Carnes HCAGB Installation Manual

1

READ AND SAVE THESE INSTRUCTIONS

ELECTRONICALLY CONTROLLED STEAM HUMIDIFIER

DESIGN SERIES “G”

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

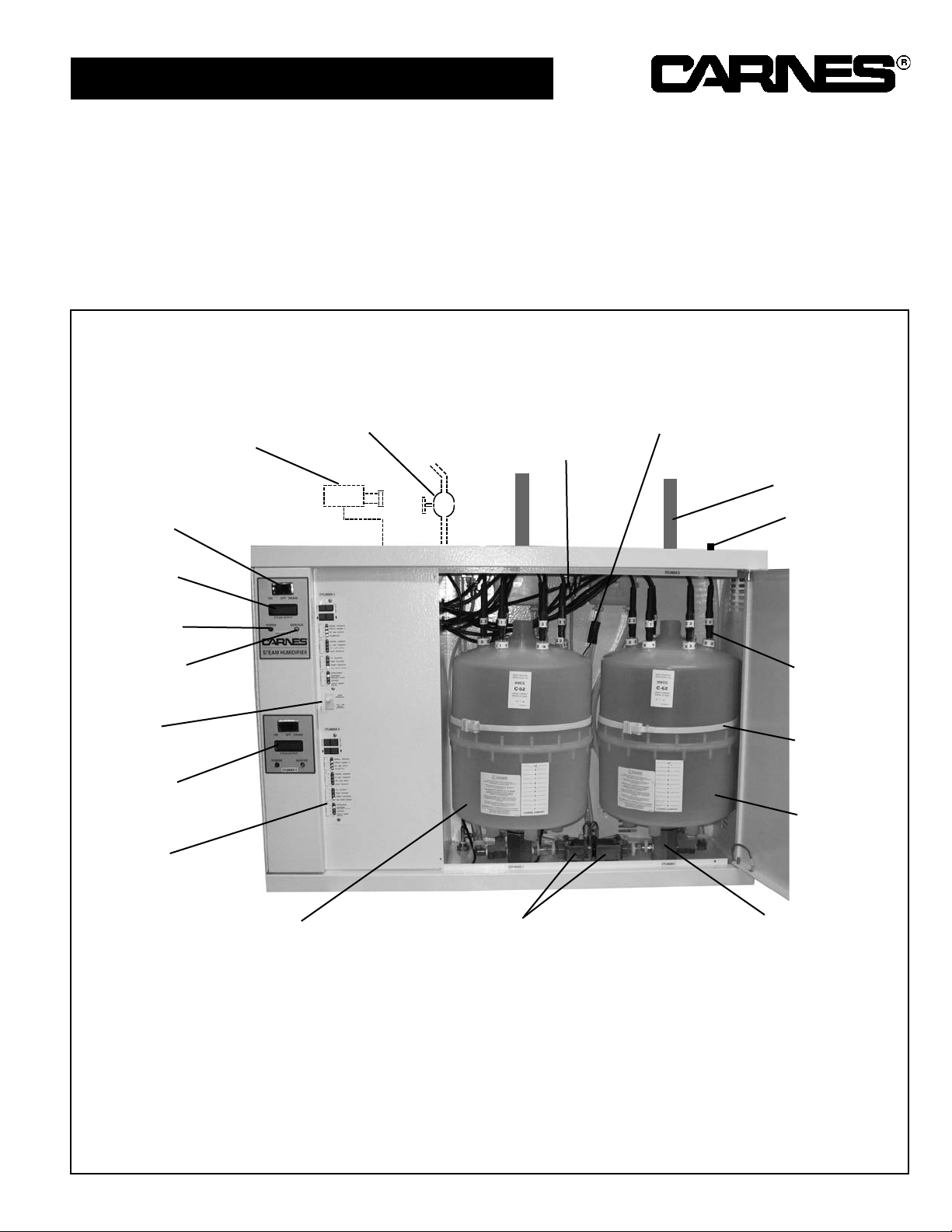

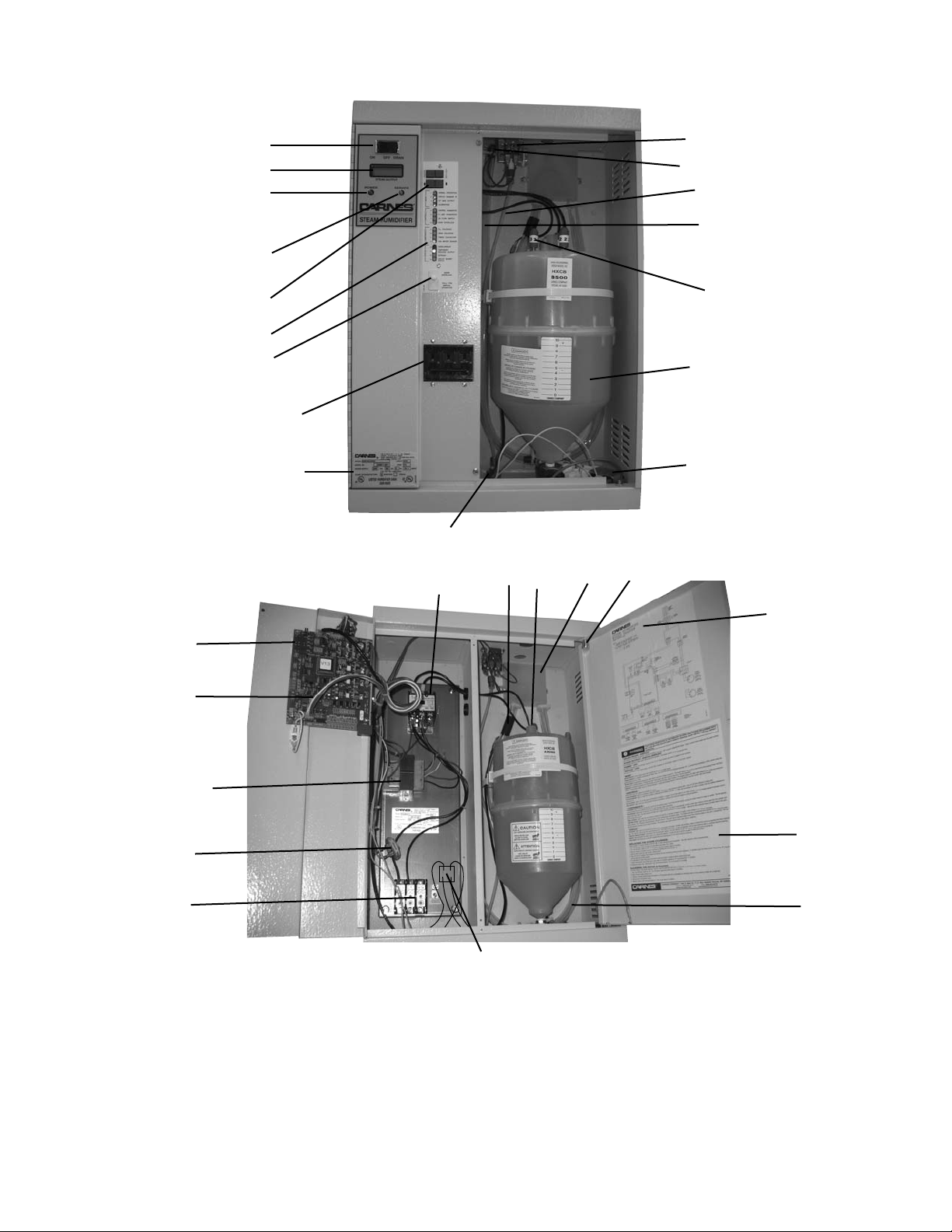

External Disconnect

or Circuit Breaker

(Not Provided by Carnes)

Water Shutoff Valve

(Not Provided by Carnes)

Digital Output

Rate Meter

for Cylinder 1

“Service”

Light

On-Off-Drain

Switch

Digital

Diagnostic

Panel

Brass Cylinder

Fittings

Drain Solenoid

Valve

Cylinder

Retaining

Band

Steam

Cylinder #2

Steam

Cylinder #1

Terminal

Connectors

Steam Hose

“On” Light

Door

Interlock

Fill

Solenoid

Valve

Photo A

(Model HCHG Shown)

FORM 16789-I

ISSUED: 04-12

Display for

Cylinder #2

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6504 www.carnes.com

High Water

Sensor

Condensate

Return Line

Connection (2)

2

INSTALLATION

UNPACKING AND INSPECTION

1. Cabinet keys are attached, by ty-rap, to side of

humidifier.

2. Open the cabinet and check for concealed shipping

damage. Report any damage immediately to the

carrier who delivered the shipment.

3. The following components are packed in a shipping

carton for connection when installing humidifier.

A. Distribution pipe.

B. Steam hose.

C. Condensate return line.

4. Optional accessories may be packed with the cabinet

or in the same shipping carton. Large accessories

may ship in separate cartons.

5. Inside the cabinet is an envelope containing the

following items:

A. Steam hose clamps.

B. Condensate return line clamps.

C. Air gap drain fitting.

D. Installation operation and maintenance manual,

operation addendum, parts replacement catalog,

customer satisfaction card, and parts order list

card.

MOUNTING THE HUMIDIFIER

Locate the humidifier cabinet level and plumb on a surface

as close to the steam distributor as possible at a convenient

height for servicing. Allow 1” or more on the side for ventilation and 16” from the bottom of the unit to floor to allow for

drain connections. If there is no common drain within close

proximity of humidifier, a drain pump (Carnes HXWA) may

be required to accommodate this distance. Allow 18”-38” in

front of cabinet for door opening or when necessary,

remove door with quick release pin. The humidifier must

never be located outside or where it may be exposed to

freezing temperatures unless a heated, ventilated weather

proof enclosure by others is provided. Do not mount humidifiers on a hot or vibrating surface.

Table 1 - MAXIMUM OPERATING WEIGHT

WATER SUPPLY CONNECTION

Use ordinary tap water (20 to 120 psi) - DO NOT use hot

water, DI (deionized water), RO (reverse osmosis)

water. If softened water is considered, please contact

factory for further assistance. A 3/8” FPT fitting is provid-

ed at the bottom of the humidifier for connection to tap water

supply. A shutoff valve, not provided by Carnes, must be

installed just ahead of this fitting.

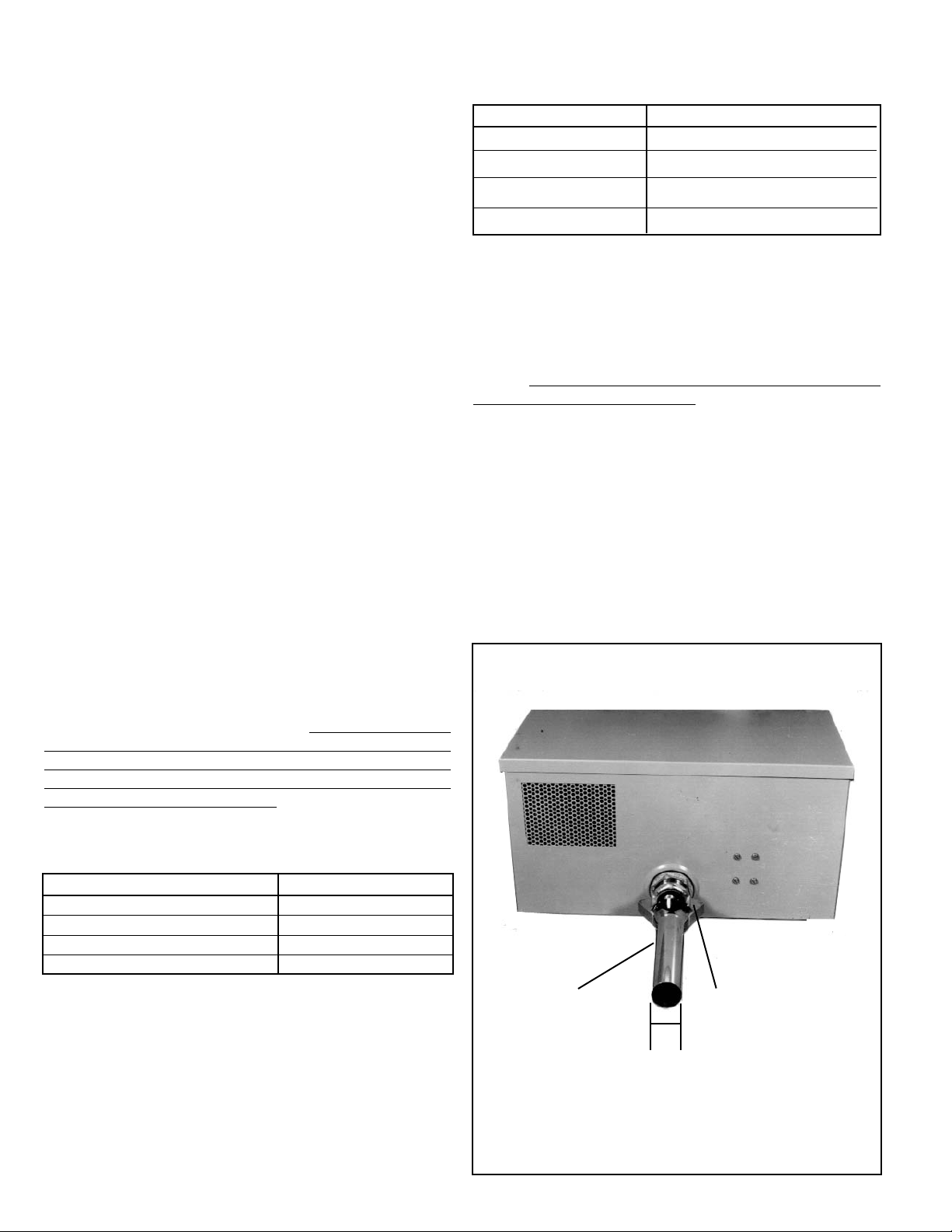

DRAIN LINE CONNECTION

1. Locate the air gap fitting in accessory bag in unit.

Have proper tooling available to attach fitting.

2. Connect the air gap drain fitting to the cabinet drain

connection. It may be necessary to cut off some of

the air gap fitting depending on available space.

3. Connect the drain or air gap fitting to S or P trap. Use

plumbing material capable of handling hot water.

Note: If the drain water pump accessory package is

used, follow instructions included with the drain water

pump package.

Model Pounds

HBAG, HCAG 80

HBDG, HCDG 85

HBGG, HCGG 105

HBHG, HCHG 185

Drain Line

Connection

Photo B

MODEL FASTENERS REQUIRED

HBAG, HCAG 4

HBDG, HCDG 4

HBGG, HCGG 4

HBHG, HCHG 6

Table 2 - FASTENER RECOMMENDATION*

*1/4” Lag Screw, 1” Minimum Length

Fasten the mounting bracket to wood studs or solid wood

using fasteners shown in Table 2 below. Place the mounting flange on the humidifier cabinet over the mounting

bracket. A sheet metal screw should be installed through

the back of the humidifier cabinet to secure the humidifier

to the mounting bracket. Fasteners are not provided by

Carnes.

1½”

Air Gap Fitting

(Included)

3

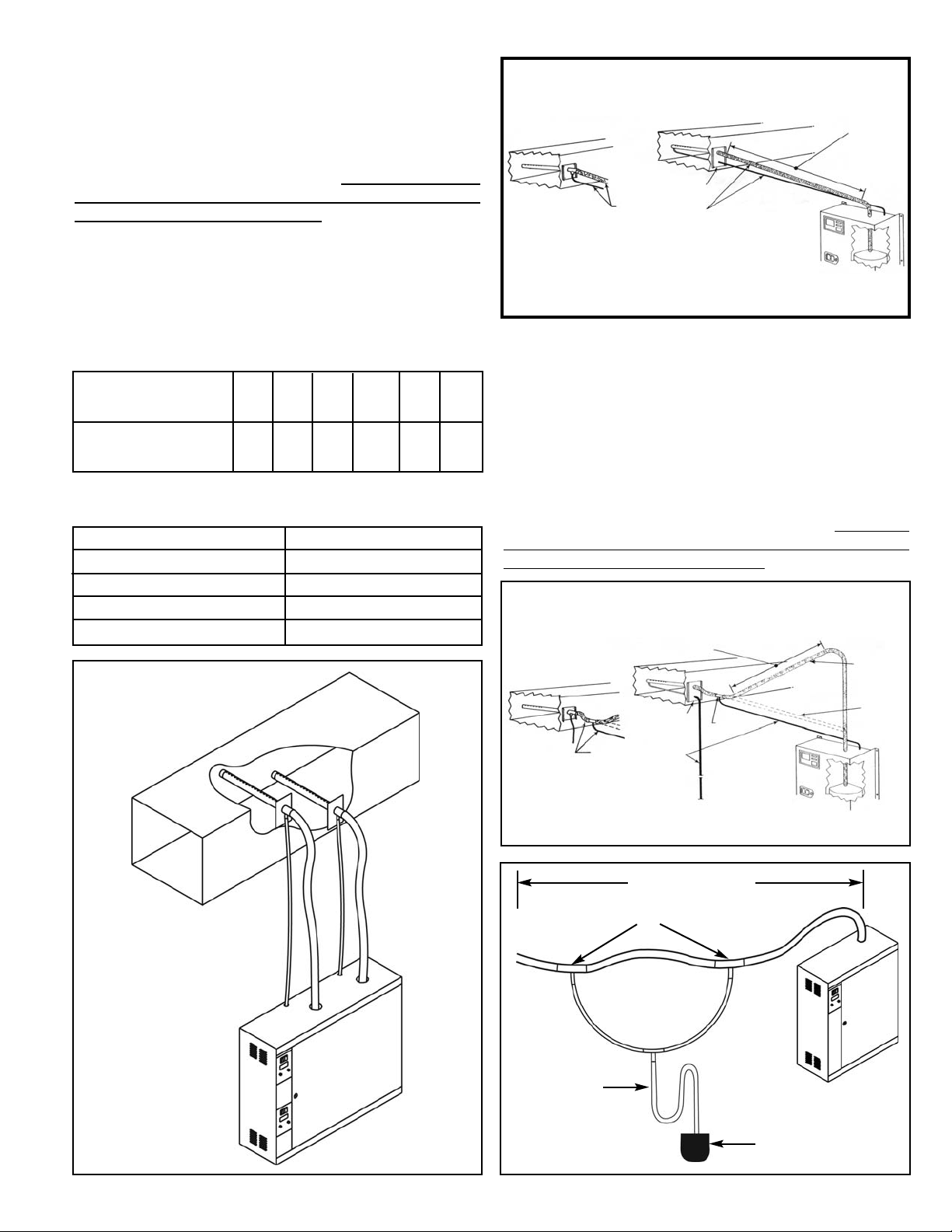

STEAM DISTRIBUTOR PIPE LOCATION

Each steam cylinder requires a separate distributor pipe,

steam hose and condensate return line. A cylinder may

supply more than one distributor pipe by using an

accessory “T” fitting but the output cannot be controlled

separately. In a typical installation the humidifier is located

below the duct as shown in Figure A. The length between

the humidifier cabinet and the steam distributor pipe should

be the minimum distance possible. Refer to Table 3 for

maximum length that may be installed, based on duct static pressure. Under less then perfect conditions, (installation

issues, routing problems for steam and condensate return

hose and extreme steam hose lengths) it is possible to lose

a certain amount of lbs. per hour capacity. See Table 3-A.

Figure A

The maximum length of steam hose that may be installed

as shown in Figure A is 12 feet. For a steam hose length

over 12 feet refer to Figure B. A drain “T”, must be used to

remove condensation that occurs in steam hose lengths

over 12 feet. It is preferable to have the steam hose rise

vertically from the cabinet and then slope downward to the

distributor pipe as shown. If sufficient headroom is not

available it is possible to install with an upward slope but

the rise should be 2” in 12” to allow for proper condensate

drainage and steam flow. Carnes electrode steam humidifiers are non-pressurized, maximum of 1/2 psi. It is critical

to provide proper routing of flexible hose and hard tubing to

maximize efficiency and effectiveness. See Figure D.

Figure B

MAXIMUM STEAM HOSE LENGTH

(Table 3)

Duct Static

Pressure “wg”

012345

Maximum Steam

Hose Length (Ft.)

40 35 30 25 15 10

AFFECT ON CAPACITY DETERMINED BY STEAM HOSE

LENGTH

(Table 3-A)

Distance Loss

10 Ft. 1.0 lb./hr.

20 Ft. 2.0 lb./hr.

25 Ft. 2.5 lb./hr.

40 Ft. 4.0 lb./hr.

Figure C

Common Drain

Trap

Condensate

Extended Length

Optional if

sufficient

head room

is not

available

When hose is difficult to support

within this length, straight

copper tube should be used

and insulation applied.

Steam line

must pitch

down toward

drain tee —

NO pockets,

sags or

horizontal

runs.

Mounting

plate must

be plumb.

Condensate hoses

must pitch down continuously to humidifier —

NO pockets, sags or

horizontal runs.

Drain Tee

To Drain

MODELS

HOSE LOCATION

FOR RUNS FROM

12 FEET TO 40 FEET

TYPICAL HOSE LOCATION

FOR LENGTHS UP TO

12 FEET

Figure A-1

Mounting plate

must be plumb.

Condensate hoses

must pitch down continuously to humidifier —

NO pockets, sags or

horizontal runs.

MODELS

If hose is difficult to

support within this

length, straight

copper tube should

be used and

insulation applied.

4

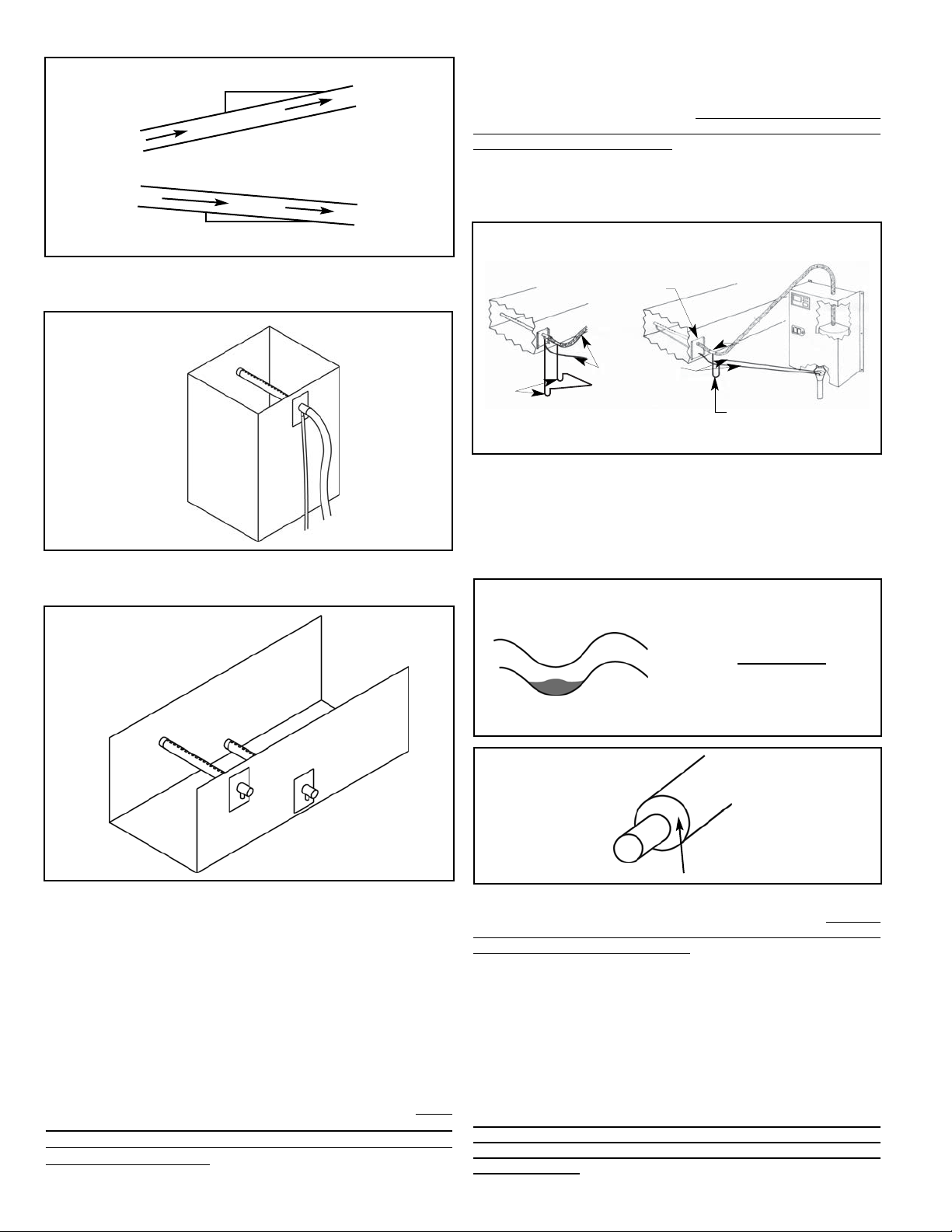

STEAM DISTRIBUTOR PIPE LOCATION (Continued)

Steam distributor pipes must be located on a plumb surface so

condensate that forms will run back into the return line. The pipe

should be located in the center of the duct to insure distribution of

steam into the airstream. A minimum clearance of 4” must be

maintained between the top of the duct and the distributor pipe.

The steam distributor pipes are usually located in the supply duct

downstream of the fan. When installed in packaged units the distributor should be mounted just downstream of the fan discharge.

It is important to locate the distributor as far upstream as possible

from any obstructions in the ductwork so that air can absorb

moisture before it impinges on a surface and accumulates. There

must be minimum of six feet between the distributor and any fans,

coils, filters, dampers, elbows or outlets downstream to reduce the

possibility of condensation.

Figure G

It is very important that both the steam hose and condensate

return line, whether flexible or hard tubing, be installed so there

are no sags, low points, dips or horizontal runs. The steam is at a

very low pressure and it cannot overcome any resistance caused

by accumulating water standing in the steam hose. Accumulation

in the condensate return hose will hamper the flow and may cause

water to enter the duct work by way of back up in distributor pipe.

In a vertical duct with either upward or downward air flow the

distributor pipe should be installed horizontally (Figure E).

If multiple pipes are used they should be staggered as shown

(Figure F).

Figure E

Figure F

If it is difficult to install the steam hose to prevent sags, it is

recommended that copper tube be used as a substitute. If copper

tube is used, a minimum of one inch of insulation must be applied

to prevent excessive condensation. A short length of steam hose

must be used to connect the cylinder

in the humidifier to the

copper tube and another short length to connect the copper tube

to the distributor pipe. Size 3/4” copper tube (with 7/8” steam hose)

can be used with steam cylinders having output rates up to 30

pounds per hour. Size 1-1/2” copper tube (with 1-5/8” steam hose)

should be used with steam cylinders having output rates over 30

pounds per hour. Length restrictions shown in Table 3 also apply

to installations where copper tube is used and any use of 90°

elbows add approximately three feet of equivalent length, thus

negatively affecting loss of capacity, efficiency and effectiveness.

Hose lengths of no longer then 10-20 ft. and proper inclines or

routing, as expressed in this manual, will provide the best chance

of having a proper operating humidifier and efficient and effective

steam dispersion.

Figure I

Figure H

Pipe Insulation

Note: Over time and extended

heat, the situations described

in the previous paragraph can

occur. That’s why it is important

to perform monthly visual

inspections to maintain and

correct, when necessary,

improper routing of steam

and condensate lines.

Exaggerated for emphasis.

Steam

2”

12”

.5”

12”

Figure D

Mounting

plate must

be plumb.

Condensate hoses

must pitch down continuously to humidifier or

common drain — NO

pockets, sags or

horizontal runs.

Drain Tee

HOSE LOCATION

WHEN DUCT IS LOWER

THAN HUMIDIFIER

Water trap required to

prevent live steam

from returning.

It may be possible to minimize the absorption distance by using

multiple distributor pipes, or for extremely short absorption

distances, a manifold may be required (See Short Absorption

Manifold Section in this manual). Duct air temperatures below

50-60°F may require a condensate drain pan supplied by others

below the steam distributor pipe.

The distributor pipe may be located below the humidifier if the

installation is made in accordance with Figure G. A trap may be

necessary to prevent steam from flowing back through the

condensate return line.

Trap to

common

drain.

5

INSTALL STEAM DISTRIBUTOR PIPE

EACH CYLINDER REQUIRES SEPARATE STEAM HOSE, CONDENSATE RETURN LINE, AND STEAM DISTRIBUTOR PIPE.

1. Steam distributor pipe must be mounted on a plumb surface.

When on a plumb surface the standard distributor pipe is

inclined upward. This is required so the condensate which

forms in the distributor pipe will drain to the return line and

back to the unit, or to common drain.

2. Insert distributor pipe into duct and secure with four sheet

metal screws, not provided by Carnes.

3. Special distributor pipes are shipped with specific instructions

on how to mount them.

4. If the optional fan distribution unit is to be used, follow the

instructions included with the unit.

CONNECT THE STEAM HOSE

COPPER OR BRASS TUBE IS THE ONLY ACCEPTABLE

SUBSTITUTE FOR CARNES STEAM HOSE OR CONDENSATE

HOSE.

1. The steam hose should be installed so there is a continuous

rise from the humidifier to the distributor pipe. Support the

steam hose at intermediate points to prevent dips, pockets,

sags or horizontal runs. See Figure H.

2. Any turns should have a minimum radius of 8” to prevent the

hose from kinking. Fasten the steam hose to the distributor

pipe with one of the hose clamps provided.

3. Push the steam hose through the opening on the top of the

humidifier cabinet and slip over the outlet stub on the top of

the cylinder. Fasten the hose clamp provided.

4. If long lengths of steam hose, (or hard tubing) are used, the

use of periodic “T’s” to drain condensate should be used.

See Figure C.

CONDENSATE RETURN LINE

1. Fasten the condensate return line to the distributor pipe with

the hose clamp provided.

2. Follow the steam hose to the humidifier cabinet and secure

the return line to the steam hose.

3. Connect the return line to the condensate return inlet with

hose clamp provided.

4. If it is impossible to maintain a drop to the top of the cabinet,

it is necessary to run the condensate return line directly to the

air gap drain fitting or some other drain.

5. A trap (of sufficient size) may be necessary to prevent loss of

steam through the return line and reduce the temperature of

condensate water to the common drain. Do not install a trap

if condensate is returned to the top of cabinet.

STEAM DISPERSION CRITERIA

1. Distributor pipe location must be at a minimum of 6 feet

upstream from any elbows, splits, coils, turning vanes, grilles,

diffusers, etc.

2. If temperature in duct is 55° to 60°F or less, recommended 10

feet of distance be used.

3. Under normal and average conditions, most absorption distances will probably fall into the 4 to 5 feet length. This is true,

whether the unit is a 30 lb./hr. or less capacity or 30 lb./hr. or

more capacity.

4. If distance recommended can not be possible, then a drain

pan with drain capability may be required.

5. If the air in the duct can not hold the volume of steam, the only

recourse may be to lower the maximum output of the unit.

6. If shorter absorption distances are required, 3 ft. or less,

multiple distributor pipes could be used. 2 pipes split off one

steam house or 2 pipes from a dual cylinder unit.

7. If even shorter absorption distances are required, 2 ft. or less,

then multi tube short absorption manifolds may be required.

NOTES: Identifying and explaining the following electrical

data and unit detail sheet

“Model” and “Optional Circuit Breaker” columns designate

presence, quantity and amp rating of optional circuit breakers. All

models have overload protection provided by the electronic circuit

board. In addition, as an option, internally mounted, switchable

on-off, circuit breakers are available in models preceded by “HB

”.

“Maximum Lb./Hr.” designates maximum capacity of humidifier.

Units are shipped from the factory preset at the maximum rate.

The output rate may be easily reset after installation anywhere

between 100% and 25% of maximum capacity.

“Voltage” and “Phase” designate available phase and nominal

voltages. Single phase units may be operated from two legs of a

three phase supply but the load will be unbalanced.

“kW” ratings shown is at maximum output rate. If a unit is reset

for less than maximum output, the kW is reduced proportionally.

“Line Amp” and “Disc. Size” are amp ratings shown for use in

selecting electrical service requirements.

“Steam Cylinder” column shows the quantity and the model of

steam generating cylinders mounted in the humidifier. Each

cylinder requires its own steam distribution pipe, steam hose and

condensate return line.

“Digital Display Code” column shows the code that will appear

on the digital display when in the “Calibration” function. The

calibration function of the circuit board can be checked for

accuracy with the model shown on the rating label.

“J4 (Set) & J5 (GND) Vdc” - test lead rating of circuit board when

in calibration mode. Consult factory for procedures.

“Cylinder Wire Current” - as a process of troubleshooting, it may

be necessary to confirm current flow through individual cylinder

wires during operation. Match humidifier with electrical data.

“Minimum Output Settings” - the minimum setting that a

maximum output can be adjusted to and still maintain normal

effective and efficient operation.

STEAM DISPERSION CRITERIA

(Continued)

You must keep in mind that there are a lot of variables involved in

proper steam distribution and absorption distances (duct length

downstream from the dispersion method, required absorption distance determined by design, capacity of humidification, velocity of

air flow, temperature of air flow, location of humidifier/s, distance

between humidifier/s to distribution point and so on). Since this is

important to successful humidification, proper planning must be a

pre-requisite to good performance - PRIOR PREPARATION

PREVENTS POOR PERFORMANCE.

ELECTRICAL CONNECTIONS

POWER MUST BE OFF BEFORE MAKING ANY ELECTRICAL

CONNECTIONS

Check unit electrical characteristics on label outside of cabinet. It

must agree with power provided to the unit. If it does not, contact

your Carnes Representative.

A fused disconnect or circuit breaker not provided by Carnes,

MUST be installed per local and national codes. See Table 4 for

recommended circuit ratings. The optional circuit breaker switch,

offered as an accessory, installed in the humidifier, is NOT for use

as a replacement for the required external disconnect switch, but

as a maintenance convenience addition.

1. Remove screws securing hinged panel for access to wiring.

2. An opening is provided on the bottom of the electrical

section. Bring electrical power lines through this opening and

connect to electric power terminals.

3. Connect cabinet ground terminals to an independent ground.

DO NOT use the neutral of a four-wire power supply.

4. Replace electrical cover panel.

6

Optional Digital Min.

Maximum

Line Disc. Circuit Steam Display J4-J5 Cyl. Wire Output

Model Lb/Hr. Voltage Phase kW Amp Size Breaker Cylinder Code VDC Current Setting

HCAGA 5 120 1 1.7 14.4 20 1-20 Amp 1-AX220 0005 3.89 14.4 1

HCAGB 5 208 1 1.7 8.3 15 1-15 Amp 1-AX380 1005 2 8.3 1

HCAGD 5 230 1 1.7 7.5 15 1-15 Amp 1-AX380 3005 1.61 7.5 1

HCAGF 5 277 1 1.7 6.2 15 1-15 Amp 1-AX380 5005 1.26 6.2 1

HCAGM 5 460 1 1.7 3.7 15 1-15 Amp 1-AX700 8005 0.52 3.7 1

HCAGN 5 575 1 1.7 3.0 15 1-15 Amp 1-AX700 9005 0.35 3 1

HCAGA 10 120 1 3.4 28.7 40 1-40 Amp 1-AX220 0010 8.72 28 2

HCAGB 10 208 1 3.4 16.6 25 1-25 Amp 1-AX380 1010 4.6 16 2

HCAGD 10 230 1 3.4 15.0 20 1-20 Amp 1-AX380 3010 4.06 15 2

HCAGF 10 277 1 3.4 12.4 20 1-20 Amp 1-AX380 5010 3.23 12.4 2

HCAGM 10 460 1 3.4 7.5 15 1-15 Amp 1-AX700 8010 1.7 7.5 2

HCAGN 10 575 1 3.4 6.0 15 1-15 Amp 1-AX700 9010 1.2 6 2

HCDGB 20 208 1 6.9 33.1 45 1-45 Amp 1-B500 1020 10.24 33.1 4

HCDGD 20 230 1 6.9 29.9 40 1-40 Amp 1-B500 3020 9.1 30 4

HCDGF 20 277 1 6.9 24.9 35 1-35 Amp 1-B500 5020 7.41 24.9 4

HCDGM 20 460 1 6.9 15.0 20 1-20 Amp 1-B700 8020 4.06 15 4

HCDGN 20 575 1 6.9 12.0 15 1-15 Amp 1-B700 9020 3.09 12 4

HCDGC 20 208 3 6.9 19.1 25 1-25 Amp 1-B500 2020 5.42 19.1 4

HCDGE 20 230 3 6.9 17.3 25 1-25 Amp 1-B500 4020 4.83 17.3 4

HCDGG 20 460 3 6.9 8.6 15 1-15 Amp 1-B700 6020 2 8.7 4

HCDGH 20 575 3 6.9 6.9 15 1-15 Amp 1-B700 7020 1.5 6.9 4

HCDGC 30 208 3 10.3 28.7 40 1-40 Amp 1-B500 2030 8.63 28.7 6

HCDGE 30 230 3 10.3 25.9 35 1-35 Amp 1-B500 4030 7.73 25.9 6

HCDGG 30 460 3 10.3 13.0 20 1-20 Amp 1-B700 6030 3.42 13 6

HCDGH 30 575 3 10.3 10.4 15 1-15 Amp 1-B700 7030 2.56 10.4 6

HCGGB 30 208 1 10.3 49.7 70 2-35 Amp 1-C62 1030 7.42 24.8 6

HCGGD 30 230 1 10.3 44.9 60 1-60 Amp 1-C62 3030 14.2 22.4 6

HCGGF 30 277 1 10.3 37.3 50 1-50 Amp 1-C62 5030 11.53 18.6 6

HCGGM 30 460 1 10.3 22.5 30 1-30 Amp 1-C65 8030 6.53 22.4 6

HCGGN 30 575 1 10.3 18.0 25 1-25 Amp 1-C65 9030 5.15 17.9 6

HCGGC 40 208 3 13.8 38.2 50 1-60 Amp 1-C62 2040 11.82 19.1 8

HCGGE 40 230 3 13.8 34.6 45 1-50 Amp 1-C62 4040 10.5 17.2 8

HCGGG 40 460 3 13.8 17.3 25 1-25 Amp 1-C65 6040 4.77 17.2 8

HCGGH 40 575 3 13.8 13.8 20 1-20 Amp 1-C65 7040 3.65 13.8 8

HCGGC 50 208 3 17.2 47.8 70 2-35 Amp 1-C62 2050 7.12 23.9 10

HCGGE 50 230 3 17.2 43.2 60 1-60 Amp 1-C62 4050 13.54 21.6 10

HCGGG 50 460 3 17.2 21.6 30 1-30 Amp 1-C65 6050 6.29 21.6 10

HCGGH 50 575 3 17.2 17.3 25 1-25 Amp 1-C65 7050 4.77 17.3 10

HCGGC 60 208 3 20.7 57.4 80 2-40 Amp 1-C62 2060 8.58 28.7 12

HCGGE 60 230 3 20.7 51.9 70 2-40 Amp 1-C62 4060 7.74 26 12

HCGGG 60 460 3 20.7 26.0 35 1-40 Amp 1-C65 6060 7.74 26 12

HCGGH 60 575 3 20.7 20.8 30 1-30 Amp 1-C65 7060 5.98 20.8 12

HCGGC 80 208 3 27.5 76.5 100 2-60 Amp 1-C62 2080 11.91 38.2 16

HCGGE 80 230 3 27.5 69.2 90 2-50 Amp 1-C62 4080 10.5 34.6 16

HCGGG 80 460 3 27.5 34.6 50 1-50 Amp 1-C12 6080 10.5 17.3 16

HCGGH 80 575 3 27.5 27.7 40 1-40 Amp 1-C12 7080 8.12 13.8 16

HCGGC 100 208 3 34.4 95.6 125 2-60 Amp 1-C62 2100 14.95 47.8 20

HCGGE 100 230 3 34.4 86.4 125 2-60 Amp 1-C62 4100 13.54 43.2 20

HCGGG 100 460 3 34.4 43.2 60 1-60 Amp 1-C12 6100 13.54 21.6 20

HCGGH

100 575 3 34.4 34.6 45 1-50 Amp 1-C12 7100 10.5 17.3 20

HCHGC 125 208 3 43 119.5 175 4-40 Amp 2-C62 2125 9.01 29.8 12 ea.

HCHGE 125 230 3 43 108.0 150 4-40 Amp 2-C62 4125 8.08 27 12 ea.

HCHGG 125 460 3 43 54.0 75 2-40 Amp 2-C12 6125 8.08 13.5 12 ea.

HCHGH 125 575 3 43 43.2 60 2-30 Amp 2-C12 7125 6.32 10.8 12 ea.

HCHGC 150 208 3 51.7 143.4 200 4-50 Amp 2-C62 2150 10.97 35.8 15 ea.

HCHGE 150 230 3 51.7 129.7 200 4-50 Amp 2-C62 4150 9.97 32.4 15 ea.

HCHGG 150 460 3 51.7 64.8 90 2-50 Amp 2-C12 6150 9.97 16.2 15 ea.

HCHGH 150 575 3 51.7 51.9 75 2-35 Amp 2-C12 7150 7.71 13 15 ea.

HCHGC 175 208 3 60.3 167.3 250 4-60 Amp 2-C62 2175 13.06 41.8 17 ea.

HCHGE 175 230 3 60.3 151.3 225 4-60 Amp 2-C62 4175 11.66 37.8 17 ea.

HCHGG 175 460 3 60.3 75.6 110 2-60 Amp 2-C12 6175 11.66 18.9 17 ea.

HCHGH 175 575 3 60.3 60.5 90 2-50 Amp 2-C12 7175 9.17 15.1 17 ea.

HCHGC 200 208 3 68.9 191.2 300 4-60 Amp 2-C62 2200 14.95 47.8 20 ea.

HCHGE 200 230 3 68.9 172.9 250 4-60 Amp 2-C62 4200 13.54 43.2 20 ea.

HCHGG 200 460 3 68.9 86.4 125 2-60 Amp 2-C12 6200 13.54 21.6 20 ea.

HCHGH 200 575 3 68.9 69.2 100 2-50 Amp 2-C12 7200 10.5 17.2 20 ea.

ELECTRICAL DATA AND UNIT DETAIL SHEET - Table 4

7

HUMIDIFIER COMPONENT LISTING -

Figure J

1. On / Off / Drain Switch

2. LCD Display

3. Power “On” Light

4. Optional Circuit Breaker

5. Service & Fault Light

6. Diagnostic Panel

7. Door Interlock Switch

8. Drain Solenoid Valve

9. Fill Water Inlet Fitting

10. Water Fill Tube Sub-Assembly

11. Red Terminal Connector (Connector

could be black for larger output units)

12. Fill Solenoid Valve

13. Molded Fill Cup

14. Internal Water Hose (Clear) 5/8” ID

15. Unit Specific Wiring Diagram

16. High Water Sensor

17. Operational Instructions

18. Circuit Board

19. Power Distribution Block

20. Current Sensing Transformer

21. Power Transformer

22. Contactor

23. Low Voltage Wiring Harness

24. Unit Identification Tag

25. Door Pivot Release

26. Condensate Return Hose

27. Condensate Return Hose Connection

Fitting From Distributor Pipe

28. Steam Hose Connection Point

29. Cylinder — Specific to Model

30. Diagnostic Panel Calibration Buttons

(Up, Down, Mode, Enter)

31. Bridge Rectifier

1

2

3

5

30

6

7

4

24

8

9

29

11

26

10

12

27

HBDG

HCAG

23

18

22

16

28

17

15

14

21

20

19

13

25

31

8

CONTROLS

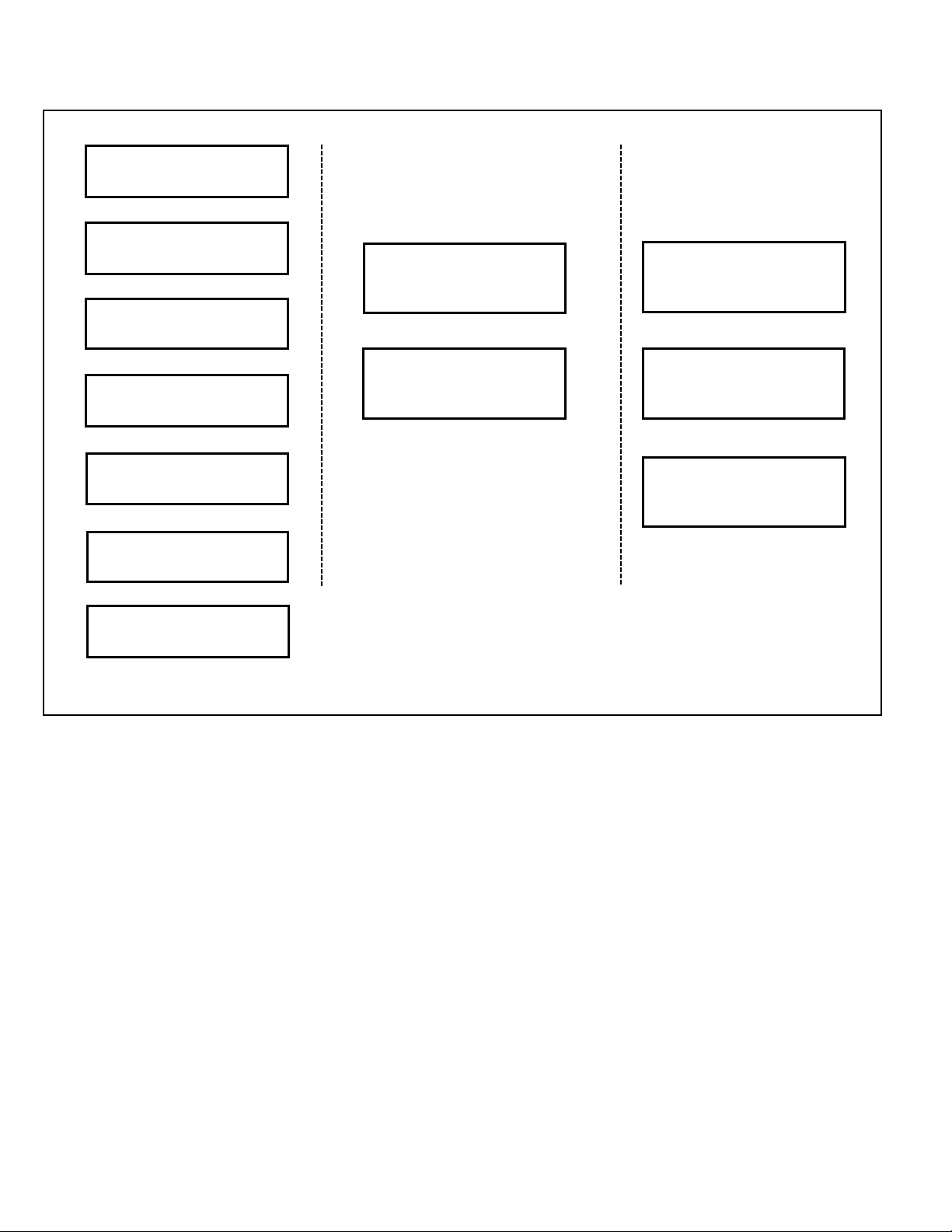

CONTROL OPTIONS - Figure K

CONTROL HUMIDISTAT

If an on-off humidistat is used the humidifier will generate

steam at the preset output rate and cycle on or off as

necessary to satisfy the conditioned area requirements. All

humidifiers are preset at the factory for the maximum rating

of the unit. The maximum output may be easily reset to a

lower limit in the range of 25-100% using the push buttons

on the front of the electronic control panel.

If Carnes proportional humidistat is used the humidifier will

automatically vary the steam output rate in the range of 25100% of the humidifiers maximum rating in response to the

signal from the humidistat. Proportional control provides

less cycling of the humidifier.

Either a wall humidistat or duct mounted humidistat in

the return air may be used. The wall mounted humidistat is

the most common as it allows the setting to be easily

changed to accommodate changing requirements or to

lower the level of relative humidity in the space to prevent

condensation on windows during extremely cold weather. In

applications where it may be desirable to prevent the occupants of a space from changing the setting, a duct mounted

humidistat in the return may be used. This is

normally mounted in the equipment room or in the duct

where it is accessible only to maintenance personnel.

AIR FLOW DETECTION

The humidifier control circuit should include some method

to determine air flow. If the steam distributor pipe is located

in a duct where there is no air flow and the control humidistat is calling for humidity, steam would be discharged into

the duct where it would immediately condense. Air flow may

be detected by several methods. The humidistat circuit may

be interlocked by using a fan relay if the fan is direct driven.

A fan relay is not recommended if a belt driven fan is used

as a broken belt would stop air flow even though the fan

relay was closed.

Among the alternatives are the use of a pressure differential switch that determines air flow by sensing a pressure

differential caused by air movement in the duct. A paddle

type switch is also available to determine air flow. The pressure differential switch is normally the preferred device as it

is less susceptible to erratic operation caused by improper

positioning in the duct system. Paddle switches require

careful positioning in the duct to insure sufficient air flow to

activate the switch. A combination return air duct on-off

humidistat and sail switch is available but care must be

taken during installation to insure proper operation.

CONTROL HUMIDISTAT AIR FLOW DETECTION CONDENSATION

PROTECTION

WALL HUMIDISTAT

PROPORTIONAL CONTROL

CARNES MODEL HXHCG

OR

WALL HUMIDISTAT

ON-OFF CONTROL

CARNES MODEL HXHAA

OR

DUCT HUMIDISTAT

PROPORTIONAL CONTROL

CARNES MODEL HXHCH

OR

PRESSURE

DIFFERENTIAL

SWITCH

CARNES MODEL HXAAE

OR

DUCT HUMIDISTAT

ON-OFF CONTROL

CARNES MODEL HXHAB

AIR

FLOW

SWITCH

CARNES MODEL HXAAF

OR

PROPORTIONAL

HIGH LIMIT

HUMIDISTAT

CARNES MODEL HXHCH

ON-OFF

HIGH LIMIT

HUMIDISTAT

CARNES MODEL HXHAD

OR

TEMPERATURE COMPENSATED

(NEW) ON-OFF HUMIDISTAT

CARNES MODEL HXHAMT

OR

PROPORTIONAL

HIGH LIMIT

HUMIDISTAT (NEW)

CARNES MODEL HXHAN

WALL HUMIDISTAT (NEW)

PROPORTIONAL CONTROL

CARNES MODEL HXHAM

OR

OR

DUCT HUMIDISTAT (NEW)

PROPORTIONAL CONTROL

CARNES MODEL HXHAN

9

CONTROLS

CONTROL CONNECTIONS

IMPORTANT: TURN OFF POWER AT EXTERNAL DISCON-

NECT BEFORE MAKING ANY CONNECTIONS TO PREVENT

POSSIBLE DAMAGE TO ELECTRONIC CIRCUIT BOARD.

1. A 7/8” opening is provided on the bottom of the cabinet.

The control wiring should pass through the opening to

the terminal strip.

NOTE: A built-in transformer provides power for the

control circuit. No outside power supply is required for

the control circuit.

2. If an air flow switch or high limit humidistat is not used

jumpers must be installed before the humidifier will operate.

CONDENSATION PROTECTION

A third device may be desirable to provide condensation

protection in the duct system. A high limit humidistat may be

installed ten feet downstream from the steam distributor pipe. This

humidistat is normally set to 90-95% RH and opens the circuit if

the humidity level in the duct exceeds the set-point. Use of this

device is recommended particularly when the humidifier is used in

applications where cooling air is being humidified or where a VAV

system may throttle back to a point where air flow is insufficient to

absorb the steam being introduced

.

Either an on-off or proportional control high limit humidistat may be

used with Carnes humidifiers. If a proportional humidistat is used

the output of the humidifier will automatically be decreased to

reduce the possibility of condensation. Two proportional humidis

tats may be used to control Carnes humidifiers if desired, one in

the area to be humidified or return duct and another as a high limit

in the supply duct. The humidifier will automatically select the

lowest signal to control the humidifier output.

CONTROL HUMIDISTAT / TEMPERATURE COMPENSATED

If your application has a requirement for an outdoor temperature

compensation feature, the HXHAT control is what would be needed. This control will provide monitoring of RH percentage and

optionally outdoor temperature, automatically adjust RH set-point

as outdoor temperature changes, automatic or manual operating

mode, display RH or outdoor temperature, installed on the duct or

within the space, relay contacts control humidity for on/off control,

can be wired for activation with heating or any time, easy to read

LCD display with blinking RH symbol when humidifier is activated

and outdoor sensor is included.

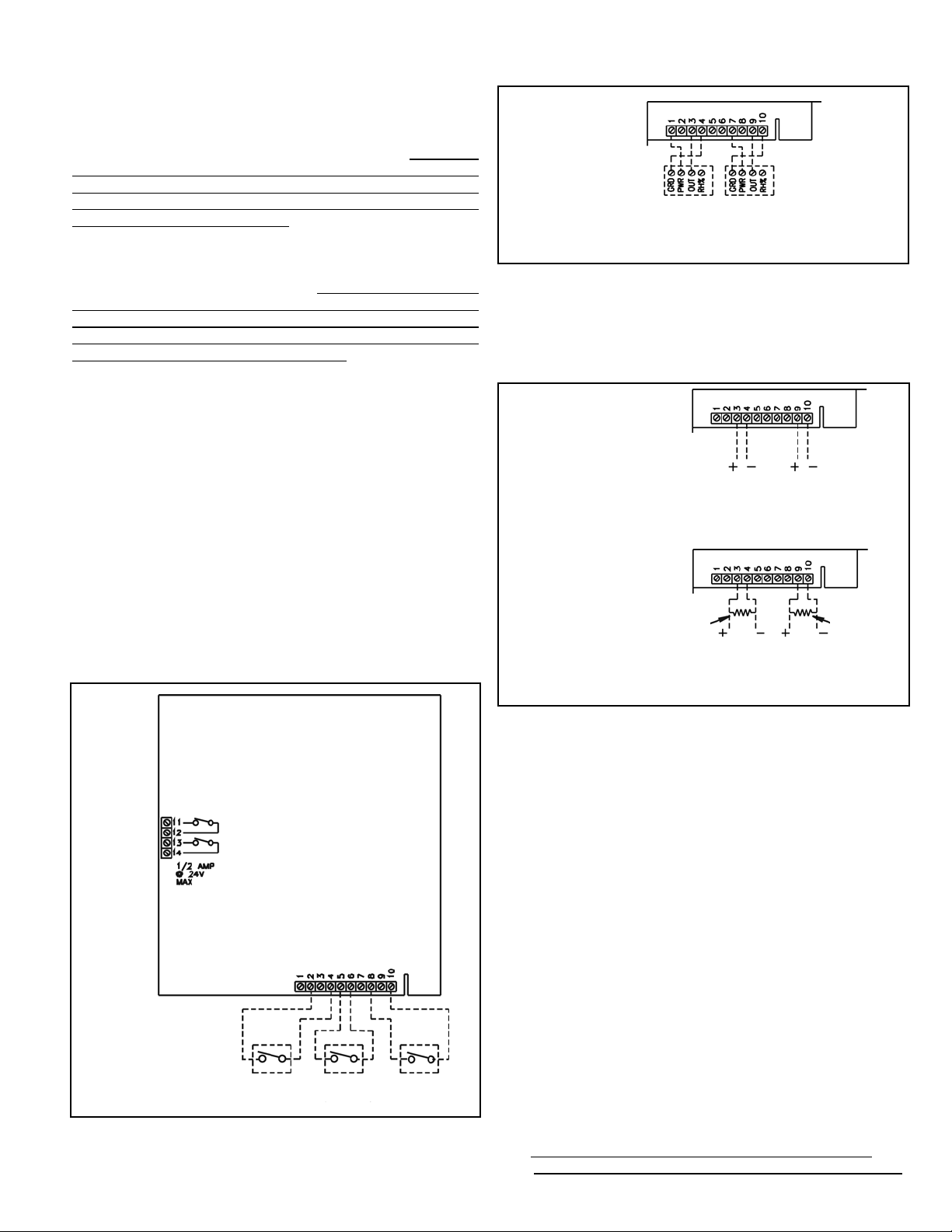

CONTROL CONNECTIONS

Two cylinder humidifiers may be wired for simultaneous or separate

and independent operation. Controls should be connected to the terminals on the electronic circuit board as shown below using No. 18

AWG wire. Avoid running control wiring near high voltage primary

wires, due to the possibility of interference and signal distortion.

Connections shown in Figure L are for typical on-off controls. For

Carnes proportional controls see the diagram Figure M. All

controls are shipped with detailed wiring instructions.

EXTERNAL DDC CONTROL SIGNALS

Carnes humidifiers can also accept a 0-10 volt DC signal to

modulate the output of the humidifier. Polarity must be observed.

Input impedance is 20K ohms. If a 4-20 mA input signal is

provided to the humidifier a 470 ohm 1/4 watt resistor must be

installed as shown below.

EXTERNAL MONITORING

Terminals 11 and 12, shown in Figure L, are provided for indicating operation of the humidifier at a remote location. When the unit

is operating terminals 11 and 12 are closed. Terminals 13 and 14

are provided to indicate the need for service. When the output of

the humidifier is less than 50% of set-point terminals 13 and 14

are closed. Each set of terminals are capable of switching 1/2 amp

at 24 volts maximum.

NETWORKING

If multiple units are required due to high capacity demand (over

200 lbs. per hour, single unit), networking can be done. Units

would be interconnected with parallel signal wiring. This set up is

usually done to facilitate running multiple units from a single signal

source. Other networking requirements please contact factory.

Figure M

Figure N

PROPORTIONAL

HUMIDISTAT

(BY CARNES)

PROPORTIONAL

HI-LIMIT

HUMIDISTAT

(BY CARNES)

0-10 VDC

PROPORTIONAL

SIGNAL

(BY OTHERS)

0-10 VDC

PROPORTIONAL

HI-LIMIT

HUMIDISTAT

(BY CARNES)

4-20ma

PROPORTIONAL

HI-LIMIT

HUMIDISTAT

(BY CARNES)

470 OHM

RESISTOR

(BY OTHERS)

470 OHM

RESISTOR

(BY OTHERS)

EXTERNAL

ON

EXTERNAL

SERVICE

ELECTRONIC CONTROL

CIRCUIT BOARD

ON/OFF

HUMIDISTAT

AIR FLOW

SWITCH

ON/OFF

HIGH LIMIT

HUMIDISTAT

Figure L

1/2 AMP

@ 24V

MAX

4-20ma

PROPORTIONAL

SIGNAL

(BY OTHERS)

Loading...

Loading...