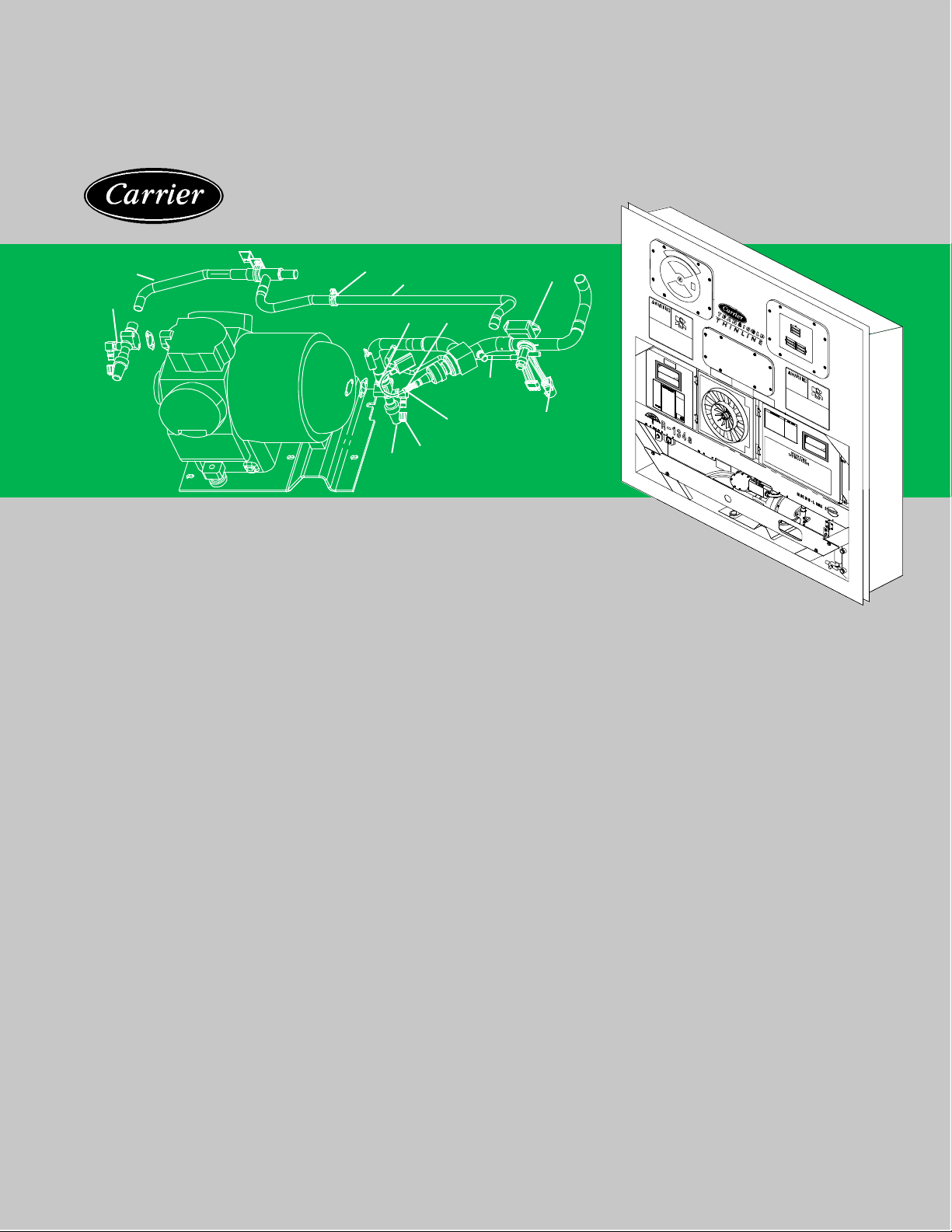

Page 1

Container Refrigeration

r

21

22

18

17

16

15

12

11

7

5

14

13

SERVICE PARTS LIST

69NT40--489--100 Series

EverFresh Controlled Atmosphere

Container Refrigeration Units

T--305PL Rev B Change 6/10

for

Page 2

SERVICE PARTS LIST

CONTAINER REFRIGERATION UNIT

EVERFRESH

CONTROLLED ATMOSPHERE

Model

69NT40-489-100 Series

Page 3

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

1 QUICK LIST -- CLAMPS, FILTER--DRIER, FUSE, TY--RAPS, AND WIRE TERMINALS 1............

2 REFRIGERATION UNIT ASSEMBLY 2....................................................

2.1 REFRIGERATION UNIT -- AREA LOCATOR 2..........................................

2.2 RAIN GUTTERS 4..................................................................

2.3 HANDLES 5.......................................................................

2.4 CONTROL BOX DOOR 6............................................................

2.5 CONTROL BOX 8..................................................................

2.6 CONTROL BOX -- STD ELECTRICAL COMPONENTS, RM AND HOURMETER 10..........

2.7 CONTROL BOX -- EVAP FAN CAPABILITY, EBS and EDS, EBS ONLY and CFS 12..........

2.8 CONTROL BOX -- CONTROLLER MODULE SECTION AND SOFTWARE CARDS 14........

2.9 CONTROL BOX -- DISPLAY MODULE AND COMMUNICATIONS INTERFACE MODULE 17.

2.10 CONDENSER FAN MOTOR AND COIL 18..............................................

2.11 CONDENSER FAN GRILLE ASSEMBLY 20.............................................

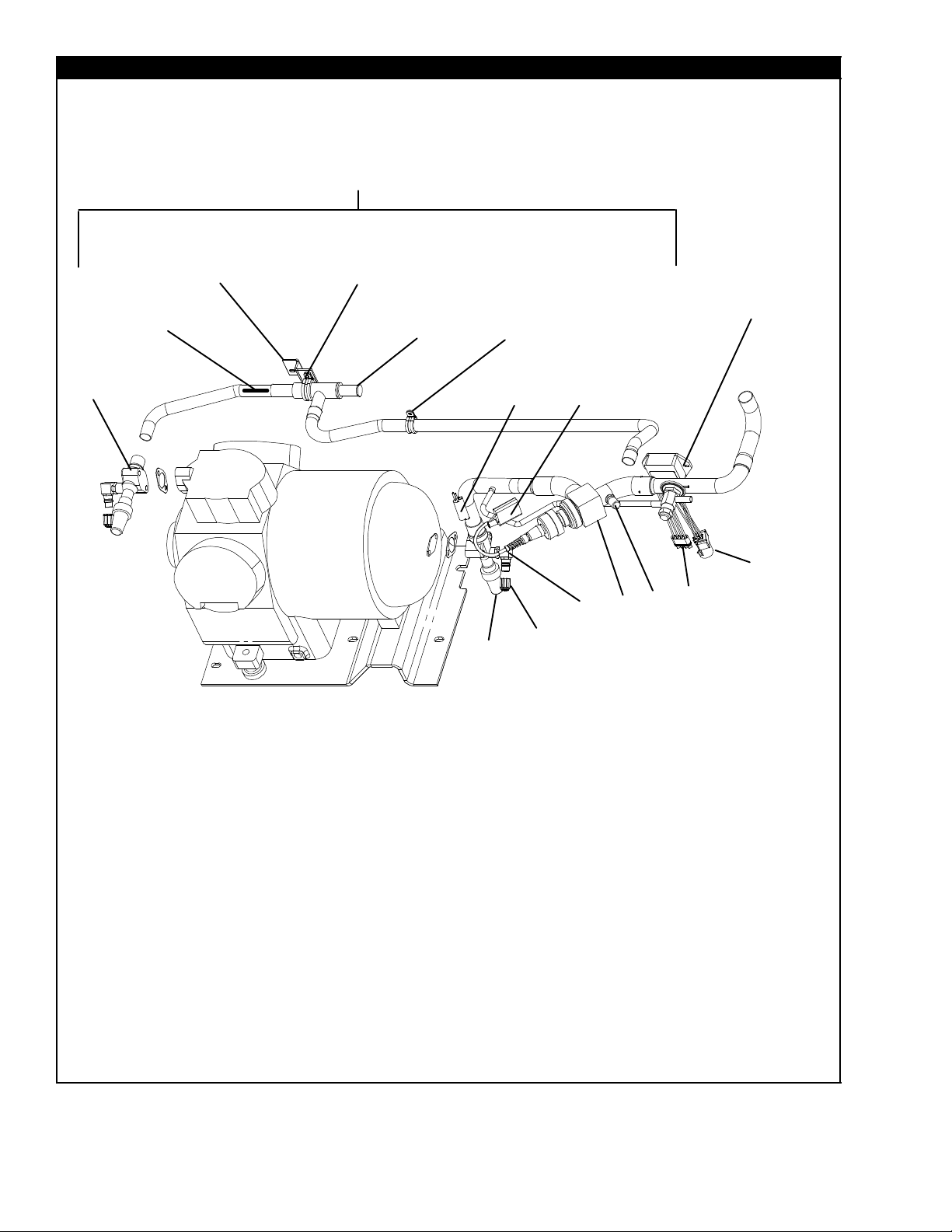

2.12 COMPRESSOR TUBING 22..........................................................

2.13 RECEIVER 24.......................................................................

2.14 WATER--COOLED CONDENSER 26...................................................

2.15 SRS AND STS 28....................................................................

2.16 BACK PANEL ASSEMBLY -- OPTION 4, Aluminum HINGED 29...........................

2.17 UPPER FRESH AIR MAKE--UP AND ACCESS PANEL 30................................

2.18 EVAPORATOR FAN ASSEMBLY 32....................................................

2.19 EVAPORATOR COIL -- REAR PANELS REMOVED 34...................................

2.20 USDA OPTION 36...................................................................

2.21 COMPRESSOR MTG., GUARD, CRANKCASE AND DRAIN LINE HEATER COMPONENTS 38

2.22 COMPRESSOR GAUGES AND TRANSDUCERS 40.....................................

2.23 CABLE RESTRAINT COMPONENTS 42................................................

2.24 VOLTAGE CABLES 44...............................................................

2.25 AUTOTRANSFORMER KIT 46........................................................

2.26 LABELS AND DECALS 48..............................................................

3 INTERROGATOR AND ACCESSORIES 50

3.1 DATAREADER 50....................................................................

3.2 INTERROGATOR RECEPTACLE 52...................................................

4 COMPRESSOR ASSEMBLY 54...........................................................

5 CONTROLLED ATMOSPHERE EQUIPMENT ASSEMBLY 58.................................

5.1 CONTROLLED ATMOSPHERE EQUIPMENT -- AREA LOCATOR 58.......................

5.2 CONTROLLED ATMOSPHERE CONTROL BOX DOOR 60...............................

5.3 CONTROLLED ATMOSPHERE CONTROL BOX 62......................................

5.4 CONTROLLED ATMOSPHERE CONTROL BOX -- SHIELD REMOVED 64..................

5.5 CALIBRATION, GAS CHARGE AND PRESSURIZATION/GAUGE PORTS 66...............

5.6 EVAPORATOR FAN DECK 68.........................................................

5.7 EVAPORATOR -- BACK PANELS REMOVED 70.........................................

5.8 DRAIN SOLENOID VALVES 74........................................................

5.9 MEMBRANE AIR FILTER ASSEMBLY 76...............................................

5.10 AIR INTAKE FILTER 78...............................................................

5.11 AIR COMPRESSOR Part Number 18--00052--03SV 80...................................

5.12 AIR COMPRESSOR Part Number 18--00099 82.........................................

.................................................

i T-305PL

Page 4

PARAGRAPH NUMBER

5.13 AIR COMPRESSOR MOUNTING 84...................................................

5.14 PRE--TRIP KIT AND DOOR INTERLOCK SYSTEM 86...................................

6 CONTROLLER CONFIGURATION 88......................................................

6.1 REFRIGERATION CONTROLLER/DATACORDER CONFIGURATION 88...................

7 TOOLS 89..............................................................................

Page

iiT-305PL

Page 5

INTRODUCTION

1 INTRODUCTION

The Carrier Transicold model 69NT40--489--100 series

units are of lightweight aluminum frame construction,

designed to fit in the front of a container and serve as the

container front wall.

2 CONFIGURATION IDENTIFICATION

Unit identification information is provided on a plate

located near the refrigeration compressor. The plate

provides the unit model number, the unit serial number

and the unit parts identification number (PID). The

model number identifies the overall unit configuration,

while the PID provides information on specific optional

equipment, factory provision to allow for field installation

of optional equipment, and differences in detailed parts.

Configuration identification for the models covered

herein are provided in the Carrier Transicold Container

Unit Matrix manual, publication T--300.

3 OPTION DESCRIPTIONS

Various options may be factory or field-fitted to the base

unit. These options are listed in the tables and described

in the following subparagraphs.

3.1 Battery

The refrigeration controller may be fitted with standard

replaceable batteries or rechargeable battery pack. The

unit is fitted with the EverFresh controlled atmosphere

option. The CA controller may be fitted with the same

battery option.

3.2 Dehumidification

The unit may be fitted with a humidity sensor. This

sensor allows setting of a humidity set point in the

controller. In the dehumidification mode, the controller

will operate to reduce internal container moisture level.

3.3 Control Box

The control box may be of aluminum or composite

material, and each type box may be fitted with a lockable

door.

3.4 Temperature Readout

The unit may be fitted with suction and discharge

temperature sensors. The sensor readings may be

viewed on the controller display.

3.5 Pressure Readout

The unit may be fitted with suction and discharge

pressure gauges, or suction and discharge transducers

or no pressure readout. The transducer readings may

be viewed on the controller display.

3.6 USDA

The unit may be supplied with fittings for additional

temperature probes, which allow recording of USDA

Cold Treatment data by the integral DataCORDER

function of the Micro--Link refrigeration controller.

3.7 Interrogator

Units that use the DataCORDER function are fitted with

interrogator receptacles for connection of equipment to

download the recorded data. Two receptacles may be

fitted; one accessible from the front of the container and

the other mounted inside the container (with the USDA

receptacles).

3.8 Remote Monitoring

The unit may be fitted with a remote monitoring

receptacle. This item allows connection of remote

indicators for COOL, DEFROST and IN RANGE.

Unless otherwise indicated, the receptacle is mounted

at the control box location.

3.9 Communications

The unit may be fitted with a communications interface

module. The communications interface module is a

slave module, which allows communication with a

master central monitoring station. The module will

respond to communication and return information over

the main power line. Refer to the ship master system

technical manual for further information.

3.10 Compressor, Refrigeration

The unit is fitted with a single-speed reciprocating

compressor.

3.11 Condenser Coil

The unit may be fitted with a 2-row or 4-row coil using

nominal 3/8 inch tubing, or a 3-row coil using 7mm

tubing. The required refrigerant charge is different for

each coil.

3.12 Autotransformer

An autotransformer may be provided to allow operation

on 190/230, 3-phase, 50/60 hertz power. The

autotransformer raises the supply voltage to the

nominal 380/460 volt power required by the base unit.

The autotransformer may also be fitted with an

individual circuit breaker for the 230 volt power.

If the unit is fitted with an autotransformer and

communications module, the autotransformer will be

fitted with a transformer bridge unit (TBU) to assist in

communications.

3.13 Gutters

Rain gutters may be fitted over the control box and

EverFresh control box to divert rain away from the

controls.

3.14 Handles

The unit may be fitted with handles to facilitate access to

stacked containers. These handles may include a fixed

handle (located at the right side of the unit) and/or

hinged handles at the left side and center (attached to

the condenser coil cover).

iii

T-305PL

Page 6

3.15 Water Cooling

The refrigeration system may be fitted with a watercooled condenser. The condenser is constructed using

copper--nickel tube for seawater applications. The

water-cooled condenser is in series with the air-cooled

condenser and replaces the standard unit receiver.

When operating on the water-cooled condenser, the

condenser fan is deactivated by either a water pressure

switch or condenser fan switch.

3.16 Back Panels

The refrigeration system may be fitted with either

aluminum or stainless steel back panels. Panels may be

fitted with access doors and/or hinge mounting.

3.17 460 Volt Cable

Various power cable and plug designs are available for

the main 460 volt supply. The plug options tailor the

cables to each customer’s requirements.

3.18 230 Volt Cable

Units equipped with an autotransformer require an

additional power cable for connection to the 230 volt

source. Various power cable and plug designs are

available. The plug options tailor the cables to each

customers requirements.

3.19 Cable Restraint

Various designs are available for storage of the power

cables. These options are variations of the compressor

section front cover.

3.20 Upper Air (Fresh Air Make Up)

The unit is fitted with an upper fresh air makeup

assembly. The openings may also be fitted with

screens.

3.21 Controlled Atmosphere

The controlled atmosphere system is of the two purity

type. This provides a second level of operation when

additional removal of carbon dioxide is required. All units

covered in this manual are fitted with the controlled

atmosphere option.

3.22 Arctic Mode

To improve operation in cold ambients, the unit may be

fitted with a crankcase heater and/or a condensate drain

line heater. The crankcase heater is operated before

start--up to warm the compressor oil and boil off any

liquid refrigerant that may be present in the crankcase.

The drain line heater is operated to prevent freezing of

the evaporator condensate drain system.

3.23 Humidification

The unit may be equipped with the Carrier Transicold

NatureFresh humidity management system. The

system includes a water tank, water pump, water

heater, and atomizer along with various control and

monitoring devices. It is designed to add additional

moisture into the supply air for control of cargo moisture

level. A separately bound manual covering operation

and parts for the CTD NatureFresh System is available

(see the following chart).

Manual

Number

T-297

Equipment

Covered

Humidity Management

System Option

Type of

Manual

Technical

Supplement

3.24 Power Correction

The unit may be fitted with a set of power factor

correction capacitors to assist in correction of

imbalance in current draw by the compressor.

3.25 Evaporator

Evaporator section options include a hermetic thermal

expansion valve with a choice of two sizes of heat

exchangers.

3.26 Evaporator Fan Operation

The units are fitted with Normal Evaporator Fan

Operation. Opening of an evaporator fan internal

protector will shut down the unit.

3.27 Labels

Operating Instruction and Function Code listing labels

will differ depending on the options installed. For

example, additional operating instructions are required

to describe start--up of a unit equipped with an

autotransformer. Where the labels are available with

additional languages, they are listed in the parts list.

3.28 Plate Set

Each unit is equipped with a tethered set of wiring

schematic and wiring diagram plates. The plate sets are

ordered using a seven digit base part number and a two

digit dash number. EverFresh controlled atmosphere

units have a second set of plates for the controlled

atmosphere system. These plate sets are numbered

and ordered in the same manner. (See Unit Matrix)

3.29 Controller

There are two controllers in the unit. The refrigeration

controller controls the temperature and the EverFresh

controller controls the Controlled Atmosphere

components. Replacement controllers may be ordered

as a universal unconfigured controller (without

configuration software) or configured.

3.30 Stepper Drive

All the units covered by this manual have suction

modulating valves, which act to control system capacity.

Units indicated as being fitted with “stepper drive” have

digital control motors fitted to the suction modulating

valve to open and close the valve in steps as required.

3.31 Condenser Grille

Two styles of condenser grilles are available -- direct

bolted grilles and hinged grilles.

3.32 Emergency Bypass

The unit may be equipped with switches to allow

emergency bypass of the controller. The EMERGENCY

BYPASS switch functions to bypass the controller in the

event of controller failure. The EMERGENCY

DEFROST switch functions to bypass the all controls

and place the unit in the defrost mode.

T-305PL

iv

Page 7

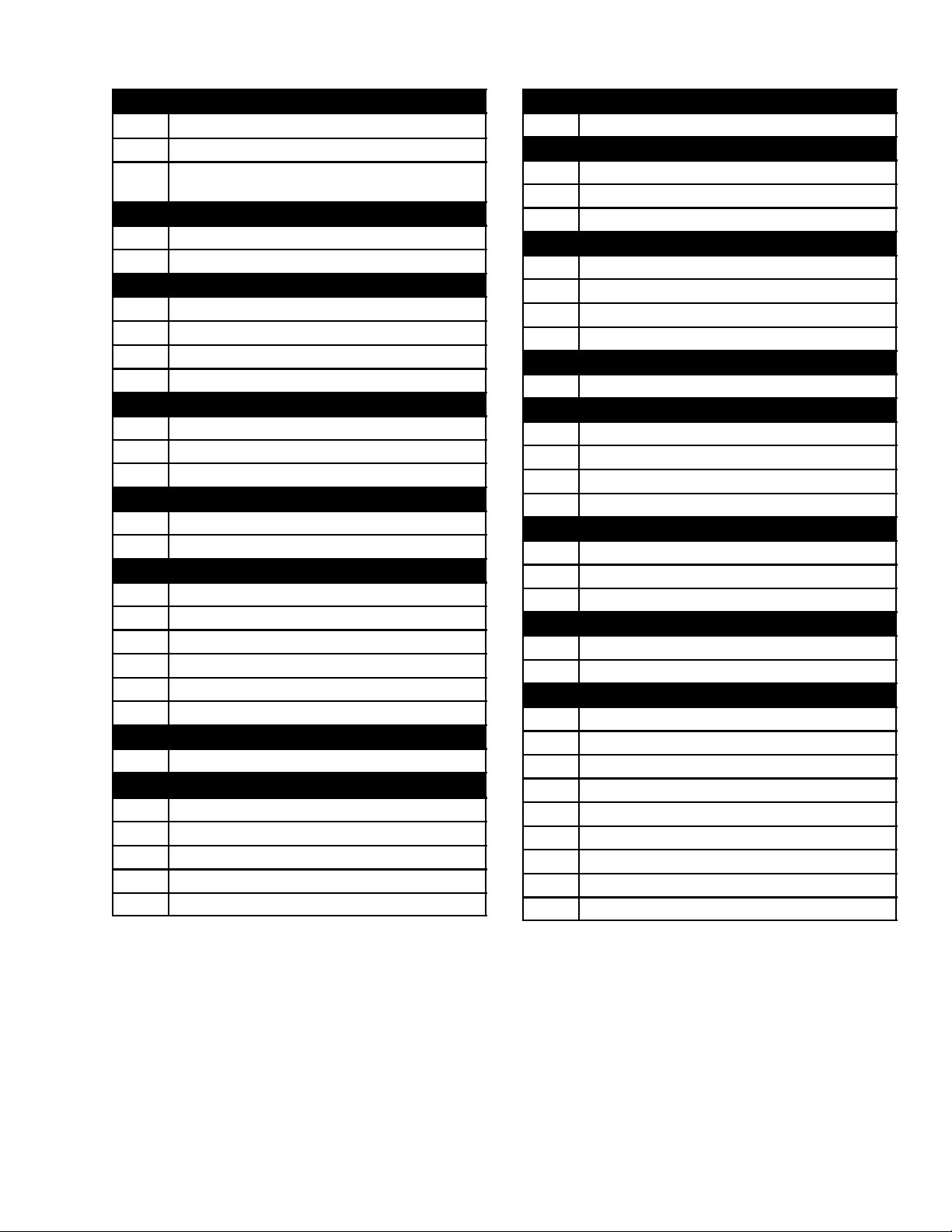

OPTION LEGEND

General

--

X Features that apply to model

P Factory Installation of Equipment to

Battery Codes

S Standard (throw away) Cells

R Rechargeable Cells

Control Box Codes

A Aluminum Box without Door Lock

AL Aluminum Box with Door Lock

C Composite Box without Door Lock

CL Composite Box with Door Lock

Pressure Readout Codes

G Factory Installed Pressure Gauges

T Factory Installed Pressure Transducers

SG Factory Installed Suction Pressure Gauge

USDA Codes

D Option D

V Option V

Interrogator Codes

1 Left Straight Mount

2 Right Mount

3 Box Mount

4 Left Mount

5 Left Angled Mount

6 Right Mount

Back Panel Codes

4 Hinged Panels

Communications Codes

1 Standard

2 HighDataRate

3 Chipset Modem

3l Chipset Modem Low Data Rate

3h Chipset Modem High Data Rate

Feature Not Applicable

Allow Field Installation

Compressor Codes

1R Single Speed Reciprocating

Condenser/Receiver Codes

2 Two Row Coil

3 Three Row (7mm) Coil

4 Four Row Coil

AutoTransformer Codes

1 Transformer Fitted

2 Transformer with CB2 Fitted

3 Transformer with CB2 and Receptacle

4 Transformer with CB2 and TBU

Gutter Codes

2 Standard Length Bolted Gutters

Handle Codes

1 Two Side and One Center

2 Two Side

3 One Center

4 One Right Side and Two Center

Thermometer Port Codes

1 Supply Air Port

2 Return Air Port

B Both Ports

Water Cooling Codes

W Water Pressure Switch

F Condenser Fan Switch

460 Volt Cable Codes

1 Option1

2 Option 2

3 Option 3

4 Option 4

5 Option 5

6 Option 6

7 Option 7

8 Option 8

9 Option 9

v

T-305PL

Page 8

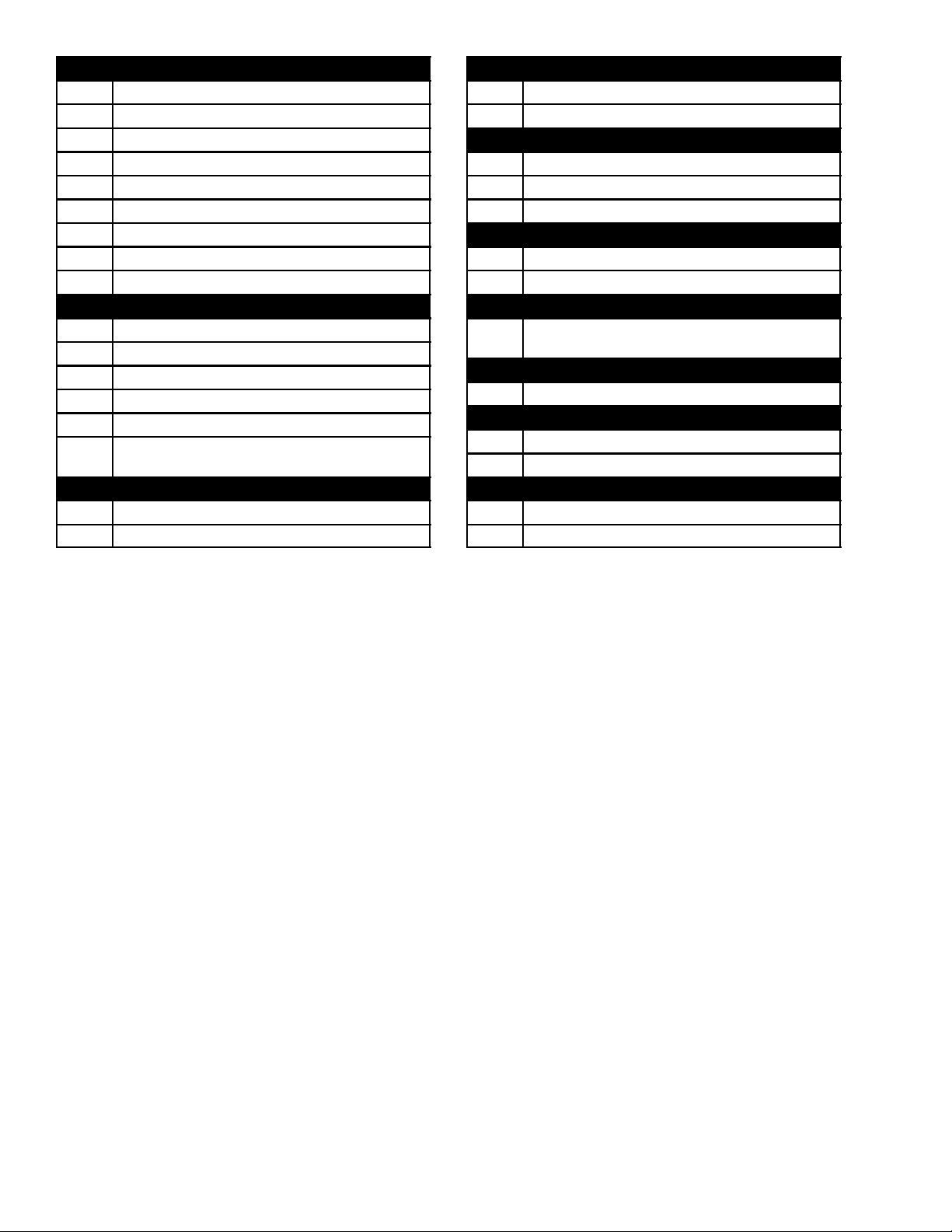

230 Volt Cable Codes

1 Option 1

2 Option 2

3 Option 3

4 Option 4

5 Option 5

6 Option 6

7 Option 7

8 Option 8

9 Option 9

Cable Restraint Codes

1 Cable Door

2 Left Bungy Cord Only

3 J--Hook

4 Left and Right Bungy Cord

5 Left Bungy Cord with Left Extended Guard

6 Left and Right Bungy Cords with Extended

Guards

Upper Air Codes

2 Upper Fresh Air Installed

3 Upper Fresh Air Installed with Screen

Controlled Atmosphere

1 TransFresh

2 Carrier Transicold EverFresh System

Arctic Mode Codes

C Crankcase Heater

L Drain Line Heater

B Both Crankcase Heater and Drain Line Heater

Condenser Grille Codes

B Bolted Grille

H Hinged Grille

Evaporator Codes

1 Original Coil with Semi--Hermetic TXV and

Standard Heat Exchanger

Evaporator Fan Codes

1 Normal Evaporator Fan Operation

Label Codes

1 English

2 English / Spanish

Emergency Bypass Codes

B Emergency Bypass and Emergency Defrost

EB Emergency Bypass Only

Ordering Instructions

All orders and inquiries for parts must include: Parts Identification Number (PID), Model Number, Unit Serial Number,

Part Number, Description of part as shown on list, and Quantity required. Address all correspondence for parts to the

following address:

CARRIER TRANSICOLD DIVISION

Replacement Components Group, TR-20

P.O. Box 4805, Syracuse, New York 13221

or FAX to: (315) 432-3778

Letter Designations

The following letter designations are used to classify parts throughout this list:

A/R = As Required

N/A = Not Available

NS = Not shown in illustration

NSS = Not sold separately -- Order next higher assembly or kit

PID = Parts Identification Number -- essential to identify unit configuration.

PL = Purchase Locally

SST = Stainless Steel -- 300 Series unless otherwise specified.

SV = Suffix SV -- added to part number designates service replacement part.

T-305PL

vi

Page 9

1 QUICK LIST -- CLAMPS, FILTER--DRIER, FUSE, TY--RAPS, AND WIRE TERMINALS

PART NO. DESCRIPTION

34--00373--51 Clamp, Tube, 1/4, SST

34--00373--53 Clamp, Tube, 3/8, SST

34--00373--05 Clamp, Tube, 1/2, SST

34--00373--07 Clamp, Tube, 5/8, SST

34--00373--59 Clamp, Tube, 3/4, SST

34--00373--11 Clamp, Tube, 7/8, SST

34--00373--65 Clamp, Tube, 1--1/8, SST

34--00373--67 Clamp, Tube, 1--1/4, SST

34--00373--69 Clamp, Tube, 1--3/8, SST

34--00373--71 Clamp, Tube, 1--1/2, SST

22--00066--01 Connector, Butt End, Wire Range -- 22 to 16 AWG

22--00066--02 Connector, Butt End, Wire Range -- 16 to 14 AWG

22--00066--03 Connector, Butt End, Wire Range -- 12 to 10 AWG

22--00041--00 Connector, Closed End, Wire Range -- 22 to 14 AWG

22--00041--02 Connector, Closed End, Wire Range -- 18 to 10 AWG

66U1--7472--1 Filter--Drier

22--02336--02 Fuse, 5 Amp (F1 and F2)

22--02336--04 Fuse, 10 Amp (F3)

22--01140--01 Ring Terminal, #6, Wire Range -- 12 to 10 AWG

22--01140--02 Ring Terminal, #10, Wire Range -- 12 to 10 AWG

22--01140--04 Ring Terminal, 3/8, Wire Range -- 12 to 10 AWG

22--00119--04 Ring Terminal, 1/4, Wire Range -- 12 to 10 AWG

22--00120--04 Ring Terminal, #10, Wire Range -- 16 to 14 AWG

22--00120--07 Ring Terminal, 5/16, Wire Range -- 16 to 14 AWG

22--00121--07 Ring Terminal, #10, Wire Range -- 22 to 16 AWG

22--01139--04 Ring Terminal, 3/8, Wire Range -- 16 to 14 AWG

22--01141--01 Spade Terminal, 1/4 X 5/16, Wire Range -- 16 to 14 AWG

22--00595--01 Spade Terminal, 3/8, Wire Range -- 12 to 10 AWG

22--01106--00 Spiral Wrap, 1/4 Diameter X 25 Feet Long

22--01107--00 Spiral Wrap, 1/2 Diameter X 25 Feet Long

66U1--3803 Tube, Heat Shrink, 1/4 ID X 2--1/8 Long

66U1--3803--1 Tube, Heat Shrink, 1/2 ID X 2--3/4 Long

44--01043--05 Ty--Raps, 5--1/2 Inches Long

44--01043--07 Ty--Raps, 11.00 Inches Long

22--50007 Series Wire Markers

07--00345--00 Sealant, Pipe (Used to seal fittings on unit with R--134a)

07--00313--00 Cleaner, Coil

76--00397--00 Paint, Compressor Touch--Up, Blue

1

T-305PL

Page 10

2 REFRIGERATION UNIT ASSEMBLY

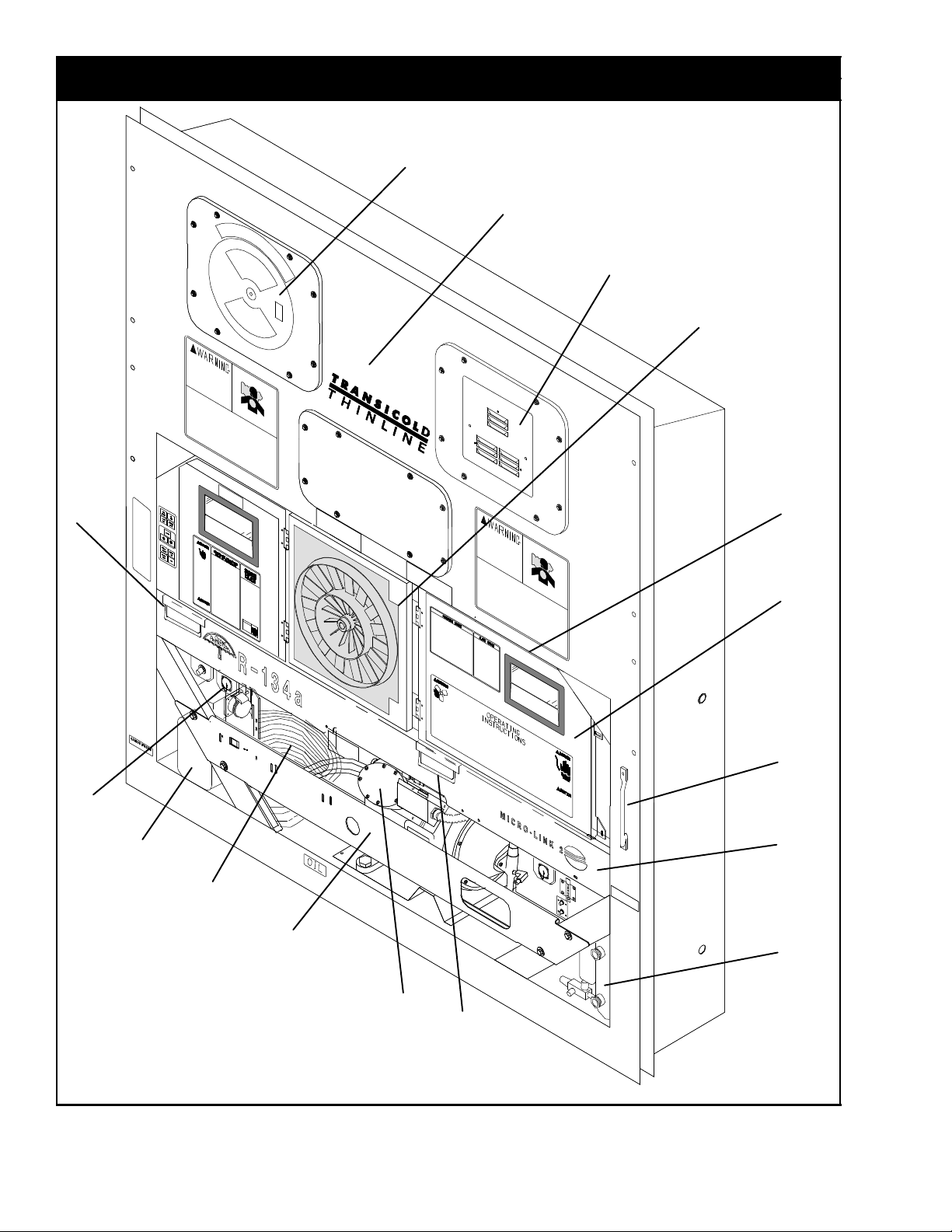

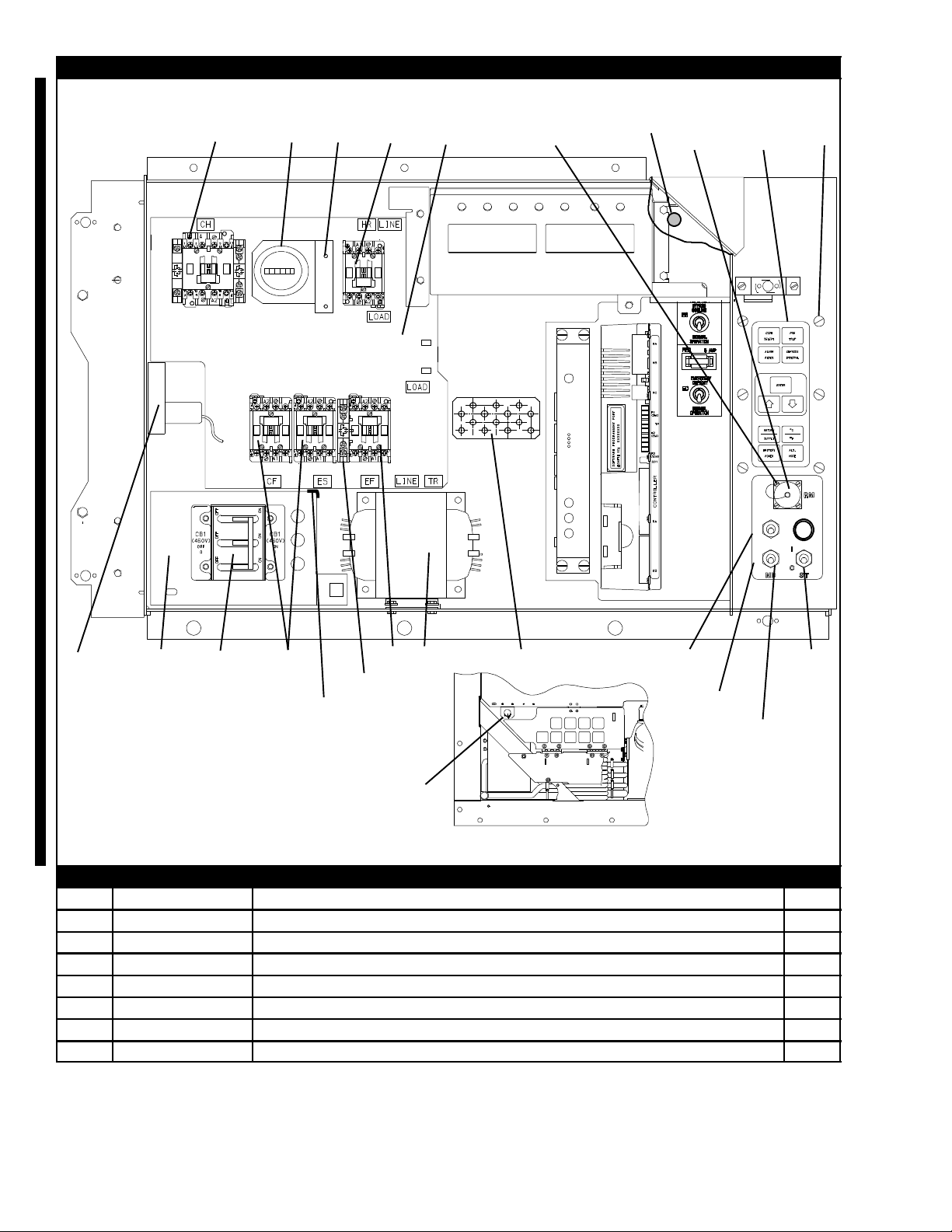

2.1 REFRIGERATION UNIT -- AREA LOCATOR

2

Item 1, Controlled Atmosphere

Equipment, Refer to Section

3

4

5

5

9

17

16

14

15

13

7

8

9

10

11

12

9

2T-305PL

Page 11

2.1 REFRIGERATION UNIT -- AREA LOCATOR (Continued)

Item Section Number Area Description

1 Refer to Section 5 Controlled Atmosphere Equipment

2 Refer to Section 2.17 Upper Fresh Air Makeup and Access Panels

3 Refer to Section 2.26 Labels and Decals

4 Refer to Section 2.18 Evaporator Fan Assembly

5 Refer to Section 2.10 Condenser Fan Motor and Coils

6 Refer to Section 2.11 Condenser Fan Grille

7 Refer to Section 2.2 Rain Gutters

8 Refer to Section 2.4-- 2.9 Box, Control

9 Refer to Section 2.3 Handles

10 Refer to Section 2.10 Condenser Coil

11 Refer to Section 2.13 or 2.14 Receiver or Water-- Cooled Condenser

12 Refer to Sections 2.21 or 4 Compressor

13 Refer to Section 2.21 Guard, Compressor

14 Refer to Section 2.24 Power Cables

15 Refer to Section 2.24 Power Plugs

16 Refer to Section 2.25 Autotransformer

17 Refer to Section 3 Interrogator and Accessories

3

T-305PL

Page 12

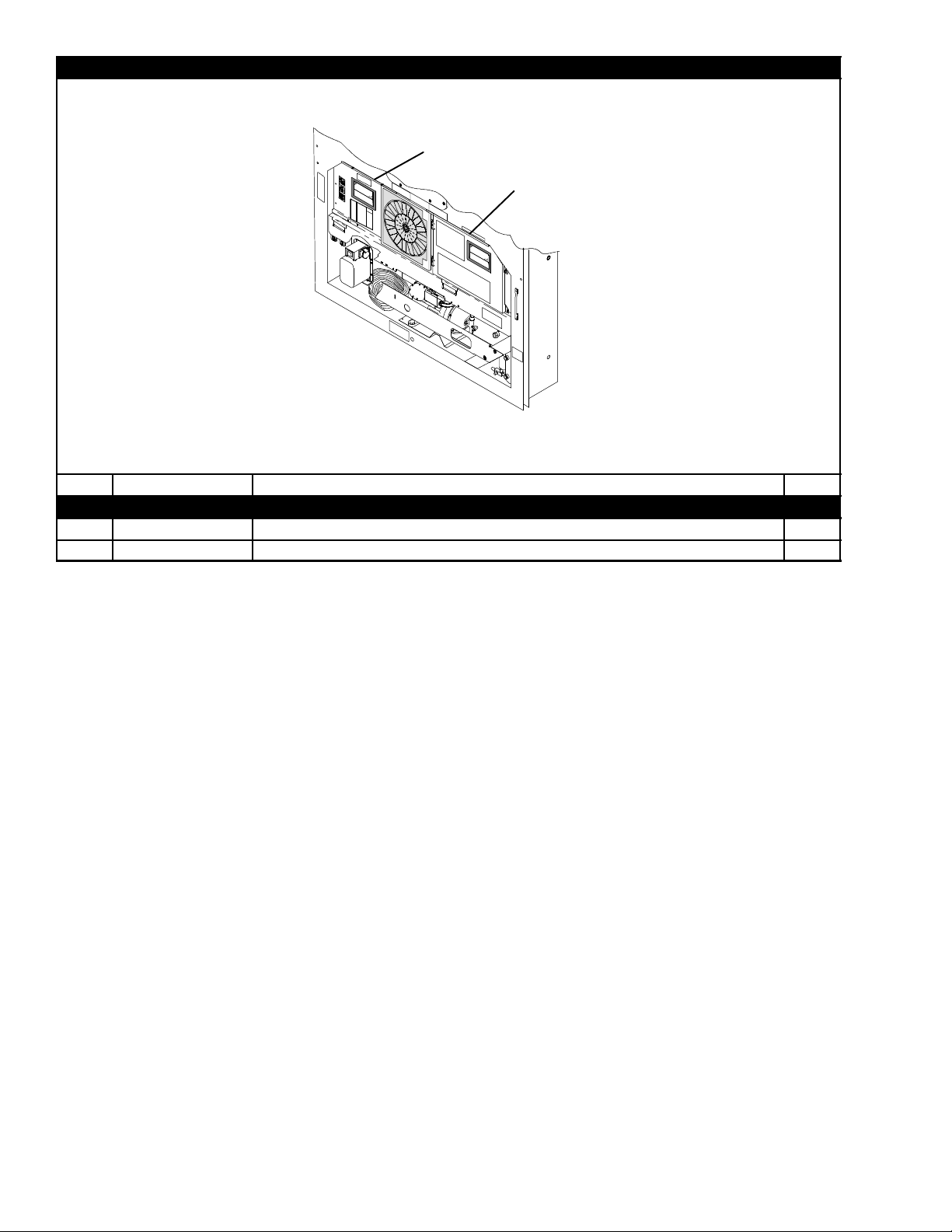

2.2 RAIN GUTTERS

2

1

Item Part Number Description Qty

OPTION 2 -- STANDARD LENGTH

1 69NT35--3987 Gutter, Rain (Standard -- Right Side) 1

2 69NT35--7078 Angle, Rain Gutter (Left Side) 1

4T-305PL

Page 13

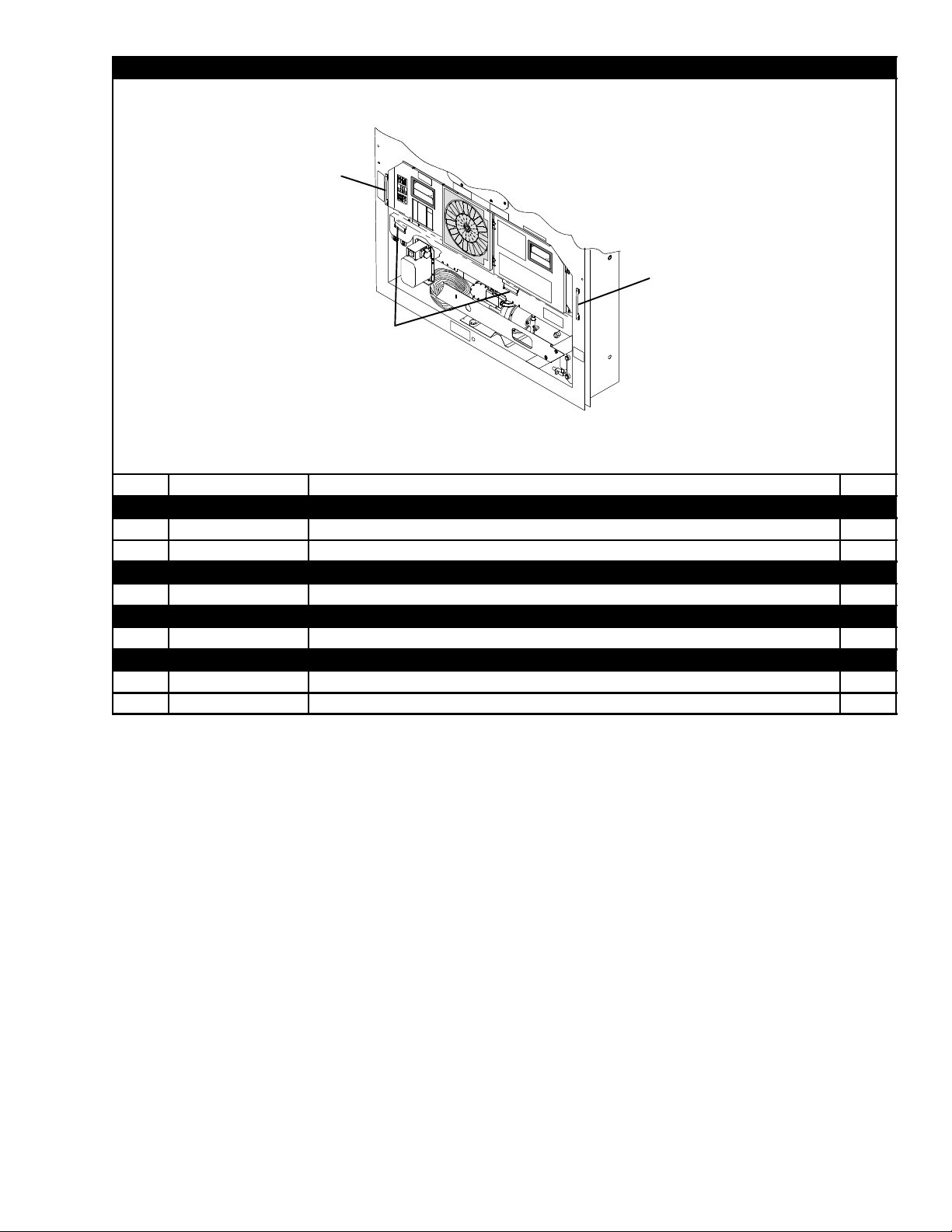

2.3 HANDLES

1

1

2

Item Part Number Description Qty

OPTION 1 -- TWO SIDE, ONE CENTER

1 69NT35--81 13 Handle, Fixed 2

2 69NT40--657-- 2 Handle, Hinged 1

OPTION 2 -- TWO SIDE

1 69NT35--81 13 Handle, Fixed 2

OPTION 3 -- ONE CENTER

2 69NT40--657-- 2 Handle, Hinged 1

OPTION 4 -- ONE RIGHT SIDE, TWO CENTER

1 69NT35--81 13 Handle, Fixed 1

2 69NT40--657-- 2 Handle, Hinged 2

5

T-305PL

Page 14

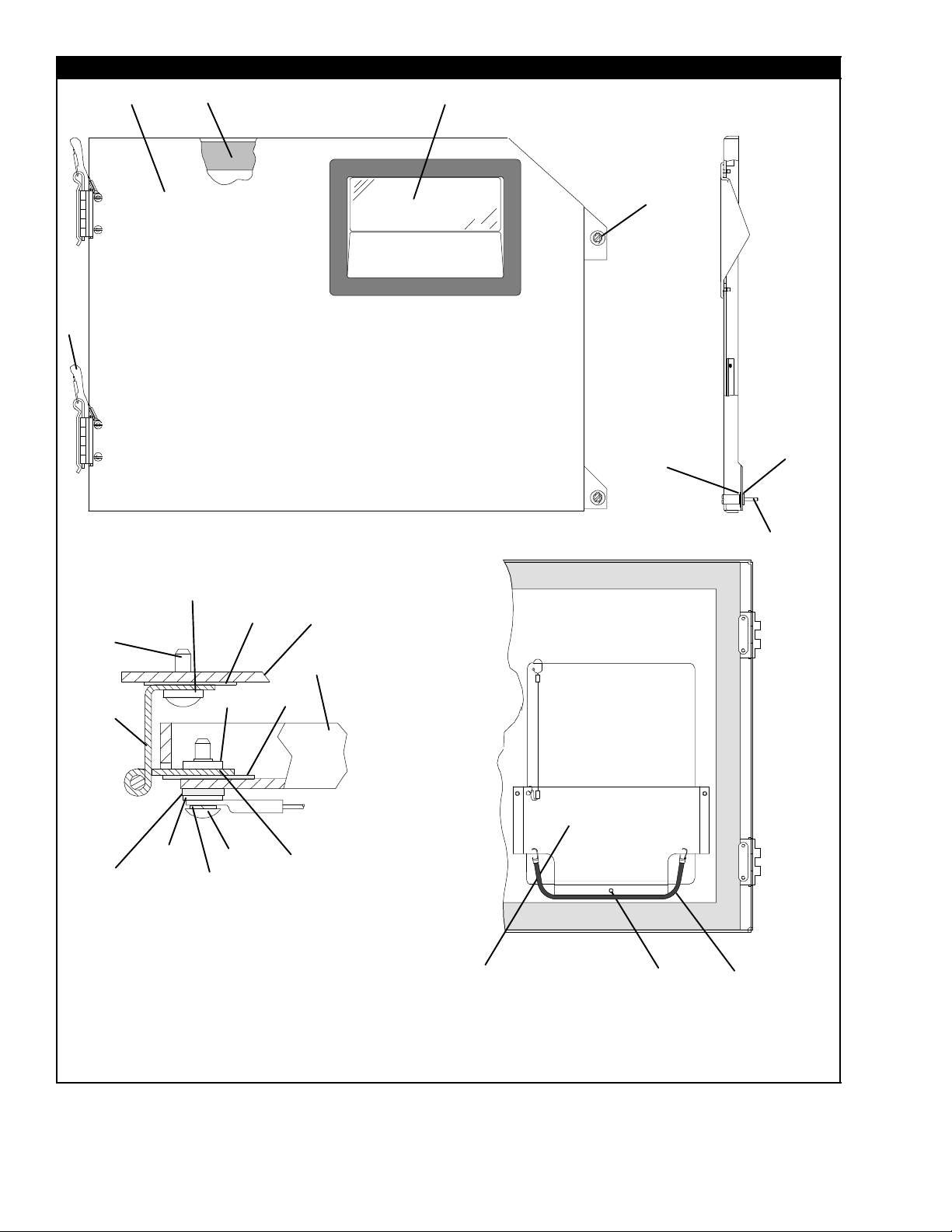

2.4 CONTROL BOX DOOR

12 4

10

6

5

7

18

16

7

19

13

9

11

12

14

15

Control Box

Control Box Door

17

8

6

5

Hinge Assembly -- Sectional View

17

Door Assembly -- Partial Back View

6T-305PL

18

15

11

19

22

Page 15

2.4 CONTROL BOX DOOR (Continued)

Item Part Number Description Qty

1 69NT42--688-- 7 Door Assembly -- Includes: 1

2 42--00270--02 Gasket, Door 1

3 58--04366--00SV Window and Gasket Assembly, Control Box Door, Lexan 1

4 34--06169--00 Washer, Retaining, SST 2

5 66U1--6811--8 Screw, Retaining, Panel, 0.300--0.625, SST 2

5 66U1--6811--15 Screw, Retaining, Wing, 0.300--0.625, SST 2

6 34--06053--00 Washer, Mylar, 0.25 ID X 0.80 OD 4

7 44--00300--01 Hinge, Half 1

8 44--00300--02 Hinge, Half 1

9 44--00300--03 Pin Assembly, with Tether 1

10 58--04101--01 Protector, Mylar (Hinge) (Not Needed with Composite Box) 2

11 34--01167--01 Retainer, Nut 2

12 58--04101--00 Protector, Mylar (Hinge) 2

13 66U1--2403--1 Screw, Truss Head, #10--24 X 3/4 Long, SST 4

14 66U1--5331--3 Washer, Lock, #10, SST 7

15 66U1--5321--8 Washer, Flat, #10, SST 7

16 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 4

17 68--13577--00 Pocket, Placard 1

18 34--00665--09 Locknut, Hex Head, #10--24, SST 3

19 34--06107--00 Rivet, Blind, 1/8 Diameter, Grip Range -- 0.188--0.250 3

20 66U1--5371--7 Screw, #10--24 X 1/2 Long, SST 4

21 66U1--5321--8 Washer, Flat, #10, SST 4

22 58--04346--00 Door Strap Kit 1

7

T-305PL

Page 16

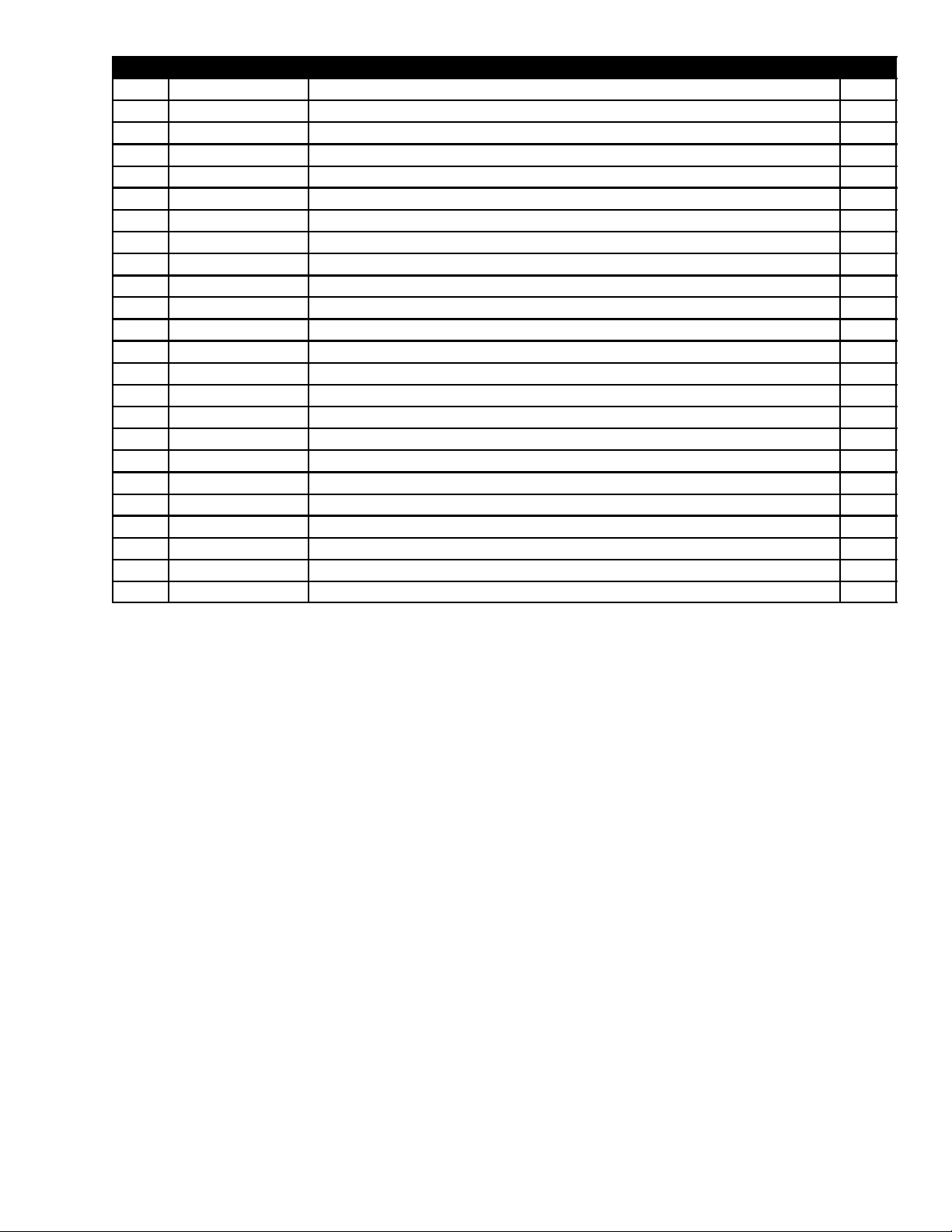

2.5 CONTROL BOX

1

3

4

6

22

7

8

5

9

12

13

14

15

2

24

26

5

9

21

26

23

22

22

OPTION C and CL -- COMPOSITE BOX

25

24

22

22

11

23

22

23

5

9

10

16

22

17

18

19

20

In Box

8T-305PL

Page 17

2.5 CONTROL BOX (Continued)

Item Part Number Description Qty

1 -- Plate, Schematic and Diagram (Refer to T--300, Container Unit Matrix) 1

2 66U1--2403 Screw, Truss Head, #10--24 X 1/2 Long, SST 2

3 69NT43--125-- 1 Shield, High Voltage (Plastic) -- Includes: 1

4 44--00343--00 Hinge 2

5 34--00928--02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8--3/16, SST 4

6 34--50015--00 Stud and Retainer Package -- Includes: 4

7 NSS Stud, Fastener 1

8 NSS Retainer, Fastener Stud 1

9 34--06139--03 Receptacle 4

10 69NT43--124-- 4SV Shield, Low Voltage (Lexan) with Tether 1

11 62--03957--02 Label, Danger--High Voltage 1

OPTION A and AL, Aluminum CONTROL BOX

12 86--04237--03 Control Box, Standard Aluminum 1

13 68--12791--00 Bracket, Lock (See Note 1) 1

34--01142--01 Receptacle, Retaining 1

14

34--01152--02 Receptacle, Retaining (See Note 2) 1

34-- 00928--01 Rivet, Blind, 1/8 Diameter, Grip Range 1/16 -- 1/8 2

15

34-- 00928--03 Rivet, Blind, 1/8 Diameter, Grip Range 3/16 -- 1/4 (See Note 2) 2

NOTES

1. The bracket is welded to the control box -- order Item #11 for locking plate.

2. When Item #11 is used, 34--01152--02 and rivets, 34--00928--03 are to be used in the upper door location.

OPTION C and CL -- COMPOSITE CONTROL BOX

16 58--04668--01 Control Box, Standard Composite 1

69NT35--6272 Bracket, Non--Locking 1

17

69NT35--2287 Bracket, Locking (See Note 3) 1

18 34--01142--01 Receptacle, Retaining 1

34-- 00928--01 Rivet, Blind, 1/8 Diameter, Grip Range 1/16 -- 1/8 2

19

34-- 00928--02 Rivet, Blind, 1/8 Diameter, Grip Range 1/18 -- 3/16 (See Note 4) 2

20 66U1--2403 Screw, Truss Head, #10--24 X 1/2 Long, SST 2

NS 76--00724--00SV Crack, Chip and Hole Repair Kit 1

NS 76--50084--00SV Insert Repair Kit -- Includes: 1

21 34--06231--01 Insert -- 17.53 X 9.91 mm (0.690 X 0.390 in) 1/4--20 Threads -- NSS 10

22 34--06231--03 Insert -- 15.88 X 6.35 mm (0.625 X 0.250 in) 10--24 Threads -- NSS 10

23 34--06231--04 Insert -- 25.15 X 7.54 mm (0.990 X 0.297 in) 10--24 Threads -- NSS 10

24 34--06231--05 Insert -- 10.16 X 9.53 mm (0.400 X 0.375 in) 10--24 Threads -- NSS 10

25 34--06231--06 Insert -- 12.70 X 9.91 mm (0.500 X 0.390 in) 1/4--20 Threads -- NSS 10

26 34--06231--07 Insert -- 9.53 X 6.76 mm (0.375 X 0.266 in) 10--24Threads -- NSS 10

NS 02--00082--00 Durabond Epoxy -- NSS 1

NS 07--00390--00 Static Mixing Tube -- NSS 1

NS 07--00391--00 Application Gun -- Required for Insert Repair 1

NOTES

3. The bracket is bolted to the control box -- order 69NT35--2287 for locking bracket.

4. When 69NT35--2287 is used, 34--00928--02, rivet, is to be used in the upper door location.

9

T-305PL

Page 18

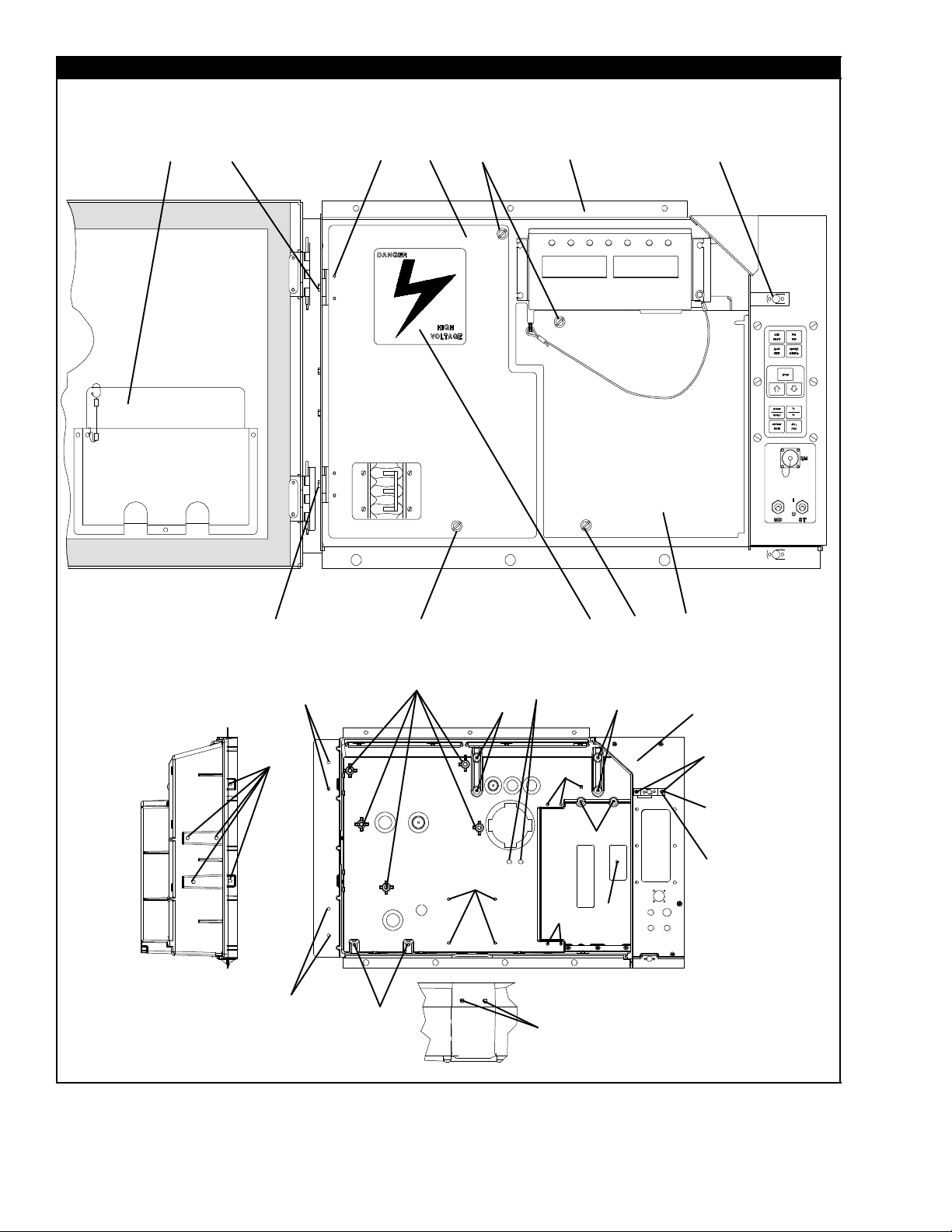

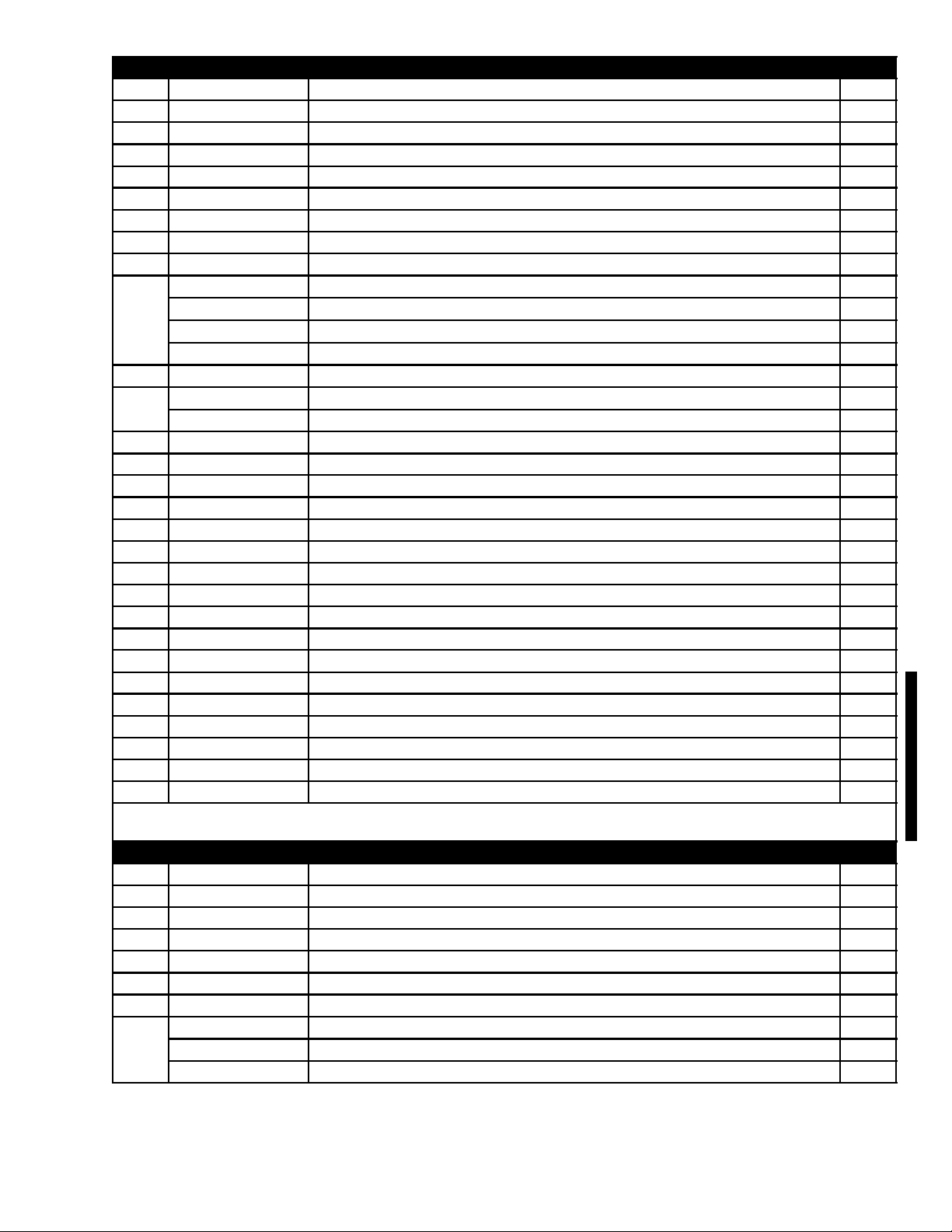

9.6 CONTROL BOX -- SHIELDS REMOVED, STD ELECTRICAL COMPONENTS, RM AND HOURMETER

3

6

1

2

4

6

7

9

10

8

40

41

42

31

36

37

38

39

30

13

32

33

34

35

5

20

26

27

28

19

20

25

22

23

24

6

7

21

18

7

19

20

17

29

16

or

43

11

12

6

14

15

44

45

Remote Monitoring ---

Lower/External Mounting

HOURMETER

Item Part Number Description Qty

1 66U1--3823

Hourmeter 1

2 66U1--6651--15 Screw, Pan Head, #4--40 X 3/4 Long, SST

68-- 12496--00 Bracket, Hourmeter 1

3

66U1-- 5381 Screw, Hex Head, #10--24 X .50 Long, SST 2

4

10-- 00431--07 Contactor, Compressor (CH) (30 Amp) 1

5

34-- 06243--00 Screw, Pan Head, (Thread Cutting) #8-- 32 X 3/4 Long, SST 10

6

10-- 00431--06 Contactors, (CF), (HR) and (EF and ES) (12 Amp) 4

7

13

14

3

10T-305PL

Page 19

9.6 CONTROL BOX -- SHIELDS REMOVED, STANDARD ELECTRICAL COMPONENTS (Continued)

Item Part Number Description Qty

68-- 13427--00SV Panel, Contactor -- Includes: 1

8

58-- 00967--00 Spacer (Used with Sheet Metal Control Box Only) 5

9

34-- 00655--08 Screw, Hex Head, 1/4-- 20 x 1.00 Long, SST 4

10

34-- 00928--01 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/16 -- 1/8 6

11

34-- 01142--01 Receptacle 1

12

10-- 01129--07SV Switch, Toggle (On--Off) 1

13

66U1-- 9752 Seal, Bushing 1

14

10-- 01129--10 Switch, Toggle (MDS) 1

15

58-- 04145--01 Plate, Switch A/R

68-- 14796--00 Plate, Switch (Start Only) NT--1200 and Up A/R

16

68-- 14796--02 Plate, Switch (Start and Defrost LED), NT-- 1200 and Up A/R

68-- 14796--05 Plate, Switch (Start and MDS), NT--1200 and Up A/R

69NT41-- 982-- 3 Plate, Ground 1

17

10-- 00332--07 Transformer, Base Unit 1

18

10-- 00332--05 Transformer, Base Unit (Do NOT use with Composite Box) 1

66U1-- 5371-- 7 Screw, Hex Head, #10-- 24 X 1/2 Long, SST A/R

19

66U1-- 5321-- 8 Washer, Flat, #10, SST A/R

20

10-- 00431--02 Contact, Auxiliary 1

21

34-- 00663--07 Washer, Lock, #6, SST 4

22

66U1-- 7842-- 13 Circuit Breaker -- 460 VAC, 25 Amp, (CB1) 1

23

66U1-- 6651-- 4 Screw, Pan Head, #6-- 32 X 3/8 Long, SST 4

24

69NT35-- 6278 Bracket, Circuit Breaker 1

25

10-- 00439--00 Transformer, Current Sensing (CS) 1

26

66U1-- 5371-- 10 Screw, Hex Head, #10--24 X 1.00 Long, SST 2

27

66U1-- 5321-- 8 Washer, Flat, #10, SST 2

28

66CH1--1172-- 46 Trim, Flexible (85 Feet Long, Cut to Length) A/R

29

30 79--66669--00 Pad, Key -- Includes: 1

31 NSS Dot, Indicator (Green) -- See Note 1

32 NSS Gasket (Between Keypad and Keypad Plate Assembly 1

33 NSS Plate Assembly, Keypad Mounting 1

34 34--66629--05 Screw, Pan Head, #10--24 X 3/4 Long, SST (Use with Composite Box) 6

35 34--06212--10 Washer, Mylar, 0.205 ID X 0.600 OD 6

NOTE: If unit is not already fitted with green indicator dot (Item 31) on upper right corner of control box door,

install dot as illustrated after the replacement of this key pad.

REMOTE MONITORING (STANDARD LOCATION)

22-- 02341--00 Receptacle, Remote Monitoring (RM) 1

36

22-- 02368--00 Plug, Remote Monitoring 1

37

22-- 02341--01 Cap and Tether, Receptacle Assembly 1

38

66U1-- 6835 Gasket, Remote Monitoring Receptacle 1

39

34-- 00848--10 Screw, Round Head, #4--40 X 5/8 Long, SST 4

40

66U1-- 5321-- 6 Washer, Flat, 0.125 ID, SST 4

41

34-- 00667--05 Nut, Self Locking, #4--40, SST 4

42

58-- 04145--00 Plate, Switch, with RM A/R

68-- 14796--03 Plate, Switch, with RM NT--1200 and up A/R

43

68-- 14796--06 Plate, Switch with RM and MDS, NT-- 1200 and Up A/R

11

T-305PL

Page 20

REMOTE MONITORING (LOWER LEFT/EXTERNAL LOCATION)

22-- 01889--00 Receptacle, Remote Monitoring (RM) 1

44

69NT40-- 222 Bracket 1

45

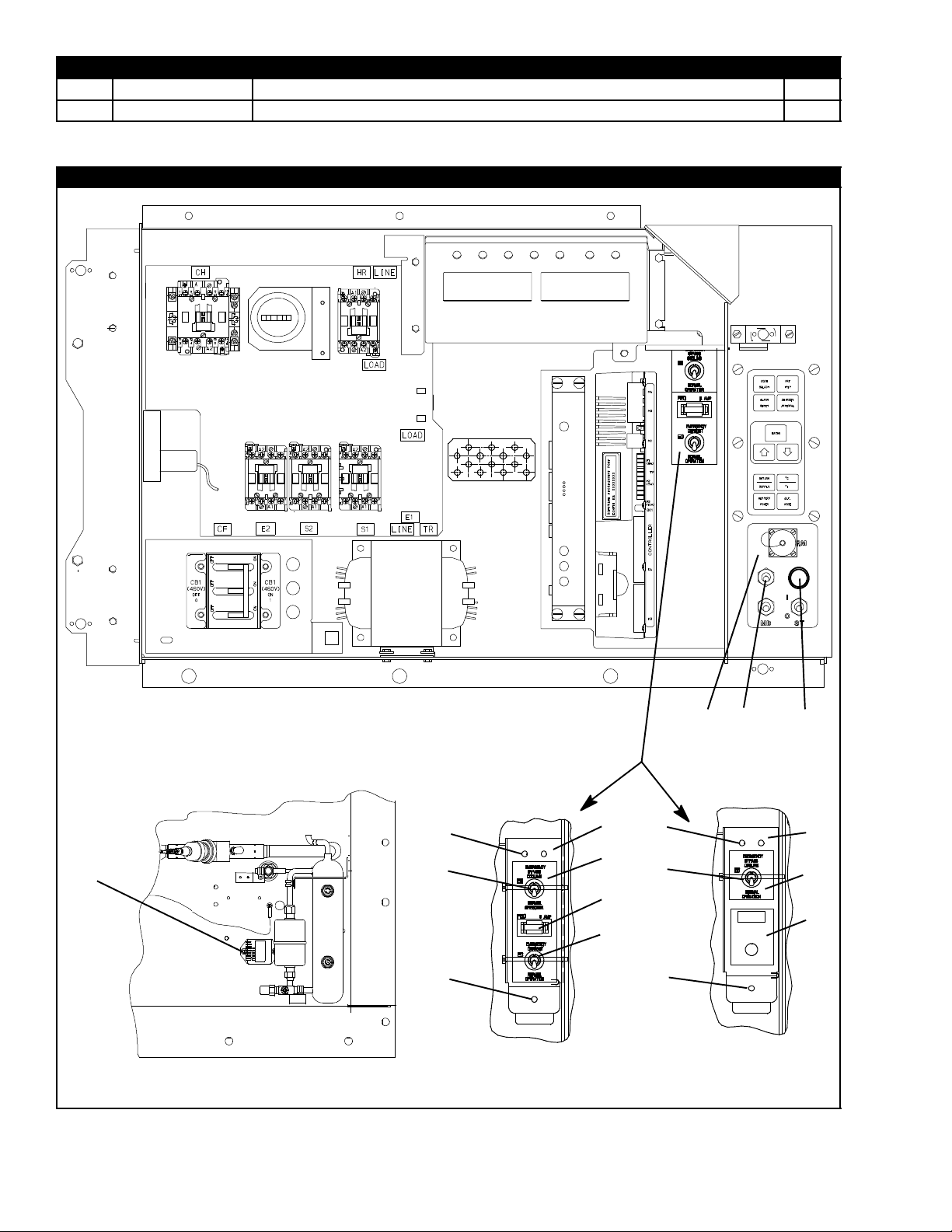

9.7 CONTROL BOX -- SHIELDS REMOVED, EV AP FAN CAPABILITY, EBS and EDS, EBS ONLY and CFS

19

5

20

21

8

1

2

3

4

Bottom Right Corner of Unit

6

9

10

8

EBS and EDS

7

13

11

12

6

9

10

8

6

9

10

8

EBS Only

14

15

16

7

17

18

12T-305PL

Page 21

2.7 CONTROL BOX -- SHIELDS REMOVED, EVAP FAN CAPABILITY (Continued)

Item Part Number Description Qty

OPTION 1 -- NORMAL EVAPORATOR FAN OPERATION

See Section 2.6 Items 6 and 7 for correct contactor placement

OPTION B -- EMERGENCY BYPASS SWITCH AND EMERGENCY DEFROST SWITCH

1 10--00416--00 Module, Emergency Bypass 1

2 66U1--5371--6 Screw, Machine Hex Head, #10-- 24 X 0.75 Long, SST 2

3 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

4 66U1--5321--8 Washer, Flat, #10, SST 2

58-- 04145--09 Plate, Switch (With Light Location) 1

58-- 04145--07 Plate, Switch (With Light Location, with RM) 1

68-- 14796--01 Plate, Switch (With Light Location) NT--1200 and up A/R

5

68-- 14796--02 Plate, Switch (With Light Location) NT--1200 and up A/R

68-- 14796--04 Plate, Switch (With Light Location, with RM) NT-- 1200 and Up A/R

6 10--01129--07SV Switch, T oggle 2

7 68--12544--01 Bracket 1

8 34--06223--00 Screw, Captive Washer, #10--24 X .56 Long, SST 2

9 10--01129--20 Hex Nut 2

10 66U1--9752 Seal, Bushing 2

11 22--01455--02 Holder Assembly, Fuse 1

12 22--02336--02 Fuse, 5 Amp 1

13 62--02874--01 Label, EB and ED 1

14 22--00518--01 Base,PilotLight 1

15 22--00519--03 Light Assembly, Pilot 1

16 22--00049--01 Lamp, 24VDC 1

OPTION EB -- EMERGENCY BYPASS SWITCH ONLY

1 10--00416--00 Module, Emergency Bypass 1

2 66U1--5371--6 Screw, Machine, Hex Head, #10--24 X 0.75 Long, SST 2

3 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

4 66U1--5321--8 Washer, Flat, #10, SST 2

6 10--01129--07SV Switch, T oggle 1

7 68--12544--01 Bracket 1

8 34--06223--00 Screw, Captive Washer, #10--24 X .56 Long, SST 2

9 10--01129--20 Hex Nut 1

10 66U1--9752 Seal, Bushing 1

17 62--02874--00 Label, EB Upper 1

18 62--02874--02 Label, EB Lower 1

OPTION F -- CONDENSER FAN SWITCH

19 10--00298--01 Switch, Toggle (CFS) 1

20 66U1--9752 Seal, Bushing 1

58-- 04145--06 Plate, Switch (With Extra Switch Location) 1

21

13

T-305PL

Page 22

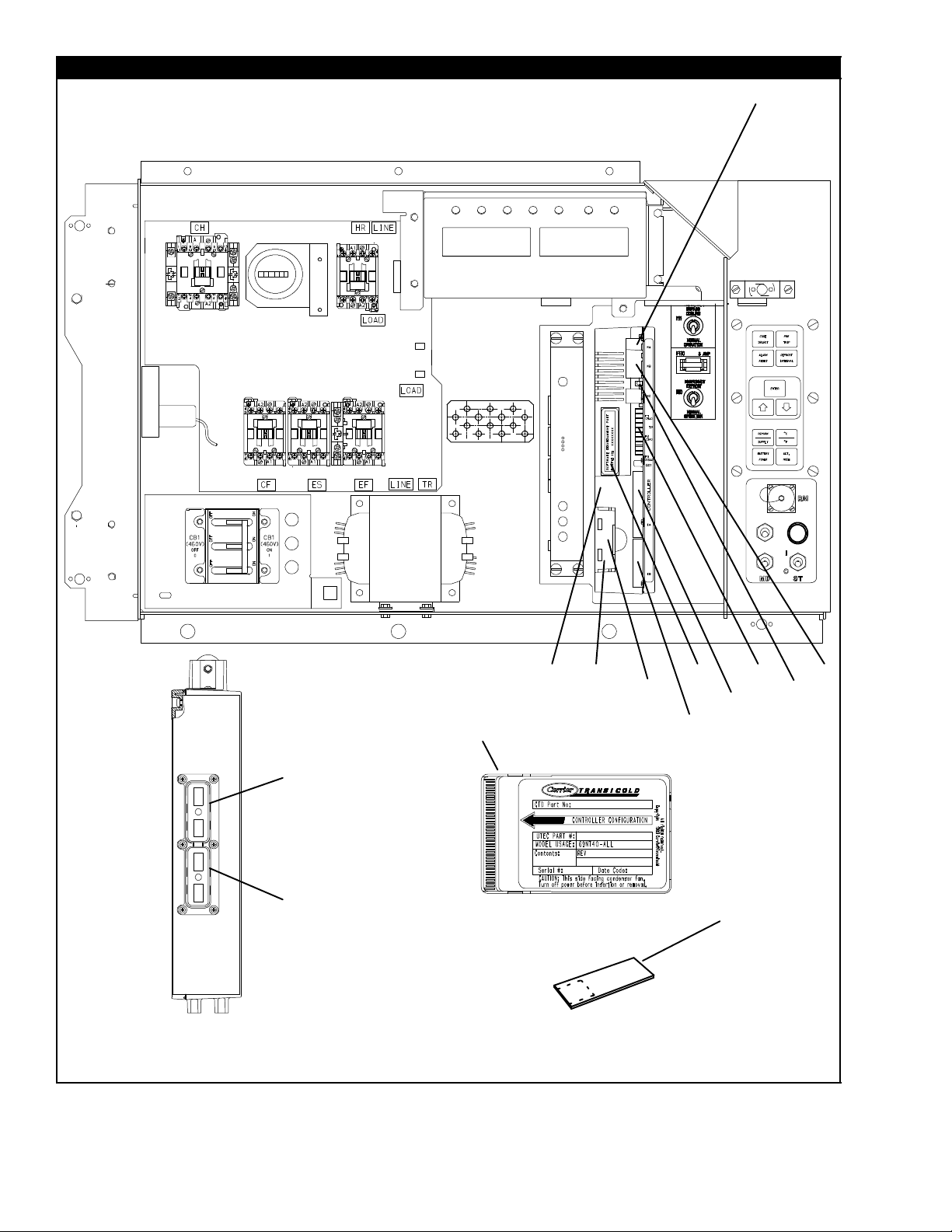

2.8 CONTROL BOX -- CONTROLLER MODULE SECTION AND SOFTWARE CARDS

16

9

10

11

12

13

10

12

View -- Back of Controller/DataCORDER Module

1

21

2

22

3

4

8

20

15

7

14

19

5

6

17

18

14T-305PL

Page 23

2.8 CONTROL BOX -- CONTROLLER MODULE SECTION AND SOFTWARE CARDS (Continued)

Item Part Number Description Qty

1 -- Module, Controller/DataCORDER -- RefertoSection6-- Includes: --

2 66U1--5371--7 Screw, Hex Head, #10--24 X 1/2 Long, SST 1

3 69NT35--2692 Washer, Fender, 0.063 Thick, SST 1

4 58--01184--00 Retainer, Screw, 0.141 ID 1

5 22--02336--04 Fuse, 10 Amp (F3) 3

6 22--02336--02 Fuse, 5 Amp (F1 and F2) 1

7 62--02719--00 Label, Controller/DataCORDER Port 1

8 12--00397- -00/5124 Card, Controller/DataCORDER Operation Software 1

NS 12--00402--xx Card, Configuration Software 1

9 22--01777--00SV Connector (EC A--K) -- 30-- Pin 1

10 22--01777--03 Socket, 20 AWG 35

11 22--50100--00 Socket, 18 AWG 4

12 22--01777--04 Plug, Sealing 21

13 22--01777--01SV Connector (EC L--Y) -- 30--Pin 1

14 22--01556--02 Connector (KA) -- 14--Pin 1

15 22--01556--01 Connector (KB) -- 10--Pin 1

NS 22--01621--23 Connector (KP) -- 9--Pin (Connects to Ribbon Cable) 1

16 22--01622--01 Connector (MA) -- 12--Pin 1

17 22--01622--02 Connector (MB) -- 16--Pin 1

18 22--01622--00 Connector (MC) -- 8--Pin 1

NS 09--00369--00SV Battery, Real Time Clock, (Within the Controller) 1

NS 22--50157--00 Wire Harness, Controller to Current Sensing Transformer) 1

NS 22--01713--06 Wire Harness, Display Module to Controller/DataCORDER Module 1

NS 62--02735--00 Label, Warning, Don’t use 12--00327 ! --(Located on Control Box Behind

the Controller/DataCORDER Module)

NS 62--02738--05 Label, Warning, 5108 Series -- (Located on the Bottom Panel of the Control

Box Between the Transformer and the Communications Interface Module)

19 76--50141--00 PC Card Adapter and Cover (For Use with 12--00594 series ML3 Cards) 1

OPTION R -- RECHARGEABLE BATTERY PACK

20 30--00407--02SV Battery Pack -- Controller/DataCORDER Module 1

OPTION S -- STANDARD CELLS

21 PL Battery (AA) 6

22 30--00407--00 Cover, Controller Battery 1

1

1

15

T-305PL

Page 24

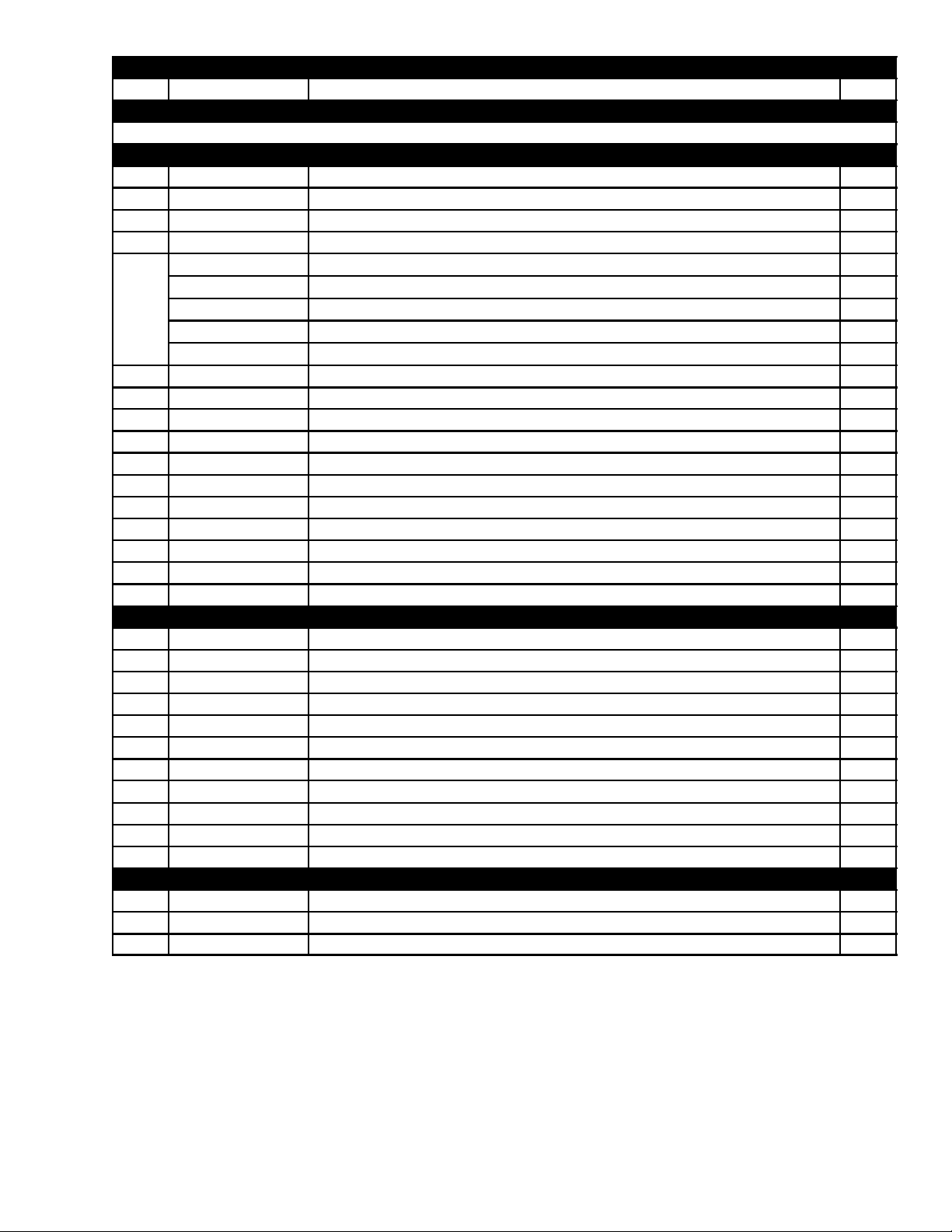

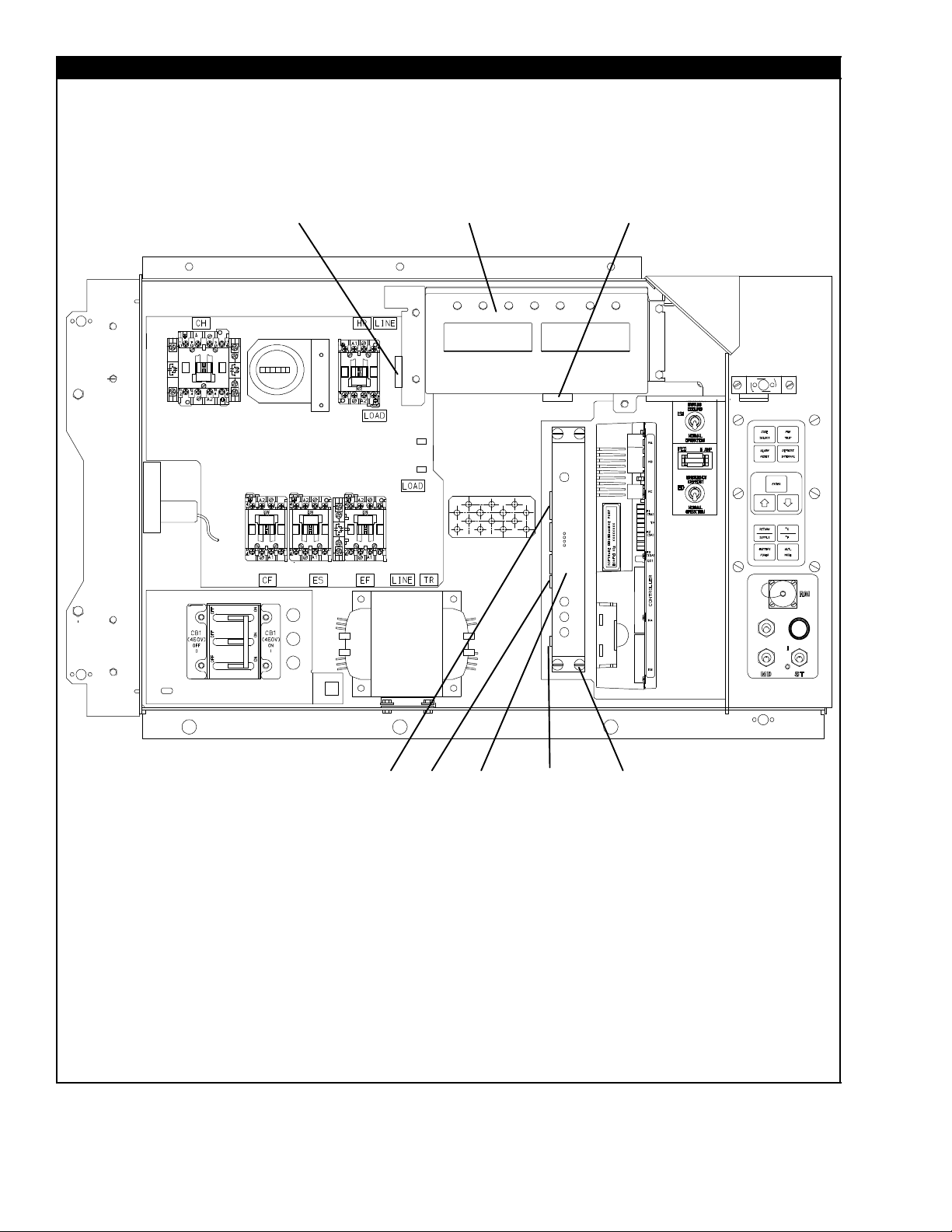

2.9 CONTROL BOX -- DISPLAY MODULE AND COMMUNICATIONS INTERFACE MODULE SECTION

1

45

2

3

6

7

9

10

11

16T-305PL

8

12

13

Page 25

2.9 CONTROL BOX -- DISPLAY MODULE AND COMMUNICATIONS INTERFACE MODULE SECTION

(Continued)

Item Part Number Description Qty

1 12--00433--00RP Module, Display 1

2 66U1--5371--7 Screw, Hex Head, #10--24 X 1/2 Long, SST 4

3 69NT35--2692-- 4 Washer, Fender, 0.063 Thick, SST 4

4 22--01621--03 Connector (MK), 9--Pin 1

5 22--01621--02 Connector (MB), 16--Pin 1

6 22--02396--03 Connector (CIC), 7--Pin 1

7 22--02396--02 Connector (CIB), 3--Pin 1

8 22--01556--00 Connector (CIA), 7--Pin 1

NS 22--01713--02 Wire Harness, Keypad to Display Module 1

OPTION 1 -- COMMUNICATIONS INTERFACE MODULE -- STANDARD

9 12--00573--00SV Module, Communications Interface -- Includes: 1

10 66U1--3442--2 Stud, Fastener, 1/4 Turn, 0.705 Long, SST 4

11 66U1--9212--1 Retainer, Push--on 4

12 34--06223--00 Screw, Captive Washer #10--24 X 0.56, SST 4

13 58--01184--00 Retainer, Screw 0.75 OD 4

OPTION 2 -- COMMUNICATIONS INTERFACE MODULE -- HIGH DATA RATE

9 12--00573--00SV Module, Communications Interface -- Includes: 1

10 66U1--3442--2 Stud, Fastener, 1/4 Turn, 0.705 Long, SST 4

11 66U1--9212--1 Retainer, Push--on 4

12 34--06223--00 Screw, Captive Washer #10--24 X 0.56, SST 4

13 58--01184--00 Retainer, Screw 0.75 OD 4

OPTION 3 -- COMMUNICATIONS I NTERFACE MODULE -- CHIPSET MODEM

9 12--00573--00SV Module, Communications Interface -- Includes: 1

10 66U1--3442--2 Stud, Fastener, 1/4 Turn, 0.705 Long, SST 4

11 66U1--9212--1 Retainer, Push--on 4

12 34--06223--00 Screw, Captive Washer #10--24 X 0.56, SST 4

13 58--01184--00 Retainer, Screw 0.75 OD 4

OPTION 4 -- COMMUNICATIONS INTERFACE MODULE -- LOW DATA RATE

9 12--00275--19SV Module, Communications Interface -- Includes: 1

10 66U1--3442--2 Stud, Fastener, 1/4 Turn, 0.705 Long, SST 4

11 66U1--9212--1 Retainer, Push--on 4

12 34--06223--00 Screw, Captive Washer #10--24 X 0.56, SST 4

13 58--01184--00 Retainer, Screw 0.75 OD 4

17

T-305PL

Page 26

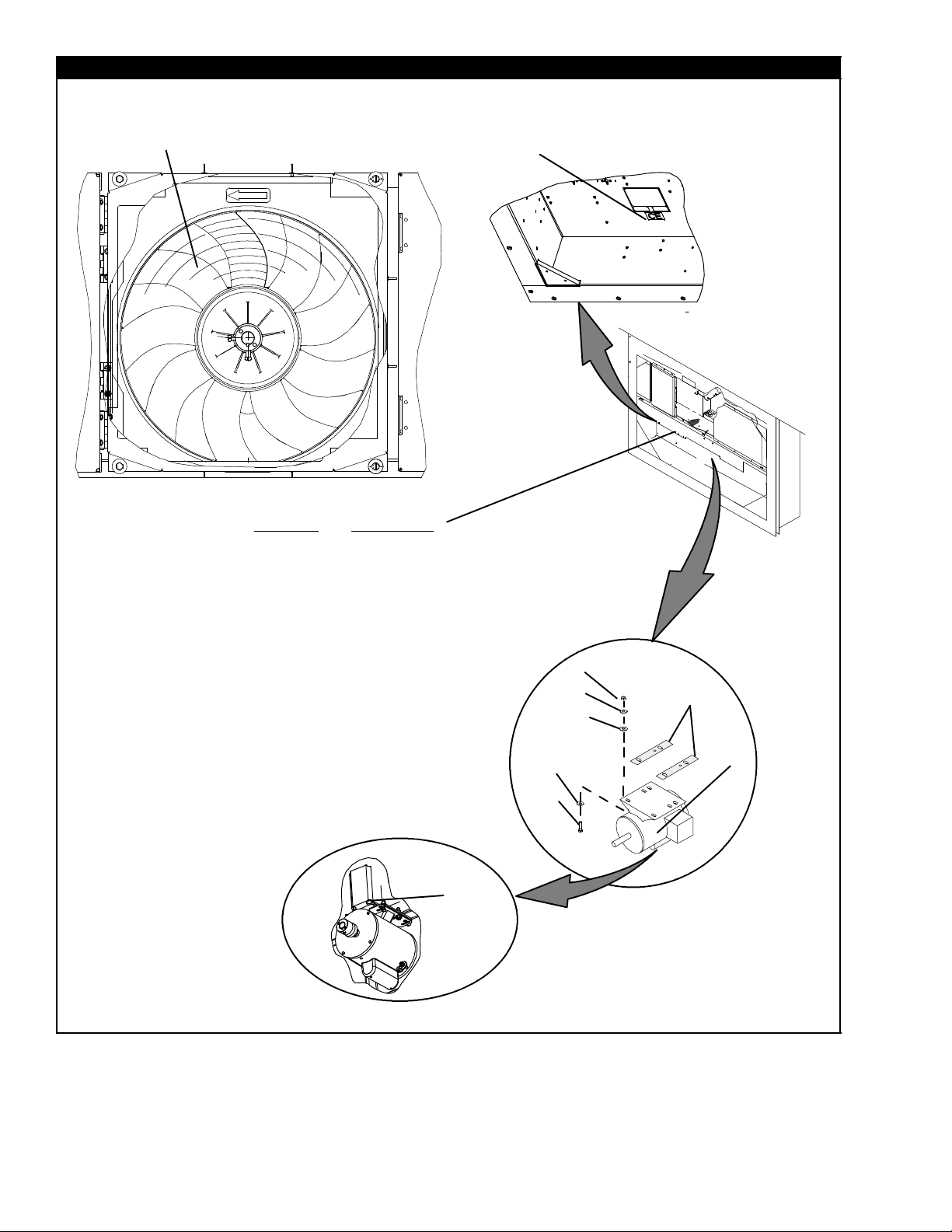

2.10 CONDENSER FAN MOTOR AND COIL

1

Option 3 or Option 2, 4

16

17

18

19

20

21

22

16

17

23

24

25

2

12

13

14

15

11

7

8

9

8

10

3

4

5

6

18T-305PL

Page 27

2.10 CONDENSER FAN MOTOR AND COIL (Continued)

Item Part Number Description Qty

1 38--00585--00 Fan, Condenser 1

2 62--02785--00 Label, CE 1

3 54--00586--20 Motor, Condenser -- Includes: 1

4 04--50029--00 Bearing 2

5 22--01997--05 Pin A/R

6 22--01997--10 Pin, Grounding A/R

7 34--00667--12 Nut, Self--Locking, 5/16--18 4

8 34--01181--01 Washer, Flat 8

9 34--06053--02 Washer, 0.375 ID X 1.000 OD 4

10 69NT35--6112 Protector, Condenser Fan Motor Mounting 2

11 66U1--5361 Screw, Cap HXHD, 5/16--18 X 1.25 4

12 69NT35--3452 Shim 1

13 69NT35--3452--1 Shim 1

14 69NT35--3452--2 Shim 1

15 69NT35--3452--3 Shim 1

OPTION 2 -- TWO ROW CONDENSER COIL

Use Option 4 for 2--Row Coil Replacement

OPTION 3 -- THREE ROW (7MM) CONDENSER COIL

68--13455--00 Cover, Condenser Coil, Blue Includes: 1

16

68--13455--03 Cover, Condenser Coil, White Includes: 1

58--04480--00 Bumper (For Use With Uncoated Center Handles) A/R

17

58--04481--00 Plug (For Use with Coated Handles or Units with no Center Handle) A/R

18 81--01575--00SV Coil, Condenser(Copper), 7MM 3--Row -- Includes Mylar Washers 1

19 66CH1--1172--16 Trim, Flexible 2

20 69NT35--8693--7 Protector (Apply Between Frame and Coil and Coil Cover) 4

21 69NT35--8693--10 Protector (Apply Between Frame and Coil and Coil Cover) 2

22 58--04026--41 Protector,Mylar (Apply Between Coil and Coil Cover, RH and LH Sides) 2

OPTION 4 -- FOUR ROW (3/8”) CONDENSER COIL

68--13201--01 Cover, Condenser Coil, Blue Includes: 1

16

69NT43--148--4 Cover, Condenser Coil, White Includes: 1

58--04480--00 Bumper (For Use with Uncoated Center Handles) A/R

17

58--04481--00 Plug (For Use with Coated Handles or Units with no Center Handle) A/R

23 69NT43--202-- 10SV Coil, Condenser (Copper), 4--Row -- Includes Mylar Washers 1

24 69NT35--8703 Protector (Apply Between Frame and Coil and Coil Cover) 4

25 58--04026--10 Protector,Mylar (Apply Between Coil and Coil Cover, RH and LH Sides) 2

19

T-305PL

Page 28

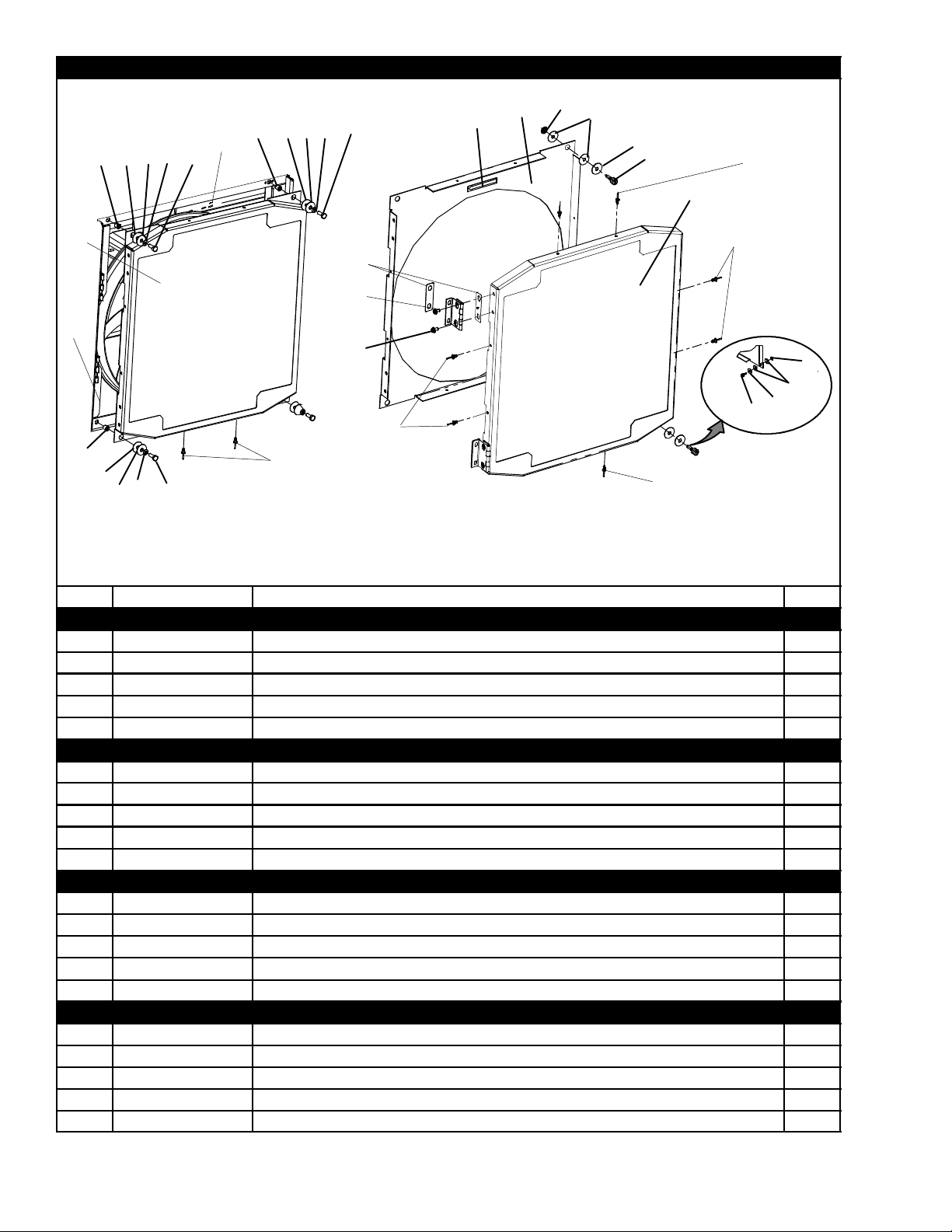

2.11 CONDENSER FAN GRILLE ASSEMBLY

234 51

234 5

1

9

13

16

9

14

15

17

1918 OR

8

7

10

11

6

12

8

1

2

3

BOLTED CONDENSER FAN GRILLE

Item Part Number Description Qty

OPTION B -- BOLTED CONDENSER FAN GRILLE, STANDARD PARTS

1 34--06051--36 Rivnut, 1/4--20 A/R

2 34--06053--03 Washer, 0.250 ID X 1.000 OD A/R

3 69NT35--2692-- 1 Washer, Fender, 1/4 A/R

4 34--00663--11 Washer, Lock, 1/4 Spring A/R

5 66U1--5361--25 Screw, Cap HXHD, 1/4--20 X 0.75 A/R

BLUE PANEL

-- 79--66635--00 Grille and Venturi Assembly, Blue -- Includes: 1

6 68--12635--05 Panel Venturi 1

7 86--04637--00 Grille Assembly 1

8 34--00928--07 Rivet, Blind 8

9 62--11273--00 Label, Rotation 1

WHITE PANEL

-- 79--66635--01 Grille and Venturi Assembly, White -- Includes 1

6 68--12635--22 Panel Venturi 1

7 86--04637--02 Grille Assembly 1

8 34--00928--07 Rivet, Blind 8

9 62--11273--00 Label, Rotation 1

ORANGE PANEL

-- 79--66635--02 Grille and Venturi Assembly, Orange -- Includes 1

6 68--12635--06 Panel Venturi 1

7 86--04637--01 Grille Assembly 1

8 34--00928--07 Rivet, Blind 8

9 62--11273--00 Label, Rotation 1

5

4

OPTION B

8

8

HINGED CONDENSER FAN GRILLE

OPTION H

8

18

OR

13

14

15

19

20T-305PL

Page 29

2.11 CONDENSER FAN GRILLE ASSEMBLY (Continu ed)

Item Part Number Description Qty

OPTION H -- HINGED CONDENSER FAN GRILLE, STANDARD PARTS

8 34--00928--07 Rivet, Blind 8

10 58--04101--07 Protector 4

11 44--00374--00 Hinge 2

12 34--06179--00 Screw, HXHD, Sems #10--24 x 7/16 4

13 34--06169--00 Washer, Retaining, SST 2

14 34--06053--03 Washer, Mylar, 1/4 ID X 1.00 OD 4

15 69NT35--2692--1 Washer, Fender, 1/4, SST 2

BLUE PANEL WITH SLOTTED SCREW

Use Standard Parts with Items Below:

-- 79--66635--03 Grille and Venturi Assembly, Blue, Slotted Screw -- Includes 1

16 68--12635--03 Panel, Venturi 1

17 86--04637--00 Grille Assembly 1

18 66U1--6811--8 Screw, Retaining, SST 2

WHITE PANEL WITH SLOTTED SCREW

Use Standard Parts with Items Below:

-- 79--66635--04 Grille and Venturi Assembly, White, Slotted Screw -- Includes 1

16 68--12635--21 Panel, Venturi 1

17 86--04637--02 Grille Assembly 1

18 66U1--6811--8 Screw, Retaining 2

ORANGE PANEL WITH SLOTTED SCREW

Use Standard Parts with Items Below:

-- 79--66635--05 Grille and Venturi Assembly, Orange, Slotted Screw -- Includes 1

16 68--12635--04 Panel, Venturi 1

17 86--04637--01 Grille Assembly 1

18 66U1--6811--8 Screw, Retaining 2

BLUE PANEL WITH PHILLIPS SCREW

Use Standard Parts with Items Below:

-- 79--66635--06 Grille and Venturi Assembly, Blue, Phillips Screw -- Includes 1

16 68--12635--03 Panel, Venturi 1

17 86--04637--00 Grille Assembly 1

19 66U1--6811--12 Screw, Retaining 2

WHITE PANEL WITH PHILLIPS SCREW

Use Standard Parts with Items Below:

-- 79--66635--07 Grille and Venturi Assembly, White, Phillips Screw -- Includes 1

16 68--12635--21 Panel, Venturi 1

17 86--04637--02 Grille Assembly 1

19 66U1--6811--12 Screw, Retaining 2

ORANGE PANEL WITH PHILLIPS SCREW

Use Standard Parts with Items Below:

-- 79--66635--08 Grille and Venturi Assembly, Orange, Phillips Screw -- Includes 1

16 68--12635--04 Panel, Venturi 1

17 86--04637--01 Grille Assembly 1

19 66U1--6811--12 Screw, Retaining 2

21

T-305PL

Page 30

2.12 COMPRESSOR TUBING

11

14

16

17

22

21

12

14

15

18

14

13

7

14

15

16

17

6

23

8

10

3

20

19

5

1

9

2

4

22T-305PL

Page 31

2.12 COMPRESSOR TUBING (Continued)

Item Part Number Description Qty

1 14--00263--00 Valve, Stepper Motor -- Includes: 1

2 14--00263--20 Piston and Motor Assembly -- Includes: 1

3 22--02392--03 Connector (To Power Pack) 1

NS 22--02393--01 Pin, 18--20 Gauge (Used on 22--02392--03) 4

NS 22--02394--03 Seal (Used on 22--02392--03) 4

4 14--00263--23 O--Ring 1

5 14--00263--22 Cap 1

6 Valve, Service (Discharge) -- See Section 4.3 1

7 14--00204--02 Valve, Discharge Pressure Regulator (DPRV) 1

8 -- Valve, Service (Suction) -- See Section 4.3 1

9 40--00542--00 Elbow, Adapter (R134a) 1

10 40--00520--02 Cap, M8 X 1.00, Nylon 1

11 69NT41--702 Bracket Assembly 1

12 66U1--3632--24 Clamp, Cushion, 1.18 Diameter 1

13 34--00373--11 Clamp, Cushion, 0.88 Diameter 1

14 66U1--5381--1 Screw, Hex Head, #10--24 X 0.75 Long, SST 4

15 34--06053--00 Washer, Mylar, 0.25 ID X 0.80 OD 3

16 66U1--5321--8 Washer , Flat, #10, SST 3

17 34--06053--05 Washer, Mylar, .205 ID X .60 OD 3

18 10--00388--00 Power Pack, Stepper Motor -- Includes: 1

19 22--01585--04 Connector (To Valve) 1

20 22--01836--00 Connector (To Harness) 1

21 81--01482--00 Tubing assembly 1

NS 22--01566--01 Socket (Used on 22--01585--04) 4

NS 22--02393--00 Pin (Used on 22--01830--00) 4

NS 22--02394--02 Seal (Used on 22--01835--00, 22--01585-- 04 and 22--01830--00) A/R

NS 22--01835--00 Connector (On Harness to Drive) 1

NS 22--01566--00 Pin (Used on 22--01835--00) 5

REFRIGERATION TEMPERATURE SENSORS

22 12--01105--02 Sensor, Thermistor (CPDS) 1

23 12--01104--05 Sensor, Thermistor (CPSS) 1

23

T-305PL

Page 32

2.13 RECEIVER

20

27

28

29

25

26

23

24

4

31

5

6

32

1

9

10

11

30

19

20

21

2

3

14

7

20

21

22

8

9

10

11

33

15

16

17

18

34

12

13

24T-305PL

Page 33

2.13 RECEIVER (Continued)

Item Part Number Description Qty

1 69NT43--403-- 2 Receiver, Electro--Coated Modular, Copper -- Includes: 1

2 14--00220--01 Glass, Sight, with Red Balls, 1/2--14 NPT 1

3 14--00221--01 Indicator, Moisture--Liquid 1

14--01032--14 Plug, Fusible, 3/8 NPT, Brass 1

4

14--00215--06 Disc, Rupture, 3/8 NPT, Alternate 1

NS 22--02448--00SV Connector, Female (Located on Wire Harness) 1

5 12--00352--00 Transducer, Condenser Pressure (CPT) 1

6 EC39DM062 Valve, Schrader 1

7 14--00341--02SV Filter--Drier with O--Rings 1

8 69NT43--277 Bracket, Liquid Line Valve 1

9 66U1--5361--25 Screw, Hex Head, 1/4--20 X 3/4 Long, SST A/R

10 66U1--5321--7 Washer, Flat, 1/4, SST 3

11 34--06053--00 Washer, Mylar, 0.25 ID X 0.80 OD 4

12 40--00520--01 Coupling, M15, Brass -- Includes: 1

13 40--00520--03 Cap, Service Port 1

14 14--00221--00 Valve, Liquid Line 1

15 66U1--5361--7 Bolt, Hex Head, 3/8--16 X 1.00 Long, SST 1

16 AU11JR241 Washer, Lock, 3/8, SST 1

17 66U1--5321--5 Washer, Flat, 3/8, SST 1

18 34--06053--02 Washer, Mylar, 0.375 ID X 1.00 OD 1

19 34--00373--05 Clamp, Cushion, 1/2 Diameter 1

20 66U1--5371--6 Screw, Machine, Hex Head, #10--24 X 0.75 Long, SST 3

21 34--06053--05 Washer, Mylar, .205 ID X .60 OD 4

22 34--00373--07 Clamp, Cushion, 5/8 Diameter 1

23 69NT43--420 Bracket Assembly, Quench Valve 1

24 34--00928--09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8--1/4, SST 2

25 66U2--1132--1 Connector 1

26 66U1--3803 Heat Shrink 1

27 34--00373--54 Clamp, Cushion, 0.44 Diameter 1

28 34--06053--03 Washer, Mylar, 0.25 ID X 1.00 OD 1

29 14--00212--03SV Valve, Quench, Thermostatic Expansion -- Includes: 1

NS 14--00212--21 Kit, Repair -- Includes: 1

NS NSS Power Head 1

30 58--04026--23 Protector, Mylar 1

31 12--00495--02SV Sensor, Ambient Thermistor (AMBS) 1

32 DE40BA203 Tee, Reducing 1/2 X 1/2 X 3/8 1

33 -- See Section 5.9 for Sensor Assembly and Related Parts -34 40--00501--50 Cap, Service Valve 1

25

T-305PL

Page 34

2.14 WATER--COOLED CONDENSER

37

38

20

40

12

22

23

24

42

43

44

39

21

41

30

31

27

28

29

25

26

43

44

45

43

44

45

11

1

2

6

19

18

17

3

Item Part Number Description Qty

-- 69NT42--914 Kit, Condenser/Receiver (For Field Installation) -- See NOTE -- Includes: 1

1 69NT42--914-- 1 Condenser/Receiver -- Includes: 1

2 14--00220--00 Sight Glass with Red Balls, 1/2 NPT 1

3 58--00956--00 Protector, Mylar 2

4 58--00957--00 Protector, Mylar 1

5 66U1--2763--5 Coupling (Water--In) 1

6 66U2--1142 Cap, Dust 1

7 40--01129--00 Coupling, Self--Draining -- Includes: 1

7 66U1--2763--6 Coupling Assembly, Socket -- Includes: 1

8 42--50000--00 Seal, O--Ring 1

9 66U2--1152 Cap, Dust (Use with 40--01129--00) 1

10 79--01757--00 Cap Assembly (Use with 66U1--2763--6) 1

11 12--01071--01SV Switch,Water Pressure Option W 1

12 14--00215--05 Disc, Rupture, 3/8 NPT 1

7

8

9

5

14

16

32

33

34

35

36

13

15

4

26T-305PL

Page 35

2.14 WATER--COOLED CONDENSER (Continued)

Item Part Number Description Qty

13 66U1--5361--7 Bolt, Hex Head, 3/8--16 X 1.00 Long, SST 1

14 66U1--5321--5 Washer, Flat, 3/8, SST 1

15 AU11JR241 Washer, Lock, 3/8, SST 1

16 34--06053--02 Washer, Mylar, 3/8 ID X 1.00 OD 1

17 66U1--5361--25 Screw, Cap, Hex Head, 1/4--20 X 3/4 Long, SST 2

18 66U1--5321--7 Washer, Flat, 1/4, SST 2

19 34--06053--00 Washer, Mylar, 1/4 ID X 13/16 OD 2

20 -- See Section 2.15 for Sensor Assembly and Related Parts --

-- 76--00677--00 Accessory Kit, Water--Cooled Condenser Tubing -- Includes: --

21 06DA403--844 Valve, Schrader 1

22 12--00352--00 Transducer, Condenser Pressure (CPT) 1

23 69NT41--477 Tube Assembly -- Includes: 1

24 40--00555--06 Tee, 1/2 X 1/2 X 3/8 NPT , Brass 1

25 14--00341--02SV Filter--Drier with O--Rings 1

26 69NP20--1031 Clamp, Filter--Drier -- Includes: 1

NS 58--50014--00 Gasket (16 Feet, Cut to Length) 1

-- 69NT41--497 Tube Assembly -- Includes: 1

27 66U1--8552--2 Valve, Liquid Line -- Includes: 1

28 40--00086--04 Cap, Flare, 1/4 1

29 17--21002--01 Cap, Valve 1

30 40--00520--01 Coupling, M15, Brass -- Includes: 1

31 40--00520--03 Cap, Service Port 1

32 68--12368--00 Bracket 1

33 66U1--5371--6 Screw, Hex Head, #10--24 X 3/4 Long, SST 2

34 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

35 69NT41--487 Tube Assembly -- Includes: 1

36 14--01092--03 Indicator, Liquid--Moisture, Brass 1

37 69NT43--420 Bracket Assembly 1

38 34--00928--09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8--1/4 2

39 14--00212--03SV Valve, Quench, Thermostatic Expansion -- Includes: 1

NS 14--00212--21 Kit, Repair -- Includes: 1

NS NSS Power Head 1

40 12--00495--02SV Sensor, Ambient Thermistor (AMBS) 1

41 DE40BA203 Tee, Reducing, 1/2 X 1/2 X 3/8 1

42 34--00373--54 Clamp, Cushion, 0.44 Diameter 1

43 34--06053--03 Washer, Mylar, 0.25 ID X 1.00 OD 3

44 66U1--5371--6 Screw, Machine Hex Head, #10--24 X 0.75 Long, SST 3

45 34--00373--07 Clamp, Cushion, 0.62 Diameter 2

NOTE

Must order tubing accessory kit 76--00677--00 when ordering P/N 69NT42--914 for field installation on units

provisioned for a water--cooled condenser.

27

T-305PL

Page 36

2.15 SRS AND STS

2

3

2

3

1

(STS)

1

(SRS)

45

Item Part Number Description Qty

1 12--00395--01SV Sensor Assembly (STS and SRS) 1

2 58--04277--00SV Cap, Probe -- Includes: 2

3 58--04278--00 Grommet NSS 2

4 58--04279--00 Cover, Probe 1

5 58--04276--00 Holder, Probe 1

6 66U1--5321--7 Washer , Flat, 1/4, SST 2

7 66U1--5371--7 Screw, Machine, Hex Head, #10--24 X 0.50 Long, SST 2

28T-305PL

6

7

Page 37

2.16 BACK PANEL ASSEMBLY -- OPTION 4, Aluminum HINGED

10

11

13

10

12

13

9

2

1

2

3

4

5

6

5

Item Part Number Description Qty

1 69NT43--1 16 Grille, Top 1

2 34--00928--09 Rivet, Blind, 5/32 Diameter, Grip Range -- 1/8--1/4 37

3 69NT41--942-- 4 Panel Assembly, Upper -- Includes: 1

NS NSS Drain Pan, Side 2

NS NSS Drain Pan, Center 1

4 42--00334--00 Gasket (Location -- Behind Upper Panel) 1

5 34--00928--02 Rivet, Blind, 1/8 Diameter, Grip Range -- 1/8--3/16 46

6 34--00928--03 Rivet, Blind, 1/8 Diameter, Grip Range -- 3/16--1/9 3

68--13475--00 Panel, Bottom, (Painted) 1

7

68--13475--08 Panel, Bottom, (Unpainted) 1

68--13475--01 Panel, Bottom (Provision for USDA Location), (Painted) 1

8

68--13475--09 Panel, Bottom (Provision for USDA Location), (Unpainted) 1

NS 66U1--8075 Gasket (25--foot, Cut to Length) A/R

9 69NT35--3282 Hinge 4

10 34--01150--30 Washer, Retaining 14

11 34--01150--06 Stud, 1/4 Turn, 1.03 Long 6

12 34--01150--03 Stud, 1/4 Turn, 0.97 Long 8

13 34--01150--31 Receptacle, Retaining 14

5

78

5

6

29

T-305PL

Page 38

2.17 UPPER FRESH AIR MAKE--UP AND ACCESS PANEL

Option 2 or 3

1

6

19

20

21

18

10

7

2

3

5

4

Back of Fresh Air Panel

8

15

14

9

16

17

11

13

12

See Section 5.10

5

4

6

30T-305PL

Page 39

2.17 UPPER FRESH AIR MAKE--UP AND ACCESS P ANEL (Continued)

Item Part Number Description Qty

OPTION 2 EVAPORATOR FAN ACCESS PANEL -- WITH FRESH AIR MAKEUP

79--01694--00 Panel, Fresh Air Make-- up with Retaining Washers -- Includes: A/R

1

79--01695--00 Panel with Fresh Air Makeup -- Includes: 1

2 42--00296--01 Gasket 1

3 42--00327--00 Gasket, -- 0.26 X 0.50 Half--Round 1

4 34--00662--1 1 Washer, Flat, 1/4, SST 8

5 34--06053--00 Washer, Mylar, 1/4 ID X 0.80 OD 8

6 34--06154--00 Screw, Hex Head, 1/4--20 X 1.00 Long -- TIR 8

7 66U1--2552--185 Gasket, 0.75 X 1.5 X 16.63 1

8 -- Label, Fresh Air (See Section 2.26 for Language Selection) 1

9 62--02783--00 Label, Fresh Air 1

OPTION 3 WITH FRESH AIR MAKEUP AND SCREENS -- USE ALL OF OPTION 2 AND ITEM BELOW

10 58--04251--00 Screen, Medfly 2

HEATER ACCESS PANEL

11 79--01697--07SV Panel, Access -- Includes: 1

12 42--00296--00 Gasket 1

13 66U1--8115 Gasket, Access Panel 1

5 34--00662--1 1 Washer, Flat, 1/4, SST 8

6 34--06053--00 Washer, Mylar, 1/4 ID X 0.80 OD 8

7 34--06154--00 Screw, Hex Head, 1/4--20 X 1.00 Long -- TIR 8

STUD ASSEMBLY KITS (REPLACEMENT)

14 74--00201--01 Kit, Gasket and Stud Assembly (See NOTE 2) -- Includes: 1

15 42--00407--00 Gasket (One Piece) 1

16 74--00201--02 Kit, Disc and Stud Assembly (See NOTE 1) -- Includes: 1

17 NSS Stud Assembly, 5/16--18 1

18 34--06185--01 Screw, Machine Pan Head, #8--32 X 1/2 Long, SST 1

19 34--06053--19 Washer, Mylar, 1.00 OD X 0.312 ID 1

20 66U1--5321--13 Washer, Flat, 5/16, SST 1

21 66U1--5362--2 Nut, Wing, 5/16--18, SST 1

NOTES

1. Disc and stud assembly kit, which will modify stud to 5/16- -18, also includes new disc and gasket.

2. Must order 74- -00201- -01 stud assembly kit, which will modify stud to 5/16- -18 and include 42--00407- -01

(one- -piece) gasket.

31

T-305PL

Page 40

2.18 EVAPORATOR FAN ASSEMBLY

EFM -- 2 (Location)

EFM-- 1 (Location)

12

11

4

3

2

1

2

3

4

5

7

8

9

6

10

32T-305PL

Page 41

2.18 EVAPORATOR FAN ASSEMBLY (Continued)

Item Part Number Description Qty

1 69NT40--476 Mounting Bracket, Evaporator Fan Assembly 4

2 66U1--5321--5 Washer , Flat, 3/8, SST 24

3 AU11JR241 Washer, Lock, 1/4, SST 24

4 66U1--5361--7 Bolt, Hex Head, 3/8--16 X 1.00 Long, SST 24

5 54--00513--00SV Motor, Evaporator Fan (Two Speed) -- Includes: 2

6 PL Key, 3/16 Square X 1--38 Long, SST 1

NS 54--00122--21 Bearing 2

NS 22--50087--00 Capacitor 1

NS 54--50044--00 Relay, Motor 1

NS 54--00521--22 Capacitor, Low Speed, 5 mF -- used ONL Y with 54--00513--00/74899 1

NS 22--50087--00 Capacitor, Low Speed, 15 mF-- used ONLY with 54--00513--00/51820 1

NS 22--50088--00 Capacitor (20 μF) High Speed (Microfarads) 1

7 34--01181--01 Washer, Flat, 5/16, SST 16

8 34--00792--10 Screw, Cap, Hex Head, 5/16--18 X 1--1/4 Long, SST 8

9 34--00667--12 Locknut, 5/16--18, SST 8

10 38--00126--00 Fan, Evaporator (EFM--1) -- Includes: 1

NS PL Setscrews, 5/16--24 X 5/8 Long, SST 2

10 38--00125--00 Fan, Evaporator (EFM--2) -- Includes: 1

NS PL Setscrews, 5/16--24 X 5/8 Long, SST 2

69NT35--1662 Shim, .063 Thick (If Required) 2

11

69NT35--1662--1 Shim, .090 Thick (If Required) 2

12 69NT35--1173 Bracket, Motor Mount 2

33

T-305PLChange

Page 42

2.19 EVAPORATOR COIL -- REAR PANELS REMOVED

(RRS and RTS)

1

20

21

22

23

2

3

8

9

6

7

8

17

10

11

18

5

6

3

4

16

15

12

13

14

19

34T-305PL

Page 43

2.19 EVAPORA T OR COIL -- REAR PANELS REMOVED (Continued)

Item Part Number Description Qty

1 12--00500--01SV Sensor Assembly (RRS and RTS) 1

2 12--00495--20SV Sensor, Thermistor, Defrost (DTS) 1

3 34--01178--22 Screw, Hex Head, #8--32 X 1/2 Long, SST (For Mounting DTS) 3

4 66U1--6912--16 Thermostat, Heat Termination (HTT) 1

5 AA06JA166 Screw, Cap, Hex Head, 1/4--20 X 1/2 Long 1

6 AU11JR171 Washer, Lock, 1/4, SST 10

7 66U1--5361--25 Screw, Cap, Hex Head, 1/4--20 X 3/4 Long, SST 9

8 69NT35--2692-- 1 Washer, Fender, 1/4, SST A/R

9 34--00655--10 Screw, Cap, Hex Head, 1/4--20 X 1--1/4 Long, SST 4

10 24--00006--02 Heater, Evaporator Coil 4

11 24--00003--00 Heater, Drain Pan 1

NS 66U1--3803--1 Tube, Heat Shrink, 1/2 X 2--3/4 Long A/R

12 -- USDA Option -- RefertoSection2.20 --

NS 69NT35--6522 Retainer (For Heaters) 3

13 56--07905--00 Tubing 1

14 69NT35--9674--1 Tubing 1

15 69NT35--4027--1 Tubing 1

16 56--07323--00 Tubing 1

OPTION 2 -- NEW COIL WITH HERMETIC TXV and STANDARD HEAT EXCHANGER

17 81--01549--00 Coil, Evaporator 1

18 14--00273--03 Valve, Thermostatic Expansion, Hermetic 1

19 65--00144--00 Exchanger, Heat 1

OPTION 3 -- NEW COIL WITH HERMETIC TXV and LARGE HEAT EXCHANGER

17 81--01549--00 Coil, Evaporator 1

18 14--00273--01 Valve, Thermostatic Expansion, Hermetic 1

19 65--00144--01 Exchanger, Heat 1

DEHUMIDIFICATION

-- 76--00675--01 Kit, Humidity Sensor (Field installation, Units Provisioned for -- Refer

to Container Unit Matrix) -- Includes:

20 10--00413--00 Sensor, Humidity (HS) 1

21 66U1--5371--10 Screw, Hex Head, #10--24 X 1.00 Long, SST 4

22 66U1--5321--8 Washer, Flat, #10, SST 2

23 68--13181--00 Bracket Assembly, Humidity Sensor 1

--

35

T-305PL

Page 44

2.20 USDA OPTION

1

2

4

6

3

5

6

Option -- D Option -- V

36T-305PL

1

2

4

6

7

8

9

Page 45

2.20 USDA OPTION (Continued)

Item Part Number Description Qty

OPTION D -- CONNECTOR

-- 76--00684--00 Kit, USDA (For field installation, units provisioned for rear--mounted

USDA -- See T--300) -- Includes:

-- 76--00760--00 Kit, USDA (For field installation, units provisioned for side--mounted

USDA -- See T--300) -- Includes:

1 22--00397--12 Plug, Sealing 4

2 22--01660--00 Receptacle (PR1, PR2, PR3, Cargo Probe 4) (3--Pin) 4

3 22--01660--03 Receptacle, Interrogator (ICR) (5--Pin) 1

NS 69NT41--992 Plate Assembly, USDA -- Includes: 1

4 69NT43--175 Cap, Dust, with Tether (3--Pin) 4

5 69NT43--176 Cap, Dust, with Chain (5--Pin) 1

6 22--01613--14 Contact, Pin, #16 (Used with 22--01660--00 and 22--01660--03) 13

NS 69NT40--507--1 Door Assembly (Included and Used with REAR-- Mount USDA only) 1

NS 22--01660--04 Plug, Interrogator Socket (ICR) (5--Pin) 1

OPTION V -- CONNECTOR

7 22--02412--00 Receptacle, Interrogator (5--Pin) 1

8 22--02413--00 Cap, Dust, with Tether (5--Pin) 1

22--02398--02 Socket, Contact (Silver Plated) A/R

9

22--02398--03 Socket, Contact (Gold Plated) A/R

USDA PROBE KITS

12--00342--03 Sensor Assembly, 15M Long (USDA Probe) -- Includes: A/R

12--00342--02 Sensor Assembly, 13.5M Long (USDA Probe) -- Includes: A/R

NS

12--00342--04 Sensor Assembly 15M Long(USDA Probe) -- Includes: A/R

NS 22--50127--00 Plug, Socket (PR1, PR2, PR3, Cargo Probe 4) 1

NS 22--01613--15 Contact, Socket, #16 (Used with 22--50127-- 00 and 22--01660--04) A/R

NOTE

Do not mix silver pins with gold pins and sockets.

--

--

37

T-305PL

Page 46

2.21 COMPRESSOR MOUNTING, GUARD, CRANKCASE AND DRAIN LINE HEATER COMPONENTS

6

See Section 2.22 for Gauge Components

26

32

27

7

28

29

25

30

31

33

34

35

Option C -- Compressor Crankcase Heater

1

8

12

9

10

13

11

14

17

15

16

Compressor Foot -- Section View

20

18

19

20

21

21

22

23 24

3

4

5

Guards -- Bottom Left Corner of Unit

2

Option L -- Drain Line Heater

OPTION L -- DRAIN LINE HEATER

Item Part Number Description Qty

1 22--01959--01 Hose Assembly 1

2 68--12960--00 Bracket, Drain 1

3 66U1--5371--6 Screw, Hex Head, #10--24 X 3/4 Long, SST 2

4 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

5 66U1--5321--8 Washer , Flat, 7/16, SST 2

38T-305PL

Page 47

2.21 COMPRESSOR MOUNTING, GUARD, CRANKCASE AND DRAIN LINE HEATER COMPONENTS

Item Part Number Description Qty

OPTION B -- CRANKCASE HEATER AND DRAIN LINE HEA TER

Use Option C and Option L for Both Crankcase Heater and Drain Line Heater

6 -- Compressor -- RefertoSection4 --

7 69NT35--6132 Protector (Compressor to Compressor Base) 1

8 AU11JR241 Washer, Lock, 3/8, SST 2

9 AA06JA232 Screw, Cap, Hex Head, 3/8--16 X 1--1/4 Long, SST 2

10 34--00829--13 Washer, Flat, 3/8, SST 2

11 34--06053--02 Washer, Mylar, 0.375 ID X 1.00 OD 2

12 69NT43--469 Base, Compressor 1

NS 66U1--5361--7 Bolt, Hex Head, 3/8--16 X 1.00 Long, SST 7

NS 66U1--5321--5 Washer, Flat, 3/8, SST 7

NS AU11JR241 Washer, Lock, 3/8, SST 7

NS 34--06053--02 Washer, Mylar, 0.375 ID X 1.00 OD 7

13 34--00849--22 Screw, Cap, 7/16--14 X 2--3/4 Long, SST 2

14 34--00667--14 Locknut, 7/16-- 14, SST 2

15 66U1--5321--8 Washer, Flat, 7/16, SST 4

16 34--06053--07 Washer, Mylar, 0.438 ID X 0.922 OD 2

17 34--06053--01 Washer, Mylar, 0.438 ID X 1.125 OD 2

68--12993--00 Panel, Guard 1

18

68--12523--00 Panel, Guard -- Large 1

19 66U1--5361--25 Screw, Hex Head, 1/4--20 X 3/4 Long, SST 1

20 66U1--5321--7 Washer, Flat, 1/4, SST 9

21 34--06053--00 Washer, Mylar, 1/4 ID X 3/4 OD 9

22 66U1--5361--11 Screw, Cap, Hex Head, 1/4--20 X 1--1/2 Long, SST 4

23 34--00667--11 Locknut, 1/4-- 20, SST 4

68--12432--00 Guard, Compressor, 0.125 Thick Aluminum (Blue) 1

68--12432--01 Guard, Compressor, 0.090 Thick Aluminum (Blue) 1

24

68--12432--02 Guard, Compressor, 0.090 Thick Aluminum (White) 1

68--12432--03 Guard, Compressor, 0.125 Thick Aluminum, for Right Extended Guard

(Blue)

OPTION C -- CRANKCASE HEATER ( for PID NT--0850 and Up Only) See Note 1

-- 76--00766--00 Crankcase Heater Installation Kit -- Includes: 1

25 24--02019--02 Heater, Compressor Crankcase (CCH) NSS 1

26 69NT--34--8248 Bracket, Heater NSS 1

27 44--00370--03 Clamp, Tube,Cushioned, 1/2 Diameter, SST 1

28 34--06053--03 Washer, Mylar, 1/4 ID X 1.00 OD 1

29 66U1--5371--6 Screw, Machine Hex Head, #10--24 X 0.75 Long, SST 1

30 58--04316--00 Wire Tie Base 1

31 66U1--3882 Wire Tie 1

NS 66U1--3803 Heat Shrink Tubing 3

NS 22--01292--00 Butt Splice 3

NS 22--00121--27 Terminal, Ring 1

NS 02--00010--01 Thermo Grease 1

32 34--00655--08 Screw, Hex Head, 1/4--20 X 1.00 Long, SST 2

33 34--06053--00 Washer, Mylar, 0.25 ID X 0.75 OD 4

34 34--00662--11 Washer, Flat, 1/4 X 0.05 Thick 4

35 34--00667--11 Locknut, 1/4-- 20 2

1

Note: Contact your local service representative for crankcase heater applications previous to PID number

NT--0850NKCA

39

T-305PL

Page 48

2.22 COMPRESSOR GAUGES AND TRANSDUCERS

10

11

6

1

2

3

4

5

OR

Option G

See Section 2.21 for Crankcase Heater

and Mounting Components

8

Option SG

16

17

18

19

23

21

7

Option G -- Center Cylinder Head View

with Both Gauges

Option -- Center Cylinder Head View

without Gauges

25

6

24

9

20

Option SG -- Center Cyl inder Head View

with Suction Gauge Only

15

13

12

14

Option T -- Center Cylinder Head View

with Pressure Transducers

13

12

22

40T-305PL

Page 49

2.22 COMPRESSOR GAUGES AND TRANSDUCERS (Continued)

Item Part Number Description Qty

OPTION G -- PRESSURE GAUGES

1 69NT41--106-- 2 Stiffener Assembly 1

NS 66U1--5321--8 Washer, Flat, #10, SST 2

NS 66U1--5371--6 Screw, Hex Head, #10--24 X 3/4 Long, SST 2

NS 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

2 68--13472--03SV Bracket Assembly, Gauge 1

3 12--01124--02 Gauge, Suction Pressure 1

4 12--01125--02 Gauge, Discharge Pressure 1

5 66U1--6651--19 Screw, Pan Head, #6--32 X 7/16 Long, SST 6

6 06DA403--844 Valve Assembly, Core, Check (Schrader Valve), Brass 2

7 12--00309--06 Switch, High Pressure (HPS) 1

NS 22--02392--00SV Connector, Female, 2--Pin, Used with 12--00309--03 (Includes Terminals

and Cable Seal)

8 69NT41--553 Tube Assembly, Low Pressure 1

9 69NT41--543 Tube Assembly, High Pressure 1

10 CA21JA051 Tee, 1/4 NPT 1

11 40--00060--02 Elbow, 90 Street, 1/4 FPT X 1/4 MPT, Brass 1

OPTION T -- PRESSURE TRANSDUCERS

12 12--00352--00 Transducer, Pressure 2

13 06DA403--844 Valve Assembly, Core, Check (Schrader Valve), Brass 2

14 12--00309--06 Switch, High Pressure (HPS) 1

NS 22--02392--00SV Connector, Female, 2--Pin, Used with 12--00309--03 (Includes Terminals

and Cable Seal)

15 40--00060--02 Elbow, 90 Street, 1/4 FPT X 1/4 MPT, Brass 1

OPTION SG -- SUCTION PRESSURE GAUGE ONLY

16 69NT41--106--2 Stiffener Assembly 1

NS 66U1--5321--8 Washer, Flat, #10, SST 2

NS 66U1--5371--6 Screw, Hex Head, #10--24 X 3/4 Long, SST 2

NS 34--06053--05 Washer, Mylar, 0.205 ID X 0.600 OD 2

17 68--13472--01 Bracket Assembly, Gauge 1

18 12--01124--01 Gauge, Suction Pressure 1

19 66U1--6651--19 Screw, Pan Head, #6--32 X 7/16 Long, SST 3

20 12--00309--06 Switch, High Pressure (HPS) 1

NS 22--02392--00SV Connector, Female, 2--Pin, Used with 12--00309--03 (Includes Terminals

and Cable Seal)

21 06DA403--844 Valve Assembly, Core, Check (Schrader Valve), Brass 2

22 69NT41--553 Tube Assembly, Low Pressure 1

23 40--00060--02 Elbow, 90 Street, 1/4 FPT X 1/4 MPT, Brass 1

OPTION -- NO GAUGES

24 40--00123--02 Plug, Pipe, 1/4--18 NPTF, Brass 1

25 12--00309--06 Switch, High Pressure (HPS) 1

NS 22--02392--00SV Connector, Female, 2--Pin, Used with 12--00309--03 (Includes Terminals

and Cable Seal)

1

1

1

1

41

T-305PL

Page 50

2.23 CABLE RESTRAINT COMPONENTS

2

2

3

4

5

1

6

3

4

8

9

10

19

13

14

15

16

17

18

7

8

9

10

11

12

29

30

31

32

33

Option 1 -- Cable Door

20

21

22

23

Options 2, 4, 5 and 6 -- Left

Side Bungy Cord

25

26

27

28

Option 3 -- J --Hook

24

Options 4 and 6 -- Right

Side Bungy Cord

35

36

37

38

Option 6 -- Right Side

Extended Guard

34

35

36

37

Options 5 and 6 -- Left Side Extended Guard

42T-305PL

Page 51

2.23 CABLE RESTRAINT COMPONENTS (Continued)

Item Part Number Description Qty

OPTION 1 -- CABLE DOOR

1 69NT41--724-- 4 Cover Assembly with Latch, Cable Storage -- Includes: 1

2 34--06126--08 Screw, Hex Head, #4--40 X 1/2 Long, SST 2

3 34--00662--05 Washer, Flat, #4 --SST 4

4 34--00667--05 Locknut, Hex Head, #4--40 2

5 34--06053--08 Washer, Mylar, 1/8 ID X 3/8 OD 2

6 44--00340--03 Latch 1

7 69NT35--8032 Hinge 2

8 66U1--2403 Screw, Truss Head, #10--24 X 1/2 Long, SST 4

9 66U1--5321--8 Washer, Flat, #10 4

10 34--00667--09 Locknut, Hex Head, #10--24, SST 4

11 34--06053--05 Washer, Mylar, 3/16 ID X 5/8 OD 4

12 58--04001--02 Protector, Mylar 2

13 58--04001--01 Protector, Mylar 1

14 34--06053--05 Washer, Mylar, 3/16 ID X 5/8 OD 2

15 34--01167--01 Retainer, Nut 1

16 66U1--2403 Screw, Truss Head, #10--24 X 1/2 Long, SST 2

17 66U1--5321--8 Washer, Flat, #10, SST 2

18 66U1--5331--3 Washer, Lock, #10, SST 4

19 44--00340--05 Latch, Catch 1

OPTION 2 -- LEFT BUNGY CORD ONLY

20 69NT35--5992 Cable Restraint 1

21 66U1--5321--7 Washer, Flat, 1/4, SST 2

22 66U1--5361--25 Screw, Cap, Hex, Head, 1/4--20 X 0.75 Long, SST 2

23 34--06053--03 Washer, Mylar, 0.25 ID X 1.00 OD 2

24 66U1--2603 Strap, Tie Down 1

OPTION 3 -- J--HOOK

25 69NT35--8382 Cable Restraint, J--Hook 1

26 58--04026--22 Protector, Mylar 1

27 66U1--5321--7 Washer, Flat, 1/4, SST 2

28 66U1--5361--25 Screw, Cap, Hex, Head, 1/4--20 X 0.75 Long, SST 2

OPTION 4 -- LEFT AND RIGHT BUNGY CORD

Use Option 2 Plus the Items Below

29 66U1--2603 Strap, Tie Down 1

30 69NT35--5992 Cable Restraint 1

31 66U1--5361--25 Screw, Cap, Hex, Head, 1/4--20 X 0.75 Long, SST 2

32 66U1--5321--7 Washer, Flat, 1/4, SST 2

33 34--06053--03 Washer, Mylar, 0.25 ID X 1.00 OD 2

OPTION 5 -- LEFT BUNGY CORD WITH LEFT EXTENDED GUARD

Use Option 2 Plus the Items Below

34 68--13310--00 Bracket, Left 1

35 66U1--2403 Screw, Truss Head, #10--24 X 1/2 Long, SST A/R

36 66U1--5321--8 Washer, Flat, #10, SST A/R

37 34--06053--05 Washer, Mylar, 3/16 ID X 5/8 OD A/R

OPTION 6 -- LEFT AND RIGHT BUNGY CORD WITH EXTENDED GUARDS

UseOption4and5PlustheItemsBelow

38 68--13310--01 Bracket, Right 1

43

T-305PL

Page 52

2.24 VOLTAGE CABLES

13

Item Part Number Description Qty

CLAMPS ON BACK WALL AND CABLE CUTTERS

34--00373--56 Clamp, Tube, Cushioned, 9/16 Diameter (Used with Transicord) A/R

1

34--00373--59 Clamp, Tube, Cushioned, 3/4 Diameter A/R

2 66U1--5381--1 Screw, Hex Head, #10--24 X 3/4 Long, SST A/R

3 34--06053--03 Washer, Mylar, 1/4 ID X 1.00 OD A/R

69NT35--6412--2 Clamp, Cable Cutter, 8 AWG cable 1

69NT35--6412 Clamp, Cable Cutter, 10 AWG cable 1

4

69NT35--6412--1 Clamp, Cable Cutter, 1 1 AWG cable 1

5 58--04026--07 Protector, Mylar A/R

6 66U1--5361--11 Screw, Machined Hex Head, 1/4--20 X 1--1/2 Long, SST A/R

7 34--00667--11 Locknut, Hex Head, 1/4--20, SST A/R

8 66U1--5321--7 Washer , Flat, 1/4, SST A/R

9 34--06053--03 Washer, Mylar, 0.25 ID X 1.00 OD A/R

STANDARD PARTS FOR ALL 460V CABLES

10 66U1--2583 Heat Shrink Tube (Coil Label) -- 460V 1

22--02324--01 Bushing (Used with Standard Cable) 4

11

22--02324--05 Bushing (Used with Transicord) 4

OPTION 1 -- STANDARD CABLE (10/4 Yellow SO) with Mennekes (3 Wire 4 Pole)

12 66U1--9782 Cable, Power -- Yellow, 10/4 (460 VAC) A/R

13 22--02378--00 Plug, Power -- Mennekes (460 VAC) 1

OPTION 2 -- TRANSICORD CABLE (11/4 Yellow) with Mennekes (3 Wire 4 Pole)

12 22- -01551--00 Cable, Power -- Yellow, 33 amp, 11 AWG (460 VAC) A/R

13 22--02378--00 Plug, Power -- Mennekes (460 VAC) 1

OPTION 3 -- STANDARD CABLE (10/4 Yellow SO) with Mipco

12 66U1--9782 Cable, Power -- Yellow, 10/4 (460 VAC) A/R

13 22--01731--00 Plug, Power -- Mipco (460 VAC) 1

OPTION 4 -- TRANSICORD CABLE (11/4 Yellow) with Mipco

12 22- -01551--00 Cable, Power -- Yellow, 33 amp, 11 AWG (460 VAC) A/R

13 22--01891--00 Plug, Power -- Mipco (460 VAC) 1

11

10

12

4

5

6

7

8

9

460V CABLES

1

2

3

44T-305PL

Page 53

2.24 VOLTAGE CABLES (Continued)

Item Part Number Description Qty

OPTION 5 -- TRANSICORD CABLE (11/4 Yellow) with KITAZAW A

12 22- -01551--00 Cable, Power -- Yellow, 33 amp, 11 AWG (460 VAC) A/R

13 22--01883--00 Plug, Power -- Kitazawa (460 VAC) 1

OPTION 6 -- TRANSICORD CABLE (11/4 Yellow) with DONG JOO

12 22- -01551--00 Cable, Power -- Yellow, 33 amp, 11 AWG (460 VAC) A/R

13 22--01891--00 Plug, Power -- Dong Joo (460 VAC) 1

OPTION 7 -- STANDARD CABLE (10/4 Yellow SO) with DONG JOO

12 66U1--9782 Cable, Power -- Yellow, 10/4 (460 VAC) A/R

13 22--01891--01 Plug, Power -- Dong Joo (460 VAC) 1

OPTION 8 -- STANDARD CABLE (10/4 Yellow SO) with KOKASHA

12 66U1--9782 Cable, Power -- Yellow, 10/4 (460 VAC) A/R