Page 1

Installation & Maintenance Instructions

2-WAY PILOT-OPERATED OR DIRECT - ACTING SOLENOID VALVES

NORMALLY CLOSED OPERATION Ċ 3/4I, 1I, OR 1 1/2I NPT

FUEL GAS SERVICE

SERIES

K3A6

K3A7

Form No.V8501

Service Notice

Except for coil replacement, the Series K3A6 and K3A7 are

not repairable. When any performance problems are

detected during routine inspection, replace valve

immediately.

DESCRIPTION

Series K3A6 and K3A7 valves are 2-way normally closed

solenoid valves designed for fuel gas service. Series K3A6 is

a pilot-operated solenoid valve, while Series K3A7 is

direct-acting. Valve bodies are made of rugged aluminum

with trim and internal parts made of steel and stainless steel.

These valves are provided with a general purpose junction box

solenoid enclosure.

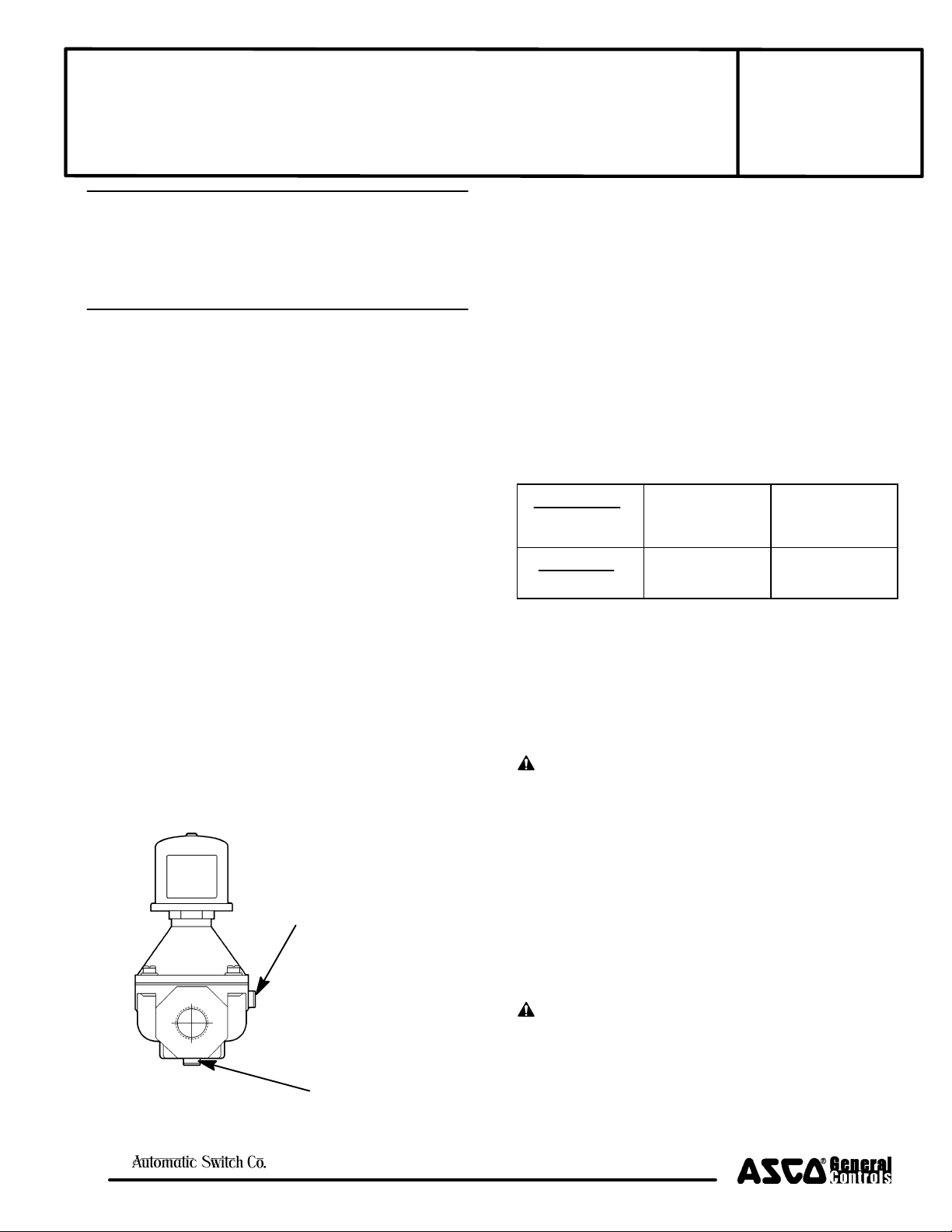

Provisions for Pressure and Seat Leakage Testing

Series K3A6 and K3A7 valves are provided with two 1/8I NPT

tapped and plugged holes (pressure taps). The upstream

tapped and plugged hole is on the side of the valve body;

downstream on the bottom of the valve body. One upstream

for pressure testing; one downstream for seat leakage testing.

Leakage testing frequency shall be at least annually in

accordance with NFPA-86 or original equipment

manufacturer recommendations. For instructions, refer to

section on Testing for Internal (Seat) Leakage and Figure 3.

Partial view of valve body showing location

of tapped and plugged holes for pressure

and seat leakage testing

Pipe plugs are 1/8I NPT

(use 3/16I Hex Key Wrench)

Tapped and pluged hole

(pressure tap)

on side of valve body

for upstream pressure

testing

OPERATION

Normally Closed: Valve is closed when solenoid is

de-energized; open when energized.

Note: No minimum operating pressure differential required.

INSTALLATION

Check nameplate for correct catalog number, pressure,

voltage, frequency, and service. Never apply incompatible

fluids or exceed pressure rating of the valve. Installation and

valve maintenance to be performed by qualified personnel.

Temperature Limitations

Coil Class

Temperature

Rating

F

311_F (155_C)

Nominal

Fluid

Temperature

77_F(25_C)

Ambient

Temperature

Range

-40_F (-40_C) to

175_F (80_C)

Positioning

Valve must be mounted with solenoid vertical and upright or

in a horizontal position only. Valves equipped with rainproof

housings (W in the 3rd character position of the valve catalog

number) must be mounted in a vertical and upright position

only.

Piping

CAUTION: Piping must comply with applicable

local and national codes and ordinances, including the

National Fuel Gas Code ANSI Z223.1/NFPA No. 54.

Connect piping to valve according to flow arrow on bottom of

valve body. Apply pipe compound sparingly to male pipe

threads only. If applied to valve threads, the compound may

enter the valve and cause operational difficulty. Avoid pipe

strain by properly supporting and aligning piping. When

tightening the pipe, do not use valve or solenoid as a lever.

Locate wrenches applied to valve body or piping as close as

possible to connection point. Valve should be checked for

external leakage at piping connections after installation, see

Testing for External Leakage section.

Tapped and pluged hole

(pressure tap)

on bottom of valve body

for downstream seat

leakage testing

Figure 1. Provisions for pressure and seat leakage testing.

e

50-60 Hanover Road, Florham Park, New Jersey 07932

MCMXCVII All Rights Reserved.

CAUTION: To avoid damage to the valve body, DO

NOT OVERTIGHTEN PIPE CONNECTIONS. If Teflon*

tape, paste, spray, or similar lubricant is used, use extra

care when tightening due to reduced friction.

*DuPont's Registered Trademark

Page 1 of 4

Printed in U.S.A.

Valves & Actuators

Page 2

CAUTION: To protect the solenoid valve, install a

strainer or filter, suitable for the service involved, in the

inlet side as close to the valve as possible. Clean

periodically depending on service conditions. See

ASCO Series 8600, 8601 and 8602 for strainers.

Wiring

Wiring must comply with local codes and the National

Electrical Code. To facilitate wiring, the solenoid enclosure

may be rotated 360_ by loosening the screw on the top of the

enclosure. Rotate enclosure to desired position, then torque

screw to 10 - 13 in-lbs [1,1 - 1,5 Nm]. The junction box

housing has two 7/8I diameter knockouts to accommodate

1/2I conduit. Drive out appropriate knockout with junction

box completely assembled (with cover) for support. Remove

J" box cover, by spreading cover and disengaging nibs (lift up

and pull down simultaneously). The coil jacket is provided

with a grounding screw (green) and a tab for the grounding

connection. Within the junction box solenoid enclosure use

field wire that is rated 90_ C or greater for connections.

Replace"J" box cover before operating.

Testing for External Leakage

WARNING: To prevent the possibility of

severe personal injury or property damage,

extinguish all open flames and avoid any type of

sparking or ignition.

1. Block gas flow on downstream side of valve.

2. Apply pressure to valve within nameplate rating and

energize solenoid.

3. Apply a soapy solution or a commercially available leak

detecting solution to the pipe connections and check for

bubbles. If the valve has been tested for seat leakage,

apply the solution around the pipe plugs.

4. If leakage exists, depressurize valve and turn off

electrical power supply. Tighten connections as required

and retest following the above steps.

Solenoid Temperature

Series K3A6 and K3A7 valves are supplied with coils designed

for continuous duty service. When the solenoid is energized

for a long period, the solenoid enclosure becomes hot and can

be touched with the hand for an instant. This is a safe operating

temperature. Any excessive heating will be indicated by the

smoke and odor of burning coil insulation.

Preventive Maintenance

S Prepare and follow a routine inspection schedule based on

the media, environment, and frequency of use. This should

include periodic internal and external leakage checks.

S Keep the medium flowing through the valve as free from

dirt and foreign material as possible.

S While in service, the valve should be operated at least once

a month to ensure proper opening and closing.

NOTE: For performance problems, refer to Troubleshooting

Chart on page 4 of 4.

Coil Replacement (Refer to Figure 2)

NOTE: It is not necessary to remove the valve from the pipeline for

Coil Replacement.

CAUTION: Exercise care to prevent damage to the

plunger tube. Do not grasp plunger tube with wrench or

pliers.

1. Remove cover and disconnect supply wires to coil,

grounding wire, and rigid conduit from coil jacket.

2. Remove screw and lockwasher, then carefully lift coil

jacket assembly off plunger tube.

3. Remove the spring, coil, coil frames and washers from

the coil jacket.

4. Reassemble in reverse order of disassembly, using a new

replacement coil.

5. Place inner washers, then coil frames onto coil as

originally configured. Coil voltage markings on coil must

face toward valve body.

6. Place the spring inside the coil jacket.

7. Insert coil lead wires through hole in coil jacket. Pull

wires all the way through, and seat coil in jacket.

8. Place bottom washer inside coil jacket.

9. Place coil/jacket assembly on plunger tube.

10. Install lockwasher, and screw onto coil jacket. Torque

screw to 10-13 in-lbs [1,1-1,5 Nm].

11. Make electrical connections to solenoid, see Wiring

section.

12. Replace J" box cover on coil jacket.

CAUTION: Solenoid must be fully reassembled as

the coil jacket and internal parts are part of and

complete the magnetic circuit.

MAINTENANCE

WARNING: To prevent the possibility of

severe personal injury or property damage, turn

off electrical power, depressurize valve,

extinguish all open flames and avoid any type of

sparking or ignition. Vent hazardous or

combustible fluid to a safe area before inspection

or removing the valve from service.

Page 2 of 4

Valves & Actuators

Form No.V8501

50-60 Hanover Road, Florham Park, New Jersey 07932

Page 3

Figure 2. Exploded view, typical K3A valve.

4. Shut off the upstream manual gas cock and de-energize

valve. Remove the plug from the leak test tap or

downstream pressure tap in the valve body. Connect leak

test equipment with the test petcock in the closed position

(Figure 3).

5. Open the upstream manual gas cock. Program the

control system to energize the valve to the full open

position, then immediately de-energize it to seat the

valve operationally.

6. Immerse the 1/4I leak test tube vertically into a jar of

water to a depth of about 1/2I. Slowly open the test

petcock. Bubbles may appear in the water as the pressure

equalizes.

7. After the rate of bubbles coming through the water

stabilizes, count the number of bubbles appearing in a 10

second period. The allowable leakage in 10 seconds for

an orifice diameter of 1 inch (25.4 mm) or less is 6

bubbles (3 cc/min). For valves with an orifice diameter

over 1 inch (25.4 mm) the allowable leakage rate is 6

bubbles (3 cc/min.) per inch (25.4 mm) of orifice

diameter. If leakage exceeds this rate, replace valve.

NOTE: The leakage rate above recognizes that some wear

and contamination from use can result in a slight amount of

leakage. The allowable leakage rate is well within the leakage

limits as recognized by applicable approval agencies.

8. Close the upstream manual gas cock and the test petcock.

Then remove the test equipment. Apply a small amount

of Loctite Corporation's PSTr Pipe Sealant 567 (or

equivalent) to the pipe plug threads. Reinstall the pipe

plug and tighten securely.

9. Turn on the gas supply at the upstream manual gas cock

and energize the valve.

10. Open the upstream manual gas cock. Program the

control system to energize and maintain the valve in the

open (energized) position. Check all valve and piping

connections for external leaks with rich soap and water

solution or a commercially available leak detecting

solution.

11. De-energize the valve. Open the downstream manual

gas cock.

12. Restore the system to normal operation.

Testing for Internal (Seat) Leakage (Refer to Figure 3)

CAUTION: Be sure valve can be tested without

affecting other equipment.

1. Shut off both the upstream and downstream manual gas

cocks. The downstream manual gas cock should remain

closed throughout the entire test procedure.

2. Program the control system to operate the valve through

five cycles. Listen carefully for the solenoid coil to click

indicating proper operation.

3. Open the upstream manual gas cock. Program the

control system to energize and maintain the valve in the

open (energized) position. Check all valve and piping

connections for external leaks with rich soap and water

solution or a commercially available leak detecting

solution.

50-60 Hanover Road, Florham Park, New Jersey 07932

Figure 3. Testing for internal seat leakage.

Page 3 of 4Form No.V8501

Valves & Actuators

Page 4

ORDERING INFORMATION

FOR COIL REPLACEMENT

When ordering coils, specify valve catalog number, voltage

and coil number, if possible.

Troubleshooting Chart

Trouble Possible Cause Remedy

Valve operation is sluggish

Valve fails to open

Solenoid coil short, or wrong voltage.

Damaged plunger assembly.

Dirt or other foreign matter restricting

operation of valve.

Timer, limit controls or other devices not

energizing circuit.

Damaged plunger assembly preventing

plunger operation.

Solenoid coil short, burned-out or

wrong voltage.

Dirt, pipe compound or other foreign

matter restricting operation of valve.

Check coil voltage. Replace solenoid

coil.

Replace valve.

Replace valve and install strainer

upstream of valve.

Check circuit for limit control operation,

blown fuse, short circuit and loose

wiring.

Replace valve.

Replace with solenoid coil of correct

voltage

Replace valve and install strainer

upstream valve.

Valve fails to close

Valve chatters"

Valves & Actuators

Damaged plunger assembly preventing

plunger operation.

Dirt, pipe compound or other foreign

matter restricting operation of valve.

Limit controls improperly installed to

grounded side.

Valve supply voltage is improper

(too low)

Dirt or chips between top of plunger

assembly and plunger tube.

Page 4 of 4

Replace valve.

Replace valve and install strainer

upstream of valve.

Wire controls in hot side of circuit.

Apply correct voltage to valve.

Replace valve and install strainer

upstream of valve.

Form No.V8501

50-60 Hanover Road, Florham Park, New Jersey 07932

Loading...

Loading...