Canon Sts-h1 Service Manual

SERVICE

MANUAL

REVISION 0

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

DEC. 1997

FY8-13F5-000

STAPLER SORTER-H1

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN, AND IS

FOR REFERENCE USE ONLY. SPECIFICATIONS AND OTHER INFORMATION CONTAINED

HEREIN MAY VARY SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN

ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki, 302 Japan

This Service Manual provides basic facts and figures needed to service the Stapler Sorter-H1 in the

field and consists of the following:

Chapter 1 “General Descriptions” shows features, specifications, and names of external parts and how

to operate the sorter.

Chapter 2 “Operations and Timing” discusses the sorter’s mechanical and electrical systems by

function and various timing of operation.

Chapter 3 “Mechanical System” shows how to disassemble, assemble, and adjust the sorter.

Chapter 4 “Maintenance and Inspection” gives lists of periodically replaced parts and consumables/

durables and a scheduled servicing chart.

Chapter 5 “Troubleshooting” shows how to troubleshoot possible faults and gives electrical parts

arrangement diagrams, VR/LED/check pin diagrams by PCB, and self diagnosis tables.

In addition to the above chapters, this Service Manual contains an Appendix consisting of a general

timing chart, a signals/abbreviations list, communications signals list, a General circuit diagram controller

circuit diagrams, special tools list, and solvent/oils list.

For installation, refer to the Installation Procedure that comes with the Sorter Mounting Kit.

i

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

ii

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS.................................1-5

A. External View ...................................1-5

B. Cross Section...................................1-6

IV. OPERATION ............................................1-7

A. Operation Panel................................1-7

B. Stapling.............................................1-8

C. Resupply of Staples to Stapler.......1-10

D. Removing a Staple Jam.................1-12

E. Removing Paper Clogging .............1-13

CHAPTER 2 OPERATIONS AND TIMING

I. CONSTRUCTION....................................2-1

A. Functional Construction....................2-1

B. Electrical Circuitry.............................2-2

C. Sorter Controller Input/Output..........2-3

D. Communication between Copier

and Sorter.........................................2-6

II. BASIC OPERATIONS..............................2-7

A. Outline..............................................2-7

B. Basic Operations..............................2-9

III. FEED DRIVE SYSTEM.........................2-16

A. Outline............................................2-16

B. Controlling the Feed Speed............2-18

C. Over Stack Condition.....................2-19

D. Jam.................................................2-22

IV. STAPLER UNIT DRIVE SYSTEM.........2-24

A. Outline............................................2-24

B. Stapler Unit.....................................2-26

C. Controlling the Swinging

Movement of the Stapler Unit.........2-32

D. Holding the Paper...........................2-36

E. Stapling Operation Timing..............2-37

V. BIN UNIT DRIVE SYSTEM...................2-38

A. Outline............................................2-38

B. Bin Unit...........................................2-39

C. Controlling the Guide Bar...............2-44

D. Sensors Inside Bin Unit..................2-47

E. Other Sensors................................2-48

VI. POWER SUPPLY..................................2-49

I. EXTERNALS ...........................................3-1

A. External Covers................................3-1

B. Feed Guide Unit...............................3-2

II. BIN UNIT.................................................3-3

A. Detaching the Bin Unit .....................3-3

B. Detaching the Bin.............................3-6

C. Detaching the Bin Shift Motor

(M1)................................................3-11

D. Lead Cam.......................................3-12

E. Detaching the Guide Bar Motor

(M3)................................................3-16

III. FEED GUIDE UNIT...............................3-17

A. Detaching the Feed Guide Unit......3-17

B. Detaching the Feed Motor (M2).....3-18

C. Detaching the Feed Roller..............3-19

IV. STAPLER UNIT.....................................3-20

A. Detaching the Stapler Unit.............3-20

V. STAPLER SWING UNIT ........................3-21

A. Detaching the Stapler Unit

Swing Motor (M4)...........................3-21

B. Detaching the Stapler Swing Unit ..3-22

CHAPTER 3 MECHANICAL SYSTEM

CONTENTS

CHAPTER 4 MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED PARTS......4-1

II. CONSUMABLES.....................................4-1

CHAPTER 5 TROUBLESHOOTING

I. STANDARDS AND ADJUSTMENTS.........5-1

A. Electrical System..............................5-1

B. Mechanical System..........................5-7

II. TROUBLESHOOTING ...........................5-9

A. Procedure.........................................5-9

III. ELECTRICAL PARTS LAYOUT

DIAGRAM..............................................5-14

A. Sensors ..........................................5-14

B. Motors, Switches, Solenoids,

PCBs ..............................................5-16

APPENDIX

A. TIMING CHART.......................................A-1

B. SIGNAL NAME/ABBREVIATION LIST.....A-5

III. PERIODICAL SERVICING......................4-1

IV. PCB.......................................................5-18

F. Dip Switch Function List.................5-19

V. SELF DIAGNOSIS.................................5-20

A. Stack Over Alarm...........................5-20

B. Stapler Alarm..................................5-20

C. Jam.................................................5-21

D. Error................................................5-22

C. LIST OF COMMUNICATION

DATA/SIGNAL WITH COPIER...............A-15

iv

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

I. FEATURES..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS.................................1-5

A. External View ...................................1-5

B. Cross Section...................................1-6

IV. OPERATION ............................................1-7

A. Operation Panel................................1-7

B. Stapling.............................................1-8

C. Resupply of Staples to Stapler.......1-10

D. Removing a Staple Jam .................1-12

E. Removing Paper Clogging .............1-13

11

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

I. FEATURES

1. Light-weight, compact design

In comparison with the existing 20-bin stapler sorters, the size, weight and number of components of

this model have been remarkably reduced, while securing the loadability over equivalence to the former

models. Reliability and serviceability have been also improved.

2. Applicable to multiple types of copiers

Straight path communication system of this model allows it to be adapted to multiple types of copiers.

(Communication can be switched between the new and former IPCs. Allowable speed range is 20 ~

60 cpm.)

× 17", B4, LGL) 25 copies/bin

Sort mode:

50 copies (A4, LTR, B5, A5, STMT,

A4R, LTR-R, B5R)

25 copies (A3, 11" × 17", B4, LGL)

Staple sort mode:

50 copies (A4, LTR, B5, A4R, LTR-R) Unavailable to

B5R, STMT, A5

25 copies (A3, 11" × 17", B4, LGL)

Group mode:

30 copies (A4, LTR, B5, A5, STMT,

A4R, LTR-R, B5R)

25 copies (A3, 11" × 17", B4, LGL)

Bin return time Approx. 10 sec.

(from 20th to 1st bin)

Limitless function Available

Bin designation function Unavailable

Control panel STAPLE key

Display panel STAPLE RESUPPLY indicator

Stapling Rotating cam

Copy paper size for A3, A4, B4, B5, A4R,11" × 17", LGL, LTR, LTR-R

auto stapling

*1. Capacity per bin may vary depending on restrictions on the host copier.

*2. When the copies are below 100 sheets, all of them are loaded into the first bin.

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

12

1. GENERAL DESCRIPTION

II. SPECIFICATIONS

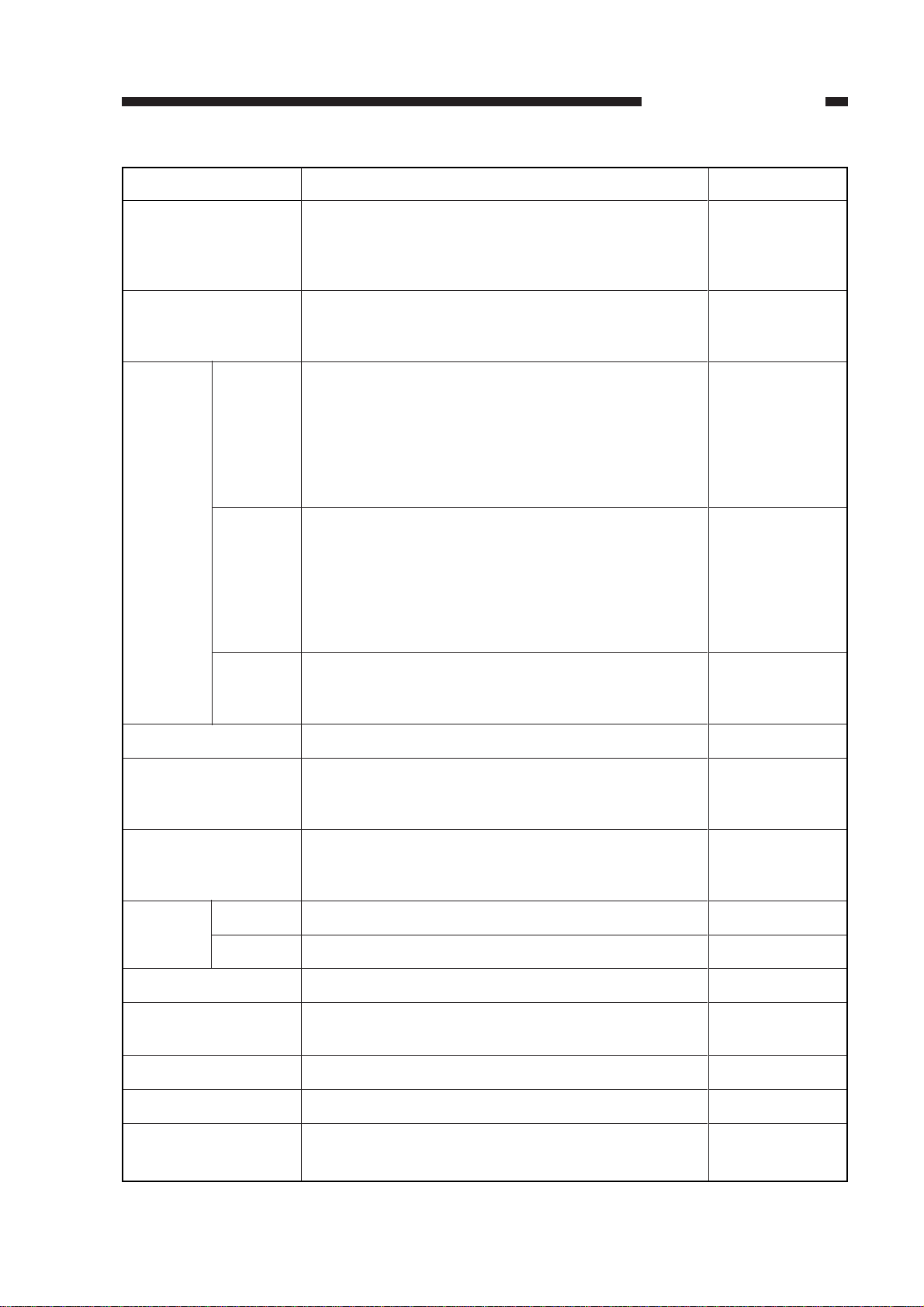

Item Spec. Remarks

Loading Face up, bin shift and open

No. of bins 20

Capacity per bin: *

equivalent to 80 g/cm

1

Non sort mode:

2

600 copies (A4, LTR, B5, STMT, 30 copies/bin *

500 copies (A3, 11"

2

A4R, LTR-R, B5R)

Item

Size of copies (for

manual stapling by key

operation after copying

process)

Size of copies (for

manual insertion and

stapling by user)

Automatic

stapling

Manual

stapling

Manually

fed paper

stapling

Staple

No staple detection

Automatic staple

feeding

Temperature

Humidity

Power supply

Max. power

consumption

Serial No.

Weight

Dimensions

(W × D × H)

Spec.

A3, A4, B4, B5, A4R, 11” × 17”, LGL, LTR, LTR-R

Any size

50 copies: A4, LTR, B5, A4R, LTR-R

25 copies: A3, 11" × 17", B4, LGL

50 copies: A4, LTR, B5, A4R, LTR-R

25 copies: A3, 11" × 17", B4, LGL

30 copies: any size

Staple for specific use (refilling type, 5,000 staples)

Available (when remaining staples are below 40 after

the stapling process, NO STAPLE indicating lamp lights

up)

Available (after staples are resupplied and the stapler

unit cover is closed, the staples are automatically fed to

the stapling position)

As per copier

As per copier

24V (from copier)

Approx. 50W

ZRVxxxxx

Approx. 20kg

348 × 595 × 626 [mm]

13

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

Remarks

48 copies of 80

g/cm2paper + 2

copies of 200g

paper or bundle

of paper below

5.5mm in

thickness

48 copies of 80

g/cm2paper + 2

copies of 200g

paper or bundle

of paper below

5.5mm in

thickness

No. of

copies

(for

stapling

paper

equivalen

t to 80

g/m2)

Operating

environm

ent

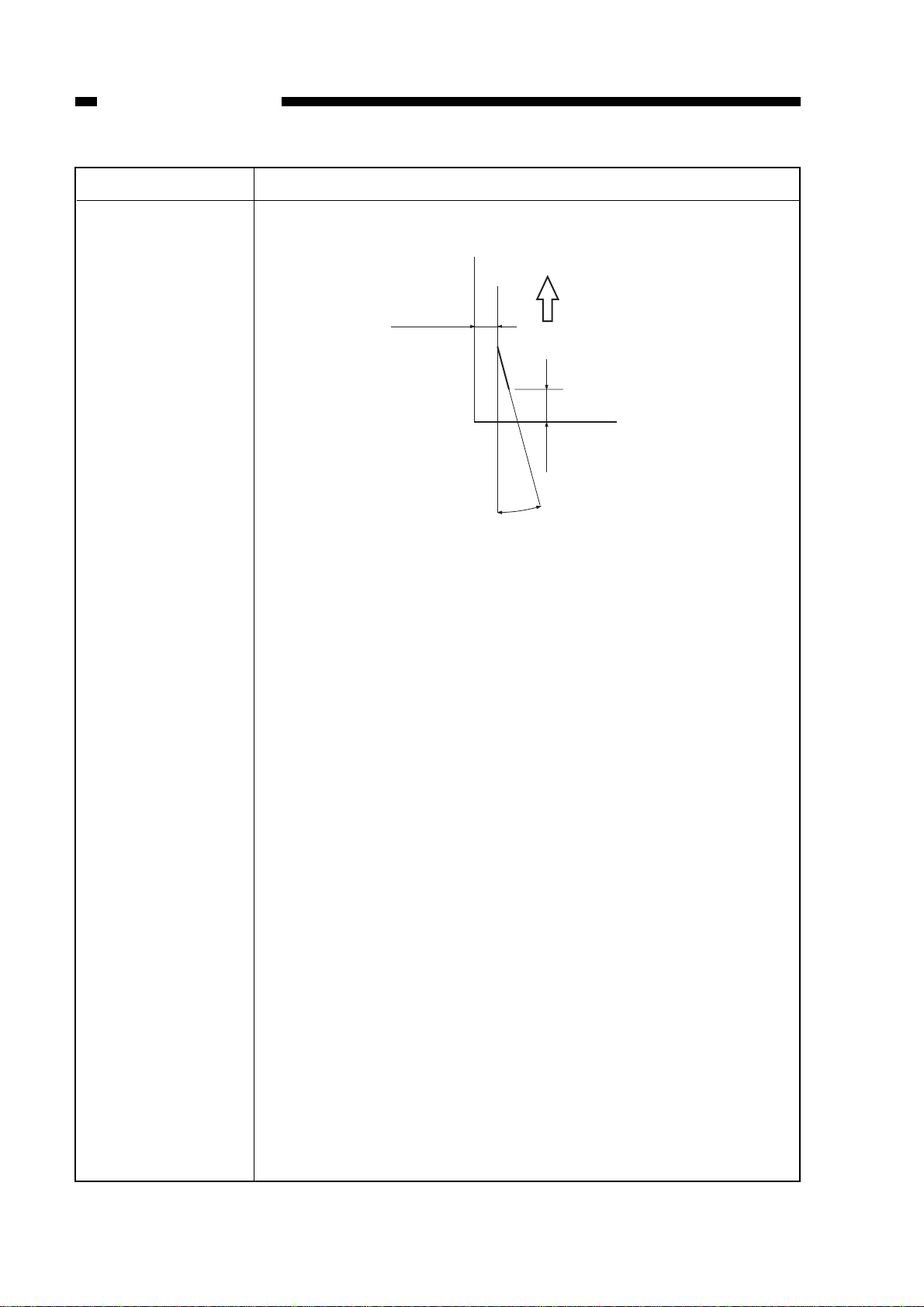

1. GENERAL DESCRIPTION

6±2mm

6±2mm

Feed direction

15˚

Item

Staple position

Spec.

14

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

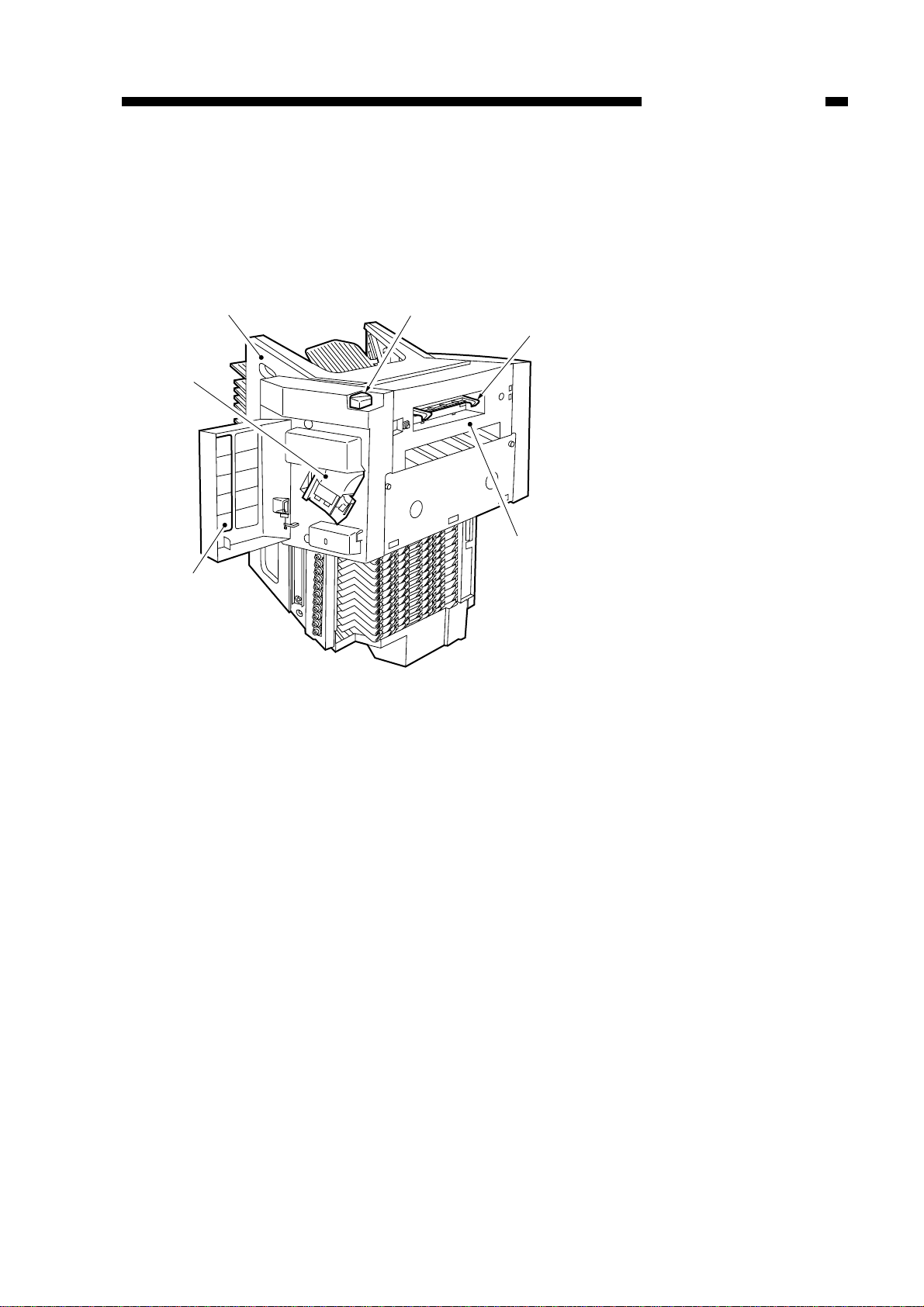

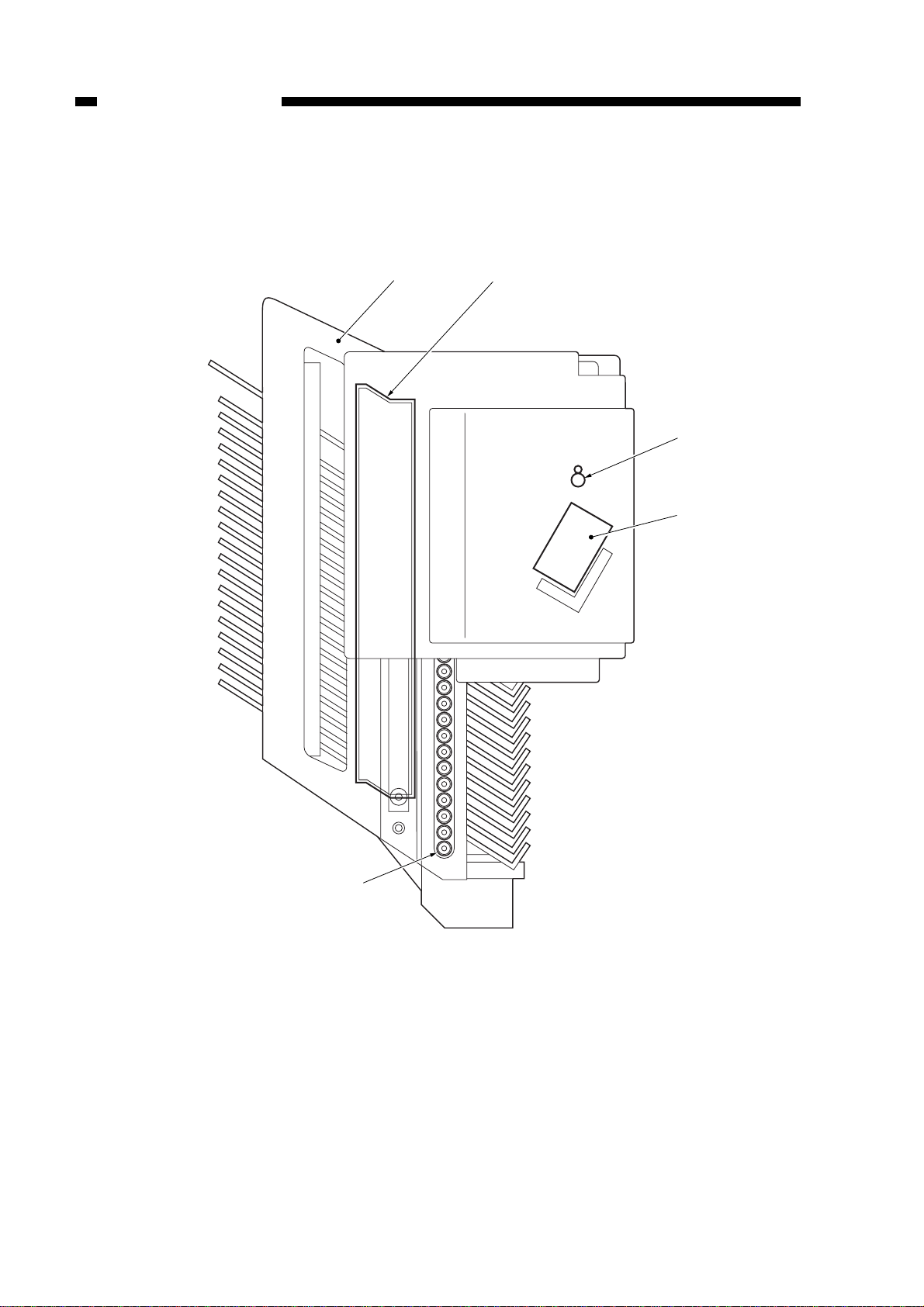

III. NAMES OF PARTS

q

e

w

t

y

r

A. External view

1. GENERAL DESCRIPTION

q Bin unit

w Stapler unit cover

e Stapler unit

r Feed guide unit

t Latch lever

y Latch

Figure 1-301

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

15

1. GENERAL DESCRIPTION

qw

t

r

e

B. Cross section

q Bin unit

w Guide bar

e Roll

r Stapler unit

t Feed roller

Figure 1-302

16

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

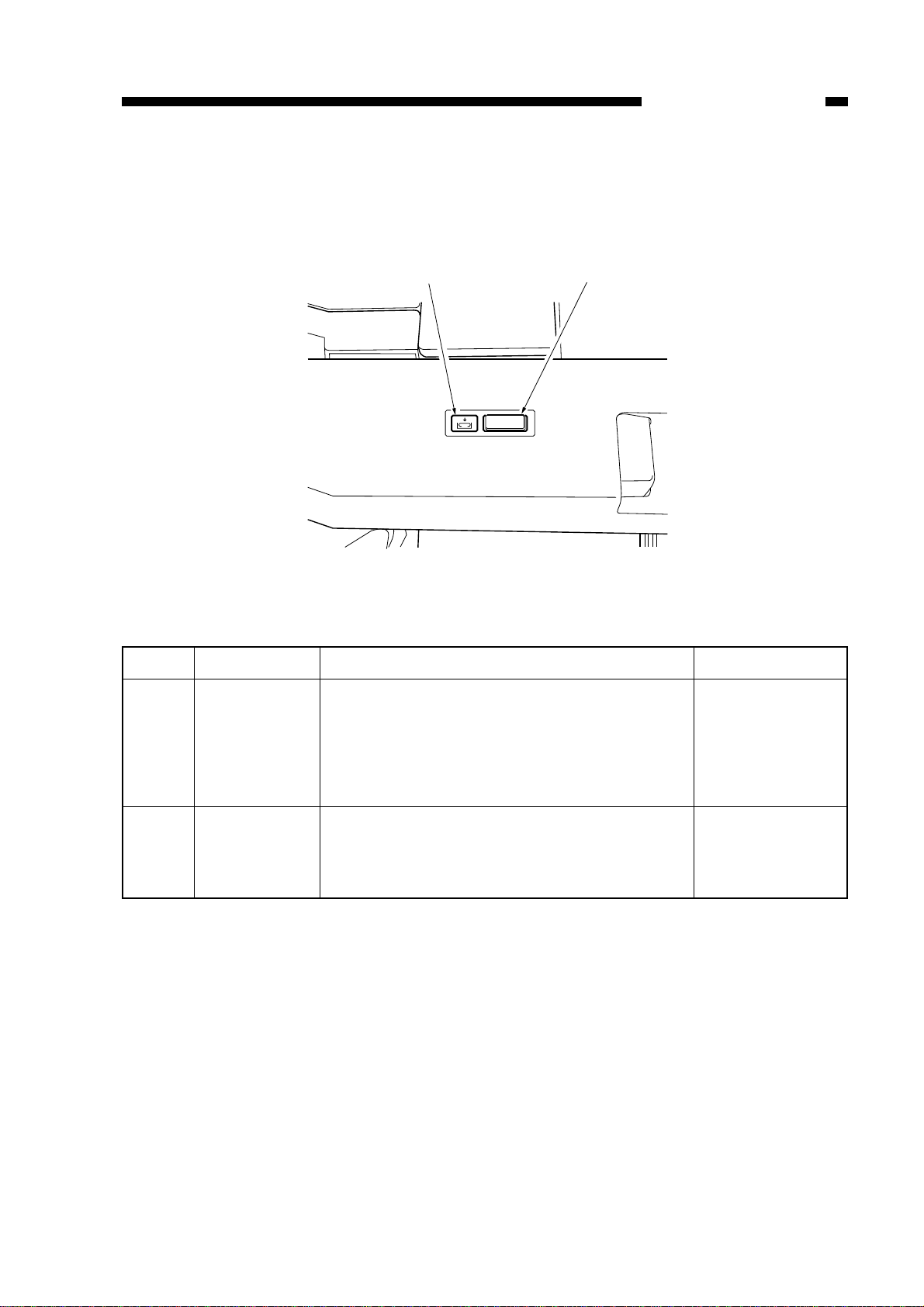

IV. OPERATION

qw

A. Operation panel

1. GENERAL DESCRIPTION

No.

1

2

Name of key

Staple key

STAPLE

RESUPPLY

indicator

Figure 1-401

Function

Pressed to start "manual stapling" or "manual

insertion/stapling" process.

If the key is pressed during the stapling process,

the process is discontinued.

The lamp blinks when the staple jam occurs in the

stapler.

The lamp lights up when the staples in the stapler

have exhausted.

Table 1-401

Remarks

The process

cannot be

discontinued

during the manual

insertion/stapling

process

When remaining

staples after the

stapling process

are below 40.

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

17

1. GENERAL DESCRIPTION

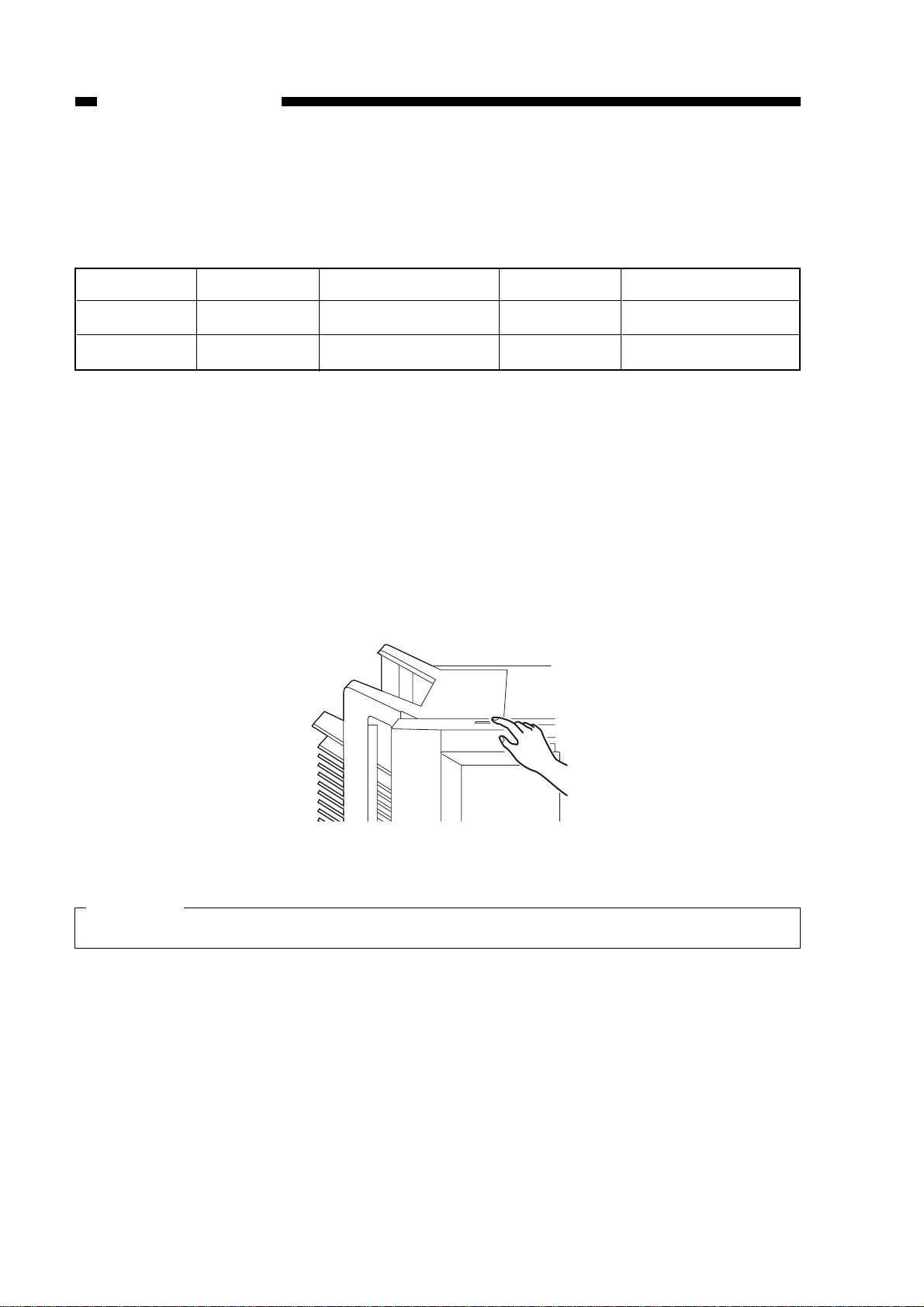

B. Stapling

Depending on the modes selected on the copier or the presence/absence of a document feeder, the

copies delivered into the bins are stapled as follows:

Mode

w/ DF used

w/o DF

Non sort

—

—

Manual

Manual

Sort

Table 1-402

Group

—

—

Staple sort

Auto

Manual

1. Auto stapling

The copies delivered to the bins with DF will be stapled automatically.

• When a document is set to the document plate, manual stapling is possible after completion of

copying.

2. Manual staple

The MANUAL STAPLE key lights when the sort mode is selected and copy operation is over; press

the key if stapling is desired. A press causes the copies in each bin to be stapled in sequence.

Figure 1-402

Reference:

To stop the stapling operation, press the MANUAL STAPLE key again.

18

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

n Otherwise, switch the copier OFF and then ON.

3) Insert the copies into the top bin of the bin unit along the guide plate.

• The MANUAL STAPLE key blinks.

n Make sure that no more than 50 copies (equivalent to paper of 80 g/m2)

4) Press the MANUAL STAPLE key.

Figure 1-403

19

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

Bring paper into contact

3. Manual insertion

Copies may be stapled by inserting them into the top bin and pressing the MANUAL STAPLE key.

1) Remove all copies from the bin unit.

• The bin unit returns to the home position.

2) Check that the bin unit is at the home position.

1. GENERAL DESCRIPTION

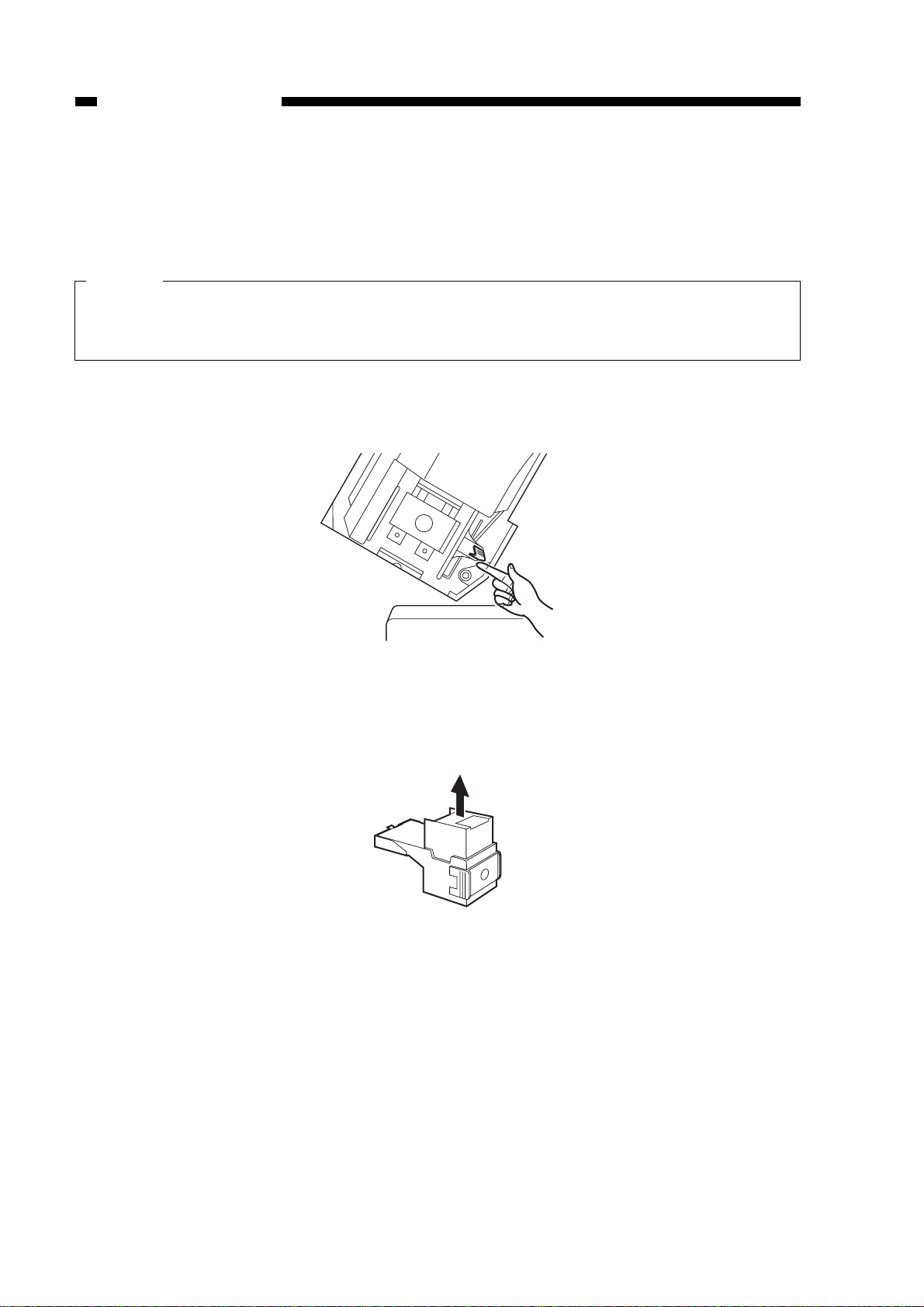

C. Resupply of staples to stapler

When staples in the staple cartridge have exhausted, the STAPLE RESUPPLY LED blinks. Then fill

the stapler with new staples in the following procedure.

Caution:

Installing and removing the staple cartridge repeatedly may cause a staple jam. Therefore, advise

customers not to remove the staple cartridge except when resupplying staples or at the time of staple

jam.

1) Open the stapler unit cover.

2) Lift up the staple cartridge removal lever and remove the staple cartridge.

3) Remove the emptied staple case.

Figure 1-404

Figure 1-405

110

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

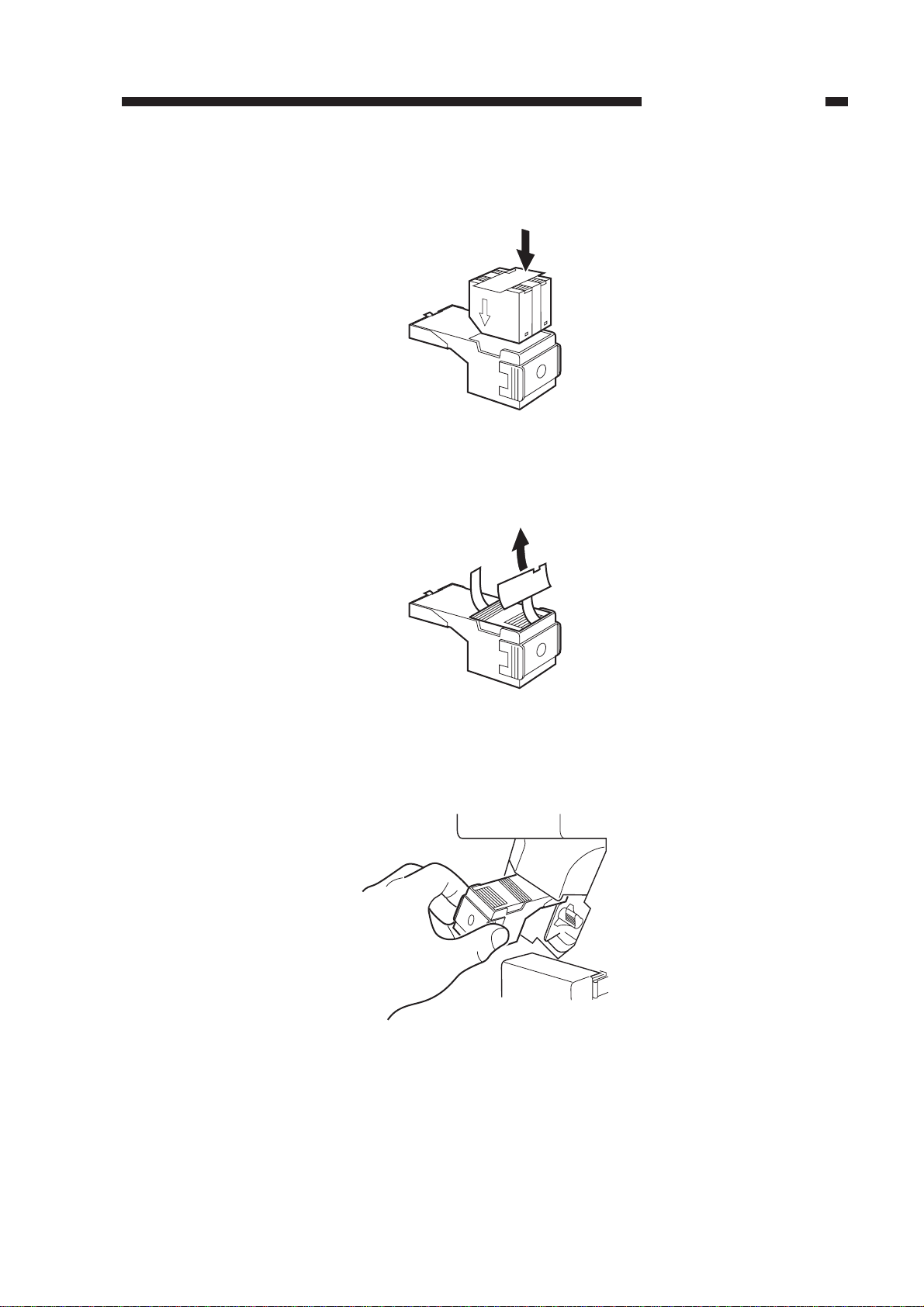

4) Set new staples correctly to the cartridge.

n Do not peel off the seal to which the staples are attached before setting the staples to the cartridge.

Figure 1-406

5) Pull out the seal attached with staples straight.

Figure 1-407

6) Set the staple cartridge.

Figure 1-408

7) Close the stapler unit cover.

Run the stapler unit idle until a staple comes out.

111

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

1. GENERAL DESCRIPTION

D. Removing a staple jam

When a staple jam occurs in the stapler, remove it in the following procedure:

1) Remove the staple cartridge.

2) Lower the face plate down to the floor and remove all jammed staples.

Figure 1-409

3) Close the face plate and set the staple cartridge.

112

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

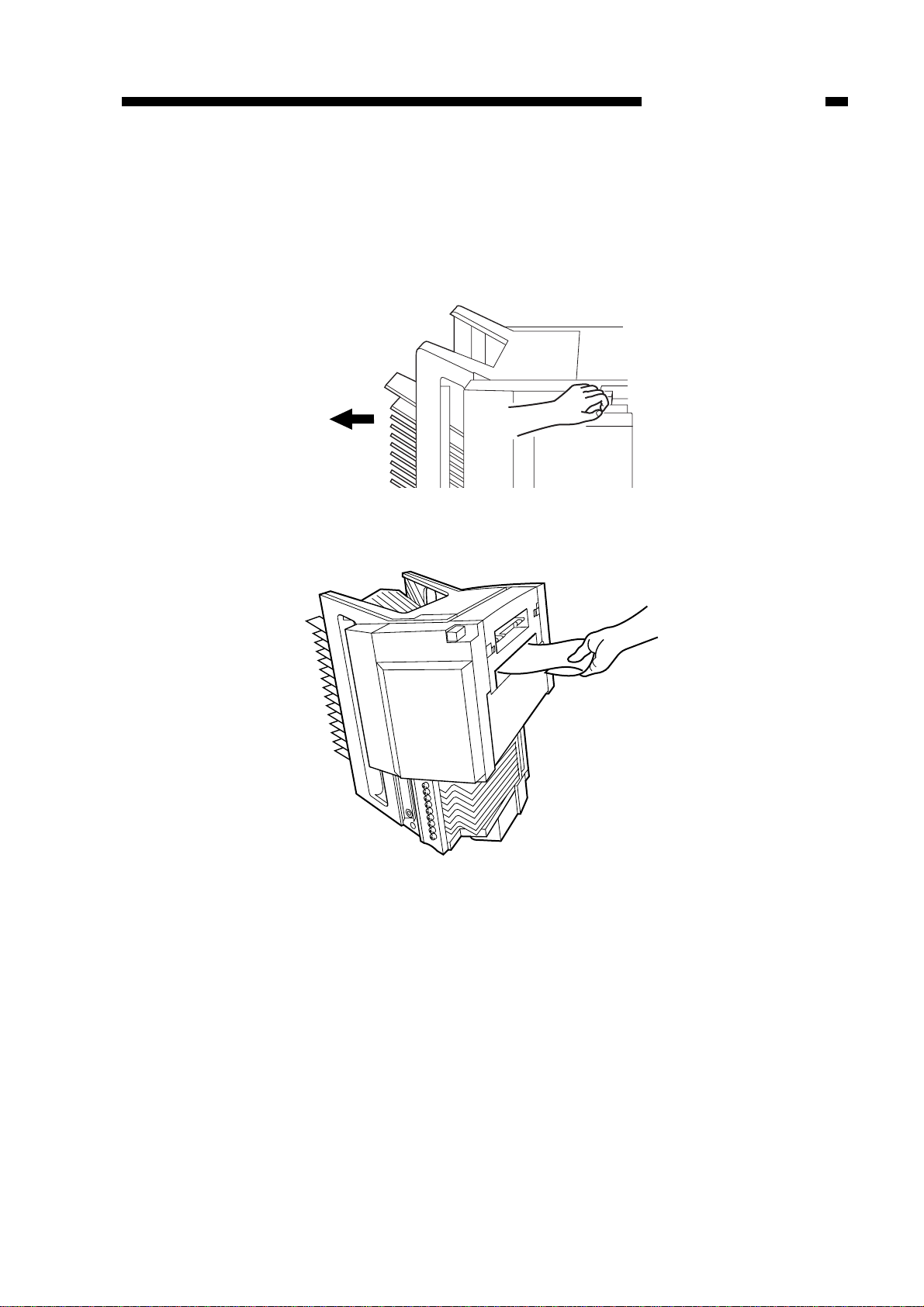

E. Removing paper clogging

1. Within sorter

a. Feed unit

1) Press the latch lever to separate the sorter from the copier.

Figure 1-410

2) Remove the clogged paper.

1. GENERAL DESCRIPTION

Figure 1-411

3) When the paper can be seen from the bin side, insert your hand from the bin side and pull out the

clogged paper.

4) Set the sorter to the copier.

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

113

1. GENERAL DESCRIPTION

114

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2

OPERATIONS AND TIMING

I. CONSTRUCTION....................................2-1

A. Functional Construction....................2-1

B. Electrical Circuitry.............................2-2

C. Sorter Controller Input/Output..........2-3

D. Communication between Copier

and Sorter.........................................2-6

II. BASIC OPERATIONS..............................2-7

A. Outline..............................................2-7

B. Basic Operations..............................2-9

III. FEED DRIVE SYSTEM.........................2-16

A. Outline............................................2-16

B. Controlling the Feed Speed............2-18

C. Over Stack Condition.....................2-19

D. Jam.................................................2-22

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

IV. STAPLER UNIT DRIVE SYSTEM.........2-24

A. Outline............................................2-24

B. Stapler Unit.....................................2-26

C. Controlling the Swinging

Movement of the Stapler Unit.........2-32

D. Holding the Paper...........................2-36

E. Stapling Operation Timing..............2-37

V. BIN UNIT DRIVE SYSTEM...................2-38

A. Outline............................................2-38

B. Bin Unit...........................................2-39

C. Controlling the Guide Bar...............2-44

D. Sensors Inside Bin Unit..................2-47

E. Other Sensors................................2-48

VI. POWER SUPPLY..................................2-49

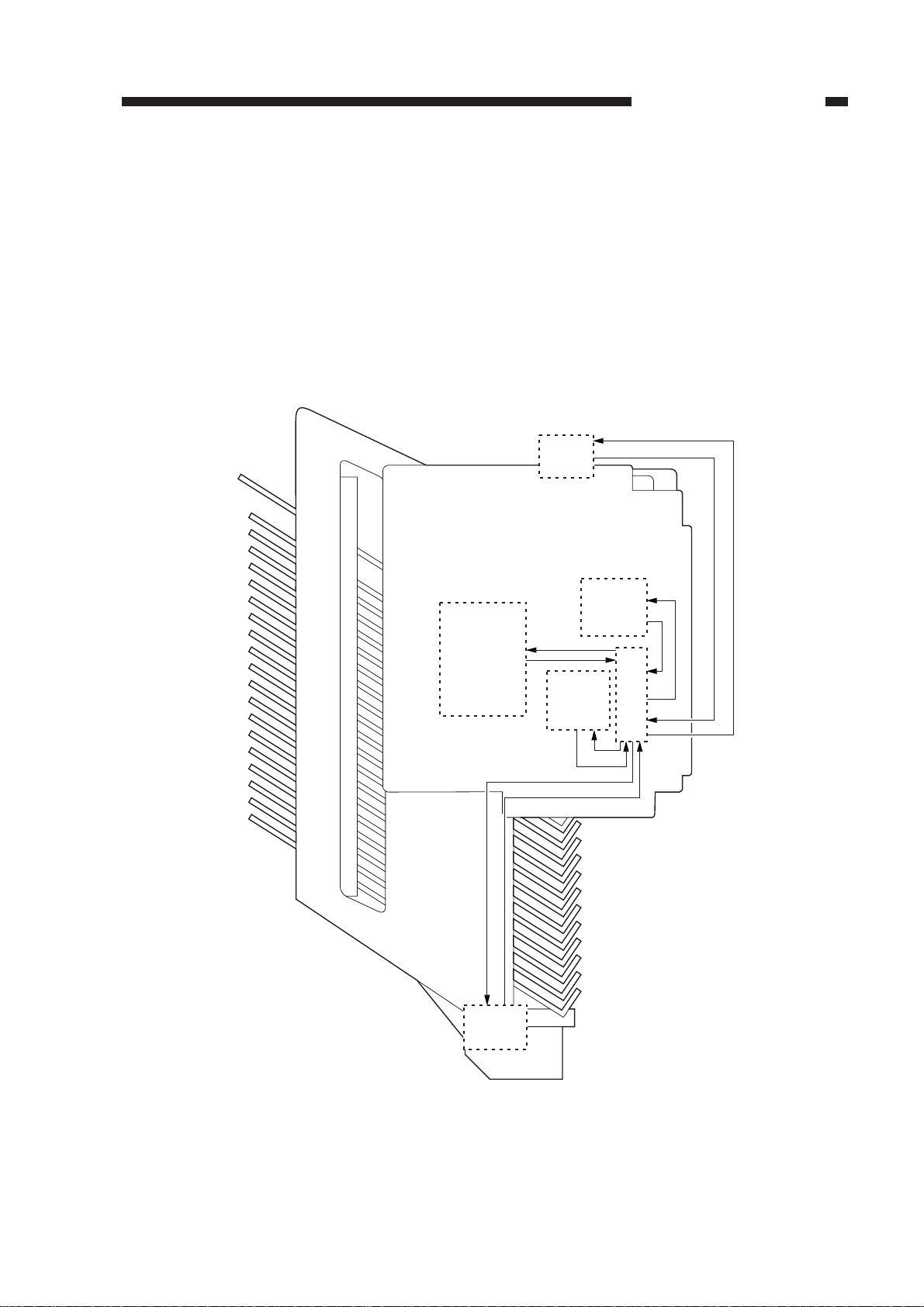

I. CONSTRUCTION

A. Functional construction

The sorter can be divided into six functional blocks; i.e., control panel, feed drive system, bin unit drive

system, stapler unit drive system*, guide bar dive system, and control system.

Figure 2-101

21

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

2. OPERATIONS AND TIMING

Control

panel

Feed

drive

system

Bin unit

drive system

Stapler

unit drive

system

Control system

Guide bar

drive

system

2. OPERATIONS AND TIMING

Sensor

Switch

Control

panel

Q1 CPU

Q2

RAM

Q3

ROM

Q4

Communication

IC

Sorter controller PCB

Motor

Copier

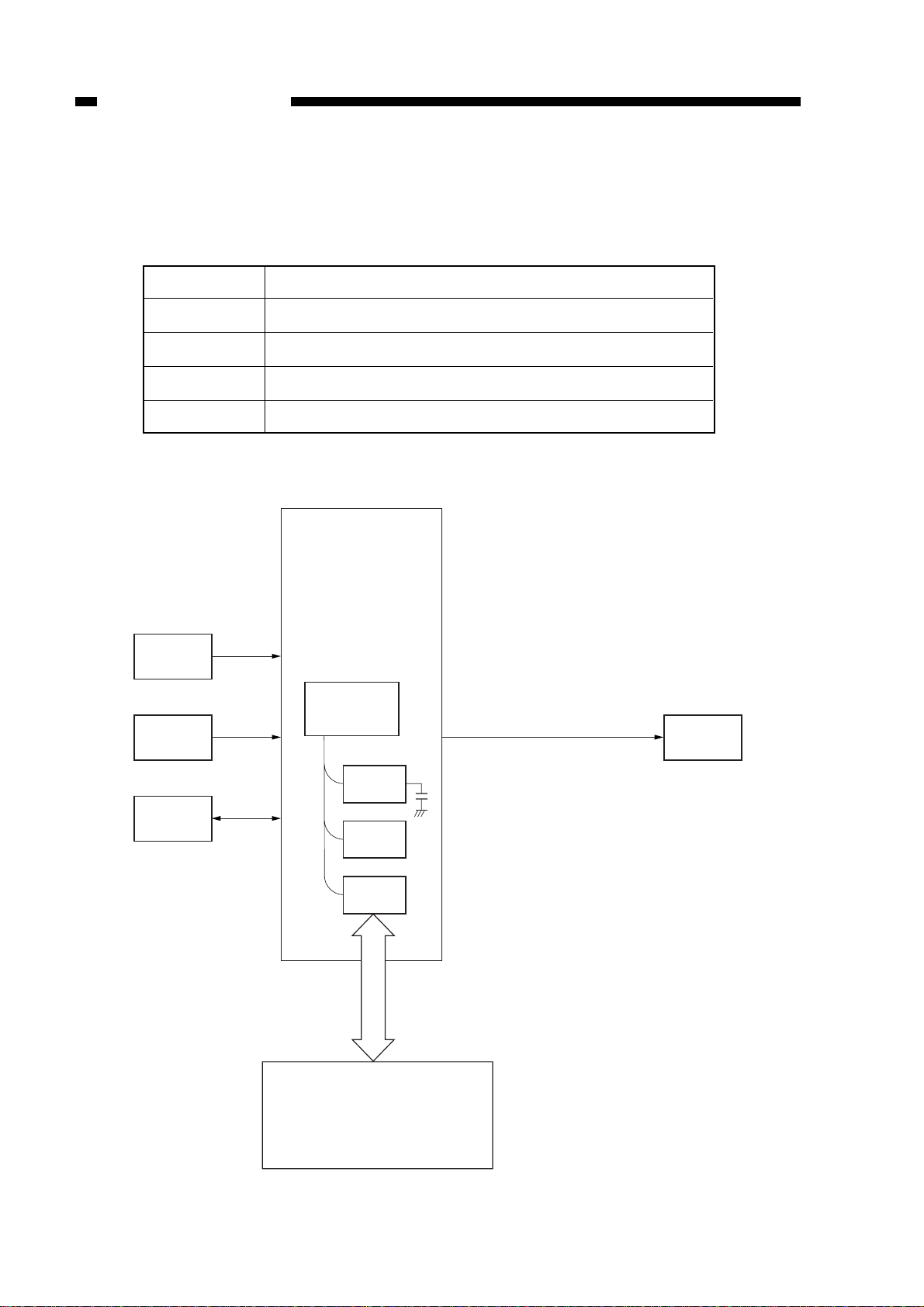

B. Electrical circuitry

The sorter is controlled by the sorter controller. The ICs on the sorter controller PCB has the functions

as shown in the table below.

Symbol

Q1

Q2

Q3

Q4

Function

Sequence control

Sensor value adjustment, operation mode control, etc.

Built-in sequence program control

Control of communication with copier

Table 2-101

Figure 2-102

22

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

C. Sorter controller input/output

Sorter controller output

23

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

2. OPERATIONS AND TIMING

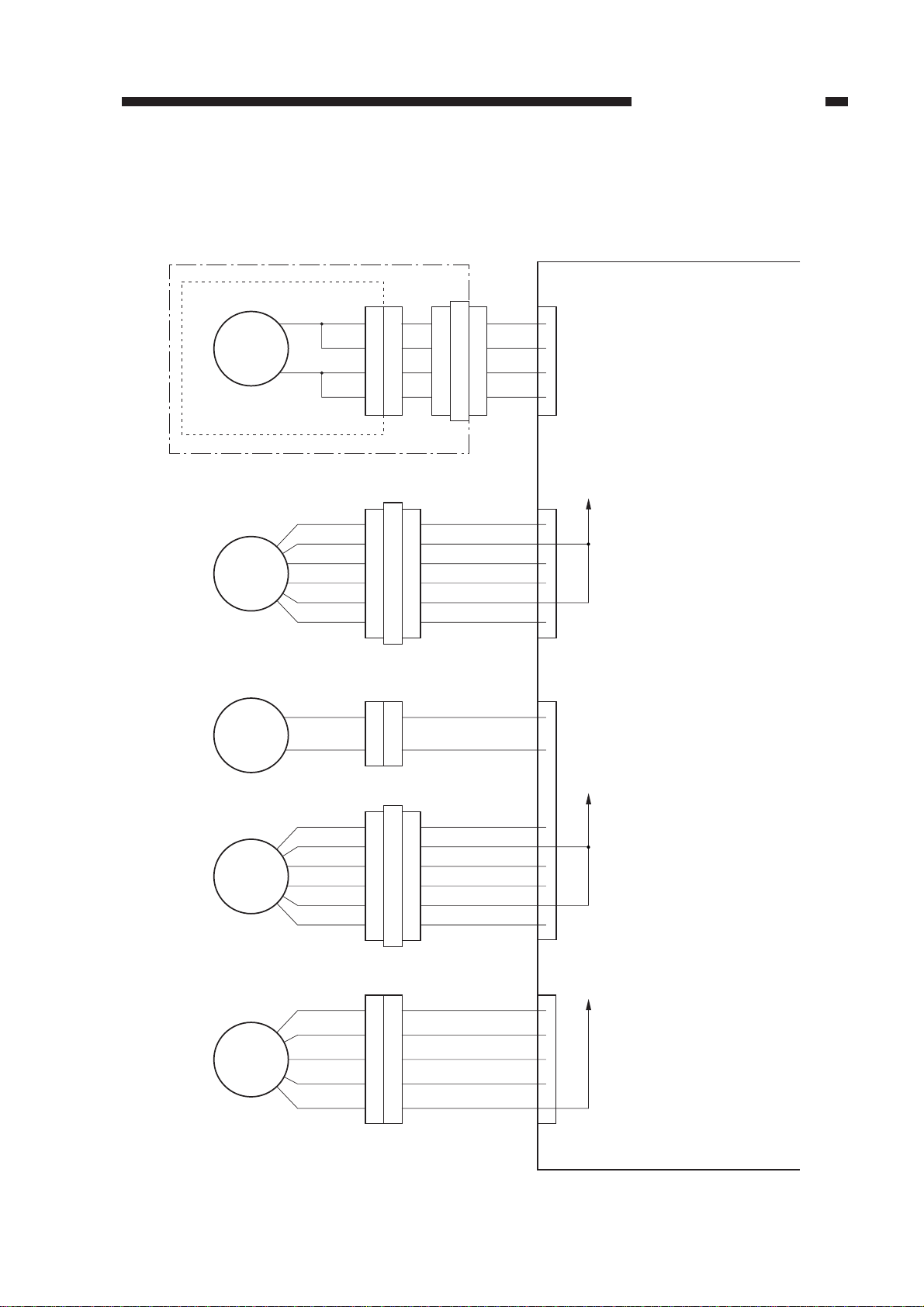

M5

M3

M1

M2

M4

Stapler motor

Guide bar swing motor

Shift motor

Feed motor

Stapler unit swing motor

J201 J7

J102

1

2

3

4

1

2

3

4

11

10

9

8

1

2

3

4

1

2

3

4

J9

A

B

A*

B*

A

B

A*

B*

A

B

A*

B*

+24V

+24V

+24V

J110

J8

J12

J112

J111

J116

1

2

3

4

5

6

1

2

1

2

1

2

6

5

4

3

2

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

1

2

3

4

5

5

4

3

2

1

6

5

4

3

2

1

3

4

5

6

7

8

Sorter controller PCB

See page 2-46 for details.

See page 2-27 for details.

See page 2-17 for details.

See page 2-42 for details.

See page 2-34 for details.

Figure 2-103

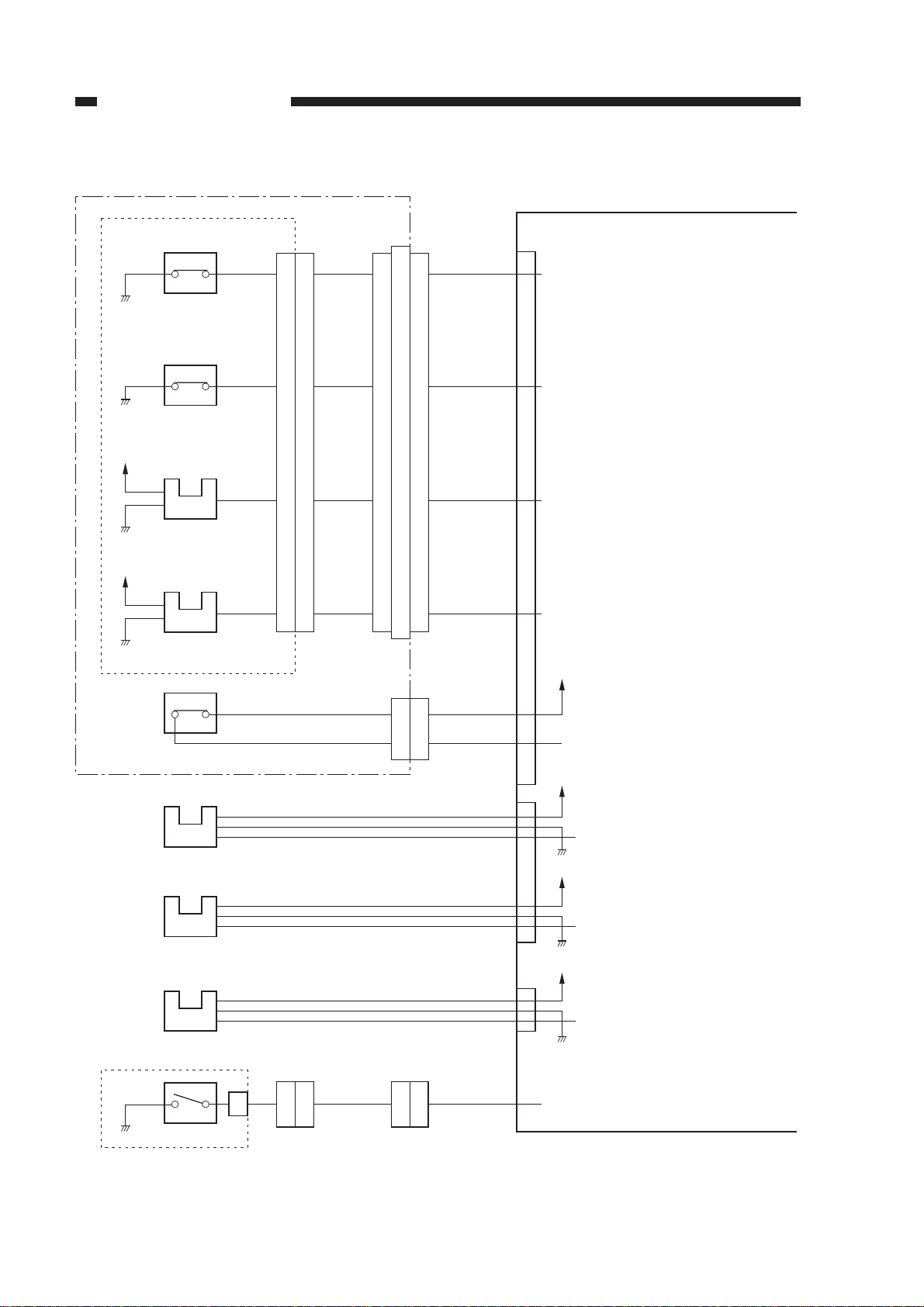

Sorter controller input (1/2)

Figure 2-104

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

24

2. OPERATIONS AND TIMING

When bin unit reaches

the lower limit, "0"

When stapling operation

is at home position, "0"

PI8

PI9

PI4

PI5

PI6

MS5

NO

NO

COM

COM

NO COM

J201

SPEMP

SP CART

SPL SW

SPLHP

SELF P

When staple is

absent, "1"

When first staple is

reached, "0"

When cartridge is

absent, "1"

IBUTU

BUL

BLL

SOP

When bin unit reaches

the upper limit, "0"

When obstacle is

detected, "0"

When sorter is

connected with copier,

"1"

In manual stapling

operation, "0"

J7

J11

+24V

+5V

+5V

+5V

J13

J102

J103

J104J201

J301

MS6

MS3

Sorter controller PCB

+5V

+5V

7

8

9

11

333223

7

8

9

11

5

4

3

1

7

8

9

11

7

8

9

11

1

2

12

13

1

2

3

3

2

1

4

5

6

3

2

1

1

2

3

3

2

1

1

2

No-staple detection

No-cartridge detection

Stapling

operation home

position sensor

Automatic

first staple sensor

Obstacle detection

Bin unit upper limit sensor

Bin unit lower limit sensor

Joint sensor

Control panel

PA CHE

BIN LED

PI1

PI3

PI2

PI7

J203

S1

S2

S3

S4

J204

J4

+5V

+5V

+5V

+5V

+5V

+24V

+24V

+24V

J10

J5

J6

J14

J108

J115

MS2

MS4

MS1

NO

NO

NO

COM

MS7 Obstacle

detection

NO COM

COM

COM

Sorter controller PCB

STYGHP

CUMH

SPLOPN

SPUHP

SHIFT CLK

When guide bar is at

the home position, "1"

When paper is present

in bin, "1"

LED emitting light at "1"

(blinking)

When lead cam is at

the home position, "1"

SPL COV When stapler unit

cover is closed, "1"

When stapler unit cover

is closed, "1"

When stapler unit

is swinging home

position, "1"

SPLED When stapling is

possible, "1";

HARI LED

when staple is absent, "1"

Pulses according to

rotation speed of

shift motor

JOI SW When sorter is connected

with copier, "1"

3

2

1

3

2

1

4

6

5

3

2

1

1

2

4

1

2

4

4

3

1

1

2

4

1

2

4

4

3

1

3

2

1

1

3

2

1

2

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

1

2

3

6

7

8

Guide bar home

position sensor

Bin inside paper

sensor

Light-emitting unit

Bin-inside paper

sensor

Light-receiving unit

Joint switch

Bin shift motor

clock sensor

Lead cam home

position sensor

Stapler unit cover switch

Stapler unit cover sensor

Control panel

Stapler unit home

position switch

1

2

2

1

1

2

2

1

1

2

3

4

4

3

2

1

1

2

J301

J202 J104

J3

3

4

Sorter controller input (2/2)

2. OPERATIONS AND TIMING

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

Figure 2-105

25

D. Communication between copier and sorter

1. Outline

The copier and sorter send status signals back and forth between them through the IPC (IC for

communication) communication.

The sorter is provided with both the new and former IPC communication functions, which can be

switched over according to the copier to be installed. The functions are changed over by turning ON or

OFF the No. 6 dip switch (SW1) on the sorter controller PCB.

These signals are first written into the RAM on the sorter controller PCB and then sent out in response

to control signals from the CPU (Q1).

Though a service man cannot check if status signals are properly transferred or not, if signals are

improperly transferred, the automatic diagnosis function of the copier is activated and an error code is

displayed on the control panel of the copier.

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

26

2. OPERATIONS AND TIMING

SW1-6

Communication system

ON

Former IPC communication

OFF

New IPC communication

2. OPERATIONS AND TIMING

II. BASIC OPERATIONS

A. Outline

The sorter sorts and staples copies delivered to it according to the modes selected on the copier.

The delivered copies can be also stapled by operating the operation keys on the copier.

Four operating modes as shown below are available.

1. Non sort mode

2. Sort mode

3. Group mode

4. Staple sort mode

1. Non sort mode

The sorter has a cascade stack function. When the number of copies is below 100, all of them are loaded

into the first bin but, when exceeding 100, 30 or 25 copies are loaded into each bin depending on the paper

size. When the 20th bin is loaded with copies, the sorter and copier stop operation. By removing all copies

from the bins and turning ON the COPY START key, copying for the remaining paper is started.

( Whether the number of copies exceeding the maximum loading value of the sorter can be designated

or not, number of copies stopping the operation, and the method of resuming the operation vary depending

on the specifications of the copier.)

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

27

2. OPERATIONS AND TIMING

Figure 2-201

2. Sort/group/staple sort mode

The copies are delivered to the sort bins.

At this time, the bin units move up and down to sort the copies.

When the copies are stapled, copies delivered into bins are stapled.

28

Figure 2-202

COPYRIGHT © 1997 CANON INC. CANON STAPLER SORTER-H1 REV.0 DEC. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...