Page 1

#

»o

cs

26H

i <

si

3 u

< “

Automatic Icemaker

Dimension Drawings

page 3

page 7

INSTALLATION

AND

SERVICE

INFORMATION

Installation Instructions

Service Instructions page 19

Page 2

-m

Carrier

CARRIER

AUTOMATIC ICEMAKER

SPECIFICATIONS_______________________

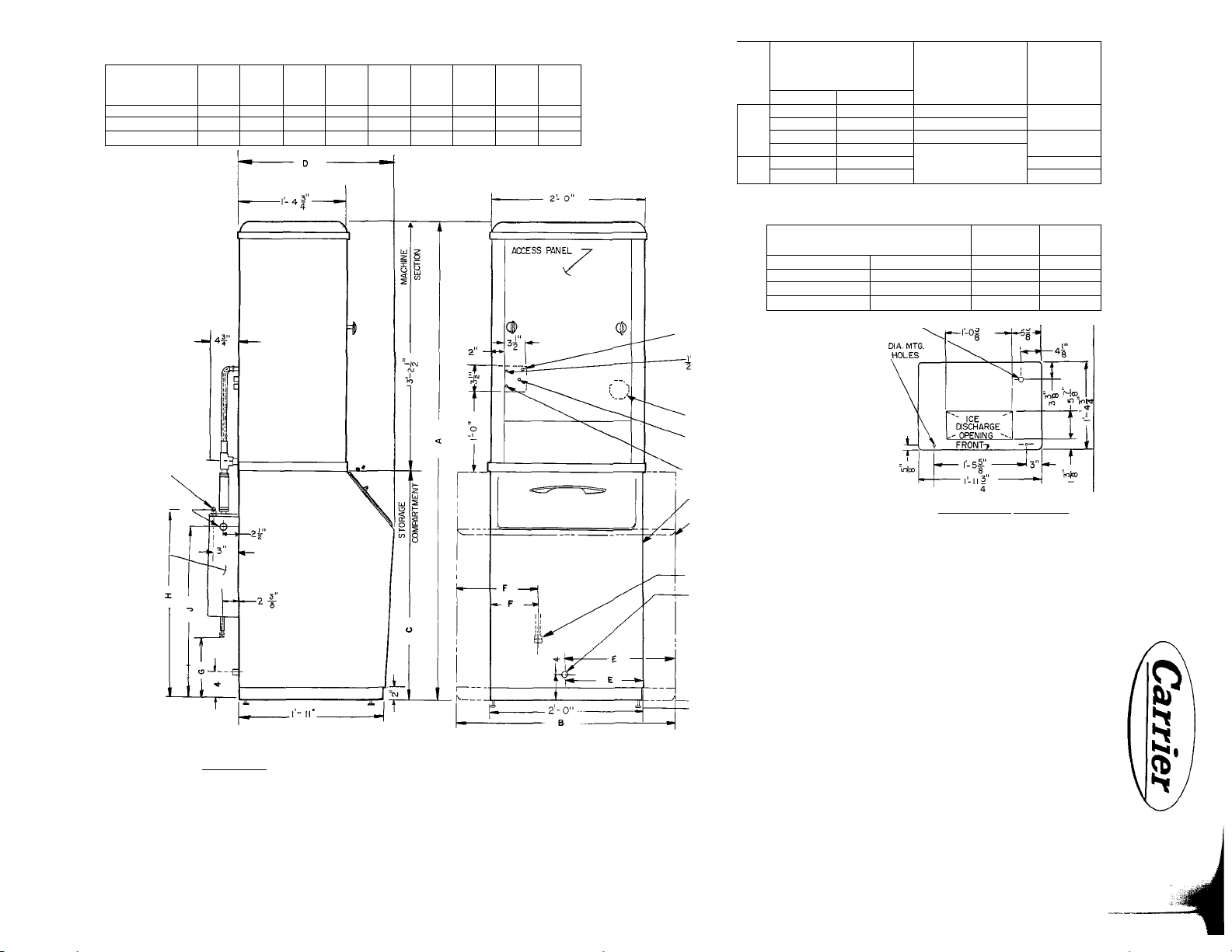

DIMENSION DRAWINGS

INSTALLATION

CONTENTS

____-____

_____________

_______________________________________

1. Check Shipment

2. Select Proper Location

3. Move Unit to Location

4. Uncrate the Bin

5. Install Leveling Screv/s

6. Unpack and Mount the Heat Interchanger

7. Move the Bin to Approximate Location....................................

8. Uncrate the Machine Section

9. Remove the Front, Top and Side Panels

10. Plage Machine Section on Top of Bin and Bolt in Position...

I I. Bolt Tie Bar at Rear of Unit................ ...........................................................12

12. Install Water Supply and Drains

13. Make Electrical Connections

14. Install Bin Thermostat Bulb..................................................................

15. Remove the Ice Deflector

16. Install Siphon Standpipe and Adjust Float

17. Replace the Ice Deflector

18. Loosen Compressor Hold Down Bolts

19. Start the Unit

20. Check Operation.................................................................................... 17

21. Final Check List

SERVICE

SERVICE PARTS

___

_______________________________________________________19-61

1. How the Automatic Ice Maker Works

2. Refrigerant Circuit.......................................................................................

3. Freezing Water Circuit

4. Electrical Circuit...........................................................................................

5. Ice Maker Service Checklist

6. Service Analysis 26H5 and 26H3

7. 26H Icemaker Rating Tables

.............

..................................................

......................................

...............................................................

______________________________

- --...................................................................

.........

............

...............................................................................10

............................................................

.......

______

.......

........................................

..........

......................

.........

......................................... .............................

......................................................................... 14

.....

.....................

.................................................................

..............................................................

...................................................................

_____________ ____________

........................

..............................

.................................................

.....

.............

...................................................

.........

.......................................................

.........................................................

____

______

___

...............

.........................

.........

.........................

................

.....................

.........

.........................

.....

..................................

___________________

___

__________ 9-i8

...........

................... 9

...................

............

.......

.....

....................

...............

.....................

_____

..........

..........

....

......

....

.....

.......

.. II

......

.......

......

26H

PAGES

3-6

7,8

9

9

.. 10

10

11

...II

11

12

13

14

14

15

16

16

17

.19

23

36

40

53

54

.60

63-64

All specifications, descriptions, detail drawings, etc.

subject to change without notice or incurring obligation.

1st Printing 7-15-57 5M

1st Reprint 5-15-58 2M

LItho in U.S.A

26H-57PD

Page 3

Carrier^

Automatic Icemaker 26H3

#

#

An automatic, low-cost ICE PLANT .

* Produces a continuous supply of ice, cubed or

crushed, automatically.

* Cubes are crystal clear, sanitary . . . untouched

by human hands. Cube's unique shape provides

larger cooling surface.

* Crushed ice delivered in three grades ... to meet

all your sized-ice needs.

* Easily, quickly installed. Requires only standard

electrical and water connections.

* Re-location a simple matter. Just disconnect

water and electricity . . . reinstall in new location.

right in your PLACE of BUSINESS!

* Compact cabinet occupies only 4 sq. ft. floor

area.

* Exterior styled to blend with finest surroundings.

Finished in sea spray green or white, stainless

steel trim.

* Minimum maintenance, maximum quietness . . .

simplified, unique mechanism delivers individually

formed cubes.

* Starts with simple on-off switch. Machine stops

automatically when bin is full, resumes operation

as soon as few cubes are removed.

* Low operating cost . . . efficient, quiet refrigera

tion cycle uses small amounts of water and power.

• Underwriters approved.

3

26H-57PD

Page 4

26H3

SPECIFICATIONS

Carrier

IDEAL for RESTAURANTS, HOTELS, MOTELS, BARS,

TAVERNS, CLUBS, HOSPITALS, DRUG STORES . . .

wherever a continuous supply of clear, sanitary ice,

cubed or crushed, is a tangible business asset. The

Carrier Icemaker freezes and delivers up to 200 pounds

of ice per day, at 90° ambient air and 70° entering

water. Quietly, without complicated cutting or chop

ping mechanism, it provides hard, sparkling cubes

or varied grades of crushed ice. The cube, too, is

designed for highest efficiency ... its unique shape

provides more-than-ordinary cooling surface.

COMPACT, ATTRACTIVE CABINET . . . takes up

only 4 square feet of floor area. Smart, modern design,

featuring rounded corners, o bonder!zed, boked-on

sea spray green or white finish, richly trimmed in

stainless steel and chrome . . . complements any

and all furnishings.

ICE CRUSHER. Entirely automatic, electric-motor

driven unit. Delivers crushed ice in three grades —coarse,

medium, or fine. User sets one control knob to "crushed"

and the other to grade as dictated by needs.

REMOVABLE PANELS provide easy access to working

parts. Access for all normal service through removable

front panel.

WELDED-TYPE HERMETIC COMPRESSOR. Quiet,

efficient, permanently oiled and vibrationless. Designed

for long life and trouble-free operation.

EXCLUSIVE DESIGN ICE-MAKING SYSTEM. NO

MOVING PARTS. Freezing coils are soldered to copper

bands and attached, at 8 different points, to each of 13

stainless steel freezing tubes. In operation, ice builds up

on inside wall of tube at these 8 separate points to form

8 cubes in each tube. Freezing completed, automatic

controls reverse cycle, releasing cubes which simply

"gravity drop" into bin or crusher, as “dialed" by user.

COMPLETELY AUTOMATIC. A simple rotary switch

starts the machine, from then on it produces ice auto

matically. When storage bin fills with cubes, or crushed

ice, the machine shuts off automatically, starting again

whenever some ice is used.

STORAGE BIN (bottom section) available in four

sizes — TOO, 160, 240 and 500 pounds capacity. It

has baked-on finish, stainless steel liner and 2 in

ches of insulation on sides. Partition separates

cubes and crushed ice.

SIPHON-INTERCHANGER. Automatically replaces

the water in the Icemaker system at the end of each

freezing cycle. Pure, crystal clear ice is assured, even in

hard water areas, with a minimum of cleaning and maxi

mum productive capacity.

MECHANICAL SPECIFICATIONS

COMPRESSOR: '/2 horsepower, single cylinder,

welded-type, hermetic compressor, driven by a capaci

tor-start, induction-run motor.

CONDENSER: Water-cooled, shell and finned copper

coil type.

REFRIGERANT: Safe, non-toxic, non-inflammable

FREON-12.

REFRIGERANT CONTROL: Single capillary tube . . .

no moving parts.

WATER PUMP: Stainless steel shaft, brass impeller

and brass housing. Directly connected to a shaded pole,

totally enclosed, thermally protected motor.

POWER CONSUMPTION: 575 watts during freezing.

SWITCH: 3-position rotary ... for manual starting

and stopping, or tor operating of water pump for

cleaning.

CURRENT: 115 volt, 60 cycle, single phase, alternat

ing current.

WATER CONSUMPTION: During freezing, 10 to 42

gallons per hour, depending upon supply water tem

peratures.

DIMENSIONS: 69 inches high, 25 inches deep. Width

is 24 inches with 100 pound storage.

26H3 ICEMAKER WEIGHTS:

Machine section, 100 lb. bin, no crusher, crated 348

Machine section, 100 lb. bin, no crusher, uncrated 305

Ma?hine section, 100 lb. bin, with crusher, crated 388

Machine section, 100 lb. bin, with crusher, uncrated 345

Machine section, 160 lb. bin, no crusher, crated 371

Machine section, 160 lb. bin, no crusher, uncrated 326

Machine section, 160 1b. bin, with crusher, crated 411

Machine section, 160 1b. bin, with crusher, uncrated 366

Machine section, 240 lb. bin, no crusher, crated 405

Machine section, 240 lb. bin, no crusher, uncrated 357

Machine section, 240 lb. bin, with crusher, crated 445

.Machine section, 240 lb. bin, with crusher, uncrated 397

ICE CRUSHER: Cast al uminum rotor, stainless steel

picks, sleeve bearings, belt-driven by a 1/6 horsepower,

drip-proof, thermally protected motor, with adjustable

drive-pulley.

Lbs.

26H-57PD

ÉM

Page 5

Automatic Icemaker 26H5

An automatic, low-cost ICE PLANT . . . right in your PLACE of BUSINESS!

* Produces a continuous supply of ice, cubed or

crushed, automatically.

* Cubes are crystal clear, sanitary . . . untouched

by human hands. Cube's unique shape provides

larger cooling surface.

* Crushed ice delivered in three grades ... to meet

all your sized-ice needs.

* Easily, quickly installed. Requires only standard

electrical and water connections.

* Re-location a simple matter. Just disconnect

water and electricity . . . reinstall in new location.

Underwriters approved.

* Compact cabinet occupies only 4 sq. ft. floor

area.

* Exterior styled to blend with finest surroundings.

Finished in sea spray green or white, stainless

steel trim.

* Minimum maintenance, maximum quietness . . .

simplified, unique mechanism delivers individually

formed cubes.

* Starts with simple on-off switch. Machine stops

automatically when bin is full, resumes operation

as soon as few cubes are removed.

* Low operating cost . . . efficient, quiet refrigera

tion cycle uses small amounts of water and power.

5

26H-57PD

Page 6

26H5

SPECIFICATIONS

Carrier

IDEAL for RESTAURANTS, HOTELS, MOTELS, BARS,

TAVERNS, CLUBS, HOSPITALS, DRUG STORES . . .

wherever a continuous supply of clear, sanitary ice,

cubed or crushed, is a tangible business asset. The

Carrier Icemaker freezes and delivers up to 450 pounds

of ice per day, at 90° ambient air and 70° entering

water. Quietly, without complicated cutting or chop

ping mechanism, it provides hard, sparkling cubes

or varied grades of crushed ice. The cube, too, is

designed for highest efficiency ... its unique shape

provides more-than-ordinary cooling surface.

COMPACT, ATTRACTIVE CABINET . . . takes up

only 4 square feet of floor area. Smart, modern design,

featuring rounded corners, o bonder!zed, boked-on

sea spray green or white finish, richly trimmed in

stainless steel and chrome . . . complements any

and all furnishings.

ICE CRUSHER. Entirely automatic, electric-motor

driven unit. Delivers crushed ice in three grades —coarse,

medium, or fine. User sets one control knob to “crushed"

and the other to grade as dictated by needs.

REMOVABLE PANELS provide easy access to working

parts. Access for all normal service through removable

front panel.

CARRIER SERVICEABLE-HERMETIC COMPRESSOR.

Provides all the advantages of ordinary, welded-type,

hermetically sealed compressors. No oiling, no belts, no

shaft seal with consequent risk of refrigerant loss. In

addition, retaining the advantages of the open-type

compressor — can be adjusted and serviced on the job.

EXCLUSIVE DESIGN ICE-MAKING SYSTEM. NO

MOVING PARTS. Freezing coils are soldered to copper

bands and attached, at 8 different points, to each of 26

stainless steel freezing tubes. In operation, ice builds up

on inside wall of tube at these 8 separate points to form

8 cubes in each tube. Freezing completed, automatic

controls reverse cycle, releasing cubes which simply

“gravity drop" into bin or crusher, as “dialed" by user.

COMPLETELY AUTOMATIC. A simple rotary switch

starts the machine, from then on it produces ice auto

matically. When storage bin fills with cubes, or crushed

ice, the machine shuts off automatically, starting again

whenever some ice is used.

STORAGE BIN (bottom section) available in

three sizes — 160 pounds, 240 pounds and 500

pounds capacity. It has baked-on finish, stainless

steel liner, 2 inches of insulation. Partition sepa

rates cubes and crushed ice.

SIPHON-INTERCHANGER. Automatically replaces

the water in the Icemaker system at the end of each

freezing cycle. Pure, crystal clear ice is assured, even in

hard water areas, with a minimum of cleaning and maxi

mum productive capacity.

ACCESSORY

208-VOLT CONVERSION PACKAGE. Consists of a

transformer which permits 230-volt model to operate

satisfactorily on 208 volts.

MECHANICAL SPECIFICATIONS

COMPRESSOR: T4-horsepower, twin-cylinder, service

able hermetic type with a capacitor-start, induction-run,

low starting torque motor.

CONDENSER: Water-cooled, shell and finned copper

coil type.

REFRIGERANT;

FREON-12.

REFRIGERANT CONTROL: Twin capillary tubes . . .

no moving parts.

WATER PUMP: Stainless steel shaft, bronze impeller

and bronze housing. Directly connected to a shaded

pole, totally enclosed, thermally protected motor.

POWER CONSUMPTION: 940 watts during freezing.

SWITCH: 3-position rotary ... for manual starting

and stopping, or for operating of water pump for

cleaning.

CURRENT: Available for 115 volt, 208 volt (with

conversion package), or 230 volt, 60 cycle, single phase,

alternating current.

Safe, non-toxic, non-inflammable

WATER CONSUMPTION: During freezing, 15 to 70

gallons per hour, depending upon supply water tem

peratures.

DIMENSIONS: 77 inches high, 25 inches deep. Width

is 24 inches for 160 pound storage model, 34 inches for

240 pound model.

26H5 ICEMAKER WEIGHTS:

Machine section, 160 lb. bin, no crusher, crated 450

Machine section, 160 lb. bin, »o crusher, uncrated 405

Machine section, 160 lb. bin, with crusher, crated 490

Machine section, 160 lb. bin, with crusher, uncrated 445

Machine section, 240 lb. bin, no crusher, crated 484

AAachine section, 240 lb. bin, no crusher, uncrated 436

Machine section,, 240 lb. bin, with crusher, crated 524

Machine section, 240 lb. bin, with crusher, uncrated 476

Machine section, 500 lb. bin, no crusher, uncroted 438

Machine section, 500 lb. bin, with crusher, uncrated 478

ICE CRUSHER: Cast al uminum rotor, stainless steel

picks, sleeve bearings, belt-driven by a 1/6 horsepower,

drip-proof, thermally protected motor, with adjustable

drive-pulley.

#

26H-57PD

Page 7

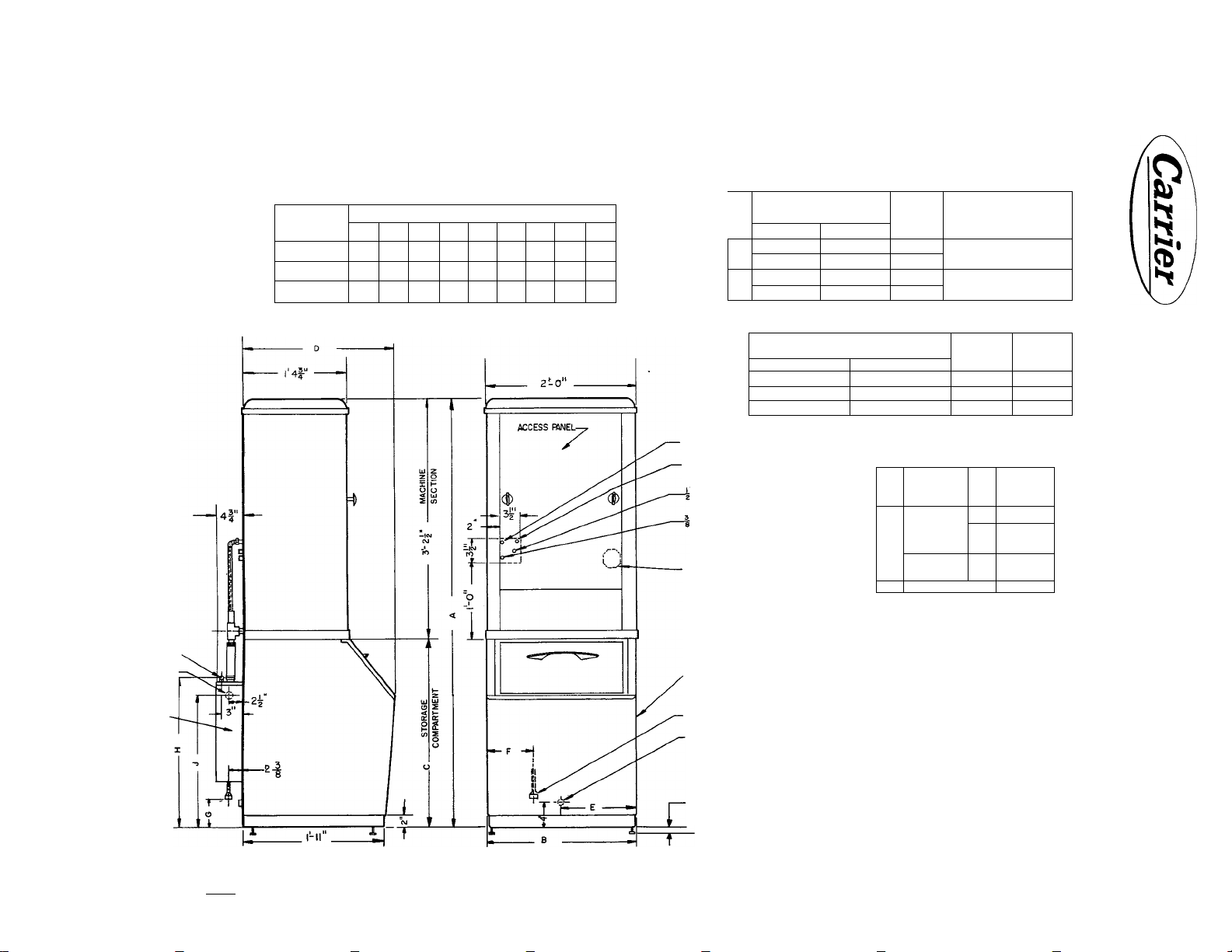

À 1

f FSAE WLET-

INTERCHANGER.

i MPT OUTLET—

NTERCH ANGER

STORAGE

COMPARTMENT

CAPAOTYILB)

100

160

A

5 -8^ 2-0"2'-6"

2-0

240 é-4| 2-10 3'-2"

B C

3'-2" 2-1"

DIMBISION

D

ÿ-o|"!-0"

2-1 " 1- 5"

E

r-o"

F G

8i"

8i'

l'l-8

3|"

III”

III"

H

!-9"

2-0"

2-5

2'-8"

2'-8 2'-5”

PART NUMBER -

MACHINE SECTION WTH

J

MSAE INLET- CONDENSER

■INTERCHANGER TO FLOAT VALVE

CCNNECTION

MSAE OUTLET-CONDENSER

MSAE OUTLET- DRIP PAN

HEAT INTERCHANGER

NO CRUSHER

26H3- 309

£

o

a

26H3- 329

26H3- 709 26H3-7I9

i

26H3- 729

s

DOMESTIC PART NUMBER -

ICE STORAGE COMPARTMENT

SEA SPRAY GREEN FINISH'

26D3-2 49

26D5- 449A

26D5-469A

WITH CRUSHER

26H3-319

26H3-339 WHITE

26H3-739

UIM. 1*1 I «

4 HpLES

FINISH

SEA SPRAY

GREEN

SEASFW

GREEN

WHITE

WHITE FINISH

26D3^ 259 100 83

26D5- 459A 160 104

26D5- 479A

3«' DIA. THERMOSTAT BULB OPENING

ELECTRICAL

CHARACTERISTICS

ALL UNITS ARE f HP)

115- 1-60

230-1-50

STORAGE

CAPACITY

(LB)

i-of- —»

240

,1 i f

-4|"

mi®

NET

WEIGHT

(LB)

135

D

s

^ ioh-

INLET OPENING TO JUNCTION

BOX - REAR PANEL

CE STORAGE COMPARTMENT

ICE

DISCHARGE

-^OPENING ^

-5-

~T

lo|CD

MACHINE SECTION- BOTTOM VIEW

FRONT-# —!—

l‘-5f -

-l-llx"

___

V-i®

• 1

__L

Z

t/>

5

z

(/)

lyTTERCHANGER.

TRi.R.0.

CHK. DE.M APPO. E.LV

DATE n-19-58

SUPERSEDES

ISSUE OF

AUTOMATIC ICE MAKER-WATER COOLED

I* FSAE CLEANOUT - INTERCHANGER

f MPT DRAW - storage COMPARTMENT

ALLOW APPROX 2" FOR LEVELING SCREWS

KJ

DWO NO

26H3 - 423

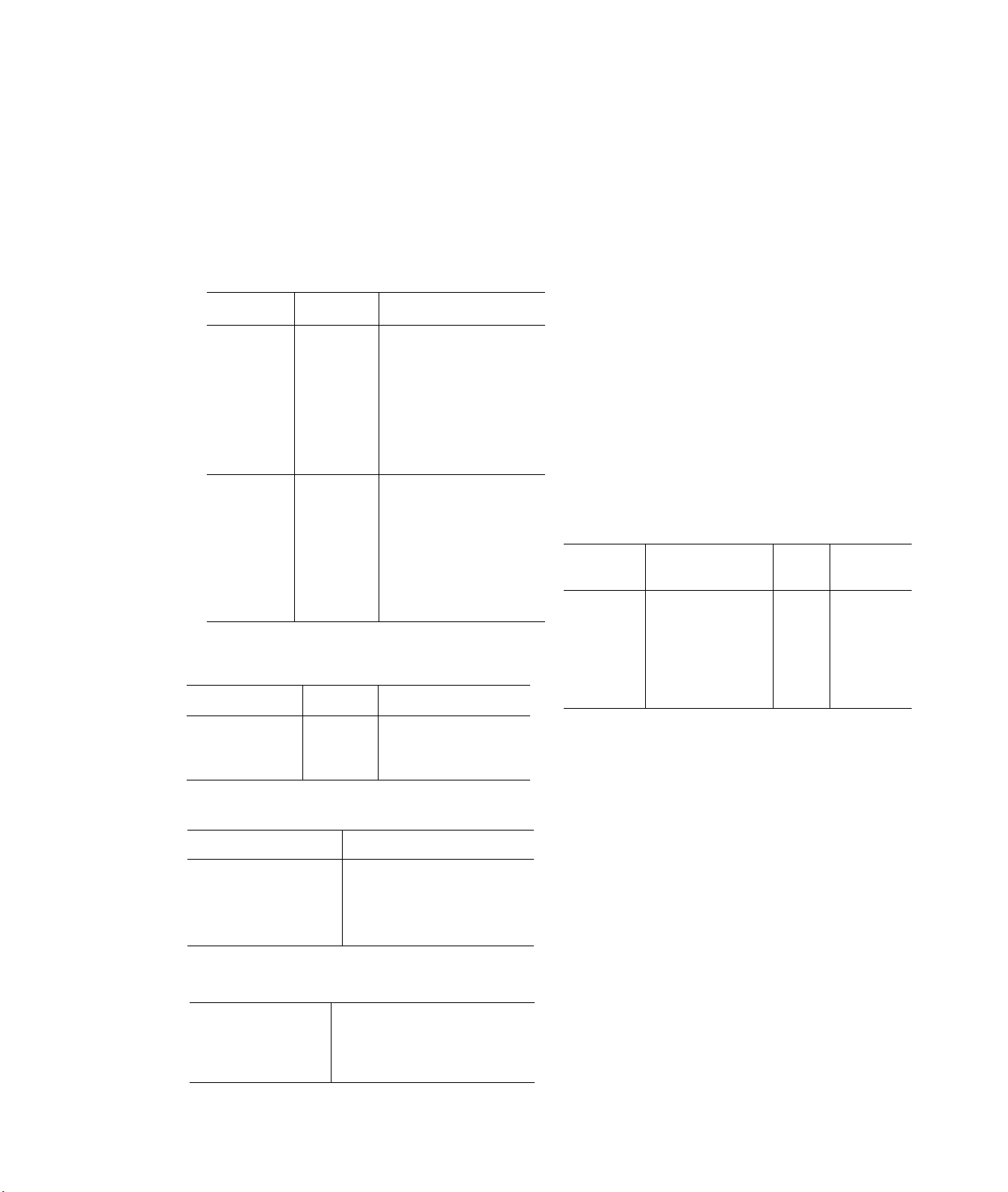

Page 8

STORAGE

COMPARTMENT

CAPACITY

16 0

240 6-41'

500

6-4j

PART NUMBER

MACHINE SECTION WITH

HEAT INTERCHANGER

A

2- O"

2- 10“

4L5"

B

C

d

3- 2"

2-1"

3^2" 2-1“

- ÿ-o" • 2-a“

E

____

1-0"

1-5"

E__..

0-8Ì 0- Ili 2-8" 2-5"

1-1 r

G

o'-Ili"

H

- J-

¿-8" 2-ë'

N0 CRUSHER

26H5-349A 26H5-369A

ü

1—

26H5-359A

CO

26H5-389A

%

Q

26H5-399A

26H5-669A 26H5- 689A

cr

26H5-679A 26H5-699A

WITH CRUSHER

26H5-379A

26H5-409A

26H5-419A

UNITS WITHOUT CRUSHER WEIGH 301 LB. NET

WITH CRUSHER, UNITS WEIGH 341 LB. NET.

ELECTRICAL

CHARACTERISTICS

(ALL UNITS ARE ^HP)

II5-I-60

230-1-60

115-1-60

230-1-60

FINISH

SEA SPRAY

GREEN

Ï'IIITC

, WHITE

KJ

|"FSAE INLET-

INTERCHANGER.

r'MPT OUTLET-

• INTERCHANGER \

INTERCHANGER

DOMESTIC PART NUMBER

ICE STORAGE COMPARTMENT

SEA SPRAY GREEN FINISH

26D5-449A

26D5-4 69A 26D5- 479A

26H5-6 2 9B 26H5- 649B

INTERCHANGER TO FLOAT

VALVE CONNECTION

MSAE INLET-CONDENSER

INLET OPENING TO JUNCTION

BOX- REAR PANEL

X MSAE OUTLET- CONDENSER

2

1 MSAE OUTLET- DRIP PAN

8

160 LB. ICE STORAGE COMPARTMENT

240 LB. ICE STORAGE COMPARTMENT

i"FSAE CLEAN OUT-INTERCHANGER

2

1"mPT drain-STORAGE COMPARTMENT-500 LB. BIN DRAIN LOCATED ON

4

BOTTOM (L OF BIN, r'MPT- CAST BRASS

ALLOW APPROX. 2"F0R LEVEUNG SCREWS

WHITE FINISH

26D5- 459A 160

JDIA. THERMOSTAT BULB OPENING

(2)1

4

STORAGE

CAPACITY

(LB.) (LBJ

240 135

500

MACHINE SECTION-BOTTOM.VIEW

NET

WEIGHT

104

225

D

£

z

(/>

5

z

U)

DR- ERA

CHK. D.E.M

DATES- 8- 62

SUPERSEDES

ISSUE OF ir-19-sa

AUTOMATIC ICE MAKER-WATER COOLED

DWG. NO.

26H5-423

Page 9

Carrier

INSTALLATION

26H

-m

1. CHECK SHIPMENT

The unit is shipped in three cartons. One contains

the machine compartment, one the storage bin and

one the siphon interchanger assembly.

TABLE 1 - PARTS LIST

MACHINE SECTION CRATE

Model

26H3 1

26H5

Quantity

1

1

1

1

1

1

1

1

1

Description

Machine Section

Outside Standpipe

Water Strainer

Crusher Guard*

Inside Standpipe &

Rubber Grommet

Machine Section

Outside Standpipe

Water Strainer

Crusher Guard*

Inside Standpipe &

Rubber Grommet

2. SELECT PROPER LOCATION

Select a location for the unit before delivery. The

following should be considered:

1. Convenience - Select a clean dry place as

close as possible to the point of ice consump

tion. Consult the user before deciding.

2. Room Temperatures

Minimum 50 F - Room temperatures below this

may cause erratic control operation.

Maximum 100 F - Room temperatures above

this overload the compressor and reduce unit

capacity.

3. Floor Strength - See Table 2.

TABLE 2 - OPERATING WEIGHT AND

DIMENSIONS

Model No.

26H3

Total Weight

(Bin Full of Ice)

389

Bin

Cap.

100 25 X 24

Floor

Area (In.)

#

On units equipped with crusher only.

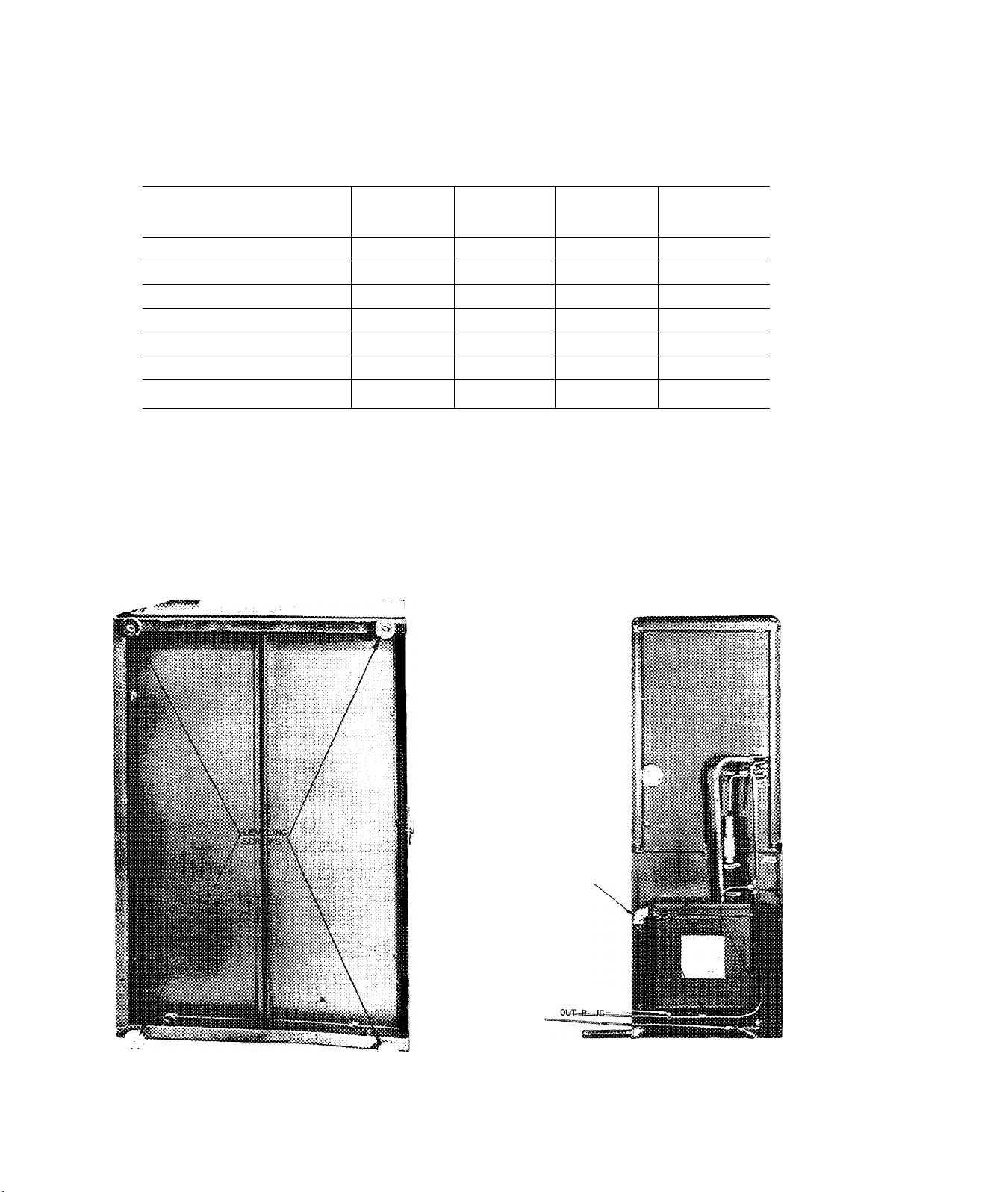

STORAGE BIN CRATE

Size, Lb. Quantity

100, 160, 240,

500 4

HEAT INTERCHANGER PACKAGE

Quantity

1

1

2 Hose Clamps

STORAGE BIN PARTITION

Quantity Description

1

1

Partition

Machine Screws

Description

Storage Bin

Leveling Screws

Description

Interchanger

Rubber Hose

26H5 565

26H5

26H5 940

NOTE: Add 40 lb for Crusher.

4. Clearance:

Top

Rear and Sides

Front

5. Water Supply - See Section 12.

6. Drain Connections - See Section 12.

7. Electrical Connections - See Section 13.

3. MOVE UNIT TO LOCATION

Move the unit to the proper location before uncra

ting. Crated dimensions are shown in Table 3.

676

10" Minimum

6" Minimum

24" Minimum

160 25 X 24

240 25 X 34

500

32 x50

26H-57PD

Page 10

26H INSTALLATION

TABLE 3 - CRATED DIMENSIONS

Carrier

Height Depth

(in.)

26H5 Machine Section

26H3 Machine Section

100 lb. Bln

160 Lb. Bin 39-1/2

240 Lb. Bin

500 Lb. Bin

Heat Interchange!

4. UNCRATE THE BIN

Uncrate the bin first since it serves as the base

for the unit.

5. INSTALL LEVELING SCREWS

Support the bin with the four leveling screws sup

plied with the bin. See Fig. 1. The top of the bin

can be used for leveling.

43-1/2

43-1/2

31-1/2

39-1/2

45-1/2

22-1/2

Width

(in.)

23-1/2

23-1/2

27

26-1/2

26-1/2

34-7/8 49-1/2

17

6. UNPACK AND MOUNT THE HEAT

Remove the interchanger and parts from the carton.

Mount the heat interchanger on the back of the bin

with the 6 sheet metal screws in the paper envelope.

The position of the interchanger on the back of the

bin is shown in Fig. 2.

(in.)

28-1/2

28-1/2 236

26

25 112

35

5 18

INTERCHANGER

Weight

(lb.)

307

95

142

225

t

FIG. 1 - LEVELING SCREWS INSTALLED

26H-57PD

10

HEAT INTERCHANGER

DRAIN

HEAT INTERCHANGER

CLEAN

FIG. 2 - POSITION OF HEAT INTERCHANGER

ON THE BIN

Page 11

Carrier

INSTALLATION

26H

7. MOVE THE BIN TO APPROXIMATE LOCATION

Move the bin as close as possible to the final lo

cation before placing the machine section on top

of it.

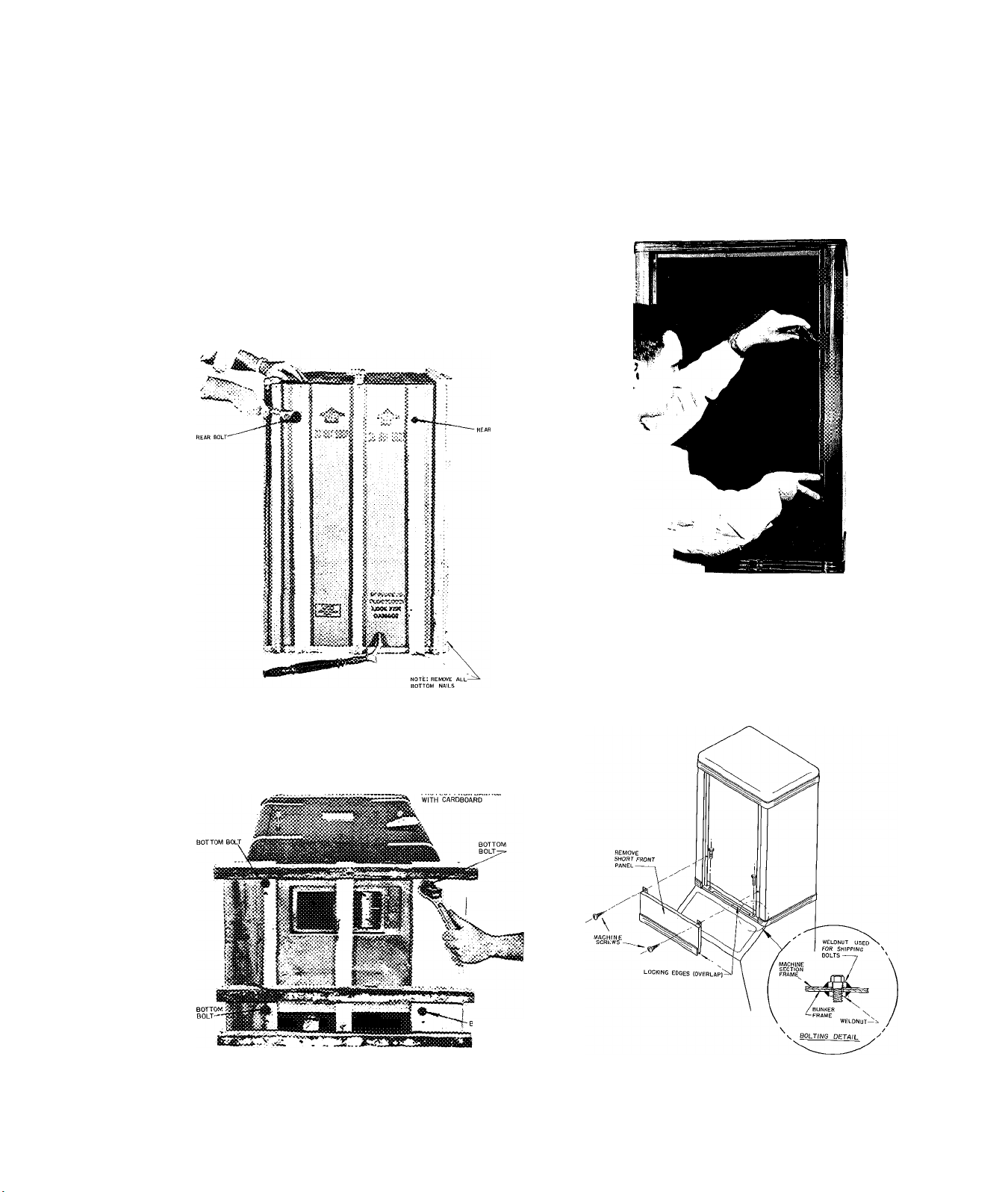

8. UNCRATE THE MACHINE SECTION

Uncrate the machine section as shown in Figs. 3

and 4.

9. REMOVE THE FRONT TOP, AND SIDE PANELS

Remove the front, top, and side panels in that order

before moving the machine section.

FIG. 5 - REMOVING SCREWS HOLDING TOP

AND SIDE PANELS

m

FIG. 3 - UNCRATING - REAR BOLTS

FIG. 4 ■ UNCRATING - BOTTOM BOLTS

10. PLACE MACHINE SECTION ON TOP OF BIN AND BOLT IN POSITION

Remove the short front panel. Using the two cap

screws in the cloth bag shipped with the bin, bolt

the machine section in place as shown in Fig. 6.

BOTTOM BOLT

FIG. 6 - BOLTING MACHINE SECTION TO BIN

II

26H-57PD

Page 12

INSTALLATION

n. BOLT TIE BAR AT REAR OF UNIT

Lock the two sections together with the tie bar

shipped on the back of the machine section. See

Fig. 7.

Carrier

^1^

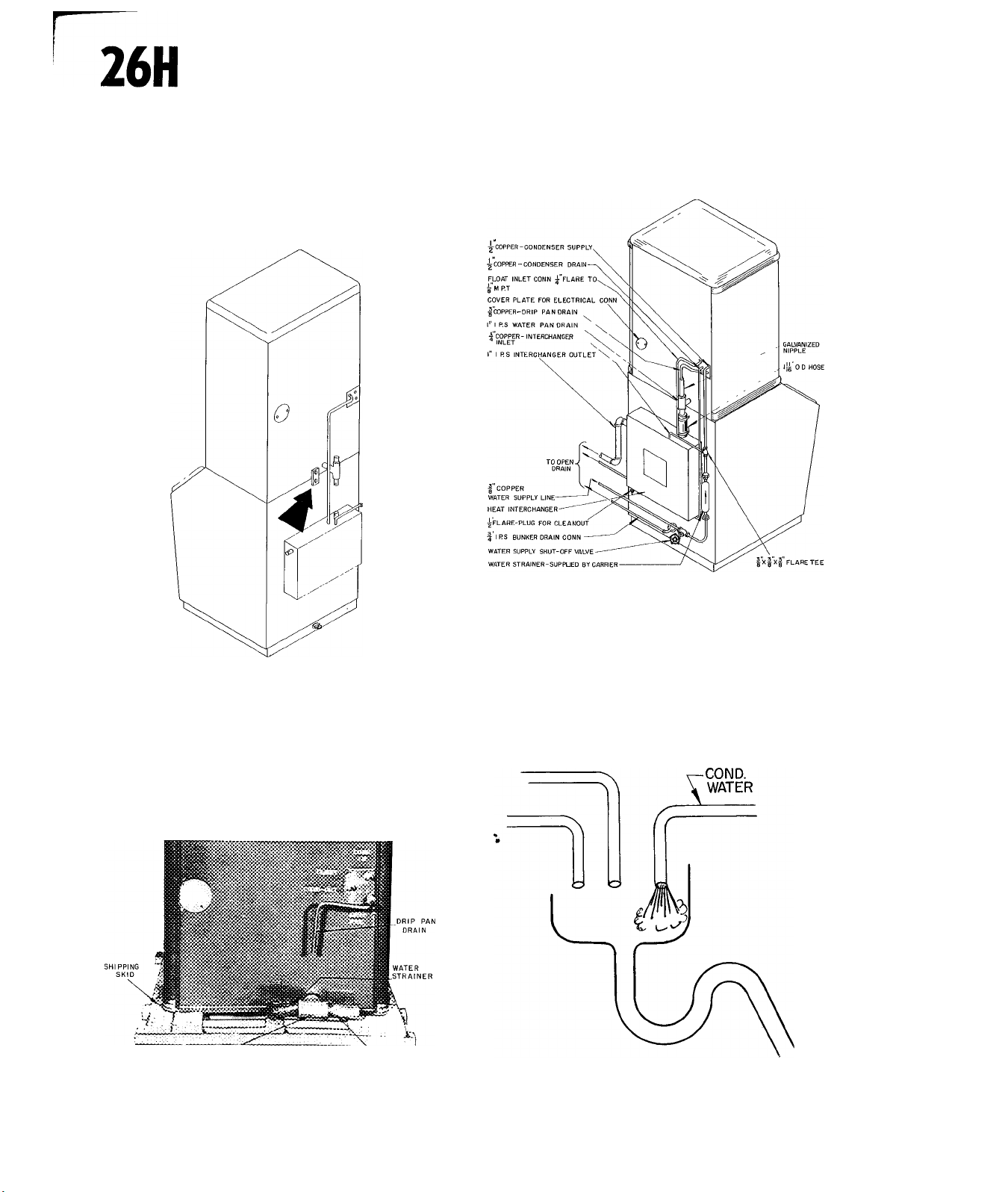

Refer to Fig. 9 for recommended piping details.

FIG. 7 - BOLTING TIE BAR AT REAR OF UNIT

12. INSTALL WATER SUPPLY AND DRAINS

Fig. 8 shows the piping connections and parts sup

plied by the factory. Any approved source of drink

ing water can be used provided a 30-60 lb. water

pressure can be maintained. If the pressure ex

ceeds 60 lbs. a pressure reducing valve must be

used.

FIG. 9 - PIPING DIAGRAM

The drain lines should be piped separately to an

open drain. The bin drain must be pitched down

ward for gravity flow. See Fig. 10.

r 6ALVAN12ED"T

FIG. 8 - PARTS SHIPPED ON BACK OF

MACHINE SECTION

26H-57PD

GALVANIZED NIPPLE

f

FIG. 10- OPEN DRAIN

12

Page 13

Carrier

INSTALLATION

26H

m

13. MAKE ELECTRICAL CONNECTIONS

Obtain a voltmeter or the special portable line vol

tage tester recommended in the Carrier Product

Information Book. For satisfactory results, the vol

tage when the unit is running must always remain

within 10 percent of the rated nameplate voltage.

Check the current supply at the customer's prem

ises and resolve any wiring problems before pro

ceeding with the installation. See Table 4 for nec

essary electrical data.

TABLE 4

FULL LOAD

MODEL VOLTAGE

26H3

26 H5

26H5

Carrier

Part No.

115

115

230 6.7

General

Electric

Part No.

CURRENT

10.8 15

13.4 17 1/2

TABLE 5 - 208V APPLICATION

Total

Amps

Allowable

208V APPLICATION "BUCK AND BOOST"

TRANSFORMER

For application on 208 volt circuits, a transformer

is recommended to boost the voltage from 208 volts

to 230 volts. The information in Table 5 should be

helpful in selecting the transformers. It is selected

on the basis of making a 10% voltage boost from

205 volts to 225 volts.

FUSETRON

SIZE

9

WIRE SIZE (AWG) TYPE R,T

LENGTH OF RUN

25'

14

12 12

14

50'

12

14

100'

10 6

8 6

14 12

200'

m

HT04AH026

HT04AH035

Not stocked

at Carrier

The wiring connections for this transformer for a 10% voltage boost are as follows:

9T51Y6171 12.5 amps.

9T91Y6172

-INPUT-

FIG. n - "BUCK AMD BOOST" TRANSFORMER WIRING

25 amps. Four units without crushers or two units with

37.5 amps.

-OUTPUT-

-—I 2

Two units without crushers or one unit with

crusher plus one without crusher.

Will NOT handle two units with crushers.

crushers plus two units without crushers.

Will NOT handle four units with crusher.

Six units without crushers or three units with

crushers plus three units without crushers

13

26H 57PD

Page 14

26H INSTALLATION

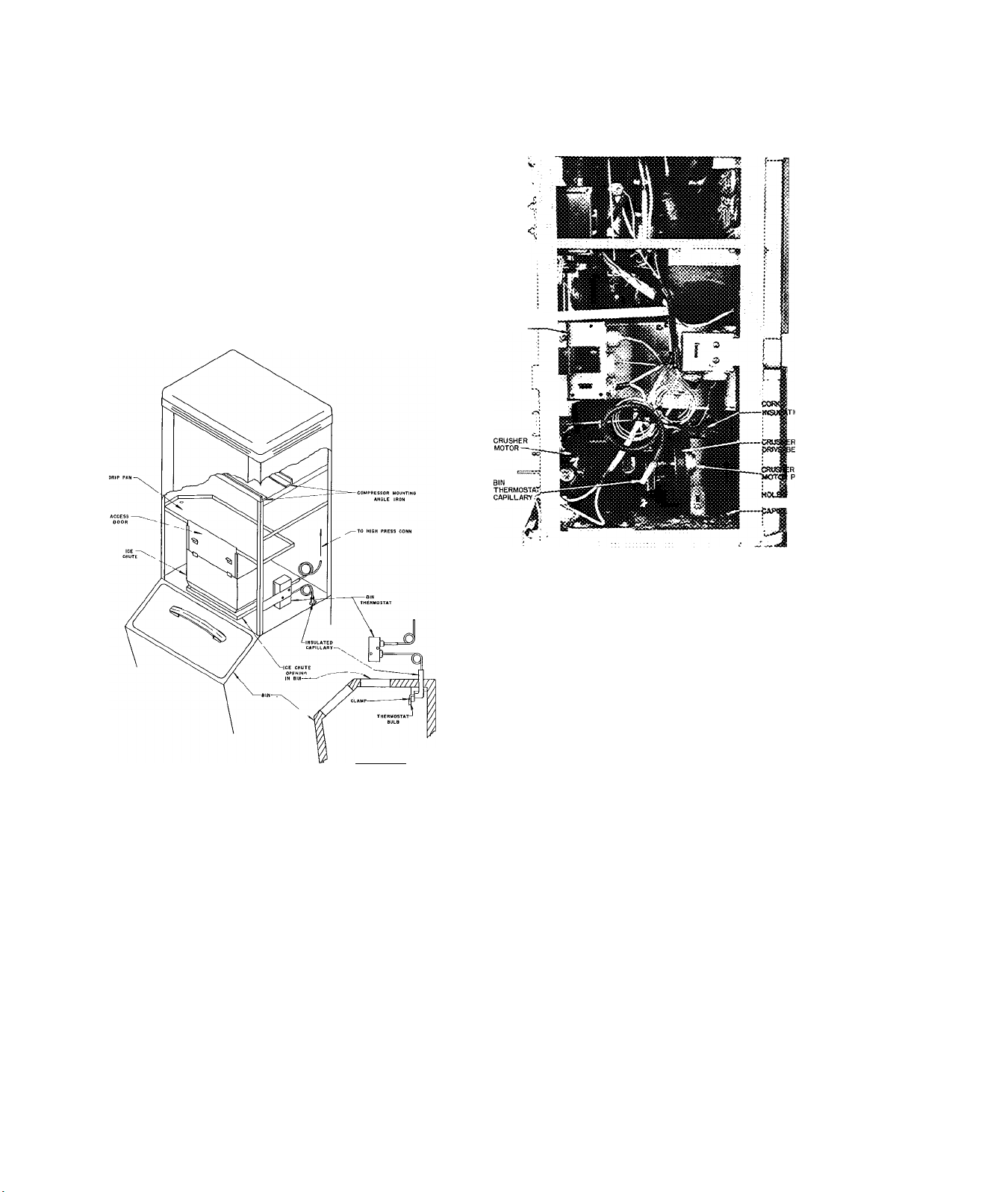

14. INSTALL BIN THERMOSTAT BULB

Remove the tope holding the bin thermostat cap

illary and bulb in a coiled position inside the right

side of the machine section. Uncoil 4 or 5 loops

of the capillary and insert the bulb through the hole

in the right rear corner of the machine section into

the bin. Run the capillary along the top of the bin

and down the back of the thermostat bulb bracket.

See Figs. 12 and 13.

BIN

THERMOST^r

a HI PRESS.

CUTOUT

Carrier

OR BIN

tmsSostat

ARY

SIDE View DETAIL

FIG. 12 - BIN THERMOSTAT CAPILLARY AND

BULB ARRANGEMENT

26H 5-500. 240 AND 160 LB. BINS

Attach the clamp to the bottom hole in the bracket;

insert the thermostat bulb in the clamp so it ex

tends 1/2" below the bottom of the bracket. Tighten

the clamp.

26H3-100 LB. BINS

FIG. 13

RIGHT SIDE OF 26H3 SECTION -

PANELS REMOVED

Instructions for mounting the thermostat capillary

and bulb on a partition are included in the partition

package.

CAUTION: Insulate the capillary where it goes

through the hole in the machine section and the

bin with tape or rubber tubing.

15. INSTALL CRUSHER GUARD

Remove crusher guard assembly from ice chute on

grusher models and install per instructions in para

graph 19 on page 39.

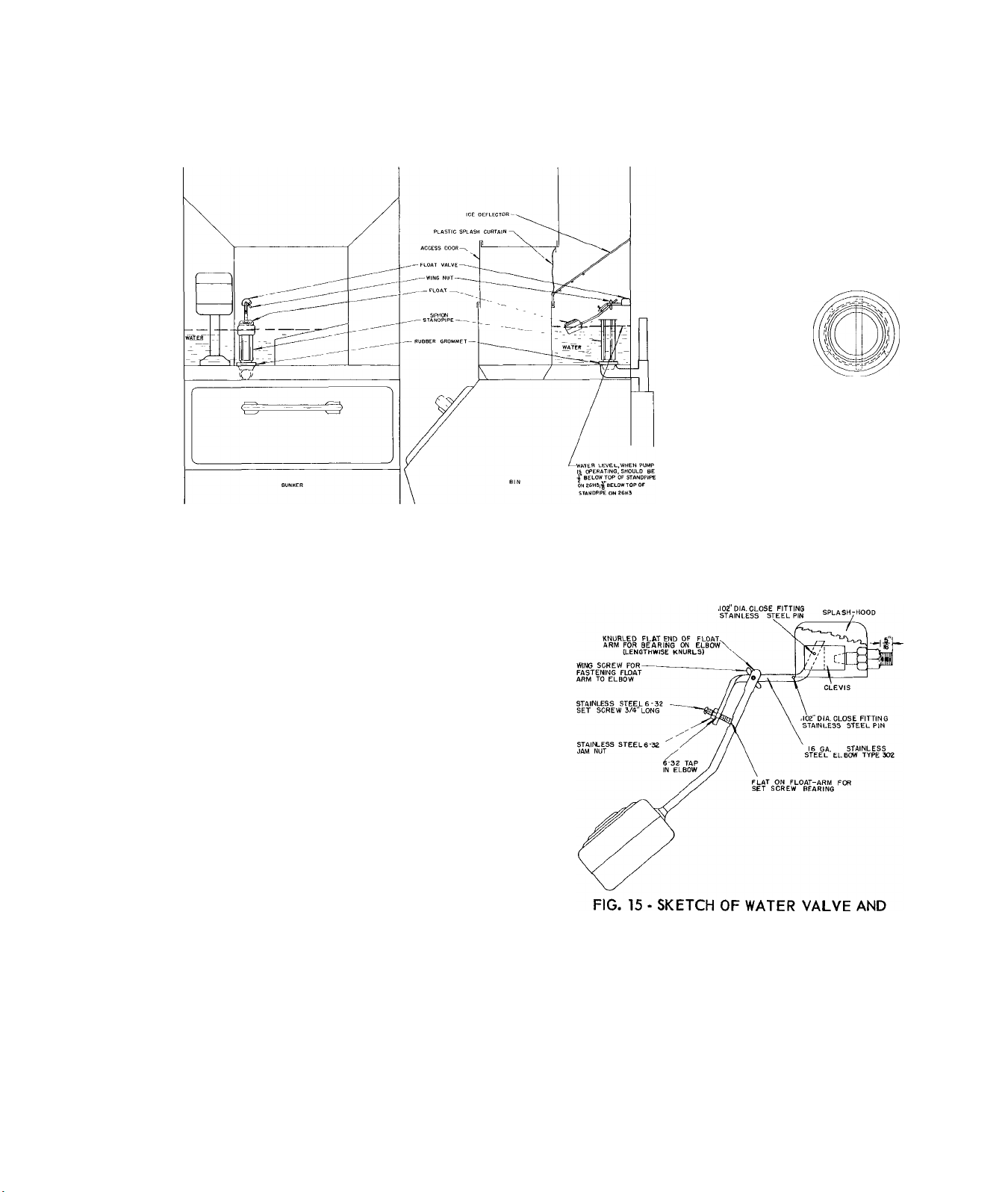

16. INSTALL SIPHON STANDPIPE AND ADJUST FLOAT

Remove the ice deflector to gain access to the water

pan. Fig. 14.

With the clamp attached to the bracket at the top

hole in the arm of the bracket, insert the thermo

stat bulb in the clamp so the clamp is approximately

in the middle of the bulb and tighten the clamp.

26H-57PD

Place standpipe assembly and rubber grommet in

water pan drain. (See Fig. 14). On 26H3 unit,

remove knockout in stainless steel jacket. (Do

not remove on 26H5 unit.)

14

t

Page 15

Carrier

INSTALLATION

26H

FIG. 14 - CORRECT WATER LEVEL

Turn on the water and set the float valve to main

tain a water level 3/8 " below the top of the siphon

stcujdpipe for the 26H3 and 1/2" below for the 26H5.

See Fig. 14.

The water level should be set with the pump off,

and checked again with the pump running, after the

water level has settled. To check the Siphon action

let the unit run on "Pump" until the float shuts ofi

the water to the pan. Turn the selector switch to

"Off". The water in the header and the water pipes

will drop down and raise the water pan level until

the Siphon action begins and the water pan is si

phoned out.

If the water pan fails to siphon out, the water level

has been set too low. If the water siphons or over

flows the inner standpipe when the pump is running,

the water level has been set too high.

FLOAT ASSEMBLY

17. REPLACE THE ICE DEFLECTOR

After the float is set, tighten the wing nut on the

float arm and the setscrew to the flat on the float

arm. See Fig. 15.

The bottom of the deflector sets in two clips fas

tened to the inside front wall of the water pan. The

back of the ice deflector rests against the front of

the evaporator shroud. See Fig. 14.

15

26H-57PD

Page 16

26H

INSTALLATION

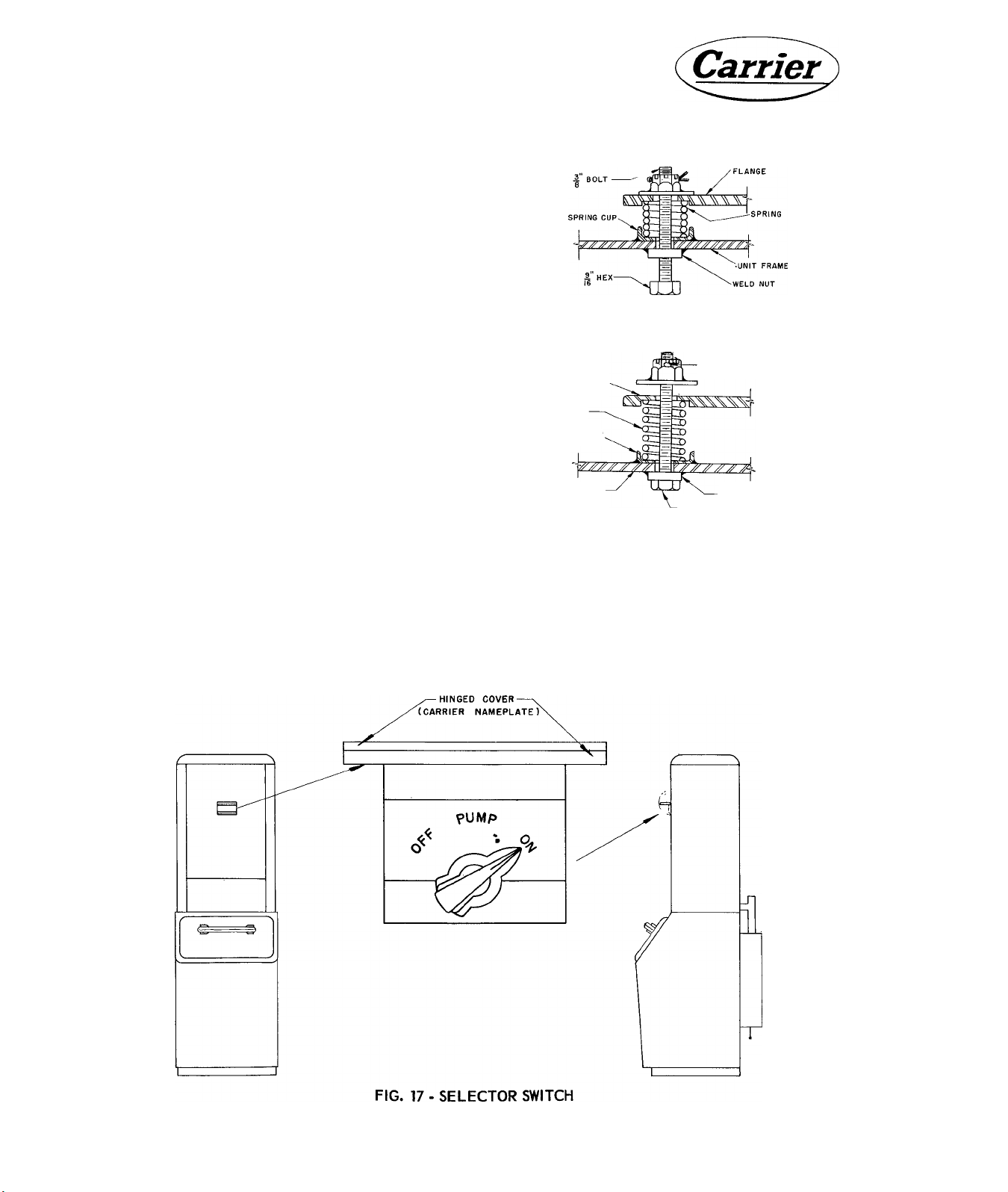

18. LOOSEN COMPRESSOR HOLD-DOWN BOLTS

26H5

Loosen the four compressor hold-down bolts. See

Fig. 16. Check to see that the compressor is float

ing freely on its mounting springs.

When the machine is to be moved, retighten the hold

down bolts to prevent damage.

26H3

The 26H3 is spring mounted internally. Do not

loosen compressor hold-down bolts.

19. START THE UNIT

Shutoff valves are backseated and the unit is ready

for operation when shipped.

Turn the selector switch located under the hinged

nameplate to the "ON "position and check the opera

tion. See Fig. 17.

If the unit fails to start^ push the reset button on

the Safety Overflow Switch.

NOTE: The 26H5 unit may cycle several times on

the high pressure cutout during initial start

up or after a prolonged shut-down. While

such cycling is perfectly normal, it may

COMPRESSOR

SHIPPING POSITION

DO NOT REMOVE

COMPRESSOR

FLANGE

SPRING

SPRING CUP

UNIT FRAME

OPERATING POSITION

COTTER PIN

WELD NUT

BOLT TIGHT AGAINST

WELD NUT

FIG. 16 - COMPRESSOR HOLD-DOWN BOLTS

be reduced by shutting off the unit for about

a half a minute then starting again.

The 26H3 may cycle on overload several

times upon attempting to start after a pro

longed shutdown.

26H-57PD

16

Page 17

Carrier

INSTALLATION

26H

nr

20. CHECK OPERATION

The operation should be as follows:

(a) Freezing for 30 or 40 minutes - compressor

operating, pump operating and hot gas so

lenoid closed. A longer freezing period may

occur where the water supply temperature is

high.

(b) Defrosting for approximately 6 minutes - com

pressor operating, hot gas solenoid open and

water pump off.

(c) Overrun - Time, which is the time between the

falling of the last cube and the start of the

next freezing cycle, should be about 1/2 a

minute to 1-1/2 minutes, to increase overrun

time, raise the setting of the righthand ele

ment (cut in) of the Main Control Thermostat.

(d) The hole in the average ice cube should be

about 3/16" diameter. Run two or three batch

es, since the first harvest will produce-cubes

with larger than overage holes.

21. FINAL CHECK LIST

3. Has the overrun time (par 20C) been set?

4. Have all the controls been checked?

5. Has the voltage been load tested and checked

against nameplate voltage?

6. Have the compressor hold-down bolts been loos

ened so that the compressor rides freely on its

mounting springs?

7. Has the float been set so water will siphon out

at the end of each freezing cycle?

8. Operate the unit for at least two or three cycles.

Is it operating properly?

9. Is the unit quiet?

10. Is the unit clean?

11. Have the installation and warranty cards been

filled out?

1. Is the unit level?

2. Have all electrical and piping connections been

made?

12. Has the owner been given the Operating Instruc

tion booklet and has he been instructed on how

to operate the machine?

17

26H-57PD

Page 18

Carrier

#

Page 19

^-rar

Carrier

1. HOW THE AUTOMATIC ICE MAKER WORKS

The Ice Cube Maker is fully automatic and operates in two alternate cycles - first the freezing cycle, then the

harvesting cycle. The compressor operates continuously during both cycles

SERVICE

26H

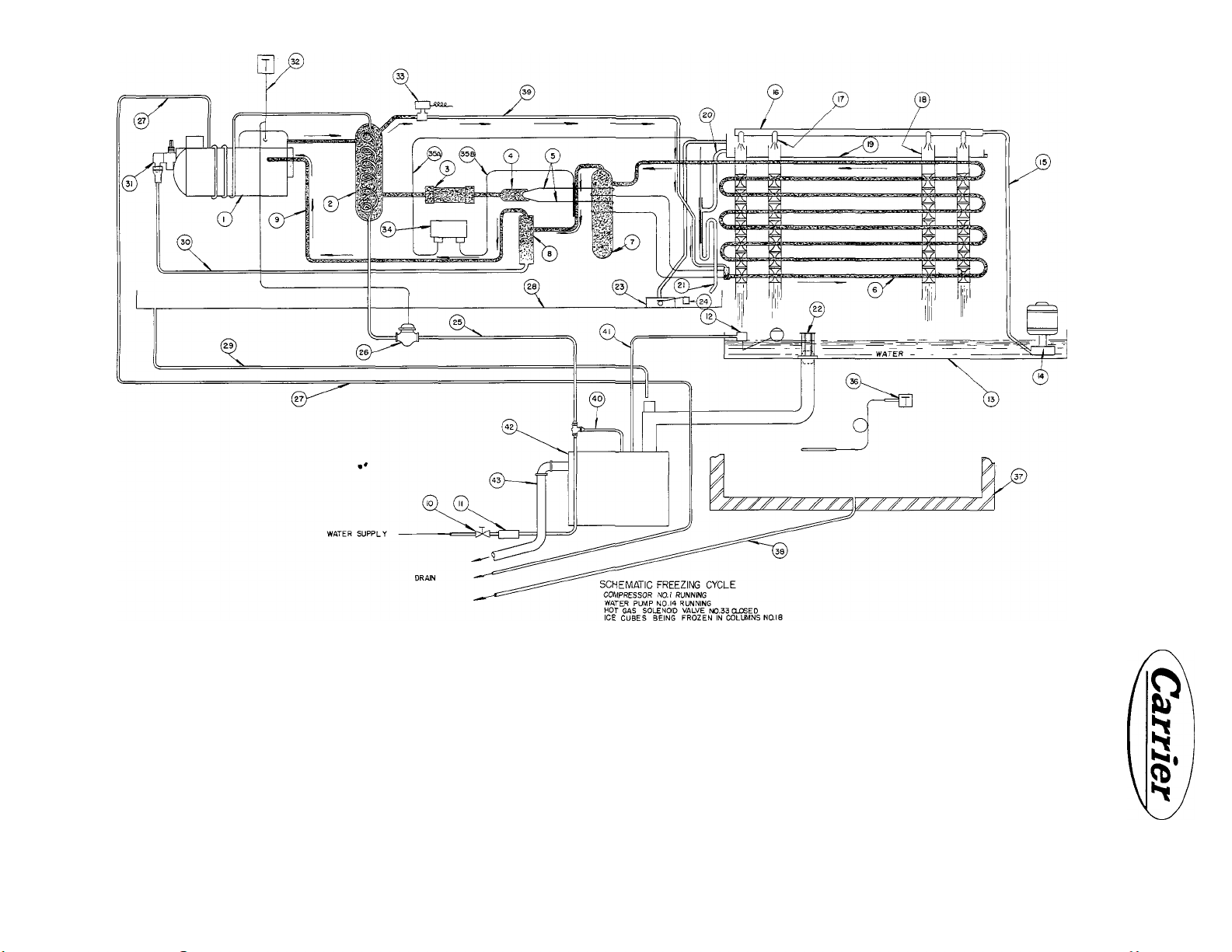

FREEZING CYCLE (SEE FIG. 1)

During the freezing cycle water is pumped from the

water pan (13) to a water header (16) at the top of

the unit. From, the water header it flows over individ

ual spreader plates, down the four inside surfaces

of each of the square, stainless steel freezing col

umns (18). Here water is frozen into individual

cubes. This is accomplished by unique evaporator

design. Copper sleeves are bonded to the outside

of each stainless steel column at eight points

spaced along its vertical dimension. Sections of

the evaporator coils are in turn soldered to these

copper bands. Because of the high rate of heat

transfer through the copper and the low conductiv

ity of the stainless steel, individual cubes start

to form inside the columns opposite each copper

band and grow from this point. The hole in the cen

ter is due to continuous water flow - necessary to

form clear cubes.

DEFROST CYCLE (SEE FIG. 2)

When the passage through any one of the columns

becomes restricted because of ice formation, water

backs into the overflow trough, (19), and drops into

the thermostat well,. (21). Here the cold water acti

vates the cut-out side of the Ranco two-bulb con

trol, (35A). This starts the harvest cycle by stop

ping the water pump (14), and opening the hot gas

solenoid valve, (33). The solenoid valve allows hot

gas to pass directly from the condenser, (2), to the

evaporator coil, (6). The cubes are melted loose

and allowed to drop through the ice chute into the

storage compartment, or bin, (37). If the cubes fail

to drop, the water will continue to build up in the

overflow trough and will flow into the safety over

flow well'(23). This actuates a safety switch (24)

and shuts the machine off.

The hot gas passing from the evaporator coil through

the suction line, warms the capillary bulb (35B)

attached to the vertical portion of the suction line

leading from the first accumulator. The warming of

this_ bulb activates the cut-in side of the Ranco

two-bulb control, which starts the machine on the

freezing cycle. As soon as the Ranco control moves

the machine into the freezing cycle, the water pump

is automatically started and the solenoid valve

closes.

19

26H-57PD

Page 20

KJ

<

1- COMPRESSOR

2- CONDENSER

3- STRAINER a DRYER

4- ADAPTER (FOR TWIN CAPILLARIES)

5- TWIN CAPLLARIES

6- EVAPORATOR COILS

7- 1ST ACCUMULATOR

8- 2ND ACCUMULATOR

9'SXTION LINE

10- SHUT-OFF VALVE (WATER SUPPLY)

11- WATER STRAINER

FUDAT VALVE

WATER PAN

WATER PUMP

WATER LINE (TWIN)TO WATER HEADER

WATER HEADER

WAT^R NOZZLES

FREEZING COLUMNS

OVERFLOW TROUGH

DRAIN LINE FROM OVERFLOW TROUGH

THERMOSTAT WELL

•SIPHON STANDPIPE (WATER PAN DRAIN)

FIG. 1 - SCHEMATIC FREEZING CYCLE

23- SAFETY OVERFLOW WELL

24- OVERFLOW SAFETY SWITCH

2 5-WATER SUPPLY TO. CONDENSER

26- WATER REGULATING VALVE

27- CONDENSER WATER DRAIN

28- DRIP PAN FOR MACHINE SECTION

29- DRIP PAN DRAIN LINE

30- OIL RETURN LINE

31 • SERVICE SHUT-OFF VALVE

32-HIGH PRESSURE CUT-OUT

33 HOT GAS SOLENOID VALVE

*

34- MAIN CONTROL THERMOSTAT

35A- MAIN CONTROL “CUT-OUT C^ILLARY

35B-MAIN CONTROL'CUT-

36 - BIN THERMOSTAT

37 - BIN

38 - BIN DRAIN

39 - HOT GAS LINE

40 - WATER SUPPLY TO HEAT INTERCHANGER

41- WATER SUPPLY TO SUMP

42- HEAT INTERCHANGER

43- HEAT INTERCHANGER DRAIN

IN" CAPILLARY

1

Page 21

~W

Carrier

SERVICE

26H

t?T

sssssss?;?;

i

ii iSi

gSesni-

II

m

_i

U

>U

I—

CO

O

Di

O

y

H

<

s

LU

X

I

CN

o

tl.

21

26H-57PD

Page 22

26H SERVICE

Carrier

FIG. 3 - ICE CRUSHER ASSEMBLED - FRONT VIEW

CRUSHER OPERATION

The defrost and freezing cycles of an Ice Maker

with a crusher are identical to those of units without

a crusher. Normally the crusher is a factory mount

ed accessory, enclosed in the machine section. If

desired, a crusher package may be purchased sep

arately for installation. (See Fig. 3)

CAUTION; When cleaning units equipped with

crushers or performing service operations, discon

nect the power supply.

The two crusher control knobs are mounted on the

lower front panel (Fig. 4). When the knob on the

left is positioned on "Crushed" the cubes pass

through the crusher and crushed ice falls into the

bin. Fineness of the crushed ice is controlled by

the knob on the right. When the knob on the left

is positioned on "Cubes", the ice cubes bypass

the crusher and fall into the bin.

The knob marked "Crushed - Cubes" controls a

switch to the crusher motor and the position of a

damper to direct the cubes. The motor is cut out of

the control circuit when the switch is turned to

"Cubes".

is in the "Crushed" position and the bin thermostat

stops the unit during the harvest cycle^ the crusher

me tor will continue to operate until the main control

switches to the freezing position or the selector

switch is turned to "Pump" or "Off". This prevents

accumulation of cubes at the crusher entrance.

#

When ice builds up in the bin and touches the ther

mostat bulb, the unit will stop. If the crusher knob

26H-57PD

FIG. 4 - ICE CRUSHER CONTROLS

22

Page 23

Carrier

SERVICE

26H

~w

REMOVING THE PANELS

To remove the top front panel turn both handles so

they are horizontal and lift it out. To remove the

top panel remove the screws shown in Fig. 5. Tilt

the panel up and back to disengage it from the back

panel. The side panels are held in place at the

front by two screws and the bottom front panel. The

side panels engage with the flanged edge of the

back panel. Do not remove the back panel except

when absolutely necessary. It is held in place by

six screws threaded into the frame.

Cleaning and inspecting can be done by removing

the front access door, splash curtain, and ice de

flector screen. The plastic curtain is riveted to a

cross arm held in place by two screws (Fig. 6).

After inspection and cleaning, be sure to reposition

the plastic curtain properly to prevent water from

splashing into the bin. (Fig. 7).

#

FIG. 5 - REMOVING SCREWS HOLDING TOP

AND SIDE PANELS

2. REFRIGERANT CIRCUIT

L SHUTOFF VALVES

Fig. 8 is a cross sectional view of a shutoff valve

in mid-position. When the unit is shipped all valves

are backseated and should be left so during normal

operation. A brass cap and gasket cover the valve

stem to prevent leaks. The gauge ports are plugged

with two 1/8" MPT plugs.

ACCESS DOOR ICE CRUSHER CRUSHER

FIG. 6 - REMOVING ACCESS DOOR AND

ICE DEFLECTOR

26H3

There are two shutoff valves in the circuit - a suc

tion valve and a discharge valve. (See Fig. 9).

26 H5

There are three shutoff valves in the circuit - a suc

tion valve, discharge valve, and oil return valve.

(See Fig. 10).

MOTOR

23

26H-57PD

Page 24

26H

SERVICE

DISCHARGE ?

SHl/T OFF VA;,'/«

FIG. 7 - FREEZING COLUMNS. ICE DEFLECTOR, SPLASH CURTAIN,

SIPHON STANDPIPE. ACCESS DOOR AND WATER PAN ARRANGEMENT

CONNECTION TO

FIG. 8 - SHUTOFF VALVE

CILRETL«»;

SHOT 0*"'

VALVE,

GAUGE CONNECTION

FIG. 9 - TOP VIEW OF 26H3 MACHINE SECTION

26H-57PD

FIG. 10 - TOP VIEW OF 26H5 MACHINE SECTION

24

Page 25

Carrier

SERVICE

26H

Hf

2. INSTALLING GAUGES

a. Backseat suction and discharge shutoff valves.

SUCTION LINE

PRESSURE GAUGE

DISCHARGE LINE

PRESSURE GAUGE-

CHARGING HOSE ATTACHED TO THE SUCTION

VALVE WITH A 1/4" HALF UNION COUPLING

b. Remove gauge plugs and install 1/8" MPT

X 1/4" flare half union coupling.

c. Attach 1/4" OD copper gauge line, flared at

both ends, to the couplings.

d. Attach suction and discharge gauges to these

lines, leaving connection slightly loose.

e. Crack the valve off back seat, allow a small

amount of refrigerant to escape, and tighten

the flare nut.

To read line pressures, turn the shutoff valves

slightly from the backseat position. If the gauge

needle vibrates, backseat the valve until there is

no vibration but the gauge still reads line pressure.

NOTE: To conserve refrigerant, use short lengths

"FREON-12 DRUM

of small bore tubing when installing gauges. This

unit is sensitive to charge and repeated installa

tion and removal of gauges with necessary purging

vl

of air will result in an undercharge of refrigerant.

FIG. 11 - CHARGING MANIFOLD ATTACHED

FOR CHARGING UNIT

3. PUMP DOWN OF COMPRESSOR

If the refrigeration system must be opened at the

compressor, first "Pump Down". Proceed as follows:

1. Install a pressure gauge to the suction shut

off valve.

2. Front seat the suction shutoff valve.

3. Front seat the oil return line shutoff valve

(on 26H5).

4. Operate the compressor intermittently until

the suction pressure gauge indicates 0 to 2

PSIG pressure is being maintained in the

crankcase.

5. With the compressor stopped, front seat the

discharge shutoff valve.

6. Loosen the discharge shutoff valve gauge

plug slightly and bleed off any remaining pres

sure. The compressor can then be opened or

removed.

7. After repairing the compressor, evacuate and

purge it to remove residual air. Remove the

pipe plug from the gauge connection of the

discharge shutoff valve. Operate the com

pressor for about 10 minutes. Place your thumb

over the discharge valve gauge connection^ at

the some time stopping the compressor. Crack

open the SUCTION shutoff valve, momentarily,

allowing a small amount of gas to enter the

compressor. Front seat the suction shutoff

valve immediately. A slight gas pressure

should not be felt against your thumb. Re

place the pipe plug. The suction, discharge

and oil return line shutoff valves can now be

backseated and the machine is ready for op

eration.

25

26H-57PD

Page 26

26H

4. CHARGING WITH REFRIGERANT

SERVICE

TABLE 1 - REFRIGERANT CHARGE (R12)

Carrier

MODEL

26H5

26H3 9 " condenser and 9 " accum. 1 lb. 11 oz.

26H3 Serial No. 331784 Change to 18"cond.-

26H3

26H3 Serial No. 510446 change to 15"cond.—

If the unit is undercharged, back seat the suction

shutoff valve. Remove a gauge port plug from the

valve; connect a charging line from a drum of re

frigerant 12. Tighten this line at the drum, but make

a loose connection at the suction shutoff valve.

Crack the valve on the drum so that refrigerant va

por will force air from the charging line out the

loose connection. After purging the air from the

charging line, tighten the connection at the suc

tion shut-off valve. Open the suction valve to a

point midway between the back-seated and frontseated positions. With the suction shutoff valve in

this position, it is possible to read the system pres

sure during the charging period. The refrigerant 12

drum should be in an upright position to admit va

por only.

No changes

9 " accumulator

Serial No. 411152 change to 15"cond.9 " accumulator

10 1/2" accumulator 2 lb. 9 oz.

IDENTIFICATION

CHARGE

3 lb. 8 oz.

2 lb. 3 oz.

2 lb. 3 oz.

WEIGHING IN CHARGE

The most accurate method of charging a refrigerant

system is weighing in the charge. Proceed as fol

lows:

1. Bleed any charge remaining in the system,

then start the compressor and pump out the

system through the discharge valve.

2. With the compressor still running, connect the

drum of refrigerant to the suction valve.

3. Back seat the discharge valve and immediately

turn off the compressor.

4. Weigh the drum of refrigerant (it is easier to

weigh a charge if the weight of the drum can

*, be checked during the charging process).

i

If the unit is overcharged, turn the unit off. Back

seat the discharge shutoff valve. Attach a charg

ing line to one of the gauge ports in the valve and

attach a charging manifold to the other end of the

charging line. Turn the shutoff valve to the middle

position; start the unit. Bleed refrigerant from the

charging manifold in 5-second intervals until the

charge is correct. Turn the unit off. Back seat the

shutoff valve and remove the charging line. Replace

the gauge port plug and start the unit.

26H-57PD

5. Open the suction valve and crack the valve

on the drum of refrigerant. Start the compressor.

6. Continue to charge until the scale shows the

proper amount of refrigerant has been fed into

the system.

7. Close the valve on the drum and then the suc

tion shutoff valve.

8. Disconnect the charging line.

9. Leak test the system.

26

t

Page 27

Carrier

SERVICE

26H

W

i

FROST LINE METHOD OF CHARGING

By establishing a frost point on the suction line,

it is possible to charge these units to within one

ounce of their specified charge. By this, frost point,

it is also possible to determine whether or not a

machine is only partially charged. Below are listed

the recommended methods for charging the H3 and

H5 ice makers, which require a partial or a full

charge. Frostline should be at the point indicated

when the machine has operated on the freezing

cycle for 20 minutes.

CAUTION: If Freon is added in small amounts, the

frost line will continue to move towards the small

accumulator. If Freon is added too rapidly, the

frost line will disappear. It is then necessary to

wait until the frost reappears before adding or

bleeding off refrigerant.

After making sure that the machine is leak free

and in good running condition, proceed as follows

with the pump runnfng during the entire freezing

cycle.

Method lA - 26H3 Ice Maker No Charge in Unit

2. Charge slowly until the suction shutoff valve

and flare nut frost

3. Bleed off gas until frost just recedes from valve.

Method 2A - 26H5 Ice Maker No Charge in Unit

1. Remove first clip immediately above small ac

cumulator, and pull back two or three inches of

the suction line insulation.

2. Start machine with pump on. Charge until suc

tion pressure is 15 PSIG.

3. Discontinue charging and allow machine to run

for 10 minutes. During this period, check to

see if the suction pressure is holding at ap

proximately 15 pounds.

4. Charge slowly until ffost forms on the suction

line between the small accumulator and the

suction shutoff valve on the compressor.

5. Bleed off gas until frost line recedes back to

the joint on the top of the second accumulator.

6. Allow machine to run through two complete cy

cles to check operating pressures.

1. Start the unit with the pump running. Charge

until the suction pressure is 15 PSIG.

2. Continue running the machine for 10 minutes

without adding to the charge.

3. Add gas slowly until frost forms on the suction

shutoff valve and the flare nut.

4. Bleed off slowly until frost just recedes from

valve.

Method IB - 26H3 Ice Maker Partial Charge in Unit

1. Start unit and let it run undisturbed for 20 min

utes.

Method 2B • 26H5 Ice Maker Partial Charge In Unit

1. Remove insulation from suction line 2 or 3"

above second accumulator.

2. Start machine and allow it to run for 20 min

utes undisturbed.

3. Charge slowly until frost forms on fhe suction

line between the small accumulator and the

suction shutoff valve.

4. Bleed off gas unfil frost line recedes back to

the top of the second accumulator.

5. Allow machine to make two complete cycles to

check its operating pressures.

27 26H-57PD

Page 28

26H SERVICE

Carrier

5. OPERATING PRESSURES

Table 2 shows suction and head pressures during

a normal freezing and defrost cycle.

6. COMPRESSOR

OIL CHARGE 26H3

The oil charge is 45 oz. Because of this large

volume, the oil charge is not critical. The com

TABLE 2 - 26H ICE MAKER OPERATING PRESSURES (PSIG)

OPERATING PRESSURES

90

TIME INTO

CYCLE

(MINUTES)

2 129 21

4

6 134

° AIR-90° WATER

26H3 *

Head Suction

131 20 134

Head

21

26H3 +

Suction

131

134 23 159

Head Suction Head Suction

24 144

23 150

pressor is a welded hermetic and there are no pro visions for checking or adding oil in the field.

OIL CHARGE 26H5

The compressor is factory charged with two pints

of Carrier PP45EB-302 oil which is a special low

temperature refrigerant duty oil. Do not use ordinary

motof oil. Before checking the oil level, operate

the unit for at least 30 minutes to balance the oil

distribution in the system.

90°

AIR - 70° WATER

26H5 26H3 * 26H3 +

Suction Head Suction

Head

29

29 131 19 132

26 131 18 131

130

20 132 24 132 27

22

21

26H5

134

134 22

23

8 134 20 132 22 149

F

R

10 133

E

15

tj

20 130

z

25

E

30 134

35

40 129 15

45

D

E

F

R

0

S

T

26H3 From Serial No. 331784 to 510446

26H3 From Serial No. 510446 to present.

130 18 130 19 130

132

130 15

129 14

2 115

122 57 103 48

4

6

20 131

17

16

16 131 16

52 79

129

129 16 128 17 132 16 131 15

131 15 128

130

128

24 132 17 131 20 130 20

21 130

17

15 128 15 129 14

130 18 130 16 131 16 130

128 16 132

22 131

19

15

131 17 130 17 127

130

17 130

15

15

•

15

34 55 30 124

70 36 128

100 58 106 44 100

55 77

62

19 129

131

132 15 131 16

133 14 131 15

132 14

96

30

38

65 33

80

20

18

17

16

41

57

¿6H-57PD

28

Page 29

Carrier

To check the oil level:

a. Install gauges and pump down the compressor.

b. Remove one of the oil fill plugs on the side

of the compressor.

c. The oil level should be 1-1/4" as shown in

Fig. 12. Oil can be added through the oil filler

plugs. Reinstall the filler plug immediately to

prevent absorption of moisture. It may damage

the motor windings.

Caution: Avoid overcharging as excess oil may

restrict the capillaries and reduce unit capacity.

On those compressors with a sight glass, oil level

should be between 1/2 and 2/3 above bottom of glass.

SERVICE

26H

TESTING THE COMPRESSOR MOTOR

Series Test Light and Hermetic Test Cord

Fig. 13 shows atest cord that is useful as a 110/220

volt test light or as a cord for starting the com

pressor without using the unit controls. When used

as a series test light, turn screw base outlet into

the lamp socket, plug into a power source and use

insulated leads indicated in Fig. 13 as probes to

determine continuity. When used as a compressor

starting cord, the fuse is used in the lamp socket.

To start compressor using test cord, disconnect

all leads from compressor terminals. Clip common

and running leads of cord to "C" and "R" terminals

respectively. Plug cord into source of power, and

NOTE MEASURE OIL LEVEL AT 45®ANGLE AS SHOWN FROM OUTSIDE

FACE OF OIL FILL HOLE. OIL GUAGE CONSISTS OF A l/4"COPPER

TEE SOLDERED TO A STRAIGHT PIECE OF 1/4"COPPER TUBING

FIG. 12 - COMPRESSOR OIL LEVEL

momentarily touch starting lead of cord to "S" on

compressor terminals. Do not leave this prong in

contact with terminal "S" for more than one or two

seconds; otherwise the starting winding will be

damaged.

Caution: When using test cord on compressor, stand

clear of terminals. If current should arc or terminal

break, terminal may blow out with considerable

force. An arc might also ignite oil entrained in es

caping gas.

NOTE: SINGLE CAPACITORS USED FOR II5V. DUTY AND

230 V DUTY ARE DIFFERENT AS NOTED ABOVE

FIG. 13 - TEST CORD DIAGRAM

29

26H-57PD

Page 30

26H SERVICE

Carrier

Portable Line Voltage Tester

APPLICATION AND OPERATION - A portable line

voltage tester with built-in phantom load which

provides a simple means of checking single phase

or direct current circuits is shown in Fig. 14. By

reading the voltage at no load and the voltage with

phantom load it can be determined if the circuit is

adequate for starting and operating the unit. The

tester is made to Carrier specifications and includes

a table for use with ice cube makers.

PHYSICAL DATA

Case Size

Voltmeter Scale

Ampere Load

Voltage

F requency

Approx. Weight

J. & W. Company 290 Roycroft Blvd., Buffalo 21, N.Y.

8"x 8"x 4"

0-150 volts (Double Reading for

230V)

11.5

115 - 230

25, 50, 60 cycles or direct current

5 pounds

Order Directly from

the suction line with a 1/2" plug to prevent

moisture from entering the system.

2. Cut the discharge line and sweat in a 1/4"

SAE male copper to flare connection. Cap this

connection to prevent moisture from entering

the system.

3. Disconnect the compressor leads at the se

lector switch and thermostat.

4. Remove the four compressor mounting bolts

and lift the compressor from the unit.

5. Seal all openings on the compressor to pre

vent moisture from entering prior to repair or

exchange.

6. If compressor failed due to motor burnout, see

"Replacement After Motor Burnout".

7. Install the replacement compressor. The re-

placemsat compressor is shipped with the dis

charge line fastened to the suction shutoff

valve gauge portby means of a 1/4" flare nut.

8. After completing all wiring and piping con

nections evacuate and purge the replacement

compressor.

FIG. 14 - VOLTAGE TESTER

COMPRESSOR REPLACEMENT 26H3

To replace the compressor use the following pro

cedure:

1. Purge the refrigerant charge and then frontseat both shutoff valves. Disconnect the suc

tion line flare nut at the shutoff valve. Seal

9. Charge the unit with refrigerant 12. See Sec

tion 4.

10. Before leaving the unit check for leaks.

COMPRESSOR REPLACEMENT 26H5

To replace the compressor, follow this procedure:

1. If the compressor is in running condition,

pump down as explained in Section 3.

•2. If the compressor is not in running condition

close the suction, discharge and oil return

shutoff valves and then slowly bleed pressure

thru the discharge gauge plug.

3. Check to see that both shutoff valves are

f rontseated and unbolt them from the com

pressor. Leave the valves connected to the

piping.

4. Disconnect the high pressure line from the

discharge side of the compressor.

5. Close the water supply valve and disconnect

the compressor cooling coil. The replacement

compressor comes supplied with this coil.

26H-57PD

30

Page 31

Carrier

SERVICE

26H

6. Remove the compressor terminal box cover

and disconnect the compressor motor connec

tions. Mark connections so they may be cor

rectly reconnected to the replacement com

pressor.

7. Remove the cotter pins and castellated nuts

from the top of the compressor mounting bolts.

8. Lift the compressor from the unit.

9. Seal all openings on the compressor to pre

vent moisture from entering prior to repair or

exchange.

10. If compressor failed due to motor burnout, see

"Replacement After Motor Burnout ".

11. Install the replacement compressor. Place

new gaskets between all shutoff valves and

the compressor flanges.

12. Make sure the oil level in the replacement

compressor approximates oil level in the

compressor removed.

13. After completing the piping and wiring, evacu

ate and purge the replacement compressor as

described in Section 3.

3. Remove strainer-drier from liquid line,

liquid line for 1/4" SAE connections.

4. Install Sporlan Catch-.'\11 Type C-162 StrainerDrier. The 1/4" liquid line coming from near

bottom of condenser should be fastened to the

inlet side of the Sporlan Catch-All. Direction

of arrow should be pointing upwards.

5. Install new compressor.

6. Evacuate the entire system as described in

Section 8 and add refrigerant as described in

Section 4.

The Sporlan Catch-All can be left in the refrigerant

circuit. In addition to drying the refrigerant in the

system, the molded, porous core of the Catch-All

will catch all scale, solder particles, carbon,

sludge, dirt or any other foreign matter with negli

gible pressure drop.

7. LIQUID-SUCTION INTERCHANGER AND

ACCUMULATOR REPLACEMENT

26H3

Flare

14. Backseat all valves and start unit.

15. After operating for at least 2 cycles, check

the refrigerant charge as described in Sec

tion 4.

16. Check for leaks. Use a halide torch, soap

bubble method or both.

REPLACEMENT AFTER MOTOR BURNOUT

When a hermetic motor compressor burns out, the

stator winding insulation decomposes - forming

carbon, water and acid. To prevent contamination

of the refrigerant system by these products of com

bustion, the refrigerant circuit must be cleaned

when installing a new compressor.

The procedure for cleaning the system is as follows:

1. Disconnect water supply line and. drain the

water from the condenser, to prevent con

denser freeze-up during purging.

2. Purge refrigerant charge.

a. Open the disconnect switch.

b. Remove all panels.

c. Slowly bleed the system to the stmosphere as

described in Section 8.

d. Front seat both the suction and the discharge

valves.

e. Unscrew the flare nut at the suction service

valve.

f. Unscrew the flare nut attaching the capillary to

the drier and loosen the clamp holding the capil

lary adapter to the frame.

g. Unsweat the capillary at the top of the evapo

rator. The evaporator shroud will not telescope

the way it does on the 26H5. Be careful when

using a torch near the evaporator as the evapo

rator tubes are soft soldered to the freezing

columns.

h. Unsweat the suction line at the evaporator.

Refer to sections 8 and 4 for evacuating and

recharging instructions.

31 26H-57PD

Page 32

26H

SERVICE

Carrier

26H5

a. Open the disconnect switch.

b. Remove all panels.

c. Slowly bleed the system to the atmosphere as

described in Section 8.

d. Front seat the compressor shutoff valves and

the oil return line shutoff valve

e. Unscrew the flare nut at the suction service

valve.

f. Unsolder the liquid line at the entrance to the

twin capillary adopter. Exercise care so that

the adapter is not oxidized internally by over

heating. Telescope the bottom evaporator re

flector shroud over the top shroud.

g. Unsweat the two capillaries at the evaporator.

Be careful when using a torch near the evapo

rator as the evaporator tubes are soft soldered

to the freezing columns.

h. Unsweat the suction line at the evaporator.

j. Disconnect the oil return line from the end bell

of the compressor motor by loosening the flare

nut at the valve.

d. Start the machine.

e. When the amount of gas coming from the 1/4"

copper tube has decreased appreciably, im

merse the copper tube into a can of refriger

ation oil.

f. The gas being expelled will bubble up through

the oil.

g. After bubbling has ceased it can be assumed

the refrigerant system has been evacuated.

h. Remove the tube from the gauge port, and with

the compressor still operating screw in the

gauge port plug. Then backseat the discharge

shutoff valve and turn off the compressor.

Add refrigerant to the system as described in Sec

tion 4 "Refrigerant Charge".

9. CONDENSER CLEANING AND REPLACEMENT

FLUSHING THE CONDENSER WATER CIRCUIT

Scale deposits on the inside of the condenser water

circuit can significantly reduce the condensèr's

capacity and increase the water consumption. If

the scale becomes too heavy, the head pressure

will increase because of poor heat transfer inside

the condenser.

#

k. Remove the compressor. The complete assembly

can then be removed. Refer to Section 8 and 4

for evacuating and recharging instructions.

8. DRYER REPLACEMENT

The original dryer has flare connections. See Fig.

10. Slowly bleed the refrigerant charge as follows:

a. Make sure the suction shutoff valve is back-

seated.

b. Remove one of the gauge port plugs.

c. Slowly turn the shutoff valve off backseat to

bleed the refrigerant charge. Bleed slowly

to prevent condenser freezeup.

Evacuate the refrigerant system as follows:

a. Backseat the suction shutoff valve.

b. Frontseat the discharge shutoff valve.

c. Remove one of the discharge gauge port plugs,

and connect a piece of 1/4" copper tubing

about '1 foot long to this gauge port.

Obtain the equipment shown in Fig. 15.

Set up the equipment as shown in Fig. 16.

Proced ure

1. Remove the front panel and turn the selector

switch to "Off. "

2. Close the water supply line shut-off valve, and

assemble the equipment to the unit.

3. Mix a solution of inhibited muriatic acid and

wiater in one of the pails. ADD THE ACID

TO THE WATER. Mix 1.5 quarts of acid into

3.5 quarts of water.

4. The level of solution in the pail should be

at least 2 " below the bottom of the pump motor.

AVOID SPILLING ANY SOLUTION.

5. Start the pump and allow it to run 20 minutes,

or until the solution draining back to the pail

contains no foam.

6. While running the pump, mix a solution of

1/4 lb. of baking soda in 8 quarts of water.

i

26H-57PD

32

Page 33

Carrier

SERVICE

26H

7. At the end of 20 minutes, turn the pump off

and place the pump in the soda and water

solution.

8. Start the pump and allow the soda and water

solution to circulate for 15 minutes.

9. While the neutralizer is being circulated, fill

the pail containing the acid solution with

water and then empty the pail in an open drain.

10. Rinse the pail and fill it with water.

11. Turn the pump off and place it in the pail of

clean water.

12. Start the pump and allow it to run for 5 minutes.

13. Turn the pump off and break the flare or hose

connection at the pump.

3 A I x| FLARE COUPLING IS USED TO

CONNECT THE TUBING FROM THE PUMP

OUTLET TO THE CONDENSER INLET

14. Lift the pump out of the water, then lift both

lines to allow the lines and condenser to drain

into the pail.

15. Break the connection at the condenser inlet.

16. Reconnect the condenser inlet line to the

water regulating valve.

17. Break the connection on the condenser outlet

and reconnect the permanent drain line.

18. Turn on the shutoff valve in the water supply

line.

19. Turn the selector switch to "On" and check the

connections to see if they ore tight.

20. Remove the cleaning equipment and clean

around the machine.

TO SAVE TIME, TWO 10 QUART PAILS

ARE USED; ONE FOR THE ACID

SOLUTION AND ONE FOR THE SODA

SOLUTION.

6 INHIBITED MURIATIC ACID MIXED WITH

WATER (1.5 PARTS ACID TO 3.5 PARTS

WATER) IS RECOMMENDED FOR THE

DESCALING SOLUTION.

<®>

iMHieifci*

Mutintic

ACl*

NOTE i AN ALTERNATE TO USE IN PLACE OF THE 8 LENGTH OF COPPER TUBING

AND THEiSWEAT TO|'FLARE COUPLING, IS TO USE AN8' LENGTH OF T

RUBBER HOSE AND 2-¿HOSE CLAMPS

FIG. 15 - REQUIRED FOR CONDENSER CLEANING

AN 8 LENGTH OFf COPPER

TUBING, FLARED AT EACH END IS

CONNECTED TO THE PUMP OUTLET

THE OTHER END IS CONNECTED

TO THE CONDENSER INLET AT THE

WATER REGULATING VALVE.

5 A 15 LENGTH OF§ COPPER TUBING

FLARED ATONE END IS CONNECTED

TO THE CONDENSER OUTLET FOR

RETURNING THE SOLUTIONS OR WATER

BACK INTO THE PAIL.

7 BAKING SODA MIXED WITH WATER

(4lB. SODA TO 8QTS. WATER) IS

RECOMMENDED FOR NEUTRALIZING

THE ACID.

I THE STANDARD 26 ICE MAKER WATER PUMP

FITTED WITH A ^ SWEAT TO FLARE

COUPLING IN ITS OUTLET IS USED FOR

CIRCULATING THE SOLUTION, NEUTRALIZER

AND WATER.

33

26H-57PD

Page 34

ACID DISSOLVES THE SCALE

FIG. 16 - CONDENSER CLEANING PROCEDURE

CONDENSER REPLACEMENT

The condenser is mounted in a vertical position

on the left side of the unit.

a. Close the water supply valve before removing

the condenser.

b. Remove front, top and left side panels.

c. Slowly bleed refrigerant from the system as

described in Section 8.

d. Unsweat all refrigerant tubing connections

while the suction valve is still open. All of

these joints are phos-copper.

e. The condenser is held by a strap screwed to

the unit frame. Lift the condenser up and out.

f. After replacing the condenser, evacuate and

recharge the system as described in Sections

4 and 8.

26H-57PD

10. EVAPORATOR REPLACEMENT

Bulged freezing columns may be indicated by "ex

cessive " defrost time; 4-5 minutes before the first

ice drops and 4 minutes or longer before all the ice

drops is considered excessive defrost time.

yo determine if columns are bulged remove spreader

plates (see Fig. 17), and place light under freezing

columns and observe from the top of each column.

If several columns are seriously bulged and unit

has excessive defrost time even with adeguate

charge, the evaporator assembly should be re

placed.

REPLACEMENT PROCEDURE

1. Remove front, top and side panels.

2. Slowly bleed refrigerant charge as described

in Section 8.

34

Page 35

Carrier

SERVICE

WATER SPREADER

IN POSITION

WATER SPREADER

REMOVED

NOTE FORMED PROJECTION

FOR SPACING SPREADER

26H

FIG. 17 - WATER SPREADER PLATES

During the period of "Blowing the charge", re

3.

move screws and clamps from each side of

lower evaporator shroud, then lift shroud up

wards as far as it will go. Capillary joints

are accessible on right side of unit.

4. Remove water distributor header.

5. After refrigerant charge is "blown", carefully

melt capillary, suction header and hot gas

header joints. Pull joints apart while applying

heat. On the left side of evaporator, melt

water trough overflow and safety overflow

which are "soft solder" joints and require

very little heat.

CAUTION: The capillary suction header and hot

gas header joints are Phos-copper which melts at

approximately 1400°F. Care should be taken not

to "over-heat" the Phos-co joints when melting or

making a connection.

6. Remove evaporator support bracket screws and

lift evaporator straight up.

8. Position replacement evaporator in unit;

fasten supporting brackets.

9. Make all connections. If Phos-co is not avail

able, silver solder maybe substituted. Pliers

may be used to guide capillary in place while

soldering. Make sure that no hard solder plugs

capillaries.

10. Fasten water header in place.

11. Check oil level of compressor. Refer to Sec

tion 6.

12. Evacuate the refrigerant system. Refer to Sec

tion 8.

13. Add refrigerant to system. Refer to Section 4.

14. Machine must be operated for many cycles to

check freezing and defrost time. While unit is

operating, check for refrigerant leaks. When

unit is satisfactory, replace evaporator shrouds

and panels.

«

7. Remove all spreader plates. Remove all scale

and clean. Place spreader plates in new

evaporator assembly.

15. When replacing the evaporator assembly, the

operation of the main control thermostat and

the safety overflow switch must be checked.

35 26H-57PD

Page 36

26H

n. FLOAT VALVE

SERVICE

3. FREEZING WATER CIRCUIT

The float valve, see Fig. 18^ meters the make-up

water which is circulated to the freezing columns

and can be observed by removing the front panel

and inner access door.

The float valve can be adjusted by loosening the

wing nut and the set screw and adjusting the con

necting arm. Raising the float will raise the water

level, and lowering the float will lower the water

level. The water level should be approximately

1/2" below the top of the siphon standpipe for

the 26H5 units, and 3/8"below for the 26H3 units.

KNURLED FLAT END OF FLOAT,

ARM FOR BEARING ON ELBOWN

(LENGTHWISE KNURLS)

WINS SCREW FOR

FASTENING FUDAT

ARM TO ELBOW

Carrier

SPLASH-HOOD

CAUTION: After adjusting the float with the set

screw, tighten the wing nut. If the float works

loose, water will overflow through the siphon stand

pipe and cause an extremely long freezing time and

a continuous siphoning action.

To replace the float valve;

a. Close the water supply valve.

b. Remove front panel and inner access panel.

c. Remove float from valve by taking out wing

nut. This float valve can be removed from

the front by turning the valve body counter

clockwise.

WATER HEADER

FIG. 18 - FLOAT VALVE ASSEMBLY

To inspect the valve seat and orifice, remove the

stainless steel pin, freeing the valve arm from the

body.

12. WATER DISTRIBUTOR

The water distributor feeds the freezing columns

and should be checked to insure that the discharge

nozzles are clear. Water flow from all ports should

be approximately the same. To inspect the headers,

disconnect the rubber hose (s). Remove the three

screws which hold the header assembly and sup

port brackets in place and lift the header from the

top of the machine compartment. See Fig. 19.

SCREW HOLE SCREW-

MACHINE

26H-57PD

t

FIG. 19 - WATER DISTRIBUTOR

36

Page 37

SERVICE

13. WATER REGULATING VALVE ADJUSTMENT

A 3/8" water regulating valve is used to control

the water flow through the condenser. This valve

is located in the inlet side of the condenser water

system. For best operation and maximum ice pro

duction the head pressure should be maintained at

approximately 125 PSIG for 26H5 and 130 PSIG for

the 26H3. This is equivalent to approximately a

20° rise in condenser water temperature. Head