Page 1

Number One

AirCcndifoninq

Maker

------- ' T

1

Division of

^1^ Carrier Corporation

Carrier Parkway • Syracuse NY 13221

f

Solaround™Heat Pump System

PUMP

PACKAGES

SOLAR

COULgCTOS PANELS

WgATHERMASTER iS

<Wt* 2SQX Coil}

© Carrier Corporation 1978

HEAT PUMP

28QX

ENCASEO.COiL

Fig. 1 — Solaround System Components

Form 28QX-1SI

Page 2

Page

SAFETY CONSIDERATIONS............................................4

INSTALLATION

Step 1 — Check Equipment and Jobsite

..................................................................

..........................

4 — 6

4

• UNPACKAGE UNITS

• INSPECT EQUIPMENT

• REVIEW SYSTEM COMPONENT DATA

• COMPLETE SYSTEM REQUIREMENTS AND

CONSIDER SYSTEM RECOMMENDATIONS

Step 2 — Install Weathermaster III

Heat Pump System

..............................................................

6

• MAKE PIPING CONNECTIONS

• MAKE ELECTRICAL CONNECTIONS

Step 3 — Install and Insulate Water Storage Tank ... 7, 8

• TANK LOCATION

• REVIEW STORAGE TANK DESIGN

REQUIREMENTS

• INSULATE STORAGE TANK

Step 4 — Install Solar Collector Panels ........................ 8 — 12

• PLAN PHYSICAL POSITION OF PANELS

• PLAN THE COLLECTOR ARRANGEMENT

AND PIPING CIRCUITS

• CONSTRUCT COLLECTOR SUPPORTS

INDEX

• MOUNT THE COLLECTORS

• MAKE PIPING CONNECTIONS

• LEAK TEST THE COLLECTOR ARRAY

• INSTALL FLASHING, INSULATION AND

FRAME ENCLOSURE

Step 5a — Install Plain Water Pump Package . . .

• MOUNT ON FLOOR

• MAKE WATER PIPING CONNECTIONS

• LOCATE AND INSTALL THERMISTOR

SENSORS AND AQUASTAT BULBS

Step 5b — Install Glycol Pump Package

MOUNT ON FLOOR

MAKE WATER/GLYCOL PIPING

CONNECTIONS

• LOCATE AND INSTALL THERMISTOR

SENSORS AND AQUASTAT BULBS

Step 6 — Make Electrical Connections ....

• INSTALL BRANCH CIRCUIT FUSED

DISCONNECTS

• CONTROLPOWER

INITIAL START-UP

..........................................

MAINTENANCE AND SERVICE DATA . .

Page

12 - 16

16 - 19

20-22

23 -26

26-30

MODEL NO.

28QX036000

280X042000

REFRIG

CONTRJOL

Bypass

Accurater

NET WEIGHT

_Jlb]

95"”

i05

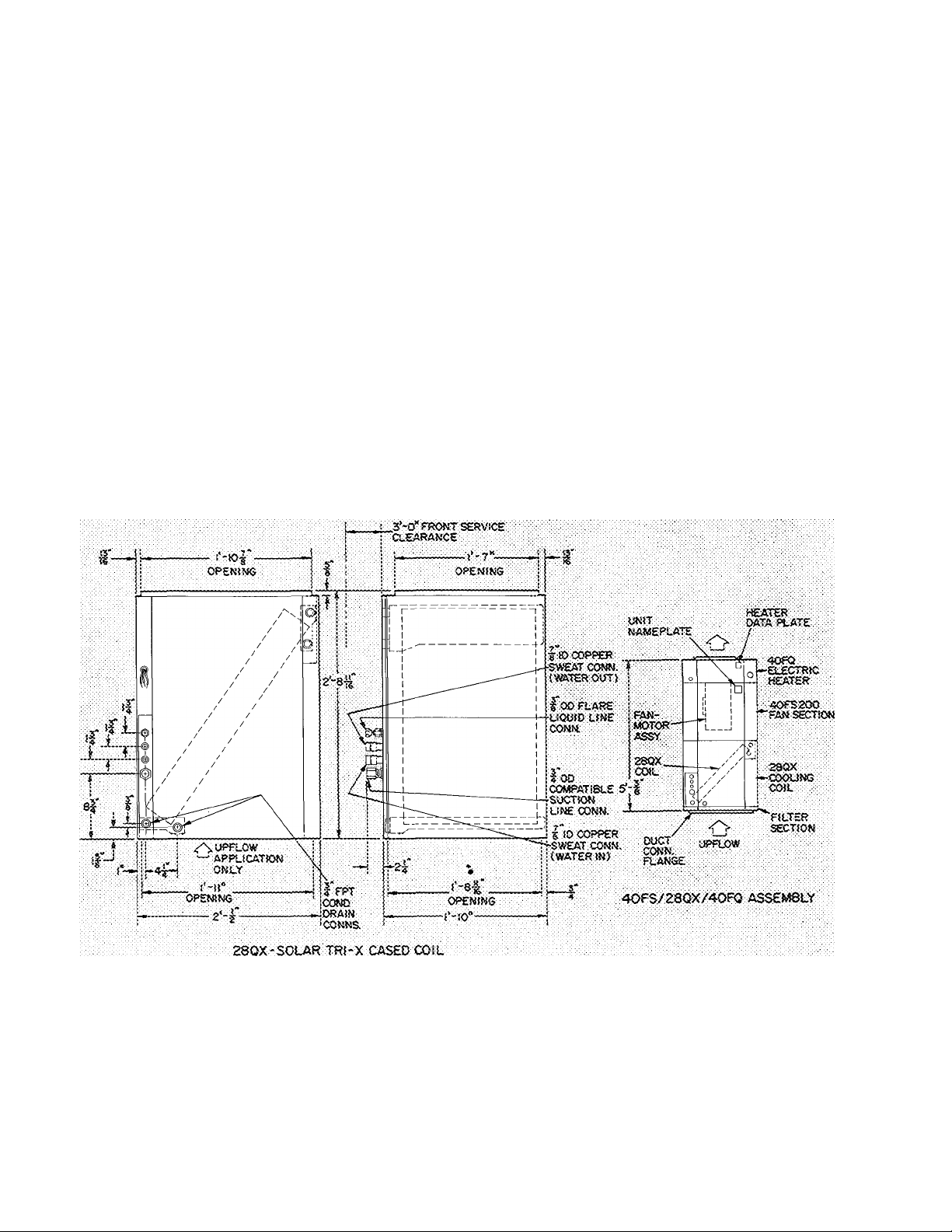

Fig. 2 — Dimensions and Connections

ACCESSORIES

F i Iter Rack

and Filters

Page 3

i FPT i.eAV»M6 l-iQUIO CONN.-

COPPER ABSORBER PLATE —.

SELECTt'.'E SypTACe

♦ FPT £NTER^^K5 WATER 'IXJNNECTiON

PUMP

UM(T

MO.

34GL167

'34gUs7

34GL367

34WA1S7

EXT??ti&£D

ALUMJRUM

ROUSINO

■NSULATiON

yjSE-!N-STR(P ■w£;G.-T7

SOU«i COtueCTOR panel

SiWGl£ GLAZED i !6 L8S

OOUSLE GLAZEO 14S LBS

Fig. 2 — Dimensions and Connections (Cont'd)

34WA257

34ifA367

NOTES;

1, Oimc-nsjiX!s ar.c connecticrw (or :3iiHO/40 r-S outnp

sections are siiow:t in tne instaiiation booklets for those

cnits.

2. Ditriensionai data for field suppiied storage tank varies,

with type and capacity of tank supplied. See Storaije'

. Tank lastaliatiod. Step s.

3

ELEC ; CAPACiTY iNETVfT'i

¡collector;

CHAR. *7 PT W.C.

(Gpin;

2;":

t:.5-;-60P-

! ACCESSORIES

(lb)

2.32

:.;is

C’'cr::c''vi 'C sN-cior

T her.'ri;>:;io-

150

Page 4

SAFETY CONSIDERATIONS

Installation, start-up and servicing of this equip

ment can be hazardous due to system pressures,

electrical components and location of equipment

(roofs, elevated structures, etc.).

Only trained, qualified installers and service

mechanics should install, start-up and service this

equipment.

Untrained personnel can perform basic main

tenance functions of cleaning coils, filters and

replacing filters. All other operations should be

performed by trained service personnel.

When working on the equipment, observe pre

cautions in the literature, tags, stickers and labels

attached to the equipment and to any other safety

precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use caution when handling or working on glass

covered equipment such as solar collectors.

• Use care in handling, rigging and setting bulky

equipment such as storage tanks and solar

collectors. Be sure power to equipment is shut

off before performing maintenance or service.

INSTALLATION

IMPORTAMT; Follow unit location,, height

proxiimty and piping requirements in this

booklet carefully to enhance system efficiency,

and to avoid system failure. Read entire book

let before starting installation.

Step 1 — Check Equipment and Jobsite

UNPACKAGE UNITS — Move units to final

location. Slide units from cartons, taking special

care not to damage service valves, pipe connec

tions, compatible fittings or grilles. Rig solar

collector panels prior to unpackaging to prevent

possible damage, see pg 8.

INSPECT EQUIPMENT — File claim with shipping

company if shipment is damaged or incomplete.

REVIEW SYSTEM COMPONENT DATA - Units

comprising a Solaround''"''^ System are shown in

Fig. 1 and Table 1. Dimensional data in Fig. 2. As

shown, the Solaround includes a standard

38HQ/40FS heat pump system with addition of

equipment to provide solar assistance during heat

ing season. The pump package, solar collector

panels, water storage tank and a section of 28QX

(Tri-X) indoor coil are a water heat transfer circuit.

Heated water, provided by solar panels, is pumped

from storage tank to indoor coil for water-toindoor-air heat transfer.

Accessory Hot Water Preheater reduces energy

required for heating domestic hot water during

cooling and heating seasons.

All Solaround system units are preselected with

the exception of field-supplied water storage tank.

Purchase or fabricate tank according to factory

specifications. See Step 3, pg 7, and 28QX

Application Data booklet.

Tri-X (28QX) Indoor Coil has separate water and

refrigerant circuits essential to the Solaround

system. The Tri-X serves 3 functions: transfers heat

pump (refrigerant) heating or cooling to indoor air;

transfers heat from storage water to indoor air;

transfers heat pump heat and heat from storage

water to indoor air.

The Tri-X is assembled to 40FS fan section and

40FQ electric heater in same manner as other 28

Series coils.

Plain Water or Glycol/Water Pump Package and

Solar Panels -- Water or glycol/water mixture is

pumped thru solar collector panels by pump

package. The liquid absorbs solar heat as it flows

thru the panels and is returned to storage tank

(plain water system) or expansion tank (glycol

system).

Both plain water or glycol systems, when

properly installed, feature fail-safe draining down

of liquid from solar panels to storage tank (when

circulating pump goes off). This prevents freeze-up

damage to panels.

CAUTION: A glycol system }.>5 preferable in

areas where prolonged periods of sab freezing

temperatures occur. Correct solar panel piping,

including a 2-1 /8 in. liquid draindown Kne, is

essential for proper system operation.

Table 1 — Solaround Systems*

PUMP PACKAGES

Water

34WaT67

34WA257

34WA367

*Any size water or glycol pump package and pre-determined number

of solar panels can be used with one of the Weathermaster III heat

pump assemblies above, i e 34WA257, 10 solar panels, 38HQ140,

38HQ960,40FS200/28QX042/40FQ920 - (15 kw) See Solaround

system Application Data booklet for Selection Procedure

Glycol

"31GÌLÌ67 '

34GL257

34 GL 367

SOLAR COLLECTOR PANELS

Min No.

Max No.

30

WEATHERMASTER III HEAT PUMPS

Indoor

Compr

Section

38HQ

J34

. - ^

NOTE:

On 40FQ-25 and 30 kw electric heaters, remove 60-va control trans

former and replace with 75-va transformer (part no HT01 BD235)

available from Carrier Service Parts Center

Outdoor

Coil

Section

38HQ

-

~940

^ 200

-200

^^960

2ÓÒ

Indoor Unit Assembly

Fan

4£FS

Coil

28QX

036^

036

042

Electric Heater

40FQ920-

10 to 30 kw

Page 5

All water supply lines leaving storage must be more than 6 in from bottom of tank but no closer than

2 ft from lowest water level

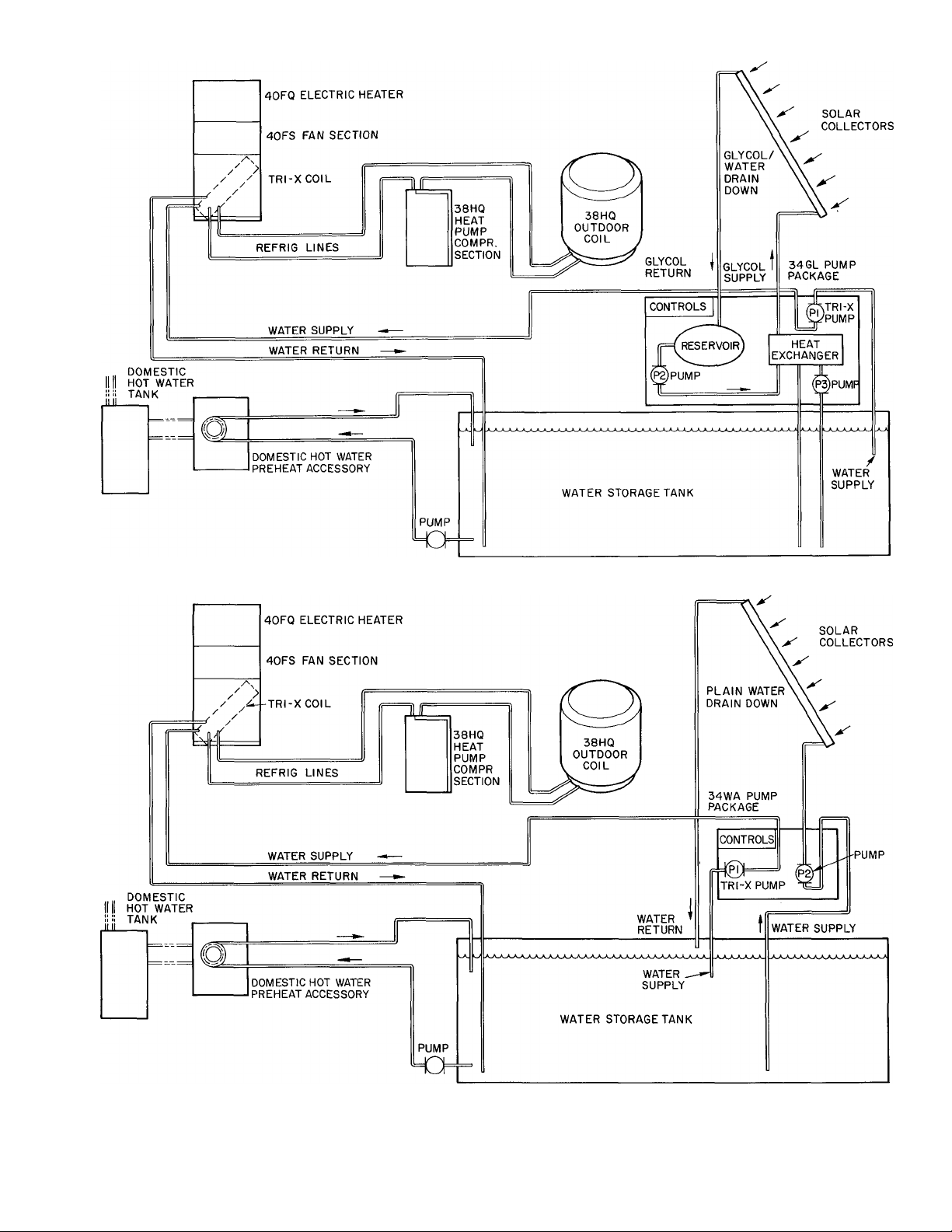

Fig. 3 — Typical Water or Glycol — Solaround System Schematic

Page 6

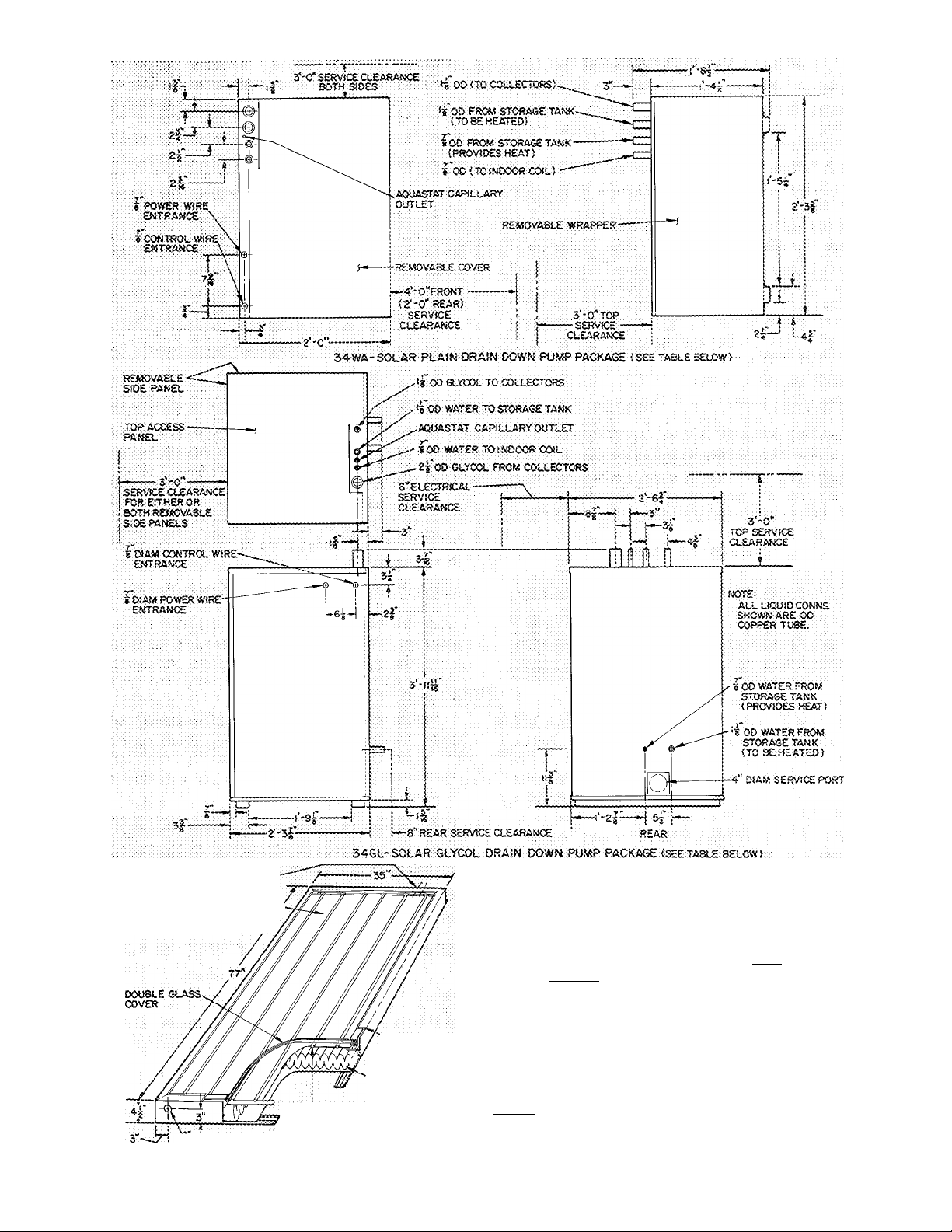

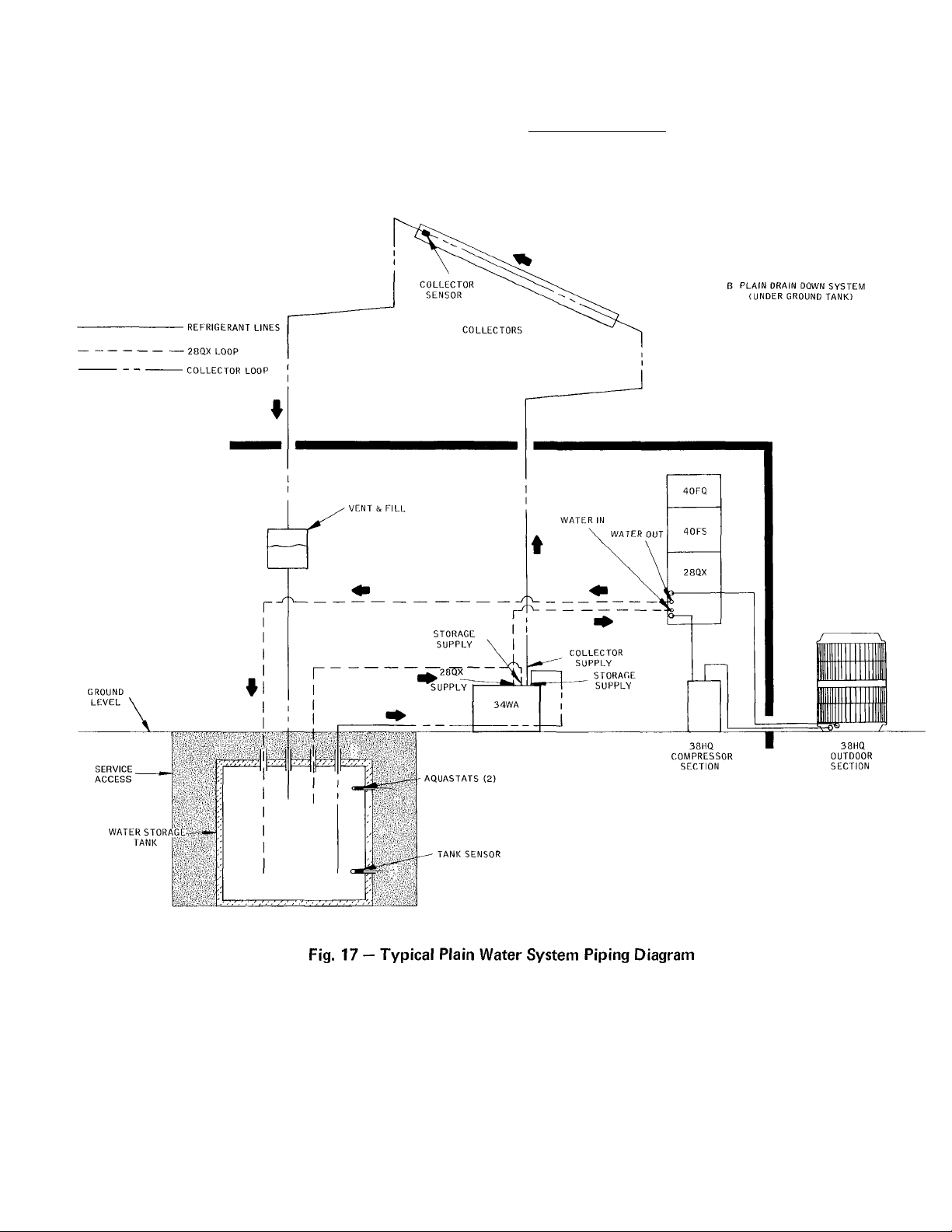

The plain water Solaround'''''^ System has 2

water piping loops — a solar collector panel loop

and a Tri-X coil loop. The glycol system has 3

piping loops — a collector panel water/glycol loop,

a water/glycol to water heat exchanger loop (thru

the pump package), and a Tri-X coil water loop.

See Typical Piping Schematic diagram. Fig. 3. Solar

panel placement on roof must be at correct angle

to absorb maximum amount of solar heat.

Solaround System Selection for each installation is

provided by Carrier Solar CLIC (Computer Load

Information Center). It computes number of solar

collector panels required, angle placement of

panels, volume of water storage tank, supply piping

sizes, and most beneficial accessory hot water

preheating arrangement. Capacity ratings and

system selection data are contained in Solaround

System Application Data.

COMPLETE SYSTEM REQUIREMENTS AND

CONSIDER SYSTEM RECOMMENDATIONS ^

Plan to locate system components as close together

as possible for easier installation, service and higher

system operating efficiency. Use piping schematics.

Fig. 16, 17, 23 and 24, as a guide. Before starting

installation, study remaining system requirements

and installation data, page 4 thru 22. Adjust

component location as required.

WARNING; An improper installation can cause

system to .maifunction and damage could result.

Summary of System Installation Requirements

necessary for proper operation of plain water or

glycol systems:

a. Pitch solar panel piping downward in vertical

plane a minimum of 1/4-in./ft for proper

drainage to storage tank.

b. Vent storage tank with 1/4-in. tubing.

c. Be sure all water pumps have a positive suction

head (minimum liquid pressure at pump inlet)

by locating pumps a minimum of 2 ft below the

lowest water level in storage tank.

d. Install a storage tank drain.

e. Provide a closed loop piping system for Tri-X

coil by terminating inlet and outlet line a

minimum of 6-in. from bottom of storage tank.

f. Horizontal runs of water supply lines leaving

the storage tank must not be above the lowest

water level in storage tank unless a closed loop

system (item e) is used. This prevents lines from

draining and loss of pump prime.

g. Install pump packages indoors and where tem

perature does not fall below freezing.

System Recommendations

a. Locate all indoor equipment, particularly the

storage tank, pump and control package and

fan coil at the same height level and in close

proximity, to each other for easier piping.

It is recommended that the Tri-X coil be at the

highest point in the coil water piping loop but

not more than 6 ft above water level in storage

tank. This ensures easier air venting and elim

inates special water filling procedure, pg 23.

b. Avoid additional installation, service and main

tenance problems by not burying the storage

tank. See pg 7.

c. Do not use any additional valves in piping other

than those that are specified by the installation

instructions.

d. Locate solar collectors directly above pump

package at a height not exceeding 30 ft from

top of water in storage tank to top of collector.

e. Actual length of piping from storage tank to

the pump package must not exceed 15 ft or

remote aquastat installation is required.

Step 2 — Install Weathermaster III Heat Pump

System

CAUTION: Observe all precautions included in

3SHQ and 40FS installation Instruciions.

Follow normal installation procedure for 38HQ

compression section, outdoor coil unit and 40FS

indoor fan coil assembly. (See wiring changes on

pg 20.) Refer to 38HQ and 40FS Installation

Instructions supplied with units. Available acces

sories for the heat pump system can be used

without deviation from an application where the

heat pump alone is installed.

Assemble the Tri-X coil (casing) with 40FS fan

section and 40FQ electric heater in same manner as

other 28 Series coil for upflow airflow. Horizontal

airflow assemblies are permissible, but require a

field fabricated horizontal condensate collector.

Unit cannot be installed in downflow position. Coil

inlet duct connection flanges are provided on 40FS

filter section rack. It is recommended that as

sembled fan coil be located in same area as other

interior system components, with the Tri-X at

highest point in water piping loop but not more

than 6 ft above water level in storage tank, pg 13.

The fan coil can be located elsewhere with restric

tions placed only by the allowable length of

interconnecting refrigerant tubing.

MAKE PIPING CONNECTIONS - Tri-X coil has

Compatible Fitting refrigerant line connections and

copper pipe stubs for water line sweat connection.

Replace the AccuRater'^^ refrigerant control

piston in the Tri-X coil as required before connec

ting refrigerant lines. See Table 2 for piston sizes.

Make refrigerant line connections. Use a back-up

wrench on AccuRater when making refrigerant

liquid line connections. Follow recommended

piping length in 38HQ booklet.

Water line connections are described under Step

5a and 5b.

MAKE ELECTRICAL CONNECTIONS

See

Step 6 on pg 20 for wiring connections.

Page 7

Table 2 — Accu Rater Refrigerant Control

Piston Data

OUTDOOR

INDOOR

COMPR

SECTION

38HQÌ27

38HQ134

38HQ140

'■'Standard factory-installed AccuRater piston. Remaining

" pistons are field installed

Step 3 — Install and Insulate Water Storage Tank

COIL SECTION

Required

Model

38HQ945 3

38HQ940

38HQ960 s

AccuRater Model

Piston (no.)

4

INDOOR COIL

Required

AccuRater

Piston (no.)

28QX036 5

28QXÓ36 6

28QX042

3

CAUTION: A large storage tank full of water

weighs several ions (l-gal. of water weighs 8.3

jbs). Structure must be able to support wei^it

of full tank. Use care wlren rigging, handling

and setting tank in place. Buried tanks are not

recomraended.

Capacity of tank (gal.) is specified by Carrier

Solar CLIC program. See Application Data for

storage tank design parameters. Review essential

tank design requirements.

Use correct type of tank for building configura

tion and construction status: Full or partial

basement, crawl space or slab-on-grade; new con

struction versus existing building (retrofit). Loca

tion of storage tank inside existing building generally

requires vessels which can be assembled on site.

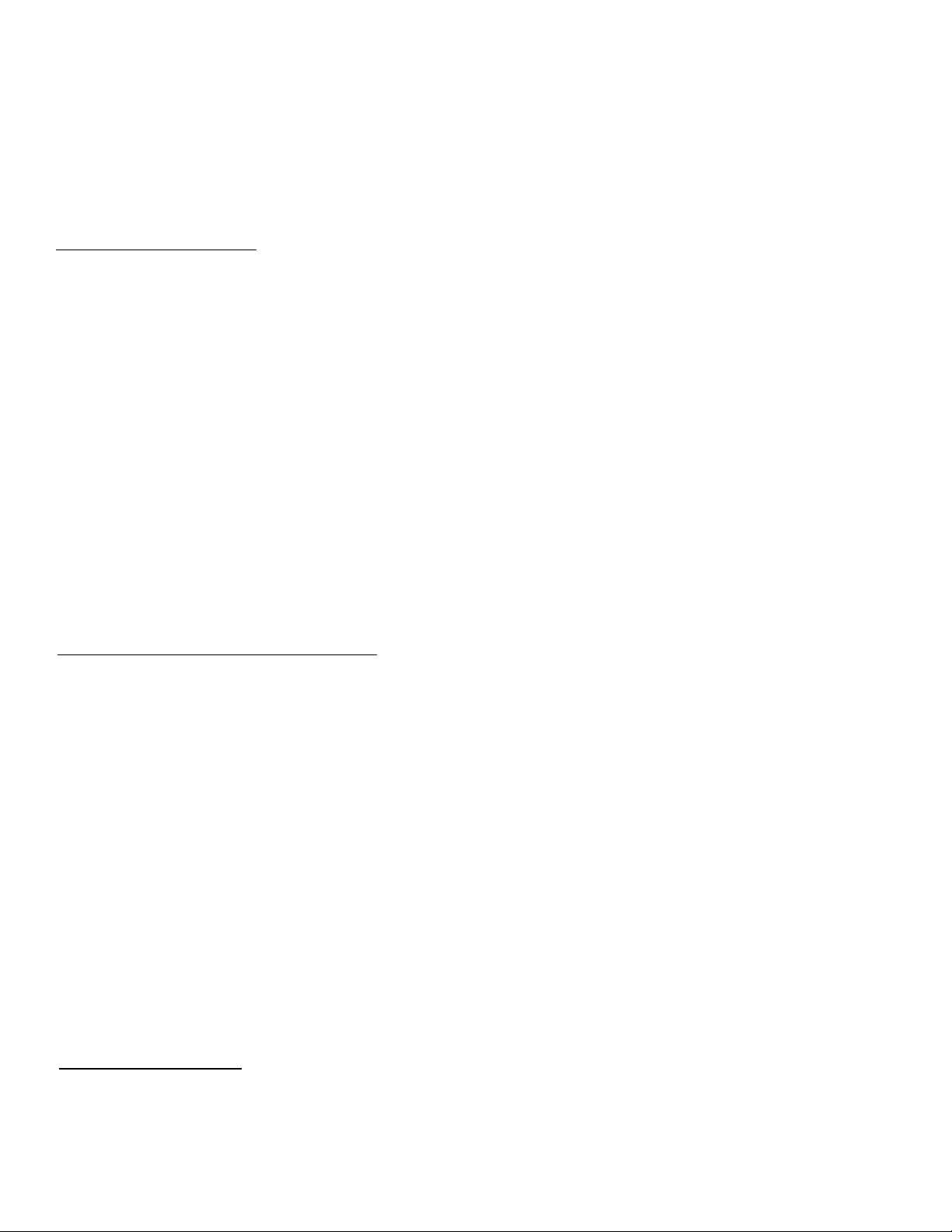

TANK LOCATION — Use an indoor, above ground

tank whenever possible. Do not install tank where

temperature falls below freezing. Consider total tank

weight full of water (a full 1000 gal. steel tank

weighs over 4 tons), possible condensation and water

leak problems, and Solaround’''''^ System compo

nent location and piping requirements (pg 6).

Above or below ground tanks require a top man

hole (access) cover and service/maintenance area

adjacent to piping, aquastat and thermistor sensor

location (see pg 14). When excavating for below

ground tank, provide service clearance as indicated.

,— SERVICE AREA—,

REVIEW STORAGE TANK DESIGN

REQUIREMENTS

1. Size — The tank should be sized to hold

approximately 1.5—2.5 gal./ft2 of solar

collector area; 750 to 2000 gallons.

2. Temperature — The tank must be able to

withstand an operating temperature range of

80 F to 200 F without degradation.

3. Durability — The tank must provide a mini

mum life of 20 years.

4. Construction — The tank must be leak resist

ant. It will be necessary to treat some tanks

(concrete, wood) to ensure leak resistance.

They must also resist corrosion and chemical

or moisture deterioration. They must be able

to withstand the hydraulic pressures exerted

by their contents.

5. Shape — The shape will be optimum when the

surface to volume ratio is a minimum (to

reduce insulation requirements). It is best to

use a tank that will require a minimum of

structural and support framing.

6. Serviceability — The tank must have an access

hole to provide for servicing and maintenance.

It must have openings available for placement

of sensors (pg 14) and for inlet and outlet

piping. The outlet piping must be: minimum

6-in. from bottom of the tank to preclude

fouling or sediment; at least 2-ft from top of

the tank so that the water pumps will have

their required suction head (supplied by the

tank’s hydraulic pressure). See Fig. 13. There

must be provision at the top of the tank for an

atmospheric vent.

7. Heat Retention — The tank must provide a

high degree of heat retention. Insulate entire

tank (including bottom) to an insulation value

of R-20. Insulation must be kept dry.

8. Codes — The tank must be in conformance

with local codes. A recommended guide is

HUD Intermediate Minimum Property

Standards.

9. Make drain provision.

10. Clean tank prior to use.

, c=:

-cz

■ - ^

■'I

, -

Disadvantages of below ground tank include:

difficult to install, insulate and maintain; limited

service access to piping and controls; higher risk of

freezing; tank leaks may be nondetectable; a leak

into tank can cause water fouling and system

damage. A rise in ground water level and a partially

filled tank can result in tank floatation and

possible damage or hazard. Insulation of buried

tanks can also be adversely affected by soil

conditions and moisture.

Fig. 4 — Typical Steel Tank

Page 8

INSULATE STORAGE TANK - Prior to making

the tank installation, consider that the tank will

have to be insulated. The insulation will have to be

placed all around the tank, including underneath it.

This can be accomplished by either placing an

insulating pad beneath the tank (one which can

carry the weight without degrading) or by mount

ing the tank on channels. The channels should be

high enough to accommodate the necessary thick

ness of insulating material. Tank should not be

completely insulated until it is leak tested. See

Initial Start-Up on pg 23. The recommended

insulation level for indoor tank locations is R-20.

Acceptable insulation materials depend upon the

tank type and location. Use only non-toxic

insulating material. Typical insulation and thick

nesses for R-20 are:

Extruded Styrofoam (not bead board)

with skin

Urethane

........................................................

4-1/2 in.

................................................................

4 in.

Fiberglass, Batt......................................................6 in.

Fiberglass, High density board

.............................

5 in.

Indoor Locations

a. Insulation must meet HUD flame spread limits

as follows (ASTM E84-70):

Plastic Foam 25

Other 150

b. For moisture permeable tanks such as concrete

or wood, the insulation should be designed to

avoid trapping moisture. Low permeability

closed cell foam insulation should be used. If

fiberglass is used, a moisture barrier should be

provided at the tank surface; and if a cover is

used over the fiberglass, it must be permeable

(such as canvas).

c. Tank lids or manholes must have a positive seal

to prevent moisture loss into the insulation or

the occupied space. Lid or indoor cover must

have positive lock in open position so that

servicing can be done safely. Do not enter tanks

without person(s) capable of pulling you out of

tank in attendance.

Outside Locations (not recommended)

a. Recommend foam in place of urethane insula

tion, or closed cell foam insulation boards such

as urethane and styrofoam.

b. Recommend a plastic film (10 mil poly

ethylene) liner for the excavation, into which

the preinsulated tank is placed, or into which

the insulation is foamed around the tank. Do

not cover controls or piping with foam. Sealing

of joints in slab type insulation should be made

with mastics or adhesives recommended for the

type of insulation used. Consider tank freeze-up

protection.

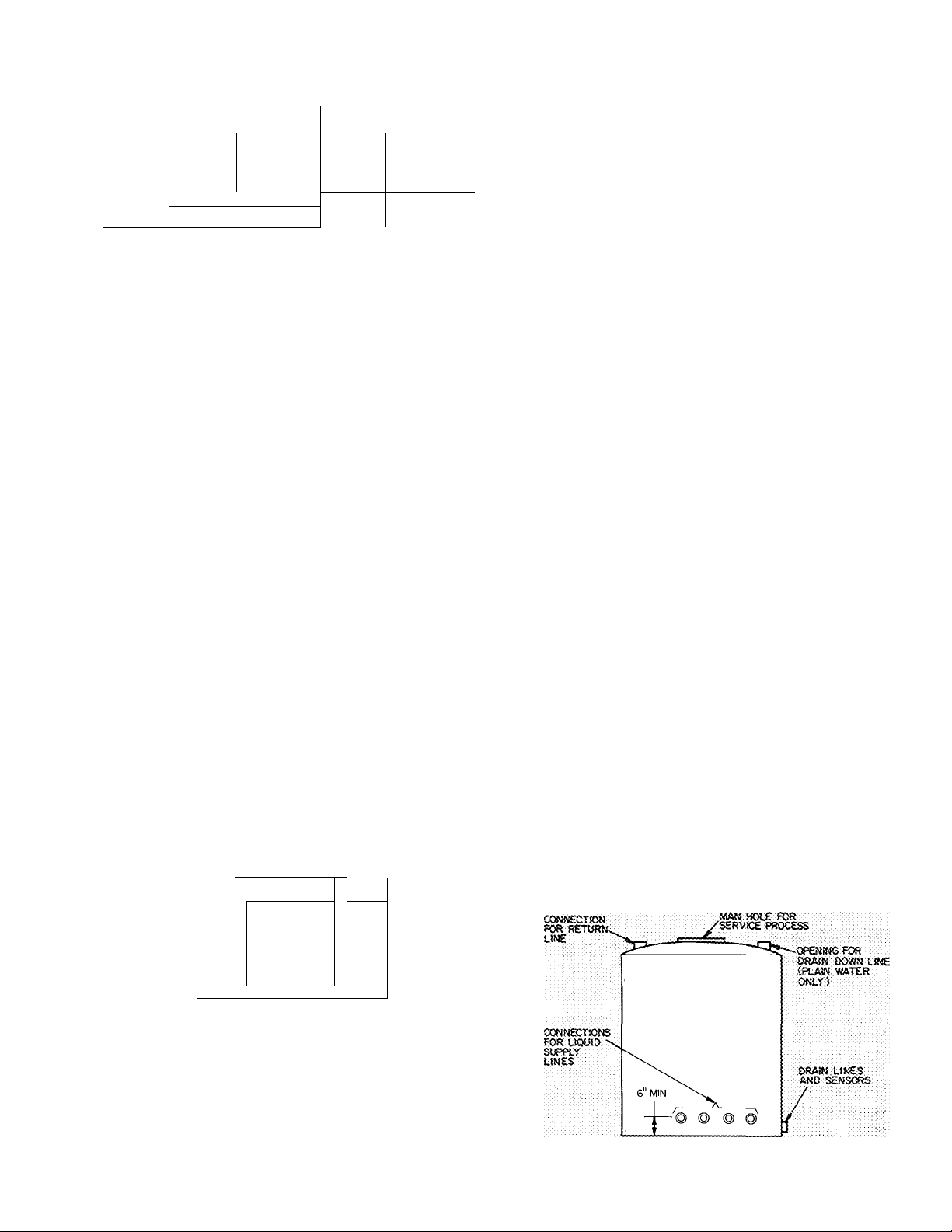

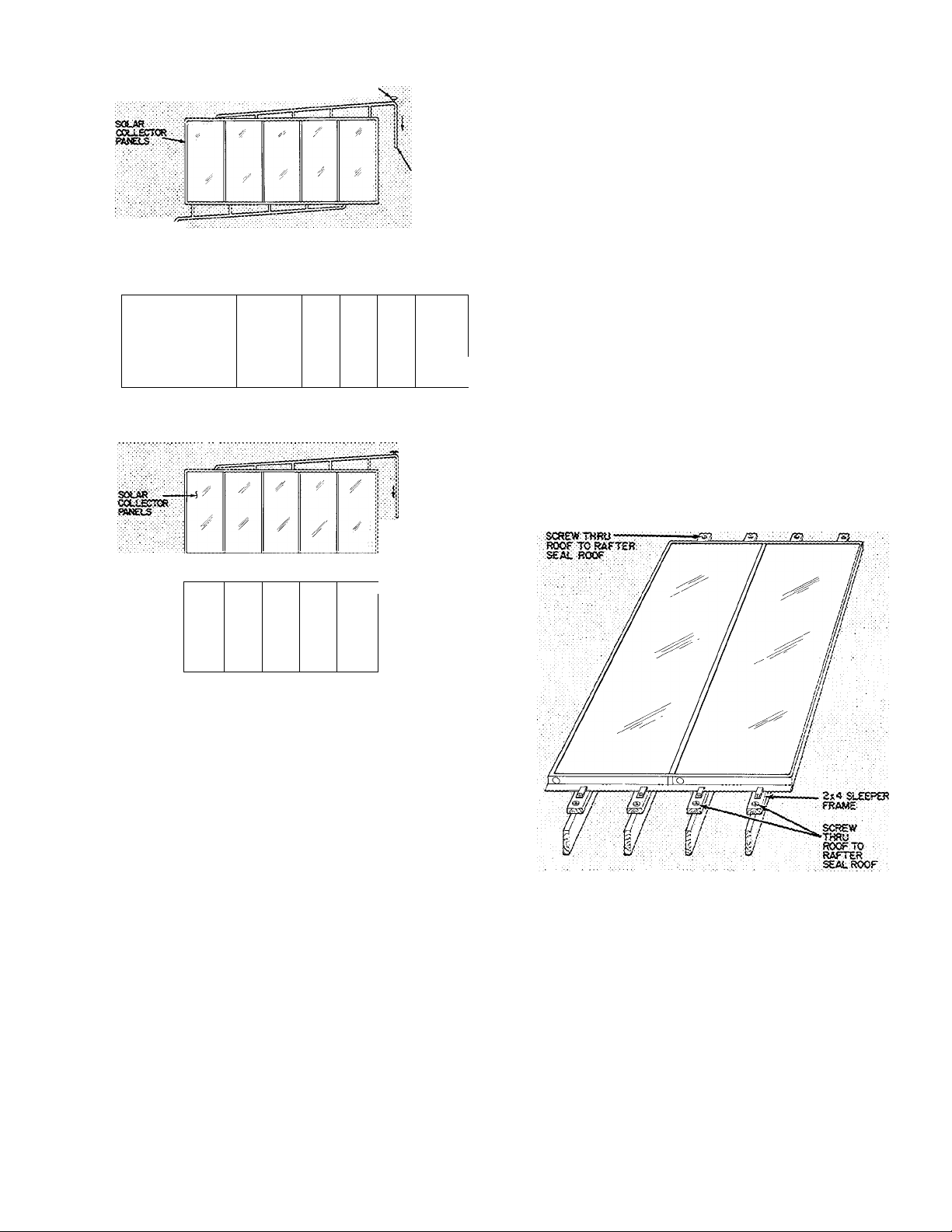

Step 4 — Install Solar Collector Panels

CAUTION: Be careful rigging, handling and

installing solar coiiectoxs. Tops of coHectors are

^ass and ЪгеакаЫе.

Rig and lift collecior(s) to roof before un

packaging from shipping crate or carton. Lift

with boom tnick or crane. If Iiand-Iifted to

roof, slide single collector up 2 ladders vrith a

guide rope on top and 2 men on roof pulling on

rope and taking weight off 2 men below. Use

extreme caution not to lose balance or control

of rope.

RIGSiNG A CRATS OF COLUSCTORS

ROiSTiNG A SlNGtX COLLECTOR UP TWO LADDERS

Do not use solar collector as a primary' roof

surface. Mount them on a roof constructed to

good roofing standards.

Properly seal all entries thru roof including

where collector sleeper frame or mounting

frante is attached to roof.

Flash sieeper frame or mounting franre to

prevent entry' of moisture and ice or snow

build-up beneath collectors installed in areas

where subfreezihg temperatures occur.

Number of panels required, mounting angle

(slope) of panels and liquid supply pipe size (OD)

is specified by Carrier solar CLIC program and

included in job plans. Refer to Fig. 2 for panel

Page 9

PRESSURE R£U£F mVE

ÎSI.VCOL SlfS^MS OWW '

EfOD.

RETliRN

UNE

SETORfi

i:

!•. ■

'i

~~ir

supply

„2^00

RETUSti

LSŒ

R£T«i»t

headers a minimum of 114-in.lft in vertical plane

for acceptable panel drainage. A slope of 3/8-in./ft

or 1/2-in./ft assures better panel drainage.

CAUTION: For proper system operation,

install eoilectors in recommended pattern arid

slope horizontal Ijeaders as specified, incorrect

instaliation can result in extensive system and

building damage.

Colleciors are made of ^ass. Use care in rigging

and handling. Do not use panels as primary roof

surface.

CONSTRUCT COLLECTOR SUPPORTS - Con

struct a framework to support the collectors based

on panel arrangement and circuiting pattern.

1

If the slope of the roof is the same as that

required for the collectors, construct a wooden

“sleeper frame.” Use 2-in. x 4-in. boards that lay

directly on the roof. Fig. 6. Construct frame so it

can be flashed and sealed. This prevents moisture

from accumulating behind the collector. Treat

sleepers with wood preservative and paint.

/

'

'

/

NCfTE;

^KR■ RECWitttENOEO DUE TO OECREASED EPFICSR«

HOWEVER ROOP /WEA L«frAT50NS MAY liECESStTSTE

TUB ARRANSEMcRT.

Fig. 5 — Collector Arrangements

'/

/

/

dimensions. Complete the following steps to install

panels:

PLAN PHYSICAL POSITION OF PANELS - For

maximum heating capacity, face the collector

panels due south ± 5 degrees. The angle or slope of

the collectors above the horizontal plan is normally

the latitude of the installation 15 degrees. Any

deviation from specified mounting position can

result in reduced heating performance. Be sure not

to place collector panels in areas shaded by trees or

buildings during portions of the day when sig

nificant amounts of solar energy can be obtained.

PLAN THE COLLECTOR ARRANGEMENT AND

PIPING CIRCUITS - There are 2 collector mount

ing arrangements recommended for installation in a

specific space, and for correct piping circuits. See

Fig. 5. Butt collectors next to each other to

minimize heat losses. Slope horizontal piping

NOTES:

1 Treat framing with preservative

2 Flash framing to prevent entry of moisture in subfreezing cli

mates (See Fig 11 )

Fig. 6 — Typical Collector "Sleeper" Framing

If an upright mounting frame is required, use

2-in. X 4-in., 2-in. X 6-in. (or heavier) boards or

aluminum framing material. Construct and install

frame perfectly level to the horizontal plane.

Locate bottom frame members directly over roof

rafter. Anchor the frame to roof rafters with

screws. Seal anchor points thoroughly to prevent

water leakage. A typical mounting frame is shown

in Fig. 7. There should be no horizontal surfaces

within 3 ft of the framebase, so that drifting snow

cannot accumulate on collectors.

Page 10

Fig. 7 — Typical Collector Mounting Frame

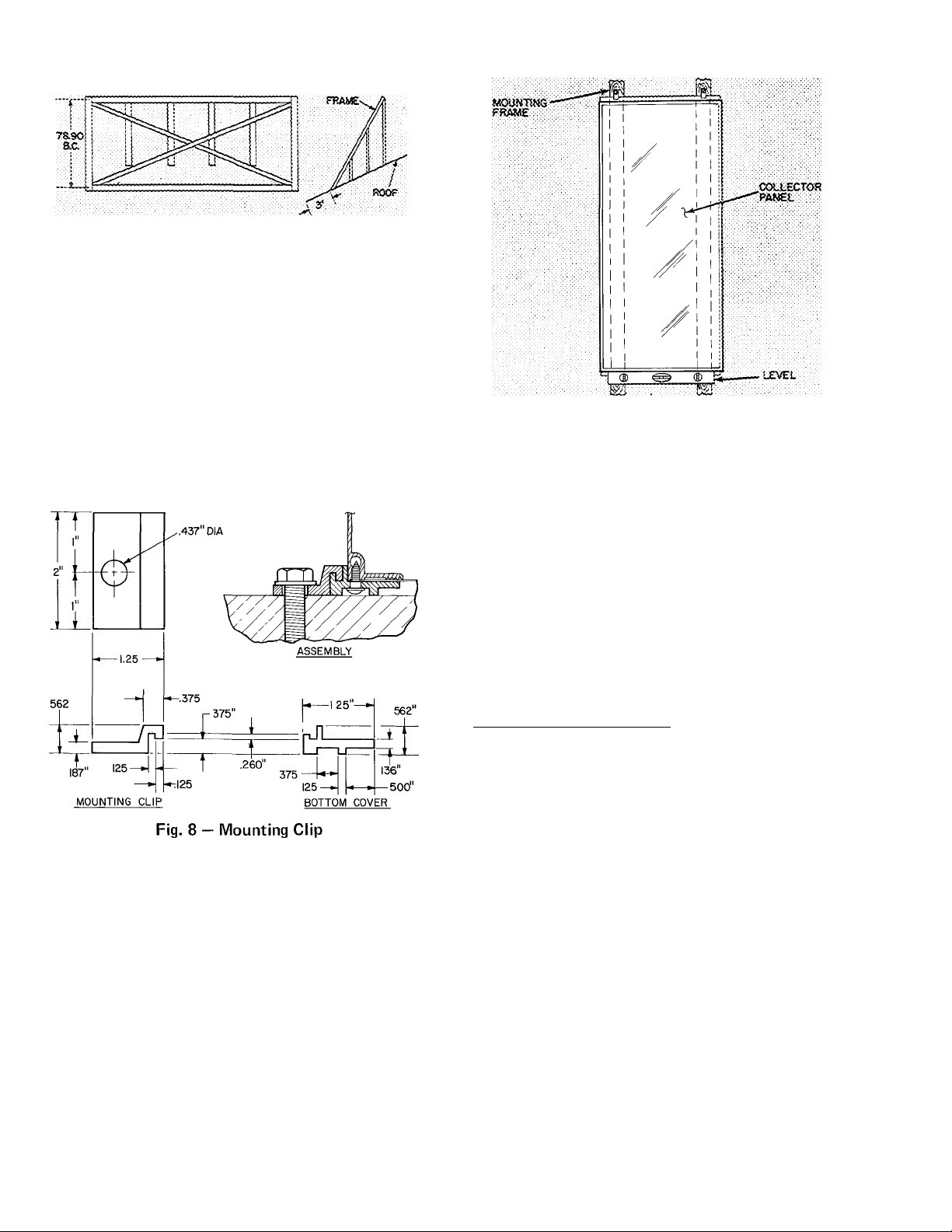

MOUNT THE COLLECTORS on completed frame

or sleepers. Lasten in place with four mounting

clips supplied with each collector. Use 2 clips on

each end of the collector. See Fig. 8. Each clip has

a .437-in. diameter hole to accept a field supplied

mounting screw. Use a level to align the collectors

exactly parallel to the horizontal plane, Fig. 9.

NOTE: There is no fixed top or bottom to a

collector. It can be installed either way,

although it may be preferable to install so

nameplate can be read.

NOTE: Supply and return piping must be sloped

Fig. 9 — Collector Panel Leveling

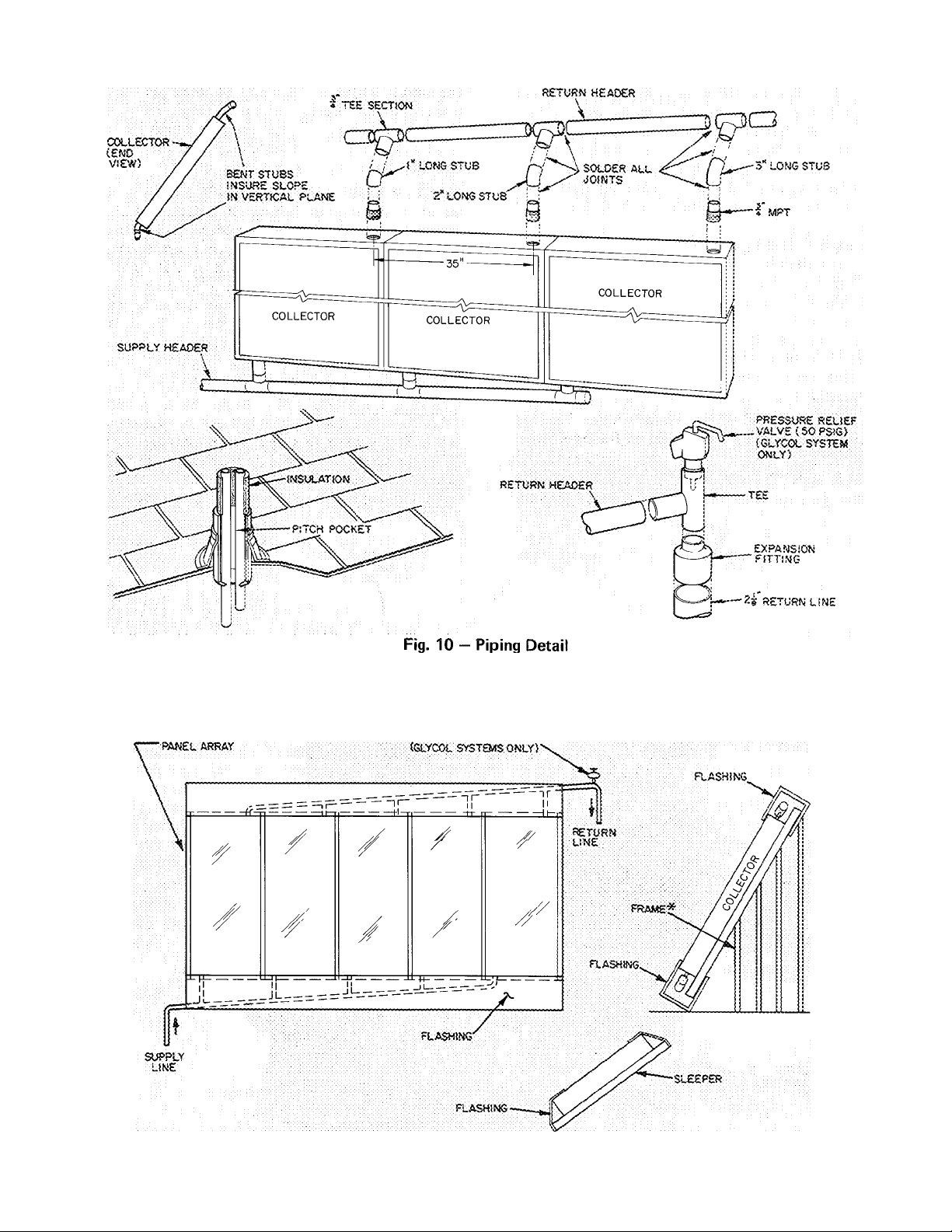

attached into the collectors and solder the headers

onto the stubs (Fig. 10). Solder the supply and

return lines in place. Install a tee with a pressure

relief valve between the leaving header and 2-1/8

in. return pipe. Use an ASME approved pressure

relief device with a 50 psig set point and a manual

release lever. (See Leak Testing below.)

If it is necessary for return and supply pipes to

penetrate the roof, install a pitch pocket to seal the

opening.

Install the Collector Sensor on an interior collector

panel after headers have been soldered in place.

Sensor location and method of attachment is

described on pg 15.

MAKE PIPING CONNECTIONS - Attach supply

and return piping headers and lines to collectors.

Piping supply line size is specified by Solar CLIC.

Return line is 2-1/8 in. O.D. on all systems. See

Fig. 10. The headers can be completely pre

fabricated. Determine distance between the

collector inlet connections and outlet connections

(35-in. if panels are butted up to each other). Make

headers with regularly spaced T-sections to mate

with the inlet and outlet of the collector array.

Acquire two 3/4-in. MPT to 3/4-in. sweat

copper fittings for each collector. To each fitting,

solder (95-5) a 3/4-in. copper pipe stub of appro

priate length to maintain a minimum vertical

1/4-in. slope/ft of header. It might be necessary to

bend the copper stubs to maintain this vertical

slope. Thread the fittings with copper stub

LEAK TEST THE COLLECTOR ARRAY ^ Using

city or well water with a minimum pressure of 30

psig, leak test the collectors and piping as follows;

;a. Soft solder (50-50) a temporary cap or end of

2-1 /8 in. collector return line.

b. Attach water supply line to collector supply

pipe.

c. Fill collector array with water using release

lever on pressure relief valve (Fig. 10) to bleed

air from collector system. If relief valve does

not have a manual release lever, temporarily

replace the relief valve with an air bleed valve.

d. Leave water pressure on to system and check

collectors and piping for leaks per local codes.

e. If leaks occur, drain water from system by

removing water pressure source. Repair leak

and repeat steps b, c, d and e.

f. Using a tubing cutter, remove temporary cap

from 2-1/8 in. return line. (This liiie will be

filled with water.)

10

Page 11

COU.SCTOR

‘Enclose exposed frame members to prevent moisture entry and soil effect

Fig. 11 — Lx)cation of Flashing Material

Pf?£SStiR£ RELIE" VALVE

11

Page 12

INSTALL FLASHING, INSULATION AND

FRAME ENCLOSURE after system has been leak

checked. Completely insulate piping with 3/4-in.

closed cell flexible rubber insulation such as

Armaflex or Rubatex. Eiberglass insulation may

also be used, however, any non-rubber insulator

must be waterproofed. Do not leave any portion of

tubing uninsulated or significant heat losses will

result.

Install a flashing over both header assemblies to

make installation weathertight, Fig. 11.

Complete the collector panel installation by

enclosing the exposed sections (ends and back) of

wooden mounting frame. Wind can lift an exposed

frame and dislodge panels. Use 1/4-in. exterior

grade plywood or similar lightweight material. This

provides some protection from wind damage, and

snow buildup.

Step 5a — Install Plain Water Pump Package

specified by Carrier. Review System Requirements,

Pg6.

MOUNT ON FLOOR — Plain water pump and

control package (Fig. 12) can be mounted directly

on a floor. A fixed mounting is not necessary as

the unit’s weight is sufficient to keep the unit in

place. Provide service access at rear, front and

sides of unit. Fig. 2. If the floor on which the unit

is placed is subject to flooding, raise the unit so

that the flood water cannot enter the unit.

MAKE WATER PIPING CONNECTIONS - Use

water grade copper tubing or better. Sweat all

connections and joints with solder (95-5). Tubing

sizes for solar collector piping loop are specified

(by Carrier) for system. (A 2-1/8 in. OD collector

loop return line is used on all systems.) Tubing

sizes for Tri-X coil water loop and domestic water

preheating piping are shown below. Four pipe

connections are required on plain water pump

package, Fig. 2. Typical piping diagrams for com

pleted systems are shown in Fig. 16 and 17.

Collector Loop (Fig. 13) — Begin this loop with a

1-1/8 in. pipe leaving the bottom of the storage

tank. The pipe enters the pump package at the

“storage supply” (second from right) stub. After

passing thru the collector pump, (No. 2), the loop

exits the unit at the “collector supply” stub and

#

LOW VOLTAGE

TERMINAL COMPARTMENT

NON-ADJUSTABLE

AQUASTAT

ADJUSTABLE AQUASTAT

CONTROL

BOX ■

WATER CONN

TO TRI-X

WATER CONN. FROM

STORAGE TANK

(TO BE .HEATED)

WATER CONN

TO SOLAR

COLLECTORS

WATER CONN. FROM

STORAGE TANK

(PROVIDES HEAT)

TRI-X COIL PUMP

(P|)

BALL VALVES

SOLAR COLLECTOR

PANEHS) PUMP (P2)

Fig. 12 — Plain Water Pump Package (Panels Removed)

12

Page 13

travels to the collectors. From here the loop goes

back to the storage tank thru a 2-1/8 in. pipe. This

down pipe terminates above the highest water level

in the storage tank and must have all horizontal

runs of tubing pitched downward a minimum of

1/4-in ./foot.

A pitch of 3/8-in./ft or l/2-in./ft is acceptable

and provides better drainage than 1/4-in./foot. It is

critically important that this pitch be incorporated

into the horizontal runs. It will assure a properly

draining system and will avoid system failures.

The pipe leaving the storage tank must be at

least 6-in. from the bottom of the tank. The run of

pipe to the pump package must not be less than

2 ft below the lowest water level in the tank. This

condition will assure that the collector pump will

have its required prime at all times. Insulate both

collector supply and collector return piping legs.

b. The pipe leaving the storage tank must always

be at least 2 ft below the lowest water level.

c. It is recommended that the 28QX coil be the

highest point in the loop. This will make the

bleed valve on the coil an effective air bleed

port. If it is not possible for the coil to be the

highest point, it will be necessary to add a field

installed air bleed valve at the highest point in

the loop.

d. If the 28QX coil is more than 6 ft above the

water level in the storage tank, it will be

necessary to employ a special fill-up procedure.

This will entail adding a booster pump and

pump fitting in the pipe between the pump

package and the 28QX coil. See the Start-Up

Instructions pg 23 for details concerning this

procedure.

RETURN

■■ ■

TERMitiATt BELOW

LOWEST WATER

LEVEL i

Fig. 13 — Solar Collector Panel(s) Piping Loop

on Plain Water System

28QX (Tri-X) Coh Loop (Fig. 14) - This loop

begins with a 7/8-in. pipe leaving the bottom of the

storage tank and entering the pump package at the

7/8-in. stub labelled “storage supply”. The loop

continues thru the Tri-X pump (P-1) and out the

pump package thru the 7/8-in. stub labelled

“28QX supply.” This pipe enters the Tri-X coil at

the “water in” stub. It exits the coil at the “water

out” stub and goes back to the storage tank (top or

bottom entry).

The pipe size and allowable lengths for the

entire loop are listed below. A value of 4 ft should

be used for the length of tubing inside the pump

package.

ALLOWABLE PIPE LENGTHS

Pipe Q.D. (in.)

7/8

1

1-1/8

Maximum Equivalent Length (ft)

60

120

240

Fig. 14 — Tri-X Coil Piping Loop

on Plain Water System

THERMjSrOfi

tNSL'LATtOK

There is no mounting height restriction on the

Tri-X coil since it is in a closed loop system. There

are, however, other installation restrictions:

a. The termination points of the loop (in storage

tank) must always be below the lowest water

level.

13

(«TERK»

panels

Fig. 15 — Collector Thermistor Location

Page 14

LOCATE AND INSTALL THERMISTOR SEN

SORS AND AQUASTAT BULBS - Located in the

low voltage terminal block compartment of the

control box are 2 thermistor sensors and 3 bulb

wells, Fig. 18.

Two of the bulb wells are to be used with the

aquastat bulbs located on the control box in pump

package, Fig. 12. These wells are to be inserted in

the storage tank so that the aquastat bulbs are

located at the same level in the storage tank as the

outlet to the Tri-X pump. The aquastats are bulb

and capillary refrigerant charged sensors. The

capillary tubes are 20 ft long. Consequently, the

pump package should be placed with this restric

tion in mind.

If it is necessary, the aquastats may be removed

from the control box and mounted close to the

storage tank. If this approach is taken, 14 gauge

wire should be used to connect the aquastat to the

appropriate wires out of the control box.

Thermistor Sensor Mounting — Mount sensors so

that good thermal contact is maintained. A small

amount of G.E. insulgrease #640 (field supplied)

between the sensor and the interior tube of the

solar panel array and also in the well used on the

storage tank sensor is recommended to improve

thermal contact.

Storage Tank Thermistor — The thermistor is not

submersible and should be placed in the remaining

bulb well at the same level in the storage tank as

the outlet to the collector pump.

#

All water supply lines leaving storage must be more than 6-in from bottom of tank but no closer than

2 ft from lowest water level

Fig. 16 — Typical Plain Water System Piping Diagram

14

Page 15

Solar Collector Panel Thermistor ~ The collector

thermistor should be placed on the leaving tube on

an interior panel in the panel array. One of the

interior panels should be used because of reduced

edge losses and higher performance. The thermistor

should be butted up against the panel and secured

in place on the tube with a hose clamp, as

illustrated in Fig. 15. Do not overtighten clamp.

Insulate sensor and tubing.

Thermistor Wiring — (See Electrical Data and

Wiring, pg 20.)

15

Page 16

BULB WELL

WATER CONN TO

STORAGE TANK

GLYCOL/WATER CONN.

TO SOLAR COLLECTORS'

GLYCOL/WATER i

HEAT

EXCHANGER

WATER CONN TO

'TRI-X COIL

, ^ , GLYCOL/WATER CONN. FROM

1 ^

-----

'^OLAR COLLECTORS

THERMISTOR

SENSOR

Fig. 18 — Thermistor Sensor and Bulb Well

HEAT

EXCHANGER

PUMP (P3)

SOLAR

COLLECTOR

PUMP (P2)

WATER CONN. FROM STORAGE

TANK (PROVIDES HEAT)

BALL VALVES

GLYCOL

LEVEL

SIGHT GLASS

Fig. 19 — Glycol Pump Package (Panels Removed)

Step 5b — Install Glycol Pump Package specified

by Carrier. Review System Requirements, pg 6.

The glycol system is composed of the same

components as the plain water system with dif

ferences only in the pump and control package.

Follow same installation requirements and

recommendations indicated for the plain water

system including solar collector and storage tank

installation found in Steps 3 and 4.

MOUNT ON FLOOR — The glycol pump package

(Fig. 19) can be mounted directly on a floor. If the

floor space is subject to flooding, elevate the pump

package so that flood water cannot enter the unit.

Provide service access at the rear, front, top and

sides of unit as shown in Fig. 2.

MAKE WATER/GLYCOL PIPING CONNEC

TIONS — Use water grade copper tubing or better.

Sweat all connections and joints with solder (95-5).

Tubing sizes for solar collector piping loop are

specified (by Carrier) for system. Tubing sizes for

Tri-X, coil water loop, heat exchanger loop and

domestic hot water preheating piping are shown

below. Size pipe connections are required on

Glycol systems. Fig. 2. Typical piping diagrams for

completed systems are shown in Fig. 23 and 24.

Fig. 20 — Solar Collector Panel(s) Piping Loop

on Glycol System

Collector Loop (Fig. 20) — This loop begins at the

“collector return” stub at top of the pump package

(2-1/8 in. O.D. pipe). It travels thru the expansion

tank, pump and heat exchanger and out of the

pump package thru the “collector supply” stub

(1-1/8 in. OD). The glycol travels thru the collec

tors and back thru the drain down pipe to the

beginning of the loop.

16

Page 17

#

Any field installed run of horizontal tubing in

the collector loop must be pitched downward a

minimum of 1/4-in. per foot. A pitch greater than

1/4-in./ft, such as 3/8-in./ft or 1/2-in./ft, is accept

able and better than 1/4-in./ft. This pitch require

ment is critical to the installation because failure to

incorporate this requirement will result in system

failure. A l/4-in./ft pitch (min.) and specified

tubing sizes allow positive liquid drainage.

The size of tubing to be used in the “collector

supply” leg of the loop is specified by Carrier.

Both “collector supply” and “collector return”

legs must be insulated.

Add a field procured and installed component

to the “collector supply” leg of the loop — an

ASME approved pressure relief device with a 50

psig set point (not required on plain water system).

Install in a T-joint in the conditioned space side of

the “collector supply” leg. The device should not

project into the supply leg pipe (see detail A of

Fig. 20).

wa,TER

OUT N

|! ¡[WATERin- , j

eXPAiiSlON

TANK

STORAOE

SUPPLY ■

Fig. 21 — Tri-X Coil Piping Loop on Glycol System

2SQX

SUPPt-Y

SUPPLY

■'I

RETUSN

,, , ,

JU

TERMIMATE

8£L0W

LOWEST

WATE3R LEVEL

28QX (Tri-X) Coil Loop (Fig. 21) — The loop

begins in the storage tank with a pipe at the

bottom of the tank. This pipe exits the tank

bottom and goes to the rear of the pump package

to the left-hand stub labeled “storage supply.” The

loop continues thru a pump and out of the pump

package thru the “28QX supply” stub. The loop

continues to the 28QX coil where it enters at the

“water-in” stub. After traveling thru the coil, the

loop exits at the “water-out” stub of the coil and

returns thru the top or bottom of the storage tank.

(This loop must terminate below the lowest water

level.)

The pipe size and allowable lengths of this loop

are listed below.

ALLOWABLE PIPE LENGTHS

operates in a closed loop system. There are,

however, other restrictions.

a. The termination points of the loop (in storage

tank) must always be below the lowest water

level in the storage tank for the loop to be a

closed system.

b. The beginning point for the pipe that enters the

“storage supply” stub on the pump package

must always be at least 2 ft below the lowest

water level in the storage tank but not less then

6 in. from bottom of tank.

c. It is recommended that the 28QX coil be the

highest part of the loop. This is accomplished

by routing the supply and return pipes below

the coil height level. The reason for having the

28QX coil at the highest point is to make the

air bleed valve in the coil effective. If it is not

possible to route the return and supply lines

below the coil, an air bleed valve (similar to the

one found on the 28QX coil water header) will

have to be installed at the highest point in the

loop.

d. If the 28QX coil is mounted more then 6 ft

above the water level in the storage tank, a

special fill-up procedure will have to be

followed. Details can be found in the Start-Up

Instructions section. However, this procedure

will require a booster pump and booster pump

inlet fitting added to the 28QX supply line

between the pump package and 28QX coil. It

will therefore be necessary to add the booster

pump fitting when installing the 28QX supply

pipe. Refer to the Start-Up Instructions for

details concerning the type of fitting to be

used.

Fig. 22 — Heat Exchanger Piping Loop

on Glycol System

Pipe O.D. (in.) Maximum Equivalent Length (ft)

7/8

1

1-1/8

60

120

240

The pipe length listed is for the entire loop length.

A value of 5 equivalent ft should be used for the

pipe inside the pump package. There is no mount

ing height restriction for the 28QX coil since it

Heat Exchanger Loop (Fig. 22) — This loop begins

in the storage tank. A pipe leaving the bottom of

the storage tank travels to the rear of the pump

package to the right stub labelled “storage supply.”

The loop continues inside the pump package thru

the pump and heat exchanger and exits the unit at

the “storage return” stub. From here, the loop

returns to the top or bottom of the storage tank

(should be below the lowest water level).

17

Page 18

The pipe diameters and the allowable lengths

for this loop are listed below.

is found in the Start-Up Instructions will have to

be followed, pg 23.

ALLOWABLE PIPE LENGTHS

Pipe O.D. (in.) Maximum Equivalent Length (ft)

7/8

1

1-1/8

25

50

100

A value of 8 equivalent ft should be used for the

pipe length inside the glycol pump package.

It is advisable to terminate the storage return

pipe below the lowest water level in the storage

tank. This will make this loop a closed loop and

will assure that no air could infiltrate the loop. It is

important that the height of the return pipe above

the storage water level not exceed 6 feet. If it is

necessary to do so, a special fill-up procedure that

LOCATE AND INSTALL THERMISTOR SEN

SORS AND AQUASTAT BULBS - Located in the

low voltage terminal block compartment of the

control box are 2 thermistor sensors and 3 bulb

wells, Eig. 18.

Two of the bulb wells are to be used with the

aquastat bulbs located on the control box in pump

package. Fig. 12. These wells are to be inserted in

the storage tank so that the aquastat bulbs are

located at the same level in the storage tank as the

outlet to the Tri-X pump. The aquastats are bulb

and capillary refrigerant charged sensors. The

capillary tubes are 20-ft. long. Consequently, the

pump package should be placed with this restric

tion in mind.

All water supply lines leaving storage must be more than 6--in. from bottom of tank, but no closer than

2 ft from lowest water level.

Fig. 23 — Typical Glycol System Piping Diagram

18

Page 19

If it is necessary, the aquastats may be removed

from the control box and mounted close to the

storage tank. If this approach is taken, 14 gauge

wire should be used to connect the aquastat to the

appropriate wires out of the control box.

Thermistor Sensor Mounting — Mount sensors so

that good thermal contact is maintained. A small

amount of G.E. insulgrease #640 (field supplied)

between the sensor and the interior tube of the

solar panel array, and also in the well used on the

storage tank sensor is recommended to improve

thermal contact.

bulb well at the same level in the storage tank as

the outlet to the collector pump.

Solar Collector Panel Thermistor — The collector

thermistor should be placed on the leaving tube on

an interior panel in the panel array. One of the

interior panels should be used because of reduced

edge losses and higher performance. The thermistor

should be butted up against the panel and secured

in place on the tube with a hose clamp, as

illustrated in Fig. 15. Do not overtighten clamp.

Insulate sensor and tubing.

Storage Tank Thermistor — The thermistor is not

submersible and should be placed in the remaining

Thermistor Wiring

Wiring, pg 20.)

(See Electrical Data and

#

Fig. 24 — Typical Glycol System Piping Diagram

19

Page 20

Step 6 — Make Electrical Connections — Field

wiring must comply with local and national fire,

safety and electrical codes. Voltage to units must

be within ± 10% of voltage indicated on nameplate.

Operation of unit on improper line voltage

constitutes abuse and is not covered by Carrier

warranty.

Electrical data for pump packages including

wire and fuse sizes are shown in Table 3. See 38HQ

and 40FS unit Installation Instructions for similar

electrical data. All line and control power wiring

connections for the Solaround"'''^ System are

shown in this booklet. Refer to Pump Package

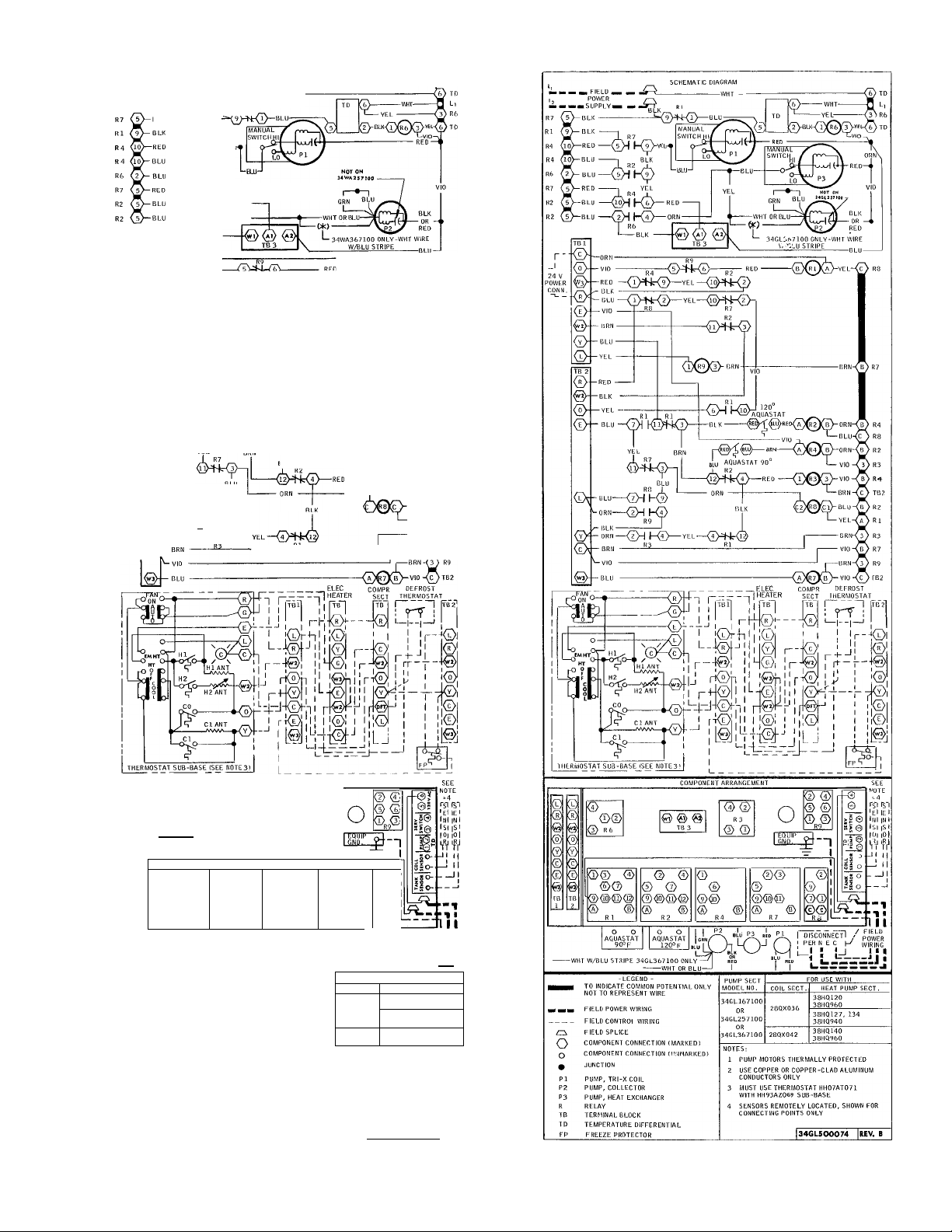

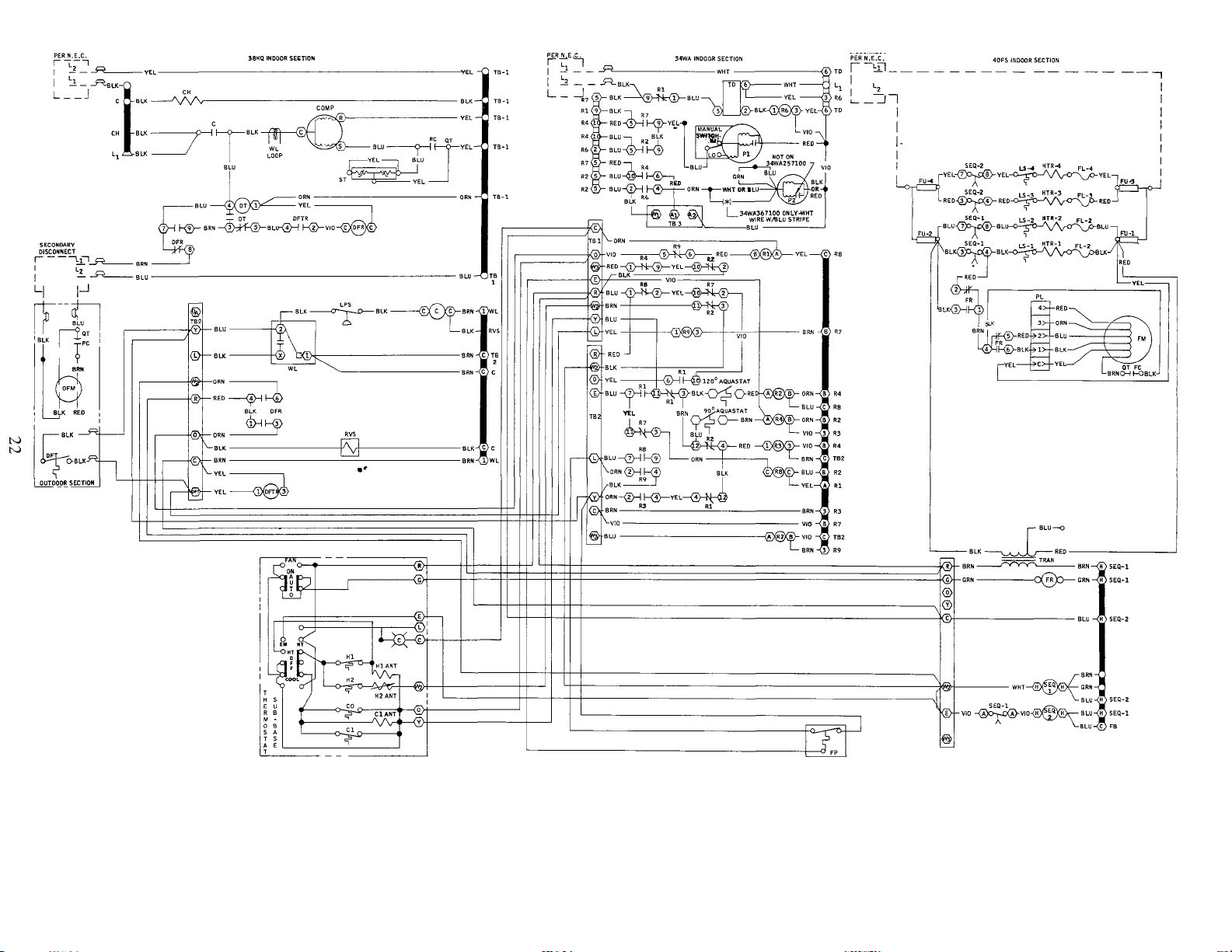

label wiring diagram, Fig. 25 and 26 and typical

system wiring schematic. Fig. 27. Be sure ther

mistor sensors are wired to terminals in pump

package control box.

INSTALF BRANCH CIRCUIT FUSED DIS

CONNECTS of adequate size to handle unit

starting current. Provide a separate fused dis

connect for each of the following; pump package,

compressor section, indoor fan coil and outdoor

coil section. Locate disconnects within sight of and

readily accessible from the unit, per section 440-14

of National Electrical Code (NEC).

Be sure all ground leads are connected to

grounding lugs provided on units.

CONTROL POWER (24 v) is supplied by indoor

fan coil with 60-va transformer. On 40FQ-25 and

30 kw electric heaters, remove 60-va transformer

and replace with 75-va transformer available from

Carrier Service Parts Center (Part No.

HT01BD235).

Use Carrier accessory room thermostat

HH07AT07 1 with thermostat subbase

HH93AZ069 for proper unit operation.

Warning Logic (WL) Control Wiring Modification Locate WL control in 38HQ compressor section

control box. Move black wire (extended from

low-pressure switch) from WL terminal 2 to WL

terminal 3. This prevents heat pump unit from

restarting when it is shut off by a safety control,

and service is required. The heat pump cannot

restart until thermostat is reset. For instance, if the

heat pump is shut off by 28QX coil freeze

protector, the WL signals a system malfunction by

illuminating a warning light on wall thermostat.

The freeze protector was activated by indoor fan

failure or low refrigerant charge. Either condition

warrants unit servicing before thermostat is reset

and unit is restarted.

Tri-X Coil Wiring — Splice connect 3 wiring leads

to pigtails on 28QX coil freeze-protector (Fig. 25,

26, 27). Use wire nuts and 16 AWG wire (up to

150 ft). Connect leads to pump package terminal

board one.

Thermistor Sensor Wiring — Connect wires from

thermistor on storage tank, and collector panel, to

barrier strip terminals provided on pump package

controller. Use 18 AWG wire for lengths up to

50 ft; 14 AWG wire for lengths up to 250 ft. Use

wire nuts for pigtail connections on thermistors.

Table 3 — Electrical Data (60-Hz)

PUMP

PACKAGE

34WA167

34WA257

34WA367

34GL167

34GL257

34GL367

FLA — Full Load Amps

‘Permissible limits of the voltage range (for limited period of time) at

which the units will operate satisfactorily.

•(-Required when using nonmetallic conduit.

:j;Maximum dual element fuse size.

V/PH

115/1 126

OPER

VOLT*

Max Min

104

Power Wire

Size (AWG)

2 5 14

5.8

8 0 . 12

3 3

6.6

8.8

• 14 48

NOTES: 1

Max Ft

Wire

14

14

12 27

All units have 24-v control circuit which requires ex

ternal power source.

2.

Copper wire size in table based on 60 C. Use copper or

copper-clad aluminum wire. Use latest National Electri

cal Code (NEC) for wire sizing.

BRANCI

63

26

30

24

■1 CIRCUIT

Gnd Wire

Sizet (AWG)

14

14

14

14

14

14

Max Pus

Ampst

■|5

15

25

15

15

25

20

Page 21

FIELD. _

POWER

SUPPLY- RI

BLK

SCHEMATIC DIAGRAM

- WHT

#

—^ K^'

---------

T R6

•® —

ORN

24 V

POWER

—REO —(D^-KD

CONN.

©“-liLU

---------------VIO

----------------

- BRN

BLU '

0--YEL ■

T6 2

-RED

—BLK

~YEL

(^BLU

-------

i^BLK --_

0 - ORN —©H h©----------------------------

®-

1 BLK

Ki)^ RED

—G)H h®— ORN

I----p

R4 W..-W R2

(T^H®

------------------

------------

1

------

YLL—

'"EL

------

<5^T+-(i)-|

------------

RI RI ^ " N—-/ AUUH3 IA I

—(^ H0H®

-----------------------------

•i.

R8 T

<Z>^K^

ORN -0-1 h0

-(Dh I-®-

BLK

-------------

;LU AQUASTAT 90° T- ^

120

AQUASTAT

0<©>®><a)0(^OI

--

BRN—¿)@(^0I

—(D©^^

------------- I—Bl

#

COMPONENT ARRANGEMENT

® 3

®

®| ®

©

® «S

®| ®

® ®

s® ®

®o

I-®®®®

® ®

R 1 R2

-LEGEND TO INDICATE COMMON POTENTIAL ONLY

NOT TO REPRESENT WIRE

FIELD POWER WIRING

FIELD CONTROL WIRING

FIELD SPLICE

COMPONENT CONNECTION (MARKED)

o

COMPONENT CONNECTION (UNMARKED)

o

JUNCTION

PUMP, TRI-X COIL

PUMP,COLLECTOR

RELAY

TERMINAL BLOCK

TEMPERATURE DIFFERENTIAL

FREEZE PROTECTOR

© @ ®

AQUASTAT orn/^

1WA3671000NLY -/ "EO ®‘i° Rtt

--------

WHT OR BLU —’I 11

TB 3

® €>

R3

®®

® ®

R4

®®®

® ®

R7

q

34WA167100

34WA257100

34WA367100

COIL SECT.

280X036

OR

OR

280X042

NOTES:

1, PUMP MOTORS THERMALLY PROTECTED

2 USE COPPER OR COPPER-CLAD ALUMINUM

CONDUCTORS ONLY

SENSORS REMOTELY LOCATED, SHOWN FOR

CONNECTING POINTS ONLY

©

3

®®

‘W

I

disconnect! /

I PER N E C K WIRING

1 I ■ * I MI

' ! M !

utr^m-a

FOR use WITH

38HQ120

38H0960

38HQ127, 134

38HQ940

38HQ140

38HQ960

I34WA500074 |REV. B

Fig. 25 — Label Diagram; 34WA167,257,367;

115-1-60

HEAT PUMP SECT.

Fig. 26 - Label Diagram; 34GLI67,257,367;

115-1-60

21

Page 22

DISCONNECT

Fig. 27 — Typical System Wiring

Page 23

#

INITIAL START-UP

Follow this start-up procedure since a proper

start-up is essential to efficient and reliable system

operation. Review Start-Up data in 38HQ heat

pump Installation Instructions and Refrigerant

Charging on pg 27 of this publication.

Plain Water System Start-Up — At this stage of the

installation, all components should be in place, all

piping connections made and all power and low

voltage wires connected. The fused disconnect

should still be in the OFF position. Leave the

disconnect in the OFF position until the procedure

directs otherwise.

SOLAR COLLECTOR PIPING LOOP ^ Begin

filling the storage tank with water. Tap water can

be used as long as dissolved solids do not exceed

800 ppm. Check the storage tank for leaks, espe

cially the area where supply pipes leave tank. Do

not completely insulate the storage tank until it

has been determined that the tank is leak tight.

Complete the insulation of tank. Add the field-

supplied inhibitor to the storage water. See pg 25.

Before start-up, lubricate collector pump (P2)

bearings on pump package models 34WA257 and

34WA367. Follow oiling instructions on oil tube

and oil warning tag attached to pump. The pump

requires yearly maintenance. Remove shipping

strap from pump on 34WA257 models only.

Fill storage tank until water level is higher than

the highest point in the supply line. Be sure pump

package ball valves and isolation valves are still at

factory set open position (screw heads parallel to

piping). To be sure the pump volute is flooded,

open the uppermost air bleed screw (on pump)

shown below. When water runs thru screw hole, all

the air has been bled out and the screws can be

tightened. Collector pump on 38WA167 does not

trap air and bleeding is not required.

Switch on pump package fused disconnect. If

the sun is out, collector pump will start. If the sun

is not out or water in storage tank is warm, start

the pump by disconnecting one of the collector

sensor leads from the differential control (in pump

sensor lead) and listen (at pipe between pump and

collectors) for the water to drain back. Visually

inspect entire system for water traps.

TRI-X COIL LOOP - Bleed air from loop. The air

bleed valve is found at the top of the leaving water

header on the Tri-X coil (or at the highest point in

the loop; see “Tri-X Coil Loop” on pg 13). The

bleed valve consists of a screw in a body with an

exit tube as shown below.

SCREW

EXIT TUBE

By loosening the screw 2 or 3 turns, a path

from the header interior to the exit tube is created.

After loosening the screw, energize the Tri-X pump

by placing a jumper wire between terminals Wi

and A] of Terminal Board 3. Air will make a

hissing sound as it is pushed out of the bleed valve

by the advancing water. When a spout of water

leaves the exit tube, close the screw on the bleed

valve. De-energize the Tri-X pump after allowing it

to run a few minutes with the bleed valve closed.

Repeat the air bleed procedure at a later time

(one-half hour) to be sure all the air is out of the

loop.

Special Water Fill-Up Procedure is required when

the 28QX is mounted more than 6-ft above the

water level in storage tank. (Procedure is same for

plain water or glycol systems.) In these closed loop

circulation systems, the circulator pump does not

have sufficient lift potential to initially fill the piping

loop.

package control box). With pump running, check

piping loop for leaks. Determine whether the

system drains properly by shutting off collector

pump, (shut off power or reconnect collector

Fig. 28 — Booster Pump Application

Be sure the storage tank is full of water.

Temporarily add a booster pump to the piping

loop. Locate the pump to discharge thru a gate

valve installed in water line between pump package

and 28QX coil. Fig. 28. (If pump is not available, a

garden hose operating at city water pressure can be

used.) Before starting pump, close the ball valve on

the flange of factory circulator pump. Fig. 12 and

23

Page 24

19. This will prevent booster pump from filling

storage tank. Open air bleed valve on top of 28QX

coil, start pump and fill piping loop with water.

If 28QX is not at highest point in the water

loop, install an air bleed valve at high point in loop

to purge air. After loop is filled, remove booster

pump and open ball valve in pump package.

CONTROL ADJUSTMENTS ^ The aquastat with

the adjustment knob on the side of the control box

must be set. It must be set to the value that is

specified by the Solar Clic Program. Room ther

mostat adjustment is same as in 38HQ Heat Pump

Installation Booklet.

Glycol System Start-Up — At this point, all

components should be in place and all piping and

electrical connections should be made. The storage

tank should not yet be insulated, and the fused

disconnect should be off. Begin filling the storage

tank as is described in the “Plain Water System

Start-Up” under “Collector Loop.” Check the tank

for leaks, especially at the tank fittings and add the

inhibitor, pg 25.

SOLAR COLLECTOR PIPING LOOP - If the

34GL257 or 34GL367 has been installed, the

collector pump must be oiled with the factory

supplied tube of oil. Follow the oiling instructions

on the oil tube and the oil warning tag. If the

34GL257 has been installed, remove the shipping

bracket from the collector pump.

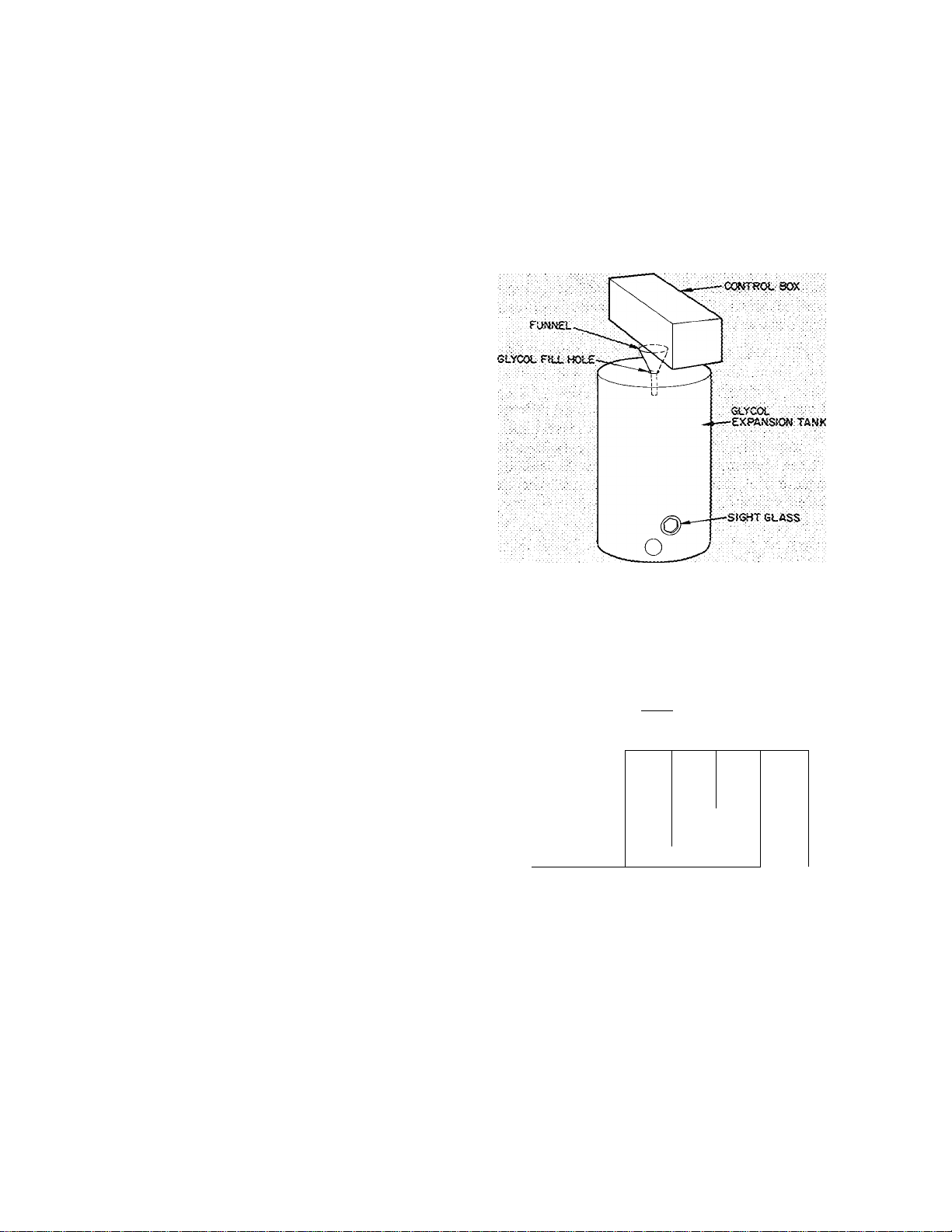

The expansion tank (Fig. 12 and 19) in the

collector loop will require the addition of a

glycol-water mixture. Standard automotive anti

freeze (Dow, Prestone, Peak, etc.) will be used as

the glycol source. Determine what percentage of

glycol is proper for the particular application using

the glycol manufacturer’s data. Use the glycol

charging chart to determine the total amount of

glycol-water mixture required. Add the required

amount to the expansion tank using the hole in the

top of the tank and a funnel as entry into the tank

(Fig. 29). If the glycol charging chart requires more

than 18 gal. (the capacity of the expansion tank),

add as much as possible and save the remainder to

be added after the collector pump is operating.

Bleed the air out of the collector pump (34GL257

and 34GL367 only) as described in the “Collector

Loop” section of the “Plain Water System

Start-Up” procedure.

Before starting collector pump locate sight glass

at bottom of expansion tank (Fig. 29). The sight

glass is for checking glycol level in tank when

collector pump is operating. If glycol level falls

below the sight glass, collector pump inlet takes in

air and pump won’t function properly. If complete

glycol-water charge was not all added initially, it

can be added when collector pump is started and

space in expansion tank becomes available.

Switch on fused disconnect to energize col

lector pump. (Follow procedure outlined in the

“Collector Loop” section of the “Plain Water

System Start-Up” instructions.) Determine that

collector piping loop is leak tight and then shut off

collector pump. After shutdown, look thru hole in

top of expansion tank to be sure the glycol drains

back.

Fig. 29 — Filling Expansion Tank

Table 4 — Glycol Charging Chart

Lineal Ft of Piping

from Collector Pump

to Collectors

10

20

30

40

50

60

When glycol/water charge is over 18 gal., the remainder

must be added after collector pump is operating

TOTAL NO. OF COLLECTORS

15

20

21

.1.

,,, : 19

25

18

22

23

10

Glycol/Water Mixture (Gal.)

11

13 15 17

13 14 16

14 16

15 17

16 .18

„JS...

J 19 20

1 20

5 "l9

TRI-X COIL LOOP - Follow the procedure

outlined in the “Tri-X Loop” section of the “Plain

Water System Start-Up” instructions.

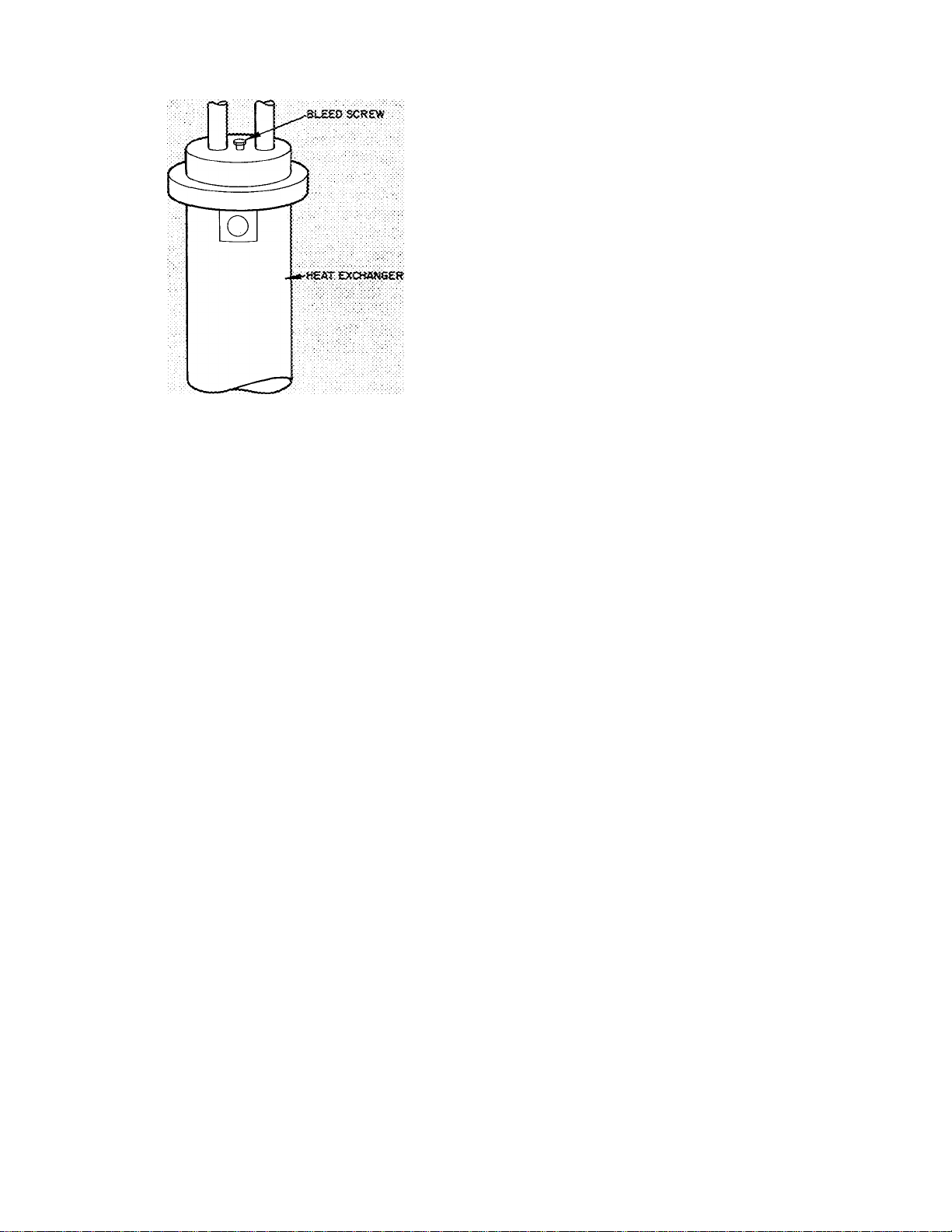

HEAT EXCHANGER LOOP - Since the heat

exchanger pump is electrically parallel to the

collector pump, it has already run. However, if the

heat exchanger loop is a closed one, bleed the air

out of the loop. If the loop is an open one (the

return pipe is not below the water’s lowest level in

storage tank), the bleed procedure does not have to

be followed. To bleed the closed loop, loosen the

bleed screw at the top of the heat exchanger as

shown in Fig. 30.

24

Page 25

Fig. 30 — Bleed Screw Position

Run the heat exchanger pump by energizing the

collector loop. When the air has been bled, tighten

the screw.

CONTROL ADJUSTMENTS - The same control

timing on the adjustable aquastat must be made

here as was the case for the plain water system. See

the section on “Control Adjustments” in the

“Plain Water System Start-Up” instructions for

details.

Inhibitors (Field Supplied) — Procure an inhibitor

from local water treatment firm. Specify an

inhibitor of fungus, rust, scale, red water and

galvanic action. The stored fluid passes thru many

parts of the Solaround''''''' System composed of

different materials, each vulnerable to the effects

of these natural and chemical actions.

Add inhibitors to the water charge in thermal

storage tank. Tap water may be used if total

dissolved solids do not exceed 800 ppm. Other

wise, dilute tap water with demineralized water to

reduce sohds below that level.

If the system is charged with antifreeze,

commercial automotive antifreeze solutions should

be used at 50% concentration to obtain the proper

inhibitor concentration.

Inhibitors will be depleted with time to a level

which may even increase corrosion rated beyond

that expected with uninhibited water. Therefore,

make bi-annual checks to test the inhibitor

strength, or replace the inhibitor, following the

manufacturer’s recommendation.

Suitable inhibitors for tap water are as follows:

1. For all copper piping systems with coated

concrete or fiberglass reinforced plastic storage

vessles, or steel vessels with plastic or rubber

liners:

NALCO 7SN-196 or equivalent. See specifica

tion below.

Dosage: 1/4 lb per 1000 gallons (30 ppm).

2. For systems with uncoated steel tanks plus

copper piping:

NALCO 2532 or equivalent. See specification

below.

Dosage: 2 oz per gallon.

NALCO 7SN-196 is in a highly soluble, pulverized

form.

Color............................................................White

Odor ............................................................ None

Density .............................................67 Ib/cu ft

pH of 1 % Solution ....................................... 12.3

Solubility in Water @ 75°F . . . . Up to an 8%

clear solution

Si02

..............................................................

30%

PO4................................................................ 25%

Very slightly hygroscopic

NALCO 2532 is a water soluble, blended liquid

product containing quaternary amine and organotin compounds with the following properties:

Color.................................................Light yellow

Odor ..............................................................Mild

Specific Gravity (@ 25°C)

Density (@ 25°C)

Freeze Point

Flash Point

...................................................

...............................

............................................

........................

8.46 Ib/gal

1.016

— 1.0°C

None

pH (Neat)....................................................... 12.2

Do not apply to potable water or domestic

water systems. Apply this product only as

specified.

Solar-Assisted Heat Pump Operating Modes

System Equipment:

1. Pump Package (34 WA/GL)

2. Compressor and O.D. Coil (38HQ)

3. Tri-X Coil (28QX)

4. Indoor Fan and Electric Heater (40FS/FQ)

5. Solar Collector Panels

MODE: SOLAR ENERGY COLLECTION

Controlling Mechanism:

• Solid State differential controller located in

pump package control box. Two thermistor

temperature sensors are remotely located. One

sensing collector panel temperature (Tc) and

the other sensing storage tank temperature (Ts).

25

Page 26

• The collector circuit pump is operated thru a

relay (Rh) which is activated by the differential

controller. The differential controller monitors

the difference in thermistor temperatures (AT =

Tc — Ts). When this AT reaches 20 F, Rg is

energized, and the collector pump runs (also

the heat exchanger pump in the GL models). If

the pump is running and the AT drops to less

than 5 F, R6 is de-energized and the pump(s)

shut down.

MODE: HEATING

Controlling Mechanism:

• 2-stage room thermostat

Located in

90° Non-adjustable Aquastat storage tank.

Senses water

125 Adjustable Aquastat temperature to

Tri-X Coil.

• The 90° aquastat is factory set.

• The 125° adjustable aquastat should be set

(between 95-125)* in the field as specified by

solar CLIC. (The set point is temperature at

which the QX coil water capacity can satisfy

the house heating design load.)

CAUTION; Do not set adjustable aquastat

above 125 F. Higher temperature can reduce

compressor life,

• The following chart defines the heating modes

as a function of water temperature (aquastats)

and room thermostat stages.

WATER TEMP

Above 125* F

(adjustable aqua

stat set point)

Below 1255^F& ■

Above 90 F

(Non-adjustable

aquastat set

point)

Below 90 F

(Non-adjustable

aquastat set

point)

I. Solar Only

li. Solar and Heat

III. Heat Pump Only

THERMOSTAT

1st Stage

- Tri-X Pump and

Indoor Fan On

Pump

— Tri-X Pump,

Compr., Outdoor

and Indoor Fan

On

~ Compr., Indoor

and Outdoor Fan

On

2nd Stage

No Action

Strip Heat

Strip Heat

MODE; COOLING

The cooling modes are same as the 38HQ heat

pump system cooling operation with one excep

tion. When the thermostat is in the cool position,

the differential controller is locked out; conse

quently, the collector pump(s) will not run during

the cooling season. (When the domestic hot water

accessory is installed, this exception does not

apply.)

MODE: EREEZE PROTECTION OPERATION

The freeze protector is a thermostat placed on the

liquid line in the QX coil. It trips at 31 E and will

reset at 46 F. Consequently, the device can only

function in the following modes: defrost and

cooling. In each of these modes the freeze pro

tector functions to prevent the coil from freezing,

but accomplishes this in different ways, as de

scribed below:

Defrost cycle:

If the freeze protector trips, the Tri-X pump

will be turned on. The only way the defrost

cycle of the heat pump is affected is by

enhancing the defrost performance, by pro

viding an additional source of heat besides the

indoor air.

Cooling cycle:

If the freeze protector trips, the compressor is

turned off and locked off until the thermostat is

reset. If the freeze protector does trip in

cooling, it is an indication of improper system

operation. This could be insufficient indoor air

or low refrigerant charge.

MAIIMTEiSIANCE AND SERVICE DATA

Pump Package

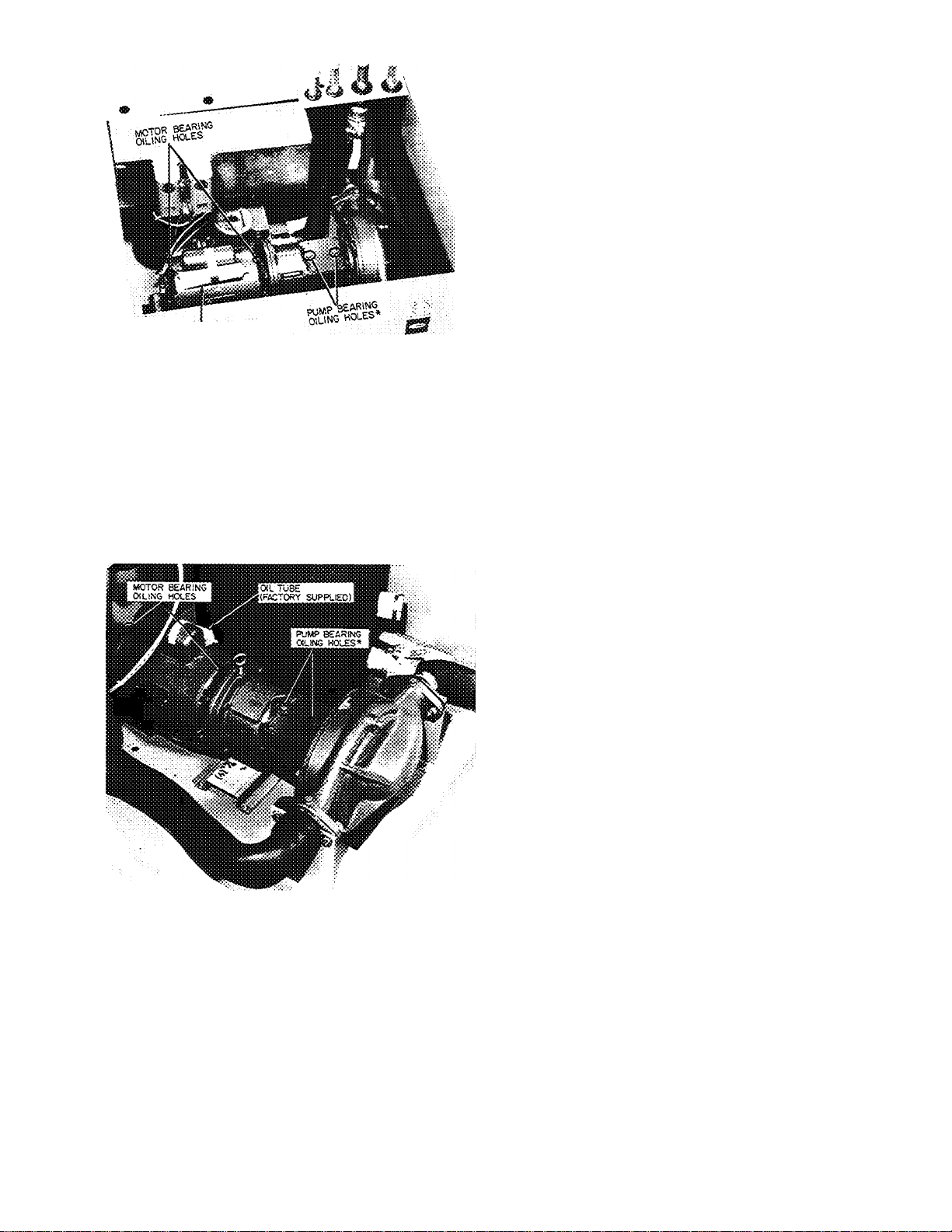

1. 34WA257/367 and 34GL257/367

a. Oil the Bell and Gossett collector (P2 —

Fig. 12 and 19)

• On start up and once a year

b. There is no maintenance required on the

Grundfos(Pi or?3 — Fig. 12 and 19) pumps.

2. 34GL167/257/367

a. Glycol level during operation

• On start-up charge the system with

enough glycol so that the level does not

drop below the sight glass during

collector pump operation.

• Check glycol level at least once a year

during collector pump operation.

b. Check inhibitor effectiveness in glycol once

a year.

Heat Pump, Indoor and Outdoor Fan and Coil,

Electric Heater and Storage Tank

1. Indoor components

a. Replace the filter once a year, sooner if it

becomes excessively dirty.

b. The 28QX036/042 should be checked and

bled of air as specified in the Start-Up

Instructions. This process should be per

formed once a year.

c. When necessary to drain the water from

Tri-X coil, apply compressed air to the coil

water headers. Direct the air alternately thru

the entering water header and then the

26

Page 27

leaving water header in approximately 60second intervals. Using this method will

remove most of water in coil circuits.

d. See fan section, electric heater, or the

compressor section Installation, Start-Up

and Service Instructions for scheduled

maintenance.

STORAGE TANK

e. As specified in the Start-Up Instructions, an

inhibitor must be added to the water in the

storage tank to prevent corrosion. Since this

is an open system, it is very important that

the effectiveness of the inhibitor is main

tained. (See Inhibitor Manufacturer’s

Instructions).

2. Outdoor components

The 38HQ940/960 coil should be cleaned

annually or as often as required.

REFRIGERANT CHARGING - The 38HQ out

door fan coil unit contains correct operating charge

for complete system. Refer to 38HQ Unit Installa

tion, Start-Up and Service booklet for refrigerant

charging method details. Cooling cycle charging

charts and heating cycle operation check charts for

38HQ/28QX systems are included in this booklet.

Fig. 31 thru 36.

CAUTION: Rapid, removal of Refrigeran.t-22

charge from heat pump system can <3ro;p pre.ssure and lower temperature and can cause water

in tire Tri~X coil to freeze and split coil tubes.

When necessary for servicing, remove ciiarge

very slowly to minimize possibility of freeze

dajnage.

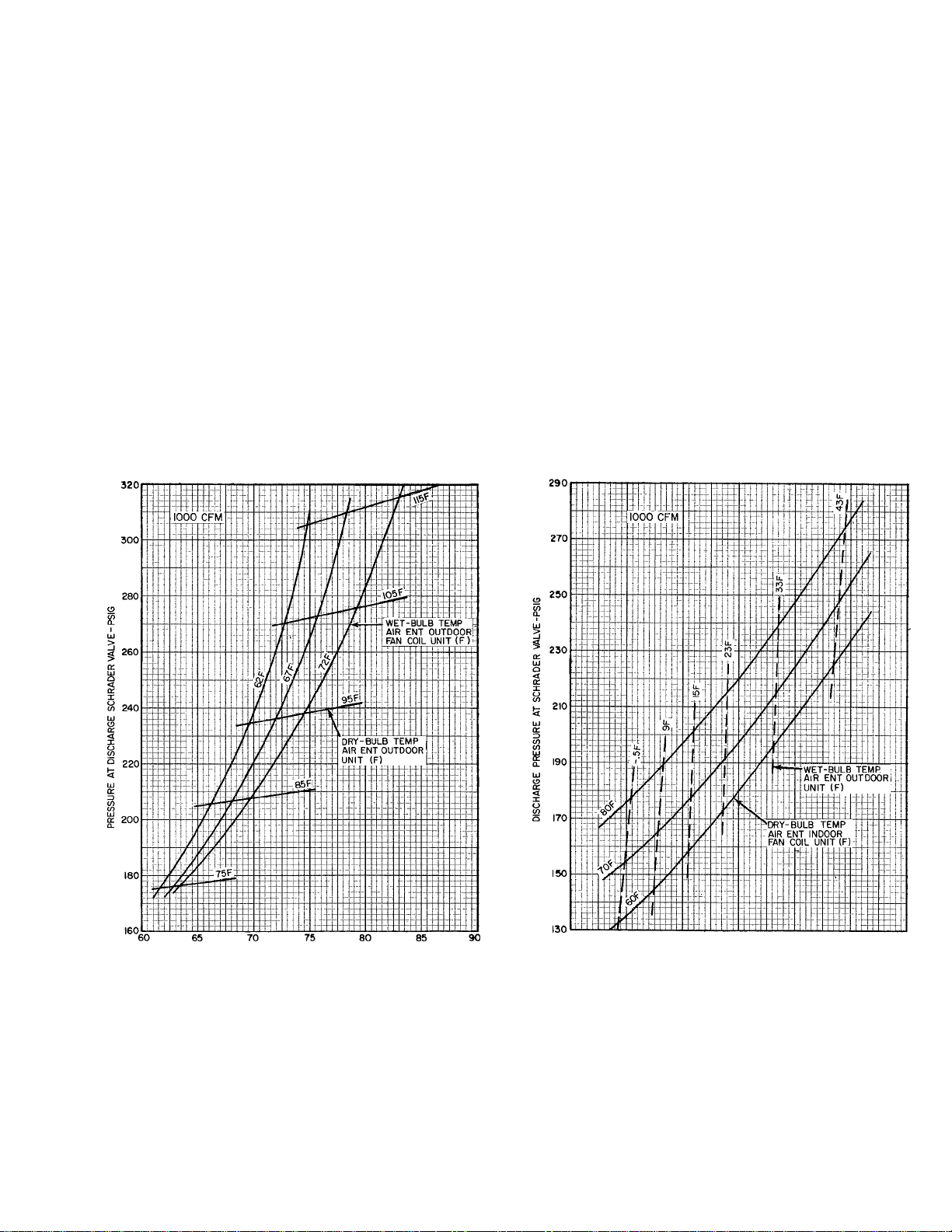

PRESSURE AT SUCTION SCHRADER VALVE-PSIG

Fig. 31 - 38HQ127/38HQ940 with 28QX036

Cooling Cycle Charging Chart

27

20 30 40 50 60

SUCTION PRESSURE AT SCHRADER VALVE-PSIG

Fig. 32 - 38HQ127/38HQ940 with 28QX940

Heating Cycle Operation Check Chart

70

Page 28

Fig. 33 - 38HQ134/38HQ940 with 28QX036

Cooling Cycle Charging Chart

Fig. 35 - 38HQ140/38HQ960 with 28QX042

Cooling Cycle Charging Chart

20 30 40 50 60

SUCTION PRESSURE AT SCHRADER VALVE-PSIG

Fig. 34 - 38HQ134/38HQ940 with 28QX036

Heating Cycle Operation Check Chart

70

Fig. 36 - 38HQ140/38HQ960 with 280X042

Heating Cycle Charging Chart

28

Page 29

ltoT^;SUPPUEO>

*On 38WA/GL367 Models, remove sheet metal plate for access

to oil reservoir

Fig. 37 — Oiling Hole Location —

Plain Water Pump Package

Start-Up and Annual Preventive Maintenance

Checklist

PUMP PACKAGE

1. Oil Bell and Gosset pump at start-up and

annually (Grundfos pumps are water lubricated

and do not need lubrication).

• Two oilers on each end of motor (Fig. 37

and 38)

• 34WA/GL367 models have sheet metal plate

over oil reservoir; remove plate and add oil

until it comes out bleed hole on side.

34WA/GL267 models have oil tube over

reservoir; fill until oil comes out bleed hole

on side.

2. Inspect for leaks.

3. Make sure ball valves are open on ends of all

Grundfos pumps; screw head should be parallel

to piping.

4. Make sure adjustable aquastat is set properly

(no higher than 125 F).

5. Check glycol level on 34GL systems. It should

be visible in sightglass when operating, if not,

add glycol to bring level up to center of

sightglass.

6. Make sure Grundfos pumps are on high speed.

Switch should be set at #2.

*On 38WA/GL367 Models, remove sheet metal plate for access

to oil reservoir

Fig. 38 — Oiling Hole Location —

Glycol Pump Package

7. Check insulation.

STORAGE TANK

1. Check inhibitor strength. Contact local water

treatment firm. Add inhibitor if necessary.

2. Check to see that insulation has not been

damaged.

3. Check for leaks.

4. Check water level in storage tank' visual

inspection.

5. Check for sediment in bottom of tank. Drain

should be located in supply line with supply

outlet at least 6-in. above bottom of tank.

Release water from drain; if this water has

sediment in it, drain tank completely and clean.

6. Make sure sensing bulbs are tight in wells and

that bulb wells are leak tight.

7. Make sure vent tube is clear and not damaged

or obstructed.

29

Page 30

40FS INDOOR AIR HANDLER AND HEAT

PUMP UNIT

1. Run Refrigerant System Performance check.

2. Refer to appropriate instructions for further

details.

28QX INDOOR COIL

1.

Inspect and clean if necessary.

2.

Change filter or clean with water and detergent

if filter is of permanent type.

3.