Page 1

Carrier

Operating and Maintenance

Instructions

Automatic Water Strainer

29D

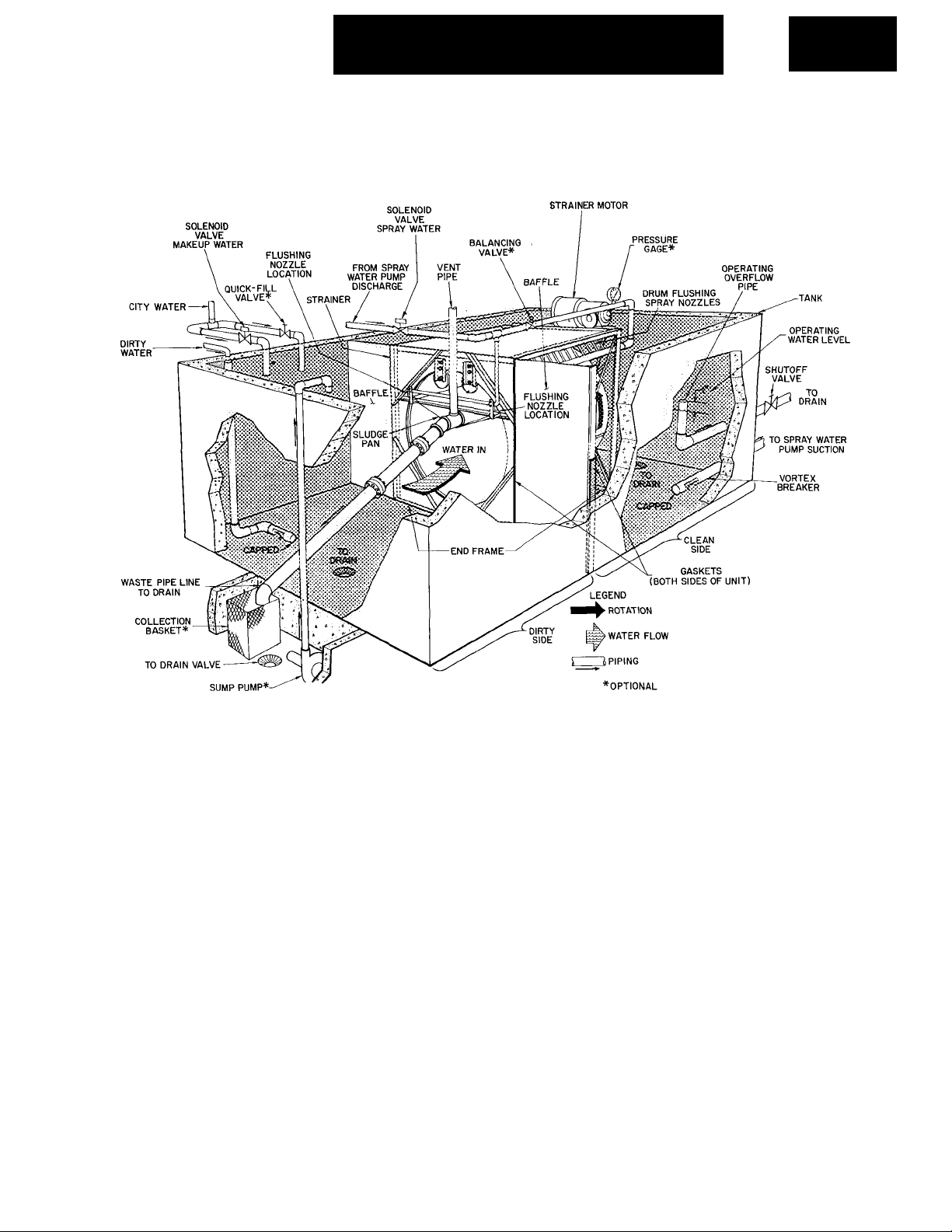

Fig. 1 - Typical Automatic Water Strainer Installation

UNIT DESCRIPTION

The 29D Automatic Water Strainer cleans

foreign matter from the return water of a

Rotaspray® system. Figure 1 shows a typical

installation.

OPERATING CYCLE

Water enters the open end of the strainer drum

and passes outward thru the perforated skin. For

eign matter is screened out of the water, and

covers the inside surface of the drum causing the

water level to rise on the dirty side of the tank.

The water level on the clean side rises until it

reaches the height of the high side electrode A

(Fig. 2). This sets the strainer into operation.

The drum begins to rotate and the drum flushing

sprays are turned on. The dirty portion of the

drum passes under the sprays, and foreign matter

is flushed from the drum into the sludge pan. The

pan flushing sprays wash the foreign matter from

the pan into a drain or a perforated collection

basket. (The water drains from this perforated

basket into a sump, and can be returned to the

dirty side of the tank by a small auxiliary pump.)

After the drum is cleaned of foreign matter, the

water levels equalize, and the strainer stops after

the timed operating cycle.

When the water falls below the low side elec

trode B level (Fig. 2) the strainer starts to pro

tect the pump suction when:

1. The "Rotaspray" units evaporate water, caus

ing the water level on the clean side to drop

without a corresponding rise in water level on

the dirty side.

2. Changes in the system water flow requirements

suddenly drop the water level in the clean side

of the tank.

3. The high side electrode fails to operate.

I Carrier Corporation 1967 Printed in U.S.A.

12-67 29D-1SO

Page 2

f

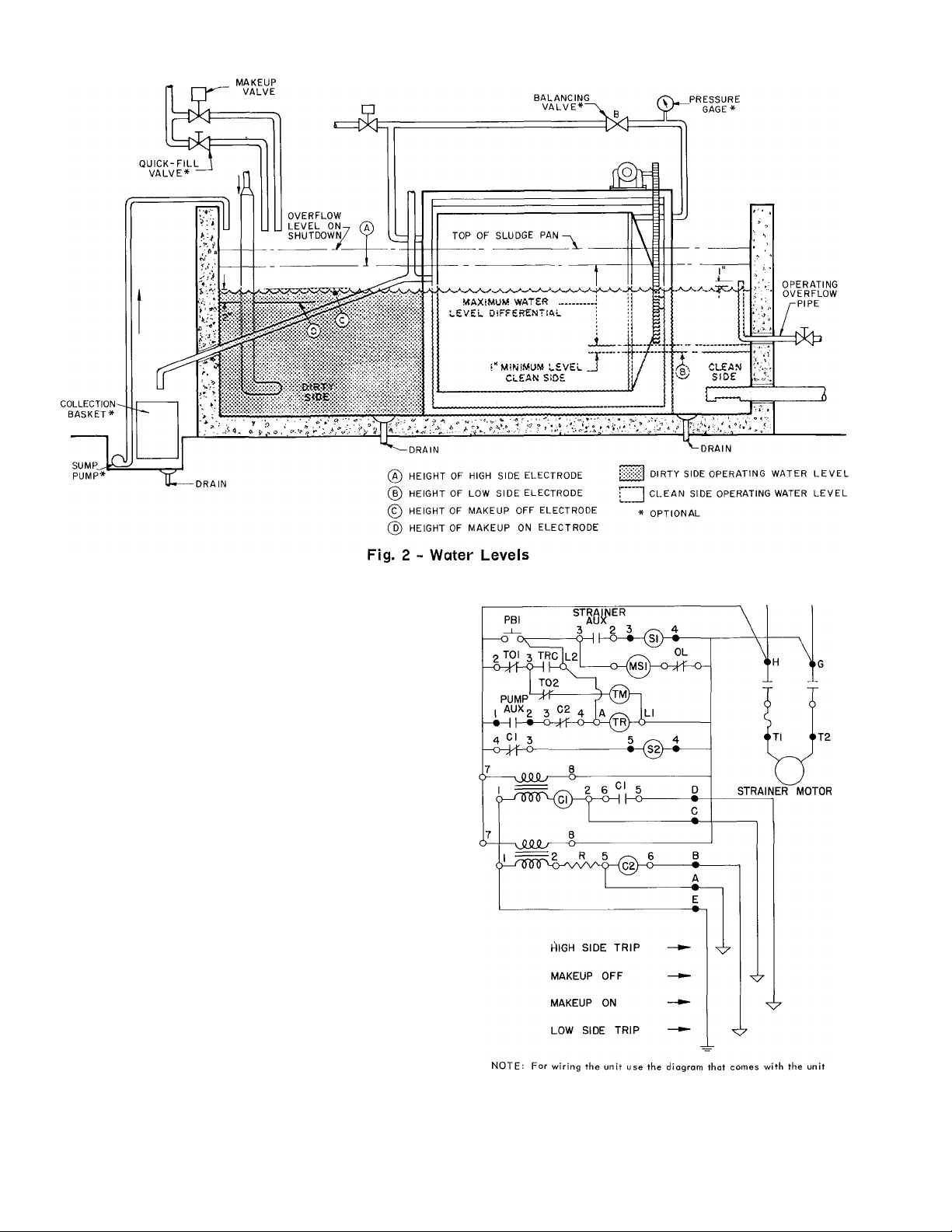

CONTROL CIRCUIT

Automatic Operation - The water strainer con

trol circuit (Fig. 3) consists of a timer and

level controller. The control circuit is wired thru

an auxiliary contact on the recirculated or chilled

water pump starter. If the fused disconnect switch

is closed, the control circuit is activated when

the pump starts. The strainer is then controlled

automatically by the high or low side electrode.

When either electrode is energized, the control

circuit is completed. This starts the drive motor,

opens the spray water solenoid valve, and trips

the timer.

Normally, as the strainer begins to operate,

the water levels begin to equalize, de-energizing

the electrode. However, the timer contacts remain

closed for the preset timed cycle to maintain

strainer operation. The length of the timed cycle

can be adjusted to suit job requirements. At the

end of the timed cycle, the timer contacts open.

This normally stops the drive motor, and closes

the spray water solenoid valve. However, if the

tank water level is too low, the low side electrode

will maintain the makeup valve open for several

minutes, until the water level rises enough to de

energize the low side electrode.

Manual Operation - A momentary contact switch

is provided to bypass the automatic tank level con

troller and operate the water strainer for one

timed cycle. This switch permits operation of the

strainer when the water pump is shut down.

Cl

^2 - Relay Coi Is

MSI - Strainer Motor Starter

PB — Push Button

SI - Spray Wtr Solenoid Valve

Fig. 3 - Elementary Control Circuit

II0-I-60

S2 - Makeup Wtr Solenoid Valve

TM - Timer Motor

TR — Timer Relay Coil

o - Terminals on Components

0 — Terminals on Terminal Strip

Page 3

LUBRICATION

Main Shaft Bearing - Lubricate strainer main

shaft bearing with waterproof grease see Table 1.

This is a sleeve bearing and does not contain

a grease reservoir. Determine frequency of

lubrication from operating conditions. Lubricate

approximately every 500 hr or three months,

whichever is earlier.

Drive Chain - Lubricate drive chain with water

proof grease whenever main shaft bearings are

lubricated. See Table 1.

Table 1 - Drive Chain Grease Guide

HU MB L E O IL CO . Neb u la EP 2

TEX A C O IN C

MO BI L OI L CO . Mo bi lte x EP 2

No nv at ex N o 2

Gear Motor - Change oil after first week of oper

ating and 1000 hr or six months thereafter

whichever is earlier. See Table 2.

NOTE: Do not lubricate gear motor while

unit is in operation.

Table 2 - Gear Case Oil

AM BI EN T

AIR T EM P ( F)

25 - 6 0

50 - n o

SU V V IS C O SI TY

SEC 2 1 0(F )

70 - 1 00

125 - 15 0

SA E N O

90

140

OIL

Tex ac o M er op a 2

or E q ua l

Tex ac o M er op a 5

or E q ua l

Drum Rollers - Lubricate every 500 hr or three

months whichever is earlier (use Texaco Regal

AFB2 or equal).

Sludge Pan Bearing - This bearing does not re

quire lubrication.

CLEANING AND INSPECTION

Frequency of tank cleaning is determined by

operating conditions, which may require draining

and cleaning once each week. Clean all foreign

matter from strainer, tank, perforated collection

baskets and control electrodes. Each time tank is

drained and cleaned, check the following:

1. Drive chain and sprockets for wear, alignment,

and proper chain tension.

2. Rubber seal on entering side of drum for tight

ness. Make certain rubber is not damaged.

Page 4

For replacement items use Carrier specified parts

Manufacturer reserves the right to change any product specifications without notice.

Tab 13 29D-lSONew 12-67 Codes C and MF Catalog No. 532-904

Loading...

Loading...