Page 1

m

Number One

AirConditbning

Maker

e

n of Carrier Corporation

Syracuse New York

Wiring Diagrams

Reciprocating Liquid Chillers

60-Hertz

These diagrams apply to 30HR,HS070—120 Model A units starting

with Serial No. FI 55985 and ending with Serial No. G448588.

INDEX

30HR,HS

070 iJ»ru tm

UNIT

30HR,HS

070

thru

120

070,

080,

090

100,

no,

120

FIGURE

NUMBER

DESCRIPTION

Wi ri rig For

Part-Winding Start

Suggested Field

Wiring Interlocks

’ ~T_ocdtTons o?

Control Components

Power Schernatic

Control CTrcu i t

{Simplified Schematic)

CornfroTTr i rcuit

(Simplified Schematic)

Power Schematic

'Locations of

Control Components

GENERAL NOTES

1. Factory wiring is in accordance with the

National Electrical Code. Any field modifica

tions or additions must be in compliance with

all applicable codes. Field-installed power wires

must be rated 75 C minimum.

2. Control circuit is 115-1-60, with 10-amp circuit

breaker.

3. Oil pressure safety switches are standard on

30HS units only. Jumpers between terminals] 1 |

and

and between and are supplied on

30HR units.

4. Manual transfer switch provides the following

starting sequences:

Three-compressor units — position 1 (terminal

A), 3-2-1; position 2 (terminal B), 1-2-3.

Four-compressor units ~ position 1 (terminal

A), 1-4-3-2; position 2 (terminal B), 3-2-1-4.

Stop unit before changing transfer switch

position.

VOLTS

All

All

208,230,

460,575

208,230,

460,575

UNIT LABEL DIAGRAM

30HR

All

080-1214

080-1224

100-1584

100-1594

Re

Same As

Below

5. All field-supplied auxiliary contacts must have a

minimum rating of 1250-va inrush and 430-va

sealed plus capacity required for field-installed

10

equipment between terminals 111 [ and

12

andpT],] 5 [and and

6. With accessory .75-kva control transformer,

additional controls up to 3800-va inrush and

175-va sealed may be used.

When using a transformer, ground control

7.

circuit by connecting green wire from trans

former terminal X2 to ground screw (detailed

instructions with transformer package).

8.

When using field-supplied 115-volt control

(L2) must be connected to24power, terminal

neutral or ground potential.

9.

Across-the-line starting is standard on all units.

If it is necessary to modify to part-winding

start, refer to “Modification For Part-Winding

Start.”

© Carrier Corporation 1971 475

Form 30HR,HS-7W

Page 2

SEQUENC^OF OPERATION

The 115-1-60 control power can be supplied

directly from a separate source thru a codeapproved fused disconnect or thru a field-installed

accessory transformer with the primary side con

nected to the unit power terminal block. A

double-pole circuit breaker protects the control

circuit and serves as the control circuit switch.

Crankcase heaters are wired in the control circuit

ahead of the START switch, so they are always

operative as long as the control circuit breaker is

closed. Heaters are wired so they are on only when

their respective compressors are cycled off.

.

..........

t..

After a prolonged shutdown of 8 hours or

more, the crankcase heaters should be on for 24

hours before starting the unit.

When power is supplied to the control circuit

and the control circuit breaker is closed, the unit is

ready for operation, providing all safety devices are

satisfied, interlocks are closed, and instructions on

warning labels have been followed.

When the START button on the control panel

is pressed, a red indicating light on the control

panel comes on and the step controller and control

relays 1 thru 4 are energized. After a maximum of

1.5 minutes, the recycle relay is energized and the

step controller cycles back (in the load direction)

to the correct cam position to begin the compres

sor starting sequence. The compressors start one at

a time at brief intervals until the load requirement

is satisfied. After completing the starting sequence,

the controller stops and starts, unloads and loads

the compressors to maintain capacity control in

response to water temperature controller demand.

Factory cam settings on the step controller protect

the compressors against rapid recycling.

Complete Unit Stoppage can be caused by any of

the following conditions: general power failure,

blown fuse in control power feed disconnect, open

control circuit breaker, STOP button depressed,

open contacts in low water temperature cutout,

open contacts in any auxiliary interlock between

terminals 11 and 12 .

recast.

Restart Procedure (after cause tor stoppage is

corrected).

GENERAL POWER FAILURE - Press START

button on control panel.

BLOWN FUSE IN POWER FEED DISCONNECT

— Replace fuse and press START button on

control panel.

LOW WATER TEMPERATURE CUTOUT - Press

reset button on control (inside control box).

Restart is automatic.

AUXILIARY INTERLOCK — Automatic restart

after condition is corrected.

OPEN CONTROL CIRCUIT BREAKER ^ Close

breaker and press START button on control panel.

HIGH-PRESSURE SWITCH - Press START

button on control panel.

LOW-PRESSURE SWITCH — Compressors will

restart automatically when pressure comes up

sufficiently.

COMPRESSOR MOTOR THERMAL PROTEC

TOR — After motor has cooled down, press

START button on control panel.

OIL SAFETY SWITCH — Press reset button on the

switch, and press START button on control panel.

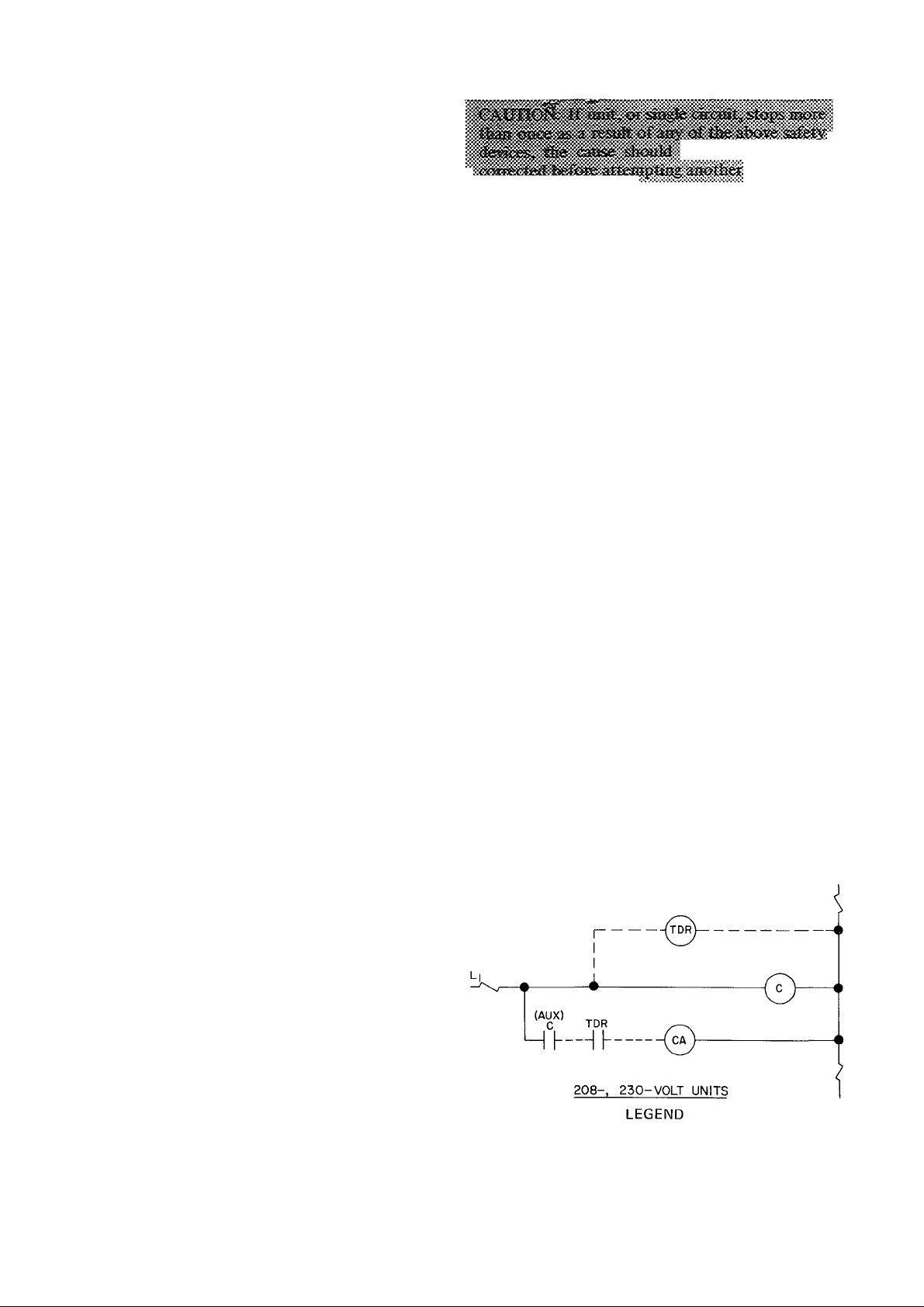

MODIFICATION FOR PART-WINDING START

(See Fig. 1,5 and 6.)

For 208-, 230-Volt Units — In the control circuit

for each compressor, add a 1.5 second time-delay

relay to actuate the second contactor coil (CA).

Time-delay relay. Carrier part number

HN67FK001, is available from Carrier Service Parts

Center, Syracuse, N.Y. Contact your local Carrier

representative. ^

Single-Circuit Stoppage can be caused by open

contacts in any motor thermal protector, open

contacts in low-pressure switch, open contacts in

high-pressure switch, open contacts in oil safety

switch (when used), blown compressor circuit fuse.

Stoppage of one circuit by safety device action

does not affect the other circuit. Besides stopping

compressors, all the devices listed except the

low-pressure switch will close the liquid line

solenoid valve for that circuit.

AUX. — Auxiliary Contacts

C — Compressor Contactor

CA — Second Compressor Contactor

TOR — Time-Delay Relay

Fig. 1 — Control Wiring for Part-Winding Start

o

---------

Field Wiring

Holding Coil

Factory Wiring

f

Page 3

REMOVE PRESENT

JUMPER 11-12

[TT]----------------1 I

CHILLED WATER

CHILLED WATER L COND PUMP OR TOWER FA

PUMP STARTER

AUX CONTACTS

[ÎÔ]---------------

ГЧ

-----------------

--------------------------------

CHILLED WATER COND. PUMP STARTER AUX. CONTACT OR FLOW SWITCH SHOULD BE

FLOW SWITCH LOCATED HERE ONLY WHEN COND PUMP STARTER IS INDEPENDENT

FC2

0~ -

FC|

41]

CONTACTOR COILS FOR COND.

FAN MOTORS WITH SEPARATE

AIR COOLED COND. FOR EACH

REFRIGERATION CIRCUIT.

-0

Fig. 2 — Suggested Field Wiring of Interlocks

----------------------------0^5

COND PUMP OR TOWER FAN MOTOR 0. L. CONTACTS IF AVAILABLE

OF 30HR, HS WIRING.

(SEE NOTES 5 AND 6)

LEGEND (For Fig. 3 thru 8)

-----------

cÿ5-

■-чт

0

----------©-----------

CONTACTOR COIL FOR COND. WATER

PUMP OR FOR FAN MOTOR(S) ON

SINGLE TWO CIRCUIT AIR COOLED

COND.

0

— Balancing Relay

BR

— Compr Contactor

C

— Second Contactor

CA

— Control Circuit Breaker

CB

— Control Relay

CR

— Fligh Pressurestat

HP

— Liquid Line Solenoid Valve

LLS

— Low Pressurestat

LP

— Limit Switch

LS

LWTC

— Low Water Temp Cutout

— Oil Pressure Safety Switch

OPSS

— Recycle Relay

RR

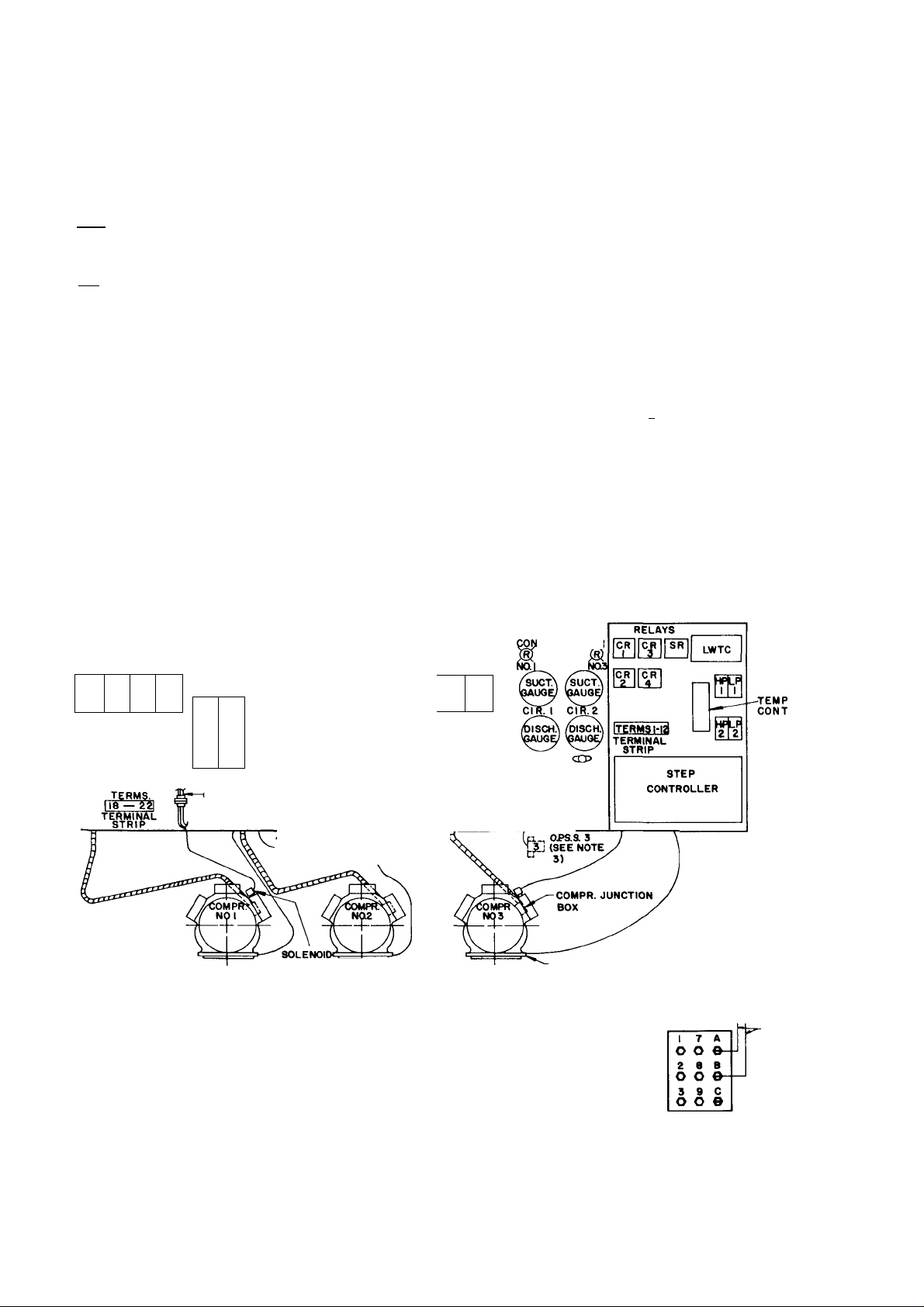

CIRCUIT N0.1

CONTACTORS

Ci

COMPR I COMPR 2

CIRCUIT

BREAKERS

C2

C

0

M

p

R

CONTACTOR COIL

POWER DISC

PLUG

1 2

c

0

M

p

R.

FIELD

POWER

SUPPLY

..... O.RS.S. I

I I J(SEE NOTE

'■ 3)

S Step Controller Switch

Starting Relay

SR -

TS -

Transfer Switch (Compr Starting Sequence)

U - Unloader (Compr)

XL - Across-the-Line

Coil

О

Light (Red)

Terminals on Step Controller

О

CIRCUIT NO. 2

П

FIELD

INSTALLEOl

¡accessory!

CONTROL

TRANS-

L. 2QRMERJ CON T. COIL

TERMS Ж

TERWNJl

STRIP

ТПхГораз. 2

TERMS [гЧ

CONTACTORS

CIRCUIT

BREAKER

C

0

M

P

R

_a_

2j(SEE NOTE

li

COMPR 3

/\ Terminals on Temp Controller

□ Terminaison Terminal Strips

--------__

___

______

----------Factory Wired, Field Connected

EXTERNAL CONTROL POWER SOURCE (IF USED)

¥

ITRÔLPOW^

M '

C3

cCP

CKT I , CKT.2

♦ 2

COMP SEQUENCE

О m О

START Ш STOP

Terminals on Compr

Factory V\/iring

Factory Wiring on 30FIS Units Only

Field Wiring

UNLOAOER CRANKCASE

• ON 208-, 230-VOLT UNITS ONLY

Fig. 3 — Locations of Control Components (All Voltages)

30HR, HS070, 080, 090

HEATER

COMPR. MOTOR

TERMINAL PLATE

THERMOTECTOR

LEADS TO CONTROL

CIRCUIT

MOTOR THERMOTECTORS INTERNALLY

WIRED IN SERIES TO TERMINALS ABB

THROUGH COMMON TERMINALS*

Page 4

CONTACTORS COMPRESSORS

-ON 208-, 230-VOLT UNITS ONLY

Fig. 4 — Power Schematic (All Voltages)

30HR, HS070, 080,090

Page 5

-ON 208-, 230-VOLT UNITS ONLY

30HR, HS070, 080, 090

Fig. 5 — Control Circuit Schematic (All Voltages)

5

Page 6

9

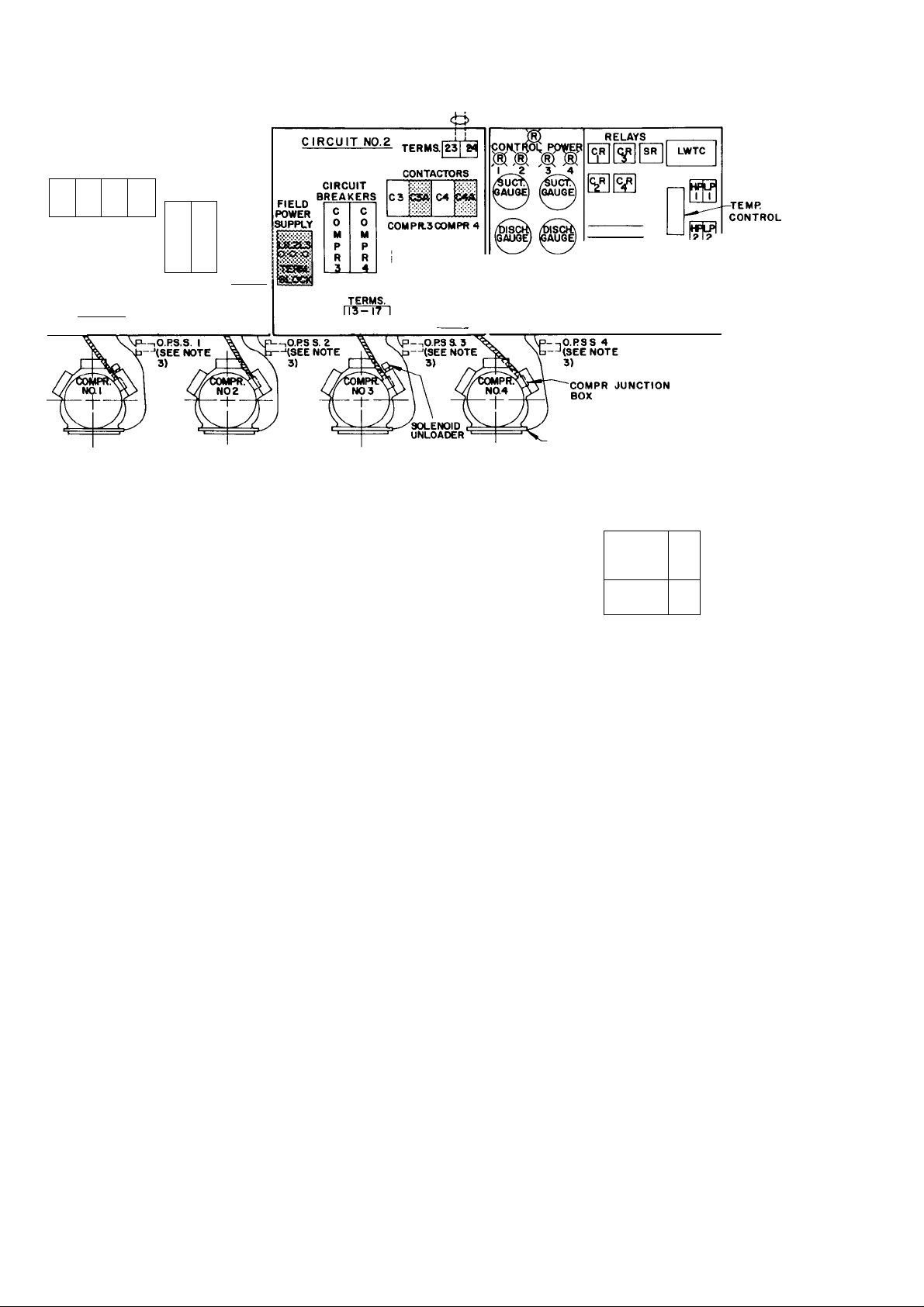

30HR, HS100, 110, 120

Fig. 6 — Control Circuit Schematic (All Voltages)

Page 7

%

CIRCUIT BREAKERS

(CALIBRATED TRIP)

CONTACTORS

COMPRESSORS

WHEN SEPARATE II5V SOURCE

NOT AVAILABLE) ^

(SEE NOTE I )

FIELD

SUPPLIED

POWER

460-, 575-VOLT UNITS

CIRCUIT

BREAKERS

(CALIBRATED TRIP)

CONTACTORS

COMPRESSORS

LI T1

L2 H u T2

^ Lii.

LI H H T7

L2 ] :T8

d b

115 V, 60 HZ

CONTROL POWER

OPTIONAL .75 KVA TRANS-

SEE NOTE

t

iji TRANSFORMER WIRING INSTRUCTIONS FURNISHED WITH ACCESSORY PACKAGE

208-,230- VOLT UNITS

FORMER-60 HZ ONLY (REQUIRED

ONLY WHEN SEPARATE II5V SOURCE NOT AVAIL ABLE) ifi

30HR, HS100, 110, 120

<1 ÌP

L3^ uTS

Fig. 7 — Power Schematics (All Voltages)

Page 8

CIRCUIT NO. I

EXTERNAL CONTROL POWER SOURCE (IF USED)

CONTACTORS

Cl

CfA

COMPR. I C0MPR.2

TERMS.

118-22 I

TERMINAL

STRIP

CZA

C2

-ON 208-, 230-VOLT UNITS ONLY

CIRCUIT

BREAKERS

C

0 0

M M

p p

R R

_i_

-CONTACTOR COIL

POWER DISC

PLUG

C

FIELD

POWER

SUPPLY

LIL2L3

o o o

TERM

BLOCK

________

TERMINAL

STRIP PLUO-

r FIELD I

INSTALLED'

.ACCESSORY'

CONTROL

TRANS-

l_FORJIJR_J

CONT.COIL f

CCP I CCP

CKTI I CKT 2

COMP SEQUENCE

О m О

START Ш STOP

CRANKCASE

HEATER

MOTOR THERMOTECTORS INTERNALLY

WIRED IN SERIES TO TERMINALS ABB

THROUGH COMMON TERMINAL*C*

iTERMS.I-ei

TERMINAL

STRIP

CONTROLLER

COMPR MOTOR

TERMINAL PLATE

1 7 A

2 8 В

3 9 C

© © ©

STEP

-THERMOTECTOR

LEADS TO CONTROL

CIRCUIT

30HR, HS100, 110, 120

Fig. 8 — Locations of Control Components (All Voltages)

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab 15 FormSOHR

HS-7W New Printed in U S A 475 10-71 Codes C and MA Catalog No 533-019

Loading...

Loading...