Page 1

Start-Up and Service Instructions

DANGER

WARNING

CAUTION

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe and

reliable service when operated within design specifications. When operating this equipment, use good judgment

and safety precautions to avoid damage to equipment and

property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in the chiller instructions as

well as those listed in this guide.

ONLY QUALIFIED Electrical Personnel familiar with the construction

and operation of this equipment and the hazards involved should install,

adjust, operate, or service this equipment.

READ AND UNDERSTAND this manual and other applicable manuals in

their entirety before proceeding. Failure to observe this precaution could

result in severe bodily injury or loss of life.

DO NOT install modification kits with power applied to the drive. Disconnect and lock out incoming power before attempting such installation or

removal. Failure to observe this precaution could result in severe bodily

injury or loss of life

UNUSED WIRES in conduit must be grounded at both ends to avoid a

possible shock hazard caused by induced voltages. Also, if a drive sharing

a conduit is being serviced or installed; all drives using this conduit should

be disabled to eliminate the possible shock hazard from cross-coupled

motor leads. Failure to observe these precautions could result in bodily

injury.

DO NOT VENT refrigerant relief valves within a building. Outlet from

rupture disc or relief valve must be vented outdoors in accordance with the

latest edition of ANSI/ASHRAE 15 (American National Standards Institute/American Society of Heating, Refrigerating, and Air Conditioning

Engineers). The accumulation of refrigerant in an enclosed space can displace oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ANSI/ASHRAE 15,

especially for enclosed and low overhead spaces. Inhalation of high concentrations of vapor is harmful and may cause heart irregularities, unconsciousness, or death. Misuse can be fatal. Vapor is heavier than air and

reduces the amount of oxygen available for breathing. Product causes eye

and skin irritation. Decomposition products are hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a chiller for any

purpose. Oxygen gas reacts violently with oil, grease, and other common

substances.

NEVER EXCEED specified test pressures, VERIFY the allowable test

pressure by checking the instruction literature and the design pressures on

the equipment nameplate.

DO NOT USE air for leak testing. Use only refrigerant or dry nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and func-

tioning before operating any chiller.

THERE IS A RISK OF INJURY OR DEATH by electrocution. High voltage may be present on the motor leads even though the motor is not running. Open the power supply disconnect before touching motor leads or

terminals.

DO NOT WELD OR FLAMECUT any refrigerant line or vessel until all

refrigerant (liquid and vapor) has been removed from chiller. Traces of

vapor should be displaced with dry air or nitrogen and the work area

should be well ventilated. Refrigerant in contact with an open flame pro-

duces toxic gases.

DO NOT work on high-voltage equipment unless you are a qualified electrician.

DO NOT WORK ON electrical components, including control panels,

switches, VFD, or oil heater until you are sure ALL POWER IS OFF and

no residual voltage can leak from capacitors or solid-state components.

19XRV

with PIC III Controls

Rockwell PowerFlex 755 VFD Option

LOCK OPEN AND TAG electrical circuits during servicing. IF WORK IS

INTERRUPTED, confirm that all circuits are deenergized before resuming

work.

AVOID SPILLING liquid refrigerant on skin or getting it into the eyes.

USE SAFETY GOGGLES. Wash any spills from the skin with soap and

water. If liquid refrigerant enters the eyes, IMMEDIATELY FLUSH EYES

with water and consult a physician.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while chiller is

under pressure or while chiller is running. Be sure pressure is at 0 psig (0

kPa) before breaking any refrigerant connection.

TO AVOID an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing. Check the DC bus

voltage at the Power Terminal Block by measuring between the +DC and DC terminals, between the +DC terminal and the chassis, and between the

-DC terminal and the chassis. The voltage must be zero for all three measurements.

THE USER is responsible to conform with all applicable local, national,

and international codes. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

THIS DRIVE contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if

ESD control procedures are not followed. For static control procedures,

reference Rockwell publication Guarding Against Electrostatic Damage, or

any other applicable ESD protection handbook.

DO NOT alter the setting of any jumper. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

USE OF power correction capacitors on the output of the drive can result

in erratic operation of the motor, nuisance tripping, and/or permanent damage to the drive. Remove power correction capacitors before proceeding.

Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

MOST CODES require that upstream branch circuit protection be provided to protect input power wiring. If fuses are chosen as the protection

method, refer to the PowerFlex 750 user manual. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

DO NOT route signal and control wiring with power wiring in the same

conduit. This can cause interference with drive operation. Failure to

observe this precaution could result in damage to, or destruction of, the

equipment.

DISTRIBUTION SYSTEM short circuit capacity shall not exceed the rating of the drive. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

DO NOT STEP on refrigerant lines. Broken lines can whip about and

release refrigerant, causing personal injury.

DO NOT climb over a chiller. Use platform, catwalk, or staging. Follow

safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or move

inspection covers or other heavy components. Even if components are

light, use mechanical equipment when there is a risk of slipping or losing

your balance.

BE AWARE that certain automatic start arrangements CAN ENGAGE

THE VFD, TOWER FAN, OR PUMPS. Open the disconnect ahead of the

VFD, tower fans, or pumps.

USE only repair or replacement parts that meet the code requirements of

the original equipment.

PERIODICALLY INSPECT all valves, fittings, and piping for corrosion,

rust, leaks, or damage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53190012-01 Printed in U.S.A. Form 19XRV-3SS Pg 1 711 3-11 Replaces: New

Page 2

CONTENTS

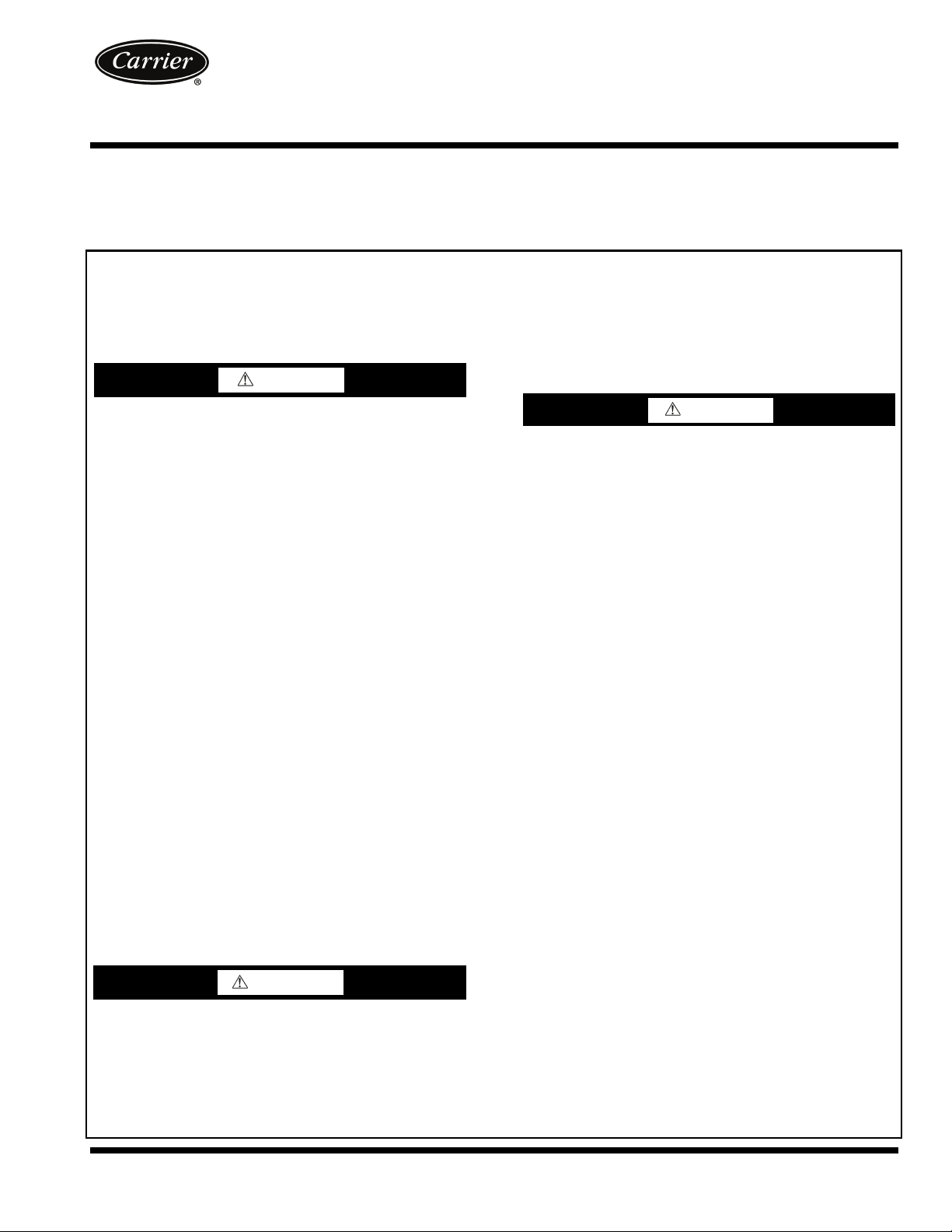

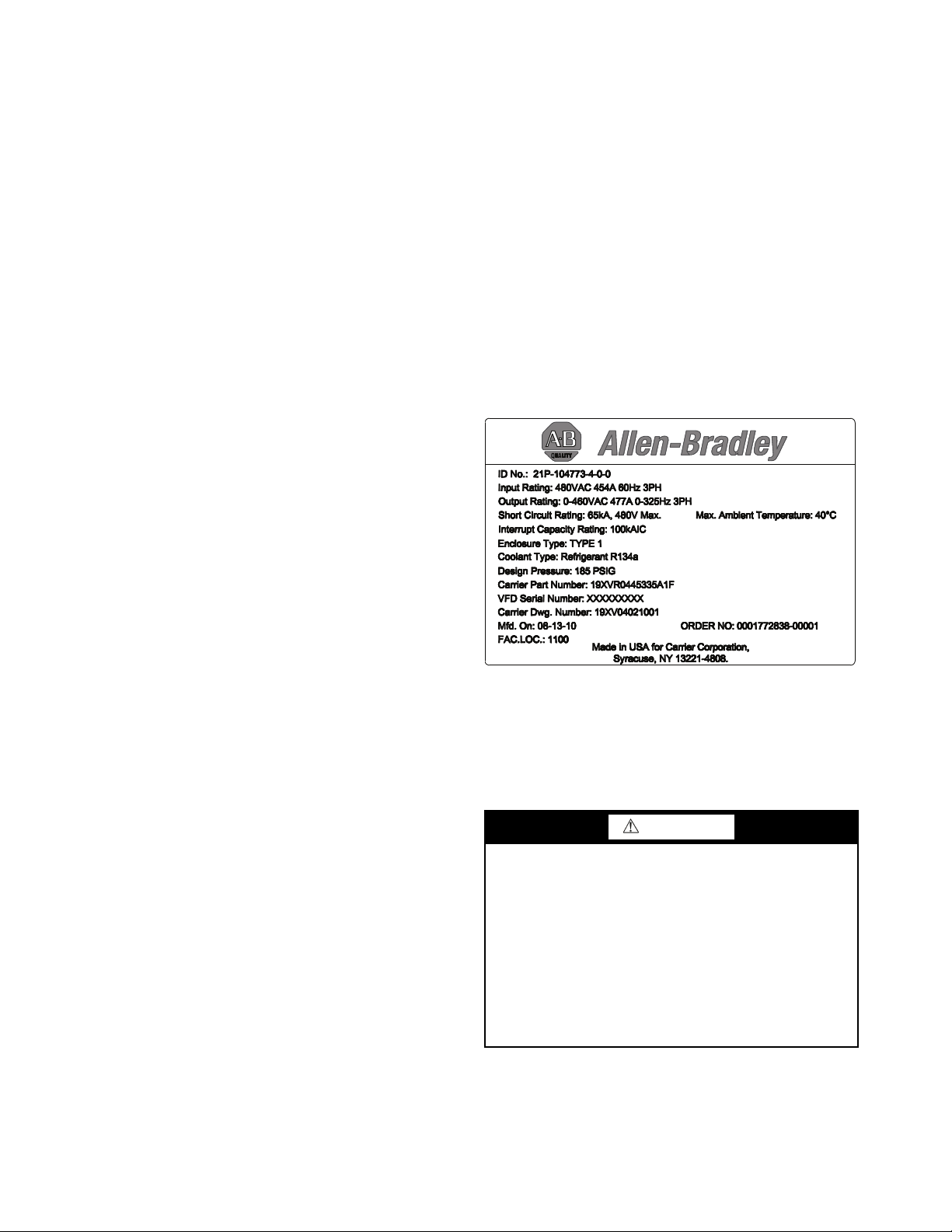

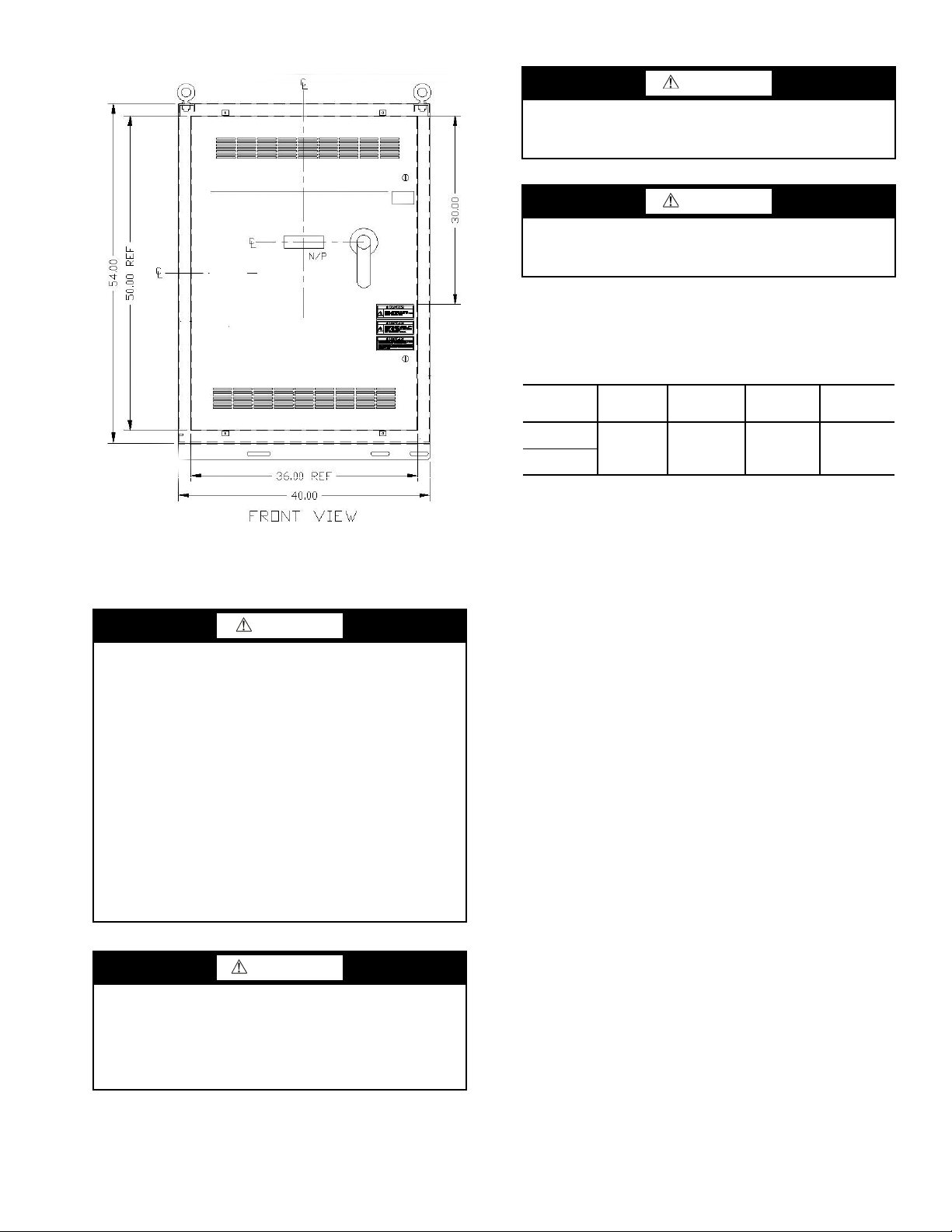

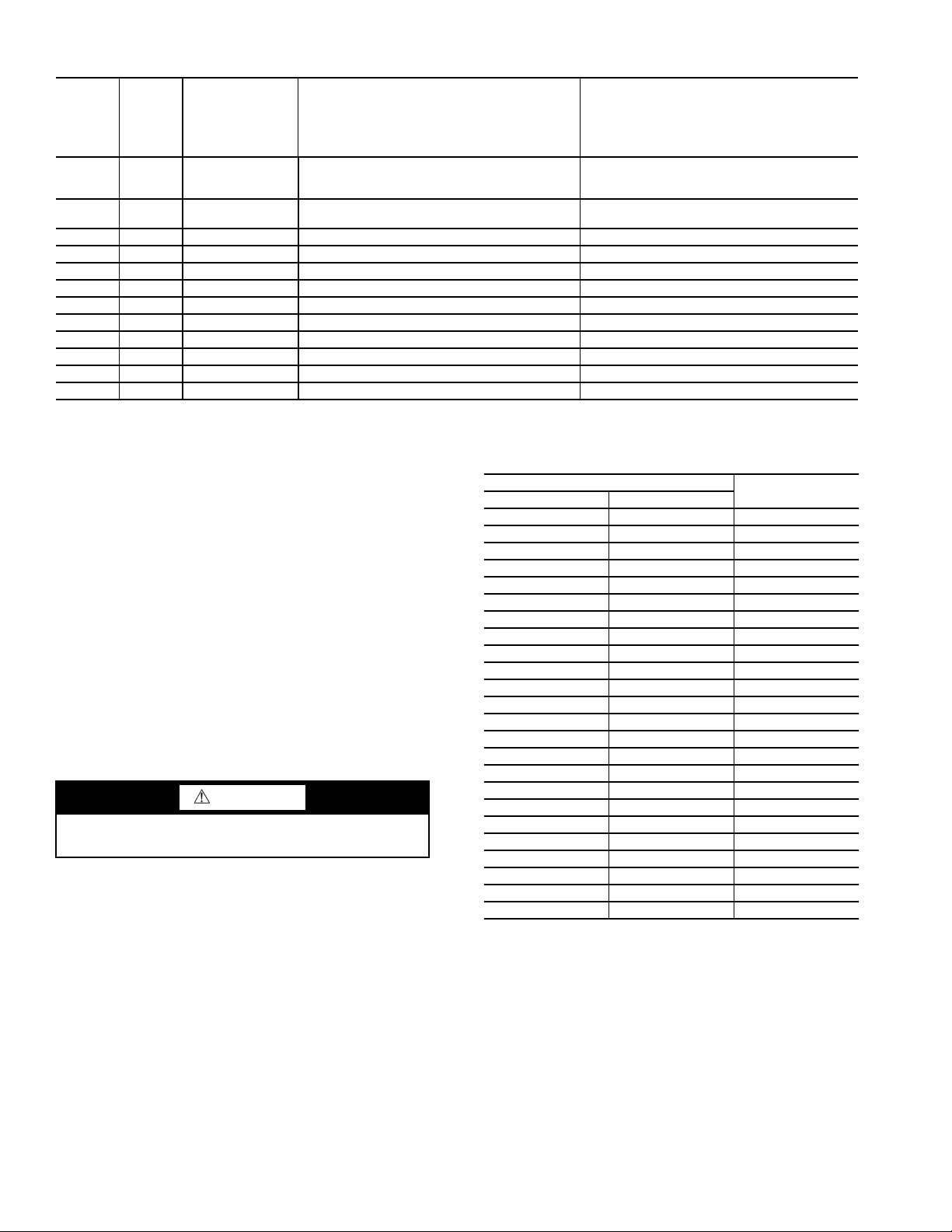

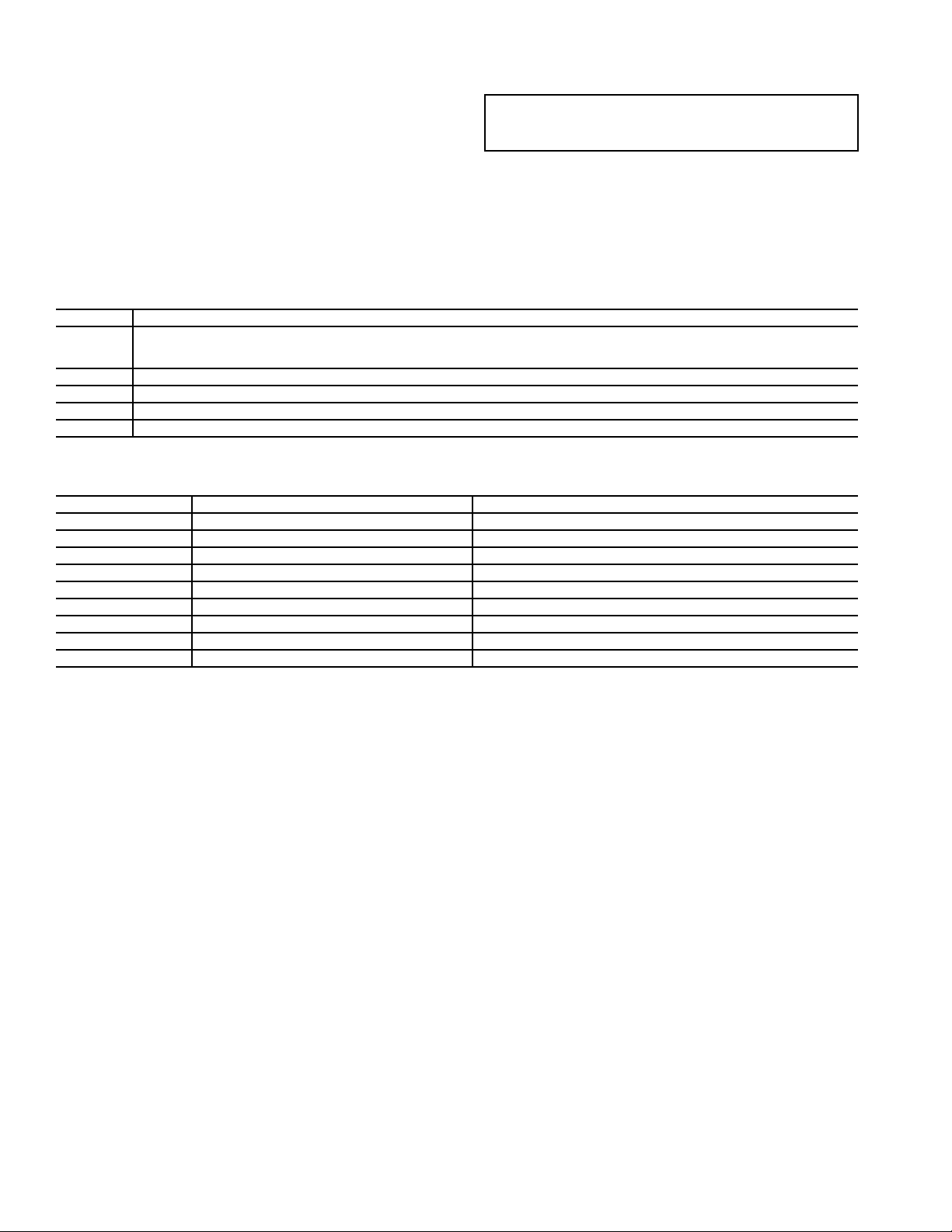

Fig. 1 — Allen Bradley Data Nameplate

A19-1830

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ABBREVIATIONS AND EXPLANATIONS . . . . . . . . . . 2

Required Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Getting Assistance from Rockwell Automation . . . 2

IDENTIFYING DRIVE COMPONENTS. . . . . . . . . . . . 2-5

Opening the VFD Access Door . . . . . . . . . . . . . . . . . . . 3

Drive Assembly Catalog Number . . . . . . . . . . . . . . . . . 3

Components and Physical Data . . . . . . . . . . . . . . . . . . 3

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Alternate Wire Lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Verify Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Configure the VFD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Commissioning the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Check Internal Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Troubleshooting the Drive . . . . . . . . . . . . . . . . . . . . . . . . 8

• ICVC ALERT CODES

• ICVC ALARM CODES

• TEST EQUIPMENT NEEDED TO TROUBLESHOOT

• VERIFYING THAT DC BUS CAPACITORS ARE

DISCHARGED

• HIGH TEMPERATURE ALARMS

• MAIN CONTROL BOARD (MCB) COMPONENTS

Checking Power Modules and Motor Input

with Input Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Servicing the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• REMOVING THE DRIVE

• RIGGING THE ENCLOSURE

• REPLACING THE GATEWAY (A-B20-750-20COMM

OPTION CARD)

• CHILL PLATE FAN AND INTERNAL FAN

REPLACEMENT

Parts Identification and Location . . . . . . . . . . . . . . . . 26

APPENDIX A — WIRING SCHEMATICS . . . . . . . 28-31

APPENDIX B — OPTIONAL BACNET

COMMUNICATIONS WIRING . . . . . . . . . . . . . . . 32-38

Page

Required Publications — The Carrier VFD option

Start-Up and Service Manual must be used with the following

manuals:

• The latest version of the PowerFlex 750-Series AC

Drives manuals

• The latest revision of the Start-Up, Operation, and Maintenance Instructions for the 19XRV with PIC III Controls

Getting Assistance from Rockwell Automation — Contact the local Rockwell Automation sales office

with any questions or problems relating to the products described in this manual. For technical support on drives between

the hours of 7:00 am and 6:00 pm CST, M-F, call 1-262-512-

8176. For information about after-hours phone support and on-

site support call 1-800-800-0522.

Before calling, have the following information available

from the Allen-Bradley data nameplate located inside the enclosure on the right wall. See Fig. 1.

• Allen-Bradley ID or CAT. NO.

• Carrier VFD Code

• Allen-Bradley serial number

INTRODUCTION

The Carrier VFD option Start-Up and Service Manual is intended for trained and qualified service personnel, and is to be

used during start up, operation, and maintenance of Rockwell/

Allen-Bradley PF755L drive.

ABBREVIATIONS AND EXPLANATIONS

Frequently used abbreviations in this manual include:

CCM — Chiller Control Module

DC — Direct Current

DPI — Drive Peripheral Interface

ENET — Ethernet

ICVC — International Chiller Visual Controller

IGBT — Insulated Gate Bipolar Transistor

I/O — Inputs/Outputs

IP — Internet Protocol

IPWM — Inverter Pulse Width Modulation

MCB — Main Control Board

MOV — Metal Oxide Varistor

PE — Protective Earthing Conductor

SIO — Sensor Input/Output

STS — Status

IDENTIFYING DRIVE COMPONENTS

A chiller control schematic and a VFD schematic are in-

cluded in Appendix A.

WARNING

DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input

power, wait five (5) minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter rated

for the DC bus voltage to ensure the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could result in severe bodily

injury or loss of life.

An isolated multimeter will be needed to measure DC bus

voltage and to make resistance checks. The drive’s DC bus

capacitors retain hazardous voltages after input power has

been disconnected.

711

2

Page 3

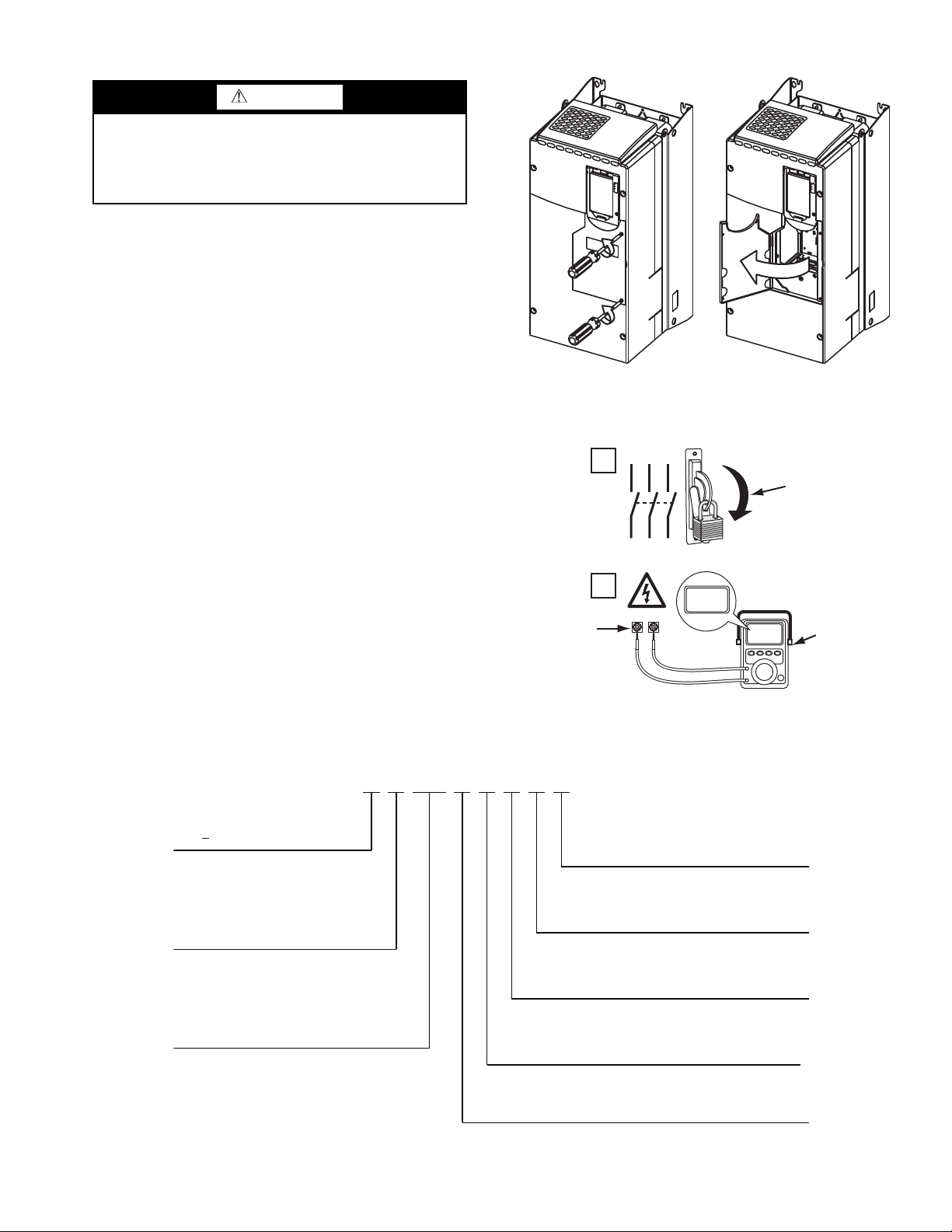

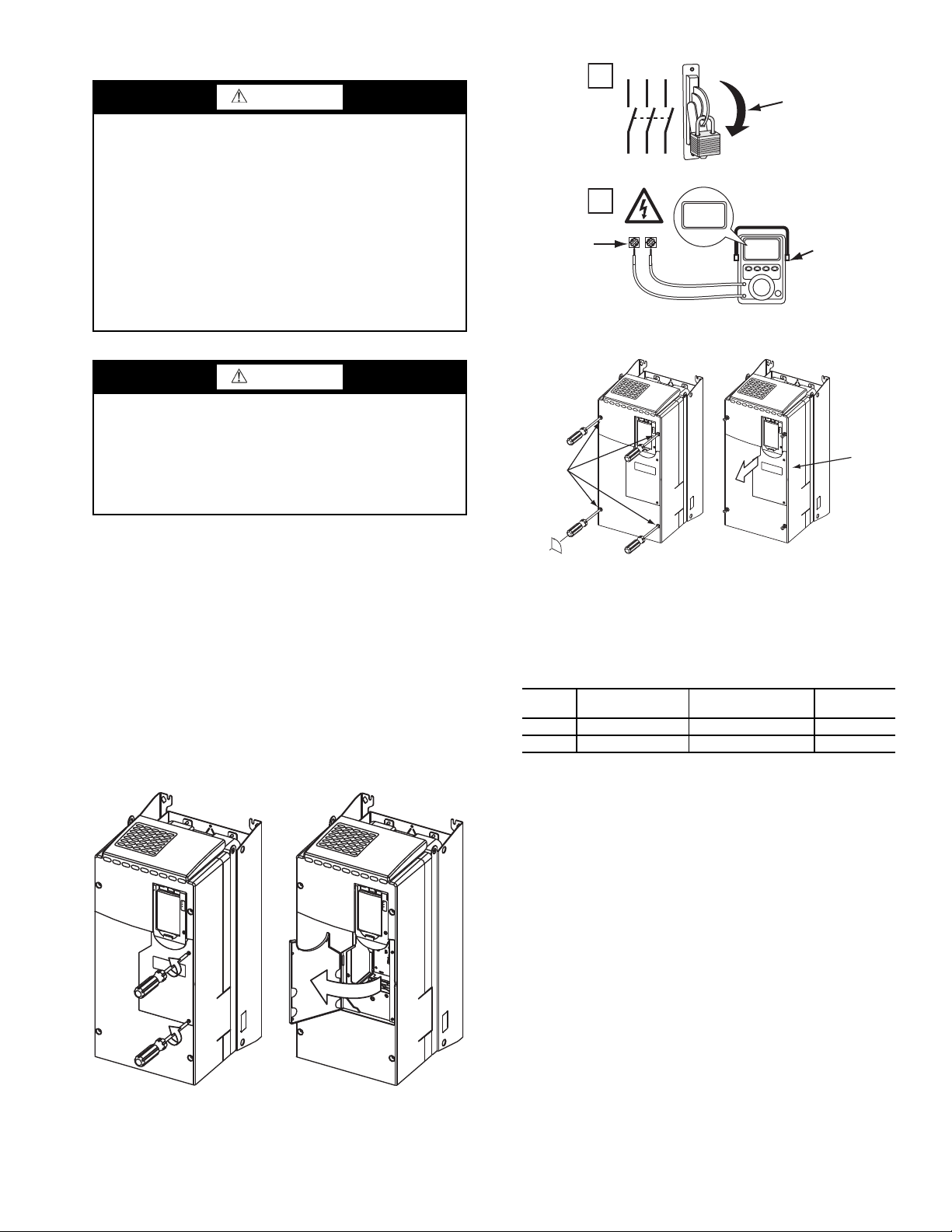

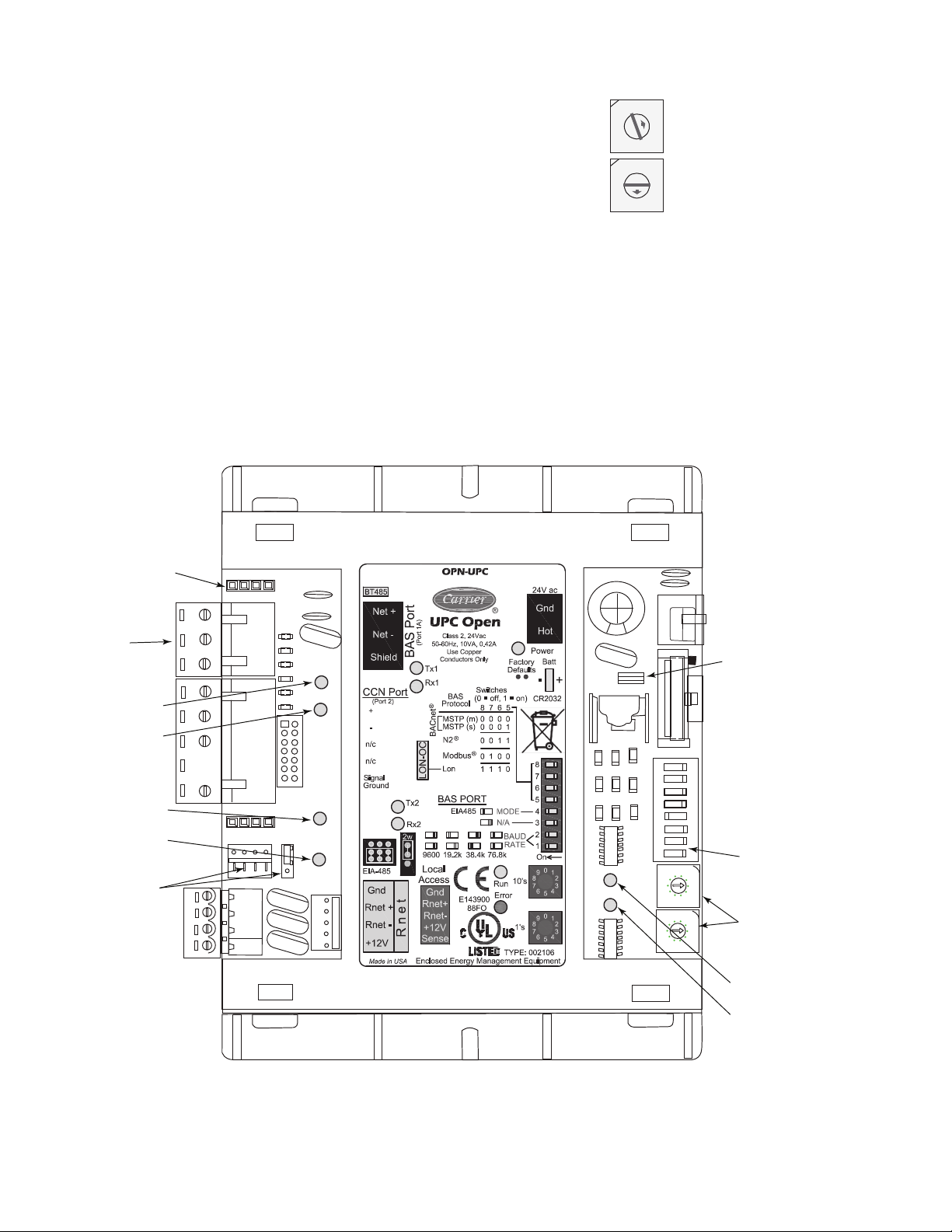

Opening the VFD Access Door

Fig. 2 — Opening Access Door

A19-1831

Fig. 3 — Check DC Bus Terminals

A19-1814

21P 1 0248 3 - 3 -0-0 C-

21P PF755 VFD

Voltage Rating

1

2

3

Customer

C –Carrier

Meter Package

0 – No Meter Package

1 –Analog Meter Package

– 460 to 480 v, 60 Hz

– 380 to 415 v, 50 Hz

– 380 to 400 v, 60 Hz

4

PF755 Full Load Amp Rating

(Maximum Continuous Amps)*

0248 – 248

0361 – 361

Disconnect/Breaker Options

Input Reactor

0 – No Input Reactor

1 – 3% Input Line Reactor

– 401 to 439 v, 60 Hz

0477–477

3–65 KAIC Capacity Breaker

4 – 100 KAIC Capacity Breaker

Drive Assembly

3 – Unit Mount NEMA 1 Liquid Cooled

Fig. 4 — Drive Assembly Catalog Number Nomenclature

A19-1842

* For Carrier applications, maximum continuous amp

ratings are 230, 335, and 445.

WARNING

Before removing the drive enclosure, open access door and

verify that the DC bus voltage has dropped to zero by

checking the terminals behind the access door. Failure to

observe this precaution could result in severe bodily injury

or loss of life.

1. Using recommended screwdriver = 6.4 mm (0.25 in.) flat

or T20 star, open access door. See Fig. 2.

2. Check to be sure that the voltage between DC+ and DCand from each DC terminal to the chassis is zero before

proceeding. See Fig. 3.

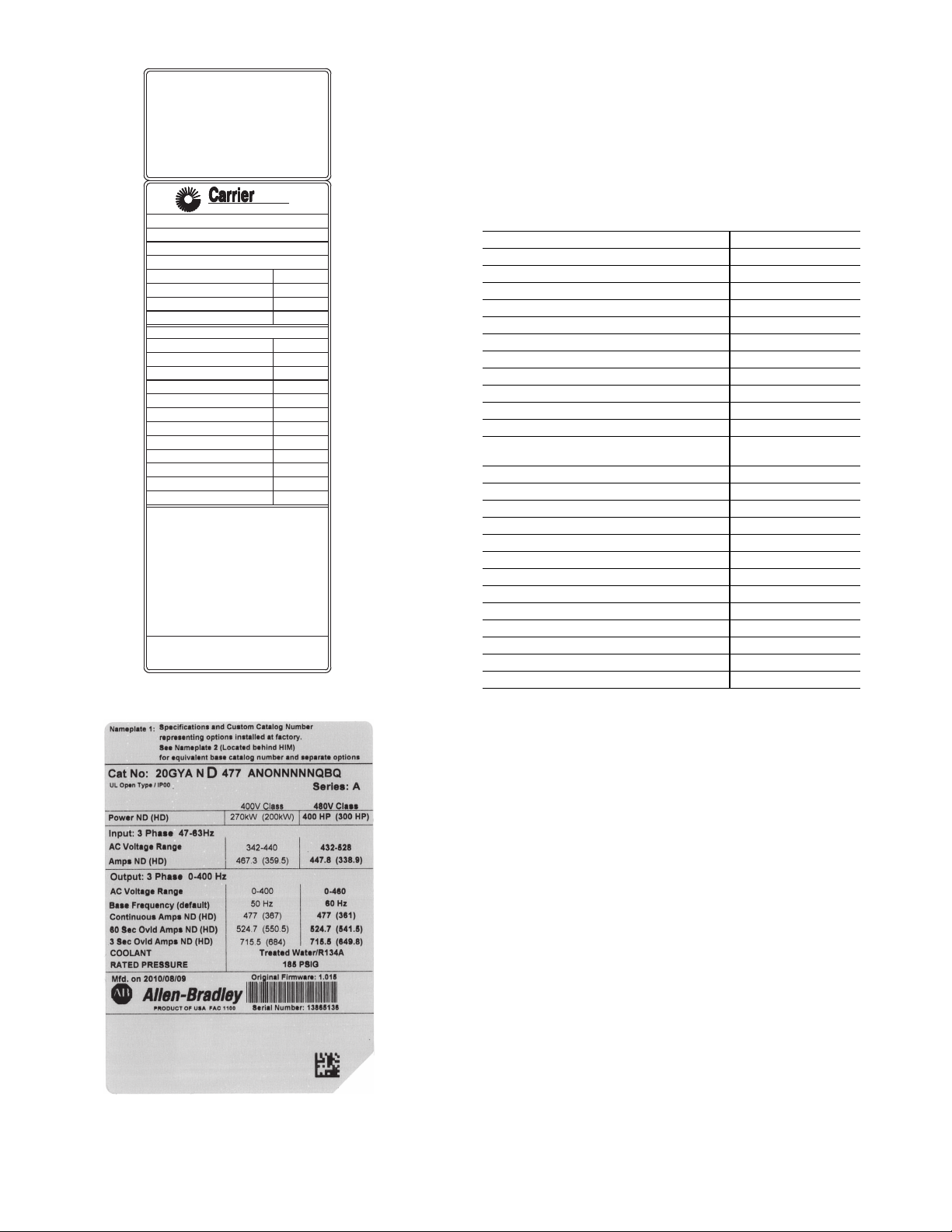

Drive Assembly Catalog Number — See Fig. 4 for

an example Catalog Number.

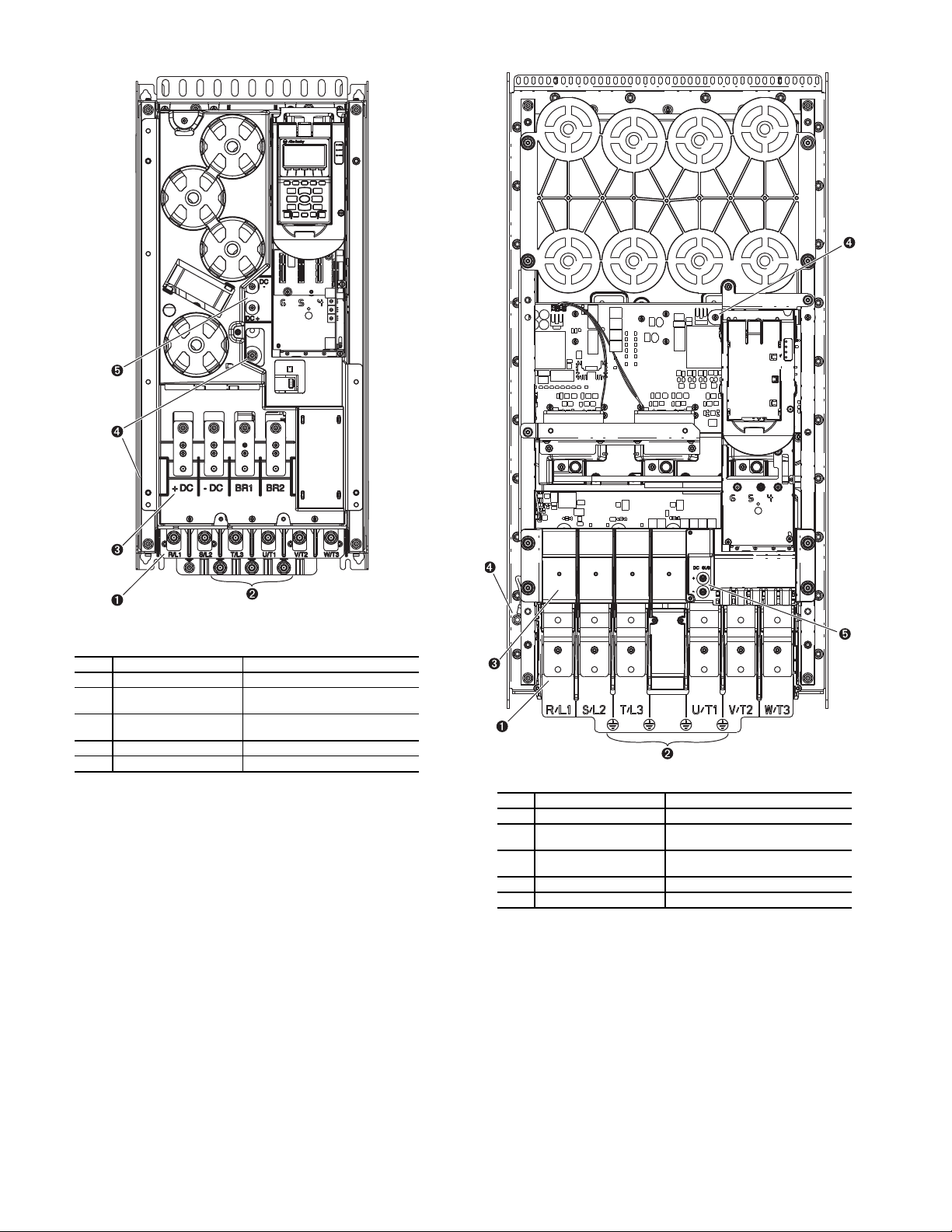

Components and Physical Data — The Allen-

Bradley PF755 Frame 6 drive is used for the 230-amp rated application (carrier Part No. 19XRV0230...). See Fig. 5.

The Allen-Bradley PF755 Frame 7 drive is used for the

335-amp and 445-amp rated application (Carrier Part No.

19XVR0335... and 19XVR0445... respectively). See Fig. 6.

See Fig. 7 for the dimensions of Frames 6 and 7.

1

L1 L2 L3

I

LOCKOUT/TAGOUT

DC BUS TEST

TERMINALS

LOCATED INSIDE

ACCESS DOOR

2

DC+ DC–

0V

O

0V

MULTIMETER

3

Page 4

LEGEND

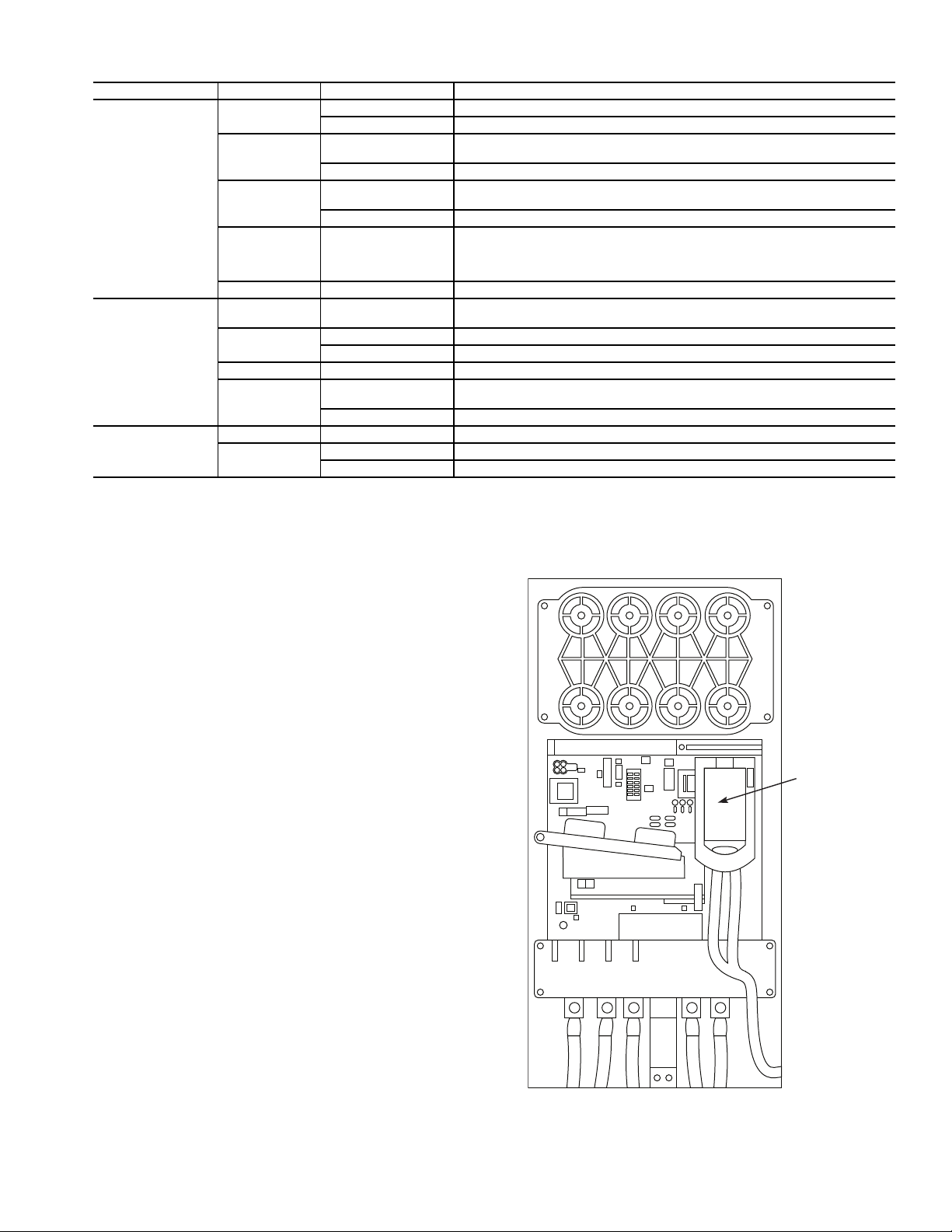

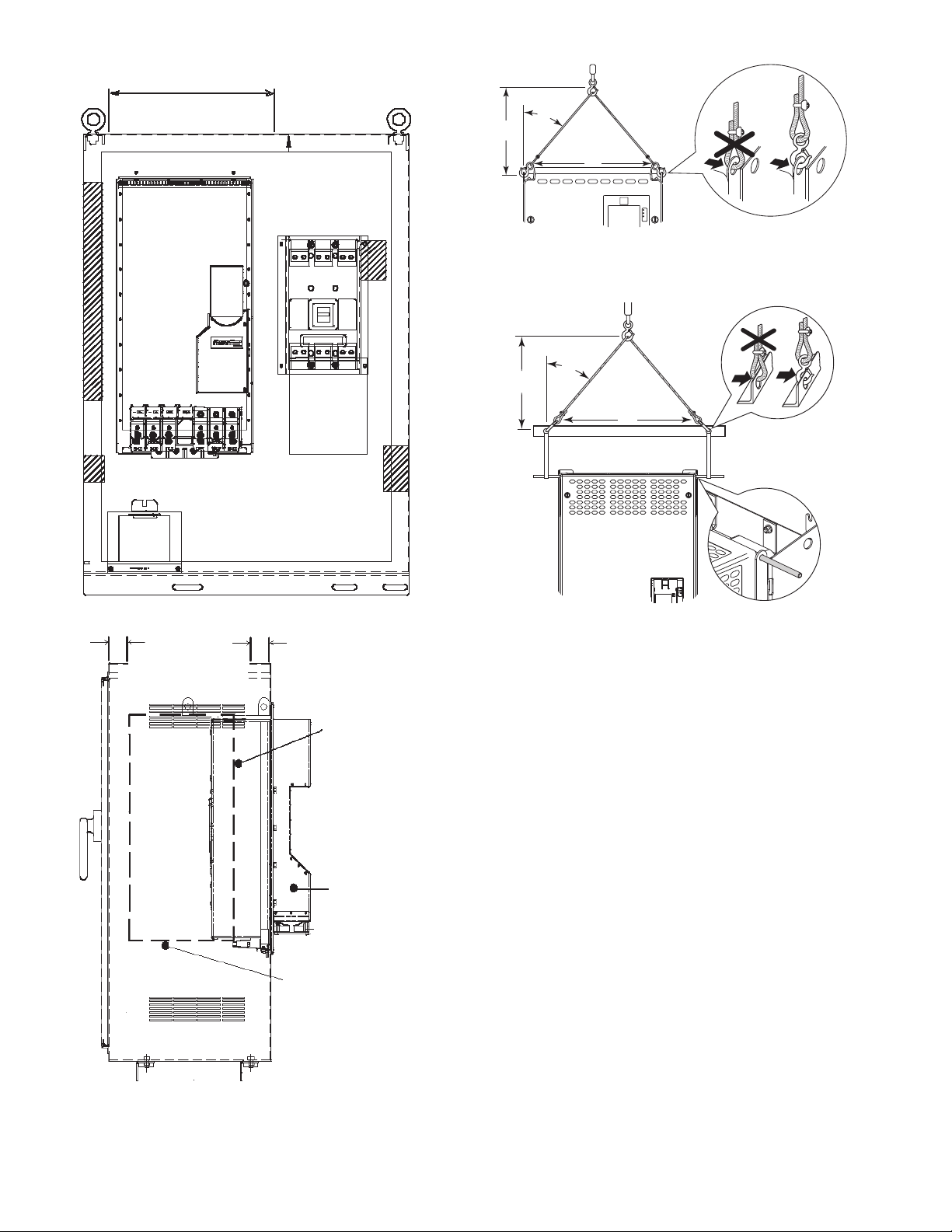

Fig. 5 — Frame 6 Drive Components

NO. NAME DESCRIPTION

1 Power Terminals R/L1, S/L2, T/L3, U/T1, V/T2, W/T3

2

PE Grounding Studs Terminating point to chassis ground

for incoming motor shield

3

DC Bus and Brake

Terminals

+DC, -DC, BR1, BR2

4 PE-A and PE-B MOV and CMC Jumper Wires

5 DC+ and DC- Bus Voltage Test Points

A19-

1832

LEGEND

Fig. 6 — Frame 7 Drive Components

NO. NAME DESCRIPTION

1 Power Terminals R/L1, S/L2, T/L3, U/T1, V/T2, W/T3

2

PE Grounding Studs Terminating point to chassis ground

for incoming motor shield

3

DC Bus and Brake

Te r mi n a ls

+DC, -DC, BR1, BR2

4 PE-A and PE-B MOV and CMC Jumper Wires

5 DC+ and DC- Bus Voltage Test Points

A19-1833

4

Page 5

Fig. 7 — Enclosure Dimensions - Frames 6 and 7

A19-1834

CAUTION

If other than refrigerant cooling is used, before connecting

the drive to the incoming power, make sure that the coolant

is circulating and has no leaks.

CAUTION

When working with the Drive Explorer, never use the

Rotate function as the motor will immediately start and

severe compressor damage could result.

START-UP

DANGER

Internal components and circuit boards of the drive are live

when the drive is connected to incoming power. Coming

into contact with this voltage is extremely dangerous and

will result in severe personal injury or death.

The motor terminals U, V, W and the DC-link/brake resistor terminals B+/R+, R- are live when the drive is connected to incoming power, even if the motor is not running.

Do not make any connections when the drive is connected

to the incoming power.

After having disconnected the drive, wait until the indicators on the keypad go out (if no keypad is attached see the

indicator through the keypad base). Wait 5 more minutes

before doing any work on drive connections. Do not even

open the cover before this time has expired..

Before connecting the drive to the incoming power, make

sure that the switchgear enclosure door is closed.

WARNING

The control I/O-terminals are isolated from the mains

potential. However, the relay outputs and other I/O terminals may have a dangerous control voltage present even

when the drive is disconnected from incoming power.

Coming into contact with this voltage could result in severe

personal injury.

Alternate Wire Lugs —

In the case where the incoming

power wire size does not fit the standard lug, alternate lugs may

be used. See Table 1. Note that lugs rated for a higher current

than the circuit breaker may be used.

Table 1 — Wire Lugs

CIRCUIT

BREAKER

65 KAIC

(Standard)

100 KAIC

(Optional)

STANDARD

ABB LUG

K6TJ

STANDARD

LUG CABLE

RANGE

(3) 2/0 - 400

MCM

ALTERNATE

ABB LUG

K6TH

ALTERNATE

LUG CABLE

RANGE

(2) 250 - 500

MCM

Verify Installation — Record the following job

information:

1. Job Name

2. Job Number

3. City

4. State

5. Zip Code

Record the following nameplate information:

1. From the Allen-Bradley nameplate (Fig. 1) located inside

the VFD enclosure:

a. Allen-Bradley ID or CAT NO.

b. Allen-Bradley Serial Number

c. Carrier Part Number

2. From the machine nameplete (Fig. 8) located inside the

VFD enclosure:

a. Chiller Serial Number

b. Chiller Model

c. Motor rated load amps

d. Motor nameplate rpm

e. Motor nameplate kW

f. Motor nameplate voltage

g. IPWM (pulse width modulation) frequency

h. Voltage

3. From the drive module label (Fig. 9) located on the drive

module:

a. Model or Cat. Number

b. Serial Number

4. From the ICVC control panel screen:

a. Carrier Part Number and Revision

b. ICVC Software Number

Rockwell PowerFlex 750 drive start-up must be registered

on the Rockwell website. Rockwell Registration site URL:

http://www.automation.rockwell.com/warp/default.asp

5

Page 6

MODEL NUMBER

SERIAL NUMBER

VOLTS/PHASE/HERTZ

LOCKED ROTOR AMPS

OVERLOAD TRIP AMPS

MAX FUSE/CIRCUIT BREAKER SIZE

MIN SUPPLY CIRCUIT AMPACITY

MOTOR NAMEPLATE VOLTAGE

COMPRESSOR 100% SPEED

RATED LINE VOLTAGE

RATED LINE AMPS

RATED LINE KILOWATTS

MOTOR RATED LOAD KW

MOTOR RATED LOAD AMPS

MOTOR NAMEPLATE AMPS

MOTOR NAMEPLATE RPM

MOTOR NAMEPLATE KW

INTERTER PWM FREQUENCY

MACHINE NAMEPLATE SUPPLY DATA

MACHINE ELECTRICAL DATA

SAFETY CODE CERTIFICATION

THE COMPRESSOR MOTOR CONTROLLER AND OVERLOAD PROTECTION MUST BE

IN ACCORDANCE WITH CARRIER SPECIFICATION Z-420.

19XV05008701 REV. 3

A United Technologies Company

Fig. 8 — Machine Nameplate

a19-

1846

Fig. 9 — Drive Module Label

a191924

Configure the VFD — All configurations required by

the VFD are supplied by the ICVC through the VFD Gateway.

Any configuration changes necessary and possible are made on

the ICVC screens. A complete set of configurations is transmitted to the VFD each time the controls are powered up.

The following is from the 19XRV PIC III ICVC screen. Parameters in italics are to be entered or confirmed at start-up. Parameters in bold are to be changed only after consulting with

Carrier service engineering. See Table 2.

Table 2

PARAMETER DEFAULT VALUE

Motor Nameplate Voltage 460

Compressor 100% Speed

Line Freq=60 Hz? (No=50) Yes

Rated Line Voltage* 460

Rated Line Amps* 200

Rated Line Kilowatts * 100

Motor Rated Load kW* 100

Motor Rated Load Amps* 200

Motor Nameplate Amps 100

Motor Nameplate RPM 3456

Motor Nameplate KW 100

Inverter PWM Frequency (0 = 4 kHz, 1 =

2kHz)

Skip Frequency 1 (Hz) 102.0

Skip Frequency 2 (Hz) 102.0

Skip Frequency 3 (Hz) 102.0

Skip Frequency Band Line (Hz) 0.0

Voltage % Imbalance 10

Line Volt Imbalance Time (sec) 10

Line Current % Imbalance 40

Line Current Imbal Time (sec) 10

Motor Current % Imbalance 40

Motor Current Imbal Time 10

Increase Ramp Time (sec) 30

Decrease Ramp Time (sec) 30

Single Cycle Dropout (DSABLE/ENABLE) DSABLE

* Parameters marked with an * are not downloadable to the VFD but are used

in other calculations and algorithms in the ICVC.

NOTES:

1. Parameters in italics are to be entered or confirmed at start-up.

2. Parameters in bold are to be changed only after consultation with service engineering.

— VFD Configurations

1

Commissioning the Unit — The commission proce-

dure is as follows:

1. If the chiller has been stored outdoors, allow at least 24

hours room temperature stabilization prior to commissioning. Ensure any condensation that occurs as a result

of the ambient temperature is allowed to evaporate.

2. Enter parameters in the VFD_CONF screen.

3. Install surge suppression devices if required.

4. Review the power wiring and grounding to ensure that it

has been properly connected.

5. Visually examine the inside of the drive enclosure to:

a. Look for signs of corrosion or moisture residue.

b. Remove any dirt or debris.

c. Make sure all vents are clear.

6. Apply power to the drive and take thermal measurements

of the capacitor bank and power connections. Do this

again before start-up.

7. Measure and record the incoming line voltage. Line-toline voltages should be balanced within 3% as calculated

by Rockwell’s procedure below:

Measure voltages phase-to-phase and phase-to-ground.

6

Page 7

Vmax = Maximum measured phase-to-phase voltage

LEGEND

NO. NAME DESCRIPTION

1 HIM Connector DPI Port 1 (HIM Cradle) connection.

2

Fan Connector Power supply for internal cooling fan

(Frames 2 & 3).

3

Battery

Receptacle

User installed CR1220 lithium coin cell

battery provides power to the Real Time

Clock (Optional, not supplied).

4

DPI Port 2 Cable connection for handheld and

remote HIM options.

5

Embedded EtherNet/

IP Address Selectors

Rotary switches for setting lowest octet

of EtherNet address (forces address to

192.168.1.xxx).

6

Embedded EtherNet/

IP Connector

Network cable connection.

7

Jumper J2 SAFETY Safety enable jumper. Removed when

safety option is installed.

8

Jumper J1 ENABLE Hardware enable jumper. Removed

when a hardware enable configuration is

utilized.

9 TB1 I/O terminal block.

Fig. 10 — PF755 Main Control Board

TB1 I/O Terminal Designations

FIXED I/O TERMINAL NAME DESCRIPTION

Di 0ac

Digital Input 120V AC Connections for AC power supply.

Di C

Digital Input Common Digital input common

Di 0dc

Digital Input 24V DC Connections for DC power supply.

+24V

+24 Volt Power Connections for drive supplied 24V power.

24VC

24 Volt Common

IMPORTANT: Wiring to pluggable terminal block connectors

should be supported by wire ties or other means to help prevent unintentional disconnection

Di 0ac

Di C

Di 0dc

+24V

24VC

a19-1921

(A to B, B to C, C to A)

Vmin = Minimum measured phase-to-phase voltage

Imbalance Calculation Formula

Va v g =

Imbalance % =

(VAB + VBC + VCA)

3

(Vmax – Vmin) x 100

Va v g

8. Take a final thermal measurement of the capacitor bank

and power after finalizing the installation to ensure all

connections are good.

9. If a ground fault occurs, then do the following:

a. Check for a ground in the motor or motor wiring.

b. Check for damage to wiring insulation and that

wiring is dry.

c. Verify the motor wiring is separated from ground

and there is no connection between phases.

d. Check for failed IGBTs.

10. If an Overcurrent fault occurs, then do the following:

a. Check for excessive load and verify load limit set-

tings on the ICVC.

b. Check motor and wiring insulation.

c. Check parameter settings on VFD_CONF screen

in the ICVC.

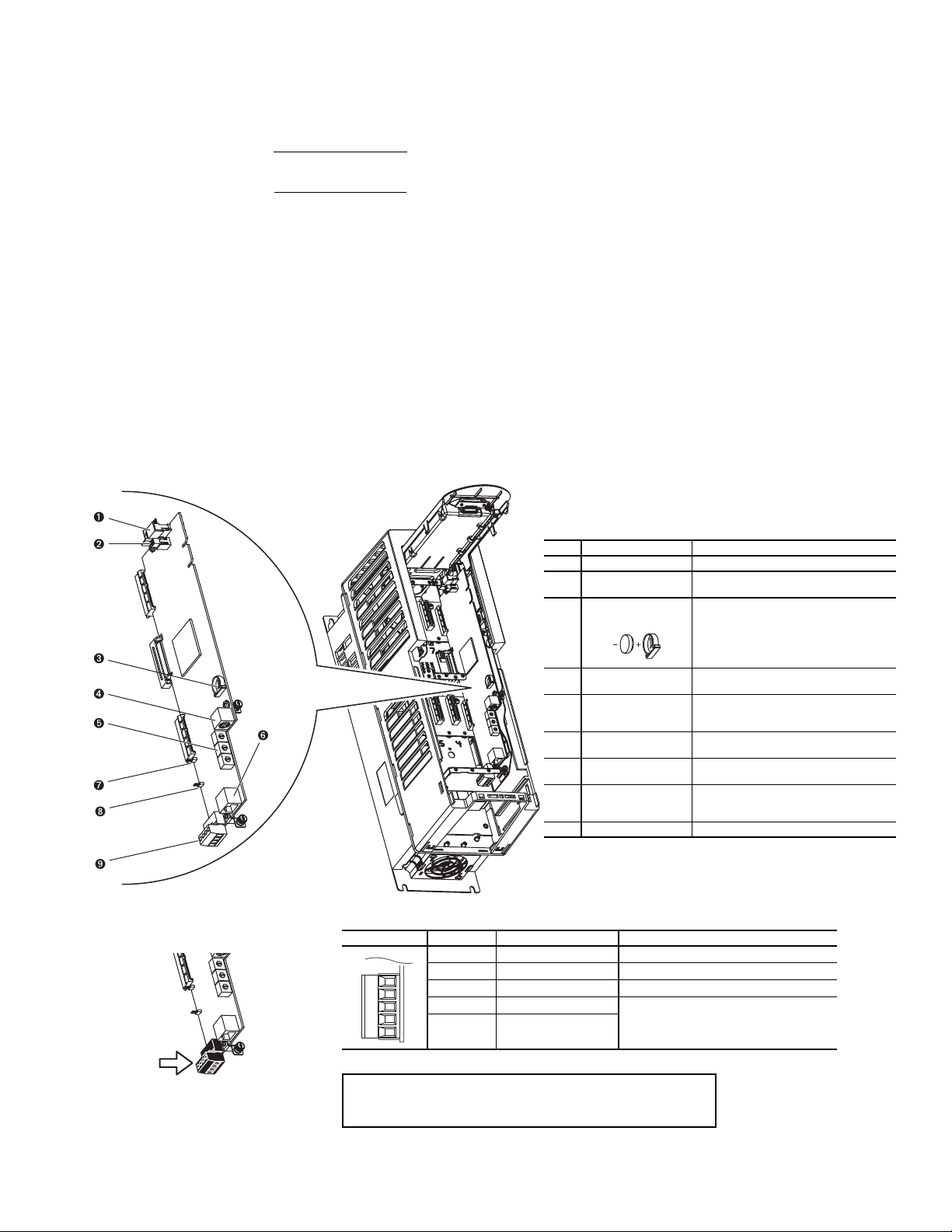

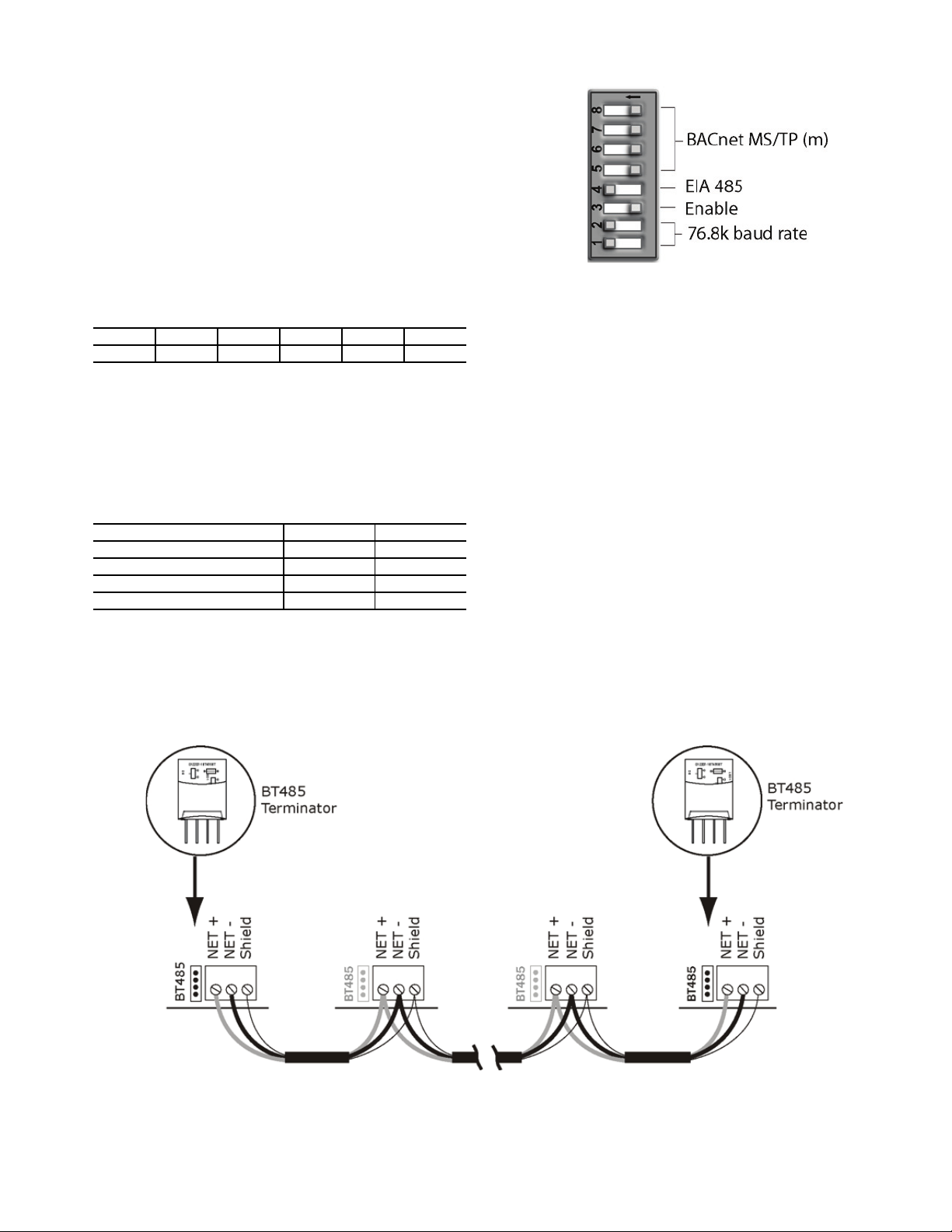

Check Internal Jumpers — On the Main VFD Con-

trol board there are two jumpers labeled J1 HARDWARE ENABLE and J2 SAFETY ENABLE. J1 should be removed and

J2 should be in place. See Fig. 10.

There are two jumper wires that connect a particular terminal to chassis ground. The MOV and AC EMI jumper should

be connected to the PE-A terminal. The COMMON MODE

CAPACITORS to GROUND jumper should be connected to a

standoff rather than the PE-B terminal.

Use the recommended tools as follows when connecting

jumper wires in Frame 6 and in Frame 7:

• Recommended torque (screws and nuts) = 1.36 N·m

(120.0 lb·in)

• Recommended hex socket = 7 mm

• Recommended screwdriver = T20 star type

See Fig. 11A and Fig. 11B for the correct positions of the

jumpers.

7

Page 8

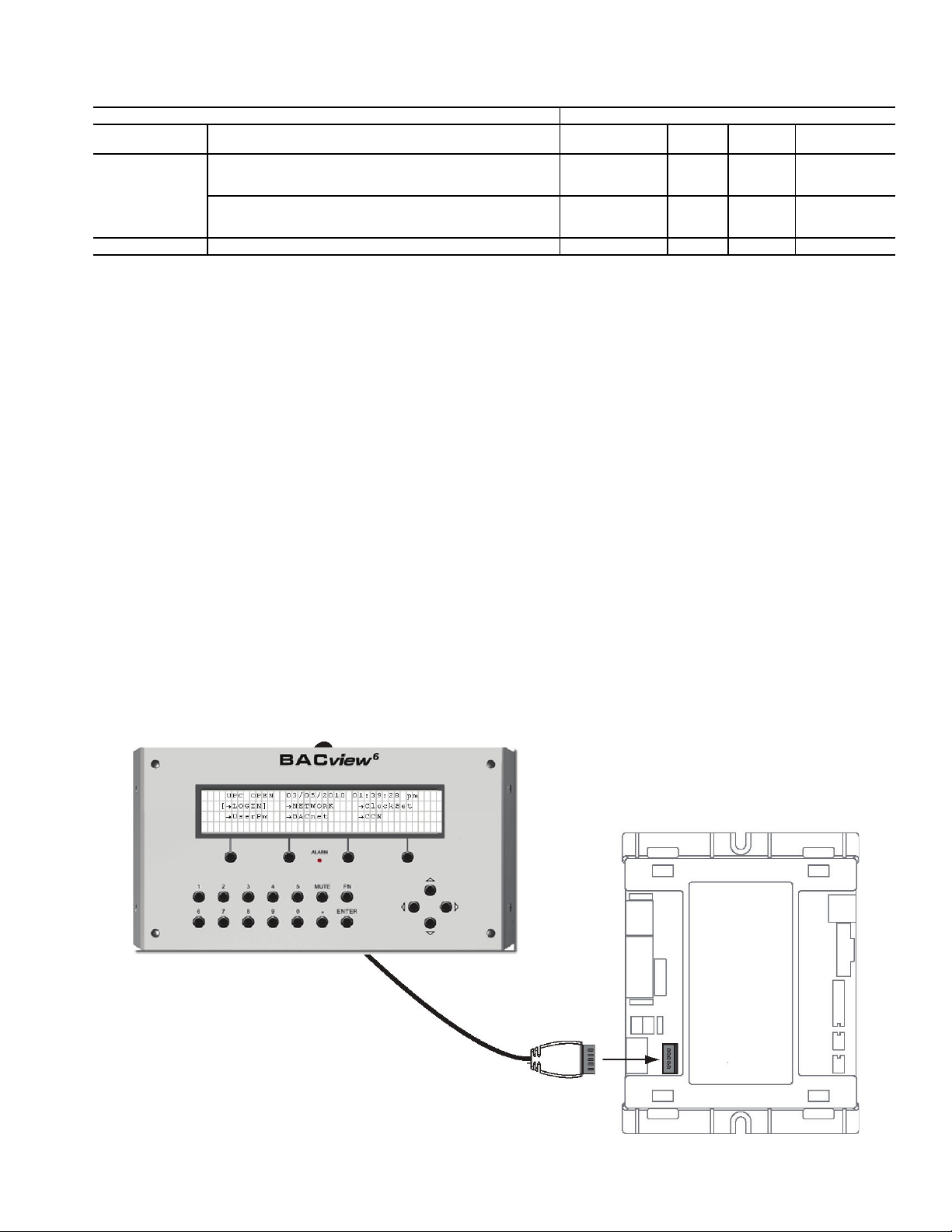

Troubleshooting the Drive —

Fig. 11A — Jumper Wire Locations — Frame 6

A19-1835

Fig. 11B — Jumper Wire Locations — Frame 7

A19-1836

2

8

5

79

13

46

Allen-Bradley

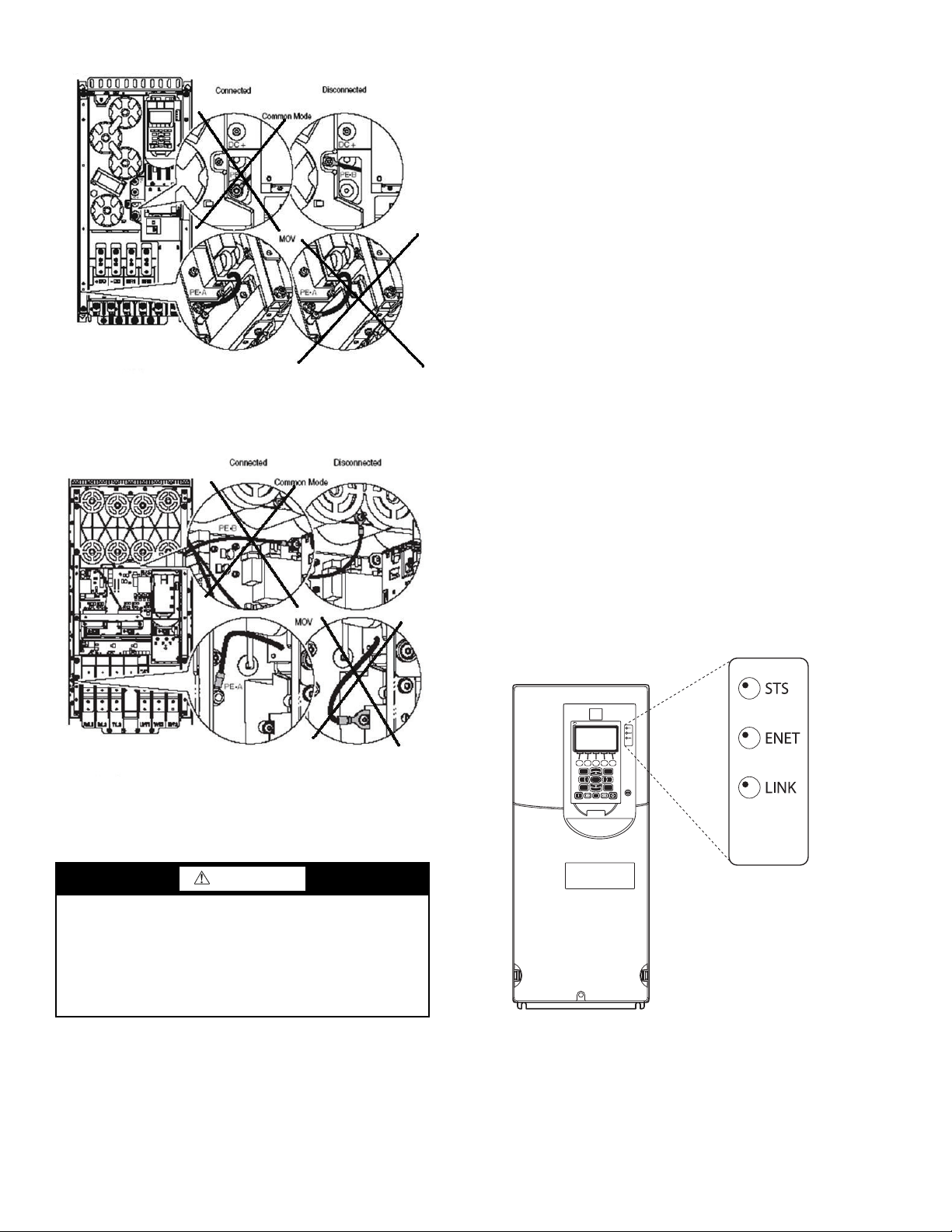

Fig. 12 — Drive Status Indicator

A1

91815

The drive can display

two kinds of error codes on the ICVC called the Alert and

Alarm codes. These codes signal a problem detected during

self tuning or drive operation. Alert and Alarm codes are located in the 19XRV Start-Up, Operation and Maintenance Instructions. Note the following differences between Carrier and

Allen-Bradley terminology:

• A warning message on the ICVC is an ALERT.

• The same warning viewed with Rockwell Drive Explorer

is a VFD ALARM.

• A failure resulting in a shutdown is seen as an ALARM

on the ICVC and as a VFD FAULT when viewed with

Drive Explorer.

CONDITION CODES

ICVC ALERT = VFD ALARM

ICVC ALARM = VFD FAULT

See Tables 3-6 and Fig. 12.

ICVC ALERT CODES — An alert condition is indicated by

a message at the top of the ICVC default screen. In addition, an

exclamation point (!) will appear next to any affected point on

an ICVC display screen. The drive will continue to operate

during the alert condition. Investigate the cause of the alert to

ensure it does not lead to a fault condition. The alert code will

automatically be cleared from the ICVC when the condition

causing the alert no longer exists. See Table 4.

ICVC ALARM CODES — An alarm condition is also indicated by a message at the top of the ICVC default screen. If an

alarm occurs, the drive coasts to stop. The STS (status) light on

the drive will turn from Green to Red or Yellow (see Table 3).

The detected fault message is maintained on the display until it

is cleared by pressing the RESET softkey. See Table 5.

TEST EQUIPMENT NEEDED TO TROUBLESHOOT —

An isolated multimeter adequately rated for the DC bus voltage will be needed to measure DC bus voltage and to make

resistance checks. Note that dedicated troubleshooting test

points are not provided.

SERVICE

WARNING

DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input

power, wait five (5) minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to

ensure the DC bus capacitors are discharged before touching any internal components. Failure to observe this precaution could result in severe bodily injury or loss of life.

8

Page 9

Table 3

SWING UP KEY PAD

MOUNT TO ACCESS

CONTROL BOARDS

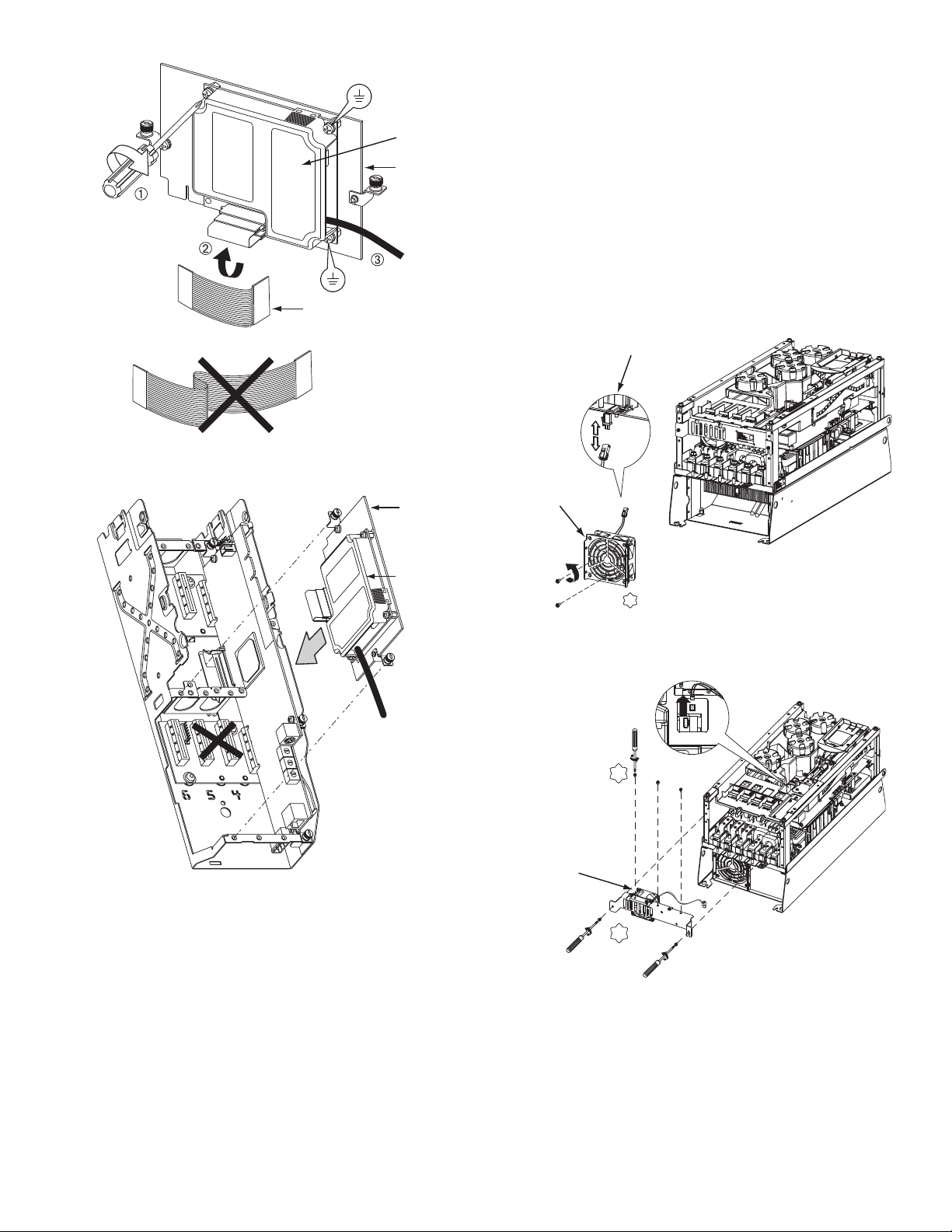

Fig. 13 — Drive Module with Cover Removed

a19-1843

NAME COLOR STATE DESCRIPTION

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing Drive is not running. A type 2 (non-configurable) alarm condition exists and the

Steady Drive is not running, a type 1 alarm condition exists. The drive can be started.

STS (Status)

ENET

LINK

NOTES:

1. A Type 1 alarm indicates that a condition exists. Type 1 alarms

are user configurable.

Red Flashing A major fault has occurred. Drive cannot be started until fault condition is

Steady A non-resettable fault has occurred.

Red/Yellow Flashing Alternately A minor fault has occurred. When running, the drive continues to run. System is

Green/Red Flashing Alternately Drive is flash updating.

None (Unlit) Off Adapter and/or network is not powered, adapter is not properly connected to

Red Flashing An EtherNet/IP connection has timed out.

Steady Adapter failed the duplicate IP address detection test.

Red/Green Flashing Alternately Adapter is performing a self-test.

Green Flashing Adapter is properly connected but is not communicating with any devices on

Steady Adapter is properly connected and communicating on the network.

None (Unlit) Off Adapter is not powered or is not transmitting on the network.

Green Flashing Adapter is properly connected and transmitting data packets on the network.

Steady Adapter is properly connected but is not transmitting on the network.

— Drive Status Indicator Descriptions

drive cannot be started.

cleared.

brought to a stop under system control. Fault must be cleared to continue. Use

parameter 950 [Minor Flt Config] to enable. If not enabled, acts like a major

fault.

the network, or adapter needs an IP address.

the network.

2. A Type 2 alarm indicates that a configuration error exists and

the drive cannot be started. Type 2 alarms are not configurable.

VERIFYING THAT DC BUS CAPACITORS ARE DISCHARGED — The drive’s DC bus capacitors retain hazardous voltages after input power has been disconnected. Perform

the following steps before touching any internal components:

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power

terminals.

3. Measure the DC bus potential with a voltmeter while

standing on a non-conductive surface and wearing insulated gloves (1000 V). Measure the DC bus potential. See

Fig. 5 for the 248-amp drive and Fig. 6 for the 361 and

477-amp drives. The voltage between DC+ and DC-, and

from each DC terminal to the chassis must be zero before

proceeding.

4. Once the drive has been serviced, reapply input power.

HIGH TEMPERATURE ALARMS — Coolant flow

through the cold plate is controlled by an orifice in the refrigerant line leaving the cold plate. The orifice looks like one of the

O-ring face seal connectors and in fact is used as one of the

connections on the coolant tubing. The difference is that the

passage through the fitting is 0.375 in. (9.5 mm). If the orifice

is present and condenser liquid flow is present, the liquid will

flash to cooler temperature at the orifice. This temperature difference is great enough to be easily felt.

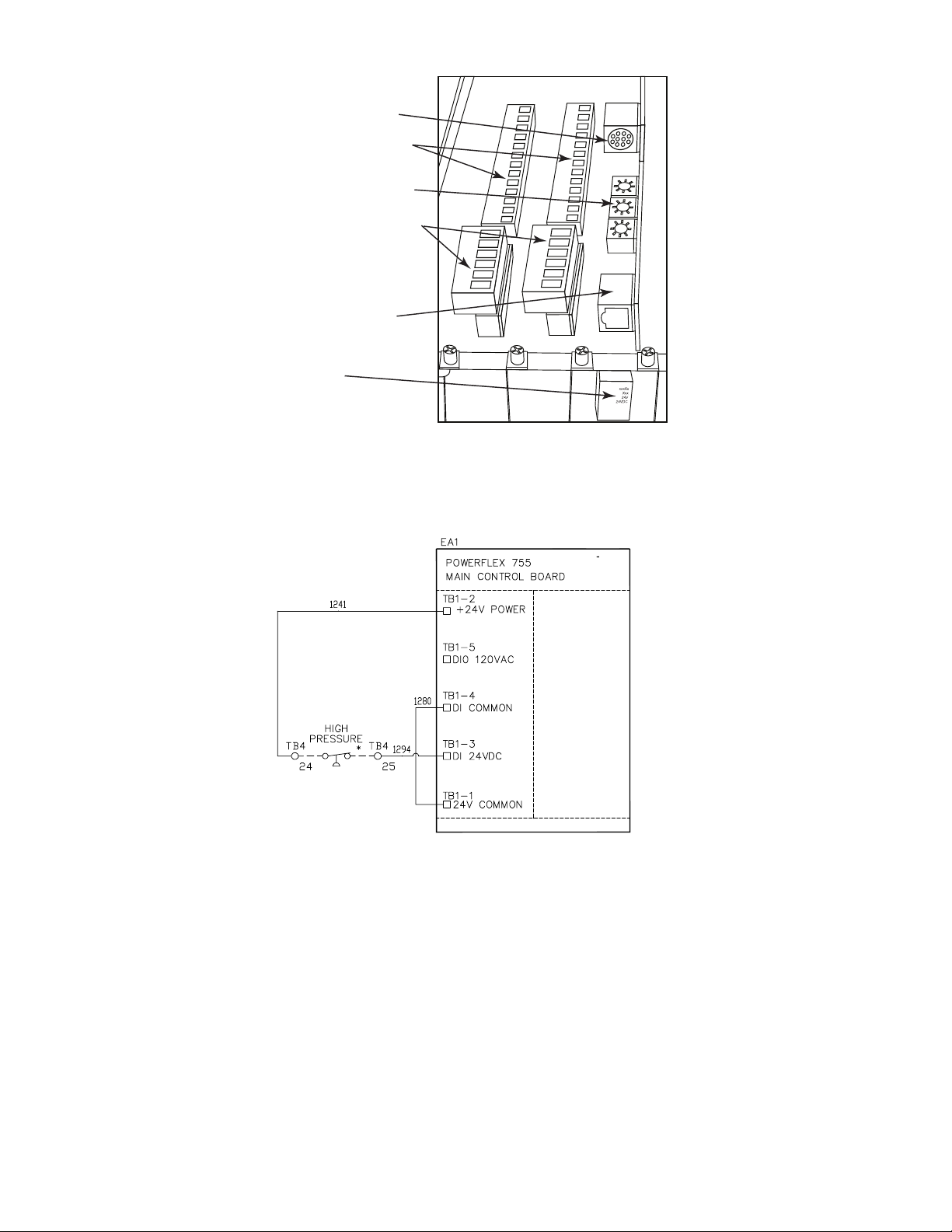

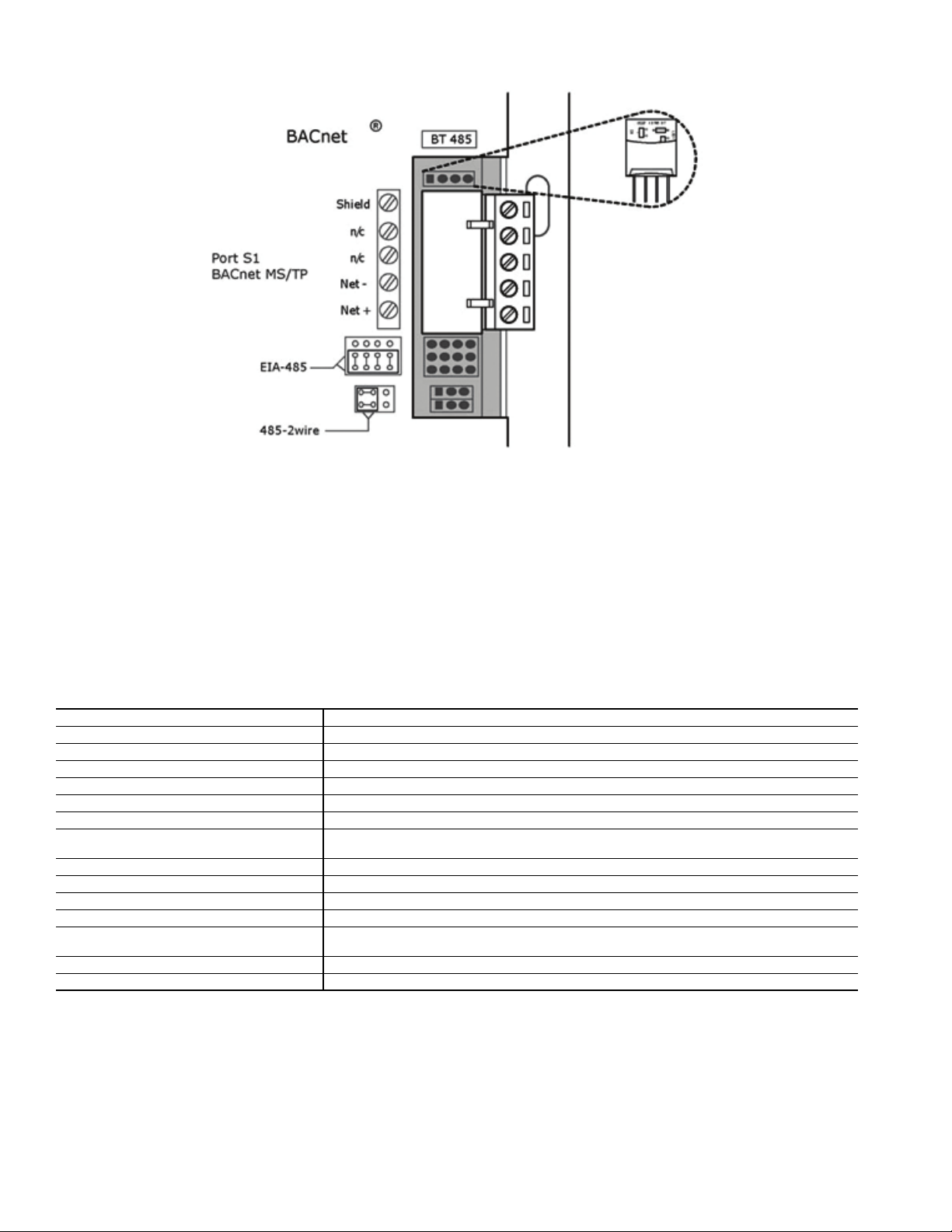

MAIN CONTROL BOARD (MCB) COMPONENTS —

Figure 13 shows the drive module with the cover removed. To

access the control boards, loosen the screw on the face of the

keypad mount and swing the keypad mount upward.

The components on the main control board (MCB) are

shown in Fig. 14. Note the location of the terminals labeled

MCB I/O. The high pressure switch is wired to these terminals

as shown in Fig. 15. In the event of a high condenser pressure

alarm, the connections at these terminals should be checked

and tightened if necessary.

A typical wiring schematic is shown in Appendix A.

9

Page 10

DPI PORT 02 (COMPUTER PORT)

DIGITAL INPUT TERMINAL BLOCKS

(SLOTS 04 & 05)

ETHERNET/IP ADDRESS SWITCHES

DIGITAL OUTPUT TERMINAL BLOCKS

(SLOTS 04 & 05)

EMBEDDED ETHERNET/IP PORT

MCB I/O TERMINALS

(AUX FAULT /

HIGH PRESSURE FAULT /

ENABLE INPUT)

Fig. 14 — MCB (Main Control Board) Components

a19-1844

*Located outside of starter; connected by field wiring.

Fig. 15 — High Pressure Switch Wiring

a19-1925

10

Page 11

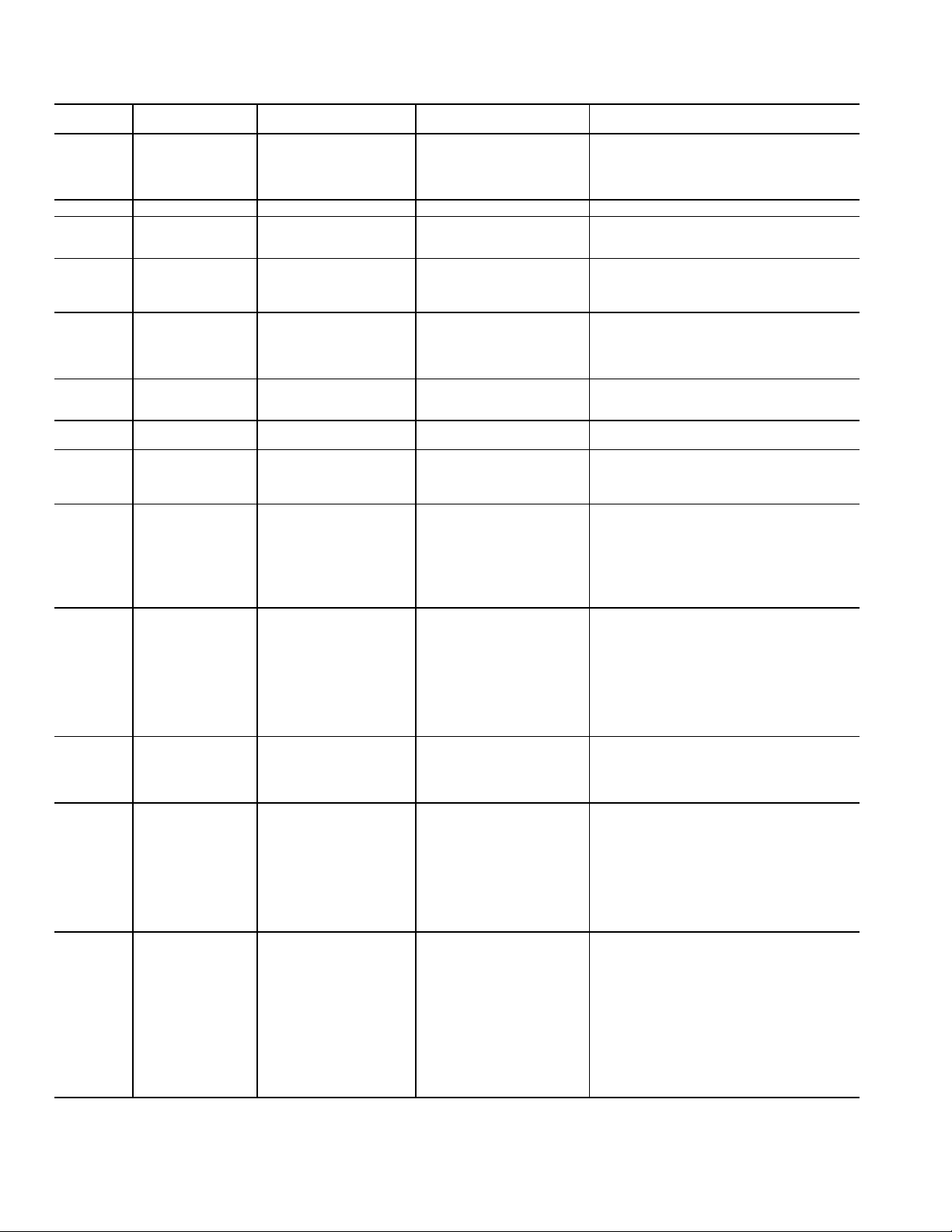

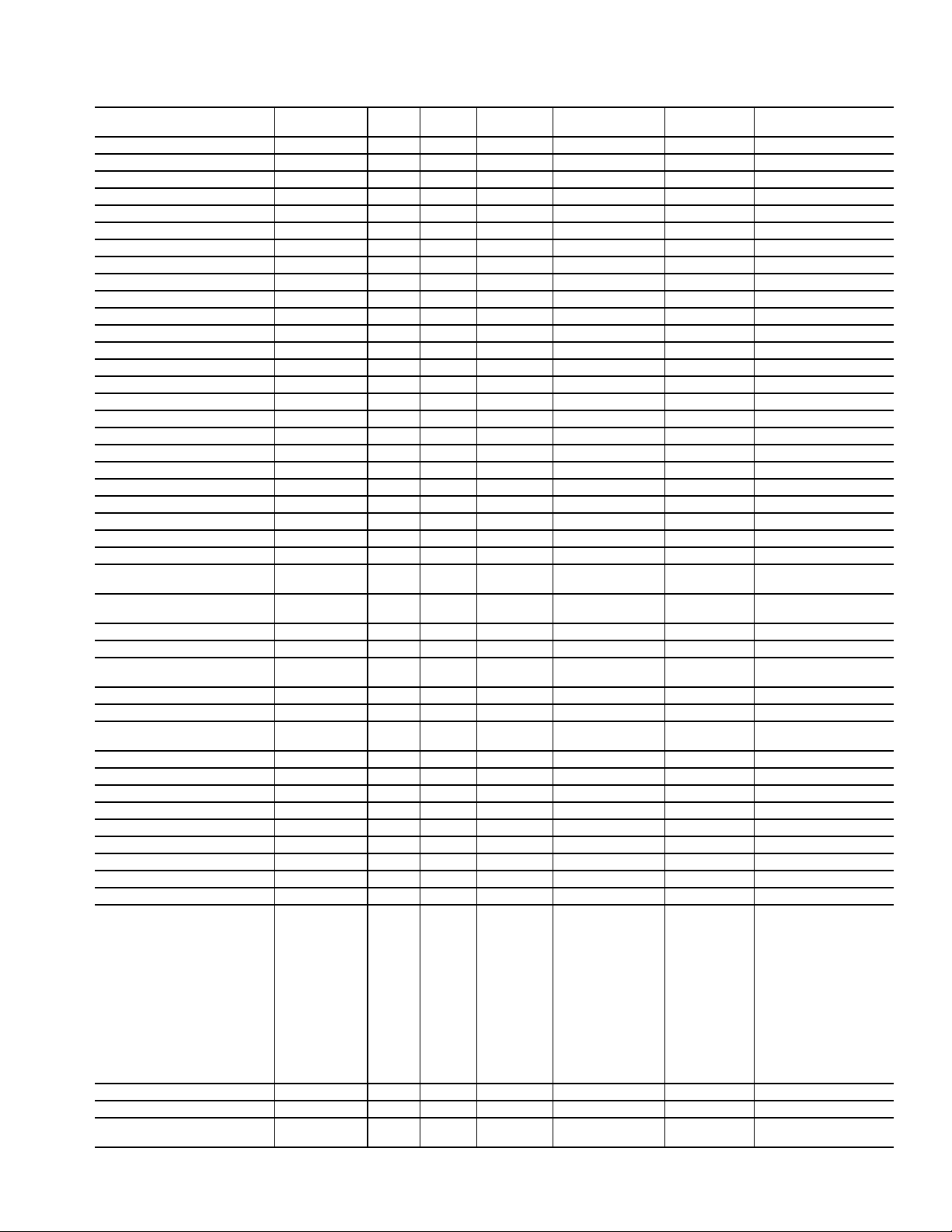

Table 4 — ICVC Alert Codes

PRE-START ALERTS: These alerts only delay start-up. When alert is corrected, the start-up will continue. No reset is

necessary.

ICVC FAULT

STATE

100 PRESTART

101 PRESTART

102 PRESTART

103 PRESTART

104 PRESTART

105 PRESTART

106 PRESTART

107 PRESTART

108 PRESTART

109 PRESTART

110 PRESTART

111 PRESTART

*[LIMIT] is shown on the ICVC as temperature, pressure, voltage, etc., predefined or selected by the operator as an override or an alert. [VALUE] is

the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

ALERT

SECONDARY

MESSAGE

STARTS LIMIT

EXCEEDED

HIGH BEARING

TEMPERATURE

HIGH MOTOR

TEMPERATURE

HIGH

DISCHARGE

TEMP

LOW

REFRIGERANT

TEMP

LOW OIL

TEMPERATURE

HIGH

CONDENSER

PRESSURE

LOW LINE

VOLTAGE

HIGH LINE

VOLTAGE

GUIDE VANE

CALIBRATION

HIGH

RECTIFIER

TEMP

HIGH

INVERTER

TEMP

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

100Excessive compressor starts

(8 in 12 hours).

101Comp Thrust Brg Temp [VALUE]

exceeded limit of [LIMIT]*.

102Comp Motor Winding Temp

[VALUE] exceeded limit of [LIMIT]*.

103Comp Discharge Temp [VALUE]

exceeded limit of [LIMIT]*.

104Evaporator Refrig Temp [VALUE]

exceeded limit of [LIMIT]*.

105Oil Sump Temp [VALUE]

exceeded limit of [LIMIT]*.

106Condenser Pressure [VALUE]

exceeded limit of [LIMIT]*.

107Percent Line Voltage [VALUE]

exceeded limit of [LIMIT]*.

108Percent Line Voltage [VALUE]

exceeded limit of [LIMIT]*.

109Actual Guide Vane Pos

Calibration Required Before Startup.

110Rectifier Temperature [VALUE]

exceeded limit of [LIMIT]*.

111Inverter Temperature [VALUE]

exceeded limit of [LIMIT]*.

Depress the RESET softkey if additional start

is required. Reassess start-up requirements.

Check oil heater for proper operation.

Check for low oil level, partially closed oil supply valves, clogged oil filters.

Check the sensor wiring and accuracy.

Check Comp Thrust Brg Alert setting in

SETUP1 screen.

Check motor sensors for wiring and accuracy.

Check motor cooling line for proper operation,

or restrictions.

Check for excessive starts within a short time

span.

Check Comp Motor Temperature Override

setting in SETUP1 screen.

Allow discharge sensor to cool.

Check sensor wiring and accuracy.

Check for excessive starts.

Check Comp Discharge Alert setting in

SETUP1 screen.

Check transducer wiring and accuracy.

Check for low chilled fluid supply

temperatures.

Check refrigerant charge.

Check Refrig Override Delta T in SETUP1

screen.

Check oil heater contactor/relay and power.

Check oil level and oil pump operation.

Check transducer wiring and accuracy.

Check for high condenser water

temperatures.

Check high condenser pressure switch wiring.

Check voltage supply.

Check voltage transformers and switch gear.

Consult power utility if voltage is low.

Check voltage supply.

Check power transformers.

Consult power utility if voltage is high.

Press STOP button on ICVC and perform

Guide Vane Calibration in Controls Test

screen.

Check guide vane actuator feedback

potentiometer.

Check that VFD refrigerant isolation valves

are open.

Check VFD refrigerant cooling solenoid and

refrigerant strainer.

Check for proper VFD cooling fan operation

and blockage.

Check that VFD refrigerant isolation valves

are open.

Check VFD refrigerant cooling solenoid and

refrigerant strainer.

Check for proper VFD cooling fan operation

and blockage.

11

Page 12

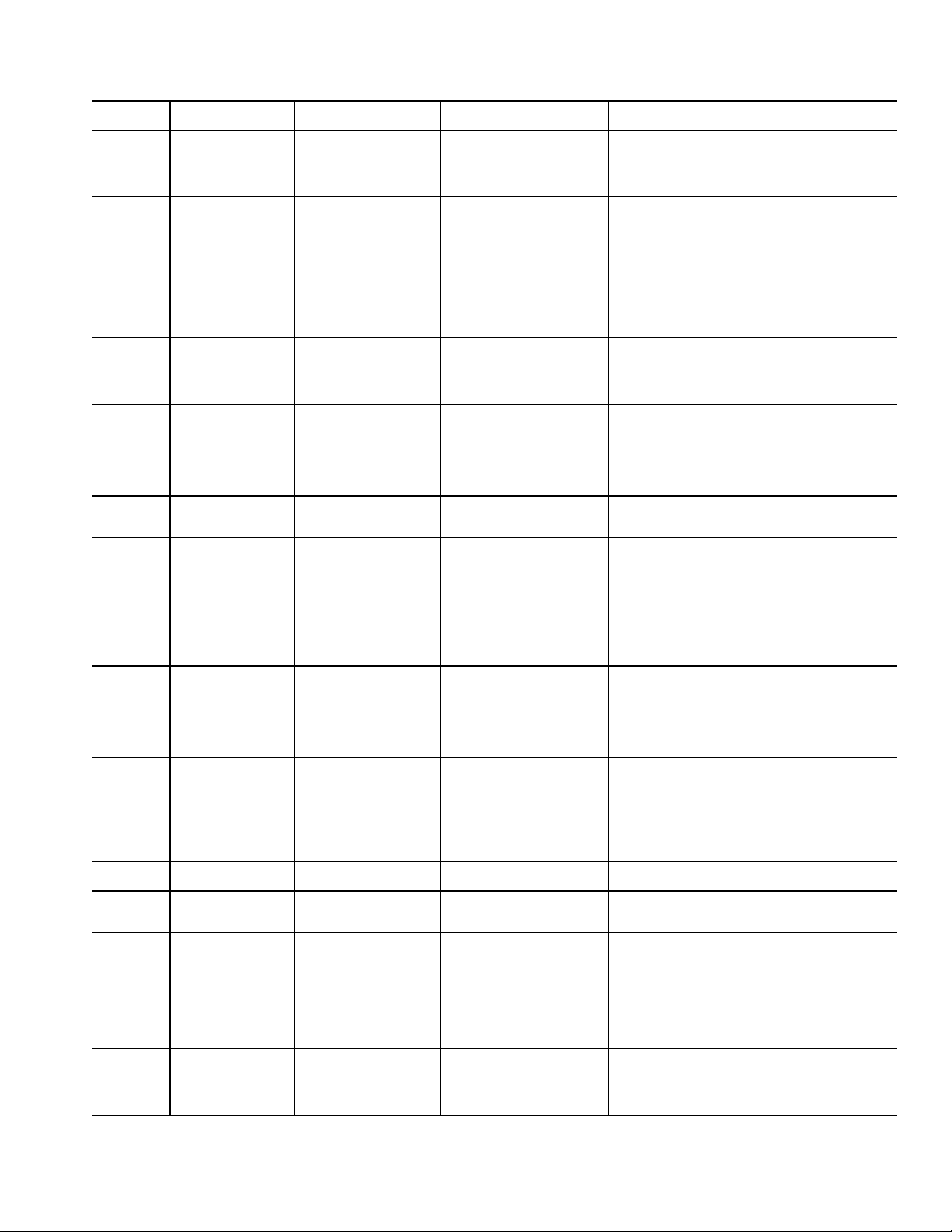

NORMAL RUN WITH OVERRIDES

Table 4 — ICVC Alert Codes (cont)

ICVC FAULT

STATE

120 RUN CAPACITY

121 RUN CAPACITY

122 RUN CAPACITY

123 RUN CAPACITY

124 RUN CAPACITY

125 RUN CAPACITY

126 RUN CAPACITY

127 RUN CAPACITY

128 RUN CAPACITY

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

LIMITED

LIMITED

LIMITED

LIMITED

LIMITED

LIMITED

LIMITED

LIMITED

LIMITED

SECONDARY

MESSAGE

HIGH CONDENSER

PRESSURE

HIGH MOTOR

TEMPERATURE

LOW EVAP REFRIG

TEMP

HIGH COMPRESSOR

LIFT

MANUAL GUIDE VANE

TA R GE T

LOW DISCHARGE

SUPERHEAT

HIGH RECTIFIER TEMP 126Rectifier Temperature

MANUAL SPEED

CONTROL

HIGH INVERTER TEMP 128Inverter Temperature

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

120Condenser Pressure

[VALUE] exceeded limit of

[LIMIT]*.

121Comp Motor Winding

Temp [VALUE] exceeded

limit of [LIMIT]*.

122Evaporator Refrig

Temp [VALUE] exceeded

limit of [LIMIT]*.

123Surge Prevention

Override: Lift Too High For

Compressor

124Run Capacity Limited:

Manual Guide Vane Target.

No Alert message. Check for oil loss or excess refrigerant charge.

[VALUE] exceeded limit of

[LIMIT]*.

No Alert message. Chiller is not in automatic temperature control.

[VALUE] exceeded limit of

[LIMIT]*.

Check condenser water pump operation.

Check for high condenser water temperatures or

low flow rate. Verify that isolation valves are

open.

Check Cond Press Override setting in SETUP1.

Check for closed valves or restriction in motor

cooling lines.

Check for closed refrigerant isolation valves.

Check Comp Motor Temp Override setting in

SETUP1.

Check refrigerant charge.

Check that optional cooler liquid line isolation

valve is fully open.

Check for excessive condenser flow or low

chilled water flow.

Check for low entering cooler temperature.

Check that condenser inlet and outlet water

nozzles are piped correctly.

Check for waterbox division plate gasket bypass.

Check for high condenser water temperature or

low suction temperature.

Check for high Evaporator or Condenser

approaches.

Check surge prevention parameters in

OPTIONS screen.

Target Guide Vane Position has been forced in

the COMPRESS screen. Select and RELEASE

force to return to normal (automatic) operation.

Verify that the valves in the oil reclaim lines are

open.

Check Rectifier Temp Override in SETUP1

screen.

Check that VFD refrigerant isolation valves are

open.

Check VFD refrigerant cooling solenoid.

Check for proper VFD cooling fan operation and

blockage.

Check Inverter Temp Override in SETUP1

screen.

Check that VFD refrigerant isolation valves are

open.

Check VFD refrigerant cooling solenoid.

Check for proper VFD cooling fan operation and

blockage.

12

Page 13

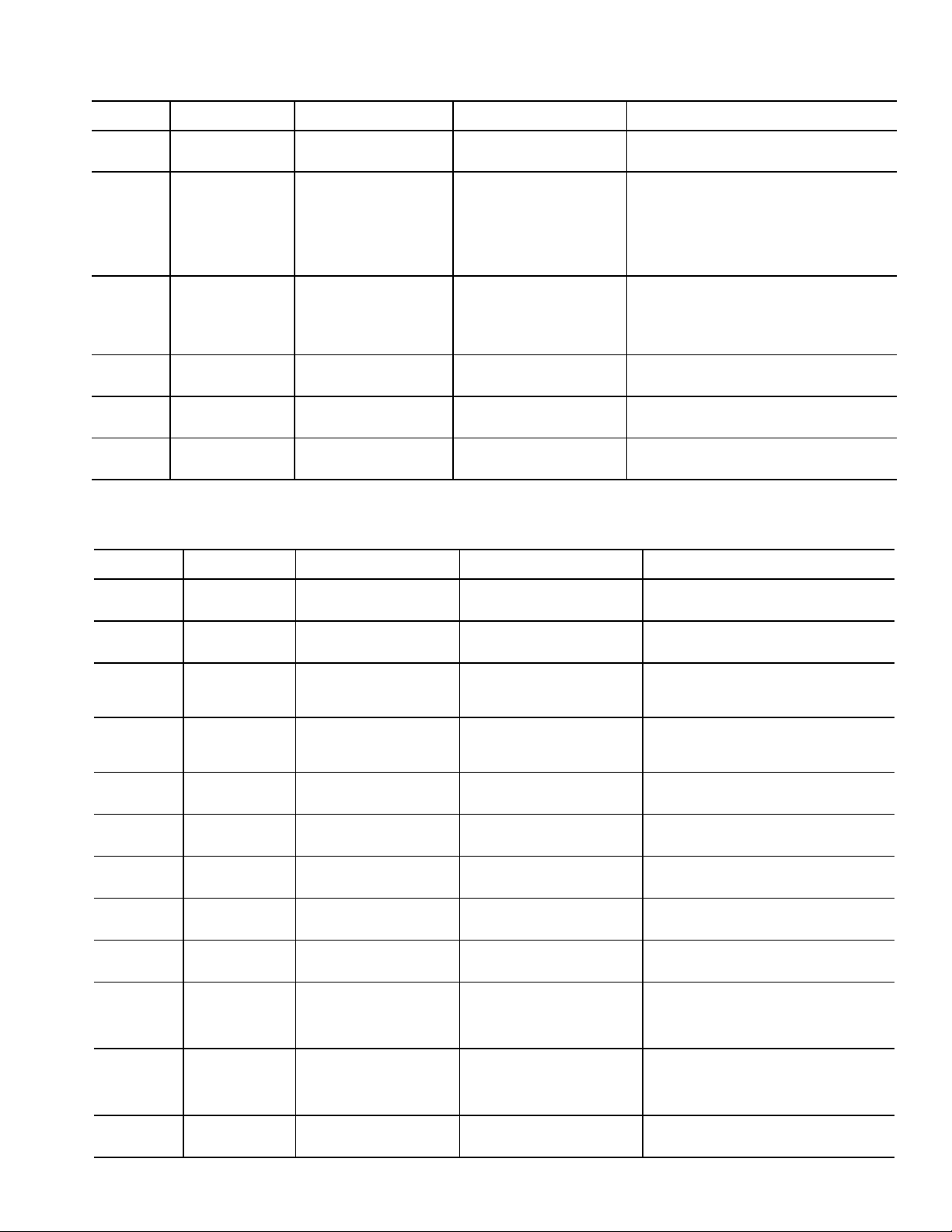

CHILLER ALERTS

Table 4 — ICVC Alert Codes (cont)

ICVC FAULT

STATE

140 SENSOR ALERT LEAVING COND WATER

141 SENSOR ALERT ENTERING COND WATER

142 LOW OIL

143 AUTORESTART

144 AUTORESTART

145 AUTORESTART

146 AUTORESTART

147 AUTORESTART

148 AUTORESTART

149 SENSOR ALERT HIGH DISCHARGE TEMP 149

150 SENSOR ALERT HIGH BEARING

151 CONDENSER

152 RECYCLE ALERT EXCESSIVE RECYCLE

153 no message:

154 POTENTIAL

155 OPTION SENSOR

156 OPTION SENSOR

157 OPTION SENSOR

158 SENSOR ALERT SPARE TEMPERATURE#1158Spare Temperature 1

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

PRESSURE ALERT

PENDING

PENDING

PENDING

PENDING

PENDING

PENDING

PRESSURE ALERT

ALERT

only

FREEZE-UP

FAULT

FAULT

FAULT

SECONDARY

MESSAGE

TEMP

TEMP

CHECK OIL FILTER 142Low Oil Pressure Alert.

LINE CURRENT

IMBALANCE

LINE VOLTAG E

DROP OUT

HIGH LINE VOLTAGE 145High Percent Line

LOW LINE VOLTAGE 146Low Percent Line

VFD MODULE RESET 147->VFD Module Power-On

POWER LOSS 148Control Power-Loss

TEMPERATURE

PUMP RELAY

ENERGIZED

STARTS

no message; ALERT only 153Lead/Lag Disabled-

COND PRESS/TEMP

TOO LOW

REMOTE RESET

SENSOR

AUTO CHILLED WATER

RESET

AUTO DEMAND LIMIT

INPUT

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

140Sensor Fault: Check

Leaving Cond Water Sensor.

141Sensor Fault: Check

Entering Cond Water Sensor.

Check Oil Filter.

143Line Current Imbalance: Check VFD Fault History for Values.

144Single Cycle Line

Voltage Dropout.

Voltage [VALUE].

Voltage [VALUE].

Reset When Running.

When Running.

Comp Discharge Temp

[VALUE] Exceeded Limit of

[LIMIT]*.

150Comp Thrust Brg Temp

[VALUE] exceeded limit of

[LIMIT]*.

151High Condenser Pressure [VALUE]: Pump Energized to Reduce Pressure.

152Excessive recycle

starts.

Config: Duplicate Chiller

Address.

154Condenser freeze up

prevention.

155Sensor Fault/Option

Disabled: Remote Reset

Sensor.

156Sensor Fault/Option

Disabled: Auto Chilled Water

Reset.

157Sensor Fault/Option

Disabled: Auto Demand Limit

Input.

[VALUE] exceeded limit of

[LIMIT]*.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for partially or closed shut-off valves.

Check oil filter.

Check oil pump and power supply.

Check oil level.

Check for foaming oil at start-up.

Check transducer wiring and accuracy.

Power loss has been detected in any phase.

Chiller automatically restarting.

A drop in line voltage has been detected within

2 voltage cycles.

Chiller automatically restarting if Auto Restart is

enabled in OPTIONS screen.

Check phase to phase and phase to ground line

power.

Check phase to phase and phase to ground line

power.

VFD Module has detected a hardware fault due

to electrical noise, power loss or software and

has reset. Chiller automatically restarting.

Check for power loss and sources of electromagnetic interference.

Check 24 vac control power supply to ICVC.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for proper inlet guide vane and optional

diffuser actuator operation.

Check for proper condenser flow and

temperature.

Check for high lift or low load.

Check for fouled tubes or noncondensables in

the chiller.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for partially closed service valves.

Check oil cooler TXV.

Check oil level and oil temperature.

Check sensor wiring and accuracy.

Check condenser flow and water temperature.

Check for fouled tubes.

This alarm is not caused by the High Pressure

Switch.

Chiller load is too low to keep compressor on

line and there has been more than 5 starts in

4 hours.

Increase chiller load, adjust hot gas bypass,

increase RECYCLE RESTART DELTA T from

SETUP1 Screen.

Illegal chiller address configuration in Lead/Lag

screen. Both chillers require a different address.

The condenser pressure transducer is reading a

pressure that could freeze the condenser tubes.

Check for condenser refrigerant leaks.

Check fluid temperature.

Check sensor wiring and accuracy.

Place the chiller in PUMPDOWN mode if the

vessel is evacuated.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J4.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J5.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J5.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J4.

Check Spare Temp #1 Limit in SETUP1 screen.

13

Page 14

CHILLER ALERTS (cont)

Table 4 — ICVC Alert Codes (cont)

ICVC FAULT

STATE

159 SENSOR ALERT SPARE TEMPERATURE#2159Spare Temperature 2

161 LOSS OF

162 SENSOR ALERT EVAPORATOR

163 SENSOR ALERT CONDENSER APPROACH 163Condenser Approach

164 VFD SPEED ALERT LOW VFD SPEED 164Actual VFD Speed

165 AUTORESTART

166 AUTORESTART

167 SYSTEM ALERT HIGH DISCHARGE TEMP 167Comp Discharge Temp

168 SENSOR ALERT HUMIDITY SENSOR

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

COMMUNICATION

PENDING

PENDING

SECONDARY

MESSAGE

WITH WSM 161WSM Cool Source —

APPROACH

LOW DC BUS VOLTAGE 165Low DC Bus Voltage:

HIGH DC BUS VOLTAGE 166High DC Bus Voltage:

INPUT

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

[VALUE] exceeded limit of

[LIMIT]*.

Loss of Communication.

162Evaporator Approach

[VALUE] Exceeded Limit of

[LIMIT]*.

[VALUE] Exceeded Limit of

[LIMIT]*.

exceeded limit of Target VFD

Speed –10%.

[VALUE] Exceeded Limit of

[LIMIT]*.

[VALUE] Exceeded Limit of

[LIMIT]*.

[VALUE] exceeded limit of

[LIMIT]*.

168Sensor Fault: Check

Humidity Sensor Input Sensor.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J4.

Check Spare Temp #2 Limit in SETUP1 screen.

Check settings in WSMDEFME screen.

Check CCN communications link with WSM

(Water System Manager) Module.

Check Supervisory Part of WSM.

Check that refrigerant charge level is adequate,

waterbox division plate gaskets are sealing,

evaporator tubes are not fouled and that oil

reclaim system is working.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check Evap Approach Alert setting in SETUP1

screen.

Check sensors resistance or voltage drop.

Check for proper wiring.

Check Cond Approach Alert setting in SETUP1

screen.

Check for noncondensable gas in the

condenser.

Check that the condenser tubes are not fouled.

Actual VFD Speed on COMPRESS screen must

be at least 90% of Target VFD Speed.

Verify phase to phase and phase to ground line

voltage.

Verify phase to phase and phase to ground line

voltage. Monitor AC line for high transient voltage conditions.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for excessive starts.

Check Comp Discharge Alert setting in SETUP1

screen.

Check humidity sensor wiring on CCM connectors J3 and J5. CCM switch SW2-1 must be in

“OFF” position.

Check Humidity Sensor Input in Controls Test.

14

Page 15

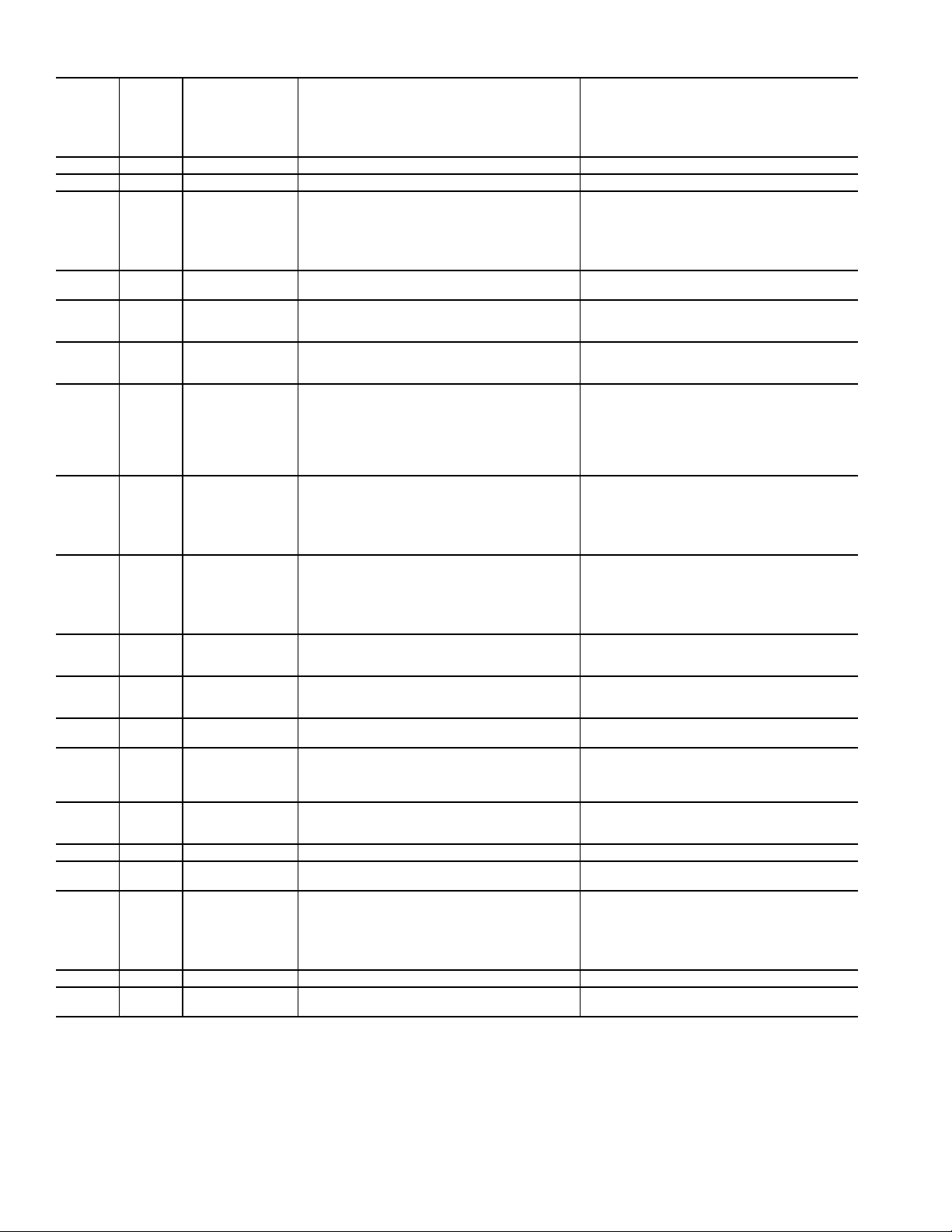

CHILLER PROTECTIVE LIMIT FAULTS

Table 5 — ICVC Alarm Codes

ICVC FAULT

STATE

200 PROTECTIVE LIMIT RECTIFIER POWER

201 PROTECTIVE LIMIT INVERTER POWER FAULT 201Inverter Power Fault:

202 PROTECTIVE LIMIT MOTOR AMPS NOT

203 FAILURE TO START MOTOR ACCELERATION

204 FAILURE TO STOP VFD SHUTDOWN FAULT 204VFD Shutdown Fault:

205 PROTECTIVE LIMIT HIGH DC BUS VOLTAGE 205High DC Bus Voltage:

206 PROTECTIVE LIMIT VFD FAULT 206VFD Fault Code:

207 PROTECTIVE LIMIT HIGH CONDENSER

208 PROTECTIVE LIMIT EXCESSIVE MOTOR

209 PROTECTIVE LIMIT LINE CURRENT

210 PROTECTIVE LIMIT LINE VOLTAGE DROPOUT 210Single Cycle Line Volt-

211 PROTECTIVE LIMIT HIGH LINE VOLTAGE 211High Percent Line Volt-

212 PROTECTIVE LIMIT LOW LINE VOLTAGE 212Low Percent Line Volt-

213 PROTECTIVE LIMIT VFD MODULE RESET 213VFD Module Power-On

214 PROTECTIVE LIMIT POWER LOSS 214Control Power Loss

215 PROTECTIVE LIMIT LOW DC BUS VOLTAGE 215Low DC Bus Voltage:

216 PROTECTIVE LIMIT LINE VOLTAGE

217 PROTECTIVE LIMIT MOTOR OVERLOAD TRIP 217Motor Overload Trip;

218 PROTECTIVE LIMIT VFD RECTIFIER

219 PROTECTIVE LIMIT VFD INVERTER

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

NOTE: ICVC Alarms 212-226 are declared as a result of VFD Faults.

PRIMARY

MESSAGE

SECONDARY

MESSAGE

FAULT

SENSED

FAULT

PRESSURE

AMPS

IMBALANCE

IMBALANCE

OVERTEMP

OVERTEMP

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

200Rectifier Power Fault:

Check VFD Status.

Check VFD Status.

202Motor Amps Not

Sensed — Average Load

Current [VALUE].

203Motor Acceleration Fault

— Average Load Current

[VALUE].

Check Inverter Power Unit.

[VALUE] exceeded limit of

[LIMIT]*.

[VALUE]; Check VFD Fault

Code List.

207High Cond Pressure

trip. [VALUE] exceeded Switch

Trippoint.

208Percent Load Current

[VALUE] exceeded limit of

[LIMIT]*.

209Line Current Imbalance: Check VFD Fault History for Values.

age Dropout.

age [VALUE].

age [VALUE].

Reset When Running.

When Running.

[VALUE] exceeded limit of

[LIMIT]*.

216Line Voltage Imbalance. Check VFD Fault History for Values.

Check VFD configurations.

218VFD Rectifier Temp

Exceeded: Check Cooling and

VFD Config.

219VFD Inverter Temp

Exceeded: Check Cooling and

VFD Config.

Malfunction within VFD Power Module.

Call Carrier Service.

Malfunction within VFD Power Module.

Call Carrier Service.

Check main circuit breaker for trip. Increase

Current % Imbalance in VFD_CONF screen.

Check that inlet guide vanes are fully closed at

start-up.

Check Motor Rated Load Amps in VFD_CONF

screen. Reduce unit pressure if possible.

VFD Circuit Board malfunction.

Call Carrier Service.

Verify phase to phase and phase to ground line

voltage. Monitor AC line for high transient voltage conditions. VFD Circuit Board malfunction.

Call Carrier Service.

See VFD Fault Code description and corrective

action.

Check Compressor Discharge High Pressure

switch wiring and accuracy.

Check for high condenser water temperatures,

low water flow, fouled tubes.

Check for division plate/gasket bypass.

Check for noncondensables in refrigerant.

Check Motor Rated Load Amps in VFD_CONF

screen. Percent Load Current > 110

Check Motor Rated Load Amps setting.

Check phase to phase and phase to ground

power distribution bus voltage.

Check Line Current % Imbalance in VFD_CONF

screen. Consult power company.

Temporary loss of voltage. Disable Single Cycle

Dropout in VFD_CONF screen.

Check phase to phase and phase to ground distribution bus voltage. Consult power company.

Check phase to phase and phase to ground distribution bus voltage. Consult power company.

Temporary loss of VFD control voltage. Check

VFD control power breaker, transformer and

fuses.

Check phase to phase and phase to ground distribution bus voltage.

Check VFD fuses.

Check 24 vac power supply to ICVC.

Consult power company.

Verify phase-to-phase and phase-to-ground line

voltage. VFD Circuit Board malfunction.

Call Carrier Service.

Check phase-to-phase and phase-to-ground

distribution bus voltage. Increase Line Voltage

% Imbalance in VFD_CONF screen.

Any phase current > 106% Rated Load Amps.

Can result from significant load side current

imbalance when running at full load.

Check entering condenser water temperature

and water flow rate.

Check Motor Rated Load Amps in VFD_CONF

screen.

Check that VFD refrigerant isolation valves are

open.

Check VFD refrigerant cooling solenoid and

refrigerant strainer.

Check for proper VFD cooling fan operation and

blockage.

Check that VFD refrigerant isolation valves are

open.

Check VFD refrigerant cooling solenoid and

refrigerant strainer.

Check for proper VFD cooling fan operation and

blockage.

%.

15

Page 16

Table 5 — ICVC Alarm Codes (cont)

CHILLER PROTECTIVE LIMIT FAULTS (cont)

ICVC FAULT

STATE

220 PROTECTIVE LIMIT GROUND FAULT 220Ground Fault Trip;

221 PROTECTIVE LIMIT UNUSED 221UNUSED

222 PROTECTIVE LIMIT LINE FREQUENCY TRIP 222Line Frequency —

223 LOSS OF

224 PROTECTIVE LIMIT VFD COMMUNICATIONS

225 PROTECTIVE LIMIT MOTOR CURRENT

226 PROTECTIVE LIMIT LINE PHASE REVERSAL 226Line Phase Reversal:

227 PROTECTIVE LIMIT OIL PRESS SENSOR

228 PROTECTIVE LIMIT LOW OIL PRESSURE 228Low Operating Oil

229 PROTECTIVE LIMIT LOW CHILLED WATER

230 PROTECTIVE LIMIT LOW CONDENSER

231 PROTECTIVE LIMIT HIGH DISCHARGE TEMP 231Comp Discharge Temp

232 PROTECTIVE LIMIT LOW REFRIGERANT

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

COMMUNICATION

SECONDARY

MESSAGE

WITH VFD GATEWAY

MODULE

FAULT

IMBALANCE

FAULT

FLOW

WATER FLOW

TEMP

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

Check Motor and Current

Sensors.

[VALUE] exceeded limit of

[LIMIT]; Check Power Supply.

223Loss of SIO Comm with

VFD Gateway: Check VFG

Module and Power.

224Loss of DPI Comm with

VFD Gateway: Check VFG to

VFD Comm.

225Motor Current Imbalance: Check VFD Fault

History for Values.

Check Line Phases.

227Oil Pressure Delta P

[VALUE] (Pump Off): Check

Pump/Transducers.

Pressure [VALUE]: Check Oil

Pump and Filter.

229Low Chilled Water Flow;

Check Switch/Delta P Config

& Calibration.

230Low Condenser Water

Flow; Check Switch/Delta P

Config & Calibration.

[VALUE] Exceeded Limit of

[LIMIT]*.

232Evaporator Refrig Temp

[VALUE] exceeded limit of

[LIMIT]*.

Check for condensation on motor terminals.

Check motor power leads for phase to phase or

phase to ground shorts. Disconnect motor from

VFD and megger motor.

Call Carrier Service.

If operating from a generator, check generator

size and speed.

Check utility power supply.

Check VFD communication wiring and

connectors on VFD Gateway and DPI board.

Check for compatibility between ICVC and

Gateway software.

Check VFD communication wiring and

connectors.

Check status lights on DPI Communications

Interface Board.

Call Carrier Service.

Check Motor Current % Imbalance in

VFD_CONF screen.

Reverse connections of any two line conductors

to circuit breaker.

Check transducer wiring and accuracy.

Check power supply to pump.

Check pump operation.

Check transducer calibration.

Check transducer wiring and accuracy.

Check power supply to pump.

Check pump operation.

Check oil level.

Check for partially closed service valves.

Check oil filters.

Check for foaming oil at start-up.

Check transducer calibration.

Perform pump control test.

Check optional transducer calibration and

wiring.

Check Evaporator Refrigerant Temperature

sensor.

Check chilled water valves.

Check for evaporator saturation temperature

< 34 F if not in Pumpdown Lockout mode. Place

unit in Pumpdown mode before removing

charge.

Perform pump control test.

Check optional transducer calibration and

wiring.

Check condenser water valves.

Check for COND PRESS OVERRIDE + 5 psig.

Check for closed compressor discharge isolation valve.

Check if chiller was operating in surge.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for proper condenser flow and

temperature.

Check compressor discharge isolation valve.

Check for proper inlet guide vane and optional

diffuser actuator operation.

Check for proper refrigerant charge.

Check float valve operation.

Check for closed condenser liquid line isolation

valve. If problem occurs at high load, check for

low condenser pressure which causes inadequate flasc orifice differential pressure.

Check for proper water flow and temperature.

Confirm that condenser water enters bottom row

of condenser tubes first.

Check Evaporator Refrigerant Temperature

sensor.

Check for division plate gasket bypass.

Check for fouled tubes.

16

Page 17

Table 5 — ICVC Alarm Codes (cont)

CHILLER PROTECTIVE LIMIT FAULTS (cont)

ICVC FAULT

STATE

233 PROTECTIVE LIMIT HIGH MOTOR

234 PROTECTIVE LIMIT HIGH BEARING

235 PROTECTIVE LIMIT HIGH CONDENSER

236 PROTECTIVE LIMIT COMPRESS SURGE/

237 PROTECTIVE LIMIT SPARE SAFETY

238 PROTECTIVE LIMIT EXCESSIVE COMPR

239 PROTECTIVE LIMIT TRANSDUCER

240 PROTECTIVE LIMIT LOW DISCHARGE

241 PROTECTIVE LIMIT RECTIFIER

242 LOSS OF

243 POTENTIAL

244 POTENTIAL

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

COMMUNICATION

FREEZE-UP

FREEZE-UP

SECONDARY

MESSAGE

TEMPERATURE

TEMPERATURE

PRESSURE

LOW SPEED

DEVICE

SURGE

VOLTAGE FAULT

SUPERHEAT

OVERCURRENT

WITH CCM MODULE 242Loss of Communica-

EVAP PRESS/TEMP

TOO LOW

COND PRESS/TEMP

TOO LOW

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

233Comp Motor Winding

Temp [VALUE] exceeded

limit of [LIMIT]*.

234Comp Thrust Brg Temp

[VALUE] exceeded limit of

[LIMIT]*.

235Condenser Pressure

[VALUE] exceeded limit of

[LIMIT]*.

236Compressor Surge:

Check condenser water temp

and flow.

237Spare Safety Device. Spare safety input has tripped or factory installed

238Compressor Surge:

Check condenser water temp

and flow.

239Transducer Voltage Ref

[VALUE] exceeded limit of

[LIMIT]*.

240Check for Oil in Or

Overcharge of Refrigerant.

241Rectifier Overcurrent

Fault: Check VFD Status.

tion With CCM, Check

Comm. Connectors.

243Evaporator Refrig

Temp [VALUE] exceeded

limit of [LIMIT]*.

244Condenser Refrig

Temp [VALUE] exceeded

limit of [LIMIT]*.

Check motor sensors wiring and accuracy.

Check motor cooling line and spray nozzle for

proper operation, or restrictions.

Check for excessive starts within a short time

span.

Check oil heater for proper operation.

Check for low oil level, par tially closed oil supply

valves, or clogged oil filter.

Check oil cooler refrigerant thermal expansion

valves.

Confirm that TXV (thermostatic expansion valve)

bulb is secured in place and insulated.

Check for sensor wiring and accuracy.

This fault can result from extended operation at low

load with low water flow to the evaporator or

condenser.

Check for high condenser water temperatures, low

water flow, fouled tubes.

Check for division plate/gasket bypass.

Check for noncondensables.

Check transducer wiring and accuracy.

Check for high condenser water temperatures, low

water flow, fouled tubes.

Check for division plate/gasket bypass.

Check for noncondensables.

Check surge prevention parameters in OPTIONS

screen. Increase VFD Increase Step in SETUP2.

Check VFD Minimum Speed in SETUP2 screen.

jumper is not present on Terminal Block 4 terminals

17 and 20 in the VFD enclosure.

Check for high condenser water temperatures, low

water flow, fouled tubes.

Check for division plate/gasket bypass.

Check for noncondensables.

Check surge prevention parameters in OPTIONS

screen.

Check cooling tower control settings and performance to design/selection temperatures across the

entire operating range of the chiller.

Check cooler approach and water flow.

Check that CCM transducer voltage reference is

between 4.5 v and 5.5 v.

Check that pressure transducers are not shorted to

ground. This fault is normally declared the first time

an ICVC is powered up if it was downloaded with

software when it was not connected to a CCM.

Call Carrier Service.

Check for oil loss or excessive refrigerant. If oil level

is low, refrigerant charge may be too low resulting in

ineffective oil reclaim. Excessive refrigerant charge

may cause liquid carryover into compressor.

Check calibration of evaporator pressure and condenser pressure sensors.

Check calibration of compressor discharge temperature sensor.

Check for high water temperatures or changes in

water flow rates.

Check wiring and control power to CCM.

Confirm that all CCM SW1 switches are in the

“OFF” position.

Check for proper refrigerant charge.

Check float valve operation.

Check for proper fluid flow and temperature.

Confirm that condenser water enters bottom row

of condenser tubes first.

Check Evaporator Refrigerant Temperature

sensor.

Check for division plate gasket bypass.

Check for fouled tubes.

Condenser water too cold or chiller shut down with

brine below 32 F in cooler so equalization temperature in chiller approached 32 F.

Check condenser pressure transducer.

Check refrigerant charge.

17

Page 18

Table 5 — ICVC Alarm Codes (cont)

CHILLER PROTECTIVE LIMIT FAULTS (cont)

ICVC FAULT

STATE

245 PROTECTIVE LIMIT HIGH VFD SPEED 245Actual VFD Speed

246 PROTECTIVE LIMIT INVALID DIFFUSER

247 PROTECTIVE LIMIT DIFFUSER POSITION

248 PROTECTIVE LIMIT SPARE TEMPERATURE #1248Spare Temperature #1

249 PROTECTIVE LIMIT SPARE TEMPERATURE #2249Spare Temperature #2

250 UNUSED UNUSED 250Unused State.

251 PROTECTIVE LIMIT VFD CONFIG CONFLICT 251VFD Config Conflict

252 PROTECTIVE LIMIT VFD CONFIG CONFLICT 252VFD Config Conflict

253 PROTECTIVE LIMIT GUIDE VANE

254 PROTECTIVE LIMIT VFD CHECKSUM ERROR 254Checksum Error:

255 PROTECTIVE LIMIT VFD DEW PREVENTION 255Dew Prevention - Cool-

256 PROTECTIVE LIMIT INDUCTOR OVERTEMP 256Inductor Overtemp Trip -

257 PROTECTIVE LIMIT VFD START INHIBIT 257VFD Start Inhibit: Check

258 UNUSED STATE UNUSED 258Unused.

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

PRIMARY

MESSAGE

SECONDARY

MESSAGE

CONFIG.

FAULT

CALIBRATION

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

exceeded limit of Target VFD

Speed + 10%.

246Diffuser Control Invalid

Configuration: Check SETUP2

Entries.

247Diffuser Position Fault:

Check Guide Vane/Diffuser

Actuator.

[VALUE] exceeded limit of

[LIMIT]*.

[VALUE] exceeded limit of

[LIMIT]*.

(VFD Uploaded): Verify to

Reset Alarm.

(VFD Downloaded): Verify to

Reset Alarm.

253Guide Vane Fault

[VALUE]. Check Calibration.

Press Reset to Restore

Configuration

ant Too Cold. Check Solenoid

& Cond T.

Check Temp Switch and Cooling Fans.

VFD Diagnostic Parameters

212/214.

Actual VFD Speed on COMPRESS screen must

not exceed Target VFD Speed by more than

10%.

Check 25%, 50%, and 75% Guide Vane and Diffuser Load Point entries in SETUP2 screen.

Confirm that Diffuser Option in SETUP 2 screen

has not been Enabled if compressor does not

have a split ring diffuser. May indicate rotating

stall condition.

Check rotating stall transducer wiring accuracy

and sealing.

Check diffuser schedule and guide vane schedule in SETUP2 screen.

Check for proper operation of diffuser and inlet

guide vane actuators including inlet guide vane

calibration.

Check diffuser actuator coupling for rotational

slip.

Check RC snubber on CCM J4-23 and J4-24.

Check 4.3k ohm resistor between CCM terminals J3-7 and J3-8.

Check for electrical noise in CCM Diffuser Pressure wiring. Do not continue to operate compressor except for diagnostic purposes.

Check Spare Temperature Enable and Spare

Temperature Limit in SETUP1 Screen.

Check Spare Temperature Enable and Spare

Temperature Limit in SETUP1 Screen.

The VFD_CONF table in the Gateway does not

match that which is in the ICVC. This is a normal

fault if an ICVC has been uploaded with software when it was not attached to the CCM.

Enter VFD_CONF screen and then exit

VFD_CONF screen by pressing EXIT then

CANCEL. Re-enter the VFD_CONF screen,

press EXIT then SAVE. Parameters stored in

the Gateway will be uploaded into the ICVC.

Confirm valid settings in VFD_CONF screen.

The VFD_CONF table in the Gateway does not

match that which is in the ICVC.

Enter CONTROL TEST and execute Guide

Vane Calibration.

Check CCM guide vane feedback terminals J4-9

and J4-10.

Check guide vane feedback potentiometer.

Alarm before start indicates guide vane opening

is not less than 4%. Alarm running indicates

guide vane position is < -1% or > 103%, or feed-

back voltage is < .045 or > 3.15 VDC.

Actual VFD checksum does not match calculated value.

VFD COLDPLATE TEMP is too close to dew

point based on VFD ENCLOSURE TEMP and

RELATIVE HUMIDITY in POWER screen.

Check for moisture in VFD enclosure.

Check Humidity Sensor in CONTROLS TEST.

Check for contamination on CCM J3-7 and J3-9

Humidity Sensor.

Check that VFD refrigerant cooling modulating

valve is closing.

Check for cooling fan air flow obstructions.

The VFD Start Inhibit is derived from the Alarm

bit being set in the VFD. The conditions causing

the alarm must be corrected in the VFD to

enable subsequent starts and operation. See

VFD parameters 212/214.

18

Page 19

Table 5 — ICVC Alarm Codes (cont)

CHILLER PROTECTIVE LIMIT FAULTS (cont)

ICVC FAULT

STATE

259 PROTECTIVE LIMIT CCN OVERRIDE STOP 259CCN Emergency/

282 PROTECTIVE LIMIT INVALID VFD CONFIG 282Line Frequency

283 PROTECTIVE LIMIT INVALID VFD CONFIG 283Compressor 100%

284VFD GATEWAY COMPATIBILITY

285VFD GATEWAY COMPATIBILITY

286 PROTECTIVE LIMIT INVERTER

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

OUT-OF-RANGE SENSOR

PRIMARY

MESSAGE

SECONDARY

MESSAGE

CONFLICT

CONFLICT

OVERCURRENT

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

Override Stop.

[VALUE] Exceeded Configuration Range.

Speed Config Ranges: 50=Hz

45-52; 60 Hz=55-62.

284VFD Gateway Compatibility Conflict: Check VFG/

VFD Versions.

285VFD Gateway Compatibility Conflict: Check VFG/

ICVC Versions.

286Inverter Overcurrent

Fault: Check VFD Status.

CCN has signaled the chiller to stop.This fault

must be manually reset from the default screen

of the ICVC.

LINE FREQUENCY in POWER screen must be

maintained between 45-52 Hz if LINE

FREQ=60Hz? is set to NO(50 Hz). LINE FREQUENCY must be maintained between

55-62 Hz if LINE FREQ=60Hz? is set to YES

(60 Hz).

Check high pressure switch and connections to

TB4-24 and TB4-25.

COMPRESSOR 100% SPEED in VFD_CONF

screen must be set between 45-52 Hz if LINE

FREQ=60Hz? is set to NO(50 Hz). COMPRESSOR 100% SPEED must be set between

55-62 Hz if LINE FREQ=60Hz? is set to YES

(60 Hz).

VFD Gateway and VFD software versions are

not compatible.

Call Carrier Service.

VFD Gateway and ICVC software versions are

not compatible.

Call Carrier Service.

Check for high entering water temperature or

low condenser water flow.

Check current settings in VFD_CONF screen.

ICVC FAULT

STATE

260 SENSOR FAULT LEAVING CHILLED WATER 260Sensor Fault: Check

261 SENSOR FAULT ENTERING CHILLED

262 SENSOR FAULT CONDENSER PRESSURE 262Sensor Fault: Check

263 SENSOR FAULT EVAPORATOR

264 SENSOR FAULT COMPRESSOR BEARING

265 SENSOR FAULT COMPRESSOR MOTOR

266 SENSOR FAULT COMP DISCHARGE TEMP 266Sensor Fault: Check

267 SENSOR FAULT OIL SUMP TEMP 267Sensor Fault: Check Oil

268 SENSOR FAULT COMP OIL PRESS DIFF 268Sensor Fault: Check Oil

269 SENSOR FAULT CHILLED WATER FLOW 269 Sensor Fault: Check

270 SENSOR FAULT COND WATER FLOW 270Sensor Fault: Check

271 SENSOR FAULT EVAP SATURATION TEMP 271Sensor Fault: Check

PRIMARY

MESSAGE

SECONDARY

MESSAGE

WATER

PRESSURE

TEMP

TEMP

PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

Leaving Chilled Water Sensor.

261Sensor Fault: Check

Entering Chilled Water

Sensor.

Condenser Pressure Sensor.

263Sensor Fault: Check

Evaporator Pressure Sensor.

264Sensor Fault: Check

Comp Thrust Brg Temp Sensor.

265Sensor Fault: Check

Comp Motor Winding Temp

Sensor.

Comp Discharge Temp Sensor.

Sump Temp Sensor.

Pump Delta P Sensor.

Chilled Water Delta P Sensor.

Cond Water Delta P Sensor.

Evap Saturation Temp Sensor.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor wiring.

Check for disconnected or shorted wiring.

Check for condensation in transducer

connector.

Check sensor wiring.

Check for disconnected or shorted wiring.

Check for condensation in transducer

connector.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

Check sensor wiring and accuracy.

Check for disconnected or shorted wiring.

If pressure transducers are not installed,

check for presence of resistors and jumpers

on lower CCM terminal block J3.

Check sensor wiring and accuracy.

Check for disconnected or shorted wiring.

If pressure transducers are not installed,

check for presence of resistors and jumpers

on lower CCM terminal block J3.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for disconnected or shorted wiring.

19

Page 20

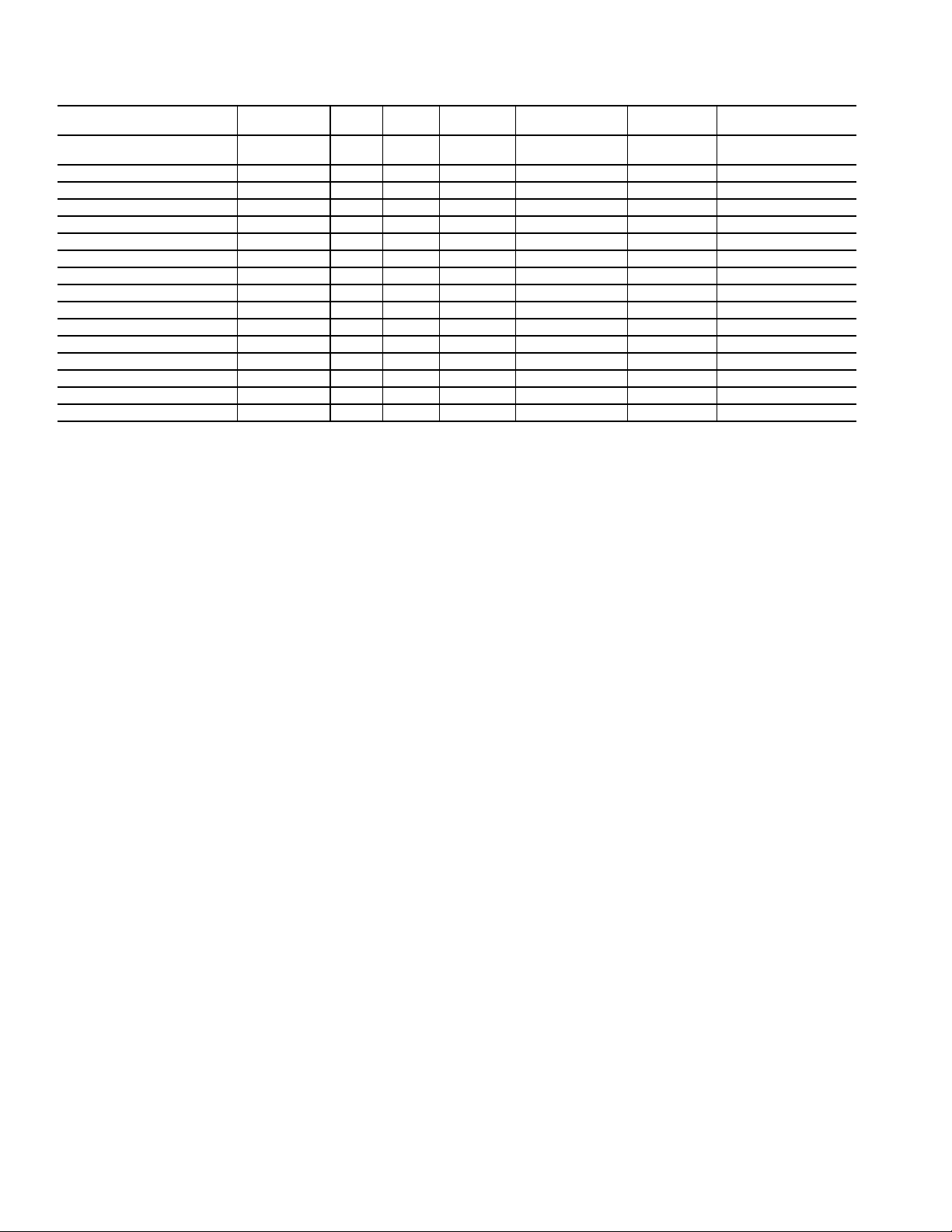

Table 6

VFD

FAULT

CODE

ON VFD

HIST

SCREEN

NONE 206 Processor memory fault Consult VFD manual to resolve generic fault.

0 No Entry

2 207 Auxiliary Input Input is open.

3 210 Power Loss Line voltage dropout

4 215 Undervoltage Low DC bus voltage

5 166 Overvoltage High DC bus voltage

7 217 Motor Overload An internal electronic overload trip has occurred.

8 219

9 219

12 286 HW Overcurrent

13 220 Ground Fault

14 206 Ground Warning

15 206 Load Loss

17 216

20 206 TorqPrv Spd Band See VFD Fault Code 15 See VFD Fault Code 15

21 225 Output PhaseLoss

24 204 Decel Inhibit

33 206 AuRsts Exhausted See VFD Fault Code 15 See VFD Fault Code 15

36 286 SW Overcurrent

ICVC

FAULT

STATE

Heat Sink Overtemp

Transistor Overtemp

The DC bus ripple

has exceeded a

preset level.

— Powerflex 755 Fault Code Descriptions and Corrective Actions

FAULT TYPE DESCRIPTION CORRECTIVE ACTION

Check Compressor Discharge High Pressure

switch wiring and accuracy.

Check for high condenser water temperatures,

low water flow, fouled tubes.

Check for division plate/gasket bypass. Check for

noncondensables in refrigerant.

Temporary loss of voltage. Disable Single Cycle

Dropout in VFD_CONF sceen.

Verify phase-to-phase and phase-to-ground line

voltage. VFD Circuit Board malfunction.

Call Carrier Service.

Verify phase to phase and phase to ground line

voltage. Monitor AC line for high transient voltage

conditions.

Any phase current > 106% RLA. Can result from

significant load side current imbalance when

running at full load.

Check entering condenser water temperature

and water flow rate.

Check Motor Rated Load Amps in VFD_CONF

screen.

Check that VFD refrigerant isolation valves are

Heat sink temperature has exceeded the maximum operating temperature