Page 1

Container

Refrigeration

Unit

Models

69NT40-511-1

to

69NT40-511-199

and

69NT40-521

DUE TO THE LARGE NUMBER OF SCHEMATIC

DIAGRAMS CONTAINED IN THIS BOOK, THE

BOOK IS PRESENTED AS TWO FILES.

REFER TO FILE T268--DIAGRAMS FOR THE

CHAPTER 7 ELECTRICAL DIAGRAMS AND

SCHEMA TICS

T-268 Rev G

Page 2

OPERATION AND

SERVICE MANUAL

CONTAINER REFRIGERATION UNIT

MODELS

69NT40-511-1

to

69NT40-511-199

and

69NT40-521

Carrier Transicold Division, Carrier Corporation, P.O. Box 4805, Syracuse, N.Y. 13221

E Carrier Corporation 1999 S Printed in U. S. A. 0499

Page 3

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and maintenance

of the equipment covered herein. The general safety noticesare presentedin the following three sections labeled:First

Aid, Operating Precautions and Maintenance Precautions. A listing of the specific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, shouldnever go unattended.Always obtain firstaid or medicalattention immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No work should be performed on the unit until all circuit breakers and start-stop switches are turned off, and power

supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

SAFETY SUMMARY

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the condenser fan grille or

evaporator access panels before turning power off, and disconnecting and securing the power plug.

Be surepower is turned off beforeworking on motors, controllers,solenoid valves and electricalcontrol switches. Tag

circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires. Problems

with the system should be diagnosed, and any necessary repairs performed, by qualified service personnel.

When performing any arcwelding on the unit or container,disconnect all wire harness connectors fromthe modules in

the control box. Do not remove wire harness from the modules unless you are grounded to the unit frame with a

static-safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO

(never use water).

2

Safety-1 T-268-07

Page 4

SPECIFIC WARNING AND CAUTION STATEMENTS

To help identify the label hazards on the Unit and explain the level of awareness each one carries, an explanation is

given with the appropriate consequences:

DANGER -- means an immediate hazard which WILL result in severe personal injury or death.

WARNING -- means to warn against hazards or unsafe conditions which COULD result in seve re personal injury or

death.

CAUTION -- means to warn against potential hazard or unsafe practice which COULD result in minor personal injury,

product or property damage.

The statements listed below are applicable to the refrigeration unit and appear elsewhere in this manual. These recommended precautions must be understood and applied during operation and maintenance of the equipment covered

herein.

WARNING

When servicing the unit, use caution when handling R-134a. The refrigerant when in contact with

high temperatures (about 1000_F) will decompose into h ighly corrosive and toxic compounds.

WARNING

Be sure to avoid refrigerant coming in contact with the eyes. S hould refrigerant come in contact

with the eyes, wash eyes for a minimum of 15 minutes with potable water only. THE USE OF

MINERAL OIL OR REFRIGERANT OILS IS NOT RECOMMENDED.

WARNING

Be sure to avoid refrigerant coming in contact with the skin. Should refrigerant come in contact

with the skin, it should be treated as if the skin had been frostbitten or frozen.

WARNING

Be sure ventilation in the workspace is adequate to keep the concentration of refrigerant below

1000 parts per million. If necessary, use portable blowers.

WARNING

Beware of rotating fan blades and unannounced starting of fans.

WARNING

Do not use a nitrogen cylinder without a pressure regulator. Never mix refrigerants with air for

leak testing. It has been determined that pressurized, air-rich mixtures of refrigerants and air can

undergo combustion when exposed to an ignition source.

WARNING

Never fill a refrigerant cylinder beyond its rated capacity. Cylinder may rupture due to excessive

pressure when exposed to high temperatures.

WARNING

When starting the unit, be sure that all manual refrigerant valves in the discharge line are open.

Severe damage could occur from extremely high refrigerant pressures.

Safety-2T-268-07

Page 5

TABLE OF CONTENTS

Section Page

SAFETY SUMMAR Y Safety-1......................................................

GENERAL SAFETY NOTICES Safety-1..............................................

FIRST AID Safety-1...............................................................

OPERATING PRECAUTIONS Safety-1..............................................

MAINTENANCE PRECAUTIONS Safety-1...........................................

SPECIFIC WARNING AND CAUTION STATEMENTS Safety-2.........................

INTRODUCTION 1-1..........................................................

1.1 INTRODUCTION 1-1...................................................

DESCRIPTION 2-1...........................................................

2.1 GENERAL DESCRIPTION 2-1...........................................

2.2 REFRIGERATION SYSTEM DATA 2-10....................................

2.3 ELECTRICAL DATA 2-11................................................

2.4 POWER AUTOTRANSFORMER (Optional) 2-12............................

2.5 UPPER FRESH AIR MAKEUP VENT 2-13.................................

2.6 LOWER FRESH AIR MAKEUP VENT (Optional) 2-13........................

2.7 REFRIGERATION CIRCUIT WITH RECEIVER 2-14.........................

2.8 REFRIGERATION CIRCUIT WITH THE

WATER-COOLED CONDENSER (Optional) 2-16............................

2.9 WATER-COOLED CONDENSER (Optional) 2-16............................

2.9.1 Water--Cooled Condenser with Water Pressure Switch (WP) 2-16.....

TABLE OF CONTENTS

2.9.2 Water-Cooled Condenser with Condenser Fan Switch (CFS) 2-16.....

2.10 SUCTION SOLENOID VALVE 2-18........................................

2.11 REMOTE MONITORING (OPTIONAL) 2-18................................

2.12 SAFETY AND PROTECTIVE DEVICES 2-19...............................

MICROPROCESSOR 3-1......................................................

3.1 MICRO-LINK 2i CONTROLLER MODULE 3-1.............................

3.1.1 Brief Description 3-1............................................

3.1.2 Controller Programming (Memory) Cards 3-2......................

3.1.3 General Layout of the Controller Section 3-4.......................

3.1.4 Controller Function Codes 3-6...................................

3.1.5 Controller Alarms 3-10...........................................

3.1.6 Condenser Pressure Control (CPC) 3-14...........................

3.1.7 Controller Temperature Control 3-14...............................

3.1.7.1 Perishable (Chill) Range Above --10_C(+14_F),

or --5_C(+23_F) Optionally. 3-14.........................

3.1.7.2 Frozen Range Below --10_C(+14_F),

or --5_C(+23_F) Optionally 3-17.........................

3.2 PRE-TRIP DIAGNOSTICS 3-17...........................................

3.2.1 Pre-Trip 3-18....................................................

3.2.2 Pre-Trip Mode 3-19..............................................

3.3 INTEGRATED DataCorder (Optional) 3-24.................................

i T-268-07

Page 6

TABLE OF CONTENTS (CONTINUED)

Section Page

3.3.1 Brief Description 3-24............................................

3.3.2 DataCORDER Configuration 3-25.................................

3.3.3 DataCORDER Function Codes 3-26...............................

3.3.4 DataCORDER Alarms 3-27.......................................

3.3.5 Access to DataCORDER Functions 3-29...........................

3.3.6 USDA/ Message Trip Comment 3-31...............................

3.3.7 USDA Recording 3-31...........................................

3.3.8 Pre-Trip Data Recording 3-31.....................................

3.3.9 DataCORDER Communications 3-31..............................

3.3.10 DataCORDER Scrollback 3-32....................................

3.4 USDA COLD TREATMENT PROCEDURE 3-32.............................

OPERATION 4-1.............................................................

4.1 PRE-TRIP INSPECTION (Before Starting) 4-1.............................

4.2 STARTING AND STOPPING INSTRUCTIONS 4-2.........................

4.3 AFTER STARTING INSPECTION 4-2.....................................

4.4 UNIT OPERATION 4-2..................................................

4.4.1 Crankcase Heater 4-2..........................................

4.4.2 Probe Check Initiation 4-2.......................................

4.4.3 Cooling -- Controller Set BELOW --10_C(+14_F), or

-- 5 _C(+23_F) optionally 4-3.....................................

4.4.4 Controller Set ABOVE --10_C(+14_F), or --5_C(+23_F) optionally 4-3

4.4.5 Heating (See Figure 4-4.) 4-10....................................

4.4.6 Defrost 4-12....................................................

4.4.7 Arctic 4-12......................................................

TROUBLESHOOTING 5-1.....................................................

5.1 UNIT WILL NOT START OR STARTS THEN STOPS 5-1....................

5.2 UNIT RUNS BUT HAS INSUFFICIENT COOLING 5-1......................

5.3 UNIT OPERATES LONG OR CONTINUOUSLY IN COOLING 5-1............

5.4 UNIT WILL NOT HEAT OR HAS INSUFFICIENT HEATING 5-2..............

5.5 UNIT WILL NOT TERMINATE HEATING 5-2..............................

5.6 UNIT WILL NOT DEFROST PROPERLY 5-2..............................

5.7 ABNORMAL PRESSURES (COOLING) 5-3...............................

5.8 ABNORMAL NOISE OR VIBRATIONS 5-3................................

5.9 TEMPERATURE CONTROLLER MALFUNCTION 5-3......................

5.10 NO EVAPORATOR AIR FLOW OR RESTRICTED AIR FLOW 5-3............

5.11 THERMOSTATIC EXPANSION VALVE MALFUNCTION 5-4.................

5.12 POWER AUTOTRANSFORMER MALFUNCTION 5-4......................

5.13 WATER-COOLED CONDENSER OR WATER PRESSURE SWITCH 5-4......

iiT-268-07

Page 7

TABLE OF CONTENTS (CONTINUED)

Section Page

SERVICE 6-1................................................................

6.1 MANIFOLD GAUGE SET 6-1............................................

6.2 SUCTION AND DISCHARGE SERVICE VALVES 6-4.......................

6.3 PUMPING THE UNIT DOWN 6-4........................................

6.4 REFRIGERANT LEAK CHECKING 6-4...................................

6.5 EVACUATION AND DEHYDRATION 6-5..................................

6.5.1 General 6-5...................................................

6.5.2 Preparation 6-5................................................

6.5.3 Procedure 6-5.................................................

6.6 REFRIGERANT CHARGE 6-5...........................................

6.6.1 Checking the Refrigerant Charge 6-5.............................

6.6.2 Adding Refrigerant to System (Full Charge) 6-8....................

6.6.3 Adding Refrigerant to System (Partial Charge) 6-8..................

6.7 COMPRESSOR -- MODEL 06DR 6-8.....................................

6.7.1 Removal and Replacement of Compressor 6-9.....................

6.8 COMPRESSOR DISASSEMBLY 6-9.....................................

6.9 COMPRESSOR REASSEMBLY 6-13......................................

6.10 COMPRESSOR OIL LEVEL 6-14.........................................

6.11 FILTER-DRIER 6-15.....................................................

6.12 HIGH PRESSURE SWITCH 6-15.........................................

6.12.1 Replacing High Pressure Switch 6-15..............................

6.12.2 Checking High Pressure Switch 6-15..............................

6.13 EVAPORATOR COIL AND HEATER ASSEMBLY 6-16.......................

6.14 EVAPORATOR COIL HEATERS 6-16......................................

6.15 EVAPORATOR FAN AND MOTOR ASSEMBLY 6-16........................

6.16 EVAPORATOR FAN MOTOR CAPACITORS 6-17...........................

6.17 CONDENSER COIL 6-18................................................

6.18 CONDENSER FAN AND MOTOR ASSEMBLY 6-18.........................

6.19 PARTLOW RECORDING THERMOMETER 6-18............................

6.20 SAGINOMIYA RECORDING THERMOMETER 6-20.........................

6.21 MAINTENANCE OF PAINTED SURFACES 6-21............................

6.22 POWER AUTOTRANSFORMER (OPTIONAL) 6-21.........................

6.23 SENSOR CHECKOUT PROCEDURE (AMBS, DTS, RRS, RTS, SRS & STS) 6-21

6.23.1 Checking Sensor (RRS, RTS, SRS or STS) 6-21....................

TABLE OF CONTENTS

6.23.2 Replacing Sensor (STS and SRS) 6-22............................

6.23.3 Replacing Sensor (RRS and RTS) 6-23............................

6.23.4 Checking Sensor (AMBS or DTS) 6-24.............................

6.23.5Replacing Sensor (AMBS or DTS) 6-24..............................

6.24 SUCTION SOLENOID VALVE (SSV) 6-25..................................

6.25 SUCTION MODULATION VALVE (SMV) 6-25...............................

iii T-268-07

Page 8

TABLE OF CONTENTS (CONTINUED)

Section Page

6.26 THERMOSTATIC EXPANSION VALVE 6-26................................

6.27 CONTROLLER/DATACORDER 6-28......................................

6.27.1 Controller/DataCORDER Programming Procedure 6-29..............

6.27.2 Controller Trouble-Shooting 6-29..................................

6.28 WATER-COOLED CONDENSER 6-30.....................................

ELECTRICAL WIRING SCHEMATIC AND DIAGRAMS 7-1........................

7.1 INTRODUCTION 7-1...................................................

INDEX Index-1...................................................................

LIST OF ILLUSTRATIONS

Figure Page

Figure 2-1 Refrigeration Unit -- Front 2-1.......................................

Figure 2-2 Refrigeration Unit -- Rear (Panels Removed) 2-3......................

Figure 2-3 Compressor Section 2-4............................................

Figure 2-4 Condenser Section 2-5.............................................

Figure 2-5 Units with Receiver 2-6.............................................

Figure 2-6 Units with Water-Cooled Condenser 2-7..............................

Figure 2-7 Control Box on Units with a Single-Speed Compressor 2-8.............

Figure 2-8 Control Box on Units with a Two-Speed Compressor (Optional) 2-9......

Figure 2-9 Power Autotransformer (Optional) 2-12................................

Figure 2-10 Refrigeration Circuit with Receiver 2-15................................

Figure 2-11 Refrigeration Circuit with Water-Cooled Condenser (Optional) 2-17.......

Figure 3-1 Micro-Link 2i Controller/DataCORDER Module 3-1.....................

Figure 3-1 Key Pad 3-4......................................................

Figure 3-2 Display Module 3-5................................................

Figure 3-3 Standard Configuration Report Sample 3-34...........................

Figure 3-4 Controller Set Point BELOW --10_C(+14_F), or

-- 5 _C(+23_F) optionally 3-35.........................................

Figure 3-5 Controller Set Point ABOVE --10_ C(+14_F), or

-- 5 _C(+23_F) optionally 3-35.........................................

Figure 3-6 Two-Speed Compressor Speed Change Logic -- Perishable Range Only 3-36

Figure 3-7 Two-Speed Compressor Speed Change Logic -- Frozen Range Only 3-37.

Figure 4-1 Cooling in High Speed with Two-Speed Compressor 4-5...............

Figure 4-2 Cooling in Low Speed with Two-Speed Compressor 4-7................

Figure 4-3 Cooling with Single-Speed Compressor 4-9...........................

Figure 4-4 Heating Mode 4-11.................................................

Figure 4-5 Defrost 4-13.......................................................

ivT-268-07

Page 9

LIST OF ILLUSTRATIONS (CONTINUED)

Figure Page

Figure 6-1 Manifold Gauge Set 6-1............................................

Figure 6-2 R-134a Manifold Gauge Set Connection 6-3..........................

Figure 6-3 Suction or Discharge Service Valve 6-4..............................

Figure 6-4 Vacuum Pump Connections 6-7.....................................

Figure 6-5 Compressor -- Model 06DR 6-9......................................

Figure 6-6 Exploded View of Valve Plate 6-10....................................

Figure 6-7 Bottom Plate Removed 6-10.........................................

Figure 6-8 Oil Pump and Bearing Head 6-11.....................................

Figure 6-9 Low Profile Gear Oil Pump 6-11......................................

Figure 6-10 Motor End Cover 6-11...............................................

Figure 6-11 Crankshaft Assembly 6-12...........................................

Figure 6-12 Removing Equalizing Tube and Lock Screw Assembly 6-12..............

Figure 6-13 Terminal Mounting Assembly 6-12....................................

Figure 6-14 Suction Valve & Positioning Springs 6-13..............................

Figure 6-15 Piston Rings 6-13...................................................

Figure 6-16 Compressor Oil Pump End View 6-14.................................

Figure 6-17 Typical Setup for Testing High Pressure Switch 6-15....................

Figure 6-18 Evaporator Fan Assembly 6-17.......................................

Figure 6-19 Partlow Recording Thermometer 6-20................................

Figure 6-20 Saginomiya Recording Thermometer 6-21.............................

Figure 6-21 Supply Sensor Positioning 6-22......................................

Figure 6-22 Sensor (RRS, RTS, SRS or STS) 6-23................................

Figure 6-23 Sensor and Cable Assembly (RRS, RTS, SRS or STS) 6-23.............

Figure 6-24 Return Sensor Positioning 6-24......................................

Figure 6-25 Sensor (AMBS or DTS) 6-24.........................................

Figure 6-26 Sensor and Wire Assembly (AMBS or DTS) 6-24.......................

Figure 6-27 Suction Solenoid Valve (SSV) -- Alco 6-25.............................

Figure 6-28 Suction Modulation Valve (SMV) 6-26.................................

Figure 6-29 Thermostatic Expansion Valve -- Alco 6-27.............................

TABLE OF CONTENTS

Figure 6-30 Thermostatic Expansion Valve Bulb 6-27..............................

Figure 6-31 Controller side of the Control Box 6-28................................

Figure 6-32 Water-Cooled Condenser Cleaning -- Forced Circulation 6-31............

Figure 6-33 Water-Cooled Condenser Cleaning -- Gravity Circulation 6-32............

Figure 6-34 R-134a Compressor Pressure and Motor Current Curves Versus

Ambient Temperature 6-37...........................................

Figures 7-1/7-68 Electrical Schematic -- See Model Chart 7-2/7-137.....................

v T-268-07

Page 10

LIST OF TABLES

Table Page

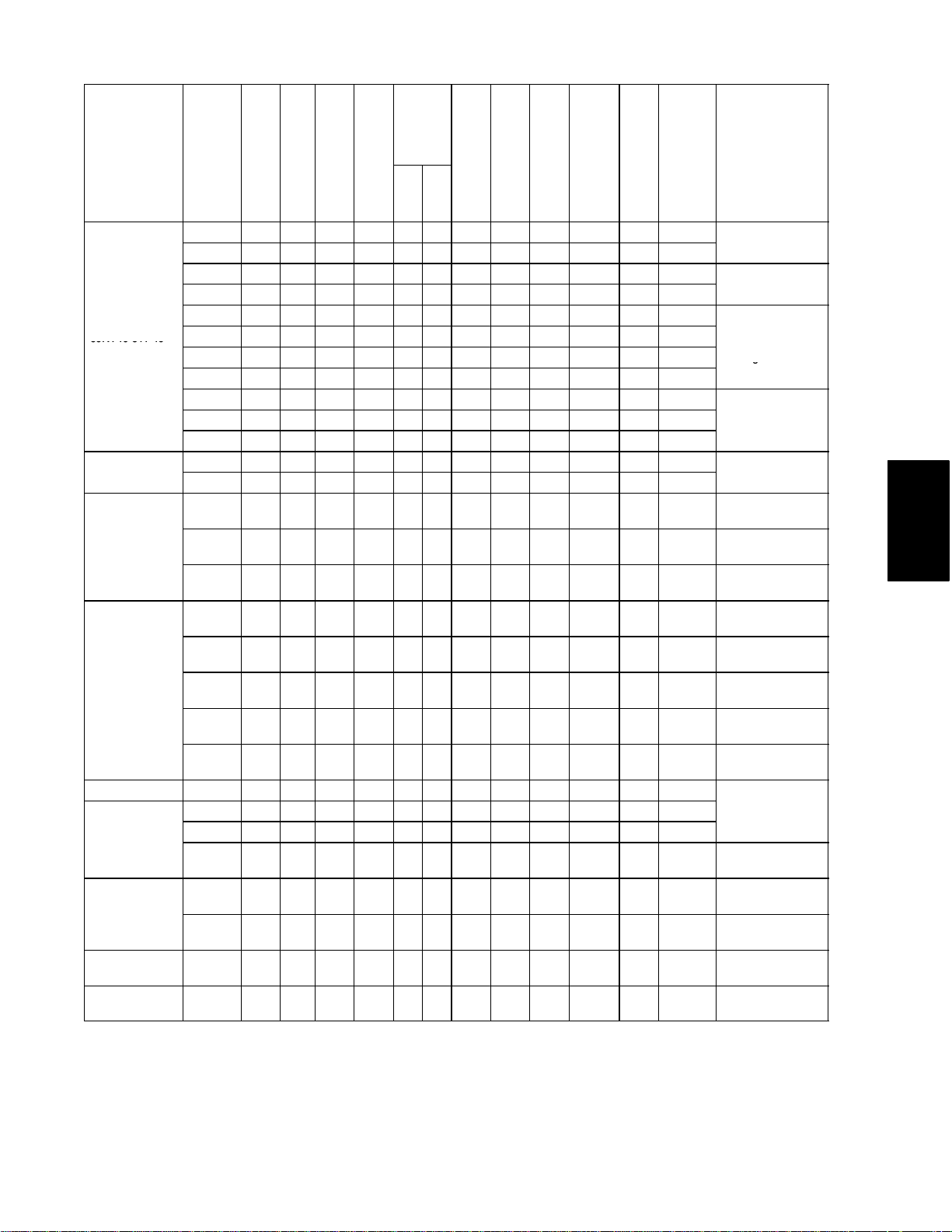

Table 1-1 Model Chart 1-2...................................................

Table 2-1 Safety and Protective Devices 2-19...................................

Table 3-1 Controller Configuration Variables 3-3................................

Table 3-2 Key Pad Function 3-4..............................................

Table 3-3 Controller Function Code Assignments 3-6...........................

Table 3-4 Controller Alarm Indications 3-11.....................................

Table 3-5 Pre-Trip Test Codes 3-19............................................

Table 3-6 DataCORDER Function Code Assignments 3-26.......................

Table 3-7 DataCORDER Alarm Indications 3-28.................................

Table 3-8 DataCORDER Alarm Configurations 3-29..............................

Table 3-9 DataCorder Standard Configuration 3-30..............................

Table 3-10 DataCORDER Pre-Trip Data 3-33....................................

Table 4-1 Electrical Control Positions -- BELOW --10_C(+14_F), or

-- 5 _C(+23_F) optionally 4-14.........................................

Table 4-2 Electrical Control Positions -- ABOVE --10_C(+14_F), or

-- 5 _C(+23_F) optionally 4-15.........................................

Table 6-1 AMBS, DTS, RRS, RTS, SRS and STS Temperature-Resistance Chart 6-32

Table 6-2 Partlow Bulb Temperature-Resistance Chart 6-32.......................

Table 6-3 Recommended Bolt Torque Values 6-33...............................

Table 6-4 Wear Limits For Compressors 6-33...................................

Table 6-5 Compressor Torque Values 6-34......................................

Table 6-6 Temperature-Pressure Chart -- R-134a 6-35............................

viT-268-07

Page 11

SECTION 1

INTRODUCTION

1.1 INTRODUCTION

WARNING

It has been determined that pressurized,

air-rich mixtures of refrigerants and air can

undergo combustion when exposed to an

ignition source.

This manual contains Operating Data, Electrical Data

and Service Instructions for the refrigeration units listed

in Table 1-1. Also, Table 1-1 charts some significant

differences between these models.

NOTE

Beginning with early 1995 production, in

addition to a model number, Carrier Transicold

began usinga parts identification(PID) number

in the format NT0000. In the parts manual, the

PID number is shown in boldface to point out

parts variations within models. The PID

number must be included when ordering and

inquiring about your unit.

The unit, of lightweight aluminum frame construction,

is an all electric, one piece, self-contained cooling and

heating refrigeration unit. The unit is designed to fit in

the frontof a container and to serve as the container front

wall. Forklift pockets are provided for installation and

removal of the unit.

The unit is complete with a charge of R-134a,

compressor lubricating oil (approved POE SW20

compressor oil for R-134a only), mode indicating

lights, and temperature controller, and is ready for

operation upon installation.

Some units are equipped with a two-speed compressor

that is used to enhance power saving.

Some units aredual voltage units designed to operateon

190/230 or 380/460 volts AC, 3-phase, 50-60 hertz

power (refer to section 2.4). Other units are designed to

operate on 380/460 volts AC, 3-phase 50/60 hertz

power only. An external autotransformeris required for

190/230 vac operation (refer to Figure 2-9 and section

2.4).

Operating control power is provided by a control

transformer which steps down the AC supply power

source to 18 and 24 volts AC , single phase control

power.

The temperature Controller/DataCORDER (Micro-Link

2i) is a micropr oce ssor- ba sed controller and a integr ate d

electronic data logging device. Refer to sections 3.1 and

3.3. Once the temperature controller is set at a desired

container temperature, the unit w ill operate automatically

to maintain the desired temperature within very close

limits. The control system automatica lly selects cooling,

holding or heating as necessar y to maintain the de sir ed

temperature within the container.

WARNING

Beware of unannounced start ing of the

evaporator and condenser fans. Do not open

the condenser fan grille before turning

power OFF and disc onnecting power plug.

Some units are equipped with a mechanical temperature

recorder.

Some units may have a TransFRESH controlled

atmosphere system added. Contact TransFRESH

Corporation, P.O. Box 1788, Salinas, CA 93902 for

information on their system.

SECTION 1

1-1 T-268-07

Page 12

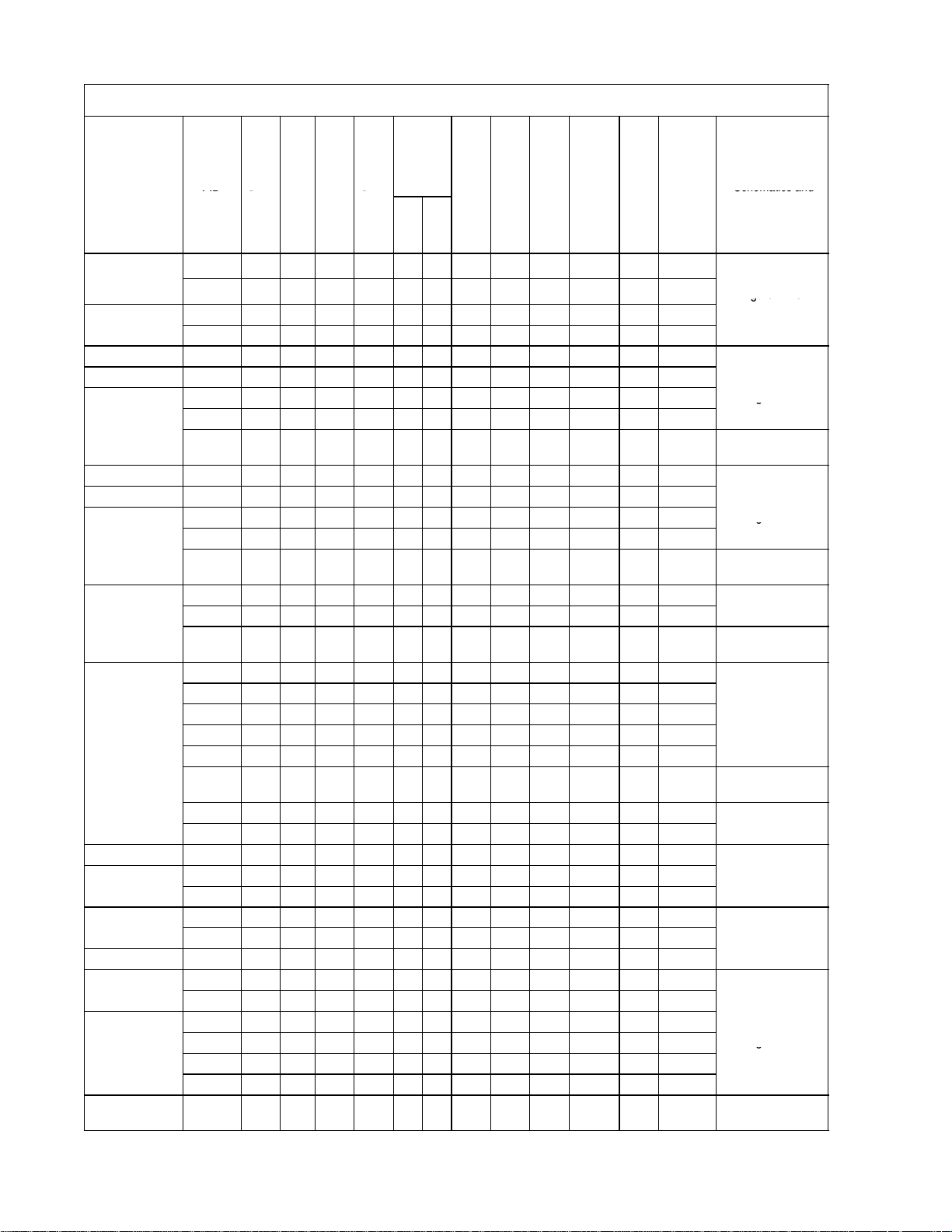

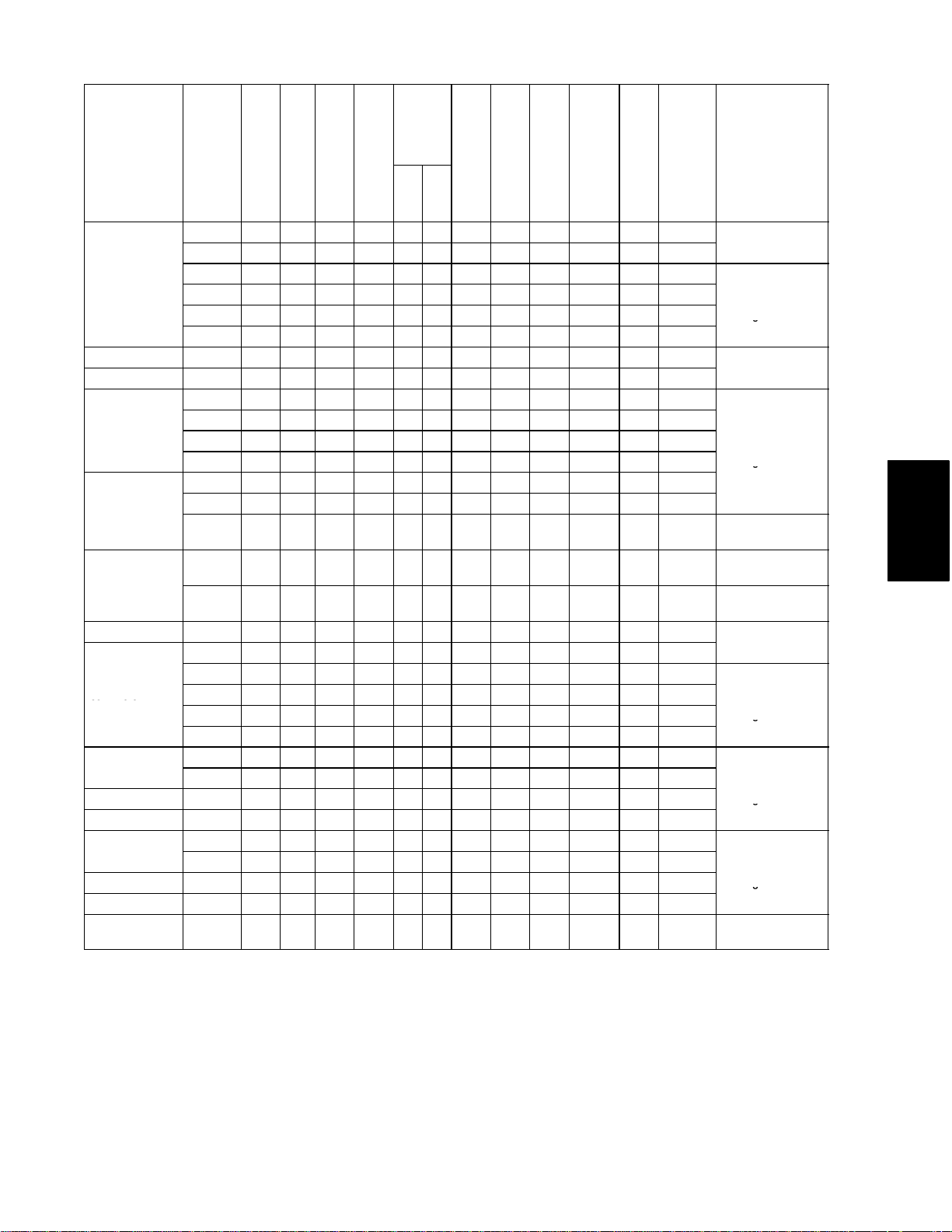

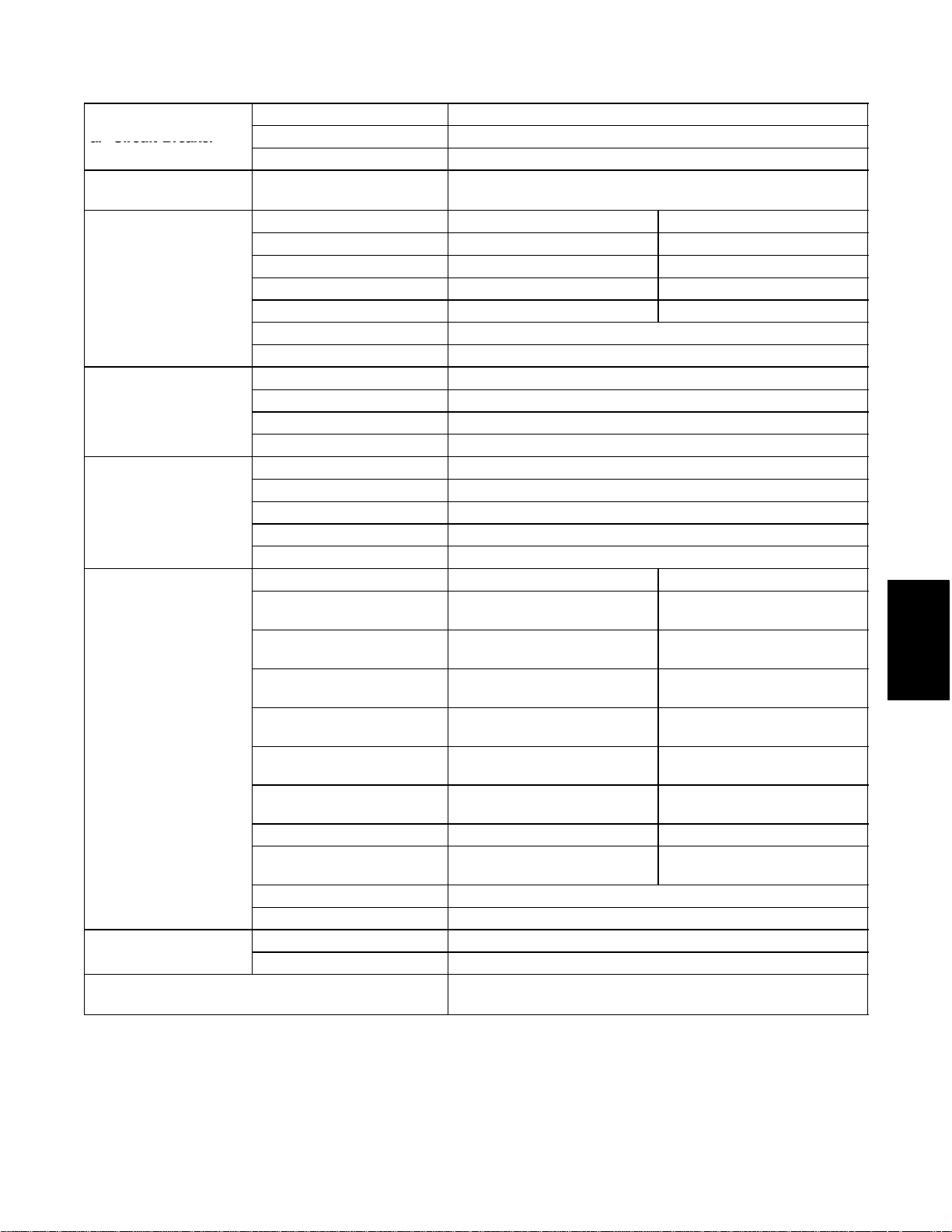

Table 1-1. Model Chart

PID

s

r

n

O

y

s

M

d

Schematicsand

Figure71&

&

Figure7-3

&

g69NT40-511-5

&

Figure7-3

&

g69NT40-511-8

&

Figure7-3

&

69NT4

0-511-9

F

i

4

&

Figure7-19&

F

i

4

F

i

6

&

Figure7-3

&

g

Condenser

MODEL

69NT40-511-1

69NT40-511-2

69NT40-511-3 NT0007 P P --- --- X --- --- X --- --- X ---

69NT40-511-4 NT0037 P X --- P X --- --- P --- --- X ---

69NT40-511-6 NT0013 P P --- --- X --- --- X --- --- --- ---

69NT40-511-7 NT0014 X P --- --- X --- --- X --- --- --- ---

69NT40-511-10

69NT40-511-11 NT0008 P X --- --- --- X A X --- P X ---

69NT40-511-12

69NT40-511-13

69NT40-511-14 NT0018 X P --- --- --- X A X --- X --- ---

69NT40-511-15

69NT40-511-16

69NT40-511-17 NT0043 X P X P X --- --- P --- --- X ---

PID

NT0001 X P X P X --- --- X --- X X ---

NT0062 X P X P X --- --- X --- X X ---

NT0002 X P X X X --- --- X --- X X ---

NT0017 X P X X X --- --- X --- X X ---

NT0011 P X --- P X --- --- P --- --- X ---

NT0038 P X --- P X --- --- P --- --- X ---

NT0099 P X --- P X --- --- P --- --- X ---

NT0005 P X --- P X --- --- P --- --- X ---

NT0037 P X --- P X --- --- P --- --- X ---

NT0094 P X --- P X --- --- P --- --- X ---

NT0064 P P --- P X --- --- P --- --- X ---

NT0089 P P --- P X --- --- P --- --- X ---

NT0152 P P --- P X --- --- P --- --- X ---

NT0024 P X --- P X --- --- P X --- X ---

NT0027 P X --- P X --- --- P X --- X ---

NT0040 P X --- P X --- --- P X --- X ---

NT0041 P X --- P X --- --- P X --- X ---

NT0104 P X --- P X --- --- P X P X ---

NT0112 P X --- P X --- --- P X P X ---

NT0173 P X --- P X --- --- P X --- X ---

NT0209 P X --- P X --- --- P X P X ---

NT0076 P P --- P X --- --- P X --- P ---

NT0082 P P --- P X --- --- P X --- P ---

NT0015 X P --- --- --- X A X --- X --- ---

NT0022 X P --- --- --- X A X --- X --- ---

NT0029 P X --- X X --- --- P --- --- X ---

NT0044 P X --- X X --- --- P --- --- X ---

NT0028 P X --- P X --- --- P --- --- X ---

NT0054 P P --- P X --- --- P --- P X ---

NT0070 P P --- P X --- --- P --- P X ---

NT0083 P P --- P X --- --- P --- P X ---

Cold

USDACTreatm

ent

ressor

nser

-Cooled

Water-CConde

peed

sformer

Tran

Two-SpComp

Coil

Discharge

y Sensor

Option

Suction &

2Row

Pressure

4Row

sFresh

Tran

Humidit

cations

CommunicInterface

odule (CI)

mperature

omiya

SaginoTem peRecor

Partlow TemRecorder

rature

der

Electrical Wiring

Schematics and

Diagrams

Figure 7-1 &

Figure 7-2

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3 &

gure7-

Figure 7-9 &

Figure 7-10

Figure 7-19

Figure 7-20

Figure 7-3 &

gure7-

Figure 7-5 &

gure7-

Figure 7-3

Figure 7-4

Figure 7-1 &

Figure 7-2

1-2T-268-07

Page 13

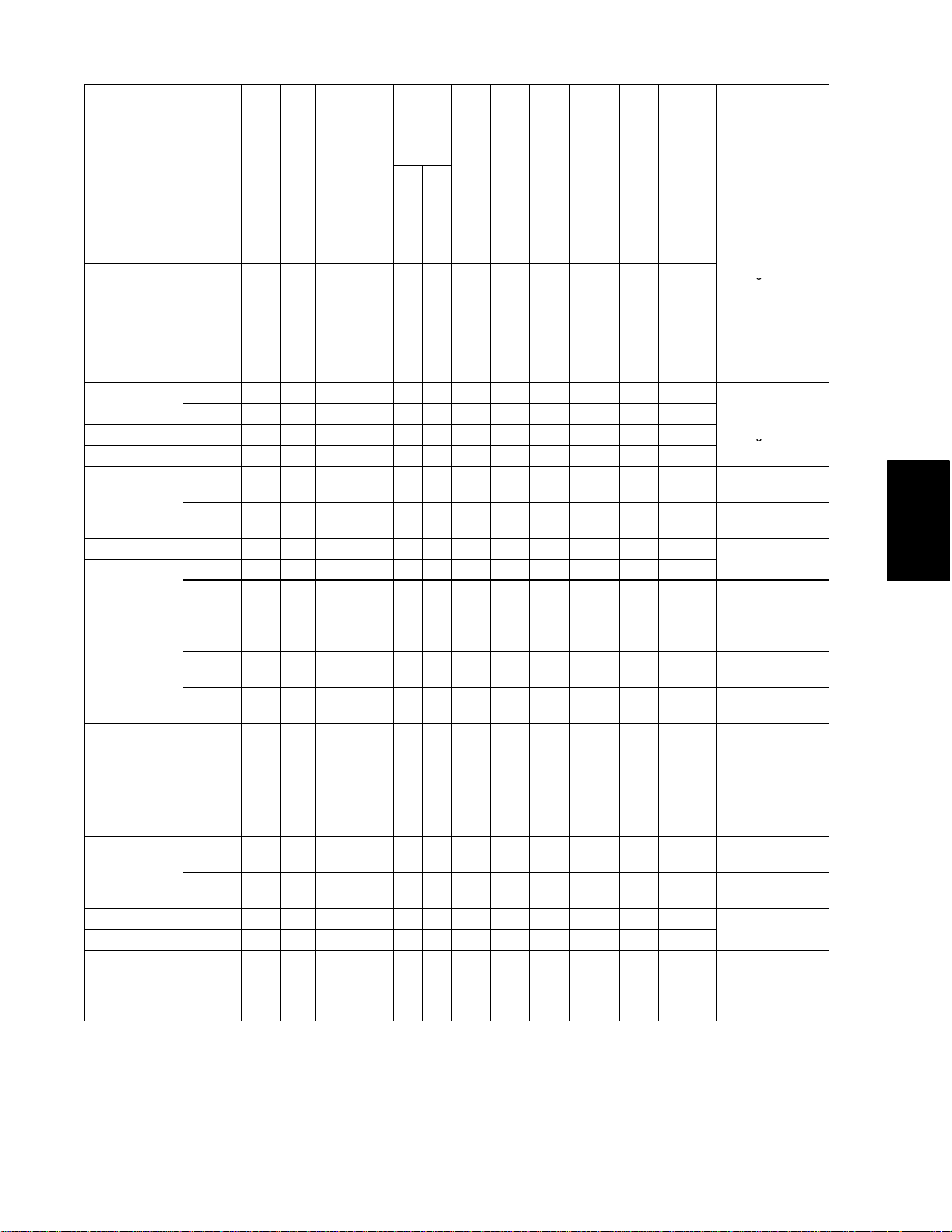

Condenser

&

Figure7-3

&

g

&

Figure7-9

&

&

Figure7-3

&

g

&

Figure7-3

&

&

Figure7-3

&

&

Figure7-3

&

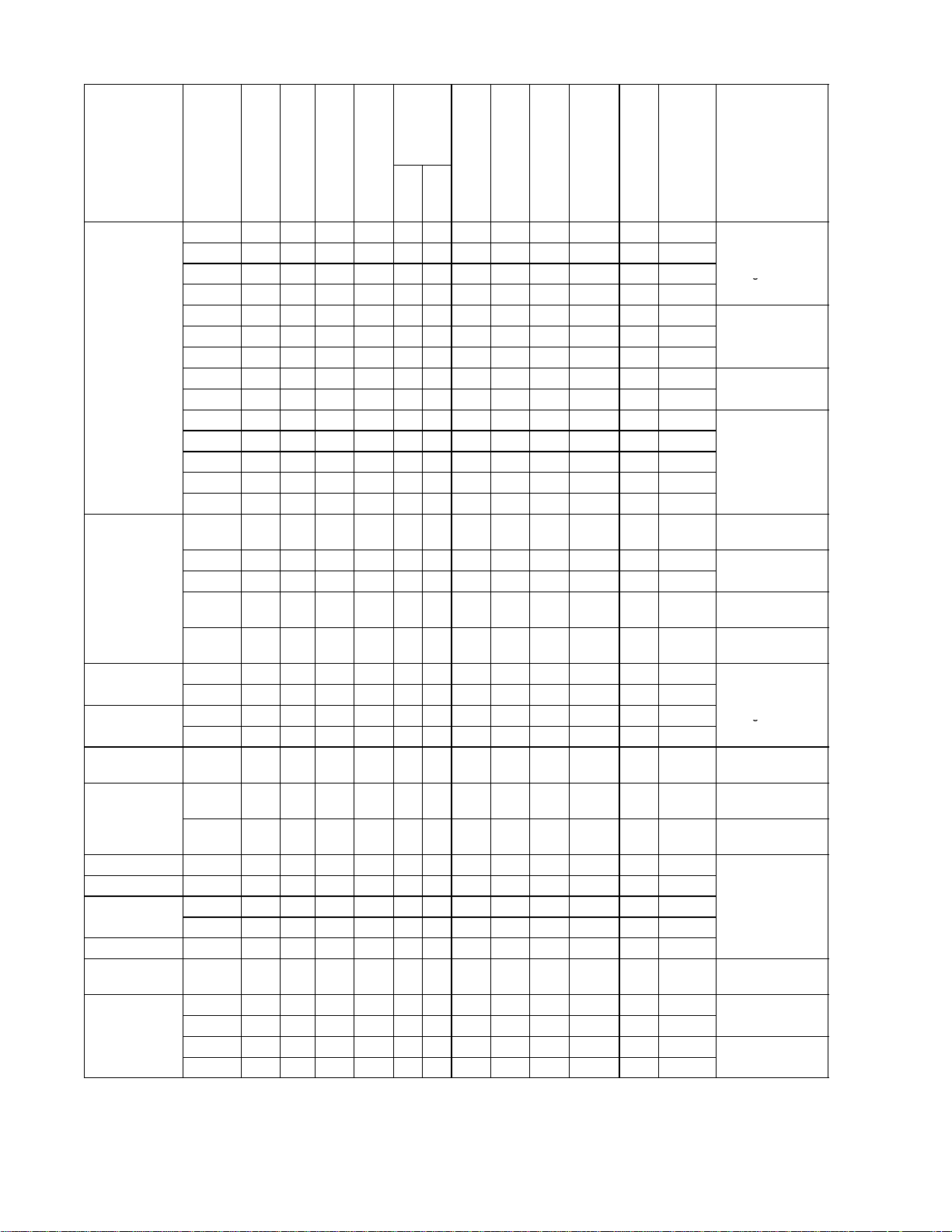

MODEL

MODEL

69NT40-511-18 NT0035 P X --- P X --- A P --- X X ---

69NT40-511-19 NT0037 P X --- P X --- --- P --- --- X ---

69NT40-511-21 NT0055 P X --- P X --- --- P X --- X ---

69NT40-511-22

69NT40-511-23

69NT40-511-24 NT0051 P P --- P X --- --- P --- P P ---

69NT40-511-25 NT0053 P P --- P X --- --- P --- --- X ---

69NT40-511-26

69NT40-511-27 NT0056 X X --- P --- X --- P --- P X ---

69NT40-511-28

69NT40-511-29

69NT40-511-30 NT0060 X --- X --- --- X A X --- X --- ---

69NT40-511-31 NT0061 P X --- P X --- --- X --- --- X ---

69NT40-511-32

69NT40-511-33

69NT40-511-34 NT0065 P P --- P X --- B P --- --- X ---

69NT40-511-35 NT0071 X P --- P --- X --- P --- P X ---

69NT40-511-36 NT0072 X --- --- --- --- X A X --- X --- ---

69NT40-511-37 NT0073 X --- --- P X --- B X X --- X ---

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0046 P X --- P --- X A P --- --- X ---

NT0121 P X --- P --- X A P --- --- X ---

NT0139 P X --- P --- X A P --- --- X ---

NT0252 P X --- P --- X A P --- --- X ---

NT0050 P X --- P X --- --- P --- P X ---

NT0069 P X --- P X --- --- P --- P X ---

NT0047 P P X P X --- --- P P P P ---

NT0175 P P X P X --- --- P P P P ---

NT0057 P P --- P X --- --- P X --- X ---

NT0132 P P --- P X --- --- P X P X ---

NT0059 P P --- X X --- --- X --- --- X ---

NT0219 P P --- X X --- --- X --- --- X ---

NT0343 P P --- X X --- --- X --- P X ---

NT0067 P X --- P X --- --- P --- P P ---

NT0097 P X --- P X --- --- P --- P P ---

NT0068 P X --- P X --- --- P X P --- ---

NT0239 P X --- P X --- --- P X P P ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure 7-3

Figure 7-4

Figure 7-9

Figure 7-10

Figure7-41&

Figure 7-42

Figure 7-3

Figure 7-4

Figure 7-1 &

Figure 7-2

Figure7-21&

Figure 7-22

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3 &

Figure 7-4

Figure7-19&

Figure 7-20

Figure7-57&

Figure 7-58

Figure 7-7 &

Figure 7-8

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3 &

Figure 7-4

Figure7-41&

Figure 7-42

Figure 7-3

Figure 7-4

Figure 7-5 &

Figure 7-6

Figure 7-3 &

Figure 7-4

SECTION 1

1-3 T-268-07

Page 14

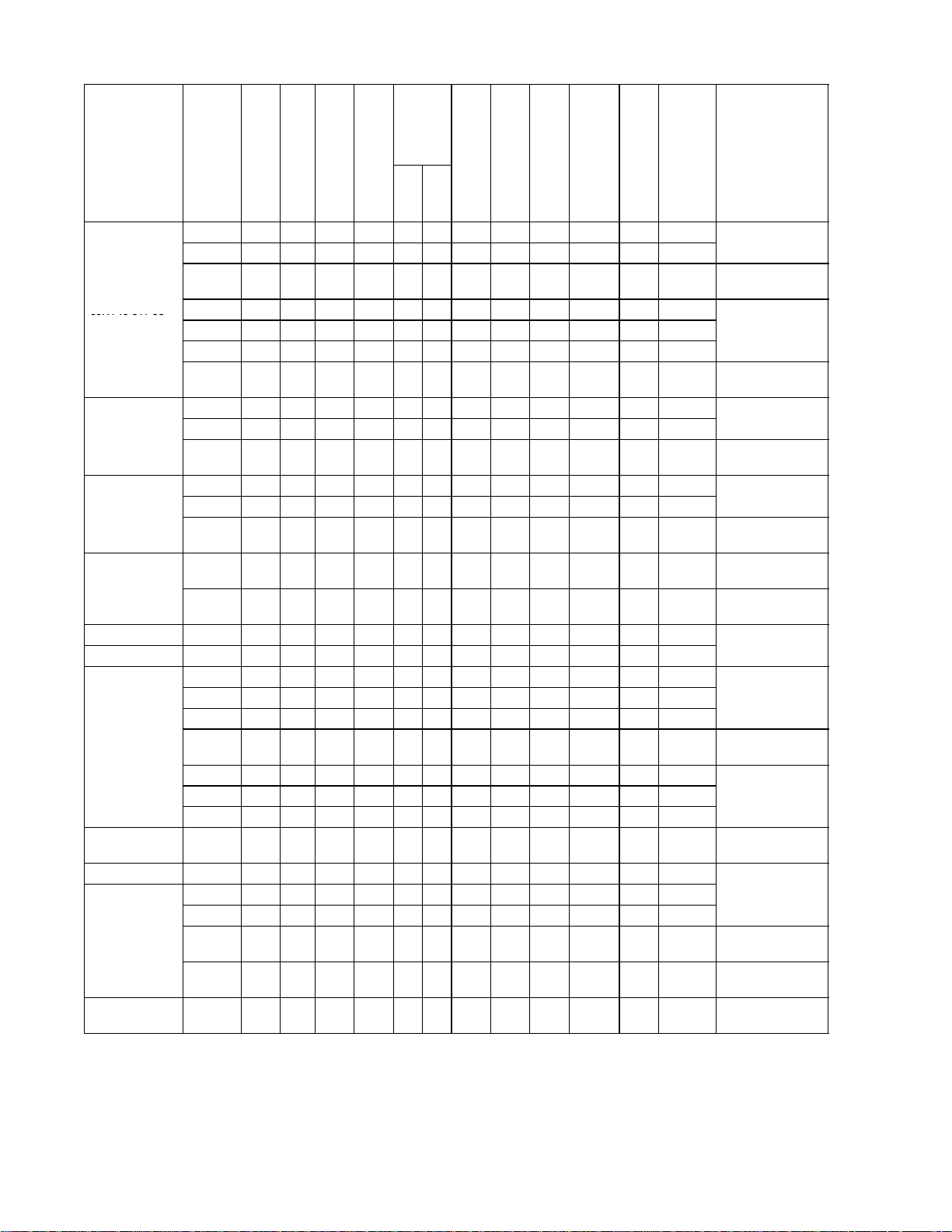

Condenser

&

Figure7-11&

69NT4051138

F

i

4

8

&

Figure7-3

&

69NT4

0-511-3

9

&

Figure7-3

&

69NT4

0-511-4

0

&

Figure7-3

&

F

i

1

0

F

i

4

2

F

i

1

0

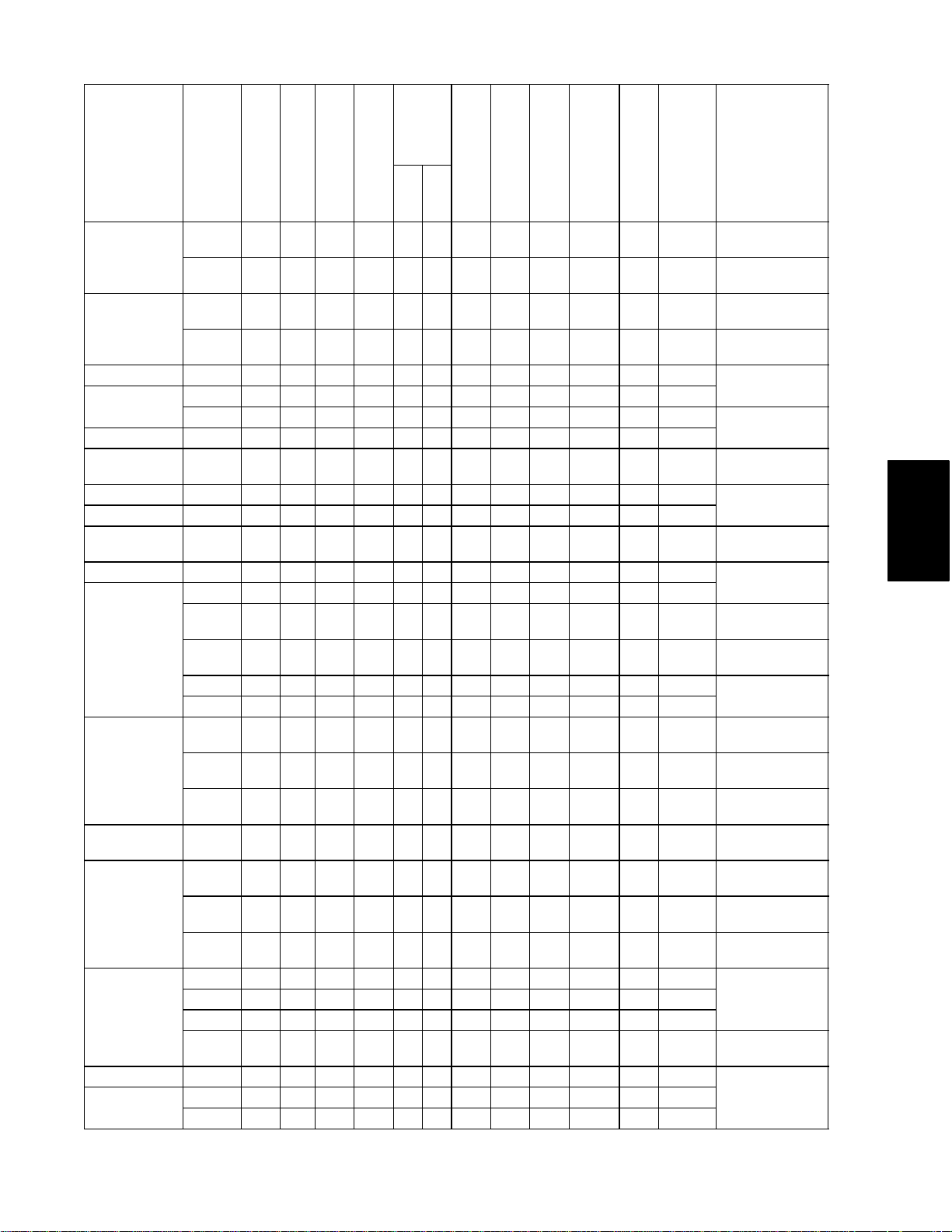

MODEL

MODEL

69NT40-511-38

69NT40-511-41

69NT40-511-42 NT0088 P P --- P X --- --- P --- --- P ---

69NT40-511-43 NT0081 P P --- P X --- --- P X --- --- ---

69NT40-511-44

69NT40-511-45 NT0092 P P --- P X --- --- P X --- P ---

69NT40-511-46 NT0110 P X --- P --- X --- P --- P X ---

69NT40-511-47

69NT40-511-48 NT0101 P P --- P --- X --- P --- P X ---

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0074 X --- --- --- --- X A X --- X --- ---

NT0135 X --- --- --- --- X A X --- X --- ---

NT0208 X --- --- --- --- X A X --- X --- ---

NT0246 X --- --- --- --- X A X --- X --- ---

NT0253 X --- --- --- --- X A X --- X --- ---

NT0267 X --- --- --- --- X A X --- X --- ---

NT0307 X --- --- --- --- X A X --- X --- ---

NT0078 X P --- X X --- --- X --- X X ---

NT0084 X P --- X X --- --- X --- X X ---

NT0095 X P --- X X --- --- X --- X X ---

NT0079 X P --- P X --- --- X --- X X ---

NT0085 X P --- P X --- --- X --- X X ---

NT0096 X P --- P X --- --- X --- X X ---

NT0080 P P --- P X --- --- P --- P --- ---

NT0090 P P --- P X --- --- P --- P --- ---

NT0091 X X --- --- --- X A X --- P X ---

NT0102 P X --- --- --- X A X --- P X ---

NT0137 P X --- --- --- X A X --- P X ---

NT0185 P X --- --- --- X A X --- P X ---

NT0213 P X --- --- --- X A X --- P --- X

NT0244 P X --- --- --- X A X --- P --- X

NT0266 P X --- --- --- X A X --- P --- X

NT0098 P X --- X X --- B P --- P --- X

NT0124 P X --- X X --- B P --- P --- X

NT0146 P X --- X X --- B P --- P --- X

NT0186 P X --- X X --- B P --- P --- X

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure 7-11

Figure 7-12

Figure7-31&

Figure 7-32

Figure7-47&

gure7-

Figure7-63&

Figure 7-64

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure 7-3 &

Figure 7-4

Figure7-65&

Figure 7-66

Figure 7-3

Figure 7-4

Figure 7-9 &

gure7-

Figure7-19&

Figure 7-20

Figure7-41&

gure7-

Figure 7-3 &

Figure 7-4

Figure 7-9 &

gure7-

Figure7-23&

Figure 7-24

Figure7-19&

Figure 7-20

Figure 7-3 &

Figure 7-4

1-4T-268-07

Page 15

Condenser

&

Figure7-9

&

&

Figure7-19&

&

69NT4051149

Figure7-41&

g

F

i

5

8

&

Figure7-9

&

F

i

1

0

69NT4

0-511-5

4

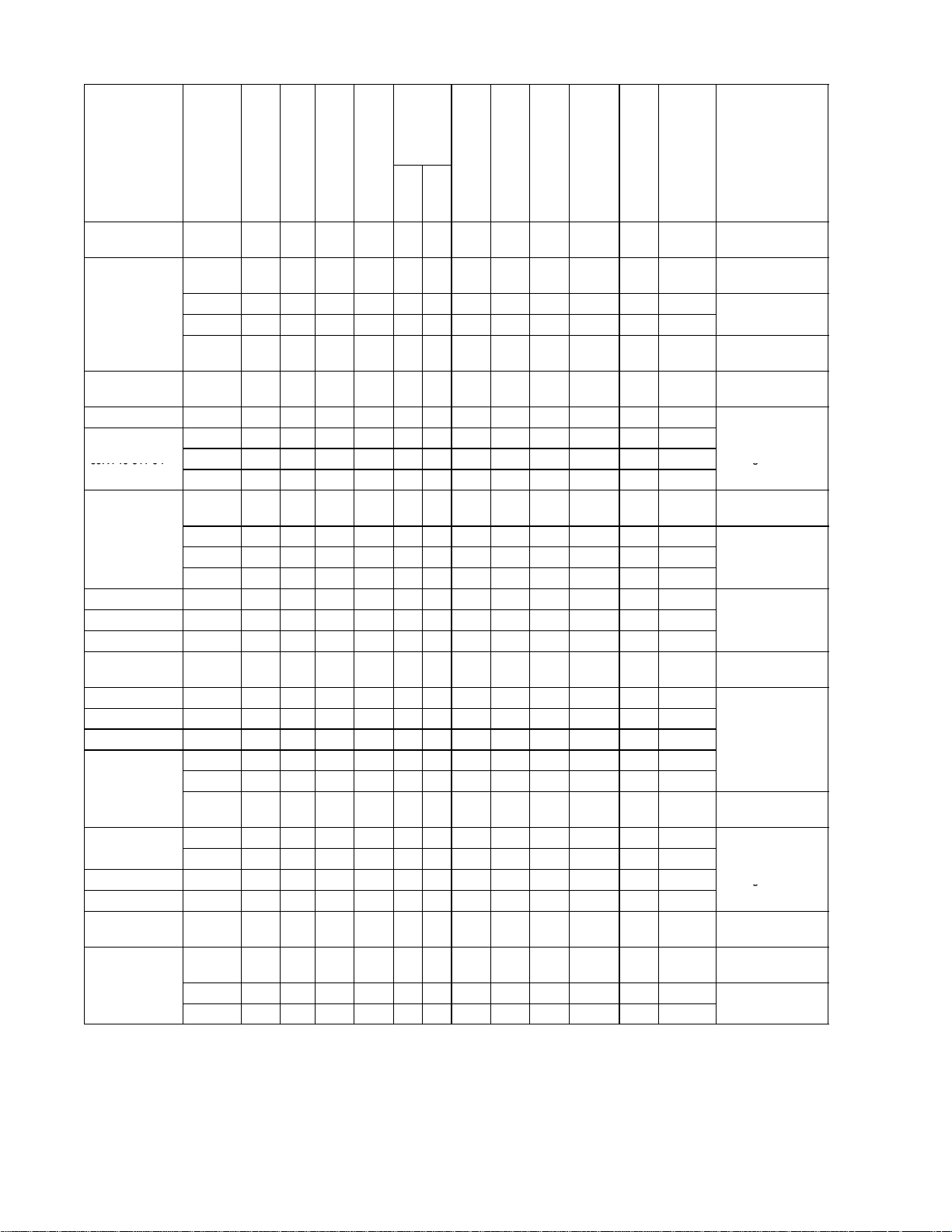

MODEL

MODEL

69NT40-511-49

69NT40-511-50

69NT40-511-51

69NT40-511-52

69NT40-511-53 NT0113 P P --- P X --- --- P X P --- ---

69NT40-511-55

69NT40-511-56 NT0242 P P --- P --- X --- P X P X ---

69NT40-511-57 NT0156 P X --- P X --- --- P --- P X ---

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0103 P P --- P X --- --- P --- P X ---

NT0134 P P --- P X --- --- P --- P X ---

NT0184 P P --- P X --- --- P --- P X ---

NT0216 P P --- P X --- --- P --- P X ---

NT0268 P P --- P X --- --- P --- P X ---

NT0282 P P --- P X --- --- P --- P X ---

NT0283 P P --- P X --- --- P --- P --- X

NT0303 P P --- P X --- --- P --- --- --- X

NT0308 P P --- P X --- --- P --- P X ---

NT0341 P P --- P X --- --- P --- P --- X

NT0345 P P --- P --- X --- P --- P X ---

NT0106 X X --- P X --- --- X --- X --- X

NT0178 X X --- P X --- --- X --- X --- X

NT0107 X X --- P --- X A P --- --- X ---

NT0207 X X --- P --- X A P --- --- X ---

NT0417 X P --- P --- X --- P --- P --- ---

NT0109 P X --- P X --- --- P --- P X ---

NT0111 P X --- P X --- --- P --- P X ---

NT0133 P X --- P X --- --- P --- P X ---

NT0162 P X --- P X --- --- P --- P X ---

NT0225 P X --- P X --- --- P --- P X ---

NT0118 P P --- P X --- --- P --- P X ---

NT0136 P P --- P X --- --- P --- P X ---

NT0215 P P --- P X --- --- P --- P X ---

NT0120 P --- --- --- --- X --- P --- --- X ---

NT0188 P --- --- --- --- X --- P --- --- X ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure 7-9

Figure 7-10

Figure 7-19

Figure 7-20

Figure 7-41

Figure 7-42

Figure7-57&

gure7-

Figure 7-9

Figure 7-10

Figure7-13&

Figure 7-14

Figure7-45&

Figure 7-46

Figure7-67&

Figure 7-68

Figure 7-9 &

Figure 7-10

Figure 7-3 &

Figure 7-4

Figure 7-9 &

Figure 7-10

Figure7-19&

Figure 7-20

Figure7-41&

Figure 7-42

Figure 7-9 &

gure7-

Figure7-41&

Figure 7-42

Figure 7-9 &

Figure 7-10

Figure7-19&

Figure 7-20

Figure7-41&

Figure 7-42

Figure 7-9 &

Figure 7-10

SECTION 1

1-5 T-268-07

Page 16

Condenser

&

Figure7-9

&

g

F

i

2

0

&

Figure7-41&

F

i

5

8

&

Figure7-19&

69NT4

0-511-5

9

&

Figure7-9

&

g

F

i

1

0

&

Figure7-41&

&

Figure7-57&

MODEL

MODEL

69NT40-511-58

69NT40-511-60

69NT40-511-61

69NT40-511-62 NT0127 P P --- P X --- --- P --- X X ---

69NT40-511-63

69NT40-511-64 NT0131 P X --- --- --- X A X X P X ---

69NT40-511-65 NT0119 P X --- X X --- --- P --- P X ---

69NT40-511-66

69NT40-511-67 NT0143 P P --- P X --- --- P --- --- P ---

69NT40-511-69 NT0177 P P --- P X --- --- P --- P P ---

69NT40-511-70

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0105 P X --- P X --- --- P --- P X ---

NT0122 P X --- P X --- --- P --- P X ---

NT0138 P X --- P X --- --- P --- P X ---

NT0141 P X --- P X --- --- P --- P X ---

NT0160 P X --- P X --- --- P --- P X ---

NT0161 P X --- P X --- --- P --- P X ---

NT0189 P X --- P X --- --- P --- P X ---

NT0240 P X --- P X --- --- P --- P X ---

NT0269 P X --- P X --- --- P --- P X ---

NT0309 P X --- P X --- --- P --- P X ---

NT0340 P X --- P X --- --- P X P P ---

NT0386 P X --- P X --- --- P X P X ---

NT0418 P X --- P X --- --- P --- P X ---

NT0428 P X --- P X --- --- P --- P --- X

NT0167 P P --- P X --- --- P --- P X ---

NT0174 P P --- P X --- --- P --- P X ---

NT0211 P P --- P X --- --- P --- P X ---

NT0272 P P --- P X --- --- P --- P X ---

NT0312 P P --- P X --- --- P --- P X ---

NT0125 X X --- P --- X A P --- --- X ---

NT0153 X X --- P --- X A P --- --- X ---

NT0126 X X --- P X --- A P --- --- X ---

NT0154 X X --- P X --- A P --- --- X ---

NT0140 X --- --- P --- X --- X X X --- ---

NT0192 X --- --- P --- X --- X X X --- ---

NT0129 P X --- X X --- --- P --- P X ---

NT0147 P X --- X X --- --- P --- P X ---

NT0241 P X --- P --- X --- X X P X ---

NT0271 P X --- P --- X --- X X P X ---

NT0311 P X --- P --- X --- X X P X ---

NT0353 P X --- P --- X --- X X P X ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure 7-9

Figure 7-10

Figure7-19&

gure7-

Figure 7-41

Figure 7-42

Figure7-57&

gure7-

Figure 7-9 &

Figure 7-10

Figure 7-19

Figure 7-20

Figure7-41&

Figure 7-42

Figure7-57&

Figure 7-58

Figure 7-9

Figure 7-10

Figure7-17&

Figure 7-18

Figure 7-9 &

Figure 7-10

Figure7-19&

Figure 7-20

Figure 7-9 &

gure7-

Figure7-19&

Figure 7-20

Figure 7-41

Figure 7-42

Figure 7-57

Figure 7-58

1-6T-268-07

Page 17

Condenser

&

Figure7-9

&

&

Figure7-19&

&

Figure7-9

&

&

Figure7-9

&

&

Figure7-41&

F

i

3

2

F

i

4

2

MODEL

MODEL

69NT40-511-71

69NT40-511-72

69NT40-511-73 NT0158 P P --- P --- X --- P --- P X ---

69NT40-511-74

69NT40-511-75 NT0163 X P --- P --- X A X --- P X ---

69NT40-511-76 NT0169 P X X P X --- B P --- P --- X

69NT40-511-77 NT0176 P X --- P X --- B P --- P X ---

69NT40-511-78 NT0182 P X --- P X --- --- X --- P X ---

69NT40-511-79 NT0190 --- X --- P X --- B P --- --- --- X

69NT40-511-80 NT0165 P P --- P X --- --- P --- P P ---

69NT40-511-81

69NT40-511-82

69NT40-511-83 NT0210 P P --- P --- X --- X --- P X ---

69NT40-511-84

69NT40-511-85

69NT40-511-87 NT0214 P P --- P X --- B P X P --- X

69NT40-511-89

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0166 P X --- P X --- --- P X P X ---

NT0235 P X --- P X --- --- P X P X ---

NT0157 P X --- P X --- --- P X P X ---

NT0200 P X --- --- X --- --- P X P X ---

NT0159 P P --- P X --- --- P --- P X ---

NT0223 P P --- P X --- --- P --- P X ---

NT0151 P X --- P X --- --- P --- P X ---

NT0168 P X --- P X --- --- P --- P X ---

NT0180 P X --- P X --- --- P --- P X ---

NT0236 P X --- P X --- --- P --- P X ---

NT0258 P X --- P X --- --- P --- P X ---

NT0187 P X --- P X --- A P X P X ---

NT0198 P X --- P X --- A P X P X ---

NT0199 P X --- P X --- A X X P X ---

NT0191 --- --- --- X --- X --- P --- P P ---

NT0201 --- --- --- X --- X --- P --- P --- ---

NT0334 --- --- --- X --- X --- P --- P --- ---

NT0183 X --- --- X --- X A P --- X --- ---

NT0226 X --- --- X --- X A X --- X --- ---

NT0280 X --- --- X --- X A X --- X --- ---

NT0317 X --- --- X --- X A X --- X --- ---

NT0212 X P --- P X --- --- P --- P P ---

NT0243 X P --- P X --- --- P --- P P ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure7-19&

Figure 7-20

Figure7-41&

Figure 7-42

Figure7-25&

Figure 7-26

Figure7-33&

Figure 7-34

Figure 7-9

Figure 7-10

Figure 7-19

Figure 7-20

Figure7-15&

Figure 7-16

Figure 7-9

Figure 7-10

Figure7-39&

Figure 7-40

Figure 7-9

Figure 7-10

Figure7-19&

Figure 7-20

Figure 7-9 &

Figure 7-10

Figure 7-41

Figure 7-42

Figure7-31&

Figure 7-32

Figure7-27&

Figure 7-28

Figure7-35&

Figure 7-36

Figure7-43&

Figure 7-44

Figure7-19&

Figure 7-20

Figure7-41&

Figure 7-42

Figure7-57&

Figure 7-58

Figure7-31&

gure7-

Figure7-55&

Figure 7-56

Figure7-41&

gure7-

SECTION 1

1-7 T-268-07

Page 18

Condenser

&

Figure7-51&

&

Figure7-29&

69NT4051194

g

69NT40-511-95

F

i

5

8

F

i

4

2

F

i

4

2

69NT4

0-511-101

&

Figure7-41&

g

&

Figure7-57&

MODEL

MODEL

69NT40-511-90 NT0222 P P --- P X --- --- P --- P X ---

69NT40-511-91

69NT40-511-92 NT0218 P X --- --- --- X A X X P --- X

69NT40-511-93 NT0197 X --- --- P --- X --- X X X --- ---

69NT40-511-94

69NT40-511-95

69NT40-511-96 NT0224 P X --- P --- X B P --- --- --- X

69NT40-511-97 NT0228 P P --- P --- X --- P --- P X ---

69NT40-511-98 NT0297 P X --- P X --- --- X --- P --- X

69NT40-511-99 NT0245 X P --- P X --- --- X --- X --- X

69NT40-511-100 NT0247 P X --- P --- X --- X --- P X ---

69NT40-511-102

69NT40-511-103 NT0259 P P --- P --- X --- X X P P ---

69NT40-511-104 NT0260 P X --- P X --- --- X --- --- X ---

69NT40-511-105 NT0274 X X --- P --- X A P --- --- X ---

69NT40-511-106

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0202 --- --- --- P --- X --- P --- P --- ---

NT0238 --- --- --- P --- X --- P --- P --- ---

NT0278 --- --- --- P --- X --- P --- P --- ---

NT0318 --- --- --- X --- X --- P --- P --- ---

NT0204 X --- --- P --- X --- X X X --- ---

NT0262 X --- --- P --- X --- X --- X --- ---

NT0265 X --- --- P --- X --- X --- X --- ---

NT0220 P P --- P --- X --- P --- P P ---

NT0322 P P --- P --- X --- P --- P X ---

NT0344 P P --- P --- X --- P --- P X ---

NT0365 P P --- P --- X --- P --- X P ---

NT0285 P P --- P --- X --- P --- P X ---

NT0322 P P --- P --- X --- P --- P X ---

NT0250 --- X --- P X --- B P --- --- --- X

NT0298 --- X --- P X --- B P --- --- --- X

NT0333 --- X --- P X --- B P --- --- --- X

NT0251 P P --- P X --- --- P --- P P ---

NT0254 P P --- P X --- --- P --- P P ---

NT0263 X P --- P X --- --- X --- P X ---

NT0414 X P --- P --- X --- X --- P X ---

NT0415 X P --- P --- X --- X X P X ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure7-19&

Figure 7-20

Figure7-37&

Figure 7-38

Figure 7-51

Figure 7-52

Figure7-61&

Figure 7-62

Figure7-41&

Figure 7-42

Figure 7-29

Figure 7-30

Figure7-19&

Figure 7-20

Figure7-57&

gure7-

Figure7-41&

gure7-

Figure7-57&

Figure 7-58

Figure7-41&

gure7-

Figure7-57&

Figure 7-58

Figure 7-41

Figure 7-42

Figure7-53&

Figure 7-54

Figure7-41&

Figure 7-42

Figure 7-57

Figure 7-58

1-8T-268-07

Page 19

Condenser

&

Figure7-49&

&

Figure7-59&

g

&

Figure7-41&

&

Figure7-41&

g

69NT4

0-511-111

&

Figure7-41&

&

69NT4051111

4

Figure7-57&

g

&

Figure7-41&

g

&

Figure7-57&

g

MODEL

MODEL

69NT40-511-107

69NT40-511-108 NT0264 P P --- P --- X --- X X P X ---

69NT40-511-109 NT0284 P P --- P --- X --- X X P X ---

69NT40-511-110

69NT40-511-112

69NT40-511-113 NT0294 P X --- X --- X --- X X P X ---

69NT40-511-114

69NT40-511-115

69NT40-511-116 NT0302 X P --- P X --- --- P --- P --- ---

69NT40-511-117 NT0348 X P --- P --- X --- X --- P X ---

69NT40-511-118

69NT40-511-119 NT0389 P X --- P --- X --- P --- P X ---

69NT40-511-120 NT0410 --- P --- P X --- --- X --- --- --- ---

69NT40-521-10 NT0108 X X --- P X --- --- X --- X --- X

PID

PID

Transformer

Transformer

Two-Speed

Compressor

Two-Speed

Compressor

Water-Cooled

Condenser

Water-Cooled

USDA Cold

Treatment

USDA Cold

Treatment

NT0275 P X --- P --- X A X X P X ---

NT0277 P X --- P --- X A X X P X ---

NT0315 P X --- P --- X A X X P X ---

NT0354 P X --- P --- X A X X P X ---

NT0381 P X --- P --- X X X X P X ---

NT0385 P X --- P --- X X X X P X ---

NT0288 X X --- P --- X --- X X P X ---

NT0296 X X --- P --- X --- X X P --- X

NT0347 X P --- P --- X --- X X P X ---

NT0349 X X --- P --- X --- X X P X ---

NT0286 X X --- X --- X --- X X P X ---

NT0295 X X --- X --- X --- X X P --- X

NT0429 X P --- X --- X --- X --- P X ---

NT0289 P P --- P X --- --- P --- --- X ---

NT0325 P P --- P X --- --- P --- --- X ---

NT0290 P P --- P --- X --- X X P X ---

NTO326 P P --- P --- X --- X X P X ---

NT0335 P --- --- --- --- X --- X --- P X ---

NT0336 P --- --- --- --- X --- X --- X X ---

NT0358 P P --- P --- X --- X X P X ---

NT0299 P X --- P --- X A X --- P X ---

NT0300 P X --- P --- X --- X --- P X ---

NT0387 P P --- P --- X --- P --- P X ---

NT0388 P P --- P --- X --- P --- P X ---

Condenser

Coil

TransFresh

TransFresh

Humidity Sensor

Humidity Sensor

Suction & Discharge

Pressure Option

Suction & Discharge

Pressure Option

4Row

2Row

Communications

Communications

Interface Module (CI)

Interface Module (CI)

Saginomiya

Saginomiya

Partlow Temperature

Recorder

Partlow Temperature

Recorder

Temperature

Recorder

Temperature

Recorder

Electrical Wiring

Electrical Wiring

Schematics and

Schematics and

Diagrams

Diagrams

Figure 7-49

Figure 7-50

Figure 7-59

Figure 7-60

Figure 7-41

Figure 7-42

Figure 7-41

Figure 7-42

Figure7-57&

Figure 7-58

Figure7-41&

Figure 7-42

Figure7-57&

Figure 7-58

Figure 7-41

Figure 7-42

Figure 7-57

Figure 7-58

Figure 7-41

Figure 7-42

Figure 7-57

Figure 7-58

Figure 7-9 &

Figure 7-10

SECTION 1

A -- Factory Installed Pressure Gauges

B -- Factory Installed Pressure Transducers.

P -- Provision.

X -- Features that apply to model.

1-9 T-268-07

Page 20

SECTION 2

DESCRIPTION

2.1 GENERAL DESCRIPTION

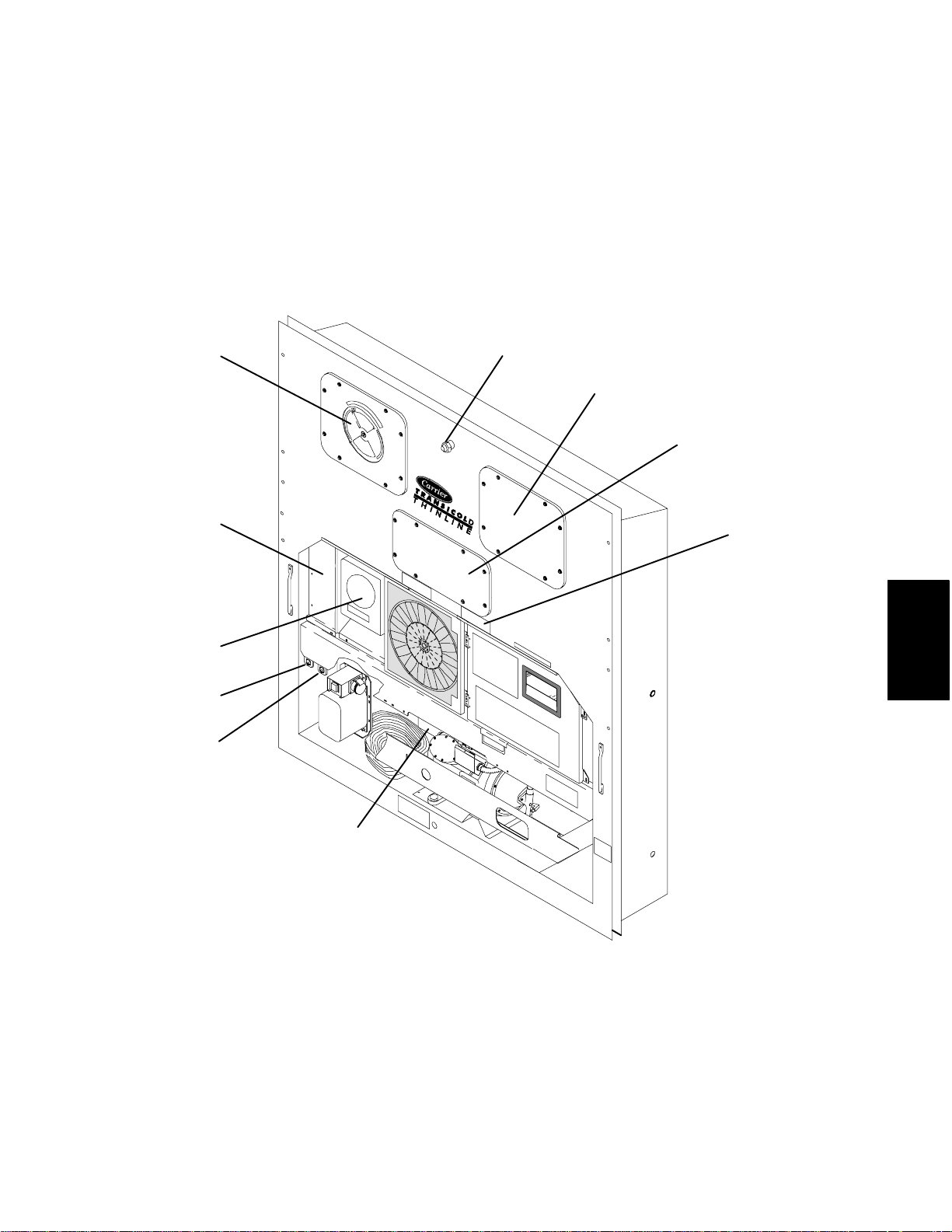

a. Refrigeration Unit -- Front Section

The front section of the refrigeration unit shows access

to most parts of t he unit (i.e., compressor, condenser,

receiver, etc.), which will be discussed in more detail of

the following sections in 2.1. The upper access panels

9

8

allow front entry into the evaporator section, and the

center access panel allows access to the thermostatic

expansion valve and evaporator coil heaters. The unit

model number, serial number and parts identification

number willbe found on the frontof the unit to theleft of

the compressor.

10

1

2

3

7

6

5

4

1. Access Panel (For Evap. Fan Motor #1)

2. Access Panel (For Heater & Thermostatic

Expansion Valve)

3. Fork Lift Pockets

4. Unit Serial Number, Model Number and Parts

Identification Number (PID) Plate

5. TransFRESH Communications Connector (TCC)

-- Optional

SECTION 2

6. Interrogator Connector (Also see Figure 2-7)

7. Mechanical Recording Thermometer -- Optional -(Partlow or Saginomiya)

8. Lower Fresh Air Makeup Vent or Blank Plate -Optional

9. Upper Fresh Air Makeup Vent and Access Panel

(For Evap. Fan Motor #2)

10. Return Air Thermometer Port -- Optional

Figure 2-1. Refrigeration Unit -- Front

2-1 T-268-07

Page 21

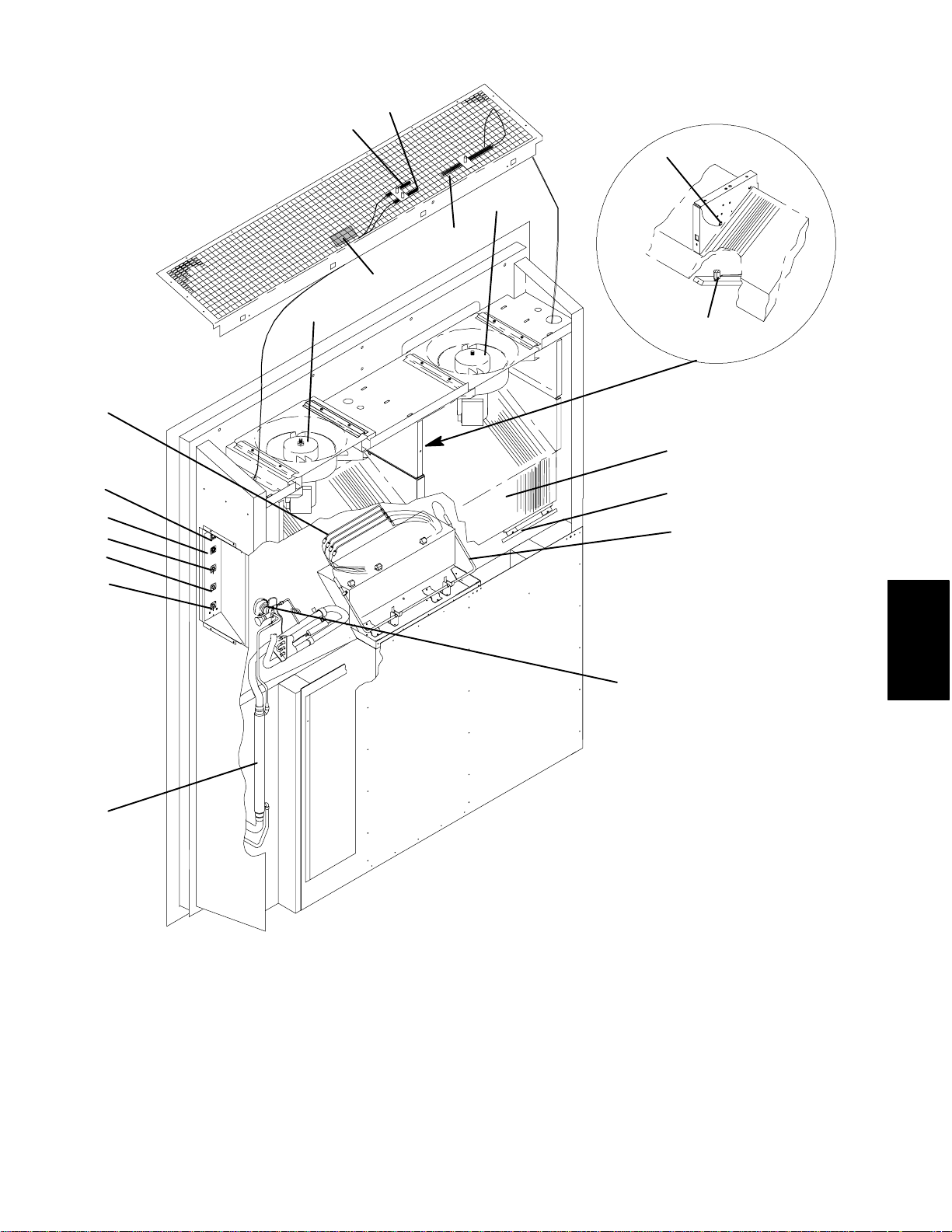

b. Evaporator Section

The evaporator section contains the optional

mechanical temperature recording bulb, return recorder

sensor (RRS), return temperature sensor (RTS),

thermostatic expansion valve, dual-speed evaporator

fan motors and fans (2), evaporator coil and heaters,

drain pan and heater, defrost termination sensor, heat

termination thermostat, and heat exchanger. See

Figure 2-2 and Figure 2-5 for sensor locations.

When transporting perishable (chilled) commodities,

the fan motors will normally be in high speed above

-- 1 0 _C(+14_ F), or --5_C(+23_F) optiona lly.

The evaporator coil heaters are accessible by removing

the front lower access panel. The defrost termination

sensor (DTS) is located on the coil center tube sheet and

may be serviced by removing the upper rear panel, or by

removing the left front upper access panel,

disconnecting the evaporator fan connector and

reaching through the access panel opening.

The evaporator fans circulate air throughout the

container by pulling air in the top of the refrigeration

unit, directing the air through the evaporator coil where

it is either heated or cooled, and discharging t he air

through the bottom of the refrigeration unit into the

container.

WARNING

Before servicing unit, make sure the unit

circuit breakers (CB-1 & CB-2) and the

start-stop switch (ST) are in the OFF

position. Also disconnect power plug and

cable.

2-2T-268-07

Page 22

4

3

8

7

5

2

19

18

17

16

15

14

1

12

9

10

6

11

SECTION 2

13

1. Evaporator Fan Motor #1 (EM1)

2. Humidity Sensor (HS) -- Optional

3. Return Recorder Sensor (RRS)

4. Return Temperature Sensor (RTS)

5. Mechanical Recording Thermometer Bulb

6. Mechanical Recording Thermometer Bulb -Used on PID NT0073

7. Evaporator Fan Motor #2 (EM2)

8. Defrost Termination Sensor (DTS)

9. Heater Termination Thermostat (HTT)

Figure 2-2. Refrigeration Unit -- Rear (Panels Removed)

10. Evaporator Coil

11. Drain Pan Heater (DPH)

12. Thermostatic Expansion Valve

13. Heat Exchanger

14. Interrogator Receptacle (IC) -- Optional

15. USDA Probe Receptacle (PR2) -- Optional

16. USDA Probe Receptacle (PR1) -- Optional

17. USDA Probe Receptacle (PR3) -- Optional

18. Cargo Probe Receptacle (PR4) -- Optional

19. Evaporator Coil Heaters

2-3 T-268-07

Page 23

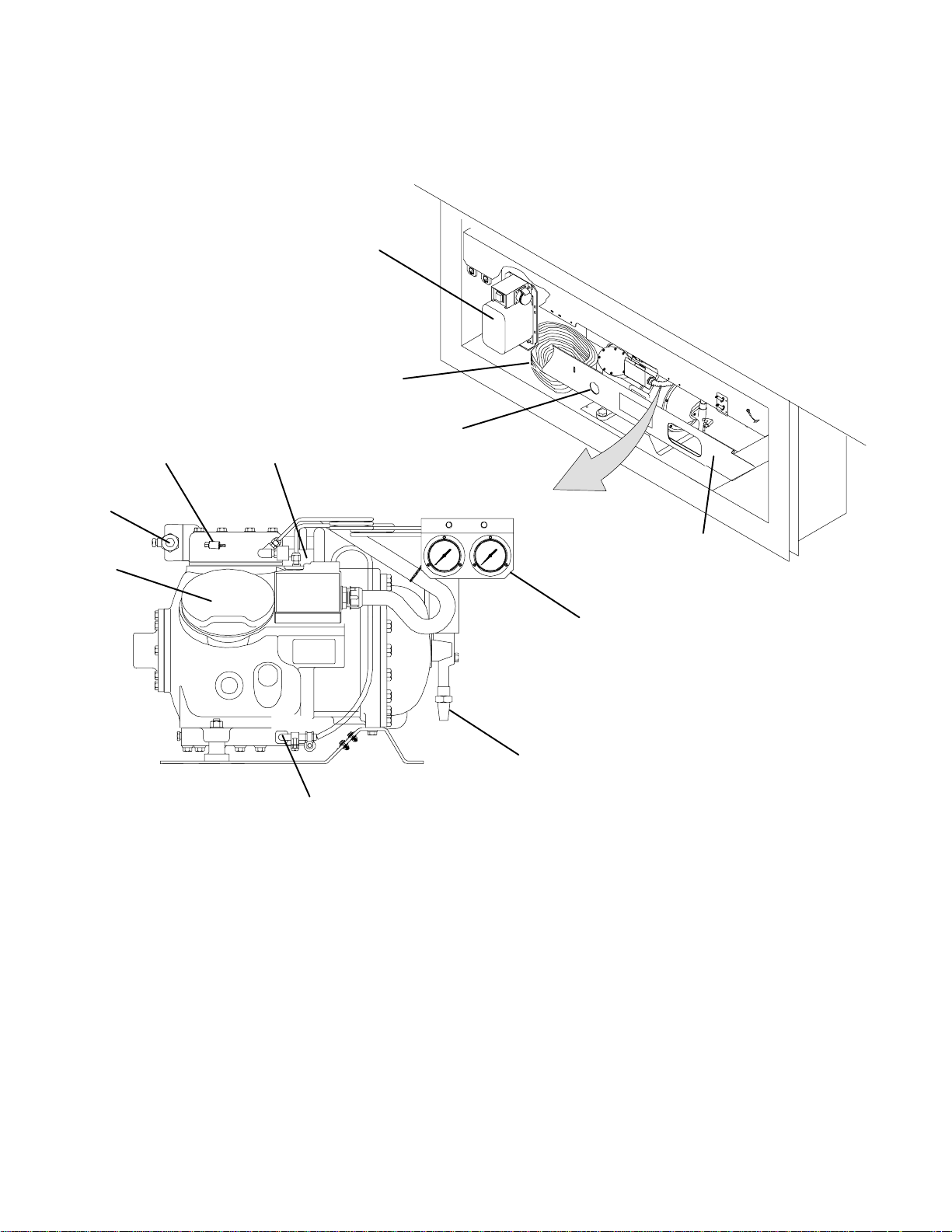

c. Compressor Section

The compressorsection includes thecompressor, power

cable storagecompartment, and an optionaltransformer

(refer to Table 1-1 and Figure 2-9), which is located to

1

2

10

9

11

the left of the compressor.

This section also contains the optional

discharge/suction pressure transducers.

3

8

7

1. Power Autotransformer -- Optional

2. Power Cables and Plug

3. Compressor Sight Glass View Port

4. Compressor Guard

5. Suction/Discharge Pressure Gauges -- Optional

6. Suction Service Valve

Figure 2-3. Compressor Section

4

5

6

7. Compressor Crankcase Heater (CCH) -- Optional

8. Compressor Motor (CP)

9. Discharge Service Valve

10. Discharge Pressure Transducer (DPT) -- Optional

11. Suction Pressure Transducer (SPT) -- Optional

2-4T-268-07

Page 24

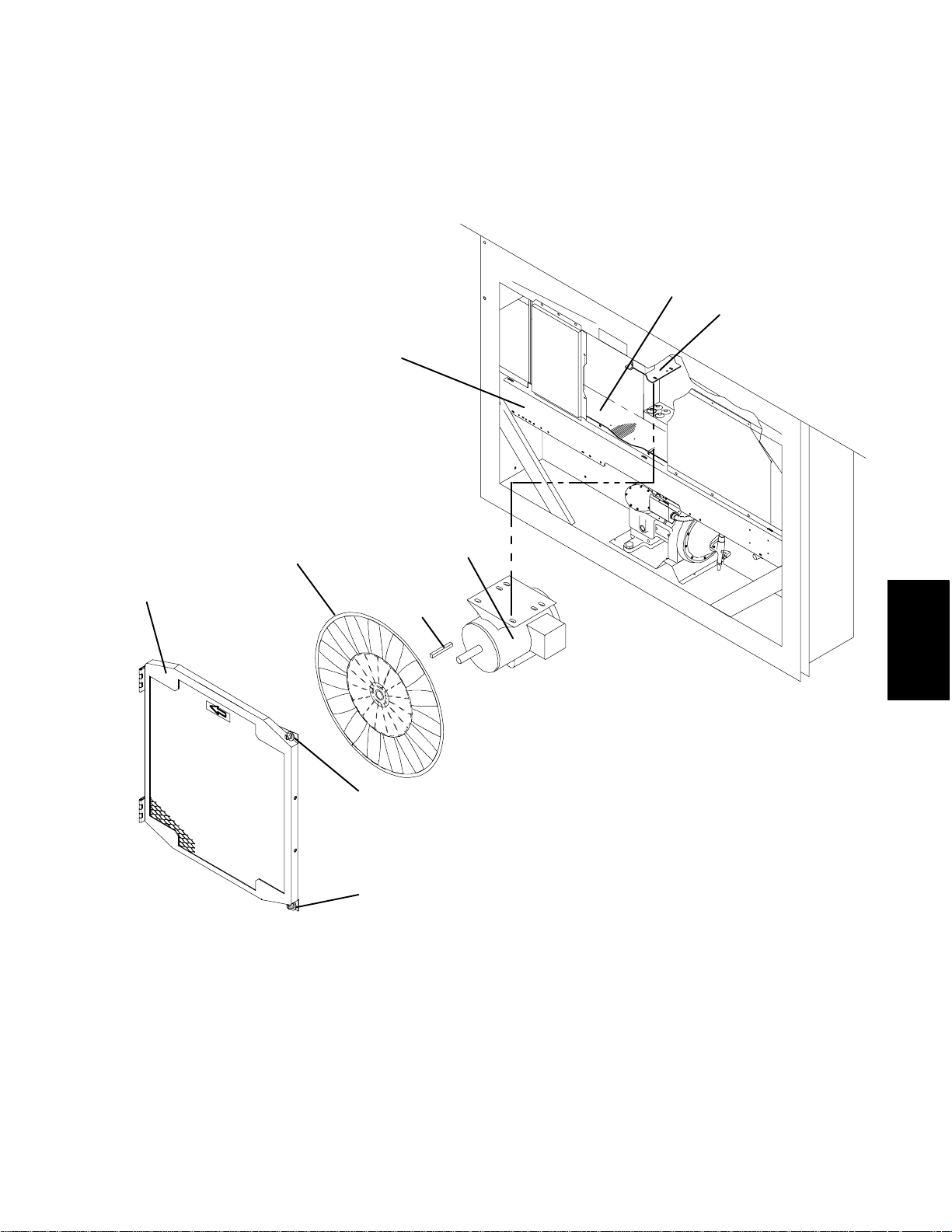

d. Condenser Section

The condensing section consists of a condenser fan

motor, a condenser fan and an air-cooledcondenser coil.

6

When the unit is operating, air is pulled in the bottom of

the coil and discharged horizontally out through the

front of the condenser fan grille.

7

8

3

1

1. Grille and Venturi Assembly

2. Retaining Screw

3. Condenser Fan

4. Key

5

4

SECTION 2

2

2

5. Condenser Fan Motor (CM)

6. Condenser Coil Cover

7. Condenser Coil

8. Condenser Motor Mount Bracket

Figure 2-4. Condenser Section

2-5 T-268-07

Page 25

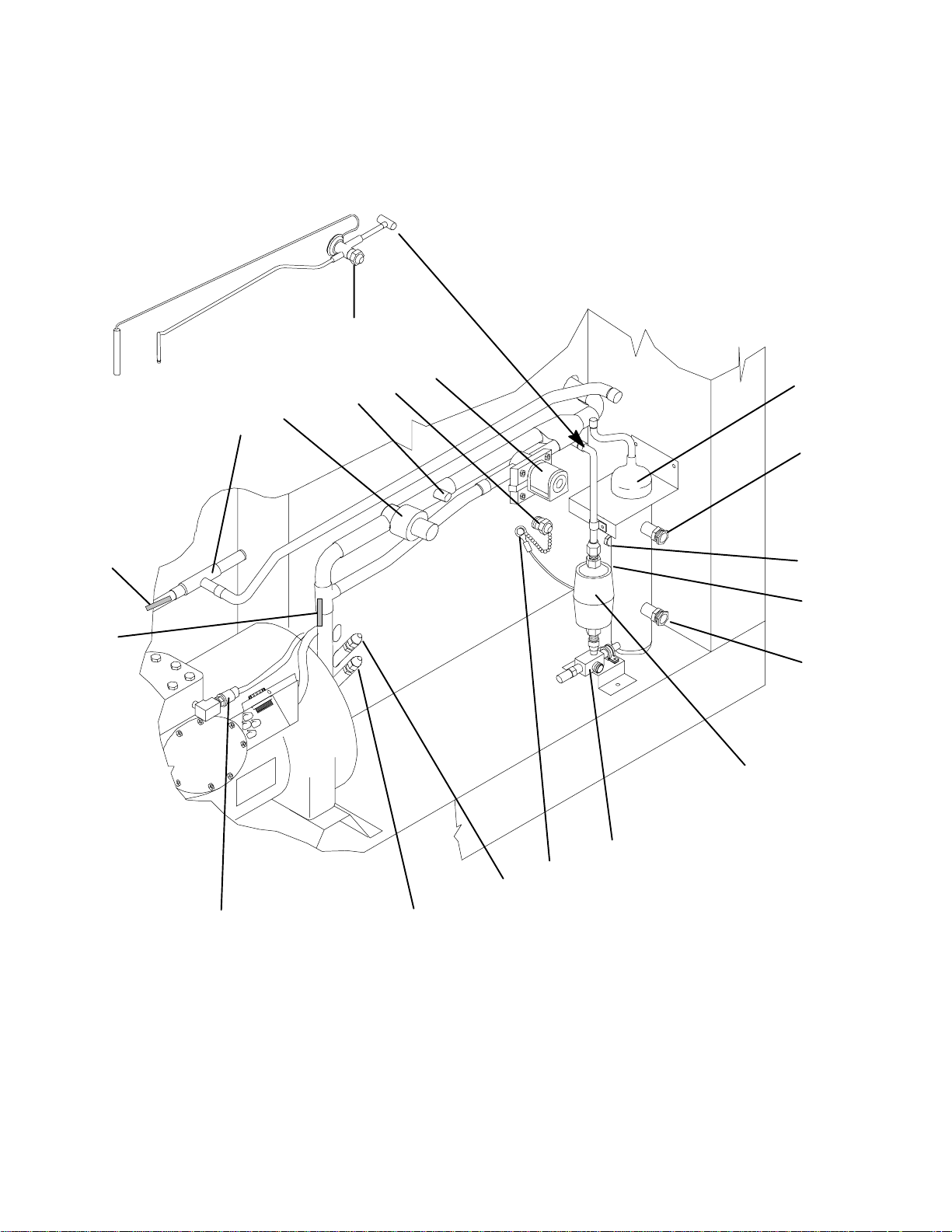

e. Receiver Section

discharge pressure regulator valve.

The receiver section consists of quench expansion

valve, manual liquid line valve, filter-drier, receiver

with sight glass/moisture-liquid indicator, condenser

pressure transducer (CPT), fusible plug, suction

modulation valve, suction solenoid valve, and

6

5

4

3

2

1

18

The supply temperature sensor (STS), supply recorder

sensor (SRS) and ambient sensor (AMBS) are located at

the right side of the compressor.

7

8

9

19

17

1. Discharge Pressure Regulator Valve

2. Suction Modulation Valve (SMV)

3. Schrader Valve

4. Supply Air Thermometer Port -- Optional

5. Suction Solenoid Valve (SSV)

6. Quench Expansion Valve

7. Electro-Coated Modular Receiver

8. Sight Glass

9. Fusible Plug

10. Condenser Pressure Transducer (CPT) --

Figure 2-5. Units with Receiver

10

11

12

13

14

15

16

Located on back side of Receiver)

11. Sight Glass/Moisture Indicator

12. Filter-Drier

13. Manual Liquid Line Valve

14. Ambient Sensor (AMBS)

15. Supply Temperature Sensor (STS)

16. Supply Recorder Sensor (SRS)

17. High Pressure Switch (HPS)

18. Thermistor Sensor (CPDS)

19. Thermistor Sensor (CPSS)

2-6T-268-07

Page 26

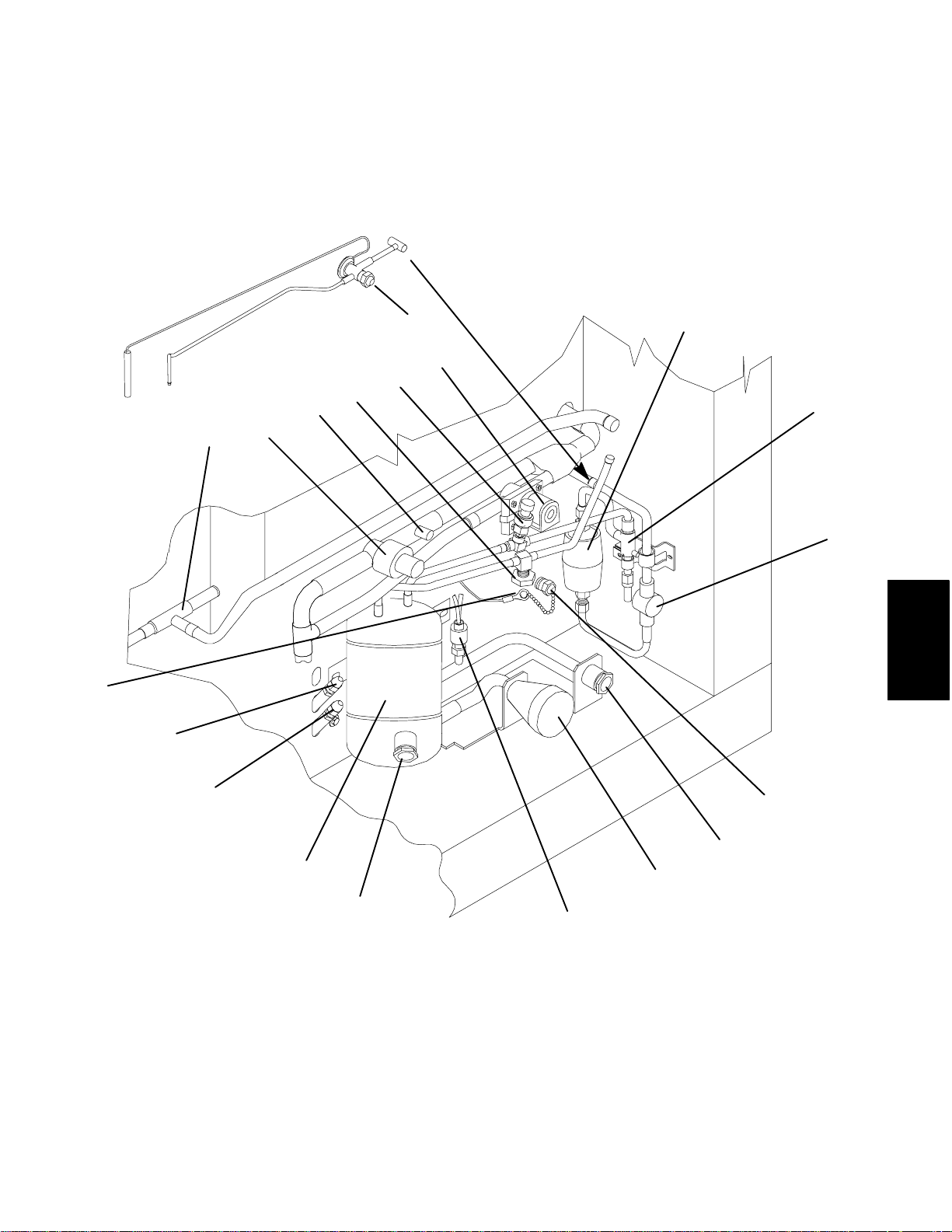

f. Water-Cooled Condenser Section (Optional)

The water-cooled condenser section consists of

water-cooled condenser, sight glass, moisture-liquid

indicator, quench expansion valve, rupture disc,

condenser pressure transducer (CPT), filter-drier,

suction modulation valve, suction solenoid valve,

discharge pressure regulator valve, water hook-up

couplings and water pressure switch.

The supply temperature sensor (STS), supply recorder

sensor (SRS) and ambient sensor (AMBS) are located at

the right side of the compressor.

19

18

7

6

5

4

3

1

2

8

9

10

SECTION 2

17

16

15

1. Discharge Pressure Regulator Valve

2. Suction Modulation Valve (SMV)

3. Schrader Valve

4. Rupture Disc

5. Condenser Pressure Transducer (CPT)

6. Suction Solenoid Valve (SSV)

7. Quench Expansion Valve

8. Filter-Drier

9. Manual Liquid Line Valve

10. Moisture-Liquid Indicator

Figure 2-6. Units with Water-Cooled Condenser

11

12

13

14

11. Supply Air Thermometer Port -- Optional

12. Coupling (Water In)

13. Self Draining Coupling (Water Out)

14. Water Pressure Switch (WPS)

15. Sight Glass

16. Water-Cooled Condenser

17. Supply Recorder Sensor (SRS) -- Optional

18. Supply Temperature Sensor (STS)

19. Ambient Sensor (AMBS)

2-7 T-268-07

Page 27

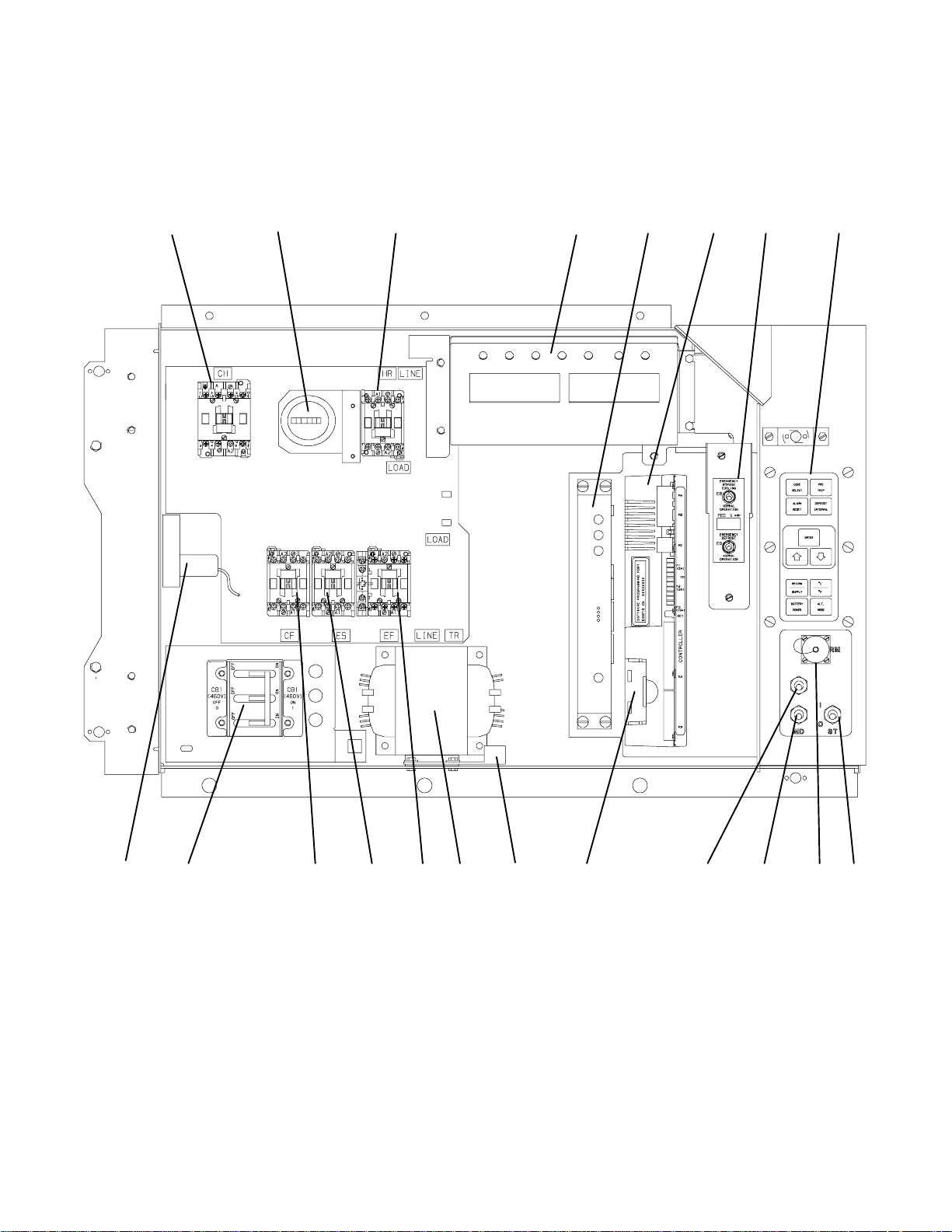

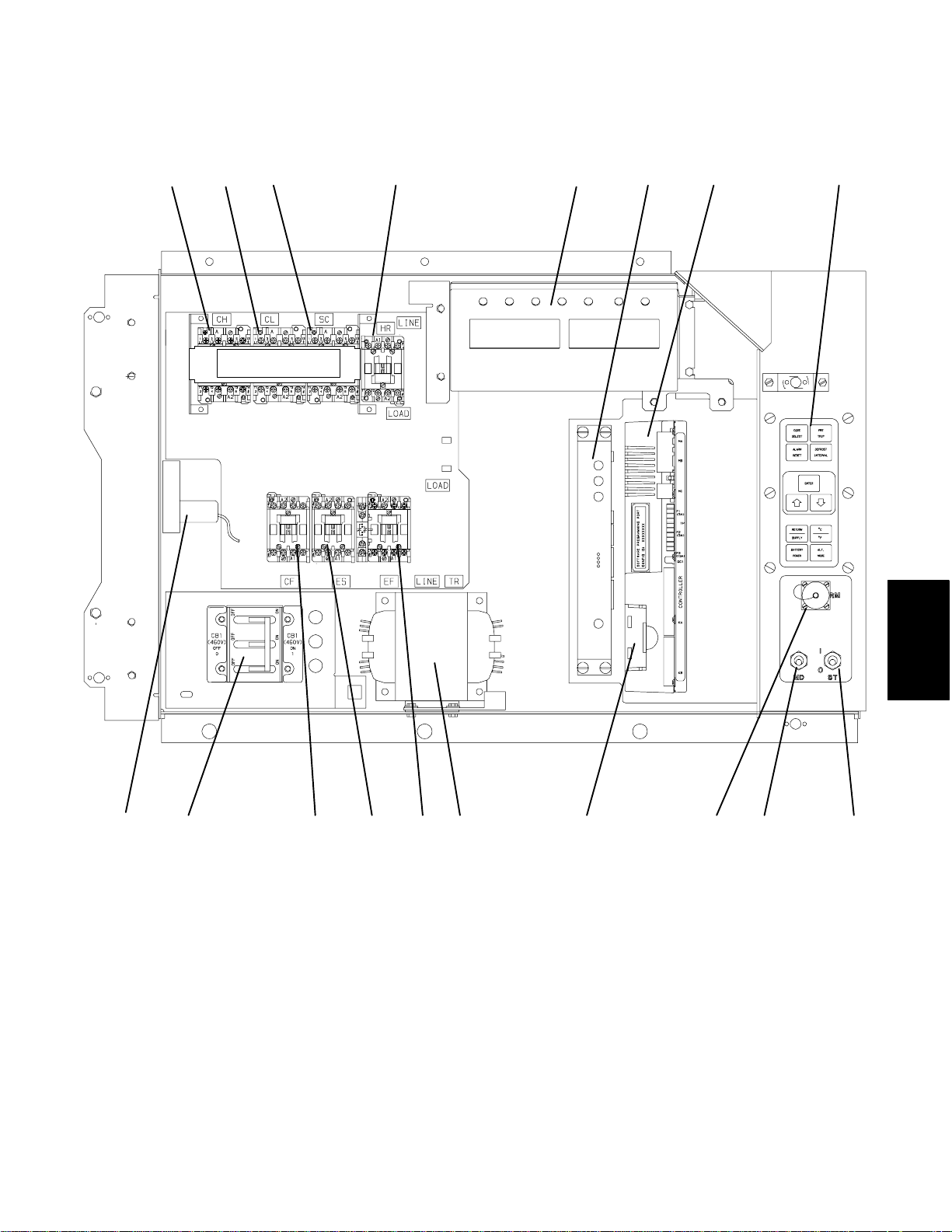

g. Control Box with a Single-Speed Compressor

1

The control box includes the manual switches, circuit

breaker(s), contactors, transformer, fuses, key pad,

display module, current sensor module,

1345610

2

Controller/DataCORDER module (See Figure 2-7), an

optional remote monitoring unit (CI), and an optional

emergency bypass cooling switch (EB), emergency

defrost switch (ED) and emergency defrost fuse (FED).

7

8

9

151718 16

1. Compressor Contactor (CH)

2. Hour Meter (HM) -- Optional

3. Heat Contactor (HR)

4. Display Module

5. Remote Monitoring Unit (RMU) -- Optional

6. Controller/DataCORDER Module

7. Emergency Bypass Cooling Switch (EB)--Optional

8. Emergency Defrost Fuse (FED) -- Optional

9. Emergency Defrost Switch (ED) -- Optional

10. Key Pad

11. Start-Stop Switch (ST)

12. Remote Monitoring Receptacle (RM) -- Optional

Figure 2-7. Control Box on Units with a Single-Speed Compressor

13. Manual Defrost Switch (MDS)

14. Condenser Fan Switch (CFS) -- Optional

15. Controller/DataCORDER Battery Pack -- Optional

16. Interrogator Connector -- Optional location for

some models

17. Control Transformer (TR)

18. Evaporator Fan Contactor (EF) High Speed

19. Evaporator Fan Contactor (ES) Low Speed

20. Condenser Fan Contactor (CF)

21. Circuit Breaker (CB-1) -- 460V

22. Current Sensor Module (CS)

2-8T-268-07

14

13 1219202122

1

Page 28

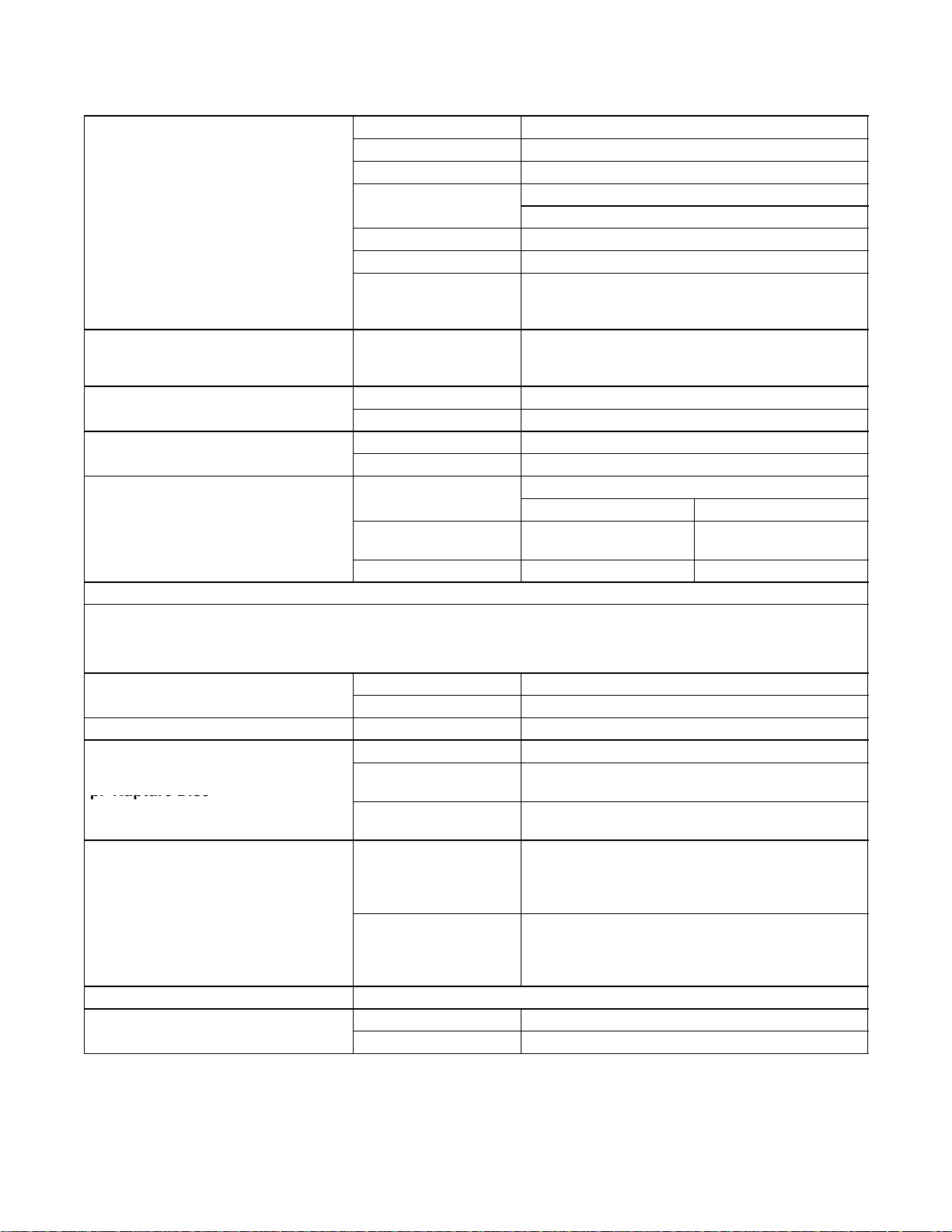

h. Control Box with a Two-Speed Compressor

(Optional)

The control box includes the manual switches, circuit

breaker(s), contactors, transformer, fuses, key pad,

1

23

CAUTION: DO NOT MANUALLY

ENGAGE CONTACTORS

45

display module, current sensor module,

Controller/DataCORDER module (See Figure 2-8),

and an optional remote monitoring unit (CI).

6

78

18

17

16

15

1. Compressor Contactor (CH) High Speed

2. Compressor Contactor (CL) Low Speed

3. Compressor Contactor (SC) Shorting

4. Heat Contactor (HR)

5. Display Module

6. Remote Monitoring Unit (RMU) -- Optional

7. Controller/DataCORDER Module

8. Key Pad

9. Start-Stop Switch (ST)

Figure 2-8. Control Box on Units with a Two-Speed Compressor (Optional)

14

13

12

11

10

10. Manual Defrost Switch (MDS)

11. Remote Monitoring Receptacle (RM) -- Optional

12. Controller/DataCORDER Battery Pack -- Optional

13. Control Transformer (TR)

14. Evaporator Fan Contactor (EF) High Speed

15. Evaporator Fan Contactor (ES) Low Speed

16. Condenser Fan Contactor (CF)

17. Circuit Breaker (CB-1) -- 460V

18. Current Sensor Module (CS)

SECTION 2

9

2-9 T-268-07

Page 29

2.2 REFRIGERATION SYST EM DATA

Weight(

Dry)

i.Compressor/MotorAssembl

y

k.H

T

h

l.H

igh

P

h

UnitConf

i

ibleP

l

p.RuptureDisc

q

q.CondenserPressure

s.WaterPressureSwitch

Number of Cylinders 6

Model 06DR

CFM 41

118 kg (260 lb) - Single-Speed

129.39 kg (285.25 lb) - Two-Speed

Approved Oil Castrol Icematic -- SW20

Oil Charge 3.6 liters (7.6 U.S. pints)

The oil level range, with the compressor off,

should be between the bottom and one-eighth

level of the capacity of the sight glass.

4.48 to 6.67 _C(8to12_F)

Charge Requirements -- R-134a

2* row condenser 4* row condenser

4.5kg(9.0lbs) 5.22 kg (11.5 lbs)

j. Expansion Valve Superheat

eaterTermination

ressureSwitc

m. Refrigerant Charge

ermostat

Oil Sight Glass

Verify at --18 _C

(0 _F) container box

temperature

Opens 54 (¦ 3) _C = 130 (¦ 5) _F

Closes 38 (¦ 4) _C = 100 (¦ 7) _F

Cutout 25 (¦ 1.0) kg/cm@ = 350 (¦ 10) psig

Cut-In 18 (¦ 0.7) kg/cm@ = 250 (¦ 10) psig

guration

Water-Cooled

Condenser

Receiver 3.74 kg (8.25 lbs) 4.88 kg (10.75 lbs)

* RefertoTable1-1.

NOTE

When replacing the components (n.), (o.) and (p.) in section 2.2, refer to the installation instructions

included with the ordered new part for additional information.

n.Fus

o. Sight Glass/Moisture Indicator Torque 8.9 to 9.7 mkg (65 to 70 ft-lbs)

p. Rupture Disc

. Condenser Pressure

Transducer (CPT)

r. Unit Weight Refer to unit model number plate, see Figure 2-1 for location of plate.

s. Water Pressure Switch

(Optional)

ug

Melting point 99 _C = (210 _F)

Torque 6.2 to 6.9 mkg (45 to 50 ft-lbs)

Bursts at 35 5% kg/cm@ = (500 5% psig)

Torque

(P/N 14-00215-03)

Torque

(P/N 14-00215-04)

Condenser Fan Starts

Condenser Fan Stops

Cut-In 0.5 ¦ 0.2 kg/cm@ (7 ¦ 3psig)

Cutout 1.6 ¦ 0.4 kg/cm@ (22 ¦ 5psig)

The condenser fan will start if the condenser

pressure is greater than 14.06 kg/cm@ (200

psig) OR the condenser fan is OFF for more

The condenser fan will stop if the condenser

pressure is less than 9.14 kg/cm@ (130 psig)

AND the condenser fan remains ON for at least

1.4to2 mkg(10to15ft-lbs)

6.2 to 6.9 mkg (45 to 50 ft-lbs)

than 60 seconds.

30 seconds.

2-10T-268-07

Page 30

2.3 ELECTRICAL DATA

a.CircuitBreake

r

Mot

d.DrainPanH

Heat

f.EvaporatorFan

CB-1 Trips at 29 amps

a. Circuit Breaker

b. Compressor

Motor

c. Condenser Fan

or

eaters

e. Evaporator Coil

ers

Motor(s)

g.Fuses

h. Compressor Crankcase Heater (CCH) --

Optional

CB-2 (50 amp) Trips at 62.5 amps

CB-2 (70 amp) Trips at 87.5 amps

Full Load Amps (FLA)

Full Load Amps 1.3 amps 1.6 amps

Horsepower 0.43 hp 0.75 hp

Rotations Per Minute 1425 rpm 1725 rpm

Voltage and Frequency 360 -- 460 vac ¦ 1.25 hz 400 -- 500 vac ¦ 1.5 hz

Bearing Lubrication Factory lubricated, additional grease not required.

Rotation Counter-clockwise when viewed from shaft end.

Number of Heaters 1

Rating 750 watts +5 /--10 % @ 460 vac

Resistance (cold) 285 ¦ 7.5% ohms nominal

Type Sheath

Number of Heaters 4

Rating 750 watts +5/--10% each @ 230 vac

Resistance (cold) 66.8 to 77.2 ohms

Ambient @20_C(68_F)

Type Sheath

Full Load Amps -- High

Speed

Full Load Amps -- Low

Speed

Nominal Horsepower -High Speed

Nominal Horsepower -Low Speed

Rotations Per Minute -High Speed

Rotations Per Minute -Low Speed

Voltage and Frequency 360 -- 460 vac ¦ 1.25 hz 400 -- 500 vac ¦ 1.5 hz

Voltage and Frequency --

using modular transformer

Bearing Lubrication Factory lubricated, additional grease not required

Rotation Clockwise when viewed from shaft end.

Control Circuit 15 amps (F3)

Controller/DataCORDER 5amps(F1&F2)

17.6 amps @ 460 vac

(with current limiting set at 21 amps)

380 vac, 3 Phase, 50 hz 460 vac, 3 Phase, 60 hz

380 vac, 3 Phase, 50 hz 460 vac, 3 Phase, 60 hz

1.6 amps 2.0 amps

0.8 amps 1.0 amps

0.70 hp 0.84 hp

0.09 hp 0.11 hp

2850 rpm 3450 rpm

1425 rpm 1750 rpm

180 -- 230 vac ¦ 1.25 hz 200 -- 250 vac ¦ 1.5 hz

180 watts @ 460 vac

SECTION 2

2-11 T-268-07

Page 31

i. HumiditySensor

i.HumiditySenso

r

()p

(HS) -- Optional

Orange wire Power

Red wire Output

Brown wire Ground

Input voltage 5vdc

Output voltage 0to3.3vdc

Output voltage readings verses relative humidity (RH) percentage:

30% 0.99 V

50% 1.65 V

70% 2.31 V

90% 2.97 V

2.4 POWER AUTOTRANSFORMER (Optional)

WARNING

Do not attempt to remove power plug(s)

before turning OFF start-stop switch (ST),

unit circuit breaker(s) and external power

source.

Make sure the power plugs are clean and dry

before connecting to any power receptacle.

a. Step-Up Power Autotransformer

The modular transformer (if equipped) is located under

the condenser coil on the left-hand side of the unit (see

Figure 2-9).

The modular transformer (item 1, Figure 2-9) provides

380/460 vac, 3-phase, 50/60 hertz power to the unit

when the 230 vac (black) power cable is connected to a

190/230 vac, 3-phase power source. The module, in

addition to thetransformer, includesa 230 vac cable and

a receptacle to accept the unit 460 vac power plug. The

modular transformer may be equipped with an optional

circuit breaker (CB-2).

WARNING

2. Plug the 230 vac (black) cable into a de-energized

190/230 vac, 3-phase power source. Energize the

power source. Set circuit breaker (CB-2 if

equipped) to position “1” (ON). C lose and secure

control box door and place the start-stop switch

(ST) in position “1” (ON) to start the unit.

c. To Operate Unit on 380/460 vac Power Supply

1. Make sure start-stop switch (ST, on control panel)

and circuit breaker (CB-1, in the control box) are in

position “0” (OFF).

2. Plug the 460 vac (yellow) cable into a de-energized

380/460 vac, 3-phase power source. Energize the

power source. Place circuit breaker (CB-1) in

position “1” (ON). Close and secure control box

door and then place the start-stop switch (ST) in

position “1” (ON) to start the unit.

3

2

Do not attempt to unplug the power cable

connected to the autotransformer before

performing the following operations: Move

the start-stop switch (ST), the unit circuit

1

breaker(s), CB-1 and CB-2 (if equipped)

and any external power source to their OFF

positions.

b. To Operate Unit on 190/230 vac Power Supply

1. Make sure that the start-stop switch (ST, on control

panel) and circuit breaker (CB-2 if equipped, on the

modular transformer) are in position “0” (OFF).

Make sure the 460 vac power plug is locked into the

1. Dual Voltage Modular Transformer

2. Circuit Breaker (CB-2) 230V (Optional)

3. 460 vac Power Receptacle

receptacle on the modular transformer and circuit

breaker (CB-1, in the control box) is in position “1”

(ON).

2-12T-268-07

Figure 2-9. Power Autotransformer (Optional)

Page 32

2.5 UPPER FRESH AIR MAKEUP VENT

The purpose of t he fresh air makeup vent is to provide

ventilation for commodities that require fresh air

circulation. The vent must be closed when transporting

frozen foods or controlled atmosphere loads.

Air exchange depends on static pressure differential,

which will vary depending on the container and how the

container is loaded. The chart below gives air exchange

values for an empty container. Higher values can be

expected for a fully loaded container.

arrow on the disc with the percentage of desired air flow

marked on the supplied label (see Figure 2-1).

2.6 LOWER FRESH AIR MAKEUP VENT

(Optional)

The purpose of the lower fresh air makeup vent is to

provide ventilation for commodities that require fresh

air circulation. The vent must be closed when

transporting frozen foods.

ZERO EXTERNAL STATIC PRESSURE, 50HZ POWER

AIR

FLOW

(CMH)

225

200

175

150

125

100

75

50

25

0

0 102030405060708090100

PERCENT OPEN

For 60HZ operation multiply air flow values from curve by 1.2

a. Full Open or Closed Positions

T-B AR

2-3/8 ”

Air exchange depends on static pressure differential,

which will vary depending on the container and how the

container is loaded. The chart across gives air exchange

values for an empty container. Higher values can be

expected for a fully loaded container.

a. Full Open or Closed Positions

The air slide is supplied with two adjustable air control

discs. The fresh air makeup can be adjusted for 15, 35,

50 and 75cubic meters perhour (CFM). The airflow has

been established at 60 Hz power, and a 2 1/2 inch T bar,

with 15 mm (0.6 inch) H

O external static above free

2

blow.

Maximum air flow is achieved by loosening the hex

nuts and rotating each disc to the maximum open

position (100% open). The closed position is 0% air

flow.

The operator may also adjustthe openings to increase or

decrease the air flow volume to meet the required air

flow.

NOTE

SECTION 2

Maximum air flow is achieved by loosening the wing

nut and rotating the disc to the maximum open position

(100% open). The closed position is 0% air flow.

Two slots and a stop are designed into the disc for air

flow adjustments. The first slot allows for a 0 t o 30% air

flow, and the second slot allows for a 30 to 100% air

flow. To increase the percentage of air flow, the wing

nut must be loosened, and the disc rotated until the

desired percentage of air flow matches with the arrow on

the disc. Tighten the wing nut. To clear the gap between

the slots, loosen the wing nut until the disc clears the

stop, and rotate the disc for the second slot.

The operator may also increase or decrease the air flow

volume to meet the required air flow by aligning the

The main air slide is in the fully closed position

during reduced air flow operation.

a. Air Sampling for Carbon Dioxide (CO2) Level

Loosen hex nuts and move the cover until the arrow on

the cover is aligned with the “atmosphere sampling

port” label. Tighten the hex nuts and attach a 3/8 hose to

the sampling port.

If the internal atmosphere content has reached an

unacceptable level, the operator may adjust the disc

opening to meet the required air flow volume to

ventilate the container.

2-13 T-268-07

Page 33

2.7 REFRIGERATION CIRCUIT WITH RECEIVER

Starting at the compressor, the suction gas is

compressed to a higher temperature and pressure.

When operating with the air-cooled condenser, the gas

flows through the discharge service valve into the

pressure regulator valve that is normally open. The

pressure regulator valve restricts the flow of refrigerant

to maintain a minimum discharge pressureof 5 kg/cm@

(70 psig). Refrigerant gas thenmoves into the air-cooled

condenser. Air flowing across the coil fins and tubes

cools the gas to saturation temperature. By removing

latent heat, the gas condenses to a high pressure/high