Casella CEL HB3283-01 User Manual

Side 4

ADVANCED INSTRUMENT SHELTER

User Instructions

7. SERVICING

For UK customers service under guarantee is offered only by the CASELLA CEL Ltd service

department at Regent House, Kempston, Bedford. There are no UK agents or repair services

authorised by us to carry out this work. In order to ensure that only approved replacement parts

are used for routine maintenance after the guarantee period we recommend that this is carried out

by our fully skilled service engineers or in the case of service required outside the UK by our

appointed agents.

CASELLA CEL LIMITED

Regent House

Wolseley Road

Kempston

Bedford

MK42 7JY

Telephone: +44 (0)1234 844100

Facsimile: +44 (0)1234 841490

E-Mail: info@casella.co.uk

Webpage: http://www.casella.co.uk

ADVANCED INSTRUMENT SHELTER

User Instructions

INSTRUMENT SHELTER

June 2001

ADVANCED

Installation Guide

HB3283-01

COPYRIGHT

The copyright in this document is vested in CASELLA CEL LIMITED. The contents of this document, which

contains proprietary information, must not be used for purposes other than that for which it has been supplied or

1. INTRODUCTION

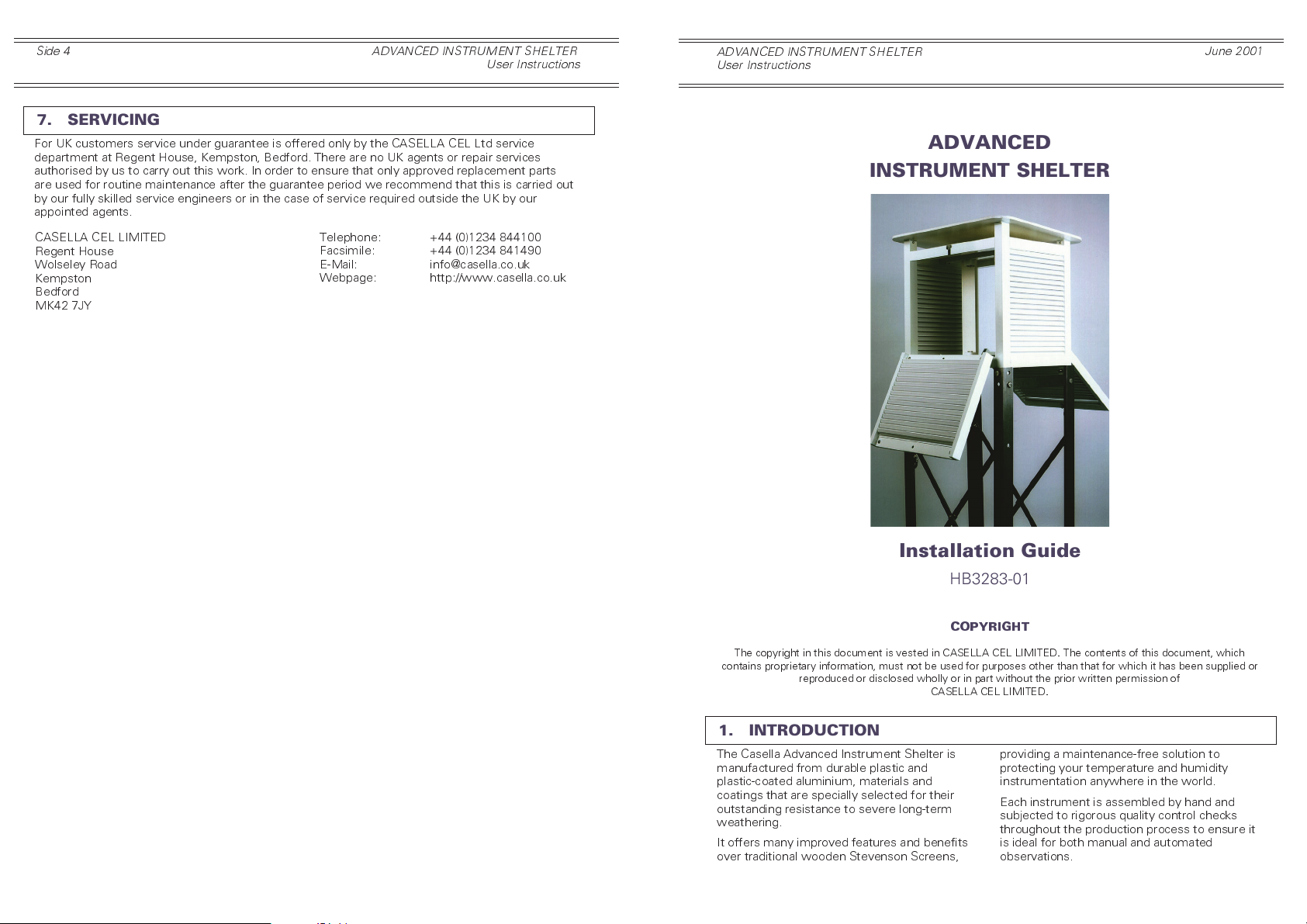

The Casella Advanced Instrument Shelter is

manufactured from durable plastic and

plastic-coated aluminium, materials and

coatings that are specially selected for their

outstanding resistance to severe long-term

weathering.

It offers many improved features and benefits

over traditional wooden Stevenson Screens,

reproduced or disclosed wholly or in part without the prior written permission of

CASELLA CEL LIMITED.

providing a maintenance-free solution to

protecting your temperature and humidity

instrumentation anywhere in the world.

Each instrument is assembled by hand and

subjected to rigorous quality control checks

throughout the production process to ensure it

is ideal for both manual and automated

observations.

Side 2

ADVANCED INSTRUMENT SHELTER

User Instructions

ADVANCED INSTRUMENT SHELTER

User Instructions

Side 3

2. SITING

The temperature measurements used in

meteorology are intended to represent general

conditions over as large an area around the

measuring point as possible. They are usually

taken at a height of 1.25 m above ground level.

To achieve the most representative local

conditions, the measurement station should be

sited in an unobstructed area open to the sun

and wind. Sites sheltered by trees or buildings,

in hollows or on the sides of hills are not

recommended, neither are sites on buildings,

as none of these locations will give

representative measurements.

The Casella Advanced Instrument Shelter is

designed to meet these conditions. It is

supplied with a 1.4 m high stand that must be

3. SCHEDULE OF PARTS

The Advanced Instrument Shelter consists of

the following parts.

M113011 Screen, with two drop-

down doors, supplied

ready assembled and

painted,

M131026A Stand, supplied as a

pre-fabricated kit.

HB3283 Installation Guide

The Stand Kit has 12 components, plus

fastenings.

4 Uprights (5 cm galvanised

angle iron)

2 Lower cross members

(5 cm galvanised angle iron)

2 Upper cross members

(5 cm galvanised angle iron)

4 Diagonal cross braces

(4 cm galvanised angle iron)

4 M10 x 60 mm bolts for

attaching the screen

18 M10 x 30 mm bolts for

assembling the stand

22 M10 nuts

22 M10 lock washers

When the equipment is delivered, please

check that all items on this schedule have

been supplied.

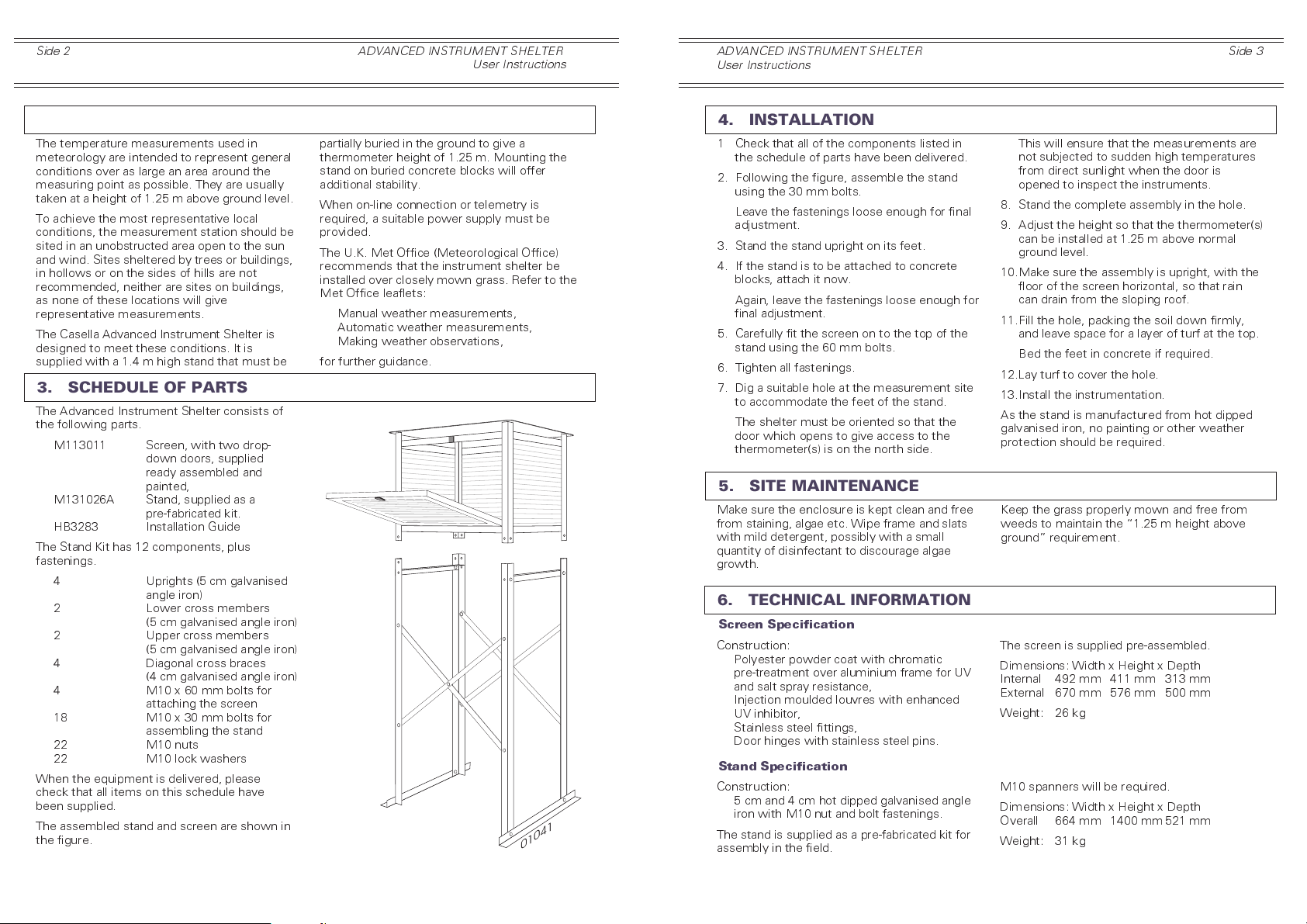

The assembled stand and screen are shown in

the figure.

partially buried in the ground to give a

thermometer height of 1.25 m. Mounting the

stand on buried concrete blocks will offer

additional stability.

When on-line connection or telemetry is

required, a suitable power supply must be

provided.

The U.K. Met Office (Meteorological Office)

recommends that the instrument shelter be

installed over closely mown grass. Refer to the

Met Office leaflets:

Manual weather measurements,

Automatic weather measurements,

Making weather observations,

for further guidance.

01041

4. INSTALLATION

1 Check that all of the components listed in

the schedule of parts have been delivered.

2. Following the figure, assemble the stand

using the 30 mm bolts.

Leave the fastenings loose enough for final

adjustment.

3. Stand the stand upright on its feet.

4. If the stand is to be attached to concrete

blocks, attach it now.

Again, leave the fastenings loose enough for

final adjustment.

5. Carefully fit the screen on to the top of the

stand using the 60 mm bolts.

6. Tighten all fastenings.

7. Dig a suitable hole at the measurement site

to accommodate the feet of the stand.

The shelter must be oriented so that the

door which opens to give access to the

thermometer(s) is on the north side.

5. SITE MAINTENANCE

Make sure the enclosure is kept clean and free

from staining, algae etc. Wipe frame and slats

with mild detergent, possibly with a small

quantity of disinfectant to discourage algae

growth.

6. TECHNICAL INFORMATION

Screen Specification

Construction:

Polyester powder coat with chromatic

pre-treatment over aluminium frame for UV

and salt spray resistance,

Injection moulded louvres with enhanced

UV inhibitor,

Stainless steel fittings,

Door hinges with stainless steel pins.

Stand Specification

Construction:

5 cm and 4 cm hot dipped galvanised angle

iron with M10 nut and bolt fastenings.

The stand is supplied as a pre-fabricated kit for

assembly in the field.

This will ensure that the measurements are

not subjected to sudden high temperatures

from direct sunlight when the door is

opened to inspect the instruments.

8. Stand the complete assembly in the hole.

9. Adjust the height so that the thermometer(s)

can be installed at 1.25 m above normal

ground level.

10.Make sure the assembly is upright, with the

floor of the screen horizontal, so that rain

can drain from the sloping roof.

11.Fill the hole, packing the soil down firmly,

and leave space for a layer of turf at the top.

Bed the feet in concrete if required.

12.Lay turf to cover the hole.

13.Install the instrumentation.

As the stand is manufactured from hot dipped

galvanised iron, no painting or other weather

protection should be required.

Keep the grass properly mown and free from

weeds to maintain the 1.25 m height above

ground requirement.

The screen is supplied pre-assembled.

Dimensions: Width x Height x Depth

Internal 492 mm 411 mm 313 mm

External 670 mm 576 mm 500 mm

Weight: 26 kg

M10 spanners will be required.

Dimensions: Width x Height x Depth

Overall 664 mm 1400 mm521 mm

Weight: 31 kg

Loading...

Loading...