version of the firmware fitted in your control unit, scroll the

display to the primary screen. This shows the current baud rate in the bottom

left corner and the current version in the bottom right.

To change the default setting within the MICROTHERM control unit remove the

top panel by unscrewing the four feet. Locate an 8-way dip switch positioned

adjacent to the memory expansion slot. Change the switch settings to match

one of the tables shown:

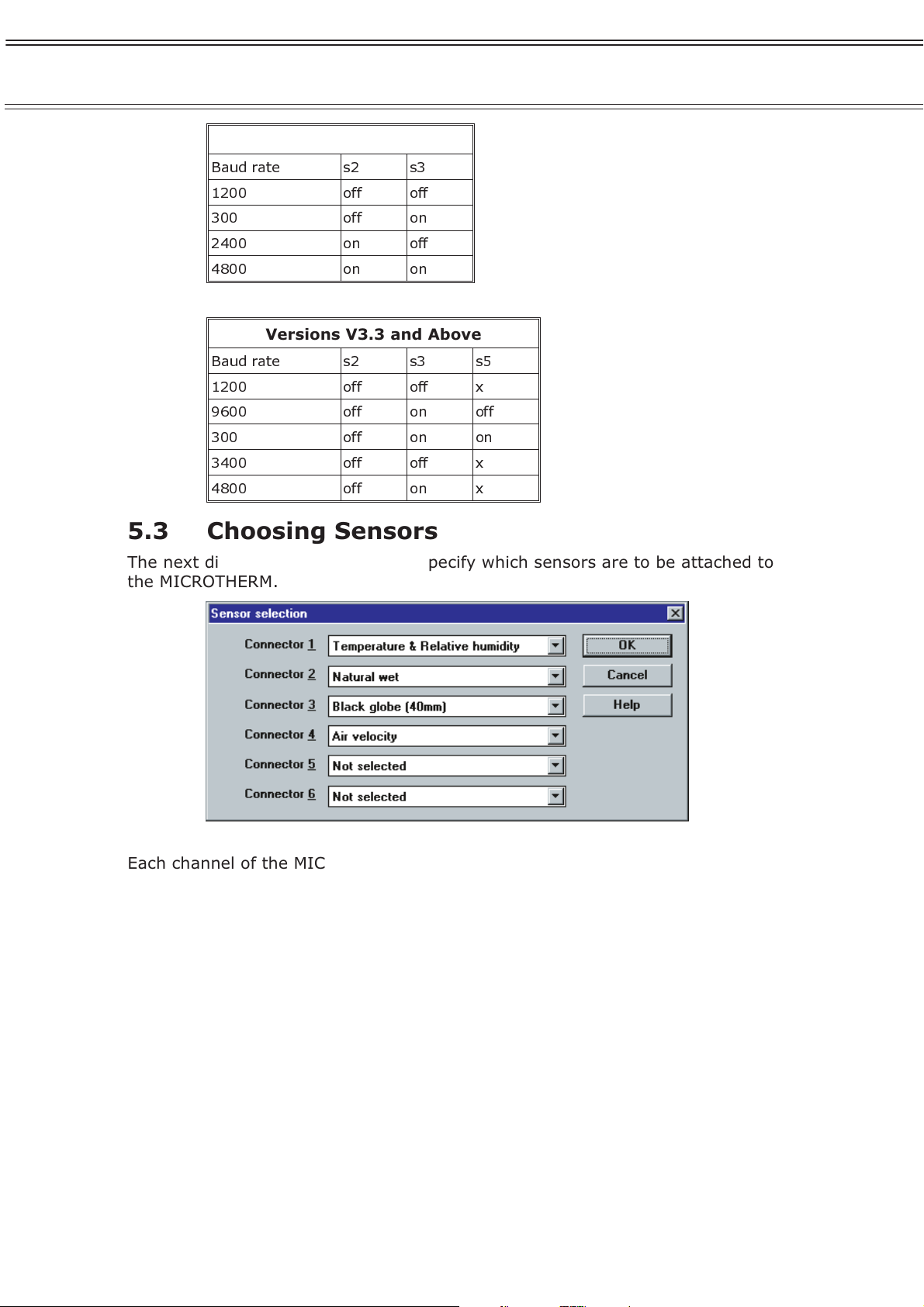

Page 11 of 42

Profiles - Basic

Versions Prior to V3.30

Baud rate s2 s3

1200 off off

300 off on

2400 on off

4800 on on

Baud rate s2 s3 s5

1200 off off x

9600 off on off

300 off on on

3400 off off x

4800 off on x

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Versions V3.3 and Above

5.3 Choosing Sensors

The next dialog box enables you to specify which sensors are to be attached to

the MICROTHERM.

Each channel of the MICROTHERM can support one or more specific sensors,

make sure you select the correct sensor(s) for each channel and leave any

unused channels as Not selected.

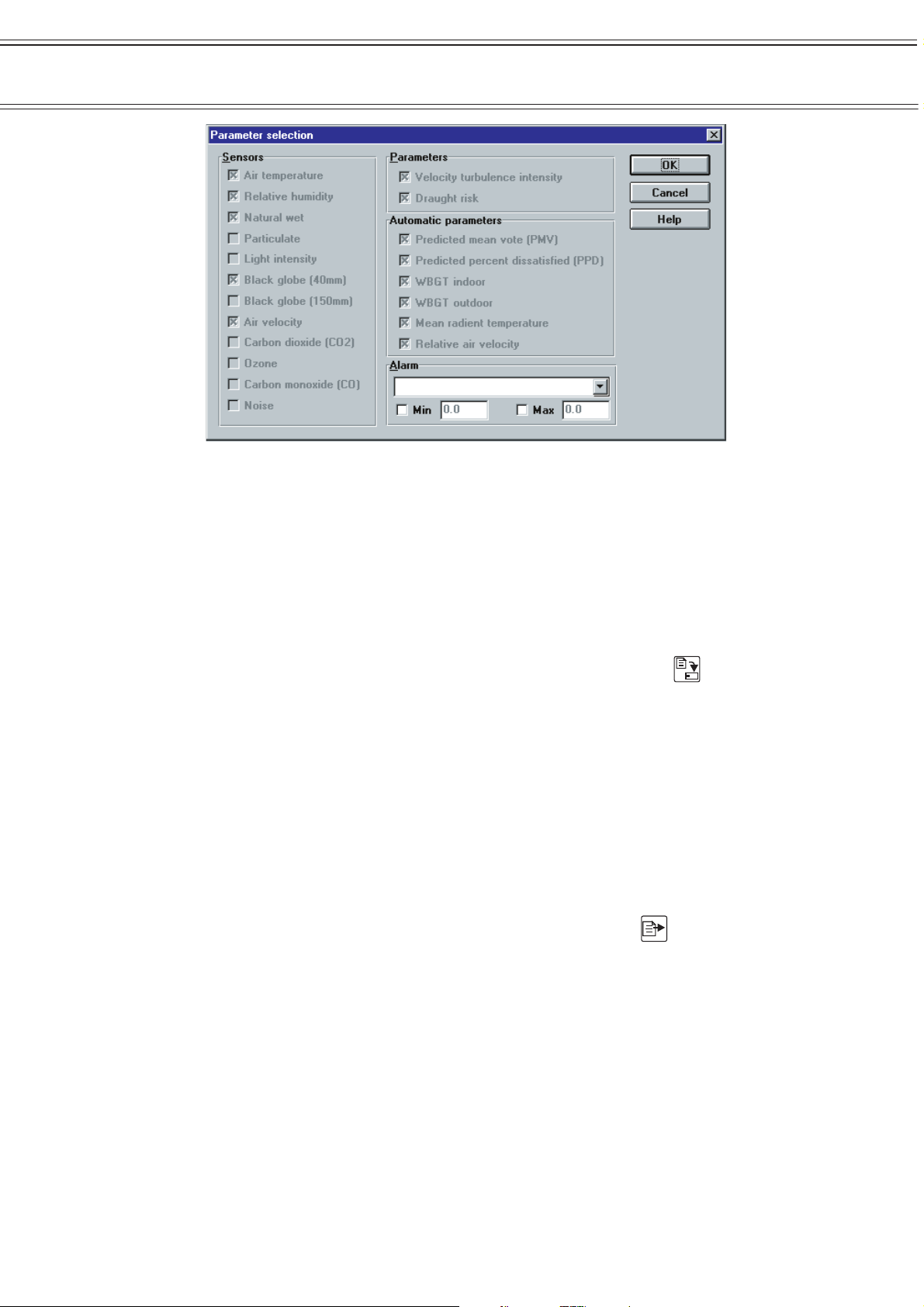

5.4 Parameters

Parameter selection is perfomed automatically by the software. Data from all of

the connected sensors, selected according to Section 5.3, will be measured and

recorded.

The next dialog box (below) shows which sensors and parameters are available.

However to indicate that no further selections can take place, the parameter

fields are “greyed out”. This dialog box has the following three main sections,

detailing the sensors and parameters measured:

Sensors Values recorded directly from the sensors,

Parameters Values calculated within the logger itself,

Automatic Parameters Values calculated by the PC software once the

data is downloaded

Page 12 of 42

MICROTHERM indoor air quality &

WinIaq Application Software - User Manual

Do not worry about the Alarm setting just yet, this will be described in a later

section.

Profiles - Basic

From Sections 1 to 4 you have created a MICROTHERM profile that will record all

available parameters at 10-minute intervals (the default setting).

Changing the default recording interval will be covered later.

Having made a new profile you should save it to disk to make it available for

future use.

To save a profile select File / Save from the menu or click on the icon.

5.5 Transferring Profiles

Before a MICROTHERM can act upon the information stored within a profile, that

profile must be transferred across to the MICROTHERM. Before you attempt to

transfer a profile make sure that:

¤ The MICROTHERM is assembled, connected to mains power and

switched ON.

¤ The serial communication cable is plugged into both the MICROTHERM

and a free serial port on your computer.

Select Logger / Send setup… from the menu or click on the icon.

Having done this, you will be warned that “All data currently stored in the

control unit will be erased”. This is true whenever you transfer a profile to a

MICROTHERM, so make sure that you have recovered the data prior to sending

the profile.

In this instance, we are not interested in the current contents of the

MICROTHERM so can ignore the message.

We can now transfer the profile to the MICROTHERM .

Click on the Send button to start the transfer.

Page 13 of 42

Loading...

Loading...