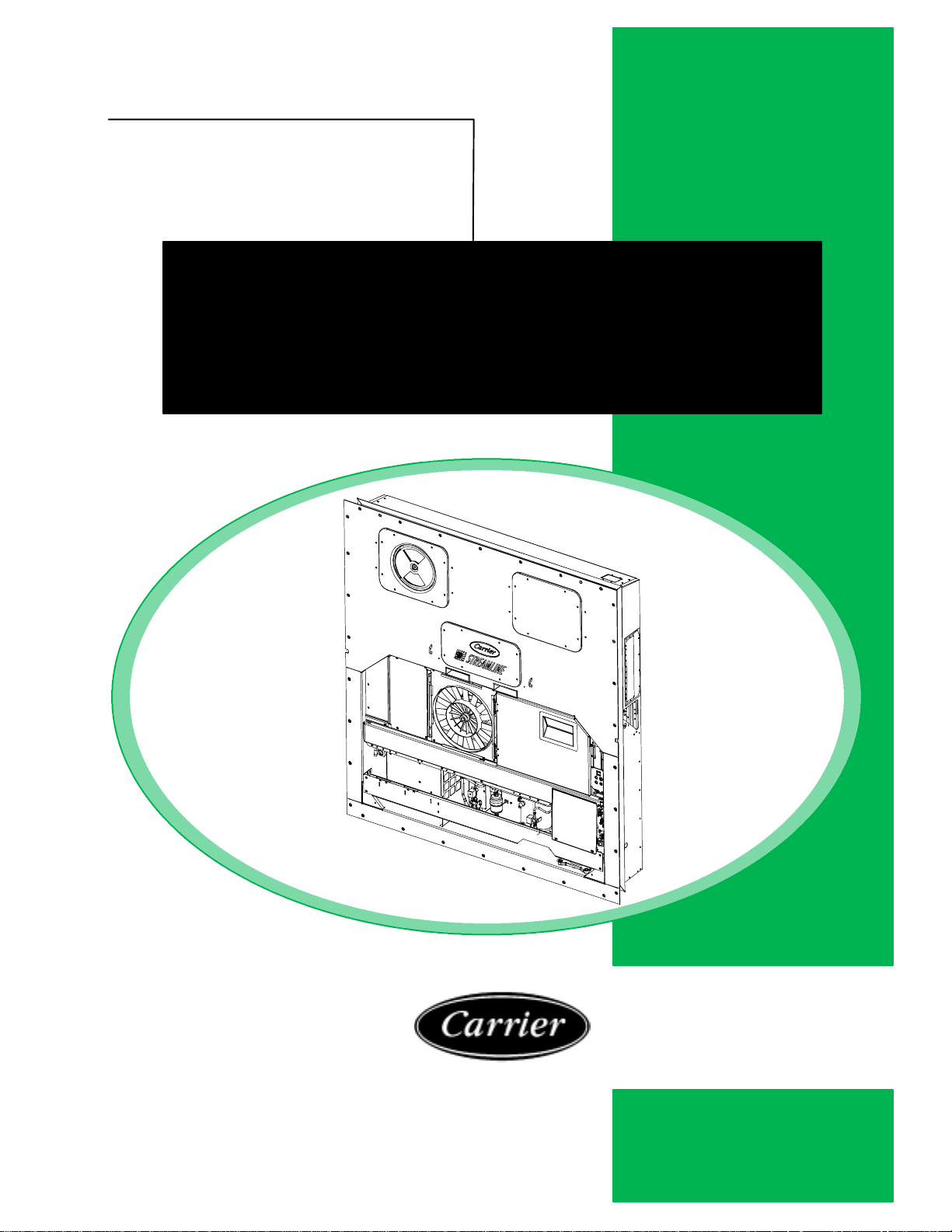

Page 1

Carrier

Transicold

Container

Refrigeration

Model 69NT20-531-300

Streamline Scroll

T-309 Rev A

Operation

&Service

Page 2

OPERATION AND SERVICE MANUAL

CONTAINER REFRIGERATION UNIT

MODEL

69NT20-531-300

Streamline Scroll

Carrier Transicold. A member of the United Technologies Corporation family. Stock symbol UTX.

Carrier Transicold Divsion, Carrier Corporation, P .O. Box 4805, Syracuse, N.Y. 13221 U. S. A.

ã 2002 CarrierCorporation D Printed in U. S. A. 07/02

Page 3

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommendedprecautions that must be understood and applied during operationand maintenance

oftheequipmentcoveredherein.Thegeneralsafetynoticesarepresentedin thefollowingthreesectionslabeled:First

Aid, OperatingPrecautions and MaintenancePrecautions. A listing of thespecific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

Aninjury,nomatterhowslight,shouldnevergounattended.Alwaysobtainfirstaidormedicalattentionimmediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

Noworkshouldbeperformedontheunituntilallcircuitbreakers,start-stopswitchesareturnedoff,andpowersupply

is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the condenser fan grille or

evaporator access panels before turning power off, disconnecting and securing the power plug.

Besurepoweristurnedoffbeforeworkingonmotors,controllers,solenoidvalvesandelectricalcontrolswitches.Tag

circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires. Problems

with the system should be diagnosed, and any necessary repairs performed, by qualified service personnel.

Whenperforminganyarcweldingontheunitorcontainer,disconnectallwireharnessconnectorsfromthemodulesin

both control boxes. Do not remove wire harness from the modules unless you aregrounded to the unit frame with a

static safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO

(never use water).

2

UNIT LABEL IDENTIFICATION

Tohelp identify the label hazards on the unit and explain the level of awareness each one carries, an explanation is

given with the appropriate consequences:

DANGER -- means an immediate hazard which WILL result in severe personal injury or death.

WARNING -- means to warn against hazards or unsafe conditions which COULD result in severe personal injury or

death.

CAUTION -- meansto warnagainst potential hazard or unsafe practicewhich could result in minor personal injury,

product or property damage.

SPECIFIC WARNING AND CAUTION STATEMENTS

The statements listed below are applicable to the refrigeration unit and appear elsewhere in t his manual. These

recommended precautions must be understood and applied during operation and maintenance of the equipment

covered herein.

WARNING

Beware of unannounced starting of the evaporator and condenser fans. The unit may cycle the fans

and compressor unexpectedly as control requirements dictate.

WARNING

Do not attempt to removepower plug(s)beforeturning OFFstart-stop switch (ST), unit circuit breaker(s) and external power source.

WARNING

Make sure the power plugs are clean and dry before connecting to any power receptacle.

Safety-1

T-309

Page 4

WARNING

Make surethatthe unitcircuit breaker(s)(CB-1 & CB-2)and theSTAR T-STOPswitch (ST)arein the

“O” (OFF) position before connecting to any electrical power source.

WARNING

Never useair for leak testing. It has been determined thatpressurized,mixturesofrefrigerant and air

can undergo combustion when exposed to an ignition source.

WARNING

Make sure power to the unit is OFF and power plug disconnected before replacing the compressor.

WARNING

Before disassembly of the compressor make sure to relieve the internal pressure very carefully by

slightly loosening the couplings to break the seal.

WARNING

Oakite No. 32 is an acid. Be sure that the acid is slowly added to the water. DO NOT PUT WATER

INTO THE ACID -- this will cause spattering and excessive heat.

WARNING

Wearrubberglovesand wash thesolution fromtheskin immediatelyif accidentalcontactoccurs.Do

not allow the solution to splash onto concrete.

WARNING

AlwaysturnOFF the unit circuit breakers(CB-1 & CB-2) and disconnectmain power supply before

working on moving parts.

WARNING

Make sure power to the unit is OFF and power plug disconnected before removing capacitor(s).

WARNING

With power OFF discharge the capacitor before disconnecting the circuit wiring.

WARNING

Do not use a nitrogencylinder without a pressureregulator. Do not use oxygen in or near a refrigeration system as an explosion may occur.

WARNING

Do not open the condenser fan grille beforeturning power OFF and disconnecting power plug.

WARNING

The Unit Power Plug Must Be Disconnected To Remove Power From Circuit Breaker Cb1

CAUTION

Donotremovewireharnessesfromcontrollermodulesunlessyouaregroundedtotheunit framewith

a static safe wrist strap.

CAUTION

Unplugallcontrollermodulewireharnessconnectorsbeforeperformingarcweldingon anypartofthe

container.

CAUTION

When condenser waterflow is below 11 lpm (3 gpm)or when water-cooled operation is notin use,the

CFS switch MUST be set to position ”1” or the unit will not operate properly.

CAUTION

Pre-trip inspection should not be performed with critical temperature cargoes in the container.

T-309

Safety-2

Page 5

CAUTION

When Pre-Tripkey is pressed, economy, dehumidification and bulb mode will be deactivated. At the

completion of Pre-Trip activity, economy, dehumidification and bulb mode must be reactivated.

CAUTION

When a failure occurs during automatic testing the unit will suspend operation awaiting operatorintervention.

CAUTION

When Pre--Triptest Auto 2 runs to completion without being interrupted, the unitwill terminatepretripanddisplay “Auto2”“end.”The unit will suspendoperationuntil the userdepressestheENTER

key!

CAUTION

Topreventtrappingliquid refrigerantin themanifoldgaugeset be suresetis broughtto suctionpressure beforedisconnecting.

CAUTION

The scroll compressor achieves lowsuction pressure very quickly.Do not use thecompressor to evacuate the system below zero psig. Never operate the compressor with the suction or discharge service

valvesclosed (frontseated).Internaldamagewillresultfromoperating the compressorina deep vacuum.

CAUTION

Use only Carrier Transicold approved Polyol Ester Oil (POE) -- Mobil ST32 compressor oil with

R-134a.Buyinquantitiesofonequartor smaller.When usingthishygroscopicoil, immediatelyreseal.

Do not leave container of oil open or contamination will occur.

CAUTION

Takenecessarysteps(placeplywoodover coil or useslingon motor)topreventmotorfromfallinginto

condenser coil.

CAUTION

DONOTdisassemblepiston fromNEWsuctionmodulatingvalvepowerheadassembly.Doing so may

result in damage to pi ston.

CAUTION

The unitmust be OFFwhenevera programming card is inserted or removed fromthe controllerprogramming port.

CAUTION

Do not allow moisture to enter wire splice area as this may affect the sensor resistance.

Safety-3

T-309

Page 6

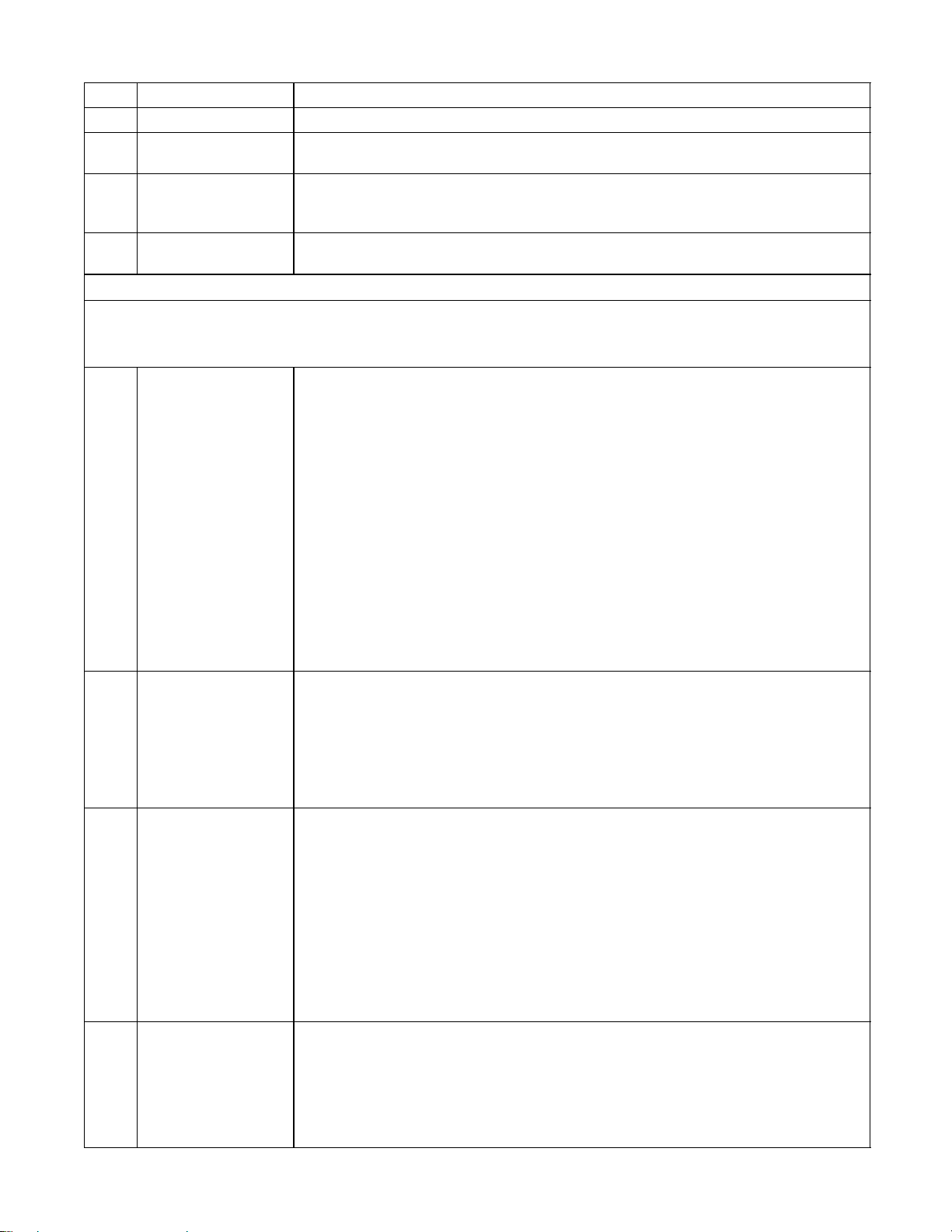

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

GENERAL SAFETY NOTICES Safety-1.....................................................

FIRST AID Safety-1......................................................................

OPERATING PRECAUTIONS Safety-1......................................................

MAINTENANCE PRECAUTIONS Safety-1..................................................

UNIT LABEL IDENTIFICATION Safety-1...................................................

SPECIFIC WARNING AND CAUTION STATEMENTS Safety-1.................................

INTRODUCTION 1-1..............................................................................

1.1 INTRODUCTION 1-1..............................................................

1.2 CONFIGURATIONIDENTIFICATION 1-1.............................................

1.3 OPTION DESCRIPTIONS 1-1.......................................................

1.3.1 Battery 1-1....................................................................

1.3.2 Dehumidification 1-1............................................................

1.3.3 Control Box 1-1................................................................

1.3.5 Pressure Readout 1-1............................................................

1.3.6 Interrogator 1-1................................................................

1.3.7 Remote Monitoring 1-1..........................................................

1.3.8 Communications 1-1............................................................

1.3.9 Compressor 1-1................................................................

1.3.10 Back Panels 1-1................................................................

1.3.11 460 Volt Cable 1-2.............................................................

1.3.12 Cable Restraint 1-2..............................................................

1.3.13 Upper Air (Fresh Air Make Up) 1-2................................................

1.3.14 Evaporator 1-2.................................................................

1.3.15 Evaporator Fan Operation 1-2.....................................................

1.3.16 Labels 1-2.....................................................................

1.3.17 Plate Set 1-2...................................................................

1.3.18 Controller 1-2..................................................................

1.3.19 Stepper Drive 1-2...............................................................

1.3.20 Condenser Grille 1-2............................................................

DESCRIPTION 2-1...............................................................................

2.1 GENERAL DESCRIPTION 2-1......................................................

2.1.1 Refrigeration Unit -- Front Section 2-1..............................................

2.1.2 Fresh Air Makeup Vent 2-1.......................................................

2.1.3 Evaporator Section 2-2...........................................................

2.1.4 Compressor Section 2-3..........................................................

2.1.5 Air Cooled Condenser Section 2-4.................................................

2.1.6 Control Box Section 2-5.........................................................

2.1.7 Communications InterfaceModule 2-5..............................................

2.2 REFRIGERATION SYSTEM DATA 2-6...............................................

2.3 ELECTRICAL DATA 2-7...........................................................

2.4 SAFETY AND PROTECTIVE DEVICES 2-8...........................................

2.5 REFRIGERATION CIRCUIT 2-9.....................................................

i

T309

Page 7

TABLE OF CONTENTS (cont)

2.5.1 Standard Operation 2-9..........................................................

2.5.2 Economized Operation 2-9.........................................................

2.5.3 Unloaded Operation 2-9...........................................................

MICROPROCESSOR 3-1..........................................................................

3.1 TEMPERATURE CONTROL MICROPROCESSOR SYSTEM 3-1..........................

3.1.1 Key Pad 3-2...................................................................

3.1.2 Display Module 3-2.............................................................

3.1.3 Controller 3-3..................................................................

3.2 CONTROLLER SOFTWARE 3-3.....................................................

3.2.1 Configuration Software (Configuration Variables) 3-3..................................

3.2.2 Operational Software(Function codes) 3-4...........................................

3.3 MODES OF OPERATION 3-4.......................................................

3.3.1 TemperatureControl -- Perishable Mode 3-4..........................................

3.3.2 Defrost Interval 3-4.............................................................

3.3.3 Failure Action 3-4..............................................................

3.3.4 GeneratorProtection 3-4.........................................................

3.3.5 Compressor High Temperature, Low Pressure Protection. 3-4............................

3.3.6 Perishable Mode -- Conventional 3-4................................................

3.3.7 Perishable Mode -- Economy 3-5...................................................

3.3.8 Perishable Mode -- Dehumidification 3-5............................................

3.3.9 Perishable, Dehumidification -- Bulb Mode 3-5.......................................

3.3.10 Temperature Control -- FrozenMode 3-6.............................................

3.3.11 Frozen Mode -- Conventional 3-6..................................................

3.4 CONTROLLER ALARMS 3-6.......................................................

3.5. UNIT PRE-TRIP DIAGNOSTICS 3-7.................................................

3.6 DataCORDER 3-7.................................................................

3.6.1 Description 3-7.................................................................

3.6.2 DataCORDER Software 3-7......................................................

3.6.3 Sensor Configuration (dCF02) 3-8.................................................

3.6.4 Logging Interval (dCF03) 3-10.....................................................

3.6.5 Thermistor Format (dCF04) 3-10...................................................

3.6.6 Sampling Type (dCF05 & dCF06) 3-10..............................................

3.6.7 Alarm Configuration (dCF07 -- dCF10) 3-10..........................................

3.6.8 DataCORDER Power-Up 3-10.....................................................

3.6.9 Pre-T rip Data Recording 3-10......................................................

3.6.10 DataCORDER Communications 3-10................................................

3.6.11 USDA Cold Treatment 3-11.......................................................

3.6.12 USDA Cold Treatment Procedure 3-11...............................................

3.6.13 DataCORDER Alarms 3-12........................................................

3.6.14 ISO Trip Header 3-12............................................................

T309

ii

Page 8

TABLE OF CONTENTS (cont)

OPERATION 4-1.................................................................................

4.1 INSPECTION (Before Starting) 4-1...................................................

4.2 CONNECT POWER 4-1............................................................

4.2.1 Connection To 380/460 vac Power 4-1..............................................

4.3 ADJUST FRESH AIR MAKEUP VENT 4-1............................................

4.3.1 Upper Fresh Air Makeup Vent 4-1..................................................

4.4 CONNECT REMOTE MONITORING

RECEPTACLE 4-2......................................................................

4.5 STARTINGAND STOPPING INSTRUCTIONS 4-2......................................

4.5.1 Starting the Unit 4-2.............................................................

4.5.2 Stopping the Unit 4-2............................................................

4.6 START--UP INSPECTION 4-2.......................................................

4.6.1 Physical Inspection 4-2..........................................................

4.6.2 Check Controller Function Codes 4-2...............................................

4.6.3 Complete Inspection 4-2.........................................................

4.7 PRE-TRIP DIAGNOSIS 4-2.........................................................

4.8 OBSERVEUNIT OPERATION 4-3...................................................

4.8.1 Probe Check 4-3................................................................

4.9 SEQUENCE OF OPERATION 4-4......................................................

4.9.1 Sequence Of operation -- Compressor Phase Sequence 4-5................................

4.9.2 Sequence Of Operation -- Perishable Mode Cooling 4-5..................................

4.9.3 Sequence Of Operation --

Perishable Mode Heating 4-6...........................................................

4.9.4 Sequence Of operation -- Frozen Mode Cooling 4-6.....................................

4.9.5 Sequence Of Operation -- Defrost 4-6...............................................

TROUBLESHOOTING 5-1.........................................................................

5.1 UNIT WILL NOT START OR STARTS THEN STOPS 5-1................................

5.2 UNIT OPERATES LONG OR CONTINUOUSL YIN COOLING 5-1.........................

5.3 UNIT RUNS BUT HAS INSUFFICIENT COOLING 5-2..................................

5.4 UNIT WILL NOT HEAT OR HAS INSUFFICIENT HEATING 5-2..........................

5.5 UNIT WILL NOT TERMINATE HEATING 5-2.........................................

5.6 UNIT WILL NOT DEFROST PROPERLY 5-2..........................................

5.7 ABNORMAL PRESSURES (COOLING) 5-3...........................................

5.8 ABNORMAL NOISE OR VIBRATIONS 5-3............................................

5.9 CONTROLLER MALFUNCTION 5-4.................................................

5.10 NO EVAPORATOR AIR FLOW OR RESTRICTED AIR FLOW 5-4.........................

5.11 THERMOSTATIC EXPANSION VALVE MALFUNCTION 5-4.............................

5.12 AUTOTRANSFORMER MALFUNCTION 5-4..........................................

5.13 WATER-COOLED CONDENSER OR WATER PRESSURE SWITCH 5-4....................

5.14 COMPRESSOR OPERATING IN REVERSE 5-5........................................

5.15 ABNORMAL TEMPERATURES 5-5..................................................

5.16 ABNORMAL CURRENTS 5-5.......................................................

iii

T309

Page 9

TABLE OF CONTENTS (cont)

SERVICE 6-1....................................................................................

6.1 SECTION LAYOUT 6-1............................................................

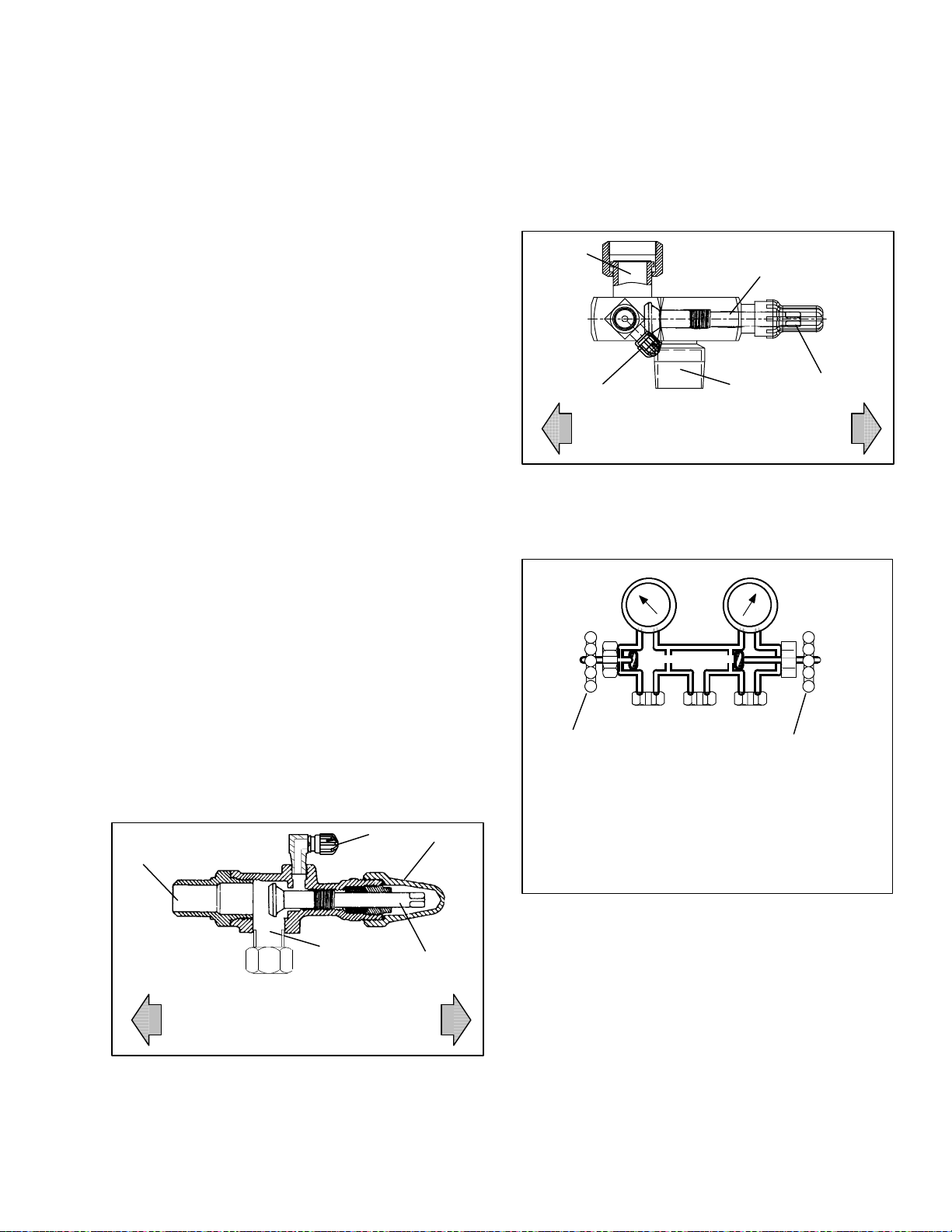

6.2 SERVICE VALVES 6-1.............................................................

6.3. MANIFOLD GAUGE SET 6-1.......................................................

6.4 PUMPING THE UNIT DOWN 6-2....................................................

6.5 REFRIGERANT LEAK CHECKING 6-3...............................................

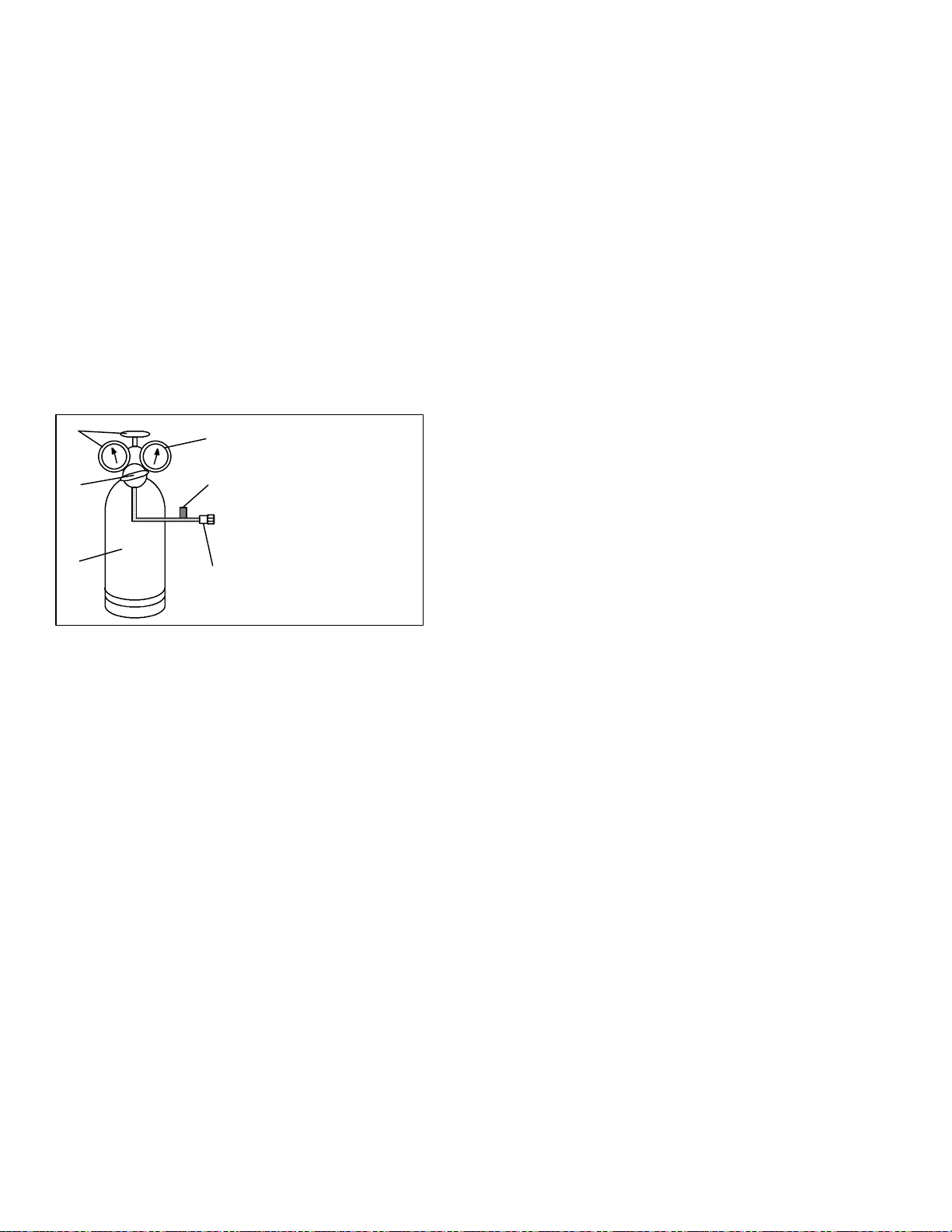

6.6 EVACUATION AND DEHYDRATION 6-3.............................................

6.6.1 General 6-3....................................................................

6.6.2 Preparation 6-3.................................................................

6.6.3 Procedure - Complete system 6-3..................................................

6.6.4 Procedure - Partial System 6-4.....................................................

6.7 REFRIGERANT CHARGE 6-5.......................................................

6.7.1 Checking the Refrigerant Charge 6-5................................................

6.7.2 Adding Refrigerant to System (Full Charge) 6-5.......................................

6.7.3 Adding Refrigerant to System (Partial Charge) 6-5.....................................

6.8 COMPRESSOR -- Model RSH105 6-5.................................................

6.8.1 Removal and Replacement of Compressor 6-5........................................

6.9 COMPRESSOR OIL LEVEL 6-7.....................................................

6.10 HIGH PRESSURE SWITCH 6-7......................................................

6.10.1 Replacing High Pressure Switch 6-7................................................

6.10.2 Checking High Pressure Switch 6-8................................................

6.11 CONDENSER COIL 6-8............................................................

6.12 CONDENSER FAN AND MOTOR ASSEMBLY 6-8.....................................

6.13 FILTER-DRIER 6-8................................................................

6.14 EXPANSION VALVES 6-9..........................................................

6.14.1 Checking Superheat. 6-9.........................................................

6.14.2 V alve Replacement 6-9..........................................................

6.15 EVAPORATOR COIL AND HEATER

ASSEMBLY 6-10........................................................................

6.15.1 Evaporator Coil Replacement 6-10..................................................

6.15.2 Evaporator Heater Replacement 6-10................................................

6.16 ECONOMIZER, UNLOADER, LIQUID INJECTION AND OIL RETURN SOLENOID VALVE 6-11

6.17 EVAPORATOR FAN AND MOTOR ASSEMBLY 6-11....................................

6.17.1 Replacing The Evaporator Fan Assembly 6-12.........................................

6.18 EVAPORATOR FAN MOTOR CAPACITORS 6-12.......................................

6.18.1 When To Check For A Defective Capacitor 6-12.......................................

6.18.2 Removing The Capacitor 6-12......................................................

6.18.3 Checking The Capacitor 6-12......................................................

6.19 VALVEOVERRIDE CONTROLS 6-13.................................................

6.20 SUCTION MODULATIONVALVE 6-13................................................

6.20.1 Precheck Procedure 6-14..........................................................

6.20.2 Checking The Stepper valve 6-14...................................................

6.21 CONTROLLER AND EXPANSION MODULE 6-14......................................

T309

iv

Page 10

6.21.1 Handling Modules 6-14...........................................................

6.21.2 Controller Trouble-Shooting 6-15...................................................

6.21.3 Controller Programming Procedure 6-15..............................................

6.21.4 Removing and Installing a Module 6-16..............................................

6.22 TEMPERATURE SENSOR SERVICE 6-16..............................................

6.22.1 Sensor Checkout Procedure 6-16....................................................

6.22.2 Sensor Replacement 6-17..........................................................

6.22.3 Sensor Re--Installation 6-18........................................................

6.23 MAINTENANCE OF PAINTEDSURFACES 6-18........................................

6.24 COMPOSITE CONTROL BOX REPAIRS 6-18...........................................

6.24.1 Introduction 6-18................................................................

6.24.2 Cracks 6-19....................................................................

6.24.3 Chips And Holes 6-19............................................................

6.24.4 Inserts 6-19.....................................................................

6.24.5 Door Hinge Inserts 6-19...........................................................

6.25 COMMUNICATIONS INTERFACE MODULE INSTALLATION 6-22........................

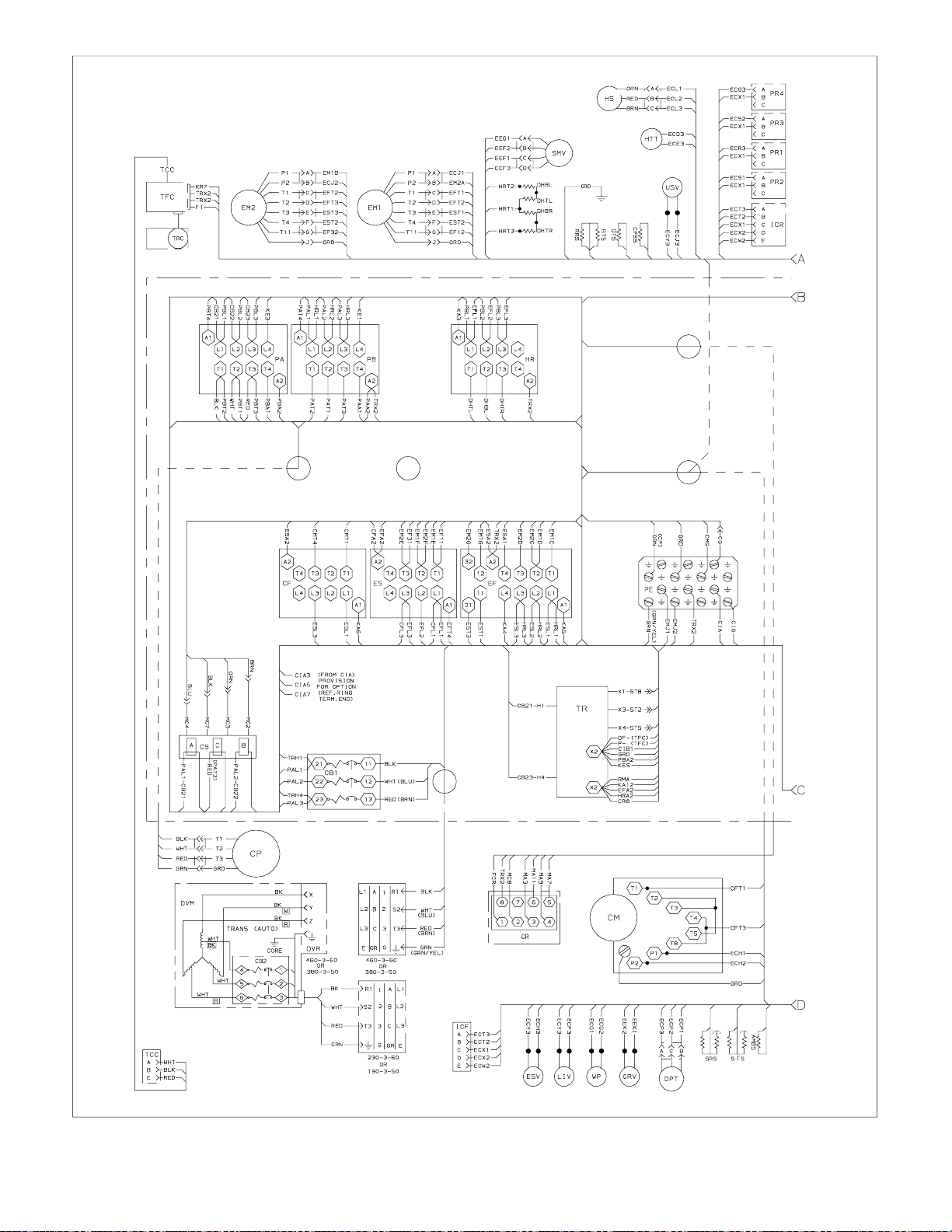

ELECTRICAL WIRING SCHEMATIC 7-1............................................................

7.1 INTRODUCTION 7-1..............................................................

v

T309

Page 11

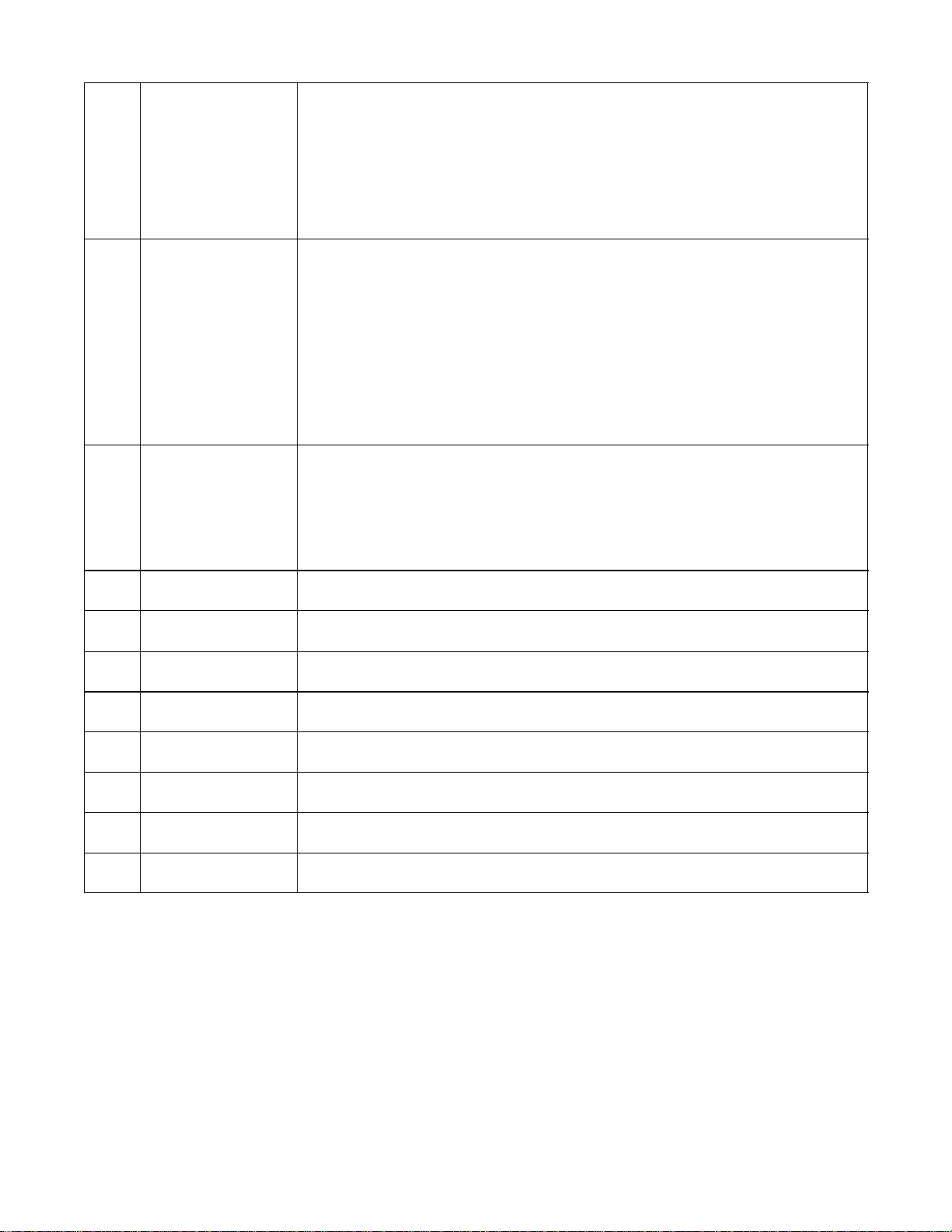

LIST OF ILLUSTRATIONS

FIGURE NUMBER Page

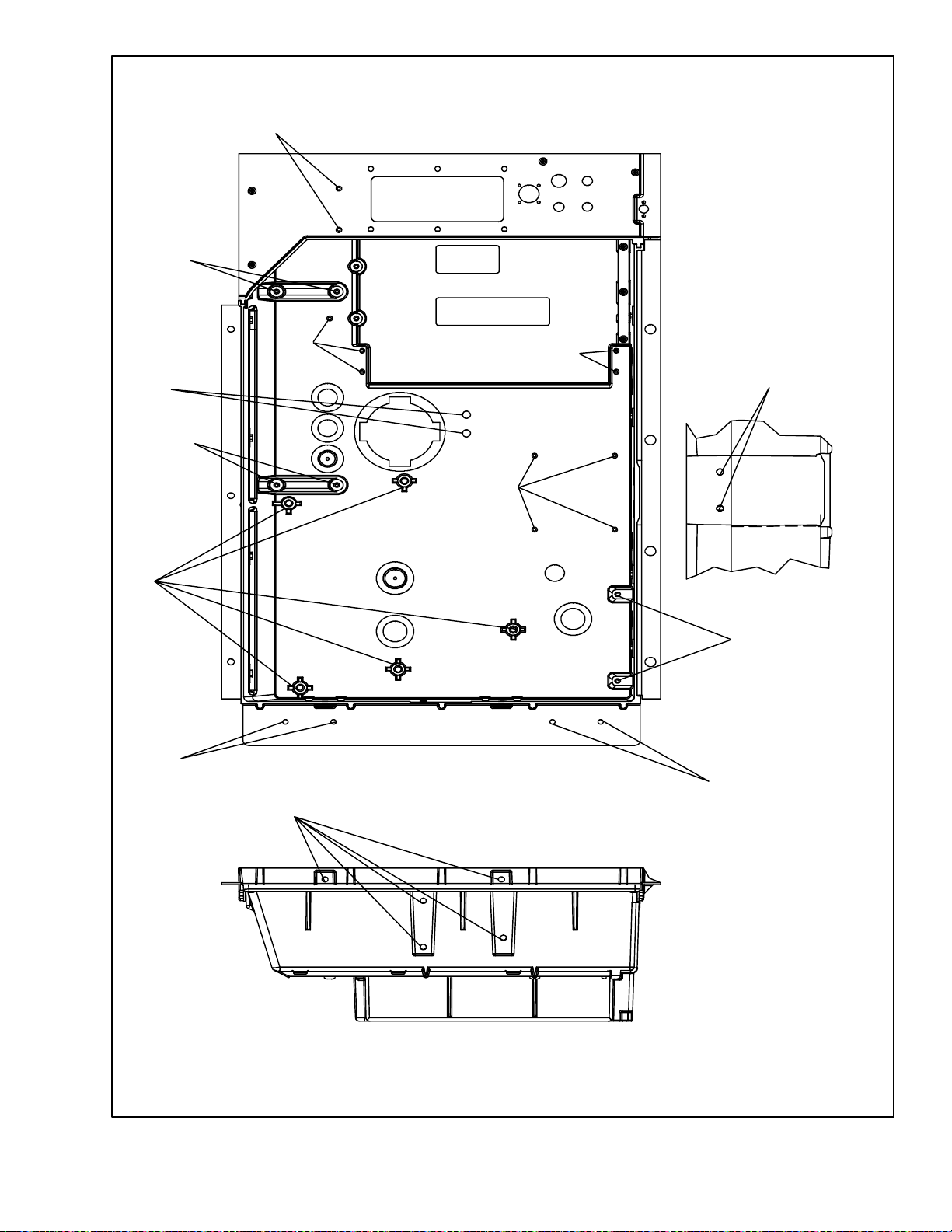

Figure 2-1 Refrigeration Unit -- Front Section 2-1...............................................

Figure 2-2 Evaporator Section 2-2............................................................

Figure 2-3 Compressor Section 2-3...........................................................

Figure 2-4 Condenser Section 2-4............................................................

Figure 2-5 Control Box Section 2-5...........................................................

Figure 2-6 RefrigerationCircuit Schematic -- Standard Operation 2-10................................

Figure 2-7 RefrigerationCircuit Schematic -- Economized Operation 2-11.............................

Figure 2-8 RefrigerationCircuit Schematic -- Unloaded Operation 2-11...............................

Figure 3- 1 TemperatureControl System 3-1...................................................

Figure 3- 2 Key Pad 3-2....................................................................

Figure 3- 3 Display Module 3-2..............................................................

Figure 3- 4 Control and Expansion Modules 3-3.................................................

Figure 3- 5 Standard Configuration Download Report 3-9.........................................

Figure 3- 6 Data Reader 3-11.................................................................

Figure 4-1 Make Up Air Flow Chart 4-1.......................................................

Figure 4-2 Controller Operation -- Perishable Mode 4-4...........................................

Figure 4-3 Controller Operation -- Frozen Mode 4-5..............................................

Figure 4-4 Perishable Mode 4-5..............................................................

Figure 4-5 Perishable Mode Heating 4-6.......................................................

Figure 4-6 Frozen Mode 4-6................................................................

Figure 4-7 Defrost 4-7.....................................................................

Figure 6-1 Service Valve 6-1................................................................

Figure 6-2 Suction ServiceValve 6-1.........................................................

Figure 6-3 Manifold Gauge Set 6-1...........................................................

Figure 6-4 R-134a Manifold Gauge/Hose Set 6-2................................................

Figure 6-5. Refrigeration System ServiceConnections 6-3.........................................

Figure 6-6. Compressor Service Connections 6-4................................................

Figure 6-7 Compressor Upper Mounting 6-6....................................................

Figure 6-8 Compressor Lower Mounting 6-6...................................................

Figure 6-9 High Pressure Switch Testing 6-8...................................................

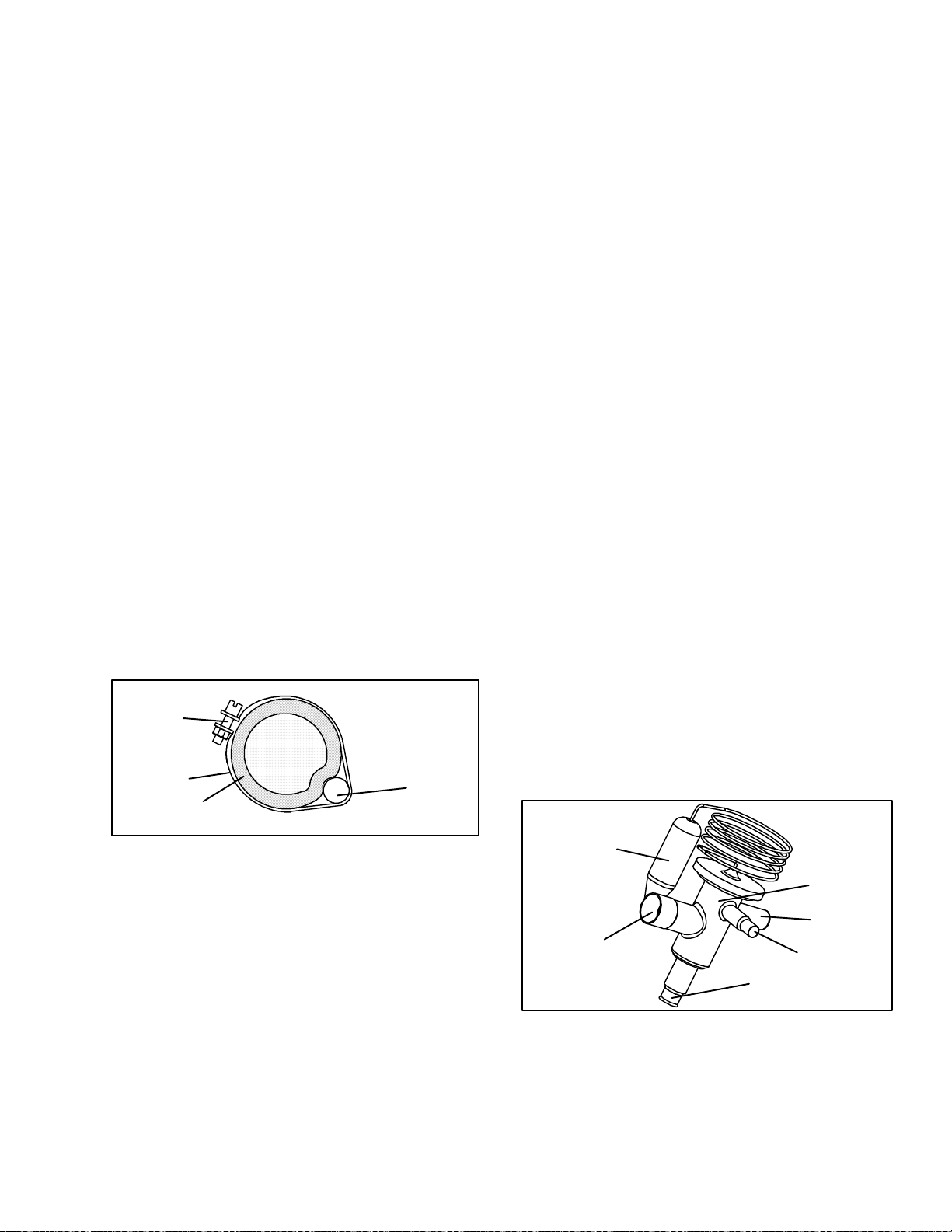

Figure 6-10 Thermostatic Expansion Valve Bulb 6-9.............................................

Figure 6-11 Evaporator Expansion Valve 6-9...................................................

Figure 6-12 Hermetic Thermostatic Expansion Valve Brazing Procedure 6-10..........................

Figure 6-13 Economizer Expansion Valve 6-10..................................................

Figure 6-14. Unloader Solenoid Valve 6-11.....................................................

Figure 6-15. Oil Return Solenoid Valve(ORV), Economizer Solenoid Valve (ESV),

Liquid Injection Solenoid Valve (LIV) 6-11...........................................

Figure 6-16. Evaporator Fan Assembly 6-12.....................................................

Figure 6-17 Suction Modulation Valve (SMV) 6-13...............................................

Figure 6-18 Controller Section of the Control Box 6-15............................................

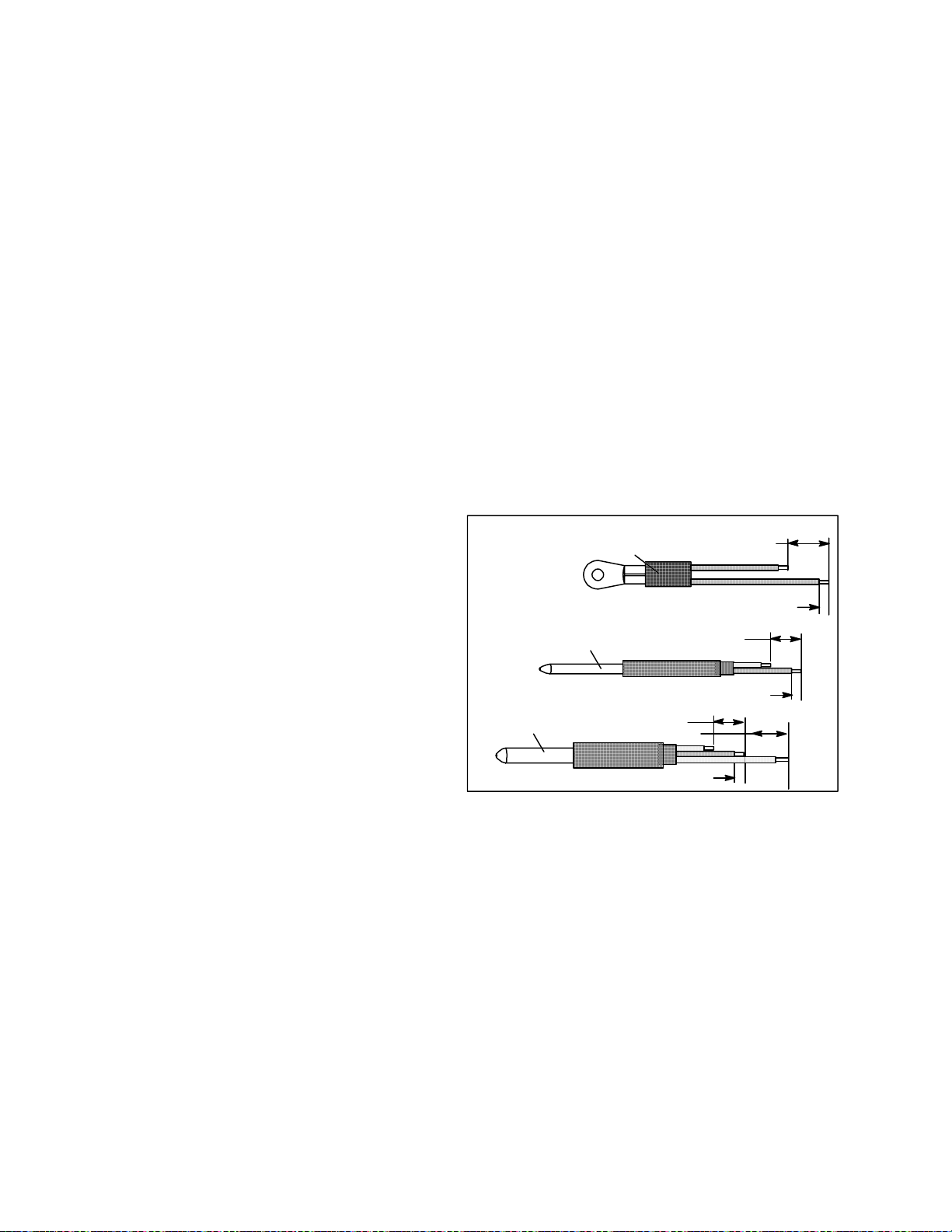

Figure 6-19 Sensor Types 6-16...............................................................

Figure 6-20 TypicalSensor and Cable Splice 6-17................................................

Figure 6-21 Supply Sensor Positioning 6-18.....................................................

T309

vi

Page 12

LIST OF ILLUSTRATIONS

FIGURE NUMBER Page

Figure 6-22 Return Sensor Positioning 6-18.....................................................

Figure 6-23 Door Hinge Repair 6-19...........................................................

Figure 6-24. Insert Location 6-21.............................................................

Figure 6-25. Communications Interface Installation 6-22...........................................

Figure 7-1 LEGEND 7-1...................................................................

Figure 7-2 SCHEMATIC DIAGRAM 7-2......................................................

Figure 7-3 WIRING DIAGRAM 7-3.........................................................

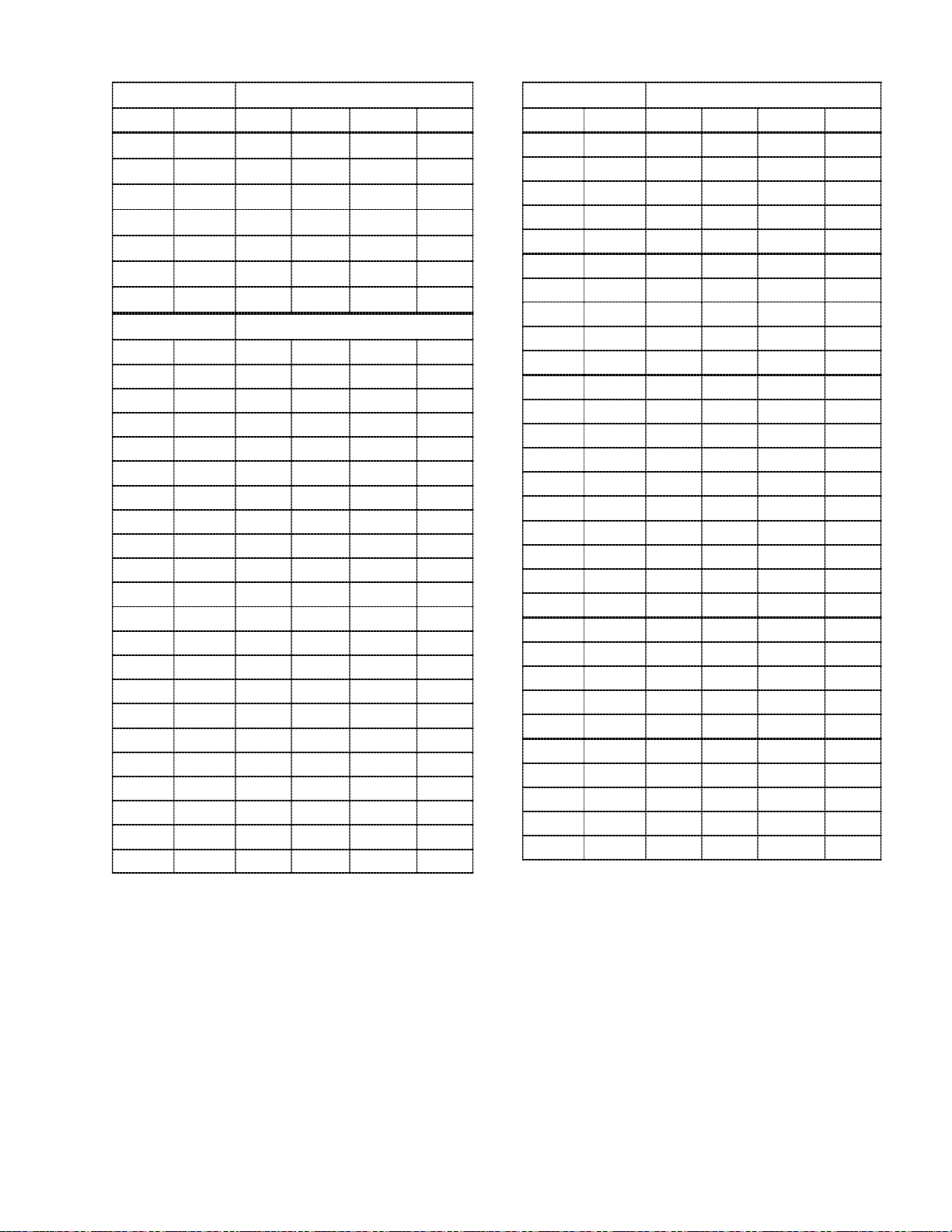

LIST OF TABLES

TABLE NUMBER Page

Table 2-1 Safety and Protective Devices 2-8.....................................................

Table 3-1 Key Pad Function 3-2..............................................................

Table 3-2 DataCORDER Configuration Variables 3-8.............................................

Table 3-3 DataCORDER Standard Configurations 3-8.............................................

Table 3-4 Controller Configuration Variables 3-13.................................................

Table 3-5 Controller Function Codes 3-14.......................................................

Table 3-6 Controller Alarm Indications 3-17.....................................................

Ta ble 3-7 Controller Pre-Trip Test Codes 3-21....................................................

Table 3-8 DataCORDER Function Code Assignments 3-25..........................................

Table 3-9 DataCORDER Pre-Trip Result Records 3-26.............................................

Table 3-10 DataCORDER Alarm Indications 3-27.................................................

Ta ble 6-1 Compressor Kit 6-6................................................................

Table 6-2 Sensor Temperature/ResistanceChart (+/--.002%) 6-17.....................................

Table 6-3 Crack, Chip & Hole Repair Kit 6-20....................................................

T able 6-4 Insert Repair Kit 6-20...............................................................

T able 6-5 Drill Information 6-20...............................................................

Table 6-6 Recommended Bolt Torque Values 6-22.................................................

Table 6-7 R-134a Temperature - Pressure Chart 6-23...............................................

vii

T309

Page 13

SECTION 1

INTRODUCTION

1.1 INTRODUCTION

The Carrier Transicold model 69NT20--531-300 units

are of lightweight aluminum frame construction,

designedtofitinthefrontofa containerandserveasthe

container front wall.

They are one piece, self-contained, all electric units

which are fitted with cooling and heating systems to

provide precise temperaturecontrol.

The units are supplied with a complete charge of

refrigerant R-134a and compressor lubricating oil and

are ready for operation upon installation. Forklift

pockets are provided for unit installation and removal.

The base unit operates on nominal 380/460 volt, 3

phase, 50/60 hertz power. An optional autotransformer

maybefittedto allow operationon nominal190/230, 3

phase,50/60 hertz power.Power forthe control system

is provided by a transformer which steps the supply

power down to 18 and 24 volts, single phase.

The controller is a Carrier Transicold Micro-Link 2i

microprocessor. The controller will operate

automatically to select cooling, holding or heating as

required to maintain the desired set point temperature

within very close limits.

The controller is fitted with a keypad and display for

viewingor changing operatingparameters.Thedisplay

isalsoequippedwithlightstoindicatevariousmodesof

operation.

1.2 CONFIGURATION IDENTIFICATION

Unit identification informationis provided on a model

plate located to the left of the economizer. The plate

provides the unit model number and the unit parts

identification number (PID). The model number

identifies the overall unit configuration while the PID

provides information on specific optional equipment,

factory provision to allow for field installation of

optional equipment and differencesin detailed parts.

Configuration identification for the models covered

hereinareprovided in the Carrier Transicold Container

Unit Matrix manual, publicationT--300. Printedcopies

ofthe T--300may be obtainedfrom CarrierTransicold.

Also,aweeklyupdatedcopymaybefoundattheCarrier

Web site, www.carrier.refrigeration.com.

1.3 OPTION DESCRIPTIONS

Various options maybefactoryorfieldfittedto thebase

unit. Brief descriptions of the options are provided in

the following subparagraphs.

1.3.1 Battery

The controller may be fitted with standard replaceable

batteries or a rechargeable battery pack.

1.3.2 Dehumidification

The unit may be fitted with a humidity sensor. This

sensor allows setting of a humidity set point in the

controller. In the dehumidificationmode the controller

willoperatetoreduce internal container moisturelevel.

1.3.3 Control Box

The control box is constructed of composite material

and may be fitted with a lockable door.

1.3.4 Temperature Readout

The unit may be fitted with suction and discharge

temperature sensors. The sensor readings may be

viewed on the controller display.

1.3.5 Pressure Readout

Theunitmaybefittedwithfactoryinstalledsuction and

discharge pressure gauges. The unit is fitted with

suctionanddischargetransducers.Thereadingsmaybe

viewed on the controller display.

1.3.6 Interrogator

UnitsthatusetheDataCORDERfunctionarefittedwith

interrogator receptacles for connection of equipment to

download the recorded data. Two receptacles may be

fitted, one accessible from the front of the unit and the

other mounted inside the container (with the USDA

receptacles).

1.3.7 Remote Monitoring

The unit may be fitted with a remote monitoring

receptacle. This item allows connection of remote

indicators for COOL, DEFROST and IN RANGE.

1.3.8 Communications

Theunitmay be fittedwitha communications interface

module. The communications interface module is a

slave module which allows communication with a

master central monitoring station. The module will

respondto communicationand return informationover

the main power line. Refer to the ship master system

technical manual for further information.

1.3.9 Compressor

The unit is fitted with a scroll compressor.

1.3.10 Back Panels

Backpanel designs that maybe fittedinclude panels of

aluminumandstainlesssteel.Panels maybe fitted with

access doors and/or hinge mounting.

1-1 T-309

Page 14

1.3.11 460 Volt Cable

Various power cable and plug designs are available for

the main 460 volt supply. The plug options tailor the

cables to each customers requirements.

1.3.12 Cable Restraint

Various designs are available for storage of the power

cables. These options are variations of the compressor

section front cover.

1.3.13 Upper Air (Fresh Air Make Up)

The unit may be fitted with an upper fresh air makeup

assembly. These assemblies are supplied in two

designs, the standard design and the micro design. The

openings may also be fitted with screens.

1.3.14 Evaporator

Theunitis fittedwith anevaporatorcoiland a hermetic

thermal expansion valve.

1.3.15 Evaporator Fan Operation

The units are fitted with Normal Evaporator Fan

Operation, opening of an evaporator fan internal

protector will shut down the unit.

1.3.16 Labels

OperatingInstruction and Function Code listing labels

will differ depending on the options installed. For

example, additional operating instructions arerequired

to describe start--up of a unit equipped with an

autotransformer. Where the labels are available with

additional languages, they are listed in the parts list.

1.3.17 Plate Set

Each unit is equipped with a tethered set of wiring

schematic and wiring diagram plates.

The plate sets are ordered using a seven digit base part

numberandatwodigit dashnumber. (See UnitMatrix

Manual, T-300)

1.3.18 Controller

Replacement controllers may be ordered as a universal

un--configured controller (without configuration

software) or configured.

1.3.19 Stepper Drive

All the units covered by this manual have suction

modulatingvalveswhichacttocontrolsystemcapacity.

Unitsindicatedasbeingfittedwith“stepperdrive”have

digital control motors fitted to the suction modulating

valve to open and close the valve in steps as required.

1.3.20 Condenser Grille

Two styles of condenser grilles are available, direct

bolted grilles and hinged grilles.

T-309

1-2

Page 15

SECTION 2

DESCRIPTION

2.1 GENERAL DESCRIPTION

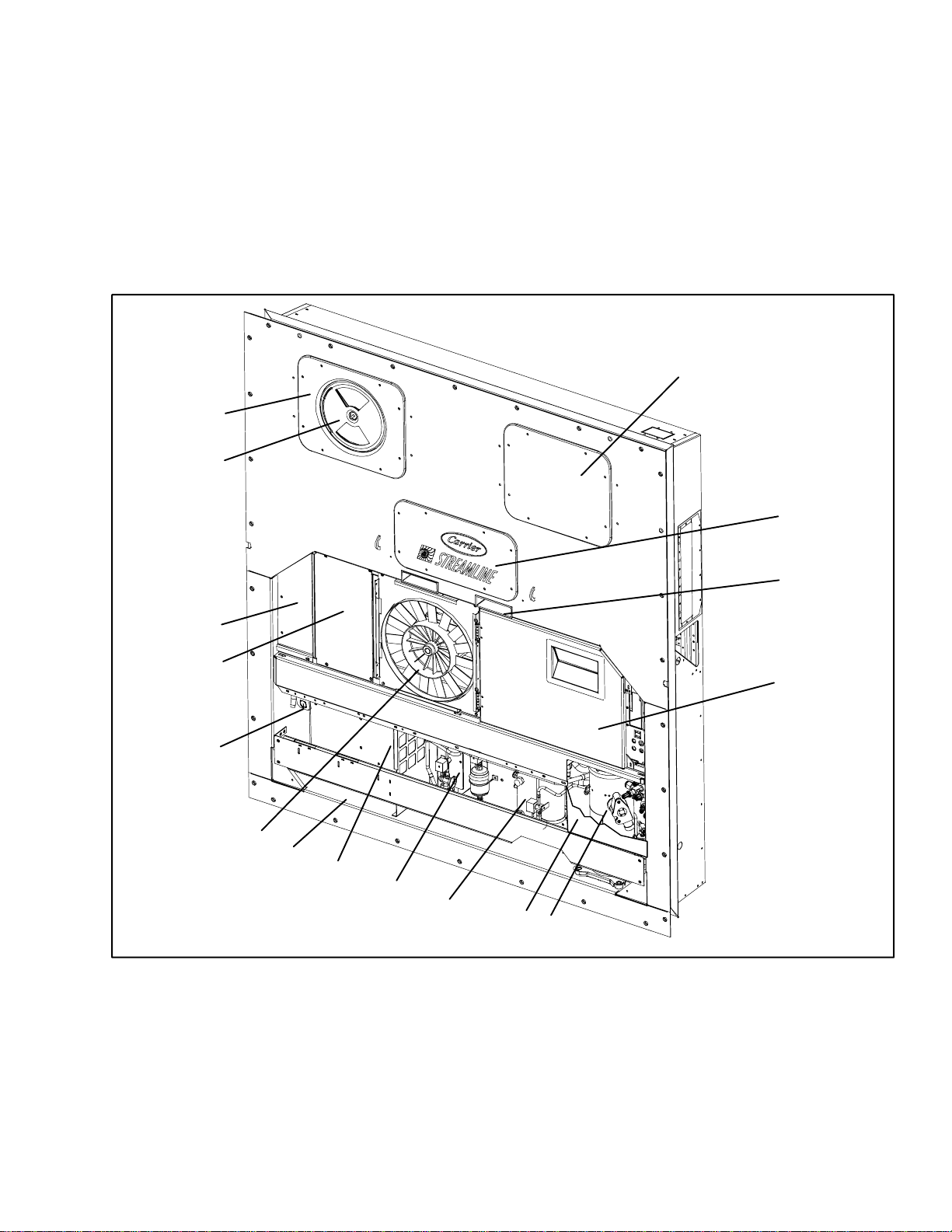

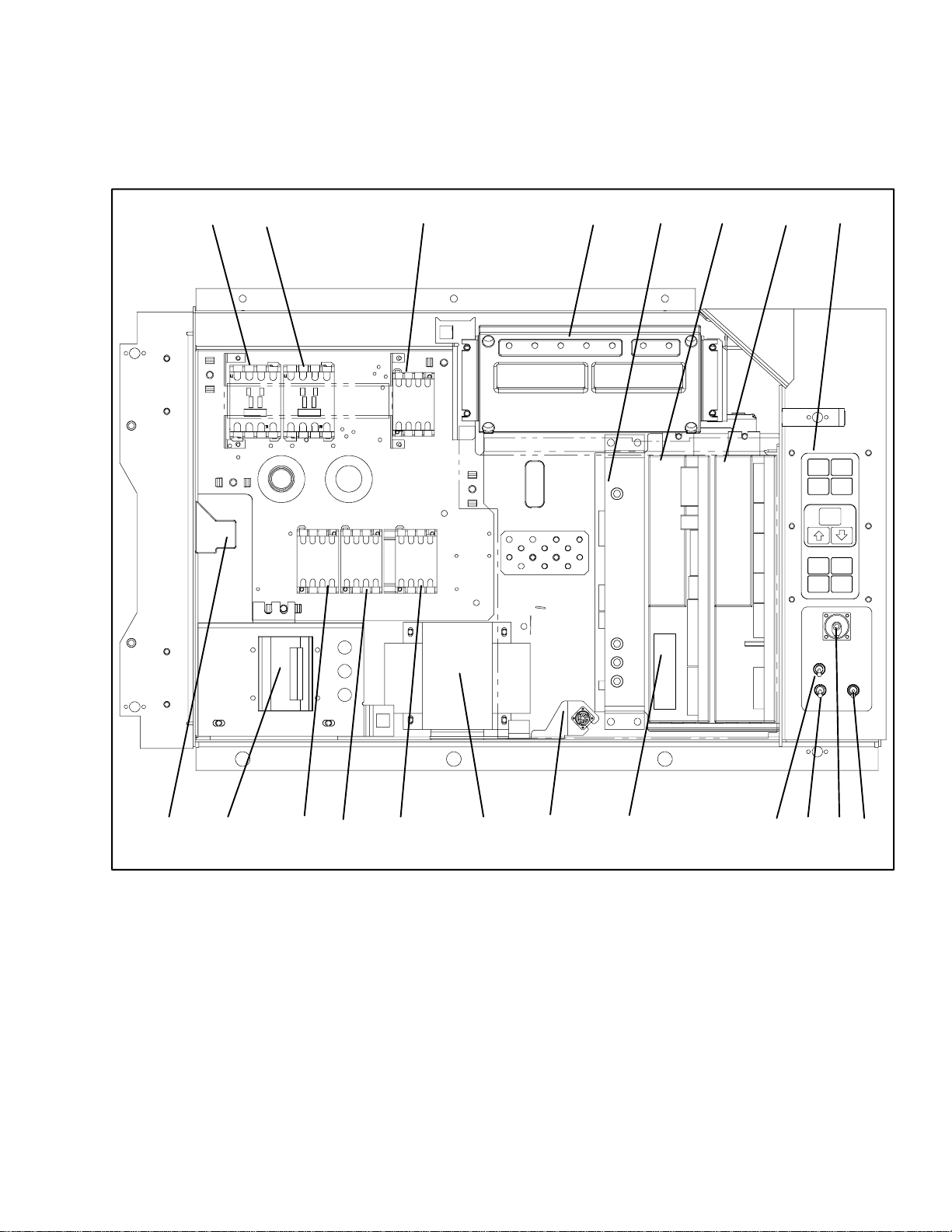

2.1.1 Refrigeration Unit -- Front Section

The unit is designed so that the majority of the

components are accessible from the front, see

Figure 2-1. Theupperaccesspanels allowentryintothe

evaporator section, and the center access panel allows

access to the evaporator expansion valve, unloader

15

14

valve, suction modulation valve and evaporator coil

heaters.Theunitmodelnumber,serialnumberandparts

identificationnumbercanbefoundon the serialplateto

the left of the economizer.

2.1.2 Fresh Air Makeup Vent

Thefunctionof the upperorlower makeup air vent isto

provide ventilation for commodities that require fresh

air circulation.

1

2

3

13

12

11

10

9

8

7

1. Access Panel (Evap. Fan #1)

2. Access Panel (Heaters, Suction Modulating

Valve, Unloader Valve & Evaporator

Expansion Valve)

3. Fork Lift Pockets

4. Control Box

5. Compressor

6. Receiver or Water Cooled Condenser

7. Economizer

8. Unit Serial Number, Model Number and

Figure 2-1 Refrigeration Unit -- Front Section

4

6

16

5

Parts Identification Number (PID) Plate

9. Power Cables and Plug

10. Condenser Fan

11. Interrogator Connector (Front left)

12. Blank Cover (Temperature Recorder Location)

13. Blank Cover (Lower Fresh Air Makeup Vent

Location)

14. Upper Fresh Air Makeup Vent

15. Access Panel (Evap. Fan #2)

16. Compressor Protection Panel (cutaway view)

2-1

T-309

Page 16

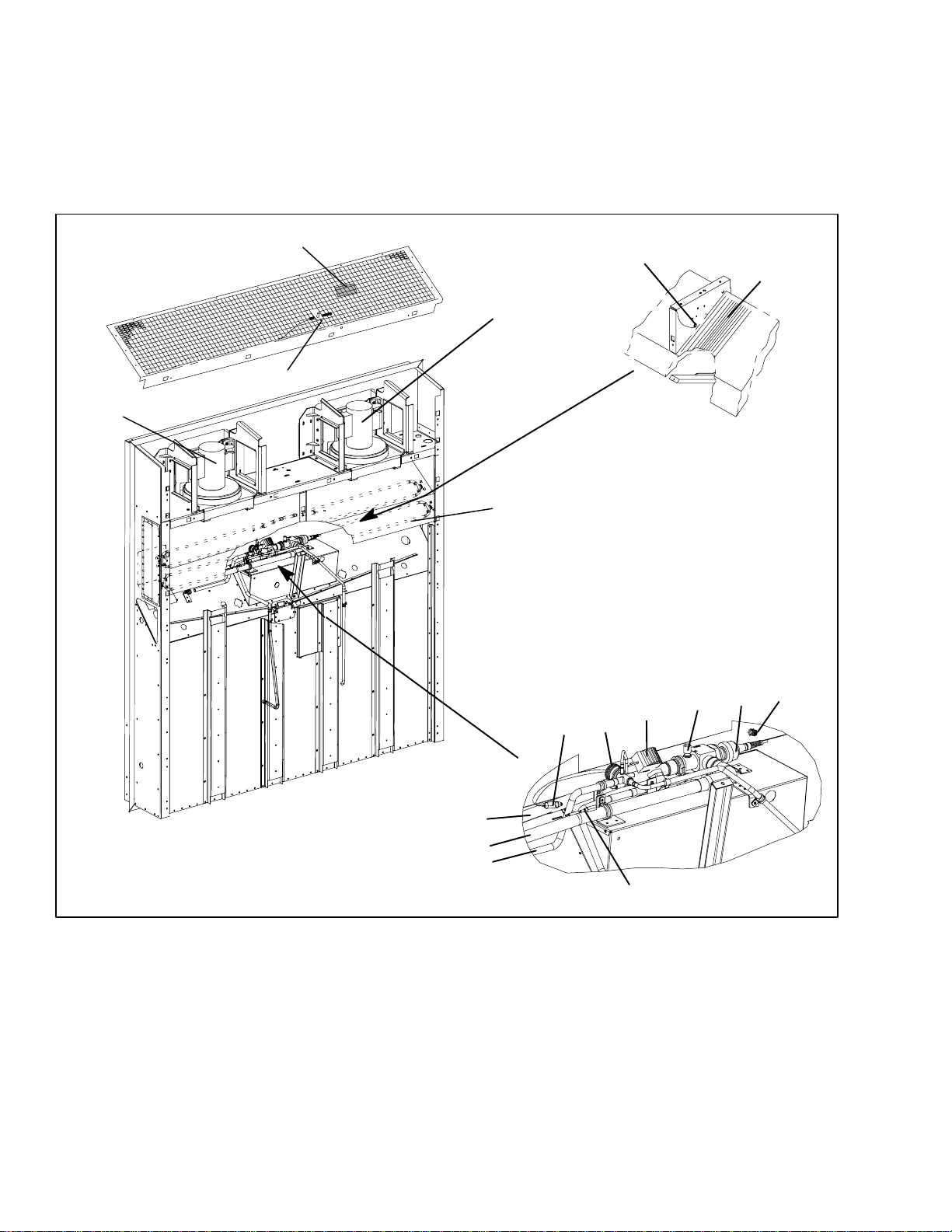

2.1.3 Evaporator Section

The evaporatorsection (Fi gure 2-2)contains the return

recorder sensor, return temperature sensor, evaporator

expansion valve, unloader valve, suction modulation

valve, dual-speed evaporator fans (EM1 and EM2),

evaporator coil and heater, defrost heaters, defrost

temperature sensor, heat termination thermostat and

suction temperature sensor.

The evaporator fans circulate air through the container

by pulling it in the top of the unit, directing it through

the evaporator coil, where it is heated or cooled, and

dischargingit at the bottom.

Theevaporatorcomponents are accessiblebyremoving

the upper rear panel (as shown in the illustration) or by

removing the front access panels.

3

4

2

1

8

9

10

5

17

11

12

7

6

1. Evaporator Fan Motor #1

2. Return Recorder/Temperature Sensor

3. Humidity Sensor

4. Evaporator Fan Motor #2

5. Defrost Temperature Sensor

6. Heater Termination Thermostat

7. Evaporator Coil

8. Evaporator Coil Heaters

9. Evaporator Expansion Valve Bulb

Figure 2-2 Evaporator Section

15

14

16

13

10. Evaporator Expansion Valve

11. Low Side Access Valve

12. Suction Modulating Valve

13. Suction Temperature Sensor

14. To Compressor

15. From Coil

16. To Coil

17. Unloader Solenoid Valve

2-2T -309

Page 17

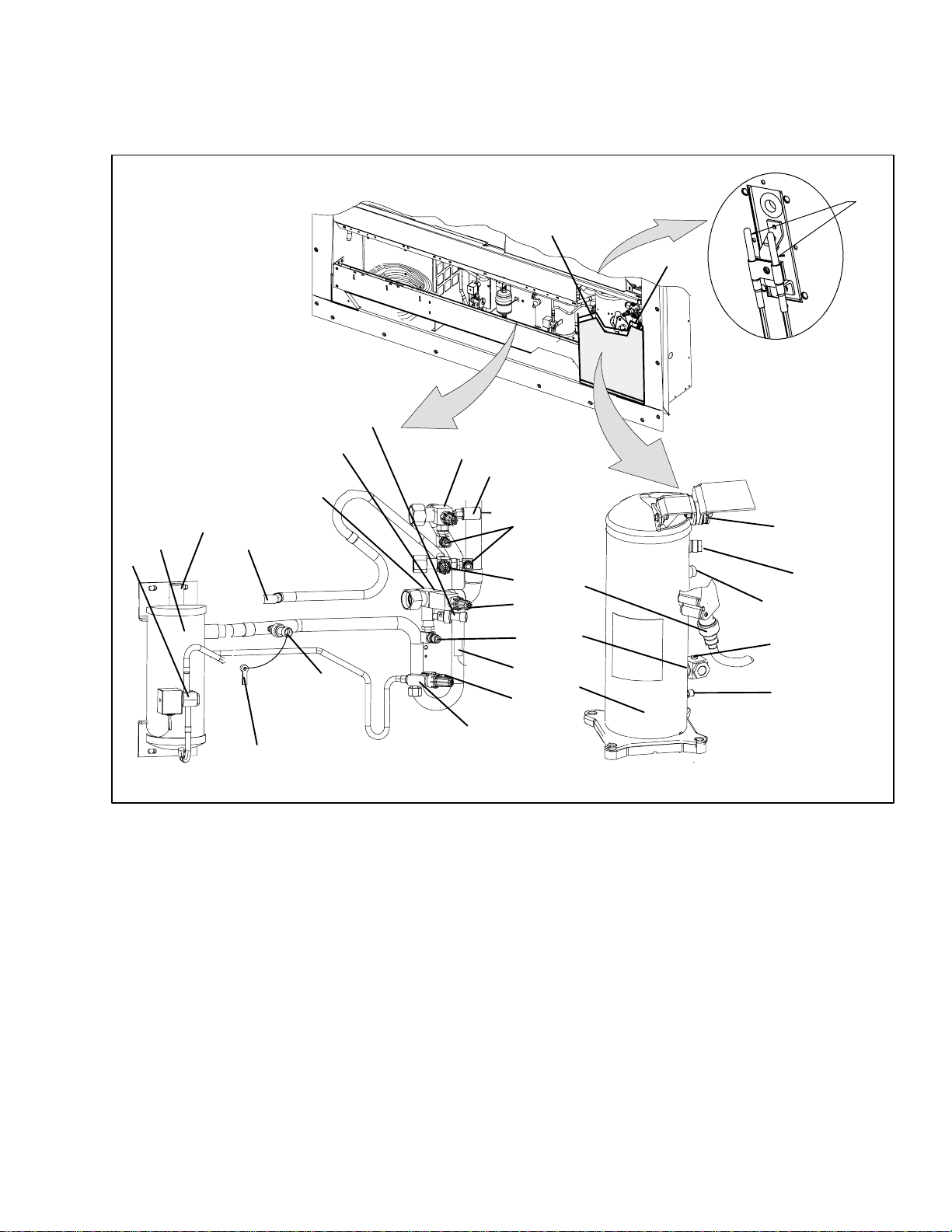

2.1.4 Compressor Section

The compressor section includes the compressor (with

high pressure switch) and the oil separator.

This section also contains the oil return solenoid,

compressor power plug, the discharge pressure

23

transducer, discharge temperature sensor and the

suction pressure transducers.

The supply temperature sensor, supply recordersensor

and ambient sensor are located at the left side of the

compressor.

2

1

4

22

21

20

18

19

17

16

3

1. Compressor Guard

2. Supply Temperature/Supply Recorder Sensor

Assembly

3. Ambient Sensor

4. Supply Air Thermometer Port (location)

5. Oil Drain

6. Compressor

7. Compressor Sight Glass

8 Compressor Power Plug

9. Discharge Service Valve

10. High Pressure Switch

11. Access Valve

Figure 2-3 Compressor Section

9

10

11

12

13

11

8

7

Discharge

Connection

(Hidden)

Economizer

Connection

Suction

Connection

Oil Return

Connection

14

11

6

5

15

12. Economizer Service Valve

13. Suction Service Valve

14. Discharge Temperature Sensor

15. Oil Return Service Valve

16. Discharge Pressure Transducer

17. Oil Return Solenoid Valve

18. Oil Separator

19. From Economizer

20. To Condenser

21. From Suction Modulating Valve

22. Suction Strainer

23. Suction Pressure Transducer

2-3

T-309

Page 18

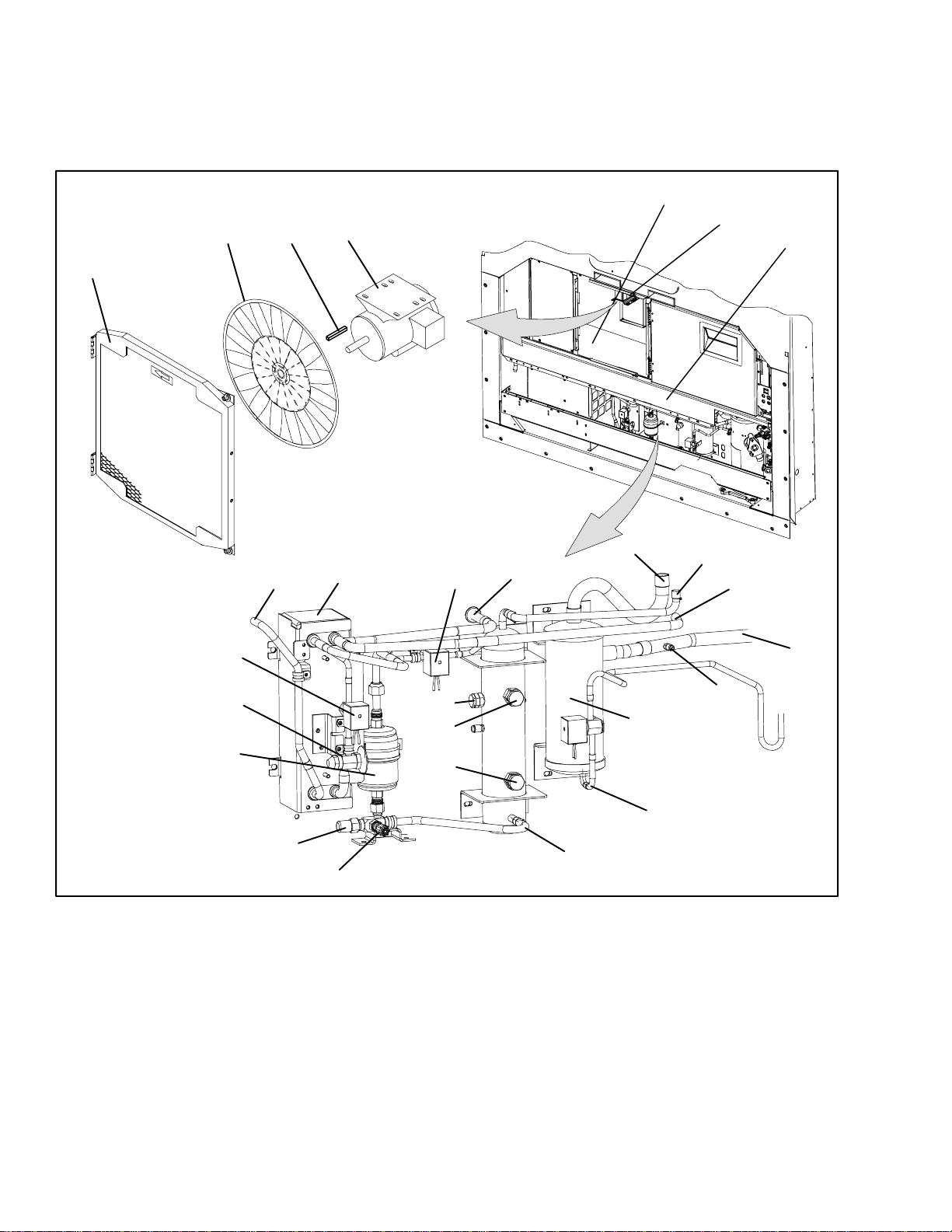

2.1.5 Air Cooled Condenser Section

The air cooled condenser section (Figure 2-4) consists

of the condenser fan, condenser coil, receiver, sight

glass/moisture indicator, liquid line service valve,

filter-drier and fusible plug.

2

1

3

4

Thecondenserfanpullsair in thebottom ofthe coiland

it is discharged horizontally out through the condenser

fan grille.

This section also contains the economizer,economizer

solenoid valve, economizer expansion valve and the

liquid injection solenoid valve.

5

6

7

9

27

26

25

24

1. Grille and Venturi Assembly

2. Condenser Fan

3. Key

4. Condenser Fan Motor

5. Condenser Coil

6. Condenser Motor Mounting Bracket

7. Condenser Coil Cover

8. Economizer

9. To Evaporator Expansion Valve

10. Liquid Injection Solenoid Valve

11. From Condenser

12. To Condenser

13. To Compressor Economizer Connection

14. To Unloader Solenoid Valve

8

23

Figure 2-4 Condenser Section

12

10

22

21

20

14

17

19

15. From Compressor Discharge

16. Discharge Pressure Transducer

17. Oil Separator

18. To Oil Return Solenoid

19. Receiver

20. Sight Glass/Moisture Indicator

21. Sight Glass

22. Fusible Plug

23. Access Valve

24. Liquid Line Service Valve

25. Filter-Drier

26. Economizer Expansion Valve

27. Economizer Solenoid Valve

11

13

15

16

18

2-4T -309

Page 19

2.1.6 Control Box Section

The control box (Figure 2-5) includes the manual

operationswitches;circuitbreaker(CB-1);compressor,

fan and heater contactors; control power transformer;

fuses;key pad;display module; currentsensormodule;

controller module expansion module and the

communications interface module.

2.1.7 Communications Interface Module

The communications interface module is a slave

module which allow communication with a master

centralmonitoring station. The module will respond to

communication and return information over the main

powerline.Referto themastersystemtechnicalmanual

for further information.

12 3 4 5 6 7

8

1920 151718

1. Compressor Phase A Contactor

2. Compressor Phase B Contactor

3. Heater Contactor

4. Display Module

5. Communications Interface Module

6. Controller/DataCORDER Module (Controller)

7. Expansion Module

8. Key Pad

9. Start-Stop Switch

10. Remote Monitoring Receptacle

Figure 2-5 Control Box Section

14

1 1. Manual Defrost Switch

12. Condenser Fan Switch

13. Controller Battery Pack

14. Interrogator Connector (Box Location)

15. Control Transformer

16. Evaporator Fan Contactor - High

17. Evaporator Fan Contactor - Low

18. Condenser Fan Contactor

19. Circuit Breaker -- 460V

20. Current Sensor Module

2-5

121316

10 911

T-309

Page 20

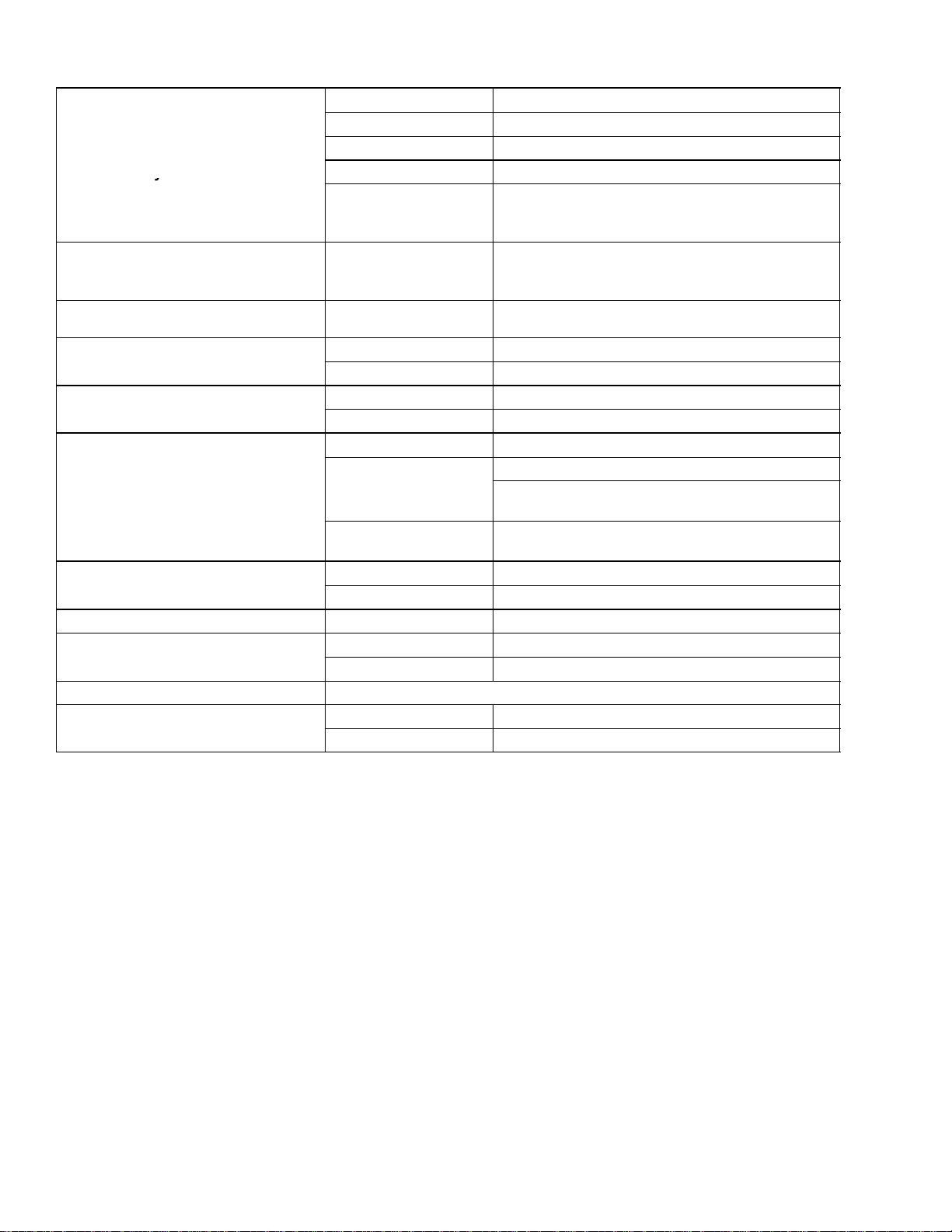

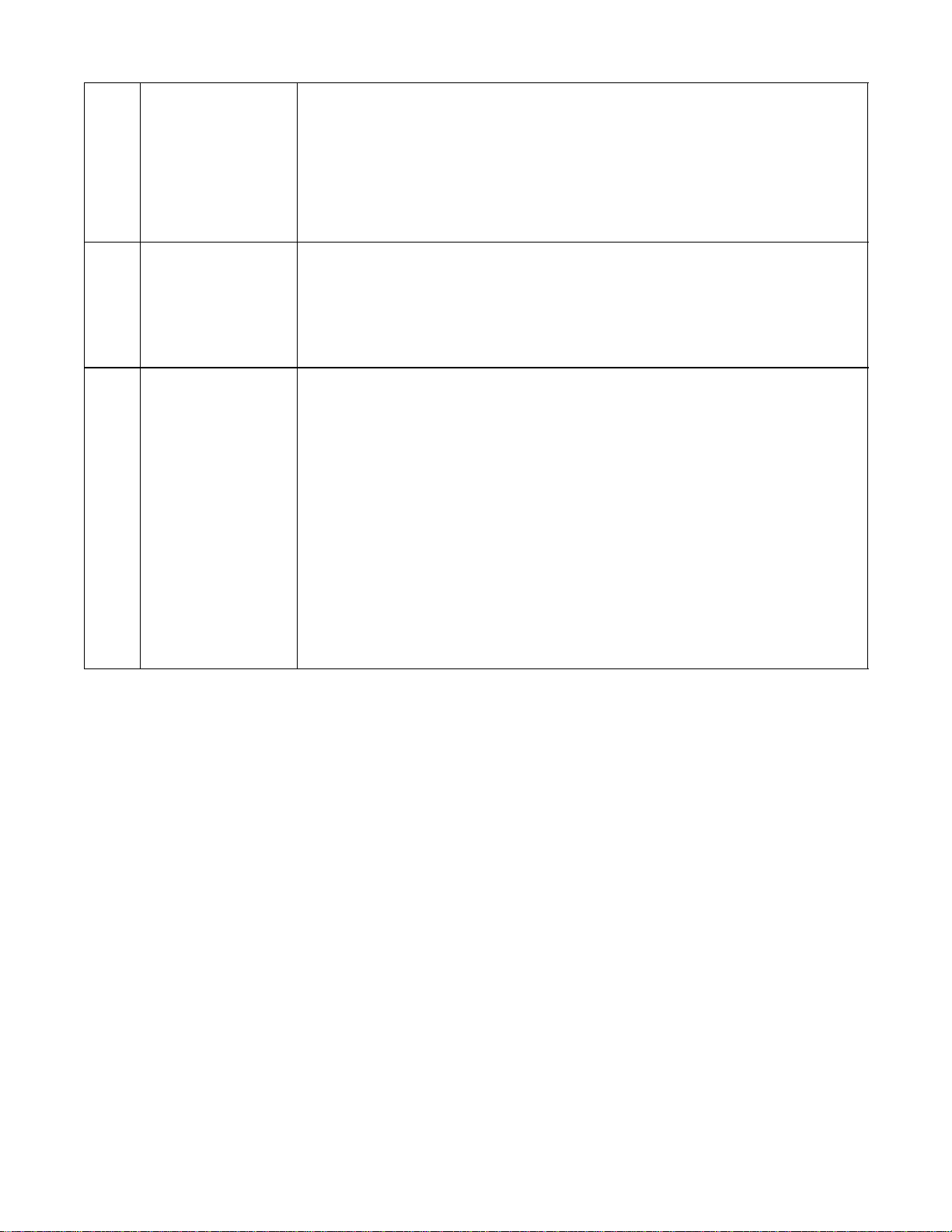

2.2 REFRIGERATION SYSTEM DATA

a.Compressor/Moto

r

y

d.H

T

h

H

igh

P

h

ibleP

l

i.R

D

i

k.W

h

Assembly

b. Evaporator Expansion

Valve Superheat

c. Economizer Expansion

Valve Superheat

eaterTermination

e.

f. Refrigerant Charge

g.Fus

h. Sight Glass/Moisture Indicator

j. Unit Weight

ressureSwitc

ug

upture

aterPressureSwitc

sc

ermostat

Model RSH105

Weight (Dry) 46.5 kg (103 lb)

Approved Oil Mobil ST32

Oil Charge 2957 ml (100 ounces)

The oil level range, with the compressor off,

Oil Sight Glass

should be between the bottom and one-eighth

level of the sight glass.

Verify at --18 _C

(0 _F) container box

4.4to6.7_C(8to12_F)

temperature

4.4 to 11.1 _C(8to20_F)

Opens 54 (¦ 3) _C = 130 (¦ 5) _F

Closes 38 (¦ 4) _C = 100 (¦ 7) _F

Cutout 25 (¦ 1.0) kg/cm@ = 350 (¦ 10) psig

Cut-In 18 (¦ 0.7) kg/cm@ = 250 (¦ 10) psig

Unit Configuration Charge Requirements -- R-134a

4--RowCoil

Water-Cooled

Condenser

Receiver

5.33 kg

(11.75 lbs)

4.99kg

(11.0 lbs)

Melting point 99 _C = (210 _F)

Torque 6.2 to 6.9 mkg (45 to 50 ft-lbs)

Torque 8.9 to 9.7 mkg (65 to 70 ft-lbs)

Bursts at 35 ¦ 5% kg/cm@ = (500 ¦ 5% psig)

Torque 6.2 to 6.9 mkg (45 to 50 ft-lbs)

Refer t o unit model number plate.

Cut-In 0.5 ¦ 0.2 kg/cm@ (7 ¦ 3psig)

Cutout 1.6 ¦ 0.4 kg/cm@ (22 ¦ 5psig)

2-6T -309

Page 21

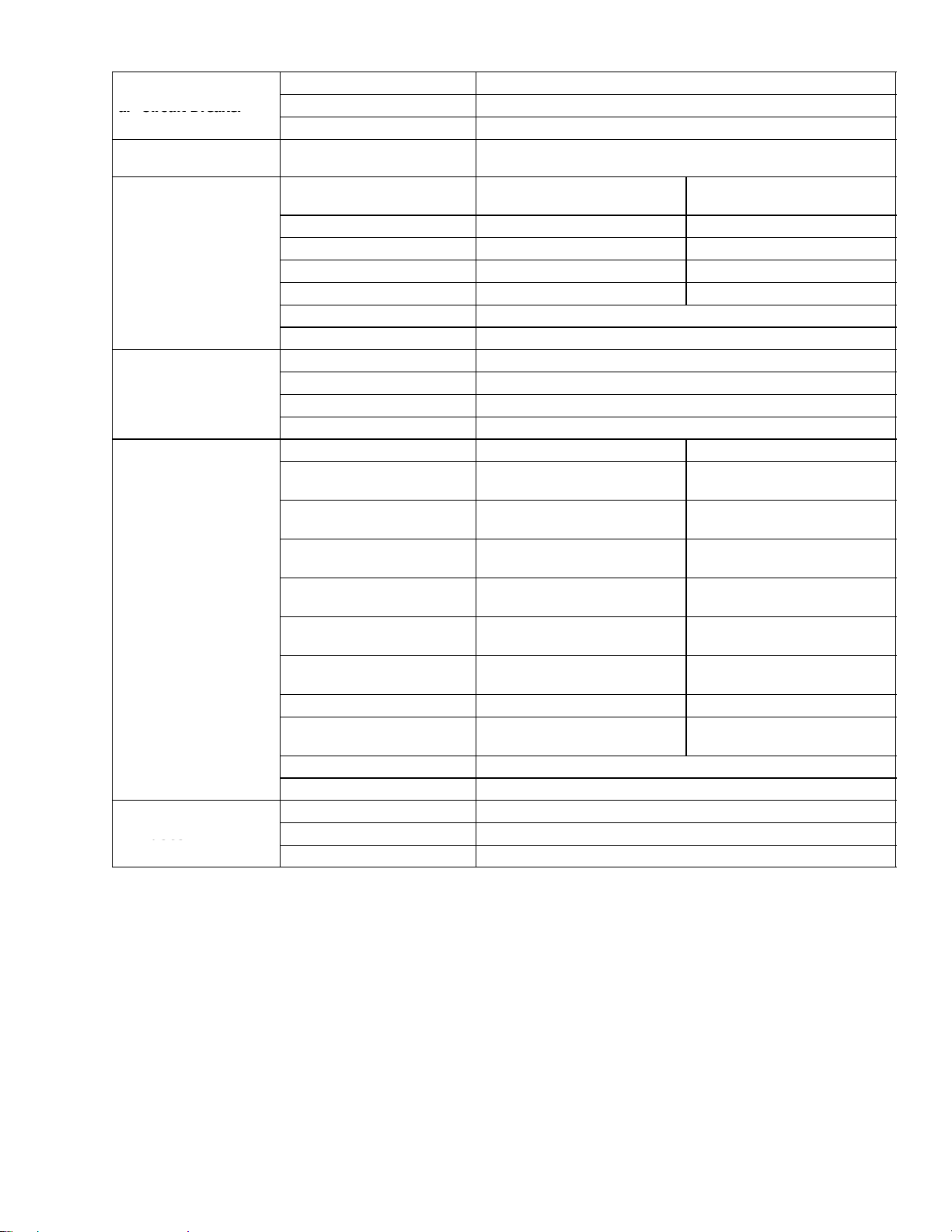

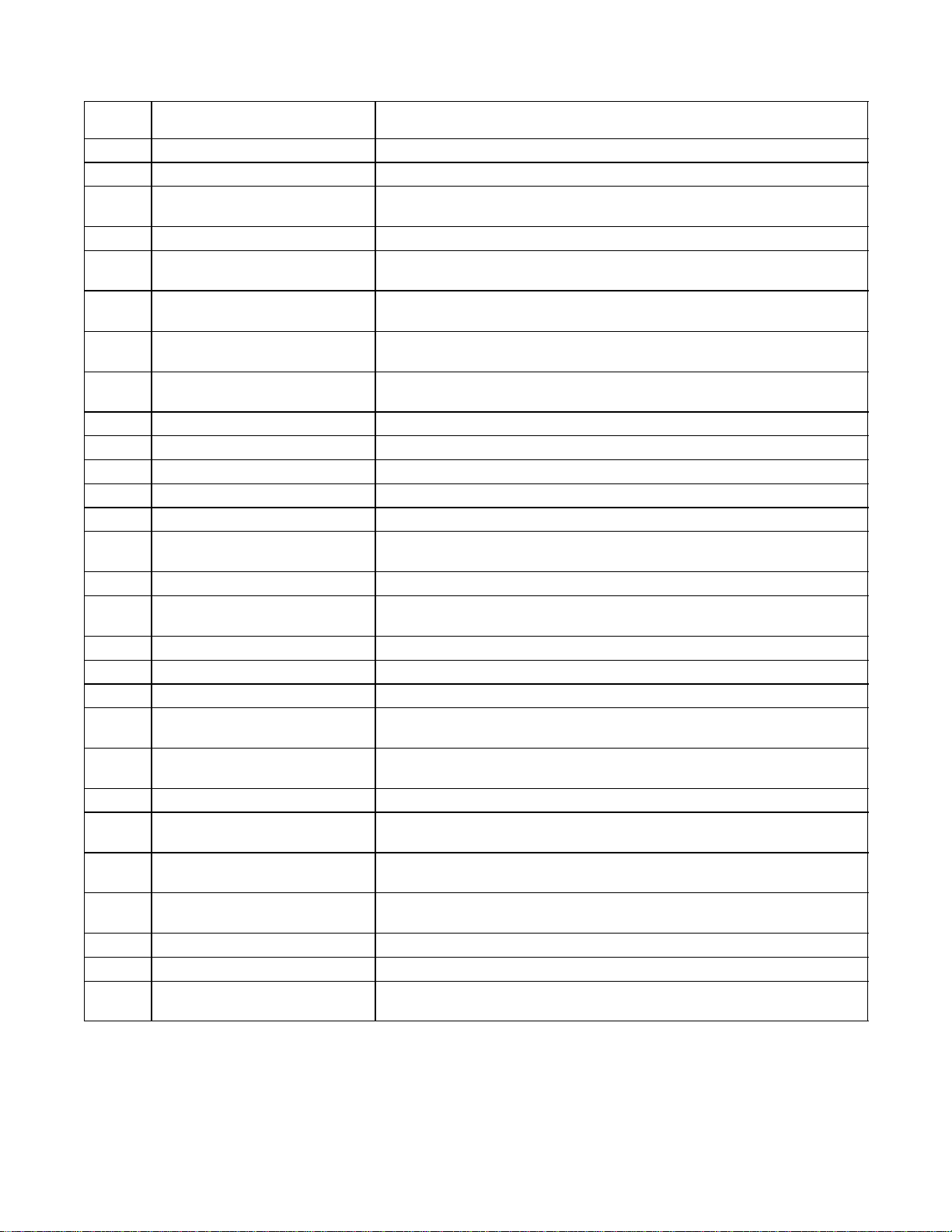

2.3 ELECTRICAL DAT A

a.CircuitBreake

r

c.CondenserFa

n

d.EvaporatorCoi

l

e.EvaporatorFan

f.Fuses

a. Circuit Breaker

b. Compressor

Motor

Motor

d. Evaporator Coil

Heaters

Motor(s)

f. Fuses

CB-1 Trips at 29 amps

CB-2 (50 amp) Trips at 62.5 amps

CB-2 (70 amp) Trips at 87.5 amps

Full Load Amps (FLA) 13 amps @ 460 vac

380 vac, Single Phase,

50 hz

Full Load Amps 1.3 amps 1.6 amps

Horsepower 0.43 hp 0.75 hp

Rotations Per Minute 1425 rpm 1725 rpm

Voltage and Frequency 360 -- 460 vac ¦ 2.5 hz 400 -- 500 vac ¦ 2.5 hz

Bearing Lubrication Factory lubricated, additional grease not required.

Rotation Counter-clockwise when viewed from shaft end.

Number of Heaters 4

Rating 750 watts +5/--10% each @ 230 vac

Resistance (cold) 66.8 to 77.2 ohms @ 20 _C(68_F)

Type Sheath

380 vac/50 hz 460 vac/60 hz

Full Load Amps

High Speed

Full Load Amps

Low Speed

Nominal Horsepower

High Speed

Nominal Horsepower

Low Speed

Rotations Per Minute

High Speed

Rotations Per Minute

Low Speed

Voltage and Frequency 360 -- 460 vac ± 1.25 hz 400 -- 500 vac ± 1.5 hz

Voltage & Frequency us-

ing power autotransformer

Bearing Lubrication Factory lubricated, additional grease not required

Rotation CW when viewed from shaft end

Control Circuit 10 amps (F3)

Controller/DataCORDER 5amps(F1&F2)

Expansion Module 10 amps (F4)

180 -- 230 vac ± 1.25hz 200 -- 250 vac ± 1.5 hz

1.6 2.0

0.8 1.0

0.70 0.84

0.09 0.11

2850 rpm 3450 rpm

1425 rpm 1750 rpm

460 vac, Single Phase,

60 hz

2-7

T-309

Page 22

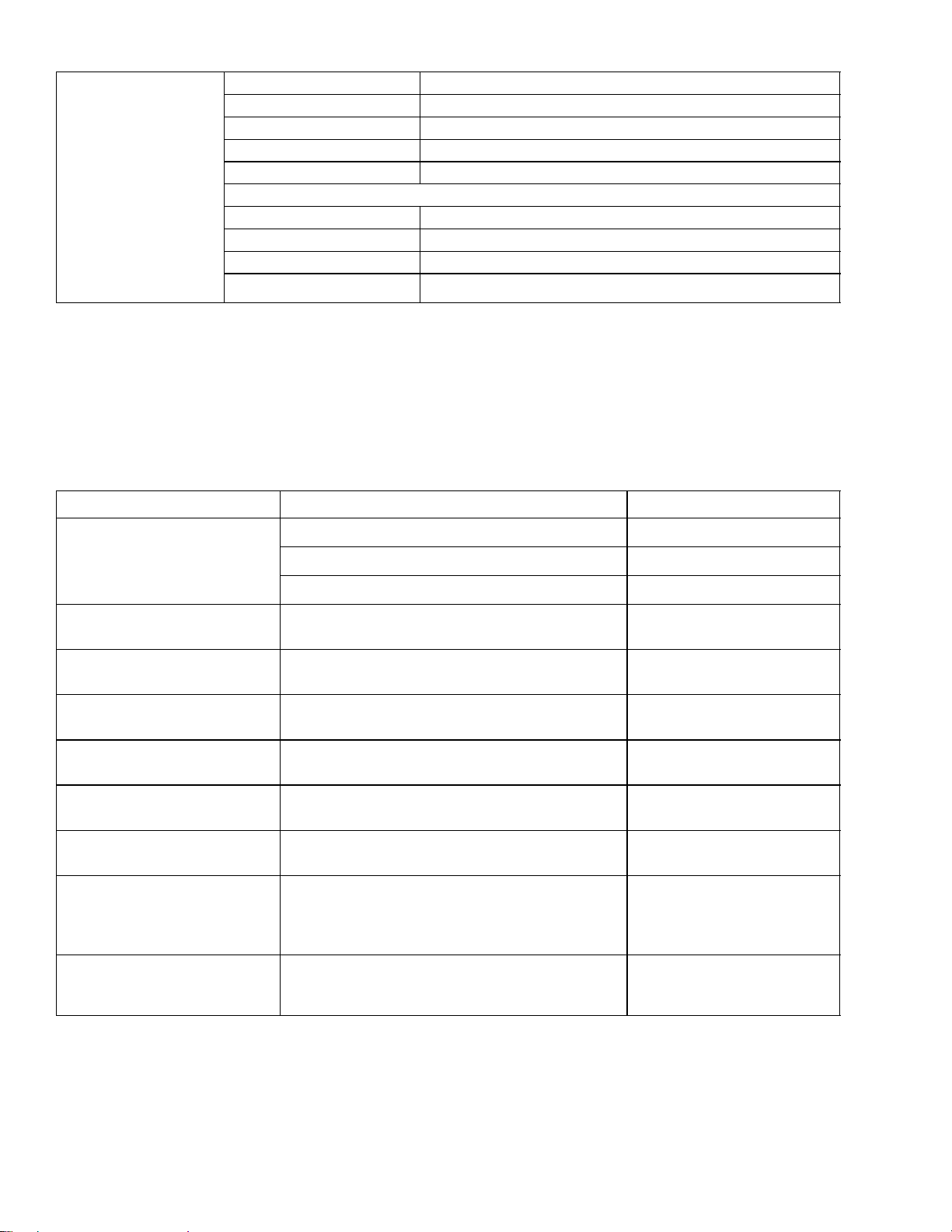

PARAGRAPH 2.3 -- Continued

idityS

Orange wire Power

Red wire Output

Brown wire Ground

Input voltage 5vdc

g.Hum

ensor

Output voltage 0to3.3vdc

30% 0.99 V

50% 1.65 V

70% 2.31 V

90% 2.97 V

Output voltage readings verses relative humidity (RH) percentage:

2.4 SAFETY AND PROTECTIVE DEVICES

Unit components are protected from damage by safety

and protective devices listed in t he following table.

Thesedevicesmonitortheunitoperatingconditionsand

open a set of electrical contacts when an unsafe

condition occurs.

Open safetyswitch contacts oneitherorbothofdevices

Table 2-1 Safety and Protective Devices

UNSAFE CONDITION

IP-CP or HPS will shut down the compressor.

Opensafetyswitch contacts ondeviceIP-CM will shut

down the condenser fan motor.

Theentirerefrigerationunit willshutdown ifoneofthe

following safety devices open: (a) Circuit Breaker(s);

(b)Fuse(F3/15A);or(c)EvaporatorFanMotorInternal

Protector(s) -- (IP-EM).

DEVICE DEVICE SETTING

Circuit Breaker (CB-1) -- Manual Reset Tripsat 29 amps (460 vac)

Excessive current draw Circuit Breaker (CB-2, 50 amp) --Manual Reset Tripsat 62.5 amps (230 vac)

Circuit Breaker (CB-2, 70 amp) --Manual Reset Trips at 87.5 amps (230 vac)

Excessive current draw in the

control circuit

Excessive current draw by the

controller

Excessive current draw by the

expansion module

Excessive condenser fan motor winding temperature

Fuse (F3) 10 amp rating

Fuse (F1 & F2) 5 amp rating

Fuse (F4) 10 amp rating

Internal Protector (IP-CM) -- Automatic Reset N/A

Excessive compressor motor

winding temperature

Excessive evaporator fan motor(s) winding temperature

Abnormal pressures/temperatures in the high refrigerant

side

Abnormally high discharge

pressure

Internal Protector (IP-CP) -- Automatic Reset N/A

Internal Protector(s) (IP-EM) -- Automatic Reset N/A

Fusible Plug -- Used on the Receiver

Rupture Disc -- Used on the Water-Cooled Con-

93 _C = (200 _F)

35 kg/cm@ = (500 psig)

denser

High Pressure Switch (HPS)

2-8T -309

Opens at 25 kg/cm@

(350 psig)

Page 23

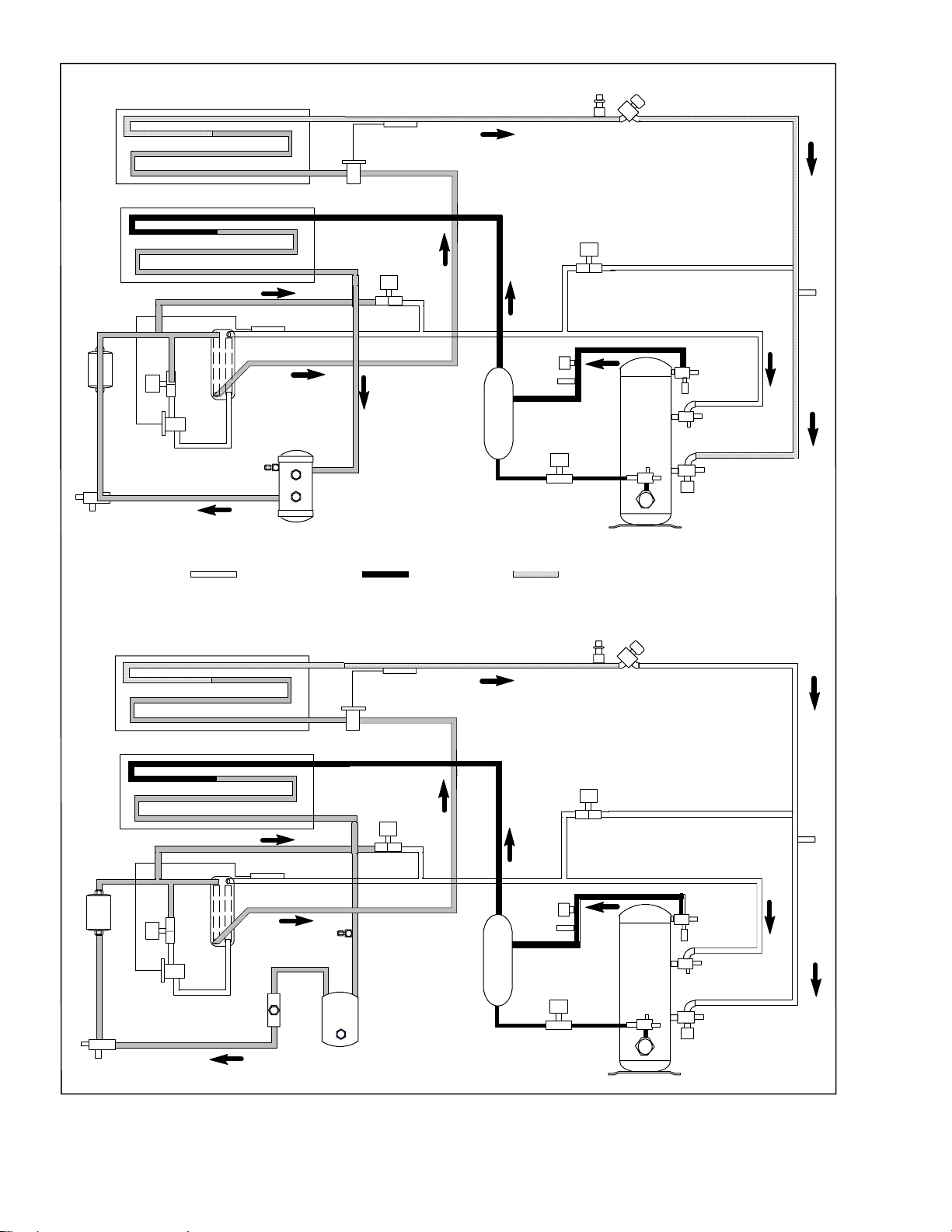

2.5 REFRIGERATION CIRCUIT

2.5.1 Standard Operation

Starting at the compressor, (see Figure 2-6, upper

schematic) the suction gas is compressed to a higher

pressure and temperature.

Inthestandardmode,boththeeconomizerandunloader

solenoid valves are closed. The gas flows through the

discharge service valve into the oil separator. In the

separator,oil is removed from the refrigerantand stored

forreturntothecompressorwhentheoil returnsolenoid

valveisopenedbythecontroller.Theoilreturnsolenoid

valveisanormallyopenvalvewhichallowsreturnofoil

during the off cycle.

The refrigerant gas continues into the air-cooled

condenser. When operating with the air-cooled

condenser active, air flowing across the coil fins and

tubes cools the gas to saturation temperature. By

removing latent heat, the gas condenses to a high

pressure/high temperature liquid and flows to the

receiver which stores the additional charge necessary

for low temperature operation.

Whenoperatingwiththewatercooledcondenseractive

(see Figure 2-6, lower schematic), the refrigerant gas

passes through the air cooled condenser and enters the

watercooled condenser shell. The waterflowinginside

thetubing coolsthe gasto saturationtemperatureinthe

same manner as the air passing over the air cooled

condenser. The refrigerant condenses on the outside of

the tubes and exits as a high temperature liquid. The

water cooled condenser also acts as a receiver, storing

excess refrigerant.

The liquid refrigerantcontinues through the liquid line

service valve, the filter-drier (which keeps refrigerant

clean and dry) and the economizer (which is not active

during standardoperation) to the evaporator expansion

valve. As the liquid refrigerant passes through the

variable orifice of the expansion valve, some of it

vaporizes into a gas (flash gas). Heat is absorbed from

the return air by the balance of the liquid, causing it to

vaporize in the evaporator coil. The vapor then flows

through the suction modulation valve to the

compressor.

Theevaporatorexpansionvalveisactivatedbythebulb

strapped to the suction line near the evaporator outlet.

The valve maintains a constant superheat at the coil

outlet regardless of load conditions.

On systems fitted with a water pressure switch, the

condenser fan will be off when there is sufficient

pressure to open the switch. If water pressure drops

belowthe switch cut out setting, thecondenser fanwill

be automatically started. When operating a system

fitted with a condenser fan switch, the condenser fan

willbeoffwhentheswitch isplaced in the“O”position.

The condenser fan will be on when theswitch is placed

in the “I” position.

2.5.2 Economized Operation

Intheeconomizedmodethefrozenrangeandpulldown

capacityoftheunitisincreasedbysubcoolingtheliquid

refrigerant entering the evaporator expansion valve.

Overall efficiency is increased because the gas leaving

the economizer enters the compressor at a higher

pressure, therefore requiring less energy to compress it

to the required condensing conditions.

During economized operation, flow of refrigerant

through the main refrigerant system is identical to the

standard mode. (The unloader solenoid valve is

de--energized [closed] by the controller.)

Liquid refrigerant for use in the economizer circuit is

taken from the main liquid line as it leaves the

filter--drier(seeFigure 2-7).Theflowis activatedwhen

thecontroller energizesthe economizer solenoid valve.

The liquid refrigerant flows through the economizer

expansion valve and the economizer internal passages

absorbingheatfromtheliquid refrigerantflowingtothe

evaporator expansion valve. The resultant “medium”

temperature/pressure gas enters the compressor at the

economizer service valve.

2.5.3 Unloaded Operation

The system will operate in the unloaded mode during

periods of low load, during periods of required

discharge pressure or current limiting, and during

start--up.

During unloaded operation, flow of refrigerantthrough

the main refrigerant system is identical to the standard

mode. (The economizersolenoid valve isde--energized

[closed] by the controller.)

In the unloaded mode, a portion of the mid--stage

compressed gas is bypassed to decrease compressor

capacity. The flow is activated when the controller

opens the unloader solenoid valve (see Figure 2-7.

Opening of the valve creates a bypass from the

economizerservicevalvethroughtheunloadersolenoid

valve and into the suction line on the outlet side of the

suction pressure modulation valve.

Asloadonthesystemdecreases,thesuctionmodulating

valve decreases flow of refrigerant to the compressor.

This action balances the compressor capacity with the

loadandpreventsoperation with low coiltemperatures.

In this mode of operation, the liquid injection solenoid

valve will open as required to provide sufficientliquid

refrigerant flow into the suction line for cooling of the

compressor motor.

2-9

T-309

Page 24

EVAPORATOR

STANDARD OPERATION WITH RECEIVER

LOW SIDE ACCESS VALVE

FILTER

DRIER

ECONOMIZER

TXV

LIQUID LINE

SERVICE

CONNECTION

CONDENSER

ESV

FUSIBLE PLUG

TXV BULB

TXV

USV

LIV

ECONOMIZER TXV BULB

ECONOMIZER

OIL SEPARATOR

RECEIVER

SIGHTGLASS

MOISTURE INDICATOR

DISCHARGE LIQUID SUCTION

DPT

CPDS

ORV

OIL RETURN

SERVICE VALVE

SMV

COMPRESSOR

DISCHARGE

SERVICE

CONNECTION

HPS

ECONOMIZER

SERVICE

CONNECTION

SUCTIONSERVICE

CONNECTION

SPT

STS

FILTER

DRIER

STANDARD OPERATION WITH WATER COOLED CONDENSER

ECONOMIZER

TXV

LIQUID LINE

SERVICE

CONNECTION

EVAPORATOR

CONDENSER

ECONOMIZER TXV BULB

ECONOMIZER

ESV

SIGHTGLASS/

MOISTURE INDICATOR

TXV

RUPTURE DISC

WATER COOLED

CONDENSER

TXV BULB

LIV

LOW SIDE ACCESS VALVE

USV

DPT

CPDS

ORV

OIL RETURN

SERVICE VALVE

SMV

COMPRESSOR

DISCHARGE

SERVICE

CONNECTION

HPS

SPT

QUENCH

TXV

BULB

ECONOMIZER

SERVICE

CONNECTION

SUCTIONSERVICE

CONNECTION

CPSS

Figure 2-6 Refrigeration Circuit Schematic -- Standard Operation

2-10T-309

Page 25

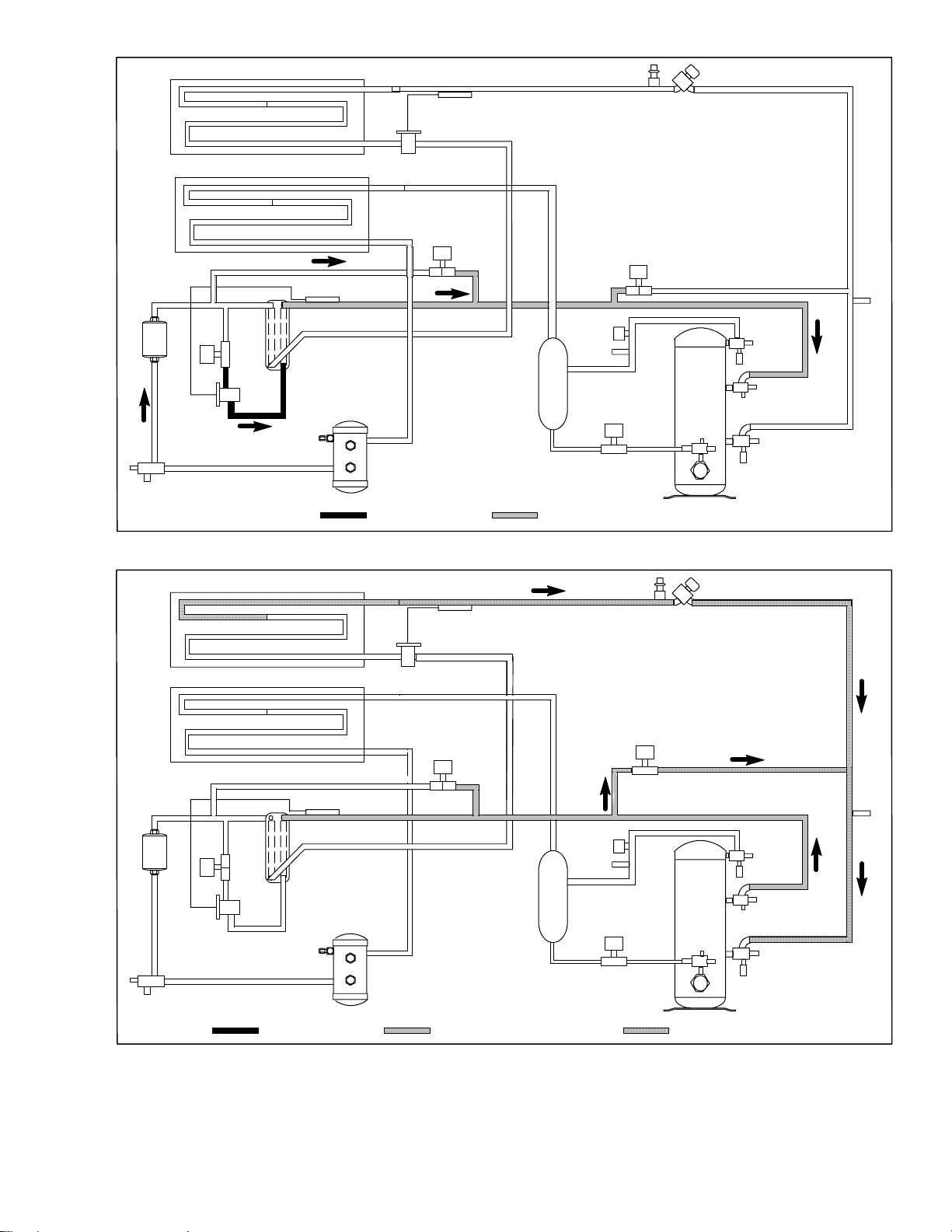

EVAPORATOR

LOW SIDE ACCESS VALVE

CONDENSER

ESV

ECONOMIZER

TXV

LIQUID LINE

SERVICE CONNECTION

ECONOMIZER TXV BULB

ECONOMIZER

RECEIVER

LIQUID ECONOMIZER PRESSURE

TXV BULB

TXV

LIV

OIL SEPARATOR

SMV

ECONOMIZER

SERVICE

CONNECTION

Figure 2-7 Refrigeration Circuit Schematic -- Economized Operation

TXV BULB

TXV

LIV

ECONOMIZER TXV BULB

OIL SEPARATOR

RECEIVER

SMV

USV

SUCTIONSERVICE

CONNECTION

LIQUID ECONOMIZER PRESSURE

SUCTION

Figure 2-8 Refrigeration Circuit Schematic -- Unloaded Operation

2-11

T-309

Page 26

SECTION 3

MICROPROCESSOR

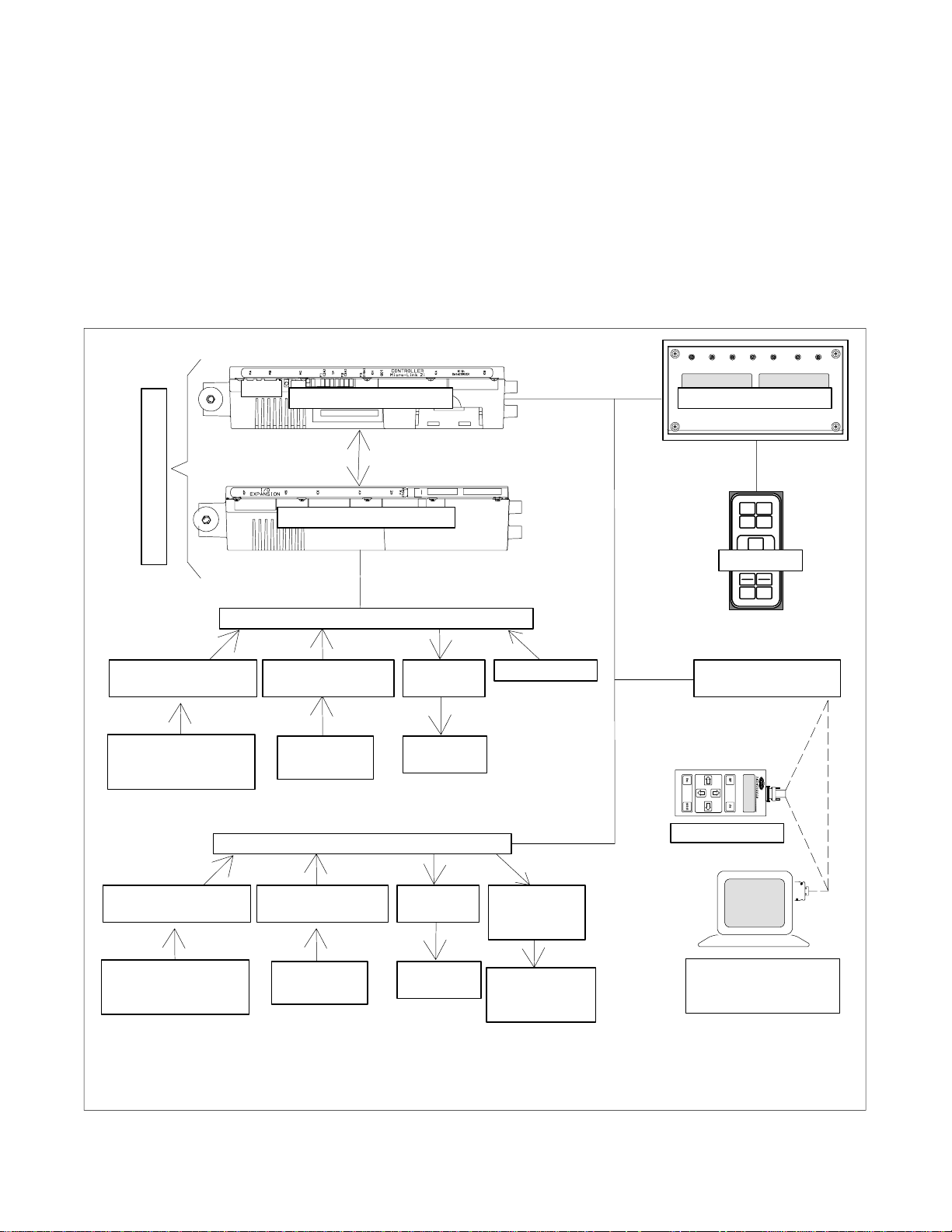

3.1 TEMPERATURE CONTROL MICROPROCESSOR SYSTEM

The temperature control Micro-Link 2i microprocessor

system (see Figure 3- 1) consists of a key pad, display

module, the control module & expansion module set

(controller)and interconnecting wiring. The controller

houses the temperature control software and the

DataCORDER Software. The temperature control

software functions to operate the unit components as

required to provide the desired cargo temperature and

humidity. The DataCORDER software functions to

record unitoperatingparameters and cargo temperature

parameters for future retrieval. Coverage of the

temperaturecontrolsoftwarebeginswithparagraph3.2.

Coverageof theDataCORDER software is providedin

paragraph 3.6.

The key pad and display module serve to provide user

accessand readoutsfor bothofthe controller functions,

temperaturecontrol and DataCORDER. The functions

are accessed by key pad selections and viewed on the

displaymodule.Thecomponentsaredesignedtopermit

ease of installation and removal.

C

O

N

T

R

O

L

L

E

R

TEMPERATURE CONTROL SOFTWARE

CONFIGURATION

SOFTWARE

CONFIGURATION

VARIABLE

(CnF##)

CONTROL MODULE DISPLAY MODULE

EXPANSION MODULE

KEY PAD

OPERATIONAL

SOFTWARE

FUNCTION

CODE (Cd)

DataCORDER SOFTWARE

ALARMS

(AL<70)

TO

DISPLAY

PRE--TRIP INTERROGATION

CONNECTOR

DATAREADER

CONFIGURATION

SOFTWARE

CONFIGURATION

VARIABLE

(dCF## read only)

OPERATIONAL

SOFTWARE

FUNCTION

CODE (dC)

Figure 3- 1 Temperature Control System

ALARMS

(AL>69)

TO

DISPLAY

STORAGE

MEMORY

(Scrollback)

3-1

DATA

TO

DISPLAY

Computer Device

With DataLine

Software

T-309

Page 27

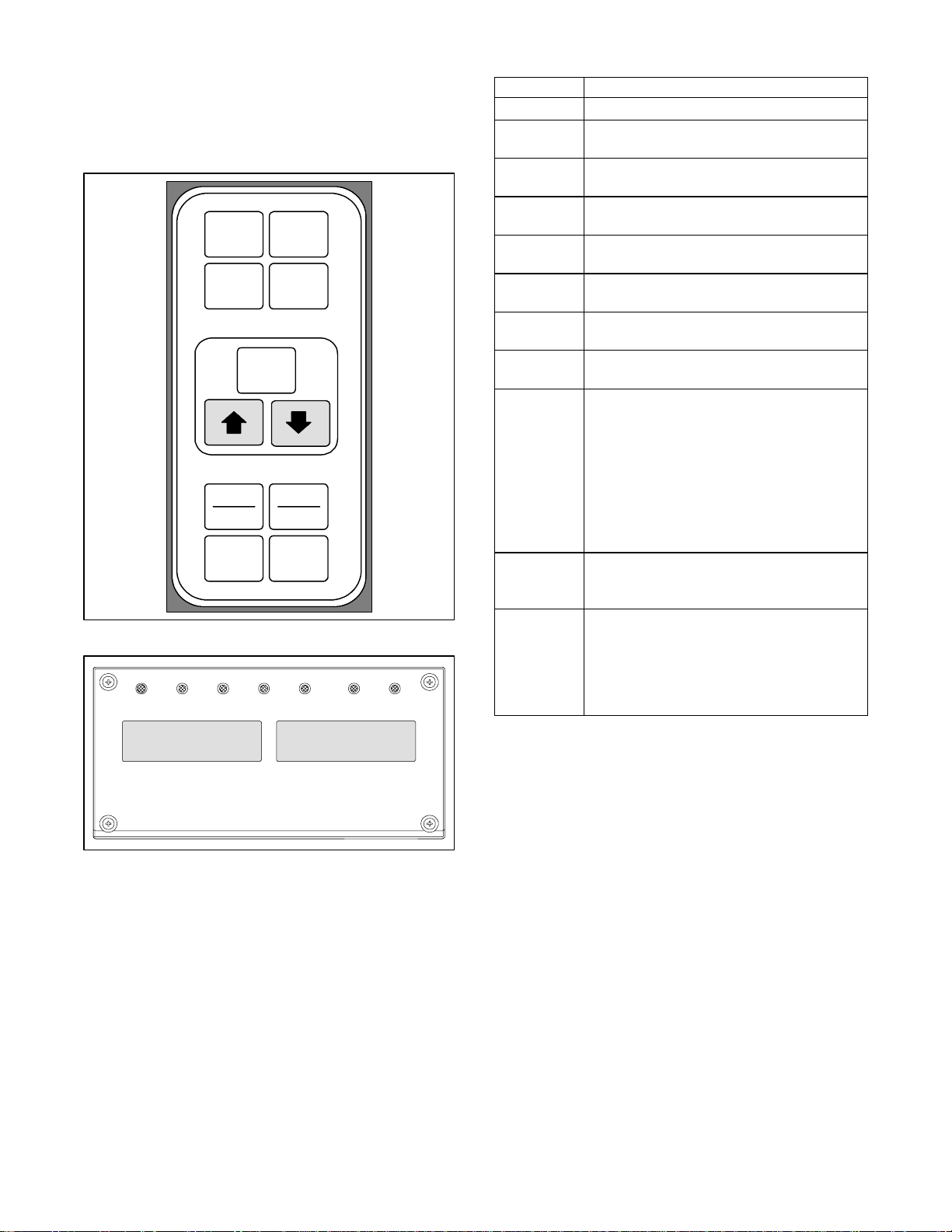

3.1.1 Key Pad

Thekey pad (Figure 3- 2)is mounted on the right-hand

side of the control box. The key pad consists of eleven

pushbuttonswitchesthatactas the user’sinterfacewith

the controller. Descriptions of the switch functions are

provided in Table 3-1.

CODE

SELECT

ALARM

LIST

RETURN

SUPPLY

BATTERY

POWER

Figure 3- 2 Key Pad

COOL HEAT DEFROST IN RANGEALARM SUPPLY RETURN

PRE

TRIP

DEFROST

INTERVAL

ENTER

_C

_F

ALT.

MODE

Table 3-1 Key Pad Function

KEY FUNCTION

Code Select Accesses function codes.

Pre-Trip

Alarm List

Defrost

Interval

Enter

Arrow Up

Arrow

Down

Return/

Supply

Displaysthe pre-trip selection menu. Discontinues pre-trip in progress.

Displaysalarm list and clears the alarm

queue.

Displaysselected defrost interval.

Confirmsa selection or saves a selection

to the controller.

Change or scroll a selection upward Pre-

trip advance or test interruption.

Change or scroll a selection downward.

Pre-trip repeat backward.

Displays non-controlling probe tempera-

ture (momentary display).

Displaysalternate English/Metricscale

(momentary display). When set to _F,

pressure is displayed in psig and vacuum

in “/hg. “P” appears after the value to in-

_C/_F

dicate psig and “i” appears for inches of

mercury.

When set to _C. pressure readings are in

bars. “b” appears after the value to indicate bars.

Battery

Power

Initiate battery backup mode to allow set

point and function code selection if AC

power is not connected.

This key is pressed to switch the functions

from the temperature software to the Da-

ALT Mode

taCORDERSoftware. The remaining keys

function the same as described above except the readings or changes are made to

the DataCORDER programming..

SETPOINT/Code AIR TEMPERATURE/Data

Figure 3- 3 Display Module

3.1.2 Display Module

The display module (Figure 3- 3) consists of two

backlightedfivedigit LCD displaysandsevenindicator

lights. The i ndicator lights include:

1. Cool -- White LED: Energized when the refrigerant

compressor is energized.

2. Heat-- OrangeLED:Energized toindicateheaterop-

eration in the heat or defrost mode.

3. Defrost-- OrangeLED: Energizedwhentheunit isin

the defrost mode.

4. In-Range -- Green LED: Energized whe n the con-

trolled temperature probe is within specified tolerance of set point.

NOTE

The controlling probe in the perishable range

will be the SUPPLY air probe and the controlling probe in the frozen range will be the

RETURN air probe.

5. Supply--YellowLED:Energizedwhenthesupplyair

probe is used for control. When this LED is illuminated,the temperaturedisplayed in the AIR TEMPERATURE display is the reading at the supply air probe.

ThisLED will flash if dehumidificationor humidification is enabled.

6. Return -- YellowLED:Energizedwhenthereturnair

probe is used for control. When this LED is illuminated, the temperature displayed in the AIR TEMPERA TUREdisplayis thereading atthe returnairprobe. This LED will flash if dehumidification or

humidification is enabled.

7. Alarm-- Red LED: Energizedwhenthereis anactive

or an inactive shutdown alarm in the alarm queue

3-2T -309

Page 28

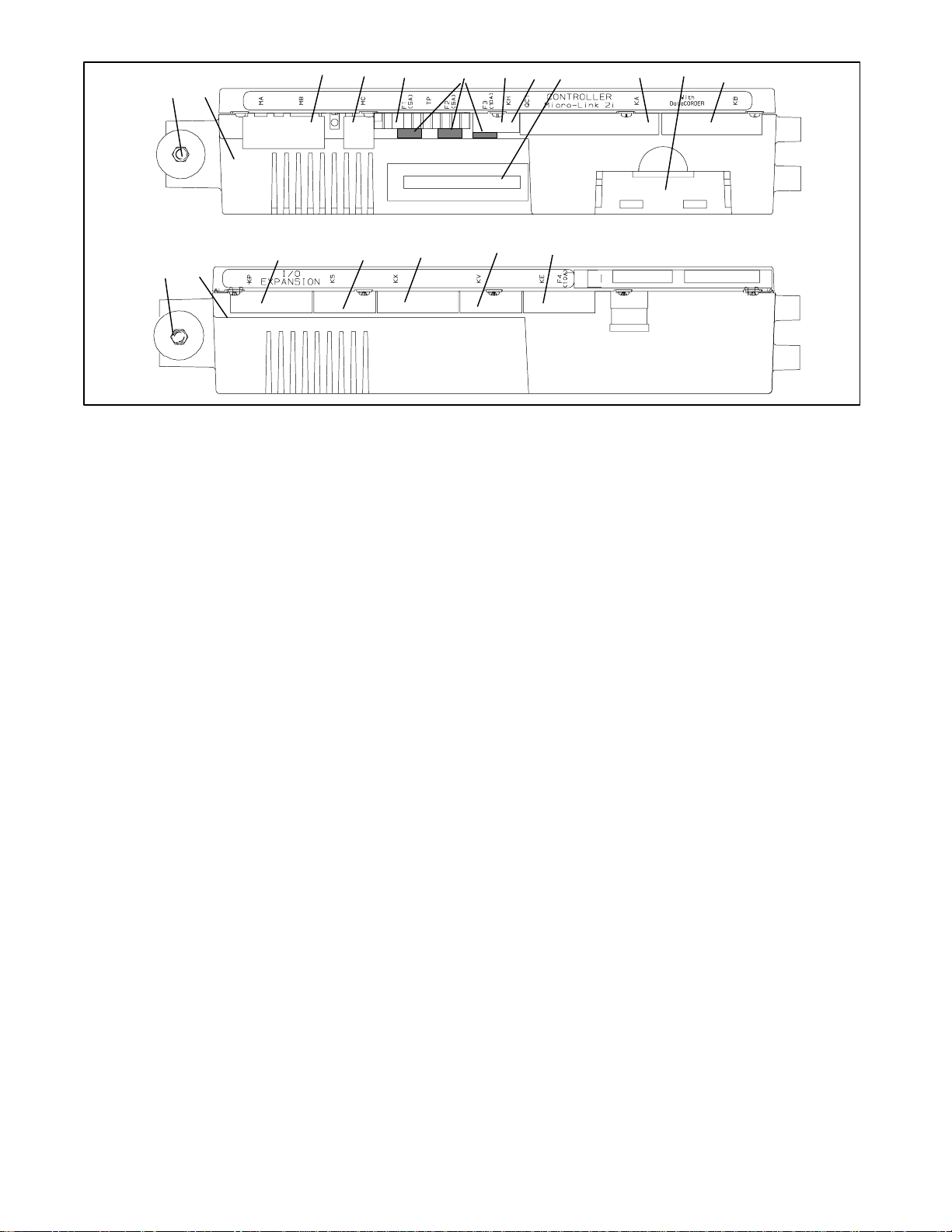

12

33 3 3 345 67

8

9

1

1. Mounting Screw

2. Micro-Link 2i Control/DataCORDER Module

3. Connectors

4. Test Points

5. Fuses

3.1.3 Controller

3

Figure 3- 4 Control and Expansion Modules

3

3 3 3

CAUTION

Do not remove wire harnesses from controller modules unless you are grounded to the

unit frame with a static safe wrist strap.

CAUTION

Unplug all controller module wire harness

connectors before performing arc welding

on any part of the container.

NOTE

Do not attempt to service the controller modules. Breaking the seal will void the warranty.

The Micro--Link 2i controller is a dual module

microprocessoras shown inFigure 3- 4. Itis fittedwith

test points, harness connectors and a software card

programming port.

3.2 CONTROLLER SOFTWARE

The controller software is a custom designed program

that is subdivided into the Configuration Software and

the Operational Software. The controller software

performs the following functions:

a. Control supply or return air temperature to required

limits, provide modulated refrigeration operation,

economized operation, unloaded operation, electric

heatcontrolanddefrost. Defrost isperformedtoclear

build up of frost and ice and ensure proper air flow

across the coil.

b. Providedefaultindependentreadoutsofsetpointand

supply or return air temperatures.

6. Control Circuit Power Connection

(Location: In back of controller)

7. Software Programming Port

8. Battery Pack

9. Expansion Module

c. Provide abilityto readand (ifapplicable)modifythe

Configuration Software Variables, Operating Software Function Codes and Alarm Code Indications.

d. ProvideaPre-Tripstep-by-stepcheckoutofrefrigera-

tion unit performance including: proper component

operation,electronicand refrigerationcontroloperation, heater operation, probe calibration, pressure

limiting and current limiting settings.

e. Provide battery powered ability to access or change

selected codes and set point without AC power connected

f. Providetheabilitytoreprogramthe softwarethrough

theuseofamemorycard. Thememorycardautomaticallydownloadsnewsoftwaretothecontrollerwhen

inserted.

3.2.1 Configuration Software (Configuration Variables)

The Configuration Software is a variable listing of the

components available for use by the Operational

Software. This software is factory installed in

accordance withthe equipmentfitted and options listed

on the original purchase order. Changes to the

Configuration Software are required only when a new

controller hase been installed or a physical change has

beenmadetothe unit suchasthe additionor removalof

an option. A Configuration Variable list is provided in

Table 3-4. Change to the factory installed

ConfigurationSoftwareis achievedvia a configuration

card or communications.

3-3

T-309

Page 29

3.2.2 Operational Software (Function codes)

The Operational Software is the actual operation

programming of the controller which activates or

deactivates components inaccordancewith currentunit

operating conditions and operator selected modes of

operation.

TheprogrammingisdividedintofunctionCodes.Some

of the codes are read only while the remaining codes

may be user configured. The value of the user

configurable codes can be assigned in accordance with

user desired mode of operation. A list of the function

codes is provided in Table3-5.

Toaccess the function codes, perform the following:

a. Press the CODE SELECT key, then press an arrow

key until the left window displays the desired code

number.

b. The right window will display the value of this item

for five seconds before returning to the normal display mode.

c. If a longer time is desired, press the ENTER key to

extend the time to 30 seconds.

3.3 MODES OF OPERATION

The Operational Software responds to various inputs.

These inputs come from the temperature and pressure

sensors,thetemperaturesetpoint,the settings of thethe

configuration variables and the function code

assignments. The action t aken by the Operational

Software will change if any one of the inputs changes.

Overall interaction of the inputs is described as a

“mode” of operation. The modes of operation include,

perishable (chill) mode and frozen mode. Descriptions

ofthe controllerinteractionand modesof operationare

provided in the following sub paragraphs.

3.3.1 Temperature Control -- Perishable Mode

With configuration variable CnF26 (Heat Lockout

Temperature) set to --10_C the perishable mode of

operation i s active with set points at or above --10_C

(+14_F). With the variable set to --5_C, the perishable

mode is active at or above --5_C(+23_F). Refer to

Table 3-4.

When in the perishable mode the controller maintains

the supply air temperature at set point, the SUPPLY

indicatorlightwillbeilluminatedonthedisplaymodule

and the default reading on the display window will be

the supply temperature sensor reading.

When the supply air temperature enters the in-range

temperature tolerance (as selected at function code

Cd30), the in-range light will energize.

3.3.2 Defrost Interval

Function code Cd27 may be operator set to initiate

defrostatintervalsof3, 6,9, 12or24hours. It mayalso

be set to OFF (no defrost). The factory default is 12

hours. (Refer to Table 3-5).

3.3.3 Failure Action

Function code Cd29 may be operator set to allow

continuedoperation in the event the control sensors are

readingout of range. The factory default is full system

shutdown. (Refer to Table 3-5).

3.3.4 Generator Protection

Function codes Cd31(Stagger Start, Offset Time) and

Cd32 (Current Limit) may be operator set to control

startupsequenceofmultipleunitsandoperatingcurrent

draw.Thefactorydefaultallowsondemandstarting(no

delay) of units and normal current draw. Refer to

Table 3-5.

3.3.5 Compressor High Temperature, Low Pressure Protection.

The controller monitors compressor suction and

discharge temperatures and pressures. If the discharge

temperature exceedsa certain limit, the liquidinjection

valve is opened to provide sufficient liquid refrigerant

flow into the economizer line to reduce the discharge

temperature. If the liquid injection is unable to reduce

the discharge temperature sufficiently and the

temperature exceeds the allowed limit, the compressor

willcycle off on a 3 minute timer. The compressorwill

alsocycleoffinasimilarmannerifthe suction pressure

fallsbelowtheallowedlimit.Condenserandevaporator

fans continue to operate during t he compressor off

cycle.

3.3.6 Perishable Mode -- Conventional

The unit is capable of maintaining supply air

temperaturet o within ¦0.25_C(¦0.5_F)of set point.

Supply air temperature is controlled by positioning of

the suction modulation valve (SMV), cycling of the

compressor and cycling of the heaters.

When cooling from a temperature that is more than

2.5_C (4.5_F)abovesetpoint, t he systemwill bein the

perishable pull down mode. It will be in economized

operation with a target S MV position of 100% open.

However, pressure and current limit functions may

restrict the valve, if either exceeds the preset value.

Once set point is reached, the unit will transition to the

perishable steady state mode. This results in unloaded

operationwith some restriction of the SMV. The SMV

will continue to close and restrict refrigerant flow until

the capacity of the unit and the load are balanced.

If the SMV is at minimum modulation, the controller

has determined that cooling is not required, or the

controllerlogicdeterminessuctionpressureisatthelow

pressure limit, the unit will transition to the perishable

idle mode. The compressor is turned off and the

evaporator fans continue to run to circulate air

throughout the container.If temperaturerises above set

point +0.2_C, the unit will transition back to the

perishable steady state mode

If the temperature drops to 0.5_C (0.9_F) below set

point, t he unit will transition to the perishable heating

3-4T -309

Page 30

mode and the heaters will be energized . The unit will

transition back to the perishable idle mode when the

temperaturerises to 0.2_C (0.4_F) below the set point

and the heaters will de-energize

3.3.7 Perishable Mode -- Economy

Theeconomy mode is an extensionof the conventional

mode. The mode is activated when the setting of

function code Cd34 is “ON”. Economy mode is

provided for power saving purposes. Economy mode

could be utilized in the transportation of temperature

tolerant cargo or non-respiration items which do not

require high airflow for removing respiration heat.

Thereisno active display indicatorthateconomy mode

has been activated. To check for economy mode,

perform a manual display of code Cd34.

In order to achieve economy mode, a perishable set

point must be selected prior to activation. When

economy mode is active, the evaporator fans will be

controlled as follows:

At the start of each cooling or heating cycle, the

evaporator fans will be run in high speed for three

minutes. They will then be switched to low speed any

time the supply air temperature is within ¦ 0.25_C

(0.45_F)ofthesetpointandthereturnairtemperatureis

less than or equal to the supply air temperature + 3_C

(5.4_F). The fans will continue to run in low speed for

onehour.Attheendofthehour,theevaporatorfanswill

switchbackto highspeedandthecyclewillberepeated.

Ifbulb mode is active, theeconomy fanactivity will be

overwritten.

3.3.8 Perishable Mode -- Dehumidification

The dehumidification mode is provided to reduce the

humidity levels inside the container. The mode is

activated when a humidity value is set at at function

codeCd33. The display moduleSUPPLY led will flash

ON and OFF every second to indicate that the

dehumidification mode is active. Once the Mode is

active and the following conditions are satisfied, the

controller will activate the heat relay to begin

dehumidification.

1. The humidity sensor reading is above the set point.

2. The unit is in the perishable steady state mode and

supply air temperatureis less than 0.25_C aboveset

point.

3. Theheaterdebouncetimer(threeminutes)hastimed

out.

4. Heater termination thermostat (HTT) is closed.

Ifthe aboveconditions aretrue theevaporatorfanswill

switch from high to low speed operation. The

evaporatorfanspeedwillswitcheveryhourthereafteras

long as all conditions are met (see Bulb Mode section

for different evaporator fan speed options). If any

condition except for item (1) becomes false OR if the

relative humidity sensed is 2% below the

dehumidification set point, the high speed evaporator

fans will be energized.

In the dehumidification mode power is applied to the

defrost and drain pan heaters. This added heat load

causes the controller t o open the suction modulating

valve to match the increased heat load while still

holding the supply air temperature very close to the set

point.

Opening t he modulating valve reduces the temperature

oftheevaporatorcoil surface,whichincreasestherateat

which water is condensed from the passing air.

Removing water from the air reduces the relative

humidity. When the relative humidity sensed is 2%