Carrier 38EB User Manual

Number One

AirCoxIitbning

l\Mer

Installation, Start-Up '

Division of

Carrier Corporatio

e

Carrier Parkway • Syracuse NY 13221

and Service Instructions

Air-Cooled Condensing Units

INDEX

SAFETY CONSIDERATIONS......................

INSTALLATION

Step 1 — Check Equipment and

Jobsite..............................................................I

• UNPACK UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER

SYSTEM REQUIREMENTS

Step 2 — Make Piping Connections

• REPLACE THE ACCURATER™

REFRIGERANT CONTROL

PISTON IN THE INDOOR

COIL IF REQUIRED

• CONNECT REFRIGERANT LINES

Step 3 — Make Electrical

Connections....................................................5

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER NEC

• ROUTE LINE POWER LEADS INTO

UNIT

• CONNECT GROUND LEAD AND

POWER WIRING

• CONNECT CONTROL POWER

WIRING

START-UP

SERVICE............................................................. 8-10

MAINTENANCE..................................................11,12

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainten

ance functions of cleaning coils and filters and re

placing filters. All other operations should be

performed by trained service personnel. When

working on air conditioning equipment, observe

precautions in the literature, tags and labels attached

to the unit and other safety precautions that may

apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing opera

tions. Have fire extinguisher available for all brazing

operations.

...........................................

_______

...........................................................

SAFETY CONSIDERATIONS

Page

.. 1

. 1-6

2

6-8

WAR-NiNG: Before perfosrmisg service or

majnteiiatice орегайоиз or system, tarn off

vaaia power to isdoor tmit tsml outdoor

■ask. Тош off accessory beater power switch is

appiicaMe, E^ecfircal sihock, could cause pers<mal injury.

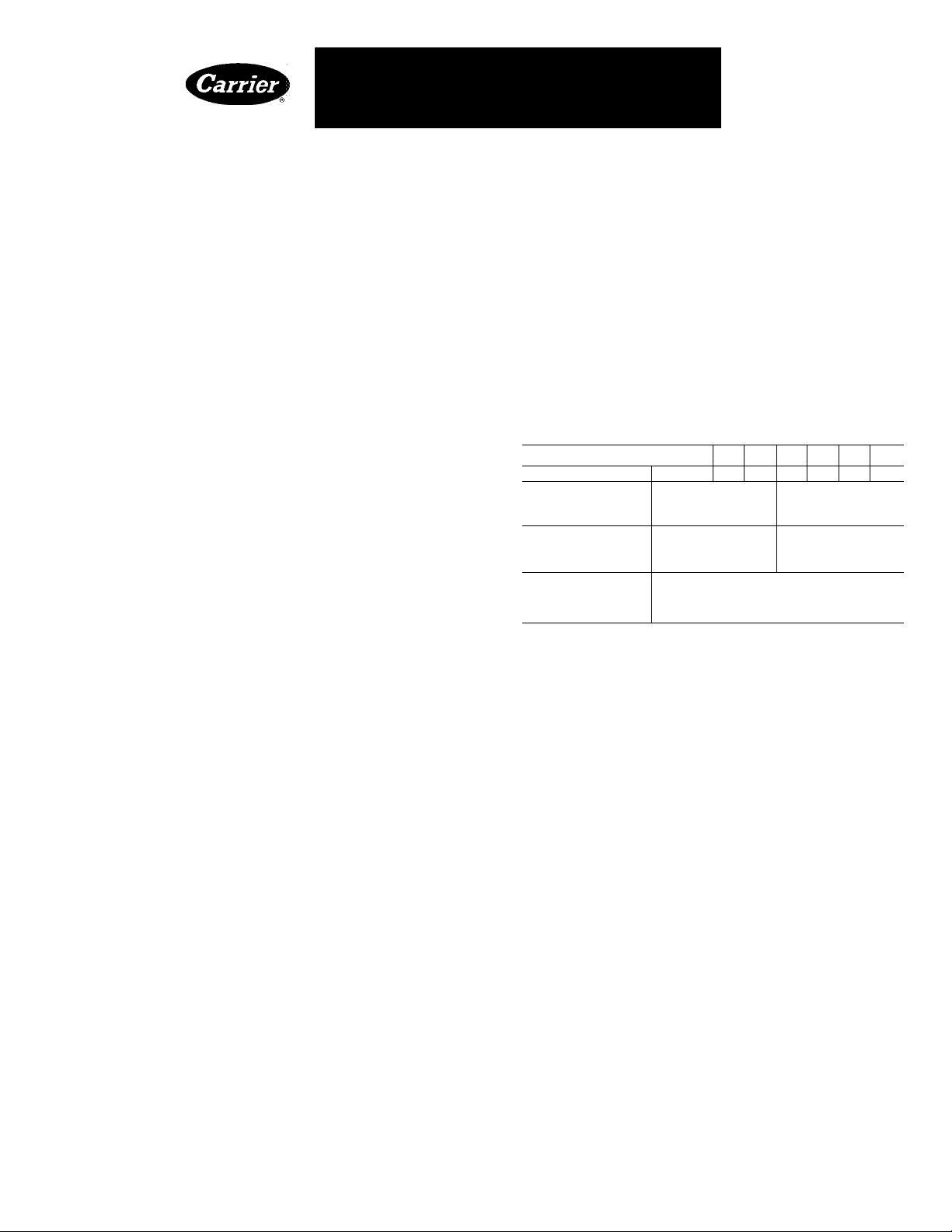

Table 1 — Physical Data (Refer to Fig. 1)

MODEL38EB

OPER WT(lb)

DIMENSIONS (ft-in.)

Diameter A

Height B

CONNECTIONS (in.)

Suction (ODF)

Liquid (ODF)

REFRIG LINES

Suction (in. ODF)

Liquid (in ODF)

*Fora1-1/8in suction line on 38EB048,060, a 3/4-in x 1-1/8 in suction

valve connection adapter is available as an accessory See Table 3

015 018

024

030

116

1-9-3/4

Recommended Field-Supplied Sizes

5/8 i 3/4 i 7/8 1 1-1/8

130

2-2-3/8 ) 2-8

5/8

137 165 181

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACK UNIT — Move to final location. Slide

from carton taking special care not to damage serv

ice valves or grilles.

INSPECT EQUIPMENT — File claim with ship

ping company if damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installation:

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and service.

Maintain a minimum of 4 ft clearance from obstruc

tions above and 18 in. on sides of unit. Maintain a

distance of 24 in. between condensing units. Posi

tion so water from roof or eaves does not flow

directly on unit.

Install on a solid, level mounting pad. It is not

necessary to attach unit to pad but if desired or

required by local code, position tiedown bolts in

pad. Fasten unit to pad using 2 holes provided in unit

base. See Fig. 1.

036

2-2-3/8 1 2-8 1 3-2

3/

8

3/8

042

048 060

212 230.

2-5-1/4

3/4*

© Carrier Corporation 1982

Form 38EB-3SI

4'-0" OVERHEAD SPACE REQUIRED

FOR SERVICE AND AIRFLOW

LIQUID VALVE SERVICE PORT

CONDENSER AIRFLOW

KW r-6''AIRFL0W

■•••••■ AND SERVICE

CLEARANCE

SUCTION VALVE SERVICE PORT

rectly sized for an evaporator of the same capacity as

the condensing unit, so piston change is not neces

sary. Mix-matching of condensing unit with evap

orator requires field replacement of piston. Refer to

Table 2. Replace piston, if required, before connec

ting refrigerant lines. Piston replacement instruc

tions are included in evaporator installation book.

After system installation is complete, use Charging

Chart to check and/or adjust refrigerant charge.

Condensing Units Connected to Carrier-Approved

Evaporators — Condensing units contain correct

system refrigerant charge for operation with evap

orator of the same size when connected by 25 ft or

less of field-supplied or Carrier accessory tubing.

Check refrigerant charge for maximum efficiency

(see Refrigerant Charging, page 6).

Table 2 — Optimization Chart

(Outdoor air design temperature, db-F,

100 F and below)

COND

UNIT

38EB

015 TWl 46 i

018 ’ . 4

024

030

036

042

048

060

Factory-installed piston. Obtain replacement pistons thru

local Carrier distributor.

ACCURATER™ PISTON NO.

Evap Size (Coil or Fan Coil)

ÒTFI”M4TCÌ301

> I j_V'

52

57

036

TXV

65

6? 70

048 060

042

— — —

— —

TXV

TXV

76

,...78...

_

62

—

p»

TXV

i 82

^CONCRETE PAD SHOULD WEIGH 1^ TO 2 TIMES WEIGHT OF UNIT

Certified dimension drawings available upon request

Fig. 1 — Dimensions, Connections and

Mounting Pad (Refer to Table 1)

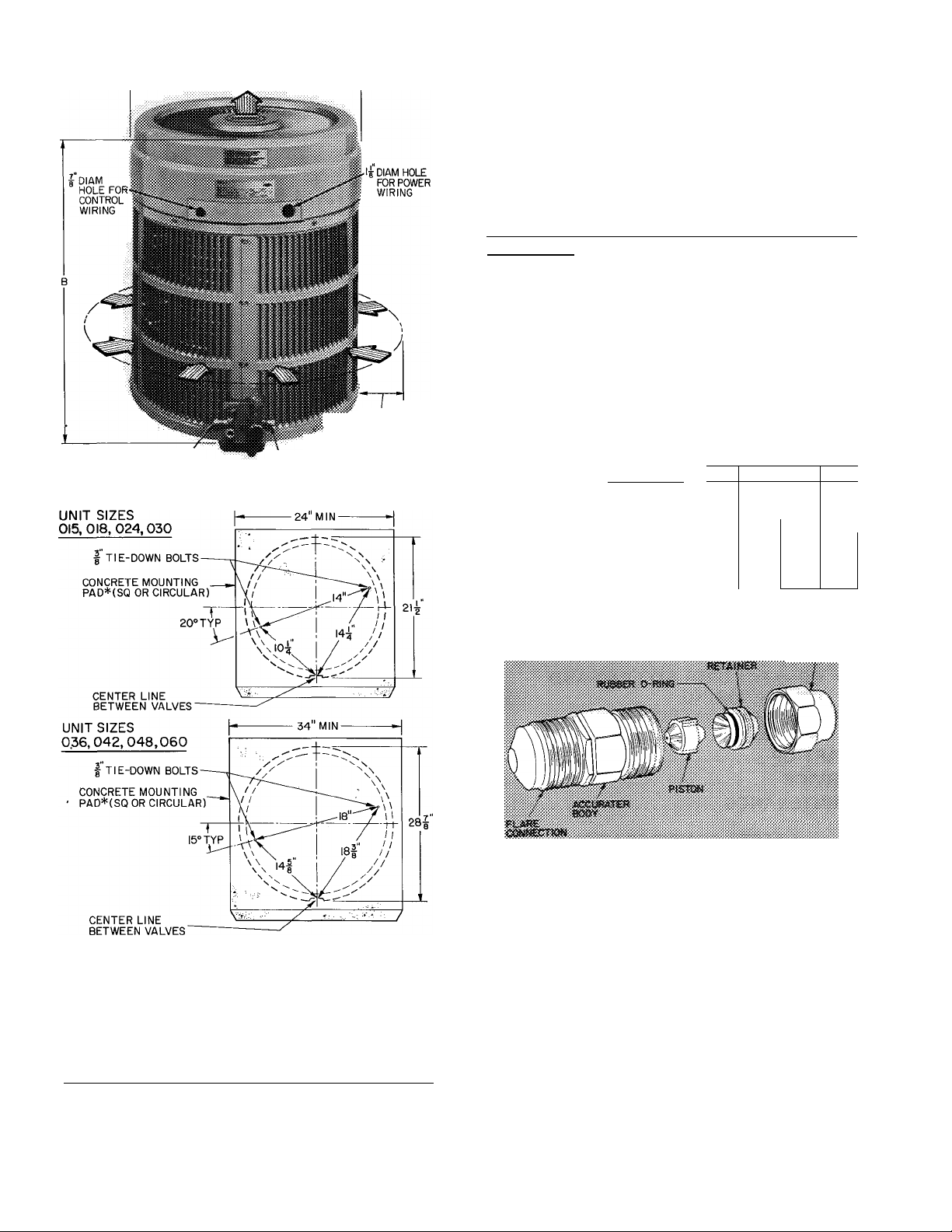

Carrier Cooling System Capacity Optimization —

AccuRater™ (bypass type) refrigerant control, with

field-replaceable piston (see Fig. 2), is supplied on

evaporator. Use Optimization Chart, Table 2 to

find AccuRater piston size required for condenser/

evaporator system being installed. Pistons are cor-

njmm

Fig. 2 — AccuRater (Bypass Type)

Components

Step 2 — Make Piping Connections — Con

densing units may be connected to evaporator sec

tions using Carrier accessory tubing package (Table

3) or field-supplied tubing of refrigerant grade,

correct size and condition (Table 1). For tubing

requirements beyond 50 ft, obtain information from

local Carrier distributor.

If or

1$ osigd wism saaldog

If 1-1/8 in. tubing is used (38EB048,060), braze

it to the accessory 1 -1 / 8 x 3/4-in. suction connection

adapter (Carrier Part No. 28VQ900011) or to cor

rectly sized field-supplied adapter, then make Com

patible Fitting connections.

WARNING: iX> NOT BURY UNESETS- If

fdfigerans

E b. veitkaS Ui« to the vah;« irastxsciioiis m

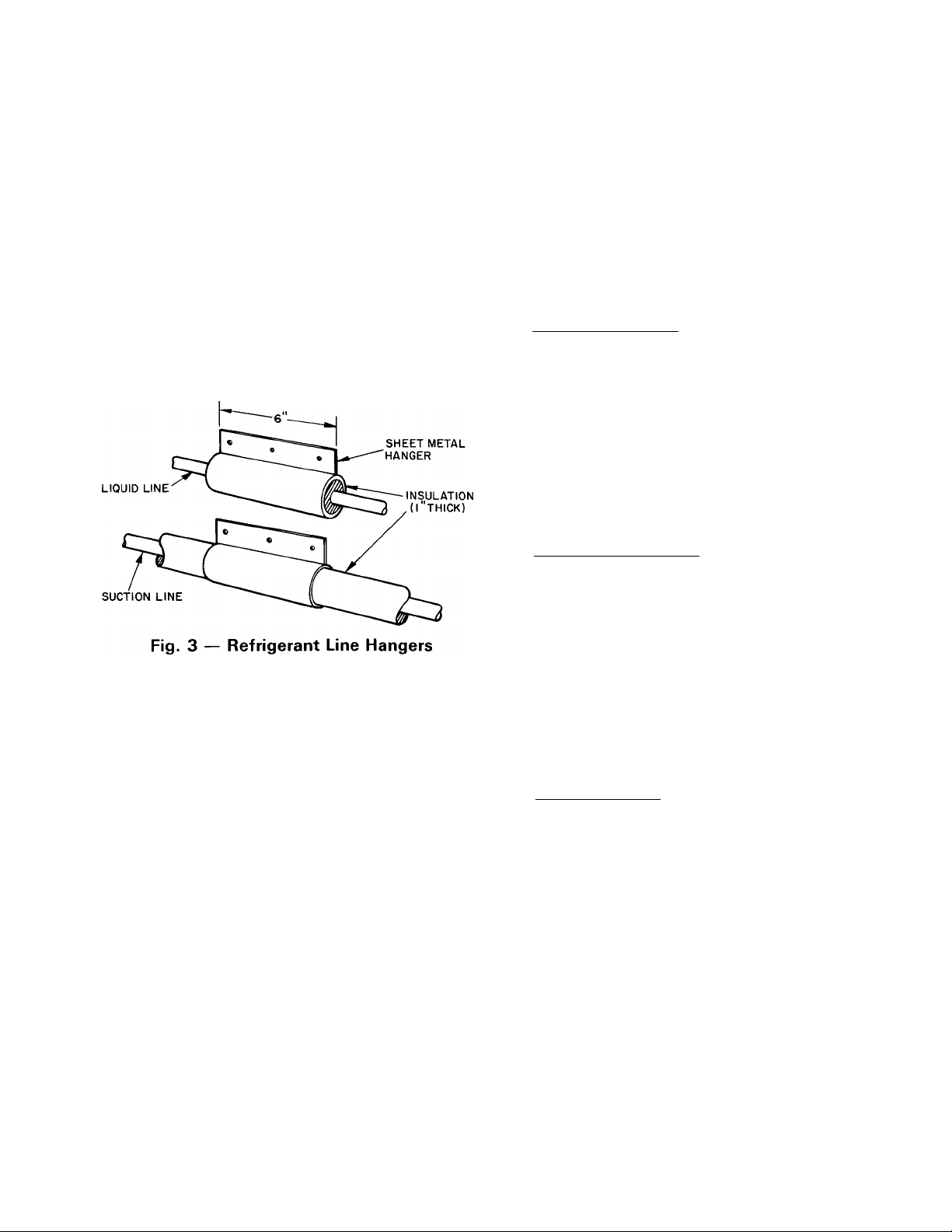

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces, en

closed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure creating objectionable sound.

For maximum capacity on 38EB048 and 060 sys^

terns use 1 -1 / 8 in. suction line. A capacity reduction

results if Carrier accessory tubing is used on these

systems. (Example; When a 25-ft accessory tubing

package is used on a 38EB048 system, the smaller

suction line results in a 3% capacity reduction.)

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements described in Start-Up, Refrigerant

Charging, page 6. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/ 16-in. or 1/4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends that, if cut, will not fit into refrigerant

line fittings. Bend or coil excess tubing to fit.

Do not use damaged, undersized or contaminated

tubing. Always evacuate or purge evaporator coil

and tubing system. When purging, use field-supplied

refrigerant, not unit holding charge refrigerant.

When making tubing connections, be sure to pro

vide clearance at unit for electrical connections.

REPLACE THE ACCURATER™ REFRIG

ERANT CONTROL PISTON IN THE INDOOR

COIL, if required, before connecting refrigerant

lines. See Carrier Cooling System Capacity Optimi

zation, page 2.

CONNECT REFRIGERANT LINES to fittings on

condensing unit suction and liquid service valves

(Fig. 1). Unit Compatible Fittings permit mechanical

(quick connect) or sweat connections.

Models 38EB048,060 — When using 1 -1 / 8 in. field-

supplied suction line, use field-supplied 3/4-in. by

1-1/8 in. suction valve connection adapter

(28VQ900011). Sweat connect refrigerant suction

line to 1-1/8 in. end of adapter. Be sure to provide

a heat sink at the service valve to prevent damage

during sweating operation. Connect 3/4-in. end of

adapter to unit suction line Compatible Fitting.

Connect liquid refrigerant line to unit. When a

7/8-in. field-supplied suction line is used, provide a

field-supplied 3/ 4-in. to 7/ 8-in. suction line adapter.

(Not necessary if 38LS accessory tubing is used.)

Mechanical Connection — (Mate one set of connec

tions at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure O-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length, deburr and size as

necessary.

4. Insert tube into Compatible Fitting until it

bottoms. Tighten nut until it bottoms on back

coupling flange. Keep tube bottomed in Compat

ible Fitting while tightening nut.

SweatT/onnection — (Use refrigerant grade tubing.-)

1. Remove locking nut, rubber O-ring and Schrader

core and cap from valve service port.

2. Cut tubing to correct length, deburr and size as

necessary.

3. Insert tube in Compatible Fitting until it bottoms.

Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with lowtemperature (430 F) silver alloy solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system using field-supplied

refrigerant.

Table 3 — Accessories

PART NO.

38CQ900141

HH01AD040

HH93AZ040

HH07AT170

&

HH07AT174

HH93AZ176

HH01AD042

HH93AZ042

HH01YA192

HH93YZ194

38GS900102

38GS900212

HT32BH246

38UE900201

HC95DE088

HN61HB513

HC95DD121

HN61HB515

HC95DE066

HN61HB513

HC95DE088

HN61HB515

HC95DE088

HN61HB506

38EB660002

09WQ036,060

38GS900321

28VQ900011 Twelve 3/4- x 1-1/8 in Connection Adapters

PACKAGES

38LS958151 15

38LS958201 20

. 38LS958251 25 3/8

38LS958301

38LS958351

38LS958401

38LS958501

38LS934151 15

38LS934201

38LS934251

38LS934301

38LS934351

38LS934401

38LS934501

38LS978151

38LS978201

38LS978251 25

38LS978301 30

38LS978351

38LS978401 40

38LS978501

Solid-State Time Guard

(Six 38CQ900152)

Low-Voltage Control Honeywell Deluxe Thermostat

Thermostat Subbase

Low-Voltage Control

Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control Grayson Thermostat

Thermostat Subbase

Indoor Fan Relay (Six HN61KJ210)

Low-Voltage Transformer (Six 38GS900091)

Crankcase Heater*

Crankcase Heater Relay (Six 38UE900212)*

Start Capacitor*

Relay*

Start Capacitor*

Relay*

Start Capacitor*

Relay*

Start Capacitor*

Relay*

Start Capacitor*

Relay*

Wire Bundle for Start Capacitors and Relays*

Refrigerant-to-Water Heat Exchanger for Chilled Water Systems

Liquid Line Filter Drier

Length

(ft)

30

35

40

50

20

25

30

35

40

50

15

20

35

50

OD

(in.)

3/8 3/8

3/8 3/8

5/16

5/16

5/16

1/4

3/8

3/8

3/8

3/8

3/8

3/8 3/8

3/8

3/8

3/8 3/8

3/8

3/8 3/8

3/8 3/8

3/8 3/8

3/8 3/8

DESCRIPTION

Liquid

Tube End

OD (in.)

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

TUBlNGt

Suctionj;

OD

(in.)

5/8

5/8

5/8

5/8

5/8

5/8

5/8

3/4 3/4 3/4

3/4

3/4 3/4 3/4

3/4

3/4

3/4 3/4

3/4

7/8

7/8

7/8

7/8

7/8

7/8

7/8

Tube End

OD (in.)

Evap

3/4**

3/4**

3/4**

3/4**

3/4**

3/4**

3/4**

3/4 3/4

3/4

3/4 3/4

3/4 3/4

3/4

3/4

3/4 3/4

3/4

3/4

3/4 3/4

3/4 3/4

Cond

MODEL

38EB

All

015300, 018300

024300, 030300

036310

042360

048310

All

048, 060

38EB

5/8

5/8

5/8

5/8

5/8

5/8

5/8

3/4 030, 036

3/4

3/4

3/4

3/4

3/4

015, 018, 024

r:'

*Available thru Carrier Service Parts

tFor maximum capacities, use suction line sizes recommended in

Table 1 Use of accessory tubing packages smaller than recom

mended may result in slight capacity loss (see Note 2)

tSuction line is insulated and has a 90 degree bend at one end

**For 5/8-in evaporator connection, cut off 3/4-in end

NOTES

1 Do not cut 3/8-in OD liquid line toa length shorterthan 10feet

Do not cut 5/16-or 1/4-in liquid line Do not cut 7/8-in OD

suction lines

2 Field-supplied 1-1/8 in suction line is recommended on

38EB048 and 060 If accessory tubing package is used, a

capacity reduction can result

Loading...

Loading...