Humidifiers | Steam Humidifiers

COMMERCIAL, INDUSTRIAL

Humidifiers

AND INSTITUTIONAL

STEAM HUMIDIFIERS

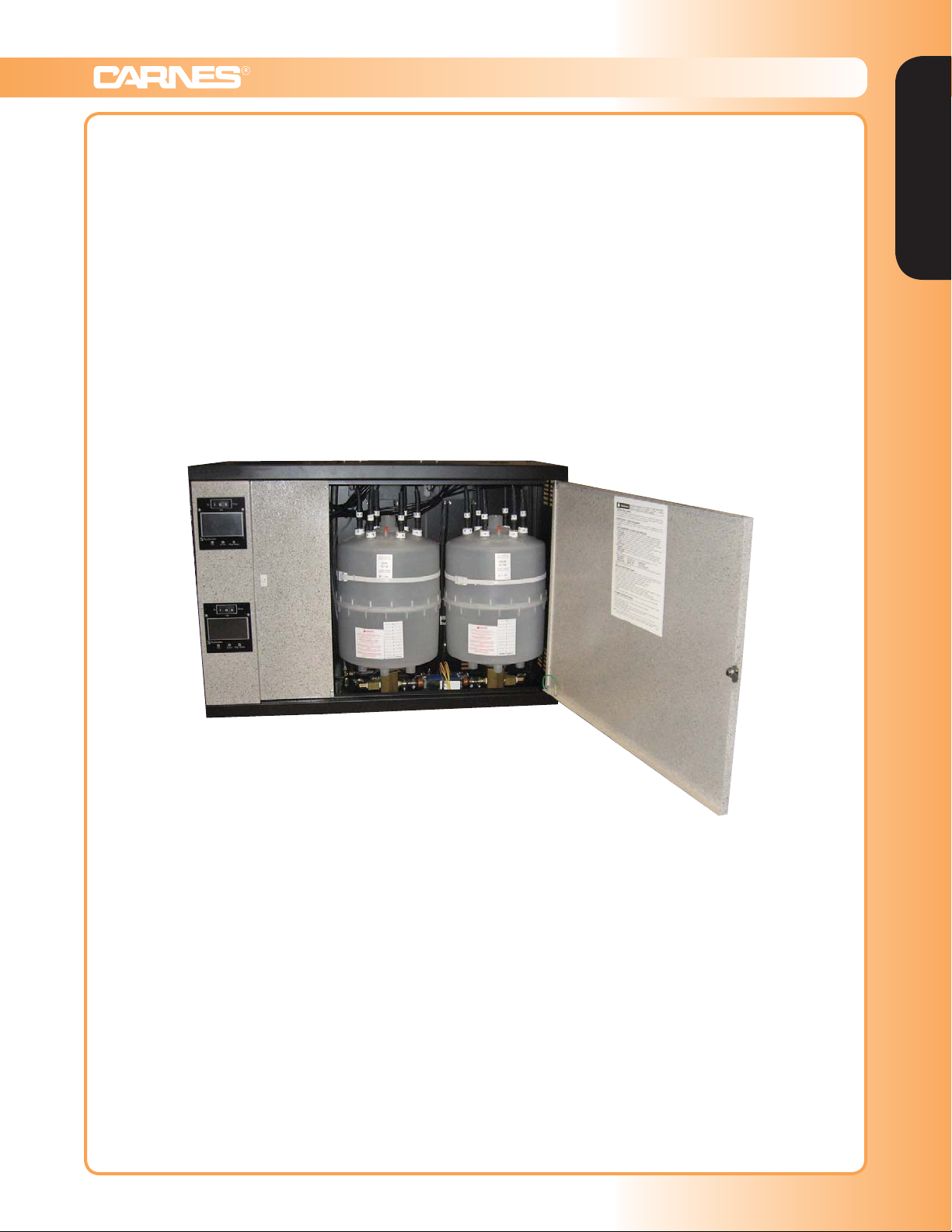

HCHH Shown

www.carnes.com G-1

Humidifiers | Steam Humidifiers

Humidifiers

CARNES MICROPROCESSOR CONTROLLED STEAM HUMIDIFIERS use ordinary

untreated tap water and convert it to mineral free steam for humidity control in commercial,

industrial, institutional and residential applications.

ECONOMICAL

Disposable Cylinders Eliminate Periodic Maintenance for Reduced Maintenance Costs

Fast and Easy Installation

Reliable Electronic Components for Long Life

EFFICIENT

Circuit Board Utilizes Microprocessor to Maximize Energy Conservation

Exclusive Circuit Board Design with Attached True Touchscreen Control Display

VERSATILE

Digital Output on a True Touchscreen Control Display Providing Status and Help Buttons For

Operational Details and Troubleshooting

Capacities up to 200 Pounds of Steam Per Hour Per Single Unit

Utilize any On-Off Humidistat, Carnes Proportional Humidistat or External Signal from DDC Controls

Flexible steam hose

distribution pipe.

Hinged and removable

door provides easy

access for service.

Door lock

prevents

unauthorized

adjustments.

connects to

HBGH Shown

Easy access

“On-Off-Drain”

Switch.

True Touchscreen

control display.

20 gauge metal partition

covers line voltage wiring

for added safety.

Optional internal circuit

breaker available. Please

note: certain units require

circuit breakers per NEC

48 amp guidelines.

Disposable plastic cylinder eliminates

periodic maintenance.

Cut-away used steam cylinder

The simplicity and unique advantages of humidity from

showing mineral deposits.

directly boiling water in disposable cylinders has been

well known since Carnes pioneered the concept in North

America in 1969. Pan type humidifiers require messy, time

consuming cleaning that may require the use of acids.

Electric heating elements in pan type units may also require

replacement. Easily changeable steam cylinders containing

electrodes can be replaced in less than five minutes.

G-2 www.carnes.com

Humidifiers | Displays & Internal Controls

FRONT PANEL DISPLAYS & CONTROLS

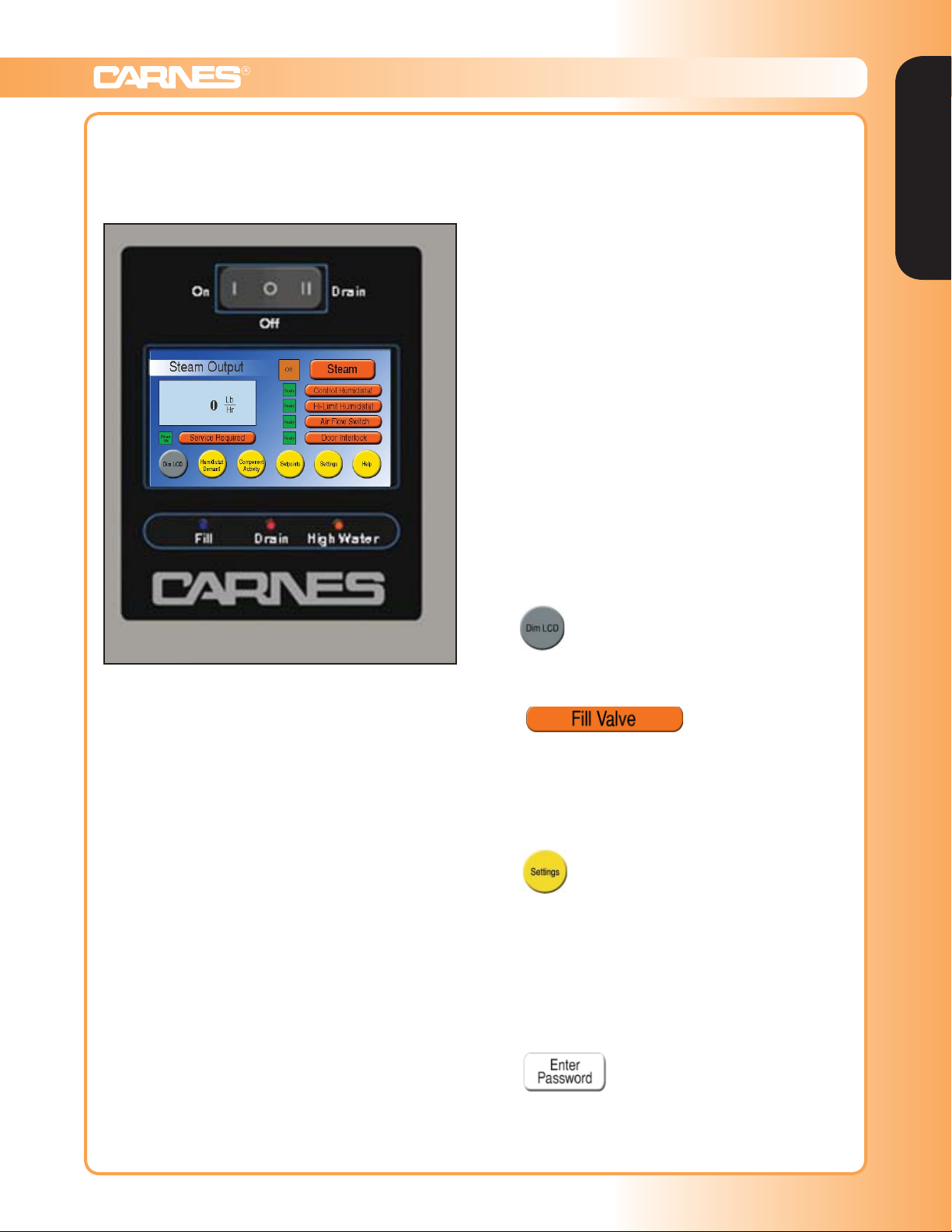

The display on the front panel of the humidifier cabinet contains the “On-Off-Drain” switch, the LCD True

Touchscreen display and the “Fill”, “Drain” and “High

Water” LED’s.

“DRAIN” LED

The DRAIN LED is a red light illuminated when the

Drain Valve is activated. An activated Drain Valve

allows water to drain from the humidifier. An analogous

indicator, and a description of its operation, is offered in

the “Component Activity” menu.

“HIGH WATER” LED

The HIGH WATER LED is an orange light illuminated

when the High Water Sensor is activated. An activated

High Water Sensor indicates that the water has risen to

the maximum allowable level in the cylinder. This can

be a normal situation, particularly if the cylinder is being

filled with mostly unconditioned water. An activated High

Water Sensor can also be a sign that the cylinder is close

to end-of-life and needs replacing, or, in rarer cases, the

cylinder is not conductive enough for the fresh water

entering the humidifier. An analogous indicator, and a

description of its operation, is offered in the “Component

Activity” menu. More information on troubleshooting High

Water situations can also be found through the “Help”

menu on the home screen.

HUMIDIFIER TRUE TOUCHSCREEN MENU PAGES

The humidifier True Touchscreen user interface uses

color conventions to help the user navigate the controls.

The colors of different buttons indicate the following.

1. Gray —

Humidifiers

Figure P

“ON-OFF-DRAIN” SWITCH

In the “On” position the humidifier will operate if all controls are calling for humidity. The “Off” position is used

for seasonal shut down if desired. The “Drain” position

is used to drain water from the steam cylinder for maintenance. The fill solenoid valve will be on whenever the

drain is activated to reduce the drain water temperature.

LCD TRUE TOUCHSCREEN DISPLAY

This LCD True Touchscreen display offers the necessary interface to control and monitor many aspects of

the humidifier. On the home screen is the current steam

output in Lbs./Hr. (or Kg/Hr). To select either is available

in the settings menu. A “Service Required” indicator

and button outlining current service issues, indicators

for the four basic controls necessary for operation

(control humidistat, high limit humidistat, air flow switch and

door interlock), and various buttons which navigate to

other menu pages when pressed are also available

on the home page screen. The menu pages and their

capabilities are detailed further in “True Touchscreen

Menu Pages” section of this document.

“FILL” LED

The FILL LED is a blue light illuminated when the Fill

Valve is activated. An activated Fill Valve allows water

to flow into the cylinder of the humidifier. An analogous

indicator, and a description of its operation, is offered in

the “Component Activity” menu.

Dim LCD is the only gray button. More information is

available in the “home” page description.

2. Orange —

Orange buttons represent the object or subject

described across the button. Most orange buttons

have an indicator next to them, which can change

in color, e.g. green, yellow or gray. Pressing orange

buttons will bring you to a page which describes the

object or subject in question.

3. Yellow —

Yellow buttons navigate a user to a new page

dedicated to a set of functions. For example, the

“Humidistat Demand” button brings the user to a

page that shows what percentage demands both

the Control and High Limit Humidistats are currently

requesting, and details their functions. The bottom

of each page, other than the home screen, has

a square “Back” or “Home” button dedicated to

directing the user back to their previous page.

4. White —

White buttons are used for confirming or entering

data into the touchscreen. For example, they are

used to confirm a change to the “Max Output”

parameter, or entering a password to access the

“Settings” menu.

www.carnes.com G-3

Humidifiers | Displays & Internal Controls

Humidifiers

5. Maize —

Help buttons are used exclusively in the “Help”

page. These help buttons answer frequently asked

questions about the operation, maintenance

and troubleshooting of the humidifier. It is also a

convenient place to look at humidifier electrical data

when an IOM is not available.

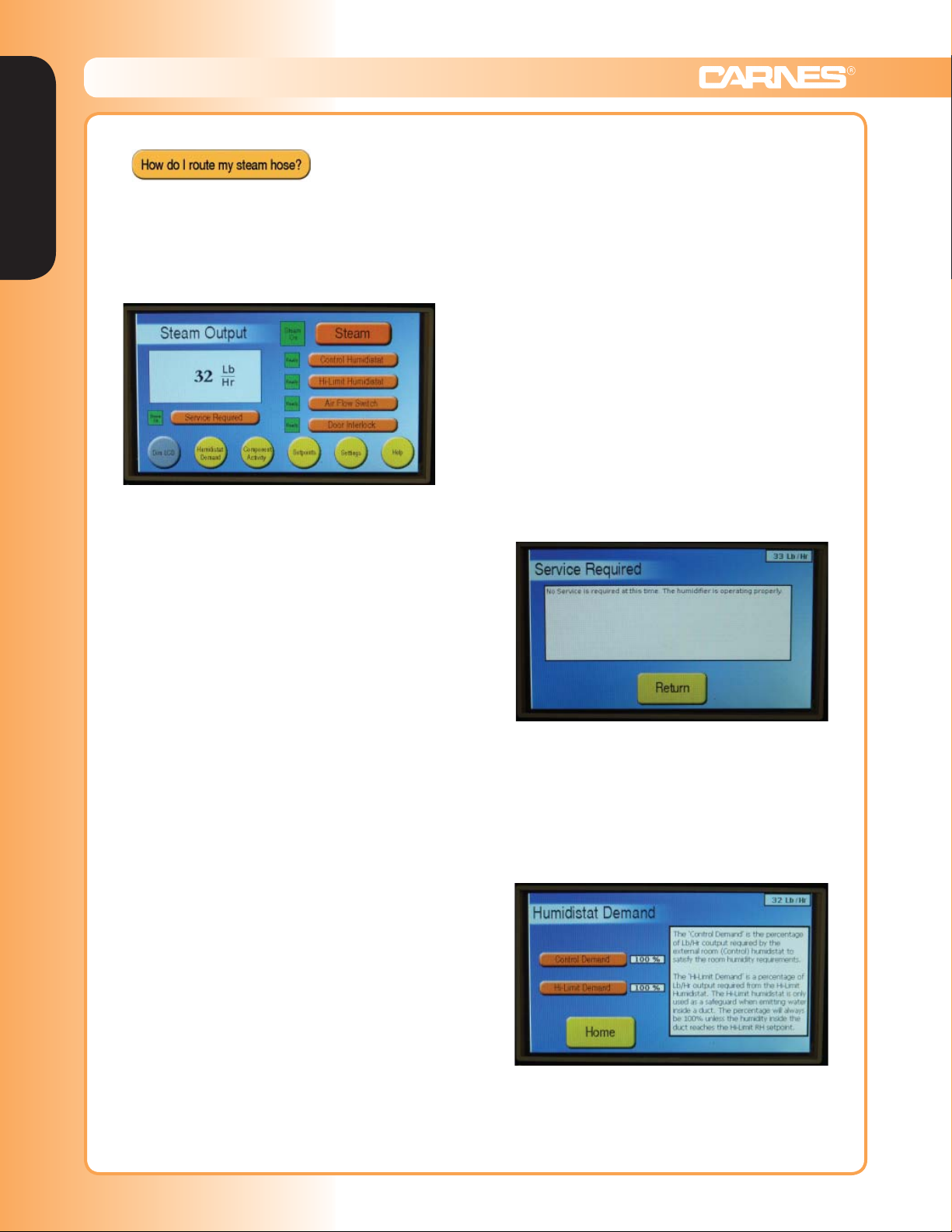

“HOME” PAGE

The home page is the main screen through which most

other pages can be accessed. The large blue square to

the left shows the steam output. The orange and yellow

buttons on the home page are considered “Operational

& Status” indicators. Touching any of these displays will

show dialog explaining the subject or status of that button.

The orange buttons also have indicator boxes to the left

showing actual status. Green shows ready to operate.

1. Dim LCD (gray) - As a power saving feature, press-

2. Humidistat Demand (yellow) - Brings the user to

3. Component Activity (yellow) - Button lists the

4. Setpoints (yellow) - The three setpoints of the unit

5. Settings (yellow) - Any settings of the humidifier,

6. Help (yellow) - Frequently asked questions about

7. Service Required (orange) - Invokes a page that

ing the Dim LCD button will shut the backlight of the

LCD off. Once off, pressing anywhere on the True

Touchscreen will turn the backlight on. The humidifier can also automatically turn off the backlight after

15 minutes. See the “Settings” page for more information on enabling/disabling the Auto-Dim feature.

a page that shows what percentage demands both

the Control and High Limit Humidistats are currently requesting, and further details their functions.

internal components used in the humidifier.

Their respective indicators showing whether the

components are activated or not. From this

page, the user can view more information on the

components and their functions.

are listed on this page. The setpoint is the target

Lb./Hr. output of the humidifier.

e.g. Max Output, Timers or Fan Speed, can be

accessed through this page. This page is password protected. For more information, refer to the

“Settings” page section.

the humidifier can be answered through the Help

page. It is a convenient resource to resolve many

issues quickly and effectively.

describes what service is needed by the humidifier,

if any. Indicator light to the left of the button turns

red when service is needed, and will otherwise

remain green. Refer to the separate “Service

Required” page for more information.

8. Steam (orange) - Explains the status of the “Steam”

indicator light. The humidifier will only produce

steam if the “Steam” indicator light is green. The

indicator will be brown when the On/Off/Drain

switch is in the “Off” position. It will turn yellow if

the switch is in the “On” position, but one or more

of the four basic controls are not satisfied (Control

Humidistat, High Limit, Air Flow, Door Interlock).

The light will turn green if all of the above switches

and controls are satisfied.

9. Control Humidistat (orange) - Explains the

status of the Control Humidistat indicator light,

and also shows the current demand of the Control

Humidistat.

10. High Limit Humidistat (orange) - Explains the

status of the High Limit Humidistat indicator light,

and also shows the current demand of the High

Limit Humidistat.

11. Air Flow (orange) - Explains the status of the Air

Flow switch.

12. Door Interlock (orange) - Explains the status of the

Door Interlock switch.

“SERVICE REQUIRED” PAGE

“SERVICE REQUIRED” PAGE

The “Service Required” page outlines any service issues

that are in need of being resolved. Many issues can be

traced back to variability in water parameters, and often

the solution can be dealt with through the changing of

cylinders or modifying timer values within the “Settings”

page. This page is used to alert the user and direct them

on the right path towards resolution.

“HUMIDISTAT DEMAND” PAGE

The Humidistat Demand page lists both the Control

Demand and the High Limit Demand of the humidifier.

Each demand signal is represented by an orange button,

and next to each button is a numerical box specifying

the percentage of demand each humidistat is currently

calling for.

G-4 www.carnes.com

Humidifiers | Displays & Internal Controls

The Control humidistat, which provides the Control

Demand, is normally the humidistat in the room being

humidified. It is either installed in the room itself or the

return air duct. The High-Limit humidistat, which provides

the Hi-Limit Demand, is a safe-guard humidistat installed

in the supply duct roughly 10-15 feet past the distribution

tube. This humidistat is usually set to a high level (8090%), and will shut down the humidifier if the humidity

gets too high in the supply duct. Without a High-Limit

humidistat properly installed, the supply duct could reach

a humidity level where any steam entering the duct would

readily condense.

Both Control humidistats and High-Limit humidistats

are wired in the same way, only Control humidistats

are wired to port J16 of the circuit board and High-Limit

humidistats are wired to port J17. Both ports have the

same number of pins and connection layout.

When using an on/off humidistat, the percentage

should be either 100% or below 20%. In this case the

control is either calling for full output or no output. On-Off

humidistats are dry-contact switches. They will have two

wires; each connected to pins 2 and 4 (in no particular

order/polarity).

For a proportional humidistat, any percentage value is

possible between 0% and 100%. In this case the humidifier can be modified to output any fraction of its max

output. If the proportional control falls to 20% or below,

the humidifier is shut off. The input signal of a proportional

humidistat must be of the 0-10V DC variety. Proportional

humidistats will have three wires, with ‘power’ going to

pin 1, ‘signal’ to pin 3, and ‘ground’ to pin 4.

In lieu of a humidistat, a DDC signal from a building

management system may also be used. Here, the ‘signal’

should be connected to pin 3, and ‘ground’ to pin 4. In

this case, ‘power’ can be ignored. A DDC signal must be

of a 0-10V DC variety, though a 4-20 mA control signal

can be converted to a 0-10V signal by adding a 470 Ohm

resistor between the ‘signal’ (pin 3) and ‘ground’ (pin 4).

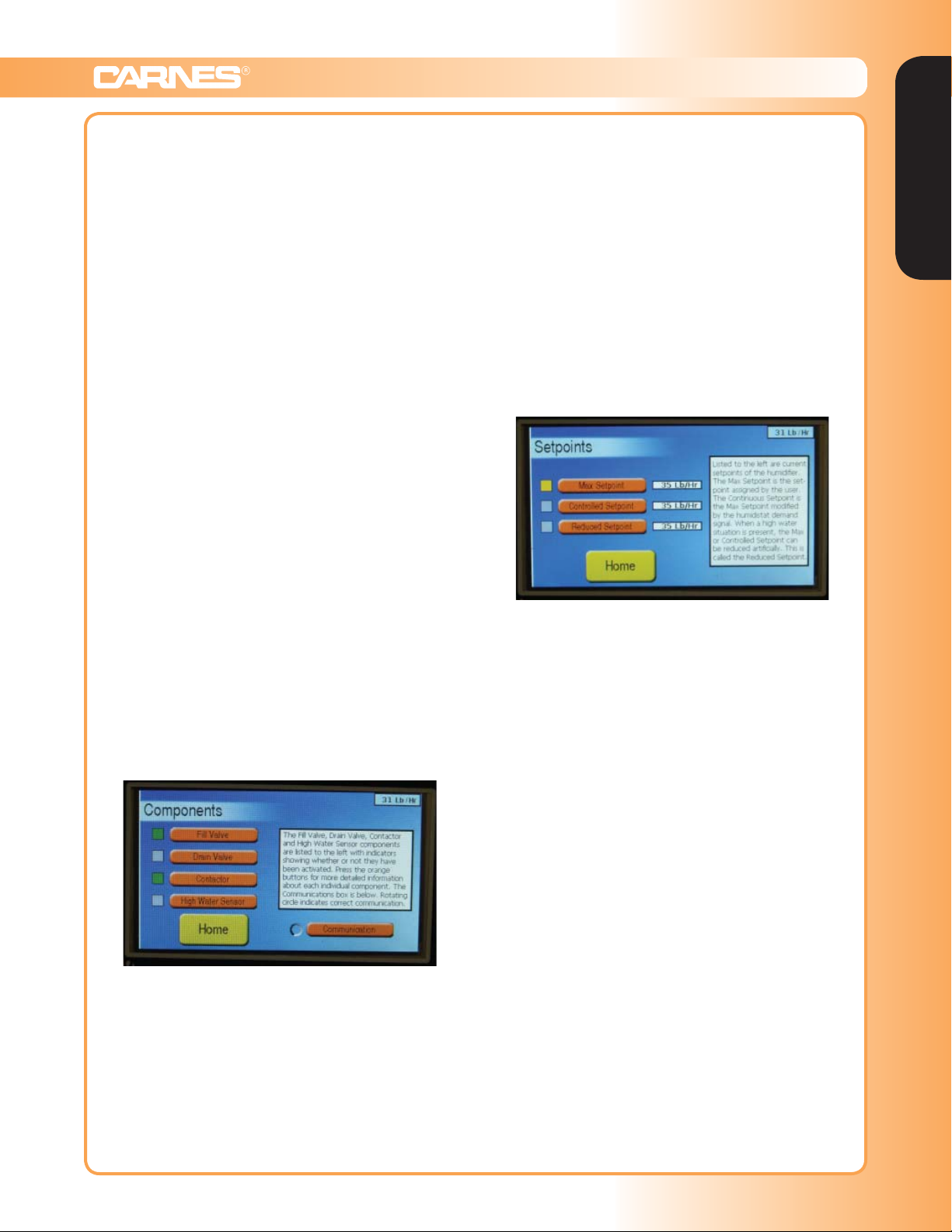

“COMPONENT ACTIVITY” PAGE

The Component Activity page lists all internal components that can switch on and off during operation. This

includes the Fill Valve, Drain Valve, Contactor, and High

Water Sensor. Each orange button in the component

list is accompanied by a colored indicator representing

whether or not the component is currently ‘on’. Green

indicates that the component is ‘on’, whereas gray

indicates the component is ‘off’. The Fill Valve is on

when the unit is either filling or draining the cylinder.

The Drain Valve is on when the humidifier is draining

the cylinder. The Contactor is on when the humidifier is

producing steam. The High Water Sensor is on when

the humidifier has identified a high water situation. When

in a high water situation, the fill valve is disabled for 5

minutes. At the end of 5 minutes the high water sensor

light will go out, the fill valve will open, if there is a call for

more humidity, and unit will continue normal operation.

High water sensors can be cumulative depending on the

condition of the water.

The other item present on this screen is the

Communication button. The Communication button has

a rotating indicator that represents whether the True

Touchscreen controller on the circuit board is properly

communicating with the microcontroller. If this icon is not

rotating and has a red ‘X’ through it, the information on

the screen is invalid and you should contact the factory.

“SETPOINTS” PAGE

The Setpoints page displays the setpoints (the target

steam output of the humidifier) associated with the unit.

There are three different setpoints, but only one setpoint

is active at any given time. Each setpoint is accompanied

by the current value of the setpoint to the right, and an

indicator that represents its status. For all setpoints, the

following colors represent the status of the setpoints:

Gray – The setpoint is inactive because it is not

currently necessary.

Green – The setpoint is active, and the humidifier is

producing steam at or above the setpoint value.

Yellow – The setpoint is active, but the humidifier is

producing steam below the setpoint value.

Yellow/Black X – The setpoint is inactive because it is

being overridden by a setpoint with a higher priority.

The three different types of setpoint are as follows: The

Max Setpoint is the user-specified setpoint active when

no external controls or internal reduction is taking place.

The Max Setpoint is always modifiable via the “Max

Output Adjust” within the settings menu. The Controlled

Setpoint is the setpoint when a humidistat (Control or

High Limit), reduces the target output of the humidifier

due to changing room requirements. The Reduced

Setpoint is active when the unit requires a reduction in

output due to a high water situation.

The setpoints have the following priorities: The Reduced

Setpoint has the highest priority and always overrides the

Controlled Setpoint and the Max Setpoint when active.

The Controlled Setpoint has the next highest priority, and

always overrides the Max Setpoint. It should be noted

that the Reduced Setpoint is always lower than or equal

to the Max Setpoint (or Controlled Setpoint, if active),

and the Controlled Setpoint is always lower or equal to

the Max Setpoint.

Humidifiers

www.carnes.com G-5

Humidifiers | Displays & Internal Controls

Humidifiers

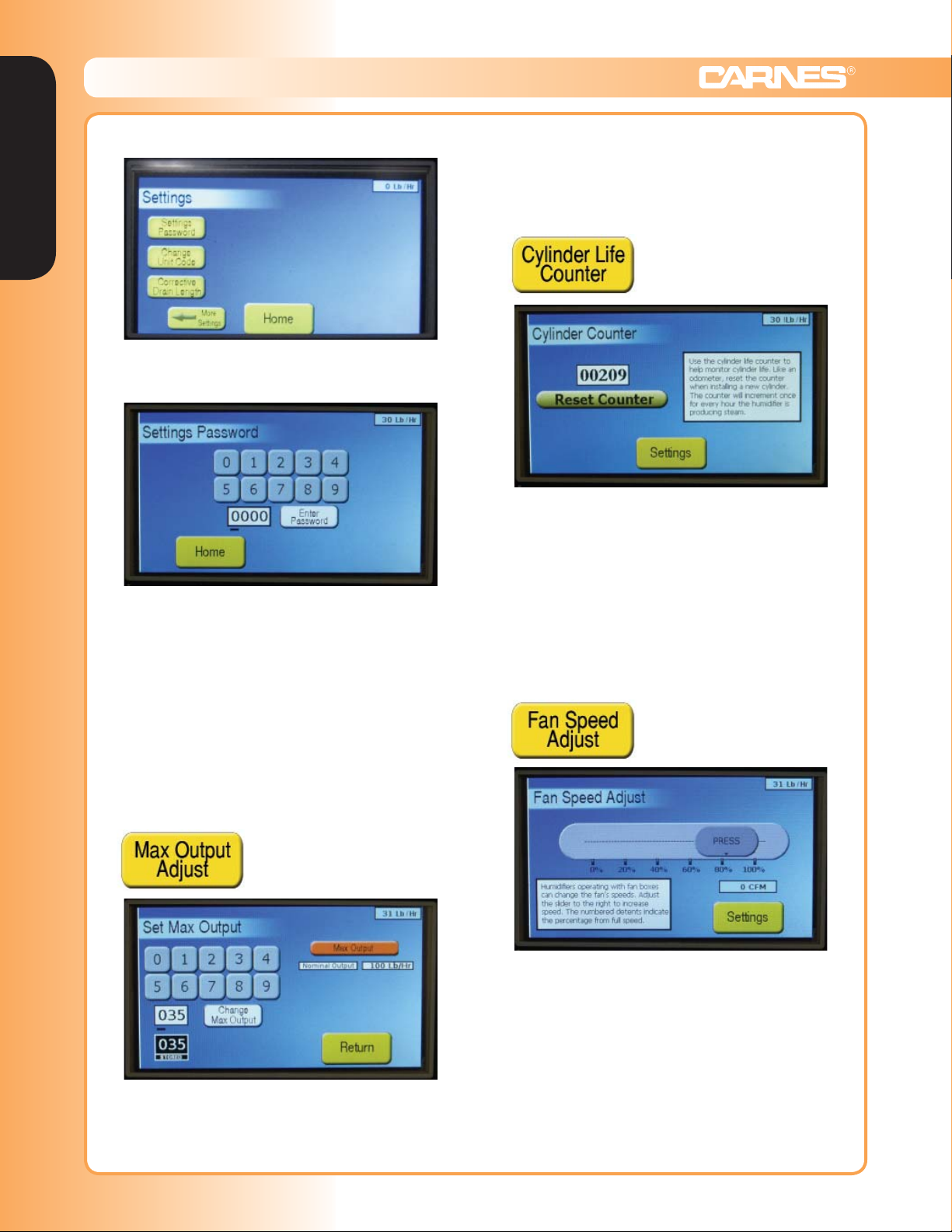

“SETTINGS”

The Settings menu is the page where all operational

values can be set. It is password protected by default,

with a default password of ‘1212’.

The password can be disabled under the ‘Settings

Password’ on the second Settings page. See ‘Settings

Password’ section for more details.

of the humidifier. The Maximum Output value, when

changed, also changes the Max Setpoint value on the

Setpoints page.

Cylinder Life Counter –

This page consists of a counter where the user can

monitor the life, in hours, of the cylinder. When changing

a cylinder, press the ‘Reset’ button on this page to reset

the timer. The Cylinder Life Counter only counts the

amount of actual runtime of the cylinder (the time when

the contactor is pulled in). The counter value is saved

even when the humidifier is powered down. The national

average cylinder life is about 1150 hours, but this can

vary greatly depending on individual water conditions.

Any adjustment made to any setting can be done ‘on-thefly’. Which means when a change occurs, the humidifier

will react accordingly without the need of shutting off the

unit or even stopping steam output. In general, any page

within the True Touchscreen system can be accessed,

monitored, or changed ‘on-the-fly’.

Max Output Adjust –

This page adjusts the Maximum Output of the humidifier.

The Maximum Output can be adjusted lower from the

nominal output value of the unit (set at the factory). The

unit cannot be set lower than 20% of the nominal value

Fan Speed Adjust –

This page consists of a slider bar that can change the

speed of the fans when the humidifier is connected to

an optional blower box. This slider bar will not affect the

operation of the humidifier if no blower box is attached.

The bar can change the speeds of the fans from 0 to

100% of the max fan speed. Also displayed on this page

is an estimate of the current fan air output, in Cubic Feet

per Minute (CFM). This adjustment is particularly useful

if the humidifier is of a smaller capacity, and less noise

from the fans is appreciated.

G-6 www.carnes.com

Humidifiers | Displays & Internal Controls

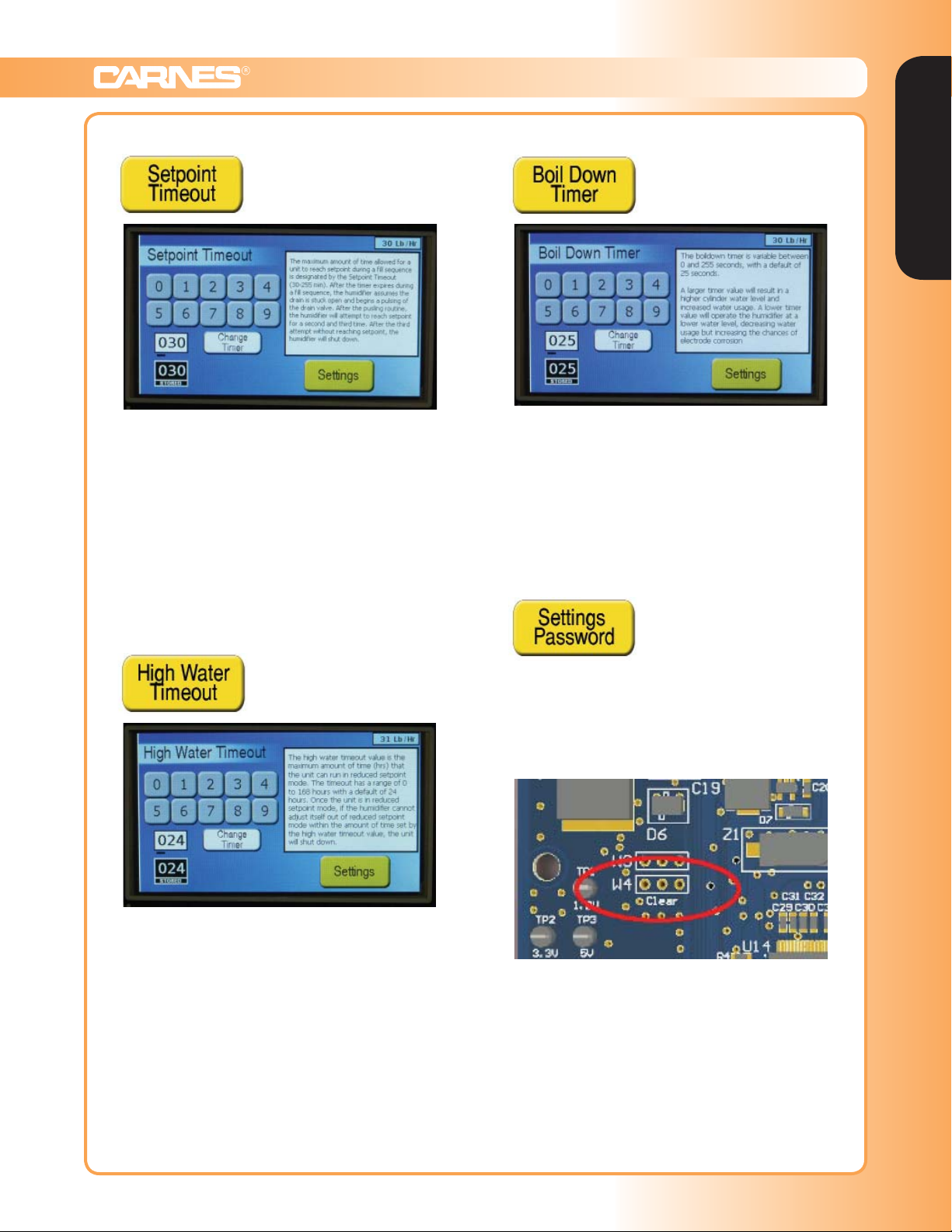

Setpoint Timeout –

This page is where the Setpoint Timeout value is set. The

maximum amount of time allowed for the unit to reach

setpoint during a fill sequence is designated by the

Setpoint Timeout. Its default value is 30 minutes, but

can be set as high as 255 minutes. After the timer

expires during a fill sequence, the humidifier assumes

the drain valve is stuck open (due to sediment buildup),

and begins pulsing the drain valve to attempt to unclog

it. After the pulsing routine, the humidifier will attempt to

reach setpoint for a second and third time. After the third

attempt without reaching setpoint, the unit will shut down.

Boil Down Timer –

Humidifiers

This page is where the Boil Down Timer is set. The Boil

Down Timer is variable between 0 and 255 seconds,

with a default value of 25 seconds. Setting the Boil Down

Timer higher will result in an increased water level, and

less-conditioned water. This may be helpful in reducing

low water level induced arcing and corrosion of cylinders.

More water is consumed by the humidifier when the Boil

Down Timer value is increased.

Settings Password –

High Water Timeout –

This page is where the High Water Timeout value is

set. This is the maximum amount of time allowed for

the unit to run in a ‘Reduced Setpoint’ mode (See

Setpoints page). The timeout has a range from 0 to 168

hours, with the default being 24 hours. If the humidifier

setpoint is artificially reduced due to a high water situation, the humidifier will continue to run. If the humidifier

cannot work it’s way back up the normal max/controlled

setpoint, the humidifier will shut down after the High

Water Timeout value elapses.

This page is where the password for the settings menu

can be changed or disabled.

If the password for the Settings menu is forgotten, it can

be reset. To do this, remove power to the humidifier,

move the jumper on W4 from pins ‘1 and 2’ to ‘2 and 3’,

and power the unit back on.

Return the jumper to pins ‘1 and 2’ afterward. Pins ‘1 and

2’ are to the left, and pins ‘2 and 3’ are to the right.

The different yellow buttons on both setting pages allow

for the changing of different values. Below is a brief

summary of each, and more information can be accessed

within the page itself.

www.carnes.com G-7

Humidifiers | Displays & Internal Controls

Humidifiers

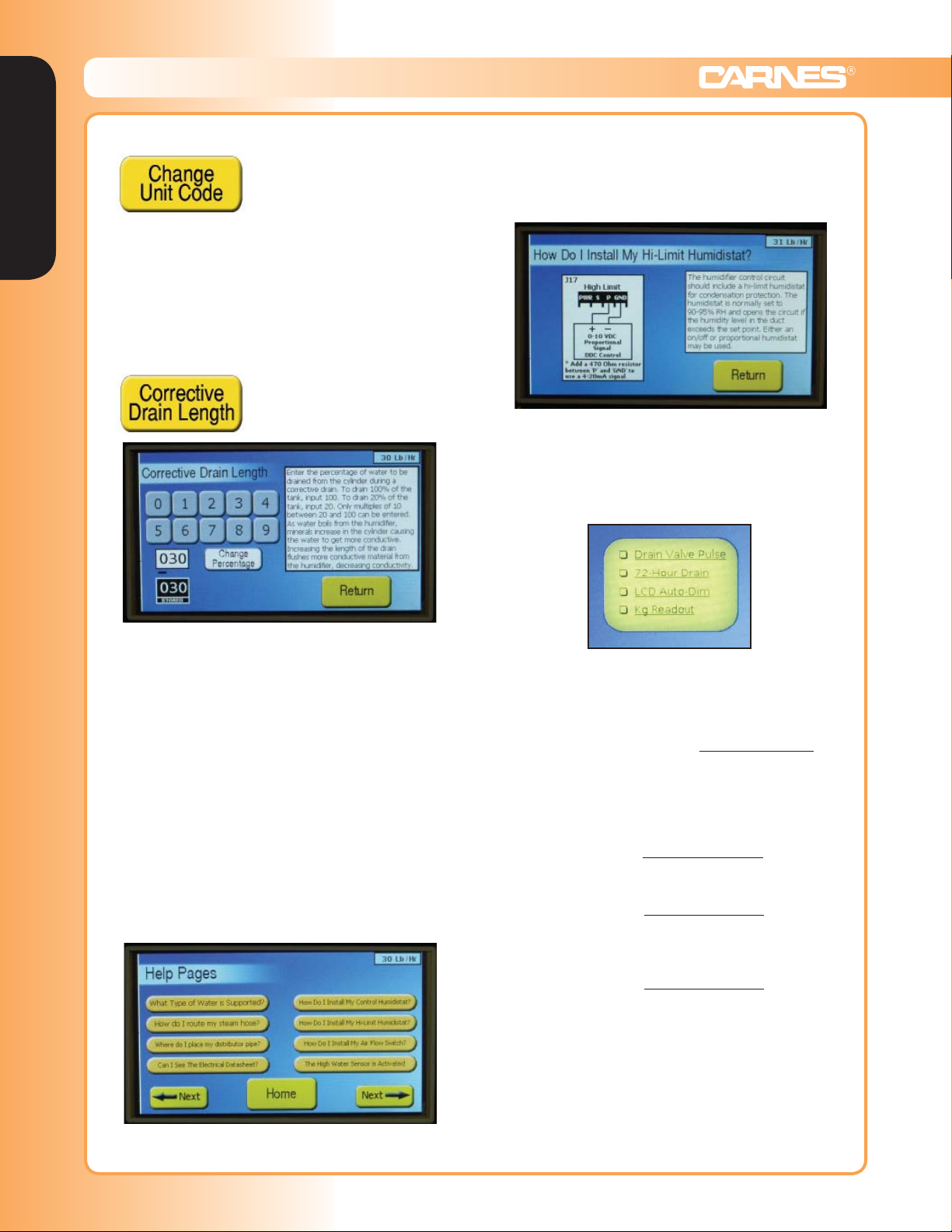

Calibration Password –

This page is where the Humidifier Unit Code, the four

digit number identifying the humidifier, is programmed

into the unit. This page is password protected, and

number should not be modified by the end user. Contact

the factory if further information is needed.

Corrective Drain Length –

The help pages consist of maize color buttons labeled

with questions. When a button is pressed, information

will be given answering and/or giving information about

the subject in question. A basic help page consists of text

and/or diagrams to help the user through basic problems.

For example, in the picture above the question of how to

install a high limit humidistat is answered with a diagram

and corresponding text. Some pages consist of more

buttons to help guide a user through different processes.

These buttons can be used and referenced as needed.

Checkboxes –

This page is where the Corrective Drain Length is set.

This value represents how much water should be drained

from the cylinder when the humidifier senses a corrective drain is needed. As water boils from the humidifier,

minerals increase in the cylinder causing the water to

get more conductive. Increasing the length of the drain

flushes more conductive material from the humidifier,

decreasing the water conductivity.

The input here is a percentage value. To set the

Corrective Drain Length to drain 20% of the cylinder

during a corrective drain, input 020. To drain all of the

tank, input 100. 30 is the default value, and only multiples

of 10 between 20 and 100 can be entered.

“HELP”

There are a few operational options that do not need

separate pages, and therefore are only enabled/disabled via checkboxes on the main Settings Page. Their

functionality is described as follows:

The Drain Valve Pulse option is enabled by default. This

option allows the drain valve to pulse when the humidifier executes a corrective drain. This actuates the water

within the drain piping, allowing for minerals buildup to

be discharged more easily. Enabling this option will make

the unit noisier whenever a corrective drain is executed.

The 72-Hour Drain is disabled by default. This option,

when enabled, allows the humidifier to drain the cylinder

completely after 72 hours of idle operation.

The LCD Auto-Dim is disabled by default. This option,

when enabled, will automatically turn off the backlight of

the LCD after 15 minutes of idleness. This feature can

save on energy consumed.

The Kg./Hr Readout is disabled by default. This option,

when enabled, will turn the steam readout on home page,

and in the upper right hand corner of other pages, into

Kg/Hr instead of Lb/Hr.

G-8 www.carnes.com

Humidifiers | Steam Humidifiers

APPLICATIONS

COMFORT

Temperature and relative humidity affect the comfort and

well being of all living things. High temperatures require

low humidity to maintain comfort conditions, while low

temperatures can more easily be tolerated at high

relative humidity. Humidification occurs when air is

moisturized by a humidification unit or when hygroscopic

materials (materials containing moisture) lose moisture

to drier air. Proper humidification is widely accepted as

healthy, minimizing employee illness and lost work time.

MATERIALS STORAGE

Paper, fabrics, wood, plastic, chemicals and most other

materials are hygroscopic. Their water content depends

on the humidity of the air around them. If air is too dry,

these substances lose moisture until an equilibrium is

reached between hygroscopic materials and the air.

PROCESS

Process operations, such as data processing areas, are

affected by two major humidity factors: hygroscopic

material and generation of static electricity.

Hygroscopic material used in the process influences

material weights, dimensions and workability.

Static Electricity can totally disrupt high speed process

operations as found in a data processing center, paper or

film handling business. Created by friction between two

substances, static electricity can be prevented by proper

humidification of the process environment.

RECOMMENDED TEMPERATURE AND HUMIDITY

RANGE - Table 1

APPLICATION TEMP F° RH %

Computer Rooms 72+2 50+5

Office Buildings 70-74 20-30

Libraries & Museums 68-72 40-55

Archival Libraries & Museums 55-65 35

Art Storage 60-72 50+2

Stuffed Animals 40-50 50

Bowling Centers 70-74 20-30

Health Facilities

Full Term Nursery 75 30min.-60max.

Special Care Nursery 75-80 30min.-60max.

Patient Rooms 75 30

Intensive Care 75-80 30min.-60max.

Operating Rooms 68-76 50min.-60max.

Recovery Rooms 75 50min.-60max.

Lasik Eye Centers

Electrical Instrument Mfg. 70 50-55

Fur Storage 40-50 55-65

Photo Film Darkroom 70-72 45-55

Photo Print Darkroom 70-72 45-55

Photo Drying Room 90-100 35-45

Photo Finishing Room 72-75 40-55

Cellophane Wrapping 75-80 45-65

Animal Laboratories

Mouse, Rat 64-79 40-70

Cat 65-85 30-70

Dog 65-85 30-70

Primate 65-84 30-70

Clean Rooms 67-77 40-55

Printing Plants

Lithography 76-80 43-47+2

Rotogravure 45-50+2

Collotype 80+2 85+2

Platemaking 75-80+2 45+2

Telephone Terminal Rooms 72-78 30-40

Radio and TV Studios 74-78 30-40

Reprinted with permission of the American Society of Heating, Refrigerating

and Air Conditioning Engineers, Inc., Atlanta, GA 30329.

+ = plus or minus

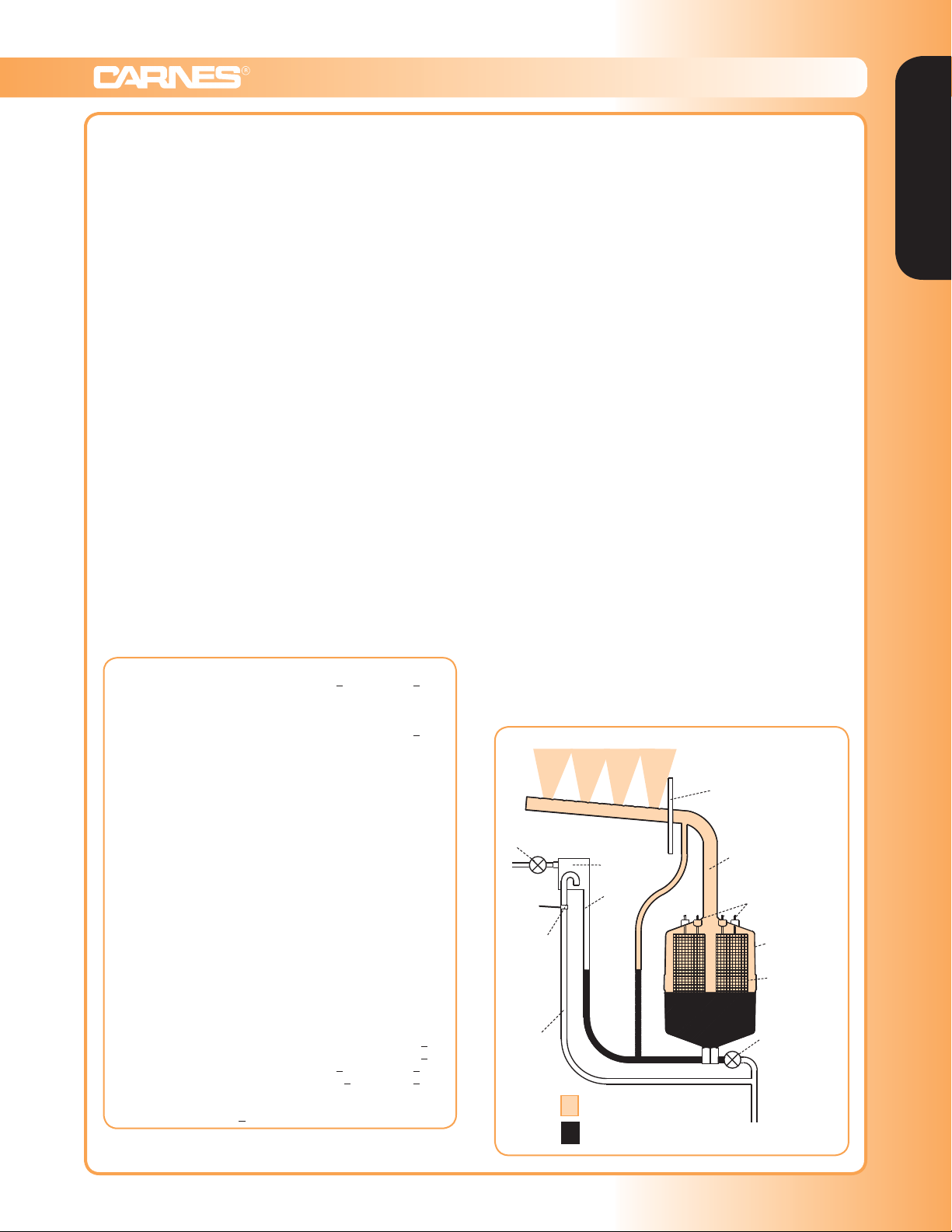

OPERATION

Upon a signal from external controls the circuit board

opens a fill solenoid valve, allowing water to flow across

an air gap into a standpipe. The standpipe provides a

column of water to be fed into the cylinder using gravity.

The air gap prevents back flow into the water supply

and prevents the cylinder from becoming a pressure

vessel. The steam cylinder operates at a pressure of

approximately 1/2 psi.

The circuit board also closes a power contactor allowing

current to flow to vertical electrodes sealed inside the

cylinder. Current flows between the electrodes using

minerals in the water as a conductor. The water is

heated to boiling and converted to steam which leaves

the cylinder through the flexible steam hose which is

connected to the steam distributor pipe.

The circuit board reacts to current flow between the

electrodes and automatically opens the fill solenoid valve

when more water is required to maintain the desired

output rate, and closes when the desired rate is

reached. The operation of the drain solenoid valve

is automatically controlled by the circuit board which

responds to any changes in water conditions and drains

the required quantity of water to provide stable operation

and long cylinder life.

As mineral deposits build up within the cylinder the water

level will slowly rise to contact clean electrode surfaces

to maintain the desired steam output rate. When mineral

deposits have covered all available electrode surface

areas, current flow will be reduced to a level where the

desired steam output cannot be reached and the service

light will signal the need for maintenance. When the

cylinder is filled with minerals it is easily changed in less

than five minutes.

Figure A

Steam

Distributor

Pipe

Fill

Solenoid Valve

Air Gap

Stand

Pipe

Non Contact

High Water

Sensor

Overflow

Tube

STEAM

WATER

Steam

Hose

From Power

Contactor

Cylinder

Vertical

Electrodes

Drain

Solenoid

Valve

To Drain

Humidifiers

www.carnes.com G-9

Humidifiers | System Design Consideration

Humidifiers

LOCATING THE HUMIDIFIER

Locate the humidifier cabinet level and plumb on a

surface as close to the steam distributor as possible at a

convenient height for servicing. Allow 1” or more on the

sides for ventilation and 16” from the bottom of the unit to

the floor to allow for drain connections. Allow 14” in front

of cabinet for door opening (Figure B).

The humidifier must never be located outside or where

it may be exposed to freezing temperatures unless a

heated, ventilated weatherproof enclosure by others is

provided. Do not mount humidifiers on a hot or vibrating

surface.

STEAM DISTRIBUTOR PIPE LOCATION

Each steam cylinder requires a separate distributor

pipe, steam hose and condensate return line. A cylinder

may supply more than one distributor pipe by using an

accessory “T” fitting but the output cannot be controlled

separately. In a typical installation the humidifier is

located below the duct as shown in Figure B. The

distance between the humidifier cabinet and the steam

distributor should be the minimum distance possible.

Refer to Table 5 for maximum length that may be

installed, based on static pressure to provide the most

effective and efficient humidification.

The maximum length of steam hose that may be installed

as shown in Figure B is 12 feet. For steam hose lengths

over 12 feet refer to Figure C. A drain “T” must be used to

remove condensation that occurs in steam hose lengths

over 12 feet. It is preferable to have the steam hose rise

vertically from the cabinet and then slope downward

to the distributor pipe as shown. If sufficient headroom

is not available it is possible to install with an upward

slope but the rise should be 2” in 12” to allow proper

condensate drainage and steam flow.

Figure C

Figure B

In a vertical duct with either upward or downward

air flow the distributor pipe should be installed

horizontally (Figure D), with output holes up.

Figure D

If multiple pipes are used they should be staggered as

shown (Figure E).

Figure E

Air Flow

MAXIMUM STEAM HOSE LENGTH

Table 5

Duct Static

Pressure “w.g.”

Maximum Steam

Hose Length (Ft.)

0 1 2 3 4 5

40 35 30 25 15 10

G-10 www.carnes.com

Humidifiers | System Design Considerations

STEAM DISTRIBUTOR PIPE LOCATION

(Continued)

Steam distributor pipes must be located on a plumb

surface so condensate that forms will run back into the

return line. The pipe should be located in the center

of the duct to insure even distribution of steam into

the airstream. A minimum clearance of 4” must be

maintained between the top of the duct and the distributor pipe.

The steam distributor pipes are usually located in the

supply duct downstream of the fan. When installed in

packaged units the distributor should be mounted just

downstream of the fan discharge.

It is important to locate the distributor as far upstream as

possible from any obstructions in the ductwork so that

air can absorb moisture before it impinges on a surface

and accumulates. There must be a minimum of six (6)

feet between the distributor and any fans, coils, filters,

dampers, elbows or outlets downstream to reduce the

possibility of condensation.

It may be possible to minimize the absorption distance

by using multiple distributor pipes. Duct air temperatures

below 50-60°F may require a condensate drain pan

supplied by others below the steam distributor pipe.

The steam distributor pipe may be located below the

humidifier if the installation is made in accordance with

Figure F. A trap may be necessary to prevent steam from

flowing back through the condensate return line when

hose goes directly to common drain.

Figure F

must be used to connect the cylinder in the humidifier

to the copper tube and another short length to connect

the copper tube to the distributor pipe. Size 3/4” copper

tube can be used with steam cylinders having output

rates up to 30 pounds per hour. Size 1-1/2” copper tube

should be used with steam cylinders over 30 pounds per

hour. Length restrictions shown in Table 5 also apply to

installations where copper tube is used and any 90°

elbows add approximately three feet of equivalent length.

Proper inclines of hard tubing is necessary for good

performance and operation.

WATER SUPPLY REQUIREMENT

Carnes humidifiers will operate at water supply pressure

from 20 to 120 psi and maximum water temperatures of

140°F. Water piping must be sized to allow the minimum

flow rate shown in Table 6. This table does NOT indicate

water consumption, only minimum flow rates. Actual

consumption is determined by steam generated and

water drained during the automatic or manual drain cycle.

Table 6

Model Minimum Flow Rate GPM

H_AH 18 .3-.5 gpm

H_DH 18 .3-.5 gpm

H_GH 24 .4-.7 gpm

H_HH 48 .8-1.0 gpm

In certain areas with extreme water conditions it may

not be possible to operate the humidifier at all voltages.

Table 7 shows acceptable water conductivity, measured

in micromhos, in relation to the primary supply voltage.

Water conductivity may be determined by contacting

the local water utility or sending a six ounce sample to

Carnes for a free analysis. Deionized water or water

treated by a reverse osmosis process may have conductivity too low to operate. It may be possible to use a water

softener to treat the water but contact the factory before

installing the equipment.

Humidifiers

ACCEPTABLE CONDUCTIVITY RANGES

(Micromhos) Table 7

VOLTAGE H_AH H_DH H_GH H_HH

Min. 50 - - 120 Max. 1300 - - Min. 50 50 50 50

It is very important that both the steam hose and condensate return line be installed so that sags and dips are

prevented. The steam is at very low pressure and it

cannot overcome resistance caused by water standing in

the steam hose. Water accumulating in sags in the return

line will restrict the flow and may cause water to backup

and enter the duct from the distributor pipe.

If it is difficult to install the steam hose to prevent sags,

it is recommended that copper tube be used as a

substitute. If copper tube is used, a minimum of one

inch of insulation must be applied to prevent excessive

condensation. A short length of steam hose

208 Max. 1300 1300 1300 1300

Min. 50 50 50 50

230 Max. 1300 1300 1300 1300

Min. 50 50 50 277 Max. 1300 1300 1300 Min. 50 50 50 50

380 Max. 1300 1100 1600 1600

Min. 50 50 50 50

415 Max. 1300 1100 1600 1600

Min. 50 50 50 50

460 Max. 1300 1100 1600 1600

Min. 50 50 50 50

575 Max. 1100 900 1250 1250

www.carnes.com G-11

Humidifiers | Controls

Humidifiers

CONTROL OPTIONS - Figure G

CONTROL HUMIDISTAT AIR FLOW DETECTION CONDENSATION

PROTECTION

TEMPERATURE COMPENSATED

WALL HUMIDISTAT

PROPORTIONAL CONTROL

CARNES MODEL HXHCG

OR

WALL HUMIDISTAT (NEW)

PROPORTIONAL CONTROL

CARNES MODEL HXHAM

OR

WALL HUMIDISTAT

ON-OFF CONTROL

CARNES MODEL HXHAA

OR

DUCT HUMIDISTAT

PROPORTIONAL CONTROL

CARNES MODEL HXHCH

OR

DUCT HUMIDISTAT (NEW)

PROPORTIONAL CONTROL

CARNES MODEL HXHAN

OR

DUCT HUMIDISTAT

ON-OFF CONTROL

CARNES MODEL HXHAB

OR

(NEW) PROPORTIONAL or

ON-OFF HUMIDISTAT

CARNES MODEL HXHAMT

PRESSURE

DIFFERENTIAL

SWITCH

CARNES MODEL HXAAE

OR

AIR

FLOW

SWITCH

CARNES MODEL HXAAF

DUCT ON-OFF

HIGH LIMIT

HUMIDISTAT

CARNES MODEL HXHAD

OR

DUCT PROPORTIONAL

HIGH LIMIT

HUMIDISTAT

CARNES MODEL HXHCH

OR

DUCT PROPORTIONAL

HIGH LIMIT

HUMIDISTAT (NEW)

CARNES MODEL HXHAN

CONTROL HUMIDISTAT

If an on-off humidistat is used the humidifier will generate

steam at the preset output rate and cycle on or off as

necessary to satisfy the conditioned area requirements.

All humidifiers are preset at the factory for the maximum

rating of the unit. The maximum output may be easily

reset to a lower limit in the range of 25-100% using the

touchscreen.

If Carnes proportional humidistat is used the humidifier will automatically vary the steam output rate in the

range of 25-100% of the humidifiers maximum rating in

response to the signal from the humidistat. Proportional

control provides less cycling of the humidifier.

Either a wall humidistat or duct mounted humidistat in

the return air may be used. The wall mounted humidistat

is the most common as it allows the setting to be easily

changed to accommodate changing requirements or to

lower the relative humidity in the space to prevent condensation on windows during extremely cold weather.

In applications where it may be desirable to prevent the

AIR FLOW DETECTION

The humidifier control circuit should include some

method to determine air flow. If the steam distributor pipe

is located in a duct where there is no air flow and the

control humidistat is calling for humidity, steam would

be discharged into the duct where it would immediately

condense. Air flow may be detected by several methods.

The humidistat circuit may be interlocked by using a fan

relay if the fan is direct driven. A fan relay is not recommended if a belt driven fan is used as a broken belt would

stop air flow even though the fan relay was closed.

Among the alternatives are the use of a pressure

differential switch that determines air flow by sensing

a pressure differential caused by air movement in the

duct. A paddle type switch is also available to determine

air flow. The pressure differential switch is normally the

preferred device as it is less susceptible to erratic

operation caused by improper positioning in the duct

system. Paddle switches require careful positioning in

the duct to insure sufficient air flow to activate the switch.

occupants of a space from changing the setting, a duct

mounted humidistat in the return may be used. This is

normally mounted in the equipment room or in the duct

where it is accessible only to maintenance personnel.

G-12 www.carnes.com

Humidifiers | Controls

CONDENSATION PROTECTION

A third device may be desirable to provide condensation

protection in the duct system. A high limit humidistat may

be installed ten (10) feet downstream from the steam

distributor pipe. This humidistat is normally set to 90-95%

RH and opens the circuit if the humidity level in the duct

exceeds the set-point. Use of this device is recommended particularly when the humidifier is used in applications

where cooling air is being humidified or where a VAV

system may throttle back to a point where air flow is

insufficient to absorb the steam being introduced.

Either an on-off or proportional control high limit

humidistat may be used with Carnes humidifiers. If a proportional humidistat is used the output of the humidifier

will automatically be decreased to reduce the possibility

of condensation. Two proportional humidistats may be

used to control Carnes humidifiers if desired, one in the

area to be humidified or return duct and another as a high

limit in the supply duct. The humidifier will automatically

select the lowest signal to control the humidifier output.

CONTROL CONNECTIONS

Two cylinder humidifiers may be wired for simultaneous

or separate operation. Controls should be connected to

the terminals on the electronic circuit board as shown

below using recommended No. 20 AWG wire. Avoid

running control wiring near high voltage primary wires.

Figure J

PROPORTIONAL HUMIDISTAT

(BY CARNES)

HXHAM control will vary slightly on the connection

identifier, compared to above.

PROPORTIONAL HI-LIMIT

HUMIDISTAT

(BY CARNES)

EXTERNAL DDC CONTROL SIGNALS

Carnes humidifiers can also accept a 0-10 volt DC

signal to modulate the output of the humidifier. Polarity

must be observed. Input impedance is 20K ohms. If

a 4-20 mA input signal is provided to the humidifier a

470 ohm 1/4 watt resistor must be installed as shown

below (Figure K).

Figure K

Humidifiers

Figure H

1/2 AMP

@ 24V

MAX

EXTERNAL

ON

EXTERNAL

SERVICE

ON/OFF

HUMIDISTAT

ON/OFF

HIGH LIMIT

HUMIDISTAT

MICROPROCESSOR CONTROL

CIRCUIT BOARD

Connections shown in Figure H are for typical on-off

controls. For Carnes proportional controls see Figure J.

All controls are shipped with detailed wiring instructions.

AIR FLOW

SWITCH

+

0-10 VDC

PROPORTIONAL SIGNAL

(BY OTHERS)

470 OHM

RESISTOR

(BY OTHERS)

+

4-20ma

PROPORTIONAL SIGNAL

(BY OTHERS)

+-

-

0-10 VDC

PROPORTIONAL

HI-LIMIT HUMIDISTAT

(BY OTHERS)

+

-

4-20ma

PROPORTIONAL

HI-LIMIT HUMIDISTAT

470 OHM

RESISTOR

-

(BY OTHERS)

(BY OTHERS)

EXTERNAL MONITORING

Terminals, shown in Figure H, are provided for indicating

operation of the humidifier at a remote location. When

the unit

Terminals are provided to indicate the need for service.

When the output of the humidifier is less than 50% of

set-point, “EXT SRV” terminals are closed. Each set of

terminals are capable of switching 1/2 amp at 24 volts

maximum.

is operating, “EXT PWR” terminals are closed.

www.carnes.com G-13

Humidifiers | Unit Availability

Humidifiers

MODELS AVAILABLE AND ELECTRICAL DATA - Table 8

HBAH

HCAH

HSAH

HTAH

HBDH

HCDH

HSDH

HTDH

HBGH

HCGH

HSGH

HTGH

G-14 www.carnes.com

Optional

Max

Model

H_AHAU 5 120 1 1.725 14.4 25 1-20 Amp AX220 14.4

H_AHBU 5 208 1 1.725 8.3 15 1-15 Amp AX380 8.3

H_AHDU 5 230 1 1.725 7.5 15 1-20 Amp AX380 7.5

H_AHFU 5 277 1 1.725 6.2 15 1-15 Amp AX380 6.2

H_AHLU 5 380 1 1.725 4.5 15 1-15 Amp AX600 4.5

H_AHQU 5 415 1 1.725 4.2 15 1-15 Amp AX600 4.2

H_AHMU 5 460 1 1.725 3.7 15 1-15 Amp AX700 3.7

H_AHNU 5 575 1 1.725 3.0 15 1-15 Amp AX700 3

H_AHAU 10 120 1 3.45 28.7 45 1-40 Amp AX220 28.7

H_AHBU 10 208 1 3.45 16.6 25 1-25 Amp AX380 16.6

H_AHDU 10 230 1 3.45 15.0 25 1-25 Amp AX380 15

H_AHFU 10 277 1 3.45 12.4 20 1-20 Amp AX380 12.4

H_AHLU 10 380 1 3.45 9.1 15 1-15 Amp AX600 9.1

H_AHQU 10 415 1 3.45 8.3 15 1-15 Amp AX600 8.3

H_AHMU 10 460 1 3.45 7.5 15 1-15 Amp AX700 7.5

H_AHNU 10 575 1 3.45 6.0 15 1-15 Amp AX700 6

H_DHBU 20 208 1 6.9 33.1 50 1-45 Amp B380 33.1

H_DHDU 20 230 1 6.9 29.9 45 1-40 Amp B380 30

H_DHFU 20 277 1 6.9 24.9 40 1-35 Amp B380 24.9

H_DHLU 20 380 1 6.9 18.1 30 1-30 Amp B600 18.1

H_DHQU 20 415 1 6.9 16.6 25 1-25 Amp B600 16.6

H_DHMU 20 460 1 6.9 15.0 25 1-25 Amp B700 15

H_DHNU 20 575 1 6.9 12.0 20 1-15 Amp B700 12

H_DHCU 20 208 3 6.9 19.1 30 1-25 Amp B500 19.1

H_DHEU 20 230 3 6.9 17.3 30 1-25 Amp B500 17.3

H_DHTU 20 380 3 6.9 10.4 20 1-20 Amp B600 10.4

H_DHWU 20 415 3 6.9 9.6 20 1-20 Amp B600 9.6

H_DHGU 20 460 3 6.9 8.6 15 1-15 Amp B700 8.6

H_DHHU 20 575 3 6.9 6.9 15 1-15 Amp B700 6.9

H_DHCU 30 208 3 10.3 28.7 45 1-40 Amp B500 28.7

H_DHEU 30 230 3 10.3 25.9 40 1-35 Amp B500 25.9

H_DHTU 30 380 3 10.3 15.6 25 1-25 Amp B600 15.6

H_DHWU 30 415 3 10.3 14.4 25 1-25 Amp B600 14.4

H_DHGU 30 460 3 10.3 13.0 20 1-20 Amp B700 13

H_DHHU 30 575 3 10.3 10.4 20 1-15 Amp B700 10.4

H_GHBU

H_GHDU 30 230 1 10.3 44.9 70 1-60 Amp C62 22.4

H_GHFU 30 277 1 10.3 37.3 60 1-50 Amp C62 18.6

H_GHLU 30 380 1 10.3 27.2 45 1-40 Amp C62 13.6

H_GHQU 30 415 1 10.3 24.9 40 1-40 Amp C62 12.5

H_GHMU 30 460 1 10.3 22.5 35 1-30 Amp C62 11.3

H_GHNU 30 575 1 10.3 17.9 30 1-25 Amp C62 9.0

H_GHCU 40 208 3 13.8 38.3 60 1-60 Amp C62 19.1

H_GHEU 40 230 3 13.8 34.6 60 1-50 Amp C62 17.2

H_GHTU 40 380 3 13.8 20.9 35 1-35 Amp C65 20.9

H_GHWU 40 415 3 13.8 19.2 30 1-30 Amp C65 19.2

H_GHGU 40 460 3 13.8 17.3 30 1-25 Amp C65 17.3

H_GHHU 40 575 3 13.8 13.8 25 1-20 Amp C65 13.8

Lb/Hr Voltage Phase kW

* 30 208 1 10.3 49.7* 80 2-35 Amp* C62 24.8

Line

Amp

Disc.

Size

* = Circuit Breaker is REQUIRED per NEC 48 amp guidelines.

Cir.

Breaker*

Steam

Cylinder

Cyl Wire

Current

Humidifiers | Unit Availability

MODELS AVAILABLE AND ELECTRICAL DATA - Table 8

Optional

Max

HBGH

HCGH

HSGH

HTGH

HBHH

HCHH

HSHH

HTHH

Model

H_GHCU 50 208 3 17.2 47.8 80 2-35 Amp C62 23.9

H_GHEU 50 230 3 17.2 43.2 70 1-60 Amp C62 21.6

H_GHTU 50 380 3 17.2 26.2 40 1-40 Amp C65 26.2

H_GHWU 50 415 3 17.2 24.0 40 1-40 Amp C65 24

H_GHGU 50 460 3 17.2 21.6 35 1-30 Amp C65 21.6

H_GHHU 50 575 3 17.2 17.3 30 1-25 Amp C65 17.3

H_GHCU* 60 208 3 20.7 57.4* 90 2-40 Amp* C62 28.7

H_GHEU

H_GHTU 60 380 3 20.7 31.4 50 1-50 Amp C65 31.4

H_GHWU 60 415 3 20.7 28.8 45 1-45 Amp C65 28.8

H_GHGU 60 460 3 20.7 26.0 40 1-40 Amp C65 26

H_GHHU 60 575 3 20.7 20.8 35 1-30 Amp C65 20.8

H_GHCU

H_GHEU* 80 230 3 27.5 69.2* 110 2-50 Amp* C62 34.6

H_GHTU 80 380 3 27.5 41.9 70 1-60 Amp C12 21

H_GHWU 80 415 3 27.5 38.4 60 1-60 Amp C12 19.2

H_GHGU 80 460 3 27.5 34.6 60 1-50 Amp C12 17.3

H_GHHU 80 575 3 27.5 27.7 45 1-40 Amp C12 13.9

H_GHCU

H_GHEU

H_GHTU* 100 380 3 34.4 52.3* 110 2-50 Amp* C12 34.2

H_GHWU 100 415 3 34.4 47.9 80 2-40 Amp C12 24

H_GHGU 100 460 3 34.4 43.3 70 1-60 Amp C12 21.7

H_GHHU 100 575 3 34.4 34.6 60 1-50 Amp C12 17.3

H_HHCU

H_HHEU* 125 230 3 43 108* 175 4-40 Amp* C62 (2) 27

H_HHTU* 125 380 3 43 65.3* 100 2-50 Amp* C12 (2) 16.3

H_HHWU

H_HHGU* 125 460 3 43 54.0* 90 2-40 Amp* C12 (2) 13.5

H_HHHU 125 575 3 43 43.2 70 2-30 Amp C12 (2) 10.8

H_HHCU* 150 208 3 51.7 143.5* 225 4-50 Amp* C62 (2) 35.8

H_HHEU

H_HHTU* 150 380 3 51.7 78.6* 125 2-60 Amp* C12 (2) 19.7

H_HHWU* 150 415 3 51.7 71.9* 110 2-60 Amp* C12 (2) 18

H_HHGU* 150 460 3 51.7 64.8* 100 2-50 Amp* C12 (2) 16.2

H_HHHU

H_HHCU* 175 208 3 60.3 167.3* 300 4-60 Amp* C62 (2) 41.8

H_HHEU* 175 230 3 60.3 151.3* 250 4-60 Amp* C62 (2) 37.8

H_HHTU

H_HHWU* 175 415 3 60.3 83.9* 150 2-60 Amp* C12 (2) 21

H_HHGU* 175 460 3 60.3 75.6* 125 2-60 Amp* C12 (2) 18.9

H_HHHU* 175 575 3 60.3 60.5* 100 2-50 Amp* C12 (2) 15.1

H_HHCU

H_HHEU* 200 230 3 68.9 172.9* 300 4-60 Amp* C62 (2) 43.2

H_HHTU* 200 380 3 68.9 104.7* 175 4-40 Amp* C12 (2) 26.2

H_HHWU* 200 415 3 68.9 95.9* 150 4-35 Amp* C12 (2) 23.9

H_HHGU

H_HHHU* 200 575 3 68.9 69.2* 110 2-50 Amp* C12 (2) 17.2

Lb/Hr Voltage Phase kW

* 60 230 3 20.7 51.9* 80 2-40 Amp* C62 26

* 80 208 3 27.5 76.5* 125 2-60 Amp* C62 38.2

* 100 208 3 34.4 95.6* 150 2-60 Amp* C62 47.8

* 100 230 3 34.4 86.4* 150 2-60 Amp* C62 43.2

* 125 208 3 43 119.5* 200 4-40 Amp* C62 (2) 29.8

* 125 415 3 43 59.8* 90 2-45 Amp* C12 (2) 15

* 150 230 3 51.7 129.7* 200 4-50 Amp* C62 (2) 32.4

* 150 575 3 51.7 51.9* 80 2-35 Amp* C12 (2) 13

* 175 380 3 60.3 91.6* 150 4-35 Amp* C12 (2) 22.9

* 200 208 3 68.9 191.2* 300 4-60 Amp* C62 (2) 47.8

* 200 460 3 68.9 86.4* 150 2-60 Amp* C12 (2) 21.6

www.carnes.com G-15

Line

Amp

Disc.

Size

* = Circuit Breaker is REQUIRED per NEC 48 amp guidelines.

Cir.

Breaker*

Steam

Cylinder

Cyl Wire

Current

Humidifiers

Humidifiers | Unit Availability

Humidifiers

NOTES: Identifying and explaining the electrical data and unit detail in Table 8 on the previous

page

“Model” and “Optional Circuit Breaker” columns designate presence, quantity and amp rating of optional

circuit breakers. In addition, as an option, internally mounted, switchable on-off, circuit breakers are available

in models preceded by “HB” or “HT”. PLEASE NOTE: Certain units require circuit breakers per NEC

48 amp guidelines.

“Maximum Lb./Hr.” designates maximum capacity of humidifier. Units are shipped from the factory preset

at the maximum rate. The output rate may be easily reset after installation anywhere between 100% and

25% of maximum capacity.

“Voltage” and “Phase” designate available phase and nominal voltages. Single phase units may be

operated from two legs of a three phase supply but the load will be unbalanced.

“kW” ratings shown is at maximum output rate. If a unit is reset for less than maximum output, the kW is

reduced proportionally.

“Line Amp” and “Disc. Size” are amp ratings shown for use in selecting electrical service requirements.

“Steam Cylinder” column shows the quantity and the model of steam generating cylinders mounted in the

humidifier. Each cylinder requires its own steam distribution pipe, steam hose and condensate return line.

“Cylinder Wire Current” - as a process of troubleshooting, it may be necessary to confirm current flow

through individual cylinder wires during operation. Match humidifier with electrical data.

G-16 www.carnes.com

Humidifiers | Unit Nomenclature

Model Series Electrical Output Capacity Options

1 2 3 4 5 6 7 8 9 10

Design Nominal Steam

H B A H A U 0 1 0

H - Humidifier

B - With Internal

Circuit Breakers*

C - Without Internal

Circuit Breakers

S - Stainless Steel (304)

Cabinet (w/o Breakers)

T - Stainless Steel (304)

Cabinet (w/ Breakers)

UNIT TYPE

A - 1 “AX” Cylinder

D - 1 “B” Cylinder

G - 1 “C” Cylinder

H - 2 “C” Cylinders

*NOTE:

AN EXTERNAL FUSED DISCONNECT SWITCH, OR OTHER SIMILAR PROTECTION, AS REQUIRED BY

LOCAL, AND NATIONAL ELECTRICAL CODES MUST BE SUPPLIED AND INSTALLED BY OTHERS. An optional circuit

breaker (except for select models over 48 amps) is available in the unit to reduce the risk of costly damage in the event of

internal failure. It is not meant to be the primary protection as may be required by local and national electrical codes. All

units include electronic overload protection as a standard feature.

VOLTAGE

A - 115V, 1PH

B - 208V, 1PH

C - 208 V, 3PH

D - 230V, 1PH

E - 230V, 3PH

F - 277V, 1PH

L - 380V, 1PH

T - 380V, 3PH

Q - 415V, 1PH

W - 415V, 3PH

G - 460V, 3PH

H - 575V, 3PH

M - 460V, 1PH

N - 575V, 1PH

AGENCY

LISTING

U - UL

C - cUL

Lb/Hr

005 - 5#/Hr

010 - 10#/Hr

020 - 20#/Hr

030 - 30#/Hr

040 - 40#/Hr

050 - 50#/Hr

060 - 60#/Hr

080 - 80#/Hr

100 - 100#/Hr

125 - 125#/Hr

150 - 150#/Hr

175 - 175#/Hr

200 - 200#/Hr

B - Blower Package

Humidifiers

UNIT VOLTAGE CHARACTERISTICS

Humidifiers may be ordered with the voltage nameplate

ratings shown below. The units may be operated at nominal system voltage shown in Table 9.

Table 9

Suitable Nominal

Unit Nameplate Voltage System Voltages

208 208

230 220, 230, 240

277 277

380 380

415 400, 415

460 440, 460, 480

575 550, 575, 600

120 115, 120

CYLINDER LIFE

Cylinders have an average life of 1150 hours when

operating at maximum output with a water supply hardness of 150 ppm. Approximate cylinder life for other

water hardness may be determined by multiplying 1150

by the correction factor shown in Table 10.

Table 10

Water Hardness (ppm) Correction Factor

50 3.00

100 1.50

150 1.00

200 0.75

250 0.60

300 0.50

Cylinder life will be extended if operated at less than

maximum output. Multiply the cylinder life calculated in

Table 10 by the correction factory shown in Table 11.

Table 11

% of Maximum Output Correction Factor

100 1.00

75 1.33

50 2.00

www.carnes.com G-17

Humidifiers | Accessories

Humidifiers

STEAM DISTRIBUTOR PIPES

Distributor Pipes for Models: H_AH, H_DH

PIPE N T

HXPBB012S 11-13/16 (300mm) 7/8

HXPBB018S 17-13/16 (452mm) 7/8

HXPBB024S 23-13/16 (605mm) 7/8

HXPBB030S 29-13/16 (757mm) 7/8

HXPBB036S 35-13/16 (910mm) 7/8

Minimum**

Maximum**

PIPE N N T

HXPBB040S 35 (889mm) 38 (965mm) 7/8

HXPBB044S 39 (991mm) 42 (1067mm) 7/8

HXPBB048S 43 (1092mm) 46 (1168mm) 7/8

HXPBB052S 47 (1194mm) 50 (1270mm) 7/8

HXPBB056S 51 (1295mm) 54 (1372mm) 7/8

HXPBB060S 55 (1397mm) 58 (1473mm) 7/8

HXPBB064S 59 (1499mm) 62 (1575mm) 7/8

HXPBB068S 63 (1600mm) 66 (1676mm) 7/8

HXPBB072S 67 (1702mm) 70 (1778mm) 7/8

HXPBB076S 71 (1803mm) 74 (1880mm) 7/8

HXPBB080S 75 (1905mm) 78 (1981mm) 7/8

HXPBB084S 79 (2007mm) 82 (2083mm) 7/8

HXPBB088S 83 (2108mm) 86 (2184mm) 7/8

HXPBB092S 87 (2210mm) 90 (2286mm) 7/8

HXPBB096S 91 (2311mm) 94 (2388mm) 7/8

HXPBB100S 95 (2413mm) 98 (2489mm) 7/8

HXPBB104S 99 (2515mm) 102 (2591mm) 7/8

HXPBB108S 103 (2616mm) 106 (2692mm) 7/8

HXPBB112S 107 (2718mm) 110 (2794mm) 7/8

HXPBB116S 111 (2819mm) 114 (2896mm) 7/8

HXPBB120S 115 (2921mm) 118 (2997mm) 7/8

**See Note A

Lengths 012-036

5”

(127)

9-1/2”

(241)

T

3/8”

N

Lengths 048-120

4”

(102)

4”

(102)

T

N

3/8”

Distributor Pipes for Models: H_GH, H_HH

PIPE N T

HXPBC012S 11-13/16 (300mm) 1-5/8

HXPBC018S 17-13/16 (452mm) 1-5/8

HXPBC024S 23-13/16 (605mm) 1-5/8

HXPBC030S 29-13/16 (757mm) 1-5/8

HXPBC036S 35-13/16 (910mm) 1-5/8

PIPE N N T

HXPBC048S 43 (1092mm) 46 (1168mm) 1-5/8

HXPBC060S 55 (1397mm) 58 (1473mm) 1-5/8

HXPBC072S 67 (1702mm) 70 (1778mm) 1-5/8

HXPBC084S 79 (2007mm) 82 (2083mm) 1-5/8

HXPBC096S 91 (2311mm) 94 (2388mm) 1-5/8

HXPBC108S 103 (2616mm) 106 (2692mm) 1-5/8

HXPBC120S 115 (2921mm) 118 (2997mm) 1-5/8

**NOTE A

The mounting plate on these pipes is adjustable to

compensate for slight variations in ductwork dimensions.

The “N” dimension is shown at both maximum and

minimum depending on position of mounting plate. An

infinite variety of settings are available between the

minimum and maximum. A mounting strap is provided

on the end of the pipe to secure to the top or side of the

duct for support.

MATERIAL

Standard distributor pipes are fabricated from stainless

steel.

Minimum** Maximum**

G-18 www.carnes.com

Humidifiers | Accessories

FAN DISTRIBUTION UNITS OPTIONS

REMOTE

MOUNTED

Humidifier Nominal Steam Remote Mounted

Model Output Rate Fan Unit Model

H_AH 005, 010 HXBHB (1 Required)

H_DH 020, 030 HXBHB (1 Required)

H_GH 030, 040, 050, 060, 080, 100 HXBHC (1 Required)

H_HH 125, 150, 175, 200 HXBHC (2 Required)

Fan distribution units are available for use in areas which

do not have duct systems or where duct air temperatures are too low to provide sufficient humidification. For

example, in computer areas the desired relative humidity

may not be possible in the conditioned space without

causing condensation in the duct.

STANDARD MOUNTING: Factory attached to

humidifier.

OPTION: Mounted remote from humidifier.

FAN VOLTAGE: 3 fans attached, 12 volt from

humidifier

*NOTE: Selected control humidifiers (HXHAA-ON/OFF,

HXHCG/Proportional or HXHAM), whether mounted or

remote units, will be mounted external to fan distribution

boxes for more consistent and accurate operation. Field

wiring, by others, will need to be done for both mounted

and remote units. (Note wiring diagram on door of fan

distribution unit.)

Humidifiers

20”

HUMIDIFIER

MOUNTED

Humidifier Nominal Steam Humidifier Mounted

Model Output Rate Fan Unit Model

H_AH 005, 010 AVAILABLE

H_DH 020, 030 AVAILABLE

H_GH 030, 040, 050, 060, 080, 100 AVAILABLE

H_HH 125, 150, 175, 200 NOT AVAILABLE

Fan distribution units must be mounted securely on a

level and plumb surface at least three feet below the ceiling for a Model HXBHB and at least four feet below the

ceiling for a Model HXBHC to prevent condensing on the

ceiling surface. Allow 20 ft. in front of the HXBHB and 30

feet in front of the HXBHC for the steam to be absorbed

into the air. Do not mount the units above any items that

would be damaged if a water leak were to develop.

7”

17-3/4”

www.carnes.com G-19

Humidifiers | Accessories

Humidifiers

WALL HUMIDISTAT,

PROPORTIONAL CONTROL

Model HXHAM

The Model HXHAM is a wall-mounted, microprocessorcontrolled humidistat solution for cutting edge humidity

control. The HXHAM employs a backlit LCD module,

which displays both the ambient temperature and humidity of the surrounding air. The embedded software allows

user navigation between temperature/humidity viewing

mode and set-point adjustment mode, and also outdoor temperature and humidity viewing mode. Set-point

range is 0 to 100%. An optional outdoor temperature

compensation sensor can be added (HXHAMT).

DUCT HUMIDISTAT,

PROPORTIONAL CONTROL

Model HXHAN

The Model HXHAN is an intelligent humidistat solution

used exclusively for duct mounted installations. The

humidistat is capable of providing both humidity and

temperature measurements from inside the duct. The

microprocessor control takes the temperature into

consideration when calculating the humidity to provide

an extra degree of precision. 0 to 100% set-point range.

WALL HUMIDISTAT, ON-OFF CONTROL

Model HXHAA

This attractive wall mounted humidistat is a convenient

control for mounting in the conditioned space. Select a

location four to five feet above the floor in freely circulating air of the temperature and humidity about average for

the entire space to be controlled. Avoid locations near

hot or cold air ducts and discharge air from the humidifier. Scale range is from 10%-90% RH Differential is 5%

non-adjustable. Humidistat is UL listed. Case dimensions

are 4-3/8” high, 2-7/8” wide and 1-5/8” deep including

control knob.

WALL HUMIDISTAT,

PROPORTIONAL CONTROL

Model HXHCG

The wall mounted HXHCG humidistat uses a monolithic

sensor and electronic circuitry to provide accurate and

reliable humidity sensing. Set-point range is 0 to 100%.

The HXHCG has a concealed set-point adjustment with

a locking cover to prevent tampering. Ambient operating

conditions are from 0° to 85°C. Case dimensions are

2-13/16” x 4-1/2” x 1-1/4”.

G-20 www.carnes.com

Humidifiers | Accessories

DUCT HUMIDISTAT, ON-OFF CONTROL

Model HXHAB

This duct mounted humidistat mounts in the return air

duct to provide control of the humidifier. The control

should be located in the duct where it will be affected

by normal air flow. The maximum temperature at the

nylon element must not exceed 125°F. The control can

be mounted in any position, but where possible locate it

on the side of the duct to make the set-point adjustment

easily accessible. Scale range is 15%-50% RH Differential

is 4%-6% non-adjustable. Humidistat is UL listed. Case

dimensions are 3-3/4” high, 2-3/8” wide. Humidistat

extends 7-1/2” into duct and projects 2-1/2” outside of

the duct.

DUCT HUMIDISTAT OR HIGH LIMIT,

PROPORTIONAL CONTROL

Humidifiers

Model HXHCH

The Model HXHCH is designed to be mounted in a duct

to provide a means of sensing relative humidity. Setpoint range is from 0 to 100% R. H. Ambient operating

conditions are from 0° to 85°C. The humidistat may be

mounted in a return duct to provide a mean of sensing

and controlling relative humidity. The humidistat may be

mounted in a supply duct a minimum of 10 feet downstream from the distributor pipe when used as a high

limit humidistat. Case dimensions are 2-13/16” x 4-1/2” x

2-1/4”. The probe extends 5-3/4” into the duct.

DUCT HIGH LIMIT HUMIDISTAT, ON-OFF CONTROL

Model HXHAD

The Model HXHAD humidistat is available for use as a

safety precaution to prevent air in the duct from exceeding a preset level. Do not use the humidistat in air that is

over 125°F or in locations where the unit could become

wet. The control must be mounted a minimum of 10

feet downstream of the distributor pipe. Scale range is

from 15%-95% RH Differential is 5% non-adjustable.

Mounting plate dimensions are 6-1/2” wide, 4-3/4” high.

Humidistat extends 1-1/4” into duct and projects 2-1/4”

outside the duct.

www.carnes.com G-21

Humidifiers | Accessories

Humidifiers

AIR FLOW SWITCH PRESSURE DIFFERENTIAL TYPE

Model HXAAE

Air flow in the duct may be sensed by using this differential pressure switch. The differential in pressure between

the interior of the duct and ambient when air is moving in

the duct closes a micro switch allowing the humidifier to

operate. Air pressure differential as low as .07 w.g. and

as high as 12.0 w.g. may be sensed with one model. The

switch may be mounted with tubing connecting to the

duct. Switch is UL listed.

AIR FLOW SWITCH, VELOCITY TYPE

Model HXAAF

This air flow switch is installed in the duct to prevent

humidifier operation when air flow is not occurring.

This switch provides a positive and economical method to detect loss of air flow velocity. The switch may

be installed on the side, top, or bottom of a horizontal

duct. Installation can be made in a vertical duct if the air

flow is upward. A horizontal flow velocity of 480 fpm or

upward vertical flow of 910 fpm is required to operate

the switch. Switch is UL listed. Case dimensions are

4-3/8 high, 3-13/16” wide. The paddle extends 7-23/32”

into the duct.

OUTDOOR AIR TEMPERATURE COMPENSATED DIGITAL HUMIDISTAT, ON-OFF CONTROL

7/8”

(22)

4-1/4”

(108)

Model HXHAT

The HXHAT humidistat can be either wall or duct mounted and includes a remote outdoor temperature sensor for

exterior wall or intake duct mounting. The humidistat

can automatically change the set-point in response to

changes in outdoor temperature or be set to maintain a

set-point regardless of temperature changes. The LCD

display shows set-point RH%, actual RH% or outdoor

temperature (from -9 to 98°F). Relay contacts provide

an on/off signal to the humidifier. Set-point range is from

30-65% RH. Default set-point is 40% RH.

The HXHAT will automatically reduce the RH set-point

as the temperature drops below 35°F. The graph below

shows the RH setting of 35° RH and as the temperature

drops the RH set-point is adjusted by the computer as

shown. Below -10° there is no adjustment.

3-1/4”

(83)

G-22 www.carnes.com

Humidifiers | Accessories

STEAM HOSE CONDENSATE RETURN LINE

Humidifiers

Carnes steam hose is made from EPDM compound to

withstand the low pressure steam without deterioration.

Model HXSAB steam hose has an I. D. of 7/8” for use

with units that use “AX” or “B” steam cylinders. Model

HXSAC has an I. D. of 1-5/8” for use with units that use

“C” cylinders. The hose may be easily cut to the exact

length at time of installation.

Two models of condensate return line are available.

Model HXRA has an I. D. of 3/8” and is used whenever

steam distributor pipes are used with the humidifier.

Model HXLA has an I. D. of 5/8” and is used with optional

fan distribution units.

STEAM HOSE DRAIN “T” FITTINGS “T” FITTINGS

Steam hose drain “T” are available for use when the duct

is located below the top of the humidifier or where the

length of steam hose is in excess of 12 feet.

Humidifier Model Drain “T” Model Dimensions

HBA, HCA

HBD, HCD

HBG, HCG

HBH, HCH

HXTABB 7/8”x7/8”x3/8”

HXTACB 1-5/8”x1-5/8”x3/8”

In some applications it may be desirable to have the

steam generator cylinder feed two steam distributor

pipes. “T” fittings can be installed in the steam hose and

condensate return line.

STEAM HOSE “T” FITTINGS

Humidifier Model Drain “T” Model Dimensions

HBA, HCA

HBD, HCD

HBG, HCG

HBH, HCH

HXTABA 7/8”x7/8”x7/8”

HXTACA 1-5/8”x1-5/8”x1-5/8”

CONDENSATE HOSE “T” FITTINGS

Humidifier Model Drain “T” Model Dimensions

ALL HXTAD 3/8”x3/8”x3/8”

www.carnes.com G-23

Humidifiers | Accessories

Humidifiers

DRAIN WATER PUMP

Model HXWA

A drain water pump is available for mounting directly

below the humidifier cabinet. This pump is ideal for an

application where the building drain is remotely located or is at a higher elevation than the humidifier drain

connection. This unit operates on a float principle which

automatically starts the pump when the reservoir is 3/4

full of water. The pump is capable of operation with a

vertical lift up to 12 feet or horizontal run of 40 feet. The

complete package includes drain pump with six feet of

cord and plug for 115 volt operation.

3-Prong

Molded Cap

3000 R. P. M. 1.4

AMP Open Motor

Access Cover

Plate 4-5/8” x 5”

9-3/4”

5-1/4”

Micro Switch

Controlled By Float

3-1/4”

Outlet:

3/8” F. P. T.

12”

Inlet Grommet For

7/8” O. D. Hose

9”

Overflow

2 Gallon Reservoir

Of Cast Aluminum

Epoxy Clad

Models Available

HXCBAX145 HXCCB145 HXCBC6F

HXCBAX220 HXCCB220 HXCBC6X

HXCBAX380 HXCBB380 HXCBC61

HXCBAX500 HXCBB500 HXCCC62

HXCBAX600 HXCBB600 HXCBC63

HXCBAX700 HXCBB700 HXCBC64

HXCBC65

HXCBC12

G-24 www.carnes.com

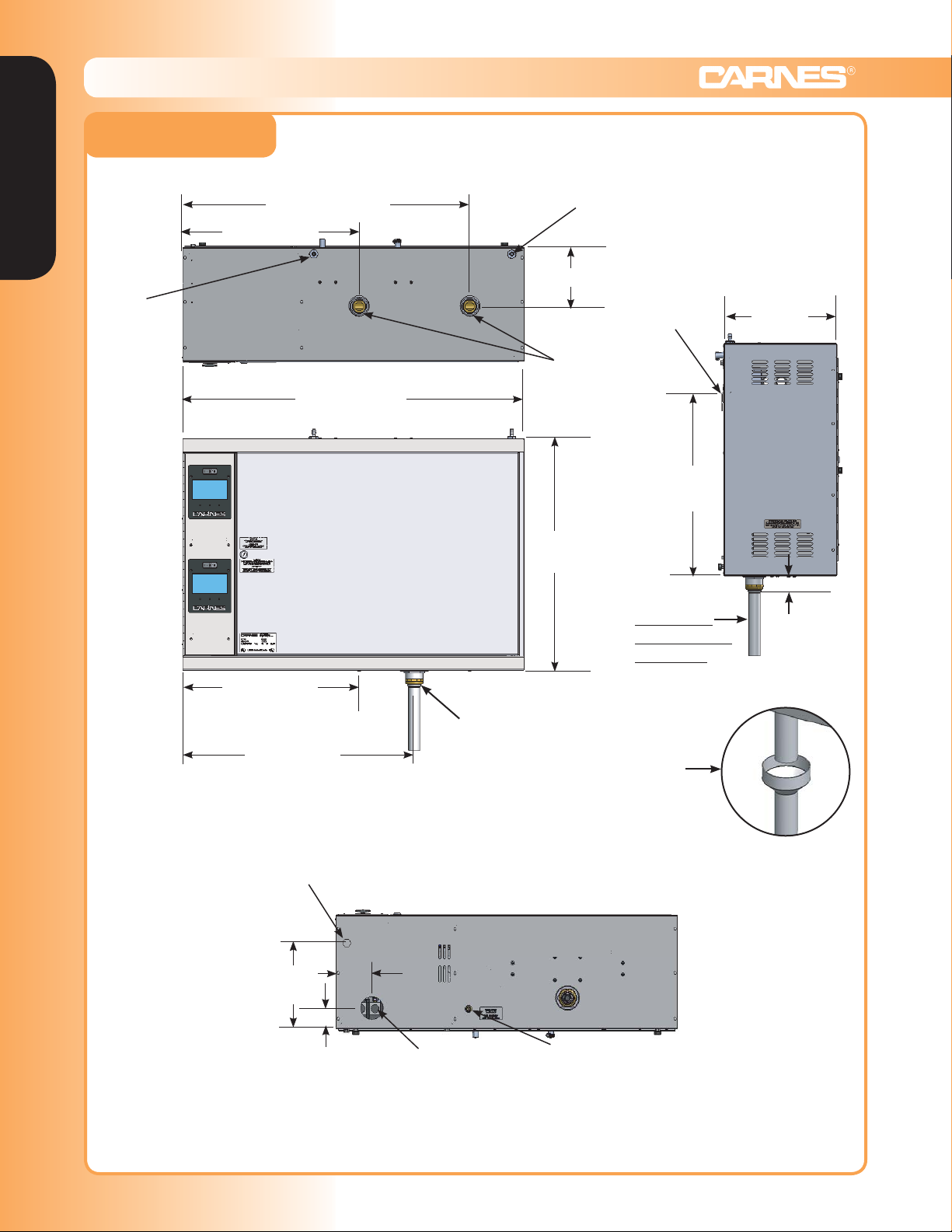

MODELS: H_AH

H_DH

H_GH

Humidifiers | Humidifier Dimensions

Steam

Output

10.625

(270)

Condensate

Return Inlet

5.875

(149)

7.590

(193)

19.968 (507)

8.375 (213)

5.125 (130)

9.000

(229)

4.654

(118)

Mounting

24.947

(634)

TOP

Flange

19.813

(503)

Humidifiers

11.703

(297)

SIDE

Drain Pipe

4.750 (121)

1-1/2” PVC

Air Gap

Connection

3/8” FPT

Water Inlet

1.500 (38)

1.500 (38)

BOTTOM

2.250

(57)

1.906

(48)

1.505

(38)

3.069 (78)

5.613 (143)

7/8” Dia. Hole For

Control Wiring

1-3/8” Dia. Hole

For Power Wiring

6.938

(176)

NOTE: Drain Pipe

is NOT an air

gap fitting.

An air gap fitting

must be included in

drain plumbing set-up

(non-Carnes installation).

See picture:

If you wish to purchase an air

gap from Carnes it is an option.

www.carnes.com G-25

Humidifiers | Humidifier Dimensions

Humidifiers

MODELS: H_HH

Condensate

Return

Inlet

31-3/4” (806)

19-5/8” (498)

38” (965)

TOP

Condensate

Return Inlet

6” (152)

Steam Outlets

26”

(660)

Mounting

Flange

20-1/4”

12-1/2”

(318)

(514)

5-5/8” (143)

14-3/4” (375)

25-3/4” (654)

7/8” Dia.

Hole For

Control

Wiring

9-1/2”

(241)

2-1/4”

(57)

Drain Pipe

BOTTOM

4”

(102)

2-1/2” Dia. Hole

For Power Wiring

NOTE: Drain Pipe

is NOT an air

gap fitting.

An air gap fitting

must be included in

drain plumbing set-up

(non-Carnes installation).

See picture

If you wish to purchase an air

gap from Carnes it is an option.

3/8” FPT

Water Inlet

SIDE

G-26 www.carnes.com

Humidifiers | Humidifier Specifications

1. Provide self-contained microprocessor controlled steam generat-

ing humidifiers of the size(s) shown on plans as manufactured by

Carnes Company, Verona, WI.

2. Carnes Humidifiers shall have the capacity to operate at

115, 208, 230, 277, 380, 415, 460 and 575 volt (or nominal value),

60 or 50 hz (cycle), single or 3 phase power. Specific combination of maximum output, voltage and phase for order application

determined by electrical data chart.

3. The humidifier(s) shall be UL and cUL listed.

4. The humidifier(s) shall have a total Color “True Touchscreen”

user interface. Features:

a. True Touchscreen navigation for all aspects of operation and

information access.

b. Cylinder life-counter (hours of operation. Found by accessing

Settings button.

c. With Fan Distribution Unit, there is a fan speed Slide Bar

control with CFM indication. Found by accessing Settings

button.

d. “Help” screen button.

e. “Service Required” button and indicator and corresponding

screen explaining service issues and possible troubleshooting

tips.

f. “Dim LCD” feature button.

g. “Humidistat Demand” indication button. Shows control

humidistat and high-limit humidistat.

h. “Settings button - where all operational values can be set.

i. “Setpoints” button - target steam output of the humidifier.

5. Steam shall be generated from tap water or softened water (see

factory representative) in a factory sealed cylinder containing

electrodes. Cylinders shall not require setting of electrode spacing, cleaning or maintenance and shall be of the disposable type.

6. The humidifier(s) shall include an automatic drain cycle controlled

electronically to maximize energy efficiency. Drain cycle shall

adapt to variations in water conditions (high/low conductivity and

high/low hardness) and not require manual setting. There is also

a default setting for a pulsing drain action to assist in keeping

drain lines open.

7. In the event of over-current, the humidifier shall signal that a

fault condition exists by message on touchscreen. Over-current

protection shall be resettable. Replacement type fuses are not

acceptable.

Option: Humidifier(s) shall also include secondary magnetic

overload switches (circuit breakers) that shall be manually

resettable and shall be of the type that positively disconnects

power to the steam cylinder.

8. Humidifier(s) shall include a door interlock safety switch to discon-

nect power to steam cylinder(s) when cabinet door is opened.

9. The system shall include one steam distributor pipe for each

steam generating cylinder mounting in the duct as shown on the

plans. Steam distributing pipe(s) shall be of corrosion resistant

design (copper or stainless steel) and be designed to provide

uniform distribution over the entire length of the pipe.

Option: Supply and install remote (or humidifier mounted) fan

distribution units to discharge steam directly into the conditioned

space.

Provide the following components:

a. Three 12VDC fans operated by circuit board.

b. Integral steam manifold trap.

b. Remote mounted on/off, proportional control humidistat.

Option: When plans call for a specific short absorption

distance from dispersion system, a multi-tube Short Absorption

Manifold is available sized specifically to duct dimensions, with

horizontal stainless steel cross tubes and vertical headers.

10. The system shall include flexible hose to connect the steam

cylinder(s) to the steam distributor pipe(s). A separate condensate return line shall return condensate to the humidifier for

reuse to minimize consumption. If due to specific routing issues

or application of unit, condensate line can not run back to unit,

the line can go directly to the common drain, and the addition of

a “circle” or “U” trap will be required (see IOM). Long distances

from unit to common drain can be accommodated with accessory

option Water Pump (HXWA). Hard tubing can be used for Steam

Hose and Condensate Return to prevent sags, restrictions or

obstructions (see IOM), but it is recommended a minimum of 12

inches of flexible hose be used from unit and before distributor

pipe. We recommend a maximum distance of 30 feet from unit

to distributor pipe(s) or short absorption manifold and proper

routing and inclination of hoses and hard tubing be adhered to for

proper, overall consistent and dependable operation.

11. The humidifier(s) shall incorporate a 1” air gap on the fill water line

to prevent backflow. It is recommended that a drain air gap fitting

be installed by a non-Carnes contractor to prevent backflow of

water. Carnes offers an air gap fitting as a purchased option.

12. The humidifier cabinet(s) shall be constructed of 20 gauge

steel with a stainless steel bottom pan, protected by a dipped

electrostatic baked enamel undercoat with multi spec textured top

coat with black accent architectural grade. The cabinet door shall

be hinged and provided with a lock and key. The main door is

also provided with a quick release pin for removal to provide easy

access to internals. The True Touchscreen Home Page will show

a digital LCD steam output meter calibrated in pounds of steam

per hour (kg of steam per hour selection is included as a built in

option), fill cycle, drain cycle and high water indicator lights will be

visible with the cabinet door closed.

13. The humidifier(s) shall be controlled by a humidistat which

operates through the solid-state circuit board. Humidifier(s) shall

incorporate terminals for connection of humidistat, air flow switch

and high limit control humidistat.

Option: Provide the following accessory controls: