Canon iRC2570, iRC3170, iRC3100 General Timing Chart, General Circuit Diagram

General Timing Chart / General

Circuit Diagram

iR C3100 Series

Jul 20 2005

IMPORTANT

This documentation is published by Canon Inc., Japan, to serve as a source of reference for

work in the field.

Specifications and other information contained herein may vary slightly from actual machine

values or those found in advertising and other printed matter.

Any questions regarding the information contained herein should be directed to the Copier Service

Department of the Sales Company.

This documentation is intended for all sales areas, and may contain information not applicable

to certain areas.

Reproduction without permission not allowed.

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Contents

1 General Timing Chart ............................................................................................................................. 1

Full Color ............................................................................................................................................... 1

Mono color............................................................................................................................................. 3

2 General Circuit Diagram......................................................................................................................... 5

Signal Names ........................................................................................................................................ 5

General Circuit Diagram........................................................................................................................ 9

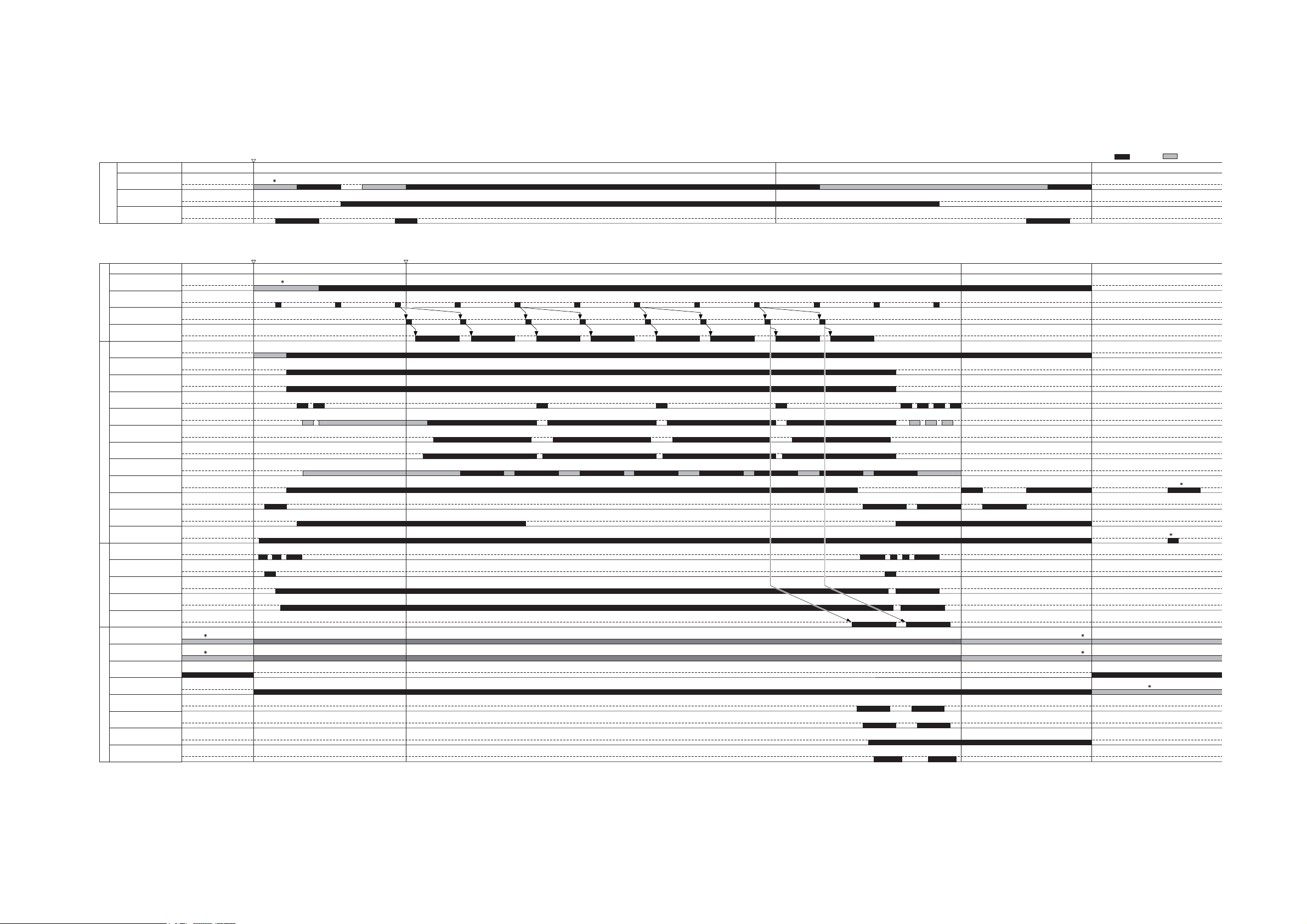

1 General Timing Chart

Full Color

iR C3100 / / / iR C3100N / / / / iR C2570 / / iR C3170 / / iR C3170i / iR C2570i

<Conditions>

reading: book mode, 1 A4 original

printing: plain paper, cassette 1, A4 single-sided, 1

Start key ON

Reader motor

(M501)

1

Scanning lamp

CIS transparency

Original exposure

system

sensor (PS501)

Image formation

enable timing

Printer unit

Laser scanner

motor (M1)

Start key ON

PINTR

1

ITB HP signal

PVREQ signal

Laser

Laser exposure system

Drum/ITB motor

(M9)

Primary charging

bias (DC)

Primary charging

bias (AC)

Developing rotary

motor (M8)

Developing bias

(DC)

Developing bias

(AC)

Developing cylinder

clutch (CL3)

Primary transfer

Image formation system

bias

Secondary transfer outside

roller swing clutch (CL9)

Secondary transfer

bias

ITB cleaning

clutch (CL8)

Main motor

(M2)

Cassette 1 pickup

motor (M6)

Cassette 1 pickup

solenoid (SL1)

Cassette 1 retry

sensor (PS10)

Registration

sensor (PS9)

Pickup/feed system

Registration

clutch (CL2)

Fixing main

heater (H1)

Fixing sub

heater (H2)

Fixing heat retention

heater (H3)

Fixing motor

(M11)

Fixing inlet

sensor (PS35)

Fixing outlet

Fixing system

sensor (PS13)

Delivery

motor 1 (M4)

Delivery sensor

(PS14)

*1: used to stabilization the rotation.

*2: moves the secondary transfer outside roller away from the ITB about 30 sec after the start of standby.

*3: executes temperature control (to 190 deg C) using the main heater or

the sub heater to suit the readings of the main thermistor (TH1) and the sub thermistor (TH2).

*4: causes the fixing roller to rotate idly according to the printing time.

(if 1 to 3 min, idle rotation for 30 sec; 3 min or more, idle rotation for 75 sec)

3

3

PRINT

Y1 Y2 M1 M2 C1 C2 Bk1 Bk2

F-1-1

LSTR

: forward

3

3

: reverse

STBYSTBY SCFW SCRW

PSTBYPSTBY

2

2

4

1

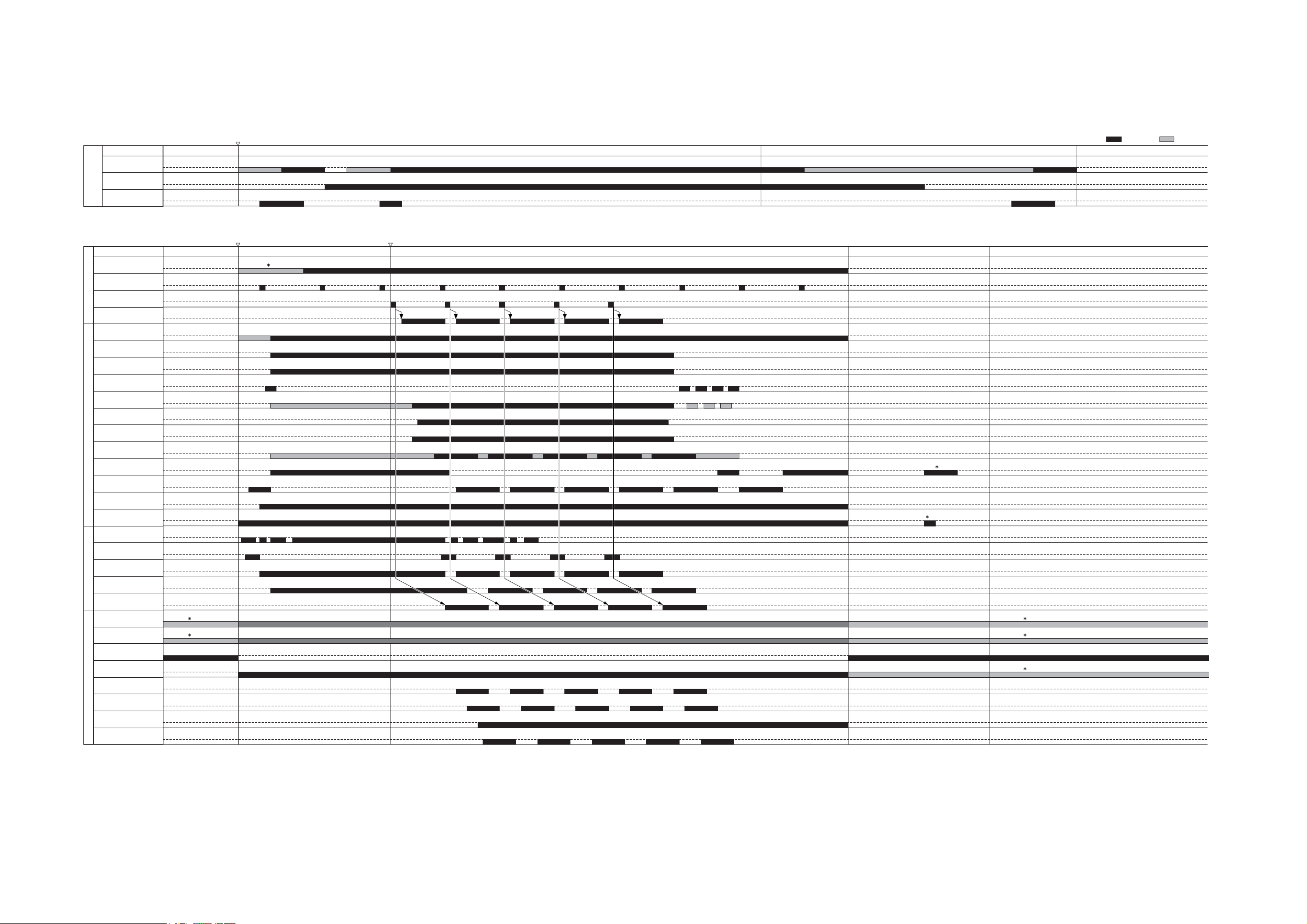

Mono color

iR C3100 / / / iR C3100N / / / / iR C2570 / / iR C3170 / / iR C3170i / iR C2570i

<Conditions>

reading: book mode, 1 A4 original

printing: plain paper, cassette 1, A4 single-sided, 5

Start key ON

Reader motor

(M501)

Scanning lamp

CIS transparency

sensor (PS501)

Original exposure

system

STBY

: forward

STBYSCFW SCRW

: reverse

Image formation

enable timing

Printer unit

Laser scanner

motor (M1)

Start key ON

PSTBY

1

ITB HP signal

PVREQ signal

Laser

Laser exposure system

Drum/ITB motor

(M9)

Primary charging

bias (DC)

Primary charging

bias (AC)

Developing rotary

motor (M8)

Developing bias

(DC)

Developing bias

(AC)

Developing cylinder

clutch (CL3)

Primary transfer

Image formation system

bias

Secondary transfer outside

roller swing clutch (CL9)

Secondary

transfer bias

ITB cleaning

clutch (CL8)

Main motor (M2)

Cassette 1 pickup

motor (M6)

Cassette 1 pickup

solenoid (SL1)

Cassette 1 retry

sensor(PS10)

Registration

sensor (PS9)

Registration

Pickup/feed system

clutch (CL2)

Fixing main

heater (H1)

Fixing sub

heater (H2)

Fixing heat retention

heater (H3)

Fixing motor

(M11)

Fixing inlet

sensor (PS35)

Fixing system

Fixing outlet

sensor (PS13)

Delivery

motor 1 (M4)

Delivery sensor

(PS14)

3

3

*1: used to stabilization the rotation.

*2: moves the secondary transfer outside roller away from the ITB about 30 sec after the start of standby.

*3: executes temperature control (to 190 deg C) using the main heater or the sub heater

to suit the readings of the main thermistor (TH1) and the sub thermistor (TH2).

*4: causes the fixing roller to rotate idly according to the printing time. (if 1 to 3 min,

idle rotation for 30 sec; 3 min or more, idle rotation for 75 sec)

PRINT

F-1-2

LSTR

PSTBYPINTR

2

2

3

3

4

2

345

Loading...

Loading...