Carnes HRAA Installation Manual

READ AND SAVE THESE INSTRUCTIONS

MODEL HRAA TECHNICAL MANUAL

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 - Phone: 608/845-6411 - Fax: 608/845-6470 carnes@carnes.com www.carnes.com

FORM 16799

ISSUED: 06-08

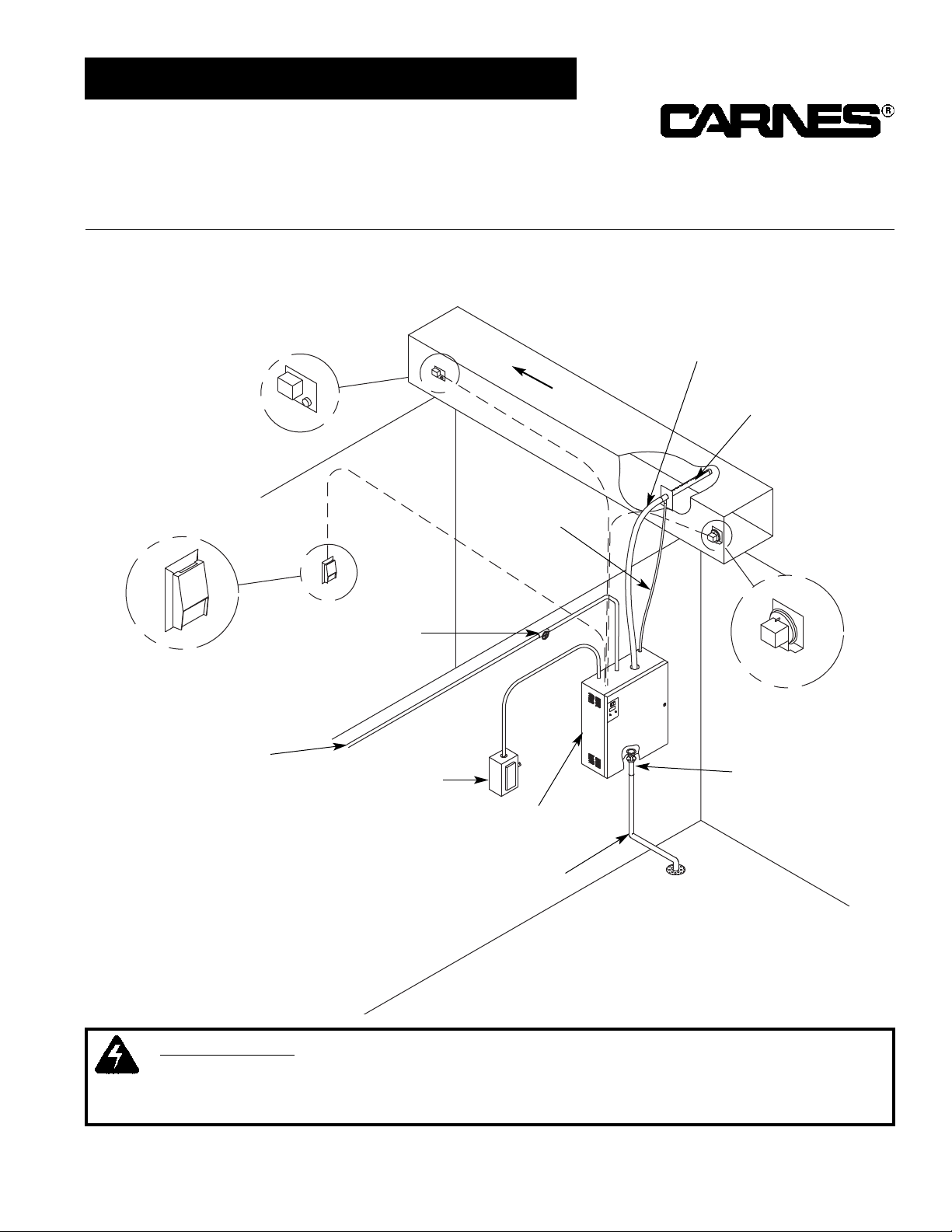

TYPICAL INSTALLATION

Figure A

High Limit

Humidistat

Steam

Hose

Steam Distributor

Pipe

Condensate

Return Line

Water Shutoff

Valve (By Others)

Wall Humidistat

Cold Water Line

Fused Disconnect

or Circuit Breaker

(By Others)

Air Flow Switch

Air Flow

Humidifier

Cabinet

Drain Line

Air Gap

Drain Fitting

WARNING:

THE HUMIDIFIER CABINET CONTAINS HIGH VOLTAGE WIRING AND HOT

SURFACES. THE CABINET DOOR INCLUDES A LOCK AND ACCESS MUST BE LIMITED TO

TRAINED AND QUALIFIED PERSONNEL ONLY. THE DOOR MUST BE LOCKED AND KEY MUST

BE KEPT IN A SECURE LOCATION AWAY FROM THE HUMIDIFIER

2

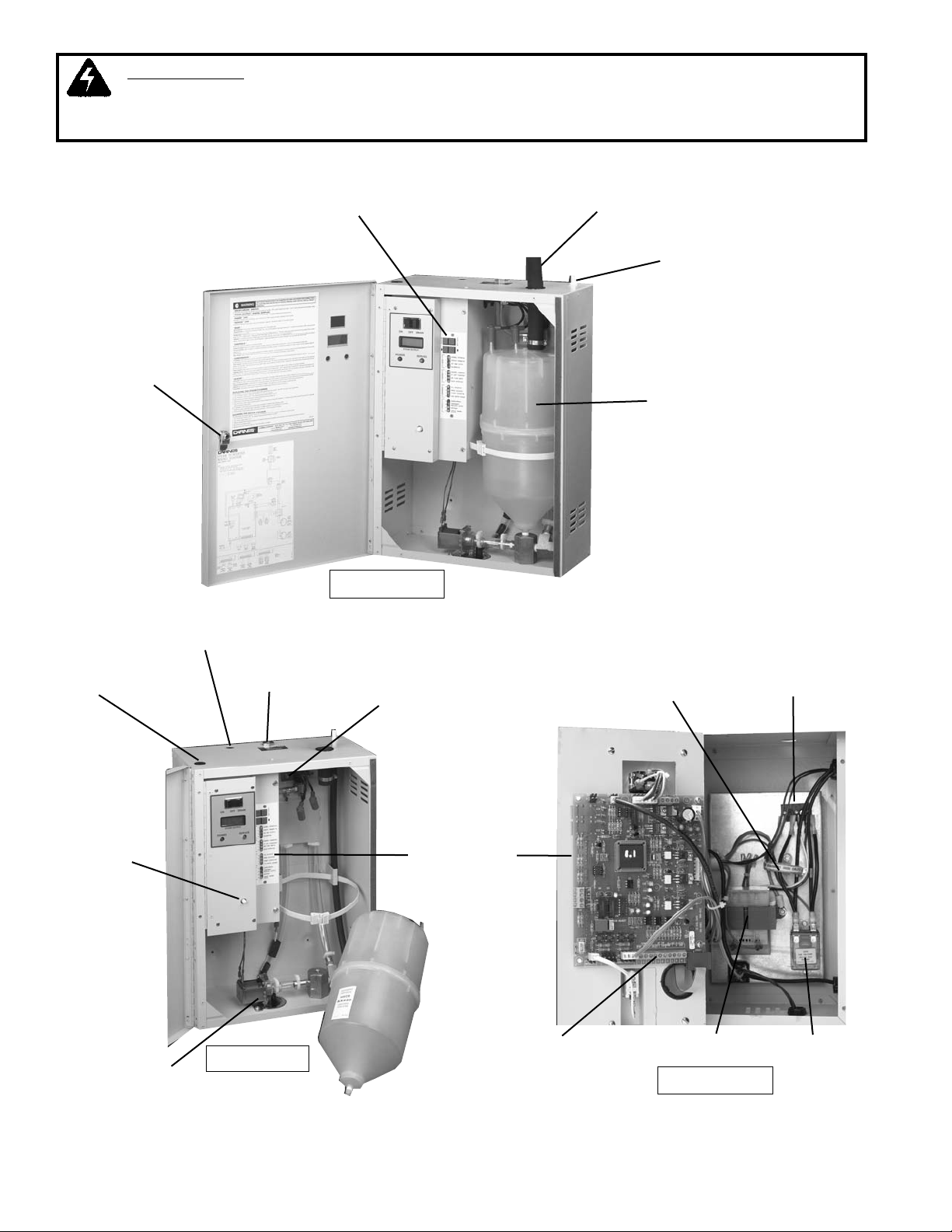

Steam

Cylinder

Hinged Door

with Key Lock

Steam Hose

Diagnostic

Display Panel

Condensate

Return Inlet

Figure B

Hole For

Power Wiring

Hole for

Control Wiring

Water Inlet

Fill Solenoid

Valve

Door

Interlock

Switch

Drain Solenoid

Valve

Figure C

Wiring Access

Panel

Electric Power

Terminals

Current

Sensing

Transformer

Control Connection

Terminals

Power

Contactor

(Relay)

Power Transformer

Figure D

WARNING:

INSTALLING AND SERVICING THIS EQUIPMENT CAN BE HAZARDOUS DUE TO

ELECTRICAL COMPONENTS AND HOT SURFACES. ONLY TRAINED AND QUALIFIED PERSONNEL

SHOULD INSTALL, REPAIR OR SERVICE THIS EQUIPMENT. INSTALLATION MUST BE MADE IN

ACCORDANCE WITH ALL APPLICABLE CODES AND STANDARDS.

INSTALLATION

UNPACKING AND INSPECTION

1. An envelope shipped with the cabinet contains the

cabinet keys and Installation, Operation and

Maintenance Instructions.

2. The following optional components are packed in a

separate shipping carton for connection when

installing the humidifier.

A. Steam Distributor Pipe.

B. Steam Hose.

C. Condensate Return Line.

D. Humidistats and Air Flow Switches.

E. Steam Hose Clamps.

F. Condensate Return Clamps.

G. Air Gap Drain Fitting.

The distributor pipe should be located to insure best

distribution of steam into the airstream. A minimum

clearance of 4” must be maintained between the top of

the duct and the distributor pipe.

The steam distributor pipe is usually located in the supply

duct downstream of the fan. It is important to locate the

distributor as far upstream as possible from any obstructions in the ductwork so that air can absorb the steam

before it impinges on a surface and condenses. There

must be minimum of three feet between the distributor

and any fans, coils, filters, dampers, elbows or outlets

downstream to reduce the possibility of condensation.

Duct air temperatures below 60°F may require a condensate drain pan, supplied by others, below the steam

distributor pipe.

STEAM DISTRIBUTOR PIPE LOCATION

In a typical installation the humidifier is located below a

duct as shown in Figure A. The distance between the

humidifier cabinet and the steam distributor pipe should

be the shortest possible.

In a vertical duct with either upward or downward air flow

the distributor pipe should be installed horizontally.

The maximum length of steam hose that may be

installed is 10 feet.

Figure E

AIR

FLOW

The distributor pipe may be located below the humidifier

if the installation is made as shown in Figure F. A trap

may be necessary to prevent steam from flowing back

through the condensate return line.

Figure F

INSTALL STEAM DISTRIBUTOR PIPE

The steam distributor pipe must be mounted on a plumb

surface so that it is inclined upward. This is required so

the condensate, which forms in the distributor pipe, will

drain into the return line.

Insert the distributor pipe into duct and secure with four

sheet metal screws, not provided.

3

DRAIN LINE CONNECTION

1. Remove the large nut and plastic gasket located on

the fitting on the bottom of the cabinet. The nut and

gasket may be used with standard type drain fitting if

an air gap fitting is not required by local codes.

2. Connect the air gap drain fitting to the cabinet drain

connection. It may be necessary to cut off some of the

air gap fitting depending on available space.

3. Connect the drain or air gap fitting to S or P trap or run

piping to a floor drain. Use plumbing material capable

of handling hot water, such as copper or CPVC.

CONNECT THE STEAM HOSE & CONDENSATE

RETURN LINE

COPPER TUBE IS THE ONLY ACCEPTABLE SUBSTITUTE FOR STEAM HOSE OR CONDENSATE RETURN

LINE.

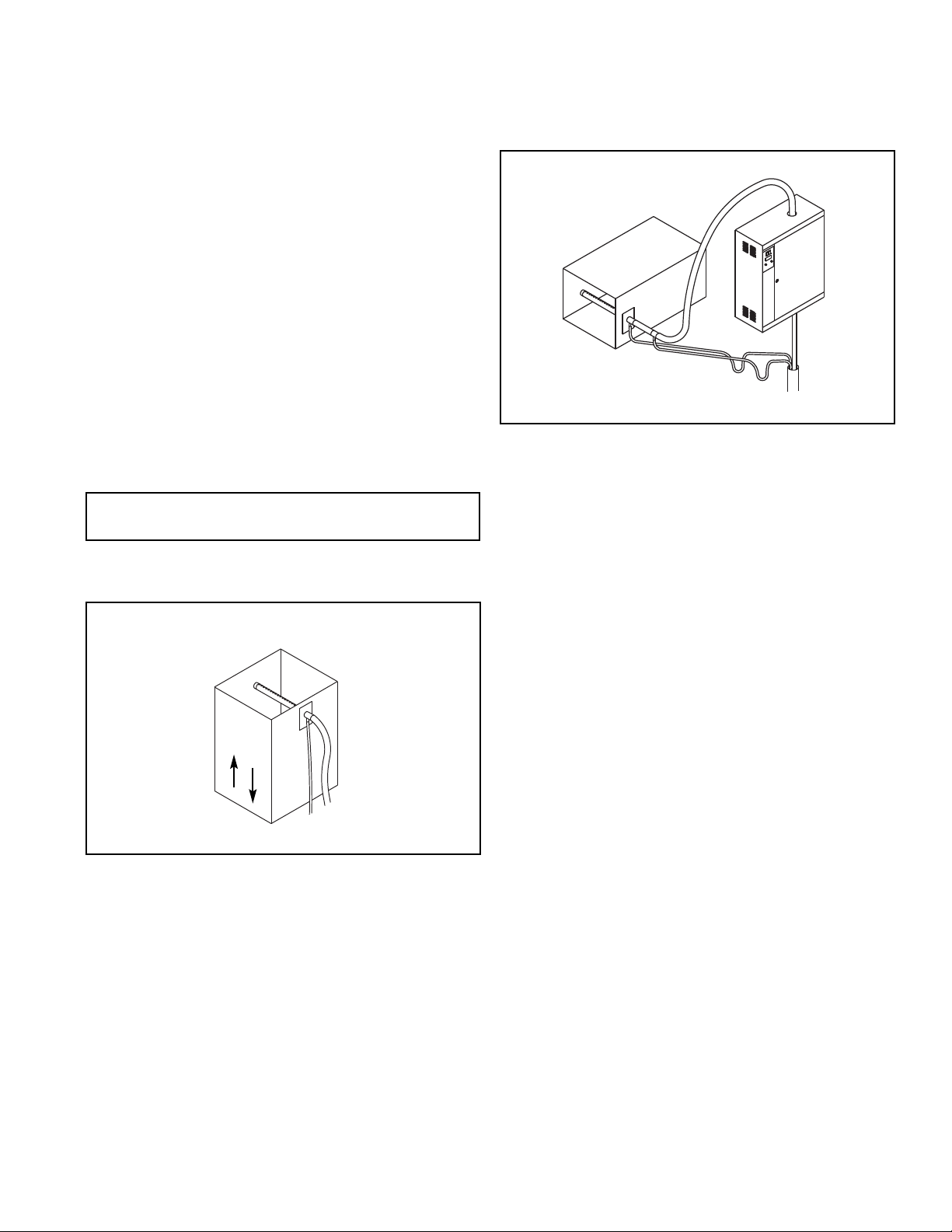

1. The steam hose should be installed so there is a

continuous rise from the humidifier to the distributor

pipe. The rise should be 2” in 12” to allow proper

condensate drainage.

Support the steam hose at intermediate points to prevent

dips or pockets. It is very important that both the steam

hose and condensate return line be installed so that sags

are prevented. The steam is at very low pressure and it

cannot overcome resistance caused by water standing in

the steam hose. Water accumulating in sags in the return

line will restrict the flow and may cause water to enter the

duct from the distributor pipe.

If it is difficult to install the steam hose to prevent sags, it

is recommended that copper tube be used as a substitute. Size 3/4” copper tube can be used. Any 90° elbows

are approximately equivalent to three feet of steam hose.

If copper tube is used, a minimum of one inch of

insulation must be applied to prevent excessive

condensation and contact with the hot pipe. A short

length of steam hose must be used to connect the

cylinder in the humidifier to the copper tube. Another

short length should be used to connect the copper tube

to the distributor pipe. Any turns in the hose should have

a minimum radius of 8” to prevent kinking.

2. Fasten the steam hose to the distributor pipe with one

of the hose clamps provided.

3. Push the steam hose through the opening on the top

of the humidifier cabinet and slip over the outlet stub

on the top of the cylinder. Fasten with the hose clamp

provided.

4. Fasten the condensate return line to the distributor pipe with

the hose clamp provided. Connect the return line to the

condensate return inlet with the hose clamp provided.

If it is impossible to maintain a drop to the top of the

cabinet, it will be necessary to run the condensate return

line directly to the air gap drain fitting or some other drain.

A trap (usually 8” is sufficient) may be necessary to prevent loss of steam through the return line. Do not install

a trap if condensate is returned to the top of the cabinet.

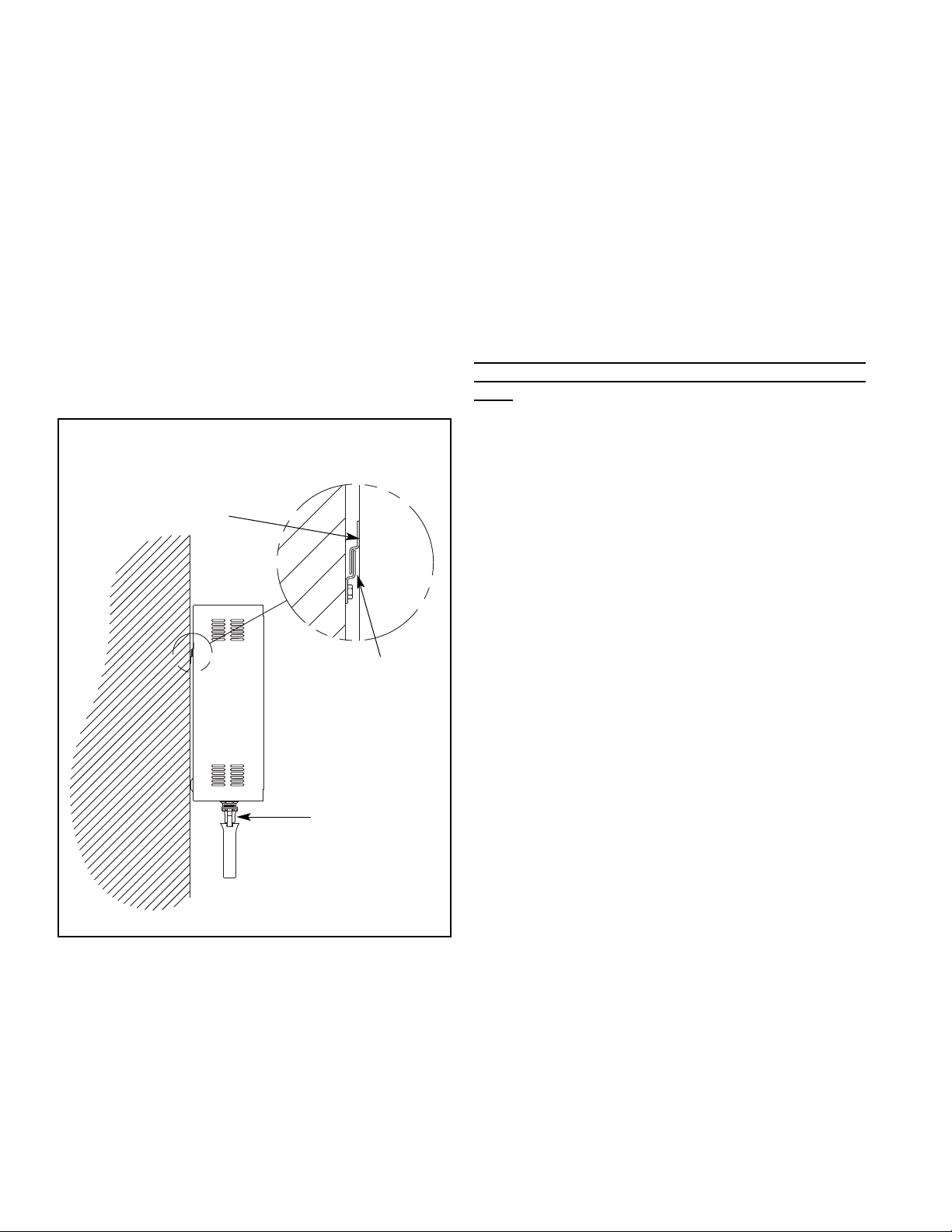

MOUNTING THE HUMIDIFIER

Locate the humidifier cabinet level and plumb on a

surface as close to the steam distributor as possible at a

convenient height for servicing. Allow 1” or more on the

sides for ventilation and 16” from the bottom to the floor

to allow for drain connections. Allow at least 16” in front

of cabinet for door opening. Consult local and national

codes prior to installation and comply with any provisions

they require.

The humidifier must never be located outside or where it

may be exposed to freezing temperatures unless a

heated, ventilated, weatherproof enclosure by others is

provided. Do not mount humidifiers on a hot or vibrating

surface.

Maximum operating weight is 70 pounds. Fasten the

mounting bracket to wood studs or solid wood.

Recommended fasteners: Four 1/4” x 1” long lag screws.

Fasteners are not provided.

Place the mounting flange on the humidifier cabinet over

the mounting bracket. A sheet metal screw should be

installed through the back of the humidifier cabinet to

secure the humidifier to the mounting bracket.

WATER SUPPLY CONNECTION

DO NOT

use hot water, deionized water, or water

that has been treated by a water softener without

consulting the factory.

Use ordinary tap water (20 to 120 psi). A 1/4” FPT fitting

is provided at the top of the humidifier. A shutoff valve,

not provided, must be installed ahead of this fitting.

MOUNTING FLANGE

MOUNTING BRACKET

AIR GAP

DRAIN FITTING

Figure G

4

5

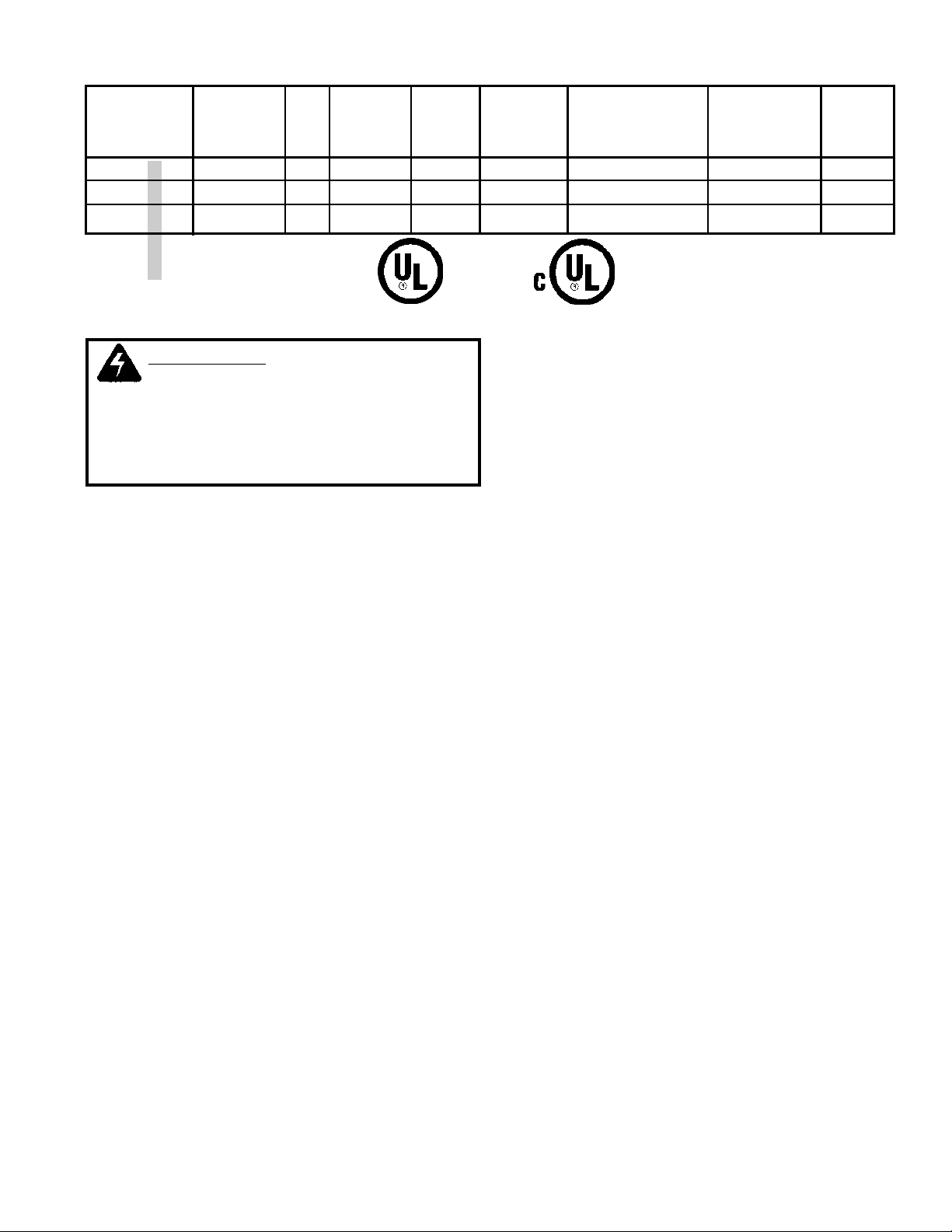

Line Recommended Digital

Maximum Amp Disconnect Steam Display

Model Lb./Hr. kW Voltage Phase Rating Size (Amps) Cylinder Code

HRAAA U 005 5 1.7 120 1 14.4 20 HXCBAX220 0005

HRAAD U 005 5 1.7 230 1 7.5 15 HXCBAX380 3005

HRAAD U 010 10 3.4 230 1 15.0 20 HXCBAX380 3010

U = UL

C = cUL

ELECTRICAL DATA

Check unit electrical characteristics on label outside of

cabinet. They must agree with power provided to the unit.

A fused disconnect or circuit breaker, not provided, must

be installed per local and national codes.

1. Remove screws securing hinged panel for access to

wiring.

2. An opening is provided on the top of the electrical

section. Bring electrical power lines through this

opening and connect to the electric power terminals

as shown on wiring diagram.

3. Replace electrical cover panel.

CONTROLS

CONTROL HUMIDISTAT

Either a wall-mounted humidistat or duct-mounted

humidistat in the return air may be used. The wall-mounted humidistat is the most common as it allows the setting

to be easily adjusted to accommodate changing requirements or to lower the level of relative humidity in the

space to prevent condensation on windows during

extremely cold weather. Room humidity is usually set in

range of 30-40% RH. Other settings may be necessary

for certain conditions.

If an on-off humidistat is used the humidifier will generate

steam at the preset output rate and cycle on or off as

necessary to satisfy the conditioned area requirements.

If a proportional humidistat is used the humidifier will

automatically vary the steam output rate in the range of

25-100% of the humidifiers maximum rating in response

to the humidistat. Proportional control provides less on-off

cycling of the humidifier.

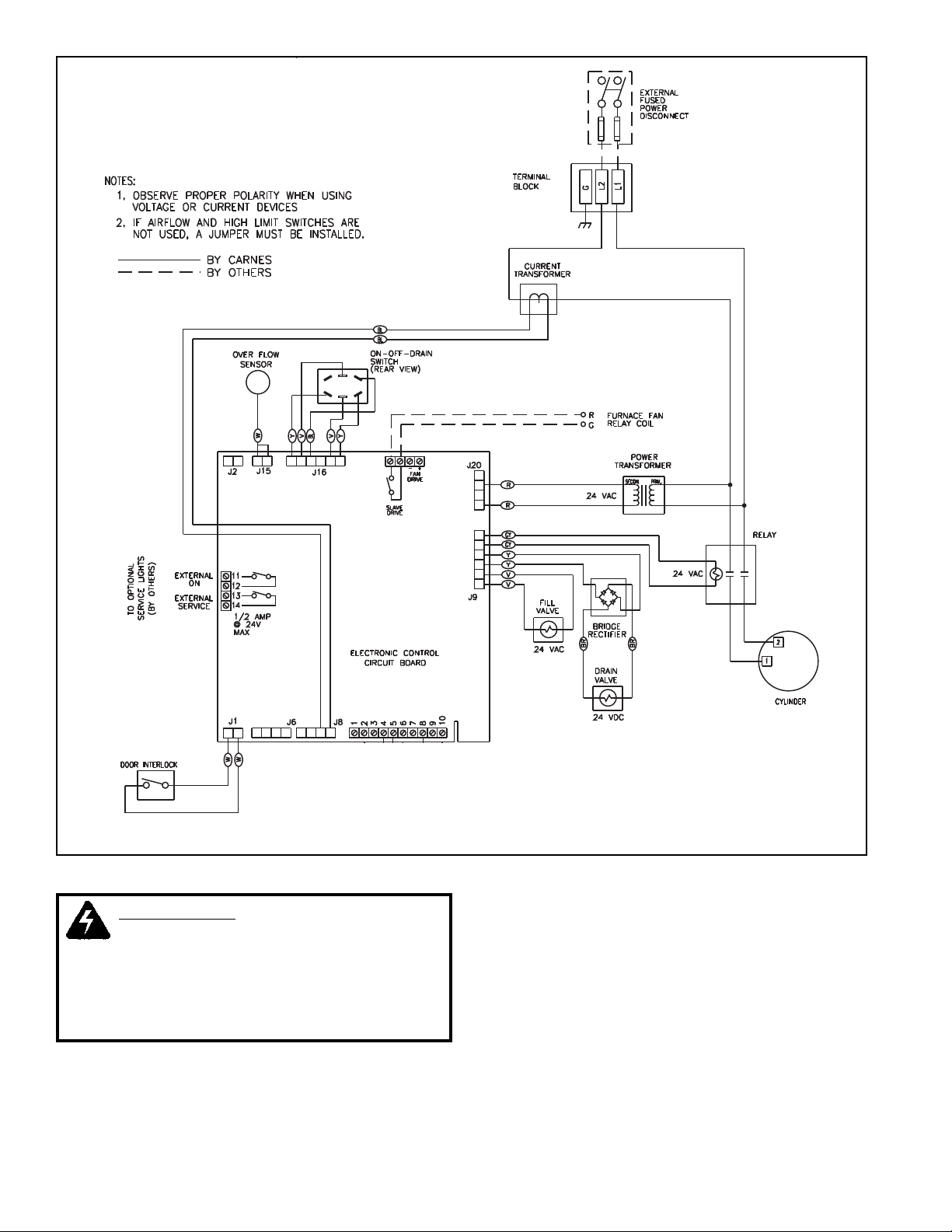

ELECTRICAL CONNECTIONS

WARNING:

BEFORE MAKING ANY

ELECTRICAL CONNECTIONS SWITCH

POWER OFF AT SERVICE PANEL, FUSED

DISCONNECT OR CIRCUIT BREAKER AND

LOCK THE DISCONNECTING MEANS TO

PREVENT POWER FROM BEING

SWITCHED ON ACCIDENTALLY.

AIR FLOW DETECTION

The humidifier control circuit should include some method

to confirm air flow. If the steam distributor pipe were

“located in a duct where there is no air flow and the

control humidistat is calling for humidity, steam would be

discharged into the duct where it would immediately

condense.

Air flow may be detected by using a pressure differential

switch that detects air flow by sensing static pressure in

the duct.

CONDENSATION PROTECTION

An additional device may be used to provide condensation protection in the duct system. A high limit humidistat

may be installed 10 feet downstream from the steam

distributor pipe. This humidistat is normally set to 90-95%

RH and opens the circuit if the humidity level in the duct

exceeds the set-point. Once the humidity level returns

below the set-point, humidifier operation will resume

following a delay of several minutes after reclosure of the

circuit. Use of this device is recommended particularly

when the humidifier is used in applications where cooling

air is being humidified.

Either an on-off or proportional high limit humidistat may

be used. If a proportional humidistat is used the output of

the humidifier will automatically be decreased to reduce

the possibility of condensation. Two proportional humidistats may be used. One may be located in the area to be

humidified or its return duct and another as a high limit in

the supply duct. The humidifier will automatically select

the lowest signal to control the humidifier output.

EXTERNAL MONITORING

Terminals 11 and 12, shown in Figure H are provided for

remote monitoring of the status of the humidifier if

desired. When the unit is on terminals 11 and 12 are

closed. When the output of the humidifier is less than

50% of set-point terminals 13 and 14 are closed indicating a need for service. Each set of terminals is capable of

switching 1/2 amp at 24 volt maximum.

WARNING:

BEFORE MAKING ANY

ELECTRICAL CONNECTIONS SWITCH

POWER OFF AT SERVICE PANEL, FUSED

DISCONNECT OR CIRCUIT BREAKER AND

LOCK THE DISCONNECTING MEANS TO

PREVENT POWER FROM BEING

SWITCHED ON ACCIDENTALLY.

CONTROL CONNECTIONS

1. A 7/8” opening is provided on top of the cabinet. The

control wiring should pass through the opening to the

terminal strip.

NOTE: A built-in transformer provides power for the

control circuit. No outside power supply is required for the

control circuit.

2. If an air flow switch or high limit humidistat is not used

jumpers must be installed before the humidifier will

operate.

Controls should be connected to the terminals on the

electronic circuit board as shown Figure H using #18

AWG wire. Avoid running control wiring near high voltage

wires.

Figure H

6

Loading...

Loading...