Page 1

30HXA,HXC076-186

Water-Cooled and Condenserless Chillers

Installation Instructions

50/60 Hz

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................1

INSTALLATION .............................1-27

Step 1 — Inspect Shipment ...................1

Step 2 — Rig and Place Unit ..................1

Step 3 — Piping Connections .................9

• COOLER FLUID, VENT, AND DRAIN

• BRINE UNITS

• PREPARATION FOR YEAR-ROUND

OPERATION

• 30HXA REFRIGERANT PIPING

• 30HXC CONDENSER CONNECTIONS

• INSTALL PRESSURE RELIEF REFRIGERANT

VENT PIPING

Step 4 — Make Electrical Connections .......14

• FIELD POWER CONNECTIONS

• FIELD CONTROL POWER CONNECTIONS

Step 5 — Install Accessories ................26

• ELECTRICAL

• 30HXA LOW-AMBIENT OPERATION

• MINIMUM LOAD ACCESSORY

• MISCELLANEOUS ACCESSORIES

Step 6 — Leak Test Unit .....................26

• 30HXC UNITS

• 30HXA UNITS

Step 7 — Refrigerant Charge ................26

• 30HXC UNITS

• 30HXA UNITS

IMPORTANT:This equipment generates, uses, and can

radiate radio frequency energy. If not installed and

used in accordance with these instructions, this equipment may cause radio interference.The equipment has

been tested and found to comply with the limits of a

Class A computing device as defined by the FCC

(Federal Communications Commission, U.S.A.) Regulations, Subpart J of Part 15, which are designed to

provide reasonable protection against such interference when operated in a commercial environment.

INSTALLATION

Step 1— Inspect Shipment —

age upon arrival. If damage is found, file a claim with the

shipping company right away. Do not store units in an area

exposed to weather because of sensitive control mechanisms and electronic devices.

Locate unit indoors. When considering unit location, consult National Electrical Code (NEC, U.S.A.) and local code

requirements. Allow sufficient space for wiring, piping, and

service. Install unit in an area which will not be exposed to

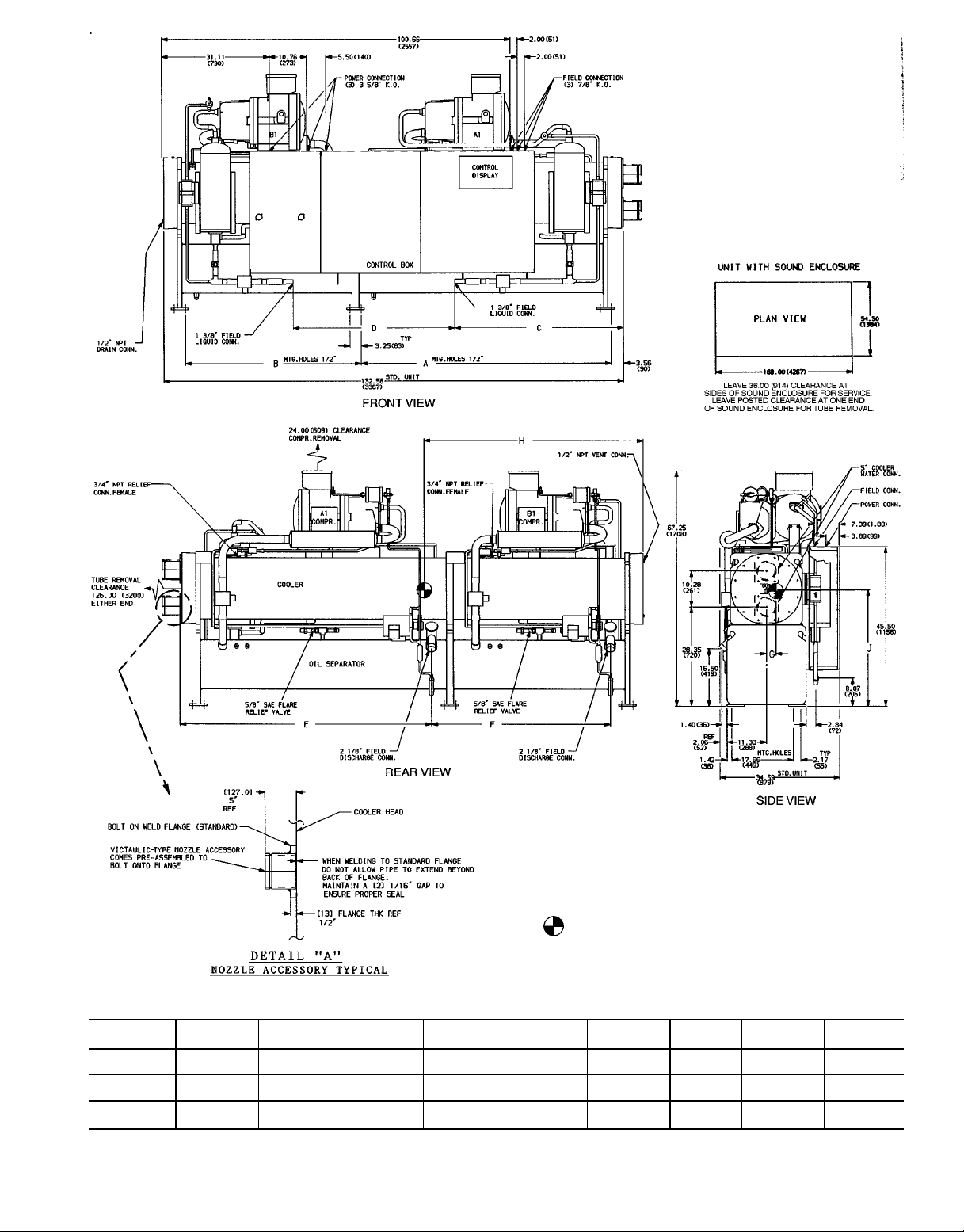

subfreezing weather. See Fig. 1-4 for clearance details.

Allow the following clearances for service access:

Front .............................. 3ft(914 mm)

Rear ............................... 3ft(914 mm)

Top ............................... 2ft(610 mm)

Ends ............... tube removal at one (either) end;

3 ft (914 mm) at opposite end.

Inspect unit for dam-

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can

be hazardous due to system pressures, electrical components, and equipment location. Only trained, qualified

installers and service mechanics should install, start up, and

service this equipment.

When working on the equipment, observe precautions in

the literature, andontags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and setting bulky

equipment.

INTRODUCTION

These instructions cover installation of 30HX liquid chillers with electronic controls and units with factory-installed

options (FIOPSs).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5c

PC 903 Catalog No. 563-052 Printed in U.S.A. Form 30HX-1SI Pg 1 5-96 Replaces: New

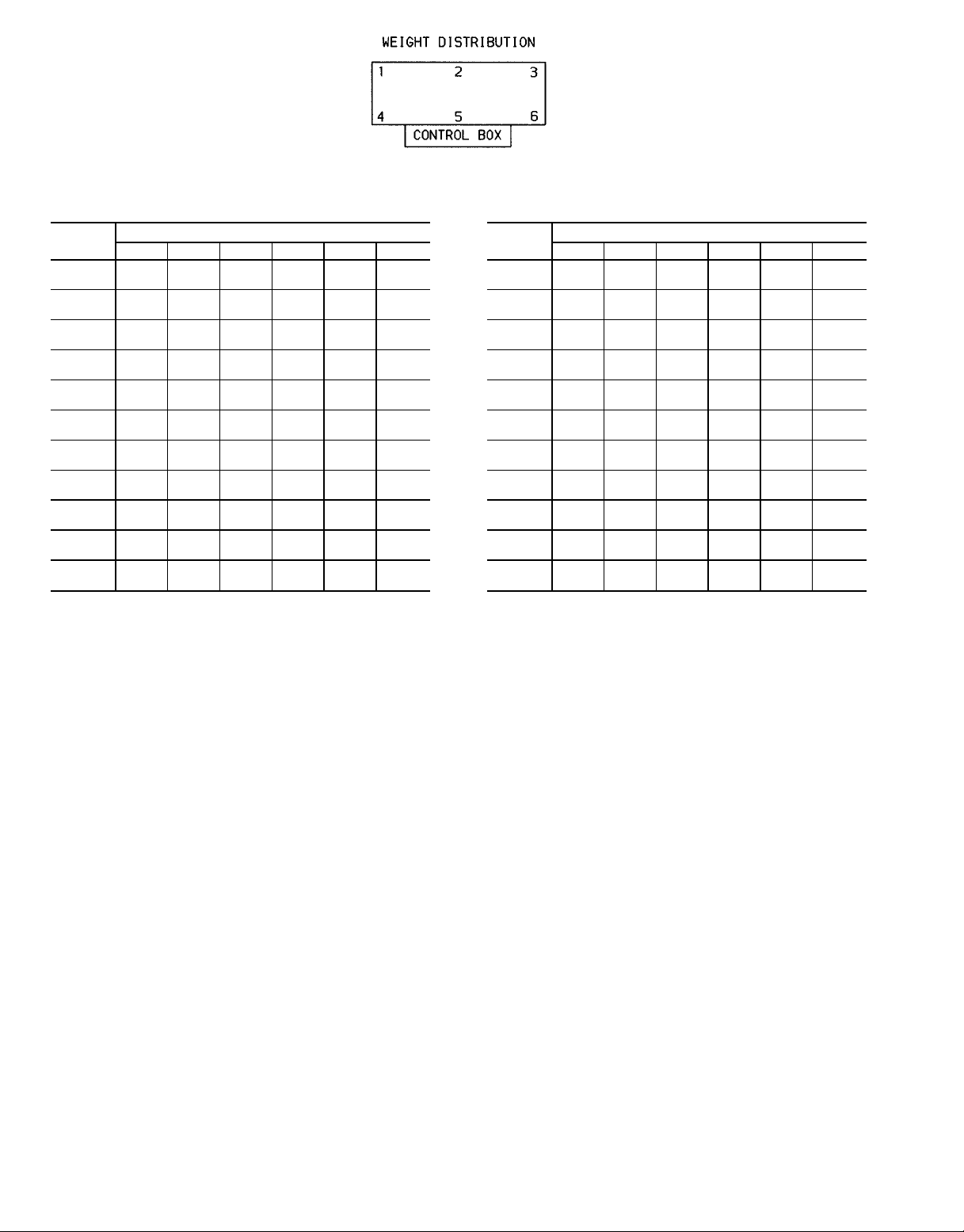

Be sure surface beneath the unit is level and is capable of

supporting the operating weight of the unit. See Fig. 5 and

Tables 1A and 1B for unit operating weights. If necessary,

add supporting structure (steel beams or reinforced concrete

slabs) to floor to transfer weight to nearest beams.

Step 2 — Rig and Place Unit

Rig unit from the top heat exchanger only. Rigging from

the bottom heat exchanger will cause the unit to be lifted

unsafely. Personal injury or damage to the unit may

occur.

Do not remove unit from skid until unit is in its

final location. Rig from the rigging holes provided in the top

heat exchanger. See Fig. 1-5 for rigging and center of gravity information. Lower the unit carefully onto the floor or

roller. Push or pull only on the skid, not the unit. If the

unit is moved on rollers, use a minimum of 3 evenly-spaced

rollers.

Copy continued on page 9.

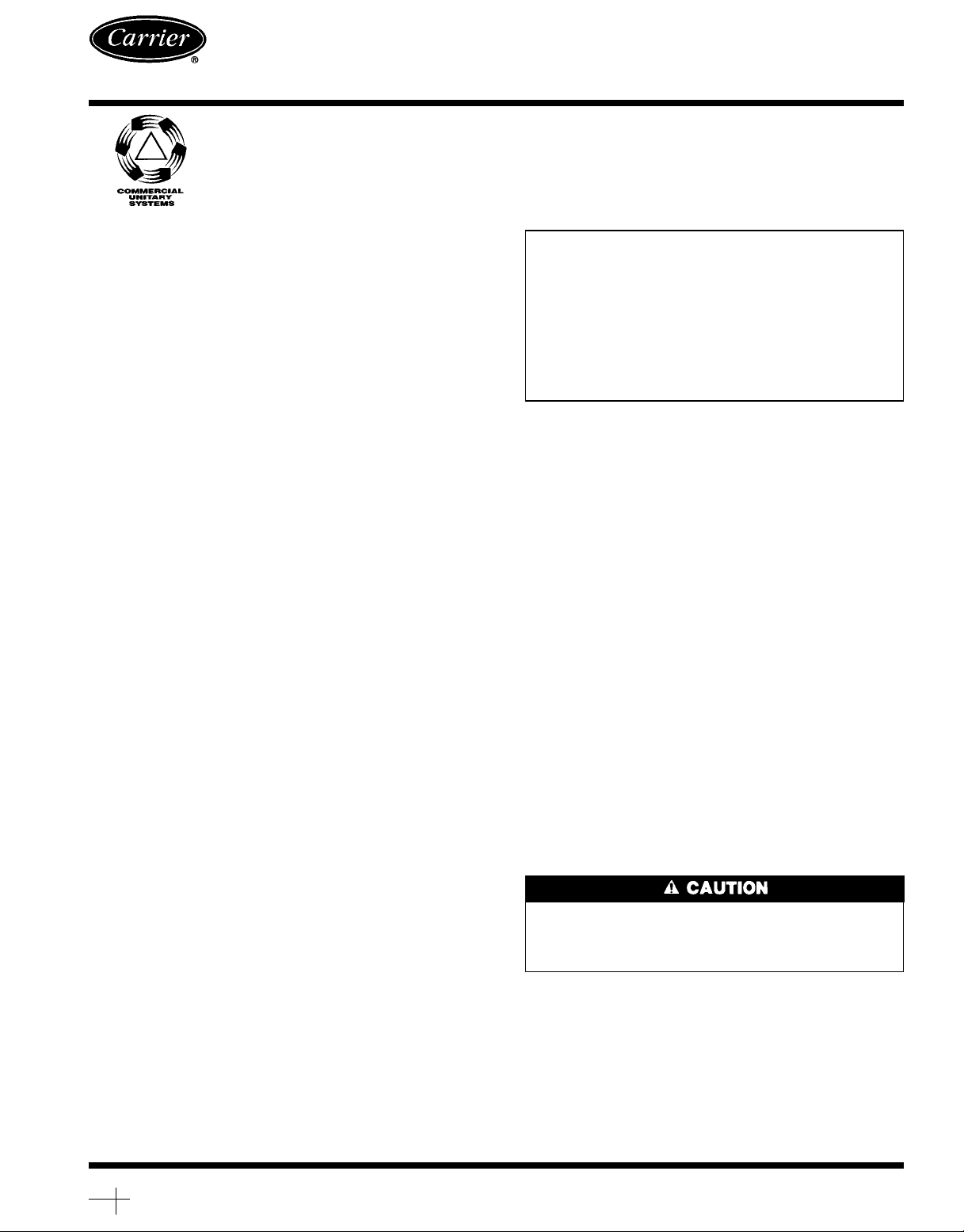

Page 2

LEGEND

K.O. — Knockout

THK — Thick

TYP — Typical

UNIT

30HXC

076

086

096

106

116

126

136

146

NOTES:

1. Denotes center of gravity.

2. Dimensions are in inches. Dimensions ( ) are in millimeters.

3. Recommended service clearance around unit (front, back, and one side) is

369 (914).

DIMENSIONS — in. (mm)

ABCDEFGHJK LMNP

102.12

(2594)

102.12

(2594)

102.12

(2594)

102.12

(2594)

132.56

(3367)

132.56

(3367)

132.56

(3367)

132.56

(3367)

45.87

(1165)

45.87

(1165)

37.63

(956)

37.63

(956)

72.12

(1832)

72.12

(1832)

72.12

(1832)

72.12

(1832)

45.87

(1165)

45.87

(1165)

54.12

(1375)

54.12

(1375)

50.63

(1286)

50.63

(1286)

50.63

(1286)

50.63

(1286)

9.87

(251)

9.87

(251)

9.87

(251)

10.47

(266)

9.87

(251)

9.87

(251)

9.87

(251)

9.87

(251)

9.36

(236)

9.36

(236)

9.36

(236)

10.28

(261)

9.36

(236)

9.36

(236)

9.36

(236)

9.36

(236)

43.50

(1105)

43.50

(1105)

43.50

(1105)

45.50

(1156)

43.50

(1105)

43.50

(1105)

43.50

(1105)

43.50

(1105)

15.60

(396)

15.60

(396)

15.60

(396)

15.60

(396)

31.11

(790)

31.11

(790)

31.11

(790)

31.11

(790)

85.15

(2163)

85.15

(2163)

85.15

(2163)

85.15

(2163)

100.66

(2557)

100.66

(2557)

100.66

(2557)

100.66

(2557)

4.00

(102)

4.00

(102)

4.00

(102)

5.00

(127)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

95.00

(2413)

95.00

(2413)

95.00

(2413)

95.00

(2413)

126.00

(3200)

126.00

(3200)

126.00

(3200)

126.00

(3200)

65.22

(1657)

65.22

(1657)

65.22

(1657)

67.22

(1707)

65.22

(1657)

65.22

(1657)

65.22

(1657)

65.22

(1657)

1.90

(48)

1.90

(48)

1.90

(48)

1.90

(48)

1.70

(43)

1.70

(43)

1.70

(43)

1.70

(43)

47.00

(1194)

47.00

(1194)

47.00

(1194)

47.00

(1194)

62.20

(1580)

62.20

(1580)

62.20

(1580)

62.20

(1580)

30.80

(782)

30.80

(782)

30.80

(782)

30.80

(782)

29.40

(747)

29.40

(747)

29.40

(747)

29.40

(747)

Fig. 1 — Base Unit Dimensions, 30HXC076-146 Units

2

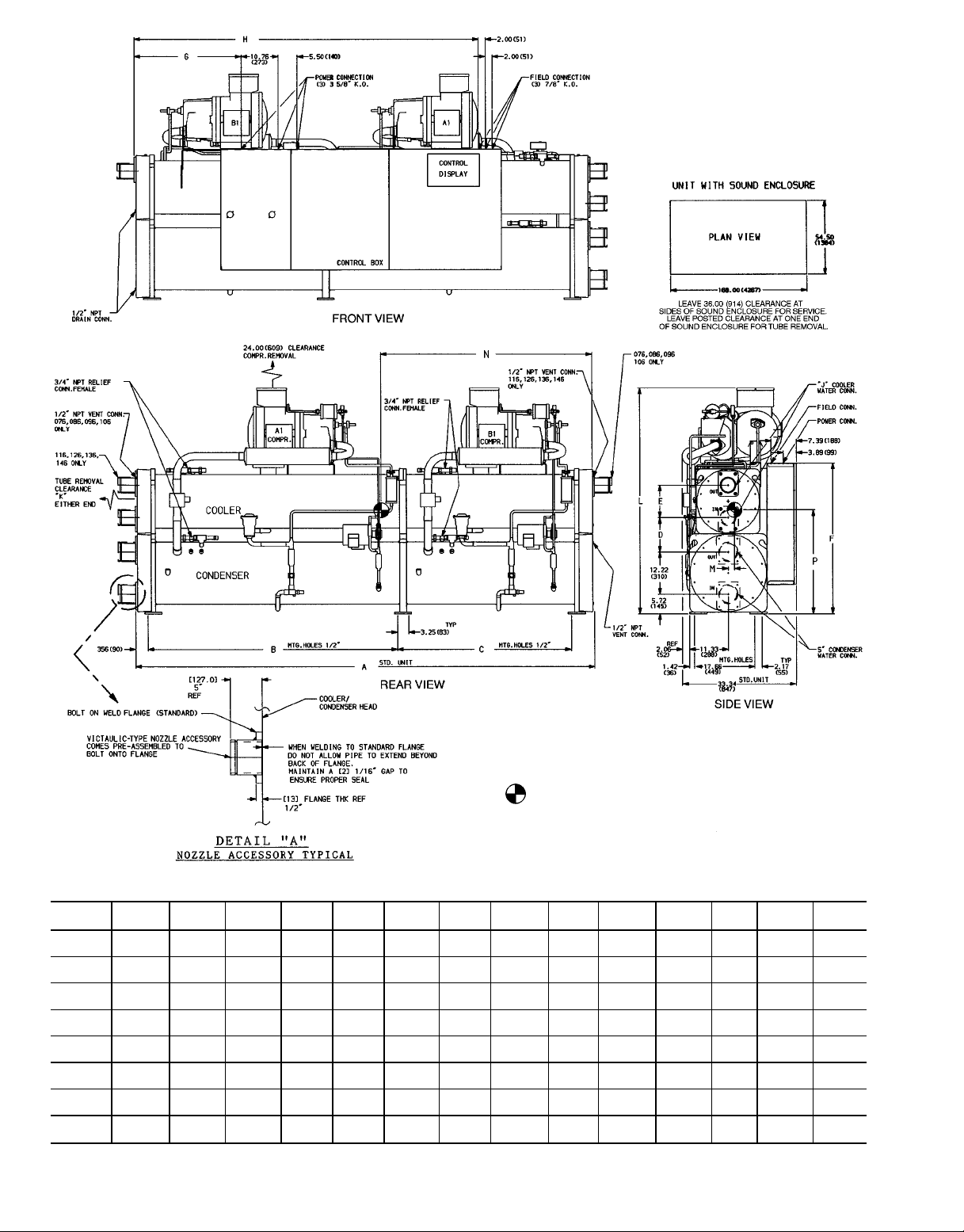

Page 3

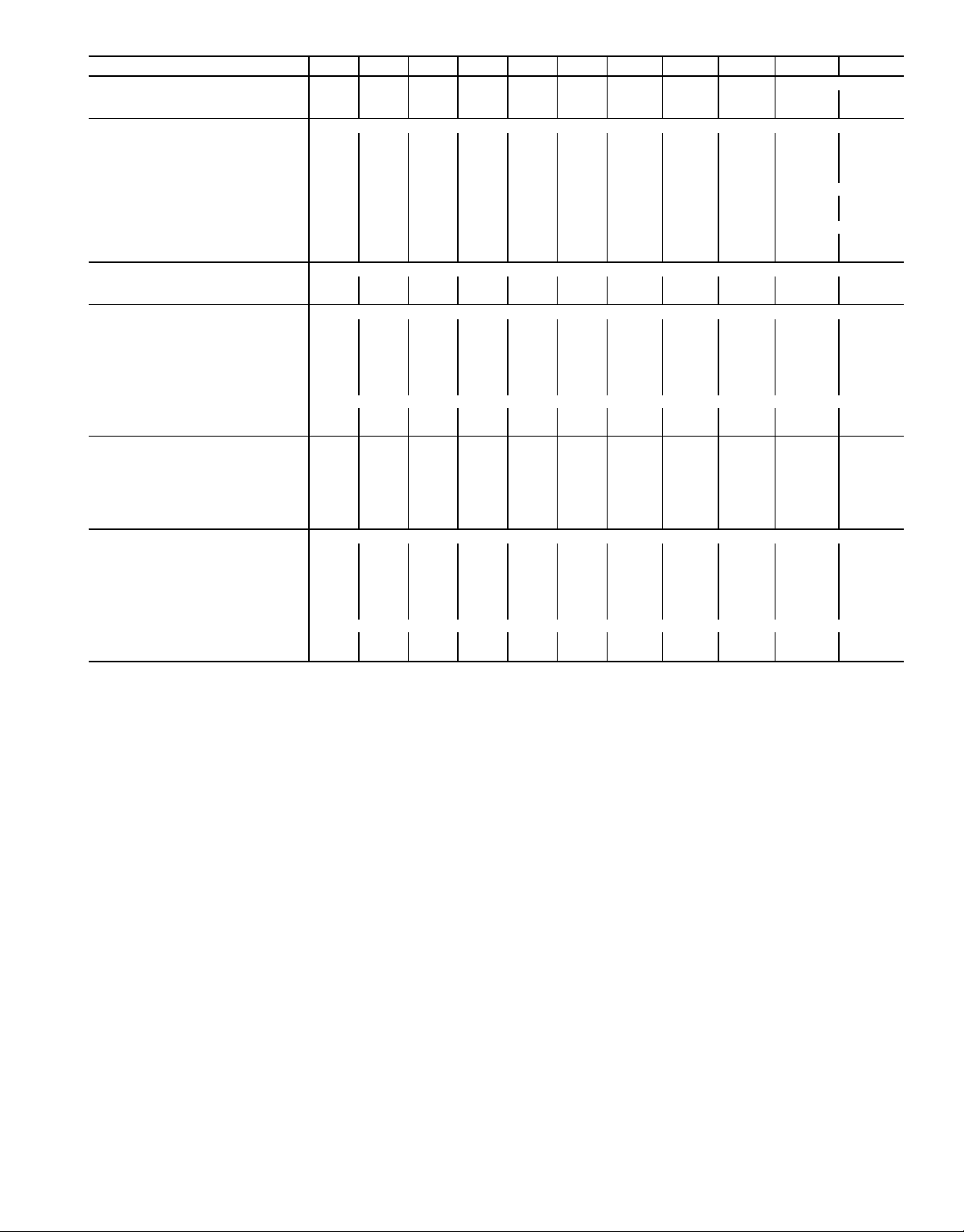

UNIT

30HXC

161

171

186

DIMENSIONS — in. (mm)

ABCD E

72.12

(1832)

61.37

(1559)

61.37

(1559)

50.63

(1286)

61.37

(1559)

61.37

(1559)

2.00

(51)

2.00

(51)

2.00

(51)

63.50

(1588)

63.50

(1588)

63.50

(1588)

31.00

(787)

31.00

(787)

31.00

(787)

Fig. 2 — Base Unit Dimensions, 30HXC161-186 Units

NOTES:

1. Denotes center of gravity.

2. Dimensions are in inches. Dimensions ( ) are in millimeters.

3. Recommended service clearance around unit (front, back, and one side) is

369 (914).

LEGEND

K.O. — Knockout

THK — Thick

TYP — Typical

3

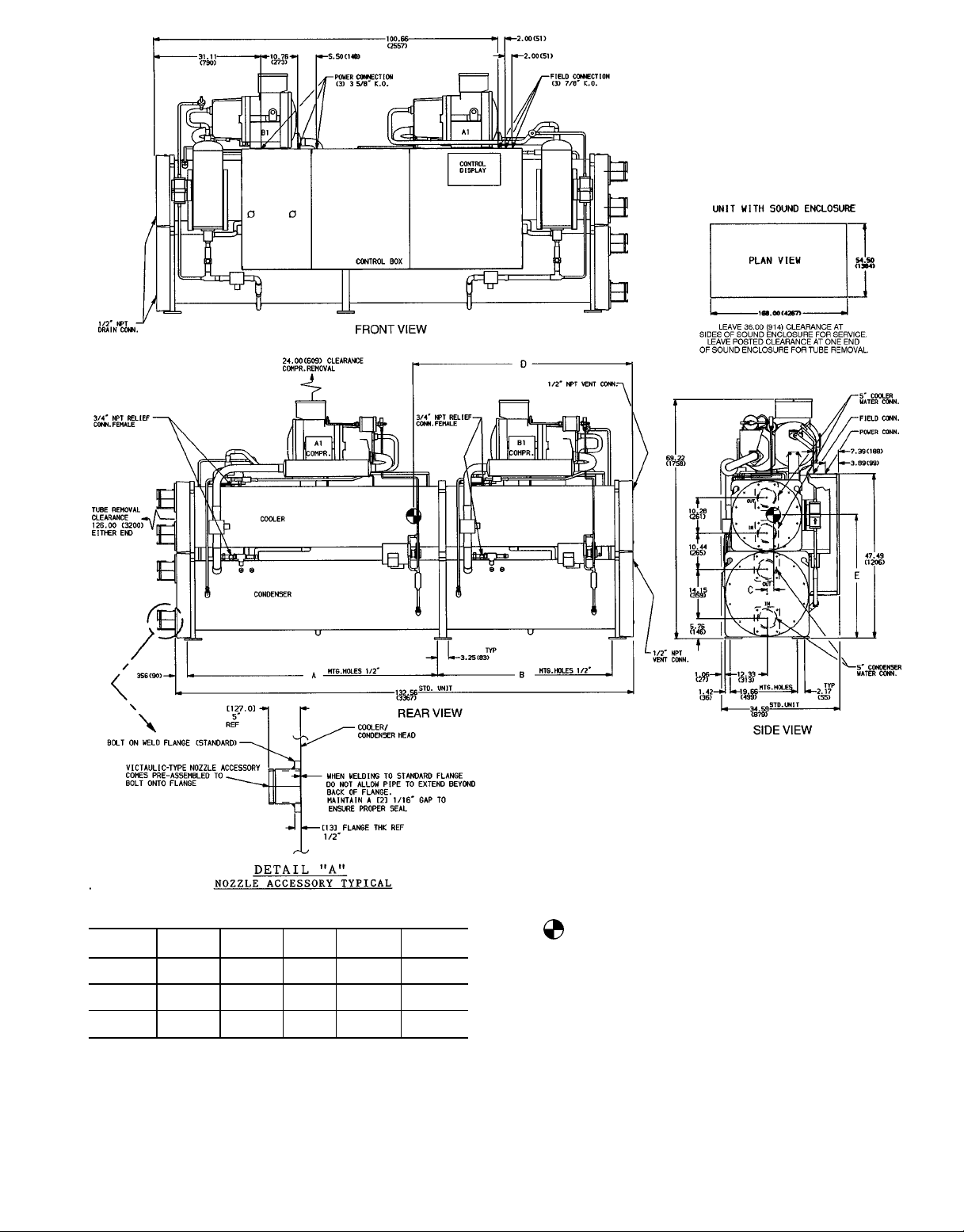

Page 4

LEGEND

K.O. — Knockout

SAE — Society of Automotive

THK — Thick

TYP — Typical

Engineers, U.S.A.

UNIT

30HXA

076

086

096

106

116

126

136

146

NOTES:

1. Denotes center of gravity.

2. Dimensions are in inches. Dimensions ( ) are in millimeters.

3. Recommended service clearance around unit (front, back, and one side) is

369 (914).

DIMENSIONS — in. (mm)

ABCDEFGHJKLMNPRSTUV

102.12

45.87

45.87

27.81

9.36

43.50

15.60

85.15

4.00

95.00

65.22

13.93

59.48

5.72

45.81

46.25

2.40

46.40

(2594)

102.12

(2594)

102.12

(2594)

102.12

(2594)

132.56

(3367)

132.56

(3367)

132.56

(3367)

132.56

(3367)

(1165)

45.87

(1165)

37.63

(956)

37.63

(956)

72.12

(1832)

72.12

(1832)

72.12

(1832)

72.12

(1832)

(1165)

45.87

(1165)

54.12

(1375)

54.12

(1375)

50.63

(1286)

50.63

(1286)

50.63

(1286)

50.63

(1286)

(706)

27.81

(706)

27.81

(706)

28.41

(721)

27.81

(706)

27.81

(706)

27.81

(706)

27.81

(706)

(236)

9.36

(236)

9.36

(236)

10.28

(261)

9.36

(236)

9.36

(236)

9.36

(236)

9.36

(236)

(1105)

43.50

(1105)

43.50

(1105)

45.50

(1156)

43.50

(1105)

43.50

(1105)

43.50

(1105)

43.50

(1105)

(396)

15.60

(396)

15.60

(396)

15.60

(396)

31.11

(790)

31.11

(790)

31.11

(790)

31.11

(790)

(2163)

85.15

(2163)

85.15

(2163)

85.15

(2163)

100.66

(2557)

100.66

(2557)

100.66

(2557)

100.66

(2557)

(102)

4.00

(102)

4.00

(102)

5.00

(127)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

(2413)

95.00

(2413)

95.00

(2413)

95.00

(2413)

126.00

(3200)

126.00

(3200)

126.00

(3200)

126.00

(3200)

(1657)

65.22

(1657)

65.22

(1657)

67.22

(1707)

65.22

(1657)

65.22

(1657)

65.22

(1657)

65.22

(1657)

(354)

13.93

(354)

22.15

(563)

22.15

(563)

40.16

(1020)

40.16

(1020)

40.16

(1020)

40.16

(1020)

(1511)

59.48

(1511)

42.77

(1086)

42.77

(1086)

64.23

(1631)

64.23

(1631)

64.23

(1631)

64.23

(1631)

(145 )

5.72

(145)

5.72

(145)

5.87

(149)

5.72

(145)

5.72

(145)

5.72

(145)

5.72

(145)

(1164)

45.81

(1164)

54.06

(1373)

54.06

(1373)

72.06

(1830)

72.06

(1830)

72.06

(1830)

72.06

(1830)

(1175)

46.25

(1175)

38.00

(965)

38.00

(965)

51.01

(1296)

51.01

(1296)

51.01

(1296)

51.01

(1296)

(61)

2.40

(61)

2.40

(61)

2.40

(61)

2.30

(58)

2.30

(58)

2.30

(58)

2.30

(58)

(1179)

46.40

(1179)

46.40

(1179)

46.40

(1179)

61.00

(1549)

61.00

(1549)

61.00

(1549)

61.00

(1549)

35.00

(889)

35.00

(889)

35.00

(889)

35.00

(889)

34.30

(871)

34.30

(871)

34.30

(871)

34.30

(871)

Fig. 3 — Base Unit Dimensions, 30HXA076-146 Units

4

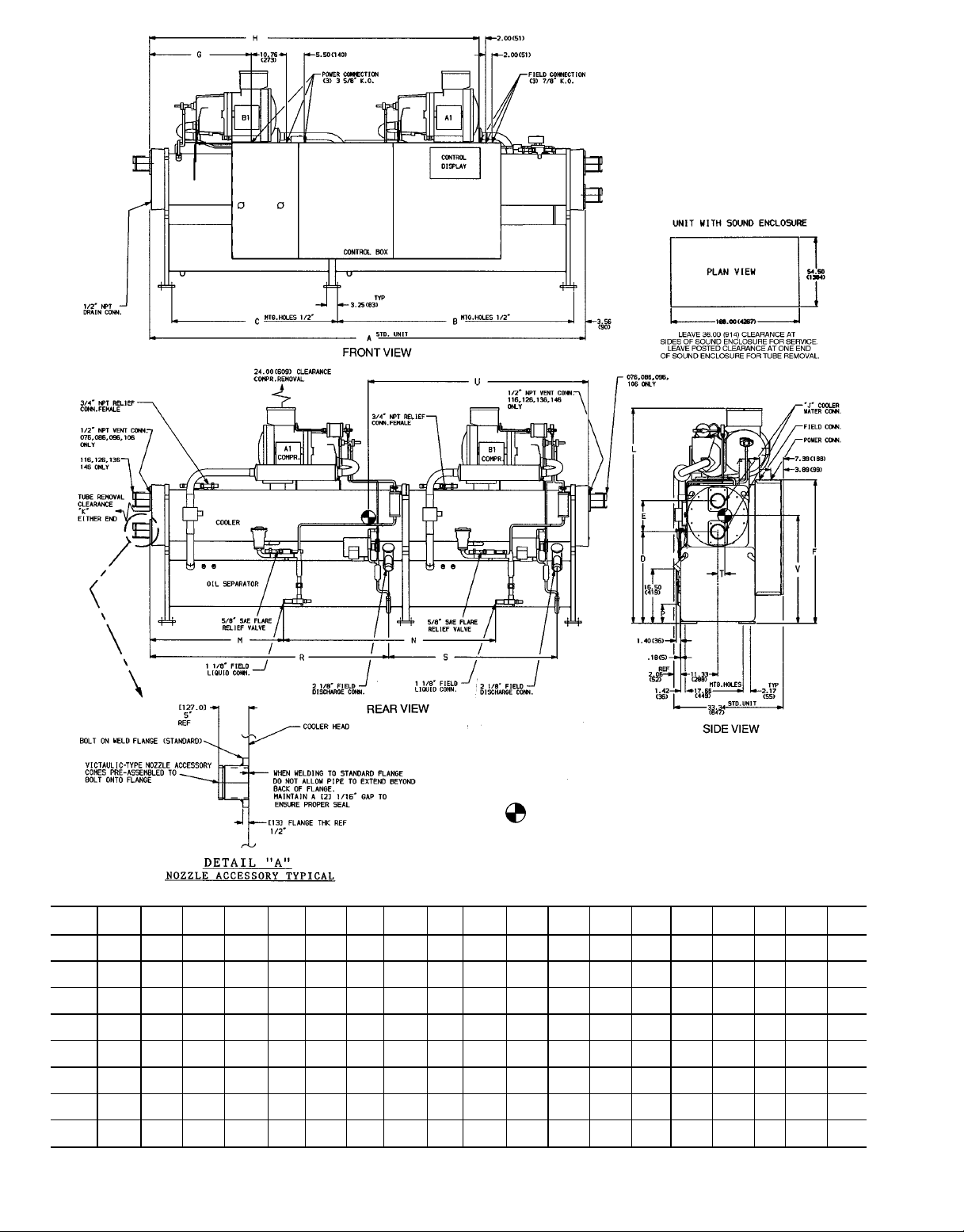

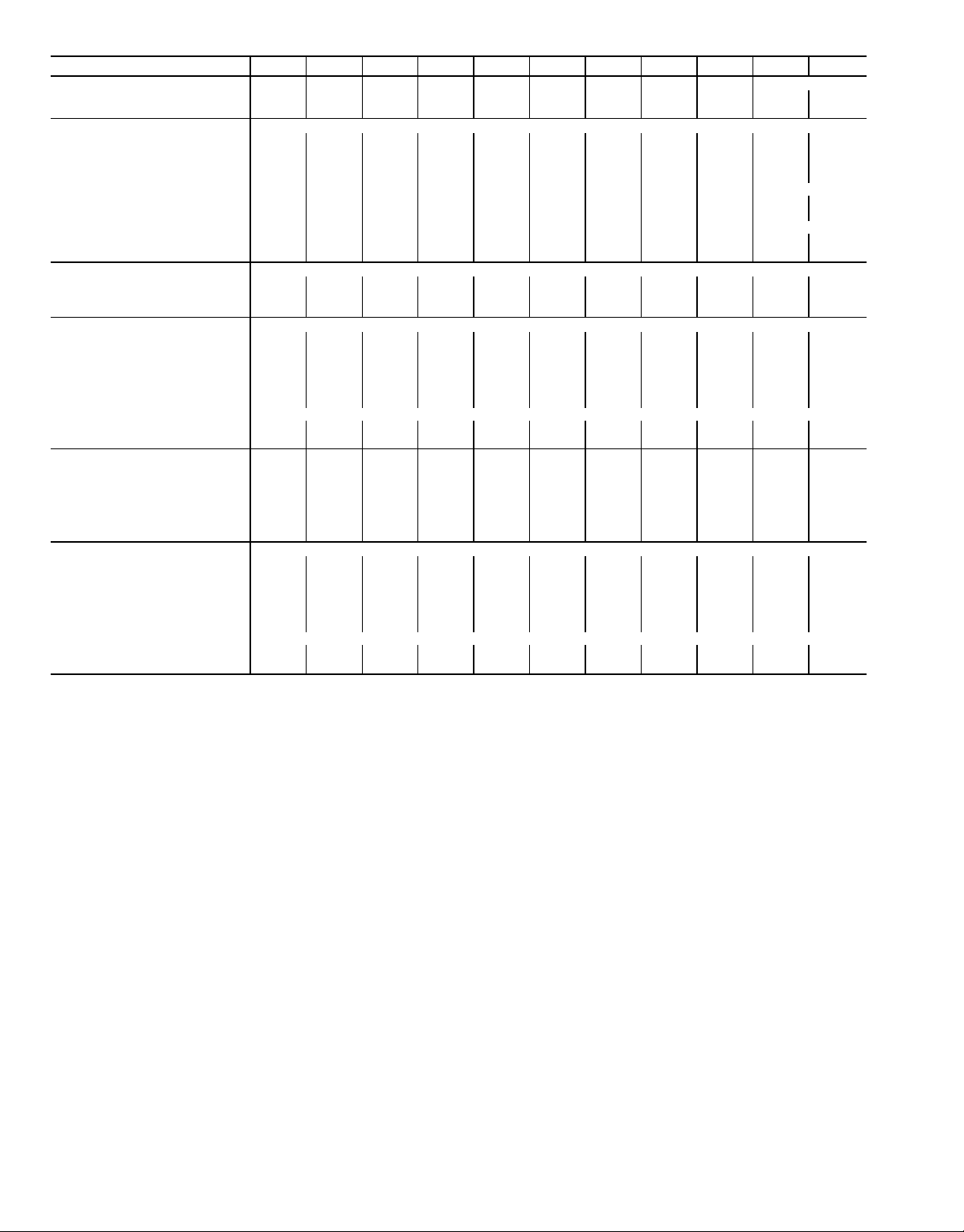

Page 5

LEGEND

K.O. — Knockout

SAE — Society of Automotive

THK — Thick

TYP — Typical

Engineers, U.S.A.

UNIT

30HXA

161

171

186

NOTES:

1. Denotes center of gravity.

2. Dimensions are in inches. Dimensions ( ) are in millimeters.

3. Recommended service clearance around unit (front, back, and one side) is

369 (914).

DIMENSIONS — in. (mm)

ABCDEFGHJ

72.12

(1832)

61.37

(1559)

61.37

(1559)

50.63

(1386)

61.37

(1559)

61.37

(1559)

48.56

(1233)

43.25

(1099)

43.25

(1099)

46.62

(1184)

46.62

(1184)

46.62

(1184)

72.06

(1830)

61.31

(1572)

61.31

(1572)

51.00

(1295)

61.75

(1568)

61.75

(1568)

2.70

(69)

2.70

(69)

2.70

(69)

62.50

(1588)

62.50

(1588)

62.50

(1588)

35.20

(894)

35.20

(894)

35.20

(894)

Fig. 4 — Base Unit Dimensions, 30HXA161-186 Units

5

Page 6

WEIGHT DISTRIBUTION AT EACH MOUNTING PLATE,

30HXC UNITS — Lb (Kg)

UNIT

30HXC

076

086

096

106

116

126

136

146

161

171

186

NOTE: See Fig. 1-4 for center of gravity details.

123456

738

(335)

738

(335)

686

(311)

730

(331)

728

(330)

738

(335)

758

(344)

763

(346)

817

(371)

936

(425)

962

(436)

MOUNTING PLATE NO.

943

(428)

947

(430)

968

(439)

1028

(466)

1114

(505)

1127

(511)

1176

(533)

1182

(536)

1272

(577)

1318

(598)

1361

(617)

595

(270)

597

(271)

693

(314)

744

(337)

777

(352)

780

(354)

811

(368)

815

(370)

908

(412)

840

(381)

860

(390)

1110

(503)

1112

(504)

1027

(466)

1073

(487)

1053

(478)

1061

(481)

1083

(491)

1085

(492)

1219

(553)

1379

(626)

1410

(640)

1418

(643)

1427

(647)

1447

(656)

1510

(685)

1615

(733)

1628

(738)

1689

(766)

1697

(770)

1890

(857)

1946

(883)

1996

(905)

(406)

(409)

1034

(469)

1092

(495)

1127

(511)

1131

(513)

1171

(531)

1172

(532)

1346

(610)

1241

(563)

1265

(574)

Fig. 5 — Rigging Information

896

902

WEIGHT DISTRIBUTION AT EACH MOUNTING PLATE,

30HXA UNITS — Lb (Kg)

UNIT

30HXA

076

086

096

106

116

126

136

146

161

171

186

123456

555

(252)

555

(252)

509

(231)

555

(252)

530

(240)

540

(245)

548

(249)

551

(250)

560

(254)

627

(284)

648

(294)

MOUNTING PLATE NO.

793

(360)

798

(362)

808

(367)

869

(394)

895

(406)

905

(410)

926

(420)

930

(422)

965

(438)

968

(439)

1004

(455)

418

(190)

418

(190)

493

(224)

541

(245)

540

(245)

541

(245)

555

(252)

555

(252)

598

(271)

534

(242)

552

(250)

926

(420)

928

(421)

848

(385)

896

(406)

855

(388)

864

(392)

8743

(396)

883

(400)

954

(433)

1072

(486)

1110

(504)

1326

(601)

1340

(608)

1350

(612)

1410

(640)

1456

(660)

1468

(666)

1498

(679)

1506

(683)

1650

(748)

1658

(752)

1703

(772)

699

(317)

705

(320)

827

(375)

880

(399)

887

(402)

887

(402)

908

(412)

908

(412)

1025

(465)

918

(416)

939

(426)

6

Page 7

Table 1A — Physical Data, English

UNIT SIZE 076 086 096 106 116 126 136 146 161 171 186

UNIT WEIGHT (lb)

Fluid Cooled (HXC) 5700 5723 5855 6177 6415 6465 6688 6718 7452 7660 7854

Condenserless (HXA) 4717 4744 4835 5151 5162 5205 5308 5333 5752 5777 5946

COMPRESSORS Semi-Hermetic, Twin Screw

Quantity 222222 2 2 2 2 2

Nominal Capacity per

Compressor (tons)

Economizer No No No No No No No No Yes Yes Yes

No. Capacity Steps

Standard 666666 6 6 6 6 6

Optional (maximum) 888888 8 8 8 8 8

Minimum Step Capacity (%)

Standard 20 20 20 20 20 20 20 20 20 20 20

Optional 10 10 10 10 10 10 10 10 10 10 10

REFRIGERANT TYPE R-134a

Charge* (lb)

Circuit A/Circuit B

COOLER TYPE Shell and Tube with Enhanced Copper Tubes

Part No. 10HX400− 001 001 002 010 007 007 006 006 104 012 013

Net Fluid Volume (gal) 17.0 17.0 19.0 22.6 21.4 21.4 24.0 24.0 28.5 28.5 33.4

Maximum Refrigerant Pressure

(psig)

Maximum Fluid-Side Pressure

(psig)

Fluid Connections (in.) Steel Weld Couplings

Inlet and Outlet 444544 4 4 5 5 5

Drain (NPT)

30HXA OIL SEPARATOR

Part No. 09RX400− 007 007 008 008 009 009 009 009 009 010 010

Maximum Refrigerant Pressure

(psig)

Refrigerant Connections (in.)

Discharge 2

Liquid 11⁄

CONDENSER (HXC) Shell and Tube with Enhanced Copper Tubes

Part No. 09RX400− 001 001 002 002 003 003 004 004 005 006 006

Net Fluid Volume (gal) 16.8 16.8 18.3 18.3 23.9 23.9 27.5 27.5 30.6 37.6 37.6

Maximum Refrigerant Pressure

(psig)

Maximum Water-Side Pressure

(psig)

Water Connections (in.) Steel Weld Couplings

Inlet and Outlet 555555 5 5 5 5 5

Drain (NPT)

*Charges listed are for 30HXC units. The 30HXA units are shipped with a holding charge only.

39/39 46/39 56/39 66/39 66/46 66/56 80/56 80/66 80/56 66/80 80/80

55/55 66/55 79/55 95/55 95/66 95/79 114/79 114/95 130/90 109/130 130/130

220 220 220 220 220 220 220 220 220 220 220

300 300 300 300 300 300 300 300 300 300 300

1

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

⁄

1

2

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

320 320 320 320 320 320 320 320 320 320 320

1

⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

13⁄

8

13⁄

8

8

220 220 220 220 220 220 220 220 220 220 220

300 300 300 300 300 300 300 300 300 300 300

1

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

⁄

1

2

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

21⁄

13⁄

1

⁄

2

8

8

1

⁄

2

7

Page 8

Table 1B — Physical Data, SI

UNIT SIZE 076 086 096 106 116 126 136 146 161 171 186

UNIT WEIGHT (Kg)

Fluid Cooled (HXC) 2586 2596 2656 2802 2910 2933 3034 3047 3380 3476 3563

Condenserless (HXA) 2140 2152 2193 2336 2341 2361 2408 2419 2609 2620 2697

COMPRESSORS Semi-Hermetic, Twin Screw

Quantity 22222222222

Nominal Capacity per

Compressor (kW)

Economizer No No No No No No No No Yes Yes Yes

No. Capacity Steps

Standard 66666666666

Optional (maximum) 88888888888

Minimum Step Capacity (%)

Standard 20 20 20 20 20 20 20 20 20 20 20

Optional 10 10 10 10 10 10 10 10 10 10 10

REFRIGERANT TYPE R-134a

Charge* (Kg)

Circuit A/Circuit B

COOLER TYPE Shell and Tube with Enhanced Copper Tubes

Part No. 10HX400− 001 001 002 010 007 007 006 006 104 012 013

Net Fluid Volume (L) 64.3 64.3 71.9 85.5 81.0 81.0 90.8 90.8 107.9 107.9 126.4

Maximum Refrigerant

Pressure (kPa)

Maximum Fluid-Side

Pressure (kPa)

Fluid Connections (in.) Steel Weld Couplings

Inlet and Outlet 44454444555

Drain (NPT)

30HXA OIL SEPARATOR

Part No. 09RX400− 007 007 008 008 009 009 009 009 009 010 010

Maximum Refrigerant

Pressure (kPa)

Refrigerant Connections (in.)

Discharge 2

Liquid 11⁄

CONDENSER (HXC) Shell and Tube with Enhanced Copper Tubes

Part No. 09RX400− 001 001 002 002 003 003 004 004 105 006 006

Net Fluid Volume (L) 63.6 63.6 69.3 69.3 90.5 90.5 104.1 104.1 115.8 142.3 142.3

Maximum Refrigerant

Pressure (kPa)

Maximum Water-Side

Pressure (kPa)

Water Connections (in.) Steel Weld Couplings

Inlet and Outlet 55555555555

Drain (NPT)

*Charges listed are for 30HXC units. The 30HXA units are shipped with a holding charge only.

137/137 162/137 197/137 232/137 232/137 232/197 281/197 281/232 281/197 232/281 281/281

24.9/

24.9

29.9/

24.9

35.8/

24.9

43.1/

24.9

43.1/

29.9

43.1/

35.8

51.7/

35.8

51.7/

43.1

59.0/

40.8

49.4/

59.0

59.0/

59.0

1517 1517 1517 1517 1517 1517 1517 1517 1517 1517 1517

2068 2068 2068 2068 2068 2068 2068 2068 2068 2068 2068

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

2205 2205 2205 2205 2205 2205 2205 2205 2205 2205 2205

1

⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

13⁄

8

13⁄

21⁄

8

13⁄

1517 1517 1517 1517 1517 1517 1517 1517 1517 1517 1517

2068 2068 2068 2068 2068 2068 2068 2068 2068 2068 2068

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

8

8

8

Page 9

IMPORTANT: Some of the unit skids are larger than

standard door openings. Be sure that the path to the

unit’s final destination is wide enough to accommodate unit shipping skid. Remove the skid if necessary.

If skid is removed and rollers are used, attach rollers

to unit tube sheets while moving unit.

Areas where unit mounting points will be located must be

level to within1⁄16in. per ft (1 mm per m) along the long

axis of the unit. Once unit is in place and level, bolt unit to

the floor. Use isolation pads under the unit to aid in vibration

isolation as required.

Step 3 — Piping Connections — See Fig. 6 and

7 for typical piping applications.

COOLER FLUID, VENT, AND DRAIN — The inlet (re-

turn) fluid connection is always the lower of the 2 cooler

connections. See Fig. 6 for locations. A screen strainer with

a minimum of 20 mesh should be installed ahead of the cooler

inlet to prevent debris from damaging internal tubes of the

cooler. Outlet (supply) fluid connection is the upper connection of the 2 cooler connections.

The cooler has weld flanges to connect the field-supplied

piping. Plan the piping arrangement in accordance with good

piping practices and so that the piping does not cross in front

of the cooler head. Use flexible connections on cooler piping to reduce vibration transmission. Offsetthe piping to permit removal of the cooler head for maintenance. Install pipe

hangers where needed. Make sure no weight or stress is placed

on the water nozzle.

To install cooler piping:

1. Remove bolts on weld flanges, and remove flanges from

cooler fluid heads.

Remove the weld flanges before welding piping to

the flanges. Refer to Fig. 1-4 for weld flange locations. Failure to remove the flanges may damage the

sensors and insulation.

2. To keep debris from entering the heat exchanger during

shipping and storage, the gaskets between the weld flanges

and the fluid heads do not have holes cut into them. The

gaskets have perforations where the holes are to be cut.

Carefully cut a hole along the designated perforations.

IMPORTANT: Be sure to remove flanges and cut

holes in the gaskets between the flanges and the fluid

heads as indicated.

3. Apply a thin coat of oil to both sides of each gasket to

help ensure a good seal, and reattach each gasket to each

fluid head.

4. Weld the field-supplied piping to the weld flanges.

5. Bolt the weld flanges back onto their respective fluid heads.

IMPORTANT:When bolting the weld flanges to the

fluid heads, be sure to locate the flange such that

the hole in each flange lines up completely with the

hole in each fluid head. If installed incorrectly, part

of the hole in the fluid head will be blocked off.

This will result in impaired fluid flow in high pressure drop applications.

Tighten all cooler head bolts to 250 ft-lb (339 N-m)

before filling system with water (or brine).

6. Install field-supplied differentialflow switches in the cooler

piping for protection against loss of flow. The differential

flow switches must be installed on top of the pipe in a

horizontal run and should be at least 5 pipe diameters from

any bend. Install the low-pressure differential flow switch

into the outlet line piping, and install the high-pressure

differentialflow switch into the inlet line piping as shown

in Fig. 8.

7. Provide openings in fluid piping for pressure gages and

thermometers (if used). These openings should be 5 to 10

pipe diameters from the unit water nozzles. For thorough

mixing and temperature stabilization, wells in the leaving fluid pipe should extend at least 2 in. (50 mm) into

the pipe.

Accessory Victaulic-type connections are available. Fol-

low the connection directions provided with the accessory.

Although cooler has an air vent, it is recommended that a

field-supplied air vent be installed in the system to facilitate

servicing. Field-supplied shut-offand balancing valves should

also be installed to facilitate servicing and flow balancing.

Locate valves in return and supply fluid lines as close to the

chiller as possible. Locate air vent at highest point of the

cooler fluid system. See Fig. 6.

Provide drain connections at all low points to permit complete drainage of the system.

BRINE UNITS — Special factory modifications to the units

are required to allow them to operate at fluid temperatures

less than 34 F (1.1 C). Be sure that the fluid has sufficient

inhibited ethylene glycol or other suitable corrosionresistant antifreeze solution to prevent cooler freeze up.

PREPARATIONFOR YEAR-ROUND OPERATION — In

areas where the piping or unit is exposed to 32 F (0 °C) or

lower ambient temperatures, freeze-up protection is recommended using inhibited ethylene glycol or other suitable

corrosion-resistant antifreeze solution and electric heater tapes.

Heater tapes should have a rating for area ambient temperatures and be covered with a suitable thickness of closed-cell

insulation. Route power for the heater tapes from a separatelyfused disconnect. Mount the disconnect within sight from

the unit per local or NEC codes. Identify disconnect as heater

tape power source with warning that power must not be turned

off except when servicing unit.

Fill the fluid loop with water (or brine) and a corrosionresistant inhibitor suitable for the water of the area. Consult

the local water authority for characteristics of area water and

a recommended inhibitor for the cooler fluid loop. It is recommended that once the cooler water lines have been

installed and leak checked that the cooler heads be insulated

with a suitable thickness of closed-cell insulation. This will

minimize the amount of condensation that will form on the

cooler heads.

IMPORTANT: Before starting the unit, be sure all of

the air has been purged from the system.

A drain connection is located at the bottom of the cooler

head. See Fig. 3 and 4 for connection location. Install shutoffvalves to the drain line before filling the system with fluid.

9

Page 10

intended to show details for specific installation. Certified field wiring and

NOTES:

1. Wiring and piping shown are for general point-of-connection only and are not

dimensional diagrams are available upon request. The 30HXA and HXC units

should be installed using certified drawings.

2. All wiring must comply with applicable codes.

LEGEND

lation are all field supplied.

3. Refer to Carrier System Design Manual for details regarding piping techniques.

4. Piping, wiring, switches, valves, vent, gages, strainers, drain, and vibration iso-

Field Wiring

Field Piping

Fig.6—Typical Cooler (30HXA, HXC) and Condenser (30HXC Only) Piping and Wiring

10

Page 11

NOTES:

1. Piping shown is for general point-of-connection only and is not intended to show details for a specific installation. Certified field wiringanddimensional drawings are available upon request. The 30HXA

units should be installed using certified drawings.

2. Refer to Carrier System Design Manual for details regarding piping techniques.

3. Piping and pressure relief devices are field supplied.

4. Vent pipes properly per local codes.

TO REMOTE

CONDENSER(S)

TO REMOTE

CONDENSER(S)

TO REMOTE

CONDENSER(S)

COOLER*

EXV

OIL

SEPARATOR

ANGLE

VALVE

LIQUID LINE

Fig.7—Typical 30HXA Refrigerant Piping to Remote Condenser

30HXA REFRIGERANT PIPING (See Fig. 7) — Take

care when running the refrigerant piping from the 30HXA

unit to the remote condenser(s) to avoid excessive pressure drops. The pressure drop using R-134a refrigerant is

differentthan when using R-22 refrigerant. See Tables 2 and

3 for an example fora2F(1.1 C) pressure drop in saturated

temperature in the discharge (hot gas) line and liquid line,

respectively. Refer to Fig. 9 and 10 for line sizing information for the discharge and liquid lines for 30HXA (R-134a)

units.

EXV

LIQUID LINE

TO REMOTE

CONDENSER(S)

PRESSURE

RELIEF

DISCHARGE

LINE

LEGEND

EXV — Electronic Expansion Valve

*See Fig. 6 for typical cooler piping.

Table 2 — Discharge Line 2 F (1.1 C) Drop in

Saturated Temperature Example

SATURATED

DISCHARGE

TEMP

F C Psig kPa Psig kPa

126 52.2 187.5 1293 281.6 1942

124 51.1 182.0 1255 274.3 1891

D PRESSURE 5.5 38 7.3 51

PRESSURE

R-134a R-22

11

COM — Common

N.O. — Normally Open

LEGEND

Fig. 8 — Differential Flow Switch

Page 12

NOTES:

1. Values are for a 2° F pressure drop at 125 F (51.7 C) saturated discharge temperature, 120 F (48.9 C) saturated condensing temperature, and 105 F (40.6 C)

liquid refrigerant temperature.

2. Size each circuit separately.

Fig. 9 — R-134a Liquid Line Sizing, 30HXA Units

Table 3 — Liquid Line 2 F (1.1 C) Drop in

Saturated Temperature Example

SATURATED

LIQUID

TEMP

F C Psig kPa Psig kPa

100 37.7 124.3 857 195.9 1351

98 36.7 120.1 828 190.2 1311

D PRESSURE 4.2 29 5.7 40

PRESSURE

R-134a R-22

Discharge lines should be looped above the compressors

to avoid having charge flowing back to the oil separator and

compressor during unit shutdown. Wrap back-pressure valve

when brazing discharge line to avoid damaging the valve.

It is recommended that field-supplied pressure relief valves

be installed in each discharge line. Most local codes require

that the relief valves be vented directly to the outdoors. The

vent must not be smaller than the relief valve outlet, and the

pressure setting should be 320 psig (2205 kPa).

Run a field-supplied

1

⁄4-in. (6.4 mm) copper line between

the back-pressure valve on the oil separator (bottom pressure vessel) to the fitting on the refrigerant line entering the

economizer port of the compressor to measure oil pressure

differential.See Fig. 11.The back-pressure valve and the fitting on the refrigerant line have a

1

⁄4-in. flare fitting for mak-

ing this connection. The flare nut is field supplied.

IMPORTANT:There is a Schrader-type fitting in each

of the two

1

⁄4-in. fittings. These Schrader-type fittings

MUST BE REMOVED before running the line.

The 30HXA units are shipped from the factory with a holding charge of R-134a. Before opening the refrigerant system, relieve system pressure and recover system refrigerant

through the charging valve on the cooler.

30HXC CONDENSER CONNECTIONS — The inlet fluid

connection is always the lower of the 2 condenser connections. It is recommended that a screen strainer with a

minimum of 20 mesh be installed ahead of the condenser

inlet to prevent debris from damaging the internal condenser

tubes.

The outlet water connection is the upper connection of

the 2 connections. The condenser has weld couplings to

connect field-supplied piping. Plan the piping arrangement

in accordance with good piping practices and so that the piping does not cross in front of the condenser head. Use flexible connections on the condenser piping to reduce vibration

transmission. Offset the piping to permit condenser head removal for maintenance purposes. Install pipe hangers where

needed. Make sure no weight or stress is placed on the water

nozzle.

12

Page 13

NOTES:

1. Values are for a 2° F pressure drop at 125 F (51.7 C) saturated discharge temperature, 120 F (48.9 C) saturated condensing temperature, and 105 F (40.6 C)

liquid refrigerant temperature.

2. Size each circuit separately.

Fig. 10 — R-134a Discharge Line Sizing, 30HXA Units

Fig. 11 — Field-Supplied1⁄4-in. Copper Tube, 30HXA Units

13

Page 14

To install condenser piping:

1. Remove bolts on weld flanges, and remove flanges from

condenser water heads.

Remove the weld flanges before welding piping to

the flanges. Refer to Fig. 1 and 2 for weld flange

locations. Failure to remove the flanges may damage the sensors and insulation.

2. To keep debris from entering the heat exchanger during

shipping and storage, the gaskets between the weld flanges

and the water heads do not have holes cut into them. The

gaskets have perforations where the holes are to be cut.

Carefully cut a hole along the designated perforations.

IMPORTANT: Be sure to remove flanges and cut

holes in the gaskets between the flanges and the water heads as indicated.

3. Apply a thin coat of oil to both sides of each gasket to

help ensure a good seal, and reattach each gasket to each

water head.

4. Weld the field-supplied piping to the weld flanges.

5. Bolt the weld flanges back onto their respective water

heads.

IMPORTANT:When bolting the weld flanges to the

water heads, be sure to locate the flange such that

the hole in each flange lines up completely with the

hole in each water head. If installed incorrectly, part

of the hole in the water head will be blocked off.

This will result in impaired water flow in high pressure drop applications.

Provide openings in water piping for pressure gages and

thermometers (if used). These openings should be 5 to 10

pipe diameters from the unit water nozzles. For thorough mixing and temperature stabilization, wells in the leaving water

pipe should extend at least 2 in. (50 mm) into the pipe.

Accessory Victaulic-type connections and condenserwater thermistors are available. Follow the connection directions as provided with the accessory. If accessory differential pressure switch, water flow switch, or condenser water

thermistor is to be installed, install the proper fittings into

the condenser water lines before water is connected.

Although condenser has an air vent, it is recommended

that a field-supplied air vent be installed in the system to

facilitate servicing. Field-suppliedshut-offand balancing valves

should also be installed to facilitate servicing and flow balancing. Locate valves in inlet and outlet lines as close to the

chiller as possible. Locate air vents at the highest point of

the system loop. See Fig. 6.

Provide drain connections at all low points in the loop to

permit complete system drainage.

For installations where entering condensing water temperature could be below 70 F (21 C), a field-supplied

leaving water temperature regulating valve is required.

Operation below 70 F (21.1 C) without this valve may cause

the unit to shut down on low oil pressure alarms.

NOTE: This valve should be a temperature-controlled

valve (DO NOT USE a pressure-controlled valve) which

controls to 80 F (26.7 C) leaving water temperature. Be sure

to add a bleed line between the entering and leaving water

lines.

INSTALL PRESSURE RELIEF REFRIGERANT VENT

PIPING — To facilitate refrigerant vent piping, units have

flares for all of the relief fittings. The low side relief valves

on all units are provided with a 3/4 in. NPT flare connections, and are located on the cooler shell. There are 2 relief

valves for the cooler; one on each circuit.

The 30HXA high side relief valve is provided with a

5/8 in. SAE (Society of Automotive Engineers, U.S.A.) flare

connection. The 30HXC high side relief valves are provided

with a 3/4 in. NPT flare connection, and are located on the

condenser shell.

There are 2 relief valves for the separator (30HXA) and

2 for the condenser (30HXC); one for each circuit. Most

local codes require that these devices be piped to the outside. If vent piping is required by local codes, these connections have been provided to aid in the connection of vent

piping in accordance with ASHRAE 15 (American Society

of Heating, Refrigeration, and Air Conditioning Engineers),

Safety Code for Mechanical Refrigeration. If vent piping is

required, do not restrict the vent flow in any way.

NOTE: When accessory suction service valve kit is installed, there are 2 additional high-side pressure relief valves.

Pipe these valves per local codes. These are located on the

discharge line between the muffler and the discharge shutoff valve.

Step 4 — Make Electrical Connections — The

electrical characteristics of the available power supply must

agree with the unit nameplate rating. Supply voltage must

be within the limits shown.

FIELD POWER CONNECTIONS(See Fig. 12) — Allpower

wiring must comply with applicable local and national codes.

Install field-supplied, branch circuit fused disconnect(s) of a

type that can be locked off or open. Disconnect(s) must be

located within sight and readily accessible from the unit in

compliance with NEC Article 440-14. See Tables 4A and 4B

for unit electrical data. See Tables 5A and 5B for compressor electrical data.

IMPORTANT:the 30HX units have a factory-installed

option available fora non-fused disconnect for unitpower

supply.If the unit is equipped with this option, all field

power wiring should be made to the non-fused disconnect since no terminal blocks are supplied.

All units have a single location for power entry to simplify the field power wiring. Maximum wire size that the

unit terminal block or non-fused disconnect will accept is

500 kcmil.

All 380/415-3-50, 460-3-60, and 575-3-60 units require

a single field-supplied power supply. All 230-3-50 and

208/230-3-60 units require 2 separate field-supplied power

supplies.

All 380-3-60 units (except the 30HXC/A186 units)

require a single field-supplied power supply. The

30HXC/A186 units require 2 field-supplied power supplies.

The 30HXA136-186 and 30HXC171,186, 346-3-50 units

require 2 field-supplied power supplies. All other 346-3-50

units require a single field-supplied source.

FIELD CONTROL POWER CONNECTIONS (See

Fig. 13) — Units with a power supply of 208/230-, 460-,

and 575-3-60 require 115-1-60 control circuit power. Units

with a 380-3-60 power supply require 230-1-60 control circuit power. All other units 230-1-50 control circuit power.

Field control power connections are made at terminals 1 and

2 of TB4.

Copy continued on page 26.

14

Page 15

Table 4A — Unit Electrical Data, 30HXC Units*

VOLTAGE

UNIT

30HXC

076

086

096

106

116

126

136

146

See legend and notes on page 16.

Nameplate

(3 Ph)

208/230-60 187 253 123/123 200/200 175/150 115-60 104 127

460-60 414 506 100 150 125 115-60 104 127 148 374

575-60 518 633 80 110 100 115-60 104 127 118 299

380-60 342 418 121 175 150 230-60 207 254 169 419

230-50 207 253 115/115 200/200 150/150 230-50 198 254 266 †

346-50 325 380 138 175 175 230-50 198 254 118 †

380/415-50 342 440 126 175 150 230-50 198 254 165 400

208/230-60 187 253 148/123 250/200 200/150 115-60 104 127

460-60 414 506 111 150 125 115-60 104 127 148 374

575-60 518 633 89 125 100 115-60 104 127 118 299

380-60 342 418 135 200 175 230-60 207 254 169 419

230-50 207 253 140/115 250/200 75/150 230-50 198 254 305 †

346-50 325 380 154 225 175 230-50 198 254 208 †

380/415-50 342 440 140 200 175 230-50 198 254 190 479

208/230-60 187 253 181/122 300/200 225/150 115-60 104 127

460-60 414 506 126 175 150 115-60 104 127 172 449

575-60 518 633 101 150 125 115-60 104 127 137 359

380-60 342 418 153 225 175 230-60 207 254 195 502

230-50 207 253 169/115 300/200 225/150 230-50 198 254 347 †

346-50 325 380 173 250 200 230-50 198 254 237 †

380/415-50 342 440 158 225 200 230-50 198 254 216 562

208/230-60 187 253 219/123 350/200 300/150 115-60 104 127

460-60 414 506 143 200 175 115-60 104 127 197 529

575-60 518 633 115 175 150 115-60 104 127 158 423

380-60 342 418 174 250 200 230-60 207 254 223 590

230-50 207 253 202/115 350/200 250/150 230-50 198 254 397 †

346-50 325 380 195 300 225 230-50 198 254 271 †

380/415-50 342 440 178 250 225 230-50 198 254 247 661

208/230-60 187 253 219/148 350/250 300/200 115-60 104 127

460-60 414 506 153 225 175 115-60 104 127 207 539

575-60 518 633 122 175 150 115-60 104 127 166 431

380-60 342 418 185 250 225 230-60 207 254 234 601

230-50 207 253 202/140 350/250 250/175 230-50 198 254 417 †

346-50 325 380 208 300 250 230-50 198 254 284 †

380/415-50 342 440 190 250 225 230-50 198 254 259 673

208/230-60 187 253 219/181 350/300 300/225 115-60 104 127

460-60 414 506 165 225 200 115-60 104 127 219 551

575-60 518 633 131 175 150 115-60 104 127 175 440

380-60 342 418 199 250 225 230-60 207 254 248 615

230-50 207 253 202/169 350/300 250/225 230-50 198 254 440 †

346-50 325 380 224 300 250 230-50 198 254 300 †

380/415-50 342 440 204 300 250 230-50 198 254 273 687

208/230-60 187 253 263/181 450/300 350/225 115-60 104 127

460-60 414 506 184 250 225 115-60 104 127 249 646

575-60 518 633 147 200 175 115-60 104 127 199 536

380-60 342 418 222 300 300 230-60 207 254 282 720

230-50 207 253 245/169 400/300 300/225 230-50 198 254 496 †

346-50 325 380 252 350 300 230-50 198 254 338 †

380/415-50 342 440 230 300 300 230-50 198 254 308 797

208/230-60 187 253 263/219 450/350 350/300 115-60 104 127

460-60 414 506 198 250 225 115-60 104 127 262 659

575-60 518 633 158 225 200 115-60 104 127 210 547

380-60 342 418 240 350 300 230-60 207 254 299 737

230-50 207 253 245/202 400/350 300/250 230-50 198 254 523 †

346-50 325 380 270 400 350 230-50 198 254 355 †

380/415-50 342 440 246 350 300 230-50 198 254 324 813

Supplied

Min Max MCA MOCP

POWER CIRCUIT CONTROL CIRCUIT ICF

Recommended

Fuse Size

Voltage

(Single

Ph)

Min Max MCA MOCP WD XL

307 †

15 15

307 †

15 15

354 †

15 15

405 †

15 15

426 †

15 15

452 †

15 15

512 †

15 15

542 †

15 15

15

Page 16

Table 4A — Unit Electrical Data, 30HXC Units* (cont)

VOLTAGE

UNIT

30HXC

161

171

186

ICF — Maximum Instantaneous Current Flow during start-up

MCA — Minimum Circuit Ampacity (for wire sizing)

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

WD — Wye-Delta Start

XL — Across-the-Line Start

*Refer to Carrier’s electronic catalog for the most current electrical

data.

†Wye-Delta Start is standard. Not available in across-the-line start.

**The 30HX186 units have 2 terminal blocks/non-fused disconnects

and 6 parallel conductors/non-fused disconnects.

††The 30HXC171 and 186 units have 2 terminal blocks/non-fused

disconnects and 6 parallel conductors/non-fused disconnects.

NOTES:

1. Main power must be supplied from a field-supplied fused electrical service with a (factory- or field-installed) disconnect located in

sight from the unit.

2. Control circuit power must besuppliedfromaseparatesourcethrough

a field-supplied disconnect. The control circuit accessory transformer may be applied to power from the main unit power supply.

3. Maximum incoming wire size for each terminal block is 500 kcmil.

4. Maximum allowable phase imbalance is: voltage, 2%; amps, 5%.

5. Units with one MCA value have one main terminal block. Units

with 2 MCA values require multiple conductors.

6. Use copper conductors only.

Nameplate

(3 Ph)

208/230-60 187 253 285/197 500/350 350/250 115-60 104 127

460-60 414 506 200 300 250 115-60 104 127 287 756

575-60 518 633 160 225 200 115-60 104 127 230 605

380-60 342 418 242 350 300 230-60 207 254 325 843

230-50 207 253 266/182 450/300 350/225 230-50 198 254 578 †

346-50 325 380 273 400 350 230-50 198 254 394 †

380/415-50 342 440 249 350 300 230-50 198 254 358 944

208/230-60 187 253 238/285 400/500 300/400 115-60 104 127

460-60 414 506 215 300 250 115-60 104 127 302 771

575-60 518 633 172 250 200 115-60 104 127 242 617

380-60 342 418 260 350 300 230-60 207 254 343 861

230-50 207 253 219/266 350/450 300/350 230-50 198 254 607 †

346-50 325 380 145/176 250/300 175/225 230-50 198 254 413 †

380/415-50 342 440 267 350 300 230-50 198 254 376 962

208/230-60 187 253 285/285 500/500 400/400 115-60 104 127

460-60 414 506 232 300 300 115-60 104 127 319 788

575-60 518 633 185 250 225 115-60 104 127 255 630

380-60 342 418 156/156 250/250 200/200 230-60 207 254 364 882

230-50 207 253 266/266 450/450 350/350 230-50 198 254 645 †

346-50 325 380 176/176 300/300 225/225 230-50 198 254 438 †

380/415-50 342 440 289 400 350 230-50 198 254 399 985

(the point in the starting sequence where the sum of the

LRA for the start-up compressor, plus the total RLA for

all running compressors, plus the total FLA for all running fan motors is at a maximum)

Supplied

Min Max MCA MOCP

LEGEND

POWER CIRCUIT CONTROL CIRCUIT ICF

Recommended

Fuse Size

7. The MOCP is calculated as follows:

8. Units have the following power wiring terminal blocks and parallel

Voltage

(Single

Ph)

MOCP = (2.25) (largest RLA) + the sum of the other RLAs. Size

the fuse one size down from the result. The RLAs are listed on the

unit nameplate.

The recommended fuse size in amps (RFA) is calculated as

follows:

RFA = (1.50) (largest RLA) + the sum of the other RLAs. Size

the fuse one size up from the result. The RLAs are listed on the

unit nameplate.

conductors:

VOLTAGE

208/230 26

460 13

575 13

380** 13

230 26

346†† 13

380/415 13

Min Max MCA MOCP WD XL

591 †

15 15

624 †

15 15

661 †

15 15

TERMINAL

BLOCKS

OR NON-FUSED

DISCONNECTS

PARALLEL

CONDUCTORS

OR NON-FUSED

DISCONNECTS

16

Page 17

Table 4B — Unit Electrical Data, 30HXA Units*

VOLTAGE

UNIT

30HXA

076

086

096

106

116

126

136

146

See legend and notes on page 18.

Nameplate

(3 Ph)

208/230-60 187 253 180/180 300/300 225/225 115-60 104 127

460-60 414 506 146 200 175 115-60 104 127 218 550

575-60 518 633 117 150 150 115-60 104 127 175 440

380-60 342 418 177 250 200 230-60 207 254 248 615

230-50 207 253 169/169 300/300 225/225 230-50 198 254 440 †

346-50 325 380 201 250 225 230-50 198 254 299 †

380/415-50 342 440 183 250 225 230-50 198 254 273 687

208/230-60 187 253 215/180 350/300 300/225 115-60 104 127

460-60 414 506 162 225 200 115-60 104 127 248 645

575-60 518 633 130 175 150 115-60 104 127 199 536

380-60 342 418 196 250 225 230-60 207 254 282 720

230-50 207 253 205/169 350/300 250/225 230-50 198 254 496 †

346-50 325 380 225 300 300 230-50 198 254 337 †

380/415-50 342 440 206 300 250 230-50 198 254 308 797

208/230-60 187 253 262/180 450/300 350/225 115-60 104 127

460-60 414 506 183 250 225 115-60 104 127 281 750

575-60 518 633 147 200 175 115-60 104 127 225 600

380-60 342 418 222 300 300 230-60 207 254 318 836

230-50 207 253 248/169 400/300 300/225 230-50 198 254 567 †

346-50 325 380 254 350 300 230-50 198 254 386 †

380/415-50 342 440 231 350 300 230-50 198 254 352 938

208/230-60 187 253 319/180 500/300 400/225 115-60 104 127

460-60 414 506 209 300 250 115-60 104 127 324 885

575-60 518 633 167 250 200 115-60 104 127 259 708

380-60 342 418 253 350 300 230-60 207 254 365 985

230-50 207 253 300/169 500/300 400/225 230-50 198 254 620 †

346-50 325 380 289 400 350 230-50 198 254 423 †

380/415-50 342 440 263 400 300 230-50 198 254 385 1042

208/230-60 187 253 319/215 500/350 400/300 115-60 104 127

460-60 414 506 222 300 300 115-60 104 127 337 898

575-60 518 633 177 250 200 115-60 104 127 269 718

380-60 342 418 269 400 350 230-60 207 254 380 1000

230-50 207 253 300/205 500/350 400/250 230-50 198 254 649 †

346-50 325 380 308 450 350 230-50 198 254 443 †

380/415-50 342 440 281 400 350 230-50 198 254 402 1059

208/230-60 187 253 319/262 500/450 400/350 115-60 104 127

460-60 414 506 239 350 300 115-60 104 127 354 915

575-60 518 633 191 250 225 115-60 104 127 283 732

380-60 342 418 289 400 350 230-60 207 254 401 1021

230-50 207 253 300/248 500/400 400/300 230-50 198 254 683 †

346-50 325 380 331 400 400 230-50 198 254 465 †

380/415-50 342 440 302 400 350 230-50 198 254 423 1080

208/230-60 187 253 389/262 700/450 500/350 115-60 104 127

460-60 414 506 271 400 350 115-60 104 127 386 1015

575-60 518 633 216 300 250 115-60 104 127 309 812

380-60 342 418 328 450 400 230-60 207 254 436 1132

230-50 207 253 369/248 600/400 450/300 230-50 198 254 817 †

346-50 325 380 245/164 400/250 300/200 230-50 198 254 557 †

380/415-50 342 440 343 500 400 230-50 198 254 507 1346

208/230-60 187 253 389/319 700/500 500/400 115-60 104 127

460-60 414 506 291 400 350 115-60 104 127 406 1035

575-60 518 633 233 300 300 115-60 104 127 325 828

380-60 342 418 353 500 400 230-60 207 254 461 1157

230-50 207 253 369/300 600/500 450/400 230-50 198 254 859 †

346-50 325 380 245/199 400/350 300/250 230-50 198 254 585 †

380/415-50 342 440 369 500 450 230-50 198 254 532 1371

Supplied

Min Max MCA MOCP

POWER CIRCUIT CONTROL CIRCUIT ICF

Recommended

Fuse Size

Voltage

(Single

Ph)

Min Max MCA MOCP WD XL

451 †

15 15

511 †

15 15

577 †

15 15

662 †

15 15

690 †

15 15

728 †

15 15

791 †

15 15

837 †

15 15

17

Page 18

Table 4B — Unit Electrical Data, 30HXA Units* (cont)

VOLTAGE

UNIT

30HXA

161

171

186

ICF — Maximum Instantaneous Current Flow during start-up

MCA — Minimum Circuit Ampacity (for wire sizing)

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

WD — Wye-Delta Start

XL — Across-the-Line Start

*Refer to Carrier’s electronic catalog for the most current electrical

data.

†Wye-Delta Start is standard. Not available in across-the-line start.

**The 30HX186 units have 2 terminal blocks/non-fused disconnects

and 6 parallel conductors/non-fused disconnects.

††The 30HXA136-186 units have 2 terminal blocks/non-fused

disconnects and 6 parallel conductors/non-fused disconnects.

NOTES:

1. Main power must be supplied from a field-supplied fused electrical service with a (factory- or field-installed) disconnect located in

sight from the unit.

2. Control circuit power must besuppliedfromaseparatesourcethrough

a field-supplied disconnect. The control circuit accessory transformer may be applied to power from the main unit power supply.

3. Maximum incoming wire size for each terminal block is 500 kcmil.

4. Maximum allowable phase imbalance is: voltage, 2%; amps, 5%.

5. Units with one MCA value have one main terminal block. Units

with 2 MCA values require multiple conductors.

6. Use copper conductors only.

Nameplate

(3 Ph)

208/230-60 187 253 437/295 700/500 600/400 115-60 104 127

460-60 414 506 304 450 350 115-60 104 127 478 1282

575-60 518 633 243 350 300 115-60 104 127 382 1025

380-60 342 418 368 500 450 230-60 207 254 539 1428

230-50 207 253 415/275 700/450 500/350 230-50 198 254 858 †

346-50 325 380 276/183 450/300 350/225 230-50 198 254 535 †

380/415-50 342 440 385 500 450 230-50 198 254 533 1398

208/230-60 187 253 359/437 600/700 450/600 115-60 104 127

460-60 414 506 327 450 400 115-60 104 127 501 1305

575-60 518 633 261 350 300 115-60 104 127 401 1044

380-60 342 418 396 500 450 230-60 207 254 567 1456

230-50 207 253 334/415 600/700 450/500 230-50 198 254 905 †

346-50 325 380 222/276 350/450 300/350 230-50 198 254 616 †

380/415-50 342 440 413 600 500 230-50 198 254 562 1427

208/230-60 187 253 437/437 700/700 600/600 115-60 104 127

460-60 414 506 355 500 400 115-60 104 127 529 1333

575-60 518 633 284 400 350 115-60 104 127 539 1066

380-60 342 418 239/239 400/400 300/300 230-60 207 254 601 1490

230-50 207 253 415/415 700/700 500/500 230-50 198 254 970 †

346-50 325 380 276/276 450/450 350/350 230-50 198 254 660 †

380/415-50 342 440 453 600 600 230-50 198 254 601 1466

(the point in the starting sequence where the sum of the

LRA for the start-up compressor, plus the total RLA for

all running compressors, plus the total FLA for all running fan motors is at a maximum)

Supplied

Min Max MCA MOCP

LEGEND

POWER CIRCUIT CONTROL CIRCUIT ICF

Recommended

Fuse Size

Voltage

(Single

Ph)

7. The MOCP is calculated as follows:

MOCP = (2.25) (largest RLA) + the sum of the other RLAs. Size

the fuse one size down from the result. The RLAs are listed on the

unit nameplate.

The recommended fuse size in amps (RFA) is calculated as

follows:

RFA = (1.50) (largest RLA) + the sum of the other RLAs. Size

the fuse one size up from the result. The RLAs are listed on the

unit nameplate.

8. Units have the following power wiring terminal blocks and parallel

conductors:

VOLTAGE

208/230 26

460 13

575 13

380** 13

230 26

346†† 13

380/415 13

Min Max MCA MOCP WD XL

979 †

15 15

1030 †

15 15

1093 †

15 15

TERMINAL

BLOCKS

OR NON-FUSED

DISCONNECTS

PARALLEL

CONDUCTORS

OR NON-FUSED

DISCONNECTS

18

Page 19

Table 5A — Compressor Electrical Data, 30HXC Units

UNIT SIZE

30HXC

076

076-WD

086

086-WD

096

096-WD

106

106-WD

116

116-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 44.3 330 44.3 330

575-60 35.4 264 35.4 264

380-60 53.7 365 53.7 365

230-50 * * * *

346-50 * * * *

380/415-50 55.8 344 55.8 344

208/230-60 98.1 209 98.1 209

460-60 44.3 104 44.3 104

575-60 35.4 83 35.4 83

380-60 53.7 115 53.7 115

230-50 92.1 174 92.1 174

346-50 61.1 120 61.1 120

380/415-50 55.8 109 55.8 109

208/230-60 * * * *

460-60 53.6 330 44.3 330

575-60 42.8 264 35.4 264

380-60 64.9 365 53.7 365

230-50 * * * *

346-50 * * * *

380/415-50 67.7 423 55.8 344

208/230-60 118.6 209 98.1 209

460-60 53.6 104 44.3 104

575-60 42.8 83 35.4 83

380-60 64.9 115 53.7 115

230-50 111.8 213 92.1 174

346-50 74.2 147 61.1 120

380/415-50 67.7 134 55.8 109

208/230-60 * * * *

460-60 65.5 405 44.3 330

575-60 52.3 324 35.4 264

380-60 79.2 448 53.7 365

230-50 * * * *

346-50 * * * *

380/415-50 81.7 506 55.8 344

208/230-60 144.9 256 98.1 209

460-60 65.5 128 44.3 104

575-60 52.3 102 35.4 83

380-60 79.2 141 53.7 115

230-50 134.9 255 92.1 174

346-50 89.5 176 61.1 120

380/415-50 81.7 160 55.8 109

208/230-60 * * * *

460-60 79.2 485 44.3 330

575-60 63.3 388 35.4 264

380-60 95.9 536 53.7 365

230-50 * * * *

346-50 * * * *

380/415-50 97.8 605 55.8 344

208/230-60 175.4 307 98.1 209

460-60 79.2 153 44.3 104

575-60 63.3 123 35.4 83

380-60 95.9 169 53.7 115

230-50 161.7 305 92.1 174

346-50 107.3 210 61.1 120

380/415-50 97.8 191 55.8 109

208/230-60 * * * *

460-60 79.2 485 53.6 330

575-60 63.3 388 42.8 264

380-60 95.9 536 64.9 365

230-50 * * * *

346-50 * * * *

380/415-50 87.8 605 67.7 423

208/230-60 175.4 307 118.6 209

460-60 79.2 153 53.6 104

575-60 63.3 123 42.8 83

380-60 95.5 169 64.9 115

230-50 161.7 305 111.8 213

346-50 107.3 210 74.2 147

380/415-50 97.8 191 67.7 134

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

19

Page 20

Table 5A — Compressor Electrical Data, 30HXC Units (cont)

UNIT SIZE

30HXC

126

126-WD

136

136-WD

146

146-WD

161

161-WD

171

171-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 79.2 485 65.5 405

575-60 63.3 388 52.3 324

380-60 95.9 536 79.2 448

230-50 * * * *

346-50 * * * *

380/415-50 97.8 605 81.7 506

208/230-60 175.4 307 144.9 256

460-60 79.2 153 65.5 128

575-60 63.3 123 52.3 102

380-60 95.9 169 79.2 141

230-50 161.7 305 134.9 255

346-50 107.3 210 89.5 176

380/415-50 97.8 191 81.7 160

208/230-60 * * * *

460-60 94.9 580 65.5 405

575-60 75.8 484 52.3 324

380-60 114.9 641 79.2 448

230-50 * * * *

346-50 * * * *

380/415-50 118.8 715 81.7 506

208/230-60 210.0 367 144.9 256

460-60 94.6 183 65.5 128

575-60 75.8 147 52.3 102

380-60 114.9 203 79.2 141

230-50 196.3 361 134.9 255

346-50 130.3 248 89.5 176

380/415-50 118.8 226 81.7 160

208/230-60 * * * *

460-60 94.9 580 79.2 485

575-60 75.8 484 63.3 388

380-60 114.9 641 95.9 536

230-50 * * * *

346-50 * * * *

380/415-50 118.8 715 97.8 605

208/230-60 210.0 367 175.4 307

460-60 94.9 183 79.2 153

575-60 75.8 147 63.3 123

380-60 114.9 203 95.9 169

230-50 196.3 361 161.7 305

346-50 130.3 248 107.3 210

380/415-50 118.8 226 97.8 191

208/230-60 * * * *

460-60 103.1 685 71.2 525

575-60 82.4 548 56.9 420

380-60 124.8 757 86.2 580

230-50 * * * *

346-50 * * * *

380/415-50 128.6 856 88.2 600

208/230-60 228.8 433 157.6 350

460-60 103.1 216 71.2 175

575-60 82.4 173 56.9 140

380-60 124.8 239 86.2 193

230-50 212.5 432 145.7 348

346-50 141.0 297 96.7 232

380/415-50 128.6 270 88.2 200

208/230-60 * * * *

460-60 86.1 580 103.1 685

575-60 68.8 484 82.4 548

380-60 104.2 641 124.8 757

230-50 * * * *

346-50 * * * *

380/415-50 105.8 715 128.6 856

208/230-60 190.6 367 228.8 433

460-60 86.1 183 103.1 216

575-60 68.8 147 82.4 173

380-60 104.2 203 124.8 239

230-50 174.8 361 212.5 432

346-50 116.0 248 141.0 297

380/415-50 105.8 233 128.6 270

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

20

Page 21

Table 5A — Compressor Electrical Data, 30HXC Units (cont)

UNIT SIZE

30HXC

186

186-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 103.1 685 103.1 685

575-60 82.4 548 82.4 548

380-60 124.8 757 124.8 757

230-50 * * * *

346-50 * * * *

380/415-50 128.6 856 128.6 856

208/230-60 228.8 433 228.8 433

460-60 103.1 216 103.1 216

575-60 82.4 173 82.4 173

380-60 124.8 239 124.8 239

230-50 212.5 432 212.5 432

346-50 141.0 297 141.0 297

380/415-50 128.6 270 128.6 270

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

21

Page 22

Table 5B — Compressor Electrical Data, 30HXA Units

UNIT SIZE

30HXA

076

076-WD

086

086-WD

096

096-WD

106

106-WD

116

116-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 64.9 485 64.9 485

575-60 51.9 388 51.9 388

380-60 78.7 536 78.7 536

230-50 * * * *

346-50 * * * *

380/415-50 81.5 605 81.5 605

208/230-60 143.8 307 143.8 307

460-60 64.9 153 64.9 153

575-60 51.9 123 51.9 123

380-60 78.7 169 78.7 169

230-50 134.8 305 134.8 305

346-50 89.4 210 89.4 210

380/415-50 81.5 191 81.5 191

208/230-60 * * * *

460-60 77.6 580 64.9 485

575-60 62.1 484 51.9 388

380-60 94.0 641 78.7 536

230-50 * * * *

346-50 * * * *

380/415-50 99.2 715 81.5 605

208/230-60 171.9 367 143.8 307

460-60 77.6 183 64.9 153

575-60 62.1 147 51.9 123

380-60 94.0 203 78.7 169

230-50 163.9 361 134.8 305

346-50 108.8 248 89.4 210

380/415-50 99.2 226 81.5 191

208/230-60 * * * *

460-60 94.8 685 64.9 485

575-60 75.7 548 51.9 388

380-60 114.7 757 78.7 536

230-50 * * * *

346-50 * * * *

380/415-50 119.9 856 81.5 685

208/230-60 209.8 433 143.8 307

460-60 94.8 216 64.9 153

575-60 75.5 173 51.9 123

380-60 114.7 239 78.7 169

230-50 198.2 432 134.8 305

346-50 131.4 297 89.4 210

380/415-50 119.9 270 81.5 191

208/230-60 * * * *

460-60 115.4 820 64.9 485

575-60 92.2 656 51.9 388

380-60 139.7 906 78.7 536

230-50 * * * *

346-50 * * * *

380/415-50 145.4 960 81.5 605

208/230-60 255.5 518 143.8 307

460-60 115.4 259 64.9 153

575-60 92.2 207 51.9 123

380-60 139.7 286 78.7 169

230-50 240.2 485 134.8 305

346-50 159.4 334 89.4 210

380/415-50 145.4 303 81.5 191

208/230-60 * * * *

460-60 115.4 820 77.6 580

575-60 92.2 656 62.1 484

380-60 139.7 906 94.0 641

230-50 * * * *

346-50 * * * *

380/415-50 145.4 960 99.2 715

208/230-60 255.5 578 171.9 367

460-60 115.4 259 77.6 183

575-60 92.2 207 62.1 147

380-60 139.7 286 94.0 203

230-50 240.2 485 163.9 361

346-50 159.4 334 108.8 248

380/415-50 145.4 303 99.2 226

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

22

Page 23

Table 5B — Compressor Electrical Data, 30HXA Units (cont)

UNIT SIZE

30HXA

126

126-WD

136

136-WD

146

146-WD

161

161-WD

171

171-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 115.4 820 94.8 685

575-60 92.2 656 75.7 548

380-60 139.7 906 114.7 757

230-50 * * * *

346-50 * * * *

380/415-50 145.4 960 119.9 856

208/230-60 255.5 518 209.8 447

460-60 115.4 259 94.8 216

575-60 92.2 207 75.7 173

380-60 139.7 286 114.7 239

230-50 240.2 485 198.2 432

346-50 159.4 334 131.4 297

380/415-50 145.4 303 119.9 270

208/230-60 * * * *

460-60 140.7 920 94.8 685

575-60 112.4 736 75.7 548

380-60 170.2 1017 114.7 757

230-50 * * * *

346-50 * * * *

380/415-50 178.8 1226 119.9 856

208/230-60 311.4 581 209.8 433

460-60 140.7 291 94.8 216

575-60 112.4 233 75.7 173

380-60 170.2 321 114.7 239

230-50 295.3 619 198.2 432

346-50 195.9 426 131.4 297

380/415-50 178.8 387 119.9 276

208/230-60 * * * *

460-60 140.7 920 115.4 820

575-60 112.4 736 92.2 656

380-60 170.2 1017 139.7 906

230-50 * * * *

346-50 * * * *

380/415-50 178.8 1226 145.4 960

208/230-60 311.4 581 255.5 518

460-60 140.7 291 115.4 259

575-60 112.4 233 92.2 207

380-60 170.2 321 139.7 286

230-50 295.3 619 240.2 485

346-50 195.9 426 159.4 334

380/415-50 178.8 387 145.4 303

208/230-60 * * * *

460-60 157.9 1175 106.6 790

575-60 126.2 940 85.1 630

380-60 191.2 1299 129.0 870

230-50 * * * *

346-50 * * * *

380/415-50 201.2 1265 133.4 1045

208/230-60 349.6 743 235.9 527

460-60 157.9 371 106.6 263

575-60 126.2 297 85.1 211

380-60 191.2 410 129.0 290

230-50 332.3 638 220.3 607

346-50 220.5 439 146.2 402

380/415-50 201.2 400 133.4 348

208/230-60 * * * *

460-60 129.6 920 157.9 1175

575-60 103.6 736 126.2 940

380-60 156.9 1017 191.2 1299

230-50 * * * *

346-50 * * * *

380/415-50 161.7 1226 201.2 1265

208/230-60 286.9 581 349.6 743

460-60 129.6 291 157.9 371

575-60 103.6 233 126.2 297

380-60 156.9 321 191.2 410

230-50 267.2 619 332.3 638

346-50 177.3 426 220.5 439

380/415-50 161.7 387 201.2 400

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

23

Page 24

Table 5B — Compressor Electrical Data, 30HXA Units (cont)

UNIT SIZE

30HXA

186

186-WD

LEGEND

LRA — Locked Rotor Amps

RLA — Rated Load Amps

WD — Wye-Delta Start

*Units are shipped with wye-delta start as standard. Across-the-line start is not available.

NAMEPLATE

V-Hz

(3 Phase)

208/230-60 * * * *

460-60 157.9 1175 157.9 1175

575-60 126.2 940 126.2 940

380-60 191.2 1299 191.2 1299

230-50 * * * *

346-50 * * * *

380/415-50 201.2 1265 201.2 1265

208/230-60 349.6 743 349.6 743

460-60 157.9 371 157.9 371

575-60 126.2 297 126.2 297

380-60 191.2 410 191.2 410

230-50 332.3 638 332.3 638

346-50 220.5 439 220.5 439

380/415-50 201.2 400 201.2 400

RLA LRA RLA LRA

A1 B1

COMPRESSOR NUMBERS

LEGEND

EQUIP — Equipment

NEC — National Electrical Code (U.S.A.)

TB — Terminal Block

Y-Delta — Wye-Delta Start

XL — Across-the-Line Start

Field Power Wiring

Field Control Wiring

Factory-Installed Wiring

NOTES:

1. Factory wiring is in accordance with NEC. Field modifications or

additions must be in compliance with all applicable codes.

2. Wiring for main field supply must be rated 75° C minimum. Use

copper for all units. Maximumincoming wire size foreach terminal

block is 500 kcmil.

Fig. 12 — Field Power Wiring

24

Page 25

LEGEND

ALM — Alarm

CCN — Carrier Comfort Network

COMM — Communications

CWFS — Chilled Water (Fluid) Flow Switch

CWP — Chilled Water (Fluid) Pump

CWPI — Chilled Water (Fluid) Pump Interlock

EQUIP — Equipment

GND, GRD — Ground

NEC — National Electrical Code (U.S.A.)

TB — Terminal Block

NOTES:

1. Factory wiring is in accordance with NEC. Field modifications or additions must be in compliance with all applicable codes.

2. Wiring for main field supply must be rated 75° C minimum. Use copper for all units. Maximum incoming wire size

for each terminal block is 500 kcmil.

3. Power for control circuit should be supplied from a separate source through a field-supplied, fused disconnect with

15 amp maximum protection for all control circuits. Connect control circuit power to terminals 1 and 2 of TB4.

Connect neutral side of supply to terminal 2 of TB4. Control circuit conductors for all units must be copper only.

4. Terminals 13 and 14 of TB2 are for field external connection for remote on-off. The contacts must be rated for dry

circuit application capable of handling a 24 vac to 50 mA load. Remove jumper between 13 and 14 ofTB2 if remote

on-off is installed.

5. Terminals 11 and 12 of TB2 are for chilled water flow switch (CWFS) and chilled water pump interlock (CWPI)

functions. The contacts must be rated for dry circuit application capable of handling a 24 vac to 50 mA load.

6. Terminals 4 and 5 of TB2 are for control of chilled water pump starter. The maximum load allowed for the chilled

water pump relay is 125 va sealed, 1250 va inrush.

7. Terminals2 and 3 of TB2 are for alarm. The maximum load allowed for the alarm is 125 va sealed, 1250 va inrush.

Field Power Wiring

Field Control Wiring

Factory-Installed Wiring

Fig. 13 — Field Control Wiring

25

Page 26

Terminals TB2-11 and TB2-12 are provided for field installation of a chilled water (fluid) pump interlock (CWPI)

and a chilled water (fluid) flow switch (CWFS). These devices are to be installed in series. Contacts must be rated for

day circuit applications capable of handling a 24-vac to

50 mA load.

Accessory remote on-off switch can be wired into TB2-13

and TB2-14. To use this feature, remove the factory-installed

jumper and install the device in series. See Fig. 13 for remote on-off, CWPI, and CWFS wiring. Contacts must be

rated for dry load application capable of handling a 24-vac

to 50 mA load.

Do not use interlocks or other safety device contacts

connected between TB2 terminals 13 and 14 as remote

on-off. Connection of safeties or other interlocks between these 2 terminals will result in an electrical

bypass if the REMOTE-OFF-LOCAL switch is in the

LOCAL position. If remote on-off unit control is required, a field-supplied relay must be installed in the

unit control box and wired as shown in Fig. 13. Failure

to wire the remote on-off as recommended will result in

tube freeze damage.

Terminals 2 and 3 of TB2 have been provided for a

field-supplied remote alarm (ALM). If an audible alarm is

installed, an alarm shutoff is also recommended. Contacts

are rated for 125 va at either 115 or 230 v control power.See

Fig. 13.

Terminals 4 and 5 of TB2 have been provided for a

field-supplied chilled water (fluid) pump relay (CWP). A

field-supplied power supply of appropriate voltage must be

provided. Contacts are rated for 125 va at either 115 or

230 v control power. See Fig. 13.

Terminals 1 and 6 of TB2 have been provided for a

field-supplied control relay for the remote condenser (30HXA)

or a condenser pump relay (30HXC). Afield-supplied power

supply of appropriate voltage must be provided.

Step 5 — Install Accessories

ELECTRICAL — Several optional control accessories are

available to provide the following features:

• control transformer

• cooler pump/flow switch interlock

• cooler pump control

• expanded display panel

• remote alarm

• remote on-off

• pulldown control

• occupancy scheduling

• demand limit control

• temperature reset (from occupied space or outdoor-air

temperature)

• dual set point control

• condenser water sensors

• level II communications (CCN

[Carrier Comfort Network])

Refer to Start-Up and Operation literature and separate accessory installation instructions for additional

information.

30HXA LOW-AMBIENT OPERATION — If outdoor

ambient operating temperatures below 60 F (15 C) are expected, refer to separate installation instructions for lowambient operation using accessory Motormastert III control.

MINIMUM LOAD ACCESSORY — If minimum load

accessory is required, use the appropriate package. Refer to

unit Price Pages or contact your local Carrier representative