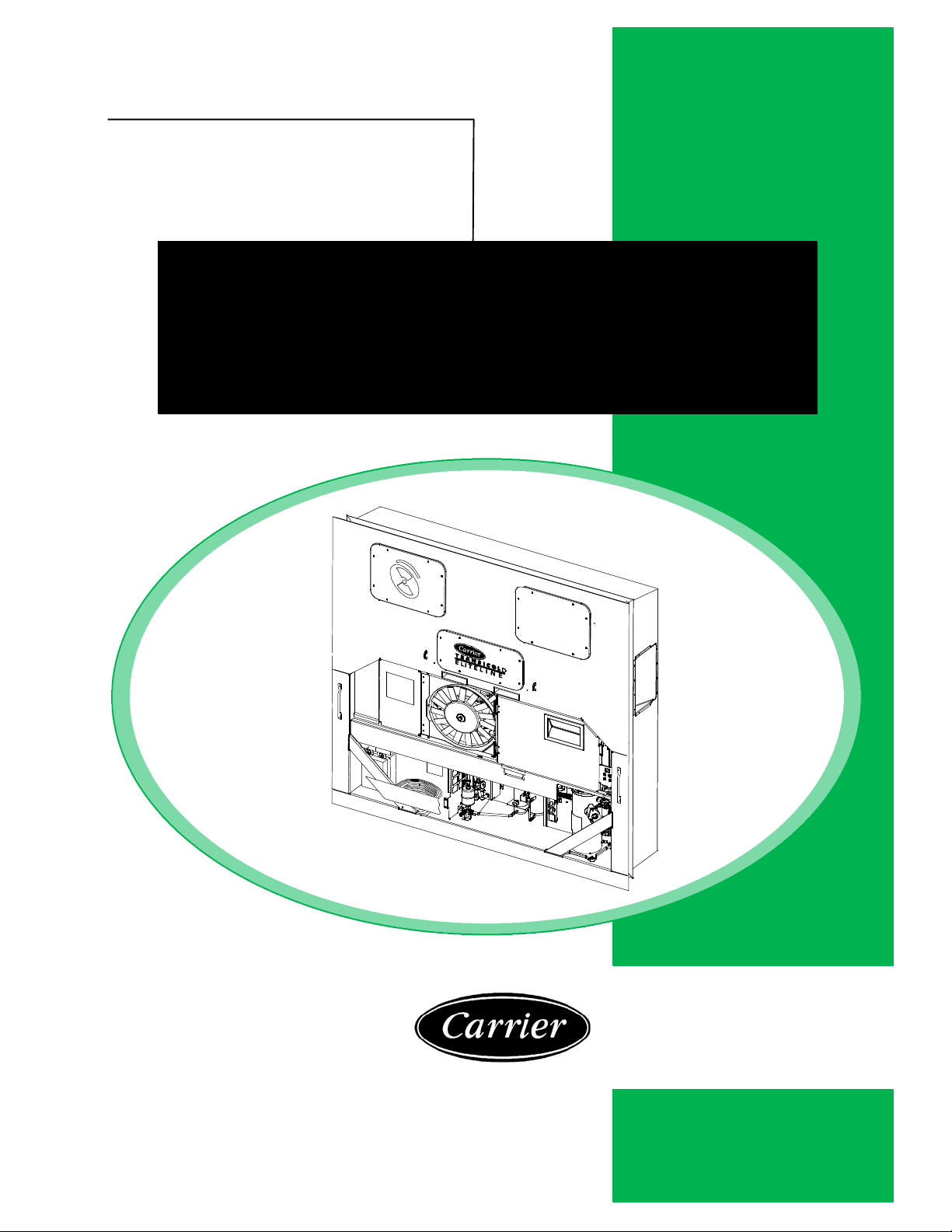

Page 1

Carrier

Transicold

Container

Refrigeration

Model 69NT40--531Series

T--292PL Rev C Change 06/10

Service

Parts List

Page 2

SERVICE PARTS LIST

CONTAINER REFRIGERATION UNIT

MODEL

69NT40-531 Series

Carrier Transicold. A member of the United Technologies Corporation family. Stock symbol UTX.

Carrier Transicold Divsion, Carrier Corporation, P .O. Box 4805, Syracuse, N.Y. 13221 U. S. A.

ã 2003 CarrierCorporation D PrintedinU.S.A.3/03

Page 3

TABLE OF CONTENTS

INTRODUCTION iii...........................................................................

CONFIGURATION IDENTIFICATION iii.........................................................

OPTION DESCRIPTIONS iii...................................................................

ORDERING INSTRUCTIONS vi................................................................

LETTER DESIGNATIONS vi...................................................................

1. QUICK LIST -- Clamps, Filter-Drier, Fuses, Ty-Raps, and Wire Terminals 1.....................

2. REFRIGERATION UNIT ASSEMBLY 2....................................................

2.1 Refrigeration Unit -- Area Locator 2....................................................

2.2 Rain Gutters 4......................................................................

2.3 Handles 4..........................................................................

2.4 Thermometer Port 5.................................................................

2.5 Control Box Door 6..................................................................

2.6 Control Box -- Composite 8...........................................................

2.7 Control Box -- Standard Electrical Components, Remote Monitoring and CFS 10.............

2.8 Control Box -- Controller Module Section and Software Cards 12...........................

2.9 Control Box -- Display Module and Communications Interface Module Section 14............

2.10 Condenser Fan Motor, Condenser Coil, and Bolted or Hinged Grille Section 16...............

2.11 Compressor Tubing Section 18........................................................

2.12 Receiver Section 20..................................................................

2.13 Water--Cooled Condenser 21..........................................................

2.14 Economizer, Economizer Expansion V alve, Economizer Solenoid V alve, & Filter Drier Section 22

2.15 STS and SRS Section 24.............................................................

2.16 Oil Separator Section 25..............................................................

2.17 Upper Fresh Air Makeup and Access Panels 26..........................................

2.18 Lower Fresh Air Makeup Vent 28.......................................................

2.19 Evaporator Fan Assembly and Transfresh 30............................................

2.20 Evaporator Coil Section 32............................................................

2.21 USDA Option, Probe Kits 34...........................................................

2.22 Back Panel Assembly -- Aluminum Bolted 36............................................

2.23 Back Panel Assembly -- Aluminum Bolted with USDA Door 38.............................

2.24 Back Panel Assembly -- Aluminum Hinged 40............................................

2.25 Back Panel Assembly -- Stainless Steel Hinged 42.......................................

2.26 Partlow Temperature Recorder 44......................................................

2.27 Saginomiya Temperature Recorder 46..................................................

2.28 Electronic Partlow Temperature Recorder 48.............................................

2.29 Temperature Recorder -- None 48......................................................

2.30 Compressor Mounting Components and Guard 50........................................

2.31 Transducers 52......................................................................

2.32 Cable Restraint Components (Bungy Cords and J--Hooks) 54..............................

2.33 Voltage Cables (460V and 230V) 56....................................................

i T-292PL

Page 4

TABLE OF CONTENTS (Continued)

2.34 Autotransformer (With and Without CB2 and Transformer Bridge Unit) 58...................

2.35 Labels and Decals 60.................................................................

3. INTERROGATOR AND ACCESSORIES 62.................................................

3.1 Datareader 64.......................................................................

3.2 Interrogator Receptacle 65............................................................

4. COMPRESSOR -- SCROLL 66............................................................

5. CONTROLLER/DATACORDER 67.........................................................

6. TOOLS 68..............................................................................

PART NUMBER INDEX Index 1.....................................................................

iiT-292PL

Page 5

INTRODUCTION

1 INTRODUCTION

The Carrier Transicold model 69NT40--531 series units

are of lightweight aluminum frame construction,

designed to fit in the front of a container and serve as the

container front wall.

2 CONFIGURATION IDENTIFICATION

Unit identification information is provided on a plate

located near the compressor. The plate provides the

unit model number, the unit serial number and the unit

parts identification number (PID). The model number

identifies the overall unit configuration while the PID

provides information on specific optional equipment,

factory provision to allow for field installation of optional

equipment and differences in detailed parts.

Configuration identification for the models covered

herein are provided in the Carrier Transicold Container

Unit Matrix manual, publication T--300. Printed copies of

the T--300 may be obtained from Carrier Transicold.

Also, a weekly updated copy may be found at the Carrier

Web site, www.carrier.refrigeration.com.

3 OPTION DESCRIPTIONS

Various options may be factory or field fitted to the base

unit. These options are listed in the tables and described

in the following subparagraphs.

3.1 Battery

The refrigeration controller may be fitted with standard

replaceable batteries or rechargeable battery pack.

3.2 Dehumidification

The unit may be fitted with a humidity sensor. This

sensor allows setting of a humidity set point in the

controller. In the dehumidification mode the controller

will operate to reduce internal container moisture level.

3.3 Control Box

The control box is composite material and may be fitted

with a lockable door.

3.4 Temperature Readout

The unit may be fitted with suction and discharge

temperature sensors. The sensor readings may be

viewed on the controller display.

3.5 Pressure Readout

The unit is fitted with standard suction and discharge

transducers. The transducer readings may be viewed

on the controller display.

3.6 USDA

The unit may be supplied with fittings for additional

temperature probes which allow recording of USDA

Cold Treatment data by the integral DataCORDER

function of the Micro--Link refrigeration controller.

3.7 Interrogator

Units that use the DataCORDER function are fitted with

interrogator receptacles for connection of equipment to

download the recorded data. Two receptacles may be

fitted, one accessible from the front of the container and

the other mounted inside the container (with the USDA

receptacles).

3.8 Remote Monitoring

The unit may be fitted with a remote monitoring

receptacle. This item allows connection of remote

indicators for COOL, DEFROST and IN RANGE.

Unless otherwise indicated, the receptacle is mounted

at the control box location

3.9 Communications.

The unit may be fitted with a communications interface

module. The communications interface module is a

slave module which allows communication with a

master central monitoring station. The module will

respond to communication and return information over

the main power line. Refer to the ship master system

technical manual for further information.

3.10 Compressor

The unit is fitted with a scroll compressor with either

standard piping (equipped with suction, discharge,

economizer and oil return service valves) or with

semi--hermetic piping (equipped with suction, discharge

and economizer service connections).

3.11 Condenser Coil

Theunitmaybefittedwitha5rowcoilusingnominal3/8

inch tubing, or the unit may be fitted with a 4 row coil

using 7mm tubing. The required refrigerant charge is

different for each coil.

3.12 Autotransformer

An autotransformer may be provided to allow operation

on 190/230, 3phase, 50/60 hertz power. The

autotransformer raises the supply voltage to the

nominal 380/460 volt power required by the base unit.

The autotransformer may also be fitted with an

individual circuit breaker for the 230 volt power.

If the unit is fitted with an autotransformer and

communications module, the autotransformer will be

fitted with a transformer bridge unit (TBU) to assist in

communications.

3.13 Temperature Recorder

One of three temperature recording devices may be

fitted to the unit. The devices include a mechanical

recorder manufactured by Partlow Corporation, a

mechanical recorder manufactured by Saginomiya

Corporation, and an electronic recorder manufactured

by Partlow Corporation.

3.14 Gutters

Rain gutters may be fitted over the control box and

recorder section to divert rain away form the controls.

The different gutters include standard length bolted

gutters, extended length gutters and riveted gutters.

iii

T-292PL

Page 6

3.15 Handles

The unit may be fitted with handles to facilitate access to

stacked containers. These handles may included fixed

handles (located at the sides of the unit) and/or a hinged

handle at the center (attached to the condenser coil

cover).

3.16 Thermometer Port

The unit may be fitted with ports in the front of the frame

for insertion of a thermometer to measure supply and/or

return air temperature. If fitted, the port(s) will require a

cap and chain.

3.17 Water Cooling

The refrigeration system may be fitted with a water

cooled condenser. The condenser is constructed using

copper--nickel tube for sea water applications. The

water cooled condenser is in series with the air cooled

condenser replaces the standard unit receiver. When

operating on the water cooled condenser, the

condenser fan is deactivated by either a water pressure

switch or condenser fan switch.

3.18 Back Panels

Back panel designs that may be fitted include panels of

aluminum and stainless steel. Panels may be fitted with

access doors and/or hinge mounting.

3.19 460 Volt Cable

Various power cable and plug designs are available for

the main 460 volt supply . The plug options tailor the

cables to each customers requirements.

3.20 230 Volt Cable

Units equipped with an autotransformer require an

additional power cable for connection to the 230 volt

source. Various power cable and plug designs are

available. The plug options tailor the cables to each

customers requirements.

3.21 Cable Restraint

Various designs are available for storage of the power

cables. These options are variations of the compressor

section front cover.

3.22 Upper Air (Fresh Air Make Up)

The unit may be fitted with an upper fresh air makeup

assembly. The openings may also be fitted with

screens.

3.24 Controlled Atmosphere

The units may be fitted with the TransFresh option.

For information on the TransFresh system, contact

TransFresh Corporation, P.O. Box 1788, Salinas CA

93902

3.25 Evaporator

The unit is fitted with an evaporator coil and a hermetic

thermal expansion valve.

3.26 Evaporator Fan Operation

The units are fitted with Normal Evaporator Fan

Operation, opening of an evaporator fan internal

protector will shut down the unit.

3.27 Labels

Operating Instruction and Function Code listing labels

will differ depending on the options installed. For

example, additional operating instructions are required

to describe start--up of a unit equipped with an

autotransformer. Where the labels are available with

additional languages, they are listed in the parts list.

3.28 Plate Set

Each unit is equipped with a tethered set of wiring

schematic and wiring diagram plates.

The plate sets are ordered using a seven digit base part

number and a two digit dash number. (See Unit Matrix

Manual, T-300)

3.29 Controller

Two different controllers are available:

1. Remanufactured -- Controller is the equivalent of a

new OEM controller and is supplied with a 12 month

warranty.

2. Repaired -- Controller has had previous faults

repaired and upgraded with the latest software.

Note: Repaired controllers are NOT to be used for

warranty repairs only full OEM Remanufactured

controllers are to be used.

Controllers will be factory equipped with the latest

version of operational software, but will NOT be

configured for a specific model number and will need to

be configured, at the time of installation or sale.

3.30 Stepper Drive

All the units covered by this manual have suction

modulating valves which act to control system capacity.

Units indicated as being fitted with “stepper drive” have

digital control motors fitted to the suction modulating

valve to open and close the valve in steps as required.

3.31 Condenser Grille

Two styles of condenser grilles are available, direct

bolted grilles and hinged grilles.

3.23 Lower Air (Fresh Air Make Up)

The unit may be fitted with a lower fresh air makeup

assembly. These assemblies are supplied in two

designs, the standard design and the macro design. The

openings may also be fitted with screens.

T-292PL

iv

Page 7

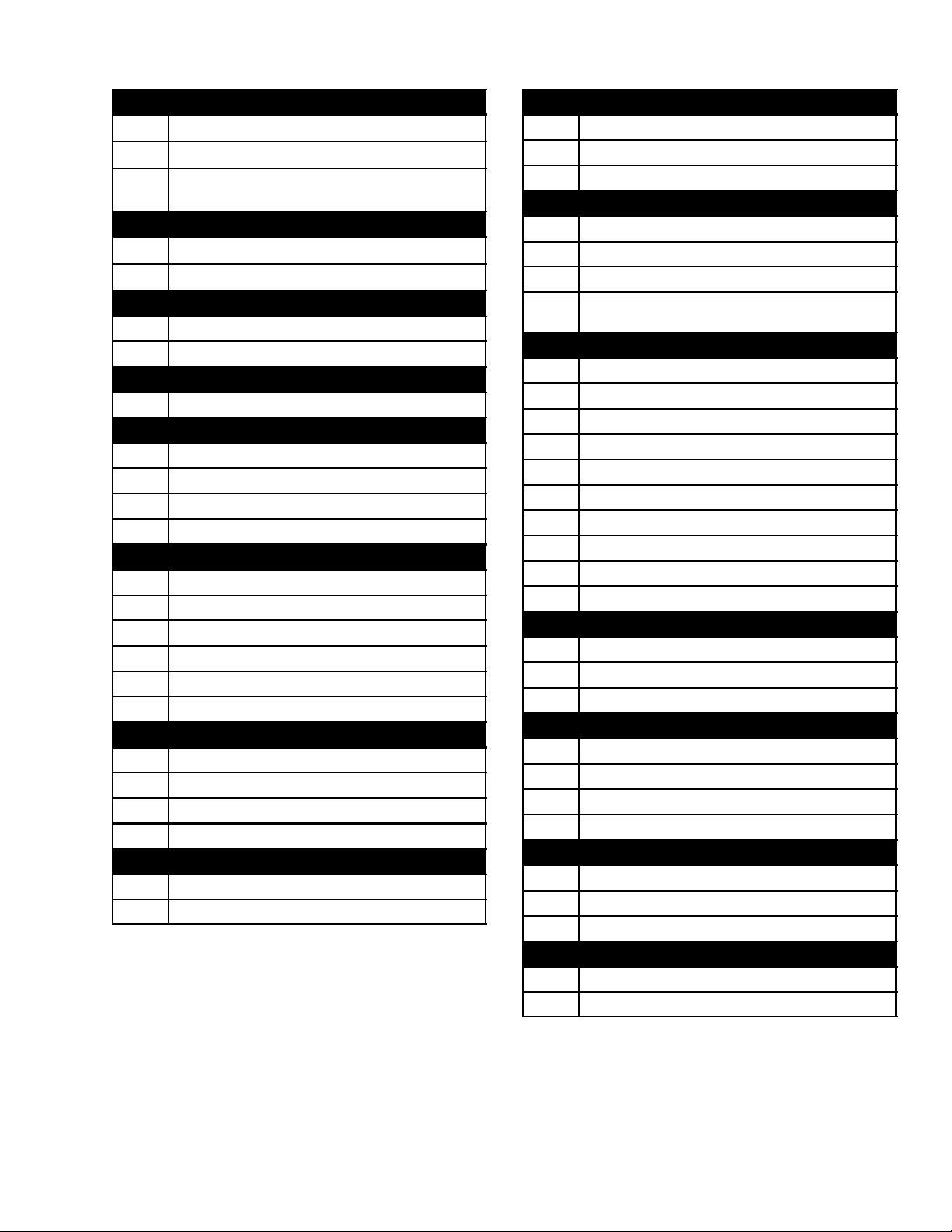

OPTION LEGEND

General

-- Feature Not Applicable

X

P

Features that apply to model

Factory Installation of Equipment to

Allow Field Installation

Battery Codes

S

R

Control Box Codes

C Composite Box Without Door Lock

CL Composite Box With Door Lock

Pressure Readout Codes

T Factory Installed Pressure Transducers

USDA Codes

D Option D

V Option V

1 Option 1

2 Option 2

Interrogator Codes

1 Left Straight Mount

2 Right Mount

3 Box Mount

4 Left Mount

5 Left Angled Mount

6 Right Mount

Communications Codes

1 Standard

2 HighDataRate

3 Chipset Modem

4 Low Data Rate

Compressor Codes

S Scroll

SS Scroll with Semi--Hermetic Piping

Standard (throw away) Cells

Rechargeable Cells

Condenser/Receiver Codes

4 Four Row Coil

5 Five Row Coil

L Large Receiver

AutoTransformer Codes

1 Transformer Fitted

2 Transformer With CB2 Fitted

3 Transformer With CB2 and Receptical

4 Transformer With CB2 and Transformer

Bridging Unit

Temperature Recorder Codes

1 Partlow Without Probe

2 Partlow With Probe

3 Battery Operated Parlow Without Probe

4 Battery Operated Parlow With Probe

5 Saginomiya Without Probe

6 Saginomiya With Probe

7 Standard Electronic Partlow

8 Special Electronic Parlow

9 No T emperature Recorder

10 Electronic Partlow (Both)

Gutter Codes

1 Standard Length Bolted Gutters

3 Extended Length Gutters

4 Rivieted Gutters

Handle Codes

1 Two Side and One Center

2 Two Side

3 One Center

4 One Right Side and Two Center

Thermometer Port Codes

1 Supply Air Port

2 Return Air Port

B Both Ports

Water Cooling Codes

W Water Pressure Switch

F Condenser Fan Switch

v

T-292PL

Page 8

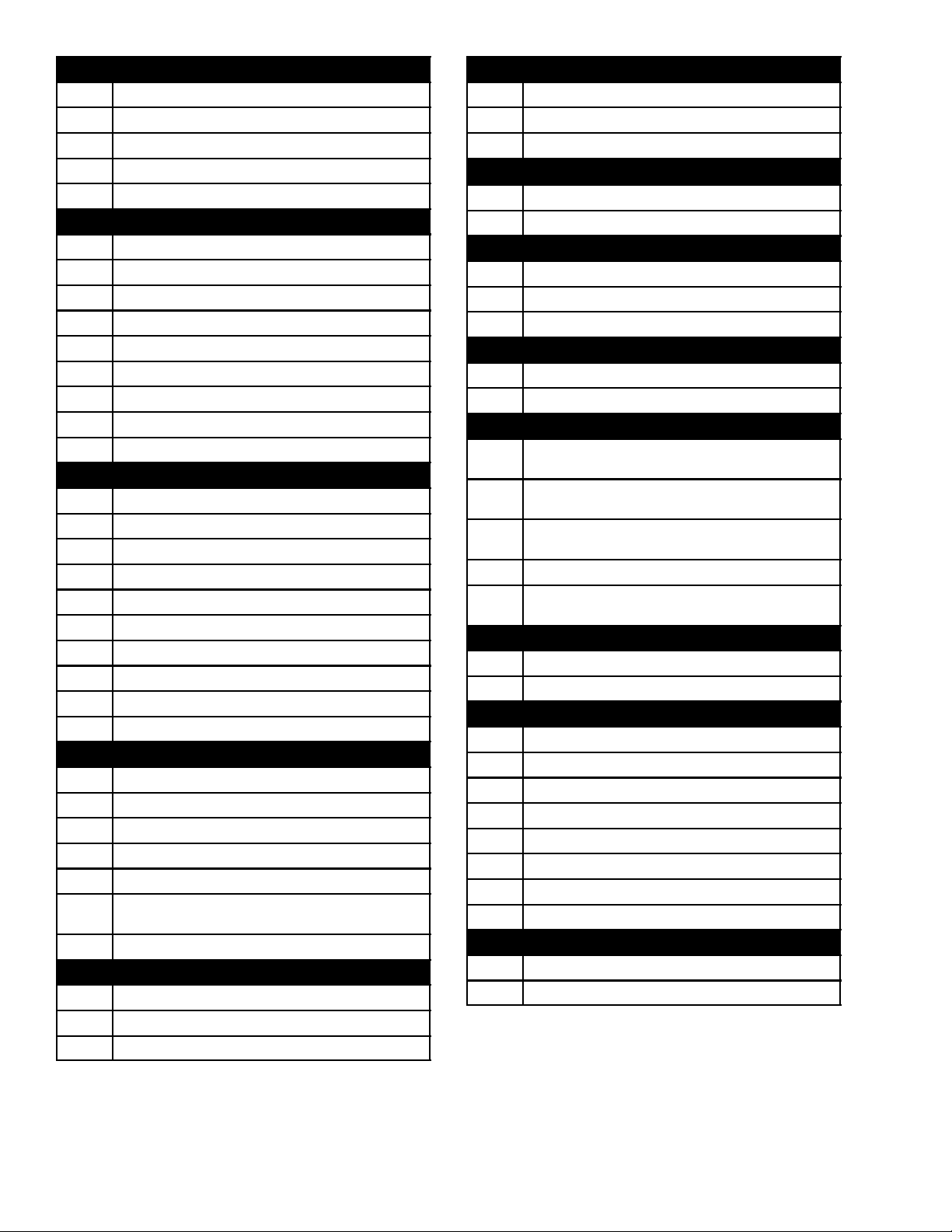

Back Panel Codes

1 Bolted Panels

2 Bolted Panels With USDA Door

3 Bolted Panels With Probe Access Door

4 Hinged Panels

5 Hinged Stainless Steel Panels

460 Volt Cable Codes

1 Option1

2 Option 2

3 Option 3

4 Option 4

5 Option 5

6 Option 6

7 Option 7

8 Option 8

9 Option 9

230Volt Cable Codes

1 Option 1

2 Option 2

3 Option 3

4 Option 4

5 Option 5

6 Option 6

7 Option 7

8 Option 8

9 Option 9

10 Option 10

Cable Restraint Codes

1 Cable Door

2 Left Bungy Cord Only

3 J--Hook

4 Left and Right Bungy Cord

5 Left Bungy Cord With Left Extended Guard

6 Left & Right Bungy Cords With Extended

Guards

R Dummy Receptical

Upper Air Codes

1 No Upper Fresh Air

2 Upper Fresh Air Installed

3 Upper Fresh Air Installed With Screen

Lower Air Codes

1 No Lower Fresh Air

2 Lower Fresh Air Installed

3 Lower Fresh Air With Screen Installed

Controlled Atmosphere

1 TransFresh

2 Carrier Transicold Everfresh System

Arctic Mode Codes

C Crankcase Heater

L Drainline Heater

B Both Crankcase Heater & Drainline Heater

Condenser Grille Codes

B Bolted Grille

H Hinged Grille

Evaporator Codes

1 Original Coil with Semi--Hermetic TXV &

Standard Heat Exchanger

2 Coil With Hermetic TXV & Standard Heat

Exchanger (4 Heaters)

3 Coil With Hermetic TXV & Large Heat

Exchanger (4 Heaters)

4 Helicox Hatched

5 Coil With Hermetic TXV & Standard Heat

Exchanger (6 Heaters)

Evaporator Fan Codes

1 Normal Evaporator Fan Operation

2 Single Evaporator Fan Operation Capability

Label Codes

1 English

2 English / Spanish

3 English / French

4 English / Korean

5 English / Traditional Chinese

6 English / Simplifed Chinese

7 English / Japanese / Chinese

8 English/German

Emergency Bypass Codes

B Emergency Bypass & Emergengy Defrost

EB Emergency Bypass Only

T-292PL

vi

Page 9

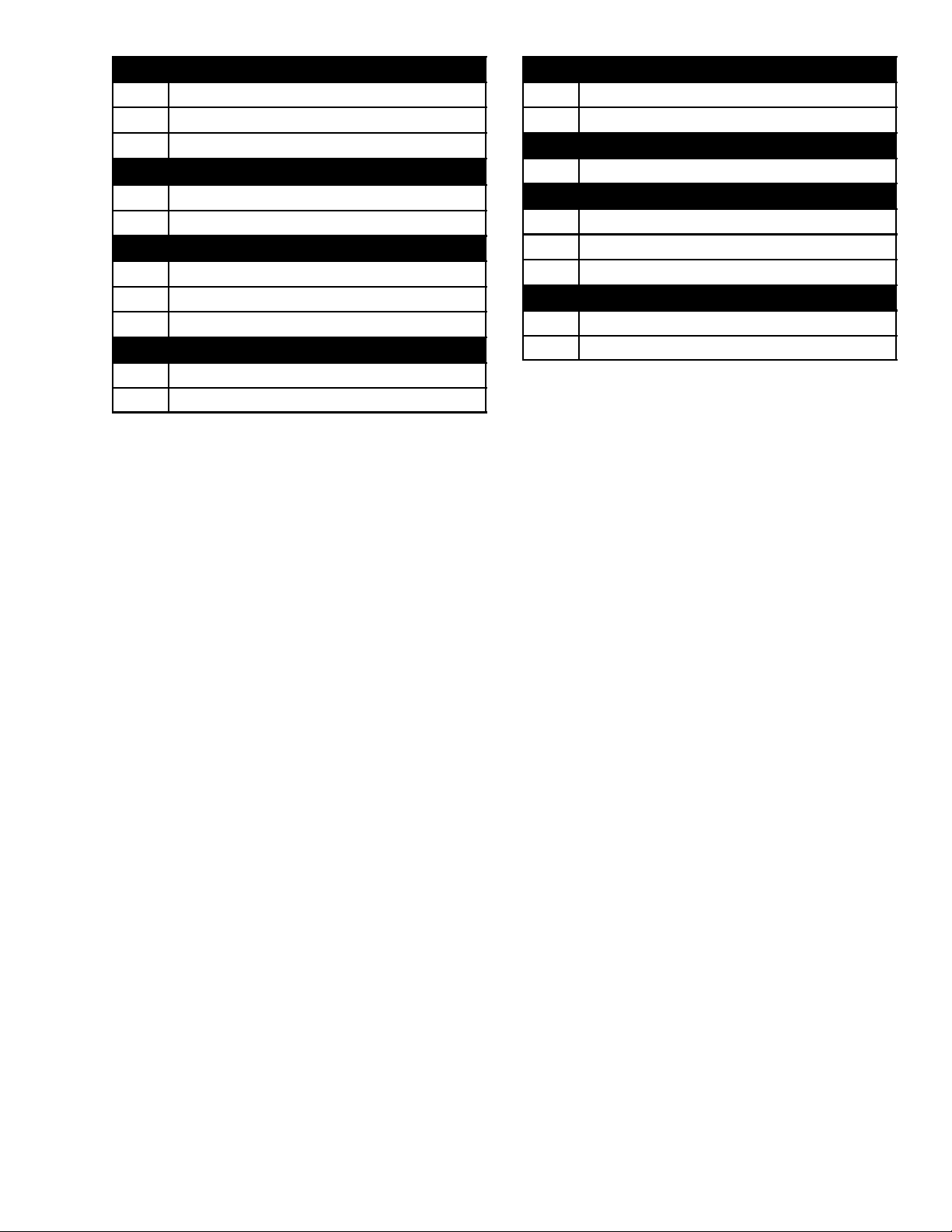

Lower Air Codes

1 No Lower Fresh Air

2 Lower Fresh Air Installed

3 Lower Fresh Air With Screen Installed

Controlled Atmosphere

1 TransFresh

2 Carrier Transicold Everfresh System

Arctic Mode Codes

C Crankcase Heater

L Drainline Heater

B Both Crankcase Heater & Drainline Heater

Condenser Grille Codes

B Bolted Grille

H Hinged Grille

Evaporator Codes

4 Helicox Hatched

6 Streamline Coil

Evaporator Fan Codes

1 Normal Evaporator Fan Operation

Label Codes

1 English

2 English / Spanish

5 English / Traditional Chinese

Emergency Bypass Codes

B Emergency Bypass & Emergengy Defrost

EB Emergency Bypass Only

Ordering Instructions

All orders and inquiries for parts must include: Parts Identification Number (PID), Model Number , Unit Serial Number,

Part Number, Description of part as shown on list and Quantity required. Address all correspondence for parts to the

following address:

CARRIER TRANSICOLD DIVISION

Replacement Components Group, TR-20

P.O. Box 4805, Syracuse, New York 13221

or FAX to: (315) 432-3778

Letter Designations

The following letter designations are used to classify parts throughout this list:

A/R= As Required

N/A = Not Available

NS = Not shown in illustration

NSS = Not sold separately -- Order next higher assembly or kit

PID = Parts Identification Number -- essential to identify unit configuration.

PL = Purchase Locally

SST = Stainless Steel -- 300 Series unless otherwise specified.

SV = Suffix SV -- added to part number designates service replacement part.

vii

T-292PL

Page 10

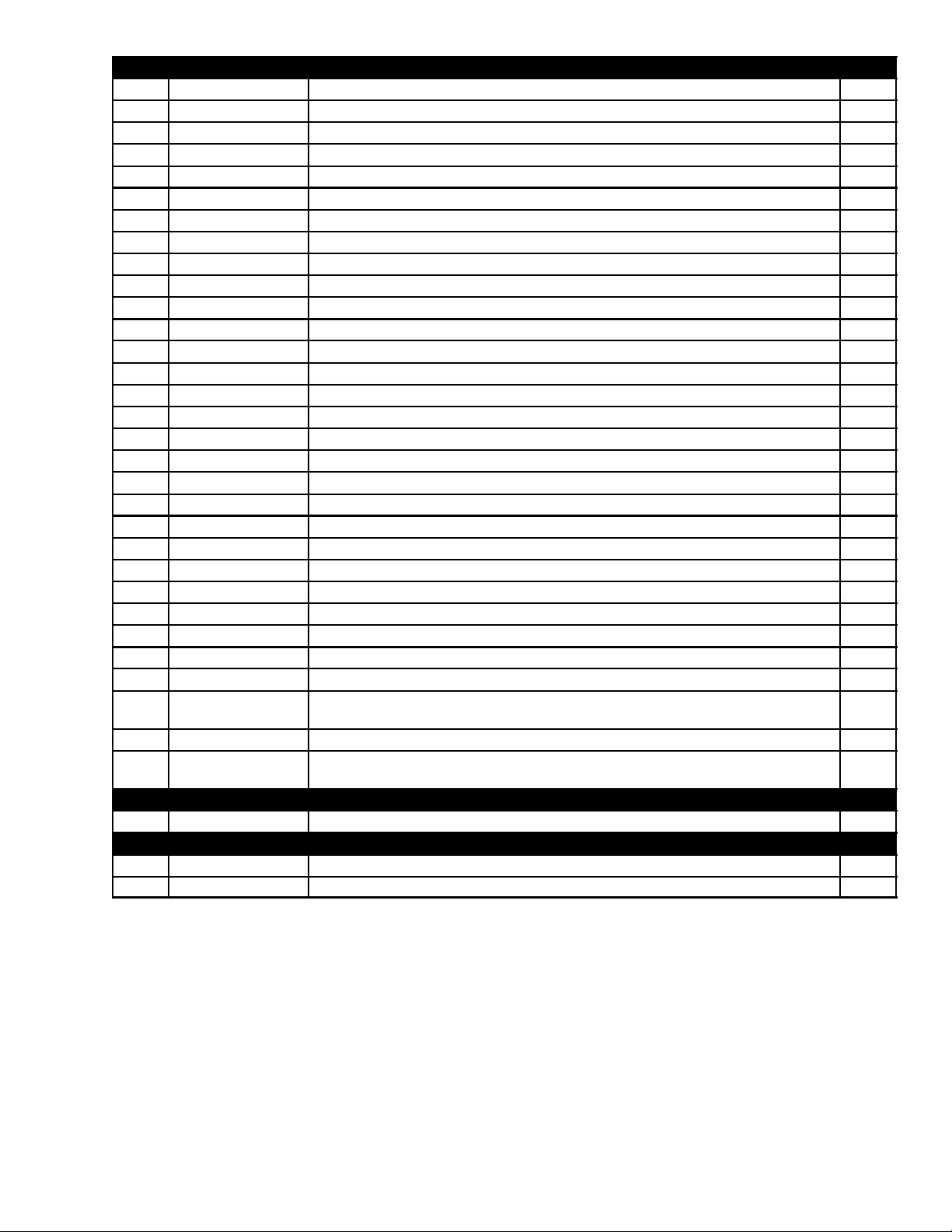

1 QUICK LIST -- CLAMPS, FILTER-DRIER, FUSE, TY-RAPS, AND WIRE TERMINALS

PART NO. DESCRIPTION

34-00373-51 Clamp, Tube, 1/4 -- SST

34-00373-53 Clamp, Tube, 3/8 -- SST

34-00373-05 Clamp, Tube, 1/2 -- SST

34-00373-07 Clamp, Tube, 5/8 -- SST

34-00373-59 Clamp, Tube, 3/4 -- SST

34-00373-11 Clamp, Tube, 7/8 -- SST

34-00373-65 Clamp, Tube, 1-1/8 -- SST

34-00373-67 Clamp, Tube, 1-1/4 -- SST

34-00373-69 Clamp, Tube, 1-3/8 -- SST

34-00373-71 Clamp, Tube, 1-1/2 -- SST

22-00066-01 Connector, Butt End, Wire Range -- 22 to 16 AWG

22-00066-02 Connector, Butt End, Wire Range -- 16 to 14 AWG

22-00066-03 Connector, Butt End, Wire Range -- 12 to 10 AWG

22-00041-00 Connector, Closed End, Wire Range -- 22 to 14 AWG

22-00041-02 Connector, Closed End, Wire Range -- 18 to 10 AWG

14--00311--02SV Filter-Drier

22-02336-02 Fuse, 5 Amp (F1 & F2)

22-02336-04 Fuse, 10 Amp (F3)

22-01140-01 Ring Terminal, #6, Wire Range -- 12 to 10 AWG

22-01140-02 Ring Terminal, #10, Wire Range -- 12 to 10 AWG

22-01140-04 Ring Terminal, 3/8, Wire Range -- 12 to 10 AWG

22-00119-04 Ring Terminal, 1/4, Wire Range -- 12 to 10 AWG

22-00120-04 Ring Terminal, #10, Wire Range -- 16 to 14 AWG

22-00120-07 Ring Terminal, 5/16, Wire Range -- 16 to 14 AWG

22-00121-07 Ring Terminal, #10, Wire Range -- 22 to 16 AWG

22-01139-04 Ring Terminal, 3/8, Wire Range -- 16 to 14 AWG

22-01141-01 Spade Terminal, 1/4 x 5/16, Wire Range -- 16 to 14 AWG

22-00595-01 Spade Terminal, 3/8, Wire Range -- 12 to 10 AWG

22-01106-00 Spiral Wrap, 1/4 Diameter x 25 ft. lg.

22-01107-00 Spiral Wrap, 1/2 Diameter x 25 ft. lg.

66U1-3803 Tube, Heat Shrink, 1/4 ID x 2-1/8 lg.

66U1-3803-1 Tube, Heat Shrink, 1/2 ID x 2-3/4 lg.

44-01043-05 Ty-Raps, 5-1/2 inches lg.

44-01043-07 Ty-Raps, 11.00 inches lg.

22-50007 Series Wire Markers

07-00345-00 Sealant, Pipe (Used to seal fittings on unit with R-134a)

07-00313-00 Cleaner, Coil

76-00397-01 Paint, Compressor Touch-Up, Blue

1 T-292PL

Page 11

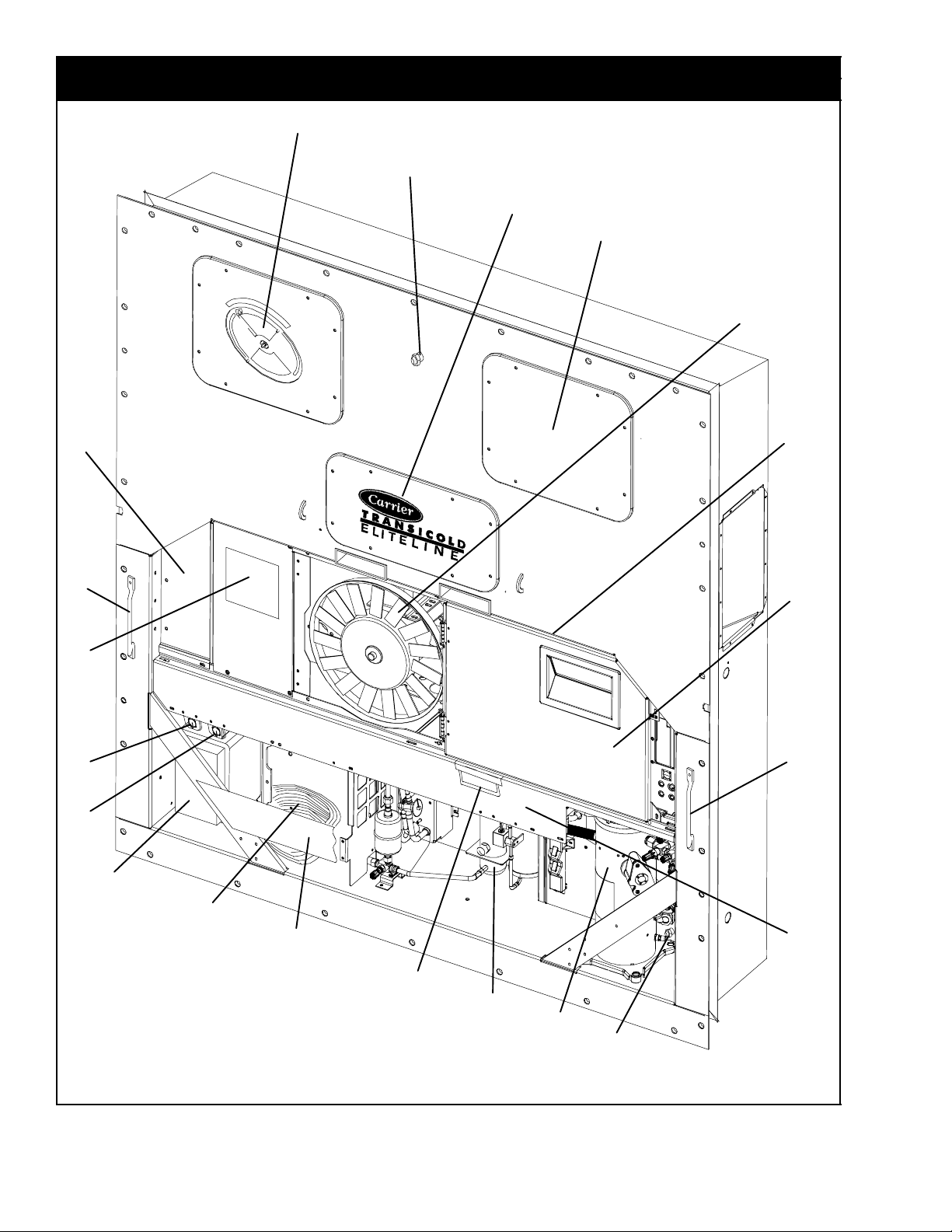

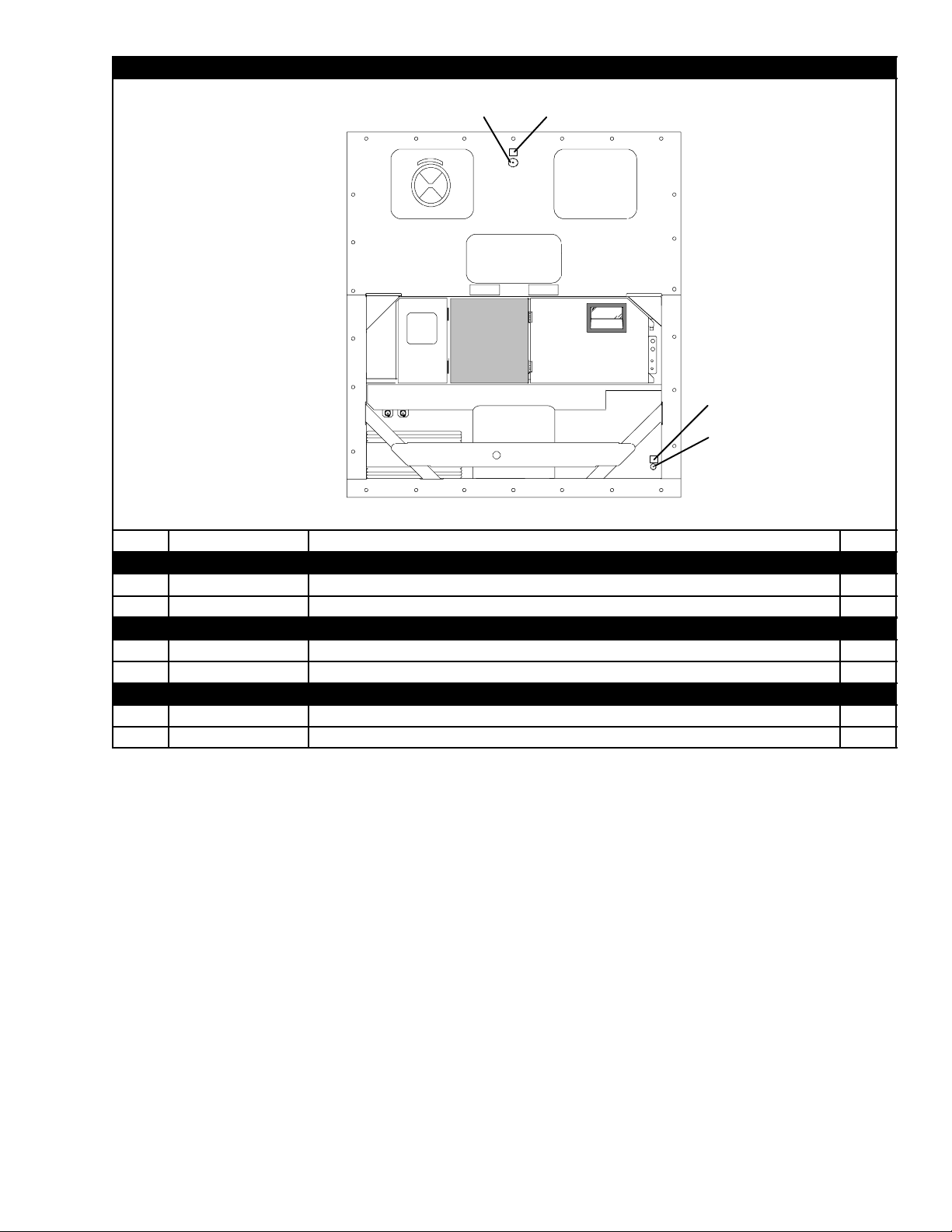

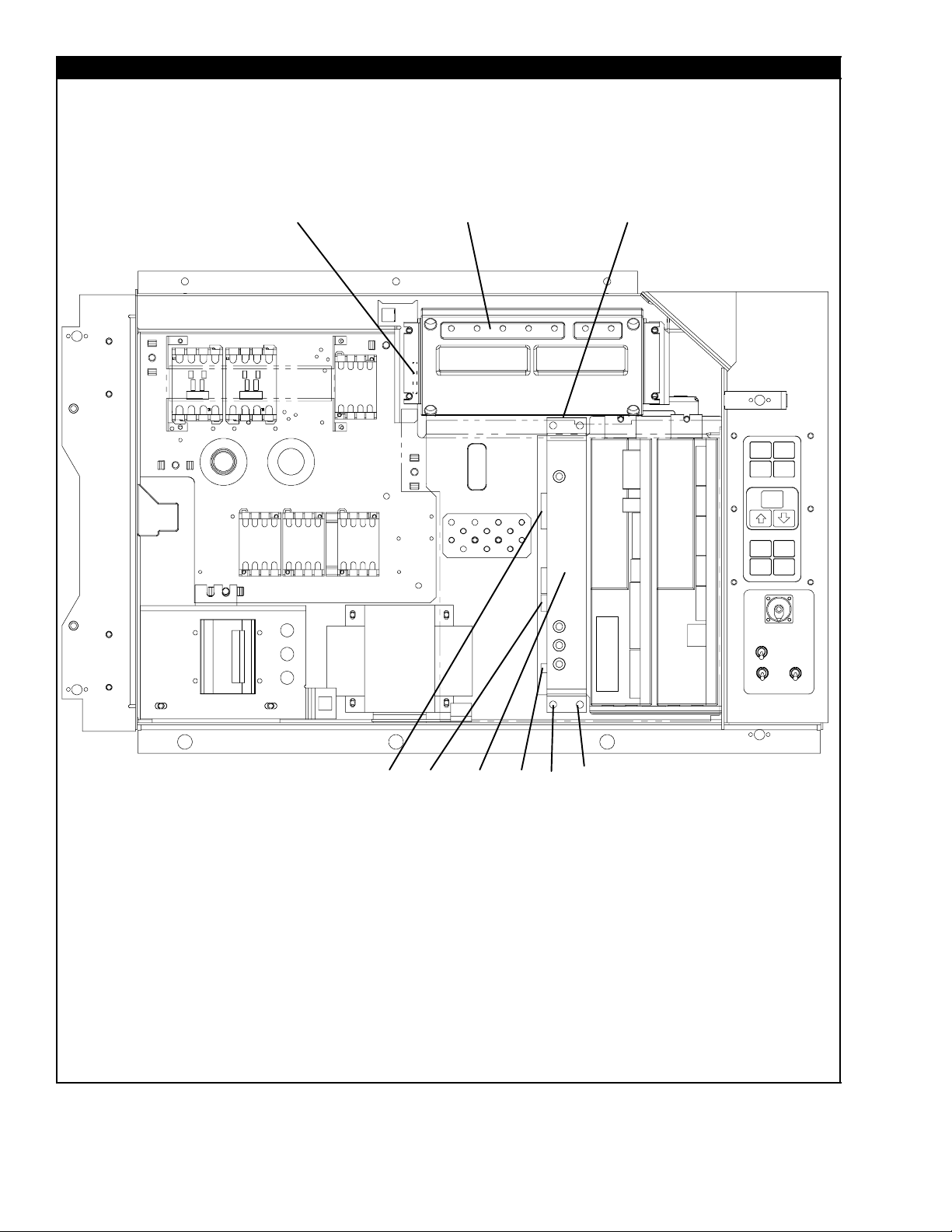

2 REFRIGERATION UNIT ASSEMBLY

2.1 REFRIGERATION UNIT -- AREA LOCATOR

1

2

3

4

5

19

18

17

16

6

8

15

7

8

13

14

12

9

8

10

11

2

2T-292PL

Page 12

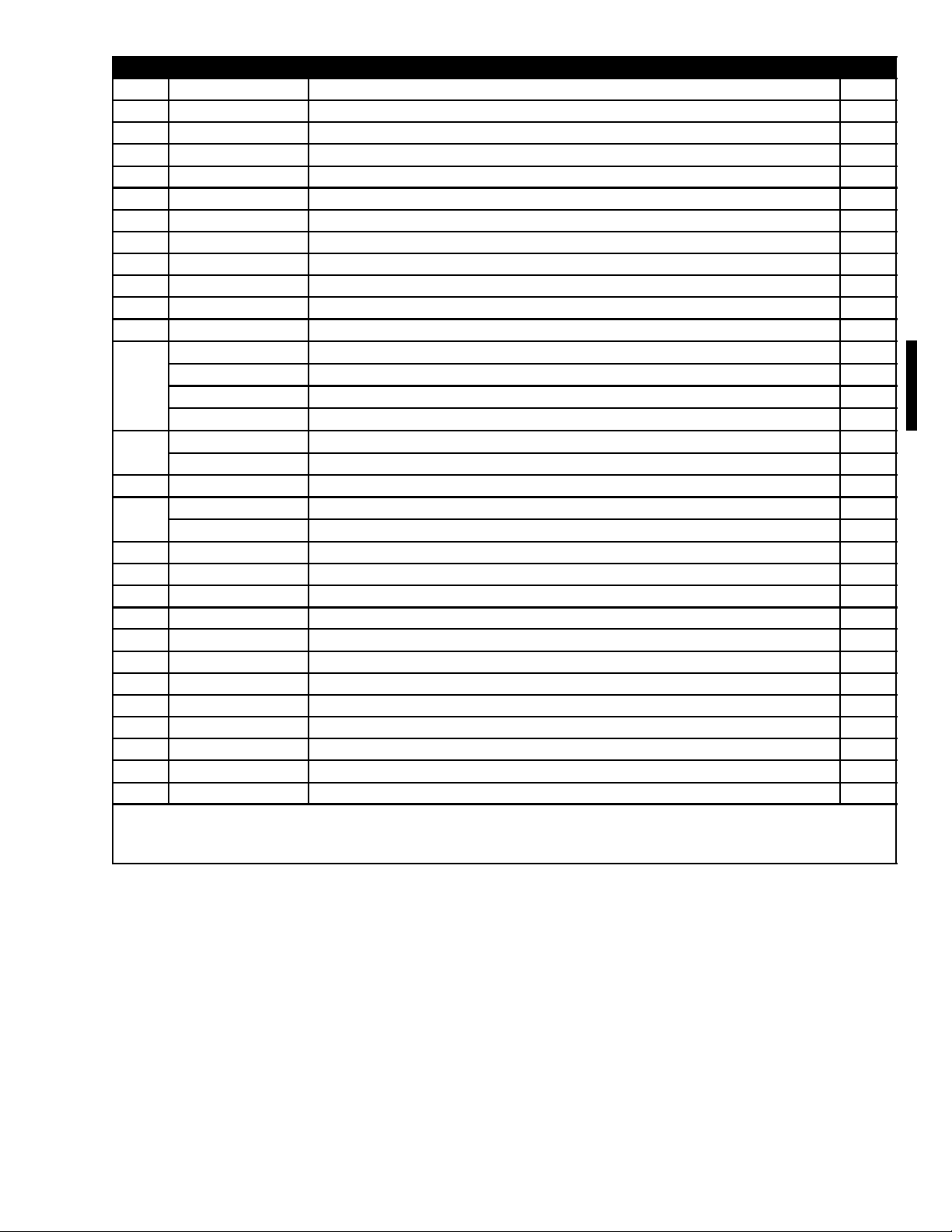

2.1 REFRIGERATION UNIT -- AREA LOCATOR

Item Section Number Area Description

1 Refer to Section 2.17 Upper Fresh Air Makeup & Access Panels

2 Refer to Section 2.4 Thermometer Port

3 Refer to Section 2.35 Labels and Decals

4 Refer to Section 2.19 Evaporator Fan Assembly

5 Refer to Section 2.10 Motor, Condenser Fan

6 Refer to Section 2.2 Rain Gutters

7 Refer to Section 2.5 -- 2.9 Box, Control

8 Refer to Section 2.3 Handles

9 Refer to Section 2.10 Coil, Condenser

10 Refer to Section 2.12 or 2.13 Receiver or Water-Cooled Condenser

11 Refer to Sections 2.30 or 4 Compressor

12 Refer to Section 2.30 Guard, Compressor

13 Refer to Section 2.33 Cable, Power

14 Refer to Section 2.33 Plug, Power

15 Refer to Section 2.34 Autotransformer

16 Refer to Section 2.19 Transfresh

17 Refer to Section 3 Interrogator and Accessories

18 Refer to Section 2.26 -- 2.29 Temperature Recorder

19 Refer to Section 2.18 Lower Fresh Air Makeup

3 T-292PL

Page 13

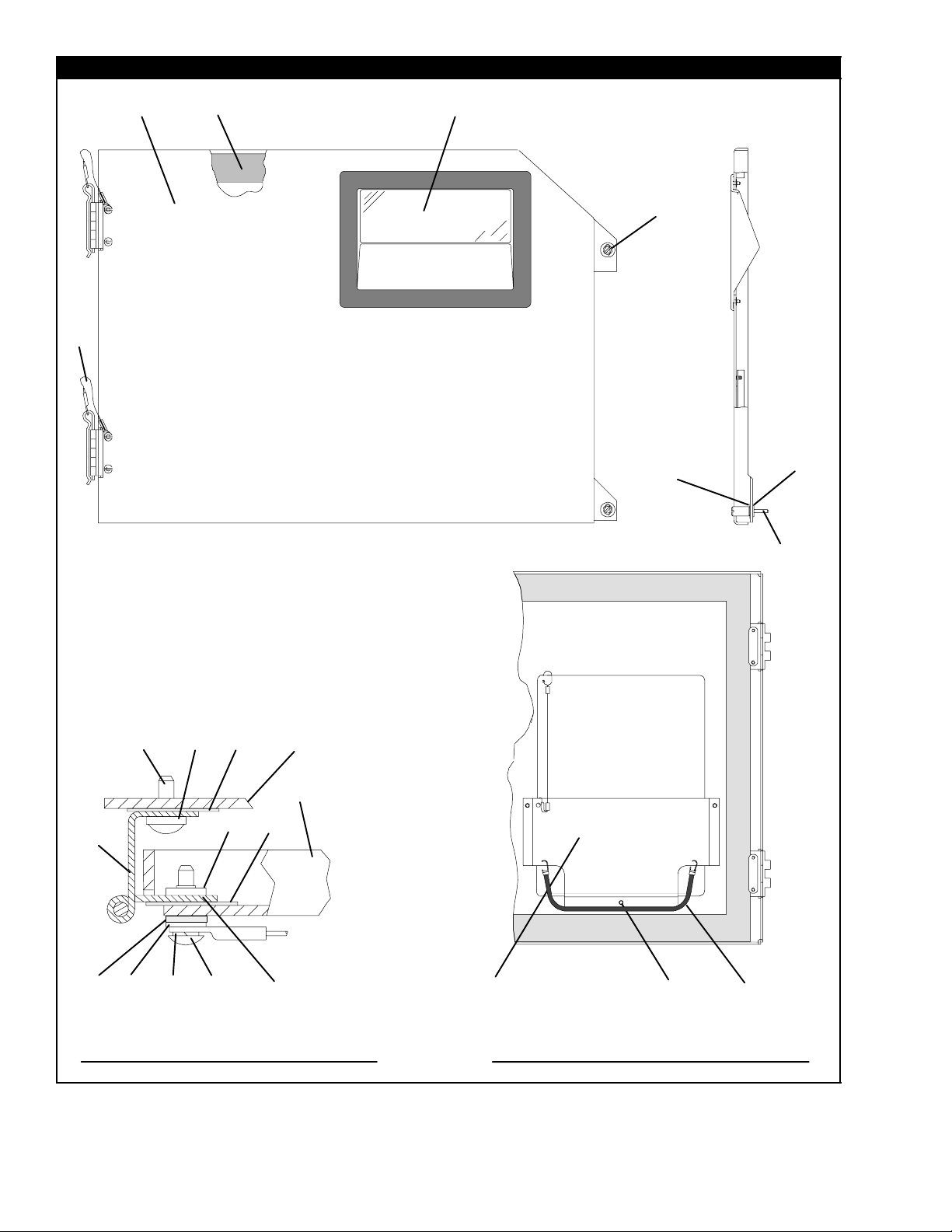

2.2 RAIN GUTTERS

2

or

4

Item Part Number Description Qty

OPTION 1 -- STANDARD LENGTH -- BOLTED

1 69NT35-3987 Gutter, Rain (Bolted, Standard -- Right Side) 1

2 69NT35-3997-1 Gutter, Rain (Bolted, Standard & Extended Length -- Left Side) 1

OPTION 3 -- EXTENDED LENGTH -- BOLTED

2 69NT35-3997-1 Gutter, Rain (Bolted, Standard & Extended Length -- Left Side) 1

3 69NT35-8548 Gutter, Rain (Bolted -- Right Side) 1

OPTION 4 -- RIVETED

4 68-12417-00 Gutter, Rain (Riveted -- Right and Left Side) 2

1

or

3

or

4

2.3 HANDLES

1

1

2

Item Part Number Description Qty

OPTION 1 -- TWO SIDE, ONE CENTER

1 69NT35-8113 Handle, Fixed 2

2 69NT40-657-2 Handle, Hinged 1

OPTION 2 -- TWO SIDE

1 69NT35-8113 Handle, Fixed 2

OPTION 3 -- ONE CENTER

2 69NT40-657-2 Handle, Hinged 1

OPTION 4 -- ONE SIDE, TWO CENTER

1 69NT35-8113 Handle, Fixed 1

2 69NT40-657-2 Handle, Hinged 2

4T-292PL

Page 14

2.4 THERMOMETER PORT

3

Item Part Number Description Qty

OPTION 1 -- SUPPLY AIR PORT

1 66U1-8662 Cap & Chain Assembly 1

2 62-10557-00 Label 1

OPTION 2 -- RETURN AIR PORT

3 66U1-8662 Cap & Chain Assembly 1

4 62-10557-00 Label 1

OPTION B -- SUPPLY AND RETURN PORTS

1&3 66U1-8662 Cap & Chain Assembly 2

2&4 62-10557-00 Label 2

4

2

1

5 T-292PL

Page 15

2.5 CONTROL BOX DOOR

12 3

9

4

5

6

8

20 21

10

11 12

Control Box

Control Box Door

6

4

5

16

HINGE ASSEMBLY -- SECTIONAL VIEW DOOR ASSEMBLY -- PARTIAL BACK VIEW

15

14

13

7

17

6T-292PL

18

14

15

19

22

Page 16

2.5 CONTROL BOX DOOR

Item Part Number Description Qty

1 69NT42-688-7 Door Assembly -- Includes: 1

2 42-00270-02 Gasket, Door 1

3 58-04366-00SV Window and Gasket Assembly, Control Box Door -- Lexan 1

4 34-06169-00 Washer, Retaining -- SST 2

5 66U1-6811-8 Screw , Retaining, Panel, 0.300-0.625 -- SST 2

5 66U1-6811-15 Screw, Retaining, Wing, 0.300-0.625 -- SST 2

6 34-06053-00 Washer, Mylar, 0.250 ID x 0.800 OD 4

7 44-00300-01 Hinge, Half 1

8 44-00300-02 Hinge, Half 1

9 44-00300-03 Pin Assembly, with Tether 1

10 58-04101-01 Protector, Mylar (Hinge) (Not Needed with Composite Box) 2

11 34-01167-01 Retainer, Nut 2

12 58-04101-00 Protector, Mylar (Hinge) 2

13 66U1-2403-1 Screw, Truss Head, #10-24 x 3/4 lg. -- SST 4

14 66U1-5331-3 Washer, Lock, #10 -- SST 7

15 66U1-5321-8 Washer, Flat, #10 -- SST 7

16 34-06053-05 Washer, Mylar, 0.205 ID x 0.600 OD 4

17 68-13577-00 Pocket, Placard 1

18 34-00665-09 Locknut, Hex Head, #10-24 -- SST 3

19 34-06107-00 Rivet, Blind, 1/8 Diameter, Grip Range -- 0.188-0.250 3

20 66U1-5371-7 Screw, #10-24 x 1/2 lg. -- SST 4

21 66U1-5321-8 Washer, Flat, #10 -- SST 4

22 58-04346-00 Door Strap Kit 1

7 T-292PL

Page 17

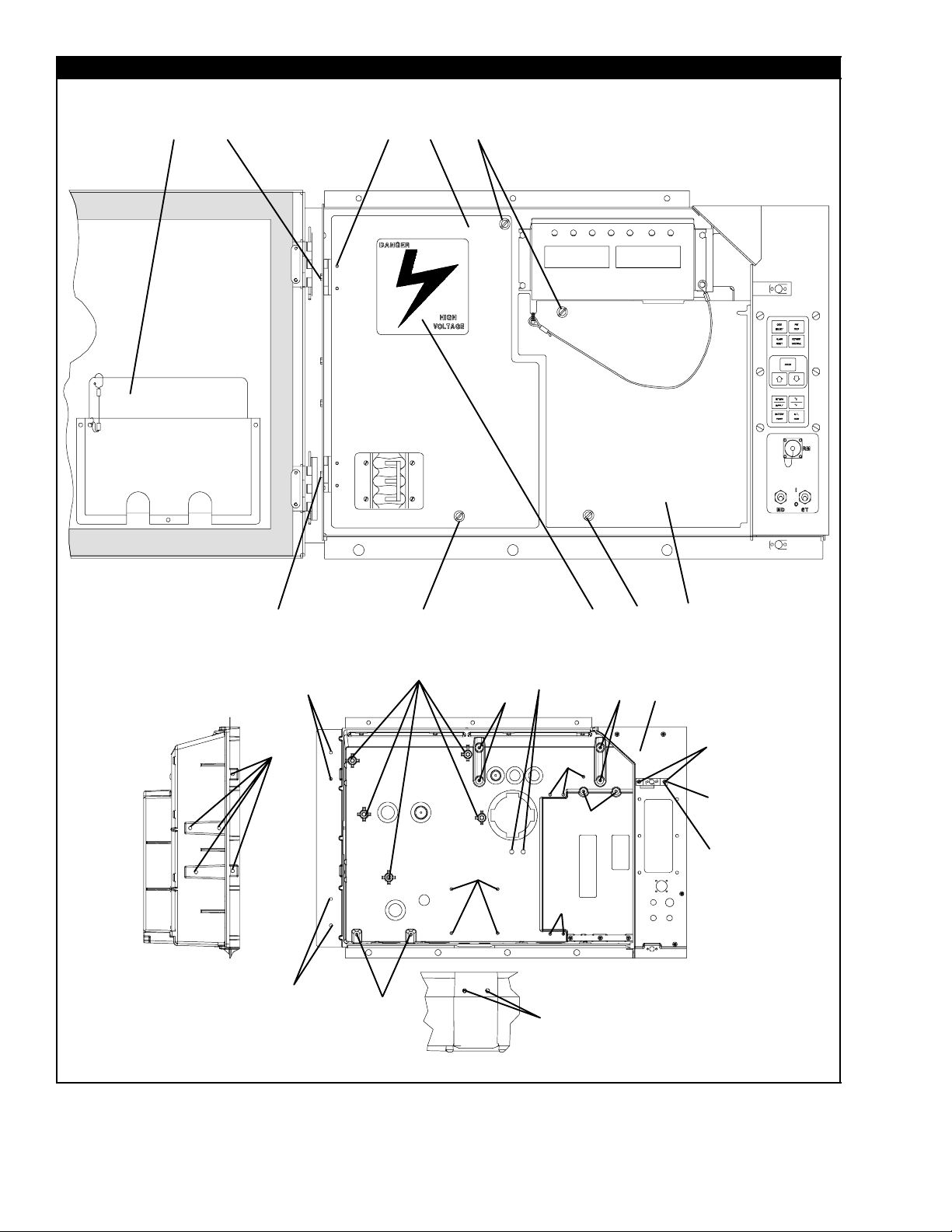

2.6 CONTROL BOX

4

1

2

3

5

6

7

2

18

20

6

7

20

OPTIONC&CL--COMPOSITEBOX

15

17

16

16

19

18

16

16

17

10

8

In Box

16

11

12

13

14

9

6

7

17

8T-292PL

Page 18

2.6 CONTROL BOX (Continued)

Item Part Number Description Qty

1 -- Plate, Schematic & Diagram (Refer to T-300, Container Unit Matrix) 1

2 66U1-2403 Screw , Truss Head, #10-24 x 1/2 lg. -- SST 2

3 69NT43-125-1 Shield, High Voltage (Plastic) -- Includes: 1

4 44-00343-00 Hinge 2

5 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8-3/16 -- SST 4

6 34-50015-00 Stud & Retainer Package -- Includes: 4

NS NSS Stud, Fastener 1

NS NSS Retainer, Fastener Stud 1

7 34-06139-03 Receptacle 4

8 69NT43-124-4 Shield, Low Voltage (Lexan) -- With Tether 1

9 62-03957-01 Label, Danger-High Voltage 1

58-04367-02 Control Box, Standard Composite (Blue) 1

58-04367-05 Control Box, Standard Composite (Orange) 1

10

58-04367-07 Control Box, Standard Composite w/EBS (Orange) 1

58-04367-08 Control Box, Standard Composite W/EBS (Blue) 1

69NT35-6272 Bracket, Non--Locking 1

11

69NT35-2287 Bracket, Locking (See Note 3) 1

12 34-01142-01 Receptacle, Retaining 1

34-00928-01 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/16 - 1/8 2

13

34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/18 - 3/16 (See Note 4) 2

14 66U1-2403 Screw, Truss Head, #10-24 x 1/2 lg. -- SST 2

NS 76-00724-00SV Crack, Chip and Hole Repair Kit 1

NS 76-50084-00SV Insert Repair Kit -- Includes: 1

15 34-06231-01 Insert -- 17.53 x 9.91 mm (.690 x .390 in) 1/4-20 Threads -- NSS 10

16 34-06231-03 Insert -- 15.88 x 6.35 mm (.625 x .250 in) 10-24 Threads -- NSS 10

17 34-06231-04 Insert -- 25.15 x 7.54 mm (.990 x .297 in) 10-24 Threads -- NSS 10

18 34-06231-05 Insert -- 10.16 x 9.53 mm (.400 x .375 in) 10-24 Threads -- NSS 10

19 34-06231-06 Insert -- 12.70 x 9.91 mm (.500 x .390 in) 1/4-20 Threads -- NSS 10

20 34-06231-07 Insert -- 9.53 x 6.76 mm (.375 x .266 in) 10-24Threads -- NSS 10

NS 02-00082-00 Durabond Epoxy -- NSS 1

NS 07-00390-00 Static Mixing Tube -- NSS 1

NS 07-00391-00 Application Gun -- Required for Insert Repair 1

NOTES

3. The bracket is bolted to the control box -- order 69NT35-2287 for locking bracket.

4. When 69NT35-2287 is used, 34-00928-02, rivet, is to be used in the upper door location.

9 T-292PL

Page 19

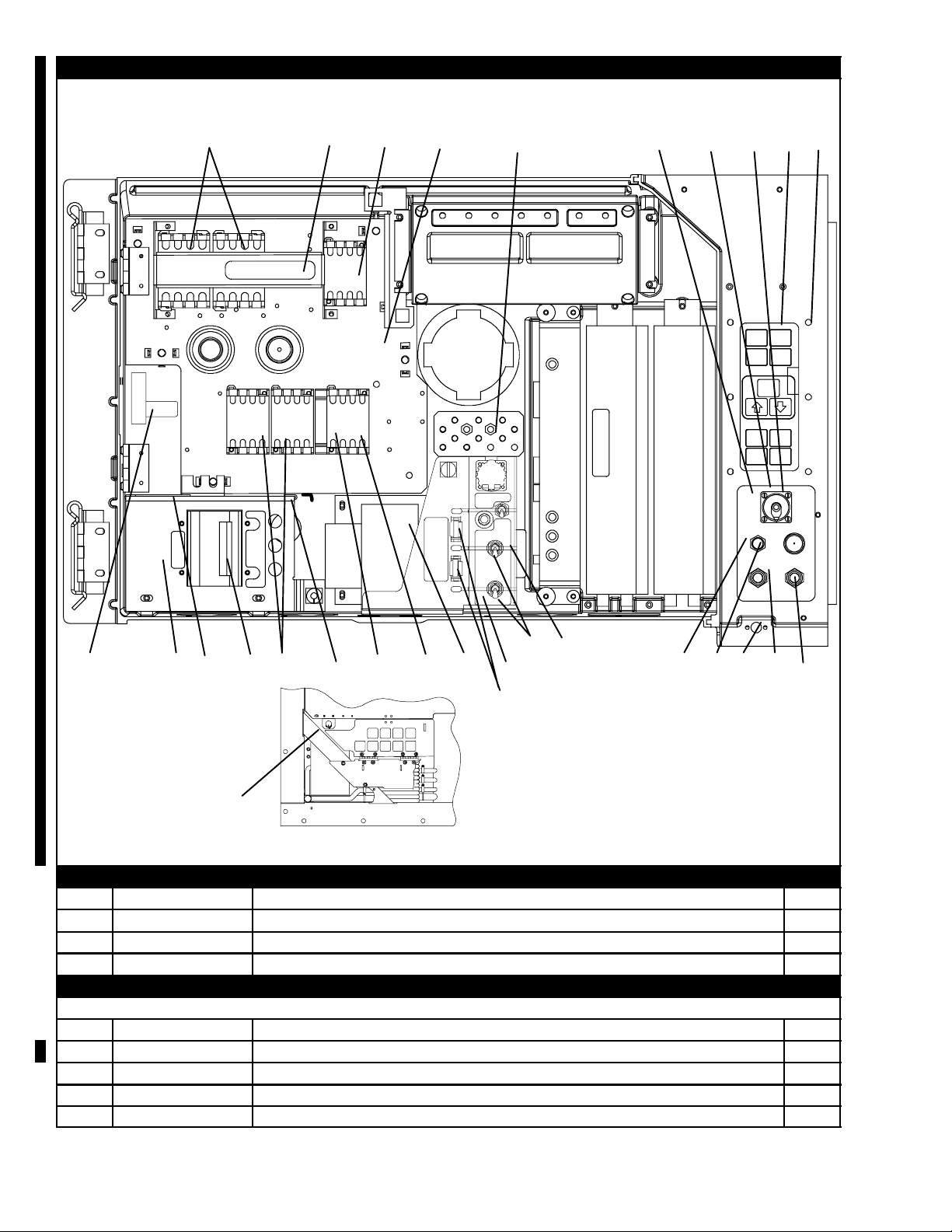

2.7 CONTROL BOX -- SHIELDS REMOVED, STD ELECTRICAL COMPONENTS, RM , CFS, EBS AND ED

28

4

5

34

35

36

5

6

7

8

9

16

44

41

42

43

37

38

39

40

29

30

31

32

33

50

19

25

26

18

19

24

27

21

22

23

12

48

47

13

5

6

27

20

17

5

18

6

19

15

1

2

3

10

11

13

14

12

13

49

45

46

REMOTE MONITORING --LOWER/EXTERNAL MTG

OPTION F -- CONDENSER FAN SWITCH

Item Part Number Description Qty

1 10-00298-01 Switch, Toggle (CFS) 1

2 66U1-9752 Seal, Bushing 1

58-04145-06 Plate, Switch (with extra switch location) 1

3

OPTION 1 -- NORMAL EVAPORATOR FAN OPERATION

See Items 5 and 6 for correct contactor placement

10-00431-07 Contactor, Compressor (CH) (30 Amp) 2

4

34-06243--00 Screw, Hex Head w/ Washer, #8-32 x 5/8 lg. -- SST 12

5

10-00431--06 Contactors, (CF), (HR) & (EF & ES) (12 Amp) 4

6

68-13427-00SV Panel, Contactor -- Includes: 1

7

58-00967-00 Spacer (Used with sheet metal control box only) 5

8

10T-292PL

Page 20

2.7 CONTROL BOX -- SHIELDS REMOVED, STANDARD ELECTRICAL COMPONENTS (Continued)

Item Part Number Description Qty

34-06224-01 Screw, Hex Head, Captive Washer 1/4-20 x .62 lg. -- SST 4

9

34-00928-01 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/16 - 1/8 6

10

34-01142-01 Receptacle 1

11

10-01129-07 Switch, T oggle (On-Off) 1

12

66U1-9752 Seal, Bushing 2

13

10-01129-10 Switch, T oggle (MDS) 1

14

58-04145-01 Plate, Switch 1

15

69NT41-982-3 Plate, Ground 1

16

10-00332-21SV Transformer, Base Unit 1

17

66U1-5371-7 Screw, Hex Head, #10-24 x 1/2 lg. -- SST A/R

18

66U1-5321-8 Washer, Flat, #10 -- SST A/R

19

10-00431--02 Contact, Auxiliary 1

20

34-00663-07 Washer, Lock, #6 -- SST 4

21

66U1-7842-13 Circuit Breaker -- 460 vac, 25 Amp, (CB1) 1

22

66U1-6651-4 Screw, Pan Head, #6-32 x 3/8 lg. -- SST 4

23

69NT35-6278 Bracket, Circuit Breaker 1

24

10--00439--01 Transformer, Current Sensing (CS) 1

25

34-06223-00 Screw, Captive Washer, #10-24 x .56 lg. -- SST 2

26

66CH1-1172-46 Trim, Flexible (85 Feet Long, Cut to Length) A/R

27

28 79--66669--00 Pad, Key -- Includes: 1

29 NSS Dot, Indicator (Green) -- See Note 1

30 NSS Gasket (Between Key Pad and Key Pad Plate Assembly) 1

31 NSS Plate Assembly , Key Pad Mounting 1

32 34--66630--00 Screw, Pan Head, #10--24 X 3/4 Long -- SST 6

33 34--06212--10 Washer, Plain, #10 6

58-04260-00 Cover, Clear 1

34

35 66U1-5391-2 Screw, Pan Head (Thread Cutting), #8-32 x 1/2 lg. -- SST 4

36 34-00662-08 Washer, Plain, #8 4

REMOTE MONITORING (STANDARD LOCATION)

22-02341-00 Receptacle, Remote Monitoring (RM) 1

37

22-02368-00 Plug, Remote Monitoring 1

38

22-02341-01 Cap and Tether, Receptacle Assembly 1

39

66U1-6835 Gasket, Remote Monitoring Receptacle 1

40

34-00848-10 Screw, Round Head, #4-40 x 5/8 lg. -- SST 4

41

66U1-5321-6 Washer, Flat, 0.125 ID -- SST 4

42

34-00667-05 Nut, Self Locking, #4-40 -- SST 4

43

58-04145-00 Plate, Switch, with RM 1

44

REMOTE MONITORING (LOWER LEFT/EXTERNAL LOCATION)

22-01889-00 Receptacle, Remote Monitoring (RM) 1

45

69NT40-222 Bracket 1

46

EMERGENCY BYPASS & EMERGENCY DEFROST

10--00446--00 Emergency Bypass Module 1

47

22--02336--04 Fuse (10A) 2

48

22--01455--03 Fuse Holder 2

49

66U1--5371--10 Wire Tire 3

50

Change 01/10

11

T-292PL

Page 21

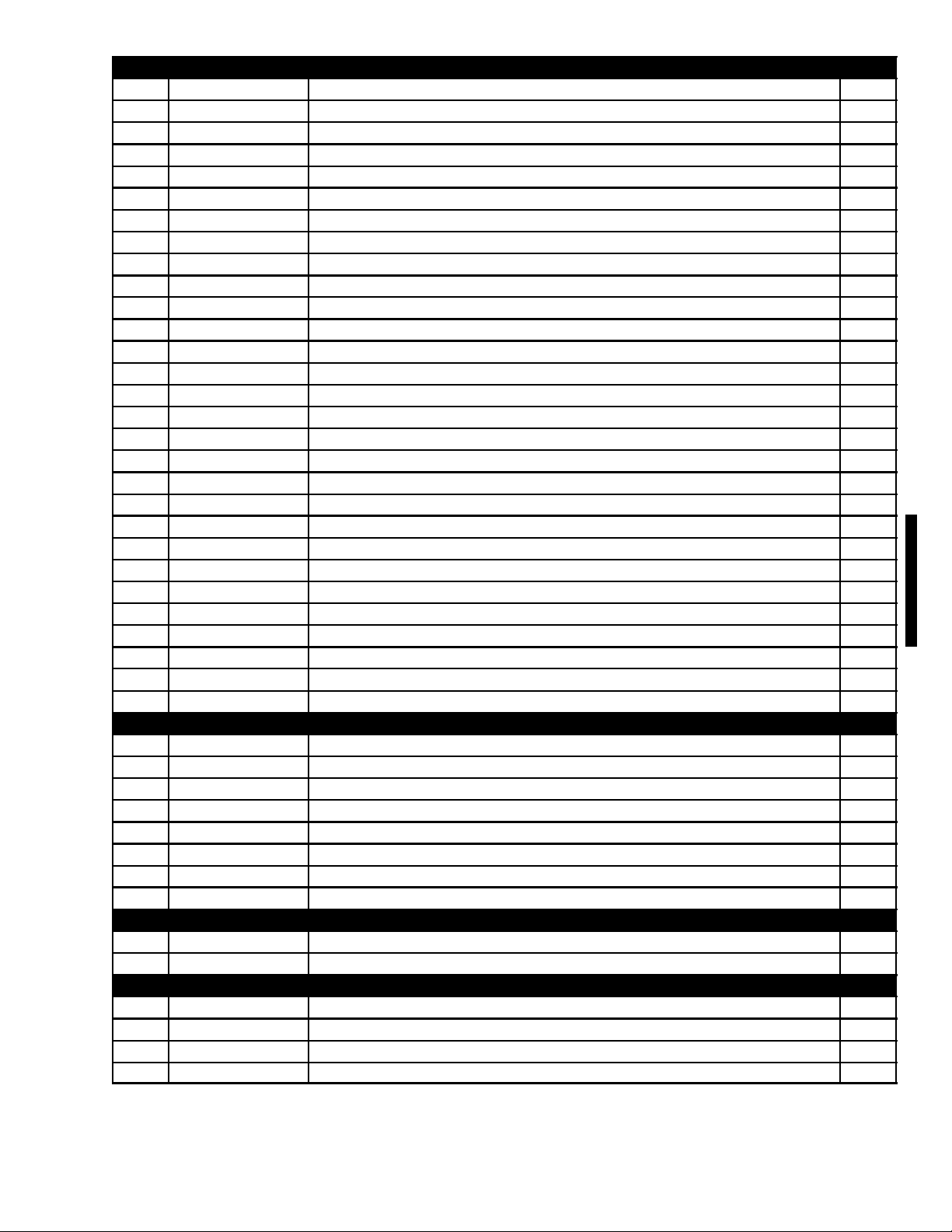

2.8 CONTROL BOX -- CONTROLLER MODULE SECTION AND SOFTWARE CARDS

16 17

19

22

21

9

10

11

12

13

10

12

View -- Back of Controller/DataCORDER and

Expansion Modules

10

12

20

1

2

3

4

24

25

23

8

1415

5

7

18

6

12T-292PL

Page 22

2.8 CONTROL BOX -- CONTROLLER MODULE SECTION AND SOFTWARE CARDS

Item Part Number Description Qty

1 -- Module, Controller/DataCORDER -- RefertoSection5-- Includes: --

2 66U1-5371-7 Screw , Hex Head, #10-24 x 1/2 lg. -- SST 1

3 69NT35-2692 Washer, Fender, 0.063 Thick -- SST 1

4 58-01184-00 Retainer, Screw, 0.141 ID 1

5 22-02336-04 Fuse, 10 Amp (F3) 3

6 22-02336-02 Fuse, 5 Amp (F1 & F2) 1

7 62-02719-00 Label, Controller/DataCORDER Port 1

8 12-00397-00/5311 Card, Controller/DataCORDER Operation Software 1

NS 12-00402-xx Card, Configuration Software 1

9 22-01777-00SV Connector (EC A-K) -- 30 Pin 1

10 22-01777-03 Socket, 20 AWG 35

11 22-50100-00 Socket, 18 AWG 4

12 22-01777-04 Plug, Sealing 21

13 22-01777-01SV Connector (EC L-Y) -- 30 Pin 1

14 22-01556-02 Connector (KA) -- 14 Pin 1

15 22-01556-01 Connector (KB) -- 10 Pin 1

NS 22-01621-23 Connector (KP) -- 9 Pin (Connects to Ribbon Cable) 1

16 22-01622-01 Connector (MA) -- 12 Pin 1

17 22-01622-02 Connector (MB) -- 16 Pin 1

18 22-01622-00 Connector (MC) -- 8 Pin 1

19 12-55535--10 Module, Controller Expansion 1

20 22-01777-05 Connector (EE A-K) -- 30 Pin 1

21 22-01556-06 Connector (KE) -- 7 Pin 1

22 22-01556-07 Connector (KR) -- 8 Pin 1

NS 09-00369-00SV Battery, Real Time Clock, (Within the Controller) 1

NS 22-50157-00 Wire Harness, Controller to Current Sensing Transformer) 1

NS 22-01713-06 Wire Harness, Display Module to Controller/DataCORDER Module 1

NS 62-02735-00 Label, Warning, Don’t use 12-00327 ! --(Located on the control box behind

the Controller/DataCORDER module.)

NS 62-02738-08 Label, Warning, 53xx Series -- (Located on the high & low voltage shields) 1

NS 62-02738-04 Label, Warning, 53xx Series -- (Located on the bottom panel of the control

box between the Communications Interface module and the switch panel.)

OPTION R -- RECHARGEABLE BATTERY PACK

23 30-00407-02SV Battery Pack -- Controller/DataCORDER Module 1

OPTION S -- STANDARD CELLS

24 PL Battery (”AA”) 6

25 30-00407-00 Cover, Controller Battery 1

1

1

13 T-292PL

Page 23

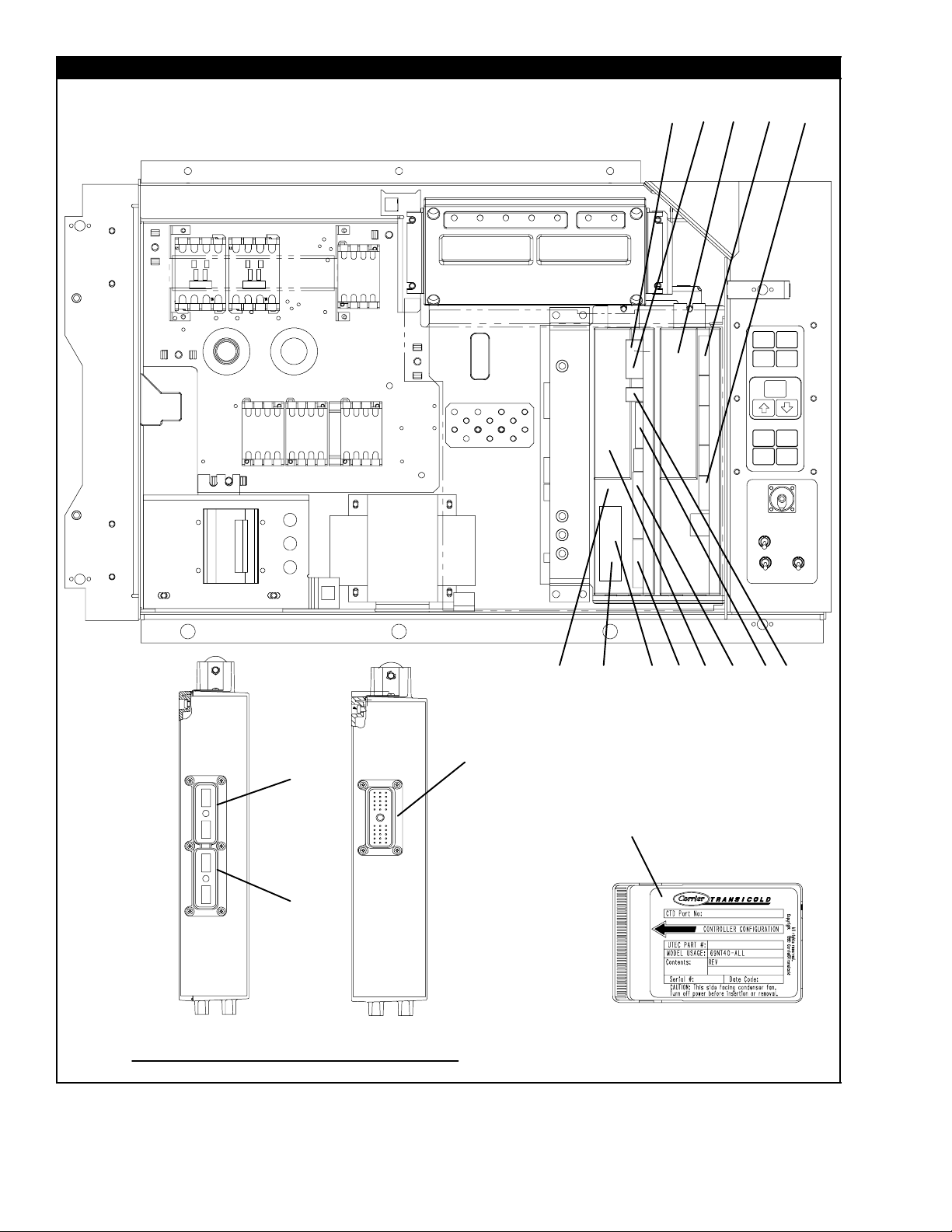

2.9 CONTROL BOX -- DISPLAY MODULE AND COMMUNICATIONS INTERFACE MODULE SECTION

1

34

2

56

14T-292PL

78

11

11

9

10

Page 24

2.9 CONTROL BOX -- DISPLAY MODULE AND COMMUNICATIONS INTERFACE MODULE SECTION

Item Part Number Description Qty

1 12-00433-00RP Module, Display 1

2 34--06223--01 Screw, Hex Head, #10-24 x 1/2 lg. w/Captive Washer 0.063 Thick -- SST 4

3 22-01621-03 Connector (MK) -- 9 Pin 1

4 22-01621-02 Connector (MB) -- 16 Pin 1

5 22-01556--06 Connector (CIC) -- 7 Pin 1

6 22-01556--04 Connector (CIB) -- 3 Pin 1

7 22-01556-00 Connector (CIA) -- 7 Pin 1

NS 22-01713-02 Wire Harness, Key Pad to Display Module 1

OPTION 1 -- COMMUNICATIONS INTERFACE MODULE -- STANDARD

8 12-00275-04SV Module, Communications Interface -- Includes: 1

9 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 2

10 34-06223-01 Screw, Captive Washer #10-24 x 0.56 -- SST 2

11 58-01184-00 Retainer, Screw .75 O.D. 4

OPTION 2 -- COMMUNICATIONS INTERFACE MODULE -- HIGH DATA RATE

8 12-00275-10SV Module, Communications Interface -- Includes: 1

9 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 2

10 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 4

11 58-01184-00 Retainer, Screw .75 O.D. 4

OPTION 3 -- COMMUNICATIONS INTERFACE MODULE -- CHIPSET MODEM

8 12-00275-17SV Module, Communications Interface -- Includes: 1

9 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 2

10 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 4

11 58-01184-00 Retainer, Screw .75 O.D. 4

OPTION 4 -- COMMUNICATIONS INTERFACE MODULE -- LOW DATA RATE

8 12-00275-19SV Module, Communications Interface -- Includes: 1

9 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 2

10 34-06223-00 Screw, Captive Washer #10-24 x 0.56 -- SST 4

11 58-01184-00 Retainer, Screw .75 O.D. 4

15 T-292PL

Page 25

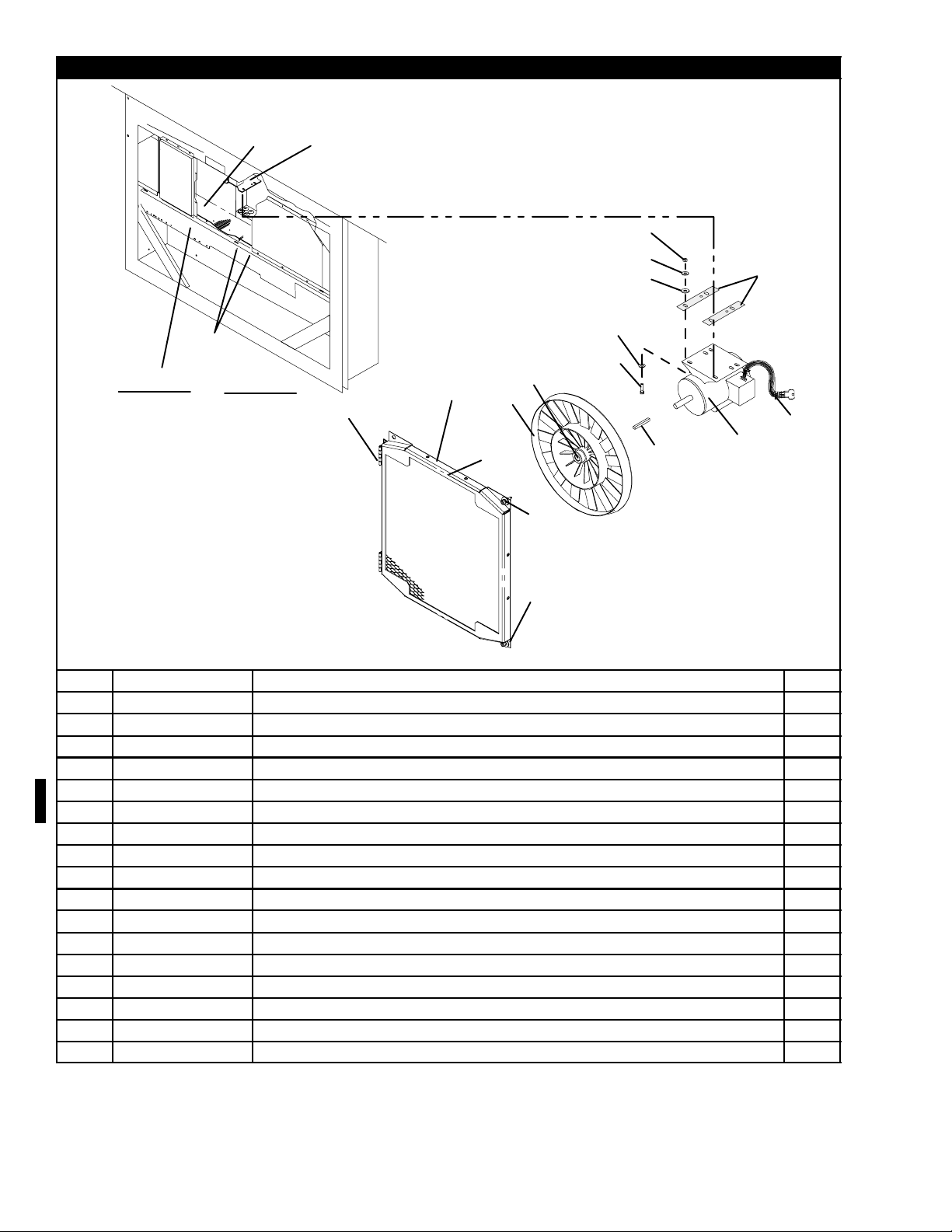

2.10 CONDENSER FAN MOTOR AND CONDENSER COIL SECTION

1

2

3

4

6

14

12

13

15

19

OPTION 4 OR OPTION 5

18

20

21

22

23

24

Item Part Number Description Qty

1 66U1-5361-25 Capscrew, Hex Head, 1/4-20 x 3/4 lg. -- SST 10

2 66U1-5321-7 W asher, Flat, 1/4 -- SST 10

3 34-06053-00 Washer, Mylar, 3/4 OD x 1/4 ID 10

4 34-06053-03 Washer, Mylar, 1.0 OD x 1/4 ID 2

5 22--04018--00SV Pigtail Connector 1

6 54--00586--00 Bracket, Condenser Motor Mount 1

7 54-00549-00 Motor, Condenser Fan -- Includes: 1

8 PL Key, 3/16 Square x 1-3/8 lg. -- SST 1

9 04-50027-00 Bearing 2

10 22-50088-02 Capacitor, 15 uF 1

11 66U1-5361 Screw, Hex Head, 5/16-18 x 1-1/4 lg. -- SST 4

12 34-01181-01 Washer, Flat, 5/16 -- SST 8

13 34-06053-02 Washer, Mylar, 1.0 OD x 3/8 ID 4

14 34-00667-12 Locknut, 5/16-18 -- SST 4

15 69NT35-6112 Protector, Condenser Fan Motor Mounting 2

16 38-00503-00 Fan, Condenser (17-1/2 diameter) -- Composite -- Includes: 1

17 PL Set Screw,Square Head, 5/16-24 x 5/8 lg. -- SST 2

25

26

28

29

30

33

34

35

36

31

17

16

32

37

38

39

40

OR

41

42

43

44

12

11

5

8

7

9

10

16T-292PL

Page 26

2.10 CONDENSER FAN MOTOR AND CONDENSER COIL SECTION (Continued)

Item Part Number Description Qty

OPTION 4 -- FOUR ROW (7MM) CONDENSER COIL

68-14546-02SV Cover, Condenser Coil, Blue Includes: 1

18

68-14546-03SV Cover, Condenser Coil, White Includes: 1

19 58-04481-00 Plug (for use with coated handle or units with no center handle) 2

20 81-01855-00SV Coil, Condenser(Copper) -- 7MM 4 Row -- Includes Mylar Washers 1

21 66CH1-1172-16 Trim, Flexible 2

22 69NT35-8693-8 Protector (Apply between frame and coil & coil cover) 4

23 69NT35-8693-9 Protector (Apply between frame and coil & coil cover) 2

24 58-04026-41 Protector,Mylar (Apply between coil & coil cover, RH &LH sides) 2

OPTION 5 -- FIVE ROW (3/8”) CONDENSER COIL

68-12757-00 Cover, Condenser Coil, Blue Includes: 1

25

68-12757-01 Cover, Condenser Coil, White Includes: 1

19 58-04481-00 Plug (for use with coated handle or units with no center handle) 2

26 81-01490-00SV Coil, Condenser(Copper) -- 5 row -- Includes Mylar Washers 1

27 66CH1-1172-16 Trim, Flexible 2

28 69NT35-8693-5 Protector (Apply between frame and coil & coil cover) 4

29 69NT35-8693-6 Protector (Apply between frame and coil & coil cover) 4

30 58-04026-10 Protector,Mylar (Apply between coil & coil cover, RH &LH sides) 2

OPTION H -- HINGED CONDENSER FAN GRILLE

31 76-00704-01 Grille and Venturi Assembly, Blue -- Includes: 1

31 76-00704-02 Grille and Venturi Assembly, White -- Includes: 1

32 66U1-8912 Label, Rotation 1

33 76-50075-00 Hinge Kit -- Includes: 1

34 44-00374-00 Hinge 2

35 58-04101-07 Protector, Mylar 4

36 34-06179-00 Screw, Hex Head, #10-24 x 7/16 lg. -- SST 8

66U1-6811-8 Screw, Retaining -- SST 2

37

66U1-6811-12 Screw, Retaining (Phillips Head) -- SST 2

38 34-06169-00 Washer, Retaining -- SST 2

39 34-06053-03 Washer, Mylar, 1/4ID x 1.00OD 2

40 69NT35-2692-1 Washer, Fender 1/4 -- SST 2

OPTION B -- BOLTED CONDENSER FAN GRILLE

31 76-00704-01 Grille and Venturi Assembly, Blue -- Includes: 1

31 76-00704-02 Grille and Venturi Assembly, White -- Includes: 1

32 66U1-8912 Label, Rotation 1

41 69NT35-2692-1 Washer, Fender 1/4 -- SST 4

42 34-06053-03 Washer, Mylar, 1/4ID x 1.00OD 4

43 34-00663-11 Washer, Lock, 1/4 -- SST 4

44 66U1-5361-25 Capscrew, Hex Head, 1/4-20 x 3/4 lg. -- SST 4

17 T-292PL

Page 27

2.11 COMPRESSOR TUBING SECTION

1,8,9

1,7,9

1,2,9

12

3,13,16

14,15

11,13,17

4,5

3,10,13,18

4,5

26

13,19

4,5

6

1,8,9

20,21

1,7,9

Units with Standard Tubing

1,2,9

12

12

3,10,24

11,22

4,5

3,10,23

4,5

26

25

6

T-292PL

Units with Semi--Hermetic Tubing

18

Change 07/04

Page 28

2.11 COMPRESSOR TUBING SECTION

Item Part Number Description Qty

Common Components

1 34-06053-00 Washer, Mylar, .25 I.D. x .80 O.D. 4

2 34-00373-07 Clamp, Cushion, .62 Dia. 1

3 42-00384-02 Seal 1 1/4” Thread (See Section 4) 2

4 40--00542-00 Elbow, Adapter, Brass A/R

5 40-00520-02 Cap, M8 x 1.0 -- Nylon A/R

6 40-00586-00 Coupling, Oil Return 1

7 66U1-3632-20 Clamp, Cushion, .88 Dia. 2

8 34-00373-53 Clamp, Cushion, .38 Dia. 1

9 66U1-5371-6 Screw, Hex Head, #10-24 x .75 lg. -- SST 4

10 14-00176-04 Strainer 1

11 42-00384-01 Seal 1” Thread (See Section 4) 1

12 58--04026--26 Tubing Protector 1

Standard Tubing Components

13 40-50025-00 Cap, Service Valve 4

14 40-00542-01 Elbow, Adapter, High Pressure, R134a -- Brass 1

15 40-00520-03 Cap, M10 x 1.0 -- Nylon 1

16 40-00583-00 Valve, Service 7/8 I.D. (11/4” Thread) 1

17 40-00583-01 Valve, Service 5/8 I.D. (1” Thread) 1

18 40-00583-03 Valve, Service 1 1/8 I.D. (11/4” Thread) 1

19 40-00585-00 Valve, Service 3/8 I.D. 1

Semi--Hermetic Tubing Components

20 66U1--3882--3 Wire Tie 2

21 58--00850--21 Tube, Slit 1

22 40--00605--03 Economizer Tubing Assembly with Fitting (1” Thread) 1

23 81--01807--01 Suction Tubing Assembly with Fitting (11/4” Thread) 1

24 58--04026--26 Discharge Tubing Assembly with Service Fitting (11/4” Thread) 1

25 81--01808--01 Oil Return Tubing Assembly with Fitting 1

REFRIGERATION TEMPERATURE SENSORS

26 12-00493-05 Sensor, Thermistor (CPDS) 1

-- -- Sensor, Thermistor (CPSS) See Section 2.20 1

Change 07/04

19

T-292PL

Page 29

2.12 RECEIVER SECTION

5

6

7

1

8

4

Item Part Number Description Qty

STANDARD RECEIVER -- USE OPTION L AND SUBSTITUTE ITEM BELOW FOR 79--01785--01

NS 79-01785-00 Receiver Assembly 1

OPTION L

1 79-01785-01 Large Receiver Assembly -- Includes: 1

2 14-00220-01 Glass, Sight 1

3 14-00221-01 Indicator, Moisture-Liquid 1

4 14-01032-14 Plug, Fusible, 3/8 npt -- Brass 1

5 58-04026-61 Protector, Mylar 2

6 66U1-5361-25 Screw, Hex Head, 1/4-20 x 3/4 lg. -- SST 4

7 66U1-5321-7 W asher, Flat, 1/4 -- SST 4

8 34--06035--00 Washer , Mylar 4

9 12-00495-20 Sensor, Ambient Thermistor (AMBS) 1

10 -- See Section 2.15 for Sensor Assembly and Related Parts --

23

910

20T-292PL

Page 30

2.13 WATER--COOLED CONDENSER SECTION

18

20

20

23

21

22

24

25

5

4

10

11

16

1

9

17

6

2

7

13

8

25

3

19

20

21

15

14

Item Part Number Description Qty

-- 76-00734-00 Kit, Condenser/Receiver (For Field Installation) -- Includes: 1

1 69NT42-954-4 Condenser/Receiver -- Includes: 1

2 14-00220-01 Sight Glass, w/red balls, 1/2 npt 1

3 58-00956-00 Protector, Mylar 2

4 58-04436-00 Protector, Mylar 1

5 66U1-2763-5 Coupling (Water-In) 1

6 66U2-1142 Cap, Dust 1

7 40-01129-00 Coupling, Self Draining -- Includes: 1

8 42-50000-00 Seal, O-Ring 1

9 66U2-1152 Cap, Dust 1

10 12-01071-01SV Switch,Water Pressure OPTION W 1

11 66U2-1132-1 Connector 2

12 66U1-3803 Heat Shrink 2

13 14-00215-05 Disc, Rupture, 3/8 npt 1

14 12-00495-20 Sensor, Ambient Thermistor (AMBS) 1

15 -- See Section 2.15 for Sensor Assembly and Related Parts -16 14-01092-03 Indicator, Liquid Moisture -- Brass 1

17 40-01129-00 Tee, 1/2 X 1/2 X 3/8 NPT -- Brass 1

18 68-13852-00 Bracket (Style 1) 1

19 68--14102--00 Bracket (Style 2)

20 66U1-5371-6 Screw, Hex Head, #10-24 x 3/4 lg. -- SST 3

21 69NT35-2692 Washer, Fender 1

22 34-00667-09 Nut, Self-Lock, #10-24 -- SST 1

23 34-06053-05 Washer, Mylar, .205 I.D. x .60 O.D. 3

24 66U1-5321-8 Washer, Plain, #10 -- SST 3

25 34-00373-05 Clamp, Cushion, 1/2 Diameter 1

21 T-292PL

Page 31

2.14 ECONOMIZER, ECONOMIZER EXPANSION VALVE, ECONOMIZER SOLENOID VALVE AND

FILTER DRIER SECTION

Item Part Number Description Qty

1 68-12864-00 Cover 1

2 34-06053-00 Washer, Mylar, 0.250 ID x 0.800 OD 18

3 66U1-5361-25 Screw, Hex Head, 1/4-20 x .75 lg. -- SST 13

4 66U1-5321-7 W asher, Flat, 1/4 -- SST 13

5 34-00667-11 Nut, Self-Lock 2

6 40-00520-01 Coupling with Cap 1

7 14-00311--02SV Filter-Drier -- Includes: 1

8 14-00284-20SV O-Ring 2

9 34-00373-54 Clamp, Cushion, .44 Diameter 1

10 34-06053-05 Washer, Mylar, .205 I.D. x .60 O.D. 9

11 66U1-5371-7 Screw, Machine, Hex Head, #10-24 x .50 lg. -- SST 1

12 68-13479-00 Bracket 1

13 66U1-5321-8 Washer, Plain #10 -- SST 4

14 66U2-1132-2 Connector 4

15 66U1-3803 Heat Shrink 6

16 14-01091-01 Coil, Solenoid Valve (Oil Return and Economizer) 1

17 DE40BA203 Tee, Reducing 1/2 x 1/2 x 3/8 1

18 34-00373-05 Clamp, Cushion, .50 Diameter 1

19 68-12863-00 Bracket 1

20 68-13167-00 Bracket 1

21 42-00389-00 Insulation, Economizer 1

22 40-00168-05 Tee 1

23 68-13784-00 Bracket 1

24 66U1-5321-3 Washer, Plain, 1/4 N Type A -- SST 2

25 68-13785-00 Bracket 1

26 66U1-5371 Screw, Machine, Hex Head, #8-32 x .50 lg. -- SST 4

27 66U1-5321-2 Washer, Plain #8 -- SST 4

28 66U1-5331-4 Washer, Lock, #8 Spring -- SST 4

29 69NT35-2692-1 Washer, Fender 1

30 14-01091-02 Coil, Solenoid Valve 1

31 14-01090-11 Solenoid Valve Body 1

32 81-01539-20 Economizer 1

33 58--00836--19 Bushing 2

34 69NT35-2692-4 Washer, Fender #10 -- SST 1

35 14-01090-10 Solenoid Valve Body 1

36 14-00232-08 Expansion Valve 1

37 34-00373-07 Clamp, Cushion, .62 Diameter 1

38 14-00222-01 Valve, King 1

39 68--14103--00 Bracket, Blue 1

39 68--14103--20 Bracket, White 1

40 42-00390-00 Insulation, Economizer 1

41 42--00174--44 Gasket, 2.0 x 2.0 1

42 69NP20--1031 Clamp, Tube, 2.88 diameter 1

43 66U1--5371--6 Screw, Machine, Hex Head, #10--24 x .75 lg.-- SST 6

44 68--10694--00 Plate 1

23 T-292PL

Page 32

2.15 SRS AND STS SECTION

2

3

2

3

1

(STS)

1

(SRS)

45

Item Part Number Description Qty

1 12-00395-01SV Sensor Assembly (STS & SRS) 1

2 58-04277-00SV Cap, Probe -- Includes: 2

3 58-04278-00 Grommet NSS 2

4 58-04279-00 Cover, Probe 1

5 58-04276-00 Holder, Probe 1

6 66U1-5321-7 W asher, Flat, 1/4 -- SST 2

7 66U1-5371-7 Screw, Machine, Hex Head, #10-24 x .50 lg. -- SST 2

24T-292PL

6

7

Page 33

2.16 OIL SEPARATOR SECTION

6

1

2

3

4

7

1011

12

13

Item Part Number Description Qty

1 34-06053-00 Washer, Mylar, 0.250 ID x 0.800 OD 4

2 66U1-5361-25 Screw, Hex Head, 1/4-20 x .75 lg. -- SST 4

3 66U1-5321-7 W asher, Flat, 1/4 -- SST 4

4 58-04026-34 Protector, Mylar 2

5 65-00180-20SV Oil Separator Includes: 1

6 56--07525--00 Tubing 1

7 66U1-5371 Screw , Machine, Hex Head, #8-32 x .50 lg. -- SST 2

8 66U1-5321-2 W asher, Plain #8 -- SST 2

9 66U1-5331-4 W asher, Lock, #8 Spring -- SST 2

10 14-00285-00 Solenoid Valve 1

11 66U2-1132-2 Connector 2

12 66U1-3803 Heat Shrink 2

13 14-01091-01 Coil, Solenoid Valve 1

5

8

9

25 T-292PL

Page 34

2.17 UPPER FRESH AIR MAKE-UP AND ACCESS PANEL SECTION

7

2

23

22

21

8

5

4

6

3

17

16

9

18

19

FRESH AIR PANEL

WITH VPS

12

11

BACK OF FRESH

AIR PANEL

10

20

14

13

6

2.17 UPPER FRESH AIR MAKE-UP AND ACCESS PANEL SECTION

Item Part Number Description Qty

OPTION 1 EVAPORAT OR FAN ACCESS PANEL -- PLAIN

1 79-01697-06SV Panel, Access (See NOTE 1) -- Includes: A/R

2 42-00296-01 Gasket 1

3 42-00327-00 Gasket, -- 0.26 x 0.50 Halfmoon 1

4 34-006212--12 Washer, Flat, 1/4 -- SST 8

5 34-06053--13 Washer, Mylar, 1/4 ID X 0.80 OD 8

6 34-06154-00 Screw, Hex Head, 1/4-20 x 1.00 lg. -- TIR 8

7 66U1-2552-185 Gasket, 0.75 x 1.5 x 16.63 1

15

7

2

1

5

4

5

4

6

3

26T-292PL

Page 35

2.14 ECONOMIZER, ECONOMIZER EXPANSION VALVE, ECONOMIZER SOLENOID VALVE AND

FILTER DRIER SECTION

2

3

4

19

10

11

13

20

28

35

10

11

18

17

10

26

10

27

11

12

13

44

9

21

22

24

24

2

23

23

29

2

3

3

2

3

24

2

2

3

3

10

11

7

8

40

2

4

5

2

3

4

1

38

36

41

6

10

42

43

39

2

3

10

4

11

34

37

2

33

14

15

16

32

10

26

27

28

31

14

15

30

22T-292PL

Page 36

OPTION 2 EVAPORAT OR FAN ACCESS PANEL -- WITH FRESH AIR MAKEUP

8 79-01694-00 Panel, Fresh Air Make--up w/Retaining Washers -- Includes: A/R

2 42-00296-01 Gasket 1

3 42-00327-00 Gasket, -- 0.26 x 0.50 Halfmoon 1

7 66U1-2552-185 Gasket, 0.75 x 1.5 x 16.63 1

9 -- Label, Fresh Air (See Section 2.35 for Language Selection) 1

10 62-02783-00 Label, Fresh Air 1

21 34-06053-19 Washer, Mylar, 1.00 OD x 0.312 ID 1

22 66U1-5321-13 Washer, Flat, 5/16 -- SST 1

23 66U1-5362-2 Nut, Wing, 5/16-18 -- SST 1

OPTION 3 WITH FRESH AIR MAKEUP AND SCREENS -- USE ALL OF OPTION 2 AND ITEM BELOW

11 58-04251-00 Screen, Medfly 2

OPTION 4 EVAPORATOR FAN ACCESS PANEL -- WITH FRESH AIR MAKEUP AND VENT POSITIONING

SENSOR (VPS)

12 79--01902--00 Panel, Fresh Air Make--up w/VPS -- Includes: A/R

2 42-00296-01 Gasket 1

3 42-00327-00 Gasket, -- 0.26 x 0.50 Halfmoon 1

7 66U1-2552-185 Gasket, 0.75 x 1.5 x 16.63 1

9 -- Label, Fresh Air (See Section 2.35 for Language Selection) 1

10 62-02783-00 Label, Fresh Air 1

21 34-06053-19 Washer, Mylar, 1.00 OD x 0.312 ID 1

22 66U1-5321-13 Washer, Flat, 5/16 -- SST 1

23 66U1-5362-2 Nut, Wing, 5/16-18 -- SST 1

HEATER ACCESS PANEL

13 79-01697-07SV Panel, Access -- Includes: 1

14 42-01052--02 Gasket 1

15 34--06212--12 Gasket, Access Panel 1

4 34-06053--13 Washer, Flat, 1/4 -- SST 8

5 34-06053-00 Washer, Mylar, 1/4 ID X 0.80 OD 8

6 34-06154-00 Screw, Hex Head, 1/4-20 x 1.00 lg. -- TIR 8

STUD ASSEMBLY KITS (REPLACEMENT)

16 74-00201-02 Kit, Gasket and Stud Assembly (See NOTE 2) -- Includes: 1

17 42-00407-00 Gasket (One Piece) 1

18 74-00201-01 Kit, Disc and Stud Assembly (See NOTE 3) -- Includes: 1

19 NSS Stud Assembly, 5/16-18 1

20 34-06185-01 Screw, Machine Pan Head, #8-32 x 1/2 lg. -- SST 1

21 34-06053-19 Washer, Mylar, 1.00 OD x 0.312 ID 1

22 66U1-5321-13 Washer, Flat, 5/16 -- SST 1

23 66U1-5362-2 Nut, Wing, 5/16-18 -- SST 1

NOTES

1. Access panels with Transfresh option should be ordered from Transfresh, See Section 2.19 for address.

2. Disc and stud assembly kit, which will modify stud to 5/16-18, also includes new disc and gasket.

3. Must order 74-00201-01 stud assembly kit, which will modify stud to 5/16-18, and include 42-00407-01 (1 piece)

gasket.

27 T-292PL

Page 37

2.18 LOWER FRESH AIR MAKE-UP VENT

22

23

18

15

3

4

5

OPTION -- 1

2

1

7

3

4

5

6

8

12

13

OPTION -- 2 & 3

19

12

13

16

9

10

11

24

16

17

20

21

9

10

11

24

16

14

28T-292PL

Page 38

2.18 LOWER FRESH AIR MAKE-UP VENT

Item Part Number Description Qty

OPTION 1 -- LOWER FRESH AIR (NONE)

1 69NT35-4047 Panel, Blank (Blue) 1

1 69NT35-4047- -20 Panel, Blank (White) 1

2 69NT43-307 Bracket, Panel 1

3 66U1-5361-25 Screw , Hex Head, 1/4-20 x 3/4 lg. -- SST 3

4 34-06053-18 Washer, Mylar, 1/4 ID x 1.00 OD 3

5 66U1-5321-3 Washer, Flat, 1/4, Type A-- SST 3

6 69NT35-2692-1 Washer , Fender 1/4 -- SST 1

7 42-00465-00 Gasket 1

OPTION 2 -- INSTALLED

8 69NT41-852-1 Cover, Fresh Air Makeup -- Includes: 1

9 69NT40-976-3 Cover Assembly, Air Bleed -- Includes: 2

10 42-00233-01 Gasket, Air Exchange 2

69NT35-1417 Label, Air Exchange, CMH -- English 2

11

69NT35-9238 Label, Air Exchange, CMF -- English/Spanish 2

34-06092-00 Nut, Hex, 1/4-20 UNC-2B -- SST 2

12

34-06183-00 Nut, Hex, (with mini handle),1/4-20 UNC-2B -- SST 2

13 34-06053-00 Washer, Mylar, 1/4 ID x 1.00 OD 2

14 42-00295-01 Gasket, Cover 1

15 42-00295-00 Gasket, Cover 1

16 66CH1-1002-33 Label, Arrow 3

17 69NT41-782 Bushing 2

18 69NT 35-1287-1 Label, Fresh Air Exchange -- English 1

19 69NT35-7012 Label, Fresh Air 1

20 66U1-5321-7 Washer, Flat, 1/4 -- SST 2

21 34-06092-00 Nut, Hex, 1/4-20 UNC-2B -- SST A/R

22 69NT35-8348 Baffle, Unpainted 1

23 34-00928-09 Rivet, Blind, .156 Diameter, Grip Range -- 3/16-1/4 4

OPTION 3 -- INSTALLED WITH SCREENS -- USE ALL OF OPTION 2 PLUS ITEM BELOW

24 58-04263-01 Screen Assembly, Medfly 2

29 T-292PL

Page 39

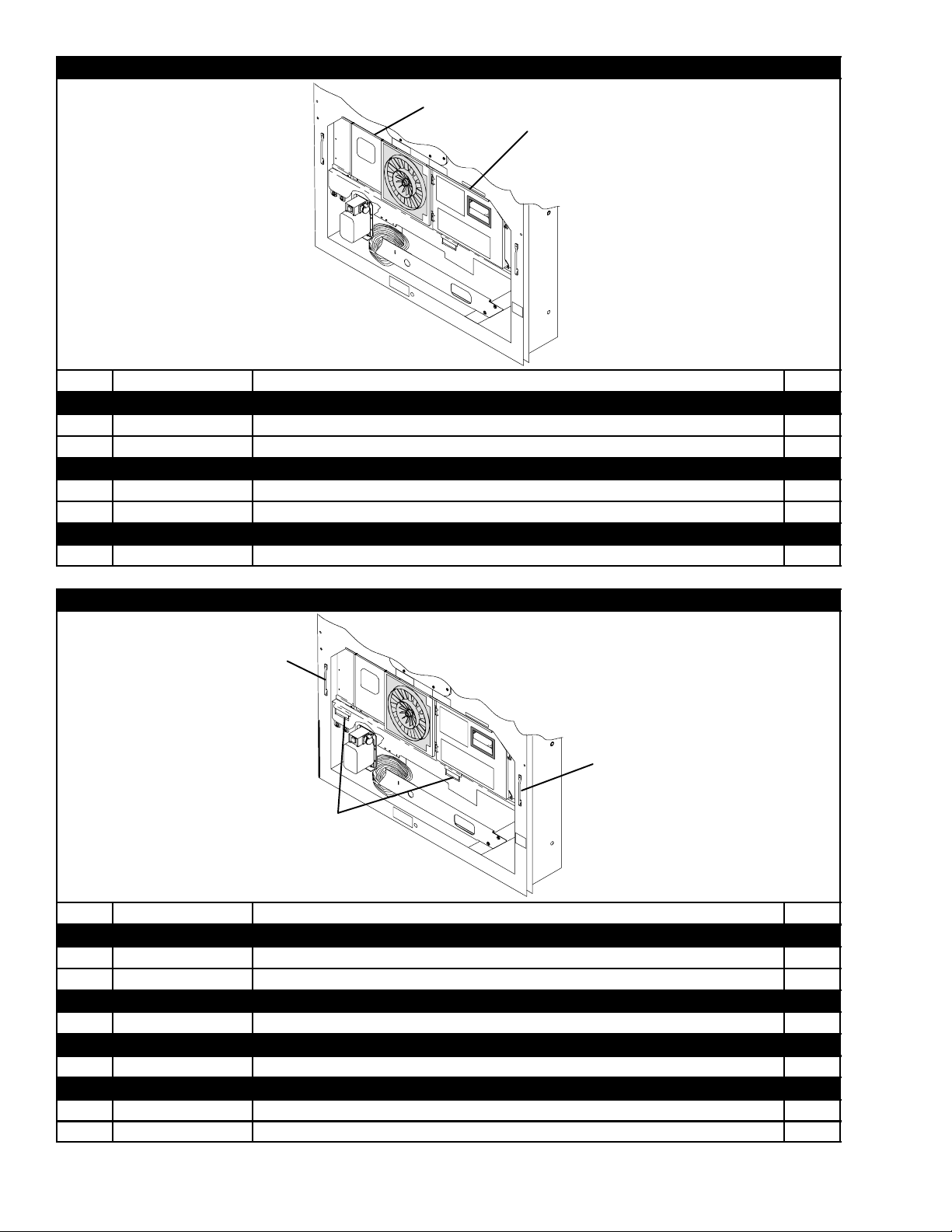

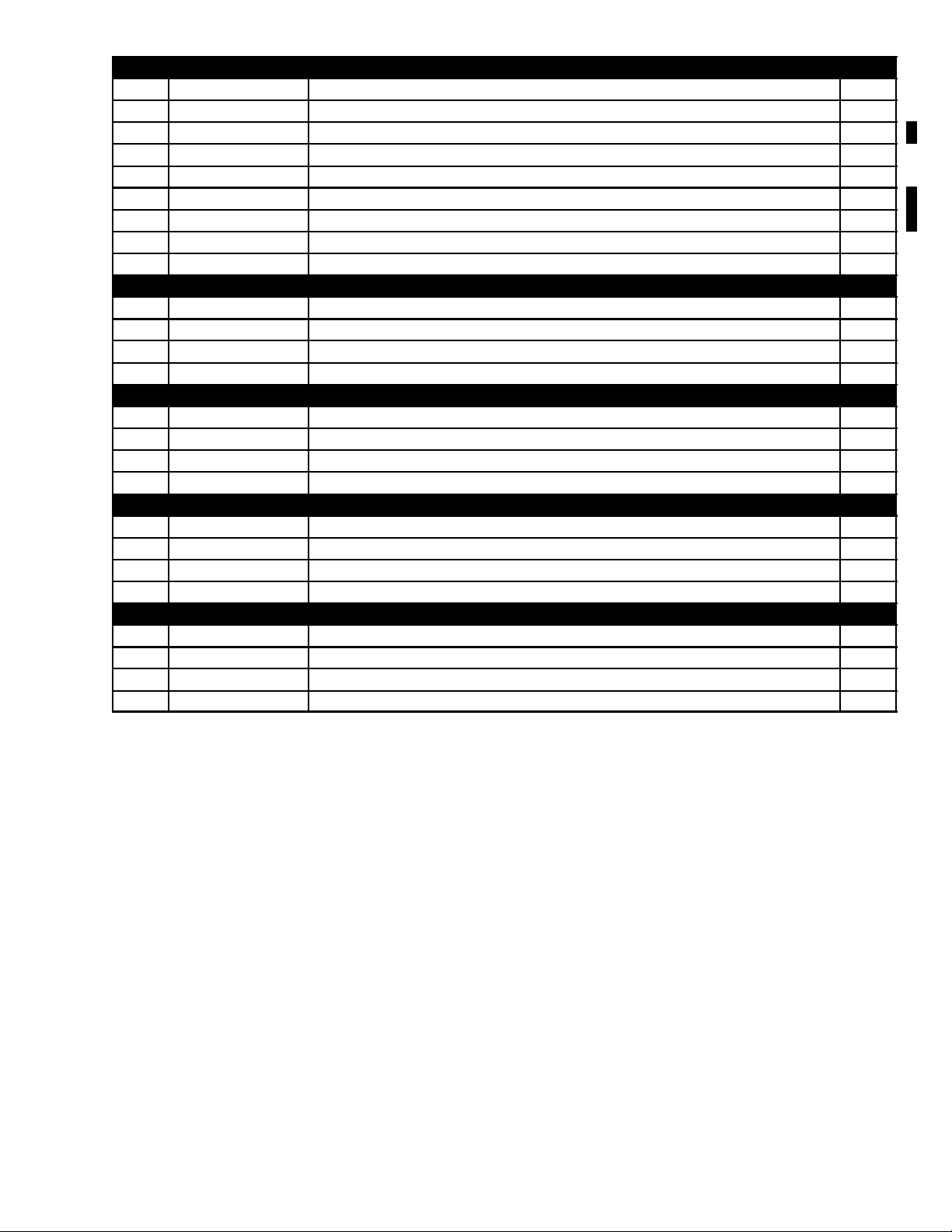

2.19 EVAPORATOR FAN ASSEMBLY AND CONTROLLED A TMOSPHERE -- TRANSFRESH SECTION

14

2

3

13

2

3

4

1

5

6

7

12

11

6

8

9

EFM-1 (Location)

10

EFM-2 (Location)

15

16

Upper back left of unit w/ evap

fan assembly removed

17

18

Partial view of the lower left

corner of the unit.

30T-292PL

Page 40

2.19 EVAPORATOR FAN ASSEMBLY AND CONTROLLED A TMOSPHERE -- TRANSFRESH SECTION

Item Part Number Description Qty

1 69NT43-295 Mounting Bracket, Evaporator Fan Assembly 4

2 69NT35-2692-1 Washer, Fender 8

3 34-00663-11 Washer, Lock, 1/4 -- SST 8

4 34-06165-09 Screw, Hex Head, 1/4-20 x 1-1/4 lg. -- SST 8

5 34-00795-17 Nut, Self Locking, 5/8-18 -- SST 2

6 34-00616-06 Washer, Special, 5/8 -- SST 4

7 38-00577-00 Fan, Evaporator 2

8 48-00262-00 Stator, Evaporator 2

9 58-04066-00 Protector -- Mylar 2

10 54-00585-00 Motor, Evaporator Fan -- Includes: 2

NS 04-50027-00 Bearing, Front (Shaft End) 1

NS 04-50027-01 Bearing, Rear (Opposite Shaft End) 1

NS 22-50088-00 Capacitor (20 mF) High Speed 1

NS 22-01613-34 Pin #16 1

NS 22-01892-00 Plug Assembly, Motor (Located on Wire Harness) -- Includes: 1

NS 22-01614-03 Plug 1

NS 22-01613-15 Contacts A/R

NS 22-01892-01 Receptacle Assembly, Motor -- Includes: 1

NS 22-01614-02 Receptacle 1

NS 22-01614-05 Strain Relief 1

NS 22-01613-14 Contacts A/R

11 66U1-5321-3 Washer, Flat, 1/4 -- SST 8

12 34-06165-09 Screw, Hex Head, 1/4-20 x 1-1/8 lg. -- SST 8

CONTROLLED ATMOSPHERE -- TRANSFRESH

-- 76-00681-01 Kit, Transfresh Field Installation (For units with NO Transfresh Provision) -Includes:

13 34-00655-28 Screw, Hex Head, 1/4-20 x 3-1/2 lg. -- SST 4

14 69NT35-6348 Bracket 2

NS 58-04290-00 Pipe Assembly, PVC 1

*15 69NT35-8734-4 Cable Assembly, Transfresh Communications Connector (TCC) 1

*16 69NT35-8734-16 Panel Assembly, Transfresh 1

*17 69NT35-8734-12 Cable, Power -- A2C (Transfresh) 1

*18 69NT35-8734-5 Hose Assembly, Air (Transfresh) 1

*NS 69NT35-8734-14 Cable Assembly, Rear (Transfresh) 1

*NS 69NT35-8734-6 Fuse Assembly, In-line (Transfresh) 1

NOTE

* Contact - - TransFresh Corp., P.O. Box 1788, Salinas, CA 93902 to order these parts.

--

31 T-292PL

Page 41

3.20 EVAPORATOR COIL SECTION -- REAR PANELS REMOVED

29

30

29

2

32

20

2020

(RTS & RRS)

1

14

6

6

11

12

3

4

7

8

9

10

4

5

T-292PL

19

32

20

16

17

18

28

22

23

13

15

242625

Change 06/10

Page 42

3.20 EVAPORATOR COIL SECTION -- REAR PANELS REMOVED

Item Part Number Description Qty

1 12-00500-01SV Sensor Assembly (RRS & RTS) 1

2 -- Sensor, Thermistor, (Temperature Recorder) -- RefertoSection3.26 --

3 12-00495-20 Sensor, Thermistor, Defrost (DTS) 1

4 34-01178-22 Screw, Hex Head, #8-32 x 1/2 lg. -- SST 3

5 66U1-6912-16 Thermostat, Heat Termination (HTT) 1

6 AU11JR171 Washer, Lock, 1/4 -- SST 10

7 69NT35-6522 Retainer (For Heaters) 3

8 69NT35-6532 Clip (For Heaters) 4

9 69NT35-2692-1 Washer, Flat, 1/4 -- SST 2

10 66U1-5371-13 Screw, Hex Head, #10-24 x 1.25 lg. -- SST 2

11 66U1-5361-25 Capscrew, Hex Head, 1/4-20 x 3/4 lg. -- SST 9

12 66U1-5321-3 Washer, Flat, 1/4 -- SST A/R

13 14-00212-03SV Valve, Quench Expansion 1

14 24-00006-02 Heater, Evaporator Coil 4

15 24-00003-00 Heater, Drain Pan 1

16 44-01050-16 Clamp, Tube -- Nylon 2

17 66U1-5371-6 Screw, Hex Head, #10-24 x .75 lg. -- SST 2

18 66U1-5321-8 Washer, Flat, #10 -- SST 2

19 -- USDA Option -- RefertoSection3.21 --

20 14-00493-11 Sensor, Thermistor, (CPSS) 1

21 58-04026-26 Protector, Mylar 2

22 KA66FA138 Clamp,Tube13/82Holes 1

23 66U1-5371-7 Screw, Machine, Hex Head, #10-24 x .50 lg. -- SST

24 14-00263-05 Valve, Stepper Motor -- Includes: 1

25 14-00263-20 Piston and Motor Assembly -- Includes: 1

26 22-02392-03 Connector (To Expansion Controller Module) 1

NS 22-02393-01 Pin, 18-20 Gauge (Used on 22-02392-03) 4

NS 22-02394-03 Seal (Used on 22-02392-03) 4

OPTION 4 HELICOX HATCHED

81-01574-00 Coil, Evaporator (Does not include thermostats or heaters) -- Used only

27

on PIDS NT0826, NT0862, and NT0865

81-01841-00 Coil, Evaporator (Does not include thermostats or heaters)

28 14-00273-02 Valve, Thermostatic Expansion, Hermetic 1

DEHUMIDIFICATION

-- 76-00675-01 Kit, Humidity Sensor(Field installation, units provisioned for -- See Unit

Matrix, T-300) -- Includes:

29 10-00413-00 Sensor, Humidity (HS) 1

30 66U1-5371-10 Screw, Hex Head, #10-24 x 1.00 lg. -- SST 4

31 66U1-5321-8 Washer, Flat, #10 -- SST 2

32 68-13181-00 Bracket Assembly, Humidity Sensor 1

2

1

--

Change 06/10

33

T-292PL

Page 43

2.21 USDA SECTION

12

10

OPTION -- D

1

2

4

6

3

5

6

OPTION -- V

1

2

4

6

7

8

9

OPTION 1 OR 2

11

34T-292PL

Page 44

2.21 USDA OPTION

Item Part Number Description Qty

OPTION D

1 22-01660-08 Plug, Sealing 4

2 22-01660-00 Receptacle (PR1, PR2, PR3, Cargo Probe 4) (3 Pin) 4

3 22-01660-03 Receptacle, Interrogator (ICR) (5 Pin)1 1

NS 69NT41-992 Plate Assembly, USDA -- Includes: 1

4 69NT43-175 Cap, Dust, with Tether (3 Pin) 4

5 69NT43-176 Cap, Dust, with Chain (5 Pin) 1

6 22-01613-14 Contact, Pin, #16 (Used with 22-01660-00 & 22-01660-03) 13

NS 22-01660-04 Plug, Interrogator Socket (ICR) (5 Pin) 1

OPTION V

1 22-01660-08 Plug, Sealing 4

2 22-01660-00 Receptacle (PR1, PR2, PR3, Cargo Probe 4) (3 Pin) 4

4 69NT43-175 Cap, Dust, with Tether (3 Pin) 4

6 22-01613-14 Contact, Pin, #16 (Used with 22-01660-00 & 22-01660-03) 13

7 22-02412-00 Receptacle, Interrogator (5 Pin) 1

8 22-02413-00 Cap, Dust, with Tether (5 Pin) 1

22-02398-02 Socket, Contact (Silver Plated) A/R

9

22-02398-03 Socket, Contact (Gold Plated) A/R

FIELD INSTALLED KITS (for units with USDA provision , see T-- 300 )

-- 76-00684-00 Kit, USDA (For field installation, units provisioned for rear-mounted

USDA -- See T-300) -- Includes all of OPTION D and the following:

NS 69NT40-507-1 Door Assembly (Included and Used with REAR-mount USDA only) 1

-- 76-00676-00 Kit, USDA (For field installation, units provisioned for side-mounted

USDA -- See T-300) -- Includes all of OPTION D:

USDA PROBE KITS

OPTION 1

10 12-00342-03 Sensor Assembly, 600” lg. (15M) (USDA Probe) -- Includes: A/R

11 22-50127-00 Plug, Socket (PR1, PR2, PR3, Cargo Probe 4) 1

12 22-01613-15 Contact, Socket, #16 (Used with 22-50127-00 & 22-01660-04) A/R

OPTION 2

12-00342-02 Sensor Assembly, 540” lg. (13.5M) (USDA Probe) -- Includes: A/R

10

12-00342-04 Sensor Assembly, 600” lg. (15M) (USDA Probe) -- Includes: A/R

11 22-50127-00 Plug, Socket (PR1, PR2, PR3, Cargo Probe 4) 1

12 22-01613-15 Contact, Socket, #16 (Used with 22-50127-00 & 22-01660-04) A/R

NOTE

Do not mix silver pins with gold pins and sockets.

--

--

35 T-292PL

Page 45

2.22 BACK PANEL ASSEMBLY -- OPTION 1 -- ALUMINUM BOLTED

10

11

3

1

2

3

13

10

11

4

5

3

6

7

9

6

66

12

8

3

6

7

36T-292PL

Page 46

2.22 BACK PANEL ASSEMBLY -- OPTION 1 -- ALUMINUM BOLTED

Item Part Number Description Qty

1 69NT43-464 Grille, Top (Unpainted) 1

2 34-00928-09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8-1/4 21

3 66U1-7982-2 Rivet, TIR, 3/16 Diameter, Grip Range -- 5/64-11/64 4

4 69NT41-942-3 Panel Assembly, Upper PID Number 0699 and below -- Includes: 1

NS NSS Drain Pan, Side (Location -- Behind upper panel) 2

NS NSS Drain Pan, Center (Location -- Behind upper panel -- Top) 1

5 42-00334-00 Gasket (Location -- Behind upper panel) 1

4 76--00746--00 Panel Assembly, Upper PID Number 0700 and above -- Includes: 1

NS NSS Drain Pan (Location -- Behind upper panel) 2

5 42-00334-00 Gasket (Location -- Behind upper panel) 1

NS 66U1-8075 Gasket (25 ft., Cut to length) A/R

6 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8-3/16 46

7 34-00928-03 Rivet, Blind, 1/8 Diameter, Grip Range -- 3/16-1/4 3

8 68-13475-00 Panel, Bottom, (Painted) 1

8 68-13475-08 Panel, Bottom, (Unpainted) 1

9 68-13475-01 Panel, Bottom (Provision for heat exchanger location), (Painted) 1

9 68-13475-09 Panel, Bottom (Provision for heat exchanger location), (Unpainted) 1

10 66U1-2403 Screw, Machine, Truss Head, #10-24 x 1/2 lg. -- SST 20

11 69NT35-2692 Washer, Fender, #10 x 1.00 OD -- SST 20

12 69NT35-2257 Duct, Air 1

13 62-02822-01 Label, Carrier Transicold 1

37 T-292PL

Page 47

2.23 BACK PANEL ASSEMBLY -- OPTION 2 -- ALUMINUM BOLTED WITH USDA DOOR

10

11

3

1

2

3

18

10

11

3

6

12

13

14

15

16

17

7

4

3

6

7

9

6

66

8

38T-292PL

Page 48

2.23 BACK PANEL ASSEMBLY -- OPTION 2 -- ALUMINUM BOLTED WITH USDA DOOR

Item Part Number Description Qty

1 69NT43-464 Grille, Top 1

2 34-00928-09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8-1/4 17

3 66U1-7982-2 Rivet, TIR, 3/16 Diameter, Grip Range -- 5/64-11/64 4

4 69NT41-942-3 Panel Assembly, Upper PID Numbers 0699 and below-- Includes: 1

NS NSS Drain Pan, Side (Location -- Behind upper panel) 2

NS NSS Drain Pan, Center (Location -- Behind upper panel) 1

5 42-00334-00 Gasket (Location -- Behind upper panel) 1

4 76--00746--00 Panel Assembly, Upper PID Numbers 0700 and and above -- Includes: 1

NS NSS Drain Pan (Location -- Behind upper panel) 2

5 42-00334-00 Gasket (Location -- Behind upper panel) 1

6 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8-3/16 41

7 34-00928-03 Rivet, Blind, 1/8 Diameter, Grip Range -- 3/16-1/4 6

8 68-12881-00 Panel, Bottom 1

9 68-12881-01 Panel, Bottom (Provision for heat exchanger location) 1

10 66U1-2403 Screw, Machine, Truss Head, #10-24 x 1/2 lg. -- SST 18

11 69NT35-2692 Washer, Fender, #10 x 1.00 OD -- SST 18

NS 66U1-8075 Gasket (25 ft., Cut to length) A/R

12 69NT40-567-2 Door Assembly, Access-- Includes: 1

13 44-00376--00 Hinge 1

14 69NT35-7662-2 Spacer, Hinge 1

15 34-01150-30 Washer, Retaining 2

16 34-01150-04 Stud, 1/4 Turn, 0.97 lg. 2

17 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/4-5/16 6

18 62-02822-01 Label, Carrier Transicold 1

39 T-292PL

Page 49

2.24 BACK PANEL ASSEMBLY -- OPTION 4 -- ALUMINUM HINGED

10

11

13

10

12

13

9

2

1

2

3

4

5

6

8

5

5

7

5

6

40T-292PL

Page 50

2.24 BACK PANEL ASSEMBLY -- OPTION 4 -- ALUMINUM HINGED

Item Part Number Description Qty

1 69NT43-464 Grille, Top 1

2 34-00928-09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8-1/4 37

3 69NT41-942-4 Panel Assembly, Upper PID Number 0699 and Below -- Includes: 1

NS NSS Drain Pan, Side 2

NS NSS Drain Pan, Center 1

4 42-00334-00 Gasket (Location -- Behind upper panel) 1

3 76--00746--01 Panel Assembly, Upper PID Number 0700 and Above -- Includes: 1

NS NSS Drain Pan 1

4 42-00334-00 Gasket (Location -- Behind upper panel) 1

5 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8-3/16 46

6 34-00928-03 Rivet, Blind, 1/8 Diameter, Grip Range -- 3/16-1/9 3

68-13475-00 Panel, Bottom, (Painted) 1

7

68-13475-08 Panel, Bottom, (Unpainted) 1

68-13475-01 Panel, Bottom (Provision for USDA location), (Painted) 1

8

68-13475-09 Panel, Bottom (Provision for USDA location), (Unpainted) 1

NS 66U1-8075 Gasket (25 ft., Cut to length) A/R

9 69NT35-3282 Hinge 4

10 34-01150-30 Washer, Retaining 14

11 34-01150-06 Stud, 1/4 Turn, 1.03 lg. 6

12 34-01150-03 Stud, 1/4 Turn, 0.94 lg. 8

13 34-01150-31 Receptacle, Retaining 14

41 T-292PL

Page 51

2.25 BACK PANEL ASSEMBLY -- OPTION 5 -- STAINLESS STEEL HINGED

10

11

13

10

12

13

9

2

1

2

3

4

5

6

8

55

7

5

6

42T-292PL

Page 52

2.25 BACK PANEL ASSEMBLY -- OPTION 5 -- STAINLESS STEEL HINGED

Item Part Number Description Qty

1 69NT43-464 Grille, Top 1

2 34-00928-09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8-1/4 37

3 69NT41-942-5 Panel Assembly, Upper PID Number 0699 and Below -- Includes: 1

NS NSS Drain Pan, Side 2

NS NSS Drain Pan, Center 1

4 42-00334-00 Gasket (Location -- Behind upper panel) 1

3 76--00746--02 Panel Assembly, Upper PID Number 0700 and Above-- Includes: 1

NS NSS Drain Pan, 2

4 42-00334-00 Gasket (Location -- Behind upper panel) 1

5 34-00928-02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8-3/16 46

6 34-00928-03 Rivet, Blind, 1/8 Diameter, Grip Range -- 3/16-1/9 3

7 69NT35-6598 Panel, Bottom. SST 1

8 69NT35-6598-1 Panel, Bottom (Provision for USDA location), SST 1

NS 66U1-8075 Gasket (25 ft., Cut to length) A/R

9 69NT35-3282 Hinge 4

10 34-01150-30 Washer, Retaining 14

11 34-01150-06 Stud, 1/4 Turn, 1.03 lg. 6

12 34-01150-03 Stud, 1/4 Turn, 0.94 lg. 8

13 34-01150-31 Receptacle, Retaining 14

43 T-292PL

Page 53

2.26 PARTLOW TEMPERATURE RECORDER

31

33

12

13

16

17

30

31

32

15

9

8

5

11

10

4

27

18

19

2

3

26

28

29

14

6

1

Item Part Number Description Qty

OPTION 1, OPTION 2, OPTION 3 AND OPTION 4

-- 76-00701-04

OPTION 1

1 12-00421-02 Temperature Recorder without Simpson Probe--Includes: 1

-- 76-00701-00

OPTION 2

1 12-00421-00 Temperature Recorder with Simpson Probe--Includes: 1

-- 76-00701-01

OPTION 3

1 12-00421-01 Temperature Recorder, Battery Operated w/o Simpson Probe

-- 76-00701-12

OPTION 4

1 12-00421-03 Temperature Recorder, Battery Operated w/ Simpson Probe --Includes: 1

Recorder Kit--Partlow without Simpson Probe -- Includes: Recorder, Box

and Door Assy’s

Recorder Kit--Partlow with Simpson Probe -- Includes: Recorder, Box and

Door Assy’s

Recorder Kit--Partlow, Battery Operated without Simpson Probe -- Includes:

Recorder, Box and Door Assy’s (For field installation, units provisioned

for -- Refer to Unit Matrix T--300 )

--Includes:

Recorder Kit--Partlow, Battery Operated without Simpson Probe -- Includes:

Recorder, Box and Door Assy’s(For field installation, units provisioned

for -- Refer to Unit Matrix T--300 )

7

22

21

20

23

24

25

1

1

1

1

1

44T-292PL

Page 54

OPTION 1 - PARTLOW WITHOUT PROBE & OPTION 2 - PARTLOW WITH PROBE (Continued)

Item Part Number Description Qty

2 09-00104-05 Kit, Stylus -- Includes: 1

3 NSS Screw , Round Head, #2-56 x 3/16 lg. 2

4 09-00296-00 Mechanism and Platen Assembly 1

5 09-00345-00 Main Lever and Push Rod Assembly (Includes Setscrews) 1

6 09-00344-00 Rod, Push 1

7 09-00114-00 Key, Clock Winding 1

8 09-00119-00 Nut and Chain, Chart (Sonceboz Clock) 1

8 09-00180-00 Nut and Chain, Chart (Gluck Clock) 1

9 PL Screw, Round Head #6-32 x 5/16 7

10 09-00118-00 Flange, Chart Drive (Sonceboz) 1

10 09-00180-01 Flange, Chart Drive (Gluck) 1

11 09-00123-00 Clock, 31 Day, CCW (Counterclockwise) 1

11 09-00302-00 Clock, 31 Day, CCW (Counterclockwise) Battery Operated

Used with P/N 12-00421-01 & 03

12 09-00137-00 O-Ring, Element Flange 4

13 09-00209-00 Element, 9 ft. lg. -- Includes: 1

NS 09-00222-00 Sensor, Thermistor (Accessory 344 and Jack) -- 15 ft. lg. 1

13 09-00236-00 Element, 10 ft. lg. Used with P/N 12-00421-01 & -02 1

14 09-00136-00 Screw, Flange 2

15 76-00701-06SV Box Assembly -- Includes: 1

16 34-01142-01 Receptacle -- #12 2

17 34-00928-01 Rivet, Blind, .125 Diameter, Grip Range .063 - .125 -- SST 4

NS 09-00303-00 Battery Cover (Includes Hardware) 1

NS 22-02243-00 Pin (Use with Partlow Thermistor Assembly) 3

NS 09-00128-00 Charts _F -- 31 Day (Box of 50) (--20_Fto+80_F) A/R

NS 09-00128-01 Charts _C -- 31 Day (Box of 50) (--25_Cto+25_C) A/R

18 76-00701-05 Door Assembly -- Includes: 1

19 42-01098-01 Gasket, Door 1

20 66U1-6811-8 Screw, Retaining -- SST 2

21 34-06053-00 Washer, 1/4 I.D. x 1 O.D. -- Mylar 2

22 34-06169-00 Washer, Retaining -- SST 2

23 69NT35-5022-5 Window 1

24 69NT35-5352-1 Gasket 1

25 34-00795-09 Nut, Selflock, 1/4-20 -- SST 4

26 44-00374-00 Hinge -- SST 2

27 58-04101-07 Protector, .010 Thick x .75 x 2.63 -- Mylar 4

28 34-06179-00 Screw, Hex Head, Slotted, #10-24 x 7/16 lg. -- SST 8

29 34-06179-04 Screw, Hex Head, Slotted, #10-24 x 5/16 lg. -- SST 4

30 66U1-5321-7 Washer, Flat, 1/4 -- SST 2

31 66U1-5361-25 Screw, Cap, Hex Head, 1/4-20 x .75 lg. -- SST 4

32 34-06053-13 Washer, Retaining, .19 I.D. x .80 O.D. -- Mylar 2

33 69NT35-2692-1 Washer, Fender, 1/4 I.D. x .993-1.015 O.D. 2

NS PL Battery -- 1.5 volt (D cell size) Alkaline 1

1

45 T-292PL

Page 55

2.27 SAGINOMIYA TEMPERATURE RECORDER

31

32

17

12

13

4

10

9

1

14

20

19

21

22

23

11

15

16

8

24

7

5

6

134

2

32 27

33

26

27

28

29

25

26

30

46T-292PL

Page 56

2.27 SAGINOMIYA TEMPERATURE RECORDER

Item Part Number Description Qty

OPTION 5 -- SAGINOMIYA WITHOUT PROBE AND & OPTION 6 -- SAGINOMIYA WITH PROBE

-- 76-00701-03

OPTION 5

1 12-01094-00 Recording Thermometer w/Return Sensor -- Includes: 1

-- 76-00701-02

OPTION 6

1 12-01094-01 Recording Thermometer w/Return and Supply Sensor -- Includes: 1

2 09-00365-00 Stylus,LiftArm(See NOTE) 1

3 09-00364-00 Element Assembly 1

4 09-00367-00 Element Assembly (Used on P/N 12-01094-01) 1

5 09-00362-00 Indicator, Voltage 1

6 09-00363-00 Plate, Recorder 1

7 PL Battery (Mallory R14P/S 1.5 vdc) 1

8 09-00326-00 Shaft, Chart 1

9 09-00329-00 Block, Terminal 1

10 09-00322-00 Timer (31 Day) 1

11 09-00325-00 Nut, Chart (Male) 1

12 69NT40-402-1 Sensor Assembly, Return Temperature (Used on 76-00701-02) --

NS 12-01095-00 Sensor, Thermistor 1

13 22-02370-00 Jack, Phono (Used on 76-00701-02) 2

14 76-00701-06SV Box Assembly, Recorder -- Includes: 1

15 34-01142-01 Receptacle, Retaining 2

16 34-00928-01 Rivet, Blind, .125 Diameter, Grip Range .063--.125 -- SST 4

17 34-06053-13 Washer, .195 I.D. x .80 O.D. -- Mylar 2

18 34-01142-01 Receptacle, Retaining 2

19 76-00701-05 Door Assembly, Recorder Box -- Includes: 1

20 42-01098-01 Gasket, Door 1

21 66U1-6811-8 Screw, Retaining -- SST 2

22 34-06169-00 Washer, Retaining -- SST 2

23 34-06053-00 Washer, 1/4 I.D. x 1.00 O.D. -- Mylar 4

24 69NT35-5022-5 Window, Lexan 1

25 69NT35-5352-1 Gasket, Window 1

26 44-00374-00 Hinge Assembly -- SST 2

27 58-04101-07 Protector, Mylar (For Hinge) 4