Page 1

Carrier

Instaliation instructions

Direct Expansion Evaporator Coil

GENERAL

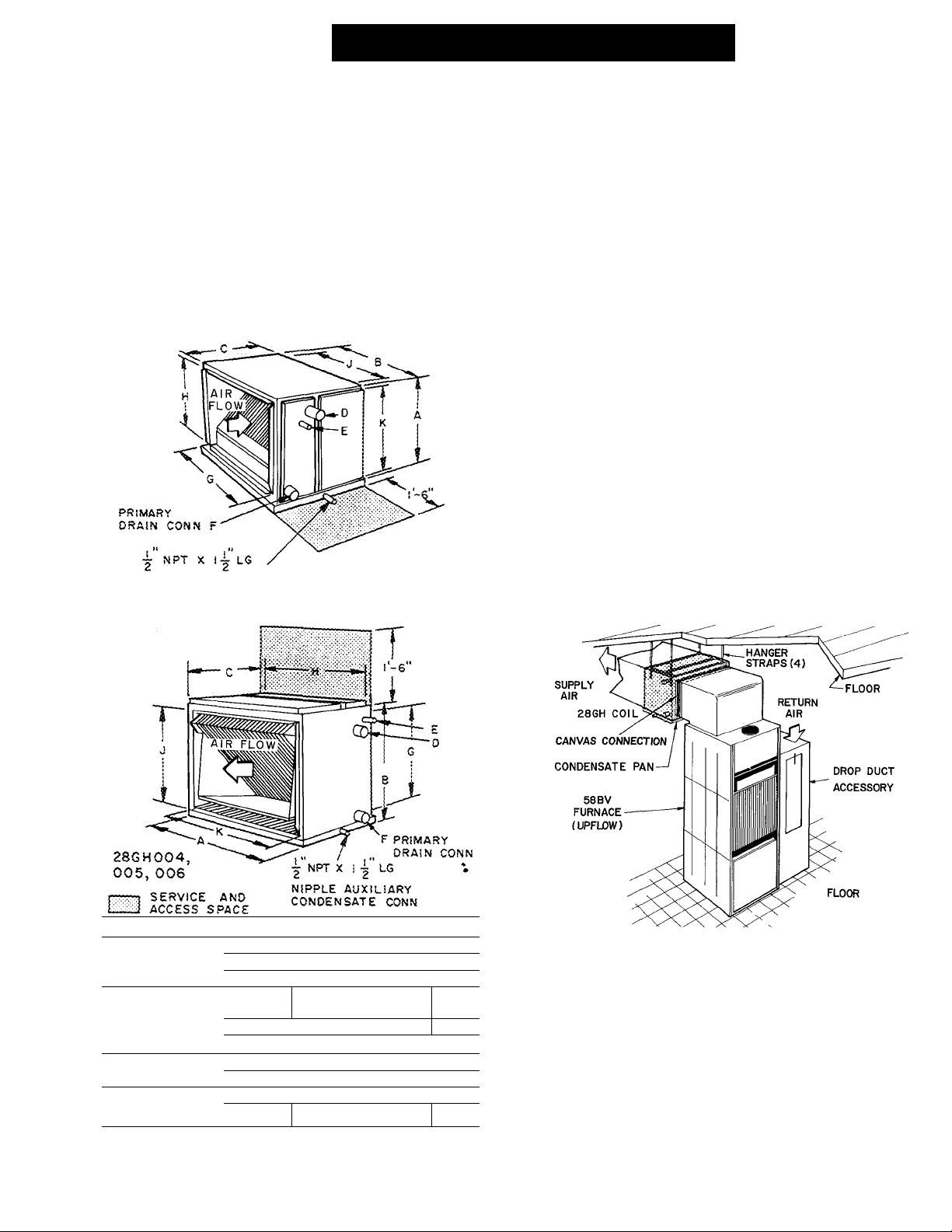

These encased coils must be used in a hori

zontal position with the air flow in the direction as

indicated in Fig. 1.

Transportation Damage — If any damage is noted

when unpacking coil, file a claim with the trans

portation agency.

NIPPLE AUXILIARY

CONDENSATE CONN

28GH002,003

INSTALLATION

Install coil in the horizontal run of a supply air

duct from any furnace. Fig. 2 shows typical

installations. Attach ductwork to encased coil. Use

straps for hanging. Do not drill or screw into coil

condensate pan. Coil must be level for proper

condensate drainage.

If the duct cross-sectional area between coil and

furnace is smaller than entering air opening of

encased coil, a transition must be made in the duct.

The ratio of transition in the duct must not exceed

more than one inch for every seven in both the

horizontal and vertical planes.

Where it is necessary to reduce fan noise or

vibration, install a canvas connection in the duct

work on the entering air side of the coil.

When encased coil is installed in a crawl space,

attic or basement with less than 18 in. service

clearance above the unit, it is not possible to

service unit thru the access panel. In these cases,

part of the ductwork must be cut away or unit

must be removed from duct for servicing.

UNIT 28GH 002 003 i 004 i 005 006

DIM. (fi-in.)

CONN, (in, ODF)

Suction

Liquid

Condensate

Duct iniet (in.)

Duct Outlet (in.)

A

s I

C i

D j

V,

E i

F i

G ;

K i 14%

J i

K j __14%

i 2-G%l 2-4% 3-0%

1-3%

1 -4%

V

%

7/

/A

13%

22% i 26%

13% i

13%

18% i

22% i 26%

Fig. 1 — Dimensions

©Carrier Corporation 1969

1%

%

34%

34%

Fig. 2 — Typical Installation

Refrigerant Piping — Connection sizes are given in

Fig. I.

COILS 002 THRU 005 use Carrier Compatible

Fittings and accessory tubing package for connec

tions. Detailed instructions are included with the

tubing package. Do not remove rubber plugs from

Carrier Compatible Fittings on the coil until ready

to connect the suction or liquid line into the

fitting. If coil piping is left open, vapor holding

charge will escape and allow moisture to enter.

Form 28GH-1SI

Page 2

COIL 006 must have the liquid and suction lines

soldered to the unit.

Refrigerant Control is a factory-installed thermal

expansion valve. For proper operation, locate the

feeler bulb outside the encased coil about 45

degrees above the horizontal center line of the

suction line.

Do not mount bulb such that capillary tube

extends from bottom of bulb. Clean suction line

for good contact with bulb. Secure bulb tightly to

suction Une with metal straps provided. If this is

not done, liquid may slug to the compressor.

Suction Line Insulation — Insulate entire suction

line. Tubing package has an insulated suction line.

Insulate suction line from encased coil to, and

surrounding, expansion valve feeler bulb on 28GH

Coils.

Refrigerant Charge — Coils 002 thru 005 have

vapor holding charge. Do not evacuate if accessory

tubing package with Carrier Compatible Fittings is

used. If sweat connections are used, purge or

evacuate coil and piping.

Coil 006 is shipped without charge. Purge or

evacuate coil and piping.

Refer to Standard Service Techniques Manual,

Chapter 1, pages 1-8 thru 1-14, and condensing

unit and/or tubing package instructions for details.

Condensate Drain

1. Connect the rubber elbow (furnished with unit)

to the primary drain. See Fig. 1.

2. Connect 7/8-in. copper tube to the elbow.

3. Form a trap in the 7/8-in. copper tube and run

the tubing to an open drain. Drain tube should

be pitched at least 1 in. per 10 ft.

4. Run individual condensate lines to the primary

and secondary drain pans. The condensate line

should discharge at a point where it can be

readily observed if a correction is needed.

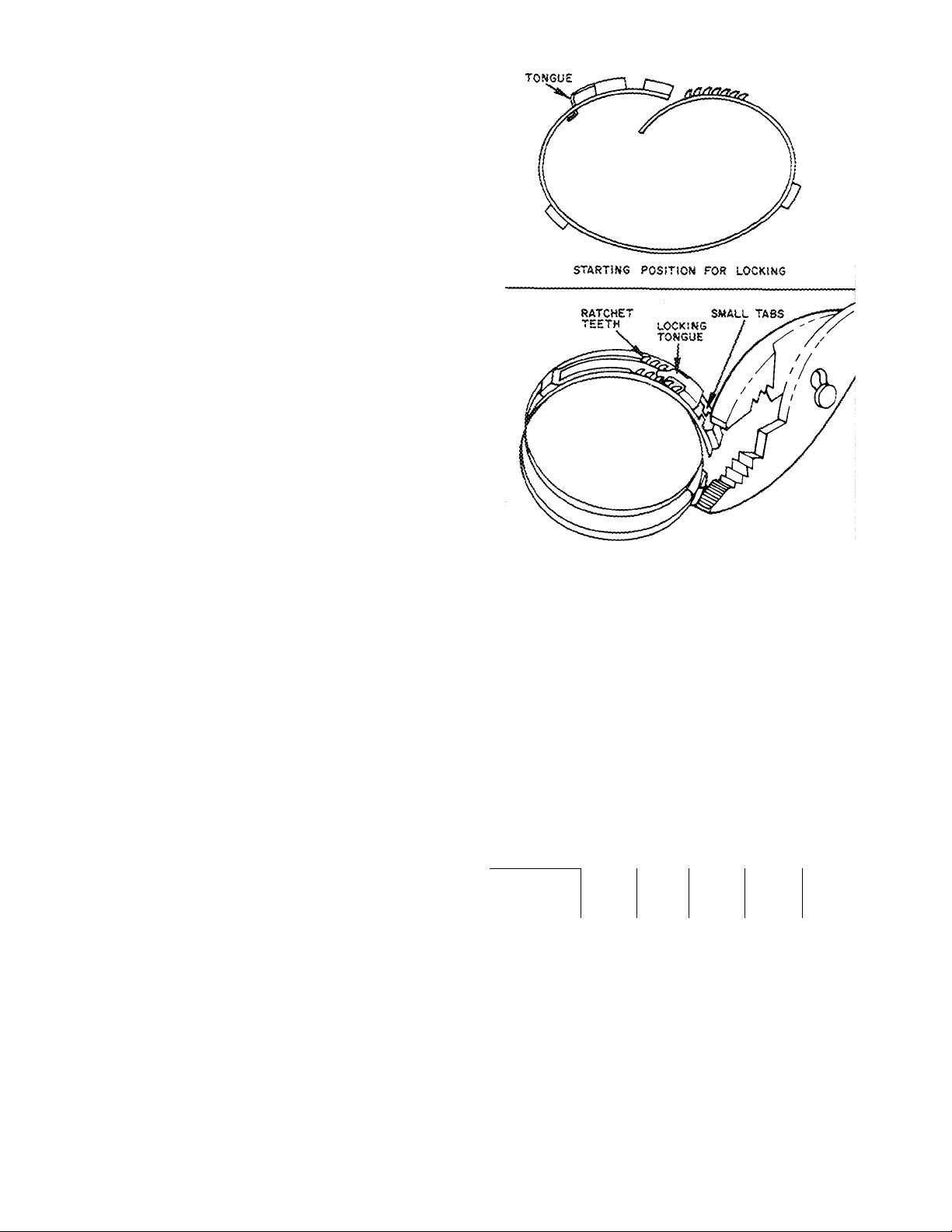

HOW TO APPLY HOSE CLAMPS

1. Pull ends apart (Fig. 3).

2. Wrap around hose with toothed end beneath.

Prelatch by compressing until last ratchet teeth

catch behind small tabs.

LOCKiNG

CLAMP IN LOCKING POSiTiON

Fig. 3 — Hose Clamp

3. Grip adjacent bridges with pliers and compress

to tight position. Pliers can be held parallel to

hose where space is limited.

4. To remove, lift the locking tongue with

screwdriver.

Protective Plastic Film — Peel from unit panels

when installation is complete.

AIR QUANTITY

To prevent moisture blowoff do not exceed

cfm shown in Table 1.

Table 1 — Maximum Allowable CFM for 28GH Coil

COIL 28GH 002

Horizontal 975

003 004 005

1200 1580 1920

006

2560

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 7

Form28GH-1SI New

Printed in U.S.A.

6-69

Codes D and MS

Catalog No. 532-841

Loading...

Loading...