Staple Finisher-S1

Product Outline

Technology

Periodic Servicing

Parts Replacement and Cleaning Procedure

Adjustment

Installation

Appendix

Service Manual Rev. 1.0

654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

consent of Canon Inc.

© CANON INC. 2014

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

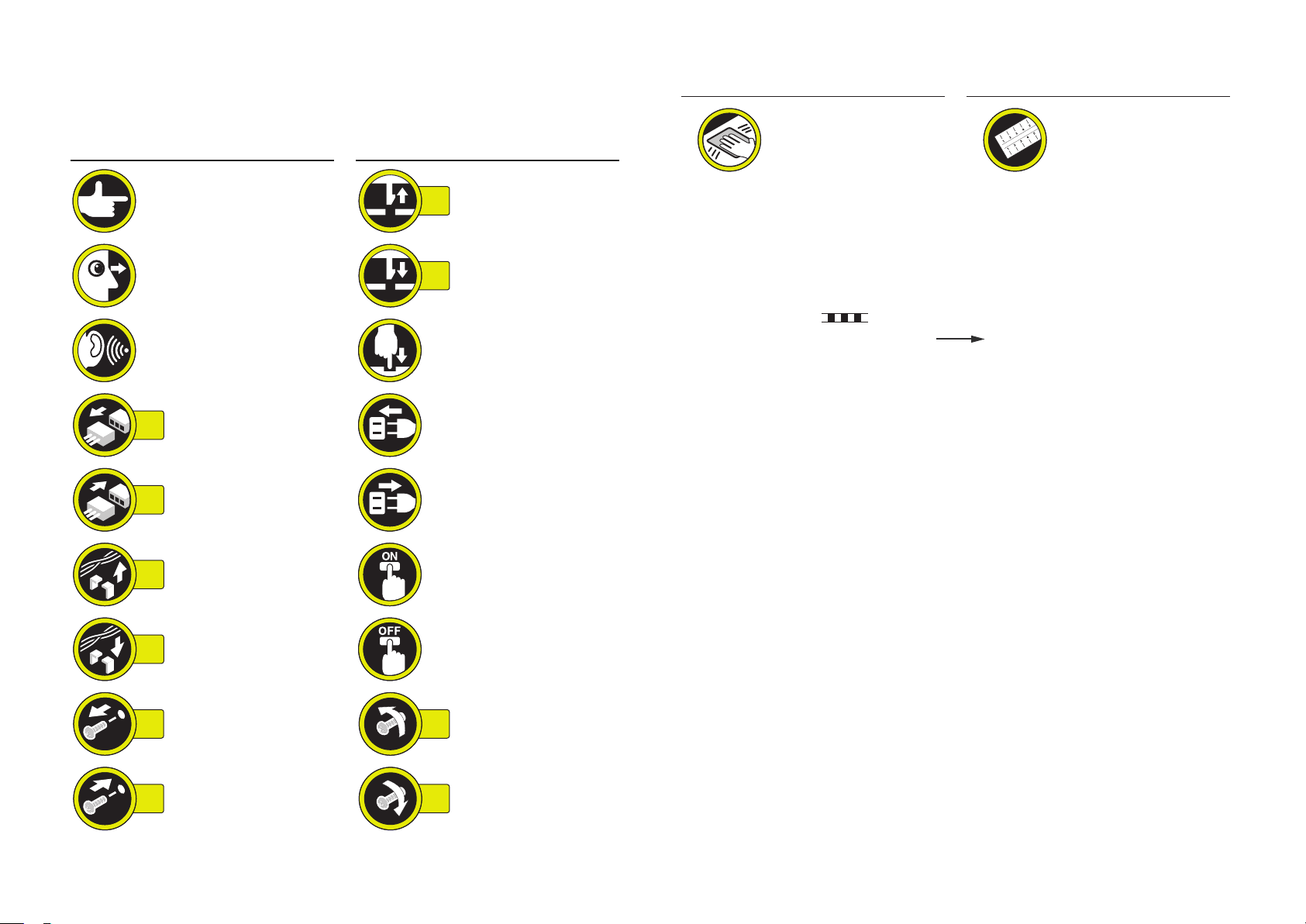

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Symbols Explanation Symbols Explanation

Check.

Check visually.

Check a sound. Push the part.

Disconnect the connector. Connect the power cable.

1x

Connect the connector.

1x

Remove the cable/wire

from the cable guide or wire

1x

saddle.

Install the cable/wire to the

1x

cable guide or wire saddle.

Remove the screw.

1x

Remove the claw.

1x

Insert the claw.

1x

Disconnect the power

cable.

Turn on the power.

Turn off the power.

Loosen the screw.

1x

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

accompanies the symbol, the arrow

signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

represents the path of mechanical drive; where a signal name

indicates the direction of the electric

Install the screw.

1x

Tighten the screw.

1x

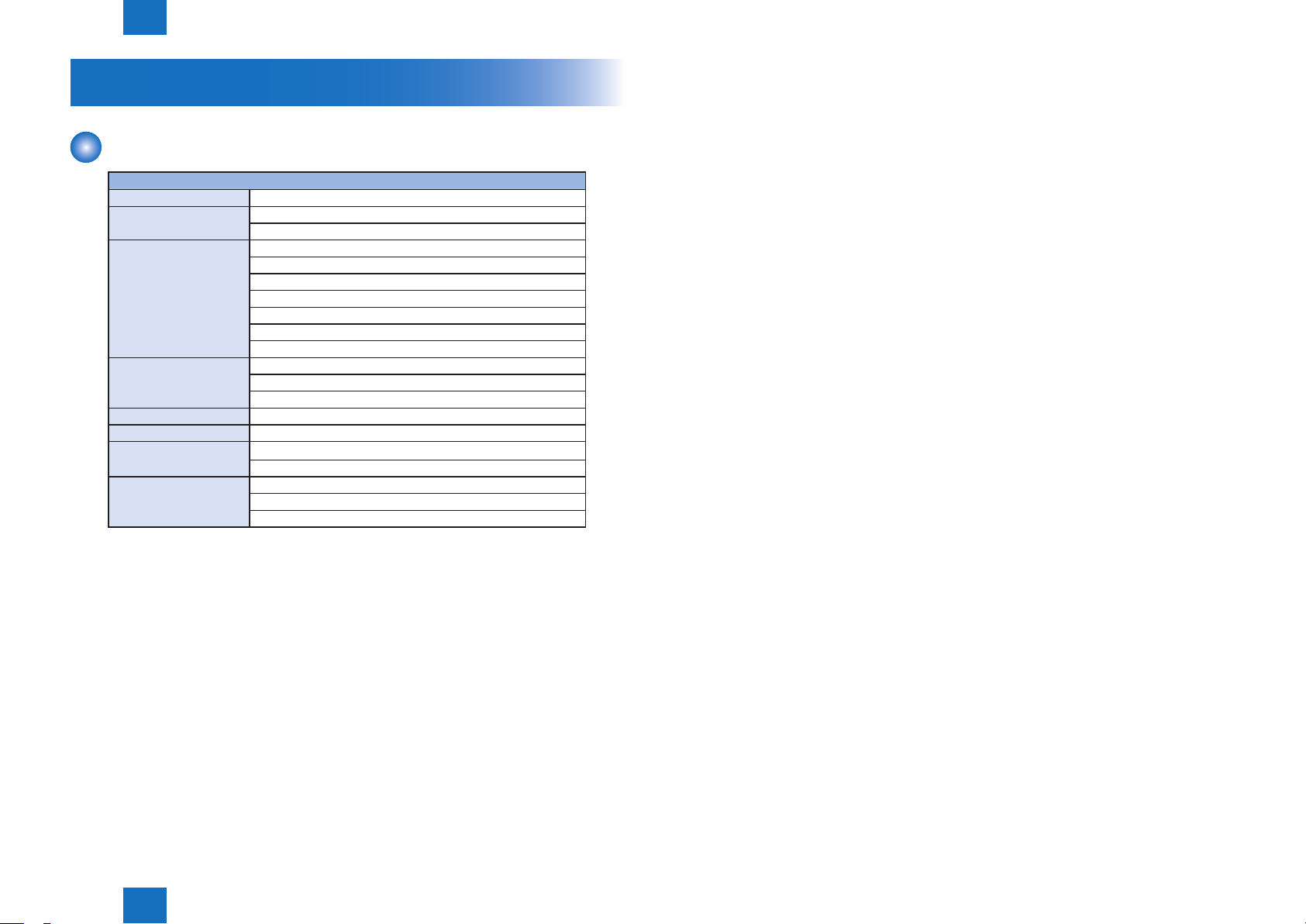

Contents

0 Safety Precautions

Notes Before Servicing ------------------------------------------------------0-2

Points to Note at Cleaning --------------------------------------------------0-2

1 Product Outline

Features -------------------------------------------------------------------------1-2

Specications ------------------------------------------------------------------1-3

Names of Parts ----------------------------------------------------------------1-4

External View ----------------------------------------------------------------------- 1-4

Cross Section ----------------------------------------------------------------------- 1-4

2 Technology

Basic Conguration -----------------------------------------------------------2-2

Functional Conguration --------------------------------------------------------- 2-2

Overview of Electrical Circuitry ------------------------------------------------- 2-2

Controls --------------------------------------------------------------------------2-3

Controls ------------------------------------------------------------------------------ 2-3

Basic Operation ---------------------------------------------------------------2-4

Outline -------------------------------------------------------------------------------- 2-4

Feed Unit ------------------------------------------------------------------------2-6

Outline -------------------------------------------------------------------------------- 2-6

Buffer Path Cover Open/Close Detection ------------------------------------ 2-6

Feeding Paper to Processing Tray Unit -------------------------------------- 2-7

Processing Tray Unit ---------------------------------------------------------2-8

Outline -------------------------------------------------------------------------------- 2-8

Stacking Operation ---------------------------------------------------------------- 2-9

Tray Auxiliary Guide Operation ------------------------------------------------ 2-11

Alignment / Shifting Operation ------------------------------------------------- 2-12

Staple Operation ------------------------------------------------------------------2-17

Stack Delivery Operation -------------------------------------------------------2-18

Stack Tray Paper Retainer Operation ---------------------------------------2-18

Stack Tray Unit -------------------------------------------------------------- 2-19

Stack Tray Shift Operation ------------------------------------------------------2-19

Stack Tray Paper Height Detection Control --------------------------------2-19

Stack Tray Paper Full Detection Control ------------------------------------ 2-20

Controller Unit ---------------------------------------------------------------- 2-21

Outline -------------------------------------------------------------------------------2-21

Detecting Jams -------------------------------------------------------------- 2-22

Outline -------------------------------------------------------------------------------2-22

Power Supply ---------------------------------------------------------------- 2-23

Outline -------------------------------------------------------------------------------2-23

Protective Functions -------------------------------------------------------------2-23

Work of Service -------------------------------------------------------------- 2-24

When replacing the parts -------------------------------------------------------2-24

Periodical Servicing --------------------------------------------------------------2-24

Upgrading ---------------------------------------------------------------------------2-24

3 Periodic Servicing

List of Work for Scheduled Servicing ------------------------------------3-2

4 Parts Replacement and Cleaning Procedure

List of Parts ---------------------------------------------------------------------4-2

External / Internal Cover --------------------------------------------------------- 4-2

List of Main Unit -------------------------------------------------------------------- 4-3

Motor ---------------------------------------------------------------------------------- 4-3

Sensor/Switch ---------------------------------------------------------------------- 4-4

PCB ----------------------------------------------------------------------------------- 4-5

List of Connectors ----------------------------------------------------------------- 4-6

Removing the Equipment ---------------------------------------------------4-9

Layout Drawing --------------------------------------------------------------------- 4-9

Removing the Finisher Unit from the Connected Equipment ----------- 4-9

Removing the Buffer Path Unit from the Connected Equipment ------ 4-11

Removing the Reinforcing Plate Cover from

the Connected Equipment ------------------------------------------------------4-12

External Cover/Internal System ----------------------------------------- 4-13

Layout Drawing -------------------------------------------------------------------- 4-13

Removing the Front Door -------------------------------------------------------4-14

Removing the Front Cover -----------------------------------------------------4-15

Removing the Rear Cover ------------------------------------------------------4-16

Removing the Upper Cover ----------------------------------------------------4-17

Removing the PCB Cover ------------------------------------------------------4-19

Removing the Grate-shaped Guide ------------------------------------------ 4-20

Major Units -------------------------------------------------------------------- 4-22

Layout Drawing -------------------------------------------------------------------- 4-22

Removing the Staple Cartridge ------------------------------------------------4-22

Removing the Staple Unit -------------------------------------------------------4-23

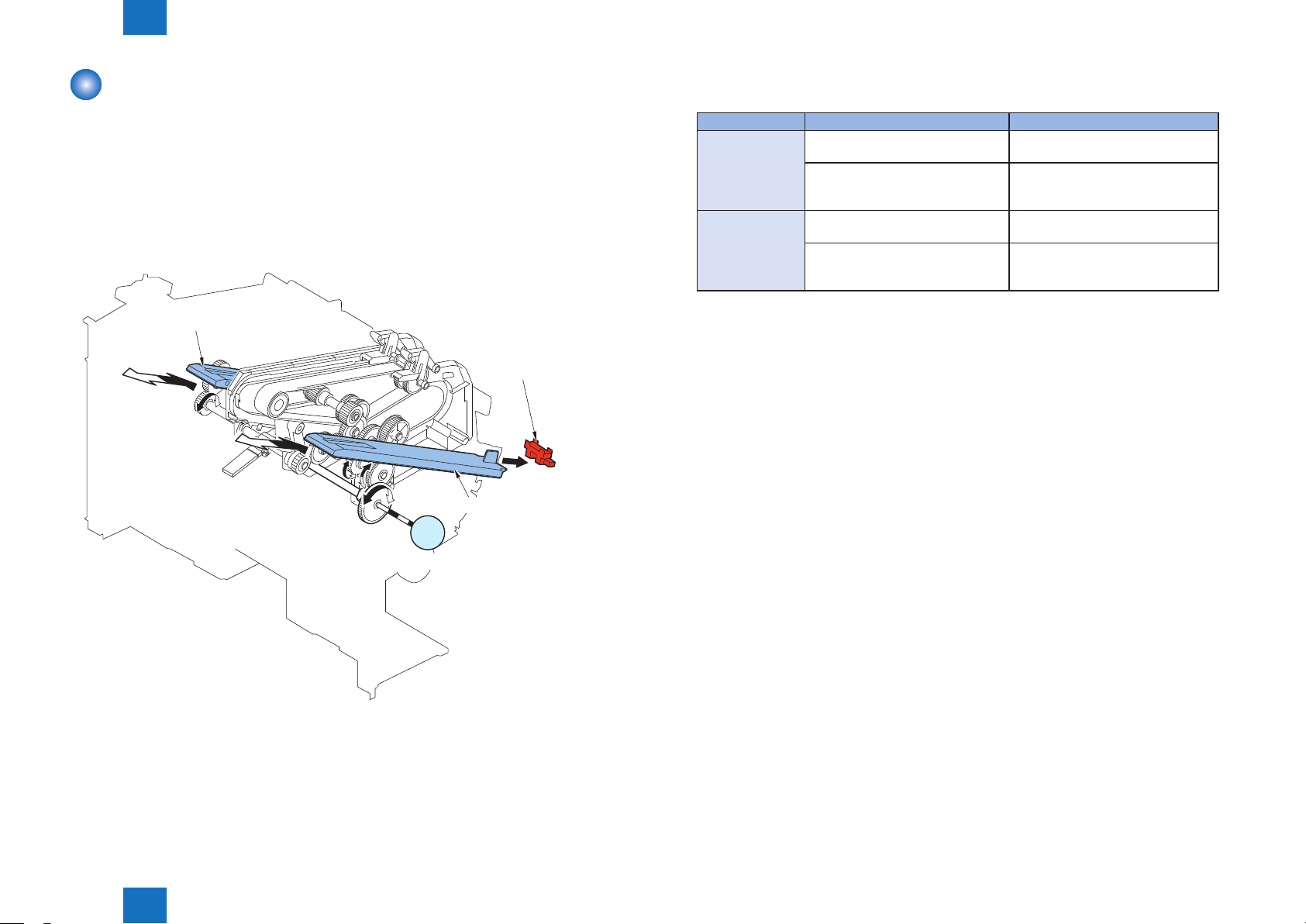

Removing the Main Paddle -----------------------------------------------------4-25

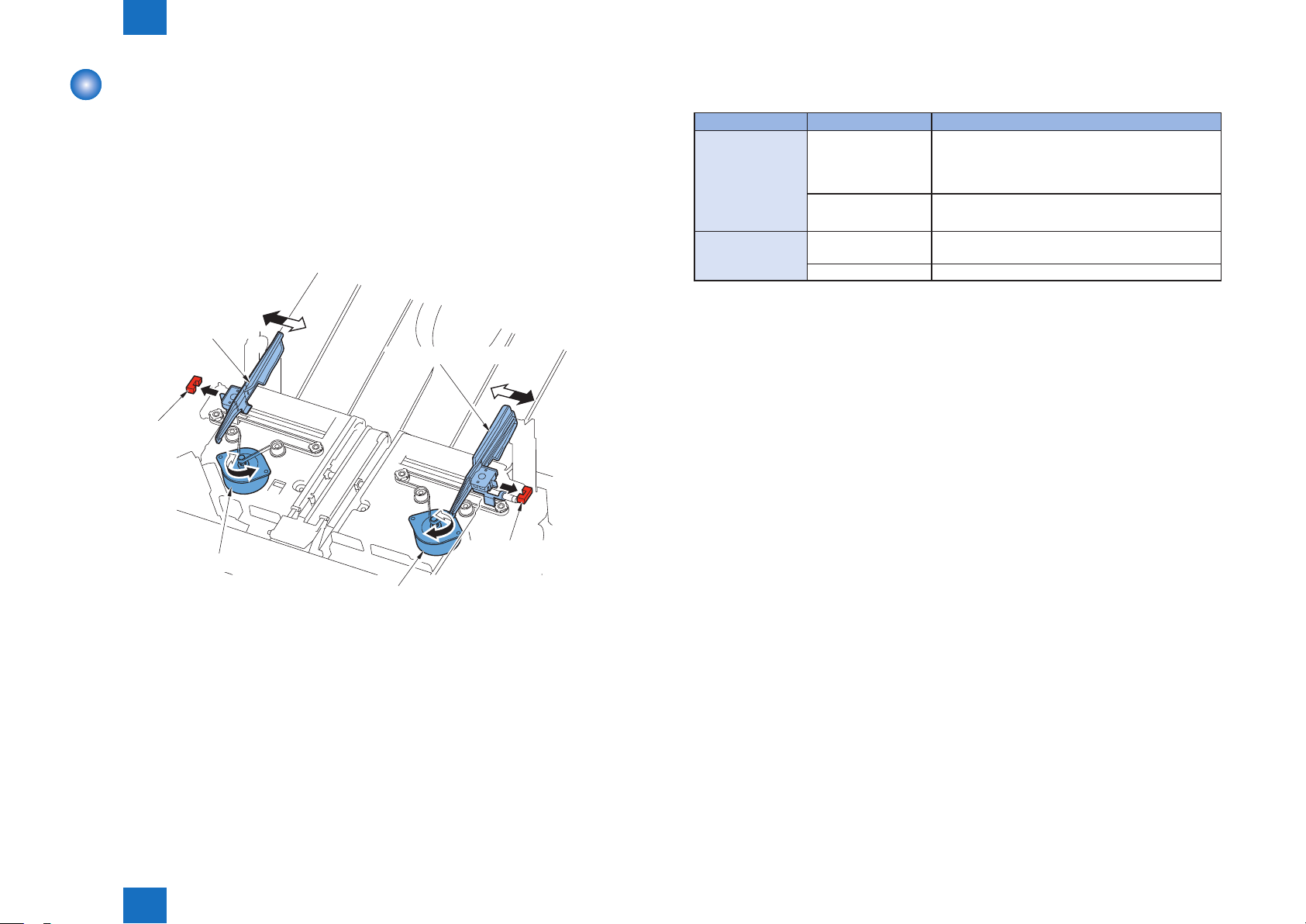

Removing the Front/Rear alignment plates --------------------------------4-26

Removing the Finisher Lower Feed Guide Unit ---------------------------4-27

Removing the Sub Paddle ------------------------------------------------------ 4-32

Removing the Process Tray Upper Unit (Front/Rear) -------------------4-34

How to assemble the Process Tray Upper Unit (Front/Rear)

and the Finisher Lower Feed Guide Unit -----------------------------------4-35

Removing the Process Tray Lower Unit -------------------------------------4-40

Separating the Buffer Upper Feed Guide Unit from

the Buffer Lower Feed Guide Unit --------------------------------------------4-41

Motors -------------------------------------------------------------------------- 4-42

Layout Drawing -------------------------------------------------------------------- 4-42

Removing the Feed Motor (M1) -----------------------------------------------4-43

Remove the Paddle Motor (M3) ----------------------------------------------- 4-44

Removing the Delivery Motor (M2) -------------------------------------------4-45

Removing the Front Alignment Motor (M4) ---------------------------------4-46

Removing the Rear Alignment Motor (M5) --------------------------------- 4-47

Removing the Tray Auxiliary Guide Motor (M6) ---------------------------4-48

Removing the Stack Tray Shift Motor (M8) ---------------------------------4-49

Switches ----------------------------------------------------------------------- 4-52

Layout Drawing -------------------------------------------------------------------- 4-52

Removing the Front Door Switch (S15) ------------------------------------- 4-53

Removing the Stack Tray Lower Limit Sensor (S10) --------------------4-54

PCBs --------------------------------------------------------------------------- 4-55

Layout Drawing -------------------------------------------------------------------- 4-55

Removing the Finisher Controller PCB -------------------------------------- 4-55

5 Adjustment

Adjustment Item ---------------------------------------------------------------5-2

Overview ----------------------------------------------------------------------------- 5-2

Dip Switch Function ----------------------------------------------------------5-3

Sensor Detection Check Mode ------------------------------------------------- 5-3

Motor Operation Check Mode -------------------------------------------------- 5-5

6 Installation

How to Check this Installation Procedure -------------------------------6-2

Symbols in the Illustration ------------------------------------------------------- 6-2

Check Items when Turning OFF the Main Power ---------------------6-2

Points to Note When Relocating the Host machine ------------------6-2

Product Name ------------------------------------------------------------------6-2

Points to Note at Installation -----------------------------------------------6-3

Unpacking -----------------------------------------------------------------------6-3

Installation Outline Drawing ------------------------------------------------6-4

Checking the Contents ------------------------------------------------------6-5

Installation Procedure --------------------------------------------------------6-5

Without Cassette Feeding Unit ------------------------------------------------- 6-5

With Cassette Feeding Unit ----------------------------------------------------6-10

Appendix

Service Tools --------------------------------------------------------------------- II

Special Tools --------------------------------------------------------------------------- II

Solvents and Oils --------------------------------------------------------------------- II

General Circuit Diagram -------------------------------------------------------III

General Circuit Diagram ----------------------------------------------------------- III

Safety Precautions

Notes Before Servicing

■

Points to Note at Cleaning

■

0

Safety Precautions > Points to Note at Cleaning

Notes Before Servicing

Caution:

At servicing, be sure to turn off the power source according to the specied steps and

disconnect the power plug.

Caution:

Do not turn off the power switch when downloading is under way.

Turning off the main power switch while downloading is under way can disable the

machine.

0-2

Points to Note at Cleaning

Caution:

When performing cleaning using organic solvent such as alcohol, be sure to check that

the component of solvent is vaporized completely before assembling.

Safety Precautions > Points to Note at Cleaning

0

0-2

Product Outline

1

Features

■

Specications

■

Names of Parts

■

Product Outline

1

1

Product Outline > Features

Features

• Compact, staple nisher which corresponds to A4 color, high-speed MFP.

• Gripper mechanism for delivering paper to the stack tray. And the paper stacking of the

high consistency is possible by the mechanism.

• Stack tray capacity of approximate 500 sheets.

• Easy to install on the host machine.

1-2

Product Outline > Features

1

1-2

1

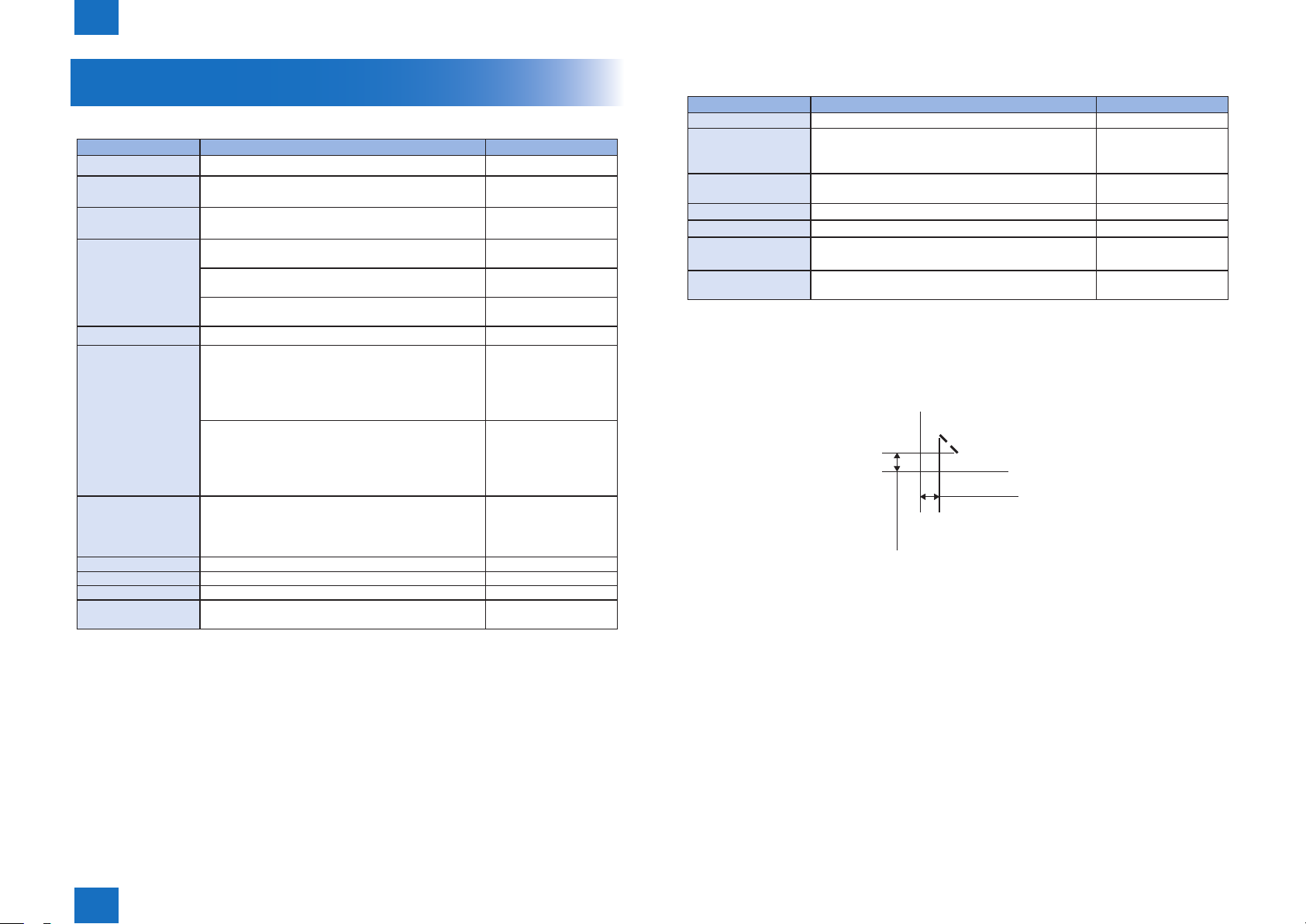

Product Outline > Specications

1-3

Specications

●Finisher Unit

Stacking method Stack tray: moving up and down

Stacking orientation Face down

Stacking paper size Feed direction: 148 to 356 mm

Alignment stacking

paper size

Paper weight 60 to 220 g/m2

Stacking capacity - Processing tray

Mixed stacking

capacity

Dimensions 301 mm (H) × 589 mm (W)× 459 mm (D)

Weight Approx. 14 kg

Power supply From host machine: 24V, 5V

Power consumption Standby: 2.5 W or less

Item Specications Remarks

Cross feed direction: 98 to 216 mm

[Non sort]

Cross feed direction: 98 to 216 mm

[Sort]

Cross feed direction: 139 to 216 mm

[Staple sort]

Cross feed direction: 182 to 216 mm

[Non sort / sort]

6 sheets or less

[Staple sort]

30 sheets or less

- Stack tray

[Non sort / sort]

73.5 mm or less in height (equivalent of 500 sheets)

[Staple sort]

73.5 mm or less in height, or 20 sets or less

[Non sort / sort]

73.5 mm or less in height

[Staple sort]

73.5 mm or less in height, or 20 sets or less

Operating: 35 W or less

- Equivalent of 81 g/m2

paper

- Equivalent of 81 g/m2

paper

T-1-1

●Staple Unit

Stapling method Punching by rotating cam - Flat clinch

Stapling capacity 30 sheets

Stapling paper size A4R, B5R, LGL, LTRR, EXECR, 16KR

Staple supply Special staple cartridge (5000 staples)

Staple detection Provided

Manual stapling Not provided

Initial feed of staple

head

* To set the maximum number of sheets to be stapled in the Finisher. When 1 is set, the

stapling capacity becomes 50 sheets. COPIER > OPTION > USER > STPL-MAX

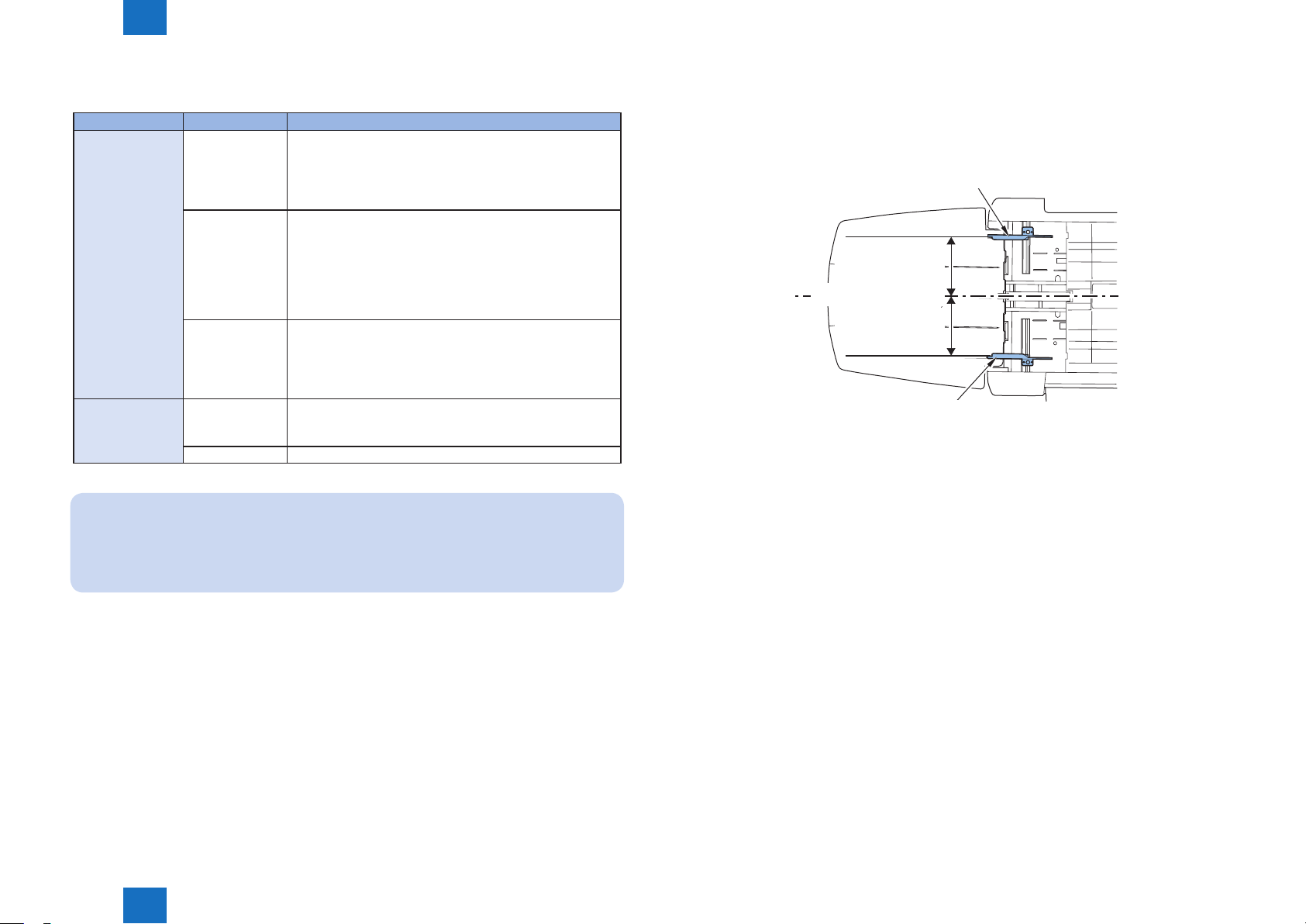

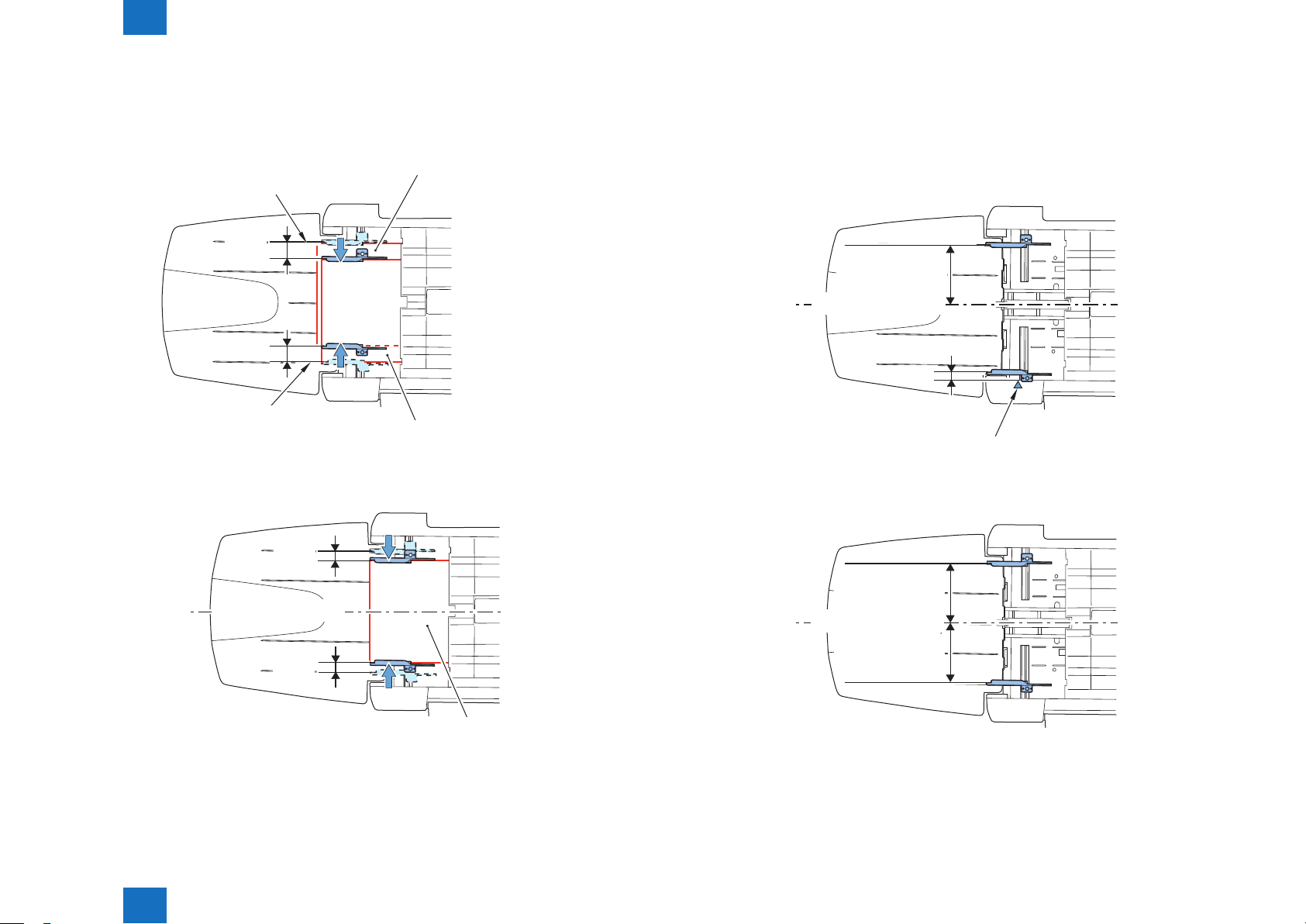

• Staple Position

Item Specications Remarks

Paper thickness: 5.7 mm or less

*

Provided

Front 1-point stapling (45 degrees)

5.0 ± 2.0 mm

5.0 ± 2.0 mm

F-1-1

- Equivalent of 105 g/

m2 paper

T-1-2

Product Outline > Specications

1

1-3

1

Product Outline > Names of Parts > Cross Section

1-4

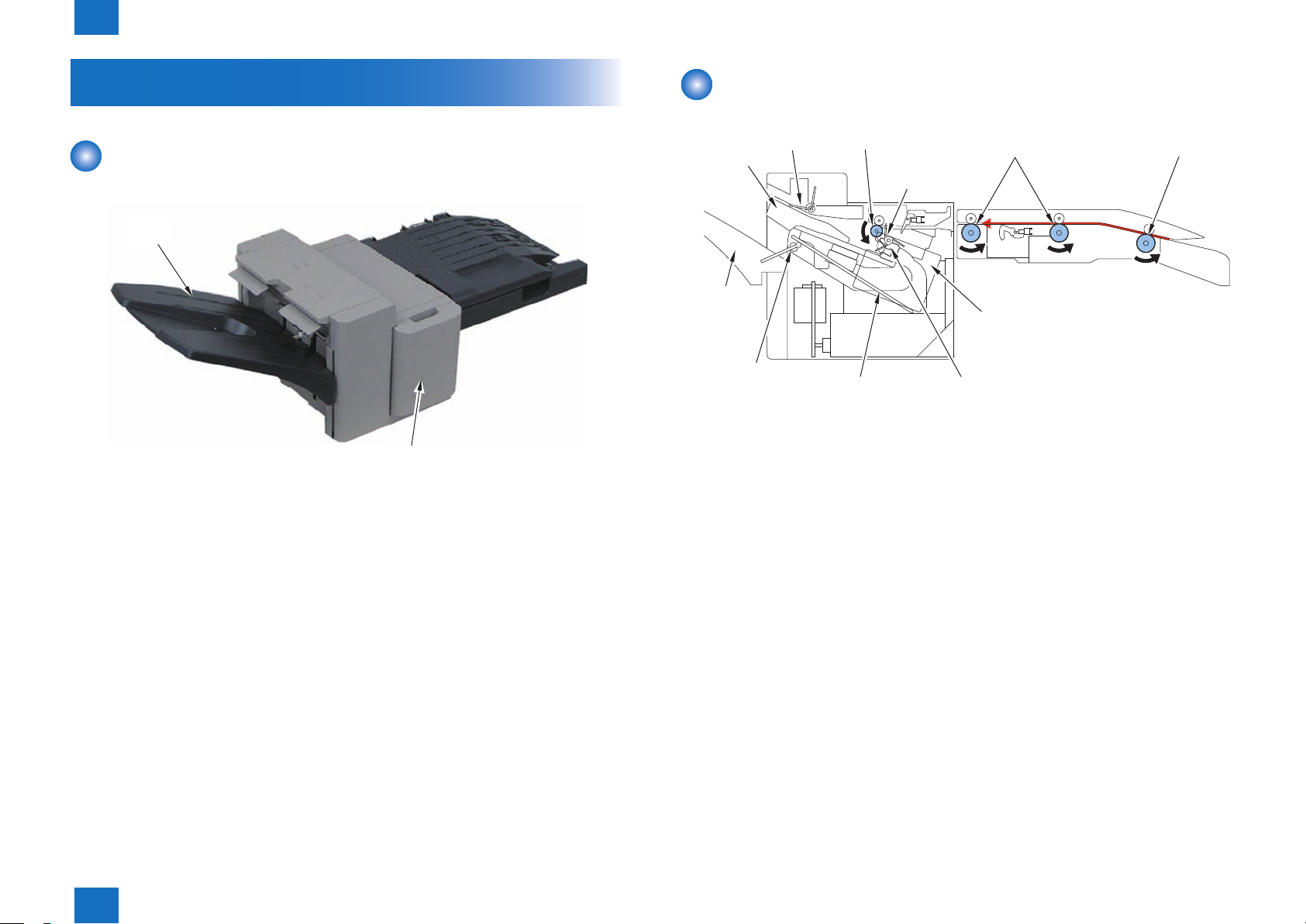

Names of Parts

External View

Stack Tray

Front Door

F-1-2

Cross Section

PaddleAlignment

Plate

Stack Tray

Stack Tray

Paper Retainer

Delivery Roller

Paper Return

Inlet RollerFeed Roller

Paddle

Stapler

GripperTray Auxiliary Guide

F-1-3

Product Outline > Names of Parts > Cross Section

1

1-4

Technology

2

Basic Conguration

■

Controls

■

Basic Operation

■

Feed Unit

■

Processing Tray Unit

■

Stack Tray Unit

■

Controller Unit

■

Detecting Jams

■

Power Supply

■

Work of Service

■

2

Technology

2

Technology > Basic Conguration > Overview of Electrical Circuitry

2-2

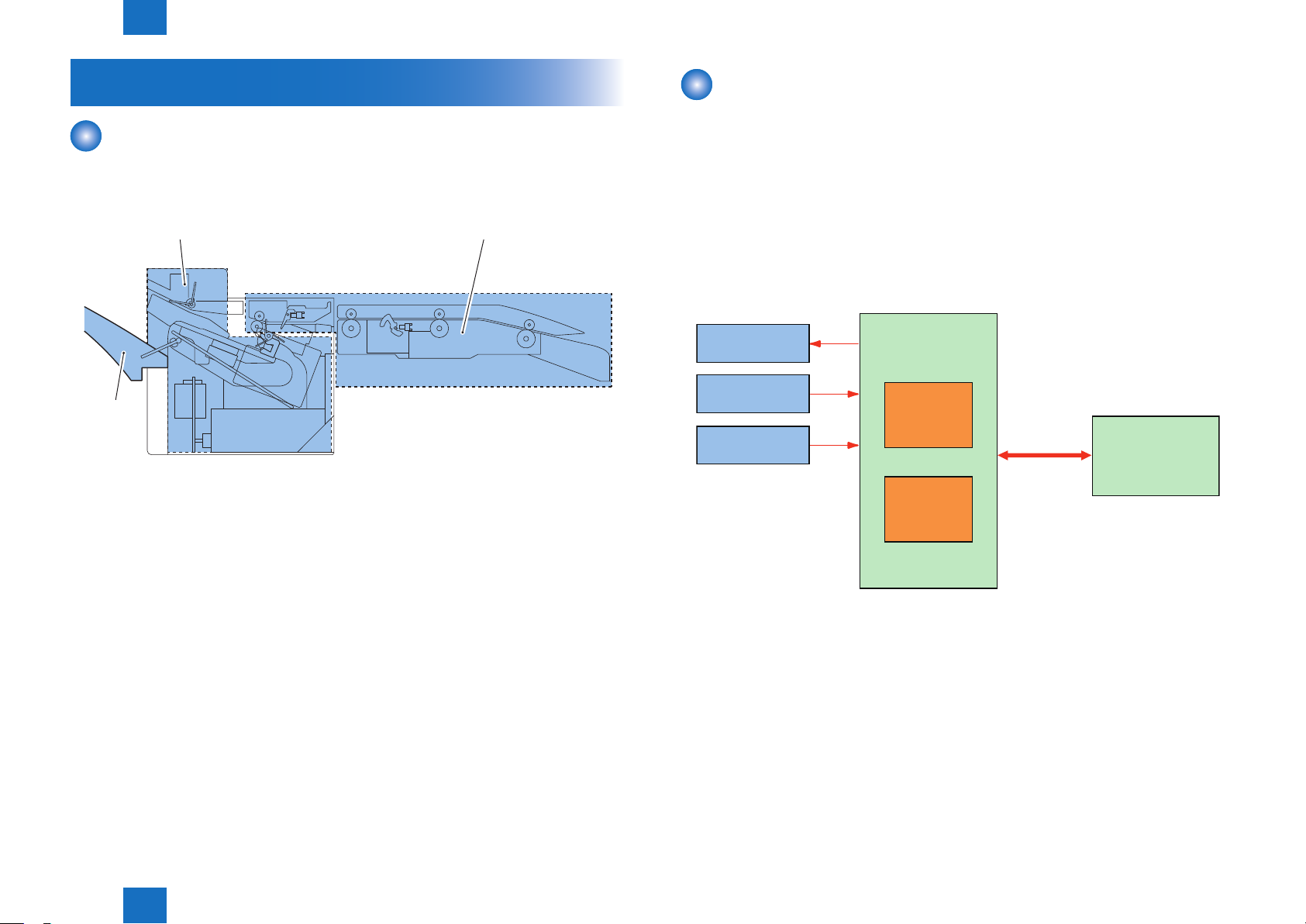

Basic Conguration

Functional Conguration

The components of this nisher are organized into 3 major blocks; feed unit, processing tray

unit and stack tray unit.

Feed AssemblyProcessing Tray Assembly

Stack Tray

Assembly

F-2-1

Overview of Electrical Circuitry

The nisher's sequence of the operation is controlled by its nisher controller PCB.

The nisher controller PCB has the 16-bit CPU, and the controller also controls the

communication with the host machine in addition to controlling the nisher's operation

sequence.

The CPU on the nisher controller PCB contains a ash ROM used to store the operating

sequence program.

The nisher controller PCB uses the serial communication line to receive various commands

from its host to drive the motors. It also uses serial communications to send information on

the sensors and switches to its host.

Motor

Sensor

Switch

Finisher Controller PCB

CPU

Motor

Driver

Serial

Communication

Host Machine

(DC Controller PCB)

Technology > Basic Conguration > Overview of Electrical Circuitry

2

F-2-2

2-2

2

Technology > Controls > Controls

Controls

Controls

Basic Operation Outline

Feed Unit Outline

Feeding Paper to Processing Tray Unit

Processing Tray Unit Outline

Stacking Operation

Tray Auxiliary Guide Operation

Alignment / Shifting Operation

Staple Operation

Stack Delivery Operation

Stack Tray Paper Retainer Operation

Stack Tray Unit Stack Tray Shift Operation

Stack Tray Paper Height Detection Control

Stack Tray Paper Full Detection Control

Controller Unit Outline

Detecting Jams Outline

Power Supply Outline

Protective Functions

Work of Service When replacing the parts

Periodical Servicing

Upgrading

2-3

Items

T-2-1

Technology > Controls > Controls

2

2-3

2

Technology > Basic Operation > Outline

2-4

Basic Operation

Outline

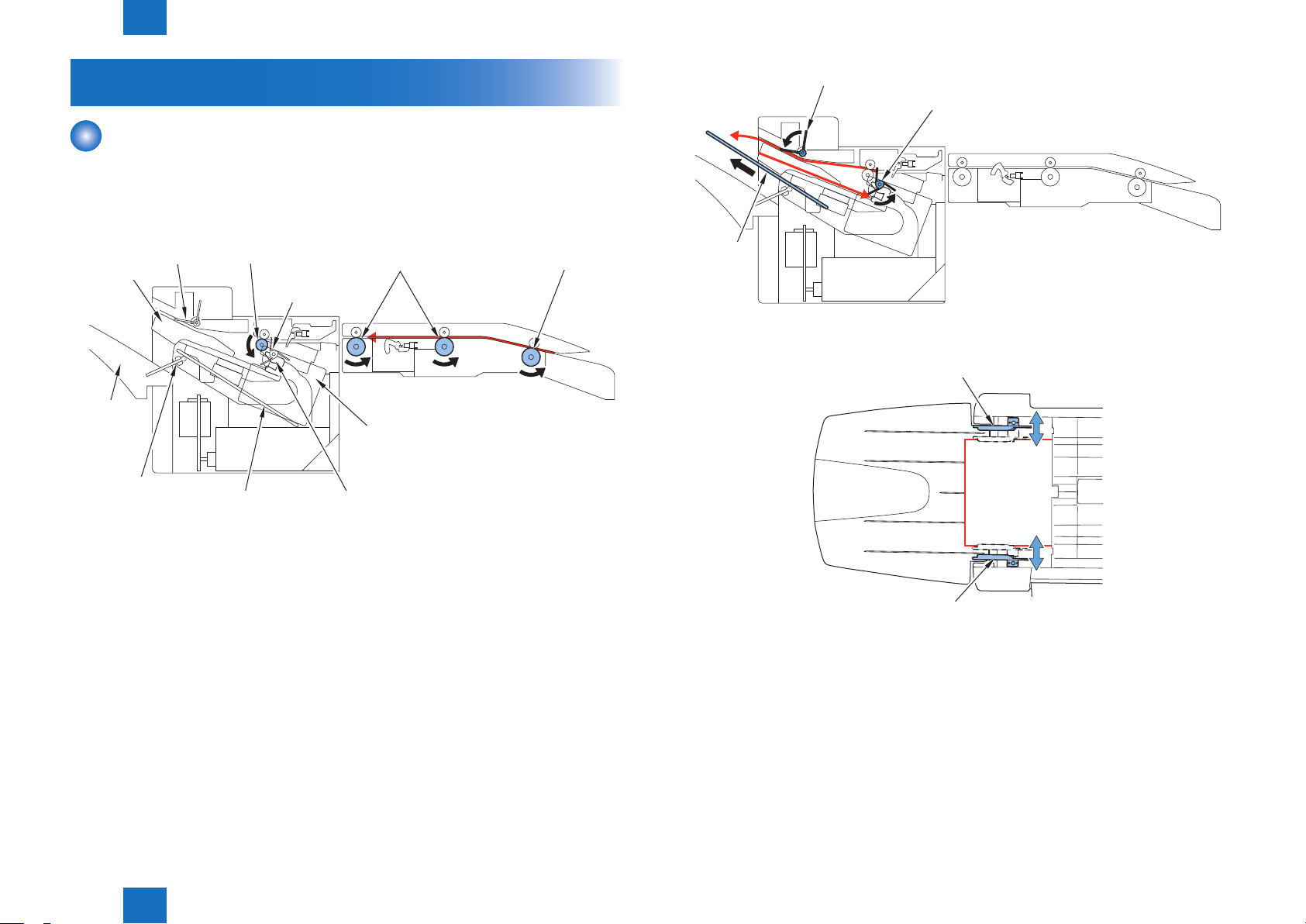

Basic operations of this nisher are described below.

(1) The paper delivered from the host machine is fed by the inlet roller, feed roller, and

delivery roller.

Plate

PaddleAlignment

Stack Tray

Stack Tray

Paper Retainer

Delivery Roller

Paper Return

Inlet RollerFeed Roller

Paddle

Stapler

GripperTray Auxiliary Guide

F-2-3

Paddle

Paper Return Paddle

Tray

Auxiliary

Guide

(3) The alignment plates are used to align paper in the width direction. (In the illustration

below, paper is aligned with reference to the central reference position.)

Rear Alignment Plate

F-2-4

(2) The paper delivered by the delivery roller is stacked on the processing tray by the

paddle. A paddle and a paper return paddle are used to align paper in the feed direction.

If two or more sheets with a length of 150 mm or more are stacked, the tray auxiliary

guides slide out.

Technology > Basic Operation > Outline

2

Front Alignment Plate

F-2-5

(4) The operations described in (1) to (3) are repeated for each sheet to be stacked on the

processing tray.

2-4

2

Gripper

Technology > Basic Operation > Outline

(5) The stacked sheets are stapled (only in the staple mode).

Stapler

F-2-6

(6) After being shifted, the sheets stacked on the processing tray are delivered to the stack

tray.

If the tray auxiliary guides have slid out, they slide back before the sheets are delivered

to the stack tray.

2-5

Technology > Basic Operation > Outline

2

F-2-7

2-5

2

Technology > Feed Unit > Buffer Path Cover Open/Close Detection

2-6

Feed Unit

Outline

The feed unit feeds the paper delivered from the host machine and feeds it to the processing

tray unit.

Two sensors, an inlet sensor (S1) and a delivery sensor (S2), are provided along the paper

feed path in the feed unit to detect the paper feed state and jam.

S2

M9

S1

M1

M4,5

M2M3

Buffer Path Cover Open/Close Detection

The Buffer Path Cover Open/Close Sensor (S16) detects whether the Buffer Path Cover is

open or closed.

<Sensor:ON> <Sensor:OFF>

M8

M1 Feed Motor M7 Gripper Motor

M2 Delivery Motor M8 Stack Tray Shift Motor

M3 Paddle Motor M9 Staple Motor

M4 Front Alignment Motor S1 Buffer Sensor

M5 Rear Alignment Motor S2 Feed Path Sensor

M6 Tray Auxiliary Guide Motor

M6

Technology > Feed Unit > Buffer Path Cover Open/Close Detection

M7

2

F-2-8

Buffer Path

Cover Open/Close Sensor

(S16)

F-2-9

2-6

2

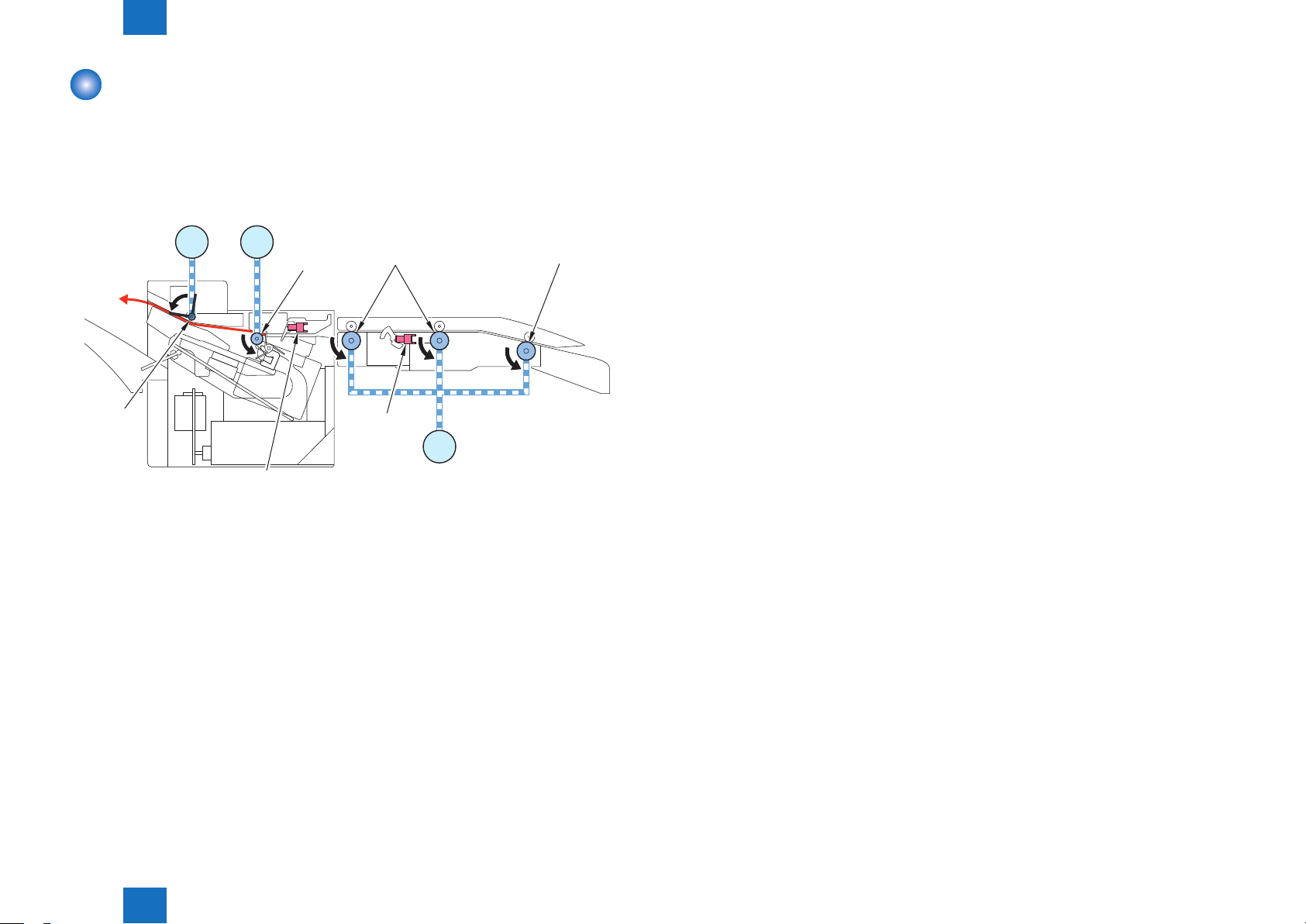

Technology > Feed Unit > Feeding Paper to Processing Tray Unit

Feeding Paper to Processing Tray Unit

The paper delivered from the host machine is fed by the inlet roller, feed roller, and delivery

roller.

The paper delivered by the delivery roller is stacked on the processing tray by the paddle.

2-7

Paddle

Paddle

Motor

Feed Path Sensor

Delivery

Motor

M2M3

(S2)

Delivery

Roller

Buffer

Sensor

(S1)

M1

Inlet RollerFeed Roller

Feed Motor

F-2-10

Technology > Feed Unit > Feeding Paper to Processing Tray Unit

2

2-7

2

Technology > Processing Tray Unit > Outline

2-8

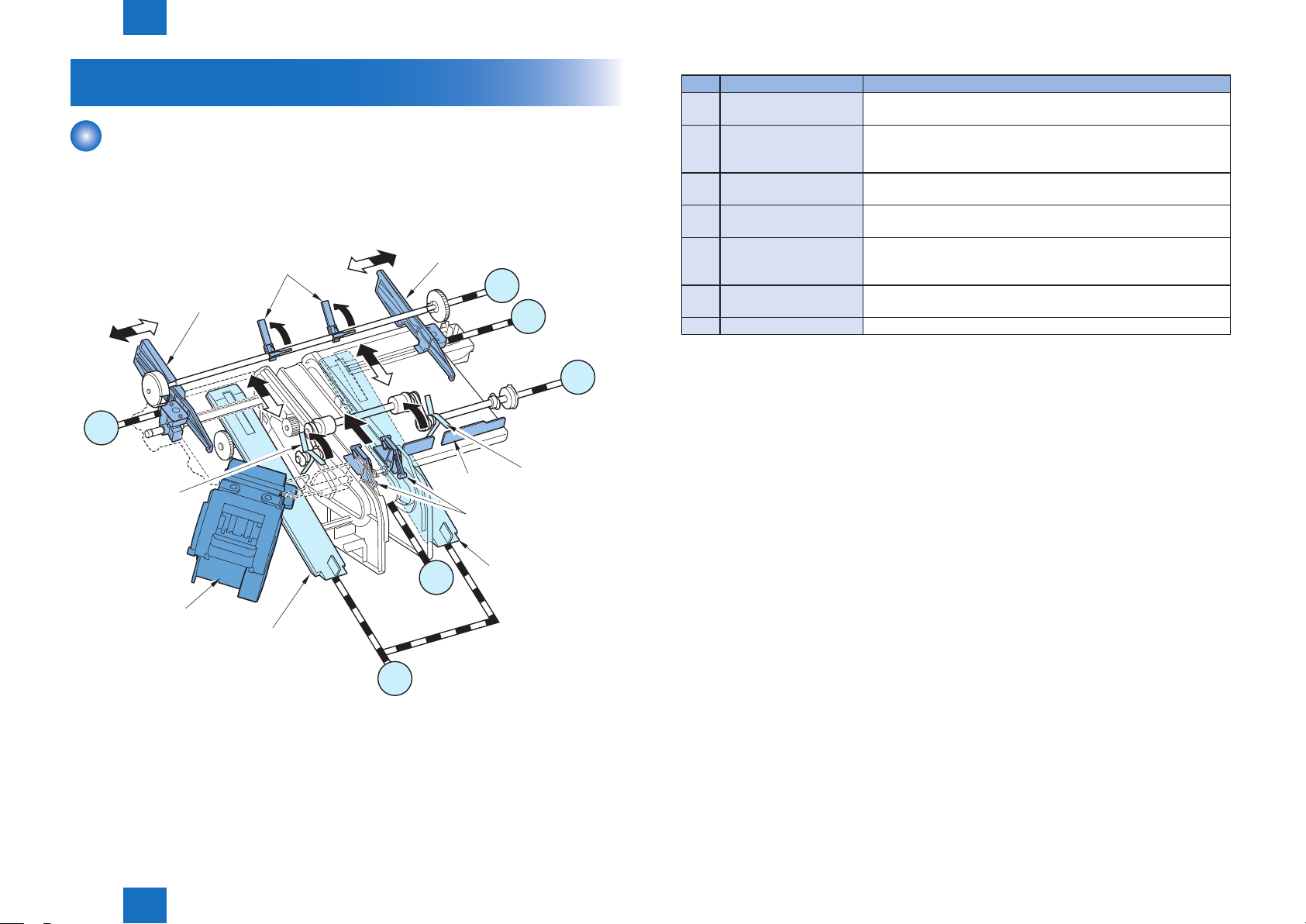

Processing Tray Unit

Outline

The processing tray unit aligns, shifts, and staples the delivered paper, and then delivers the

paper onto the stack tray using a gripper.

Names and roles of the components of the processing tray are as follows:

Paddle

Front Alignment Plate

M4

Front Alignment

Motor

Paper Return

Paddle

Rear Alignment Plate

M3

Rear Alignment

Motor

Stopper

Paper Return

Paddle

Gripper

Paddle

Motor

M5

M2

Delivery

Motor

No. Name Function

[1] Paddle Stacks the paper delivered from the delivery roller on the

processing tray.

[2] Paper Return Paddle Presses the paper stacked on the processing tray against

the stopper (alignment in the feed direction) and prevents the

previously stacked paper from being fed/delivered.

[3] Front / Rear Alignment

Plate

[4] Gripper Grips the paper stack on the processing tray, and then delivers it

[5] Tray Auxiliary Guide When two or more sheets with a length of 150 mm or more are

[6] Stopper Allows the paper stacked on the processing tray to be pressed

[7] Stapler Staples sheets of paper.

Aligns the paper stacked on the processing tray in the width

direction and shifts the paper.

to the stack tray.

stacked on the processing tray unit, prevents misalignment of

paper due to curl.

against itself to align the paper in the feed direction.

T-2-2

Stapler

Tray Auxiliary Guide

Technology > Processing Tray Unit > Outline

2

M7

Gripper Motor

M6

Tray Auxiliary Guide Motor

Tray Auxiliary Guide

F-2-11

2-8

2

Tray

Technology > Processing Tray Unit > Stacking Operation

2-9

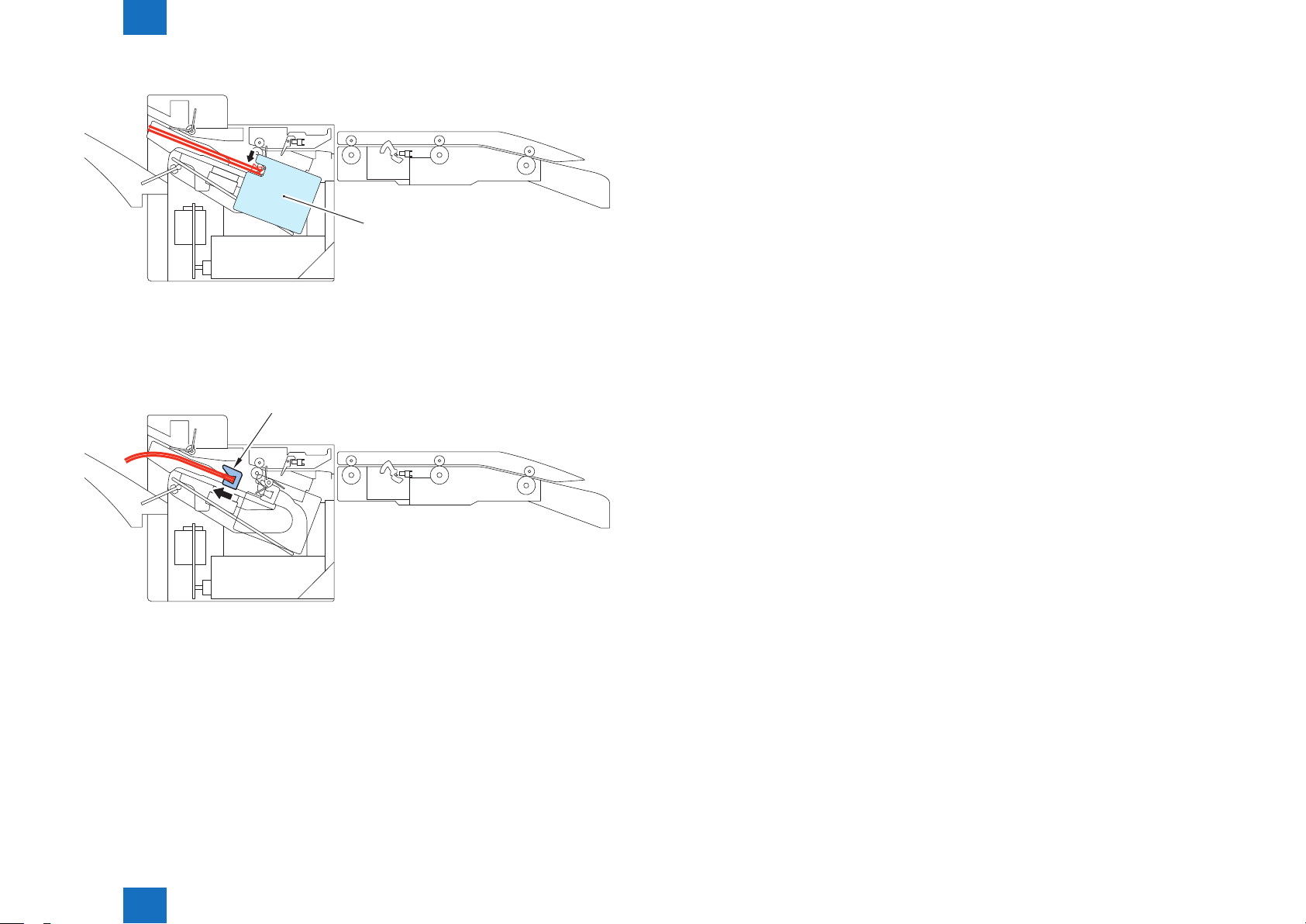

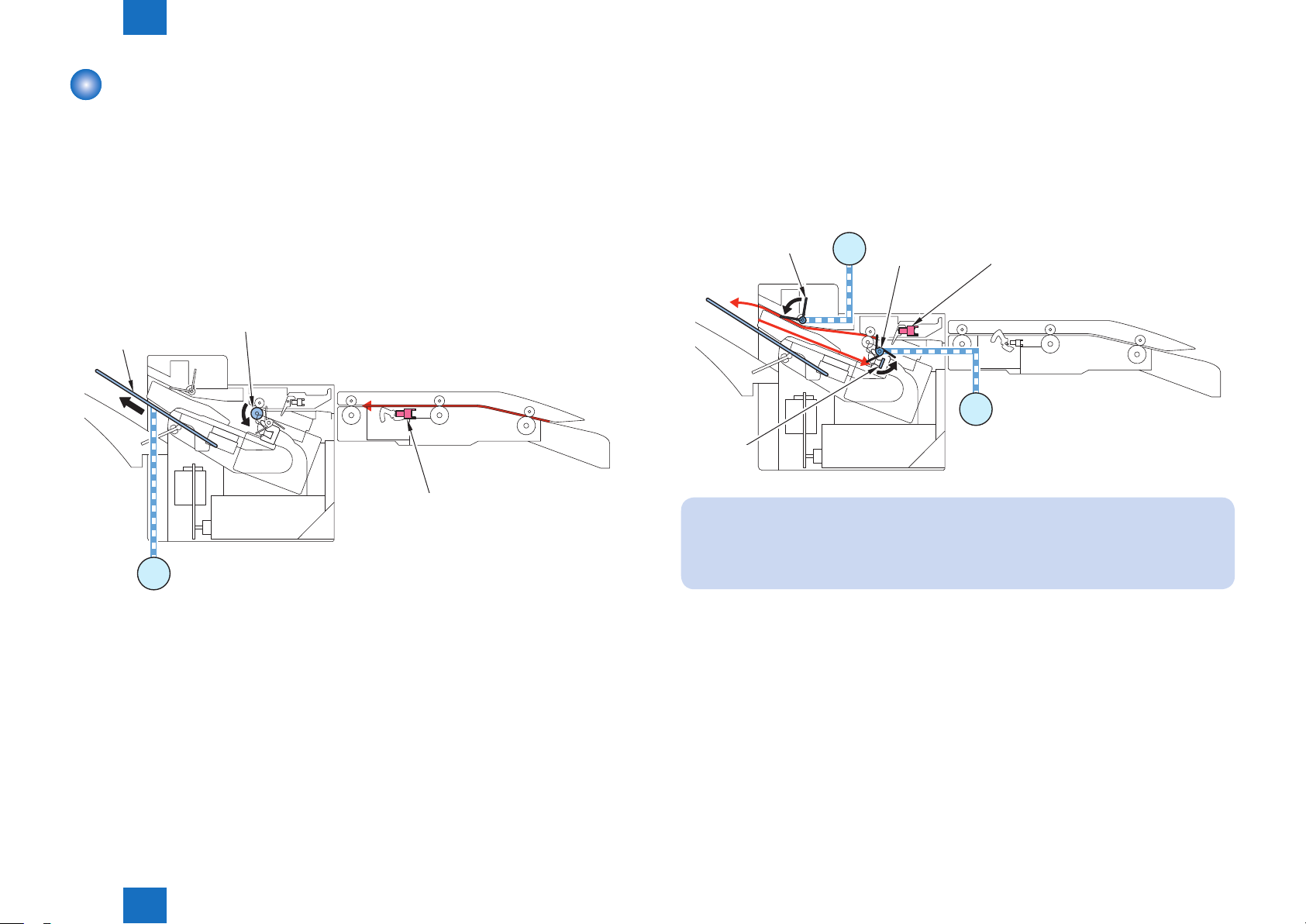

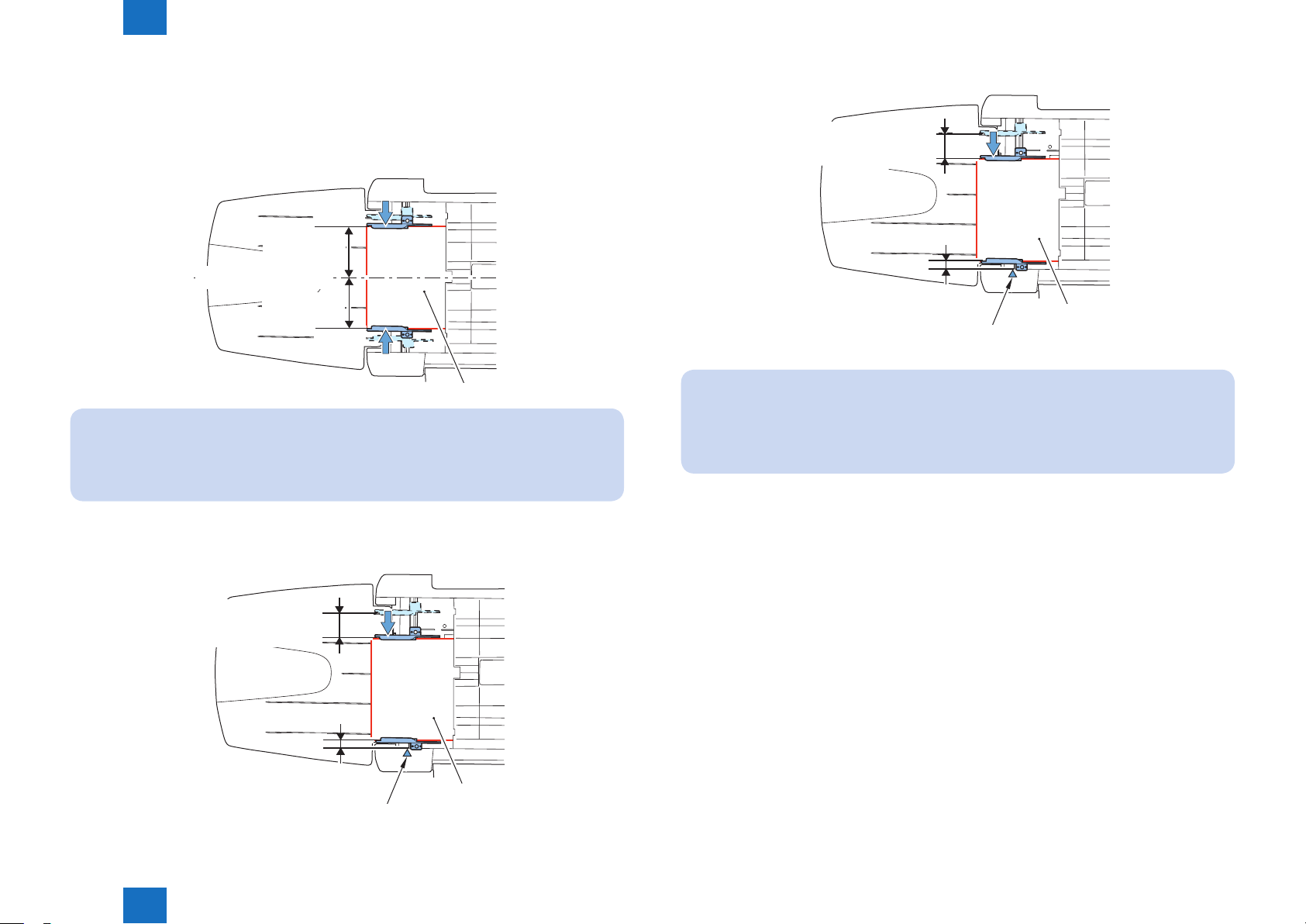

Stacking Operation

The paper delivered from the delivery roller is stacked on the processing tray and the paper is

aligned in the feed direction.

How paper is delivered from the delivery roller and stacked on the processing tray is

described below.

(1) When two or more sheets with a length of 150 mm or more are stacked, the tray

auxiliary guide motor (M6) operates after lapse of the specied time since detection of

paper by the Buffer Sensor (S1), thus sliding out the tray auxiliary guides.

Auxiliary

Guide

Delivery Roller

Buffer Sensor

(S1)

(2) After the specied time has lapsed since paper has passed through the Feed Path

Sensor (S2), the paddle motor (M3) operates to rotate the paddle once to stack the

paper on the processing tray.

The stacked paper is pressed against the stopper by the paper return paddle which is

driven by the delivery motor (M2), thus aligning the paper in the feed direction.

Paddle

Motor

Paddle

Stopper

NOTE:

M3

Paper

Return

Paddle

Feed Path Sensor

(S2)

Delivery Motor

M2

F-2-13

M6

Tray Auxiliary Guide Motor

Technology > Processing Tray Unit > Stacking Operation

2

When a postcard or a sheet shorter than 150 mm is stacked, the paddle does not

rotate.

F-2-12

2-9

2

Technology > Processing Tray Unit > Stacking Operation

(3) The front and rear alignment motors (M4 and M5) operate to move the front and rear

alignment plates, thus aligning the paper in the width direction. (In the illustration below,

the paper is aligned with reference to the central reference position.)

Operations described in (2) and (3) are repeated for each sheet.

Rear Alignment Plate

Front Alignment Plate

F-2-14

2-10

Technology > Processing Tray Unit > Stacking Operation

2

2-10

2

Technology > Processing Tray Unit > Tray Auxiliary Guide Operation

2-11

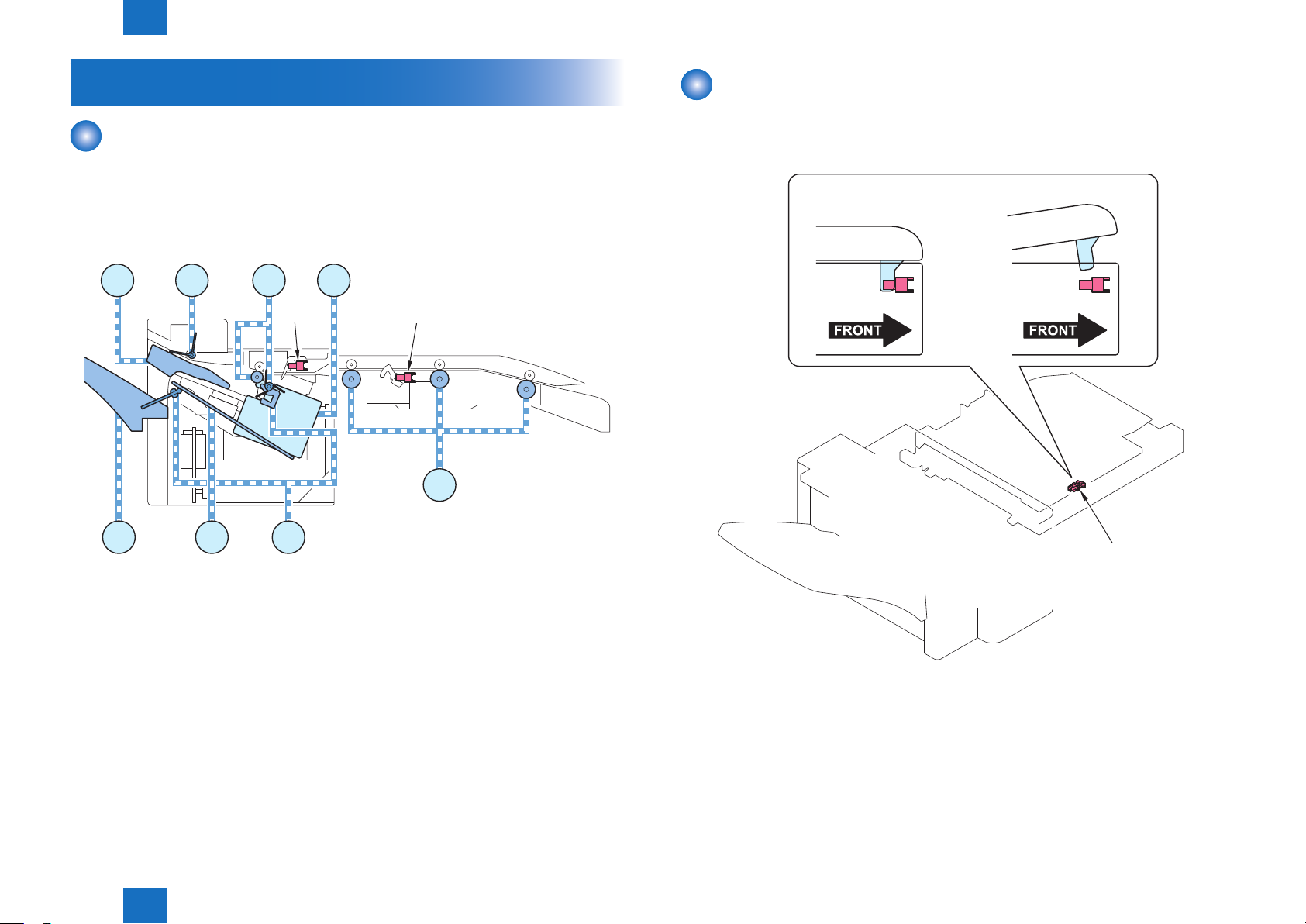

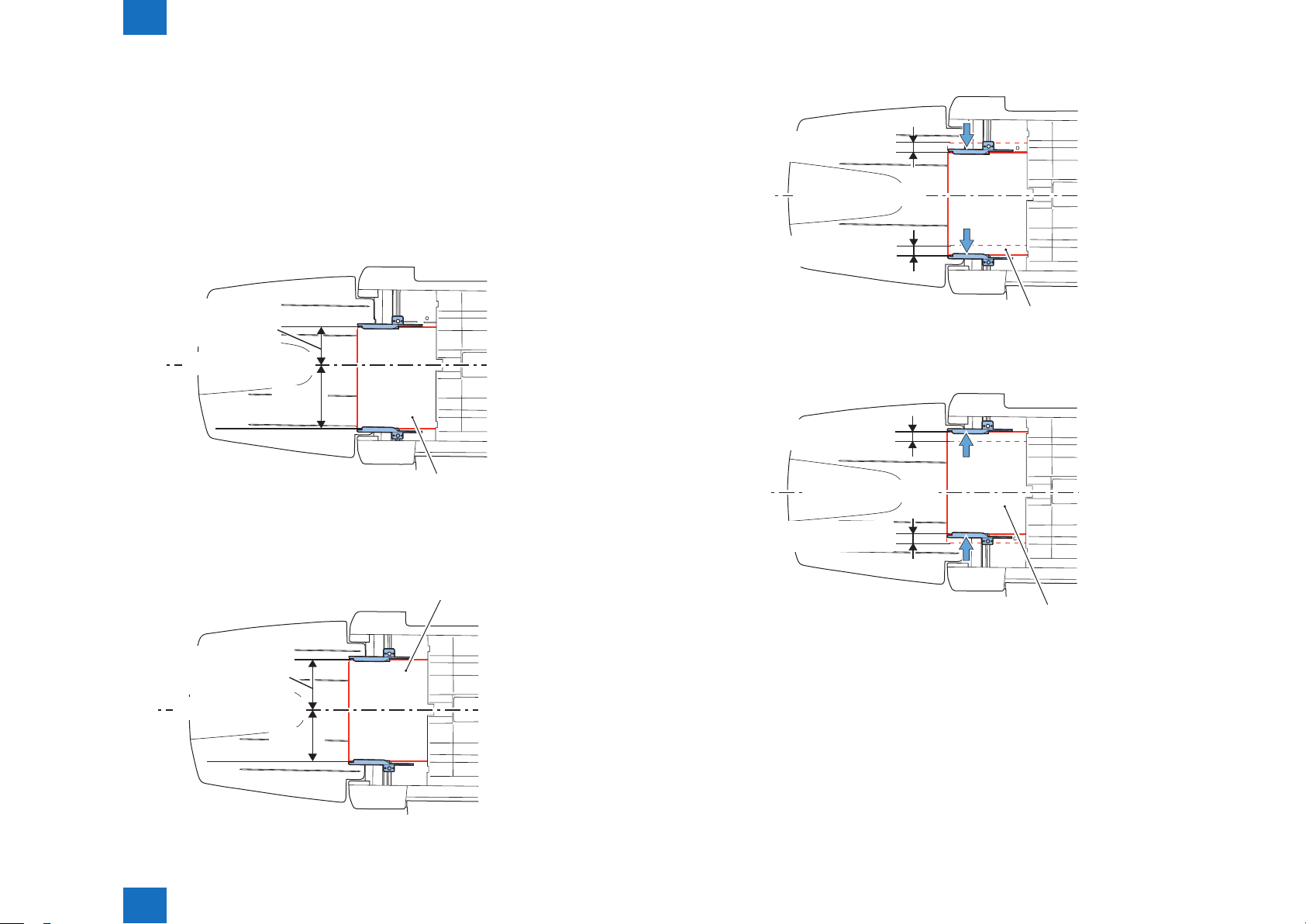

Tray Auxiliary Guide Operation

When two or more sheets with a length of 150 mm or more are stacked on the processing

tray, the tray auxiliary guides slide out to prevent misalignment of paper due to curl.

The tray auxiliary guides are driven by the tray auxiliary guide motor (M6). They slide out

when the inlet Buffer Sensor (S1) detects paper and they slide back when paper is delivered

by the gripper.

The home position of each tray auxiliary guide is detected by the Tray Auxiliary Guide HP

Sensor (S6).

Tray Auxiliary Guide

Tray Auxiliary Guide

HP Sensor (S6)

Tray Auxiliary Guide

The tray auxiliary guide slide-out amount varies depending on the operation mode and paper

length as follows:

Operation Mode Paper Length Amount of Slide Out

Non-Sort / Sort 150 mm or more to less than 217 mm55 mm

217 mm or more to less than 300 mm55 + ("Paper Length" - 216) mm

* The maximum slide-out amount is

120 mm.

Staple 150 mm or more to less than 217 mm55 mm

217 mm or more 55 + ("Paper Length" - 216) mm

* The maximum slide-out amount is

120 mm.

T-2-3

M6

Tray Auxiliary Guide Motor

Technology > Processing Tray Unit > Tray Auxiliary Guide Operation

2

F-2-15

2-11

2

Technology > Processing Tray Unit > Alignment / Shifting Operation

2-12

Alignment / Shifting Operation

The paper stacked on the processing tray is aligned in the width direction by the front and

rear alignment plates. Then, the paper is shifted to the position where it is delivered to the

stack tray.

The front alignment plate is driven by the front alignment motor (M4) and the rear alignment

plate is driven by the rear alignment motor (M5). The home positions of the front and rear

alignment plates are detected by the Front Alignment Plate HP Sensor (S4) and Rear

Alignment Plate HP Sensor (S5).

Front Alignment Plate

Rear Alignment Plate

Front Alignment Plate

HP Sensor (S4)

The relationship between operation modes and alignment positions is summarized in the

following table:

Operation Mode Paper Width Alignment Position

Non-Sort / Sort 180 mm or more • Front alignment position: 10 mm frontward from

the central reference position

• Rear alignment position: 10 mm backward from

the central reference position

139 mm or more to

less than 180 mm

Staple 200 mm or more • Top paper: Central reference position

less than 200 mm Stapling position

Central reference position

• Second and subsequent sheets: Stapling position

T-2-4

Front Alignment Motor (M4)

Rear Alignment Motor (M5)

Technology > Processing Tray Unit > Alignment / Shifting Operation

2

Rear Alignment Plate

HP Sensor (S5)

F-2-16

2-12

2

Technology > Processing Tray Unit > Alignment / Shifting Operation

2-13

The relationship between operation modes and shifting positions is summarized in the

following table:

Operation Mode Paper Width Shifting Position

Non-Sort / Sort 210 mm or more • Front shift position: 10 mm frontward from the central

reference position (Same as the alignment position)

• Rear shift position 10 mm backward from the central

reference position (Same as the alignment position)

*: Shift amount: 20 mm

180 mm or more

to less than 210

mm

139 mm or more

to less than 180

mm

Staple 203 mm or more • Front shift position: 10 mm frontward from the central

less than 203 mm Stapling position

NOTE:

• Front shift position: F mm frontward from the central

reference position

F = 110 - ("Paper width" / 2)

• Rear shift position: R mm frontward from the central

reference position

R = 85 - ("Paper width" / 2)

*: Shift amount: 25 mm

• Front shift position: 10 mm frontward from the central

reference position

• Rear shift position: 10 mm backward from the central

reference position

*: Shift amount: 20 mm

reference position

*: Shift amount: 20 mm

●Alignment Operation in Non-sort / Sort Mode

(1) After lapse of the specied time since detection of paper by the Feed Path Sensor (S2),

the front and rear alignment plates move to the standby position (paper width + 10 mm).

Rear Alignment Plate

Half of Paper Width

+10mm

Middle of Feeding Path

Half of Paper Width

+10mm

Front Alignment Plate

F-2-17

T-2-5

In the non-sort mode, paper is aligned/shifted at the position which is different from the

position where paper was aligned/shifted at the end of the previous copy job.

Technology > Processing Tray Unit > Alignment / Shifting Operation

2

2-13

2

Technology > Processing Tray Unit > Alignment / Shifting Operation

2-14

(2) After lapse of the specied time since detection of the trailing edge of paper by the Feed

Path Sensor (S2), the front and rear alignment plates move for paper alignment.

• Front / Rear alignment position (when the paper width is 180 mm or more)

Paper (when aligning in the rear)

Rear Alignment Position

20mm

20mm

Front Alignment Position

Paper (when aligning in the front)

F-2-18

• Alignment position of central reference (when the paper width is less than 180 mm)

●Alignment Operation in Staple Mode

(1) After lapse of the specied time since detection of paper by the Feed Path Sensor (S2),

the front and rear alignment plates move to the standby position (Front alignment plate:

Home position + 2 mm; Rear alignment plate: Paper width + 10 mm).

• Standby position of central reference (when the paper width is 200 mm or more)

Half of Paper Width

+10mm

Middle of Feeding Path

2mm

Front Alignment Plate Home Position

F-2-20

• Front standby position (when the paper width is less than 200 mm)

10mm

Middle of Feeding Path

10mm

Paper

Technology > Processing Tray Unit > Alignment / Shifting Operation

2

F-2-19

Half of Paper Width

+10mm

Middle of Feeding Path

Half of Paper Width

+10mm

F-2-21

2-14

2

Technology > Processing Tray Unit > Alignment / Shifting Operation

2-15

(2) After lapse of the specied time since detection of the paper’s trailing edge by the Feed

Path Sensor (S2), the front and rear alignment plates move to align paper.

• Alignment position of the center reference (in the case of the paper width being 200

mm or more, and top paper)

Half of Paper

Width

Middle of Feeding Path

Half of Paper

Width

Paper

F-2-22

NOTE:

When the paper length is 300 mm or more, alignment of the top paper executed at the

staple position as well.

• Staple alignment position (when the paper width is less than 200 mm)

The position that aligns

paper by the front and

rear alignment plates

+

dmm

2mm

Paper

Front Alignment Plate Home Position

F-2-24

NOTE:

The length d varies by the number of stacking papers on processing tray.

• If the number of sheets stacked is 1 to 3: 2.0 mm

• If the number of sheets stacked is 4 or more: 4.0 mm

• Alignment position of the staple position (in the case of the paper width being 200 mm

or more, and the second and subsequent sheets)

The position that aligns

paper by the front and

rear alignment plates

2mm

Paper

Front Alignment Plate Home Position

F-2-23

Technology > Processing Tray Unit > Alignment / Shifting Operation

2

2-15

2

Technology > Processing Tray Unit > Alignment / Shifting Operation

2-16

●Shifting Operation in Non-sort / Sort Mode

(1) After alignment of the sheet stacked on the processing tray lastly, it is shifted according

to the paper width.

• Front / Rear shift position (when the paper width is 210 mm or more)

The shift position is the same as the alignment position

• Front shift position (when the paper width is from 180 mm or more to less than 210

mm)

The position that aligns

paper by the front and

rear alignment plates

Middle of Feeding Path

110mm

Paper (when aligning in the front)

F-2-25

• Rear shift position (when the paper width is from 180 mm or more to less than 210

mm)

• Front shift position (when the paper width is less than 180 mm)

Alignment position

+10mm front side

Middle of Feeding Path

Alignment position

+10mm front side

Paper (when aligning in the front)

F-2-27

• Rear shift position (when the paper width is less than 180 mm)

Alignment position

+10mm rear side

Middle of Feeding Path

Alignment position

+10mm rear side

Paper (when aligning in the rear)

The position that aligns

paper by the front and

rear alignment plates

Middle of Feeding Path

85mm

Technology > Processing Tray Unit > Alignment / Shifting Operation

2

Paper (when aligning in the rear)

F-2-28

F-2-26

2-16

2

Technology > Processing Tray Unit > Staple Operation

2-17

●Shifting Operation in Staple Mode

(1) After completion of stapling, the paper stack is shifted according to the paper width.

• Front shift position (when the paper width is 203 mm or more)

The position that aligns

paper by the front and

rear alignment plates

Middle of Feeding Path

Half of Paper Width

+10mm

F-2-29

• Rear shift position (when the paper width is 203 mm or more)

Shifting position and stapling posion is same.

Staple Operation

When the staple mode is selected, paper is stapled by the stapler after it has been stacked

on the processing tray and aligned.

The stapler is provided at the front of the nisher. Paper is stapled at only one position at the

front.

A maximum of 30* sheets can be stapled.

NOTE:

When the following service mode value set 1, the stapling capacity becomes 50 sheets.

To set the maximum number of sheets to be stapled in the Finisher.

• COPIER > OPTION > USER > STPL-MAX

Stapler

Paper

Technology > Processing Tray Unit > Staple Operation

2

F-2-30

2-17

2

Technology > Processing Tray Unit > Stack Tray Paper Retainer Operation

2-18

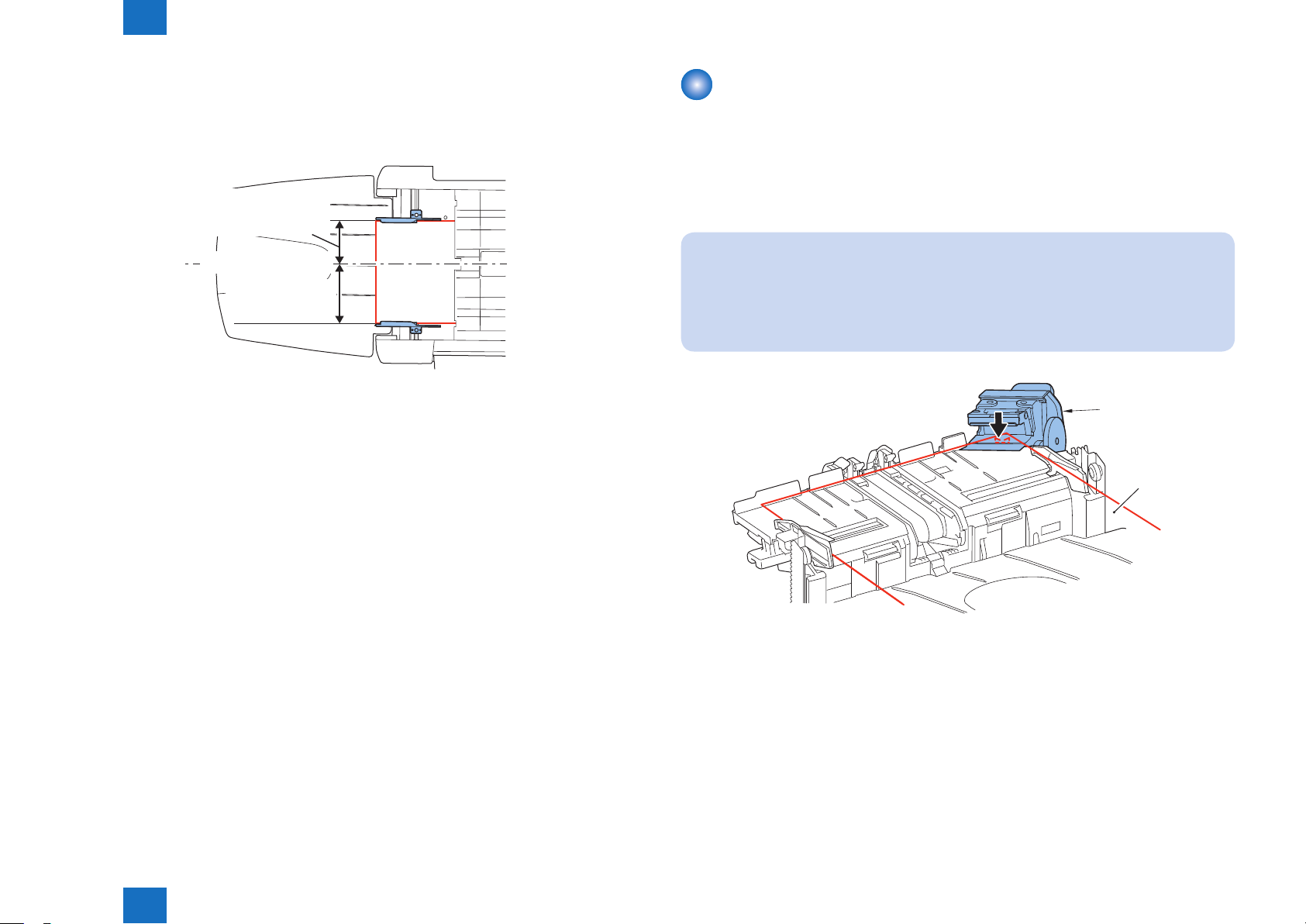

Stack Delivery Operation

The paper stacked on the processing tray is delivered to the stack tray by the gripper after

being shifted and stapled.

The gripper is driven by the gripper motor (M7) via the gripper drive belt.

The home position of the gripper is detected by the gripper HP sensor (S7).

Gripper HP Sensor (S7)

Gripper Drive Belt

Gripper Motor

Gripper

M7

Stack Tray Paper Retainer Operation

The paper delivered to the stack tray is retained by the stack tray paper retainer to prevent

wrong detection of paper height and misalignment caused by curl.

The tray paper retainer is released when the gripper presses portion A of the gear stopper

after it has delivered paper to the stack tray. Then, it is rotated by the driving force of the

gripper motor (M7).

Gear Stopper

Stack Tray Paper Retainer

M7

Gripper Motor

A

Technology > Processing Tray Unit > Stack Tray Paper Retainer Operation

2

F-2-31

F-2-32

2-18

2

Technology > Stack Tray Unit > Stack Tray Paper Height Detection Control

2-19

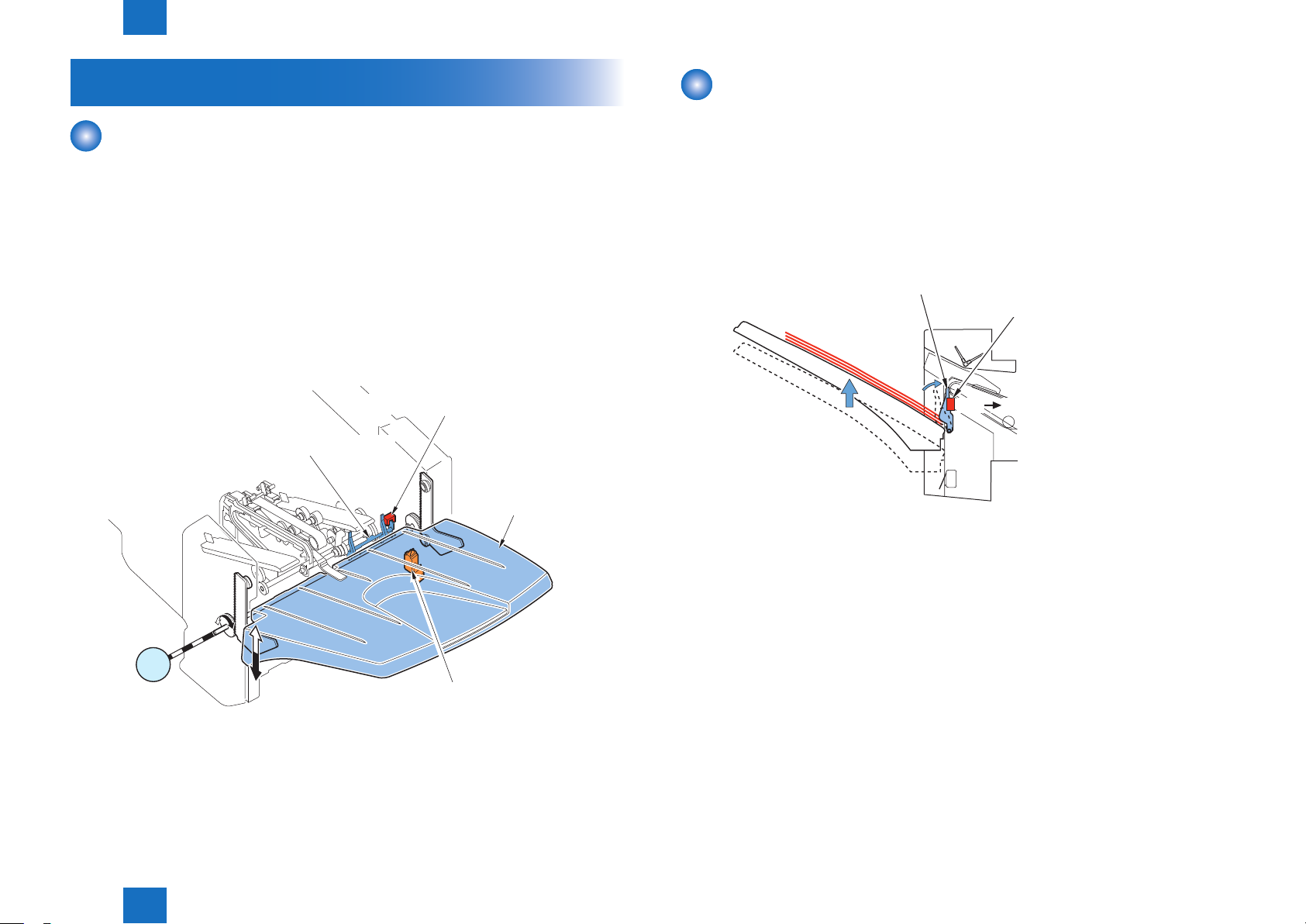

Stack Tray Unit

Stack Tray Shift Operation

The paper delivered from the processing tray by the gripper is then stacked on the stack tray.

The stack tray is moved up and down by the stack tray shift motor (M8).

When the power is turned on or before start of printing, the stack tray shift motor (M8) is

driven to move the stack tray up/down to the position where the stack tray paper height

sensor (S9) detects the stack tray top surface.

After the paper has been delivered from the processing tray, the stack tray moves down by

the specied amount. Then, the stack tray moves up until the stack tray paper height sensor

(S9) detects the stack tray top surface (top surface of the stacked paper) with the stack tray

paper height sensor ag.

Stack Tray Paper Height Sensor (S9)

Stack Tray Paper Height Sensor Flag

Stack Tray

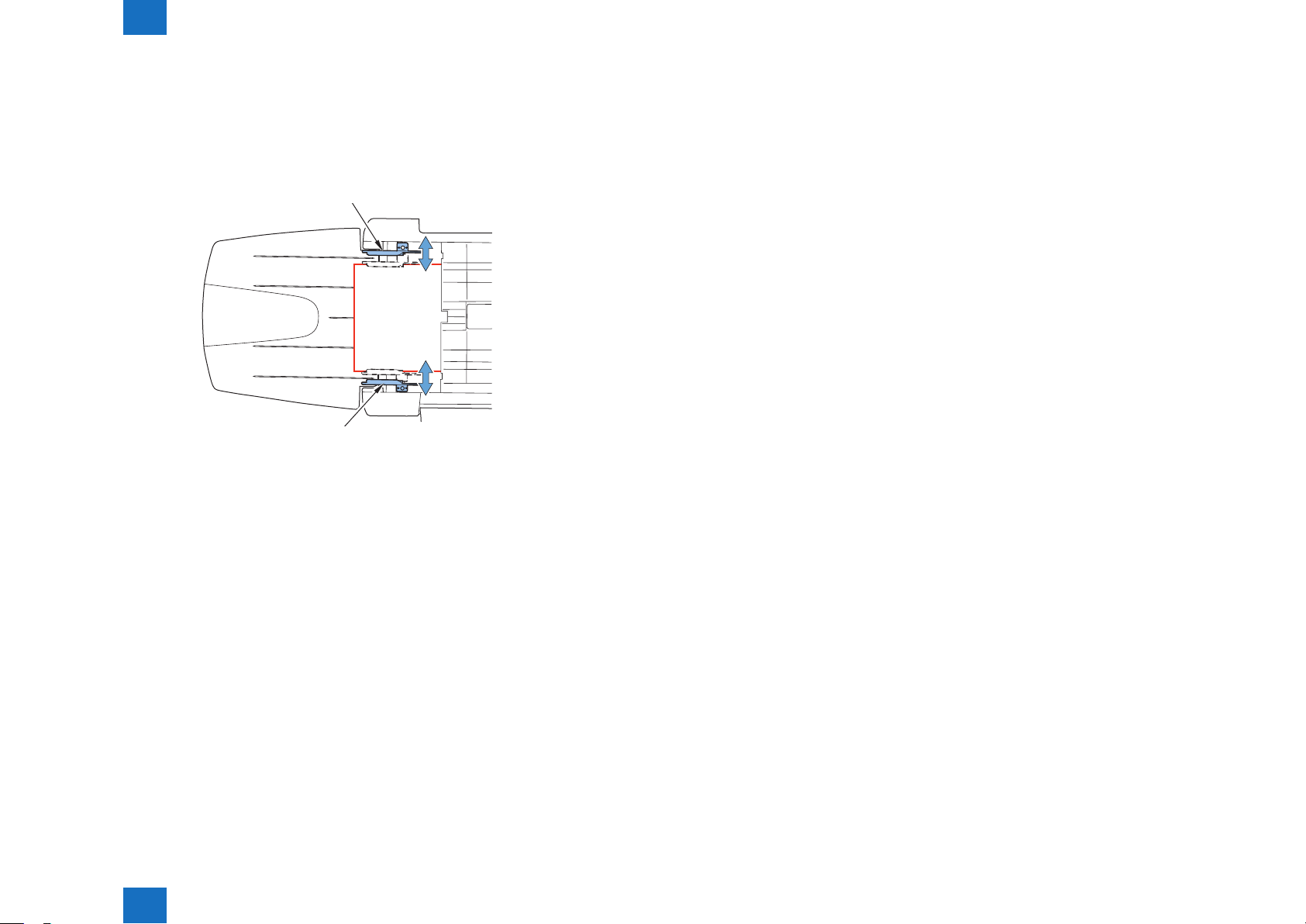

Stack Tray Paper Height Detection Control

The height of the paper stack on the stack tray is detected by the stack tray paper height

sensor (S9).

After paper has been delivered to the stack tray, the stack tray moves down by the specied

amount.

Next, the stack tray paper height sensor (S9) turns on (the top surface of the paper on the

stack tray is detected).

The above operations are repeated each time paper is delivered to the stack tray.

Stack Tray Paper Height Sensor Flag

Stack Tray Paper Height Sensor (S9)

OFF ON

F-2-34

M8

Stack Tray Lower Limit Switch (SW2)Stack Tray

Shift Motor

Technology > Stack Tray Unit > Stack Tray Paper Height Detection Control

2

F-2-33

2-19

Loading...

Loading...