Page 1

30GX080-265

AIR-COOLED LIQUID CHILLER

— PERFORMANCE DATA

— CERTIFIED DIMENSION PRINT

30GX-4SB

— FIELD WIRING DIAGRAM

R 1997 Carrier Corporation • Syracuse, New York 13221

Form 30GX-4SB Supersedes 30GX-3SB Printed in U.S.A. 12-97 Catalog No. 513-450

Page 2

Date: Supersedes: 30GX080-265

AIR-COOLED LIQUID CHILLER

30GX

JOB NAME: LOCATION:

BUYER: BUYER P.O. # CARRIER #

UNIT NUMBER: MODEL NUMBER:

PERFORMANCE DATA CERTIFIED BY: DATE:

DESCRIPTION

Packaged air-cooled liquid chiller factory wired, piped, and charged with HFC-134a. Upward

discharge airflow minimizes directional sound and dissipates heat away from surrounding areas.

FEATURES

Cooler is mechanically cleanable ‘‘flooded’’ shell-and-tube type

with removable heads. It is tested and stamped in accordance

with ASME Code for a refrigerant working side pressure of

220 psig (1517 kPa) and a maximum fluid side pressure of

300 psig (2068 kPa) (250 psig [1724 kPa] in Canada) and is

insulated with

Cooler can be equipped with electric heater to help protect against

cooler freeze-up (use of inhibited glycol anti-freeze recommended

for freeze protection).

Compressor is semi-hermetic twin screw design with refrigerant

gas cooled motor and integral oil filter and discharge gas muffler.

Complete thermal and electrical protection is provided.

Air-cooled condenser is constructed of fins mechanically bonded

to seamless copper tubes. Coils are leak and pressure tested at

450 psig (3103 kPa).

Condenser fans are direct driven 11-blade, shrouded axial type,

statically and dynamically balanced, discharging air vertically

upward, protected by coated steel wire safety guards.

3

⁄4-in. (19 mm) closed-cell polyvinyl chloride foam.

Condenser fan motors are totally enclosed 3-phase with permanently lubricated bearings and Class F insulation (except speed

control motors).

Each refrigerant circuit includes oil separator, high side pressure

relief device, liquid and discharge line shutoff valve, filter drier,

moisture indicating sight glass, expansion/level control device.

Microprocessor control includes keypad with diagnostic display

displaying set points, time, system status (including temperatures,

pressures and % loading) and the alarm conditions.

Automatic compressor lead/lag.

Capacity control based on leaving chilled water temperature with

return water temperature sensing.

7-Day time scheduling of pump(s) and chiller.

60-Hz Models: 080, 090, 106, 115, 125, 136, 151, 161, 176, 206,

226, 251, and 265.

50-Hz Models: 080, 090, 105, 106, 115, 125, 136, 150, 160, 161,

175, 205, 225, 226, 250, and 265.

Rev.:

-4SB

PERFORMANCE DATA

UNIT

Capacity

Compressor Input Power kW

Unit Input Power

Minimum Outdoor Operating Temperature

Capacity Control Steps

Minimum Capacity % %

EER

Entering Air Temperature

Weight

kW

ELECTRICAL DATA

Power Supply to Unit Volts Ph Hz

Power Supply to Control Circuit

Minimum Amps Circuit 1

Maximum Fuse Amps Circuit 1

M

M

M

M

Volts Ph Hz

Amps

Amps

OPTIONS

COOLER

Cooler Fluid

Entering Fluid Temperature

Leaving Fluid Temperature

Flow Rate

Pressure Drop

Fouling Factor

Control Circuit Fuse Amps

Maximum Instantaneous Current Flow

Minimum Amps Circuit 2

Maximum Fuse Amps Circuit 2

M

M

M

M

Amps

Amps

Amps

Amps

2

Page 3

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

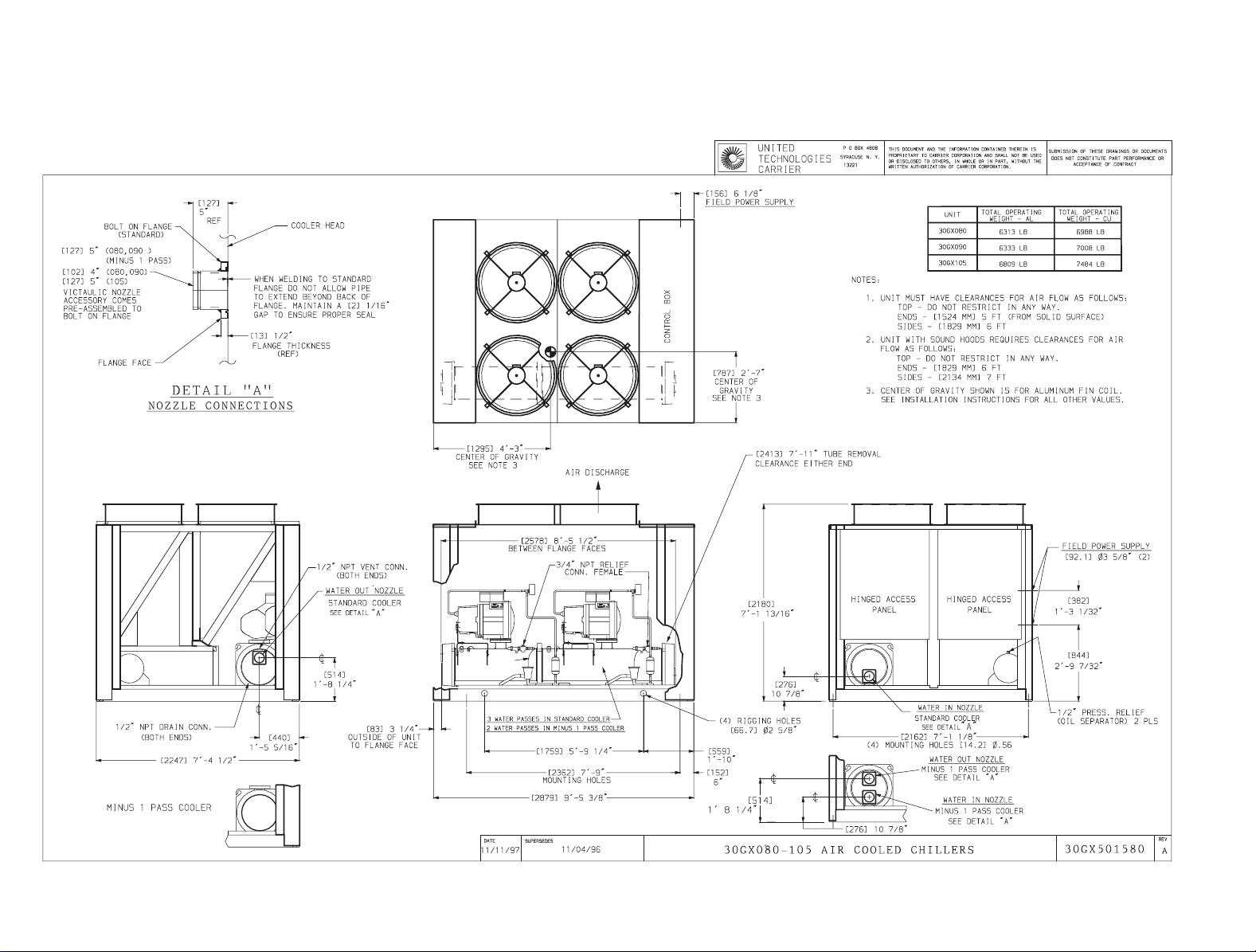

CERTIFIED DIMENSION PRINT

3

Page 4

4

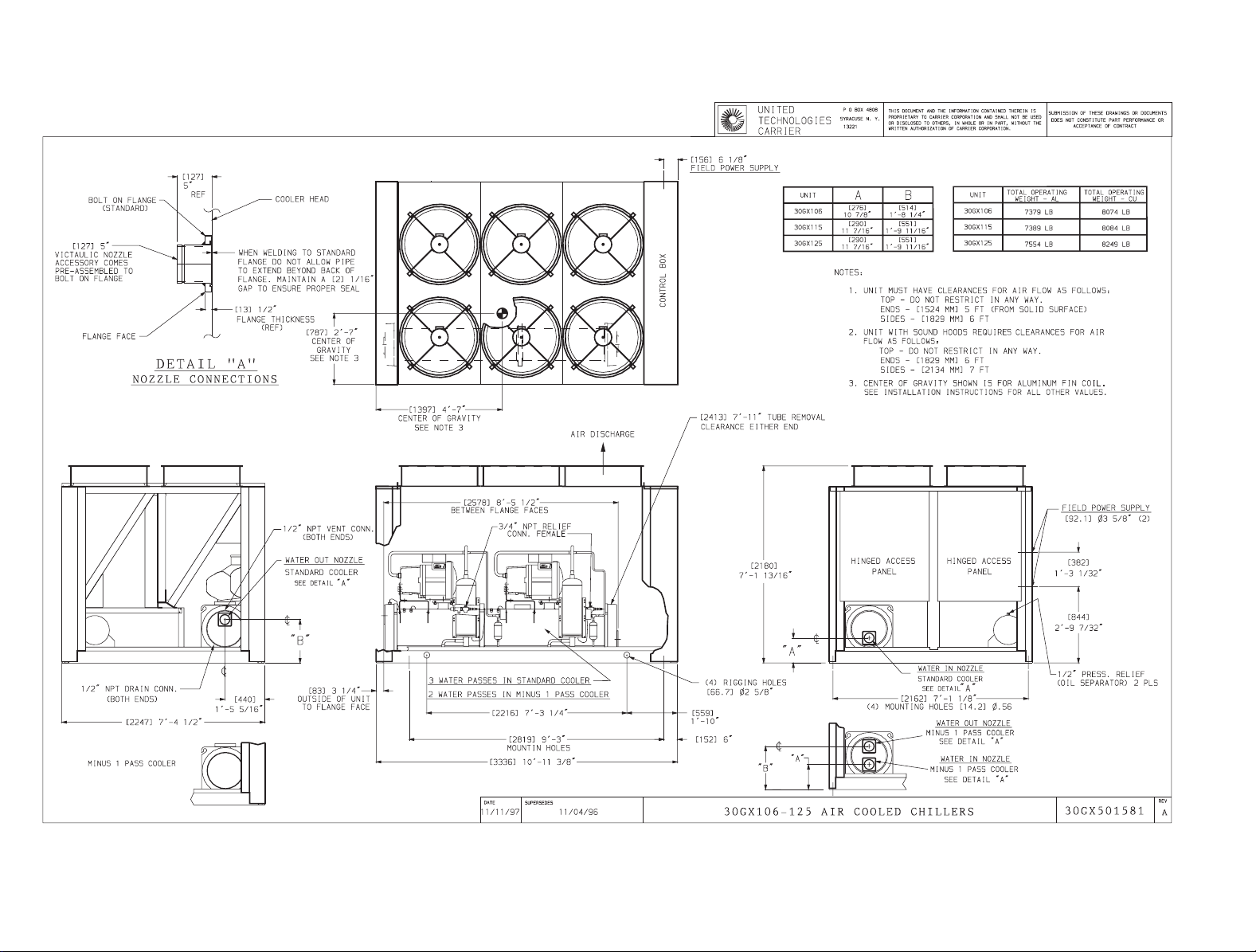

CERTIFIED DIMENSION PRINT

Page 5

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

5

Page 6

6

CERTIFIED DIMENSION PRINT

Page 7

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

7

Page 8

8

CERTIFIED DIMENSION PRINT

TOTAL OPERATING

UNIT

30GX

205 12,184 5,538 13,569 6,168

225 12,364 5,620 13,749 6,250

NOTES:

1. Unit must have clearances for air flow as follows:

Top — Do not restrict in any way

Ends — (1524 mm) 5 ft (from solid surface)

Sides — (1829 mm) 6 ft

2. Unit with sound hoods requires clearances for air flow as

follows:

Top — Do not restrict in any way

Ends — (1829 mm) 6 ft

Sides — (2134 mm) 7 ft

3. Center of gravity shown is for aluminum fin coil. See installation instructions for all other values.

WEIGHT

Aluminum Fin Copper Fin

lb kg lb kg

TOTAL OPERATING

WEIGHT

Page 9

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

CERTIFIED DIMENSION PRINT

TOTAL OPERATING

UNIT

30GX

206 12,794 5,815 14,462 6,574

226 12,974 5,897 14,642 6,655

250 13,194 5,997 14,862 6,755

NOTES:

1. Unit must have clearances for air flow as follows:

Top — Do not restrict in any way

Ends — (1524 mm) 5 ft (from solid surface)

Sides — (1829 mm) 6 ft

2. Unit with sound hoods requires clearances for air flow

as follows:

Top — Do not restrict in any way

Ends — (1829 mm) 6 ft

Sides — (2134 mm) 7 ft

3. Center of gravity shown is for aluminum fin coil. See installation instructions for all other values.

WEIGHT

Aluminum Fin Copper Fin

lb kg lb kg

TOTAL OPERATING

WEIGHT

9

Page 10

10

CERTIFIED DIMENSION PRINT

TOTAL OPERATING

UNIT

30GX

251 13,774 6,621 15,549 7,068

265 13,829 6.286 15,604 7,093

NOTES:

1. Unit must have clearances for air flow as follows:

Top — Do not restrict in any way

Ends — (1524 mm) 5 ft (from solid surface)

Sides — (1829 mm) 6 ft

2. Unit with sound hoods requires clearances for air flow

as follows:

Top — Do not restrict in any way

Ends — (1829 mm) 6 ft

Sides — (2134 mm) 7 ft

3. Center of gravity shown is for aluminum fin coil. See

installation instructions for all other values.

WEIGHT

Aluminum Fin Copper Fin

lb kg lb kg

TOTAL OPERATING

WEIGHT

Page 11

----------------------------------------------------------------------------------------

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

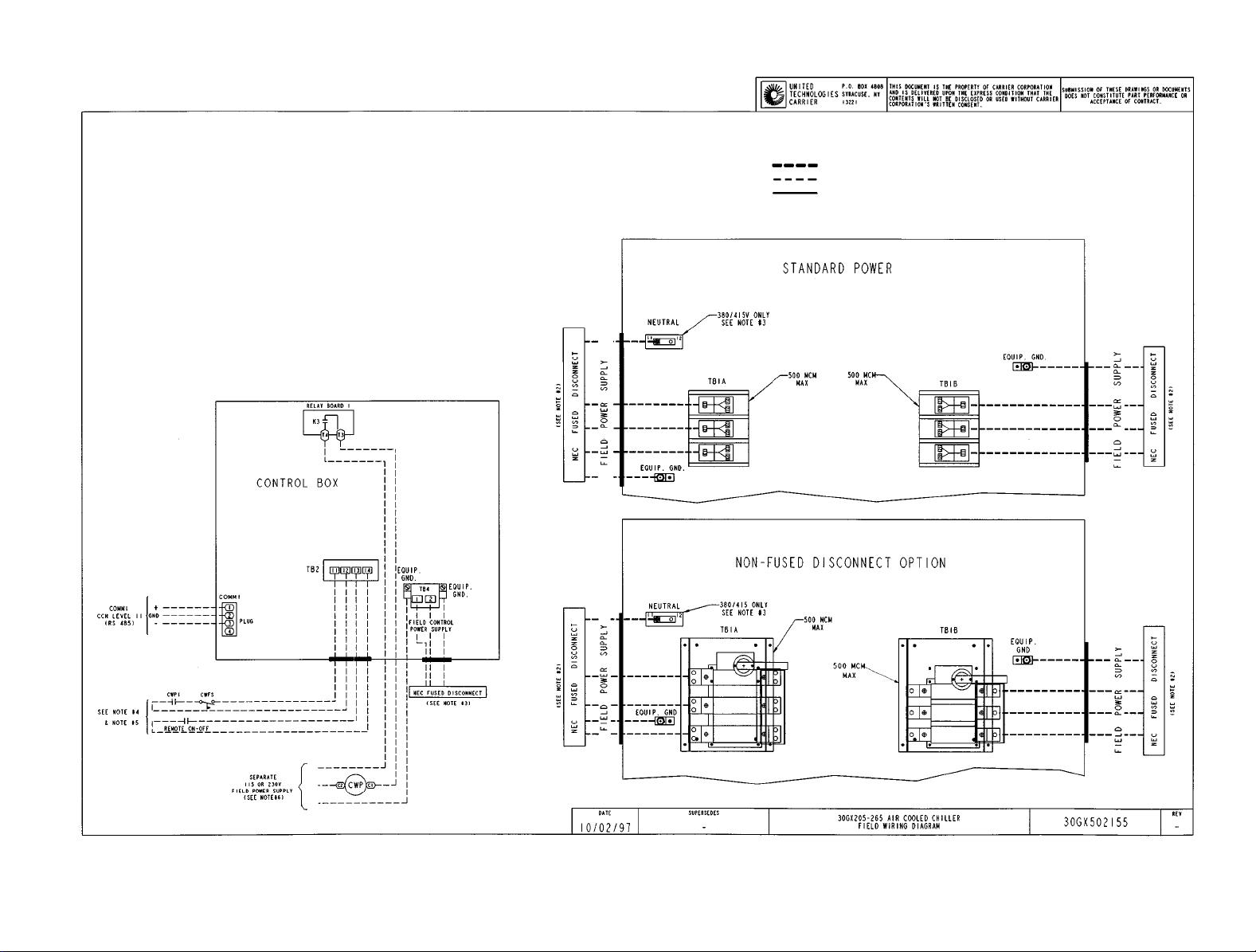

FIELD WIRING DIAGRAM

NOTES:

1. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications or additions must be in compliance with all applicable codes.

2. Wiring for main field power supply must be rated 75° C minimum. Use copper for all

units. Maximum incoming wire size for each terminal block is 500 kcmil.

3. Power for control circuit should be supplied from a separate source through a field

supplied fused disconnect with 30 amp maximum protection for 115voltcontrolcircuits

and 15 amp maximum protection for 230 volt control circuit. Connect control circuit

power to terminals 1 and 2 of TB4. Connect neutral side of supply to terminal 2 of TB4.

Control circuit conductors for all units must be coppr only. 380/415 control power wired

at factory. Requires field supplied neutral connection.

4. Terminals 13 and 14 of TB2 are for field external connection for remote ON-OFF. The

contacts must be rated for dry circuit application capable of handling a 24 vac to 50 mA

load.

5. Terminals 11 and 12 of TB2 are for chilled water flow switch (CWFS) and chilled water

pump interlock (CWPI) functions. The contacts must be rated for dry circuit application

capable of handling a 24 vac to 50 mA load.

6. Terminals T3 and T4 on relay board are for chilled water pump. The maximum load

allowed for the chilled water pump relay is 125 va sealed, 1250 va inrush at 115 or

230 volt.

LEGEND

CCN — Carrier Comfort Network

CWFS — Chilled Water Flow Switch

CWP — Chilled Water Pump

CWPI — Chilled Water Pump Interlock

EQUIP — Equipment

GND,GRD — Ground

TB — Terminal Block

Field Power Wiring

Field Control Wiring

Factory Installed Wiring

11

Page 12

12

FIELD WIRING DIAGRAM

NOTES:

1. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications or additions must be in compliance with all applicable codes.

2. Wiring for main field power supply must be rated 75° C minimum. Use copper for

all units. Maximum incoming wire size for each terminal block is 500 kcmil.

3. Power for control circuit should be supplied from a separate source through a field

supplied fused disconnect with 30 amp maximum protection for 115 volt control

circuits and 15 amp maximum protection for 230 volt control circuit. Connect control circuit power to terminals 1 and 2 of TB4. Connect neutral side of supply to

terminal 2 of TB4. Control circuit conductors for all units must be coppr only. 380/

415 control power wired at factory. Requires field supplied neutral connection.

4. Terminals 13 and 14 of TB2 are for field external connection for remote ON-OFF.

The contacts must be rated for dry circuit application capable of handling a 24 vac

to 50 mA load.

5. Terminals 11 and 12 of TB2 are for chilled water flow switch (CWFS) and chilled

water pump interlock (CWPI) functions. The contacts must be rated for dry circuit

application capable of handling a 24 vac to 50 mA load.

6. TerminalsT3andT4on relay board are for chilled water pump. The maximum load

allowed for the chilled water pump relay is 125 va sealed, 1250 va inrush at 115 or

230 volt. Minimum load required is 25 va sealed.

CCN — Carrier Comfort Network

CWFS — Chilled Water Flow Switch

CWP — Chilled Water Pump

CWPI — Chilled Water Pump Interlock

EQUIP — Equipment

GND — Ground

LEGEND

TB — Terminal Block

Field Power Wiring

Field Control Wiring

Factory Installed Wiring

Loading...

Loading...