Canon iRC2570, iRC3170, iRC3100 f-im-6488-000

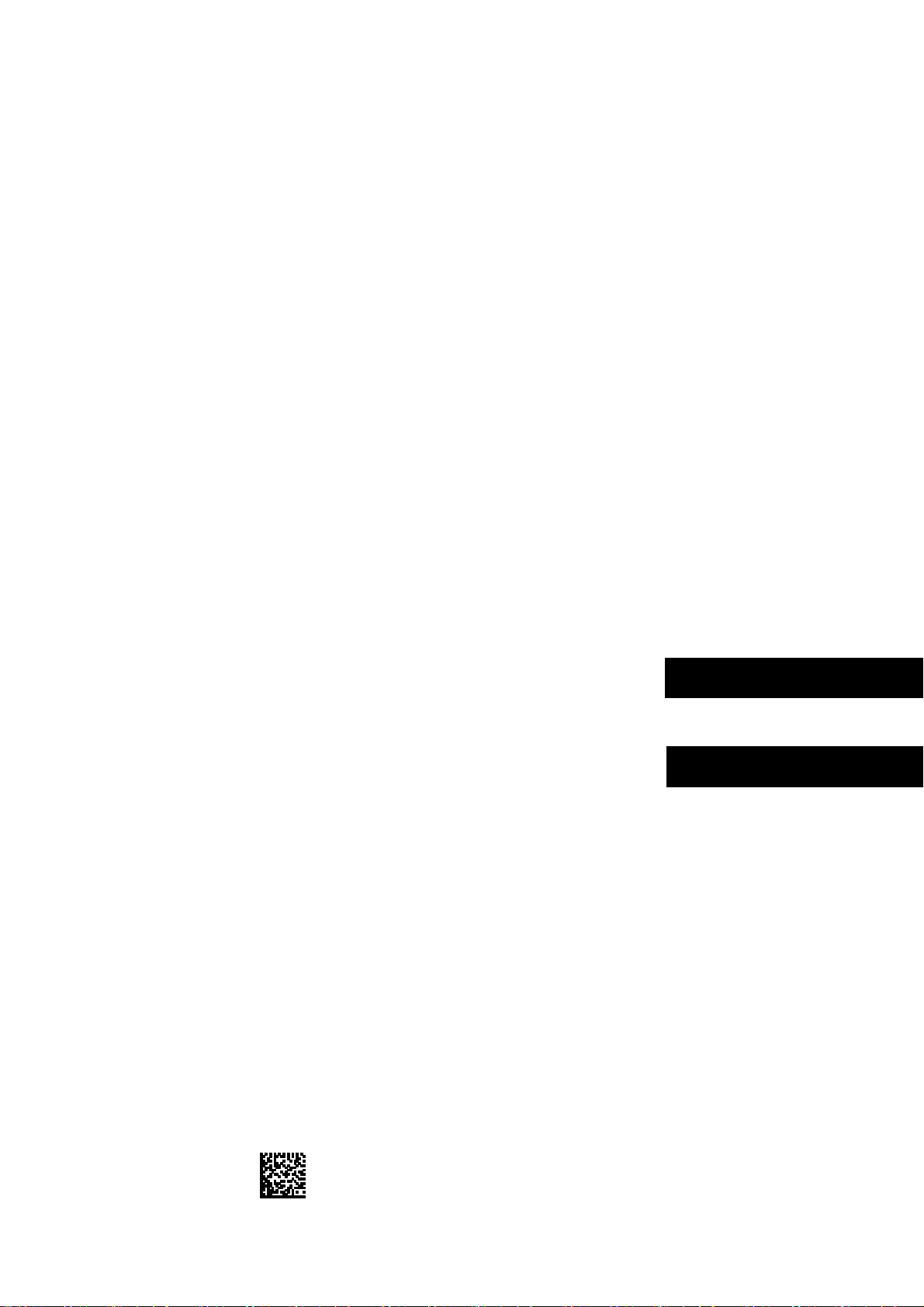

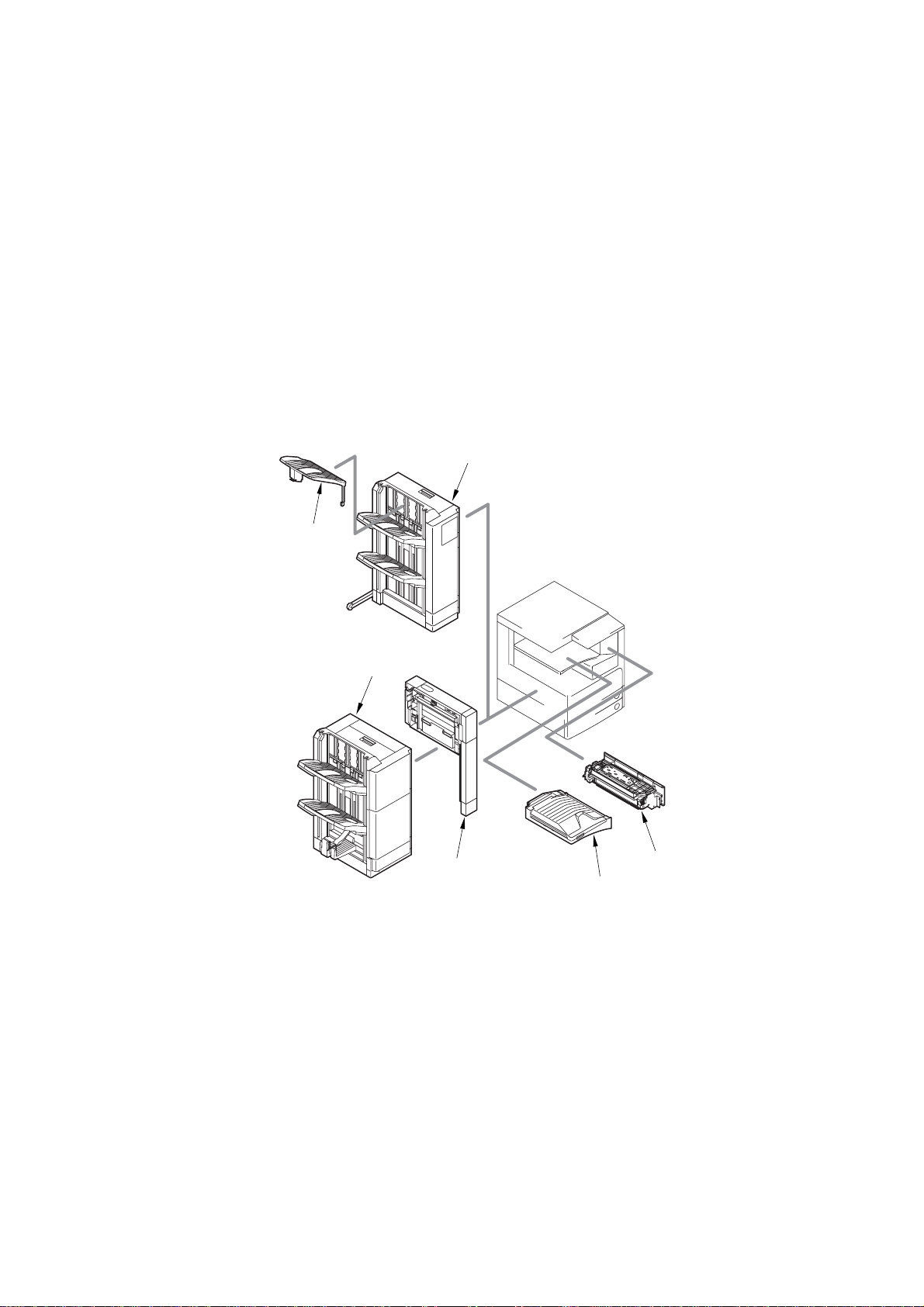

Finisher-Q1/Q3

Saddle Finisher-Q2/Q4

Installation Procedure

フィニッシャー・Q1/Q3

サドルフィニッシャー・Q2/Q4

設置手順書

Follow the instructions herein when installing the Product to its host machine.

本製品を iR 本体に接続する際は、以下の手順に従ってください。

PUB No.F-IM-6488-000 PRINTED IN JAPAN or CHINA

E N G L I S H

日 本 語

1.1 Making Pre-Checks

1.1.1 Checking the Contents (iR C3100Series)

Finisher-Q1/Finisher-Q3/Saddle Finisher-Q2/Saddle Finisher-Q4

[12]

[12]

[7]

[8]

[10]

[8]

[7]

[12]

[9]

[12]

[13]

[13]

[14]

[13]

[2]

[11]

[13]

[15]

F-1-1

[15]

[4]

[13]

[13]

[15]

[1]

[15]

[3]

[11]

[5]

[16]

[6]

[17]

[18]

T-1-1

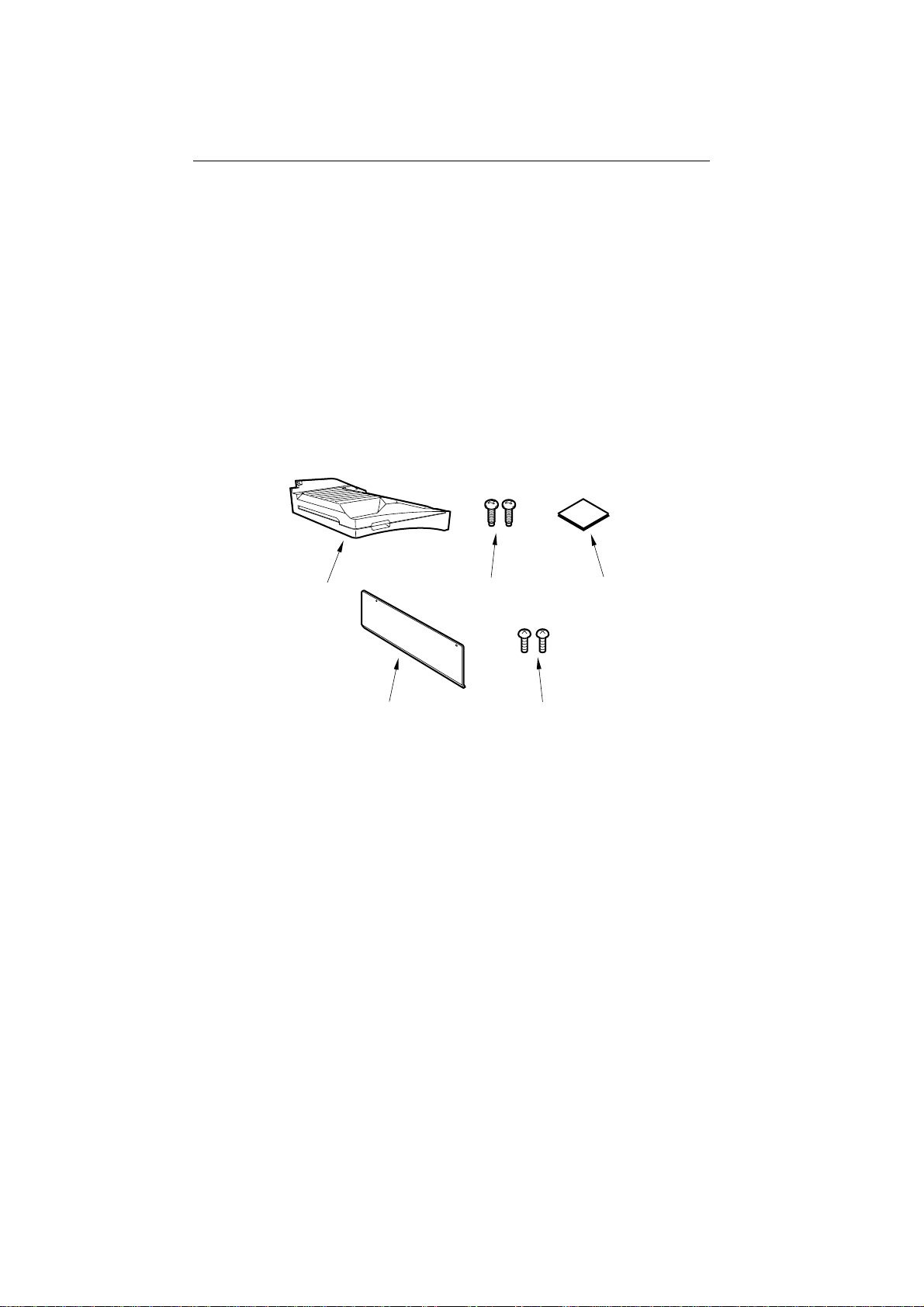

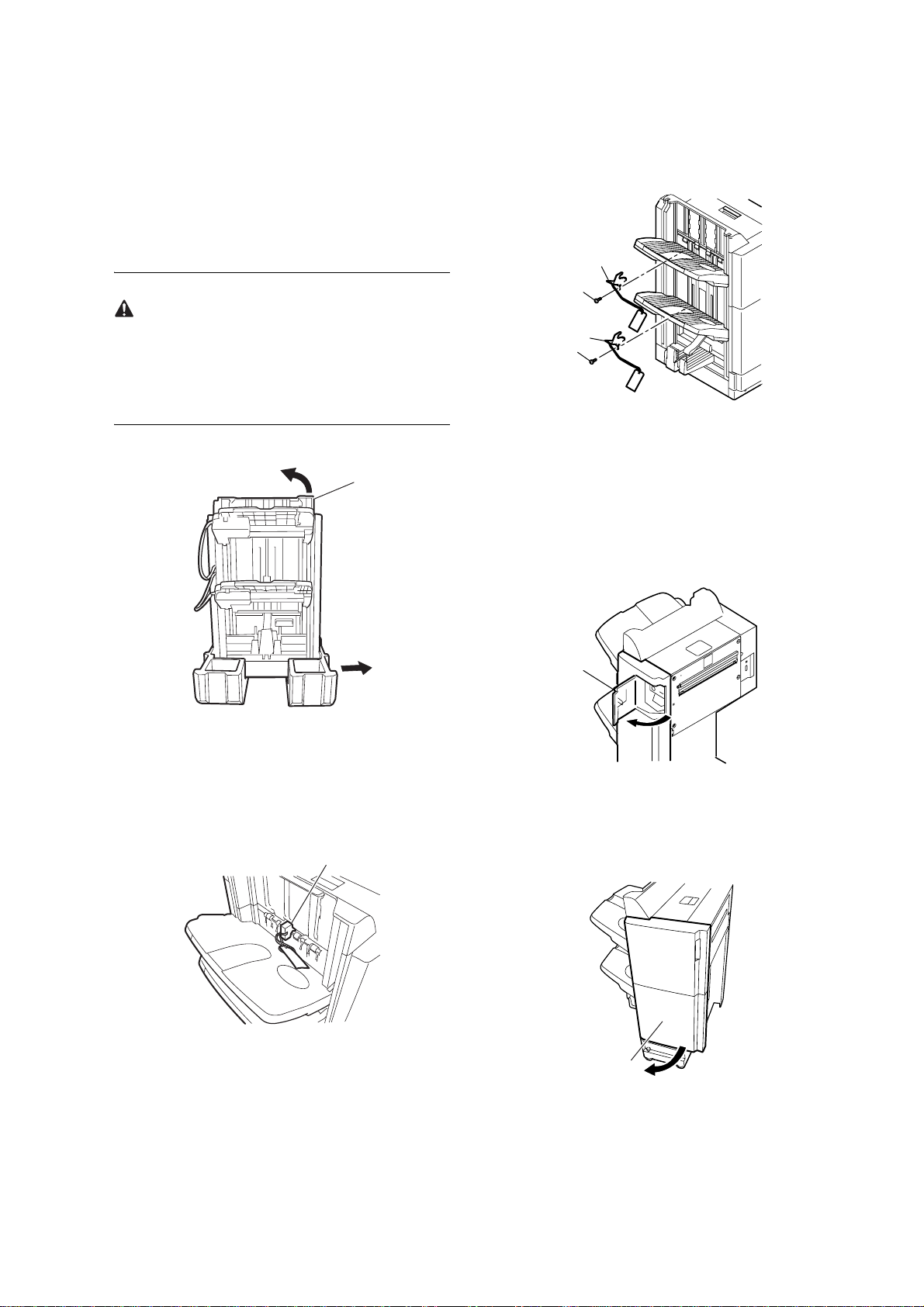

<Finisher-Q1/Q3> <Saddle Finisher-Q2/Q4>

[1]Fixing plate (FC5-6463) 1 pc. [3]Fixing plate (FC5-4976) 1 pc.

[2]Fixing plate (FC5-6185) 1 pc. [4]Fixing plate (FC5-4196) 1 pc.

[5]Staple cartridge 1 box

(3 pc.)

[7]Front foot cover 1 pc. [6]Cartridge for saddle 1 box

[8]Front lower extension

1 pc. [7]Front foot cover 1 pc.

cover

[5]Staple cartridge 1 box

(3pc.)

(2 pc.)

2

<Finisher-Q1/Q3> <Saddle Finisher-Q2/Q4>

[11]Rail 1 pc. [9]Front lower extension stay 1 pc.

[12]Screw

(RS tightening; M3x8)

[13]Screw (binding; M4X6) 6 pc. [10]Rear foot cover 1 pc.

[15]Stepped screw (M4) 2 pc. [11]Rail 1 pc.

[16]Tray label 1 pc. [12]Screw (RS tightening; M3X8) 5 pc.

[17]Settings label 1 pc. [13]Screw (binding; M4X6) 6 pc.

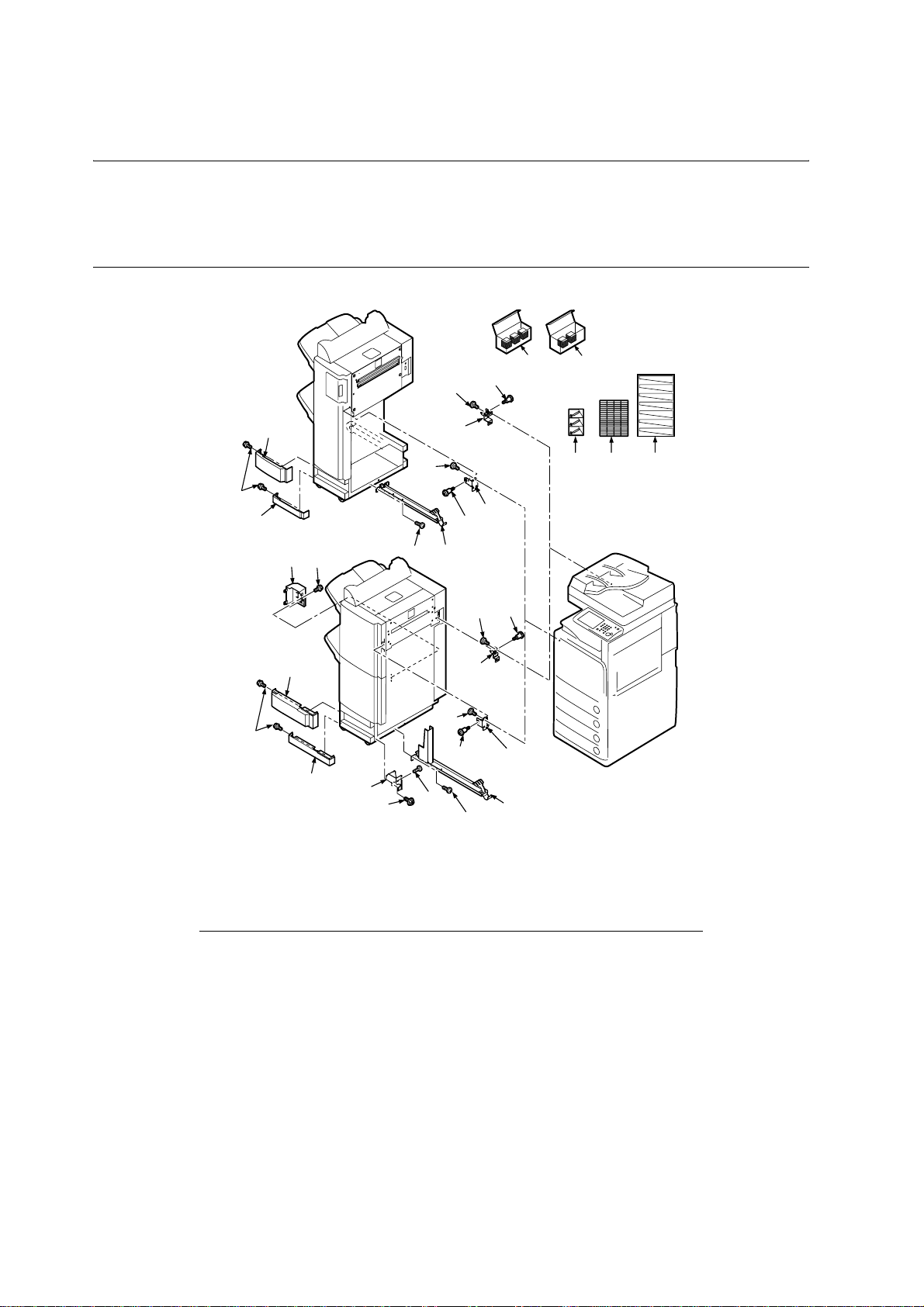

Buffer Pass Unit-C1

[1]

2 pc. [8]Front lower extension cover 1 pc.

[14]Screw (tapping; M4X12) 1 pc.

[15]Stepped screw (M4) 2 pc.

[16]Tray label 1 pc.

[17]Settings label 1 pc.

[18]Bookmaking label 1 pc.

[2] [3]

[4] [6][5] [7] [8]

F-1-2

T-1-2

[1]Relay delivery unit 1 pc.

[2]Buffer pass unit 1 pc.

[3]Protective cover 1 pc.

[4]Joint shaft 1 pc.

[5]Joint plate 1 pc.

[6]Screw (tapping; M4X12) 3 pc.

[7]Screw (RS tightening; M3X8) 4 pc.

[8]Rubber sheet 1 pc.

3

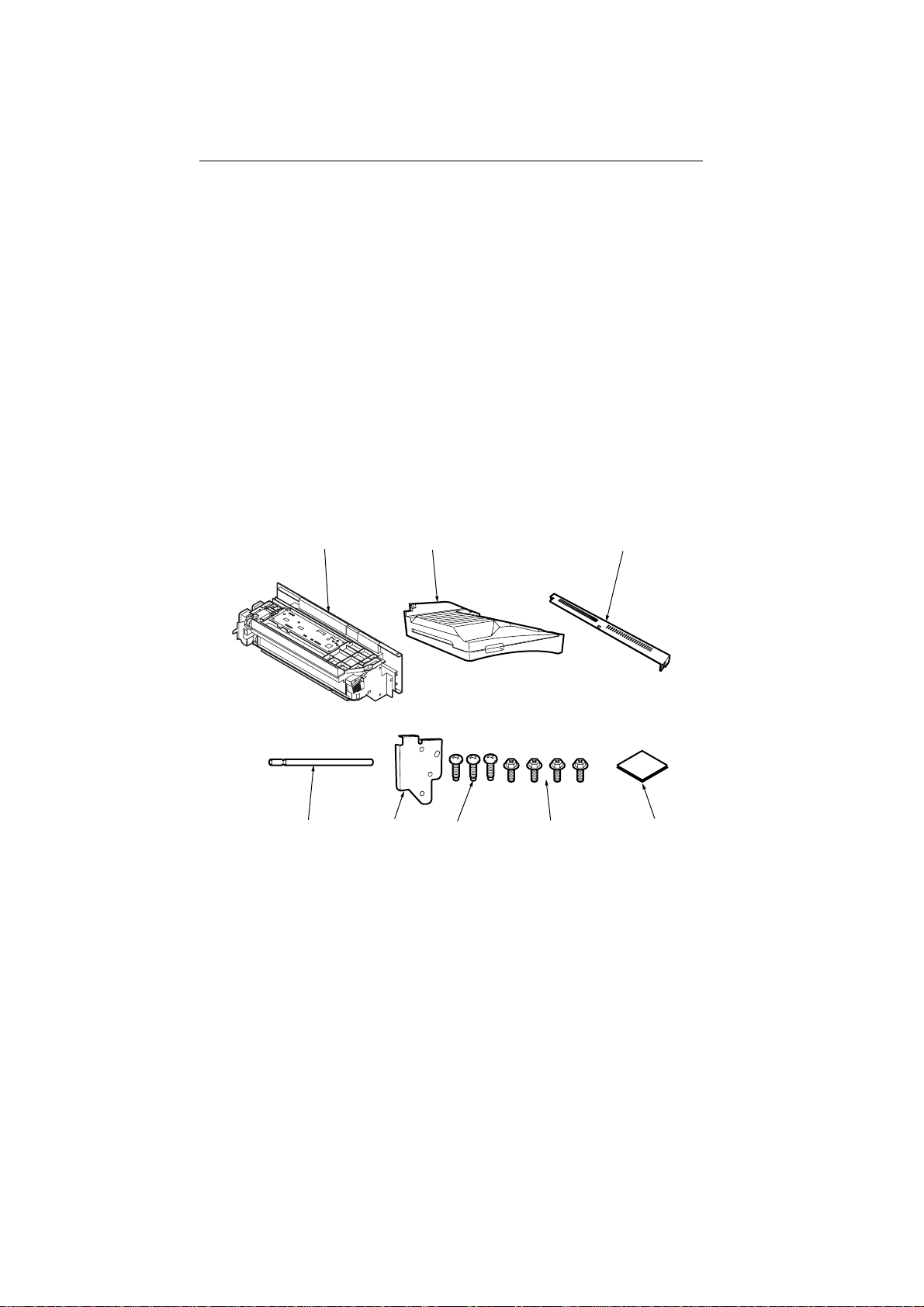

1.1.2 Checking the Contents (iR4570/3570series, 2870/2270series)

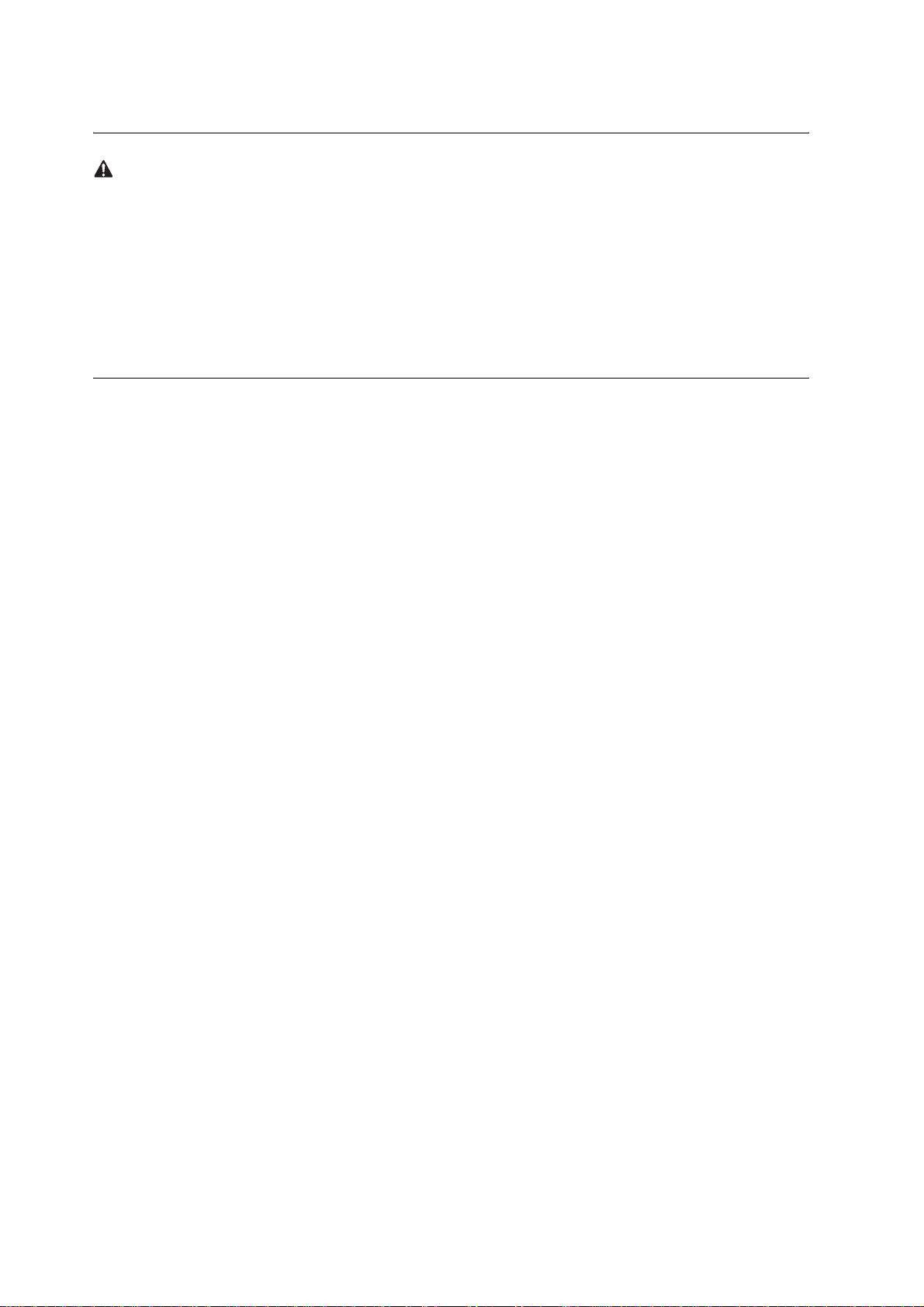

Finisher-Q3/Saddle Finisher-Q4

[12]

[12]

[7]

[8]

[10]

[8]

[7]

[12]

[9]

[12]

[13]

[13]

[14]

[13]

[2]

[11]

[13]

[15]

F-1-3

[15]

[4]

[13]

[13]

[15]

[1]

[15]

[3]

[11]

[5]

[16]

[6]

[17]

[18]

T-1-3

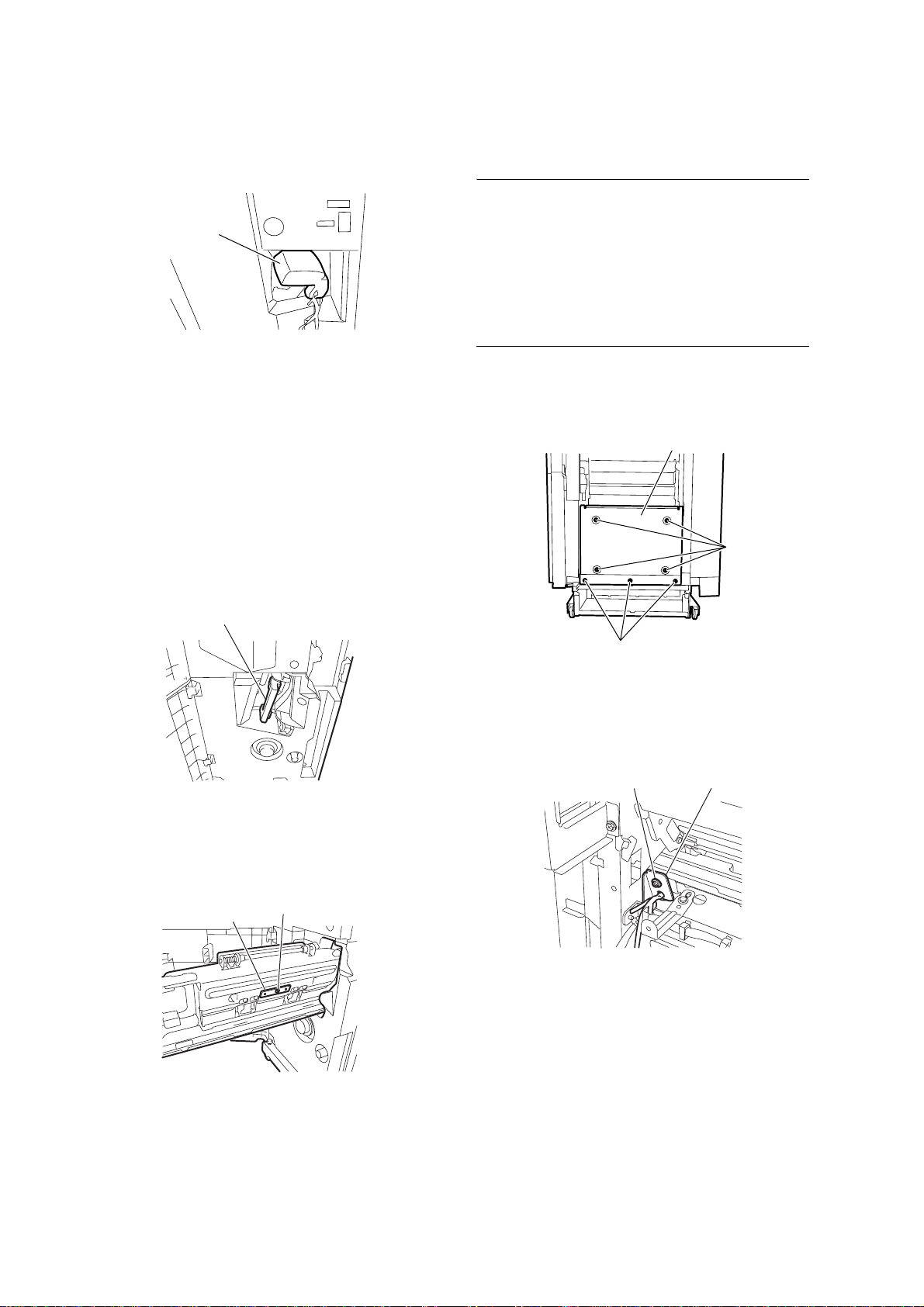

<Finisher-Q3> <Saddle Finisher-Q4>

[1]Fixing plate (FC5-6463) 1 pc. [3]Fixing plate (FC5-4976) 1 pc.

[2]Fixing plate (FC5-6185) 1 pc. [4]Fixing plate (FC5-4196) 1 pc.

[5]Staple cartridge 1 box

(3 pc.)

[7]Front foot cover 1 pc. [6]Cartridge for saddle 1 box

[8]Front lower extension cover 1 pc. [7]Front foot cover 1 pc.

[11]Rail 1 pc. [9]Front lower extension stay 1 pc.

[12]Screw

2 pc. [8]Front lower extension cover 1 pc.

(RS tightening; M3X8)

[5]Staple cartridge 1 box

(3 pc.)

(2 pc.)

4

<Finisher-Q3> <Saddle Finisher-Q4>

[13]Screw (binding; M4X6) 6 pc. [10]Rear foot cover 1 pc.

[15]Stepped screw (M4) 2 pc. [11]Rail 1 pc.

[16]Tray label 1 pc. [12]Screw (RS tightening; M3x8) 5 pc.

[17]Settings label 1 pc. [13]Screw (binding; M4X6) 6 pc.

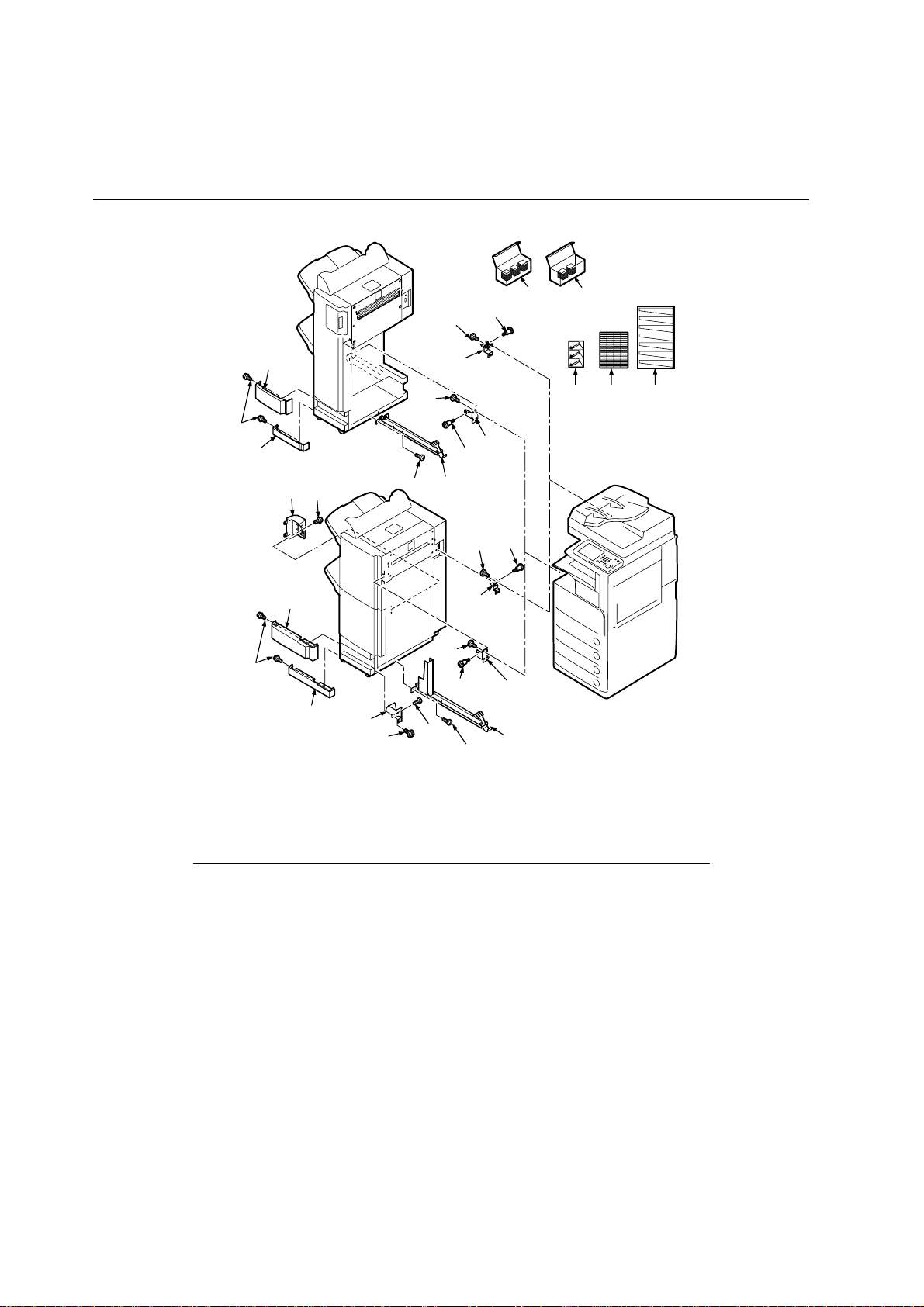

Buffer Pass Unit-E1

[14]Screw (tapping; M4X12) 1 pc.

[15]Stepped screw (M4) 2 pc.

[16]Tray label 1 pc.

[17]Settings label 1 pc.

[18]Bookmaking label 1 pc.

[1]

[4]

[2]

F-1-4

T-1-4

[1]Buffer pass unit 1 pc.

[2]Screw (tapping; M4X12) 2 pcs.

[3]Rubber sheet 1 pc.

[4]Blanking plate 1 pc.

[5]Screw (binding; M4X6) 2 pcs.

[3]

[5]

5

1.1.3 Pre-installation Check/ Setup (iR C3100Series)

This accessory requires the host machine to be equipped with the following version of firmware:

System: Ver.10.17 or later

DCON: Ver.10.16 or later

Before mounting this accessory, be sure to take the following steps:

1) Specify Service Mode > COPIER > Display > VERSION to check the host machine for the firmware version.

When an earlier version of firmware is installed, use the service support tool to upgrade the firmware.

2) Specify Service Mode > COPIER > Counter > DRBL-2 to check the counters of the following finisher-related

consumable parts. When some counters have the upper limit cleared back to "0" in response to upgrade, enter a prop-

er value if necessary.

- SORT (3000000)

- FIN-STPR (500000)

- SADDLE (300000)

- SDL-STPL (100000)

- PUNCH (1000000)

- PNCH-HRS (3000000)

- FN-BFFRL (1000000)

- TY-TQLMT (1280000)

* The values in parentheses show factory settings.

Be sure to take the step 2) above whether the parts are subject to upgrade or not.

6

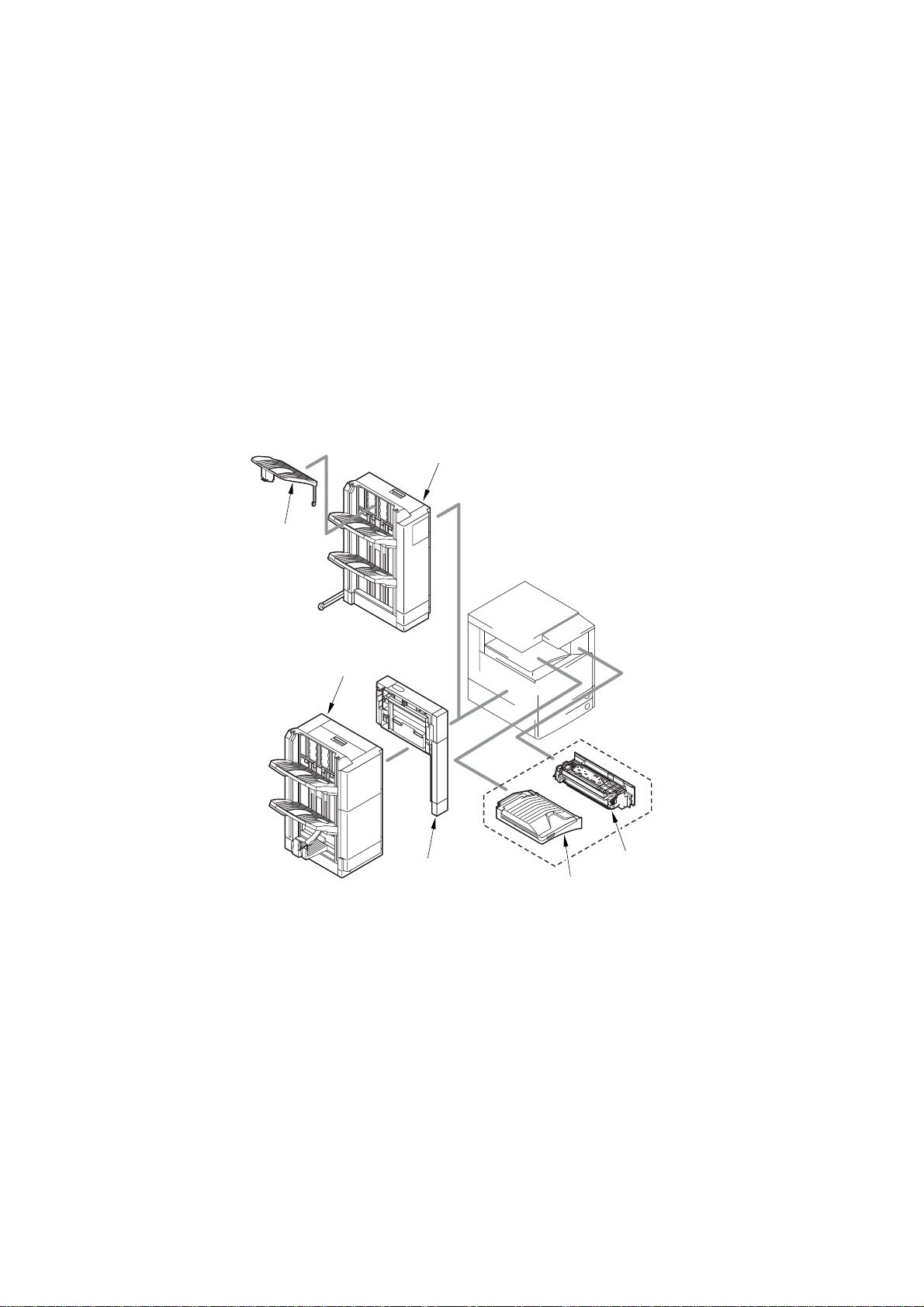

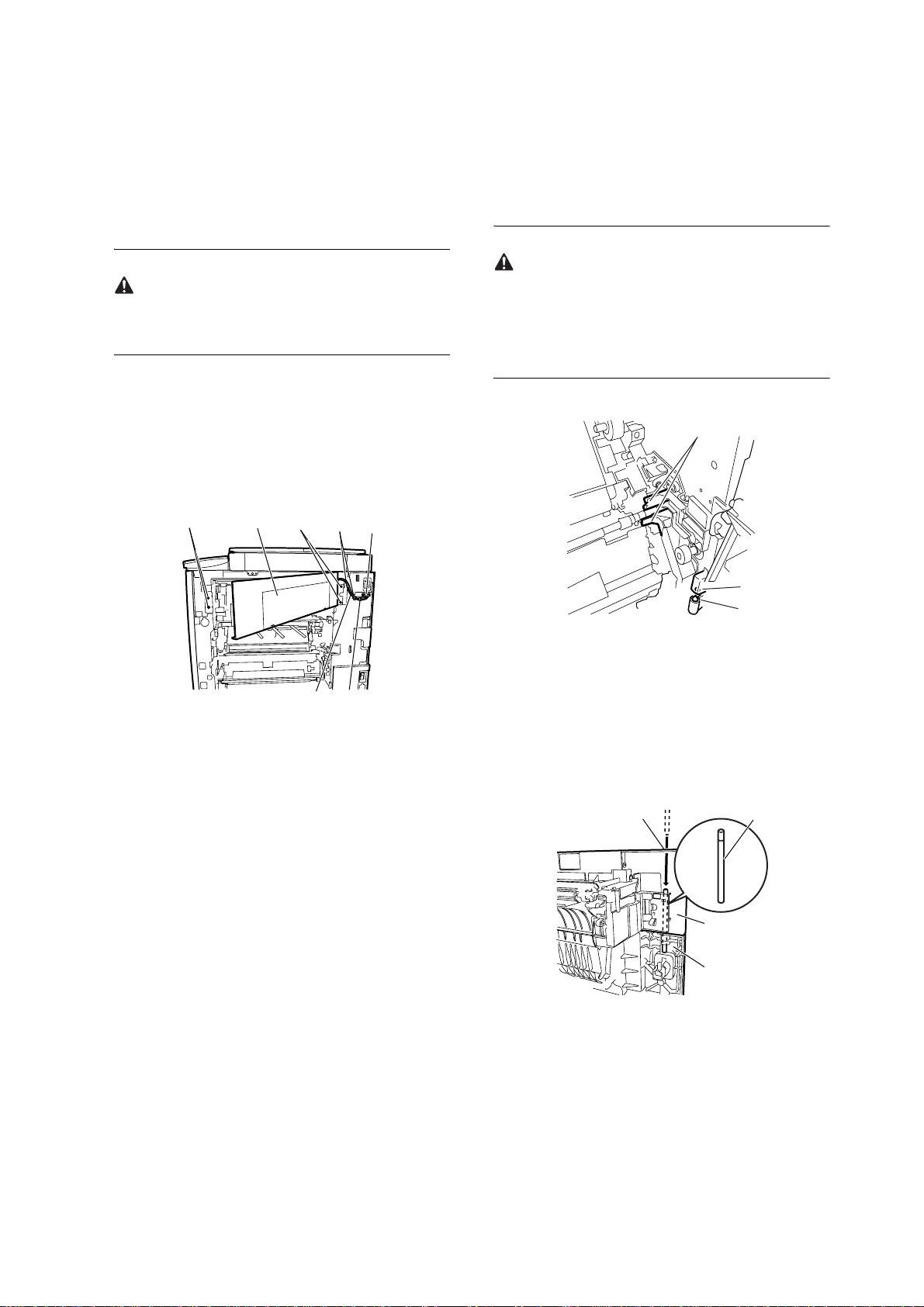

1.1.4 Installing the Accessories (iR C3100Series)

If you are installing accessories at the same time as you are installing the host machine,install the host machine first

and then the accessories in the following sequence:

1. Side paper deck (see its Installation Procedure)

2. Finisher [1], [2] (see the steps up to "Making Preparations on the Host Machine" herein)

3. Relay delivery unit [3] and buffer pass unit [4] (see "Installing the Relay Delivery Unit and the Buffer Pass Unit"

herein)

4. Additional finisher tray [5] (see its Installation Procedure)

5. Puncher unit [6] (see its Installation Procedure)

6. Connection to the host machine (see "Connecting to the Host Machine" herein or the steps in "Connecting to the

Host Machine" and thereafter in the Puncher Unit Installation Procedure)

[1]

[5]

[2]

[6]

[3]

[4]

F-1-5

7

Turning Off the Host Machine

iR C3170/2570 excluded

Turning Off the Main Power

[1] Turn off the control panel power switch.

[2] Turn off the main power switch.

[3] Disconnect the power cable (from the power outlet).

iR C3170/2570

Turning Off the Main Power

When turning off the main power, be sure to go through the following in strict sequence to protect the machine's hard

disk:

[1] Hold down on the power switch on the control panel for 3 sec or more.

[2] Operate on the touch panel according to the shut-down sequence indicated so that the main power switch may be

turned off.

[3] Turn off the main power switch.

[4] Disconnect the power cable (for the power outlet).

8

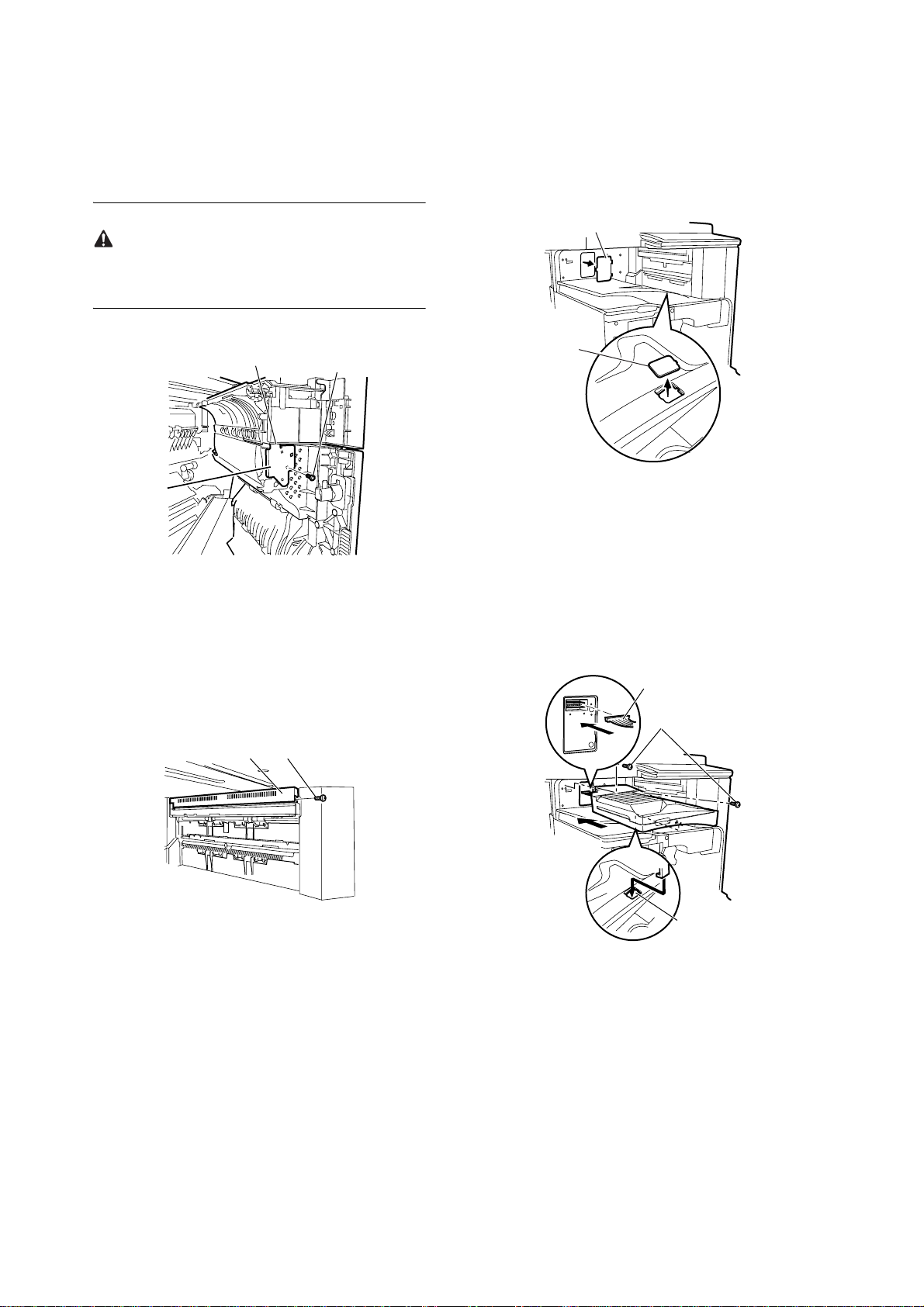

1.1.5 Installing the Accessories (iR4570/3570series, 2870/2270series)

If you are installing accessories at the same time as you are installing the host machine,install the host machine first

and then the accessories in the following sequence:

1. Side paper deck (see its Installation Procedure)

2. Finisher [1], [2] (see the steps up to "Making Preparations on the Host Machine" herein)

3. Mounting the 3 Way Unit (See the installation manual on the 3 Way Unit.)*

4. Mounting the Buffer Path Unit (See "Mounting the Buffer Path Unit" in this manual.)

5. Additional finisher tray [5] (see its Installation Procedure)

6. Puncher unit [6] (see its Installation Procedure)

7. Connection to the host machine (see "Connecting to the Host Machine" herein or the steps in "Connecting to the

Host Machine" and thereafter in the Puncher Unit Installation Procedure)

[1]

[5]

[2]

*3 Some machines are fitted with the 3 way unit.

[6]

F-1-6

[3]

[4]

9

Turning Off the Main Power

When turning off the main power, be sure to go through the following in strict sequence to protect the machine's hard

disk:

[1] Hold down on the power switch on the control panel for 3 sec or more.

[2] Operate on the touch panel according to the shut-down sequence indicated so that the main power switch may be

turned off.

[3] Turn off the main power switch.

[4] Disconnect the power cable (for the power outlet).

10

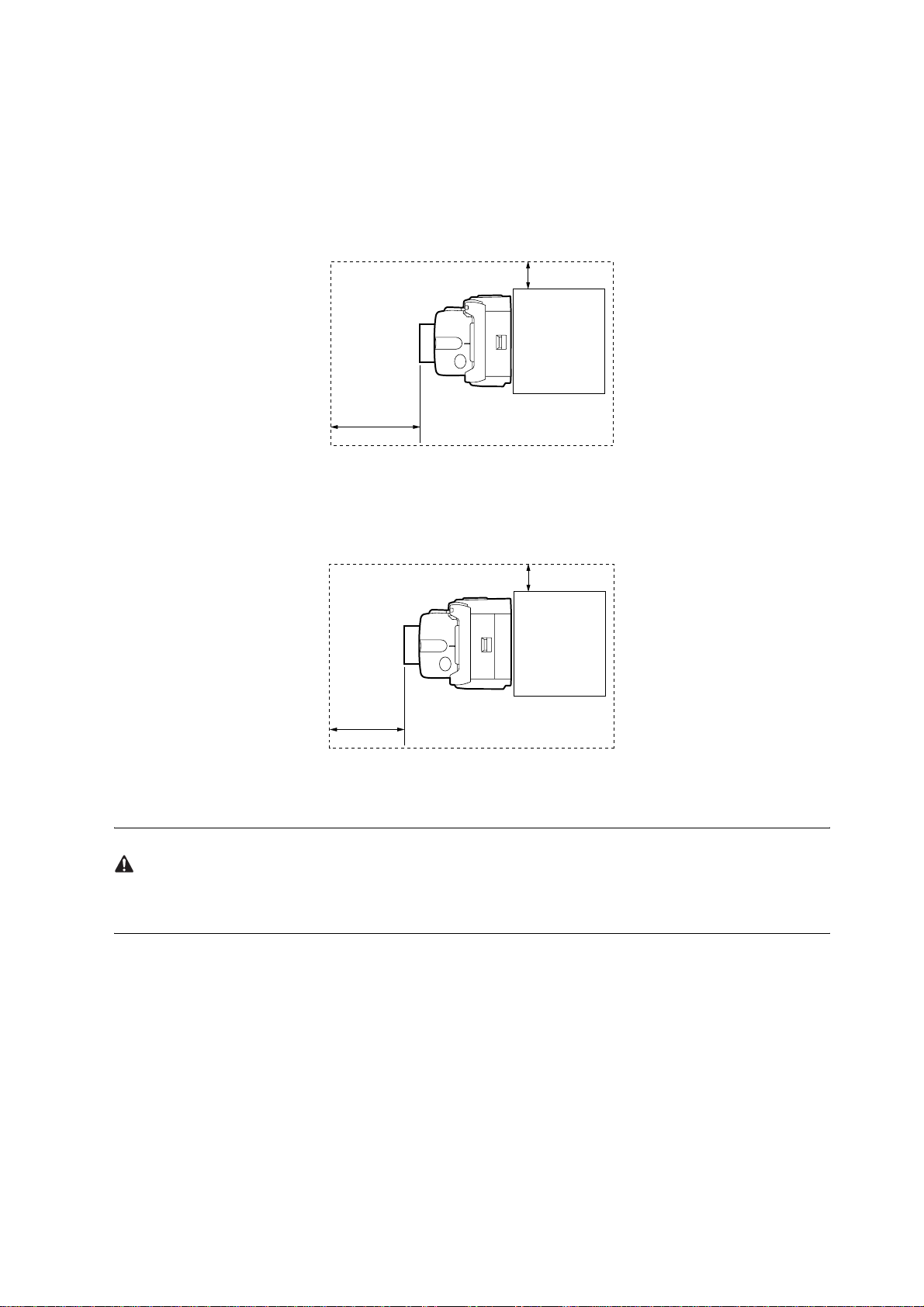

1.1.6 Selecting the Site of Installation

Select the site of installation, making sure there will be enough space for work (e.g., removal of paper). Be sure also

that there will be no gap between the finisher and the host machine.

<Finisher-Q1/Q3>

100 or more

500 or more

unit: mm

F-1-7

<Saddle Finisher-Q2/Q4>

100 or more

500

or

more

unit: mm

F-1-8

Be sure to install the host machine and the finisher on a level surface without any step or gap. Otherwise, faults as-

sociated with paper movement can occur.

11

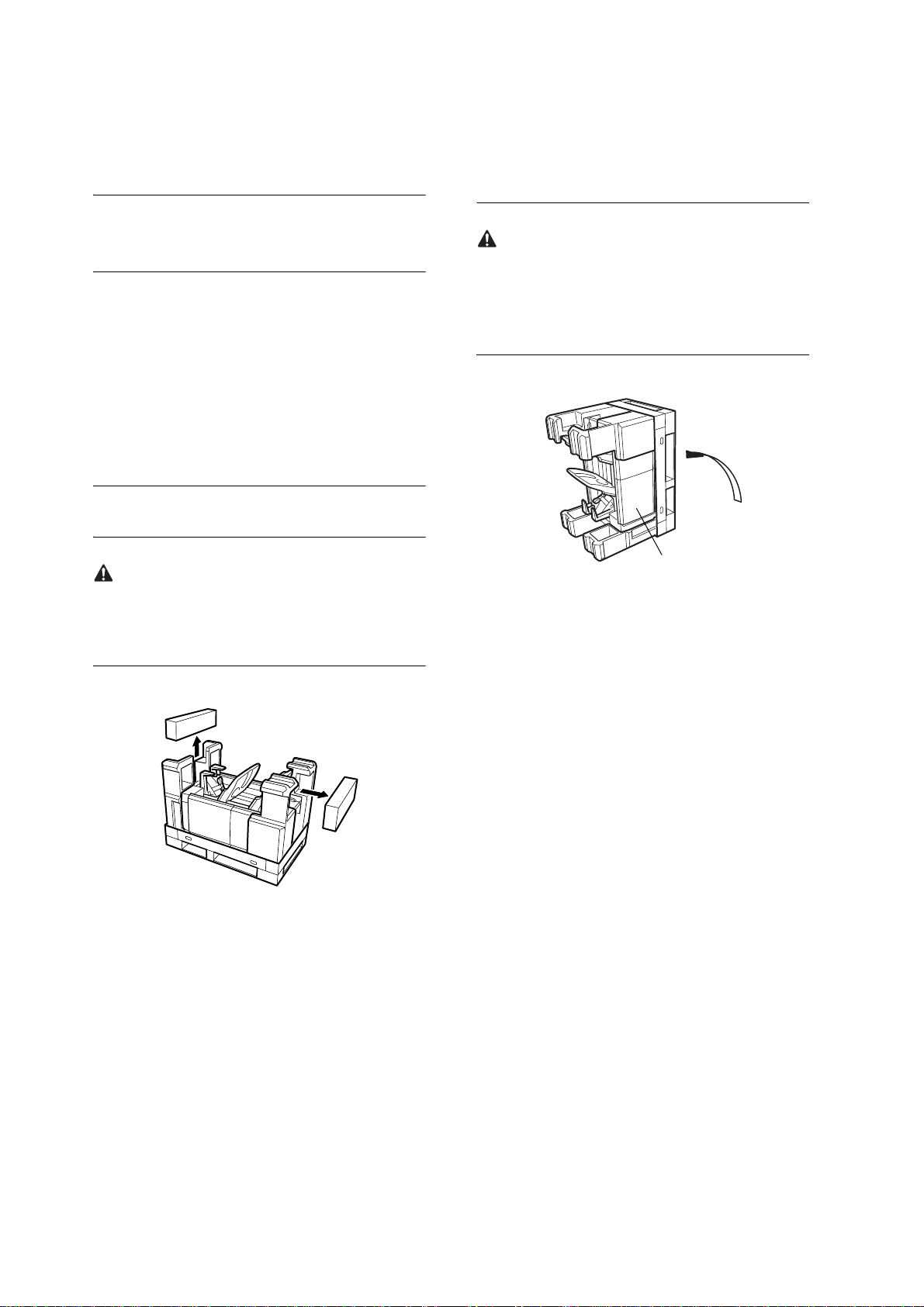

1.2 Unpacking and Checking

the Components

1.2.1 Unpacking

MEMO:

The machine is packed using tape and cushioning ma-

terial to protect against vibration and shock during

transit. Be sure to remove them before starting to in-

stall the machine. (It is a good idea to store away the

removed tape and cushioning material for possible re-

location of the machine, e.g., to a new site or for re-

pairs.)

1) Take out the accessory box from the shipping box.

At this point, do not remove the 4 cushioning materi-

als (Styrofoam) from the finisher. Otherwise, you

would likely deform some areas of the machine.

2) Lift the finisher together with its cushioning base

(Styrofoam). Be sure to work in a group of 2 per-

sons.

If you shift up the finisher on its side, you would likely

deform or damage the machine. Moreover, in the case

of the Saddle Finisher-Q2/Q4, force applied to the

front cover [1] can deform the hinge.

[1]

F-1-10

F-1-9

12

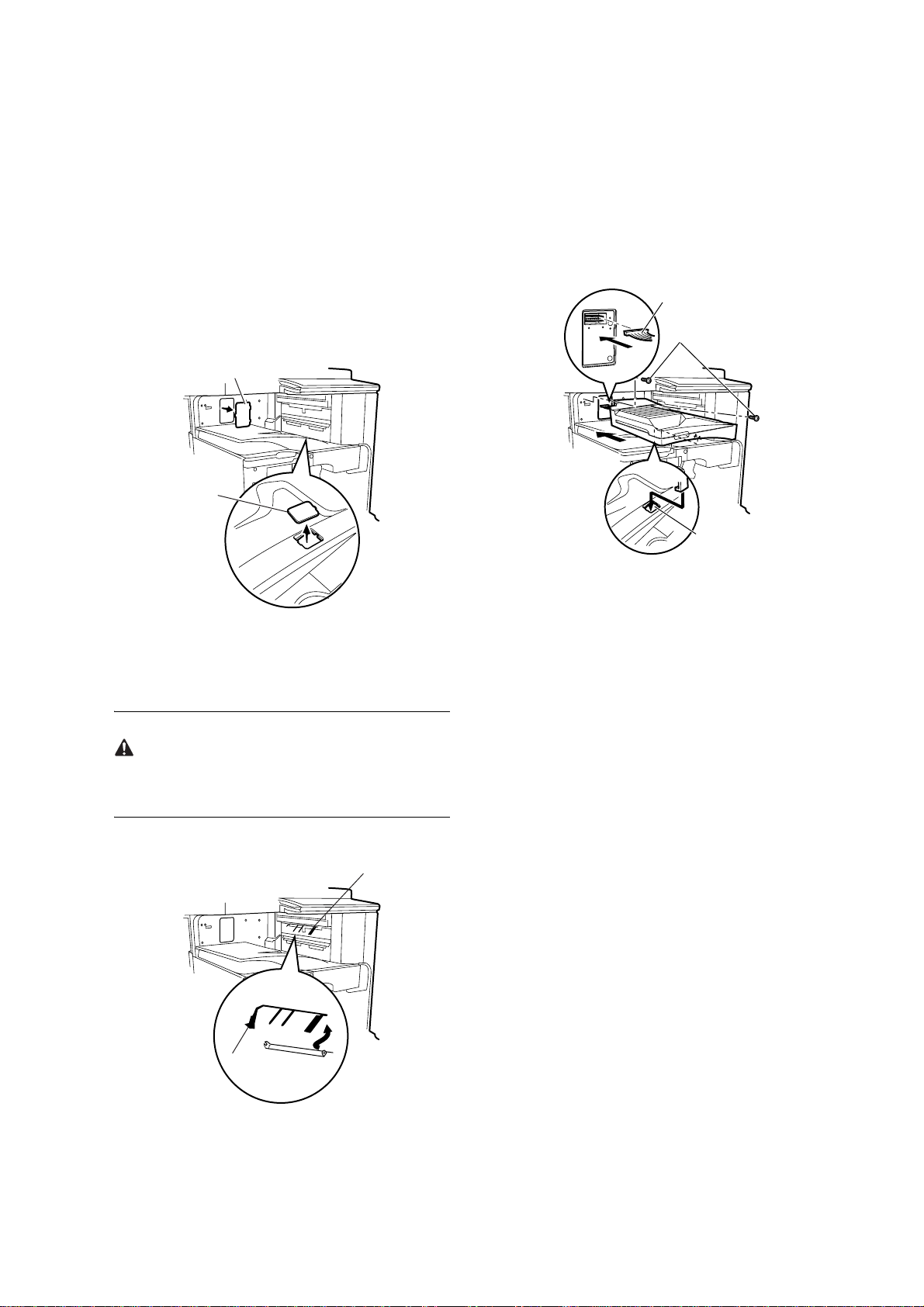

3) Remove the cushioning material (Styrofoam) from

the upper cover.

4) Slightly lift the front and rear casters, and remove

the cushioning material (Styrofoam). Be sure to

shift up the finisher by holding the upper left cover

[1] (gray area).

7) Remove the fixing screw [1], and remove the 2 tray

fixings [2].

[2]

[1]

The finisher is rather heavy. Be sure to work in a group

of 2 persons. Particularly when moving it over a step

on the floor, be sure to take full care not to let it tumble

over.

[1]

F-1-11

5) Remove the tape used on the outside of the finisher.

6) Remove the cushioning material [1] (Styrofoam) of

the tray.

[2]

[1]

F-1-13

8) In the case of the Finisher-Q1/Q3, open the front

door [1]. In the case of the Saddle Finisher-Q2/Q4,

open the front cover [2].

<Finisher-Q1/Q3>

[1]

F-1-14

F-1-12

[1]

<Saddle Finisher-Q2/Q4>

[2]

F-1-15

13

9) Remove the tape and the cushioning material [1]

(Styrofoam) from the stapler.

[1]

F-1-16

Removing the Folding Roller Releasing Plate (only

for the Saddle Finisher-Q2/Q4)

MEMO:

The releasing plate must be mounted to prevent roller

deformation, as otherwise occurring when the ma-

chine is not used for a long time. Once you have re-

moved the plate and its fixing screws, it is a good idea

to store them away for future use.

10) In the case of the Finisher-Q1/Q3, close the front

door. In the case of the Saddle Finisher-Q2/Q4, go

to the next step while keeping the front cover open.

Removing the Stitcher Fixing Member (only for

the Saddle Finisher-Q2/Q4)

1) Slide out the stitcher unit [1] to the front, and re-

move the tape.

[1]

F-1-17

1) Remove the 7 screws [1], and detach the lower right

cover [2].

[2]

[1]

[1]

F-1-19

2) Remove the fixing screw [1], and detach the releas-

ing plate (front) [2].

[1]

[2]

2) Remove the screw [1], and remove the stitcher fix-

ing member [2].

[2]

[1]

F-1-18

3) Put the stitcher back in and close the front cover.

F-1-20

3) Remove the fixing screw [1], and detach the releas-

ing plate (rear) [2].

14

[2]

4) Mount the lower right cover you have removed us-

ing the 7 screws.

[1]

F-1-21

1.3 Installation Procedure

1.3.1 Preparing for the

Installation of the Finisher

(iR C3100Series)

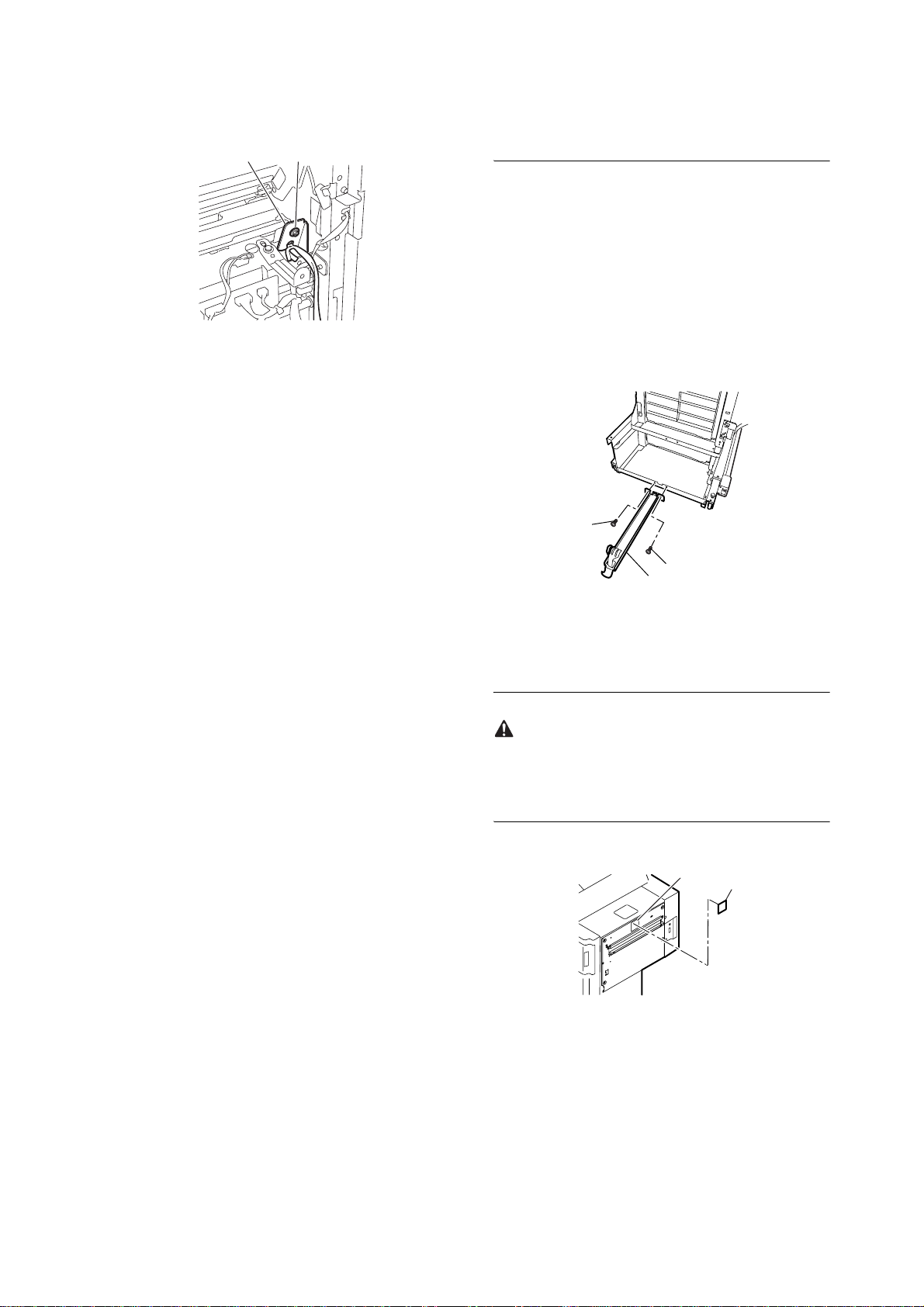

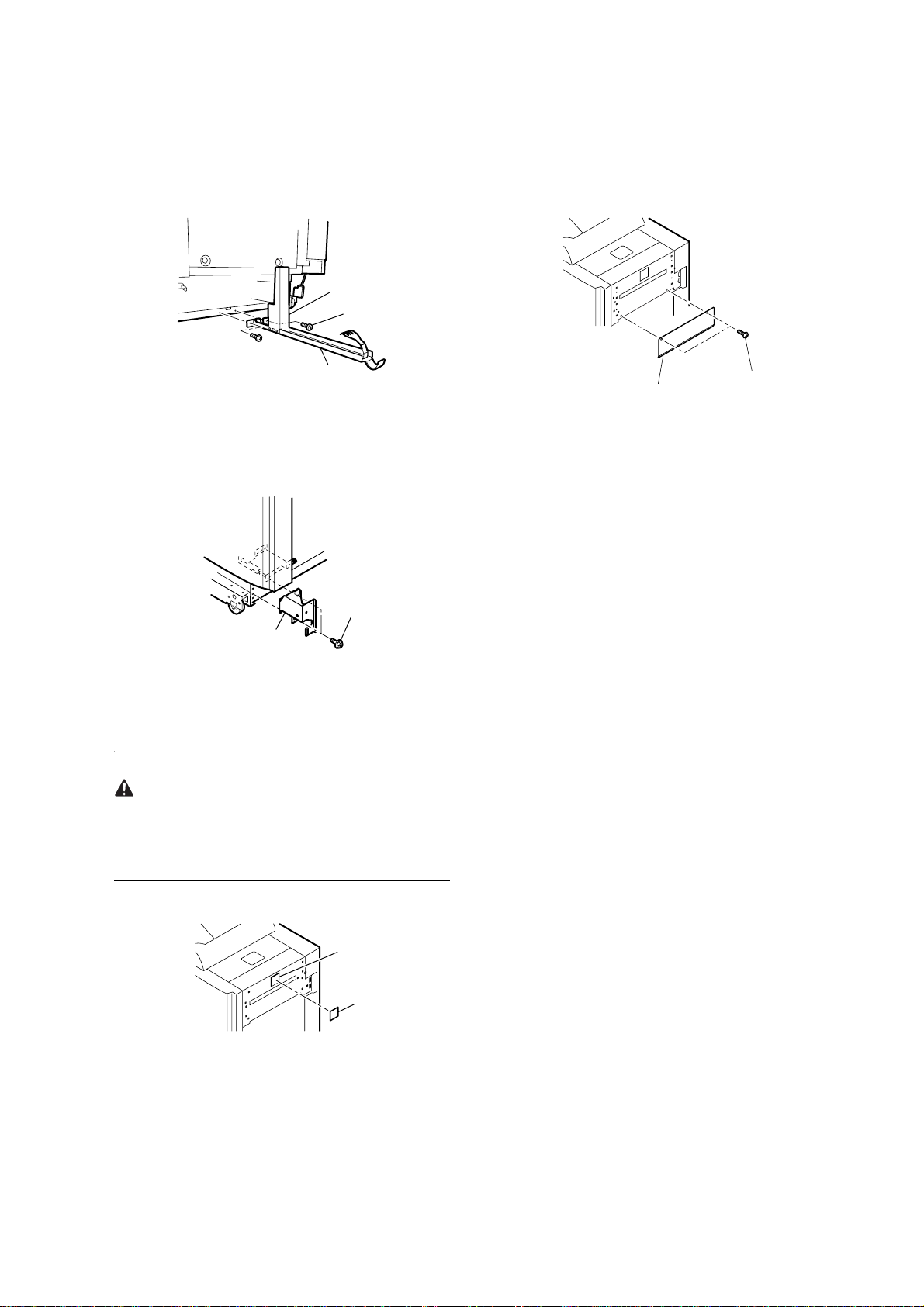

<Finisher-Q1/Q3>

1) Mount the rail [1] to the finisher using 2 screws [2]

(binding; M4X6).

[2]

[2]

[1]

F-1-22

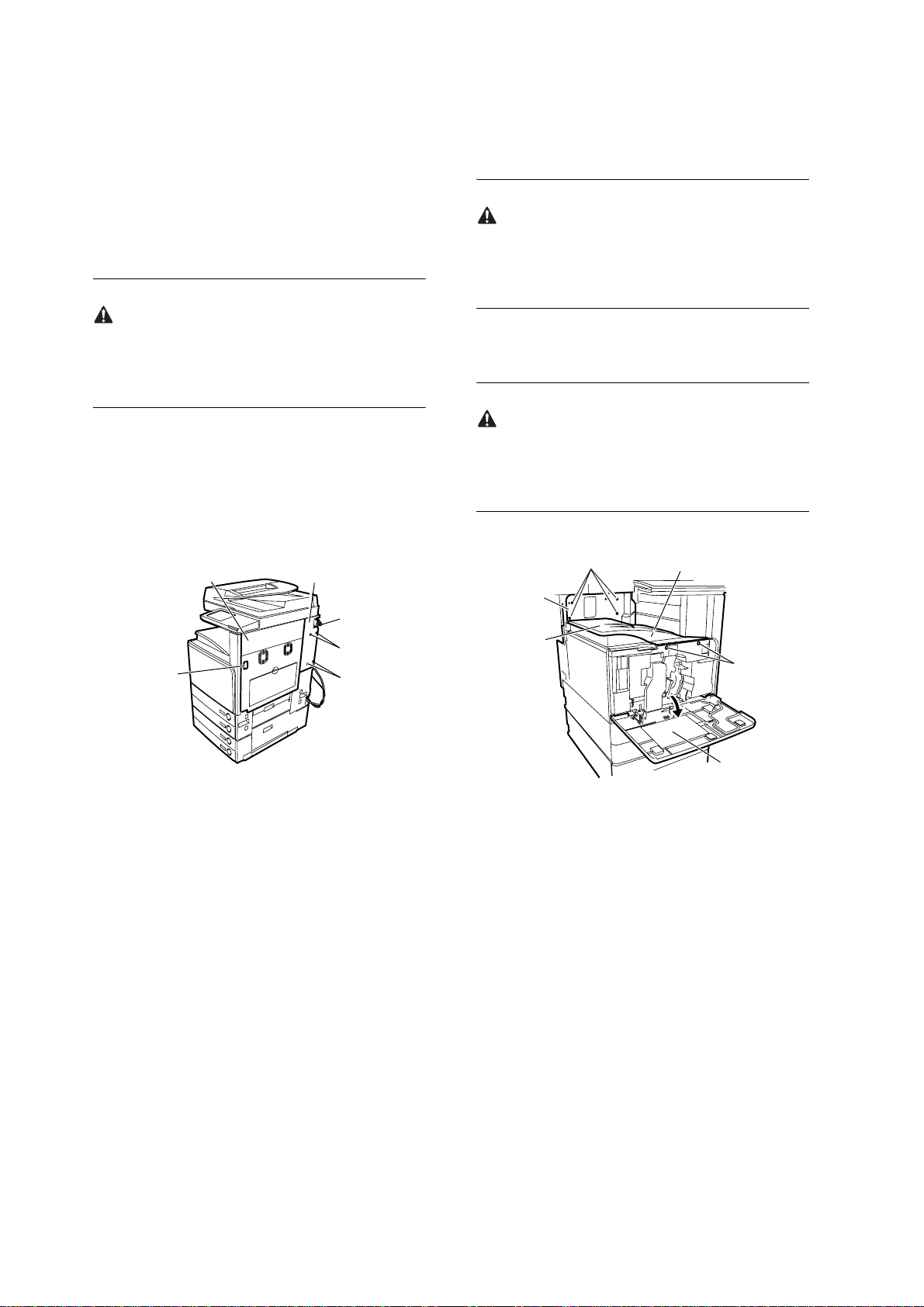

2) Attach the included rubber sheet [1] to the Buffer

Pass Unit-C1 along the line of reference [2].

If you are installing a puncher unit, do not attach the

rubber sheet; for instructions, see the Puncher Unit In-

stallation Procedure.

[2]

F-1-23

[1]

15

<Saddle Finisher-Q2/Q4>

1) Mounting the rail [1] to the finisher using 2 screws

[2] (binding; M4X6).

[2]

[1]

F-1-24

2) Mount the lower front extension stay [1] using 2

screws [2] (RS tightening; M3X8).

1.3.2 Preparing for the

Installation of the Fin-

isher (iR4570/3570series,

2870/2270series)

<Finisher-Q3>

1) Mount the rail [1] to the finisher using 2 screws [2]

(binding; M4X6).

[2]

[2]

[1]

F-1-27

[2]

[1]

F-1-25

3) Attach the included rubber sheet [1] to the Buffer

Pass Unit-C1 along the line of reference [2].

If you are mounting the puncher unit, do not attach the

rubber sheet; for instructions, see the Puncher Unit In-

stallation Procedure.

[2]

[1]

F-1-26

2) Attach the included rubber sheet [1] to the Buffer

Pass Unit-E1 along the line of reference [2].

If you are installing a puncher unit, do not attach the

rubber sheet; for instructions, see the Puncher Unit In-

stallation Procedure.

[2]

[1]

F-1-28

16

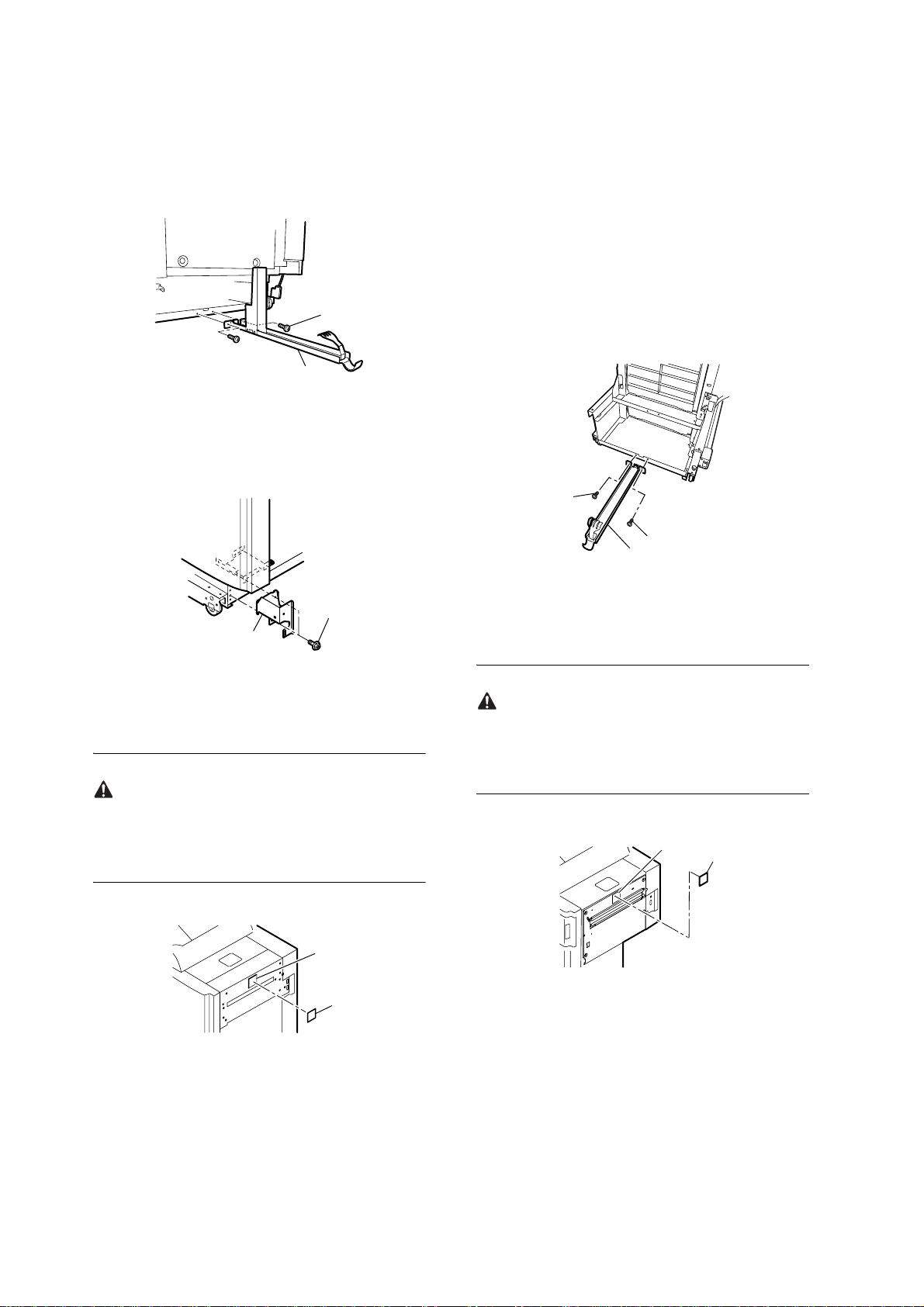

<Saddle Finisher-Q4>

1) Mounting the rail [1] to the finisher using 2 screws

[2] (binding; M4X6).

[3]

[2]

4) Mount the face plate [1] (included with the Buffer

Path Unit-E1) using the screw (binding, M4X6) [2]

that comes with the Buffer Unit-E1

[1]

F-1-29

2) Mount the lower front extension stay [1] using 2

screws [2] (RS tightening; M3X8).

[2]

[1]

F-1-30

3) Attach the included rubber sheet [1] to the Buffer

Pass Unit-E1 along the line of reference [2].

If you are mounting the puncher unit, do not attach the

rubber sheet; for instructions, see the Puncher Unit In-

stallation Procedure.

[1]

[2]

F-1-32

F-1-31

[2]

[1]

17

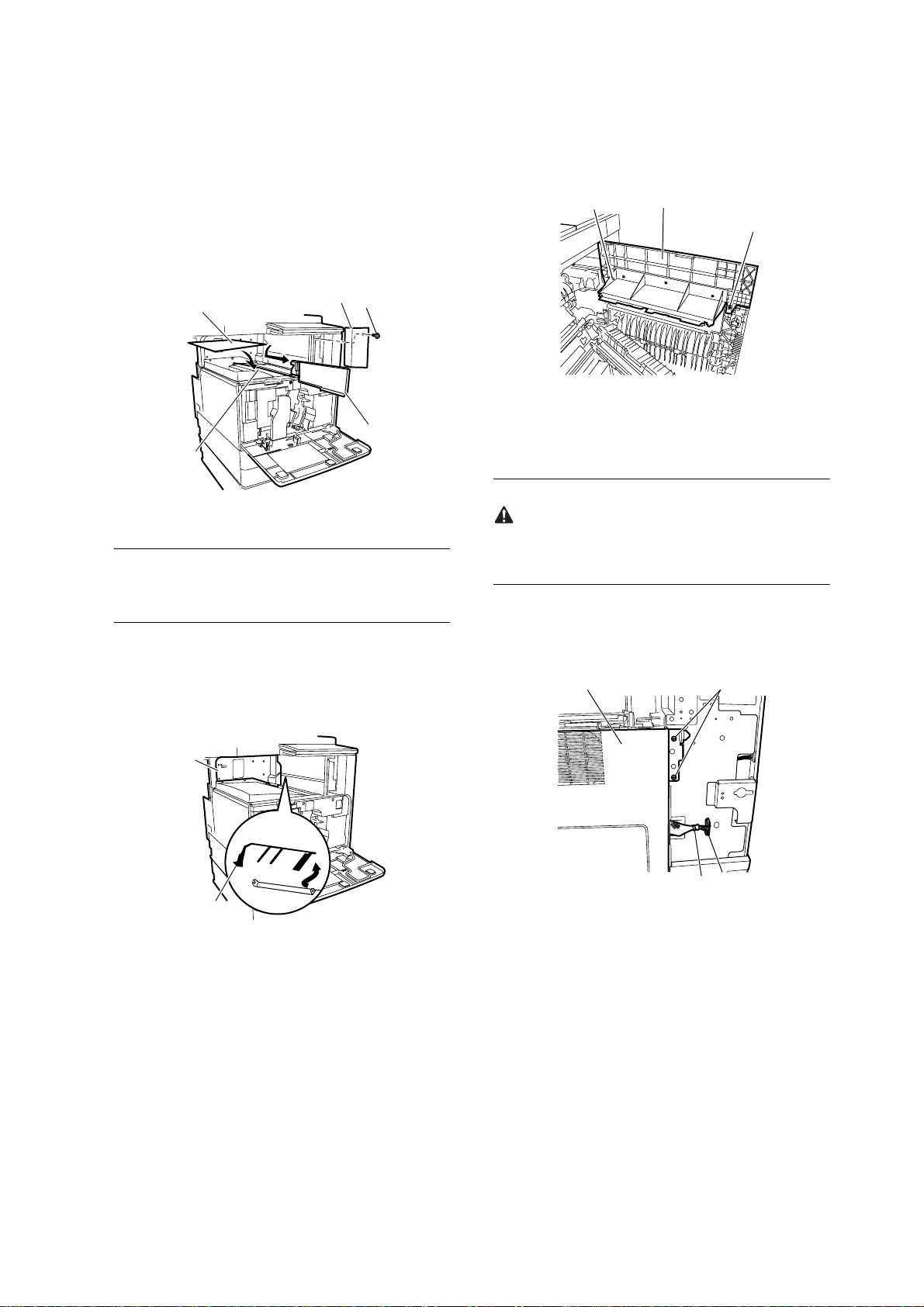

1.3.3 Installing the Relay

Delivery Unit and the

Buffer Pass Unit (iR

3) Remove the 4 screws [2] of the inside rear cover

[1].

C3100Series)

Before connecting the finisher to its host machine, be

sure to install the relay delivery unit and the buffer

pass unit.

1) Disconnect the reader power cables [1]; then, re-

move the 4 screws [2], and detach the rear right

cover [3].

2) Push the open/close button [4], and open the right

door [5].

[5]

[4]

[3]

[1]

[2]

[2]

The reason to remove these 4 screws at this time is that

the delivery tray receives the screws if they are

dropped by accident at the time of removing.

4) Open the front cover [3]; then, loosen the 2 screws

[4], and detach the delivery tray [5].

When detaching the delivery tray, be sure to take full

care not to damage the intermediate transfer belt (ITB)

[6] found at the bottom.

[2]

[1]

[5]

[6]

[4]

F-1-33

[3]

F-1-34

18

5) Place paper (single A3 sheet) [2] on the ITB [1] to

protect against damage.

6) Remove the screw [3], and detach the support cover

[4].

7) Detach the inside right cover [5] by shifting it to the

left.

[4]

[2]

[3]

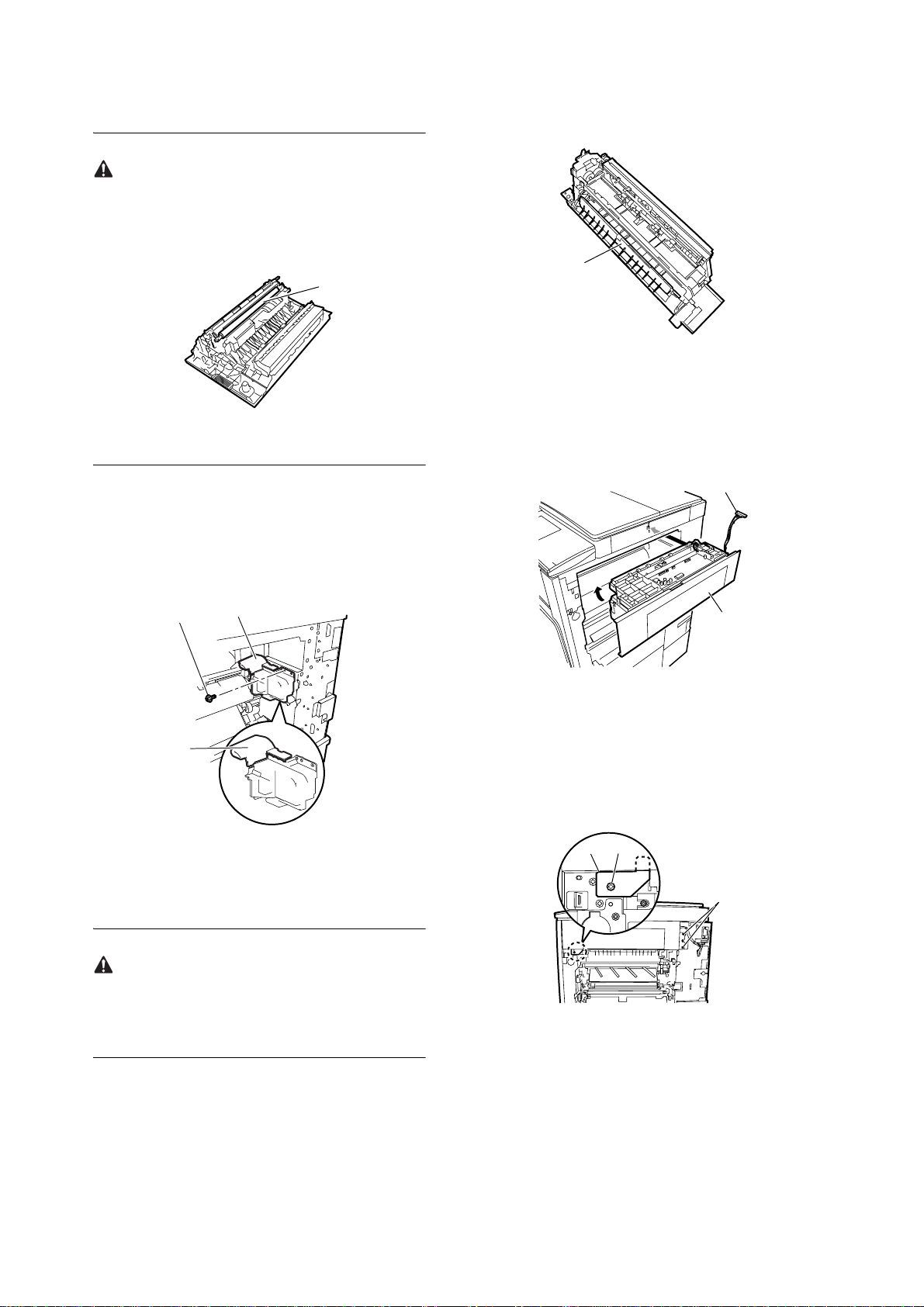

12) Remove the 2 screws [1], and detach the right cov-

er [2].

[1]

[2]

[1]

F-1-37

[5]

[1]

F-1-35

MEMO:

The detached inside right cover will no longer be used.

8) Detach the inside rear cover [1].

9) Remove the paper full sensor flag [2] for the deliv-

ery tray 1, and mount the rear internal cover [1].

[1]

13) Remove the reusable band [1], and disconnect the

connector [2].

Do not cut the reusable band; rather, pick its connector

to detach.

14) Remove the 2 screws [3], and lift the right door [4]

to detach.

[4]

[3]

[2]

F-1-36

10) Remove the paper used to protect the ITB, and

mount the support cover using a screw.

11) Mount the delivery tray, and tighten the 2 screws;

then, close the front cover.

19

F-1-38

[1]

[2]

When detaching the right door, take full care not to

touch the secondary transfer outside roller [1], which

will come off with the door.

[1]

F-1-39

[1]

F-1-41

18) Route the connector cable [1] to the right side, and

mount the relay delivery unit [2] to the machine. To

do so, fit its claw at the rear into the slit.

15) Remove the screw [1], and detach the fixing con-

nector cover [2].

16) Cut the face cover [3] with nippers, and put the

fixing connector cover back to its initial position.

[1]

[3]

[2]

F-1-40

17) Remove all the packing tapes and the cushioning

materials from the relay delivery unit.

[1]

[2]

F-1-42

19) Temporarily tighten the 2 screws [1](RS tighten-

ing: M3X8).

20) Remove the screw [2], and detach the fixing plate

[3].

[3] [2]

[1]

When handling the relay delivery unit, be sure to take

care not to damage the No. 1 delivery flapper [1]

found at the bottom.

F-1-43

20

21) Open the door of the relay delivery unit [1], and fix

it in place using 2 screws [2] (RS tightening:

M3X8).

22) Tighten the 2 screws [3] that you have previously

tightened temporarily.

When tightening the screws, make sure that the fixing

plate is not placed over the boss.

23) Close the door of the relay delivery unit, and con-

nect the connector [5] of the cable [4] to the ma-

chine. Be sure to lead the cable through the cable

clamp [6], and fix it in place using the 2 reusable

bands [7].

[7]

[2]

[1]

[3]

[5]

24) Match the hinge hole [2] of the right door against

the protrusion [1] of the connecting assembly of the

machine; then, fit the right door, and fix it in place

using 2 screws.

Do not close the right door without fixing it in place.

Moreover, when mounting it, take full care not to

break the high-voltage contact [3] for the secondary

transfer outside roller.

[3]

[2]

F-1-44

[4] [6]

[1]

F-1-45

25) Put back the reusable band and the connector re-

moved in step 13).

26) Open the relay delivery unit [1], and lift it to match

the right door [2]; then, fit the joint shaft [3] through

the top hole [4] until it stops.

[4]

[1]

[2]

[3]

F-1-46

21

27) Remove the screw [1], and match the joint plate

[2] against the slit [3]; then, fix it in place using a

screw [1].

Be sure to fit the joint plate correctly in the slit of the

relay delivery unit.

32) Free the claw using a flat-blade screwdriver, and

detach the face cover [2] of the delivery tray and the

face cover [1] of the inside rear cover.

[1]

[3]

[2]

[1]

F-1-47

28) Close the right door.

29) Mount the rear right door using 4 screws.

30) Connect the reader power cable.

31) Mount the protective cover [1] using a screw [2];

(tapping; M4X12).

[1] [2]

[2]

F-1-49

33) Remove all packing tape of the buffer pass unit.

34) Place the buffer pass unit on the delivery tray, and

connect the connector [1] to the machine.

35) Mach the claw of the buffer pass unit against the

connecting assembly [2], and fix it in place using 2

screws [3] (tapping; M4X12).

[1]

[3]

F-1-48

[2]

F-1-50

22

1.3.4 Mounting the Buffer

Path Unit (iR4570/

3570series, 2870/

2270series)

3) Remove all packing tape of the buffer pass unit.

4) Place the buffer pass unit on the delivery tray, and

connect the connector [1] to the machine.

5) Mach the claw of the buffer pass unit against the

connecting assembly [2], and fix it in place using 2

screws [3] (tapping; M4X12).

1) Free the claw using a flat-blade screwdriver, and de-

tach the face cover [2] of the delivery tray and the

face cover [1] of the inside rear cover.

[1]

[2]

F-1-51

2) Remove the paper full sensor flag [1] for the deliv-

ery tray 1.

[1]

[3]

[2]

F-1-53

Do not remove the delivery tray 2 paper full sensor flag

[2].

[2]

[1]

F-1-52

23

Loading...

Loading...