CaptiveAire LF120-SUS Installation Manual

44

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

LF Series Spring Return Direct Coupled Actuator

Applications

Minimum 35 in-lb torque

● For damper areas up to 8 sq-ft*

LF Series - at a glance

* 4 in-lb/ft2damper torque loading. Parallel blade. No edge seals.

LF… actuator

circuit board cover (removed)

Cost effective quality and performance

for a range of applications including:

• Classroom Unit Ventilators

• Fan/Coil Units

• VAV Terminal Units

• Economizer Units

• Airhandlers

• Control Dampers

Torque: 35 in-lb ●●●●●●●●●●●●

Power supply:24 VAC/DC ●● ●●●●●●

120 VAC ●●

230 VAC ●●

Control signal: on-off ●●●●●●●

Control signal: floating point ●●●●

Control signal: proportional 2 to 10 VDC ●●

Control signal: 6 to 9 VDC

Feedback: 2 to 10 VDC ●●

Auxiliary output, 20 VDC (to power controller)

Running time: motor <75 sec ●●●●●●

motor 150 sec constant ●● ●●

motor 90 sec constant ●●

spring <25 sec ●●●●●●●●●●●●

External direction of rotation switch ●●●● ●●

Plenum rated cable, 18 GA ●● ●

Conduit fitting ●●●●●●●●●●●●

Appliance cable ●●●●●● ●● ●

Built-in auxiliary switch ●●● ●●●

Installation instructions......(p. 56–62) General wiring ..............(p. 58) Start-up and checkout......(p. 65)

Actuator sizing ..................(p. 57) Special wiring ................(p. 63–64)

LF24 US (p. 46)

LF24-S US (p. 46)

LF120 US (p. 48)

LF120-S US (p. 48)

LF230 US (p. 48)

LF230-S US (p. 48)

LF24-3 US (p. 50)

LFC24-3-R US (p. 52)

LFC24-3-S US (p. 52)

LF24-3-S US (p. 50)

LF24-SR US (p. 54)

LF24-SR-S US (p. 54)

®

45

D20230/ 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

LF

BENEFITS

LF Series Spring Return Direct Coupled Actuator

®

● Cut labor costs with (10 min. installation) simple direct

coupling centers on 1/2” shaft. (K6-1, 3/4” clamp optional)

● True mechanical spring return - the most reliable failsafe.

● Mount for clockwise or counterclockwise fail-safe.

● Easy-to-adjust mechanical stop to limit damper rotation.

● Check damper position easily with clear position indicator.

● Don’t worry about actuator burn-out.

Belimo is overload-proof throughout rotation

● Need to change control direction?

Do it easily with a simple switch. (modulating actuators)

● Built-in auxiliary switch is easy to use, offers feedback

or signal for additional device.

● Microprocessor-controlled brushless DC motor increases

actuator lifespan and reliability, provides constant running

time. (modulating actuators)

● Rugged metal housing withstands rough handling in the

mechanical room.

● 3 ft. cable and conduit connector eases installation.

B

e

l

i

m

o

’

s

C

o

m

m

i

t

m

e

n

t

t

o

Q

u

a

l

i

t

y

S

i

n

c

e

1

9

9

1

I

S

O

9

0

0

1

The Belimo Difference

● Customer Commitment.

Unconditional warranty. Same-day shipments. Knowledgeable, full-time technical support.

Worldwide sales and distribution.

●

Low Installed and Life-Cycle Cost.

High degree of control accuracy. Easy to install and operate, durable.

No maintenance.

●

Long Service Life.

Components tested before assembly. Final product tested before shipment.

Designed with over 20 years of experience in direct coupled applications.

LISTED

94D5

TEMP. IND &

REG. EQUIP.

U

L

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

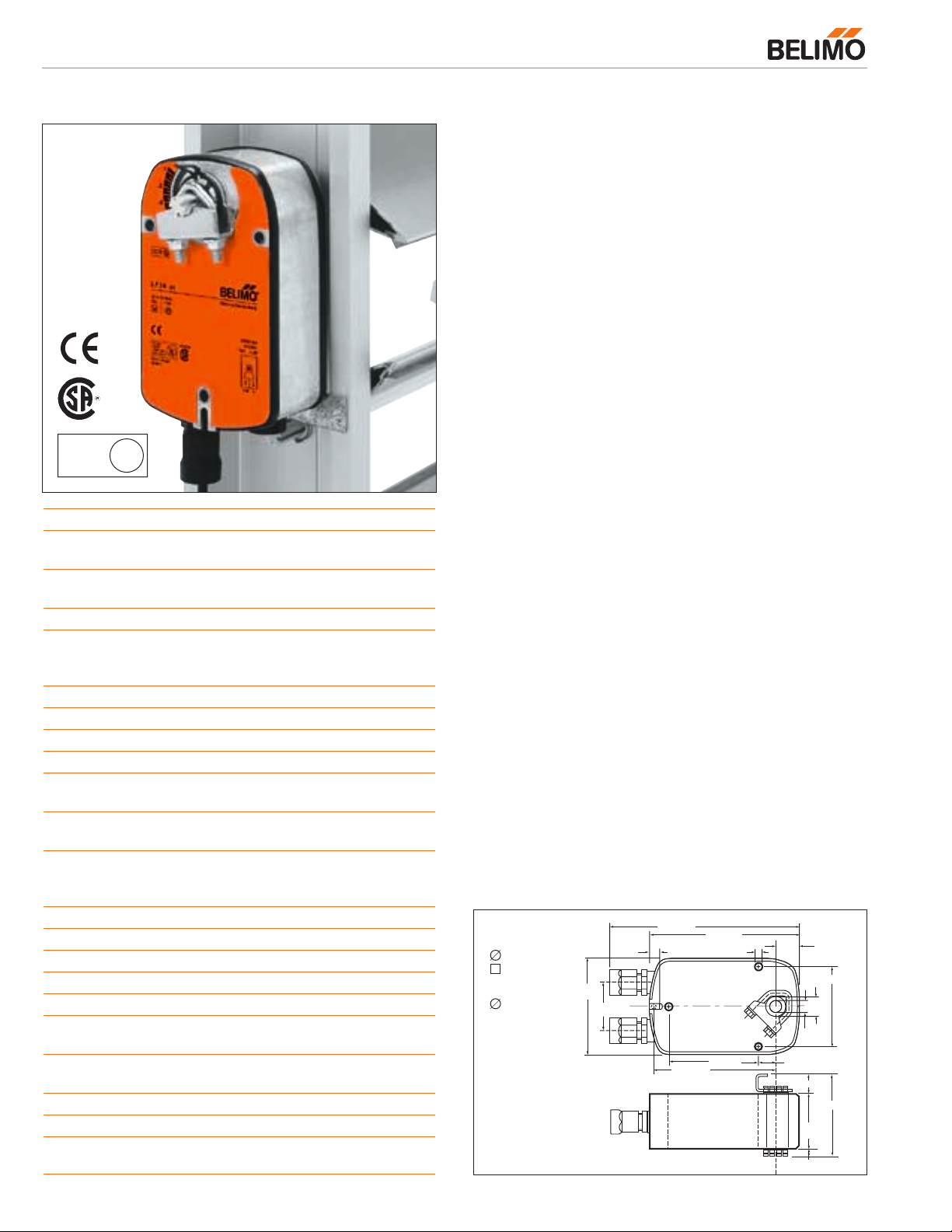

LF24 (-S) US

On-off, spring return safety, 24 V

®

Torque min. 35 in-lb, for control of air dampers

Application:

For on-off, fail-safe control of dampers in HVAC systems.

Actuator sizing should be done in accordance with the damper

manufacturer’s specifications. Control is on-off from an auxiliary contact, digital output, or a manual switch.

The actuator is mounted directly to a damper shaft from 3/8”

up to 1/2” in diameter by means of its universal clamp, 1/2”

shaft centered at delivery. For shafts up to 3/4” use K6-1

accessory. A crank arm and several mounting brackets are

available for applications where the actuator cannot be direct

coupled to the damper shaft.

Operation

The LF series actuators provide true spring return operation for

reliable fail-safe application and positive close off on air tight

dampers. The spring return system provides consistent torque

to the damper with, and without, power applied to the actuator.

The LF series provides 95° of rotation and is provided with a

graduated position indicator showing 0° to 90°.

The actuator may be stalled anywhere in its normal rotation

without the need of mechanical end switches. Power consumption is reduced in holding mode.

The LF24-S US version is provided with 1 built in auxiliary

switch. This SPDT switch is provided for safety interfacing or

signaling, for example, for fan start-up. The switching function

is adjustable between 0° and 95°. The auxiliary switch in the

LF24-S is double insulated so an electrical ground connection

is not necessary.

Dimensions

(All numbers in brackets are metric.)

Technical Data LF24 (-S) US

Power supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power consumption running: 5 W

holding: 2.5 W

Transformer sizing 7 VA (class 2 power source)

Electrical connection 3 ft, 18 GA appliance cable

(LF24-S US has 2 cables)

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Angle of rotation max. 95°, adjust. with mechanical stop

Torque 35 in-lb [4 Nm]

Direction of rotation reversible with cw/ccw mounting

Position indication visual indicator, 0° to 90° (0° is spring

return position)

Auxiliary switch 1 x SPDT 6A (1.5) @ 250 VAC,

UL listed

adjustable 0° to 95° (double insulated)

Running time motor: < 40 to 75 sec

spring: < 25 sec

@-4°F to +122°F [-20°C to +50°C]

< 60 sec

@-22°F [-30°C]

Humidity 5 to 95% RH noncondensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA type 2 / IP54

Housing material zinc coated steel

Agency listings UL 873 listed, CSA C22.2 No.24

certified, CE

Noise level max: running < 50 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight LF24 3.1 lbs (1.40 kg.)

LF24-S 3.2 lbs (1.45 kg.)

LISTED

94D5

TEMP. IND &

REG. EQUIP.

U

L

(LF24-S)

(nominal)

46

D010

Standard:

3/8" to 1/2"

3/8" to 7/16"

Optional

1/2" to 3/4"

w/K6-1

accessory

3.86"

[98]

1.93"

[49]

7.67" [195]

0.39" [10]

4.92" [125]

6.10" [155]

0.256" [6.5]

3.66" [93]

0.98"

[25]

0.71" [18]

0.25" [6.3]

0.79"

[20]

0.5"

[12.7]

0.74" [18.7]

2.24"

[57]

3.15" [80]

3.23" [82]

47

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

LF24 (-S) US

On-off, spring return safety, 24 V

®

Accessories

AV 10-18 Shaft extension (K6-1 is required)

IND-LF Damper position indicator

K6-1 Universal clamp for up to 3/4” diameter shafts

KH-LF Crankarm for up to 1/2” round shaft

Tool-01 10 mm wrench

ZG-LF2 Crankarm adaptor kit for LF

ZG-112 Mounting bracket for Honeywell Mod IV, M6415

type actuators, and new installations

ZG-LF112 Crankarm adaptor kit for Honeywell Mod IV,

M6415 type actuators, and new installations

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

Note: When using LF24 US and LF24-S US actuators,

only use accessories listed on this page.

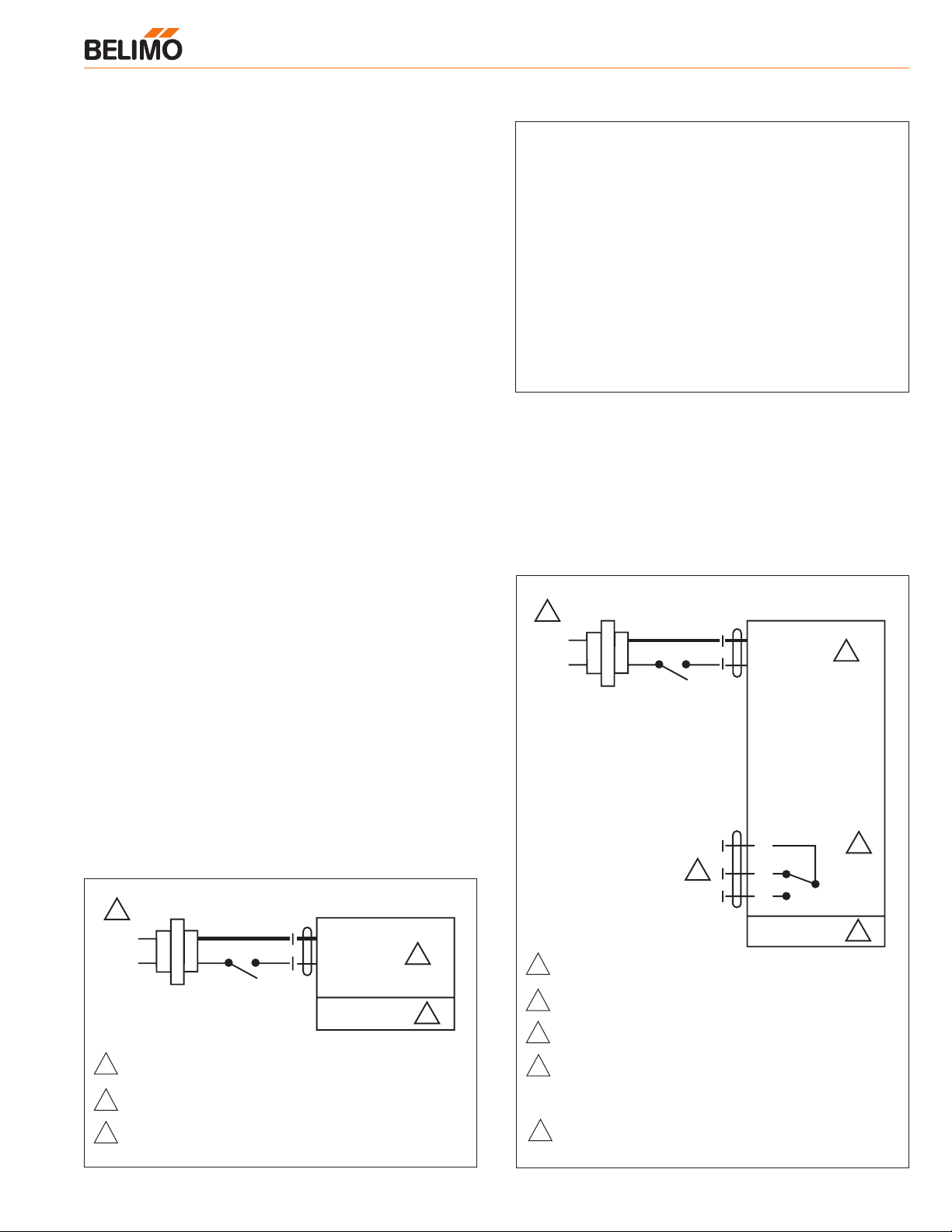

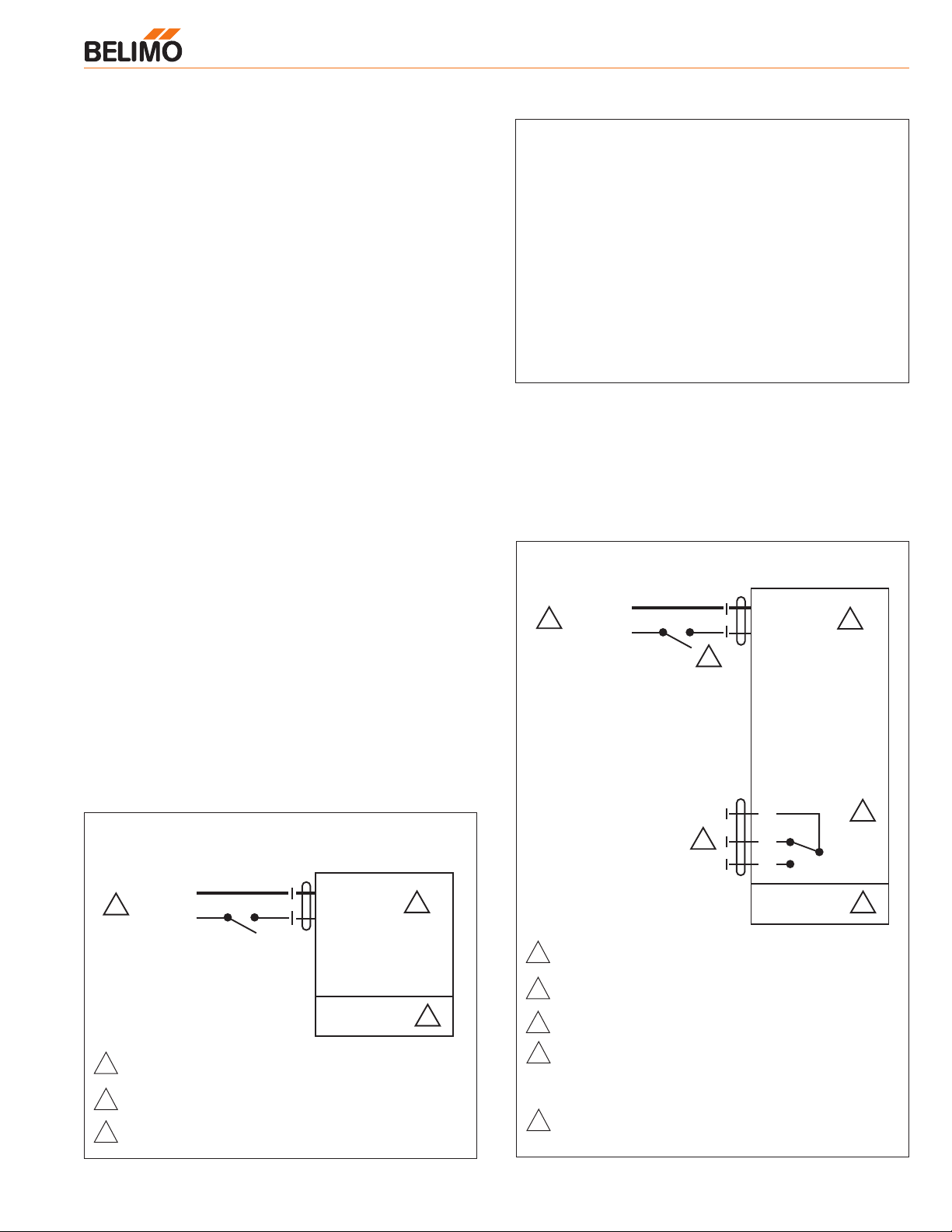

Wiring diagrams

LF24 (-S) US Typical Specification

On-off spring return damper actuators shall be direct coupled

type which require no crankarm and linkage and be capable

of direct mounting to a shaft up to a 3/4” diameter and center

a 1/2” shaft. The actuators must be designed so that they may

be used for either clockwise or counterclockwise fail-safe

operation. Actuators shall be protected from overload at all

angles of rotation. If required, 1 SPDT auxiliary switch shall be

provided having the capability of being adjustable. Actuators

with auxiliary switch must be constructed to meet the requirements for Double Insulation so an electrical ground is not

required to meet agency listings. Actuators shall be UL listed

and CSA certified, have a 2 year warranty, and be manufactured under ISO 9001 International Quality Control Standards.

Actuators shall be as manufactured by Belimo.

2

3

1

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power con-

sumption must be observed.

Actuator may also be powered by 24 VDC.

2

3

1

4

5

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power con-

sumption must be observed.

Actuator may also be powered by 24 VDC.

For end position indication, interlock control, fan startup, etc., LF24-S

US incorporates a built-in auxiliary

switch: 1 x SPDT, 6A (1.5A) @250 VAC, UL listed,

adjustable 0° to 95°.

Meets UL and CSA requirements without the need of an

electrical ground connection.

On-off wiring for LF24 US

On-off wiring for LF24-S US

W047

W048

24 V AC Transformer

1

Line

Volts

1 Common

2 + Hot

LF24 US

24 V AC Transformer

1

Line

Volts

5

3

2

1 Common

2 + Hot

S1

NC

S2

S3

NO

LF24-S US

3

4

0° to 95°

2

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

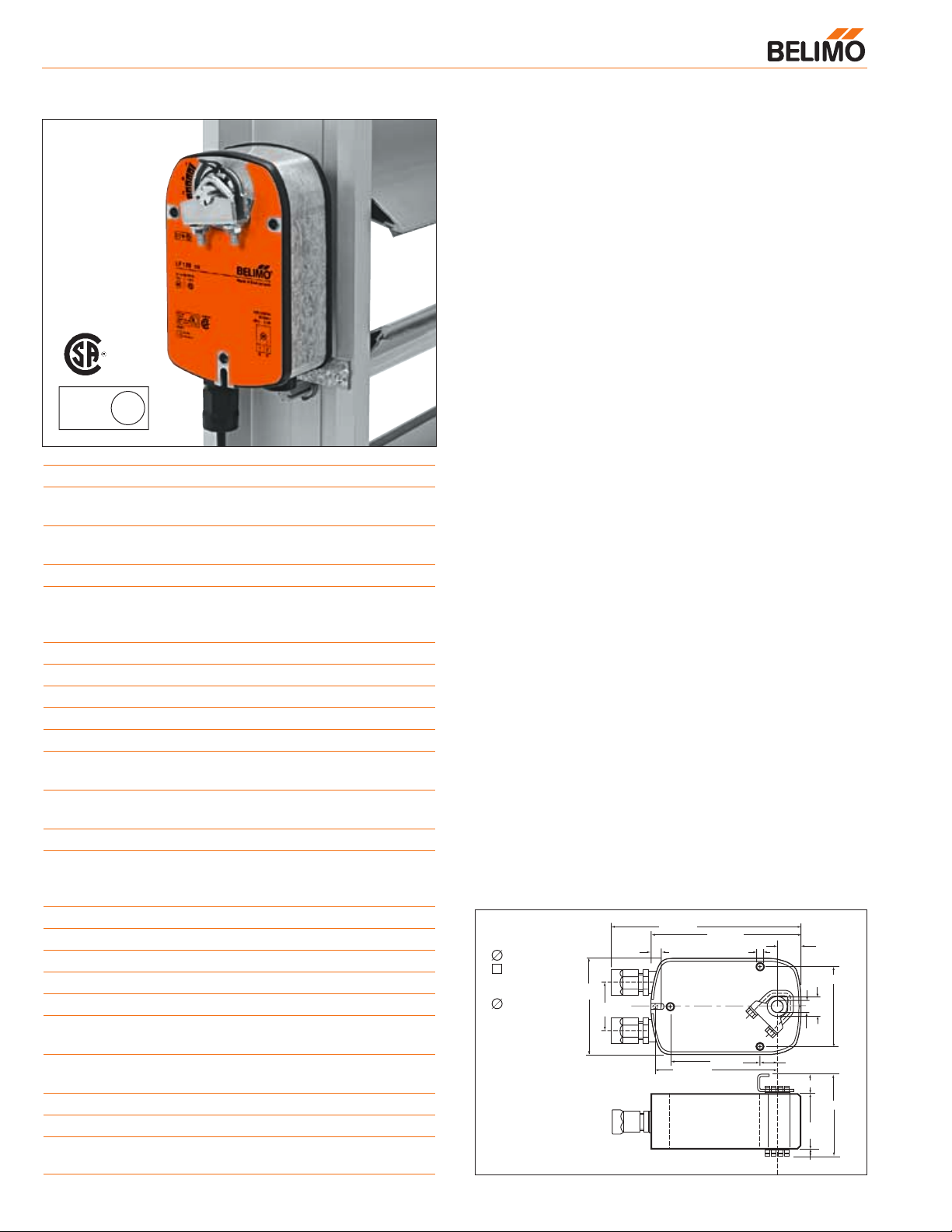

Torque min. 35 in-lb, for control of air dampers

Application:

For on-off, fail-safe control of dampers in HVAC systems.

Actuator sizing should be done in accordance with the damper

manufacturer’s specifications. Control is on-off from an auxiliary contact, or a manual switch.

The actuator is mounted directly to a damper shaft from 3/8”

up to 1/2” in diameter by means of its universal clamp, 1/2”

shaft centered at delivery. For shafts up to 3/4” use K6-1

accessory. A crank arm and several mounting brackets are

available for applications where the actuator cannot be direct

coupled to the damper shaft.

Operation

The LF series actuators provide true spring return operation for

reliable fail-safe application and positive close off on air tight

dampers. The spring return system provides consistent torque

to the damper with, and without, power applied to the actuator.

The LF series provides 95° of rotation and is provided with a

graduated position indicator showing 0° to 90°.

The actuator may be stalled anywhere in its normal rotation

without the need of mechanical end switches. Power consumption is reduced in holding mode. The actuator is double

insulated so an electrical ground connection is not necessary.

The LF120-S US and LF230-S US versions are provided with

1 built-in auxiliary switch. This SPDT switch is provided for

safety interfacing or signaling, for example, for fan start-up.

The switching function is adjustable between 0° and 95°.

Dimensions

(All numbers in brackets are metric.)

LF120 (-S) US / LF230 (-S) US

On-off, spring return safety, 120/230 VAC

Technical Data LF120 (-S) US LF230(-S) US

Power supply 120 VAC ± 10% 230 VAC ± 10%

50/60 Hz 50/60 Hz

Power consumption running: 5.5 W 5 W

holding: 3.5 W 3 W

Transformer sizing 7.5 VA 7 VA

Electrical connection 3 ft, 18 GA appliance cable

(-S models have 2 cables)

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Electrical protection actuators are double insulated

Angle of rotation max 95°, adjust. with mechanical stop

Torque 35 in-lb [4 Nm] constant torque

Direction of rotation reversible with cw/ccw mounting

Position indication visual indicator, 0° to 90° (0° is

spring return position)

Auxiliary switch 1 x SPDT 6A (1.5A) @ 250 VAC,

UL listed

(-S models) adjustable 0° to 95°

Electrical protection actuators are double insulated

Running time motor: < 40 to 75 sec

spring: < 25 sec

@-4°F to +122°F [-20°C to +50°C]

< 60 sec

@-22°F [-30°C]

Humidity 5 to 95% RH noncondensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA type 2 / IP54

Housing material zinc coated steel

Agency listings UL 873, CSA C22.2 No. 24 Certified,

CE [LF230(-S) US]

Noise level max: running < 50 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight LF120/230 3.4 lbs (1.54 kg.)

LF120/230-S 3.5 lbs (1.60 kg.)

(nominal)

48

D010

®

LISTED

94D5

TEMP. IND &

REG. EQUIP.

U

L

Standard:

3/8" to 1/2"

3/8" to 7/16"

Optional

1/2" to 3/4"

w/K6-1

accessory

3.86"

[98]

1.93"

[49]

7.67" [195]

0.39" [10]

4.92" [125]

6.10" [155]

0.256" [6.5]

3.66" [93]

0.98"

[25]

0.71" [18]

0.25" [6.3]

0.79"

[20]

0.5"

[12.7]

0.74" [18.7]

2.24"

[57]

3.15" [80]

3.23" [82]

49

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

LF120 (-S) US / LF230 (-S) US

On-off, spring return safety, 120/230 VAC

Accessories

AV 10-18 Shaft extension (K6-1 is required)

IND-LF Damper position indicator

K6-1 Universal clamp for up to 3/4” diameter shafts

KH-LF Crankarm for up to 1/2” round shaft

Tool-01 10 mm wrench

ZG-LF2 Crankarm adaptor kit for LF

ZG-112 Mounting bracket for Honeywell Mod IV, M6415

type actuators, and new installations

ZG-LF112 Crankarm adaptor kit for Honeywell Mod IV,

M6415 type actuators, and new installations

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

Note: When using LF120/230 US and LF120-S/230-S US

actuators, only use accessories listed on this page.

LF120 (-S) US / LF230 (-S) US Typical Specification

On-off spring return damper actuators shall be direct coupled

type which require no crankarm and linkage and be capable of

direct mounting to a shaft up to a 3/4” diameter and center a

1/2” shaft. The actuators must be designed so that they may

be used for either clockwise or counterclockwise fail-safe operation. Actuators shall be protected from overload at all angles

of rotation. If required, 1 SPDT auxiliary switch shall be provided having the capability of being adjustable. Actuators

must be constructed to meet the requirements for Double

Insulation so an electrical ground is not required to meet

agency listings. Actuators shall be UL listed and CSA certified,

have a 2 year warranty, and be manufactured under ISO 9001

International Quality Control Standards. Actuators shall be as

manufactured by Belimo.

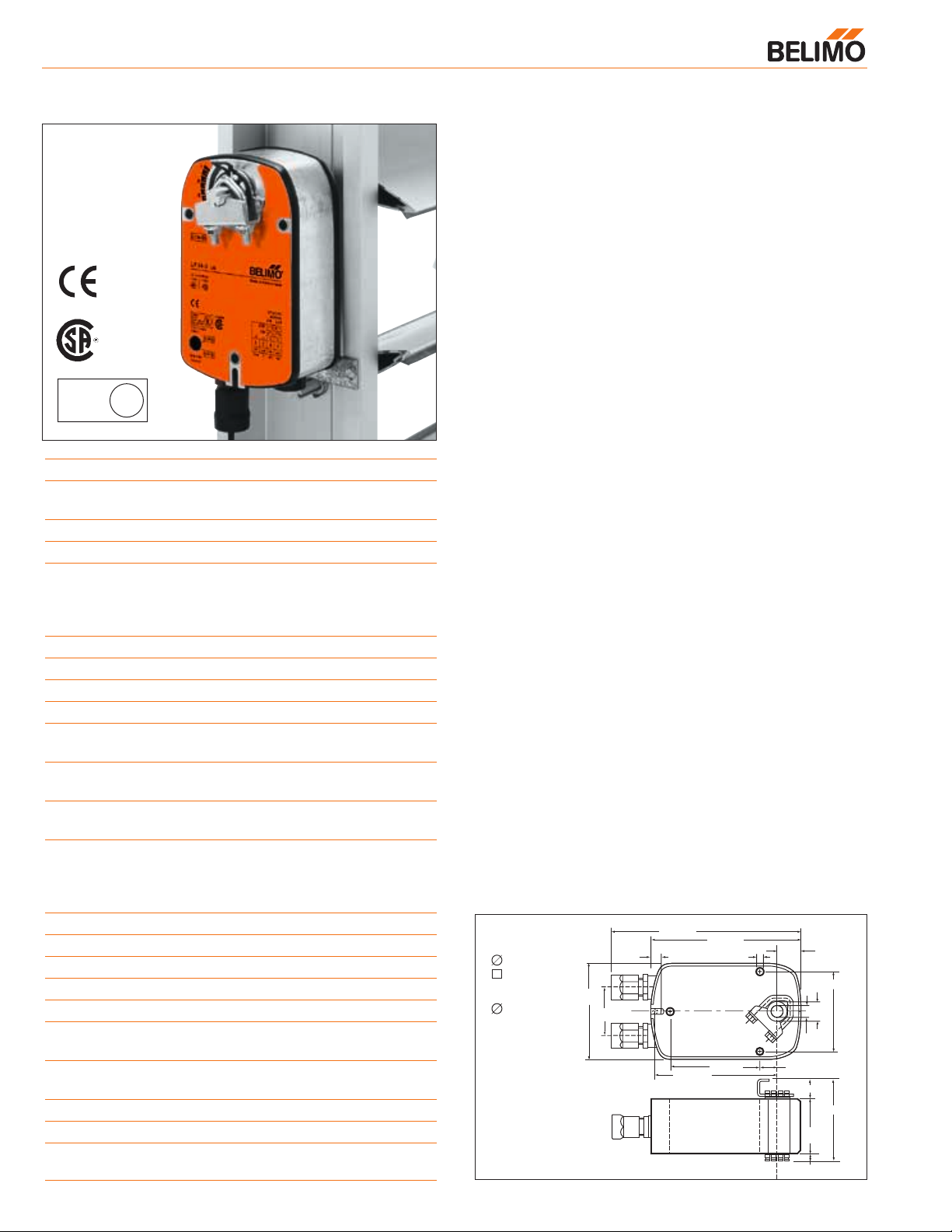

Wiring diagrams

2

1

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power con-

sumption must be observed.

No ground connection is required.

2

3

1

3

Provide overload protection and disconnect as required.

Actuators may be connected in parallel. Power con-

sumption must be observed.

No ground connection is required.

For end position indication, interlock control, fan startup, etc., LF120-S US and LF230-S US incorporate

one built-in auxiliary switch: 1 x SPDT, 6A (1.5A)

@250 VAC, UL listed, adjustable 0° to 95°.

Meets UL and CSA requirements without the need of an

electrical ground connection.

®

4

5

On-off wiring for LF120 US / LF230 US

On-off wiring for LF120-S US / LF230-S US

W049

W050

120 V AC

(230 VAC for LF230 US)

L1 N

1

L2 H

5

1 Neutral

2 Hot

3

120 V AC

(230 VAC for LF230 US)

L1 N

1

L2 H

1 Neutral

2 Hot

LF120 US

LF230 US

3

2

5

S1

NC

S2

S3

NO

LF120-S US

LF230-S US

4

0° to 95°

2

D20230 / 5 4 3 2 1 -10/01-20M-IL-Subject to change. © Belimo Aircontrols (USA), Inc.

LF24-3 (-S) US

On-off, spring return safety, reversible, floating point, 24V

Torque min. 35 in-lb, for control of air dampers

Application

For modulation or on-off control of dampers in HVAC systems.

Actuator sizing should be done in accordance with the damper

manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 3/8”

up to 1/2” in diameter by means of its universal clamp, 1/2”

shaft centered at delivery. For shafts up to 3/4” use K6-1

accessory. A crank arm and several mounting brackets are

available for applications where the actuator cannot be direct

coupled to the damper shaft.

Control is 3 wire, floating point from a triac or relay, or on-off

from an auxiliary contact from a fan motor contactor, controller, or manual switch.

Operation

The LF series actuators provide true spring return operation for

reliable fail-safe application and positive close-off on air tight

dampers. The spring return system provides consistent torque

to the damper with, and without, power applied to the actuator.

The LF series provides 95° of rotation and is provided with a

graduated position indicator showing 0 to 90°.

The LF24-3 (-S) US uses a brushless DC motor which is controlled by an Application Specific Integrated Circuit (ASIC) and a

microprocessor. The microprocessor provides the intelligence to

the ASIC to provide a constant rotation rate. The ASIC monitors

and controls the brushless DC motor’s rotation and provides a

digital rotation sensing function to prevent damage to the actuator in a stall condition. The actuator may be stalled anywhere in

its normal rotation without the need of mechanical end switches.

Power consumption is reduced in holding mode.

The LF24-3-S US version is provided with 1 built-in auxiliary

switch. This SPDT switch is provided for safety interfacing or

signaling, for example, for fan start-up. The switching function

is adjustable between 0° and 95°. The auxiliary switch in the

LF24-3-S US is double insulated so an electrical ground is not

necessary.

Dimensions

(All numbers in brackets are metric.)

Technical Data LF24-3 (-S) US

Power supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power consumption running: 2.5 W ; holding: 1 W

Transformer sizing 5 VA (class 2 power source)

Electrical connection LF24-3 US 3 ft, plenum rated cable

LF24-3-S US 3 ft, 18 GA appliance

cables (2)

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Input impedance 1000 Ω (0.6w) control inputs

Angle of rotation max. 95°, adjust. with mechanical stop

Torque 35 in-lb [4 Nm]

Direction of rotation spring: reversible with cw/ccw mounting

motor: reversible with built-in switch

Position indication visual indicator, 0° to 90° (0° is

spring return position)

Auxiliary switch 1 x SPDT 6A (1.5A) @ 250 VAC,

UL listed

(LF24-3-SUS) adjustable 0° to 95° (double insulated)

Running time motor: 150 sec constant,

independent of load

spring: < 25 sec

@-4°F to +122°F [-20°C to +50°C]

< 60 sec

@-22°F [-30°C]

Humidity 5 to 95% RH noncondensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA type 2 /IP54

Housing material zinc coated metal

Agency listings UL 873 listed; CSA C22.2 No. 24

certified, CE

Noise level max: running < 30 db (A)

spring return 62 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight LF24-3 3.1 lbs (1.40 kg.)

LF24-3-S 3.6 lbs (1.45 kg.)

LISTED

94D5

TEMP. IND &

REG. EQUIP.

U

L

®

50

D010

Standard:

3/8" to 1/2"

3/8" to 7/16"

Optional

1/2" to 3/4"

w/K6-1

accessory

3.86"

[98]

1.93"

[49]

7.67" [195]

0.39" [10]

4.92" [125]

6.10" [155]

0.256" [6.5]

3.66" [93]

0.98"

[25]

0.71" [18]

0.25" [6.3]

0.79"

[20]

0.5"

[12.7]

0.74" [18.7]

2.24"

[57]

3.15" [80]

3.23" [82]

Loading...

Loading...