Canon iR5800C, iR5800CN, iRC6800C, iRC6800CN color network printer unit-d1-sg

CANON IMAGEPASS-D1/

COLOR NETWORK PRINTER UNIT-D1

SERVICE GUIDE

Part Number: 45039028

16 April 2004

3

5

10

26

28

29

Contents

Overview

Scope of this guide 1

About the illustrations in this guide 1

Terminology and conventions 2

Tools you will need 2

Precautions

Accessing the imagePASS-D1

Checking connections

External connections 5

Internal connections 6

Power scheme 9

Replacing the imagePASS-D1 motherboard

Replacing imagePASS-D1 components

DIMM 16

BIOS chip 17

Battery 18

CPU cooling assembly 19

Enclosed fans 20

Power supply 20

PCC board 22

Hard disk drive 23

Restoring functionality after service

Printing imagePASS-D1 pages

Printing the Configuration page 27

Printing the Test Page 27

Verifying connection to the network

Verifying the parallel port connection

System software

System software installation reminders 31

Installing system software over the parallel port 32

Specifications

Hardware features 39

Networking and connectivity 39

User software 39

Safety and emissions compliance 39

15

26

31

39

1

5

Contents

Troubleshooting

Where problems occur 41

Before you go to the customer site 42

Preliminary on-site checkout 43

Checking connections 43

Checking the network 44

Error messages and conditions 44

Printing to the imagePASS-D1 49

Normal startup sequence

40

51

Index

6

Overview

Overview

The imagePASS-D1 Print Server adds computer connectivity and highly efficient

PostScript and PCL printing capacity into print engines and provides support for PCL.

Generally, the imagePASS-D1 does not require regular maintenance. The

imagePASS-D1 is shipped with all necessary software already installed.

Use the procedures in this book to inspect, remove, reseat, or replace major hardware

components and to reinstall system software. Replacement parts for the imagePASS-D1

are available from your authorized service support center. You need to reinstall system

software if you replace the hard disk drive or receive a more recent version of the system

software. You may also reinstall system software as a way to troubleshoot the system.

Scope of this guide

This service guide describes how to remove or replace major imagePASS-D1 hardware

components and how to reinstall system software. It also includes product specifications

and troubleshooting information. See the Table of Contents for each topic (in bold type)

and each sub topic. Also use the Index to find the location of specific information.

This service guide does not describe in detail how to install the imagePASS-D1 into the

print engine or remove it and does not include information on the imagePASS-D1’s

dedicated power supply, power switch connector, PCC board, or cables that do not

connect to the motherboard. For information on these topics, see the documentation

from the print engine manufacturer.

This service guide is intended for authorized imagePASS-D1 and print engine service

technicians installing or servicing the imagePASS-D1. If you are not an authorized

service technician, you should not attempt to install or service the imagePASS-D1.

Electronics for Imaging does not warrant the performance if the imagePASS-D1 is

installed or serviced by non-authorized personnel.

N

OTE

:

The term “imagePASS-D1” is used in this manual to refer to either the

imagePASS-D1 or the Color Network Printer Unit-D1.

OTE

imagePASS-D1 customers should not use the technical service documentation. Do

N

:

not leave your copy of this service guide at the customer site after you make a service call.

About the illustrations in this guide

The illustrations in this guide reflect the current shipping version of the imagePASS-D1

at the time of publication. Components shown in these illustrations are subject to

change. To receive information about any imagePASS-D1 components that do not

match the illustrations in this guide, contact your authorized service/support center.

1

Overview

Terminology and conventions

The terms “replace” and “replacing” are typically used throughout this manual to mean

reinstallation of existing components. Install new components only when necessary.

The term “ network administrator” refers to the person responsible for maintaining the

network at the customer site.

The term “system software” refers to the software installed on the imagePASS-D1 hard

disk drive.

References to other imagePASS-D1 manuals, such as the Configuration Guide, are

displayed in italics.

N

:

OTE

The note format highlights important messages and additional information.

The Caution icon indicates a need for special care and safety when handling the

equipment.

Tools you will need

To install or service the imagePASS-D1, you should bring the following tools and parts

to the customer site:

• ESD wrist grounding strap and antistatic mat

• #0 and #1 Phillips head screwdrivers (non-magnetic)

You should also bring this guide, documentation for any optional service kits you may be

installing, and any technical notes for the imagePASS-D1.

2

Precautions

Precautions

Always observe the following general precautions when servicing the imagePASS-D1

assembly:

1. Report any shipping damage.

If there is any evidence of shipping or handling damage to packing boxes or their

contents, save the damaged boxes and parts, call the shipper immediately to file a claim,

and notify your authorized service/support center.

2. Never alter an existing network without permission.

The imagePASS-D1 is probably connected to an existing Local Area Network (LAN)

based on Ethernet hardware. The network is the link between the customer’s computer,

existing laser printers, and other prepress equipment. Never disturb the LAN by breaking

or making a network connection, altering termination, installing or removing

networking hardware or software, or shutting down networked devices without the

knowledge and express permission of the network administrator.

3. Never assign an IP address in Network Setup.

Only the network administrator should assign an IP address on a network device.

Entering an incorrect IP address to the imagePASS-D1 can cause unpredictable errors on

any or all devices.

4. Follow standard ESD (electrostatic discharge) precautions while working on the internal

components of the print engine.

Static is always a concern when servicing electronic devices. It is highly unlikely that the

area around the print engine is static-free. Carpeting, leather-soled shoes, synthetic

clothing fibers, silks, and plastics may generate a static charge of more than 10,000 volts.

Static discharge is capable of destroying the circuits etched in silicon microchips, or

dramatically shortening their life span. By observing standard precautions, you may avoid

extra service calls and save the cost of a new board.

When possible, work on a ground-connected antistatic mat. Wear an antistatic

wristband, grounded at the same place as the antistatic mat. If that is not possible:

•Attach a grounding strap to your wrist. Attach the other end to a good ground.

• When you remove an electronic component, place it into an antistatic bag

immediately. Do not walk across a carpet or vinyl floor while carrying an unprotected

board.

• Leave new electronic components inside their antistatic bags until you are ready to

install them.

• When you unpack the electronic components, touch a metal area of the print engine to

discharge the static on your body. Place the components on a grounded antistatic

surface, component-side up.

5. Avoid flexing a printed circuit board, and handle it by opposing edges (not corners) only.

6. Never set a cup of coffee—or any liquid—on or near any components or the print device.

3

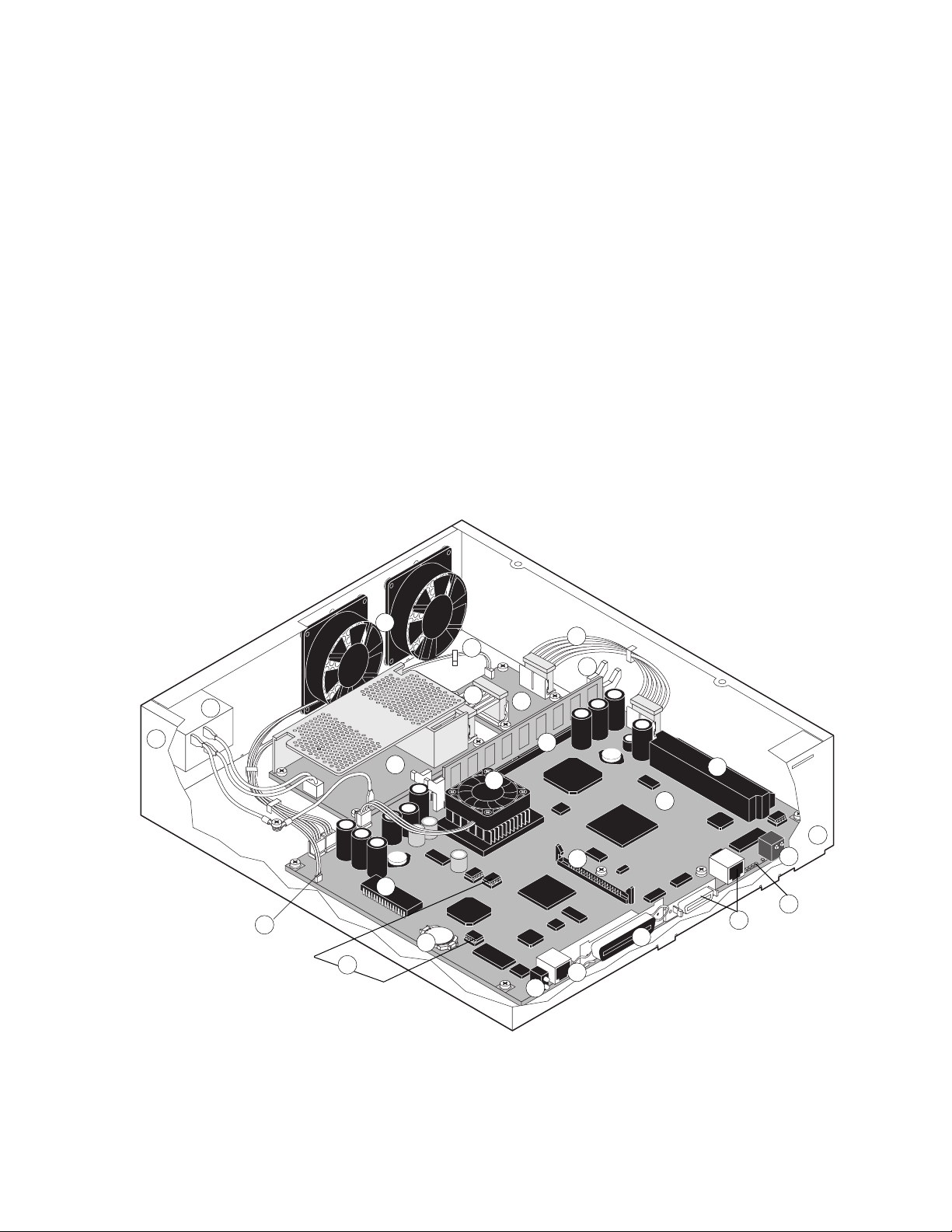

K

Precautions

ey

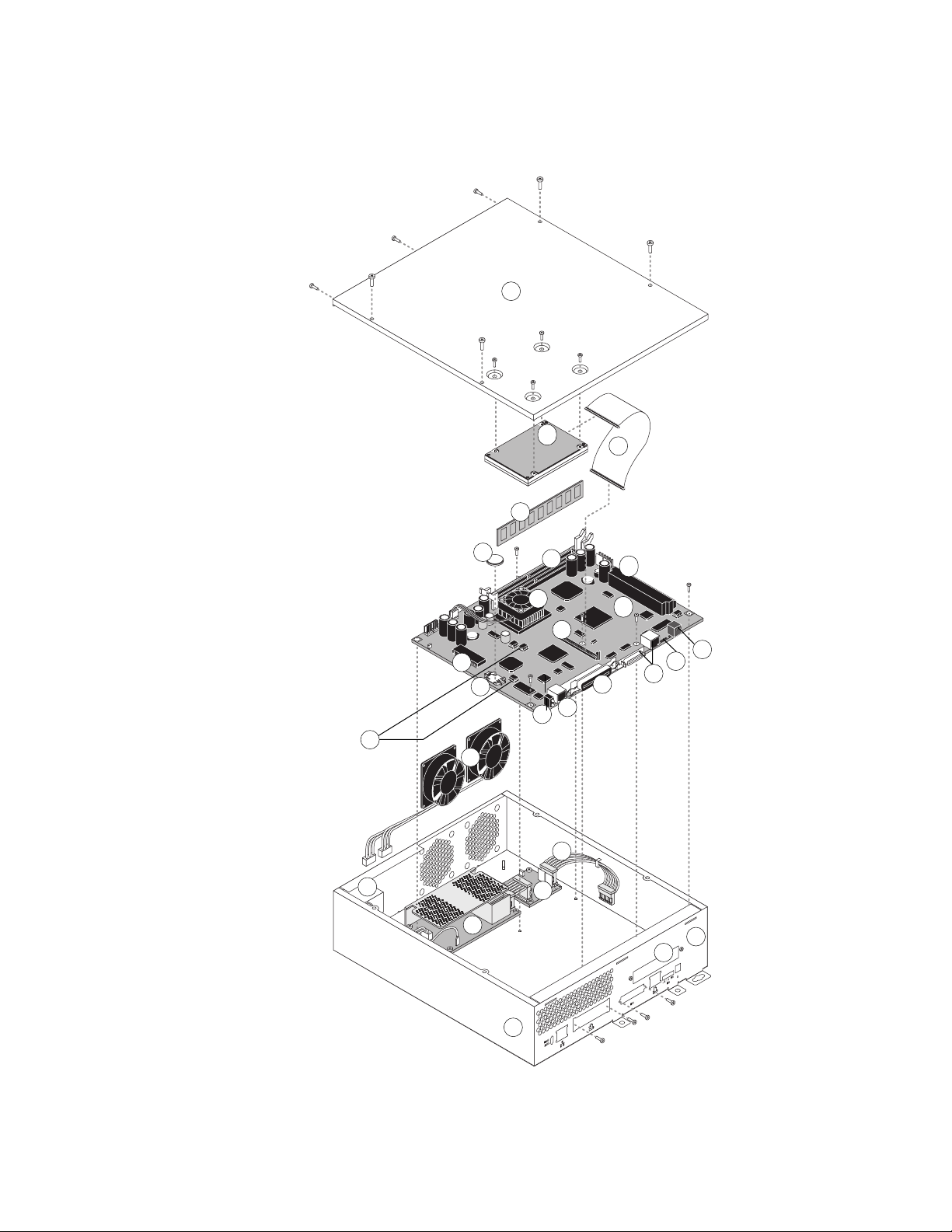

1. Lid

2. HDD

3. HDD cable

4. DIMM

5. Battery

6. DIMM sockets (2)

7. CPU cooling assembly

8. BIOS (U4)

9. Option board connector

10. MAC chip set at U29 and U514

11. Battery socket

12. HDD cable connector

13. imagePASS-D1 motherboard

14. Network LEDs (2)

15. RJ-45 network connector

16. Parallel port connector

17. Print Engine interface

connectors

18. DIAG (4) and PWR (1) LEDs

19. Download (DL) switches (2)

20. Enclosed fans (2)

21. Power switch/connector

22. Power supply

23. Chassis

24. Slot cover for option board

25. Connector panel

26. PCC board

27. Power cable

8

NOTE: For details on power

cabling, see page 9.

10

20

11

1

2

4

5

7

14

6

12

15

16

3

13

9

19

18

17

27

IGURE

F

21

22

imagePASS-D1 exploded view

A

26

25

24

23

4

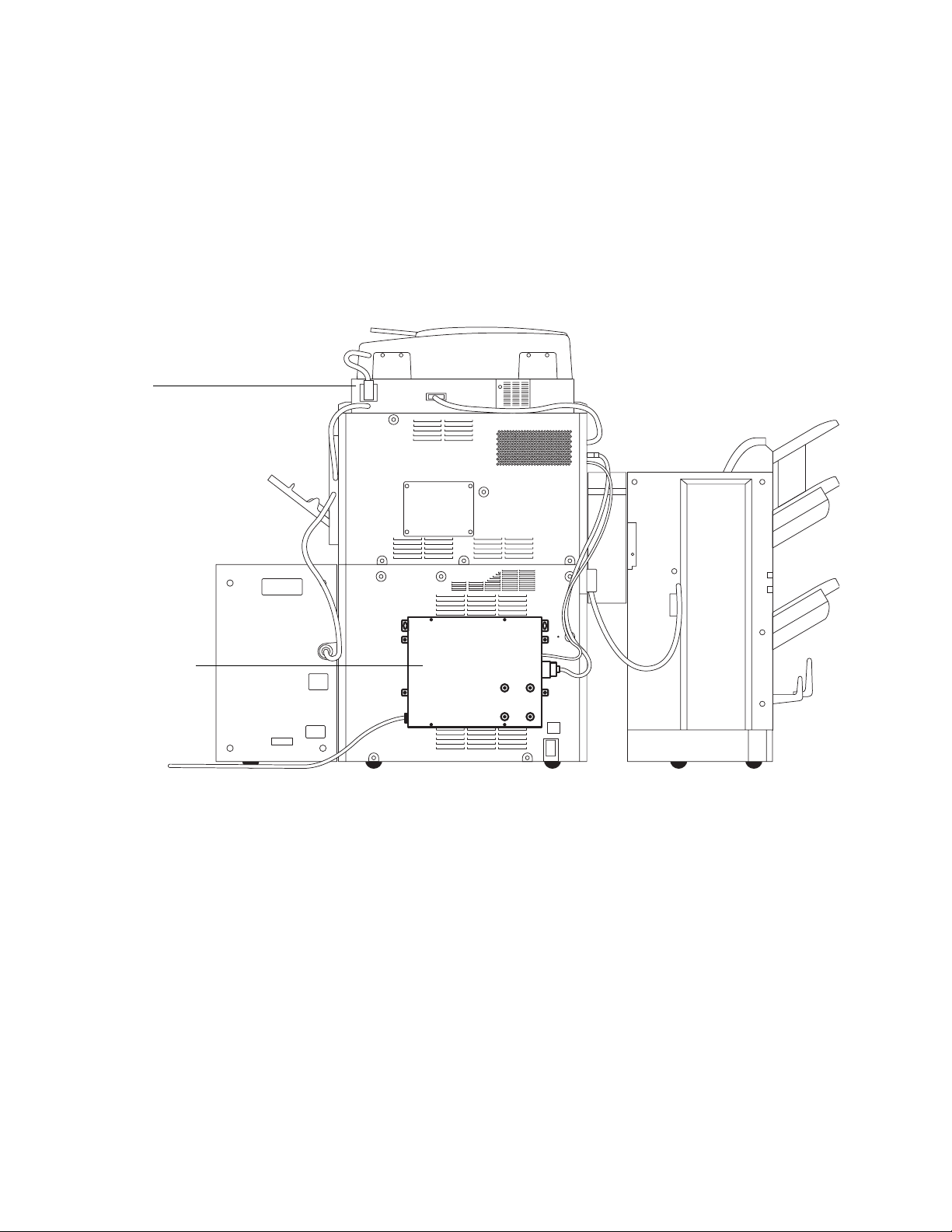

Copier

Accessing the imagePASS-D1

Accessing the imagePASS-D1

To service the imagePASS-D1, you need to power off and unplug the print engine,

remove the imagePASS-D1 from the mounting bracket on the back of the print engine,

and open the lid of the imagePASS-D1. You do not need to remove the mounting

bracket.

OTE

Detailed imagePASS-D1 installation instructions are not provided in this guide.

N

:

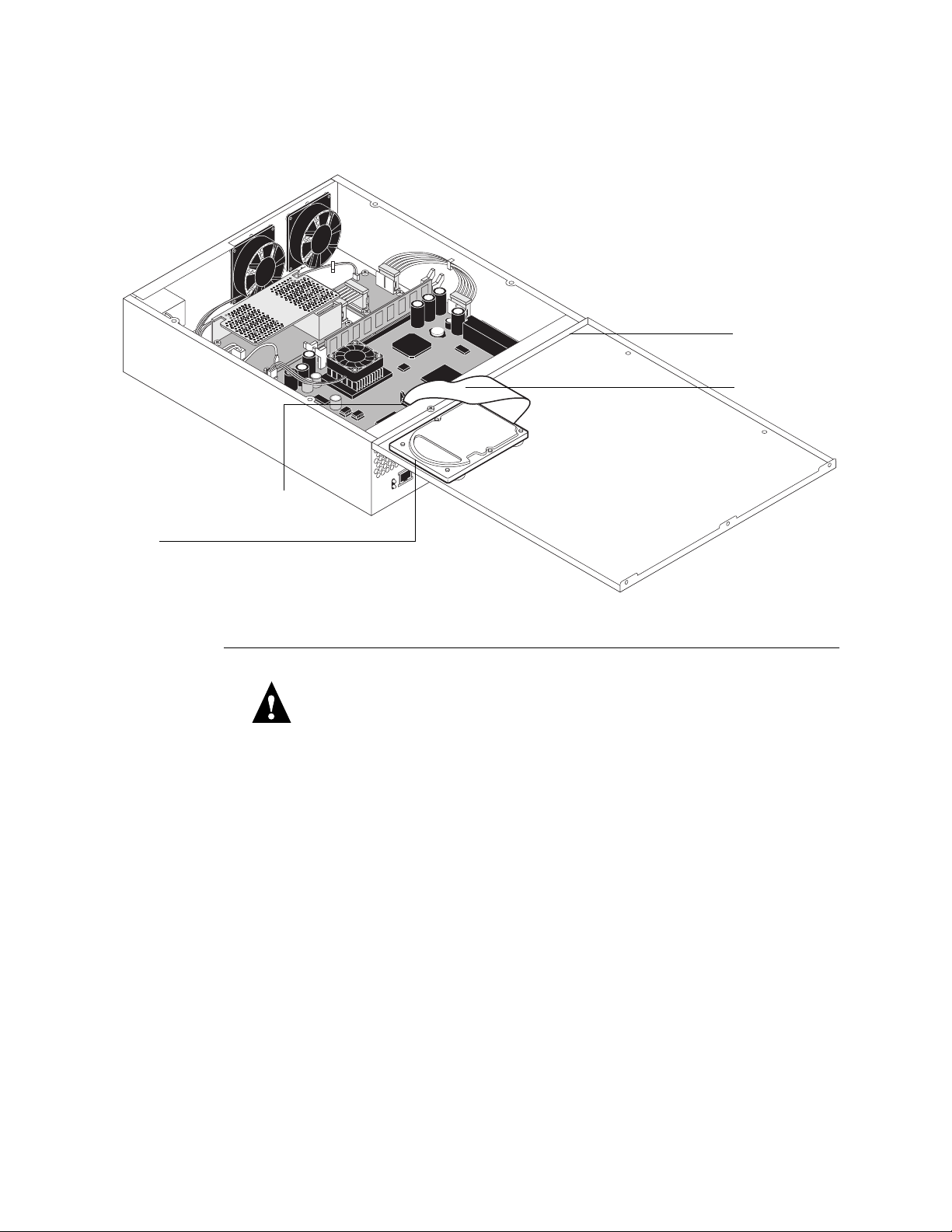

imagePASS-D1

IGURE

F

imagePASS-D1 attached to the print engine

B

Checking connections

The most common causes of hardware problems are faulty or loose connections. Make

sure that imagePASS-D1 cables are intact and that both ends of each cable are properly

aligned and well seated on the appropriate connectors.

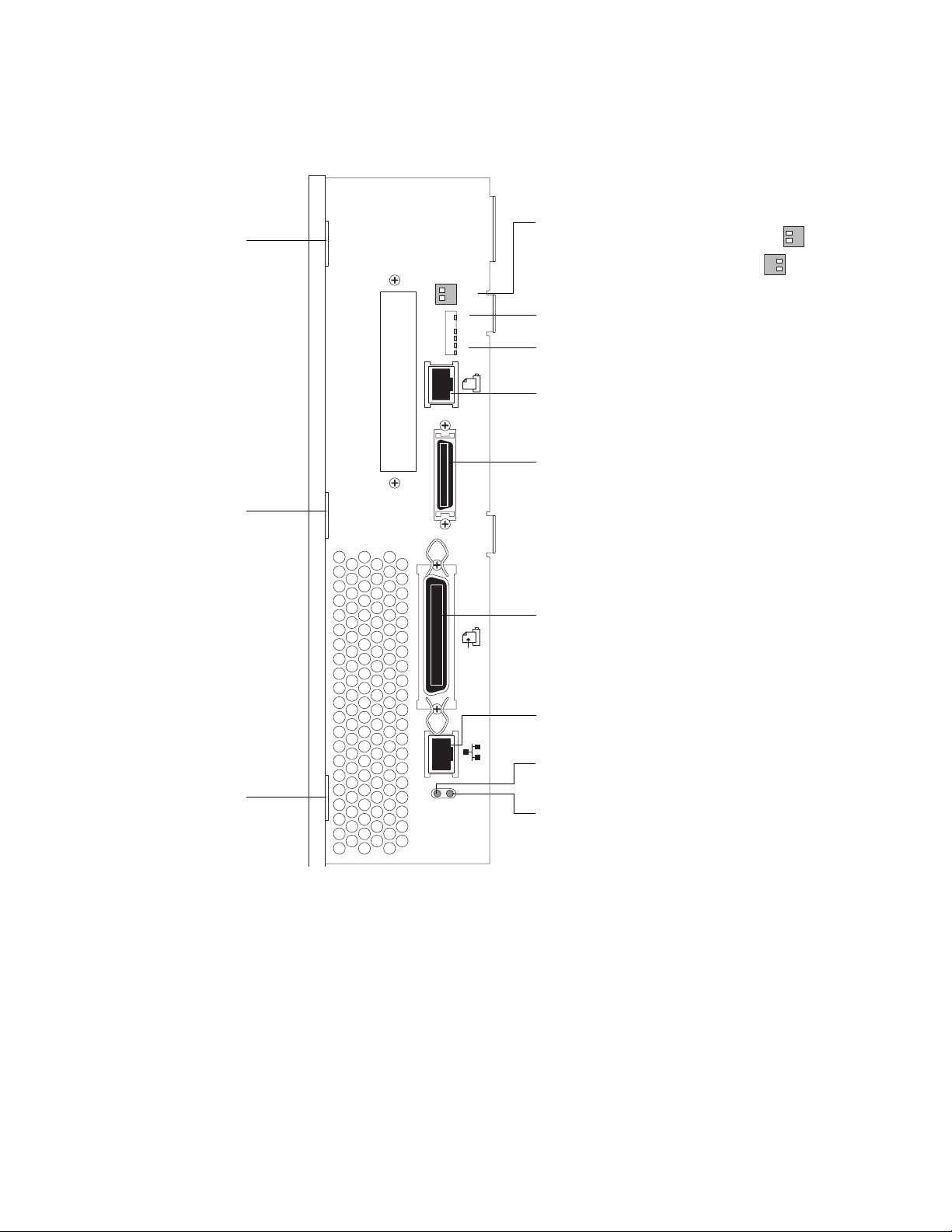

External connections

Connectors for external cables are located on the connector panel and a power cord is

located at the back of the imagePASS-D1. Check the imagePASS-D1 power cord and

then check all external cables at the imagePASS-D1 connector panel (see the following

figure). Also check the positions of the two switches on the connector panel.

5

Checking connections

Tab slot

Tab slot

1 2

3210 PWR

DL

DIAGVIDEO

Download (DL) switches:

Normal position (away from the motherboard):

Service position (toward the motherboard):

Service position disables the parallel port timeout.

PWR LED

DIAG LEDs 3-0

Print Engine interface connector

Print Engine interface connector

Parallel port connector

1 2

DL

1 2

DL

10BaseT/100BaseTX connector for

twisted pair Ethernet

100MHz LED—Network speed

ON = 100BaseTX

Tab slot

IGURE

F

100 MHZ

LINK/COL

imagePASS-D1 connector panel

C

OFF = 10BaseT

LINK/COL LED—Network activity

BLINKING = Active

After you conclude that all external connections are good, check the internal

connections.

Internal connections

Check the internal connections according to the procedure on page 8. See Figure D on

page 7 for locations of most internal connections. For the HDD, see Figure G on

page 13.

6

Checking connections

Key

1. Chassis

2. Power switch connector

3. Enclosed fans

4. Power supply

5. DIMM2 socket (for optional upgrade)

6. DIMM1 socket (for standard DIMM)

7. CPU cooling assembly

8. BIOS (U4)

9. MAC chip set: U29 and U514

10. Battery

11. HDD cable connector

12. imagePASS-D1 motherboard

13. Option board (e.g., Token Ring) connector

14. Network LEDs (2)

15. RJ-45 network connector

16. Parallel port connector

17. Print Engine interface connectors

18. DIAG LEDs

19. Download (DL) switches (2)

20. Connector panel

21. PCC board

22. PCC power cable

23. Power cable

24. PCC cable (motherboard J790 to PCC J3)

25. J790

NOTE: For details on power cabling, see page 9.

3

24

2

1

4

8

25

U514

IGURE

F

9

U29

D

Chassis components

22

10

21

7

14

23

5

6

13

12

20

11

17

16

15

19

18

7

T

O

CHECK

Checking connections

INTERNAL

CONNECTIONS

AUTION

C

Before you touch any parts inside the print engine, make sure to wear an ESD

:

grounding wrist strap.

1. Make sure that any imagePASS-D1 cables, boards, and DIMMs are intact, properly

aligned, and well seated in their connectors (see Figure D on page 7 and Figure E on

page 9).

•Hard disk drive (HDD) and cable

• DIMM

•Enclosed fans and cables (2)

• CPU cooling assembly and fan cable

• Cables connected to the power switch connector, PCC board, and power supply (see

Figure E on page 9):

•Power switch cables (2) to power supply

•Power switch ground cable: Power switch to Frame GND

•Power supply ground cable: Power supply FG to Frame GND

• PCC power cable: power supply CN2 to PCC board J1

•Power cable: PCC board J2 to motherboard J29 POWER

• PCC cable: motherboard J790 PCC to PCC board J3

2. If an option board is present (such as a Token Ring board), check the imagePASS-D1

connector. For more information, see the documentation in the specific option kit.

3. After verifying connections, if one or more imagePASS-D1 components are still not

getting power, check again the two connections between the imagePASS-D1 and the

print engine, and then check the print engine power supply (see print engine

documentation).

8

Checking connections

Power scheme

If the AC power cord is connected both to a proper power outlet and to the

imagePASS-D1, and if the imagePASS-D1 dedicated power switch is the ON position,

then power goes from the dedicated power supply to the PCC board and then to the

motherboard. The system will not start up until the Print Engine is powered on.

When you power on the Print Engine, it sends a signal through the Print Engine

interface cable to the motherboard; the motherboard sends a signal through the PCC

cable to the PCC board; the PCC board supplies power to the motherboard through the

power cable; the system starts up.

to motherboard J790 and

PCC cable

to PCC board J3

Power switch/AC power cord

connector (cable not shown)

Power switch cables

Power switch GND cable

PCC board GND cable to FG

J790 PCC connector

PCC power cable:

to power supply CN2 and

to PCC board J1

Power cable: to PCC board J2

and to motherboard J29

J29 POWER

connector

Print Engine

interface connector

(cable not shown)

F

IGURE

E

Power cabling

J3

J2

J1

CN2

PCC

Power Supply

Motherboard

Power on

In normal usage, the customer can leave the imagePASS-D1 plugged in and with the

dedicated power switch in the ON position so that the imagePASS-D1 powers off and on

by means of the print engine power switch.

Before you perform service on the imagePASS-D1 hardware, however, make sure to

power off the imagePASS-D1 using both the imagePASS-D1 power switch and the print

engine power switch according to the procedure page 10. After service, remember to

return the imagePASS-D1 dedicated power switch to the ON position according to the

procedure on page 26.

9

Replacing the imagePASS-D1 motherboard

Replacing the imagePASS-D1 motherboard

When the imagePASS-D1 motherboard needs to be replaced, use the following

procedures.

T

O

SHUT

DOWN

THE

IMAGE

PASS-D1

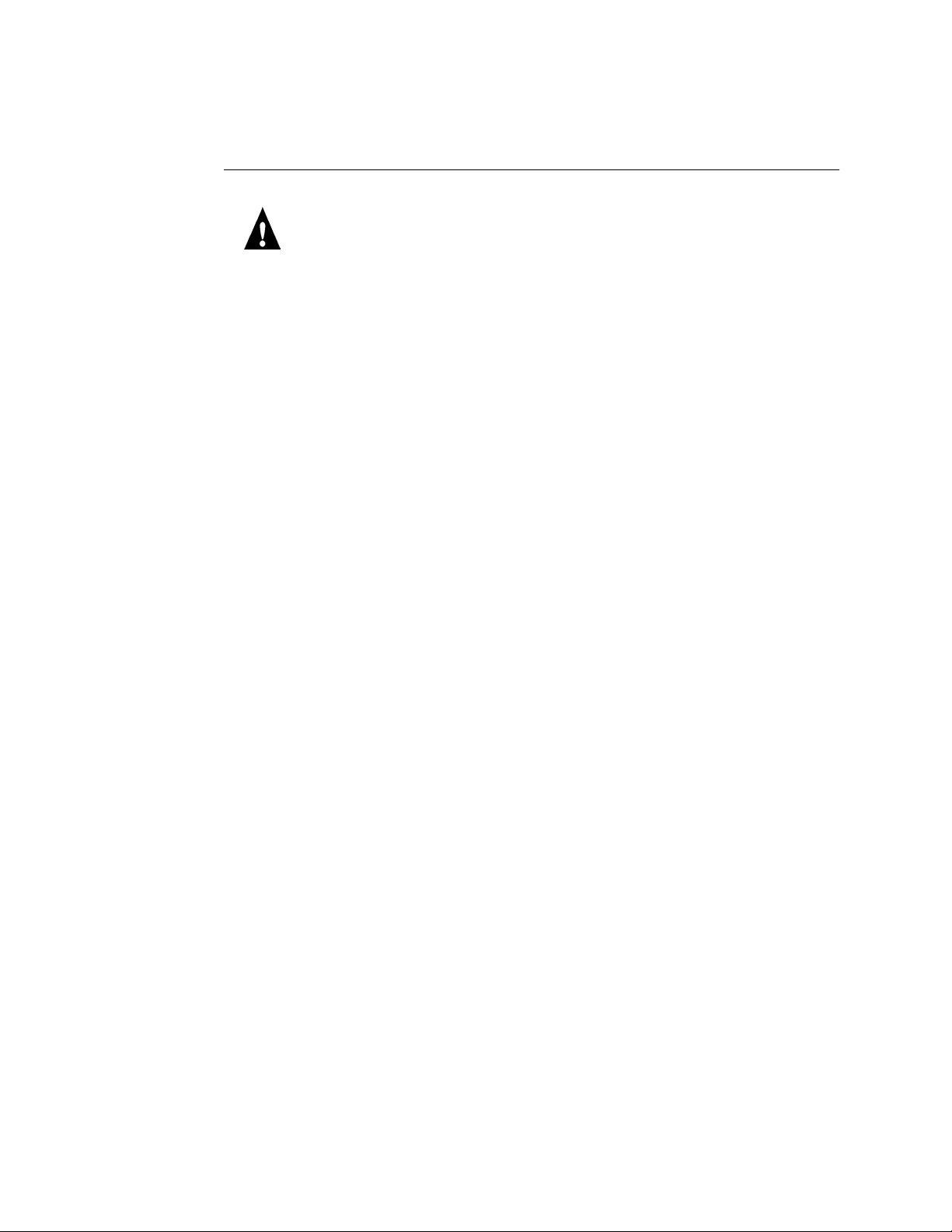

1. If the print engine is in its main mode, select the Printer tab on the Control Panel LCD

and then select Printer Status/Setting.

Depending on the number of feature tabs, you may need to press the arrow key to display

the screen with the Printer tab.

FROM

THE

C

ONTROL

P

ANEL

LCD

Printer tab

Idle appears on the

Control Panel LCD

Printer

Printer Status/

Settings

Online...Scanner

System Monitor

Printer Status/

Settings

2. Make sure that the imagePASS-D1 is idle (not processing) and select Functions from the

info screen.

Info

Indus

Idle

x.xx

10

7744MB

FunctionsDone

Functions

System Monitor

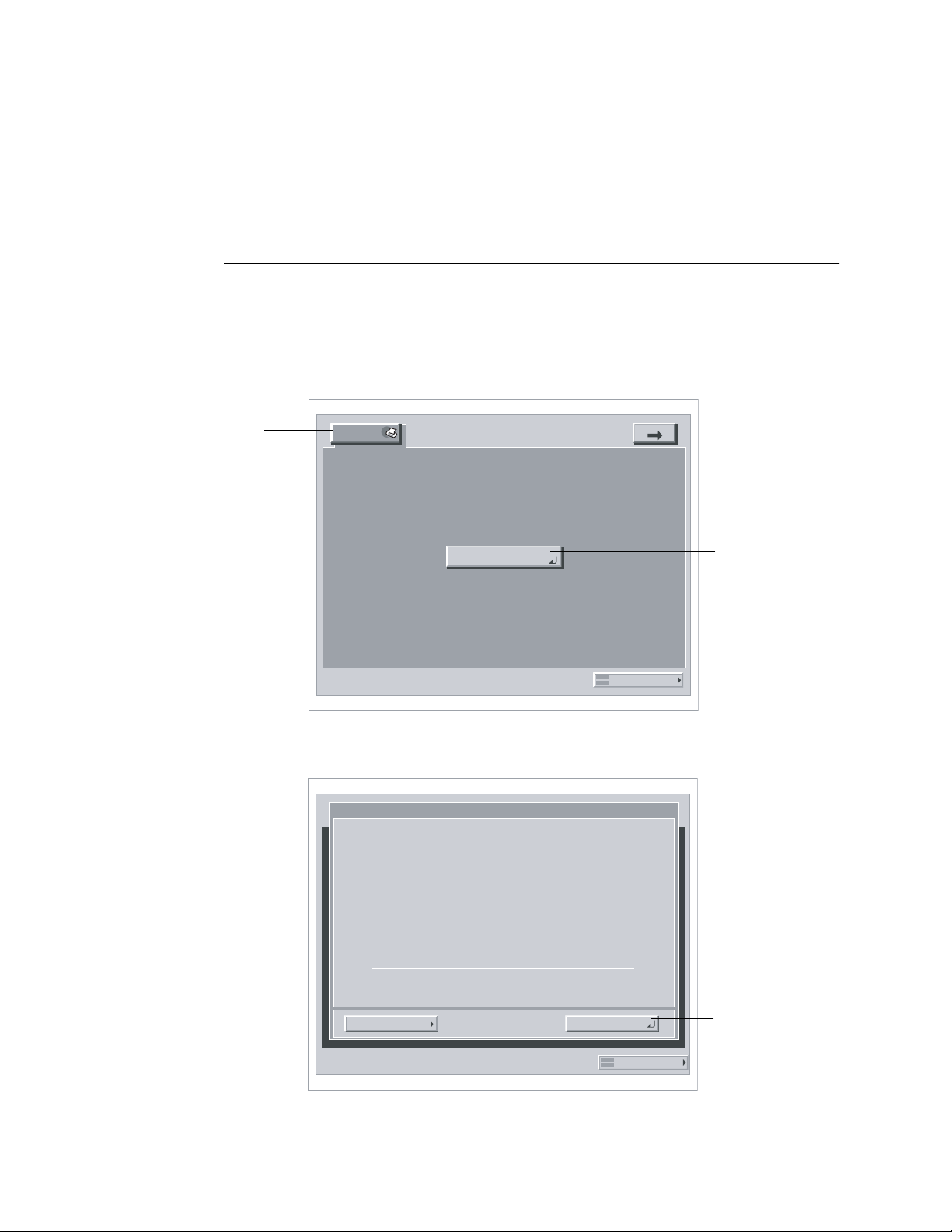

Replacing the imagePASS-D1 motherboard

3. Select Shut Down from the Functions screen.

Functions

Print Pages

Scan Job

Suspend Printing

Resume Printing

Shut Down

1/2

DONE

4. Select Shut Down System from the Shut Down screen.

Shut Down

Restart System

Shut Down System

Reboot System

1/1

DONE

Shut Down

System Monitor

Shut Down System

System Monitor

5. After a message is displayed that it is safe to power off the system, power off the

imagePASS-D1 using its dedicated power switch.

N

OTE

:

If you are recycling power, wait at least 10 seconds before powering back on.

6. Power off the print engine using the print engine’s main power switch.

11

Replacing the imagePASS-D1 motherboard

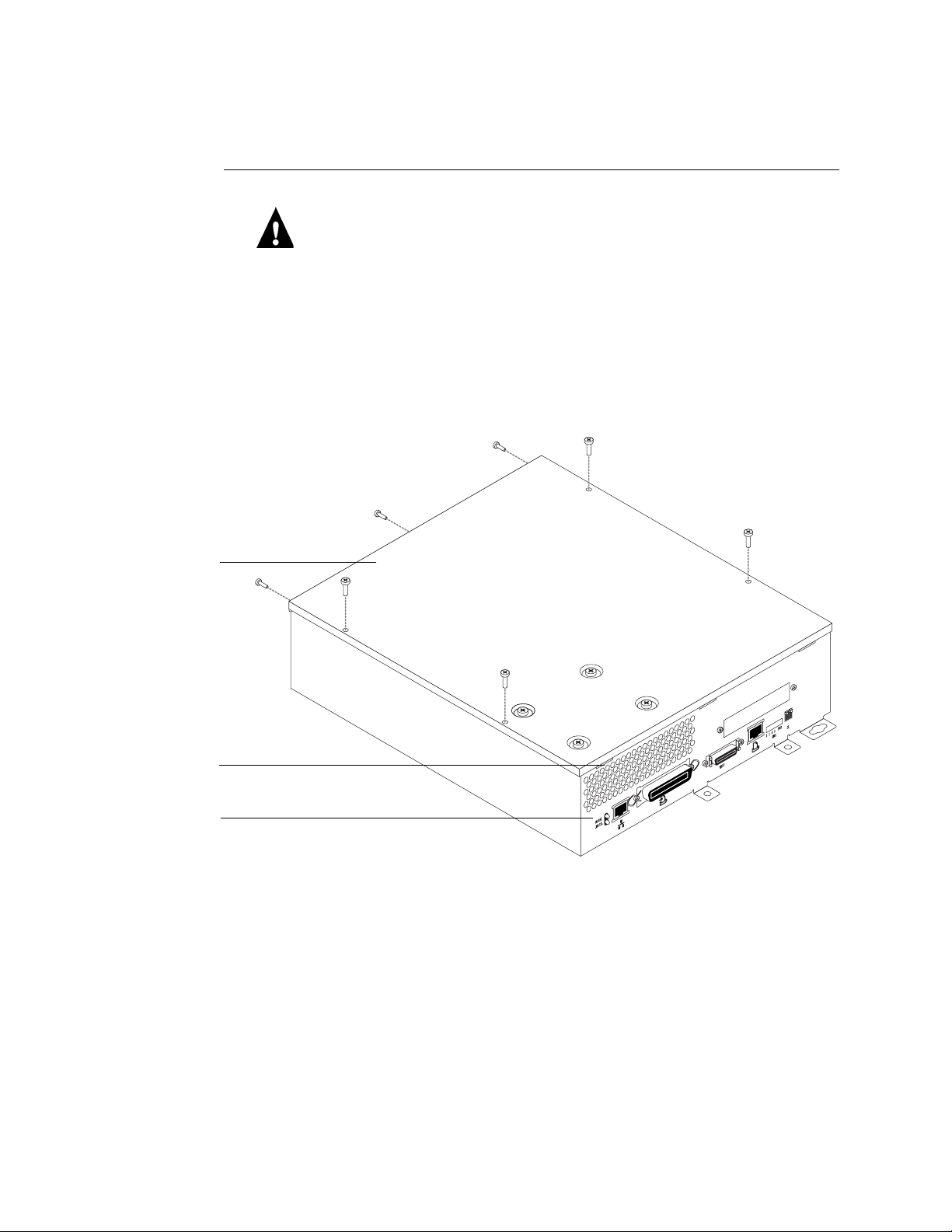

T

O

OPEN

THE

IMAGE

PASS-D1

Lid

AUTION

C

Make sure you use an ESD grounding wrist strap and follow standard

:

ESD (electrostatic discharge) precautions while performing this procedure.

1. Shut down the imagePASS-D1 as described on page 10.

2. Unplug the print engine and remove the imagePASS-D1.

For information on removing the imagePASS-D1 from the print engine, see the

imagePASS-D1 installation instructions, not provided in this guide.

3. Position the imagePASS-D1 so that the screw holes in the lid are facing up.

4. Remove the screws that secure the lid to the imagePASS-D1 and set them aside.

Tab slot (1 of 3)

Connector panel

12

F

IGURE F imagePASS-D1 lid screws

5. Lift up the lid and disconnect the HDD cable from the motherboard.

The HDD mounted inside the panel is connected to the motherboard by a short cable.

Be careful not to damage the cable or the HDD connector. To disconnect the HDD

cable, grasp the connector at the end of the cable where it is connected to the

motherboard and carefully remove it.

NOTE: The lid hinges on three tabs. To remove the lid from the chassis, unhook the tabs

from the slots on the connector panel. Set the lid aside.

HDD cable connector

(see also Figure D on page 7)

HDD

Replacing the imagePASS-D1 motherboard

Lid

HDD cable

IGURE G Accessing the imagePASS-D1

F

TO REMOVE THE IMAGEPASS-D1 MOTHERBOARD

CAUTION : Make sure you use an ESD grounding wrist strap and follow standard

ESD (electrostatic discharge) precautions while performing this procedure.

1. Shut down and open the imagePASS-D1 as described on page 10 and page 12.

2. Disconnect the following cables from the motherboard (see Figure D on page 7).

•Two enclosed fan cables from motherboard FAN connectors

• PCC board cable from motherboard PCC connector

• PCC board power cable from the motherboard POWER connector

3. Remove the screws that secure the imagePASS-D1 motherboard to the chassis (5) and

connector panel (4). (See Figure A on page 4 for locations of screws.)

Note which screws are used for each connector and for the motherboard and keep like

screws together.

4. Pinch the locks on any locking standoffs to release the board.

5. Remove the motherboard from the connector panel cutouts and lift the motherboard out

of the chassis and set it on a flat anti-static surface.

As you remove it, be careful to avoid stressing or flexing the motherboard and avoid

scraping any components.

13

Replacing the imagePASS-D1 motherboard

TO REPLACE THE MOTHERBOARD IN THE CHASSIS

1. If you are replacing an old motherboard with a new motherboard, then unpack the new

motherboard and install the following components from the old motherboard:

• DIMM (see page 16)

• BIOS chip: U4 (see page 17)

•MAC chip set: U29 and U514 (see Figure D on page 7)

Note that the MAC address chip from U29 has laser mark CH and the Engine ID Key

chip from U514 has laser mark CN. Code in the Engine ID key chip was permanently

linked on initial power up to the code in the MAC address chip in U29. Make sure to:

•Install each chip in its correct location

•Orient the chip indicator for pin 1 with the board indicator for pin 1

•Avoid bending or breaking pins when inserting each chip into the socket

2. Insert the edge connectors into the connector panel cutouts and align the motherboard

screw holes with the standoffs in the chassis.

As you install it, be careful to avoid stressing or flexing the motherboard and avoid

scraping any components.

3. Align the motherboard with any locking standoffs and snap into place.

4. Install the screws that secure the motherboard to the connector panel (4) and to the

chassis (5). (See Figure A on page 4 for locations of screws.) Connect the following

cables to the motherboard (see Figure D on page 7):

• PCC board cable to the motherboard PCC connector

• PCC board power cable to the motherboard POWER connector

•Two enclosed fan cables to motherboard ENCL FAN connectors

5. Reassemble the unit and verify functionality (see page 26).

Make sure to connect the HDD cable to the motherboard HDD connector. The

motherboard connector is keyed so that the cable is inserted in the proper orientation.

Use the connector’s locking levers to make sure the cable connection is secure.

14

Loading...

Loading...