Page 1

High Capacity Stacker-C1

ENG

Page 2

Structure of Users Guide

Read here first.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

1

2

3

4

Before You Begin

Operating Procedures

Troubleshooting

Appendix

Page 3

Page 4

Important Information

• This manual is designed to help you to install, operate and maintain the stacker. Please read and understand this manual, and keep it in a safe and convenient place.

• Do not operate the stacker until you read and understand the instructions in this manual.

• Canon shall not be liable for incidental or consequential damages resulting from: improper or inadequate

maintenance by the customer, unauthorized modification or misuse, or operation outside of the environmental specifications for the product.

• Canon pursues a policy of continuing improvement in design and performance of the product. Therefore, the

product design and specifications are subject to change without prior notice and without our legal obligation.

• All rights are reserved. No part of this manual may be photocopied, reproduced or translated to another language without the prior written consent of your local authorized dealer.

• This product applies to the CE Marking.

• This manual describes the operating procedures for the stacker. For the functions and installing operation

for the host machine (printer), see the operating manual of the host machine (printer.)

i

Page 5

Safe Use of Machine

To use this machine safely, proper operation and periodical maintenance are indispensable. Read the safety precautions described in this manual thoroughly, and do not perform operations or maintenance procedures until you understand them completely.

The operating procedures and safety precautions described in

machine. Responsibility for any improper use or operation of this machine, lies with the user.

Safety precautions are indicated in this manual as follows:

Indicates a warning concerning operations that may lead to death or injury to per-

WARNING

CAUTION

sons if not performed correctly. In order to use the machine safely, always pay

a

ttention to these warnings.

Indicates a caution concerning operations that may lead to injury to persons, or

damage to property if not performed correctly. In order to use the machine safely,

always pay attention to these cautions.

This symbol indicates the range of acceptable values and operating conditions.

This symbol indicates useful supplementary information for operational procedures.

this manual are valid only for proper use of this

Operating Safety Precautions

WARNING

Do not remove the covers and screws unless instructed to do so in this manual. There are high

voltages and moving parts which may cause electrical shock and injury in the machine.

When moving the machine, be sure to turn off the power of operation section and the main power

switch, then disconnect the power cord and contact your local authorized dealer. Otherwise, the

cord may be damaged and may result in a fire or electric shock.

Take care not to be caught between the top cover and the horizontal transport section.

When you remove the sheets from the stacking section, take care not to be caught between the

stack guide and the stack tray. Otherwise, it may lead to severe injury.

Usually, the rollers do not rotate when any cover is opened. But by some chance such as machine

breakdown, it may rotate with the cover opened. When you remove the sheets from the left turnover section, take care not to be caught by the roller. Otherwise, it may lead to severe injury.

CAUTION

This machine weighs about 200 kg (440 lb). When you operate the machine, consider the

machine weight and use the machine safely.

Turn off the power switch before connecting the power cable. It may cause damages on the machine.

Do not use paper which does not meet the specifications. Poor quality paper can cause paper jams.

Do not open the covers during the stacking operation. The machine will stop and cause a paper jam.

If the power is turned off, wait at least 10 seconds before turning it on again.

Do not place any object on or under the stack tray. It may cause damages on the machine.

Use this machine at office or commercial environment. Do not use this machine at industrial environment.

ii

Page 6

Warning Label Locations and Meanings

When you remove the

sheets from the stacking

section, take care not to

be caught between the

stack guide and the stack

tray. Otherwise, it may

lead to severe injury.

Usually, the rollers do not

rotate when any cover is

opened. But by some

chance such as machine

breakdown, it may rotate

with the cover opened.

When you remove the

sheets from the left turnover section, take care

not to be caught by the

roller. Otherwise, it may

lead to severe injury.

FCC NOTICES

NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at this own expense.

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

iii

Page 7

CONTENTS

Important Information ................................................................................................................i

Safe Use of Machine ..............................................................................................................

Operating Safety Precautions...................................................................................................ii

Warning Label Locations and Meanings ................................................................................. iii

FCC NOTICES ........................................................................................................................ iii

Chapter 1 Before You Begin

Features of the Machine....................................................................................................... 1-2

Machine Description .............................................................................................................1

Section Descriptions........

[1] Entrance Section ....................................................................................................... 1-4

[2] Horizontal Transport Section ...

[3] Left Turn-Over Section .............................................................................................. 1-6

[4] Offset Section ............................................................................................................ 1-

[5] Right Turn-Over Section ............................................................................................ 1-8

[6] Stacking Section ........................................................................................................ 1-9

[7] Top Cover-OUTPUT TRAY Section ...............

[8] Control Panel ........................................................................................................... 1-10

Paper Path .......................................................................................................................

Single-Unit Operation ................................................................................................... 1-11

Control Displays ................................................................................................................ 1-12

..ii

-3

..................................................................................................... 1-4

.................................................................................. 1-5

7

......................................................... 1-10

.. 1-11

Chapter 2 Operating Procedures

Stacking Sheets ................................................................................................................... 2-2

Removing Sheets ................................................................................................................2-4

Chapter 3 Troubleshooting

Error Messages .................................................................................................................... 3-2

Service Call Error ........................................................................................................... 3-2

Error Message Chart .................

Clearing Paper Jams ............................................................................................................ 3-

Correcting Paper Curl...........................................................................................................3

Powering Problem (Circuit Breaker Check) .......................................................................... 3-8

Chapter 4 Appendix

Specifications ...................................................................................................................... 4-2

Specifications .................................................................................................................4

Index ............................................................................................................................

..................................................................................... 3-3

5

-6

-2

........ 4-3

iv

Page 8

Before You Begin

1

CHAPTER

Features of the Machine ...................................................................................................................... 1-2

Machine Description ............................................................................................................................ 1-3

Section Descriptions ............................................................................................................................ 1-4

[1] Entrance Section........................................................................................................................ 1-4

[2] Horizontal Transport Section ..................................................................................................... 1-5

[3] Left Turn-Over Section............................................................................................................... 1-6

[4] Offset Section ............................................................................................................................ 1-7

[5] Right Turn-Over Section ............................................................................................................ 1-8

[6] Stacking Section ........................................................................................................................ 1-9

[7] Top Cover-OUTPUT TRAY Section ......................................................................................... 1-10

[8] Control Panel ........................................................................................................................... 1-10

Paper Path ......................................................................................................................................... 1-11

Single-Unit Operation.................................................................................................................... 1-11

Control Displays............................................................................................................................ 1-12

1-1

Page 9

Before You Begin

1

Features of the Machine

OUTPUT TRAY

Ejecting prints such as sample or interrupt prints on the OUTPUT TRAY enables highly productive performance without interrupting the stacking operation. The maximum stack height is 100

mm (3.94").

Possible Configurations

You can use this machine as a stand-alone unit. Or you also can send the sheets straight through

to the downstream unit without stacking.

Double-unit Operation

You can join two stackers together and use as double-unit. (To use as double-unit, it is necessary

to purchase two stackers.)

Maximum Stacking Capacity

The maximum stack height in the main stack tray is 570 mm (22.44").

Offset Mechanism

The offset mechanism does offset stacking without slowing down the production speed.

1-2 Features of the Machine

Page 10

1

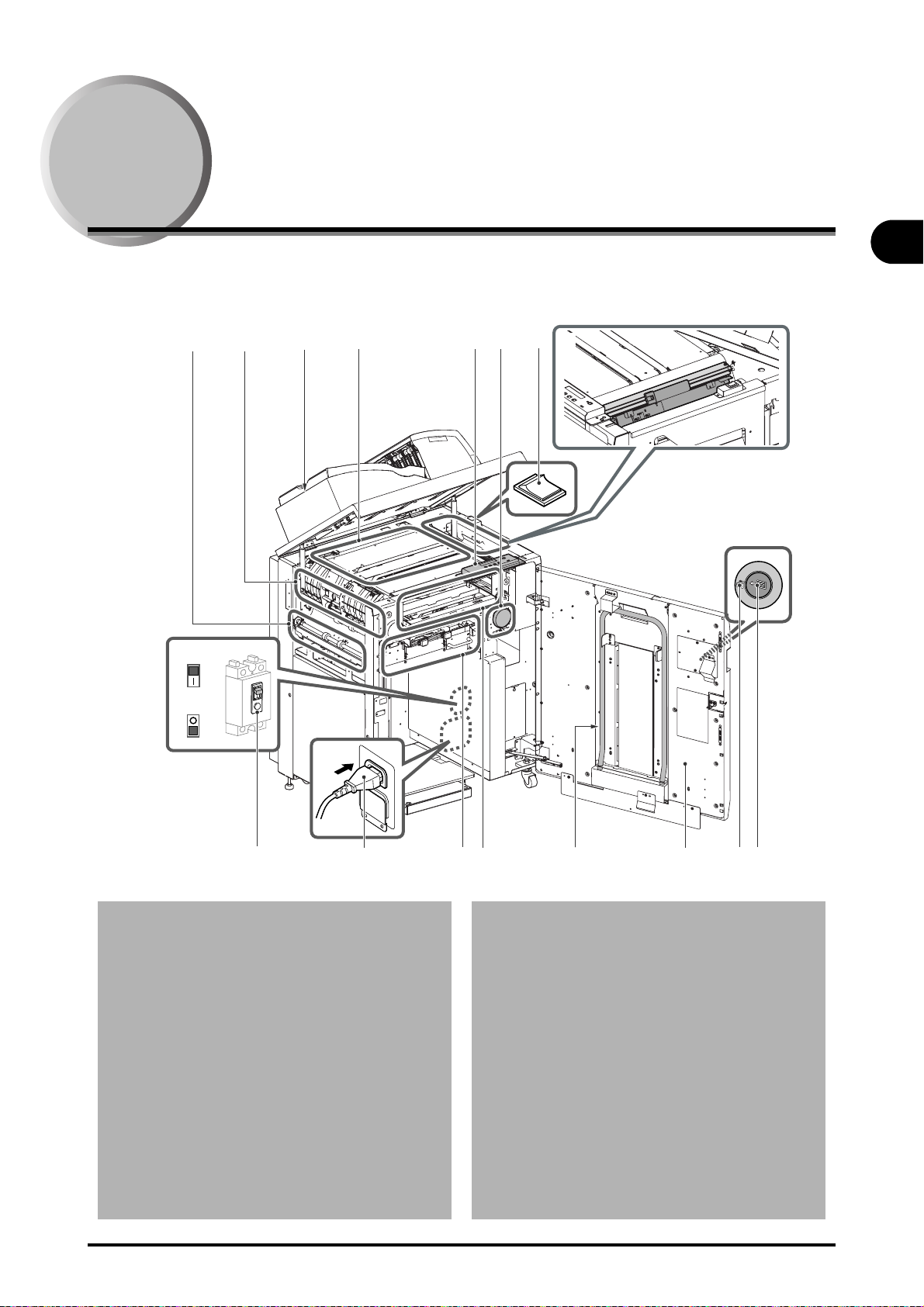

Machine Description

ON

OFF

[B]

[A][8]

[4]

[7]

[C]

[3]

[D]

[6]

[5] [1][2]

[E]

[F]

[G]

[H]

[1] Entrance Section (See page 1-4).

[2] Horizontal Transport Section (See page 1-5).

[3] Left Turn-Over Section (See page 1-6).

[4] Offset Section (See page 1-7).

[5] Right Turn-Over Section (See page 1-8).

[6] Stacking Section (See page 1-9).

[7] Top Cover-OUTPUT TRAY Section (See

page 1-10).

[8] Control Panel (See page 1-10).

[A] Power Switch

[B] Stack Status LED

Lit :Stacker is full.

Blinking :Stacker is operating.

[C] Front Cover Open Button (and LED)

Lit: Cover unlocked.

Blinking: Stack tray is moving up or down.

[D] Downstream Exit Section (See page 1-11).

[E] Handle

Use this handle to remove sheets from the

stacking section.

[F] Front Cover

Press the front cover open button to open.

When the machine is running, press the button and wait until the lamp lights up, and

then open the cover.

[G] Power Cable

[H] Circuit Breaker

OFF

ON

Before You Begin

Machine Description 1-3

Page 11

Before You Begin

1

First Gate

This gate diverts the sheet

transport path, to the stack

tray/downstream unit, or to

the OUTPUT TRAY.

Entrance Transport Guide [ B]

If any sheets jam in the entrance section,

open the top cover, hold the green handle and

open this guide, and remove the jammed

sheets.

Section Descriptions

[1] Entrance Section

This section receives each sheet as it is delivered from the upstream machine (printer). The first

gate sends the sheets to the stack tray or to the OUTPUT TRAY.

1-4 Section Descriptions

Page 12

1

[2] Horizontal Transport Section

Left Turn-Over

Section

Sheets delivered from the entrance section, pass here before being carried to the Left Turn-Over

section.

Before You Begin

Section Descriptions 1-5

Page 13

Before You Begin

1

Second Gate

This gate sends the

sheets, to the stack tray of

this machine, or to the connected downstream unit.

Downstream Exit Section

Any sheets which are sent to the downstream unit pass through this section.

Left Upper Guide

[C]

If any sheets jam in the left

turn-over section, hold the

green handle to open this

guide, and remove the

jammed sheets.

Left Lower Guide

[E1]

If any sheets jam in the

downstream exit section,

hold the green handle to

open this guide, and

remove the jammed

sheets.

Left Dial [ D2 E2]

If any sheets jam, turn this dial

counterclockwise and move the

sheets manually. Dial idles by

turning it clockwise.

[3] Left Turn-Over Section

This section turns over sheets delivered from the horizontal transport section. The second gate

sends the sheets to the stack tray or to the next machine in the line.

1-6 Section Descriptions

Page 14

1

[4] Offset Section

Offset Section Guide

[D1]

If any sheets jam in the offset

section, open this guide and

remove the jammed sheets.

In this section, sheets can be shifted during transport to enable offset stacking. As a result, the

ejected sheets are offset on the stack tray.

Before You Begin

Section Descriptions 1-7

Page 15

Before You Begin

1

Right Upper Guide

[D3]

If any sheets jam in the right

turn-over section, hold the

green handle to open this

guide, and remove the

jammed sheets.

Right Dial

[D5]

If any sheets jam, turn this

dial clockwise to move the

sheets manually.

Right Lower Guide

[D4]

If any sheets jam in the right

turn-over section or stacking

section, hold the green handle

to open this guide, and

remove the jammed sheets.

[5] Right Turn-Over Section

This section turns over each sheet after it is delivered from the offset section.

1-8 Section Descriptions

Page 16

1

[6] Stacking Section

Stack Stopper

This stopper moves automatically to match the sheet size

which has been set on the

control panel.

Front Stack Guide

This guide arranges the sheets which are

ejected onto the stack tray. To enable offset

stacking, the inner plate of the rear stack guide

and front stack guide lift alternately, offsetting

the sheets.

Rear Stack Guide

This guide arranges sheets

which are ejected onto the stack

tray.

It moves automatically to match

the sheet size which has been

set on the control panel.

Stack Tray

This tray can stack the sheets up

to a maximum of 570 mm

(22.44").

When the stack tray is full, it

moves down automatically to the

lowest point. Insert the handle,

which is attached inside the front

cover, and pull out the tray.

Inner Plate

of Front

Stack Guide

Inner Plate

of Rear

Stack Guide

Opening the Front Stack Guide

If the sheets stack height exceeded

the stack height 550 mm (21.65”),

open the front stack guide before

pulling the stack tray.

Hold the blue handle shown in the

illustration to the left and turn it

upward. Make sure to close the

front stack guide before closing the

front cover.

When you remove the sheets from the stacking section, take care not to be caught

between the stack guide and the stack tray.

Otherwise, it may lead to severe injury.

WARNING

Handle

Sheets delivered from the offset section are transported to the stacking section, and then ejected

on the stack tray. The maximum stack height is 570 mm (22.44").

Before You Begin

Section Descriptions 1-9

Page 17

Before You Begin

1

Top Cover

If any sheets jam in the

entrance section or horizontal transport section, open

this cover and remove the

jammed sheets.

OUTPUT TRAY

By ejecting prints, such as

sample or interrupt prints on

this tray, it enables highly productive performance without

interrupting the stacking operation. The maximum stack

height is 100 mm (3.94".)

When you open the top cover, remove sheets on

the OUTPUT TRAY first, then open the top

cover. Otherwise, the top cover may fall because

of the weight of the sheets on OUTPUT TRAY,

and your finger may be caught.

CAUTION

Error

Enter

Menu

Stack ON/OFF

+//

Stack ON/OFF Button

This button activates or deactivates

stacking. This button is invalid during a

job.

ON: Activate

OFF: Deactivate

When the LED on the left of the button

lights up (green), the stacking function is

active.

LCD Display

This displays status

messages (See

page 1-12 to 1-14) or

error messages

(See page 3-2 to 3-4).

Error Lamp

This lamp lights up or blinks if an error

occurs.

Blinking: An error (paper jam, cover

open, stack tray full) occurs.

Lit: Service call error occurs.

Control Keys

These keys are used to switch the menu

such as curl correction or indicated language

select. (See page 1-13)

[7] Top Cover-OUTPUT TRAY Section

[8] Control Panel

Perform settings and operations for the machine using the controls on this panel.

1-10 Section Descriptions

Page 18

1

Paper Path

[7] OUTPUT TRAY Section

[2] Horizontal Transport Section

[3] Left Turn-Over Section

[D] Downstream Exit Section

[1] Entrance Section

[5] Right Turn-Over Section

[4] Offset Section

[6] Stacking Section

Single-Unit Operation

Before You Begin

Paper Path 1-11

Page 19

1

Control Displays

Power On

Machine processing settings.

Preparation complete.

Ready message

Operating message

Ready message

Ejecting to the OUTPUT TRAY

Ready message

Operating message

Ready-Paper removal message

Ejecting to the Stack Tray

Ready message

Paper is output to the OUTPUT TRAY.

Operation complete.

Paper is output to the stack tray.

Operation complete.

See page 1-14 for paper removal and

door open operation.

Powering on message

Power on the host machine (printer).

Appears only when the power on the stacker is

turned on before the host machine (printer).

Before You Begin

1-12 Control Displays

Page 20

1

JAPANESE - ENGLISH - FRENCH

-

GERMAN - ITALIAN

Press Menu.

Curl Correction / Indicated Language Select

Indicated language changes to

Japanese - English - French German - Italian in order.

Ready message

Press Menu.

Press Menu.

Press

Enter.

Menu screen for

switching language

Screen for setting

language

Press

Menu.

Press

Enter.

Press

Enter.

Press

Enter.

Press

+/- Key.

Screen for setting

curl correction

Menu screen for

curl correction

Before You Begin

- To correct the curl, perform the steps below in order.

1. Set up the curl correction to [AUTO].

2. If the sheets are still curled after step

tion amount on the printer.

3. If the sheets are still curled after step 2

to [CONVEX], [CONCAVE], or [OFF].

- If the curl correction function is set incorrectly, paper jam or stacking error may

occur. Refer to 3-6 [Correcting Paper Curl] for details.

- Curl correction function is available only for the sheets delivered to the stack tray.

1 is performed, change the curl correc-

is performed, set up the curl correction

Control Displays 1-13

Page 21

1

Machine is operating or Machine is ready

Press the Front

Cover Open button.

When you press the Front Cover Open

button again while the stack tray is

moving down, the stack tray stops and

you can remove the sheets in the

stack, but not the stack tray.

Open the front cover.

Stack tray

moved down.

Remove the

stack tray.

When you press the front

cover open button while

the stack tray is moving up,

the stack tray moves down.

Reset the stack tray.

Close the front

cover.

Open the

front cover.

Paper Removal and Door Open Operation

Stack tray

moves up.

Close the

front cover.

Before You Begin

1-14 Control Displays

Page 22

Operating Procedures

2

CHAPTER

Stacking Sheets ................................................................................................................................... 2-2

Removing Sheets................................................................................................................................. 2-4

2-1

Page 23

2

Stacking Sheets

WAIT...

ON

OFF

Wait Screen

Ready Screen

Operating Procedures

1 Turn on the power switch of the main unit, then turn on the power

When different sizes paper are stacked together, the paper cannot be

squared-up neatly. To square-up the paper neatly, stack only same size

paper.

switch of the stacker.

The LCD display presents the Wait screen.

2 When the machine preparation completes, the LCD display changes

to the Ready screen.

3 Power on the host machine (printer.)

2-2 Stacking Sheets

If the power switch on the machine is turned on while the power of the

upstream machine (printer) is off, the message shown below appears.

Turn on the power switch for the upstream machine (printer).

Page 24

2

4 Press the front cover open button and open the front cover.

Front Cover Open

Button

Lit: Front cover can be

opened.

Blinking: Do not open the

front cover.

Stack Tray

Stack

Stack ON/OFF Button

This button is invalid during a job.

ON: Activate

OFF: Deactivate

5 Place the stack tray and close the front cover.

· Push the stack tray to the rear until it is held by the magnet of the support.

· If the tray is placed incorrectly, it will not move up when the front cover is

closed.

Operating Procedures

6 Turn on the stacking function.

Press the Stack ON/OFF button. When the LED to the left of the button lights up (green),

the stacking function is active.

If the stacking function is not turned on, you cannot select the stacker for the out-

from the printer.

put,

Set up the printer and start printing. See the operating manual for the printer.

+/

ON/OFF

Enter

Error

Stacking Sheets 2-3

Page 25

2

Removing Sheets

Front Cover Open

Button

Lit: Front cover can be

opened.

Blinking: Do not open the

front cover.

CAUTION

1 When the stacking operation is complete, press the Front Cover

Operating Procedures

When pressing Front Cover Open Button during the

machine is running, wait until the lamp lights up, and then

open the cover.

Open button and remove the stacked sheets.

While the stack tray is moving down, the button blinks.

2-4 Removing Sheets

Page 26

2

2 When the button lights up, open the front cover. Attach the handle to

Handle

CAUTION

Handle

Front Stack Guide

CAUTION

the stack tray and pull it out to the front.

The handle is mounted to the back of the front cover.

If the sheets stack height exceeded the stack height 550

mm (21.65”), the stack may fall over when pulling out the

stack tray. In case when the sheets stack height

exceeded 550 mm (21.65”), open the front stack guide

before pulling the stack tray.

front stack guide before closing the front cover.

Make sure to close the

Operating Procedures

Use the handle to pull the tray straight forward. If you tilt

the tray, the stack may fall over.

Removing Sheets 2-5

Page 27

2

3 Replace the empty stack tray and close the front cover.

Stack Tray

Support

Handle

Operating Procedures

The stack tray will move up automatically.

· After you place the stack tray on the support, remove the handle. (If the handle is

ached to the stack tray, you will not be able to close the front cover.)

att

· Push the stack tray to the rear until it is held by the magnet of the support. If the

stack tray is placed incorrectly, it will not be able to move up.

· If the front stack guide is opened before pulling out the stack tray, make sure to

close the front stack guide before closing the front cover. Stacking operation cannot be performed with the front stack guide opened.

· Mount the handle to the back of the front cover as shown in the illustration below.

2-6 Removing Sheets

Page 28

Troubleshooting

3

This section explains how to identify problems and correct them.

CHAPTER

Error Messages.................................................................................................................................... 4-2

Service Call Error............................................................................................................................ 4-2

Error Message Chart....................................................................................................................... 4-3

Clearing Paper Jams ........................................................................................................................... 4-5

Correcting Paper Curl .......................................................................................................................... 4-6

Powering Problem (Circuit Breaker Check) ......................................................................................... 4-8

3-1

Page 29

3

Error Messages

WARNING

CAUTION

Troubleshooting

When an error occurs and the machine does not work properly, the following screen will be

shown. If the screen indicates the “SERVICE CALL ERROR”, perform as follows:

Do not plug in and out the power plug by wet hand.

It causes electrical shock.

When you plug out the power plug, be sure to hold

the plug. If you pull the power cable, it may expose

or cut the core wires and cause a leak of electricity,

and result in fire or electrical shock.

Service Call Error

When SERVICE CALL ERROR is shown on the LCD, turn off the power switch of the stacker

and the upstream machine (printer). Wait about 10 seconds, and turn on the power switch of the

stacker and then turn on the power switch of the upstream machine (printer) again. If the SERVICE CALL ERROR is still shown on the LCD, check the following items, turn off the main power,

and disconnect the power plug. Then contact your local authorized dealer.

- Product Name

- State of trouble

- Code number indicated on the screen

3-2 Error Messages

Page 30

3

Error Message Chart

2

1

3

D2 E2

D4

D1

D3

B

A

E1

C

D5

When you remove the

sheets from the left

turn-over section, take

care not to be caught

by the roller. Otherwise, it may lead to

severe injury.

When you remove the

sheets from the stacking section, take care

not to be caught

between the stack

guide and the stack

tray. Otherwise, it may

lead to severe injury.

WARNING

1

2

3

3

1

2

Troubleshooting

Error Message Cause Remedy

CLOSE COVER

TOP COVER

CLOSE COVER

OUTPUT TRAY COVER

REMOVE PAPER FROM

OUTPUT TRAY

REMOVE PAPER FROM

STACKER

UNEVEN STACK

REMOVE STACKER PAPER

/

IF PAPER IS CURLED

PERFORM CURL ADJUST.

STACK TRAY NOT SET The stack tray is not placed cor-

CLOSE GUIDE

STACK GUIDE F. COVER

REMOVE JAMMED PAPER

B

REMOVE JAMMED PAPER

A

The top cover is open. Close the top cover .

The OUTPUT TRAY cover is

op

en.

The OUTPUT TRAY is full. Remove the paper from the OUT-

The stack tray is full. Remove the paper from the stack

1. The paper is curled.

2. Paper on the stack tray is

leant.

rectly.

Front cover is closed without

closing

A paper jam occurred in B

section.

A paper jam occurred in the A

section.

the front stack guide .

Close the OUTPUT TRAY cover

PUT TRAY.

tr

Check the message displayed on

he host machine (printer) control

t

panel.

Place the stack tray correctly.

Open the front cover and close

the front stack guide , then

close the front cover.

Open the top cover and open

the B guide to remove the

jammed paper. Close the guide

an

will be restarted. *1

Open the OUTPUT TRAY cover

remove the jammed paper. Close

th

printing will be restarted.

.

ay.

d the cover, and the printing

and open the A guide to

e guide and the cover, and the

Error Messages 3-3

Page 31

3

Error Message Cause Remedy

1

1

3

1

3

*1

When you open the top cover, remove sheets on

the OUTPUT TRAY first, then open the top

cover. Otherwise, the top cover may fall because

of the weight of the sheets on OUTPUT TRAY,

and your finger may be caught.

CAUTION

REMOVE JAMMED PAPER

C

REMOVE JAMMED PAPER

D1 2

REMOVE JAMMED PAPER

D1

Troubleshooting

REMOVE JAMMED PAPER

D1 3

REMOVE JAMMED PAPER

D4 5

REMOVE JAMMED PAPER

E1 2

REMOVE JAMMED PAPER

*

A paper jam occurred in C

section.

A paper jam occurred in D1

and D2 E2 section.

A paper jam occurred in D1

section.

A paper jam occurred in D1,

D3 section.

A paper jam occurred in D4,

D5 section.

A paper jam occurred in E1

and D2 E2 section.

A paper jam occurred in the

acking section.

st

Open the top cover , C

guide and remove the jammed

paper. Close the guide and the

cover, and the printing will be

restarted. *1

Open the top cover , C

guide, front cover, D1 guide

and turn the D2 E2 dial

counterclockwise to remove the

ed paper. Close the guide

jamm

and the cover, and the printing

will be restarted. *1

Open the front cover, D1 guide

and remove the jammed paper.

Close th

and the printing will be restarted.

Open the front cover, D1

guide, D3 guide and remove

the jammed paper. Close the

gu

printing will be restarted.

Open the front cover, D1

guide, D3 guide, D4 guide

and stack guide . Turn the

the jammed paper. Close the

gu

printing will be restarted.

Open the top cover , C

guide, front cover, E1 guide

and turn the D2 E2 dial

counterclockwise to remove the

jamm

and the cover, and the printing

will be restarted. *1

Open the front cover, turn the

the jammed paper completely.

The

Close the guide and the cover,

and the printing will be restarted.

e guide and the cover,

ide and the cover, and the

D5 dial clockwise and remove

ide and the cover, and the

ed paper. Close the guide

D5 dial clockwise to transport

n open the front stack guide

to remove the jammed paper.

3-4 Error Messages

Page 32

3

Clearing Paper Jams

Jam in the downstream exit section

• Paper chip is left. (See the

Remedy 1)

Jam in the left turnover section

• Paper chip is left. (See the

Remedy 1)

Jam in the stacking

section

• Paper chip is left. (See the

Remedy 1)

Jam in the entrance

section

• Paper chip is left. (See the

Remedy 1)

• Sheet loaded on the printer

does not fit the setting on

the printer. (See the Remedy 2)

Jam in the horizontal

transport section.

• Paper chip is left. (See the

Remedy 1)

Remedy 1

Open the guides and check to see if any paper chips are left on the sheet transport

path where paper jams frequently. (See page 4-3, 4-4)

Remedy 2

Load the correct sheet which fits the setting on the printer.

Troubleshooting

Clearing Paper Jams 3-5

Page 33

3

Correcting Paper Curl

Error

Enter

Menu

Stack ON/OFF

+//

Enter

+ Key

Menu

- Key

If the stacked sheets are curled, correct the curl from the operation panel.

Troubleshooting

To correct the curl, perform the steps below in order.

1. Set up the curl correction to [AUTO].

2. If the sheets are still curled after step

tion amount on the printer.

3. If the sheets are still curled after step 2

to [CONVEX], [CONCAVE], or [OFF].

1 is performed, change the curl correc-

is performed, set up the curl correction

Curl Correction

1 Press the [Menu] on the Standby screen

[MENU CURL CORRECTION] will be displayed on LCD.

2 Press [Enter] on the operation panel.

3-6 Correcting Paper Curl

Page 34

3

3 Press the +/- key on the operation panel and setup the curl correction.

CONVEX

CONCAVE

Curl Correction and Sheet Condition

Troubleshooting

When + key is pressed, [AUTO] - [OFF] - [CONVEX +1] - [CONVEX +2] - [CONVEX +3] -

[CONVEX +4] is displayed in order on

When - key is pressed, [AUTO] - [CONCA

If the stacked sheets are curled upward, select [CONCAVE].

If the stacked sheets are curled downward,

- If the curl correction function is set incorrectly

- Curl correction function is available only

LCD.

VE -1] is displayed on LCD.

select [CONVEX].

4 Press [Enter] on the operation panel.

, paper jam or stacking error may occur.

for the sheets delivered to the stack tray.

Correcting Paper Curl 3-7

Page 35

3

Powering Problem (Circuit Breaker Check)

ON

OFF

WARNING

Troubleshooting

If the machine does not operate although the power switch is turned on, check if the circuit

breaker is turned off. If the circuit breaker is turned off, contact your local authorized dealer without turning on the circuit breaker.

If the circuit breaker is turned off, do not turn on it

again. Otherwise, it may result in electrical shock,

fire, fuming, or trip of the building circuit breaker.

3-8 Powering Problem (Circuit Breaker Check)

Page 36

Appendix

4

CHAPTER

Specifications....................................................................................................................................... 4-2

Index .................................................................................................................................................... 4-3

4-1

Page 37

4

Specifications

Appendix

Specifications

Product Name High Capacity Stacker-C1

Sheet Size/Paper Weight Range Stack Tray A3, A4, B4, B5, 11” x 17”, 12” x 18”, 13” x 19”,

OUTPUT TRAY A3, A4, A4R, A5R, B4, B5, B5R, 11” x 17”, 12”

Downstream

Output

Tray Capacity Stack Tray 5000 sheets (All sizes / 80 gsm)

OUTPUT TRAY 1000 sheets (All sizes / 80 gsm)

Machine Dimensions 860 (W) x 765 (D) x 1,240 (H) mm (33 7/8" × 30 1/8" × 48 7/8")

Weight Approximately 217 kg (478.5 lb)

Installation Space with Host Machine 3,451 (W) × 1,152 (D) mm (135 7/8" × 45 3/8")

Voltage / Power Consumption 120-127V AC, 50/60Hz, 7A / 300W max.

Maximum Load Current 2.3 A

Noise Level 70 dBA or less

Environmental Temperature

in Use

Temperature

in Storage

Temperature

in Transportation

Relative Humidity 30 to 70% (RH)

Pressure 608 to 1013 hPa

*1

When the tab paper is delivered to the stack tray, the paper cannot be squared-up neatly.

*2

Paper weight differs depending on the connected host machine.

*3

Depending on the content of the print or sheet type, the maximum stack capacity differs and stacked sheets may not

be aligned.

Maximum stack capacity is limited to 2000 sheets when B5 or EXEC sheets are used.

20 to 27 °C (68 to 80.6 F)

-30 to 50 °C (-22 to 122 F)

-30 to 50 °C (-22 to 122 F)

LGL, LTR, LTRR, EXEC, 8K (270 x 390 mm),

16K (270 x 195 mm), Tab Paper (A4, LTR)*1,

320 x 450 mm (SRA3), User custom size (Max:

330.2 x 487.7 mm, Min: 216 x 182 mm)

64 to 325 gsm

x 18”, 13” x 19”, LGL, LTR, LTRR, EXEC,

STMTR, Post card, 8K (270 x 390 mm), 16K

(270 x 195 mm), Tab Paper (A4, LTR), User

custom size (Max: 330.2 x 487.7 mm, Min:

139.7 x 182 mm)

60 to 325 gsm

A3, A4, A4R, A5R, B4, B5, B5R, 11” x 17”,

12” x 18”, 13” x 19”, LGL, LTR, LTRR, EXEC,

STMTR, 8K (270 x 390 mm), 16K (270 x 195

mm), Tab Paper (A4, LTR), User custom size

(Max: 330.2 x 487.7 mm, Min: 139.7 x 182

mm)

60 to 325 gsm

*2

*2

*2

*3

4-2 Specifications

Page 38

4

Index

C

Circuit Breaker ......................................... 1-3

Control Displays ..................................... 1-12

Control Panel ......................................... 1-10

Curl Correction ................................ 1-13, 3-6

D

Downstream Exit Section .................. 1-3, 1-6

E

Entrance Section...................................... 1-4

Entrance Transport Guide........................ 1-4

Error Lamp ............................................. 1-10

Error Message Chart................................ 3-3

Error messages........................................ 3-2

F

First Gate ................................................. 1-4

Front Cover .............................................. 1-3

Front Cover Open Button........... 1-3, 2-3, 2-4

Front Stack Guide .................................... 1-9

H

Handle............................................... 1-3, 2-5

Horizontal Transport Section.................... 1-5

L

LCD Display ........................................... 1-10

Left Dial.................................................... 1-6

Left Lower Guide...................................... 1-6

Left Turn-Over Section............................. 1-6

Left Upper Guide...................................... 1-6

O

Offset Section........................................... 1-7

Offset Section Guide ................................ 1-7

OUTPUT TRAY...................................... 1-10

P

Power Cable............................................. 1-3

Power Switch ........................................... 1-3

Powering Problem.................................... 3-8

R

Rear Stack Guide .................................... 1-9

Right Dial ................................................. 1-8

Right Lower Guide ................................... 1-8

Right Turn-Over Section .......................... 1-8

Right Upper Guide ................................... 1-8

S

Second Gate............................................ 1-6

Specifications........................................... 4-2

Stack ON/OFF Button ..................... 1-10, 2-3

Stack Status LED..................................... 1-3

Stack Stopper .......................................... 1-9

Stack Tray......................................... 1-9, 2-3

Stacking Section ...................................... 1-9

System Errors .......................................... 3-2

T

Top Cover .............................................. 1-10

Appendix

Index 4-3

Page 39

Appendix

4

4-4 Index

Page 40

CANON INC.

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146-8501, Japan

CANON U.S.A., INC.

One Canon Plaza, Lake Success, NY 11042, U.S.A.

CANON CANADA INC.

6390 Dixie Road Mississauga, Ontario L5T 1P7, Canada

CANON EUROPA N.V.

Bovenkerkerweg 59-61 1185 XB Amstelveen, The Netherlands

(See http://www.canon-europe.com/ for details on your regional dealer)

CANON LATIN AMERICA, INC.

703 Waterford Way Suite 400 Miami, Florida 33126 U.S.A.

CANON AUSTRALIA PTY. LTD

1 Thomas Holt Drive, North Ryde, Sydney, N.S.W. 2113, Australia

CANON CHINA CO., LTD

15F Jinbao Building No.89 Jinbao Street, Dongcheng District, Beijing 100005, China

CANON SINGAPORE PTE. LTD.

1 HarbourFront Avenue #04-01 Keppel Bay Tower, Singapore 098632

CANON HONGKONG CO., LTD

19/F., The Metropolis Tower, 10 Metropolis Drive, Hunghom, Kowloon, Hong Kong

USRM2-0157-00

© CANON INC. 2011

Loading...

Loading...