Casella CEL CEL-360S User Manual

Instructions specific to hazardous area

installations

(reference European ATEX Directive

94/9/EC, Annex II, 1.0.6.)

The following instructions apply to equipment covered by certificate

number Sira 05ATEX2027X for the CEL-320/IS and CEL-360/IS:

1 The equipment may be used with flammable gases and vapours

with apparatus Groups IIA, IIB and IIC and with temperature

classes T1, T2, T3 and T4.

2 The equipment is only certified for use in ambient temperatures in

the range -20oC to +40oC and should not be used outside this

range.

3 The certificate marking is detailed on drawing numbers

13-1920001A/IS-03 and 13-1920002A/IS-03.

4 Repair of this equipment shall be carried out by the manufacturer

or in accordance with the applicable code of practice.

5 The certification of this equipment relies on the following

materials used in its construction: Polybutylene terephlhalate

(PBT) and Polycarbonate (PC)

If the equipment is likely to come into contact with aggressive

substances, then it is the responsibility of the user to take

suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection is not

compromised.

Aggressive substances e.g. solvents that may affect polymeric

materials

Suitable precautions e.g. regular checks as part of routine

inspections or establishing from the material’s data sheet that it

is resistant to specific chemicals.

6 The certificate number has an ‘X’ suffix that indicates that the

following special condition of certification applies;

Under certain extreme circumstances, the non-metallic parts

incorporated in the enclosure of this equipment may generate an

ignition-capable level of electrostatic charge. Therefore, when it

is used for applications that specifically require group II, category

1 equipment, the equipment shall not be installed in a location

where the external conditions are conducive to the build-up of

electrostatic charge on such surfaces. Additionally, the

equipment shall only be cleaned with a damp cloth.

CEL-320/360 Getting Started - Page 1

Page 2 - CEL-320/360 Getting Started

CEL-320/360 SERIES

01038

ta

e

its

d

g

e

ys

d

Issue: 2

If you want to get on and use the instruments without any background

information, skip Sections 3 - 5 and go straight to Section 6.

USERS GUIDE

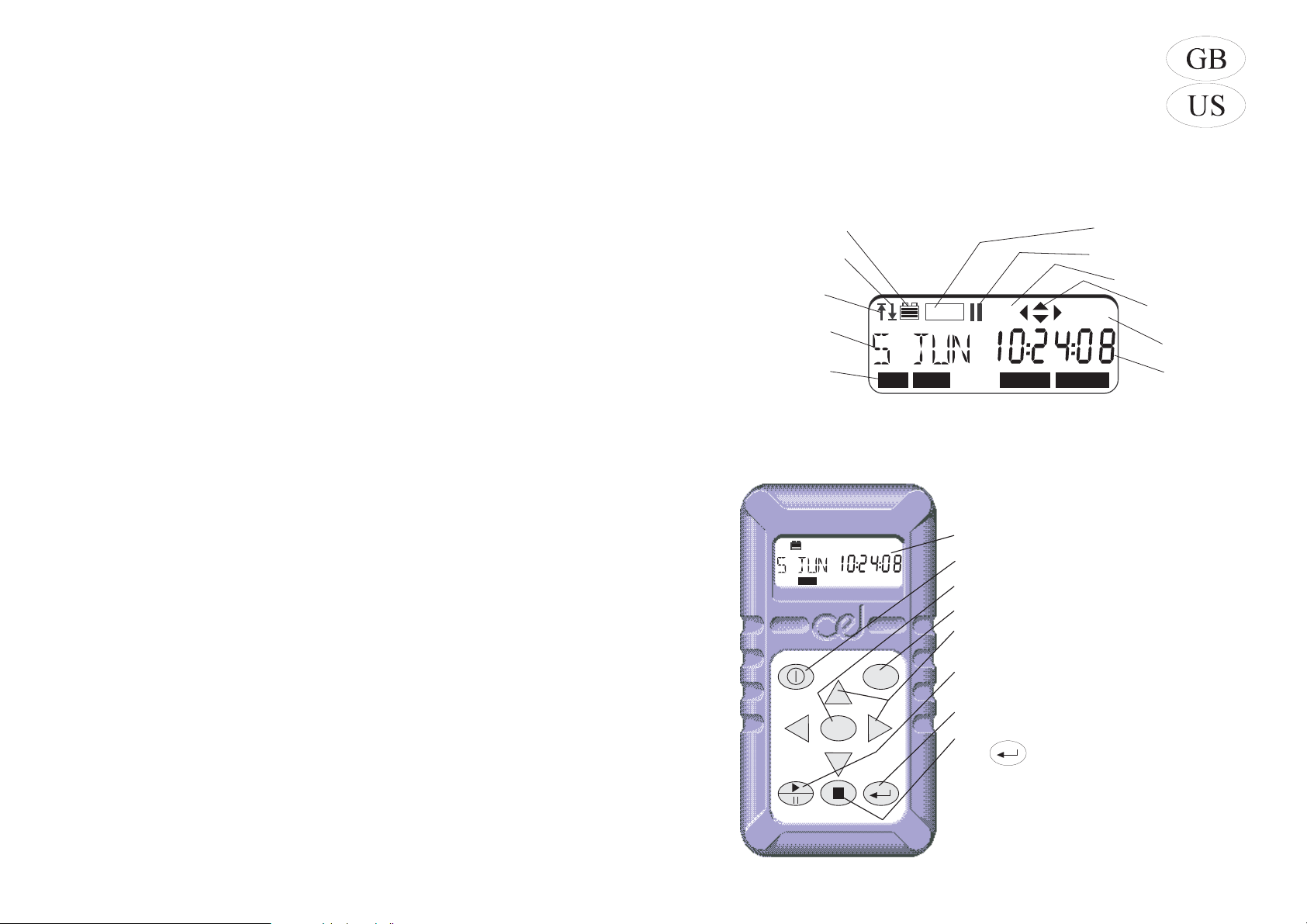

1. Display

Battery Condition

Under range has

Occurred

Overload has

Occurred

Measurement

Identity or Date

Current Mode,

Pressing the MENU

key will select each

of these in turn

REC

SLM DATA SET UP OPTION

CA

Data is Being Recorde

Measurement is Pause

Frequency Weightin

dB%

01037e

Indicates Activ

Option Ke

Current Un

Current Da

or Tim

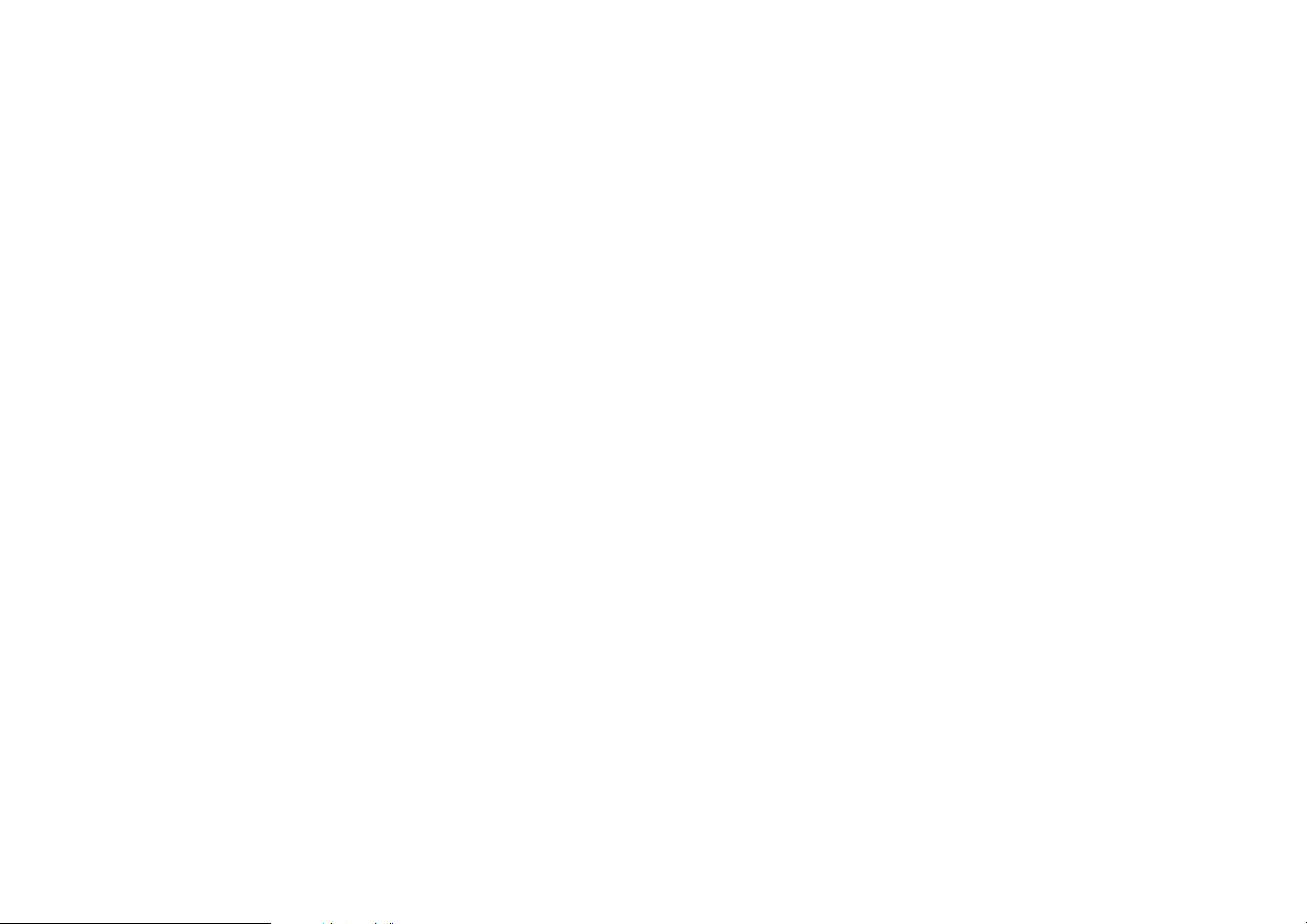

2. Keys

Display

Switches instrument ON/OFF

DATA

DATA

MENU

Changes operating mode

Accesses stored data

Select active options from the current

menu

Starts/Pauses/Restarts a measurement

record

Confirms actions of other keys

Stops a measurement when followed

by

CEL-320/360 Getting Started - Page 3

3. Contents

Section . . . . . . . . Page

1 Display . . . . . . . . . . . 3

2 Keys . . . . . . . . . . . . 3

3 Contents . . . . . . . . . . 4

4 Introduction to the

Dosimeters . . . . . . . . 4

4.1 Sound Level Meter Models 5

4.2 CEL-320/320S Noise

Dosimeters . . . . . . . 5

4.3 CEL-360/360S Logging

Noise Dosimeters . . . . 6

5 Preparation for Use . . . . 7

5.1 Install Battery and

Microphone . . . . . . . . 7

5.2 Perform Acoustic Calibration 7

6 Operation as a Dosimeter . 9

6.1 Select Dose Set Up for Use 9

6.2 Measure and Store

Dose Data . . . . . . . . 9

6.3 Recall Dose Data . . . . . 10

Section . . . . . . . . Page

6.4 Review Stored Data . . . . 10

6.5 Print Standard Report . . . 11

7 Operation as a Sound Level

Meter ...........12

8 Selecting and Changing

Options ..........13

8.1 Review Options . . . . . . 13

8.2 Set Time & Date . . . . . . 14

8.3 Change Timer and Run

Duration (CEL-360 Series) . 14

9 Technical Information . . . 16

9.1 Specification . . . . . . . . 16

9.2 CE Compliance . . . . . . 18

9.3 Default Parameter Settings 18

9.4 Parameter Identities . . . 19

10 Parts, Servicing & Warranty 20

10.1 Schedule of Parts . . . . . 20

10.2 Servicing &

Warranty Arrangements . . 20

11 Intrinsically Safe Models . 22

4. Introduction to the Dosimeters

The CEL-320 and CEL-360 Noise Dosimeters have been developed from

the successful CEL-420/460 range of instruments by adding features and

improving the control procedures. They measure the frequency weighted

noise exposures and peak sound levels simultaneously.

The dosimeter microphone and lead on both models can be replaced by

a sound level meter microphone to offer comprehensive sound level

measurement. The CEL-320/360 series instruments have the following

features.

¤ Seven built-in standard dose measurement setups:

OSHA, MSHA, DOD, ACGIH, ISO85*, ISO90* and METER

¤ Up to 13 user specified dose measurement setups,

¤ A single sound level meter (SLM) setup,

¤ 50 dose (DATA) result stores,

¤ Storage of up to 10 profiles attached to each CEL-360 dose

measurement, as specified by dB10 or dB12 software,

¤ Self configured storage.

The instruments are built to withstand rough industrial conditions with

cases formed from a polyester/polycarbonate material that gives them a

Note*: ISO procedures using Criterion 85 dB and 90 dB.

Page 4 - CEL-320/360 Getting Started

high resistance to damage. Data integrity is further protected by a dose

microphone lead which is designed to resist knocks and abrasions

without affecting the signal passing from microphone to instrument.

Both instruments can be operated and deliver dose and SLM

results without the need for other equipment, beyond an acoustic

calibrator. However, they become even more versatile when their

measurement and setup data is transferred via a PC using the CEL-6702

dB10 or CEL-6704 dB12 Windows™ based software.

These programs enable the instruments to be fully configured.

Dose (DATA) setups can be added or removed from the instrument,

while the individual measurement parameters can be added, deleted or

changed in a setup. Some setup parameters, such as measurement

range, can either be set to a particular value or left to the user to change

via the instrument keypad.

dB10 and dB12 have the facilities expected of fully featured 32

TM

bit Windows

packages, enabling report production with cut and paste

between applications and comprehensive word processing capabilities.

In addition, dB12 has extensive on screen graphing facilities.

4.1 Sound Level Meter & Intrinsically Safe (IS) Models

Both dosimeters can be converted to a miniature sound level meter by

fitting a CEL-425 SLM Microphone Adaptor. The CEL-320 becomes a

CEL-320S Sound Level Meter,

while the CEL-360 becomes a

CEL-360S Logging Sound Level

Meter.

For sound level meter

operation refer to Section 7.

Intrinsically safe versions

Table 1: Models Available

Standard

Model

CEL-320 Noise Dosimeter

CEL-320S Sound Level Meter

CEL-360 Logging Noise Dosimeter

CEL-360S Logging Sound Level Meter

Description

are available of both dosimeter

and sound level meter models.

The part numbers have “/IS” after their standard part number. The

model line up is shown in Table 1.

4.2 CEL-320/320S Noise Dosimeters

The following features apply to the CEL-320 and CEL-320S. These

instruments are ideal for quick on-site surveys and for monitoring

personal noise exposure in accordance with European ISO or USA

OSHA, MSHA, DOD and ACGIH standards.

For dose measurement, they are passive instruments with

settings that may be reviewed by key strokes, but which can be selected

only by means of the dB10 or dB12 software.

CEL-320/360 Getting Started - Page 5

However, all sound

level measurement

parameters can be set from

the keypad. There are three

overlapping measurement

ranges: 30 - 100, 50-120 &

70-140 dB, A & C RMS

weightings, Linear & C Peak

weightings, Fast, Slow &

Impulse time weightings, and

energy exchange rates (Q) of

3, 4, 5 & 6. In dose measurement mode, they display %

dose, % dose projected for

an 8 hour period, peak level

Table 2: Setups and Configuration Files

Parameter settings that do not modify preset

measurement protocols can be changed by using

the instrument keys.

All available parameter settings can be changed

from a PC by means of dB10 or dB12 Software.

Parameter settings that modify preset measurement protocols must first be saved by dB10 or

dB12 under a new setup identity in an instrument

“configuration file”.

A “configuration file” contains a complete

instrument set of setups, i.e. seven fixed dose

setups, up to 13 user defined setups, one SLM

setup, and one timer setup common to all dose

setups.

Parameter settings on an instrument can be

changed ONLY by using dB10 or dB12 to replace

the configuration file in the instrument by another

configuration file loaded from the PC.

and measurement duration.

For countries that are subject to European Union regulations or

the equivelent ISO standards, these instruments measure the daily

sound exposure level (L

identical with the L

EX,8h

Aeq,8hr

Pa2h according to IEC 1252, which is

required by ISO 1999), while for USA

OSHA/MSHA regulations they measure the Time Weighted Average

level (TWA).

When used as a sound level meter they display sound level,

maximum sound level, minimum sound level, peak, time-averaged (L

or L

) sound levels and sound exposure level (SEL).

Avg

Aeq

4.3 CEL-360/360S Logging Noise Dosimeters

In addition to the features available to the CEL-320 Dosimeters, the

following additional features apply to the CEL-360 and CEL-360S. These

instruments are recommended for detailed measurements as they

include extended processing and memory functions.

There are automatic run timing facilities controlled by the built-in

clock and time-history recording capabilities that allow up to 10 profiles

to be saved with each dose (DATA) result set, in a separate profile store.

Sampling times can be specified between 1 s and 1 hour by dB10 and

dB12 software, while profile storage is in excess of 220 000 data points,

where any single run can use up to 99 999 points.

The instruments are able to measure and save up to five user

specified L

specified via instrument keys, by dB10 or dB12, and start and stop times

preset via dB10 or dB12 can be switched on or off from the instrument

keys. Other settings can be changed only by dB10 and dB12 Software.

values (exceedance level percentiles). Run durations

n

Page 6 - CEL-320/360 Getting Started

Once data saved by a CEL-360 instrument has been downloaded

e

to a PC, the user can specify a period over which to re-calculate the

projected % dose values. The software can also calculate six

exceedance time percentiles with levels preset to values specified by

measurement standards, plus one user specified time percentile.

5. Preparation for Use

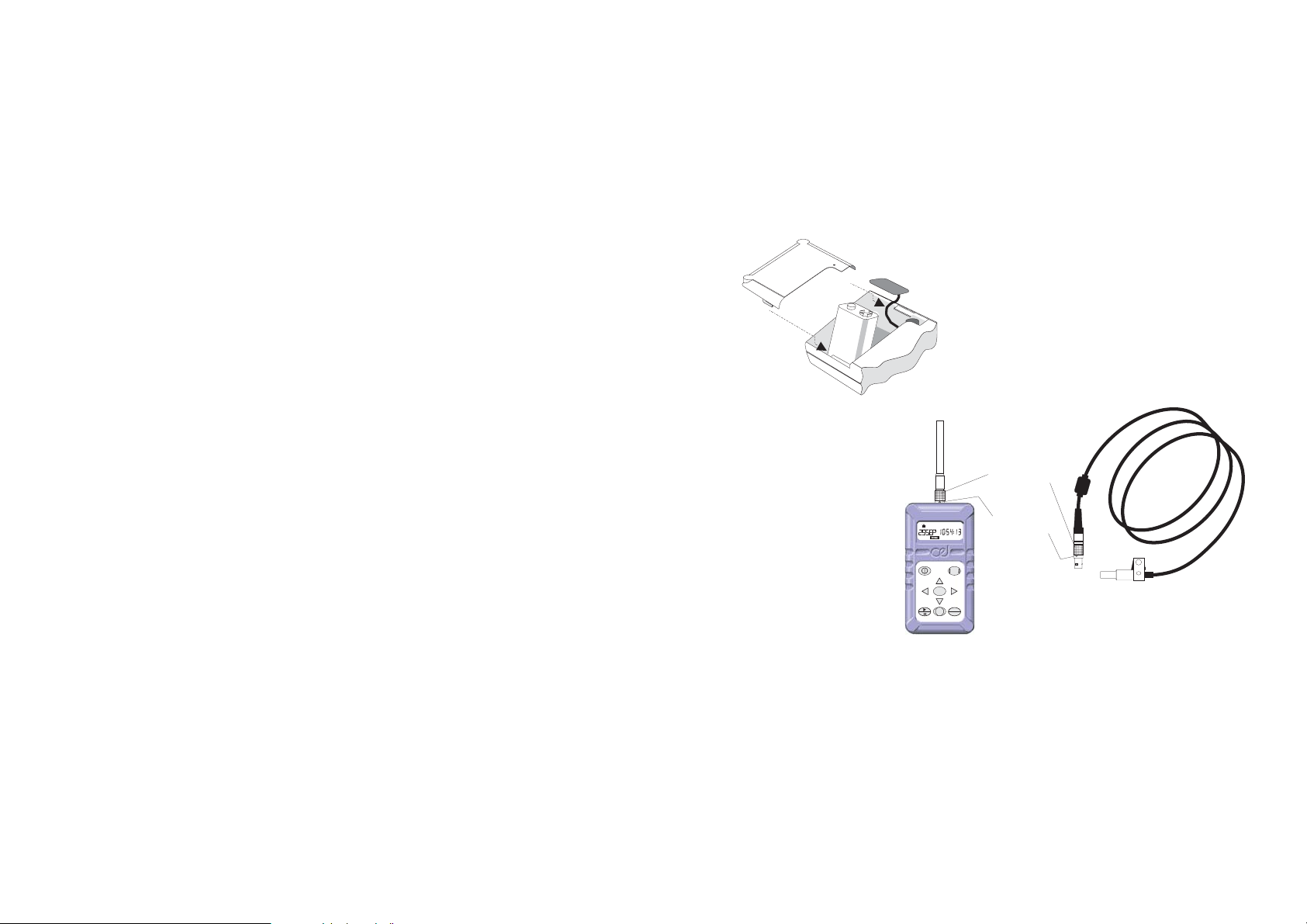

5.1 Install Battery & Microphone

Connect a new 6LF22 or equivalent 9 V

battery to the terminals in the battery

compartment in the rear of the instrument.

DO NOT disconnect the battery

once runs have been stored as they

will be lost !

With the instrument switched

OFF, insert the lead connector of the

960079

CEL-6681 Dosimeter Microphone or the

connector on the

CEL-425 SLM Adaptor

stalk into the socket

on the top end of the

case with the red dot

facing the front of the

dosimeter.

Remove the

connector ONLY by

pulling on the knurled

sleeve.

CEL-425

SLM Adaptor

Knurled

Red "Dot"

DATA

MENU

SET

STOP

ENTER

Sleeve

CEL-6681

Dosimeter Microphon

01042e

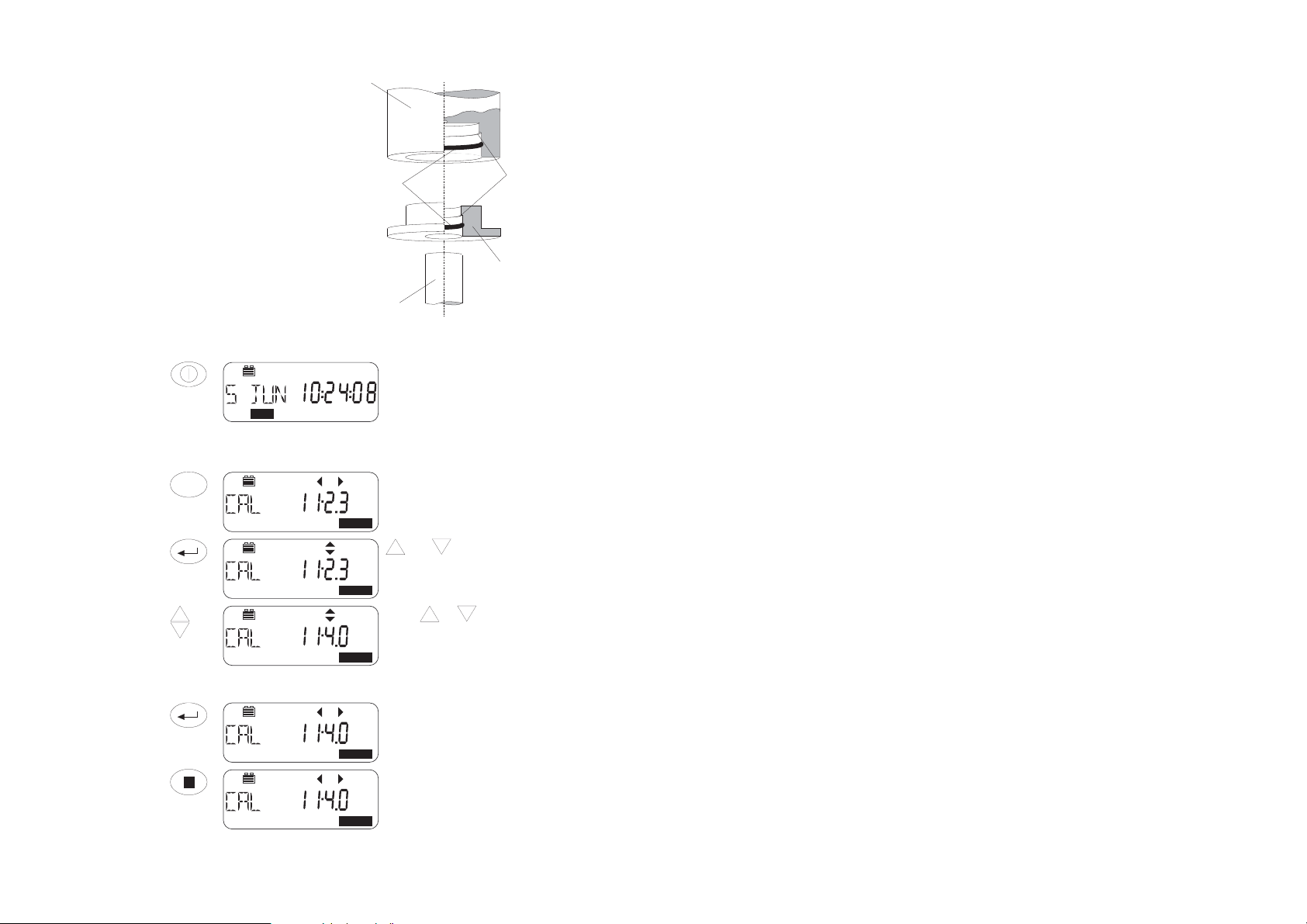

5.2 Perform Acoustic Calibration

Operations are controlled by a sequence of key strokes.

Perform a field accuracy check each time the instrument is

switched ON using a CEL-110/2 (Class 2) or CEL-110/1 (Class 1)

Calibrator as follows. It is also recommended that another acoustic

calibration be performed immediately after completing a measurement

run.

The calibration levels from both before and after are stored with

the run. When the second calibration occurs much later, provided the

same microphone assembly is used, the second level is attached to any

stored run that has no second calibration.

CEL-320/360 Getting Started - Page 7

Calibrator

980057

'

er

e

Fit the CEL-4726 Coupler

supplied with the calibrator (CEL-110/1 or

110/2 ) into the calibrator cavity, making

sure it is firmly in contact with the

shoulder in the cavity. (To aid removal,

the coupler flange does not fit close

against the calibrator housing).

O'Ring

Fit the microphone into the

coupler cavity, again ensuring that it

makes contact with the shoulder in the

coupler cavity.

Then follow these instructions.

1/4"

Microphone

Operation Press Display Shows Comments

1. Switch the

instrument

ON

2. Change

Operating

Mode

3. Enable

Level

Change

4. Change

Indicated

Level

5. Set

Calibration

Level

6. If the

calibration is

to be aborted

MENU

repeatedly

or

DATA

Start Up messages show:

Instrument Type,

Serial Number (when set),

Print (when printer cable

connected),

Firmware Version,

finishing with the Last Used

Operating Mode.

To select OPTION, to enable

Acoustic Calibration, it shows

current SPL.

OPTION

and are now enabled.

The display shows current

sound level.

OPTION

Press or .

Indicated level rises (falls)

0.05 dB for each key press.

Adjust to correct level for

OPTION

CEL-320/360 microphones at

standard temperature and

pressure: 114.0 dB.

The 114.0 dB calibration level

is now set, and will be stored

in the microphone assembly.

OPTION

The calibration level is

NOT SAVED and the

instrument continues to use

the last saved calibration.

OPTION

Should

Microphon

Coupler

Page 8 - CEL-320/360 Getting Started

Loading...

Loading...