Canon N1000, N2000 Service manual

N1000/2000

SERVICE

MANUAL

2002 MAY CANON INC.

Application

This manual has been issued for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may

be information in this manual that does not apply to your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or changes in

the products. When changes occur in applicable products or in the content of this manual, Canon will release

technical information as the need arises.

The following paragraph does not apply to any countries where such provisions are inconsistent with

local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent of

Canon Inc., except in the case of internal business use.

Copyright

CANON INC.

NB Quality Assurance Div.

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146-8501, Japan

This manual has been produced with the following applications.

All logos and illustration were created with Adobe

All documents and page layouts were created with Microsoft

©

2002 by Canon Inc.

®

Illustrator®8.0.

®

Word 2000.

TABLE OF CONTENTS

Part1_PRODUCT SPECIFICATIONS Page

1. PRODUCT OVERVIEW 1-1

2. SPECIFICATIONS 1-2

2.1 Printer Specifications

2.1.1 Printer Specifications

2.1.2 Printer life

2.1.3 Print head/ink tank life 1-3

2.2 Paper Specifications

2.2.1 Paper sizes and weights

2.2.2 Paper types

2.2.3 Printing area 1-4

2.3 BJ Cartridge/Ink Tank Specifications

2.3.1 Print head

2.3.2 Ink tank

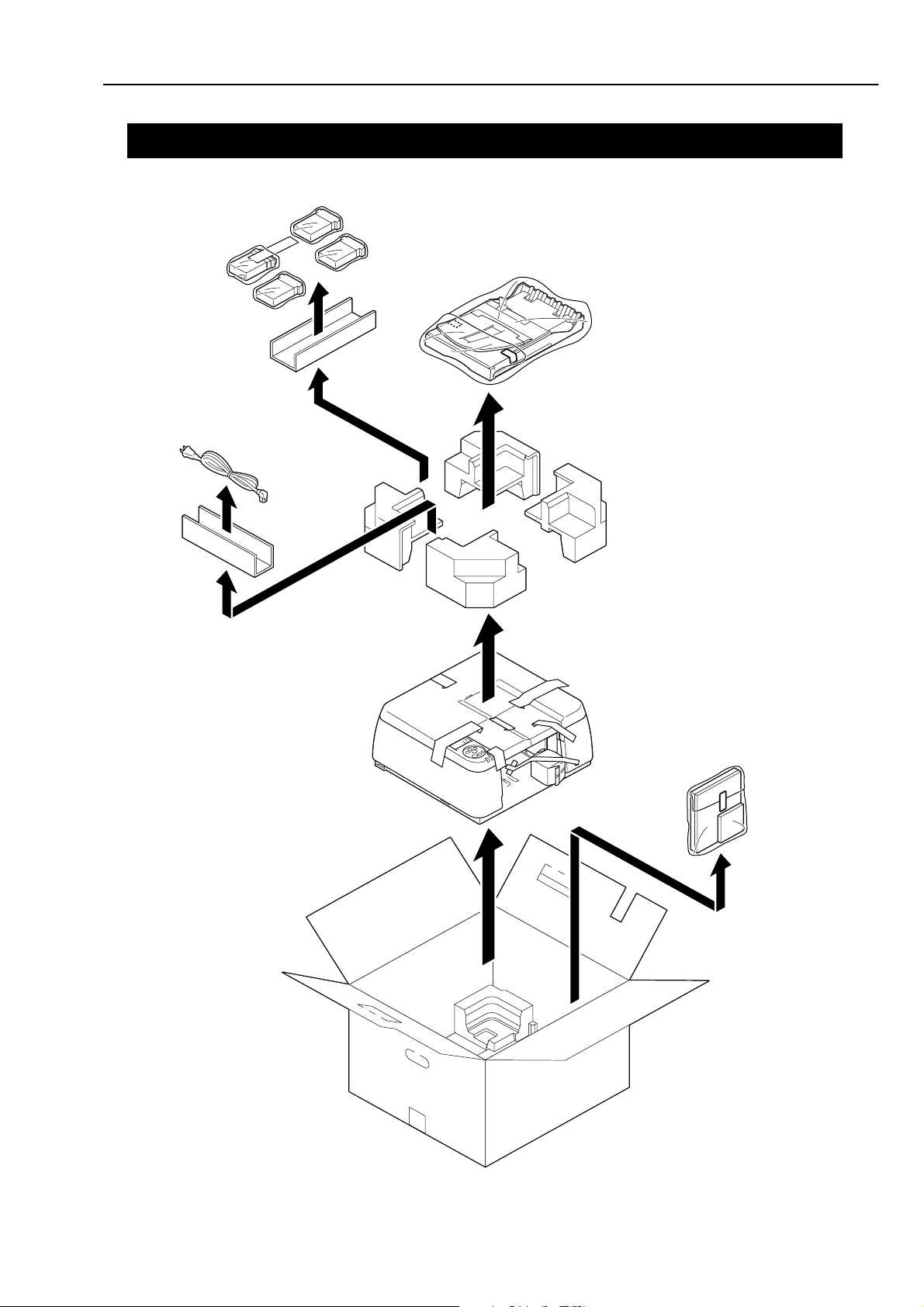

3. PACKAGING CONFIGURATION 1-5

4. PARTS CODE LIST 1-6

Part2_TROUBLESHOOTING

1. PRINTER OPERATION 2-1

1.1 Printer Operation Procedure

1.2 Status Indicator

1.3 Printer Panel Operation 2-2

2. SERVICING 2-5

2.1 Before Troubleshooting

2.2 Detectable Problems When System Startup Completed 2-6

2.3 Troubleshooting by Phenomenon 2-9

2.4 Printer Status Indication 2-10

2.5 Troubleshooting by Error 2-11

Error Indication 2-11, 12

Service Call Indication 2-13, 14

3. DISASSEMBLY AND REASSEMBLY 2-15

3.1 Cautions for Disassembly and Reassembly

3.1.1 Cautions for ink stains

3.1.2 Damage by static electricity

3.1.3 Deformation of spur tips

3.1.4 Ink drain

3.2 Exploded View 2-16

Main parts list 2-17, 18

3.3 Disassembly and Reassembly 2-19

3.3.1 Carriage lock release

3.3.2 Installing and removing the purge unit

3.3.3 Removing and installing tap screws

3.3.4 Installing and removing the carriage encoder film 2-20

3.3.5 Handling the encoder film

3.3.6 Installing and removing the carriage unit

3.3.7 Removal of red screws prohibited

3.3.8 Installing and removing the ink supply unit

3.3.9 Installing and removing the carriage motor

i

Page

3.3.10 Installing and removing the print head 2-20

3.4 Adjustments and Settings After Disassembly and Reassembly 2-21

3.4.1 Adjustments and setting list

3.4.2 Print Adjustment

3.4.3 Control board’s EEPROM initialization / destination settings 2-22

3.4.4 Clear the control board’s EEPROM waste ink counter

3.4.5 NIC board’s IP address settings 2-23

4. OPERATION CHECK AFTER DISASSEMBLY AND REASSEMBLY 2-24

4.1 Check Procedure

4.2 Cautions when Replacing the Control Board

5. TRANSPORTING THE PRINTER 2-25

5.1 Preparation before Transportation (place in the carton)

5.2 Moving the Printer

6. PARTS REPLACEMENT, PERIODIC INSPECTIONS & TOOL 2-26

6.1 Parts Replacement

6.2 Periodic Inspections

6.3 Tool List

7. SERVICE MODE 2-27

7.1 How to Enter the Service Mode

7.2 Shipment Inspection Pattern 2-28

7.3 EEPROM Information Print Pattern 2-29

7.4 Firmware Updating Function 2-30

7.4.1 How to update the Flash ROM

7.4.2 Cautions during the update

7.4.3 Errors during the download process

Part3_TECHNICAL REFERENCE

1. PRINTER CONTROL SECTION 3-1

1.1 Printing Data and Control Signal Flow

1.2 Printing Drive Control 3-2

1.3 Control during printing

1.4 Detection Functions 3-3

1.4.1 Detection by sensors

1.4.2 Detection by others

2. PRINT HEAD 3-4

3. INK SUPPLY 3-5

4. ELECTRICAL PARTS 3-6

4.1 Block Diagram

4.2 Electrical Part

5. NIC BOARD 3-7

6. PRINTER’S MECHANICAL PARTS 3-8

6.1 Carriage Section

6.2 Purge Section

6.3 Paper Feed Section

7. CLEANING MODE AND INK SUCTION AMOUNT 3-9

Part4_APPENDIX

1. PRINT HEAD 4-1, 2

2. CONTROL BOARD CONNECTOR 4-3

ii

Part 1

PRODUCT

SPECIFICATIONS

N1000/2000 Part 1_Product Specifications

1. PRODUCT OVERVIEW

The N1000 series is the Network Color BJ Printer for Office Use.

This printer is targeted for internal work group users who need to output the large volume document in a short

period, small business work group users who are difficult to introduce the color laser printer due to high cost,

users who need to repurchase the printer from the middle range monochrome printers and add-on users.

1) High speed printing

Monochrome text: 20 ppm

Color DTP: 18 ppm

Full color: 4 ppm (Reference)

2) Network support

Supports standard printer MIB, Canon MIB and NetSpot (MIB: Management Information Base)

3) Printer with high durability and large capacity of ink tank that supports printing of large amount of

documents

Large capacity of ink tank: 2800 pages/Bk ink tank, 3400 pages/color ink tank

Capability of stacking approx. 250 pages of plain paper on a standard cassette

4) Low power consumption

1-1

Part 1_Product Specifications N1000/2000

2. SPECIFICATIONS

2.1 Printer Specifications

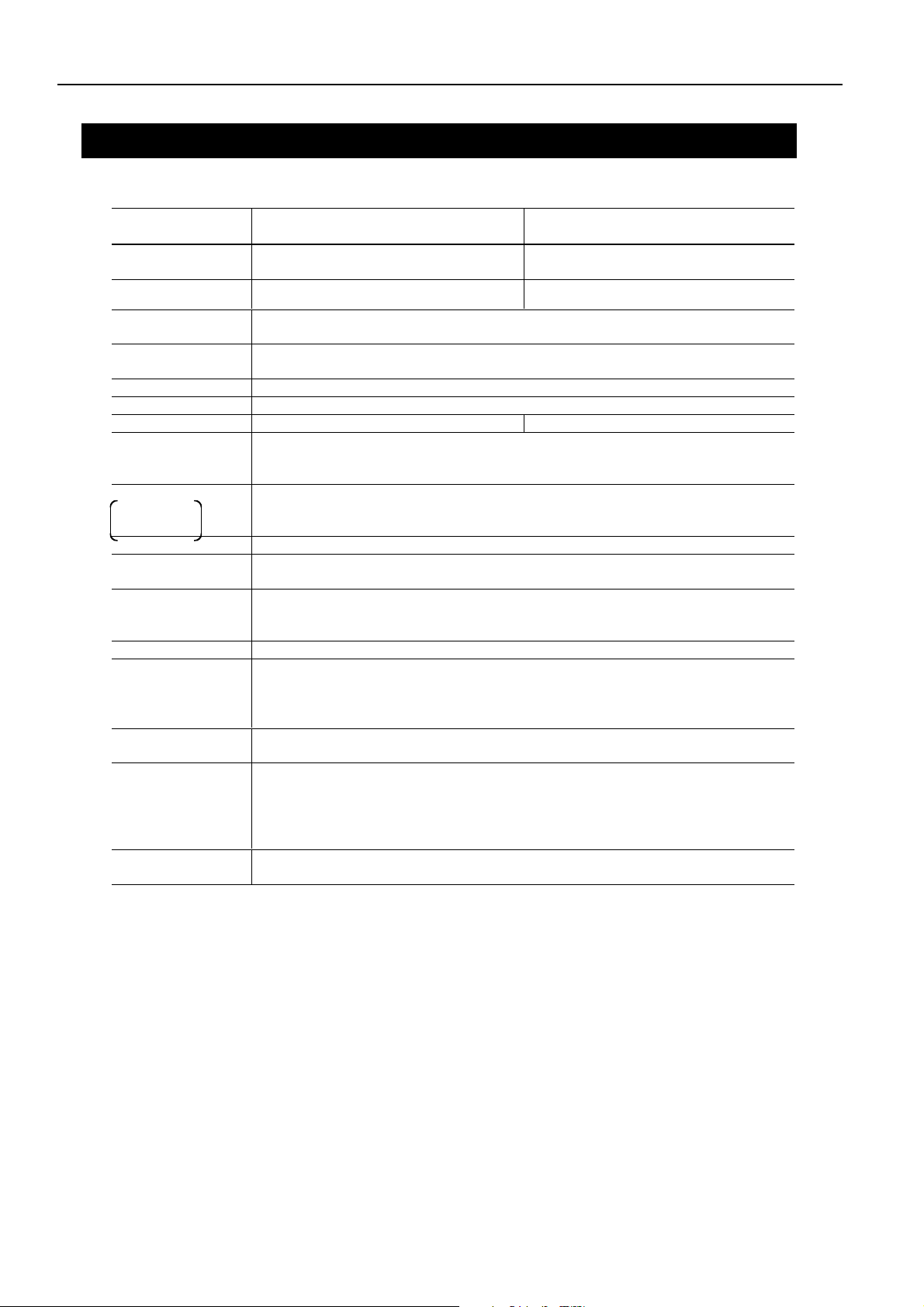

2.1.1 Printer Specifications

Model name

Item

External

465 (W) x 440 (D) x 207 (H) 587(W) x 626(D) x 209(H)

dimension mm

Unit weight kg Approx. 12 kg

(Including ink tanks, print head and cassette.)

Paper Feeding

Cassette feed (U-turn pass) and Manual feed

Method

Paper delivery

Front delivery (Print surface upward)

method

Resolution Bk: 600 x 1200 dpi__Color: 1200 x 2400 dpi

Printing Direction Uni-/Bi-directional

Print size Up to A4 Up to A3+

Throughput

Media size: A4

Bk: 20 ppm

Color: 18 ppm (DTP) 4 ppm (Photo) Reference

Interface

IEEE1284 Compatible / USB Rev 1.1

Standard

equipment

Network support 10/100BASE-T,TX (with optional network interface board)

Printer Driver Canon specified.

GARO (Graphic Arts Language with Raster Operations)

Detection

functions

Front cover-open, Carriage position, Presence of paper, Paper width, Presence of BJ

print heads, BJ print head mis-installation, Ink remaining amount, Waste ink tank

full and Paper feed roller rotating position

Operating Noise 48dB (5.8 Bels) during printing

Environmental

During operation: ___Temperature 5 to 35˚C

requirements

During non-operation: _Temperature 0 to 35˚C

Power

consumption

44Wh (during printing)

13Wh (standby)

Safety standards Radio wave interference: VCCI, FCC, Taiwan/Korea EMC, CE-Mark, C-tick and

Electrical safety: Electrical appliance regulation, UL1950, cUL, CE-Marking, TUV,

Serial No.

Behind the printer and on the rating plate

Location

N1000 N2000

Approx. 15 kg

(Including ink tanks, print head and cassette.)

HS HQ

Humidity 10 to 90%RH (No condensation)

Humidity _5 to 90%RH (No condensation)

CCIB

FIMKO, SASO, Energy Authority, PSB, CB/CCIB, GOST-R

and Korean Electric Commerce

2.1.2 Printer life

Whichever comes first:

1) A total of 100, 000 sheets printed.

2) Five years of use.

1-2

N1000/2000 Part 1_Product Specifications

2.1.3 Print head/ink tank life

1) Print head life

Whichever comes first:

For color printing: 50,000 pages (A4, 5% duty pattern)

For monochrome printing: 50,000 pages (A4, 5% duty pattern)

2) Ink tank life (No. of printable pages per ink tank)

Black: 2800 pages (A4, 5% duty pattern)

Colors: 3400 pages (A4, 5% duty pattern)

2.2 Paper Specifications

2.2.1 Paper sizes and weights

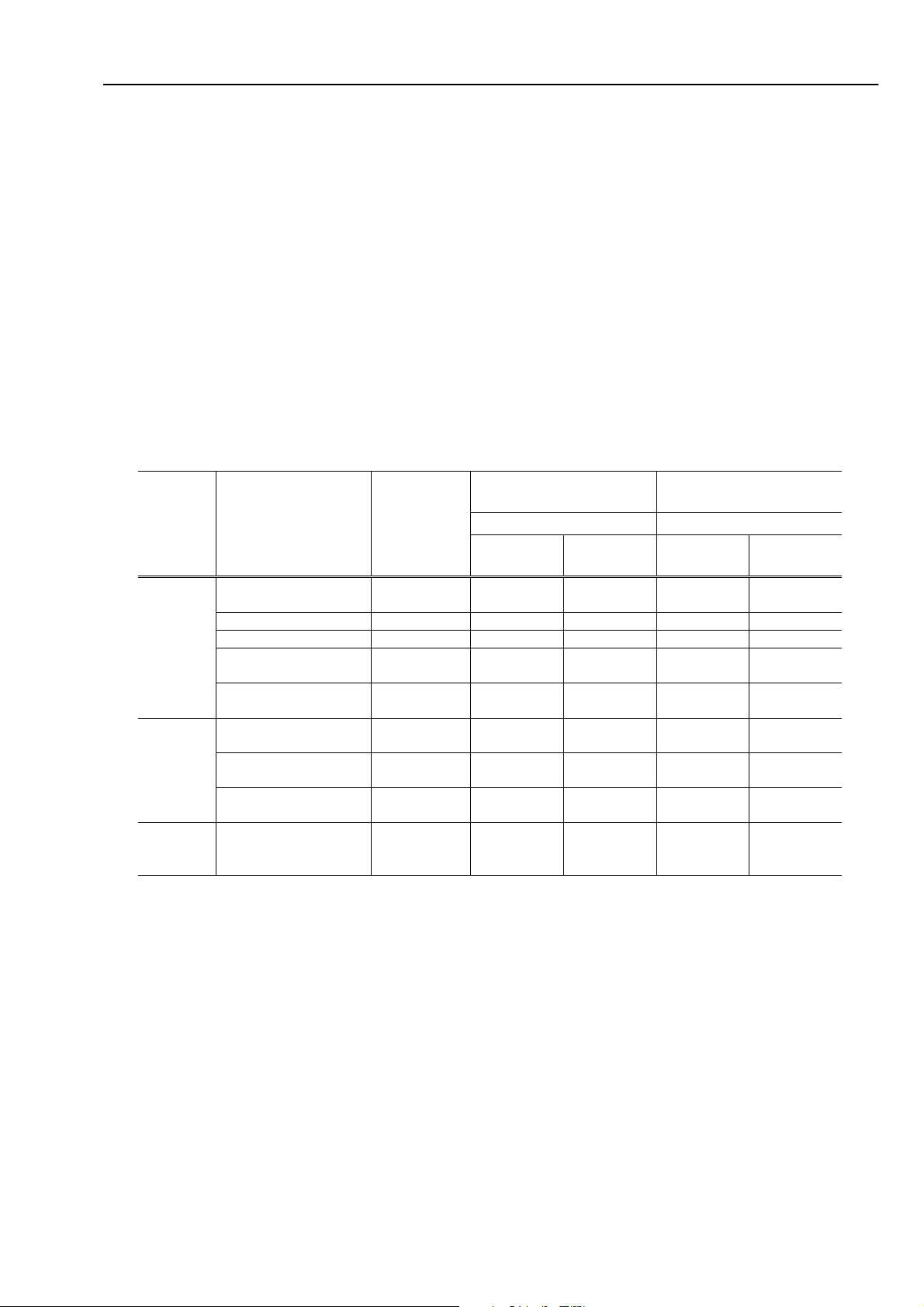

1) Paper size See the table below.

2) Weight For cassette feeding, the paper’s weight should be 64 to 75 g/m_

3) Paper height on cassette 23 mm or less

2.2.2 Paper types

N1000 N2000

Paper feeding method Paper feeding method

Type Size

Plain

paper

Special

paper

PB (SK/DK) A4/B5

A3

KANGAS A4 Yes Yes Yes Yes

NEUDIEDLER A4 Yes Yes Yes Yes

BOISE CASCADE LTR

LGL

LC-301 B5/A4/LTR

B4/A3/LGL

HR-101 B5/A4/LTR

B4/A3

CF-102

(Transparency)

GP-301N A4/LTR

Postcard

(postal card)

A4/LTR

LGL

A3

100 x 148

(Min.)

mm

Cassette Manual Cassette Manual

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

No

No

Yes (with a

post card

support)

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

No

No

No Yes (with a

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

Post card

Support)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

1-3

Part 1_Product Specifications N1000/2000

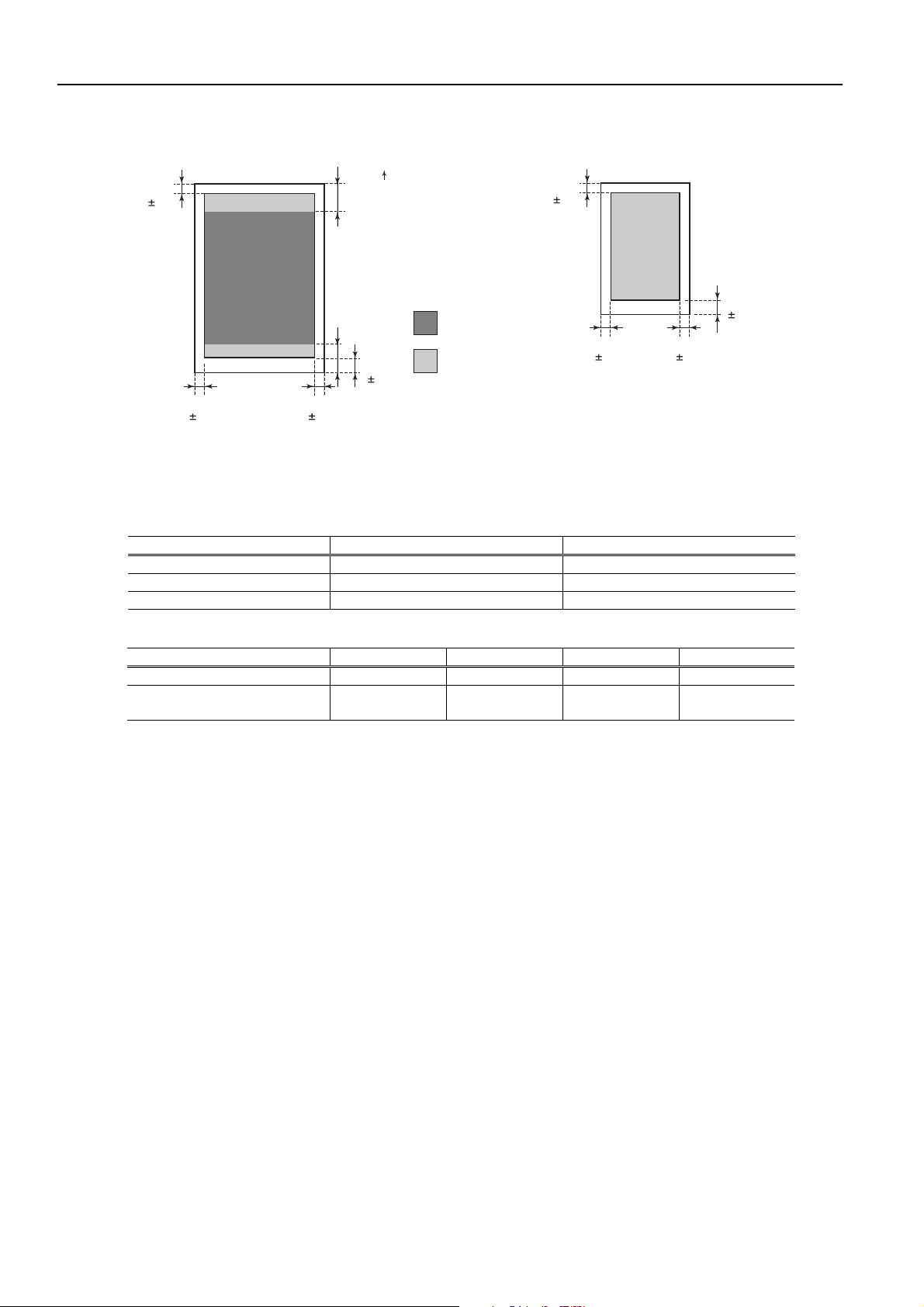

2.2.3 Printing area

- A3/B4/A4/B5/LTR/LGL - Postcard

5mm

1.5

5mm 5mm

1.5 1.5

46.2mm

26.8mm

When media is fed from second/third cassettes, or by manual, both left and right edges will become 5.0

mm +/- 2.5.

2.3 BJ Cartidge Tank Specifications

2.3.1 Print head

Black Color (each)

Nozzle density 600 dpi 1200 dpi

Number of nozzles 640 nozzles 1280 nozzles

Recording density 2400 dpi 2400 dpi

Paper feed direction

Print Quality

Assurance Area

5mm

1.5

Printable Area

5mm

1.5

5mm 5mm

1.5 1.5

5mm

1.5

2.3.2 Ink tank

Black Yellow Magenta Cyan

Ink component Pigment ink Dye ink Dye ink Dye ink

Ink tank capacity 130 ml 80 ml 80 ml 80 ml

1-4

N1000/2000 Part 1_Product Specifications

3. PACKAGING CONFIGURATION

After opening the box, make sure all the items below are included.

There is no storage box for storing the BJ cartridge. Keep the original box for transportation.

1-5

Part 1_Product Specifications N1000/2000

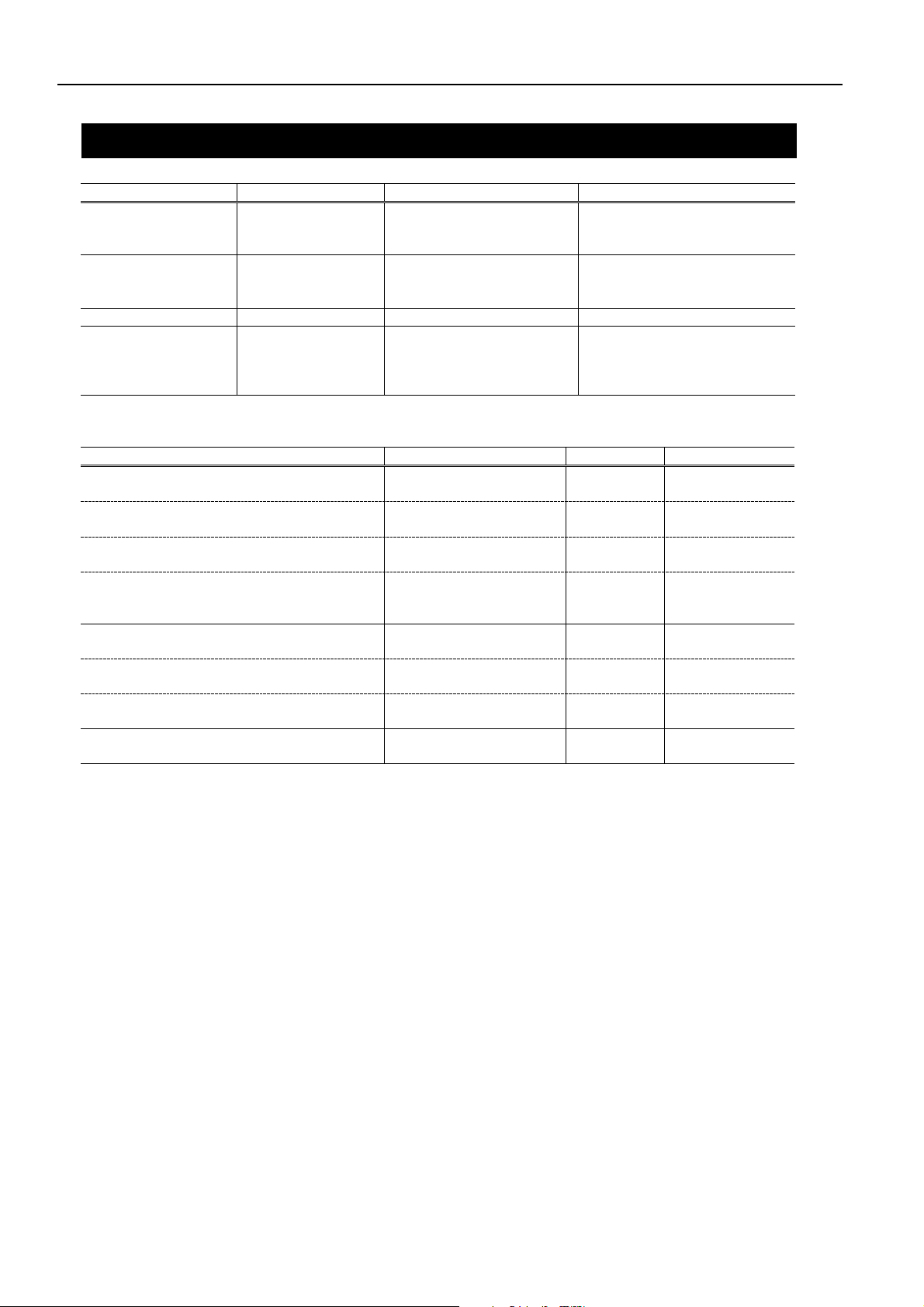

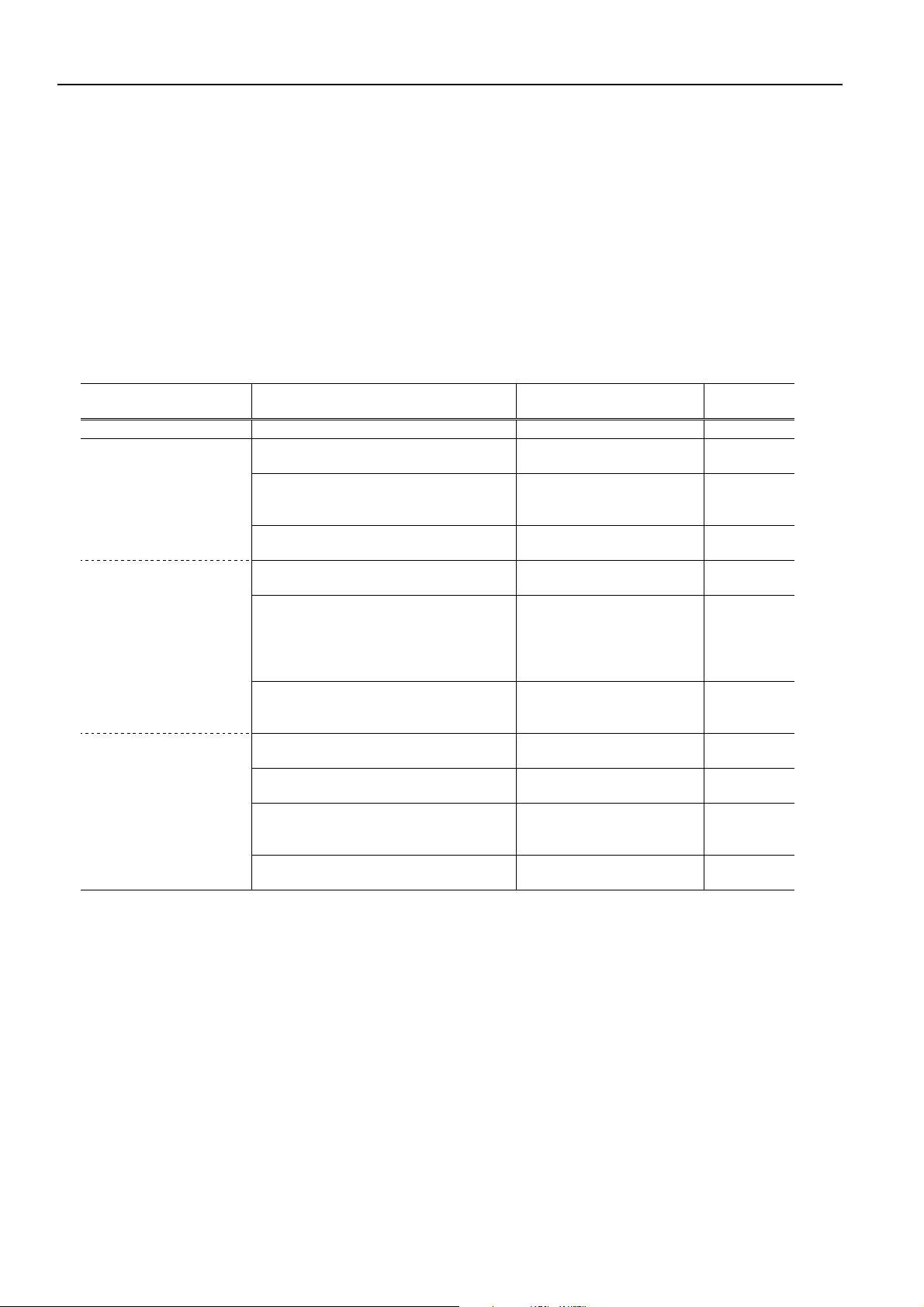

4. PARTS CODE LIST

Items Description Code No. Remarks

Printer N1000 JPN Q51-1051 A4 printer

N1000 LV/US Q51-1052 A4 printer

N1000 HV Q51-1053 A4 printer

N2000 JPN Q51-1041 A3 printer

N2000 LV/US Q51-1042 A3 printer

N2000 HV Q51-1043 A3 printer

Print head QY6-1000 Supplied as a service part

Ink tank BCI-1201Bk AG6-8438

BCI-1201Cyan AG6-8439

BCI-1201Magenta AG6-8440

BCI-1201Yellow AG6-8441

Options

Items Description Code No. Remarks

N1000 Paper feed unit For A4 media

Paper feed unit (Second unit) PFN-12 Q55-1020

Paper feed unit For A4 mediaN1000

Paper feed unit (Third unit)

N1000 Universal cassette For A4 media

Universal cassette (First cassette) UCN-11 Q55-1100

N1000 Universal cassette For A4 media

Universal cassette UCN-12 Q55-1110

(Second/third cassettes in common)

N2000 Paper feed unit For A3 media

Paper feed unit (Second unit) PFN-22 Q55-1010

N2000 Universal cassette For A3 media

Universal cassette (First cassette) UCN-21 Q55-1120

N2000 Universal cassette For A3 media

Universal cassette (Second cassette) UCN-22 Q55-1130

Network interface card Network interface card

Note: The network interface card is not originally installed in the printer. When the printer is used as a network

printer, install the network interface card in which the LAN cable can be connected.

PFN-13 Q55-1080

Q55-1030 For N1000/2000

NB-11FB

1-6

Part 2

TROUBLESHOOTING

N1000/2000 Part 2 : Troubleshooting

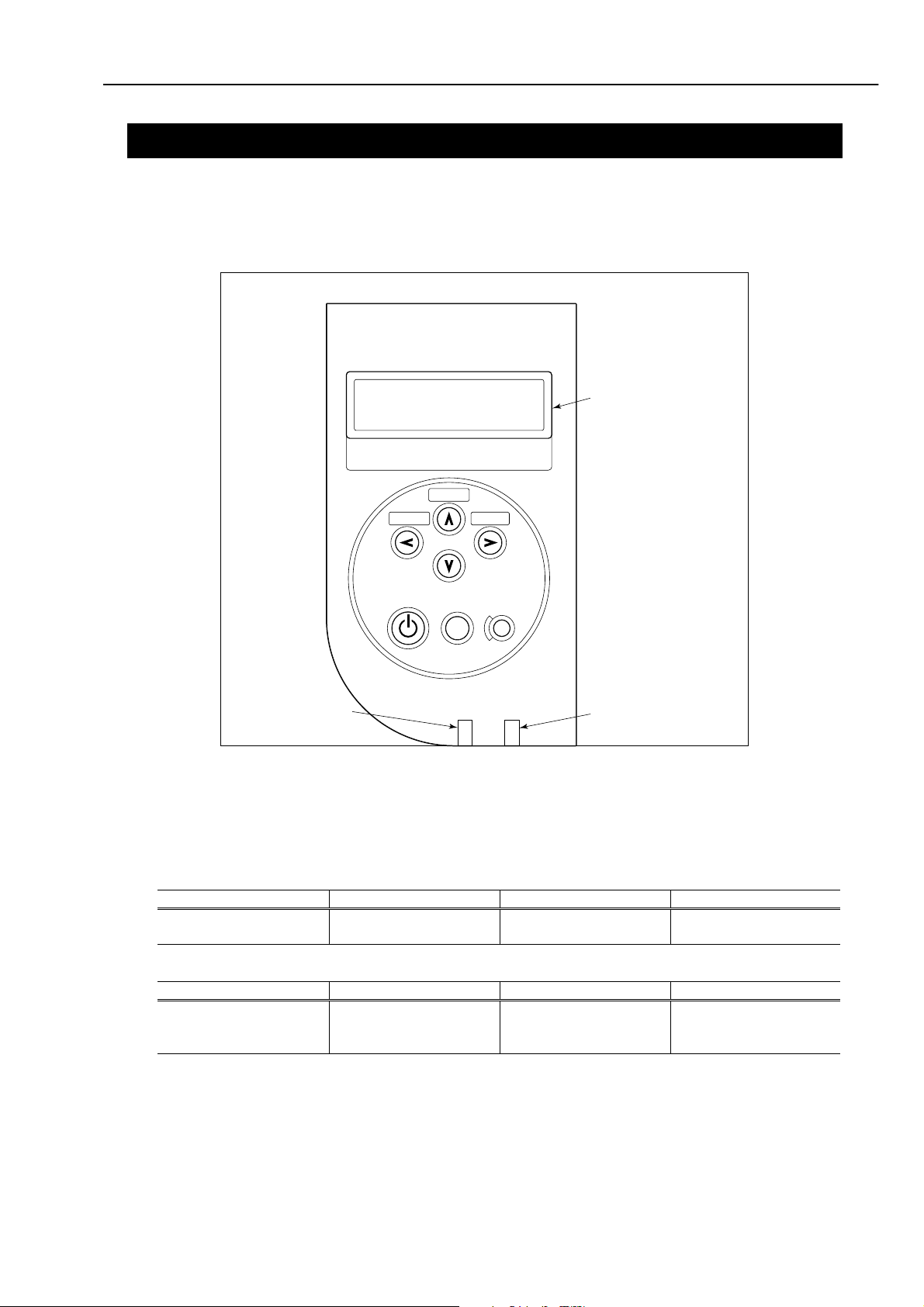

1. PRINTER OPERATION

The printer’s operation procedures, which are necessary for the troubleshooting, are explained below.

1.1 Printer Operation Procedure

From the printer’s operation panel, it is possible to make settings during printing or network settings, and

cancel printing or an error.

Operation Panel

LCD

(Message display)

Set Media

Cancel Job

Utility

Setup

Reset/Enter

Power

Online LED: Green

Online

Online

Ink Replace

Message

Message LED: Orange

1.2 Status Indicator

When the printer is operated, a message is shown on the LCD. When the printer operates properly, it

indicates the operation status and the instruction what the user should operate. When an error occurs or the

user has to perform some operation, the message that indicates the operation status and the error code are

indicated.

Normal operation

LCD display Online LED Message LED Operation status

Printable Light Light off Power ON

*1 Blinks Light off Printing in progress

During error or service call

LCD display Online LED Message LED Operation status

Each message Light off Blinks Error/Service call

*2 Light off Blinks Offline

Light off Light Warning display

*1: Refer to the status indication list.

*2: Refer to the error indication list.

2-1

Part 2 : Troubleshooting N1000/2000

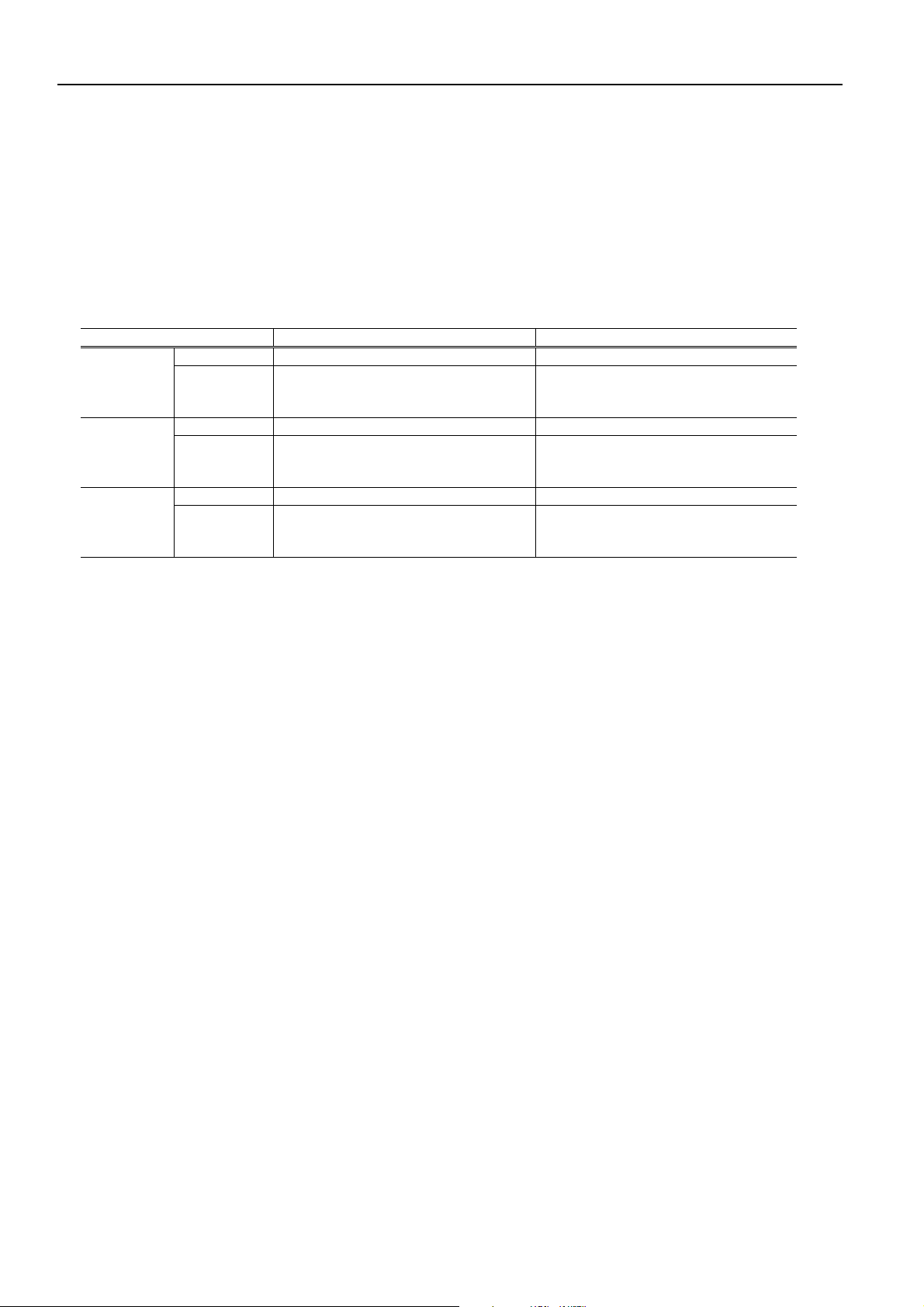

1.3 Printer Panel Operation

Printer settings or maintenance can be performed by operating the printer panel. (Mode open to users.)

Depending on purposes, three types of menu are prepared for the panel operation.

1) Setup menu

Menu to set each printer operation environment

2) Utility menu

Menu to perform self-printing or maintenance function

3) Media set menu

Menu to set the media size and media type of cassettes

Operation method

With the printer offline state, hold down the key decided by each menu, and you will be able to enter the

menu.

Menu Key to enter menu / LCD display Key to move within menu

/ function

Setup menu

Expansion function Warning Display Sets whether or not to

Print adjustment Adjust Printer Prints the head adjustment

Interface settings

Setup key

Wait Time Sets the fixing wait time

Language Sets the language on the

Adjust Printhead

Print Pattern

Band Adjust Sets the banding process

Select Interface Sets to select the interface,

Set Centronics

ECP / Nibble / None

Ext. Network

Initial Settings *1

Set TCP/IP Sets the TCP/IP setting of

_key _key

display the warnings.

when it is not set from the

computer.

display.

pattern.

Sets the registration

adjustment values of the bidirectional and odd/even of

the adjustment pattern.

Use _key to change values.

value.

Use _key to change values.

IEEE1284 or USB.

Designates the mode of

IEEE1284.

Restores the network card

settings to the factory

shipment values.

the network card.

Execution

key

_key

_key

_key

_key

_key

_key

_key

_key

_key

_key

2-2

N1000/2000 Part 2 : Troubleshooting

Menu Key to enter menu / LCD display Key to move within menu

/ function

Maintenance settings

Utility menu

Media set menu *3

Cleaning at ON Sets whether or not to

perform purging at

powering on.

Initialize Panel *2 Restores the setup menu set

values except for the

extension network setting

to the factory shipment

values.

Utility key

Nozzle Check Prints nozzle check pattern. _key

Status Print Prints status print. _key

Ext. I/F Print Prints NIC board status. _key

Head Cleaning A Performs cleaning

Head Cleaning B Performs cleaning with ink

Head Cleaning C Fills ink in the print head

Move Printer Drains internal ink into the

Replace Head Performs head

Ink Remains

Bk=xx% C=xx%

M=xx% Y=xx%

Set Media key

Cassette 1 Sets the media size and

Cassette 2 Sets the media size and

Cassette 3 (N1000 only) Sets the media size and

_key _key

operation.

consumption amount

higher than Cleaning A.

and tubes on arrival. (Ink

consumption amount is

higher than Cleaning B.)

waste ink absorber when

the printer is transported.

replacement.

Displays ink remaining

amount. Displays black

and cyan first, and then

magenta and yellow when

_key is pressed.

_key _key

media type of cassette 1.

media type of cassette 2.

media type of cassette 3.

Execution

key

_key

_key

_key

_key

_key

_key

_key

_key

_key

_key

_key

2-3

Part 2 : Troubleshooting N1000/2000

*1: Items to be initialized when “Ext. Network / Initial Settings“ is executed and their initial values are:

IP Address=192.168.0.215, Subnet Mask=0.0.0.0, Default G/W=0.0.0.0 and IP Setting= Manual

*2: Items to be initialized when “Initialize Panel“ is executed and their initial values are:

Warning Display=On, Wait Time=Standard, Cleaning at ON=Off, Media Size=A4, Media Type=Plain Paper,

Adjust Printhead (Adj. Setting A to F)=0 and Band Adjust (Adj. Setting G)=0

*3 Media size and type which can be set by each cassette.

For the N2000, the supported media size can be detected by aligning the end guide in the cassette to the media

size. As for the media size, which is supported but cannot be detected by the end guide, should be set from the

operation panel. Those media sizes need to be set are B5 and postcard in Cassette 1, and B5 in Cassette 2.

Destination JP (Japan) US (Overseas)

Cassette 1 Media size A4 / B5 / Letter / Post Card A4 / B5-JIS / Letter

Media type Plain Paper / Post Card / Coated Paper

/ IJ Post card / Transparency / Quick

Dry Tran / Special 5

Cassette 2 Media size A4 / B5 / Letter A4 / B5-JIS / Letter

Media type Plain Paper / Coated Paper /

Transparency / Quick Dry Tran /

Special 5

Cassette 3 Media size A4 / Letter A4 / Letter

Media type Plain Paper / Coated Paper /

Transparency / Quick Dry Tran /

Special 5

Plain Paper / Coated Paper /

Transparency / Quick Dry Tran /

Special 5

Plain Paper / Coated Paper /

Transparency / Quick Dry Tran /

Special 5

Plain Paper / Coated Paper /

Transparency / Quick Dry Tran /

Special 5

2-4

N1000/2000 Part 2 : Troubleshooting

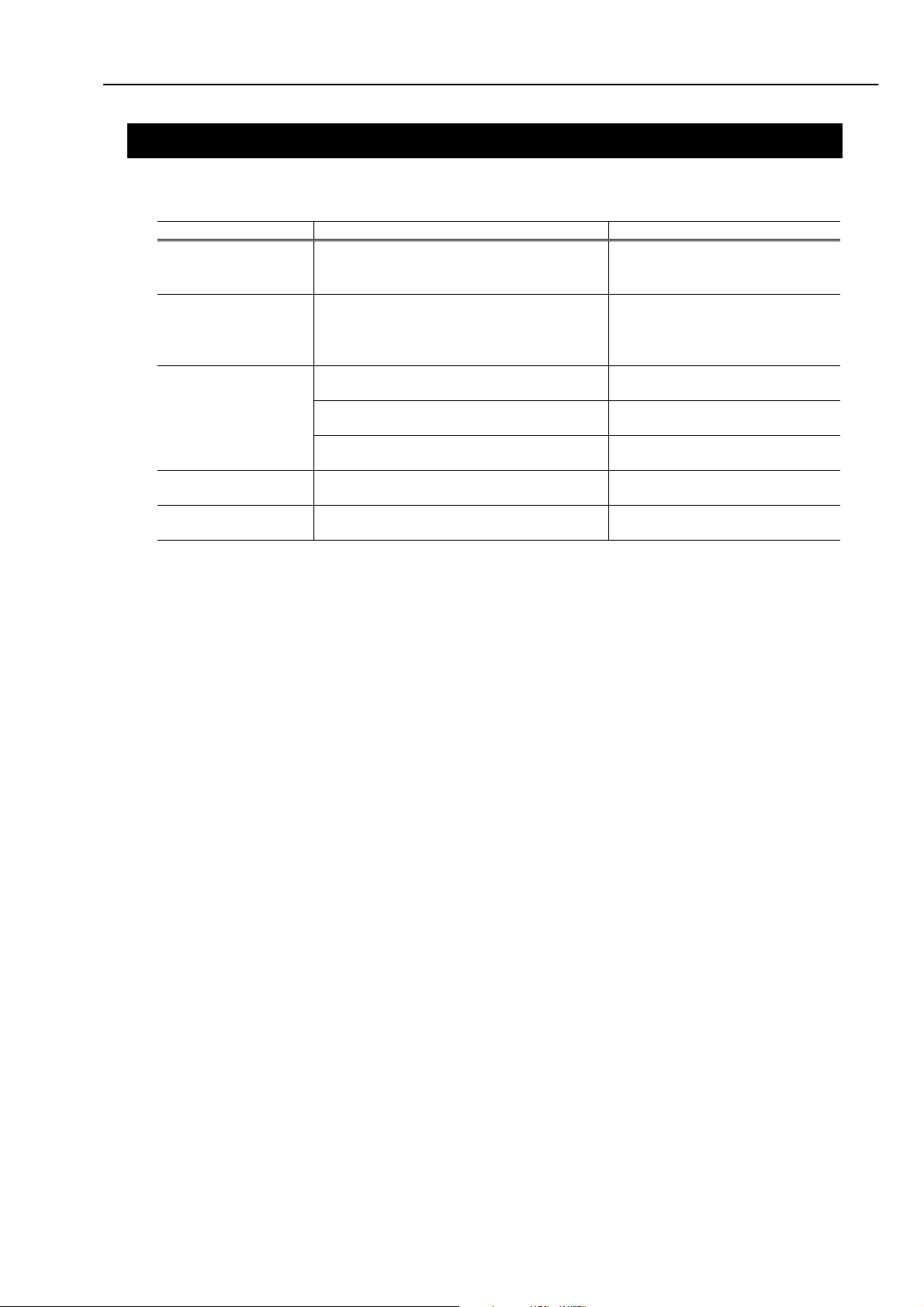

2. SERVICING

2.1 Before Troubleshooting

Before troubleshooting, check the following and see if any of the applicable problems can be fixed.

Problem Confirmation item Countermeasure

Printer does not

operate at all.

Paper is not fed. Remove the jammed paper.

Printer does not print.

Vertical lines

misalignment occurs.

Image is mispositioned.

Is the power cord properly connected?

Is the I/F cable properly connected?

Isn’t the fuse of the power unit blown?

Check the paper type on the cassette.

Isn’t the paper jammed?

Is the manual lever set properly?

Does the ink remaining amount warning

appear?

Perform cleaning and check whether ink

flows into the tube.

Can the test print be performed? Confirm the carriage cable

Has the print head position adjustment

performed?

Does the carriage move correctly? Confirm the CR encoder

Check that the cables are

connected properly.

Confirm the media height on

the cassette.

Lower the manual lever.

Replace the ink tank indicated on

the warning display.

Perform cleaning operation.

connection.

Perform the print head position

adjustment.

contamination.

2-5

Part 2 : Troubleshooting N1000/2000

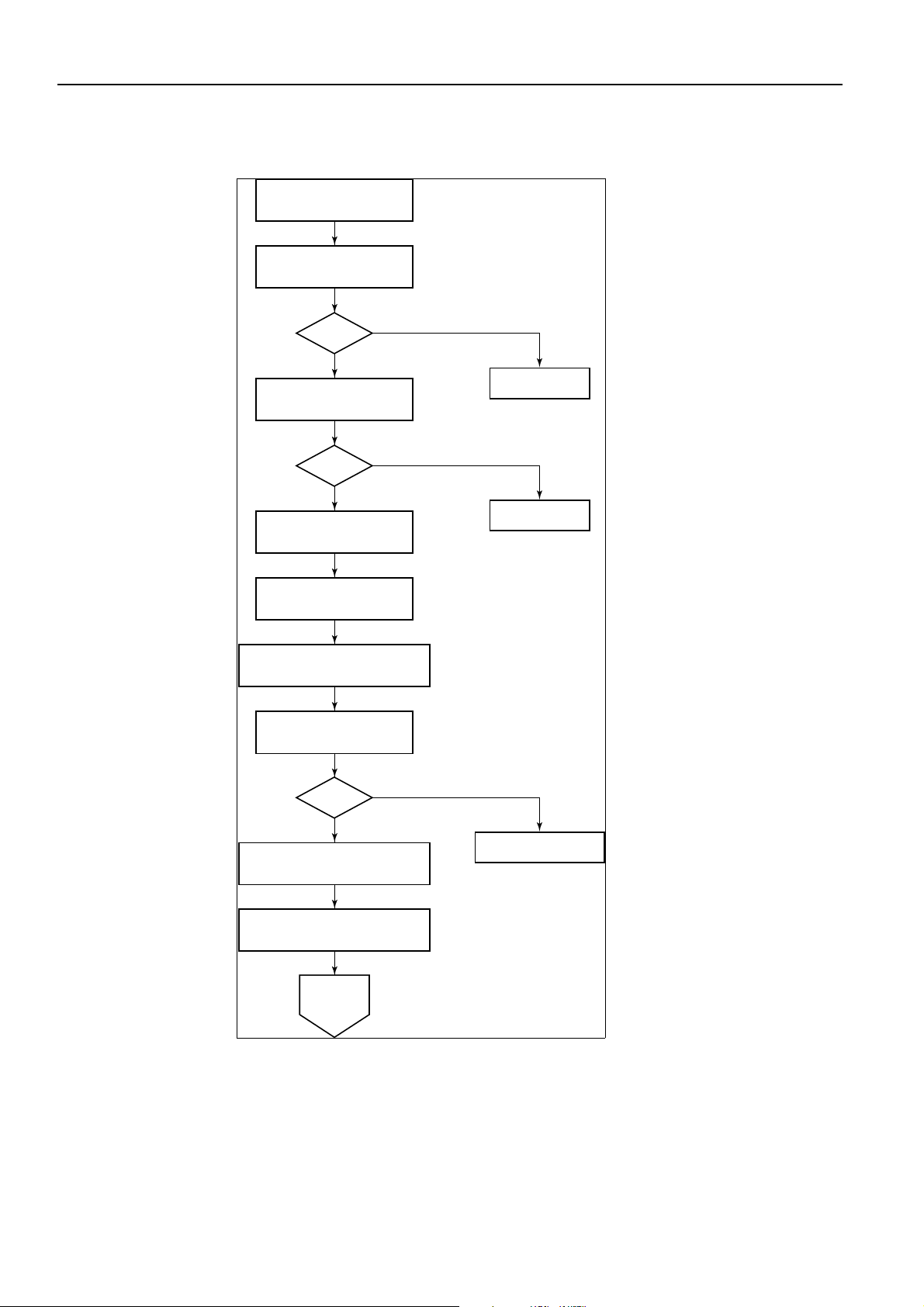

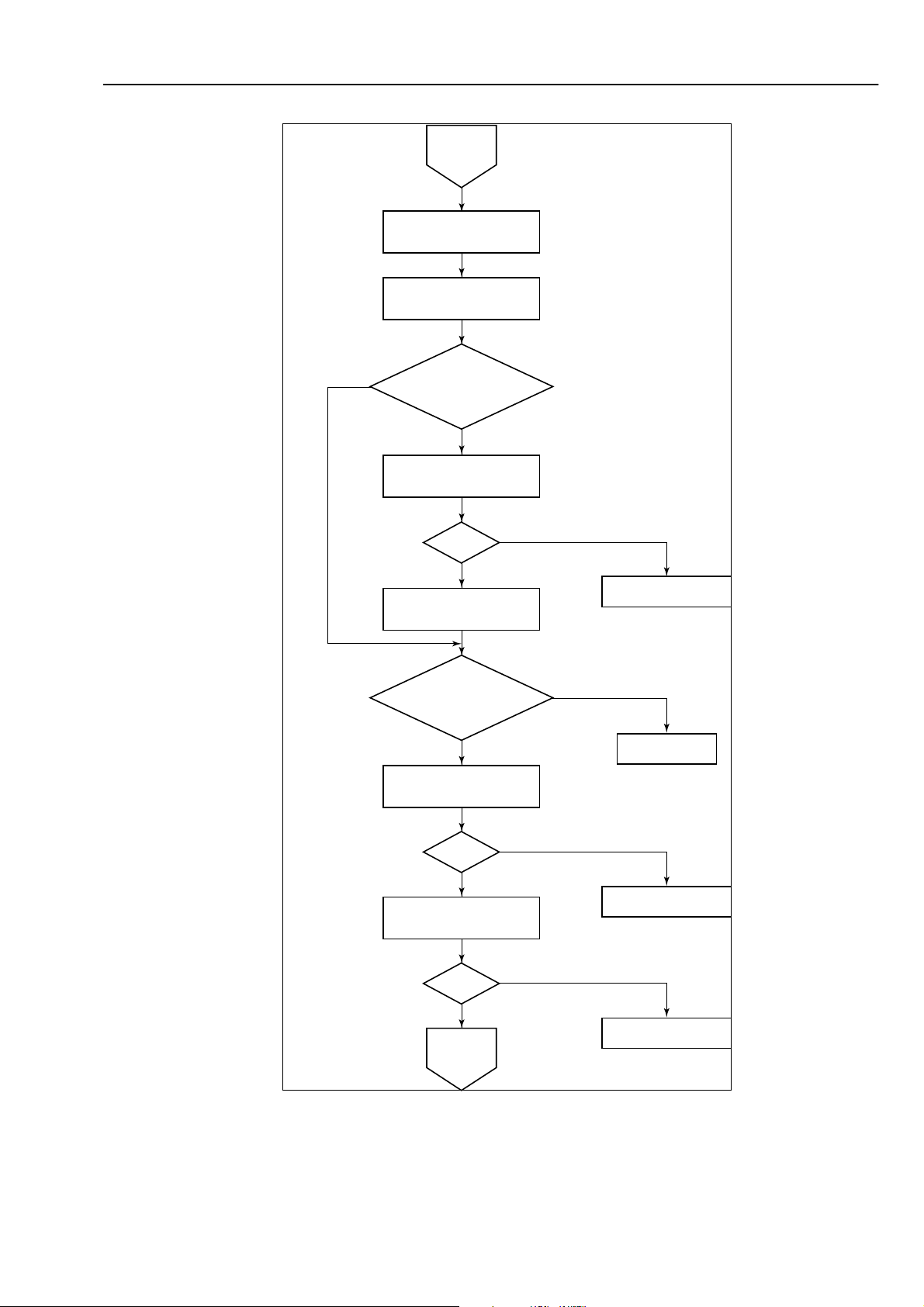

2.2 Detectable Problems When System Startup Completed

Some of the errors irresolvable by the user can be checked before the system startup is completed.

AC Power connection

CPU & printer

controller initialization

OK?

ROM check

OK?

Sensor power ON

Head 5V ON

Head temperature detection

Current setting

Control board

EEPROM check

No

Yes

No

Yes

RAM error

ROM error

OK?

Head presence detection

Head EEPROM check

Ink tank presence detection

Ink tank EEPROM check

To

next page

No

Yes

EEPROM error

2-6

N1000/2000 Part 2 : Troubleshooting

From

preceding

page

Head temperature detection

Offset voltage setting

Head diode

sensor check

Purge

unit cap

open or closed?

Open

Closed

Cap open

OK?

Yes

No

Carriage moved

from capping position

CR encoder

any change?

Yes

Purge unit

initialization

OK?

No

Purge error 2

No

CR error

Yes

Pump initialization

OK?

Yes

To

next page

No

2-7

Purge error 2

Purge error 1

Loading...

Loading...