Page 1

Number One

AirConditbninq

Maker

^8^ Oivision of

Carrier Corporation

Carrier Parkway • Syracus

All units have single-pumpout control. Low-voltage units have extended voltage (208/230 v)

compressor motors. All units have compressors with suction cutoff electric unloaders.

N Y 13221

Reciprocating Liquid Chillers

60-Hertz Air-Cooled Packages

0 0 0

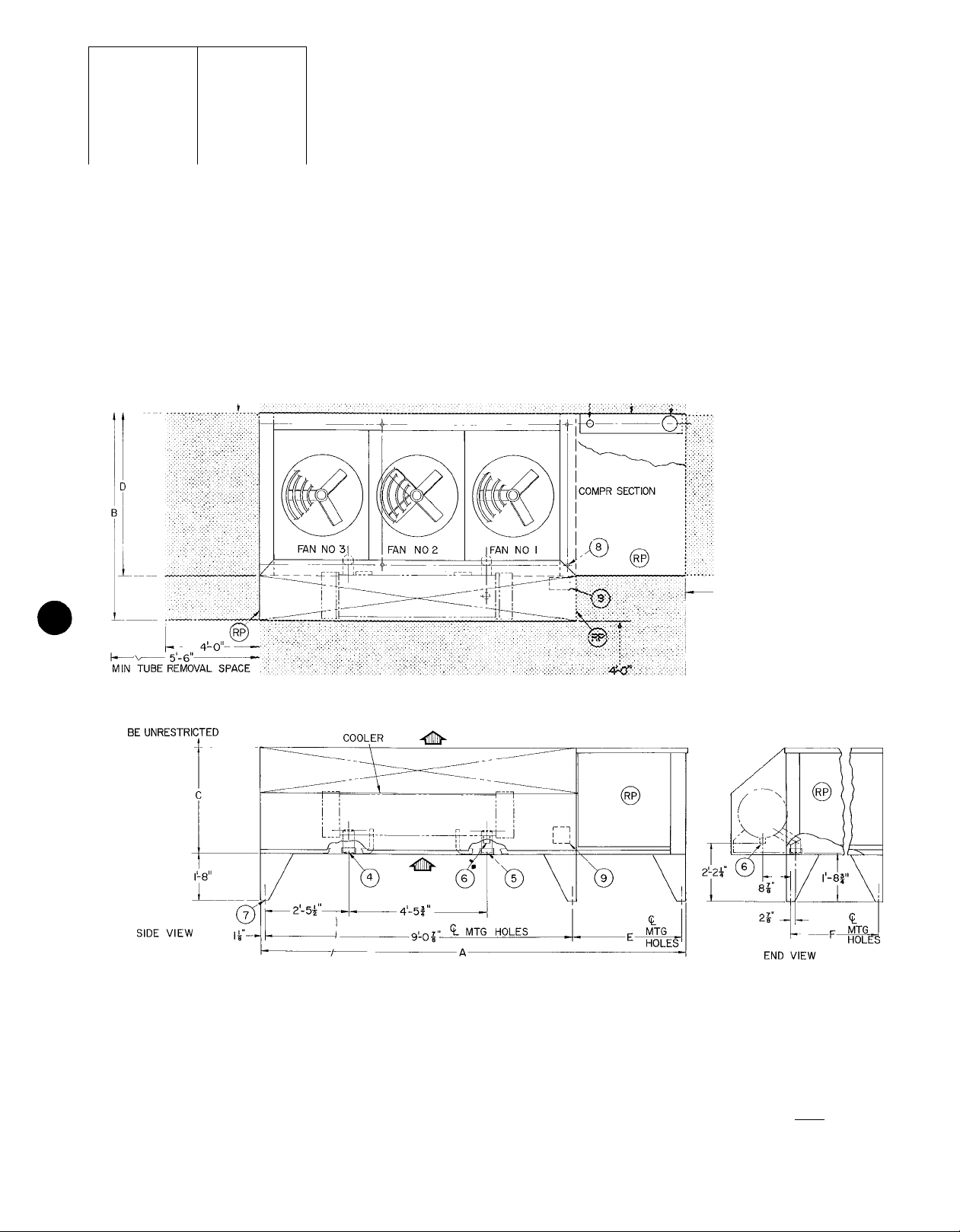

OVERHEAD AIR SPACE MUST

Control Box

3-5/8 in diameter hole in control box

for field main power supply

7/8-in diameter hole in control box

for control circuit wiring

3-in FPT water inlet (return)

3-in FPT water outlet (leaving)

LEGEND

RP — Removable Panel

TOP VIEW

1-in FPT water drain

5/8-in diameter hole for floor

mounting — 6 legs

1/2-13 thd for lifting eyebolt — 4 holes

115-1-60 receptacle box

Fig. 1 — Dimension Drawing

UNIT

30 G A

a”

B

c

D

E

F

'Common

4-0-

—1 SPACE FOR SERVICE

AND AIRFLOW

r\ AIRFLOW THRU

t/ CONDENSER

DIMENSIONS (ft-in.)*

020

5- 4 Va

2- 4Va

3- 1IV

025

5- 4V8

2- 4Va

3- 1IV2

3- 1%

3- 9V4

dimensions

shown on

030

6- 2V8

3- r/a

4- 10

drawing

© Carrier Coiporation 1980

Form 30GA-28SI

Page 2

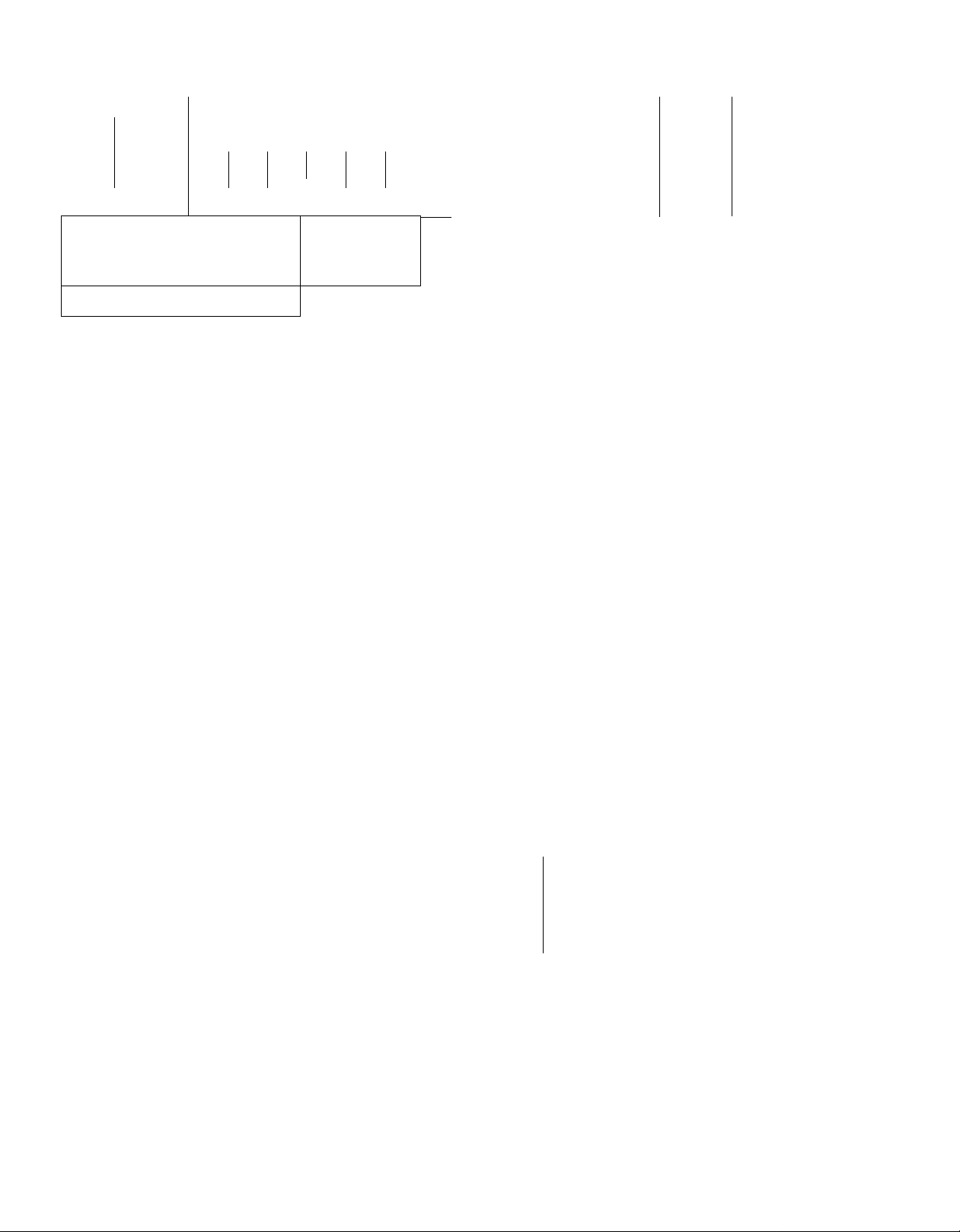

Table 1 — Weight Distribution

UNIT

30GA

020 ”

025

030

APPROX

OPER WT

(lb)

2695

2875 790

3270 830

CONDENSER SECTION

COOLER SECTION

1.

756 190

location

.3 J J. .

2

Weight (lb)

905

960

200

330 990

372

415 235

540

4

COMPR SECTION

3 5

6

5

2^'2

260

275

270 310

PLAN VIEW — SUPPORT POINTS

^ SAFETY CONSIDERATIONS

Installation, start-up and servicing of this equip

ment can be hazardous due to system pressures,

electrical components and equipment location

(roofs, elevated structures, etc.).

Only trained, qualified installers and service

mechanics should install, start-up and service this

equipment.

Untrained personnel can perfonn basic main

tenance functions of cleaning coils, cleaning and

replacing filters. All other operations should be

performed by trained service personnel.

When working on the equipment, observe pre

cautions in the literature, tags, stickers and labels

attached to the equipment and to any other

safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky

equipment.

WARNING; Be sure power to equipment is shut

off before performing maintenance or service.

INSTALLATION

Rigging — Preferred method is with spreader bars

from above the unit, utilizing the 4 eyebolts and

washers provided in fastener package (Table 3,

items 4, 5). Otherwise, rig with chains or cables

from above, using the eyebolts. Adjust cable or

chain length so that suspension angle with top of

unit is 45° or greater. If movement with rollers is

required, do not remove the unit from the skid

until it is in final position.

Placing Unit — Locate so condenser airflow is un

restricted on all sides and on top (see Fig. 1 ).

Provide ample room for servicing cooler For re

moval from compressor end, the 4-ft clearance

shown is sufficient for all units. For removal from

opposite end, see clearance dimension on Fig. 1.

"fàble*^2 — Physical Data

025

UNIT 30 G A

APPROX NET WT (lb)

REFRIG CHARGE, R-22 (lb)

COMPR 06E*

No. Cyl...Rpm

Oil Charge (pt)t

6

COND FANS, Rpm

Motor Hp

Total Airflow (cfm)

COND COILS

Rows...Fins/ln.

Total Face Area (sq ft)

COOLER

Max Work. Press, (psig)

RefrIg Side

Water Side

Refrig Circuits

*N0 of electric unloaders: 2 = one: 3

fSee OH Charge for Carrier approved oil

020 ’

2600

55

2250

4 Ï 750

14

Propel 1 er.

V4 1

18,200 ! 25,200

V Type, Plate

2780

57 5

3265

3 124

35 4 I 39

30HR030

235

250

2

6

19

030

3175

63

3275

1750

irive, 1140

1

28,200

49 6

Erecting Unit — When unit is in proper location,

attach the 6 legs. Legs are lagged to skid at com

pressor end; screws, lockwashers and nuts are in

fastener package (Table 3, items 1, 2, 3), taped to

unit frame at condenser end. Remove 8 bolts and

2 nuts holding unit to skid and raise unit to remove

skid. Secure legs at 1,2, 3, 4, 5, 6 (Table 1). Three

mounting holes are provided at each of the 6 desig

nated points. Ten of the holes (inside compressor

section) are provided with weld nuts. Loose nuts

are furnished for the other 8 holes. In the bearing

plate at the bottom of each leg is a hole for secur

ing to supporting structure or mounting on vibra

tion isolators if required (see Fig. 1 ). Fasteners for

this mounting must be field supplied.

Table 3 — Fastener Package

TEM

i

2

3

4

5

6

7

REQ

PER

UNIT

Ï8

18

8

4

4

1

1

Screw, Hex Hd %

Lockwasher, %

Nut, Hex % - 16

Eyebolt, ^/2 — 13x1 in Lg

Washer, SAE %

Clamp, Tube

Screw, Hex Hd no 8 — 32 x %

DESCRIPTION

16x1

Lg

Lg

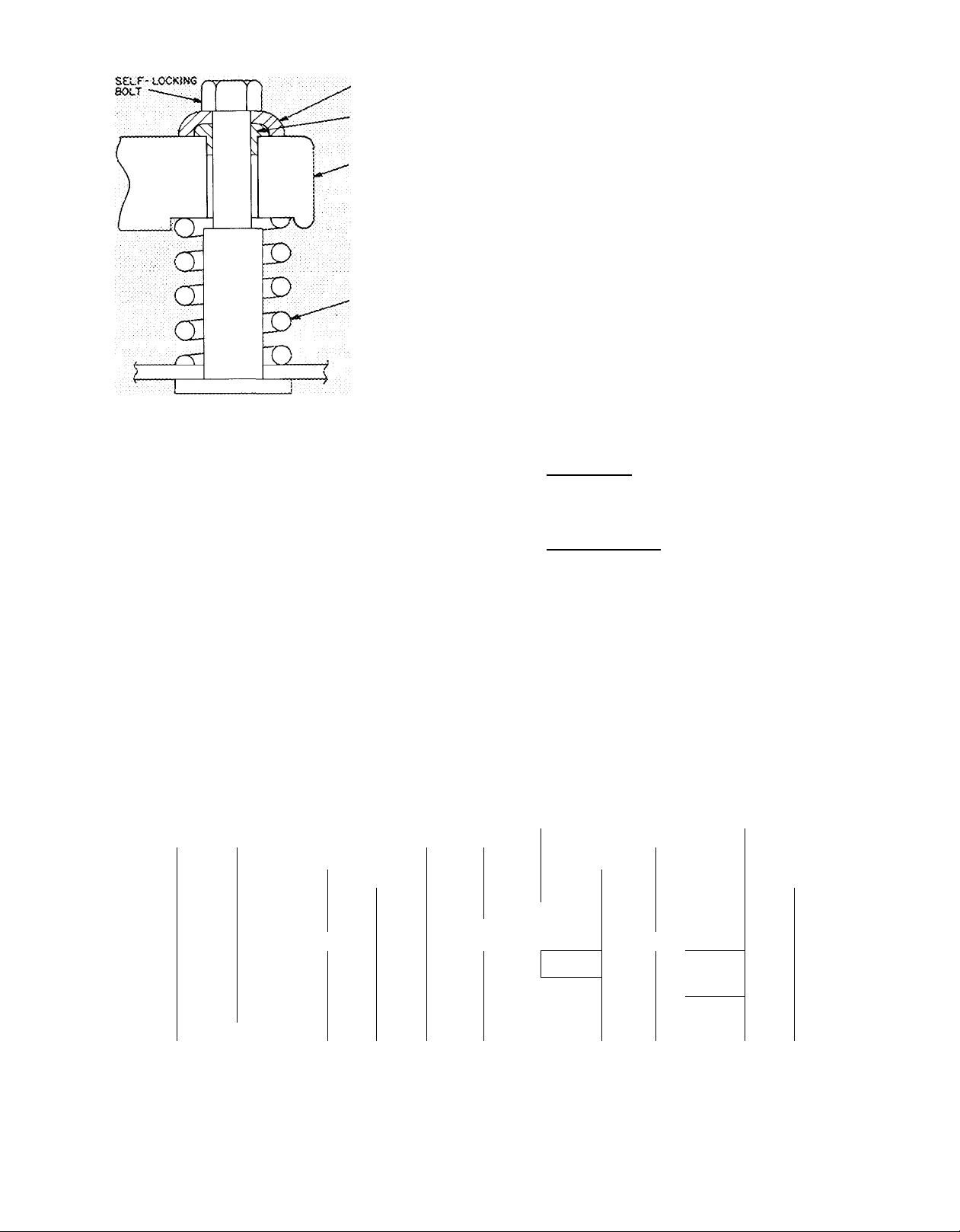

Compressor Mounting — As shipped, compressor is

held down by special self-locking bolts and plain

lock washers. After unit is installed, remove the

self-locking bolts one at a time and reassemble with

flanged washers and neoprene snubbers as shown in

Fig. 2. Special flanged washers and neoprene snub

bers are shipped in a cloth bag tied to one of the

compressor feet. Tighten all 4 bolts. Then loosen

each until the flanged washer can be moved side

ways with finger pressure.

Page 3

$»«je8ER Fl.AN«ED

WASHER

MEORRERE

SNUB8ER

Water Treatment — Consult local water authority

on characteristics of water in the area and add a

recommended inliibitor to the chilled water.

. COMPRESSOR POOT

(SOCATJON SPRiNC

Fig. 2 — Compressor Mounting

Chilled Water and Drain Piping — Facing the cooler

side of the unit, the return water connection is on

the left and the leaving water connection is on the

riglrt (see Fig. 1). The connections are oriented

vertically to minimize pressure losses and to facili

tate field piping for roof-mounted installations. A

means of venting air from the high point of the

field-installed piping should be provided. After

field piping is complete, wrap all piping with elec

tric heating tape and cover with suitable thickness

of closed-cell insulation. The power source for the

electric heating is the 115-volt (60-FIertz only) con

venience outlet in the bottom of the cooler section,

at compressor end. The cooler drain connection is

at compressor end (see Fig. 1). Drain piping can be

installed directly thru hole provided in cooler

section base pan. Insulate this piping, similar to

the chilled water piping, for at least one foot

from cooler.

Power Supply ~ Electrical characteristics of avail

able power supply must agree with unit nameplate

rating. Supply voltage must be within the limits

shown in Table 4.

IMPORTANT; Operation on improper supply

voltage or with excessive phase unbalance con.stitutes abuse and is not covered by Carrier

Warranty,

Power Wiring — All power wiring must comply

with applicable local and national codes. Install a

field-supplied branch circuit disconnect switch per

NEC of a type that can be locked OFF or OPEN.

FIELD CONNECTIONS

1. Main Power — Bring wires from the disconnect

switch thru hole in bottom of unit control box

(Fig. 1) and connect to terminals LI, L2, L3 on

line side of terminal block TBl (see Fig. 3).

2. Auxiliary Power — Bring separate source power

(115-1-60) into unit as shown in Fig. 1 and Fig. 3.

This supplies power for control circuit, compres

sor crankcase heater, cooler heater and conven

ience outlet for miscellaneous auxiliary 115-volt

applications. Connect incoming wires to TB2 in

unit control box (LI toQ] and L2 to[2]). In the

auxiliary power supply, a field-supplied dis

connect with 15-amp circuit protection must be

provided to take care of crankcase heater and

cooler heater cable.

In compliance with NEC Article 440-14, the dis

connect must be located within sight of and

readily accessible from the unit.

30GA Mode I

530 208/230

020

025

030

CCB -

FCB FLA LRA -

MCA -

630

130

530 208/230

630 460 414 508 69

130

530 208/230 187

630 460

130

RLA for each motor winding is half the value shown

MTA shown is for eacli 3-pole section of the CB (each

motor winding)

Compressor Circuit Breaker

Fan Circuit Breaker (one for all fans)

Full Load Amps (fan motors)

Locked Rotor Amps

Minimum Circuit Amps Complies with NEC, Section

430-24

Table 4 — Electrical Data

UNIT COMPRESSOR

V

dUs

Supp lied* MCA >"use RLA LRA

Min Max

187

460

575

575

575 518 632 63 5

414

518 632 41

187

518 632 61,7

414 508 72

253

508 51

253 145

253

103 175

168 275

Max

..

.......76......

80

60

225 100 446 6

1 10

70

110

80

36 173

28 6

48

4d> .6

\\o

ZiO

45 176 3 63

MTA — Must Trip Amps (factory-installed circuit breaker)

P — No of poles in CCB

RLA — Rated Load Amps (compressor)

*Units are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the min

and max limits shown

■fAdjacent to compressor compartment (non-cycling)

NOTE Maximum allowable phase unbalance is volts, 2%:

amps, 10%

^ 345 ~6

120 3

223 6

164 3

506 6

253

P

3

6

CCB

1 MTA

S3

DO 1 9

1 40

.......

7(Г“

1 oT

83

; 35

“ Fl

EACi-

Fan

It

4.5

1 6

6.2

3 0

2.4

6 2

3 0

2 4

No.

2.3

4 6

1 9

1 6

6 6

3 0

2 4

6 6

3 0

2.4

FCB

MTA

29

18

14

29

18

14

29

18

14

Page 4

IMPORTANT: Make provisi-on for the auxiiiaxy power to be always on (except for servicmg or prolonged shutdown) to ensure power

to the heaters.

A toggle switch (marked SW) in the control box

allows the control circuit to be manually discon

nected when necessary. This switch does not

affect the crankcase heater, cooler heater cable

or convenience outlet.

3. Control Circuit Interlocks — A flow switch

should be installed in the chilled water line to

prevent the unit from running when water is not

circulating thru the cooler. This switch (no.

HR81LG005) is available as an accessory from

the Syracuse parts center, or equivalent can be

field purchased. Also, auxiliary contacts for the

chilled water pump starter should be installed in

the control circuit as additional protection

against unit operation when pump is not run

ning. Both of these items should be electrically

interlocked in the control circuit, between

terminals [T] and [2 on TBS. See Fig. 3 for field

wiring.

UNIT CONTROL BOX

T8 I

CD [I]

L3 L2 LI

FIELD POWER SUPPLY

CWFS — Chilled Water Flow Switch

CWPS — Chilled Water Pump Starter Auxiliary Contacts

SW — On.Off Switch, Control Circuit

TB — Terminal Board

START-UP AND SERVICE

Initial Check — Do not attempt to start the liquid

EQUIP

GND

TB4

Fig. 3 — Field Wiring Connections

chiller, even momentarily, until the following steps

have been completed.

1. Check all auxiliary components such as chilled

liquid circulating pump, air handling equip

ment, or other equipment to which the chiller

supplies liquid. Consult the manufacturer’s

instructions. Pump auxiliary contactor and

flow switch interlocks must be properly in

stalled (see Fig. 3, Field Wiring Connections).

2. Check chilled water safety thermostat. (See

Safety Thermostat for adjustment.)

3. Backseat (open) compressor suction and dis

charge shutoff valves. Close valves one turn to

allow pressure to reach test gages.

4. Open liquid line valve.

5. Fill chilled liquid circuit with clean water or

other noncorrosive fluids to be cooled. Bleed

all air out of high points of system.

6. Set temperature controller (see Multiple-Step

Controller).

7. Check tightness of all electrical connections.

LEGEND

A-

SW

REMOVE RED WIRE BETWEEN Q] AND

TBS TB3

m

L_

-|cWFsh'*~'ICWPsM

CONTROL CIRCUIT

INTERLOCKS (ACCESS)

[T]

I I

(AUX)'--

___

Field Control Wiring

— Field Power Wiring

_ Factory Wiring

8. Compressor oil should be visible in bull’s-eye

(see Oil Charge).

9. Be sure there are no refrigerant leaks (see Leak

Test and Dehydration).

10. Be sure unit is fully charged with refrigerant

(see Refrigerant Charge).

11. Electrical power source must agree with name

plate rating.

12. Temperature sensor of fan cycling control must

be unobstructed (see Fan Cycling).

13. Crankcase heater must be firmly locked into

compressor crankcase. Be sure crankcase is

warm (heater should be on for 24 hours before

starting compressor).

14. Be sure compressor floats freely on the mount

ing springs. See Compressor Mounting section

and Fig. 2 for installation of loose washers and

snubbers.

Leak Test and Dehydration — All 30GA units are

shipped with complete operating charge of Refrig

erant 22 (Table 1) and should be under sufficient

pressure to conduct leak test after installation. If

there is no system pressure, admit refrigerant until

a pressure is observed and then proceed to test for

EQUIP GND

(Z)—1

TB2

p

3 q

LI L2

AUXILIARY

POWER SUPPLY

r+-

DISCONNECT PER NEC

Page 5

leaks. After leaks are repaired, the system must be

dehydrated. For leak testing and dehydration pro

cedures, refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants, Sections 6

and 7.

Refrigerant Charge — When additional or complete

field charging is required, refer to Table 1 and use

the Liquid Charging Method. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants, Section 8, for charging procedures.

Immediately ahead of the filter-drier is a factoryinstalled liquid shutoff charging valve. A 1/4-in.

flare connection is provided for field charging.

CAUTION: Never charge liquid in to low-pressure

side of system.

Auxiliary Power Circuit — Switch 115-1-60 field

disconnect to ON. The cooler heater is factory

wired into the control circuit. Compressor crank

case heater should be on as soon as auxiliary circuit

is energized. Allow crankcase heater to operate at

least 24 hours before starting unit, then close main

power circuit breaker.

COMPRESSOR SECTION Removable top cover

and quick-access side and front panels permit ser

vicing without disturbing the condenser and fans.

In this section are the replaceable-core filter-drier,

liquid line shutoff charging valve, and moistureliquid indicator.

CONDENSER SECTION — Each fan motor is

clamped in a formed-wire mount. Each clamp con

sists of 2 formed-steel straps with 2 sets of bolts,

washers and nuts. The motor mount is supported

from the fan deck. If a fan motor is repaired or re

placed, be sure the wire fan guard is in place over

each fan before starting unit. See Fig. 4 for proper

fan adjustment. Secure fan hub on motor shaft

with 2 setscrews, which bear against the key. Be

sure Permagum is applied to exposed end of motor

shaft to ensure against moisture causing fan to rust

on shaft.

Actual Start-Up should be done only under super

vision of a qualified refrigeration mechanic:

1. Open any compressor and system valves that

were closed during charging.

2. Turn control circuit toggle switch to ON.

3. Push control reset button and chilled water

safety thermostat reset button to ensure circuit

operation.

4. Be sure all safety devices are satisfied.

^ 5. Check to see that the leaving chilled water

temperature agrees with the dial setting on the

temperature controller. If it is not the same as

the dial setting, the variation can be compensated

by shifting the control point slightly to obtain

the proper leaving chilled water temperature.

Access for Servicing (See Fig. 5)

UNIT CONTROL BOX has a gasketed removable

outer cover held on with thumb screws. An inner

panel is hinged and fastened with 2 screws. When

the inner cover is closed, the following components

are accessible; compressor and fan circuit breakers,

control circuit reset buttons, control circuit ONOFF switch, water safety thermostat reset button

and chilled water temperature controller set point

adjustment.

UNIT 3ÒGA

020

025-030

End Fans

Fig. 4 — Fan Adjustment

DIMENSION A (in.)

U/32 ;

COOLER SECTION -- Removable service panels

are provided at each end for general servicing. For

more extensive work on cooler, the full length

cover can be removed. If it is necessary to remove

cooler tubes or cooler, place a support under frame

at point “A” (Fig. 5) at each end and remove (2)

struts.

Do not remove supports until the struts are

replaced.

Cooler Head Bolt Tightening — If the cooler heads

are removed for any reason, use the following

torques and follow the given tightening sequence

when reassembling;

Torques — 5/8-in. diam bolts

..........

150 to 170 Ib-ft

1/2-in. diam bolts,

or nuts

...................•.........

70 to 90 Ib—ft

Page 6

COOLER SECTION

END PANEL

(EACH END)

COOLER

----------

SAFETY

THERMOSTAT

BULB

THE FAN CYCLING TEMPERATURE

SWITCH IS LOCATED IN THE LOWER

RIGHT CORNER OF THE PANEL BELOW

THE CONDENSER COIL

UNIT CONTROL

BOX

FILTER DRIER

LOW SIDE HIGH SIDE

OIL PRESSURE

CONNECTIONS

OIL

SIGHT

GLASS

Fig. 5 — 30GA Unit with Access Panels Removed

(30GA025 Shown)

Page 7

BOLT TIGHTENING SEQUENCE (See Fig. 6)

Step 1 — Tighten moderately (without torquing)

all the flange bolts in the sequence shown.

Step 2 — Tighten moderately (without torquing)

the hex nuts on the center studs (no specified

sequence).

Step 3 — Repeat Step 1, tightening the bolts to the

specified torque.

Step 4 ~ Repeat Step 2, tightening the nuts to the

specified torque.

Step 5 — Not less than one hour later, retighten the

center stud nuts to the specified torque.

TOP

Fig. 6 — Tightening Sequence, Cooler Head Bolts

cage assembly can be removed for servicing with

out removing the body flange from the liquid line.

The thennostatic expansion valves have non

condensable-charge power elements.

-^Liquid Line Solenoid Valves, one in each of the

2 refrigerant circuits, are interlocked with the

water temperature controller to shut off the flow

of refrigerant to the cooler when the water temper

ature controller (WTC) call for cooling is satisfied.

They are located immediately upstream of the

thermostatic expansion valves. With single pumpout

control, the compressor continues to run after the

WTC is satisfied and the refrigerant flow is shut off

Tliis causes pumpout of refrigerant from the cooler

and subsequent shutdown of the compressor on

low-pressure control. The compressor will not

restart until the WTC again calls for cooling.

Discharge Line Check Valve — A check valve in the

compressor discharge line prevents migration of

refrigerant from the condenser to the compressor

during the off cycle.

Moisture-Liquid Indicator — Clear flow of liquid

refrigerant indicates sufficient charge in system.

Bubbles indicate undercharged system or presence

of noncondensables. Moisture, measured in parts

per million (ppm), in system changes color of indi

cator. Green — moisture is below 45 ppm, char

treuse (caution) — 45 to 130, yellow (wet) — above

130. Change filter-drier cores at first sign of mois

ture in system.

Oil Charge — Compressor is factory charged with

oil. Each 30GA020 unit has 14 pints of oil; each

30GA025 and 030 unit has 19 pints. When addi

tional oil or a complete charge is required, use only

Carrier approved compressor oil

Sun Oil Company

Texaco, Inc

.....................................

................................

Suniso 3GS

Capella WFI-32-150

E.I. DuPont Company...........................Zephron 150

(Synthetic)

IMPORTANT; Do not reuse drained oil or use

oil tiiat has been exposed to atmosphere. Refer

to Cssrrier Standard Sendee Teclmiques Manual,

Chapter 1, Refrigerants for procedures to add or

remove oil.

Thermostatic Expansion Valves, one for each of

the 2 refrigerant circuits, are factory set to main

tain 6 — 7 F superheat of vapor leaving cooler to

control flow of liquid refrigerant to cooler. Super

heat can be reset but should be done only if abso

lutely necessary. The complete power head and

IMPORTANT: Unit musí be m operation at

least 12 hours before moisture indicator can give

an accurate reading. With unit running, indicat

ing element mxist be in contact with liquid

reirigexant to give true moisture indication.

Filter-Drier — Whenever the moisture-liquid indi

cator shows presence of moisture, replace filterdrier core. Refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants for details

on servicing filter-driers.

Liquid Shutoff/Charging Valve is located imme

diately ahead of filter-drier, provided with 1/4-in.

flare connection for field charging.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual

reset, magnetic. Protects against motor overload

and locked rotor conditions.

THERMAL PROTECTOR - A sensor in the dis

charge side of the compressor reacts to excessively

high discharge temperature and shuts off the com

pressor. The high discharge temperature indicates

overtemperature in the compressor motor.

TIME GUARD® function protects compressor

against short cycling. See Sequence of Control.

Page 8

CRANKCASE HEATER prevents absorption of

liquid refrigerant by oil in crankcase during brief or

extended shutdown periods. Source of 115-volt

power is the auxiliary control power, independent

of the main unit power. This assures compressor

protection even when main unit power disconnect

switch is off.

BiPORTANT; Never open any switch or discon

nect that de-energizes fee craxrkcase heater unless

unit is being serviced ox is to be shut down for a

prolonged period. After a pr<^osged slrutdown

or a service job. energiae fee crankcase heater

for 24 hours before starting the compiessor.

Cooler Freeze-Up Protection

HEATER CABLE — A lead-sheathed 200-watt cable

is helically wound around the entire length of the

cooler. A thermostat energizes the cable whenever

the ambient temperature is 35 F or lower. The cable

is between the cooler and the 2-in. thick insulation

blanket around the cooler. The heater cable and

the insulation protect the cooler down to —20 F

ambient.

Since the 115-volt auxiliary power source for the

heater cable is separate from main unit power

source, power to heater is assured even though the

main unit power may be off. From the same source,

a 115-1-60 convenience outlet is provided for fieldsupplied heating elements for chilled water piping.

CAUnON; Do noi disconrteci iieafer cable

power vfeen sexvicfeg compressor jf mbient

hafoperamre is below 40 F. ifpowertofee beater

is cat off, or if ami is to be down for a pro-

kaiged period^ drain fee cooler.

SAFETY THERMOSTAT (Freezestat or Low Water

Temperature Cutout) is a noncycling, manual reset

type, to protect against freeze-up due to operating

malfunction. The sensing bulb is installed in top of

the cooler shell at leaving chilled water end. Freeze

stat is set to break the control circuit at 36 ± 2 F,

locking out the unit. The thermostat must be reset

before the unit can restart under Time Guard®

control. The chilled water circulating pump con

tinues to operate during the lockout period.

When cooling below 33 F (glycols or brines), use

thermostat no. HH22PB030, with well no. 30HH

406102. Install well in connection provided in

leaving chilled waterline elbow at exit from cooler.

Check thermostat at installation and at least

once each season thereafter. (See Fig. 7.)

TEMPERATURE

SENSING-~____|;

BULB

STOP LUG

dial screws

RESET BUTTON

capillary

Fig. 7 — Safety Thermostat

temperature where thermostat cuts out. This

should be within one or 2 degrees of dial setting.

Recalibrate if variation is greater.

To Recalibrate — Break painted seal at dial screw.

With a screwdriver in the adjusting slot, hold the

angular position of the dial assembly while com

pleting the following steps:

1. Loosen the 2 dial screws.

2. Rotate dial only until the number under the

fixed indicator is the observed temperature of

the mixture.

3. Re tighten dial screws.

Turn dial assembly until desired compressor cut

off temperature is directly under fixed indicator.

Recalibration is now complete.

WINTER SHUTDOWN — At the end of the cooling

season, drain the water from the cooler (see drain

location in Fig. 1). Replace the drain plug and put

2 gallons of ethylene glycol in the cooler to prevent

any residual water in the cooler from freezing. At

the beginning of the next cooling season, refill the

cooler and add the recommended inhibitor.

To Check — Insert screwdriver into adjusting slot

and turn dial assembly until desired cutoff temper

ature is directly under fixed indicator. Place bulb

in vacuum bottle filled with mixture of water and

crushed ice. Stir mixture with thermometer. As ice

melts, temperature of mixture goes down. Note

High-Pressure Switch has fixed, nonadjustable

settings.

TO CHECK — Open the condenser fan circuit

breaker. Head pressure will build up until the com

pressor shuts down. This should be at the cutout

Page 9

pressure in Table 5. Close condenser fan circuit

breaker. After pressure drops to cut-in setting, reset

the control circuit by opening and then closing the

control circuit switch. After control circuit is reset,

the Time Guard® timer will cycle and in approxi

mately 5.5 minutes the compressor will restart.

Low-Pressure Switch has fixed, nonadjustable set

tings. The switch is mounted on the suction line.

TO CHECK — Slowly close liquid shutoff valve and

allow compressor to pump down. Compressor

should shut down when suction pressure drops to

cutout pressure in Table 5, and should restart when

pressure builds up to cut-in pressure shown.

troller is factory set to control from return water

temperature thm a cooling range of 10 F. The

sequence switches are factory calibrated and sealed

and should not require any field changes. Table 7

shows the factory-set temperature steps for the 2and 3-step controllers.

IMPORTANT: if a dilTerent retum-\yaier cool

ing range a ieaving-waier control is specified,

or if htine is to be used,^ the coniroBer must be

changed. Consult local Carrier representative

for proper co.ntrc4 device.

Table 7 — Capacity Control Steps

Table 5 — Pressure Switch Settings (psig)

UNIT

30GA

020,025,030

HIGH PRESSURE

Cutout Cut-in Cutout

...

374 +5 274 ±5 27 +4

LOW PRESSURE

*■

60 ^ 0

Cut-In

Winter Start Control — Switch “D” in the 4-

function timer bypasses low-pressure switch for

2-1/2 minutes on unit start-up.

Head Pressure Control reduces condensing capac

ity under low ambient conditions.

FAN CYCLING — These 30GA units have stand

ard provision for fully automatic intermediateseason head pressure control thru condenser fan

cycling. Fan No. 2 is cycled by a pressure con

troller which responds to variation in discharge

pressure. The pressure sensor is located in the

liquid line of the refrigerant circuit. Fan No. 3

cycling is controlled by outdoor air temperature.

The temperature switch is located in the lower

right comer of the rear panel of the compressor

compartment, below the condenser coil (see Fig. 4).

Thru a hole in the panel, the sensing element is ex

posed to air entering the No. 1 fan compartment.

Fan No. 1 is non-cycling. Table 6 shows the oper

ating settings of the pressure and temperature

controllers.

UNIT

30GA

020

.... .

025,

030

‘Return chilled water temperature

|-Design set point

CONTROL % OPER T TEMP

STEPS

T'

2 100

1

2 67

3 100 6

CAP. CYL

” ”2 '

4

33

4 50 47V2

Cut-in Cutout

”441

527,

46V2

53V2 51

50

44 f

The return water temperature at which the last

step of capacity unloads is indicated by the leaving

water temperature design set point on the adjust

able dial (Fig. 8). Example; design set point is at

44 F. On a reduction in load, the capacity of the

unit is reduced to zero when return water tempera

ture drops to 44 F.

WARNING; Any alteration of factory settings,

except de.sign set point, without Carrier author

ization, may void the Carrier Warranty'.

Design Set Point Adjustment — When unit is ready

for operation, insert small screwdriver in adjusting

slot (Fig. 8) and rotate to turn dial (the dial may

be turned by hand if desired).

Rotate until the design set point for the installa

tion appears directly under the pointer. Insert a

thermometer in the return chilled water connec-

Table 6 — Fan Cycling Control

CONTROL BY

Temp (±3 F)

Pressure (±5)

SWITCH OPENS

70

1 óÒ psig

SWITCH CLOSES

80

2óÒ psig

Capacity Control System consists of a multiple-

step water temperature controller, electric cylinder

bank unloader(s) and 2 separately controlled refrig

erant circuits (liquid-line solenoid valves). A hot

gas bypass arrangement on the final step of unload

ing is factory supplied.

MULTIPLE-STEP CONTROLLER - Consists of

load switches actuated by pressures developed in a

temperature-sensing bulb located in the return

water line of the chilled water system. The con-

AOiSLiSTiÌÌG

SLO'

LEAViNG

mTSR

OESiGii

SET-

CALiSRATSO

Fig. 8 — Set Point Adjustment

POttiTER

STOA

Page 10

tion and allow the unit to run thru a cycle. At the

instant the last step of capacity unloads (switch

no. 1 opens), read the temperature. If it is not the

same as the dial reading, the variation can be com

pensated by shifting the control point sliglrtly.

C'AUTION: Do not force tlie dial pasit the stop.

'Hus could cause loss of the control point and

dajnage the instrument,

HOT GAS BYPASS VALVE modulates flow of hot

gas into no. 1 refrigerant circuit in response to vari

ations from preset suction pressure. A sudden de

crease in suction pressure causes valve to admit

more hot gas to restore the preset pressure level.

The hot gas enters the refrigerant circuit thru the

connecting tube between the thermal expansion

valve and the cooler. With hot gas bypass, the 30GA

units operate down to a lower load condition; the

result is less off-on cycling of the chiller.

The remote pressure sensing tubing is factory in

stalled running from a 1/4-in. flare connection in

the power head of the valve to the outlet of no. 1

refrigerant circuit, adjoining the external equalizing

connection for the thermal expansion valve. The

bypass valve is factory set to maintain 66 psig suc

tion pressure. For other than control from return

water temperature thru a 10 F range with 44 F

leaving water temperature, the set point may be

adjusted in the pressure range of 0 ^ 80 psig. One

full turn clockwise of the adjustment stem raises

set pressure approximately 5 psig, and vice versa.

> OPERATION

Refer to Control Circuit diagram on the unit, or

in the Wiring Diagrams publication.

Timer Functions (See Fig. 9 — Timer Cycle)

1. Switch “A” (contacts A-Al and A-A2) provides

Time Guard® function. Start of compressor is

delayed approximately 5.5 minutes after shut

off. The minimum time between starts of com

pressor is 8 minutes.

2. Switch “B” (contacts B-Bl and B-B2) starts com

pressor and provides one-second time delay for

part-winding start.

3. Switch “D” (contacts D-Dl) bypasses the lowpressure switch (LPS) for 2.5 minutes at start-up

for winter start control.

(BLACK DENOTES CLOSED CONTACTS) TIMER POSITION DURING

0 MIN OR

|_— 12 SEC +2

4—— 1 SEC ± 0.5

|— 5 SEC t2

2-6 SEC

150 SEC - 5

Fig. 9 — Timer Cycle

Sequence of Control

UNIT OPERATION-

-H h-2-6 SEC

5 5 MIN -

At start-up, with the water temperature con

troller (WTC) calling for cooling and all safety

devices satisfied, the control circuit switch is closed.

With minimal demand for cooling, only the first

WTC switch is made. The timer motor starts, liquid

line solenoid valve no. 1 (LLSl) opens and the con

denser fans start. After a delay by the Time Guard

control of 12 seconds to approximately 8 minutes

depending on the timer position, the compressor

starts, unloaded. As cooling demand increases, the

unit capacity increases as follows:

30GA020 (Two-Step Controller)

The second WTC switch makes and LLS no. 2

opens. The compressor loads and the unit is oper

ating at full capacity.

30GA025, 030 (Three-Step Controller)

The second WTC switch makes: LLS no. 2 opens

and one compressor unloader is de-energized in

creasing the capacity.

The third WTC switch makes: the second com

pressor unloader is de-energized increasing the unit

to full capacity.

A pumpout relay (FOR) in the control circuit is

energized when WTC no. 1 switch makes. A set of

normally open FOR contacts close, completing a

compressor control circuit which bypasses the

WTC switches.

As cooling demand is satisfied, WTC switches

break in descending sequence. The LLS valves close,

stopping the flow of liquid refrigerant to the cooler

and subsequent suction gas to the compressor.

After the last WTC switch breaks, the compressor

continues to run because of the WTC switch bypass.

10

Page 11

With no refrigerant returning to the compressor,

low side pumpout takes place and the compressor

shuts down on low-pressure control. The compres

sor will not restart until the WTC again calls for

cooling.

TROUBLESHOOTING

HOT GAS BYPASS

On the last step of capacity control (only WTC

switch no. 1 made), the Hot Gas Bypass valve is

energized. This allows the unit to operate at a

lower load condition than is provided in the normal

function of the WTC, with less on-off cycling of

the compressor.

SYMPTOMS

Compressor does

not run

Compressor Low-pressure control Raise differential

stops on

low-pressu re

control

Compressor

cyles on high-

pressure control

PROBABLE CAUSE REMEDY

Power line open Reset circuit breaker

Control circuit

breaker tripped for ground or short;

Safety thermostat Reset thermostat

tripped

Tripped starter

overloads

Contactor stuck open Replace contactor

Loose terminal

connection

Improperly wired

controls

Low line voltage

Compressor motor

defective ing for open or short

Seized compressor Replace compressor

erratic in action

Compressor suction

shutoff valve

partially closed

Low refrigerant charge

Liquid line

solenoid valve(s)

fails to open

High-pressure control

erratic in action

Compressor discharge Open valve, or re-

valve partially closed place if defective

Air in system

Condenser fan(s)

not operating

Check control circuit

repair and reset

breaker

Check the controls

Find cause of trip

and reset overloads

Check connections

Check wiring and

rewire

Check line voltage —

determine location

of vol Lage drop and

remedy deficiency

Check motor wind-

Replace compressor,

if necessary

setting

Check capillary for

pinches

Replace control

Open valve

Add refrigerant

Check liquid line

solenoid valve(s)

and coils for

proper operation

Replace if necessary

Check capillary tube

for pinches

Set control as

required

Purge

Check motor and

wiring Repair or

replace if defective

SYMPTOMS PROBABLE CAUSE

Unit operates

long or

continuously

System Noises Piping vibration

Compressor

loses oil

Frosted or

sweating suetion line

Hot liquid line

Frosted liquid Restricted

line

Compressor will

not unload

Compressor will

not load

High Suction

Chattering

unloader

Low refrigerant charge

Control contacts fused

Air in system

Partially plugged or

plugged expansion

valve or strainer

Compressor noisy

Leak in system

Crankcase heater

not energized dur-

ing shutdown

Expansion valve

admitting excess

refrigerant

Shortage of refrigerant

due to leak

Expansion valve

opens too wide

....

filter-drier

Burned out coil

Leaky bypass piston

Miswired solenoid

Weak bypass piston

Spring

Damaged bypass

piston

Miswired solenoid

Plugged bypass

port strainer

(high side)

Stuck check valve

in valve plate

Stuck check valve

in valve plate

_

___________

REMEDY

Add refrigerant

Replace control

Purge

Clean or replace

Support piping as

required

Check for loose pipe

connectors

Check vaive plates

for valve noise

Replace compressor

(worn bearings)

Check for loose

compressor hold

down bolts

Repair leak

Check wiring and

relay Check

heater — replace

if defective

Adjust expansion

valve

Repair leak and

recharge

Adjust expansion

valve

Remove restriction

or replace filter-drier

Replace coil

Replace

Wire correctly

Replace

Replace

Wire correctly

Clean

Examine check valve

components Clean or

replace as necessary

Examine check valve

components Clean or

replace as necessary

11

Page 12

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab

5c

Form 30GA-28SI Supersedes 30GA-24SI Printed in U S A

10-80 PC 1 11 Catalog No 533-080

Loading...

Loading...