Canon iR5800C, iR5800CN, iRC6800C, iRC6800CN Service Handbook

SERVICE HANDBOOK(temp)

iR C6800 Series

iR C6800CN

Feb 4 2004

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may be

information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information

as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will

issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical

and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol ,

the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the

delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to

indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in

"DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the

operations of the microprocessors used in the machines are not discussed: they are explained in terms of from

sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant

Service Information bulletins and be able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts............................................................................................................................... 1- 2

1.1.1Overview ..................................................................................................................................................... 1- 2

1.1.2Reader Unit.................................................................................................................................................. 1- 2

1.1.3Printer Unit .................................................................................................................................................. 1- 2

1.2 Durables and Consumables ............................................................................................................................... 1- 4

1.2.1Overview ..................................................................................................................................................... 1- 4

1.2.2Reader Unit.................................................................................................................................................. 1- 4

1.2.3Printer Unit .................................................................................................................................................. 1- 4

1.3 Scheduled Servicing Basic Procedure............................................................................................................... 1- 7

1.3.1Scheduled Servicing Basic Procedure......................................................................................................... 1- 7

1.3.2Scheduled Servicing (reader unit) ............................................................................................................... 1- 8

1.3.3Scheduled Servicing (printer unit) .............................................................................................................. 1- 9

1.4 Cleaning........................................................................................................................................................... 1- 17

1.4.1Cleaning the Photosensitive Drum ............................................................................................................ 1- 17

1.4.2Cleaning the Secondary Transfer Rear Guide ........................................................................................... 1- 18

1.4.3Cleaning the Registration Roller, Registration Guide, and Transparency Sensor .................................... 1- 19

1.5 Upgrading........................................................................................................................................................ 1- 22

1.5.1Outline of the Version Upgrade ................................................................................................................ 1- 22

1.5.2Outline of the Service Support Tool.......................................................................................................... 1- 22

1.5.3Network Interface of the Machine with the SST in Use ........................................................................... 1- 25

Chapter 2 Standards and Adjustments

2.1 Image Adjustments.......................................................................................................................................... 2- 30

2.1.1Image Position........................................................................................................................................... 2- 30

2.1.2Checking the Image Position..................................................................................................................... 2- 30

2.1.3Cassette...................................................................................................................................................... 2- 31

2.1.4Manual Feed Tray ..................................................................................................................................... 2- 31

2.1.5Front Deck................................................................................................................................................. 2- 32

2.2 Scanning System ............................................................................................................................................. 2- 35

2.2.1After Replacing the CCD Unit .................................................................................................................. 2- 35

2.2.2After Replacing the Copyboard Glass ....................................................................................................... 2- 35

2.2.3After Replacing the Reader Controller PCB or Initializing the RAM ...................................................... 2- 35

2.3 Laser Exposure System ................................................................................................................................... 2- 38

2.3.1After Replacing the Laser Scanner............................................................................................................ 2- 38

2.4 Image Formation System................................................................................................................................. 2- 39

2.4.1After Replacing the Black Developing Unit ............................................................................................. 2- 39

2.4.2Replacing the Color Developing Unit ....................................................................................................... 2- 39

2.4.3Replacing the Starter of the Color Developing Unit ................................................................................. 2- 41

2.4.4After Replacing the Primary Charging Assembly..................................................................................... 2- 43

2.4.5After Replacing the Primary Charging Wire............................................................................................. 2- 43

2.4.6After Replacing the Pre-Transfer Charging Wire ..................................................................................... 2- 43

Contents

2.4.7After Replacing the Pre-Transfer Charging Wire......................................................................................2- 43

2.4.8After Replacing the Waste Toner Box.......................................................................................................2- 43

2.4.9After Replacing the ITB Cleaner Blade.....................................................................................................2- 43

2.4.10After Repacking the Photosensitive Drum Cleaning Blade ....................................................................2- 43

2.4.11After Replacing the Photosensitive Drum ...............................................................................................2- 44

2.4.12After Repacking the ITB ........................................................................................................................2- 44

2.4.13After Replacing the Primary Transfer Roller ..........................................................................................2- 44

2.4.14After Replacing the Primary Transfer Outside Roller.............................................................................2- 44

2.4.15After Replacing the Primary Transfer Static Eliminator.........................................................................2- 44

2.4.16After Replacing the ITB Unit ..................................................................................................................2- 44

2.5 Fixing System ..................................................................................................................................................2- 45

2.5.1Points to Note When Mounting the Fixing Assembly...............................................................................2- 45

2.5.2After Replacing the Fixing Roller .............................................................................................................2- 45

2.5.3After Replacing the Fixing Web................................................................................................................2- 45

2.5.4Position of the Fixing inlet Guide..............................................................................................................2- 45

2.5.5Points to Note When Mounting the Pressure Roller..................................................................................2- 45

2.5.6Adjusting the Position of the Feeding Web Solenoid (SL2) .....................................................................2- 46

2.5.7Points to Note About the Position of the Fixing Thermal Switch .............................................................2- 46

2.5.8Points to Note When Mounting the Shift Thermal Switch ........................................................................2- 46

2.5.9Points to Note When Mounting the Outside Heating Roller Thermal Switch ..........................................2- 47

2.5.10Points to Note When Mounting the Fixing Upper Thermistor ................................................................2- 47

2.5.11Points to Note When Mounting the Fixing Lower Thermistor................................................................2- 47

2.5.12Points to Note When Mounting the External Heat Thermistor ...............................................................2- 48

2.6 Electrical Components.....................................................................................................................................2- 49

2.6.1When Replacing the Reader Controller PCB ............................................................................................2- 49

2.6.2After Replacing the DC Controller PCB ...................................................................................................2- 50

2.6.3Points to Note When Mounting the DC Controller PCB/ DC Controller Box..........................................2- 50

2.6.4After Replacing the Main Controller PCB (main).....................................................................................2- 51

2.6.5After Repacking the SRAM Board............................................................................................................2- 51

2.6.6After Replacing the HDD ..........................................................................................................................2- 52

2.6.7When Replacing the HV2 PCB .................................................................................................................2- 52

2.6.8When Replacing the ATR Sensor/Patch Image Read Sensor....................................................................2- 53

2.7 Pickup/Feeding System ...................................................................................................................................2- 54

2.7.1Adjusting the Horizontal Registration After Replacing the Pickup Cassette............................................2- 54

2.7.2Adjusting the Manual Feed Pickup Horizontal Registration .....................................................................2- 54

2.7.3Adjusting the Front Deck Pickup Horizontal Registration........................................................................2- 54

2.7.4Registering the Paper Width Basic Value .................................................................................................2- 56

Chapter 3 User Mode Items

3.1 Common Settings............................................................................................................................................. 3-60

3.2 Setting the Timers............................................................................................................................................ 3-62

3.3 Adjustment, Cleaning ...................................................................................................................................... 3-63

3.4 Report .............................................................................................................................................................. 3-64

3.5 System Control Settings .................................................................................................................................. 3-65

3.6 Copier Settings................................................................................................................................................. 3-66

3.7 Common Transmission Settings ...................................................................................................................... 3-67

3.8 Box Settings..................................................................................................................................................... 3-69

3.9 Printer Settings................................................................................................................................................. 3-70

Contents

3.10 Address Book Settings .................................................................................................................................. 3-71

Chapter 4 Service Mode

4.1 Test Print ......................................................................................................................................................... 4- 74

4.1.1Overview ................................................................................................................................................... 4- 74

4.1.2Test Print TYPE ........................................................................................................................................ 4- 74

4.1.3Selecting Test Print TYPE ........................................................................................................................ 4- 74

4.1.416-Gradation (TYPE=4)............................................................................................................................ 4- 75

4.1.5Grid (TYPE=6).......................................................................................................................................... 4- 75

4.1.6MCYBk Horizontal Stripes (TYPE=10) ................................................................................................... 4- 76

4.1.764-Gradation (TYPE=12).......................................................................................................................... 4- 77

4.1.8Full Color 16-Gradation (TYPE=14) ........................................................................................................ 4- 77

Chapter 5 Outline of Components

5.1 Clutch/Solenoid ............................................................................................................................................... 5- 80

5.1.1Clutches and Solenoids ............................................................................................................................. 5- 80

5.2 Motor ............................................................................................................................................................... 5- 83

5.2.1Motors ....................................................................................................................................................... 5- 83

5.3 Fan ................................................................................................................................................................... 5- 89

5.3.1Fans ........................................................................................................................................................... 5- 89

5.4 Sensor .............................................................................................................................................................. 5- 93

5.4.1Sensors....................................................................................................................................................... 5- 93

5.5 Switch............................................................................................................................................................ 5- 103

5.5.1Switches................................................................................................................................................... 5- 103

5.6 Lamps, Heaters, and Others .......................................................................................................................... 5- 105

5.6.1Heaters, Lamps, and Others .................................................................................................................... 5- 105

5.7 PCBs.............................................................................................................................................................. 5- 108

5.7.1PCB ......................................................................................................................................................... 5- 108

Chapter 6 System Construction

6.1 System Construction...................................................................................................................................... 6- 114

6.1.1System Configuration with Pickup/Delivery Accessories ...................................................................... 6- 114

6.1.2System Configuration with Printing/Transmission Accessories ............................................................. 6- 114

6.2 Function List.................................................................................................................................................. 6- 116

6.2.1Print Speed .............................................................................................................................................. 6- 116

6.2.2Paper Type............................................................................................................................................... 6- 119

6.2.3Accessories .............................................................................................................................................. 6- 120

Chapter 1

Chapter 1 Maintenance

and Inspection

1-1

Chapter 1

1.1 Periodically Replaced Parts

1.1.1 Overview

0002-9397

Some parts of the machine must be replaced on a periodical basis for the machine to maintain a specific level of

performance. They must be replaced regardless of the presence/absence of external changes or damage, as the

performance of the machine will be considerably affected once they fail.

If possible, plan any replacement to coincide with a scheduled visit.

The intervals indicated may vary depending on the site environment and user habit.

- Checking the Timing of Replacement

The timing of replacement may be checked using the following service mode items:

- Copier

COPIER>COUNTER>PRDC-1

- Accessory

COPIER>COUNTER>PRDC-2

1.1.2 Reader Unit

0000-9633

The machine's reader unit does not have parts that must be replaced on a periodical basis.

1.1.3 Printer Unit

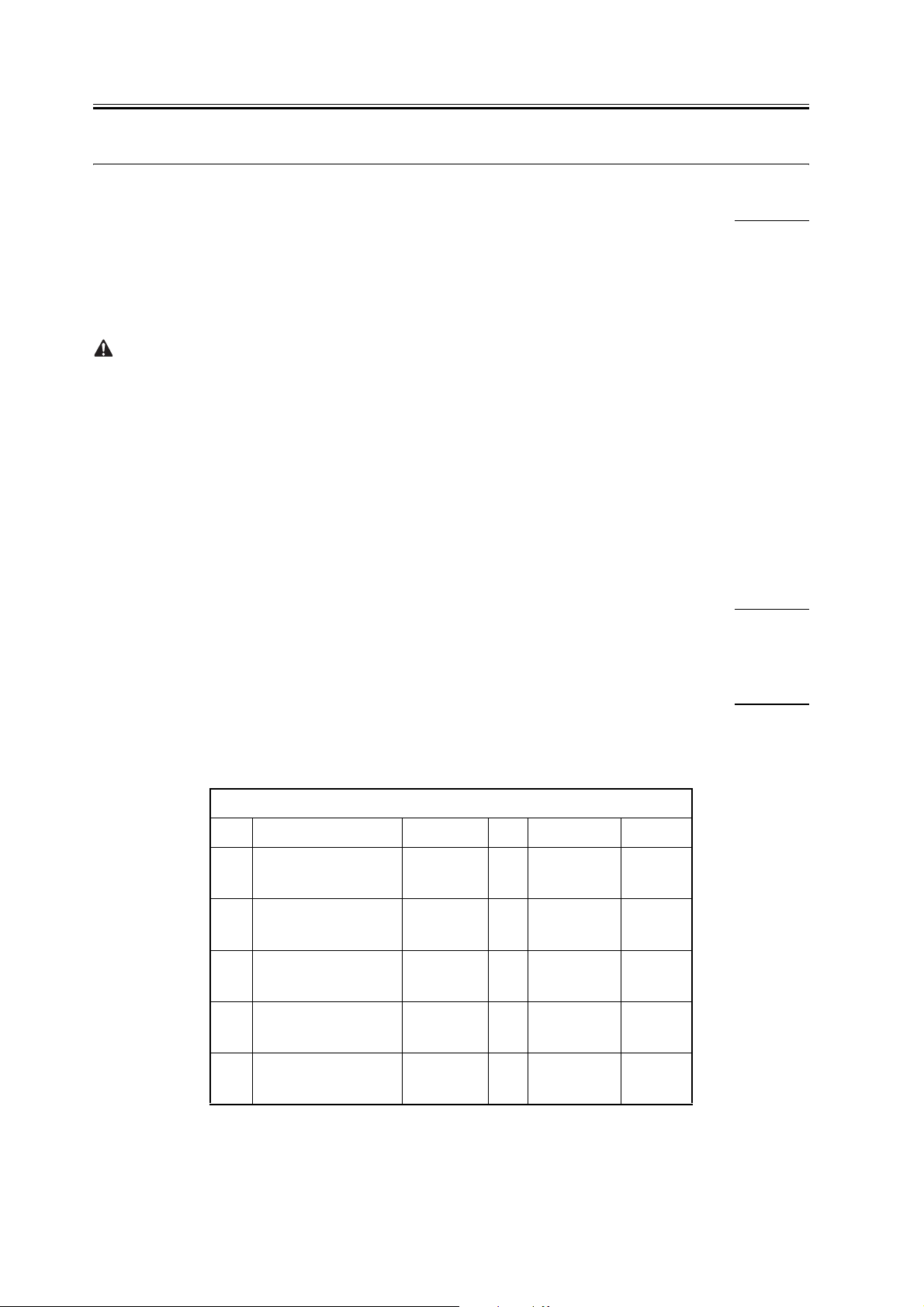

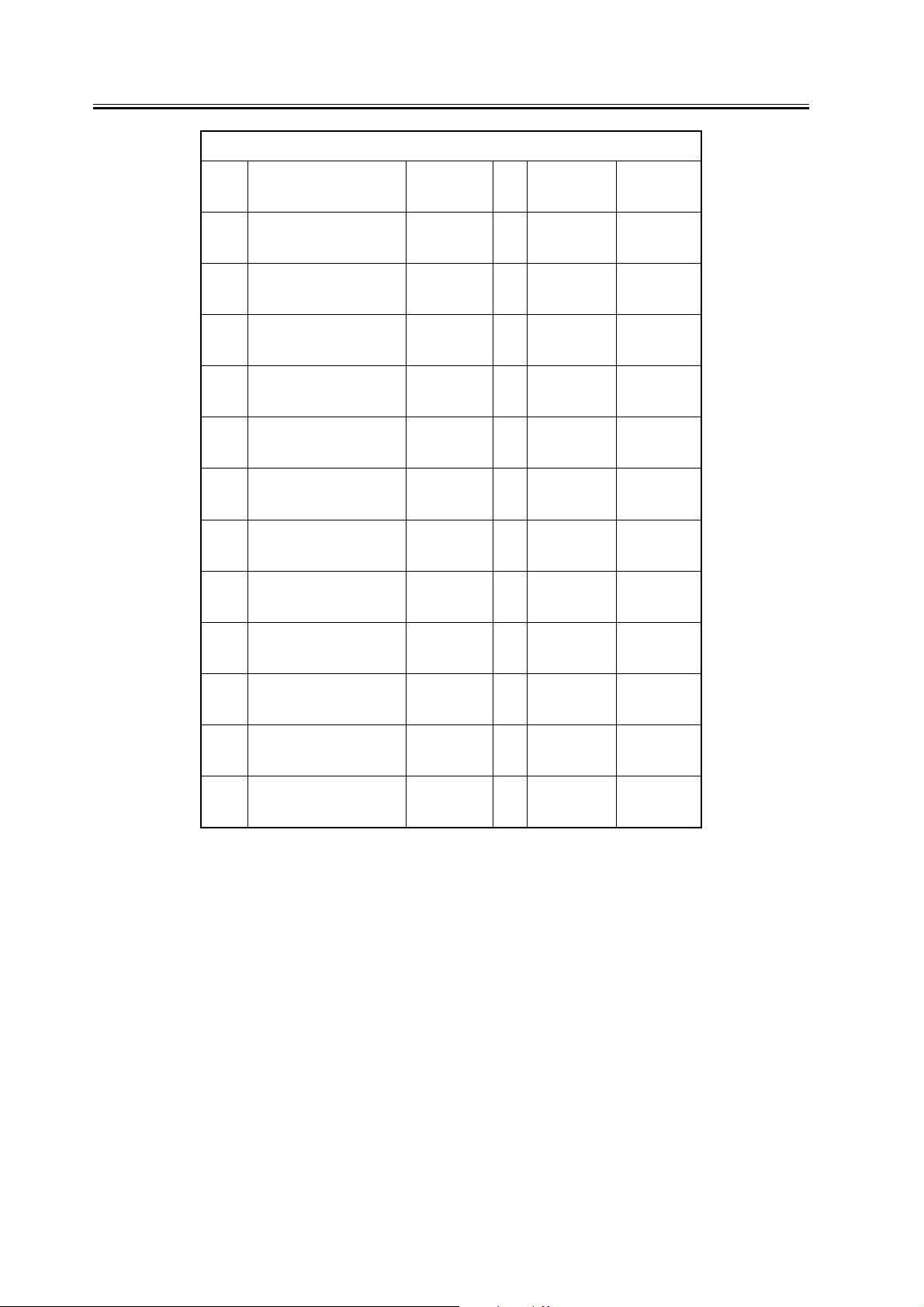

Ref. Parts name Parts No. Q'ty Interval Remarks

1 Ozone filter

2 Toner filter

3 Primary charging wire

4 Charging wire cleaner 1

5 Charging wire cleaner 2

T-1-1

FC5-2486-

000

FL2-0554-

000

FB4-3687-

000

FL2-2427-

000

FL2-2428-

000

AR

1

1

1

1

as of February 2004

250,000

images*

250,000

images*

500,000

images*

500,000

images*

500,000

images*

0002-9400

(*)

(*)

(*)

(*)

1-2

as of February 2004

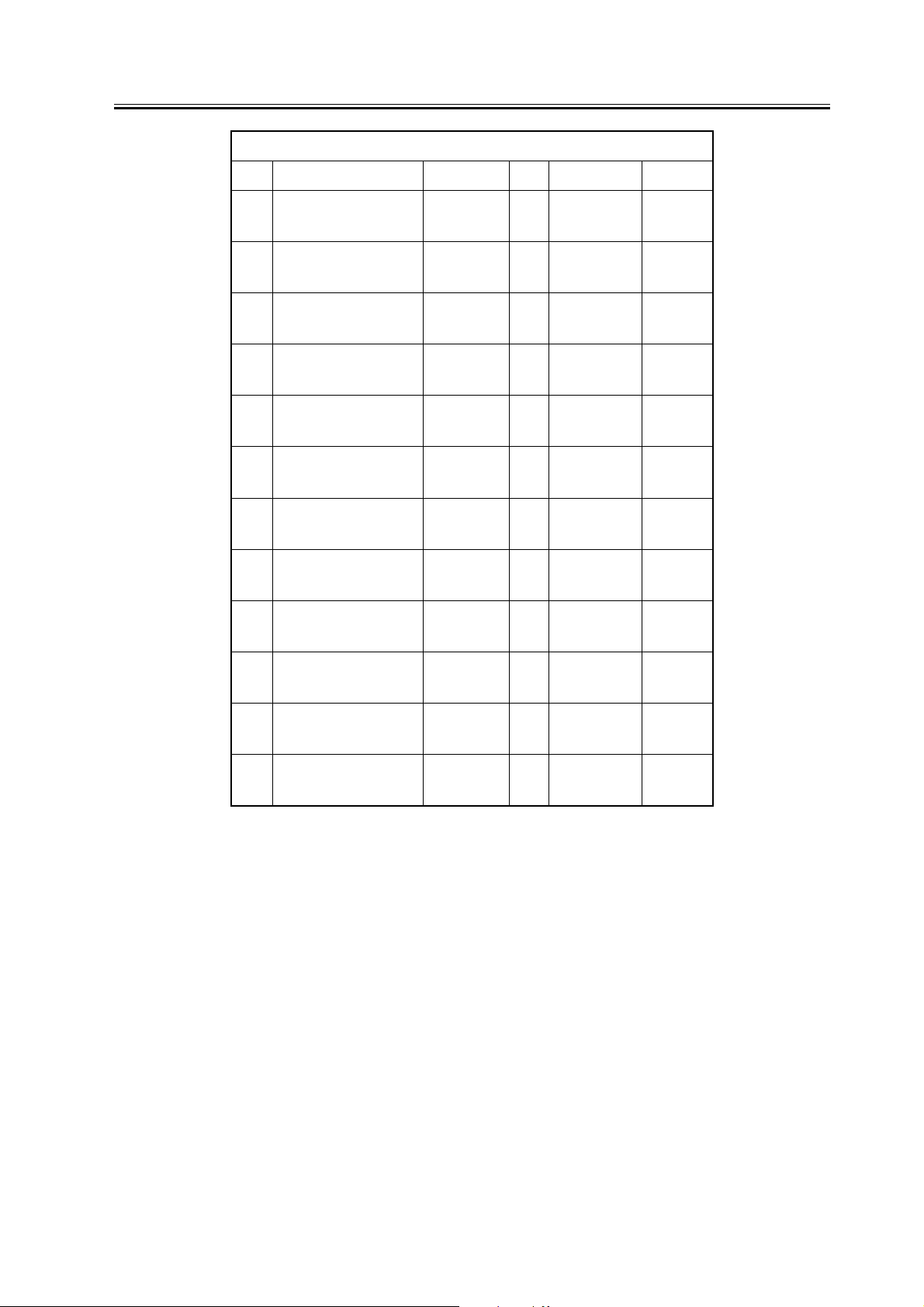

Ref. Parts name Parts No. Q'ty Interval Remarks

Chapter 1

Pre-transfer charging

6

assembly

Pre-transfer charging

7

assembly wire cleaner 1

Pre-transfer charging

8

assembly wire cleaner 2

9 Primary grid wire

10 Fixing thermistor

11 Pressure thermistor

Outside heating roller

12

thermistor

13 Primary charging assembly

Pre-transfer charging

14

assembly

FB4-3687-

000

FL2-2427-

000

FL2-2428-

000

FY1-0883-

000

FK2-0013-

000

FK2-0013-

000

FK2-0013-

000

FM2-0429-

000

FM2-0427-

000

500,000

AR

images*

500,000

1

images*

500,000

1

images*

500,000

1

images*

1 500,000 prints

1 500,000 prints

1 500,000 prints

1,000,000

1

images

1,000,000

1

images

(*)

(*)

15 Fixing thermal switch

16 Pressure thermal switch

Outside heating thermal

17

switch

FM2-0497-

000

FM2-0498-

000

FM2-0499-

000

1

1

1

1,000,000

prints

1,000,000

prints

1,000,000

prints

* In the case of a black mono color print, counted as 1; in the case of a full color print, counted as 4 images.

1-3

Chapter 1

1.2 Durables and Consumables

1.2.1 Overview

0005-8047

Some parts of the machine may have to be replaced once or more over the period of machine warranty because of

wear or damage. Replace them as needed by referring to the table of estimated lives (expressed in terms of the

number of prints they make).

Making Checks When Replacing Durables

Use the following service mode items to find out when to replace parts:

- Machine

COPIER>COUNTER>DRBL-1

- Accessory

COPIER>COUNTER>DRBL-2

1.2.2 Reader Unit

0000-9645

The machine's reader unit does not have parts that are classified as durables.

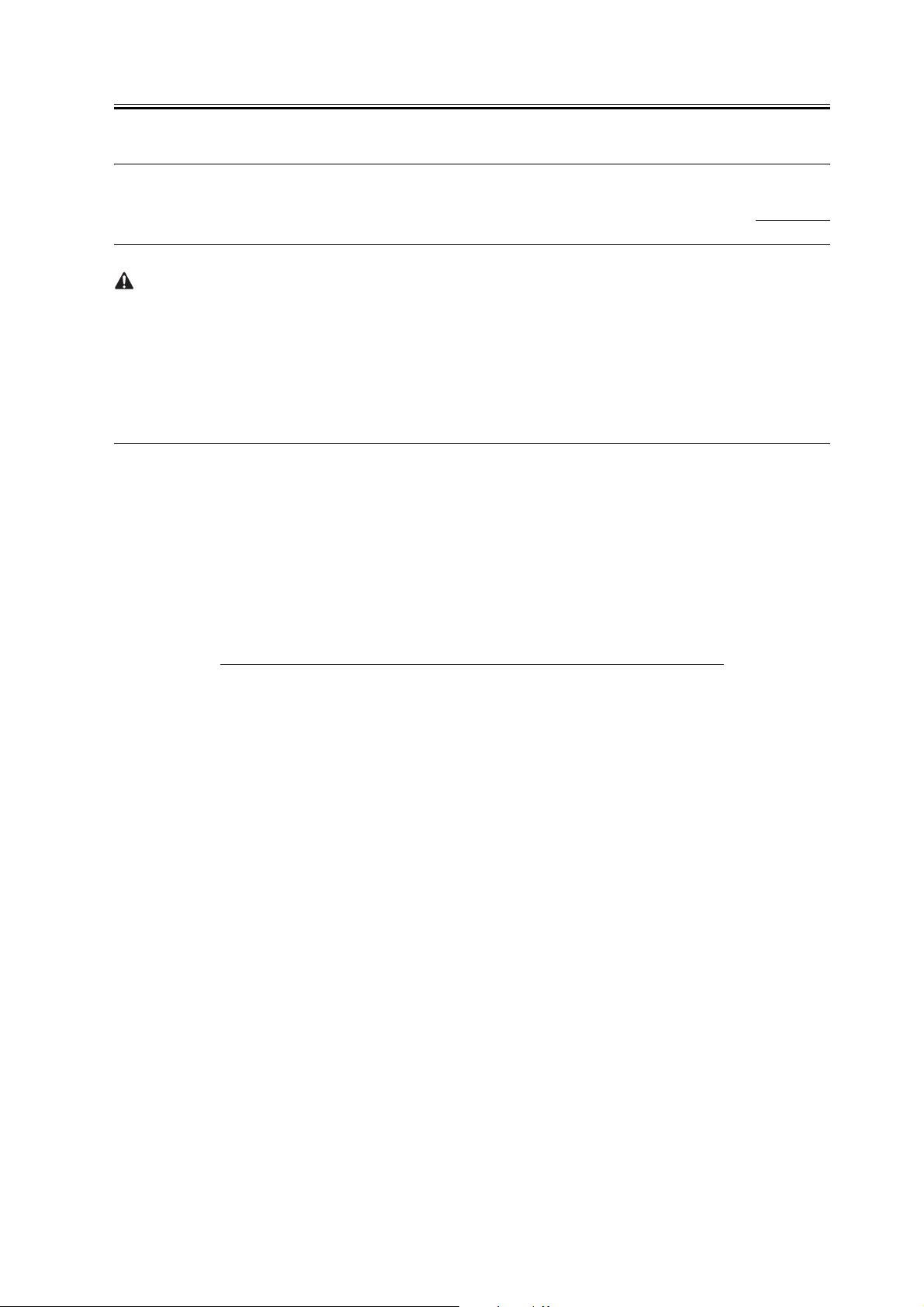

1.2.3 Printer Unit

0002-9470

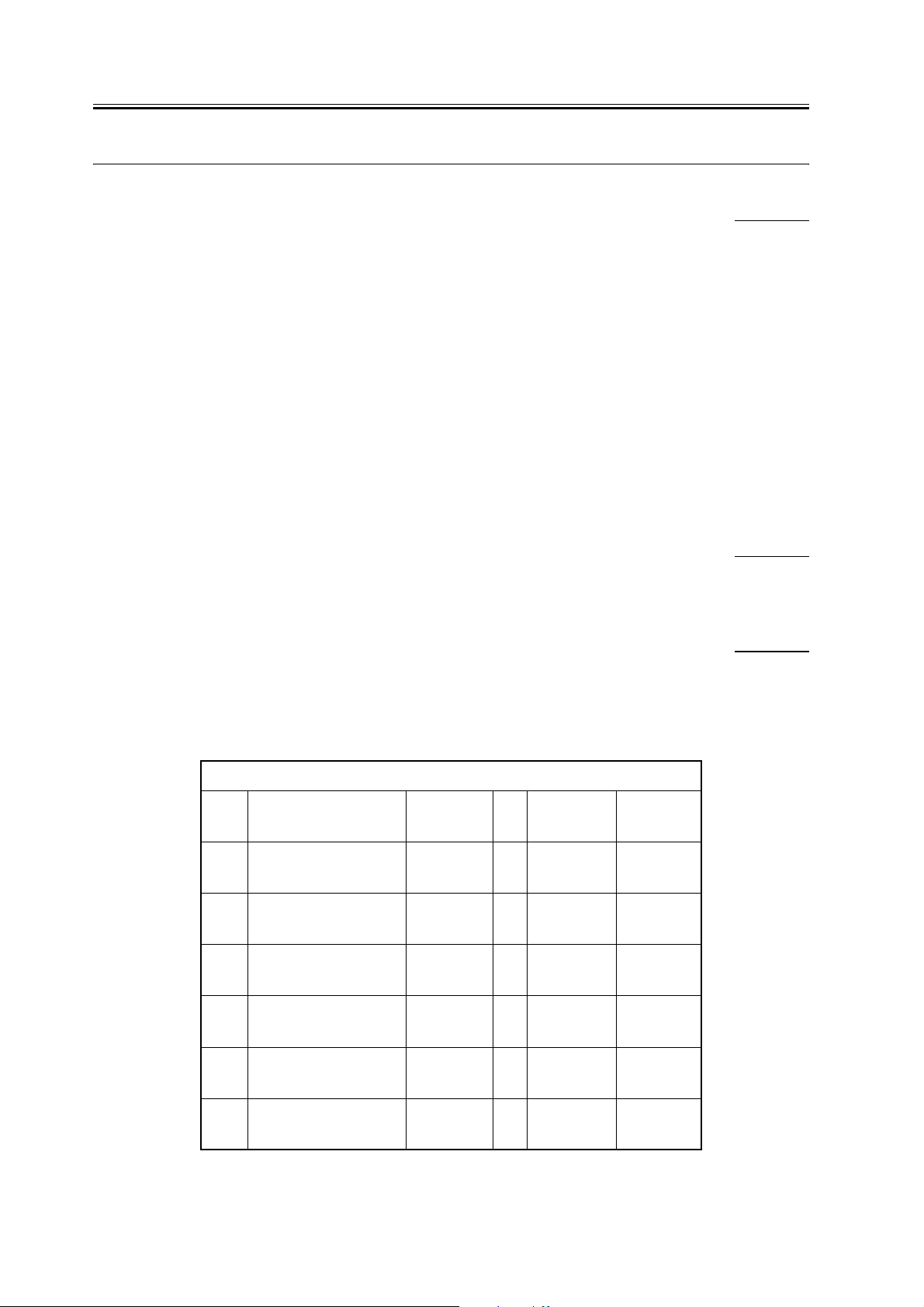

T-1-2

2

as of February 2004

Ref. Parts name Parts No.

[1] Feed roller (manual feed)

Separation roller (manual

[2]

feed)

[3] ITB cleaner blade

[4] ITB cleaner scoop-up sheet

Primary transfer outside

[5]

roller

Secondary transfer static

[6]

eliminator holder

FB1-8581-

000

FB5-0873-

000

FC5-1662-

000

FL2-0411-

000

FC5-2157-

000

FL2-0598-

000

Q't

Interval Remarks

y

1 120,000 prints

1 120,000 prints

1 150,000 prints

1 150,000 prints

1 150,000 prints

1 150,000 prints

1-4

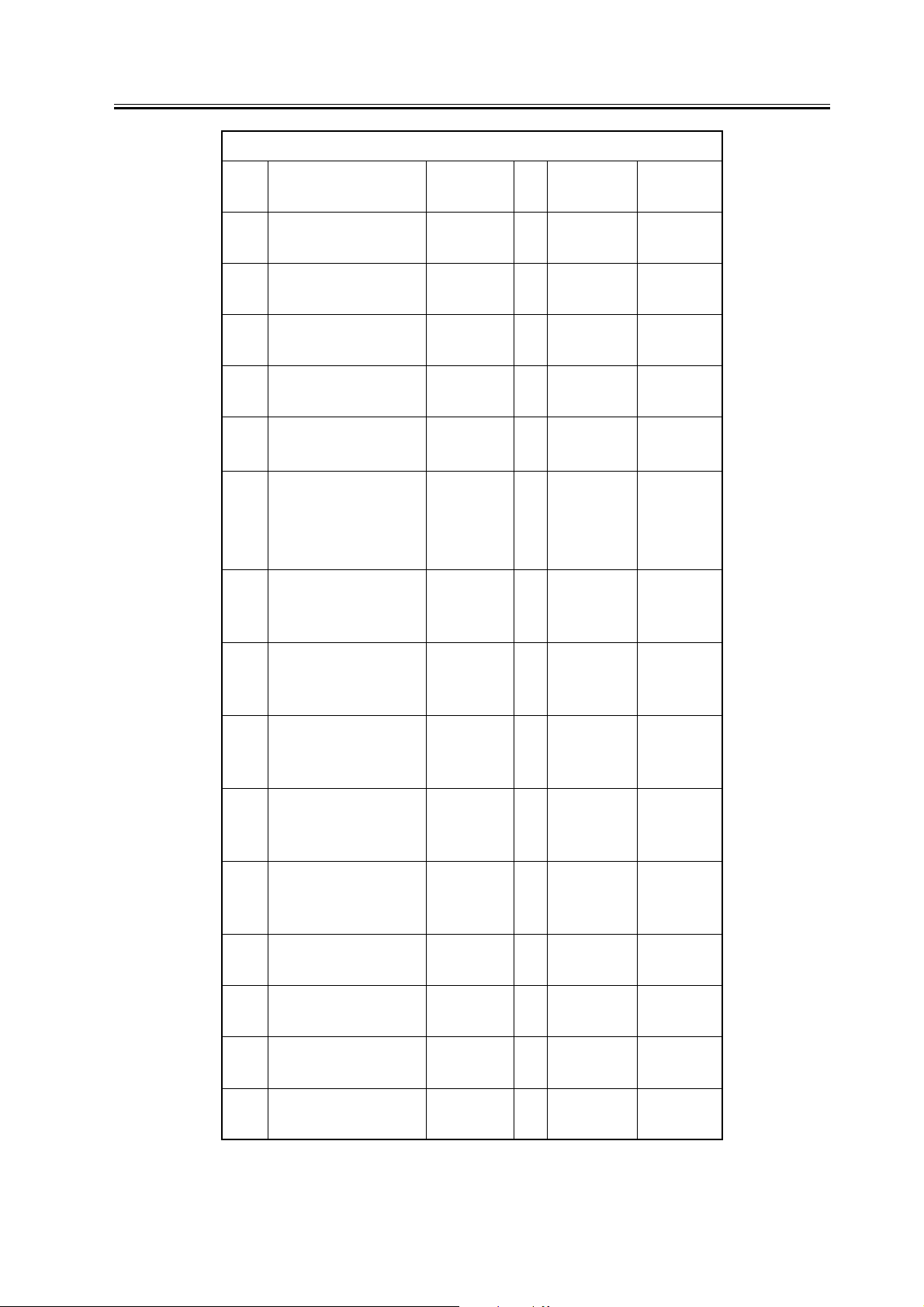

as of February 2004

Chapter 1

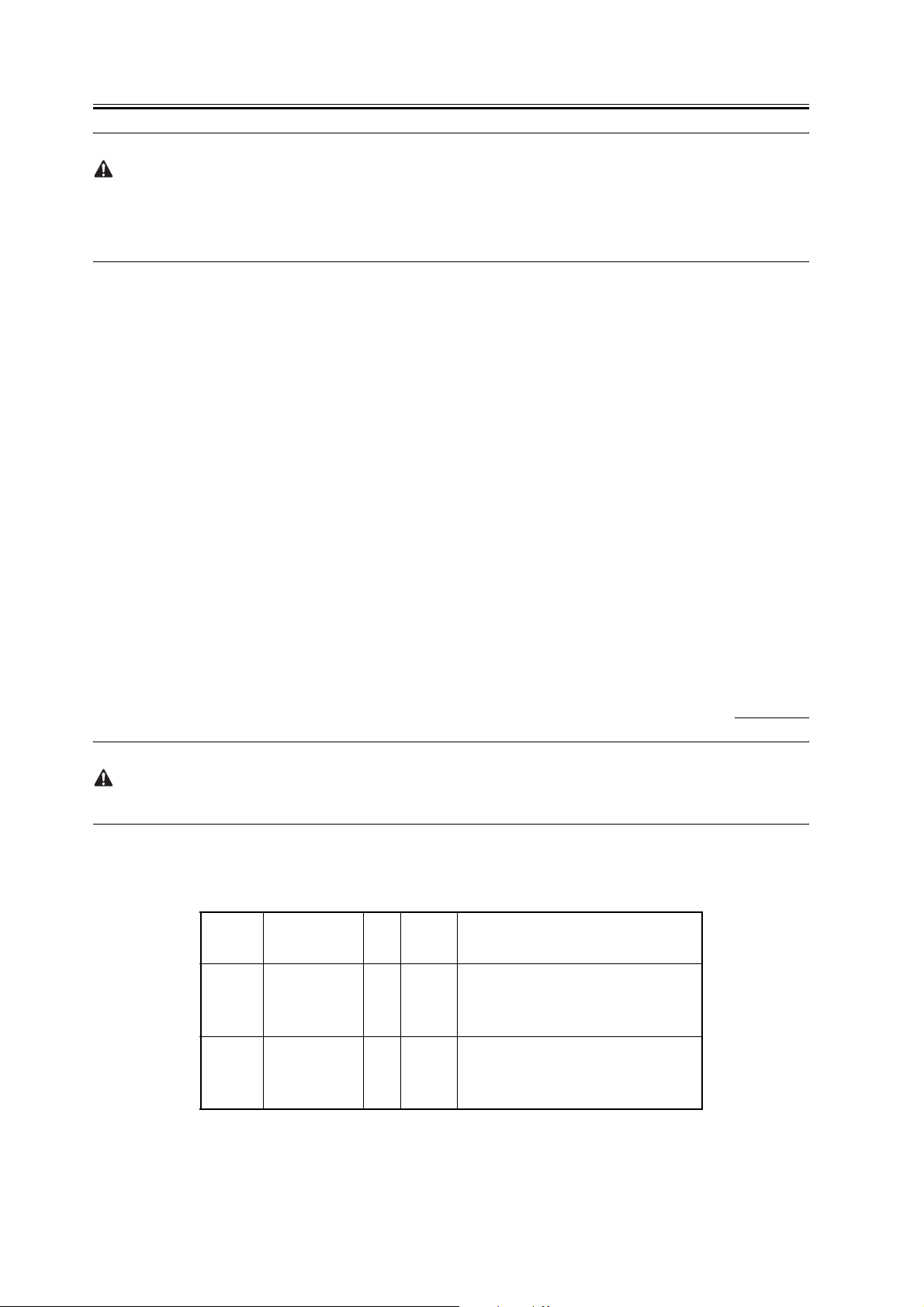

Ref. Parts name Parts No.

[7] Fixing roller

[8] Pressure roller

[9] Outside heating roller

[10] Cleaner scoop-up sheet

[11] Cleaner blade

Pickup roller (left/right

[12]

paper deck)

Feed roller (left/right paper

[13]

deck)

FC5-6298-

000

FC5-6299-

000

FC5-2285-

000

FL2-0422-

000

FC5-1788-

000

FC5-2524-

000

FC5-2526-

000

Q't

eac

each250,000 prints

Interval Remarks

y

150,000

1

prints*

150,000

1

prints*

150,000

1

prints*

250,000

1

images*2

1

250,000

images*2

2

250,000 prints

h

2

(one edge in

use)

Separation roller (left/right

[14]

paper deck)

[15] Pickup roller (cassette 3/4)

[16] Feed roller (cassette 3/4)

Separation roller (cassette 3/4)FC5-2528-

[17]

[18] Primary transfer roller

Primary transfer static

[19]

eliminator

[20] ITB

Secondary transfer inside

[21]

roller

FC5-2528-

000

FC5-2524-

000

FC5-2526-

000

000

FC5-1660-

000

FM2-0420-

000

FC5-1658-

000

FC5-1661-

000

2

each250,000 prints

2

each250,000 prints

2

each250,000 prints

2

each250,000 prints

300,000

1

images*2

300,000

1

images*2

300,000

1

images*2

1 300,000 prints

1-5

Chapter 1

as of February 2004

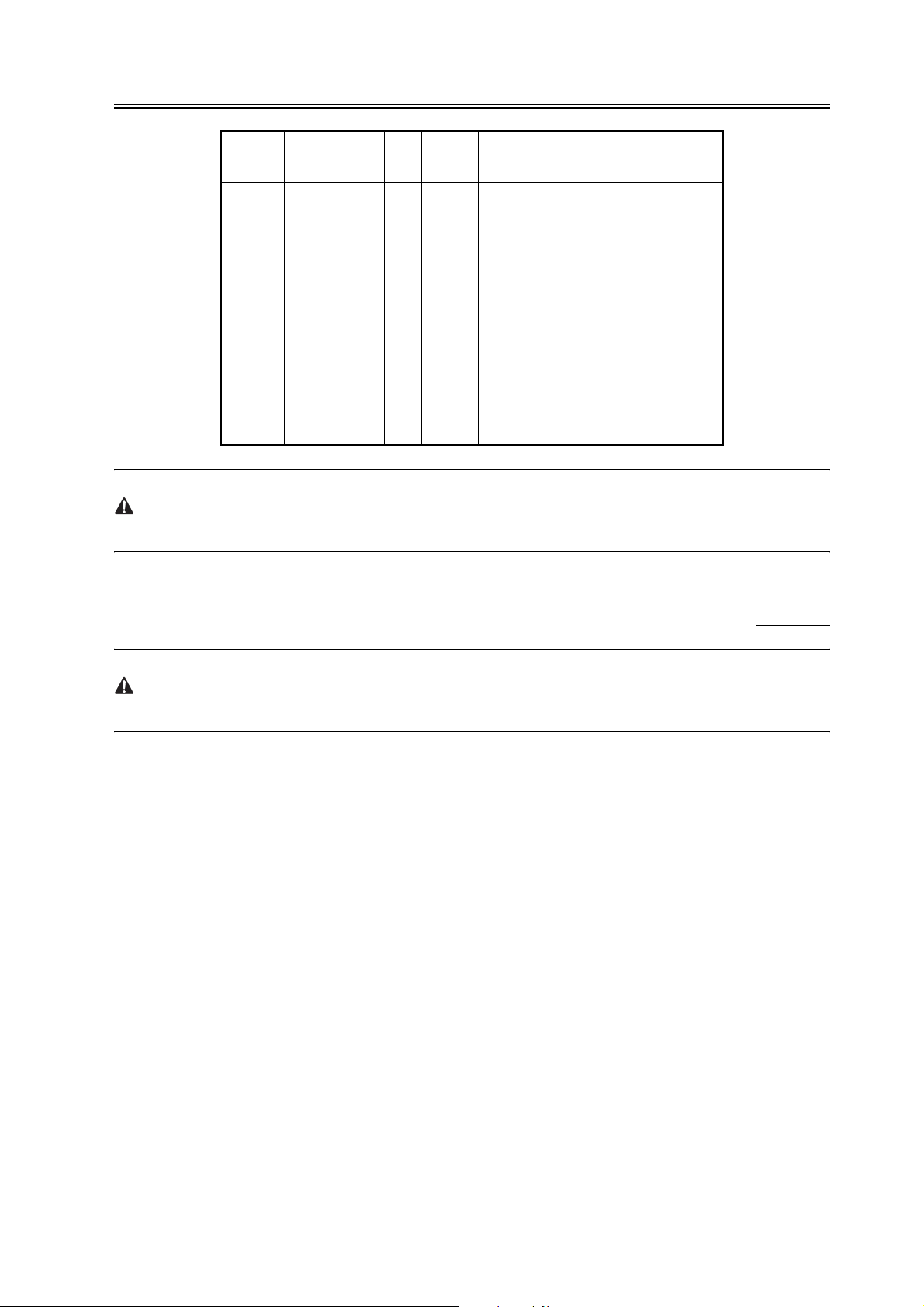

Ref. Parts name Parts No.

[22] Edge scraper

[23] Color developing assembly

[24] Fixing web

[25] Fixing heat insulating bush

Delivery upper separation

[26]

claw

Delivery lower separation

[27]

claw unit

[28] Pressure insulating bush

[29] Outside heat insulating bush

FC5-5136-

000

FM2-0446-

000

FC5-2286-

000

FB5-3613-

000

FM2-1672-

000

FM2-0501-

000

RB1-0325-

000

FC5-2582-

000

Q't

Interval Remarks

y

500,000

2

images*2

3 500,000 prints

1 500,000 prints

2 500,000 prints

4 500,000 prints

6 500,000 prints

2 500,000 prints

2 500,000 prints

Fixing heat discharge ozone

[30]

filter

[31] Tner filter (inside)

Bk developing cylinder

[32]

(black developing assembly)

Developing roll (black

[33]

developing assembly)

FC5-6370-

000

FL2-0554-

000

FM2-0434-

000

FC5-1863-

000

1

2

1

2

1,000,000

images

1,000,000

images

1,000,000

prints

1,000,000

prints

*1: in the case of a color ratio of 10%; if 100%, 60,000 prints; if 0%, 180,000 prints.

*2: in the case of a black mono color print, counted as 1 image; in the case of a full color print, counted as 4 images.

1-6

1.3 Scheduled Servicing Basic Procedure

Chapter 1

1.3.1 Scheduled Servicing Basic Procedure

0003-4125

- As a rule, provide scheduled servicing every 150,000 prints.

- Check with the Service Book before setting out for a scheduled service visit, and take parts for which replacement

is expected.

- If the power plug is left connected for a long time in a place subject to dust, humidity, or oil smoke, a fire hazard

is a possibility (i.e., the dust collecting around the plug can absorb moisture, resulting in insulating failure). Be sure

to disconnect the power plug on a periodical basis, and wipe off the dust and dirt collecting around it.

<Work Procedure>

1) Report to the person in charge, and check the general condition.

2) Record the counter reading, and check the faulty prints.

3) Make the following checks, and clean/adjust the items that are indicated:

T-1-3

Items

Text copy against image density standard

for soiling of back of paper

for clarity of characters

for margin

for fixing misplaced registration, soiled

back of paper

for margin standards (single-

sided print)

(double-sided print) leading edge: 4.0+1.5/-1.0mm

Feeding system registration upper/lower roller

for paper lint along front edge

of registration assembly

leading edge: 4.0+1.5/-1.0mm

left edge: 2.5+/- 1.5mm

left edge: 2.5+/- 2.0mm

4) Check the waste toner case.

If half full or more, dispose of the waste toner in a vinyl bag or the like for collection; or, replace the waste toner case.

1-7

Chapter 1

- If you need to dispose of the waste toner, be sure to do so in strict accordance with the regulations imposed by the

local authorities.

- Do not dispose of waste toner in a fire. Doing so may cause an explosion.

5) Clean the copyboard glass and the reading glass.

6) Make test copies.

7) Make sample copies.

8) Check the operation of the leakage breaker.

With the power switch at ON, push the test switch of the leakage breaker to see that it operates normally (i.e., the

breaker switch shifts to the OFF side to cut off the power).

If the leakage beaker fails to operate normally, replace it, and run a check once again.

<Resetting the Breaker>

When you have made the check, turn off the main power switch, and turn on the breaker switch, and then turn the

main power switch back on.

9) Put the sample copies in order, and clean up the area around the machine.

10) Record the final counter reading; at this time, be sure to fill out the blanks for 'FX-UP-RL' and 'DV-UNT-K'

(service counters).

11) Fill out the Service Book, and report to the person in change. Be sure to update the history of checks on the

leakage breaker in the Service Book.

1.3.2 Scheduled Servicing (reader unit)

Do not use solvents or oils other than those indicated herein.

T-1-4

Unit Location

Original

exposure

system

Original

exposure

system

Copyboard glass cleanas

ADF reading

glass

WorkInterva

ls

needed

cleanas

needed

0003-4139

Remarks

clean the face, back, and the white plate on the

back.

clean the back and the face.

1-8

Chapter 1

Unit Location

Original

exposure

system

Original

exposure

system

Original

exposure

system

Scanner rail clea

Scanner mirror

(No. 1 through

No. 3 mirrors)

Reflecting plate clean250,000

WorkInterva

ls

as

n/

needed

lubr

icat

e

clean250,000

images

images

Remarks

The foreign values are estimates only, and are subject to change based on future data.

1.3.3 Scheduled Servicing (printer unit)

Do not use solvents or oils other than those permitted.

0003-4126

1-9

Chapter 1

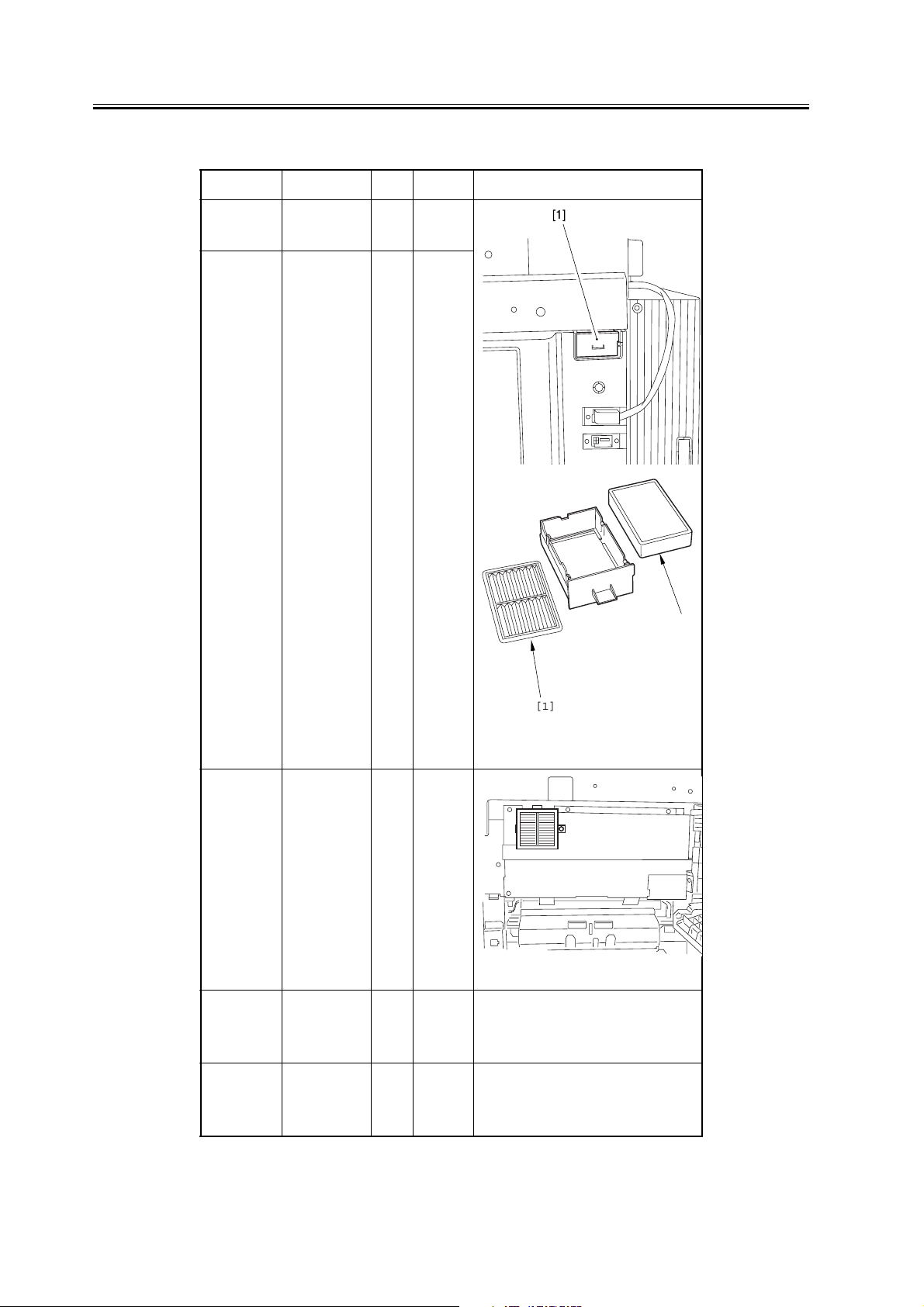

T-1-5

Unit Location Item Interval Remarks

Externals

and controls

Externals

and controls

Ozone filter replace250,000

images

Toner filter replace250,000

images

[1]

[2

Externals

and controls

Laser

exposure

system

Charging

assembly

Dust-

collecting

filter (primary)

Dust-colleting

glass

Primary

charging

assembly

[1]

[1]Toner filter

[2]Ozone filter

clean 250,000

prints

inside of the right upper cover

clean 250,000

prints

replace1,000,00

0 images

1-10

Unit Location Item Interval Remarks

Chapter 1

Charging

assembly

Charging

assembly

Charging

assembly

Charging

assembly

Primary

charging wire

Primary grid

wire

Charging wire

cleaner 1/2

(primary

changing

assembly)

Pre-transfer

charging

assembly

clean upon

installati

on

replace500,000

images

clean upon

installati

on,

250,000

images

replace500,000

images

replace500,000

images

replace1,000,00

0 images

Charging

assembly

Charging

assembly

Charging

assembly

Photosensiti

ve drum

Pre-transfer

charging wire

Charging wire

cleaner 1/2

(pre-transfer

charging

assembly)

Charging

assembly

shielding plate

Photosensitive

drum

clean upon

installati

on

replace500,000

images

replace500,000

images

clean upon

installati

on,

250,000

images

clean 250,000

images

1-11

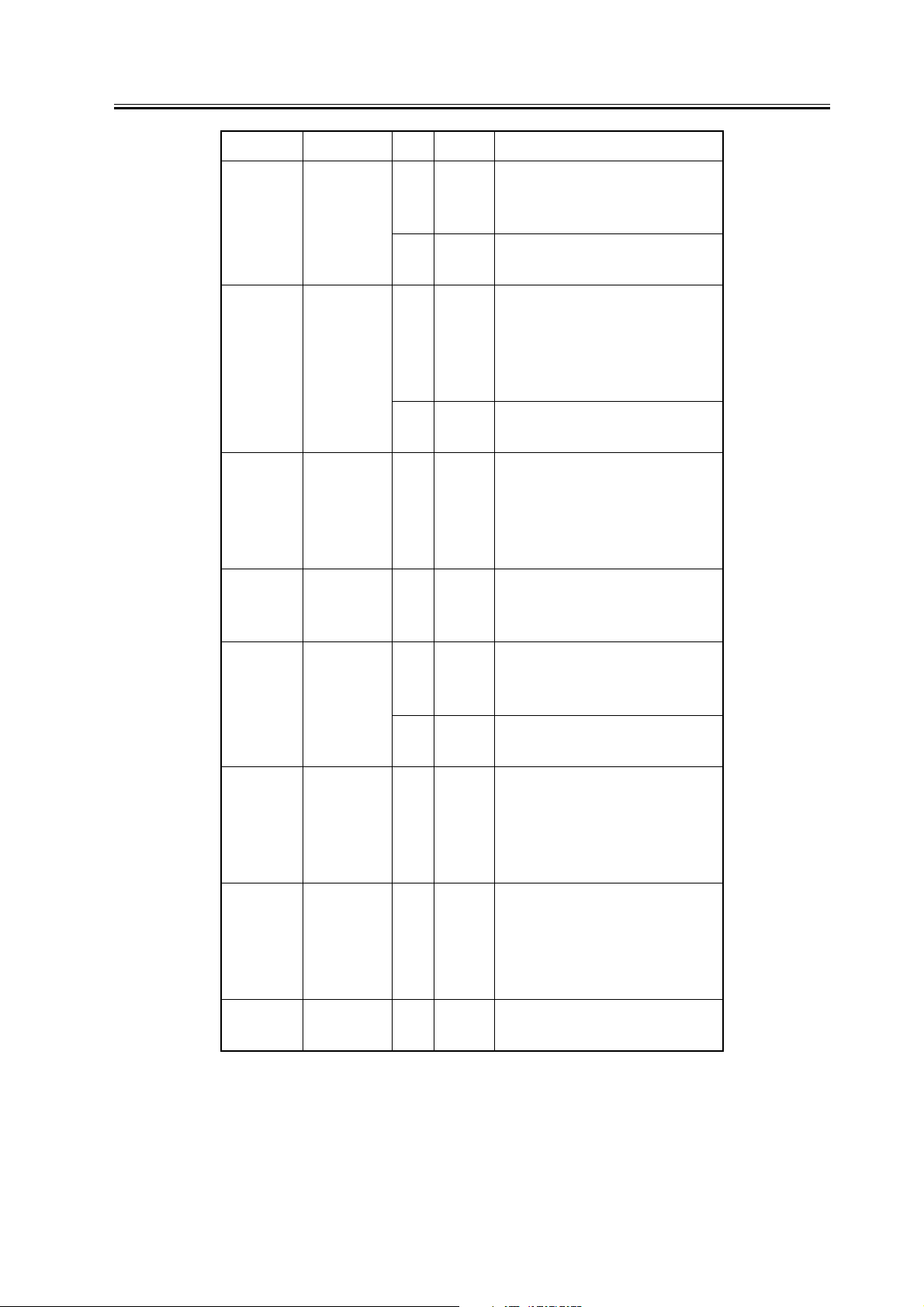

Chapter 1

[

Unit Location Item Interval Remarks

Photosensiti

ve drum

Black

developing

assembly

Black

developing

assembly

Drum heater

sliding area

Developing

cylinder

Developing

stray toner-

blocking sheet

clean

1,000,00

/

0 images

lubri

cate

checkupon

installati

on

clean 250,000

prints

[1] [1]

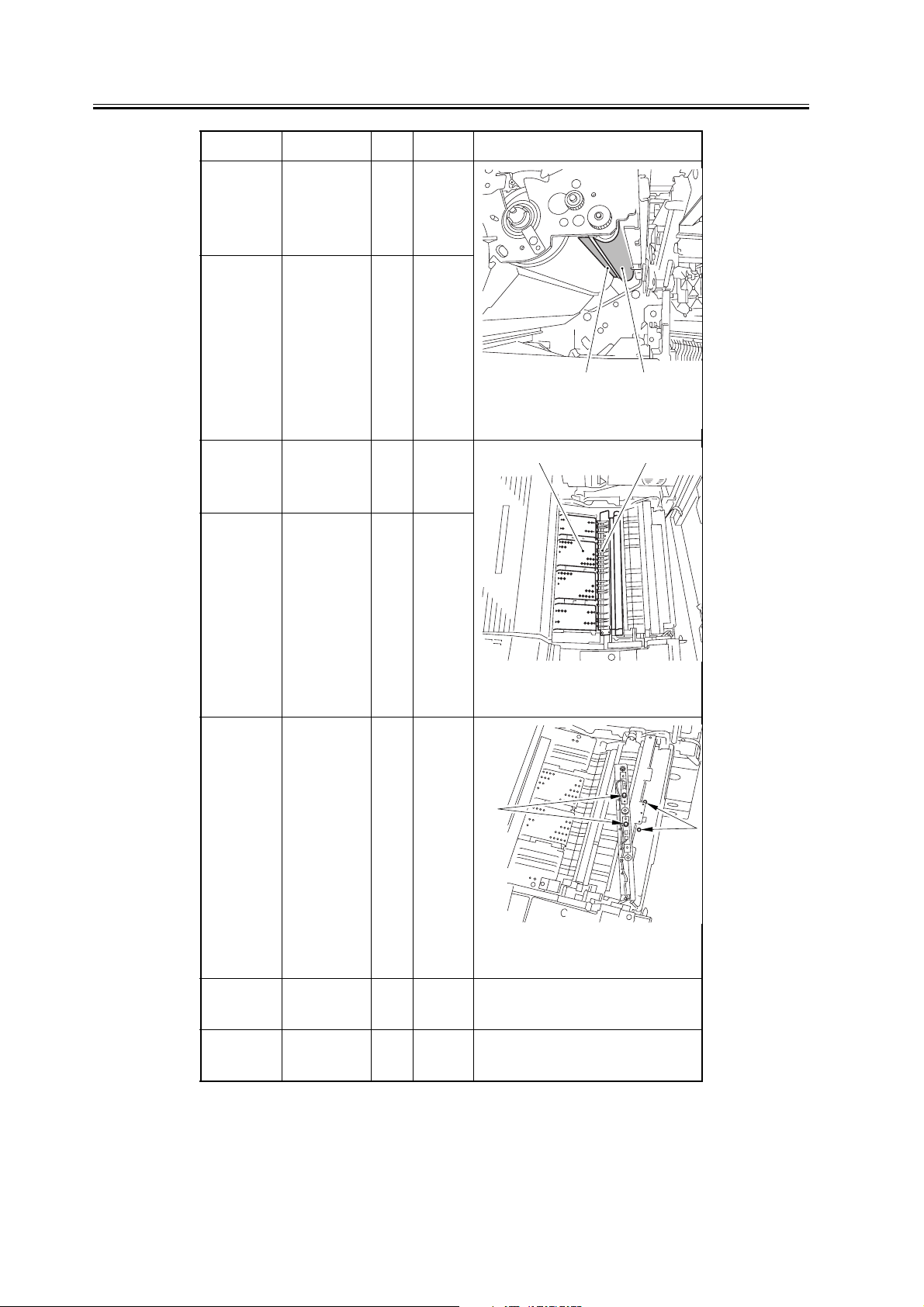

Clean the terminal [1] of the slip ring using

alcohol; then, apply a small amount of

lubricant (FY9-6008).

Black

developing

assembly

Black

developing

assembly

Black

developing

assembly

Color

developing

assembly

Color

developing

assembly

Developing

drive gear

Developing

roll

Bias roller

toner

collection case

Developing

stray toner-

blocking sheet

ATR sensor

window

clean 250,000

prints

clean 250,000

prints

clean 250,000

images

clean 250,000

prints

clean 250,000

images

[4][3] [1]

[1]Developing stray toner-blocking sheet

[2]Developing drive gear

[3]Developing roll

[4]Bias roller toner collection case

[3]

1-12

Unit Location Item Interval Remarks

Chapter 1

Color

developing

assembly

Color

developing

assembly

Color

developing

assembly

Color

developing

assembly

Color toner

cartridge level

sensor window

Developing

cylinder

bushing

Bottle cover clean 250,000

Color toner

cartridge

placement

sensor window

clean 250,000

images

clean 250,000

images

images

clean 250,000

images

Intermediate

transfer

assembly

Intermediate

transfer

assembly

area

Patch image

sensor window

Rail,

thereunder

[1]

[1]Color toner cartridge placement sensor

window

clean 250,000

images

clean 150,000

prints

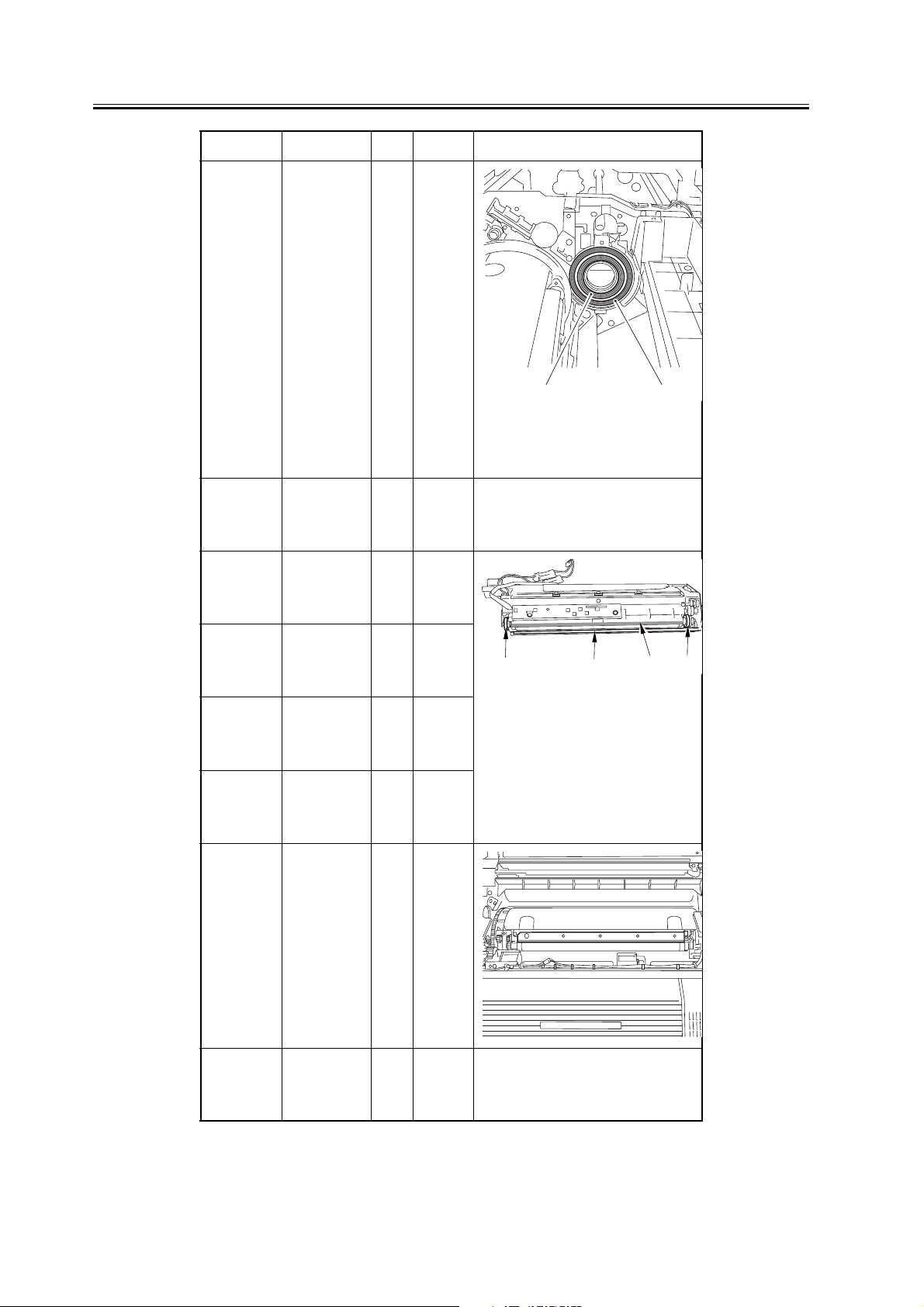

1-13

Chapter 1

e

d

Unit Location Item Interval Remarks

Intermediate

transfer

assembly

area

Intermediate

transfer

assembly

area

Secondary

transfer

assembly

Feeding

assembly

Scoop-up

sheet base,

thereunder

Cleaner

container,

hereunder

Secondary

transfer rear

guide

Feeding belt clean 150,000

clean 150,000

prints

clean 150,000

prints

clean 150,000

prints

prints

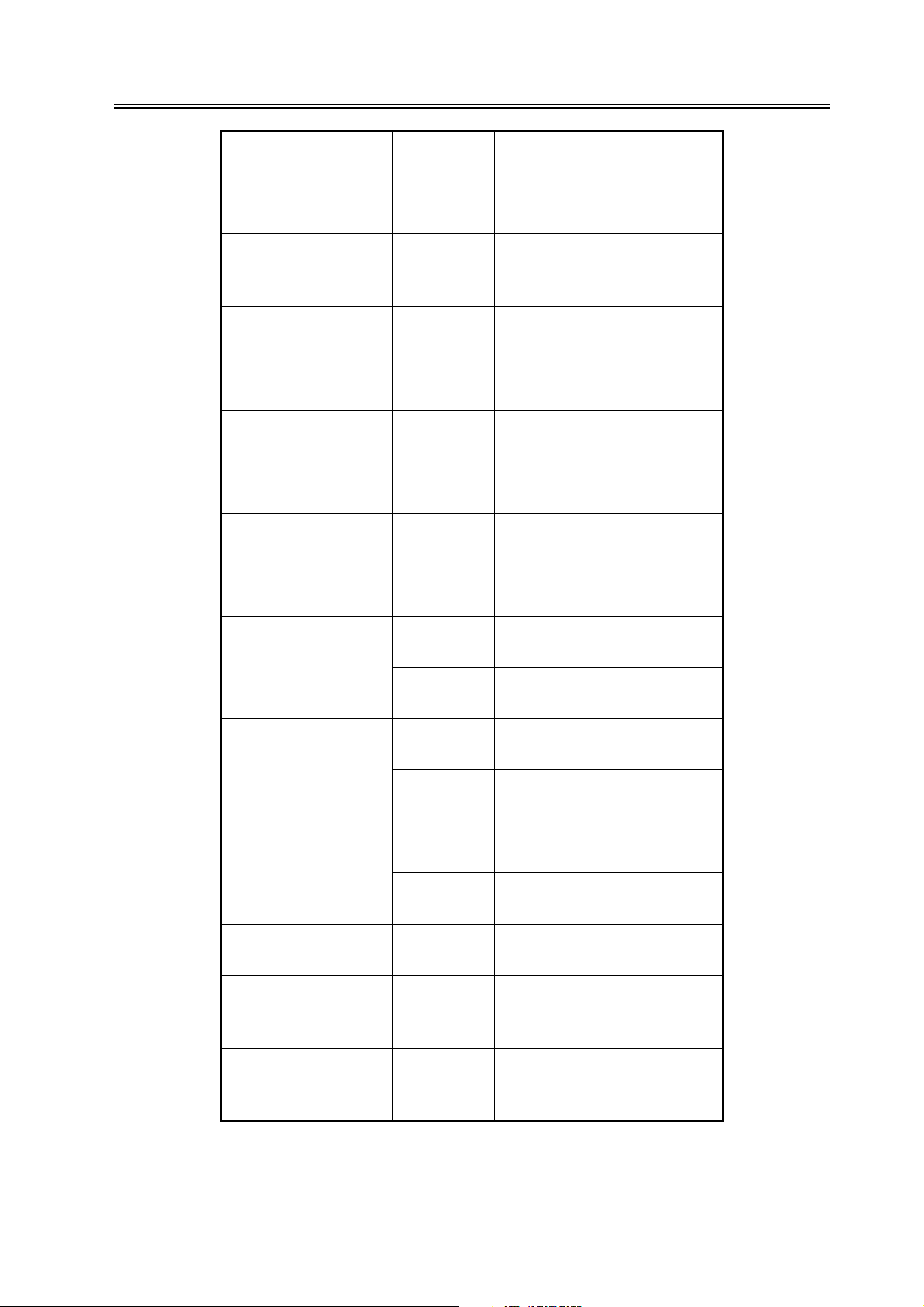

[1] [2]

Scoop-up sheet base, ther

[1]

[2]

Cleaner container, hereun

[2] [1]

Feeding

assembly

Feeding

assembly

Feeding

assembly

OHP sensor clean 250,000

prints

Registration

roller

Registration

guide

clean 250,000

prints

clean 250,000

prints

[1] Secondary transfer rear guide

[2] Feeding belt

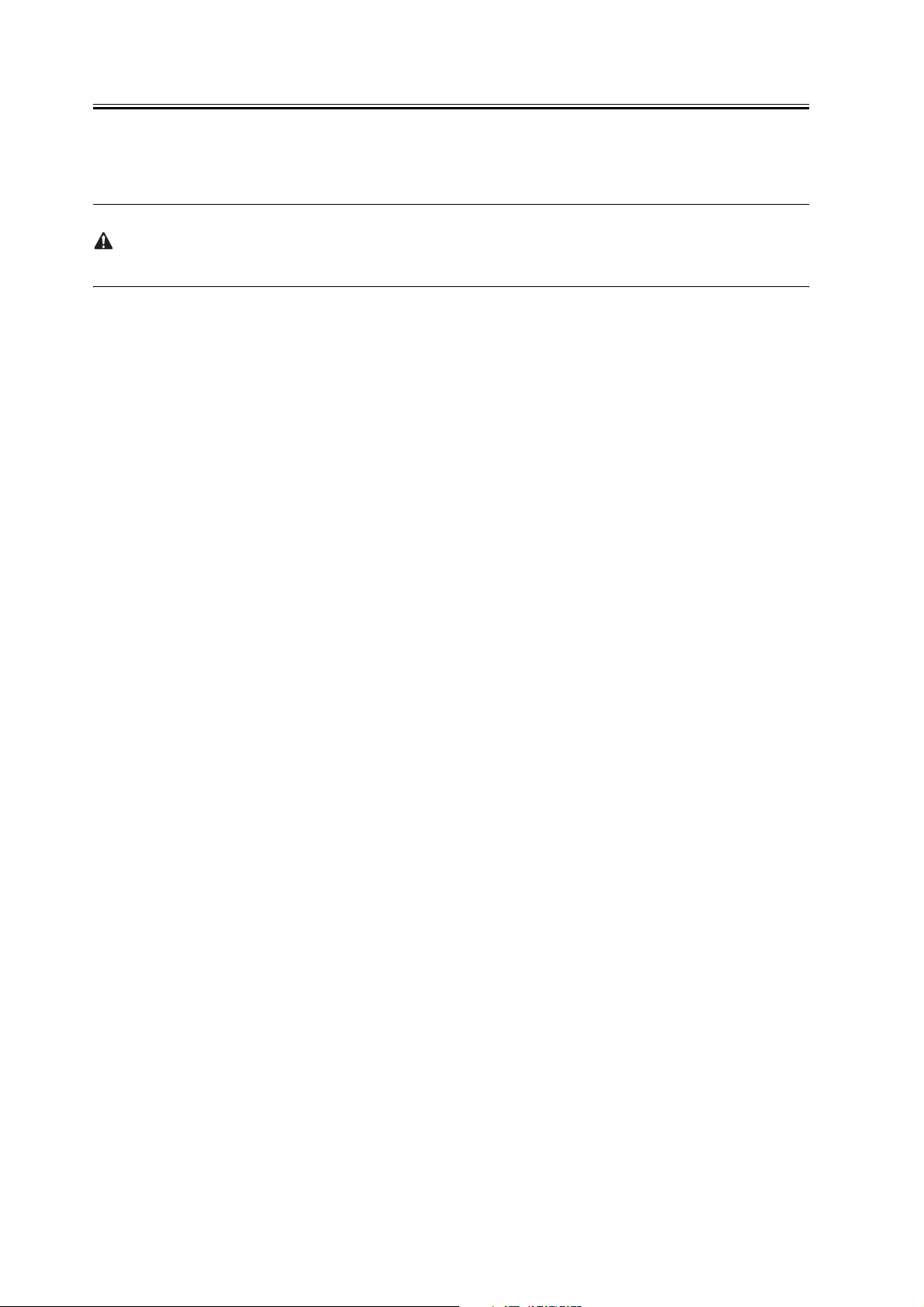

[1]

[

[1]clean upper/lower OHP sensor using

blow brush

1-14

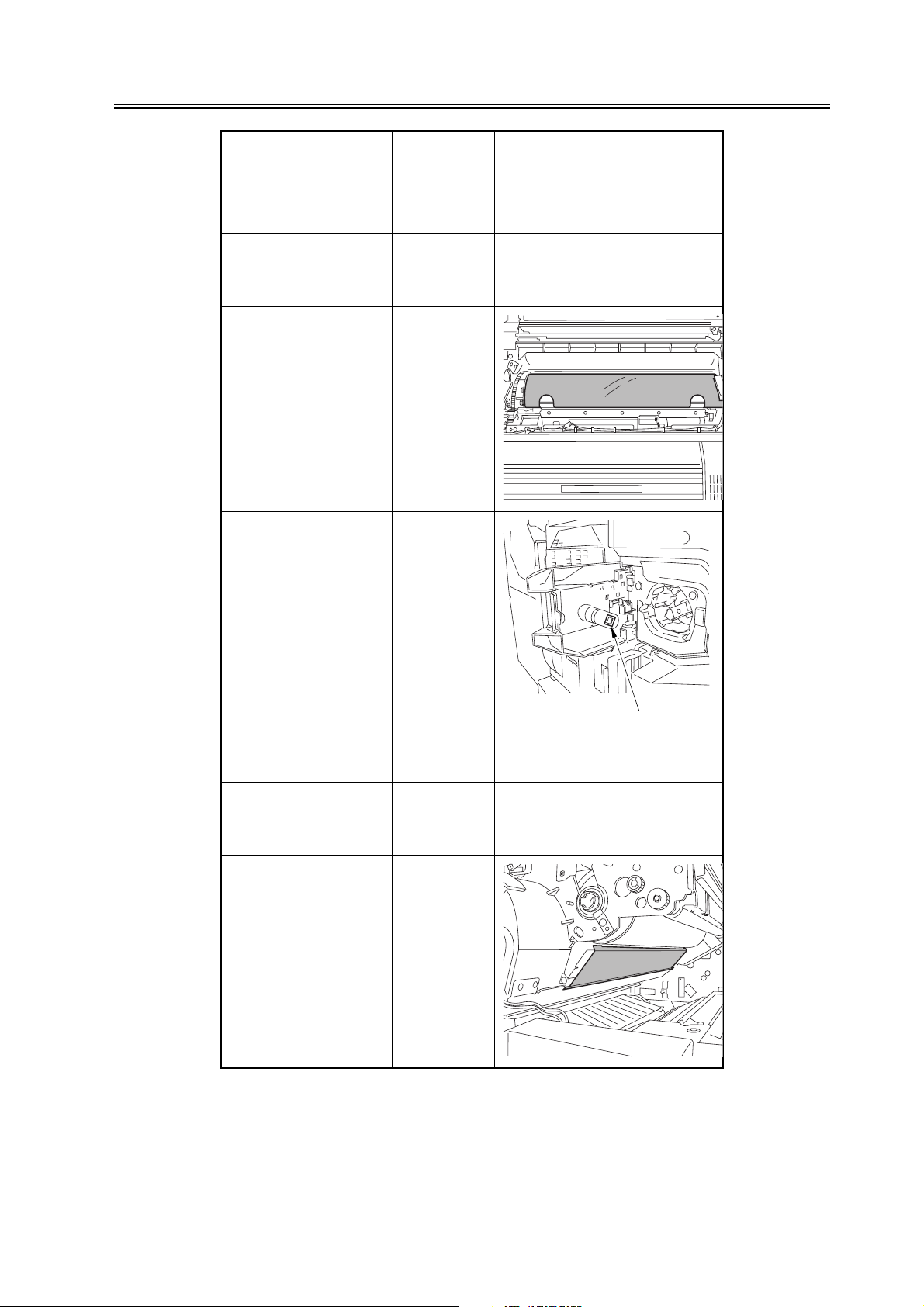

Unit Location Item Interval Remarks

Chapter 1

Hopper

assembly

Fixing

assembly

Fixing

assembly

Fixing

assembly

Fixing

assembly

Toner

receptacle/

supply mouth

Fixing web checkupon

Fixing

thermistor

Pressure

thermistor

Outside

heating roller

thermistor

clean 250,000

prints

installati

on

clean 150,000

prints

replace500,000

prints 枚

clean 150,000

prints

replace500,000

prints

clean 150,000

prints

replace500,000

prints

Fixing

assembly

Fixing

assembly

Fixing

assembly

Fixing

assembly

Delivery

assembly

Waste toner

collection

assembly

Fixing thermal

switch

Pressure

thermal switch

Outside

heating

thermal switch

Inlet guide clean 150,000

Upper/lower

separation

claw

Waste toner

box

clean 300,000

prints

replace1,000,00

0 prints

clean 150,000

prints

replace1,000,00

0 prints

clean 150,000

prints

replace1,000,00

0 prints

prints

clean 150,000

prints

inspect250,000

images

use lint-free with specified solvent.

use lint-free paper with specified solvent.

1-15

Chapter 1

note:

The black developing cylinder need not be cleaned on a periodical basis. If you must clean the surface of the cylinder,

be sure to dry wipe it with lint-free paper, NEVER using water or solvent.

The foregoing values are estimates only, and are subject to change based on future data.

1-16

1.4 Cleaning

Chapter 1

1.4.1 Cleaning the Photosensitive Drum

Do not rotate the magnetic roller during the work. Otherwise, waste toner can start to fall out of the cleaning

assembly.

1) Remove the photosensitive drum.

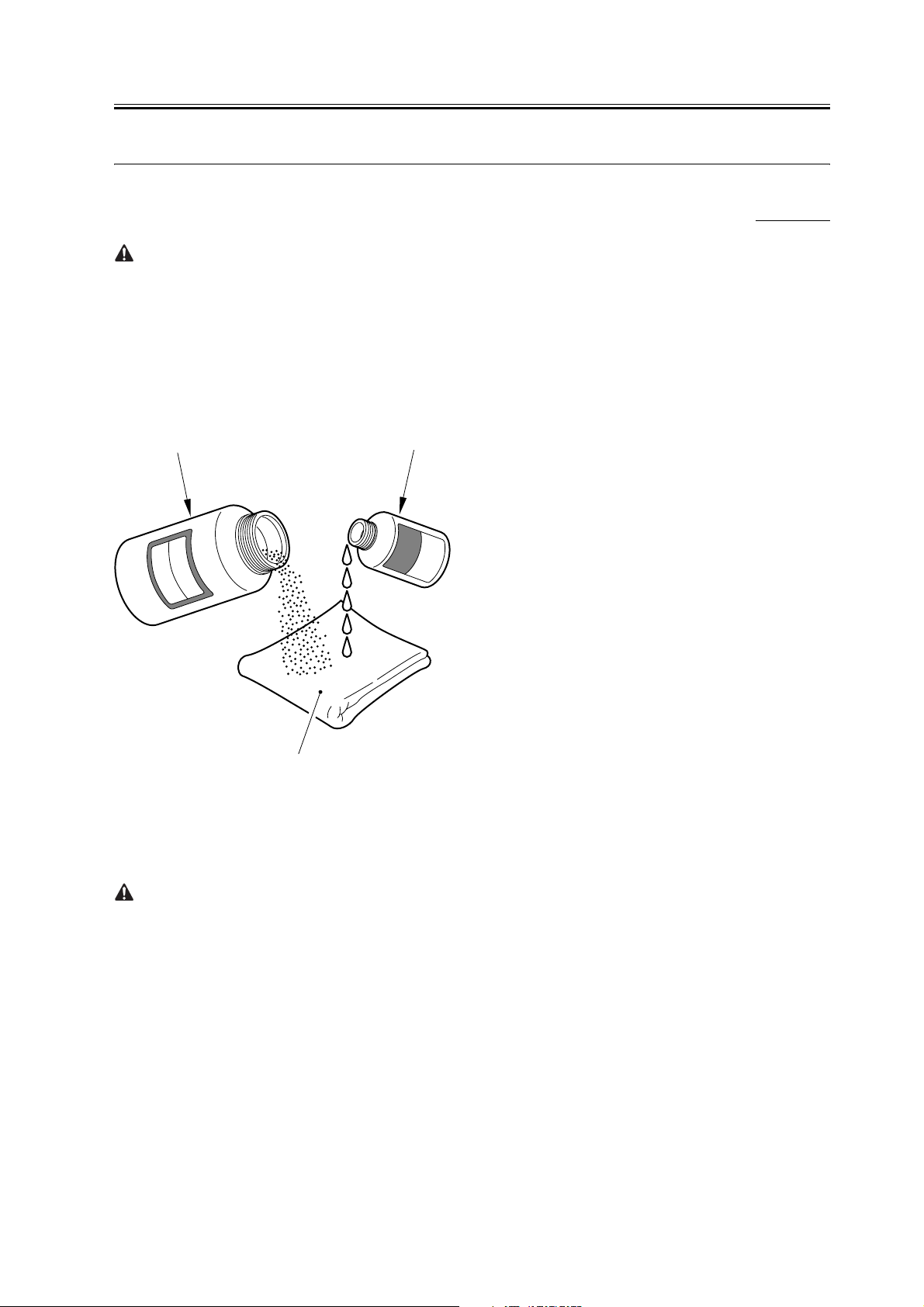

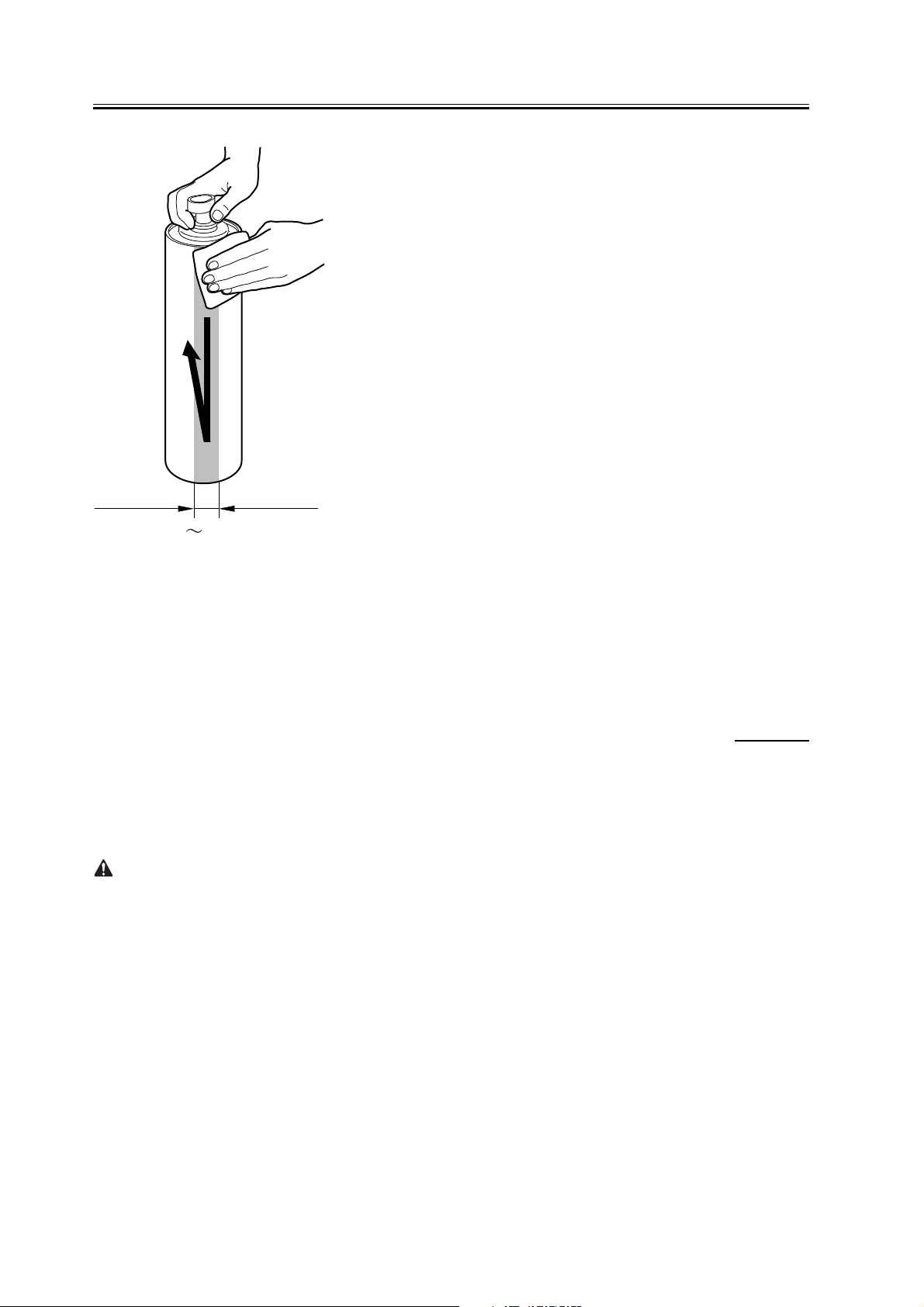

2) Moisten lint-free paper [1] with 5 to 10cc of alcohol [2]; then, collect 0.2 to 0.3g of drum cleaning powder (CK-

0429) [3] on the lint-free paper.

0004-1175

[3]

CK-0429

[2]

[1]

F-1-1

3) Force the lint-free paper against the photosensitive drum, and wipe from the front to the rear and from the rear to

the front as if to rub the surface of the drum.

- Keep the width of cleaning to 5 to 10 cm in the drum axial direction.

- Limit the number of back-and-froth movements of the lint-feed paper to 15 to 20 times. Forcing the paper against

the drum surface will rarely affect the life of the drum.

1-17

Chapter 1

F-1-2

5 10cm

4) When the alcohol has evaporated, dry wipe the surface of the drum with lint-free paper. If there is an uneven layer

of cleaning powder, go back to step 3), and clean the surface by increasing the number of back-and-forth movements.

5) Rotate the drum for the width that has been cleaned (5 to 10cm), and repeat steps 2 through 4 until the entire

surface has been cleaned.

1.4.2 Cleaning the Secondary Transfer Rear Guide

1) Open the front cover.

2) Slide out the fixing/feeding assembly.

3) Wipe the ribs one by one by moving lint-free paper moistened with alcohol in the direction of the arrow in the

figure.

1. Do not dry wipe, as the ribs are likely to become charged.

2. The ribs of the secondary transfer rear guide are located near the static eliminating brush [3]; do not move the lint-

free paper in the wrong direction to avoid trapping and bending the static eliminator.

0004-6732

1-18

F-1-3

Chapter 1

1.4.3 Cleaning the Registration Roller, Registration Guide, and

Transparency Sensor

1) Slide out the fixing/feeding assembly.

2) Push the leaf springs on both sides, and slide the fixing/feeding assembly farther out.

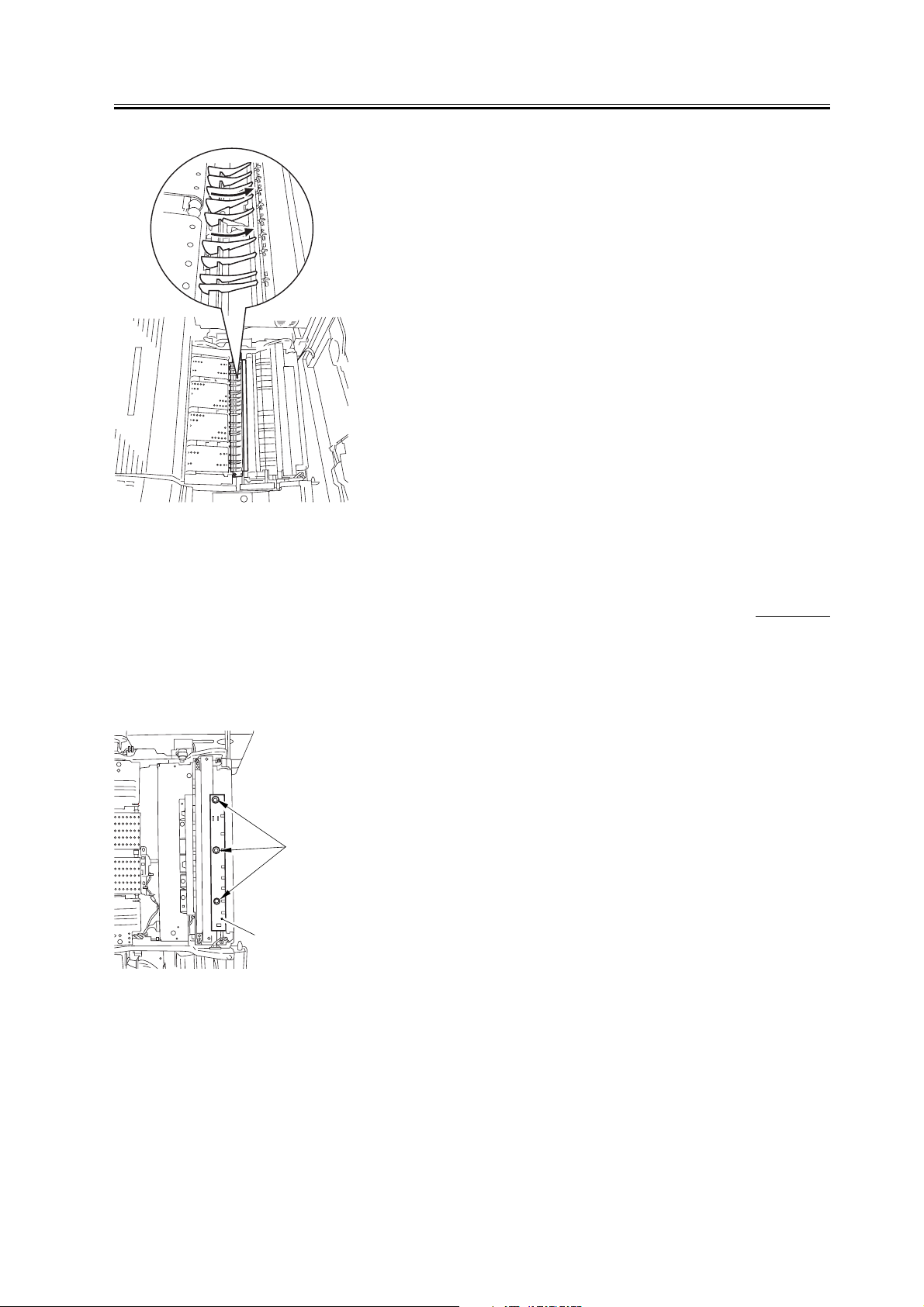

3) Remove the 3 screws [1], and turn overt the transparency upper sensor unit [2].

[1

[2]

F-1-4

0005-6999

4) Remove the paper lint building up over the transparency sensor [1] using a blower brush.

1-19

Chapter 1

[1]

F-1-5

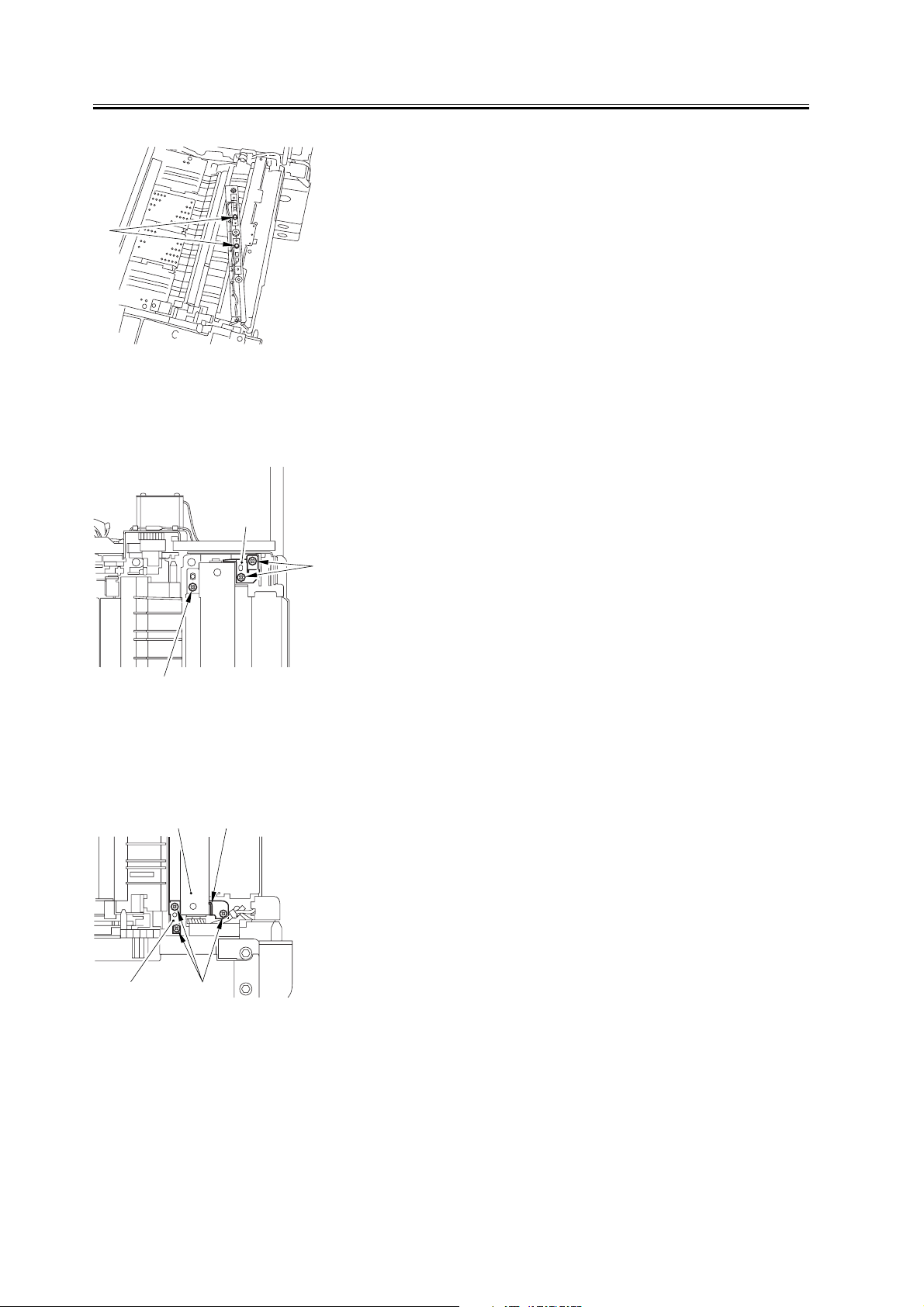

5) Remove the 2 screws [1], and detach the grounding spring [2].

6) Remove the screw [3].

[2]

[1]

[3]

F-1-6

7) Remove the 3 screws [1], and detach the registration roller upper stay [3] together with the grounding spring [4]

while freeing the spring [2] off its hook.

[3] [2]

[4] [1]

F-1-7

8) Open the registration upper guide [1], and clean the back [1] of the upper guide and the lower guide [2] using lint-

free paper moistened with alcohol.

9) Remove the paper lint building up on the transparency sensor [3] using a blower brush.

1-20

Loading...

Loading...