Canon iRC2570, iRC3170, iRC3100 f-im-6417-000

DADF-L1 Installation Procedure

DADF-L1 設置手順書

Follow the instructions herein when installing the DADF-L1

to its host machine.

本製品を iR 本体に接続する際は、以下の手順に従ってください。

PUB No.F-IM-6417-000 PRINTED IN JAPAN or CHINA

E N G L I S H

日 本 語

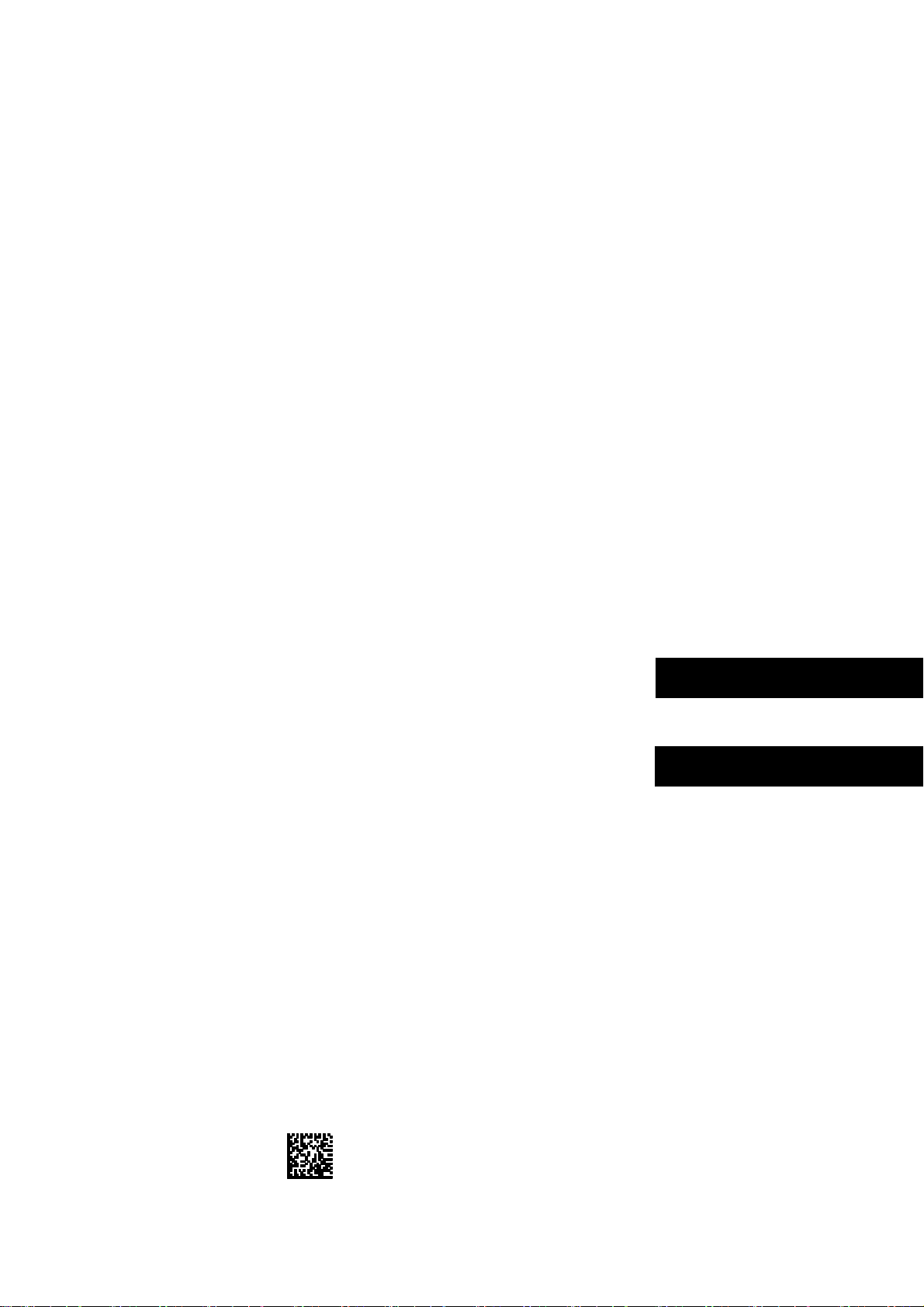

1.1 Unpacking and Checking the Components

1.1.1 Unpacking and Checking the Components

1) Open the shipping box used to hold the DADF-L1.

2) Remove the packing material used for the DADF-L1.

3) Check to see that none of the following is missing:

[9]

[10]

[1]

[2]

[11]

[7]

[3]

[2]

[5]

[6]

[7]

[8]

[4]

[6]

F-1-1

T-1-1

[1] DADF 1

[2] Face sticker 2

[3] Stamp 1

[4] Hinge cover (right) 1

[5] Hinge cover (left) 1

[6] Stepped screw (M5X6) 2

[7] Stepped screw (M4X10) 3

[8] Tapping screw (M3X8) 4

2

[9] Size label (small) 1

[10] Copyboard glass cleaning in-

structions label

[11] Warning label 1

1

3

1.2 Installation Procedure

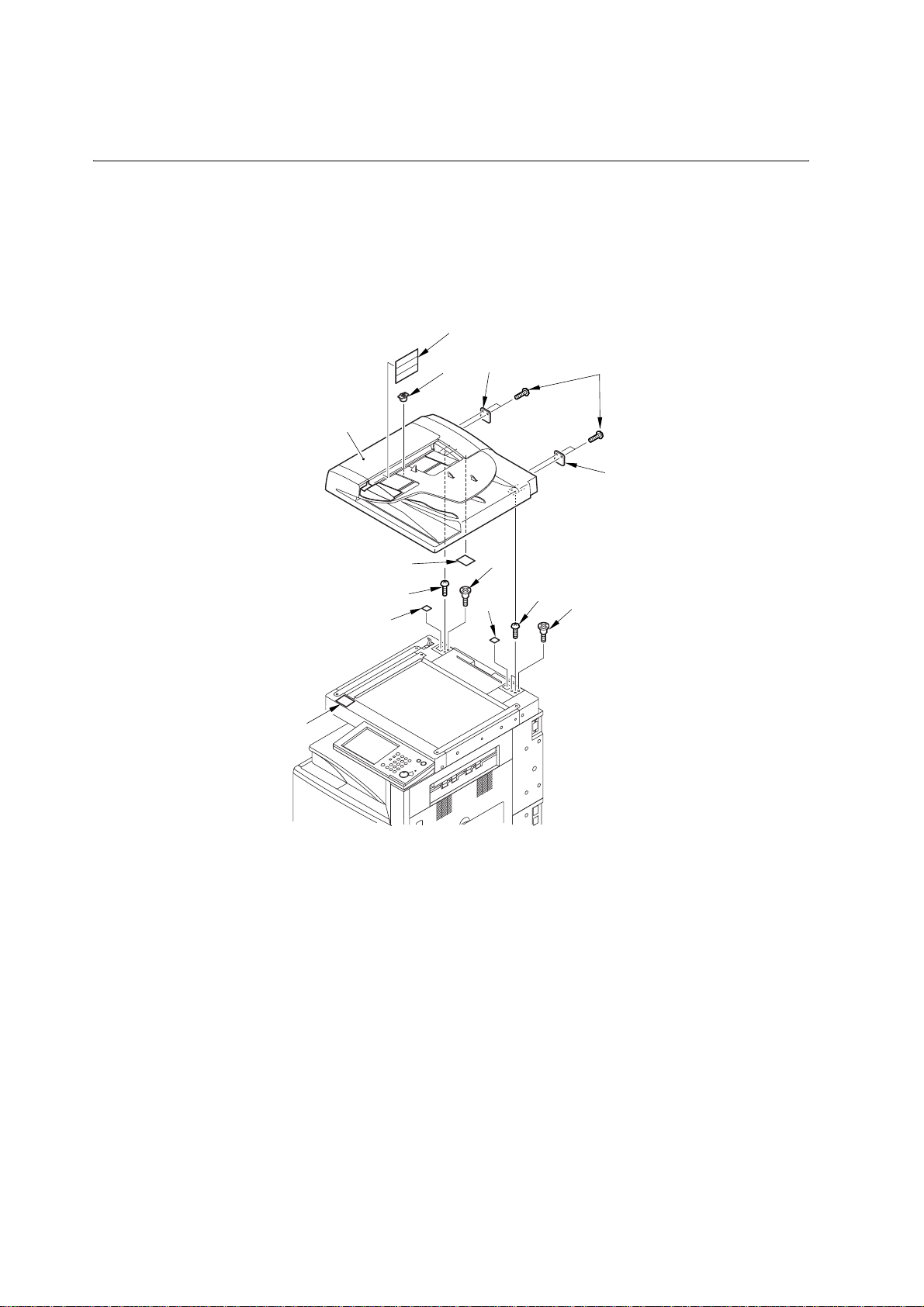

ON/OFF

1.2.1 Turning Off the Host

Machine (iR C3100

Series (iR C3170/

2570) excluded)

Be sure of the following before starting the work:

1. Turn off the control panel power switch.

2. Turn off the main power switch.

3. Disconnect the power cable (for the wall outlet).

[1]

iR C3170/2570

How to turn OFF the main power. To protect the hard

disk of the product, perform the following steps when

turning OFF the main power.

[1] Press the power switch on the control panel unit

for 3 sec. or more.

[2] Operate the touch panel by following the instruc-

tions on the shutdown sequence screen so that the

main power switch will be ready to be OFF.

[3] Turn OFF the main power switch.

[4] Turn on the main power.

[2]

[3]

F-1-2

[4]

4

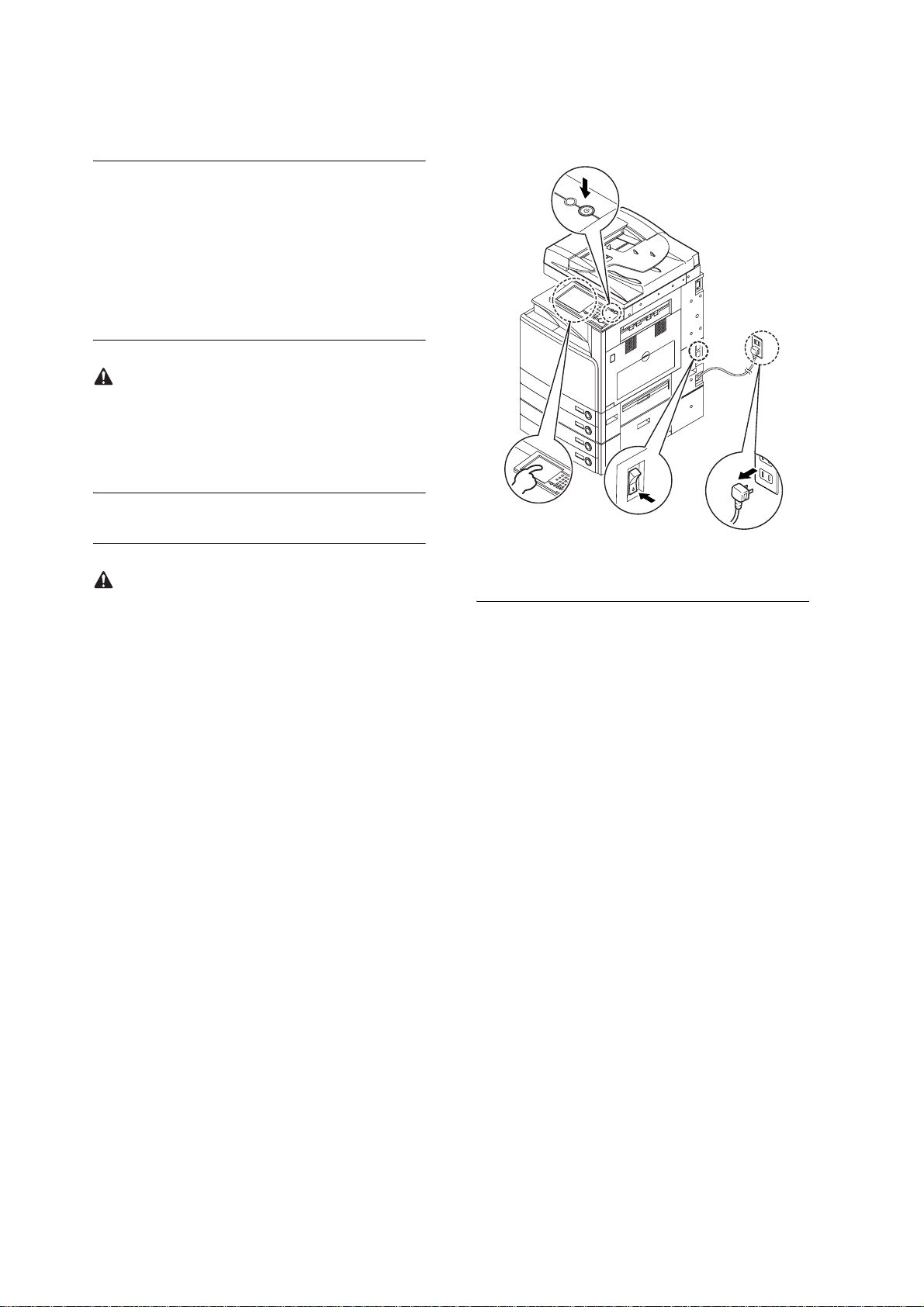

1.2.2 Installing the DADF

1) Remove the copyboard cover of the host machine;

then, attach the face stickers over the hinge holes.

F-1-3

2) Remove the 5 screws from the top of the host ma-

chine. (You will no longer need these screws.)

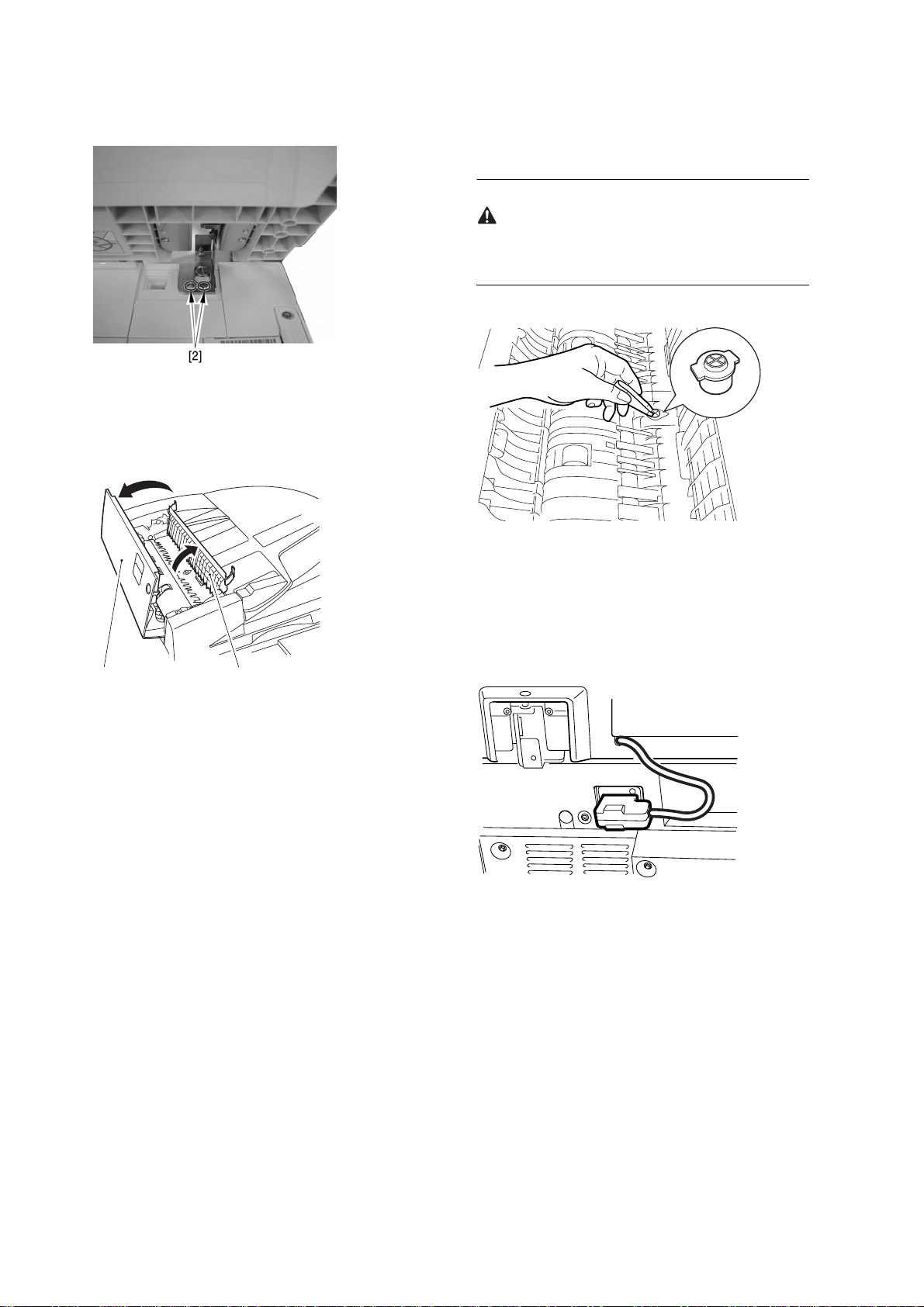

4) From behind the host machine, hook the hinges of

the DADF on the stepped screws [1]; then, slide the

DADF toward the front of the host machine.

When holding the DADF, be sure not to touch the

platen roller [2].

F-1-6

F-1-4

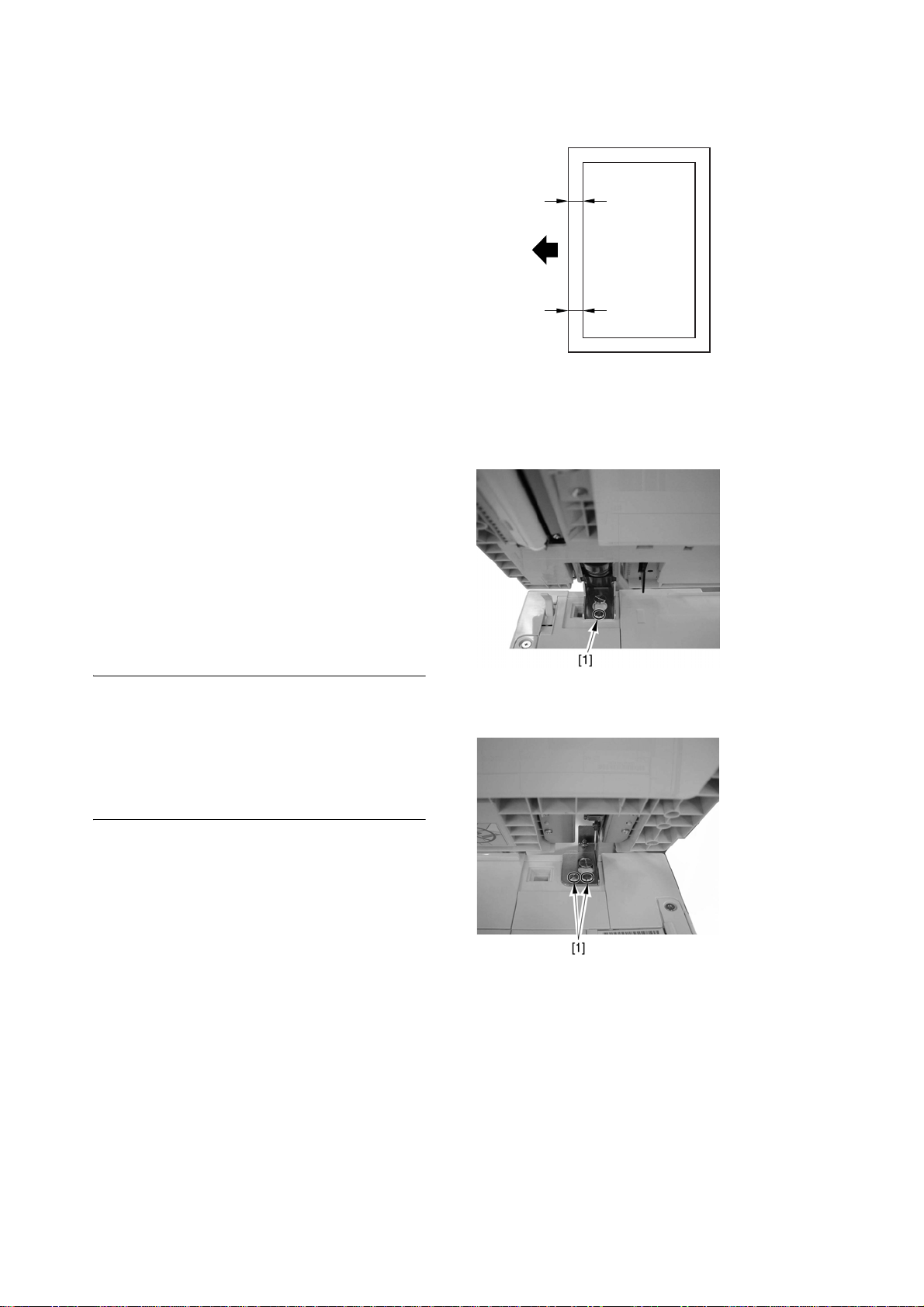

3) Fit 2 stepped screws (M5X6) [1] at the rear top of

the host machine.

[1]

F-1-5

5) Using the stepped screw (M4X10) [2], fix the hinge

in place; use 1 screw for the left, and use 2 screws

for the right. Make sure that the left sides of the

DADF and the host machine are flush when the

DADF is closed.

F-1-7

5

F-1-8

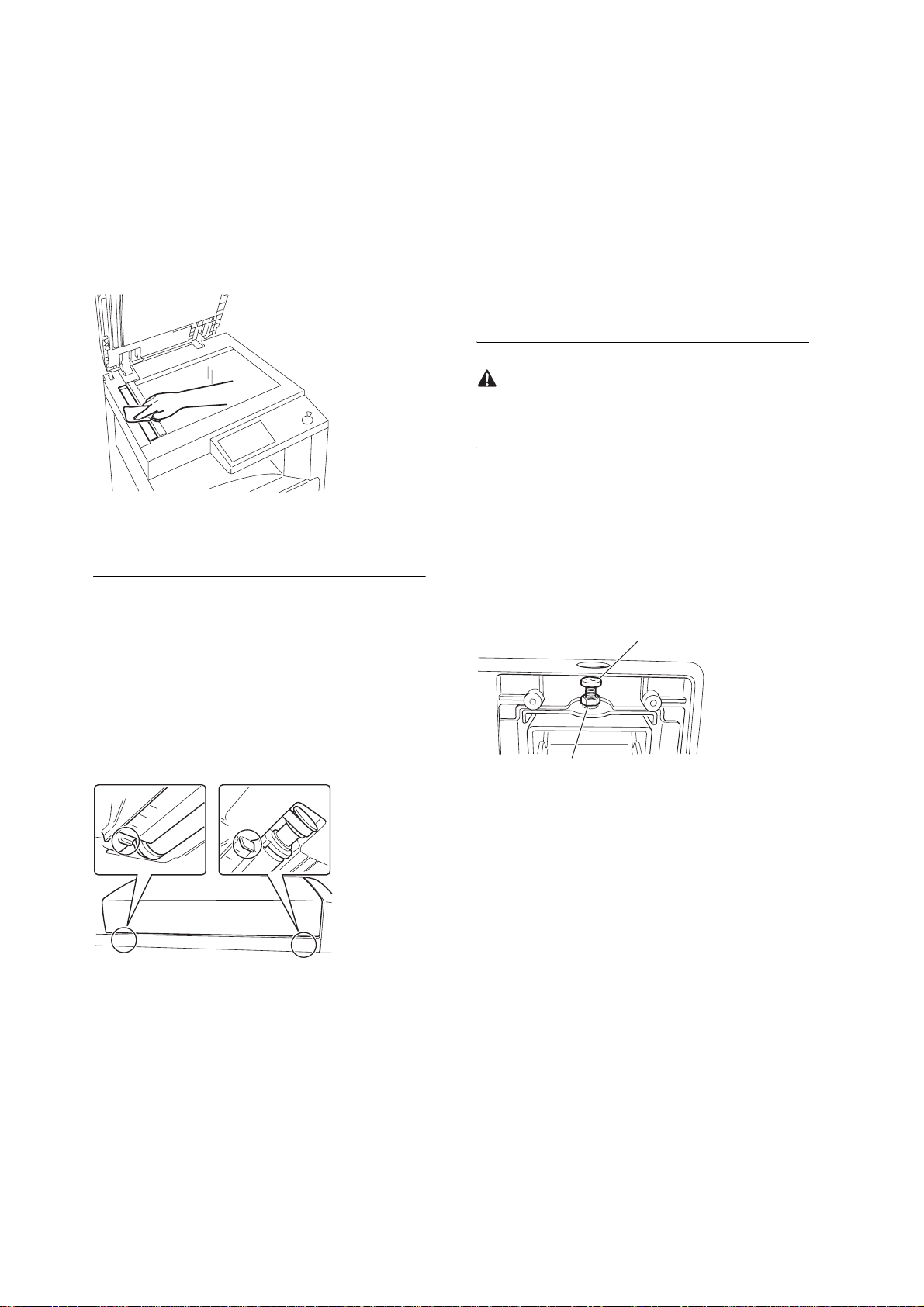

6) Open the pickup assembly cover [1] and the jam ac-

cess cover[2].

7) Using tweezers, fit the stamp. Be sure that the

stamping side faces upward.

Jams can occur if the stamp is not firmly in place. Be

sure to push it in until a click is felt.

F-1-10

8) Close the jam access cover and the pickup assembly

cover.

[1] [2]

F-1-9

9) Connect the cable of the DADF.

F-1-11

6

1.2.3 Cleaning the Copy-

board Glass

1) Wipe the glass of the original reading surface of the

DADF with a cloth moistened with water. (Be sure

the cloth is well wrung.)

F-1-12

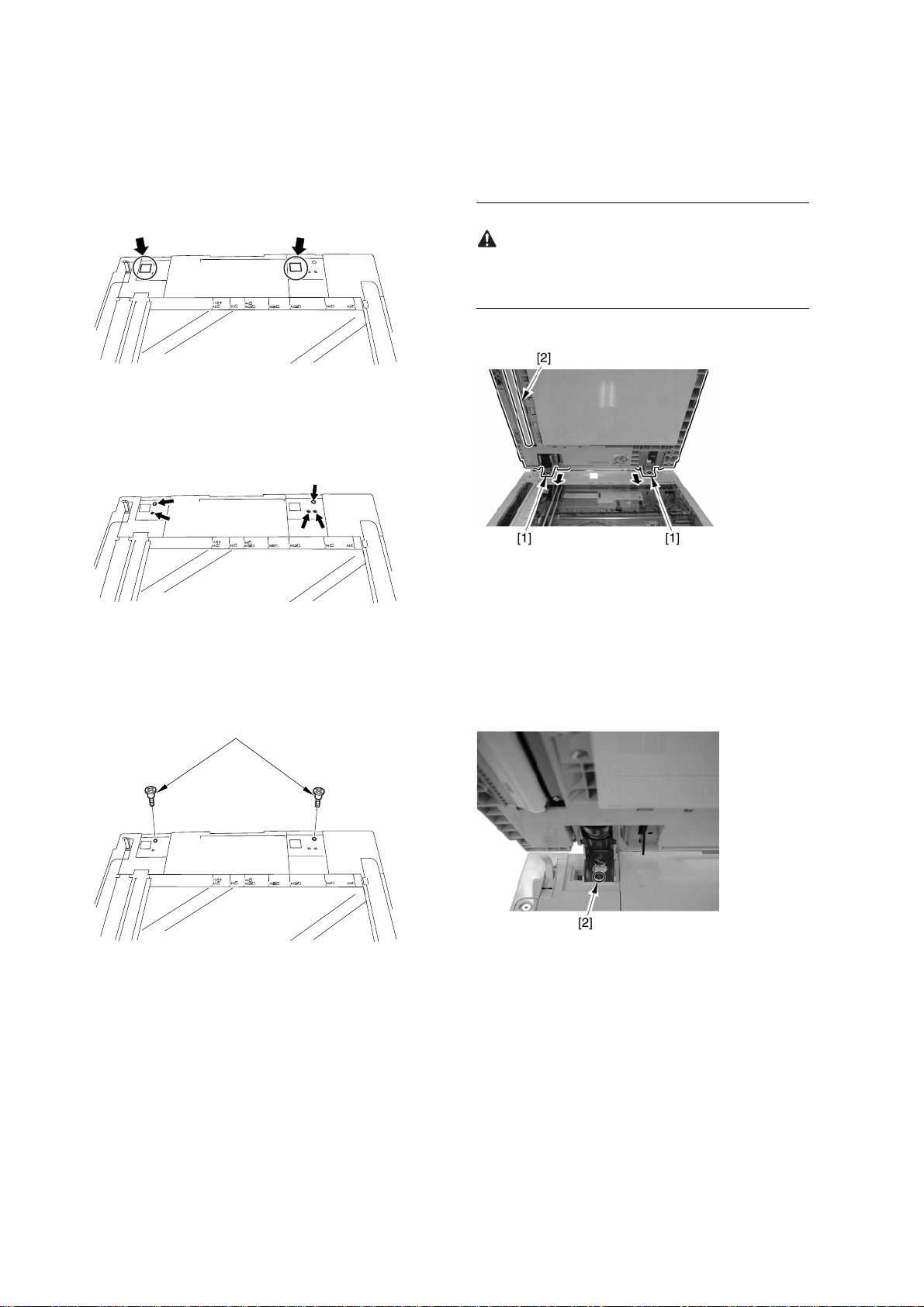

1.3 Making Adjustments

1.3.1 Adjusting the Height

1. Making Pre-Checks

Check to see that that the original butting segment on

the pickup side is in full contact with the copyboard

glass at both front and rear when the DADF is

closed.

- if the butting segment is not in contact at both sides

1) adjust the left hinge (see 3)

2) adjust the right hinge (see 4)

3) adjust the left hinge (see 3)

4) adjust the right hinge (see 4) or check the right

hinge

3. Adjusting the Height of the Left Hinge

1) Turn the height adjusting screw [1] of the left hinge

to make adjustments.

Be sure to loosen the fixing nut [2] prior to the adjust-

ment, and tighten it back after the adjustment.

- if the front side is not in contact, turn the adjusting

screw clockwise so that the front will be in contact

with the glass.

- if the rear or both sides are not in contact, turn the ad-

justing screw counterclockwise so that the rear will

be in contact with the glass.

[1]

[2]

F-1-14

F-1-13

2. Making Adjustments

- if the butting segment is not in contact at the front or

the rear,

1) adjust the left hinge (see 3)

2) adjust the right hinge (see 4)

3) adjust the left hinge (see 3) or check the left hinge

7

4. Adjusting the Height of the Right Hinge

1) Close the DADF, and check the following 2 points:

- the rubber foot [1] must not be in contact wit the cov-

er of the reader unit (i.e., there must be a gap, A).

- the original retaining sheet [2] is in contact with the

copyboard glass.

[1]

A

[2]

F-1-15

2) If the height is not correct, turn the height adjusting

screw [1] of the right hinge to make adjustments.

1.3.2 Turning On the Host

Machine

1) Connect the power cable (for the wall outlet).

2) Turn on the main power switch.

1.3.3 Adjusting the Tray

Width

The result of this adjustment is retained on the reader

controller PCB. As such, unlike previous ADFs, you

will need to make this adjustment at time of installa-

tion so that you will be able to store its result in the

reader unit. If you omit this adjustment, the following

will likely occur:

- wrong original size detection

Be sure to loosen the fixing nut [2] prior to the adjust-

ment, and tighten it back after the adjustment.

F-1-16

- turn the adjusting screw clockwise to increase the

gap A.

- turn the adjusting screw counterclockwise to de-

crease the gap A.

3) Make the checks indicated in sep 1) under "adjust-

ing the height of the left hinge"; if a discrepancy is

found, make adjustments once gain.

Adjust the tray width by performing either AB-con-

figuration adjustment or inch-configuration adjust-

ment.

1. AB-Configuration Adjustment

1) Start service mode.

Starting Service Mode

Press the User Mode key, press the 2 and 8 keys at

the same time, and press the User Mode key once

gain.

2) Touch the following notations in sequence to bring

up the Adjustment screen:

1 FEEDER

2 FUNCTION

3 TRY-A4 (to highlight)

3) Adjust the tray side guide to the A4/A3 index.

4) Touch [OK] to register the A4 width.

5) Touch [TRY-A5R] to highlight.

6) Adjust the tray side guide to the A5R index.

7) Touch [OK] to register the A5R width.

8) Press the Reset key twice to end service mode.

8

2. Inch-Configuration Adjustment

1) Start service mode.

Starting Service Mode

Press the User Mode key, press the 2 and 8 keys at

the same time, and press the User Mode key once

again.

2) Touch the following notations in sequence to bring

up the Adjustment screen:

1 FEEDER

2 FUNCTION

3 TRY-LTR (to highlight)

3) Adjust the tray side guide to the LTR/11x17 index.

4) Press [OK] to register the LTR width.

5) Press [TRY-LTRR] to highlight

6) Adjust the tray side guide to the STMT/LTRR/LGL

INDEX.

7) Touch [OK] to register the LTRR width.

8) Press the Reset key twice to end service mode.

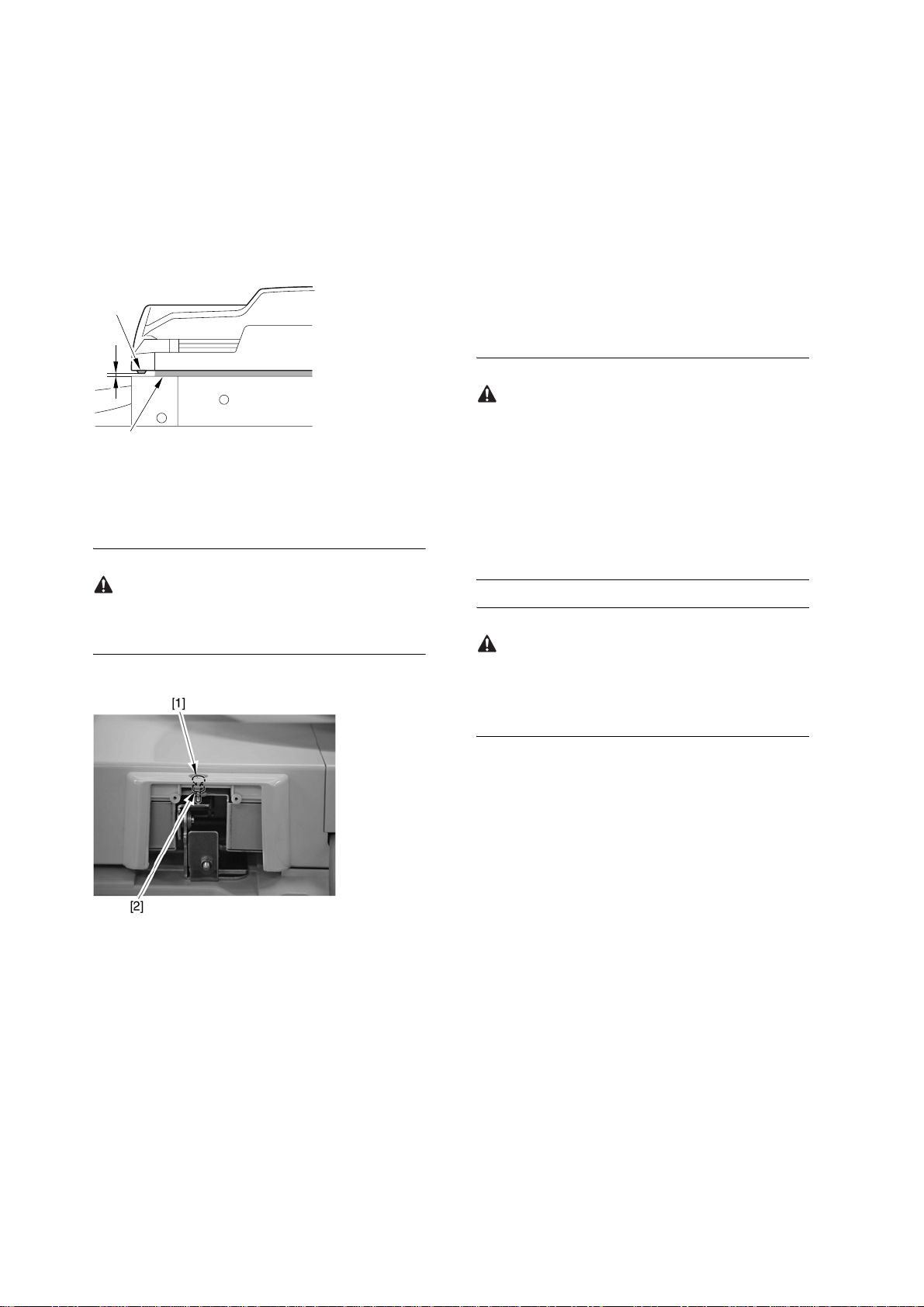

1.3.4 Adjusting the Right

A

Chart

feed

direction

B

F-1-17

3) Loosen the 3 screws [1] used to fix the hinge in

place.

Angles

1) Place a test chart in the DADF, and make a copy.

MEMO:

The Test Chart is printed on the back cover of the In-

stallation

Procedure. Make a copy of the Chart or cut it off for

use.

2) Check the right angles of the image along the lead-

ing edge of the copy. Specifically, check the differ-

ence between dimensions A and B of the leading

edge; if there is a difference, go to step 3) to make

adjustments.

F-1-18

F-1-19

9

Loading...

Loading...