Page 1

40VMF009A-048A

4-Way Cassette Indoor Unit for

Variable Refrigerant Flow (VRF) Systems

Installation and Maintenance Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Step 1 — Unpack and Inspect Units . . . . . . . . . . . . 6

• PROTECTING UNITS FROM DAMAGE

• PREPARING JOBSITE FOR UNIT INSTALLATION

• IDENTIFYING AND PREPARING UNITS

Step 2 — Position the Unit . . . . . . . . . . . . . . . . . . . . 6

Step 3 — Mount the Unit . . . . . . . . . . . . . . . . . . . . . . 7

• INSTALLING HANGER BOLTS

• MOUNTING UNIT

• INSTALLING PANEL

Step 4 — Connect Piping . . . . . . . . . . . . . . . . . . . . . . 8

• CONDENSATE PIPING

• REFRIGERANT PIPING

Step 5 — Complete Electrical Connections. . . . . . 9

Step 6 — Position and Connect Controller . . . . . 11

ACB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pre-Start Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Operation Check . . . . . . . . . . . . . . . . . . . . 15

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INDOOR UNIT ADDRESSING. . . . . . . . . . . . . . 15-17

Wireless Remote Controller (40VM900001) . . . . . 15

Non-Programmable Controller (40VM900002). . . 16

Programmable Controller (40VM900003). . . . . . . 16

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . 17-19

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 19

APPENDIX A — DIP SWITCH SETTINGS . . . . . . . . 20

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury or

property damage. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this

product.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes and the current editions of the National

Electrical Code (NEC) ANSI/NFPA (American National

Standards Institute/National Fire Protection Association) 70. In

Canada, refer to the current editions of the Canadian Electrical

Code CSA (Canadian Standards Association) C22.1.

Understand the signal words — DANGER, WARNING,

and CAUTION. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies hazards that could result in personal

injury or death. CAUTION is used to identify unsafe practices,

which would result in minor personal injury or product and

property damage.

Recognize safety information. This is the safety-alert

symbol ( ). When this symbol is displayed on the unit and in

instructions or manuals, be alert to the potential for personal

injury. Installing, starting up, and servicing equipment can be

hazardous due to system pressure, electrical components, and

equipment location.

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all

disconnect locations to alert others not to restore power

until work is completed.

WARNING

When installing the equipment in a small space, provide

adequate measures to avoid refrigerant concentration

exceeding safety limits due to refrigerant leak. In case of

refrigerant leak during installation, ventilate the space

immediately. Failure to follow this procedure may lead to

personal injury.

WARNING

DO NOT USE TORCH to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective gloves and

goggles and proceed as follows:

a. Shut off electrical power to unit.

b. Recover refrigerant to relieve all pressure from

system using both high-pressure and low pressure

ports.

c. Traces of vapor should be displaced with nitrogen

and the work area should be well ventilated.

Refrigerant in contact with an open flame produces

toxic gases.

d. Cut component connection tubing with tubing cutter

and remove component from unit. Use a pan to catch

any oil that may come out of the lines and as a gage

for how much oil to add to the system.

e. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Failure to follow these procedures may result in personal

injury or death.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 18-40VMF002-01 Printed in U.S.A. Form 40VMF-2SI Pg 1 1-18 Replaces: 40VMF-1SI

Page 2

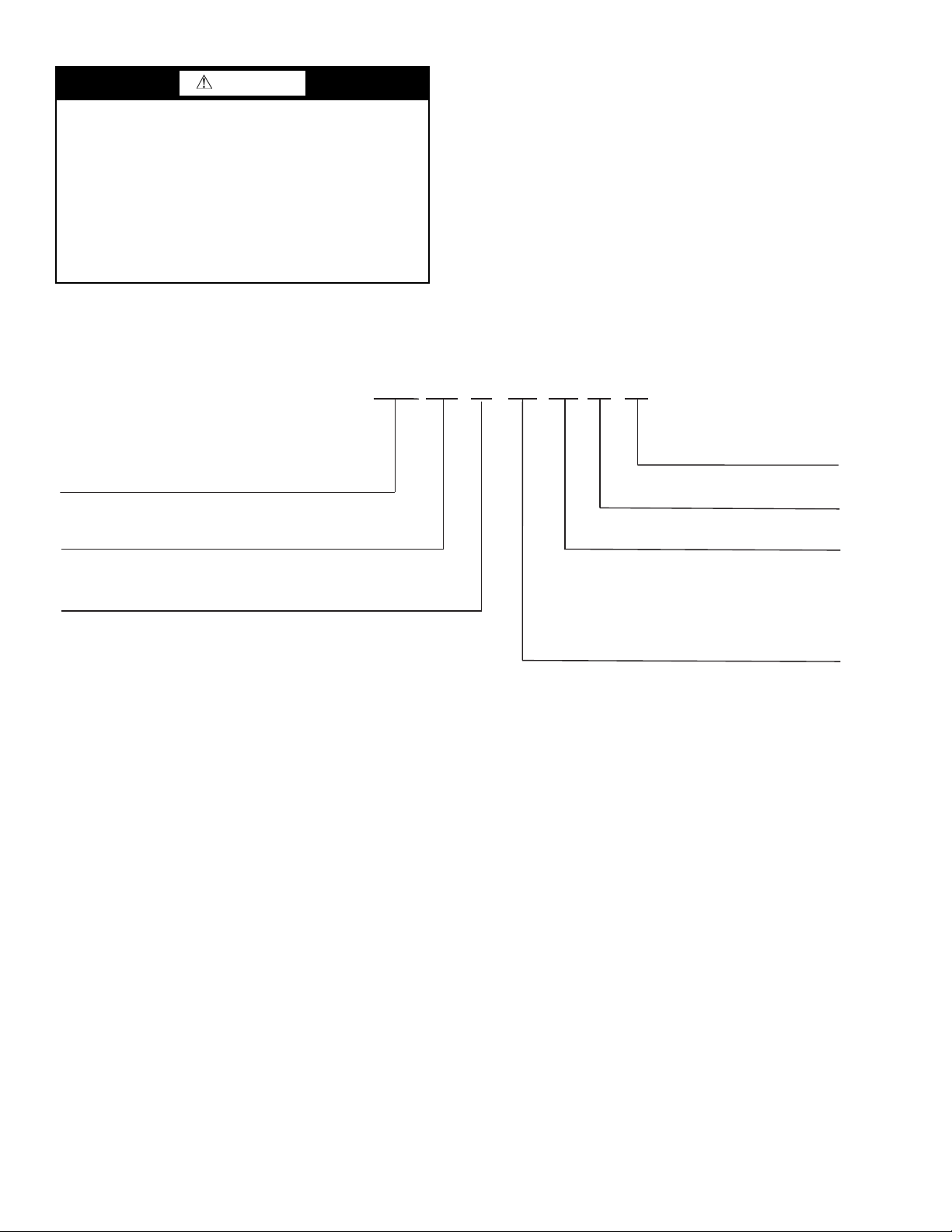

CAUTION

LEGEND

VRF — Variable Refrigerant Flow

40 VM F

009

--

3

Equipment Type

40 —

Indoor Unit

Product Type

VM — VRF

Blank

Voltage (V-Ph-Hz)

3 — 208/2 3 0-1-60

Model Type

F — 4-Way Cassette

Capacity (Btuh)

009

— 9,000

012

— 12,000

015

— 15,000

024

— 24,000

018

— 19,100

030

— 30,000

036

— 36,000

A40-1914

048

— 48,000

LEGEND

VRF — Variable Refrigerant Flow

A

Design Revision

DO NOT re-use compressor oil or any oil that has been

exposed to the atmosphere. Dispose of oil per local codes

and regulations. DO NOT leave refrigerant system open to

air any longer than the actual time required to service the

equipment. Seal circuits being serviced and charge with

dry nitrogen to prevent oil contamination when timely

repairs cannot be completed. Failure to follow these

procedures may result in damage to equipment. For

information about replacement oil type and viscosity, see

the Installation, Start-Up, and Service Instructions for the

38VMAH and 38VMAR outdoor units.

GENERAL

The 40VMF 4-way ceiling cassette effectively makes each

area served an independently controlled temperature zone.

Through thermostatic control of operations, conditions can be

varied to suit diverse requirements and activities.

The equipment is initially protected under the

manufacturer’s standard warranty; however, the warranty is

provided under the condition that the steps outlined in this

manual for initial inspection, proper installation, regular

periodic maintenance, and everyday operation of the unit be

followed in detail. This manual should be fully reviewed in

advance before initial installation, start-up and any

maintenance. Contact your local sales representative or the

factory with any questions BEFORE proceeding.

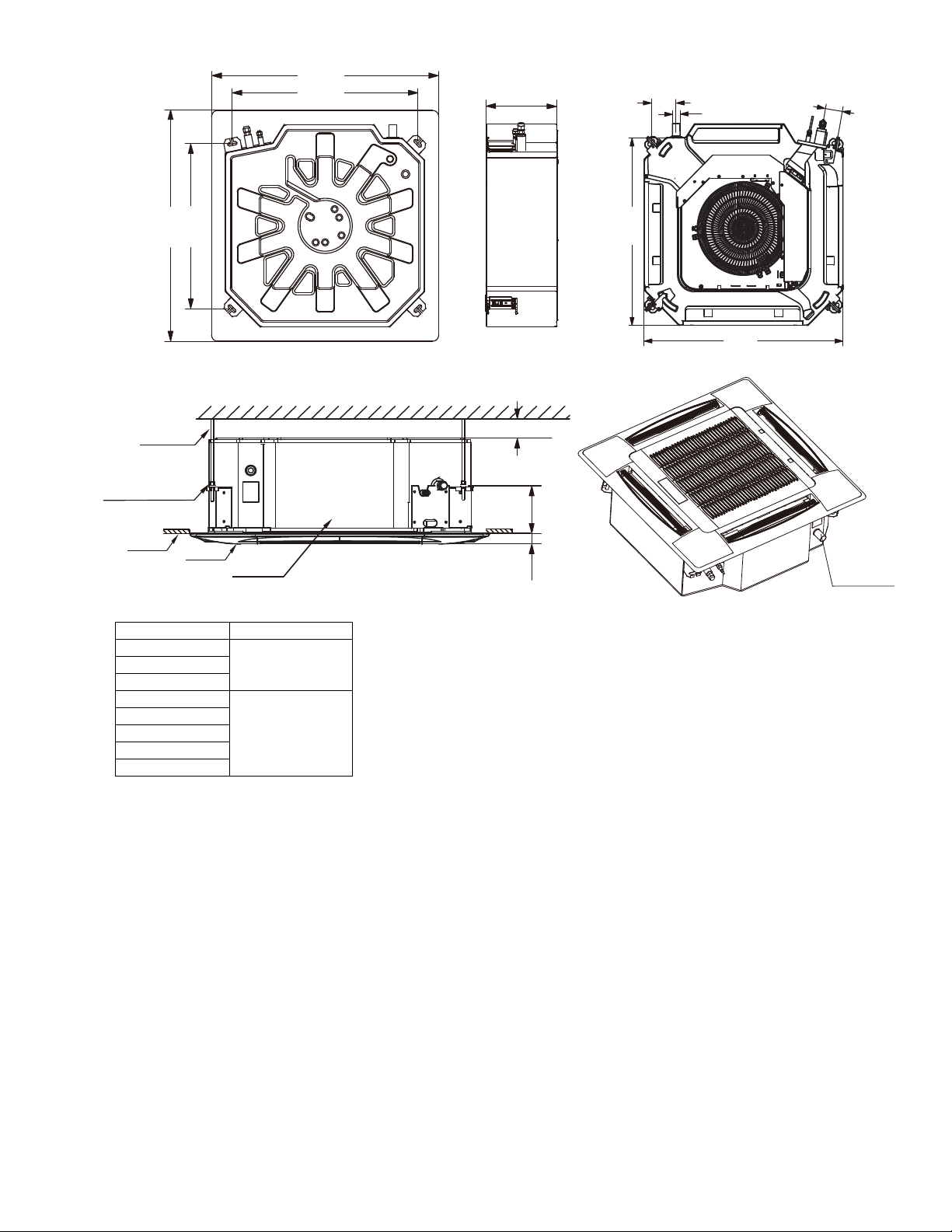

Table 1 lists physical data for each unit size. See Fig. 1 for

model number nomenclature. Figure 1 shows unit dimensions.

Table shows components that may or may not be used for a

particular installation.

Fig. 1 — Model Number Nomenclature

2

Page 3

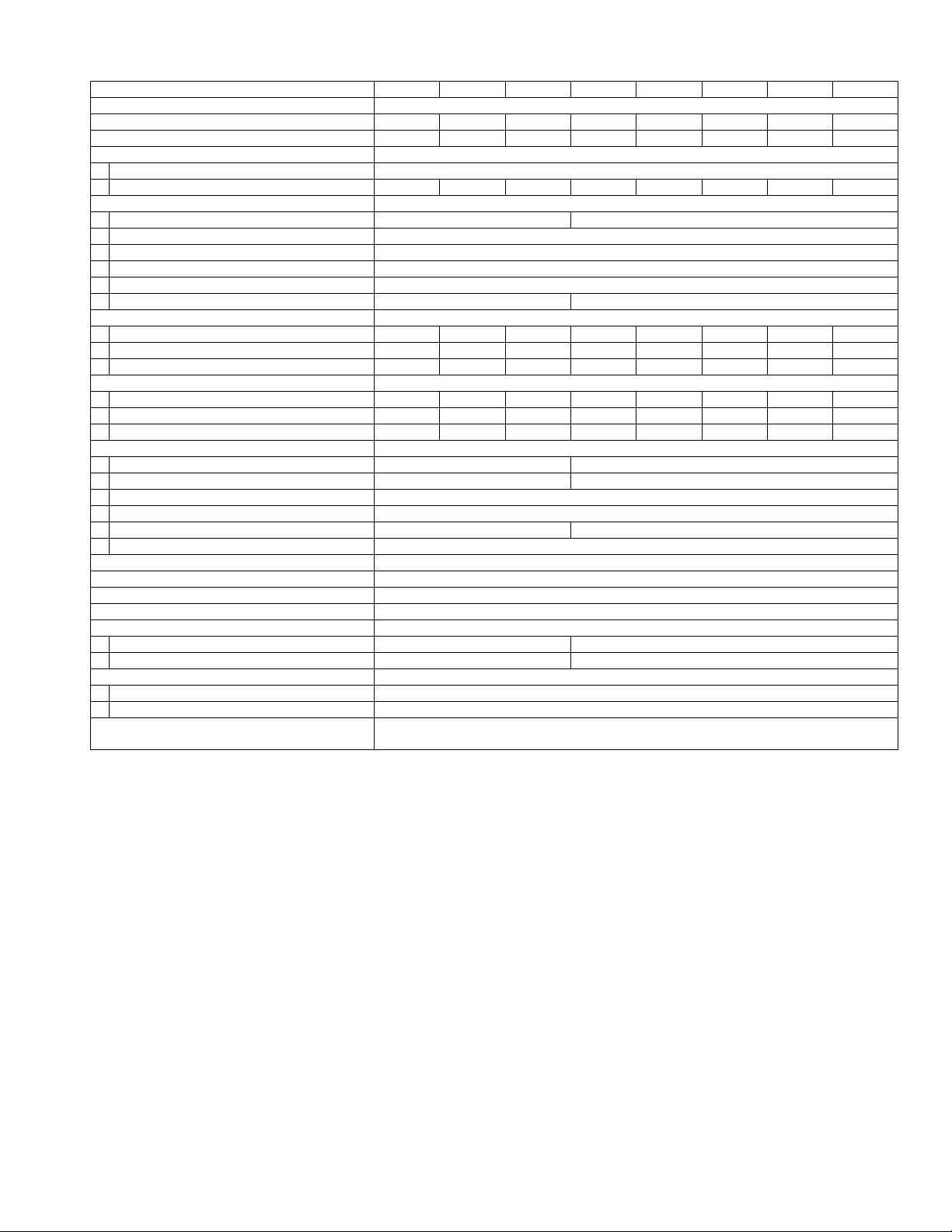

Table 1 — 40VMF Physical Data

UNIT 40VMF 009 012 015 018 024 030 036 048

POWER SUPPLY (V-Ph-Hz) 208/230-1-60

COOLING CAPACITY (Btuh) 9,000 12,000 15,000 19,100 24,000 30,000 36,000 48,000

HEATING CAPACITY (Btuh) 10,900 13,600 17,000 21,500 27,000 34,000 42,000 54,000

ELECTRICAL CHARACHTERISTICS

Typ e DC

Input (W) 40

INDOOR COIL

Number of Rows 23

Fin Spacing (fins/in.) 17

Fin Type Hydrophilic Aluminum

Tube Diameter, OD (in.) 0.276

Tube Type Inner Groove

Number of Circuits 412

INDOOR AIRFLOW (cfm)

Low 330

Medium 390

High 460

INDOOR NOISE LEVEL (dBA)

Low 32.1

Medium 34.0

High 36.7

UNIT

Unit Dimensions, W x H x D (in.) 33

Packing Dimensions, W x H x D (in.) 37 5/8 x 10 5/8 x 37 5/

Panel / Grille Dimensions, W x H x D (in.) 37 3/8 x 1 3/4 x 37 3/

Panel / Grille Dimensions (in.) 40 7/8 x 3 5/8 x 40 7/

Unit Net/Gross Weight (lb) 54/71 69/86

Panel/Grille Net/Gross Weight (lb) 13.2/20

REFRIGERATION TYPE R-410A

EXPANSION DEVICE EEV

DESIGN PRESSURE, High/Low (psig) 580/320

AIR FILTER —

REFRIGERANT PIPING (in.)

Liquid Side, OD (Flare)

Suction Side, OD (Flare)

CONNECTING WIRING

Power Wiring Sized per NEC and local codes based on nameplate electrical data

Signal Wiring 2-core shielded twisted pair cable 20 AWG-16 AWG

CONDENSATE DRAIN PIPE DIAMETER, OD

(in.)

LEGEND

AWG — American Wire Gage

EEV — Electronic Expansion Valve

54

390

460

560

33.0

37.3

41.4

1

/8 x 9 x 33 1/

1

/

4

1

/

2

67 153.5 85.4 131.7 182.7 202.3

460 610 610 680 800 950

560 700 700 800 950 1100

680 1000 800 950 1100 1200

37.0 40.2 40.2 42.1 47.3 50.5

41.5 43.1 42.5 45.1 50.4 54.0

45.6 52.5 44.7 49.5 53.9 55.4

8

8

1

33 1/8 x 11 3/4 x 33 1/

37 5/8 x 13 x 37 5/

8

8

1

/

4

8

8

3

/

8

5

/

8

3

Page 4

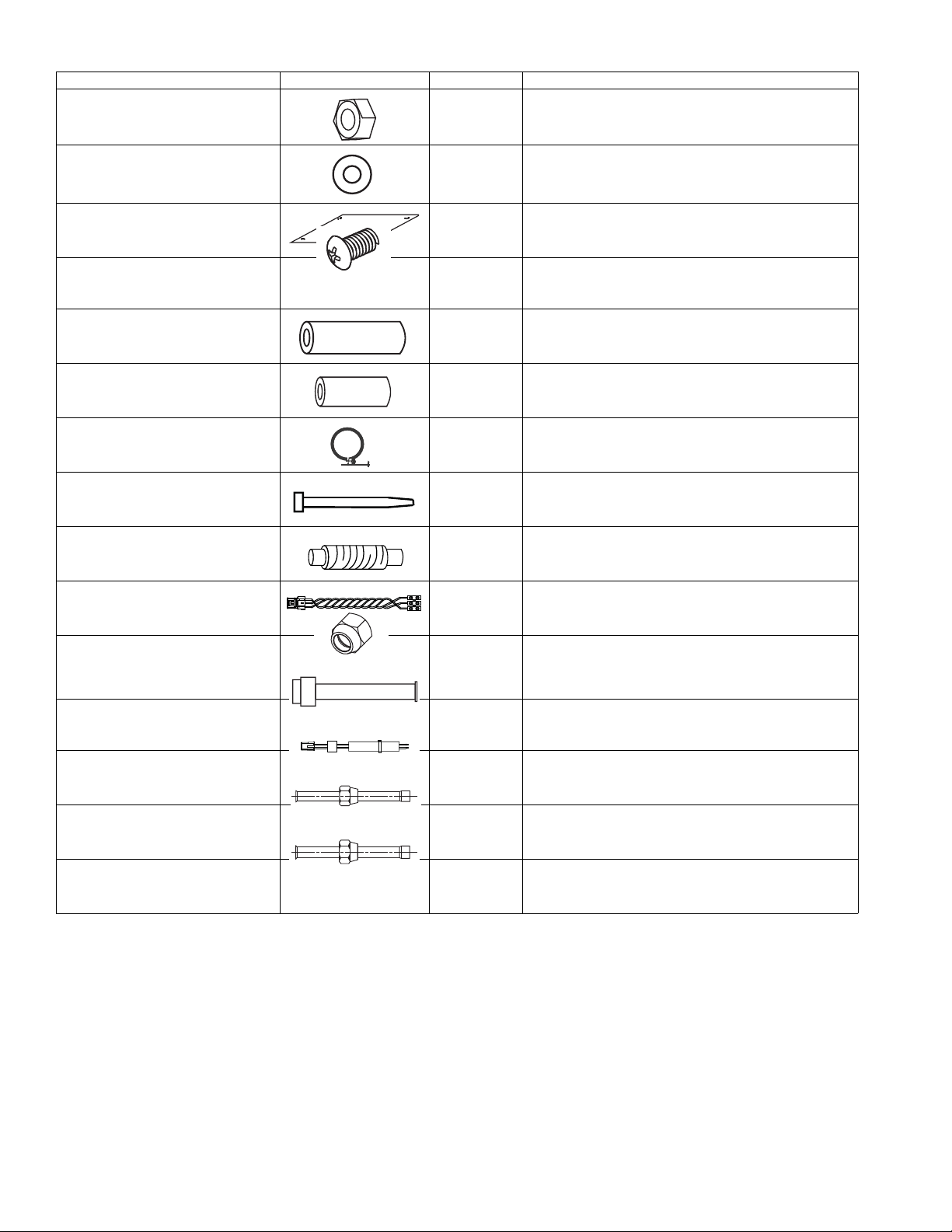

Table 2 — Components Shipped With Unit

NAME SHAPE QUANTITY FUNCTION

Nut 8 To connect the construction cover board to the fan motor

Washer 8 To connect the construction cover board to the fan motor

Construction cover board 1 Used to cover the fan motor

Bolt 4 To connect the construction cover board to the fan motor

Insulation 2 For covering the coil stub outs

Insulation 1 For covering the condensate drain

Clamp 1 For connecting the drain

Tie rope 5 For insulation

Condensate connection 1 For connecting drain

PQE connection wire 2 To connect outdoor unit, indoor unit, and sub MDC

Copper nut 1 Connect piping

Flexible conduit and connectors 1 Routing power lines

Connecting wire 1 For connecting occupancy sensor

Copper pipe for gas side 1 For connecting the refrigerant pipe

Copper pipe for liquid side 1 For connecting the refrigerant pipe

LEGEND

MDC — Multiport Distribution Controller

4

Page 5

Fig. 1 — 40VMF009-048 Dimensions

NOTE: All dimensions shown in inches.

40VMF UNIT SIZE DIMENSION A

009

9012

015

018

11

3

/

4

024

030

036

048

´

´-1

´

Install hanger

Panel

Ceiling

Main body

Hexagon nut

(For adjust to balance)

í

í

í

í

A

Drainage pipe

2í

í

í

í

DRAIN

CONNECTION

í

5

Page 6

Step 1 — Unpack and Inspect Units —

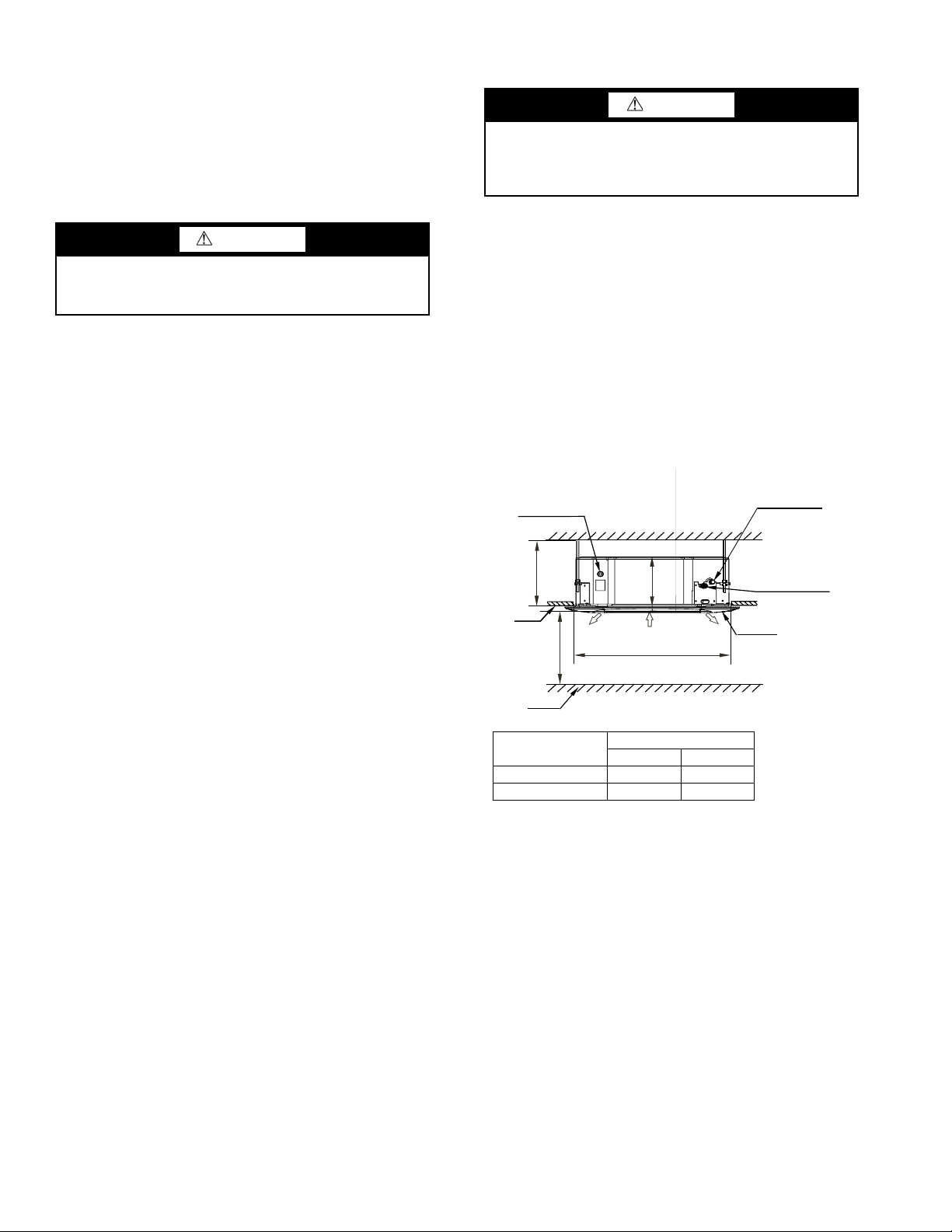

Fig. 2 — False Ceiling Installation

40VMF UNIT SIZE

DIMENSION (in.)

AH

009-015 9 ³ 10

1

/

4

018-048 11 3/

4

³ 13

A

H

>8-1/4 ft.

Connect to the outlet

of

drainage pipe

Connection port of

(Gas side)

refrigerant pipe

(Liquid side)

Connection port

of refrigerant pipe

Floor

Ceiling

Panel

Air outlet Air inlet

2-7/8 ft. (Ceiling hole)

Air outlet

packaged for shipment to avoid damage during normal transit

and handling. It is the receiving party’s responsibility to inspect

the equipment upon arrival. Any obvious damage to the carton

and/or its contents should be reported on the bill of lading and a

claim should be filed with the transportation company and the

factory. Unit should always be stored in a dry place, and in the

proper orientation as marked on the carton.

To avoid equipment damage, do not lift unit by the drain

pipe or refrigerant piping. Unit should be lifted using the

mounting brackets.

After determining the condition of the carton exterior,

carefully remove each unit from the carton and inspect for

hidden damage. Check to make sure that items such as

thermostats, controller etc. are accounted for whether packaged

separately or shipped at a later date. Any hidden damage

should be recorded, a claim should be filed with the

transportation company, and the factory should be notified. In

the event a claim for shipping damage is filed, the unit,

shipping carton, and all packing must be retained for physical

inspection by the transportation company. All units should be

stored in the factory shipping carton with internal packaging in

place until installation.

PROTECTING UNITS FROM DAMAGE — Do not apply

force or pressure to the coil, piping, or drain stub-outs during

handling. All units should be handled by the chassis or as close

as possible to the unit mounting point locations.

The unit must always be properly supported. Temporary

supports used during installation or service must be adequate to

hold the unit securely. To maintain warranty, protect units

against hostile environments (such as rain, snow or extreme

temperature), theft, vandalism, and debris on jobsite.

Equipment covered in this manual is not suitable for outdoor

installations. Do not allow foreign material to fall into drain

pan. Prevent dust and debris from being deposited on motor,

fan wheels and coils. Failure to do so may have serious adverse

effects on unit operation and in the case of motor and blower

assembly, may result in immediate or premature failure. Failure

of any unit caused by deposits of foreign material on the motor

or blower wheels will not be covered by the manufacturer’s

warranty. Some units and/or job conditions may require some

form of temporary covering during construction.

PREPARING JOBSITE FOR UNIT INSTALLATION —

To save time and to reduce the possibility of costly errors, set

up a complete sample installation in a typical room at jobsite.

Check all critical dimensions such as pipe, wire, and duct

connections requirements. Refer to job drawings and product

dimension drawings as required. Instruct all trades in their

parts of the installation. Units must be installed in compliance

with all applicable local code requirements.

IDENTIFYING AND PREPARING UNITS — Be sure

power requirements match available power source. Refer to

unit nameplate and wiring diagram. In addition:

• Check all tags on unit to determine if shipping screws are

to be removed. Remove screws as directed.

• Rotate the fan wheel by hand to ensure that the fan is

unrestricted and can rotate freely. Check for shipping

damage and fan obstructions. Adjust blower motor as

required.

INSTALLATION

CAUTION

Units are

Step 2 — Position the Unit

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere. If this

instruction is not followed exactly, a fire or explosion may

result, causing property damage, injury, or loss of life.

Install the unit in a location that meets the following

requirements:

• Allow adequate space for installation, service clearance,

piping and electrical connections, and necessary

ductwork. For specific unit dimensions, refer to Table 1

and Fig. 1. Allow clearance according to local and

national codes.

• Confirm that the ceiling is able to support the weight of

the unit. See Table 1 for nominal weight.

• There should be enough room within the false ceiling for

installation and maintenance. See Fig. 2 below.

• The false ceiling should be horizontal and leveled.

• Install the unit in a location within the room that allows

uniform air flow in all directions.

Select the unit position with the following points in mind:

• The unit should be installed in a position that is suitable

to support the total weight of the unit, refrigerant piping

and condensate.

• Proper access should be provided for maintenance for

refrigerant piping, EEV (electronic expansion valve),

electrical box, and condensate pump. A 2-ft clearance is

recommended all around the unit.

• The unit should be at least 3

obstruction. See Fig. 3 below.

6

1

/4 ft from a wall or similar

Page 7

• Do not position where the discharge air could blow

Fig. 3 — Distance from Wall or Obstruction

40 in. MIN.

40 in. MIN.

40 in. MIN.

40 in. MIN.

a40-1720

Unit body

Install the paper board

Central hole

Screw M6×12

Fig. 4 — Paper Board Mounting Hole Locations

Fig. 5 — Example of Buffer Locations

Buffer

Fig. 6 — Mounting Hole Locations

í

í

í

í

directly on the thermostat.

• Recommended distance between 2 units is 10 ft to avoid

conflicting airflow and recirculation.

• The unit should not be positioned directly above any

obstruction.

• The unit must be installed square and level.

• The condensate drain should have sufficient downward

slope (1 in. per 100 in.) in any horizontal run between

unit and drain. Maximum condensate lift is 29

1

/2 inches.

See Fig. 5 for an example of some buffer locations.

The actual quantity

shall prevail

Step 3 — Mount the Unit

INSTALLING HANGER BOLTS — Install the hanger bolts

at the locations shown in Fig. 6. Use

For unit weight, see Table 3.

3

/8-in. all-threaded rod.

IMPORTANT: Be sure that the ceiling grid is supported

separately from the unit. The ceiling grid must not be

supported by an part of the unit or any associated

wiring or piping work.

In case of new construction, once the unit is installed, please

cover the fan motor opening using the construction cover board

to avoid any dust and debris from settling inside the unit. Use

the M6 bolt, washer and nut as shown in Fig. 4 below.

Remove all buffers between the fan and the flared mouth

before installing the indoor unit. Failure to do so will cause

CAUTION

damage to the fan motor.

CAUTION

To avoid equipment damage ensure the unit is placed

horizontally.

Table 3 — Unit Weight

40VMF UNIT WEIGHT (lb)*

009 71.0

012 71.0

015 71.0

018 86.0

024 86.0

030 86.0

036 86.0

048 86.0

*Includes grille weight.

MOUNTING UNIT — The unit can now be lifted on to the

hanging rods for mounting.

1. Use rods and fasteners to suspend the unit at the factoryprovided mounting holes.

2. Adjust the height of the unit until the bottom (without

grille) is level with the false ceiling.

3. Secure the unit in position with locknuts and washers on

both sides of the unit bracket. Ensure that the threaded

rod does not protrude more than 2 in. below the mounting

brackets as shown in Fig. 7.

7

Page 8

INSTALLING PANEL

Fig. 7 — Threaded Rod

a40-1722

Fig. 8 — Removing Grille from Panel

GRILLE

LATCHE

S

CORD

45°

Fig. 9 — Mounting Panel

Louver motor

Louver

motor

Drainage

pipe joint

Hook

Panel hook

Piping joint

Hook bolt

Phillips

screwdriver

Fig. 10 — Condensate Piping

MIN. GRADIENT

2

5

8

TO 3

14

ft

INSULATION

INDOOR

UNIT

FLEXIBLE DRAIN

CONDENSATE HOSE CLAMP

CONNECTOR

PVC DRAIN

PIPE

Fig. 11 — Condensate Drain Connection

NOTE: Panel is ordered separately.

1. Remove the grille from the panel by sliding the grille

latches toward the center of the panel.

2. Lift the grille up at a 45-degree angle and pull to detach it

from the panel.

3. Unscrew the bolts on the 4 corners of the cover panel.

Remove the cover by loosening the cord. See Fig. 8.

5. When the panel is secure, insert the grille at a 45-degree

angle and latch it in place.

Step 4 — Connect Piping

CONDENSATE PIPING — The unit is supplied with a 1 1/4inch OD drain connection to connect copper or plastic drain

piping. When installing condensate piping, follow these

recommendations:

• Maximum pump lift is 29

• The highest point in the condensate piping should be as

close to the unit as possible. See Fig. 10-12 below.

1

/2 inches.

4. Secure the panel (without the grille) onto the unit, using

M5 x 16 screws and washers. Before tightening the

screws, be sure the panel is flush with the false ceiling.

See Fig. 9.

8

Page 9

• Condensate piping should slope downward in the

Fig. 12 — Using a Main Drain to Serve Multiple Indoor Units with Internal Condensate Pumps

2“~4”

2“~4”

2“~4”

Max. 3-3/4 ft.

7-7/8”

7-7/8”

7-7/8”

Connection assembly of water outlet Main drainage pipe

Gradient: 1/50~1/100

direction of condensate flow, with a minimum gradient

of 1 in. per 100 inches.

• When multiple units are connected to a common

condensate drain, ensure that the drain is large enough to

accommodate the volume of condensate from all units. It

is also recommended to have an air vent in the

condensate piping to prevent air lock.

• Condensate piping must not be installed where it may be

exposed to freezing temperatures.

REFRIGERANT PIPING

CAUTION

When connecting from an indoor unit to an outdoor unit,

the isolation valve at the outdoor unit should be in the

closed position throughout the refrigerant piping process.

Failure to follow this procedure may result in equipment

damage.

When connecting from an indoor unit to an outdoor unit,

follow these procedures:

• Check maximum height drop and length of refrigerant

piping between the indoor and outdoor units. To ensure

the drop and length are acceptable, refer to the

refrigerant piping allowable limits in the outdoor unit

installation manual.

• The number of bends in the refrigeration piping must be

fewer than 15.

• Refrigerant piping connection between indoor and

outdoor units should be performed once the units are

secured at their respective installation locations.

• The refrigeration piping starts at the indoor unit and ends

at the outdoor unit or Multiport Distribution Controller

(Heat Recovery systems).

• The refrigerant piping should be dry and free of dust and

other impurities.

• The bending angle of the refrigerant pipe should not

exceed 90 degrees and the bending radius should be as

large as possible to prevent any breakage in piping.

• Use proper cutting and flaring tools to avoid leakage.

• Use a torque wrench for flare nuts. Refer to Table 4 for

flare nut torque recommendations.

Table 4 — Flare Nut Torque Recommendations

OUTSIDE DIAMETER (in.) RECOMMENDED TORQUE (ft-lb)

1/4 15

3/8 26

1/2 41

5/8 48

• Before insulating the suction and liquid refrigeration

pipes, perform pressure and leak tests. For details, see

the outdoor unit installation manual. Insulating both

suction and liquid refrigerant pipes is mandatory.

• Vacuuming and charging of the system should be carried

out as described in the outdoor unit installation manual.

Step 5 — Complete Electrical Connections —

Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric

Code ANSI/NFPA (American National Standards Institute/

National Fire Protection Association) 70, current editions.

Units must be electrically grounded in conformance with the

code. In Canada, wiring must comply with CSA (Canadian

Standards Association) C22.1, Electrical Code.

WARNING

Electrical shock can cause personal injury and death.

Disconnect power supply before making wiring

connections. There may be more than one disconnect

switch. Tag all disconnect locations to alert others not to

restore power until work is completed.

WARNING

All units must be wired strictly in accordance with the

wiring diagram furnished with the unit. Any wiring

different from the wiring diagram could result in personal

injury and property damage.

CAUTION

Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 221 F.

Ensure supply voltage to the unit, as indicated on the serial

plate, is not more than 10% over the rated voltage or 10%

under the rated voltage.

Failure to follow these recommendations may result in

equipment damage.

This equipment in its standard form is designed for an

electrical supply of 208/230-1-60. Any damage to or failure of

units caused by incorrect wiring or voltage is not covered by

warranty.

Electric wiring must be sized to carry the full load amp

draw of the motor, starter, and any other controls that are used

with the unit. See Table 5 for electrical data.

After the pipe work is complete, the electrical supply can be

connected by routing the cable through the appropriate casing

holes or knockouts and connecting the supply and ground

cables to the unit’s power terminal.

9

Page 10

Be sure the power wiring and control wiring do not cross, as

Fig. 13 — 40VMF009-048 Typical Wiring Diagram

LEGEND

NOTE: Field wiring must use copper conductors only.

ACB — Auxiliary Control Board

AUXH — Output For Auxiliary Heat

CS — Condensate Switch

CTON — Output for Cooling Operation

EEV — Electronic Expansion Valve

FAN — Output for Fan Operation

FM — Indoor Fan Motor

GM — Louver Motor

HTON — Output For Heating Operation

MDC — Multiport Distribution Controller

PUMP — Pump Motor

T1 — Indoor Temperature Sensor

T2A — Evaporator Temperature Sensor

T2B — Evaporator Outlet Temperature Sensor

XP1-9 — Plug

XS1-9 — Jack

XT1-2 — Terminal Block

----------- Optional Component or Field Wiring

Main Board

HA

HB

To

wired controller

comm. bus

ENC2

SW8

T2A T1

T2B

XP1-XP3

XS1-XS3

BLUE

WHITE

RED

XS4

XP4

XP6

XS6

XP5

XS5

CN2

POWER IN

Attention:

For the convenience of

terminals can be pulled

wiring, the

communication

out from the main board.

SW1

CS

CN12

CN11

MDC units comm. bus

T

o outdoor/indoor/

BLUE

RED

CN3

CN18

XT1

FM

ALARM

CN24

CN52

CN9

EEV

CN21

CN5

CN8

CN50

15NC15NC

ACB interface

PUMP

GM

GM

Display board

CN15

L1 L2

Y/G

( Current range: 0-1A)

FAN

CTON

HTON

AUXH

( Voltage range: 0-24V AC/DC)

CN54

ON/OFF

SWITCH

XP7

XP8

P

Q

P

Q

CN14

Occupancy

sensor/ON-OFF

(Dry contact)

ENC1

“ +5V GND +12V ”

ONLY USED

FOR TESTING

this might cause disturbance on the controls side. See Fig. 13

for wiring diagram.

NOTE: The indoor unit requires its own power supply. Indoor

units are not powered through outdoor units.

Table 5 — 40VMF Electrical Data

40VMF UNIT SIZE

009 0.73 15

012 0.91 15

015 1.10 15

018 2.00 15

024 1.30 15

030 1.70 15

036 2.30 15

048 2.40 15

LEGEND

MCA — Minimum Circuit Amps

MOPD — Maximum Overcurrent

Protective Device

POWER SUPPLY

MCA MOPD

10

Page 11

Step 6 — Position and Connect Controller —

Fig. 14 — Communication Wire Connection

To outdoor/indoor/MDC units

comm. bus

To wired controller comm. bus

XT2

Fig. 15 — Shearing Outdoor Connector

Fig. 16 — Stripping the Wire

Fig. 17 — Connecting Communication Wire to

Outdoor Unit Communication Terminal

Fig. 18 — Connecting the Communication Wires

Wired controllers should be installed in a position that

maintains good temperature control:

• Position the thermostat approximately 48 in. above floor

level.

• Do not position thermostat where it can be directly

affected by the unit’s discharge airstream.

• Avoid external walls and drafts from windows and doors.

• Avoid positioning near shelves and curtains as these

restrict air movement.

• Avoid heat sources such as direct sunlight, heaters,

dimmer switches, and other electrical devices

• See Fig. 14 for an example of communication wire

connection.

CONTROL WIRING

1. Use copper core PVC insulated sheathed shielded twisted

cord.

2. For IDU (indoor unit) and ODU (outdoor unit)

communication, use ‘P, Q” terminals. Shielded core

should be used for ground.

3. Wiring should be done according to wiring diagram.

4. Communication wire must not form a closed loop.

3. Use a suitable screwdriver to fix the communication wire

on the outdoor unit communication terminal as shown in

Fig. 17 below.

If communication wires are use to connect indoor units,

then find the corresponding port and plug it directly as shown

in Fig. 18.

OPTION/EXTENSIONS OF COMMUNICATION

WIRING — To extend control wiring or make terminal

connections, use the PQE connection wire supplied in the

accessory kit and follow the steps below.

1. Cut the connector on the outdoor unit side as shown in

Fig. 15 below.

If for any reason it is not possible to buy communication

wires from Carrier, connect the indoor unit side of the

communication wires using the connector provided with the

accessories as shown in Fig. 19. See Fig. 20 and 20 for typical

communication wiring of the heat pump and heat recovery

systems.

CAUTION

Failure to follow these procedures may result in personal

injury or damage to equipment.

NEVER CONNECT the main power source to the control

or communication terminal block.

USE AN APPROPRIATE SCREWDRIVER for

tightening the terminal screws. Do not over tighten the

terminal screws.

IMPORTANT: Communication wiring shall be 2 in. or

more apart from power source wiring to avoid electric

noise. (Do not insert control/communication and power

source wire in the same conduit.)

Pay attention to the polarity of the communication

wire.

2. Strip a suitable length of the insulation layer as shown in

Fig. 16 below.

11

Page 12

Connector in accessory kitConnector on indoor unit Communication cable

in field

Fig. 19 — Connecting the Communication Cable to Indoor Unit to Outdoor Unit Using the Supplied Connector

12

Page 13

P Q

X Y

X Y

MDC unit

Centralized controller

outdoor unit

P Q

P Q

P Q

P Q

P Q

P Q

To No.1

indoor

To No.2

indoor

To No.3

indoor

To No.4

indoor

To No.1

indoor

To No.2

indoor

To Sub MDC

To outdoor

Main MDC unit

To outdoor

L1

L2

L3

L3

L3

L3

L4

L4

L5

L6

L7

L8

L9

L10

L11

Indoor unit 1#

HA HB

Indoor unit 2#

HA HB

Indoor unit 3#

HA HB

Indoor unit 4#

HA HB

Indoor unit 5#

HA HB

Indoor unit 6#

HA HB

HA HB

Touch screen

NOTE: 24 v. DC Power

wired controller

(Field Supplied)

wired controller

HA HB

NOTE: Power from IDU

Maximum wiring length:

L1+L2 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L3 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L4 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L5 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L6+L7+L8+L9 </= 820 ft 18 AWG, 2-Core Stranded Shield

L10+L11 </= 820 ft 18 AWG, 2-Core Stranded Shield

LEGEND

MDC

—

Multiport Distribution Controller

IDU

—

Indoor Unit

Fig. 20 — Typical Heat Recovery Communication Wiring Diagram

13

Page 14

Fig. 20 — Typical Heat Pump Communication Wiring Diagram

P Q

X Y

X Y

Centralized controller

outdoor unit

P Q

P Q

P Q

P Q

P Q

P Q

L1

L3

L5

L6

L7

L8

L9

L10

L11

L3

L3

L3

L3

Indoor unit 1#

HA HB

Indoor unit 2#

HA HB

Indoor unit 3#

HA HB

Indoor unit 4#

HA HB

Indoor unit 5#

HA HB

Indoor unit 6#

HA HB

P

Q

Network Resistor

HA HB

Touch screen

NOTE: 24 v. DC Power

wired controller

(Field Supplied)

wired controller

HA HB

NOTE: Power from IDU

Maximum wiring length

L1+L3 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L5 </= 3937 ft 18 AWG, 2-Core Stranded Shield

L6+L7+L8+L9 </= 820 ft 18 AWG, 2-Core Stranded Shield

L10+L11 </= 820 ft 18 AWG, 2-Core Stranded Shield

LEGEND

IDU

—

Indoor Unit

NOTE: Network resistor is shipped with the outdoor unit for field installation on

heat pump systems.

14

Page 15

ACB Interface — The ACB interface is a dry contact

LEGEND

ACB

—

Auxiliary Control Board

AUXH

—

Output For Auxiliary Heat

CTON

—

Output For Cooling Operation

FAN

—

Output For Fan Operation

HTON

—

Output For Heating Operation

MAX AMPS 1A

MAX VOLTAGE 24V

Fig. 21 — ACB Interface

CN51

ACB interface

CN50

FAN

CTON

HTON

AUXH

board, it can output up to four signals controlling devices.

Please refer to Fig. 21 for connecting devices to the ACB

interface board.

Pre-Start Check —

the following pre-start checks:

1. All indoor and outdoor units are properly installed.

2. All piping and insulation is complete.

3. All electrical connections (both power and control) are

properly terminated.

4. All condensate drains are installed correctly.

5. The power supply is of the right voltage and frequency.

6. The units are properly grounded in accordance with

current electrical codes.

7. Suction and liquid line isolation valves are in open

position.

System Operation Check — Once the installation

and pre-start checks are completed, follow these steps:

1. Using remote controller, select cooling or heating mode

to check the operation of the system.

2. While the system is in operation, check the following on

indoor unit:

a. Switches or buttons on the remote controller are easy to

push.

b. Indicator light is showing normal operation and no

error is indicated.

c. Swing mode of air louvers is working (if applicable to

unit).

d. Drain pump operation is normal (if applicable).

e. No abnormal vibration or noise is noticed.

3. While the system is in operation, check the following on

outdoor unit:

a. No abnormal vibration or noise is noticed.

START-UP

Once installation is complete, make

b. Condenser fan is in operation.

c. Indicator light is showing normal operation and no

error is indicated.

NOTE: If the unit is turned off or restarted, there is a time

delay of 3 minutes for the compressor to start from the time the

power is restored.

MAINTENANCE

CAUTION

When servicing or repairing this unit, use only factoryapproved service replacement parts. Refer to the rating

plate on the unit for complete unit model number, serial

number and company address. Any substitution of parts or

controls not approved by the factory will be at the owner’s

risk and may result in equipment damage.

CAUTION

To avoid equipment damage, do not attempt to reuse any

mechanical or electrical controllers that have been wet.

Replace defective controller.

EVERY 3 MONTHS:

• Check the air filter condition. Clean or replace if

necessary.

EVERY 6 MONTHS — Follow 3-month maintenance

schedule. In addition:

• Clean condensate tray with suitable cleaning agent.

• Clean the grille and panel.

EVERY 12 MONTHS — Follow 6-month maintenance

schedule. In addition:

• Be sure all electrical connections are secure.

• Check condensate pump operation.

• Check the heating and cooling action to confirm proper

operation.

INDOOR UNIT ADDRESSING

For proper system operation each indoor unit must have a

unique address set from 0 to 63. When setting an address by

remote controller the outdoor units, indoor units, and MDC

must be powered on. If “FE” is displayed on the LED screen or

display board this unit has no address. After setting all indoor

units’ addresses, turn off the power supply to all indoor units to

clear errors.

Indoor units’ addressing can be distributed automatically in

the heat pump system. When dip switch “S6” on the outdoor

units main PCB board is set to 00 (default set in factory) indoor

unit’s are set for auto-addressing. When powering on for the

first time it takes 6 minutes or more to finish auto-addressing

each indoor unit. The heat recovery system cannot accomplish

this function at this time.

Wireless Remote Controller (40VM900001) —

Indoor unit addressing can be performed using the wireless

remote controller. When using the wireless controller, the user

must maintain a line of sight with the receiver on the indoor

unit. See Fig. 22 for a description of the buttons on the wireless

remote.

15

Page 16

Use a tool to press and hold the LOCK button for at least 10

RESET

TIMERON

TIMEROFF

SWING

AIRDIRECTION

CLOCK

OK

SWING

MODE

FAN

AUTO

COOL

DRY

HEAT

FAN

TEMP

SET

CLOCK

SET

HOUR

FANSPEED

LOCK

C/H

6 – AIR DIRECTION

2 – FAN SPEED SETTING

4 – ADJUST UP

9 – CLOCK SETTING

14 – OK (CONFIRM)

10 – TIMER ON

11 – TIMER OFF

1 – MODE SETTING

3 – ADJUST DOWN

12 – RESET

13 – LOCK

15 – COOL/HEAT

5 – ON/OFF

7 – AIR VERT. SWING

A40-1734

Fig. 22 — Wireless Remote Controller

(40VM900001)

MODE

FAN TEMP. DOWN

OK

TEMP. UP ON/OFF

TIMER

ROOM TEMP.

SWING

#

Fig. 23 — Non-Programmable Controller

(40VM900002) IDU Addressing Menu

#

MODE

FAN TEMP. DOWN

OK

ON/OFFTEMP. UP

TIMER

ROOM TEMP.

SWING

Fig. 24 — Non-Programmable Controller

(40VM900002) Setting IDU Address

Fig. 25 — Programmable Controller

(40VM900003) IDU Addressing Menu

MODE

FAN

MENU

TEMP. DOWN

TEMP. UP

OK

BACK

ON/OFF

seconds, then press to activate. Click or to select an

address and press to send the setting.

To display an indoor unit address, use a tool to press and

hold the LOCK button for at least 10 seconds, and press to

query the addresses.

Non-Programmable Controller (40VM900002)

When setting an address, connect only one wired controller to

an indoor unit.

Press ROOM TEMP and SWING simultaneously for 3

seconds. If there is no address for this indoor unit, the display

shows FE# 00 (see Fig. 23). Otherwise, the display shows the

current address of the indoor unit.

Click TEMP. UP or TEMP. DOWN to change 00 to the

desired address as shown in Fig. 24. Then press OK to confirm

and exit the setting interface.

Programmable Controller (40VM900003) —

When setting an address, connect only one wired controller to

an indoor unit.

1. Press FA N and BACK simultaneously for 5 seconds to

access parameter settings as shown in Fig. 25.

2. Press TEMP. UP or TEMP. DOWN to move the cursor

and choose IDU ADDRESSING, then MENU/OK to

access this setting.

16

Page 17

3. Press TEMP. UP or TEMP. DOWN to choose the

Fig. 26 — Programmable Controller

(40VM900003) Setting IDU Address

MODE

FAN

MENU

TEMP. DOWN

OK

TEMP. UP

BACK

ON/OFF

Fig. 27 — LED Display Panel

A40-1716

OPERATION TIMER DEF./FAN ALARM

a40-1842

address you want to set, see Fig. 26. Press MENU/OK to

send this address to the IDU.

4. Press BACK twice or wait 30 sec. to automatically exit

the parameter settings menu.

TROUBLESHOOTING

Figure 27 shows the LED display panel on the indoor unit.

See Table 6 for a summary of display indicators. Table 7 lists

problems, possible causes, and possible solutions.

17

Page 18

Table 6 — Display Indicators

TYPE DIGITAL DISPLAY MODE/STATUS

Setting Temperature Starting

“--” Shutdown

“--” Standby

[NO ERROR]

ERROR

LEGEND

ACB — Auxiliary Control Board

EEPROM — Electronically Erasable Programmable Read-

EEV — Electronic Expansion Valve

MDC — Multiport Distribution Controller

only Memory

“--” Timing ON

“--” Timing OFF

Setting Temperature System Defrost ON

Setting Temperature System Defrost OFF

Room Temperature Only Fan

dd Heating / Cooling Mode Conflict Error

E1 Communication Error Between Indoor and Outdoor Unit

E2 Check Indoor Temperature Sensor (T1)

E4 Check Evaporator Outlet Temperature Sensor (T2B)

E5 Check Evaporator Temperature Sensor (T2A)

E6 Check DC Fan

E7 EEPROM Error (Data Storage)

E9 Communication Error Between Indoor Unit and Wired Controller.

Eb EEV Error

Ed Outdoor Unit Error

EE Condensate Overflow

FE No Address When Powered ON For First Time

UU MDC In Auto System-Check Mode.

18

Page 19

Table 7 — Troubleshooting

Fig. 28 — Unit Serial Plate (Example)

MODEL

R410A

HIGH

LOW

4-WAY CASSETTE UNIT

REFRIGERANT

0.73 A

15 A

0.59 A

80W (1/8HP)

40VMF009A--3

208/230V-1Ph- 60Hz

320 PSIG

580 PSIG

DESIGN

PRESSURE

POWER SUPPLY

MINIMUM CIRCUIT AMPACITY

FAN MOTOR

FLA

MAX FUSE OR HAC R BREAKER

OUTPUT

CONFORMS TO ULS TD 1995

CERTIFIED TO CSA STD.

C22. 2 No. 236

3124627

ELECTRIC CHARACTERISTICS ARE

ONLY FOR INDOOR UNIT.

SERIAL NO .

1616V000 01

Carrier Corporation

DIGITAL

DISPLAY

dd Heating/Cooling Mode Conflict

DESCRIPTION POSSIBLE CAUSES POSSIBLE SOLUTIONS

System is in cooling or fan mode only

and heating signal is received from a

All units should be in cooling mode for system to

stay in cooling mode.

unit in the system.

System is in heating mode and cooling

signal is received from a unit in the

All units should be in heating mode.

system.

E1

Communication Error Between Indoor

and Outdoor Unit

Signal wires are short-circuited or

disconnected.

Signal wires close to electromagnetic

source.

Check or reconnect signal wire.

Distance signal wires from electromagnetic

source.

PC board fault. Replace PC board.

Loose connection at port on PC board. Tighten the connection at port on PC board.

E2, E4, E5 Check Temperature Sensor

Sensor is short-circuited. Using multi-meter, measure resistance of the

sensor. If the resistance is ≤ 100 ohms, change

the sensor.

PC board fault. Replace PC board.

Operating beyond limits. Check and correct external static pressure on the

E6 Check DC Fan Motor

DC motor fault. Replace DC motor.

unit.

PC board fault. Replace PC board.

E7 EEPROM Error (Data Storage) Chip or PC board fault. Replace PC board.

E9

Communication Error Between Indoor

Unit and Controller

Signal wires are short-circuited or

disconnected.

Signal wires close to electromagnetic

source.

Check or reconnect signal wires.

Distance signal wires from electromagnetic

source.

PC board fault. Replace PC board.

Eb EEV Error

EEV wires are short-circuited or

disconnected.

EEV stop. Replace EEV.

Check or reconnect signal wire.

PC board fault. Replace PC board.

Ed Outdoor Unit Error Outdoor unit fault. Refer to outdoor unit troubleshooting guide.

EE Condensate Overflow

Loose connection or disconnected at

port on PC board.

Condensate switch float is stuck. Inspect the float.

Trap slope is too steep. Adjust the trap slope.

Tighten the connection or reconnect at port on

PC board.

Drain pipe is too long. Adjust the length of the drain pipe.

Drain pump faulty. Replace the drain pump.

Run automatic addressing option at the outdoor

FE

No Address When Powered ON For

First Time

Indoor unit without address.

unit.

Use remote wireless or wired controller to

readdress the indoor unit.

UU MDC In Auto System-Check Mode MDC Fault. Refer to MDC troubleshooting guide.

LEGEND

EEPROM — Electronically Erasable Programmable Read-only

Memory

EEV — Electronic Expansion Valve

MDC — Multiport Distribution Controller

PC — Process Controller

Replacement Parts — Quote the unit type and unit

serial number when ordering replacement parts or contacting

the factory about the unit. This information can be found on the

serial plate attached to the unit. See Fig. 28.

19

Page 20

APPENDIX A — DIP SWITCH SETTINGS

ON

OFF

ON

OFF

1234

a40-1923

ON

OFF

1234

a40-1923

ON

OFF

1234

a40-1923

ON

OFF

12

a40-1925

There are 2 DIP switches on the main board. Figures A and B

show the settings for each parameter controlled by a switch.

Switches are shown in the default settings.

POSITION 1, 2 — NOT USED

POSITION 1 — START-UP

OFF — Auto Addressing Mode (Default)

ON — Factory Test Mode

POSITION 2

OFF — Normal Mode (Default)

ON — Factory Self-Checking Mode

POSITION 3 — NOT USED

Fig. B — SW8 SETTINGS

POSITION 4 — INDOOR UNIT IDENTIFICATION

OFF — Standard Indoor Unit (Default)

ON — Mode Priority Indoor Unit (HP Only)

(IDU address must be 63)

Fig. A — SW1 SETTINGS

© Carrier Corporation 2018

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 18-40VMF002-01 Printed in U.S.A. Form 40VMF-2SI Pg 20 1-18 Replaces: 40VMF-1SI

Loading...

Loading...