Portable Manual

Finisher, Sorter, DeliveryTray

Saddle Finisher-T2

Feb 21 2005

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may be

information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information

as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will

issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical

and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol ,

the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the

delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to

indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in

"DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the

operations of the microprocessors used in the machines are not discussed: they are explained in terms of from

sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant

Service Information bulletins and be able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts............................................................................................................................... 1- 1

1.1.1Periodically Replaced Parts (Finisher Unit)................................................................................................ 1- 1

1.1.2Periodically Replaced Parts (Saddle Stitcher Unit)..................................................................................... 1- 1

1.2 Durables............................................................................................................................................................. 1- 2

1.2.1Durables (Finisher Unit).............................................................................................................................. 1- 2

1.2.2Durables (Saddle Stitcher Unit) .................................................................................................................. 1- 3

1.3 Periodical Servicing .......................................................................................................................................... 1- 4

1.3.1Periodical Servicing (Finisher Unit)............................................................................................................ 1- 4

1.3.2Periodical Servicing (Saddle Stitcher Unit) ................................................................................................ 1- 4

Chapter 2 Standards and Adjustments

2.1 Basic Adjustment .............................................................................................................................................. 2- 1

2.1.1Upward Curl Mode...................................................................................................................................... 2- 1

2.1.2Special Curl Mode....................................................................................................................................... 2- 1

2.1.3Downward Curl Mode................................................................................................................................. 2- 2

2.1.4Heavy Paper Upward Curl Mode ................................................................................................................ 2- 2

2.1.5Stack Delivery Mode................................................................................................................................... 2- 3

2.1.6Offset Stack Mode....................................................................................................................................... 2- 4

2.1.7Saddle Delivery Tray Limitless Mode ....................................................................................................... 2- 4

2.2 Adjustment at Time of Parts Replacement........................................................................................................ 2- 5

2.2.1Adjusting the Alignment Position ............................................................................................................... 2- 5

2.2.2Adjusting the Staple Position ...................................................................................................................... 2- 5

2.2.3Adjusting the Folding Position.................................................................................................................... 2- 6

2.2.4Adjusting the Stitching Position (adjusting center stitching) ...................................................................... 2- 7

2.2.5Adjusting the Stitcher Unit.......................................................................................................................... 2- 7

Chapter 3 Error Code

3.1 User Error Code................................................................................................................................................. 3- 1

3.1.1Staple is absent ............................................................................................................................................ 3- 1

3.1.2Stapler safety protection function activated ................................................................................................ 3- 1

3.1.3Stack tray overstacking ............................................................................................................................... 3- 2

3.1.4Staple is absent (Saddle Stitcher Unit)........................................................................................................ 3- 2

3.1.5Mixed paper sizes (Saddle Stitcher Unit).................................................................................................... 3- 3

3.1.6Stack exceeded (Saddle Stitcher Unit) ........................................................................................................ 3- 3

3.1.7Stitching capacity error (Saddle Stitcher Unit) ........................................................................................... 3- 3

3.2 Service Error Code ............................................................................................................................................ 3- 4

3.2.1E500............................................................................................................................................................. 3- 4

3.2.2E503............................................................................................................................................................. 3- 4

3.2.3E505............................................................................................................................................................. 3- 4

3.2.4E514............................................................................................................................................................. 3- 5

Contents

3.2.5E530.............................................................................................................................................................3- 5

3.2.6E531.............................................................................................................................................................3- 6

3.2.7E532.............................................................................................................................................................3- 6

3.2.8E535.............................................................................................................................................................3- 7

3.2.9E537.............................................................................................................................................................3- 7

3.2.10E540...........................................................................................................................................................3- 8

3.2.11E542...........................................................................................................................................................3- 9

3.2.12E584.........................................................................................................................................................3- 10

3.2.13E5F0.........................................................................................................................................................3- 10

3.2.14E5F1.........................................................................................................................................................3- 11

3.2.15E5F2.........................................................................................................................................................3- 11

3.2.16E5F3.........................................................................................................................................................3- 12

3.2.17E5F4.........................................................................................................................................................3- 12

3.2.18E5F5.........................................................................................................................................................3- 12

3.2.19E5F6.........................................................................................................................................................3- 13

3.2.20E5F9.........................................................................................................................................................3- 14

3.2.21Temporary Functional Limit....................................................................................................................3- 14

Chapter 4 Outline of Components

4.1 Outline of Electrical Components .....................................................................................................................4- 1

4.1.1Sensors (Finisher Unit) ................................................................................................................................4- 1

4.1.2Microswitches (Finisher Unit).....................................................................................................................4- 4

4.1.3Solenoids (Finisher Unit).............................................................................................................................4- 5

4.1.4Motors (Finisher Unit).................................................................................................................................4- 6

4.1.5Clutches (Finisher Unit) ..............................................................................................................................4- 8

4.1.6PCBs (Finisher Unit) ...................................................................................................................................4- 9

4.1.7Sensors (Saddle Stitcher Unit)...................................................................................................................4- 10

4.1.8Microswitches (saddle Stitcher Unit) ........................................................................................................4- 12

4.1.9Motors (Saddle Stitcher Unit)....................................................................................................................4- 14

4.1.10Solenoids (Saddle Stitcher Unit) .............................................................................................................4- 15

4.1.11PCBs (Saddle Stitcher Unit) ....................................................................................................................4- 16

4.2 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB ........................................4- 17

4.2.1Overview....................................................................................................................................................4- 17

4.2.2Finisher Controller PCB ............................................................................................................................4- 17

4.2.3Saddle Stitcher Controller PCB .................................................................................................................4- 18

Chapter 5 System Construction

5.1 Product Specifications .......................................................................................................................................5- 1

5.1.1Finisher Unit ................................................................................................................................................5- 1

5.1.2Saddle Stitcher Unit.....................................................................................................................................5- 4

Chapter 1 Maintenance

and Inspection

Contents

Contents

1.1 Periodically Replaced Parts................................................................................................................................ 1-1

1.1.1 Periodically Replaced Parts (Finisher Unit) ................................................................................................ 1-1

1.1.2 Periodically Replaced Parts (Saddle Stitcher Unit)..................................................................................... 1-1

1.2 Durables.............................................................................................................................................................. 1-2

1.2.1 Durables (Finisher Unit).............................................................................................................................. 1-2

1.2.2 Durables (Saddle Stitcher Unit) .................................................................................................................. 1-3

1.3 Periodical Servicing ........................................................................................................................................... 1-4

1.3.1 Periodical Servicing (Finisher Unit)............................................................................................................ 1-4

1.3.2 Periodical Servicing (Saddle Stitcher Unit) ................................................................................................ 1-4

1.1 Periodically Replaced Parts

Chapter 1

1.1.1 Periodically Replaced Parts (Finisher Unit)

The Finisher unit does not have parts that must be replaced on a periodical basis.

1.1.2 Periodically Replaced Parts (Saddle Stitcher Unit)

The Saddle stitcher unit does not have parts that must be replaced on a periodical basis.

0009-2560

0009-2571

1-1

Chapter 1

1.2 Durables

1.2.1 Durables (Finisher Unit)

0009-2561

Some of the parts of the machine may need to be replaced one or more times because of wear or tear during the

machine's warranty period. Replace them as necessary.

T-1-1

As of

November,

2004

No. Name No. QuantityApprox.

life

1 Stapler FM2-0665-

000

2 Delibery static

charge eliminator

(L)

FC5-3667-

000

1 500,000

times

1 1,000,000

sheets

Remark

1 cartridge lasts

approximately

5,000 times

3 Delibery static

charge

eliminator (R)

4 Inlet static

charge

eliminator

5 Swing guide

inside

static charge

eliminator

6 Buffer roller FC5-3442-

7 Return roller

(Rear)

8 Return roller

(Front)

FC5-5571-

000

FL2-0822-

000

FL2-0817-

000

000

FC5-3457-

000

FC5-6873-

000

1 1,000,000

sheets

1 1,000,000

sheets

1 1,000,000

sheets

2 1,000,000

sheets

1 1,000,000

sheets

1 1,000,000

sheets

Color;White

Color;Black

1-2

Chapter 1

1.2.2 Durables (Saddle Stitcher Unit)

0009-2572

Some of the parts of the machine may need to be replaced one or more times because of wear or tear during the

machine's warranty period. Replace them as necessary.

T-1-2

As of

November,

2004

No. Name No. QuantityApprox.

life

1 Stitcher FL2-0846-

000

2 100,000

times

Remark

1 cartridge lasts

approximately

2,000 times

1-3

Chapter 1

1.3 Periodical Servicing

1.3.1 Periodical Servicing (Finisher Unit)

Does not have parts that must be serviced on a periodical basis.

1.3.2 Periodical Servicing (Saddle Stitcher Unit)

Does not have parts that must be serviced on a periodical basis.

0009-2562

0009-2573

1-4

Chapter 2 Standards and

Adjustments

Contents

Contents

2.1 Basic Adjustment ............................................................................................................................................... 2-1

2.1.1 Upward Curl Mode...................................................................................................................................... 2-1

2.1.2 Special Curl Mode....................................................................................................................................... 2-1

2.1.3 Downward Curl Mode................................................................................................................................. 2-2

2.1.4 Heavy Paper Upward Curl Mode ................................................................................................................ 2-3

2.1.5 Stack Delivery Mode................................................................................................................................... 2-4

2.1.6 Offset Stack Mode....................................................................................................................................... 2-5

2.1.7 Saddle Delivery Tray Limitless Mode ....................................................................................................... 2-6

2.2 Adjustment at Time of Parts Replacement......................................................................................................... 2-7

2.2.1 Adjusting the Alignment Position ............................................................................................................... 2-7

2.2.2 Adjusting the Staple Position ...................................................................................................................... 2-7

2.2.3 Adjusting the Folding Position .................................................................................................................... 2-8

2.2.4 Adjusting the Stitching Position (adjusting center stitching) .................................................................... 2-11

2.2.5 Adjusting the Stitcher Unit........................................................................................................................ 2-11

Chapter 2

2.1 Basic Adjustment

2.1.1 Upward Curl Mode

a. Outline

Paper tends to curl upward in certain conditions,

preventing normal delivery/stacking. (See the

following figure.)

0009-2563

conditions (e.g., the use of paper with little curl or

paper with downward curl) can cause improper

stacking. In this regard, it is very important to study

the type of paper that is most often used by the user

before enabling this mode item.

2.1.2 Special Curl Mode

a. Outline

If paper with irregular curl is deposited*, its edges can

block the delivery slot of the finisher, pushing forward

the exiting stack when the next sheet arrives. (See the

following figure.)

*LDR size only (mainly, Boise Cascade; 75 g/m2 in

weight).

Paper with

appreciable body.

0009-2564

F-2-1

If such is the case,

1) Turn over the stack of paper inside the paper source

(e.g., cassette). If doing so makes the upward curling

worse than before, turn back over the stack. If the

paper still develops upward curl and, thus, fails to

deposit itself normally, try enabling the upward curl

mode item.

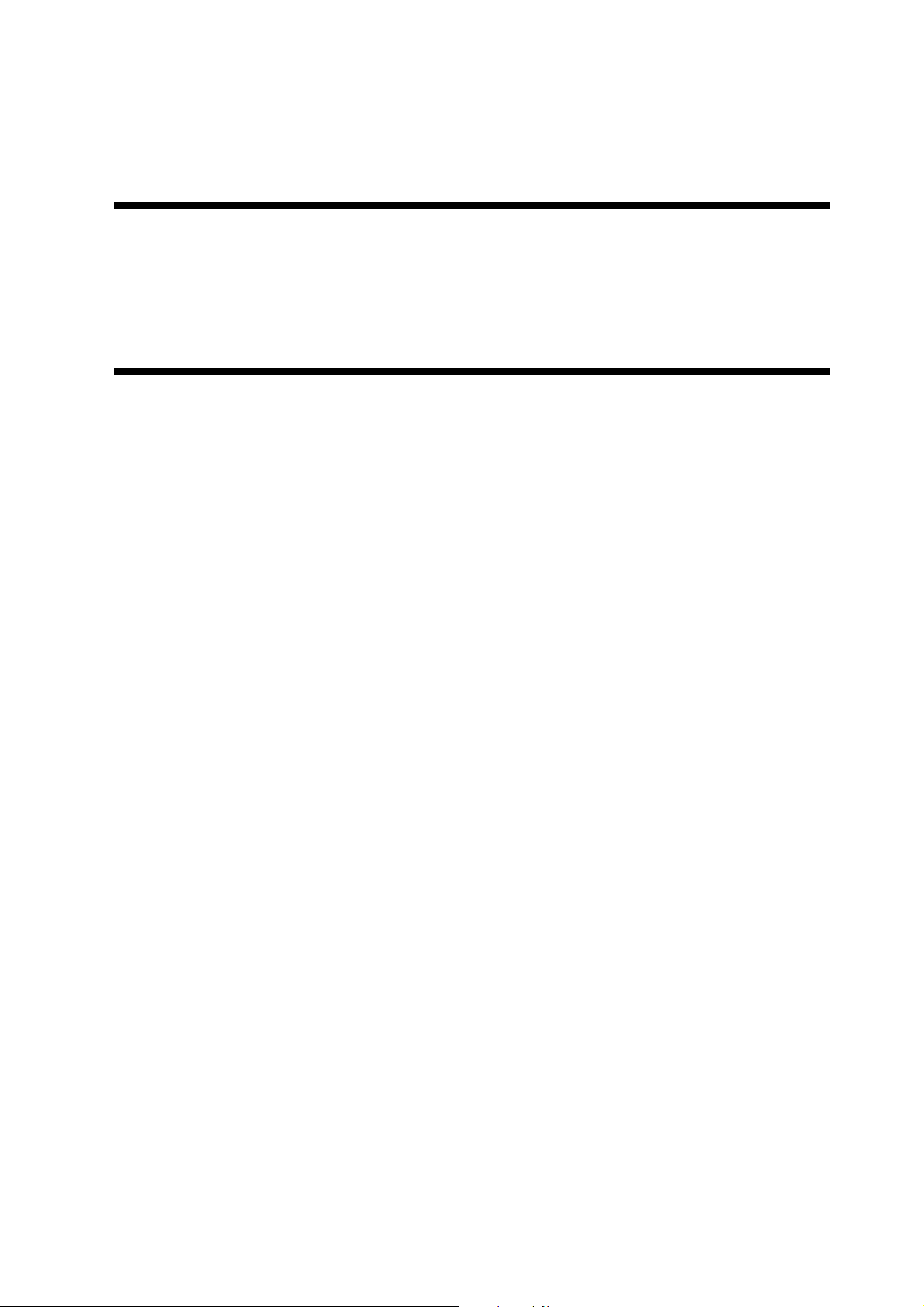

b. Enabling the Upward Curl Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

ON

12345678

F-2-2

3) Turn on the host machine.

- When this mode item is enabled, the machine

changes the speed of its stack delivery roller to ensure

proper stacking.

- When this mode item has been enabled, changes in

F-2-3

If this is the case,

1) Turn over the stack of paper inside the source (i.e.,

cassette). If paper starts to curl more than before, turn

back over the stack. If the curling is not corrected as a

result, try enabling the special curl mode item.

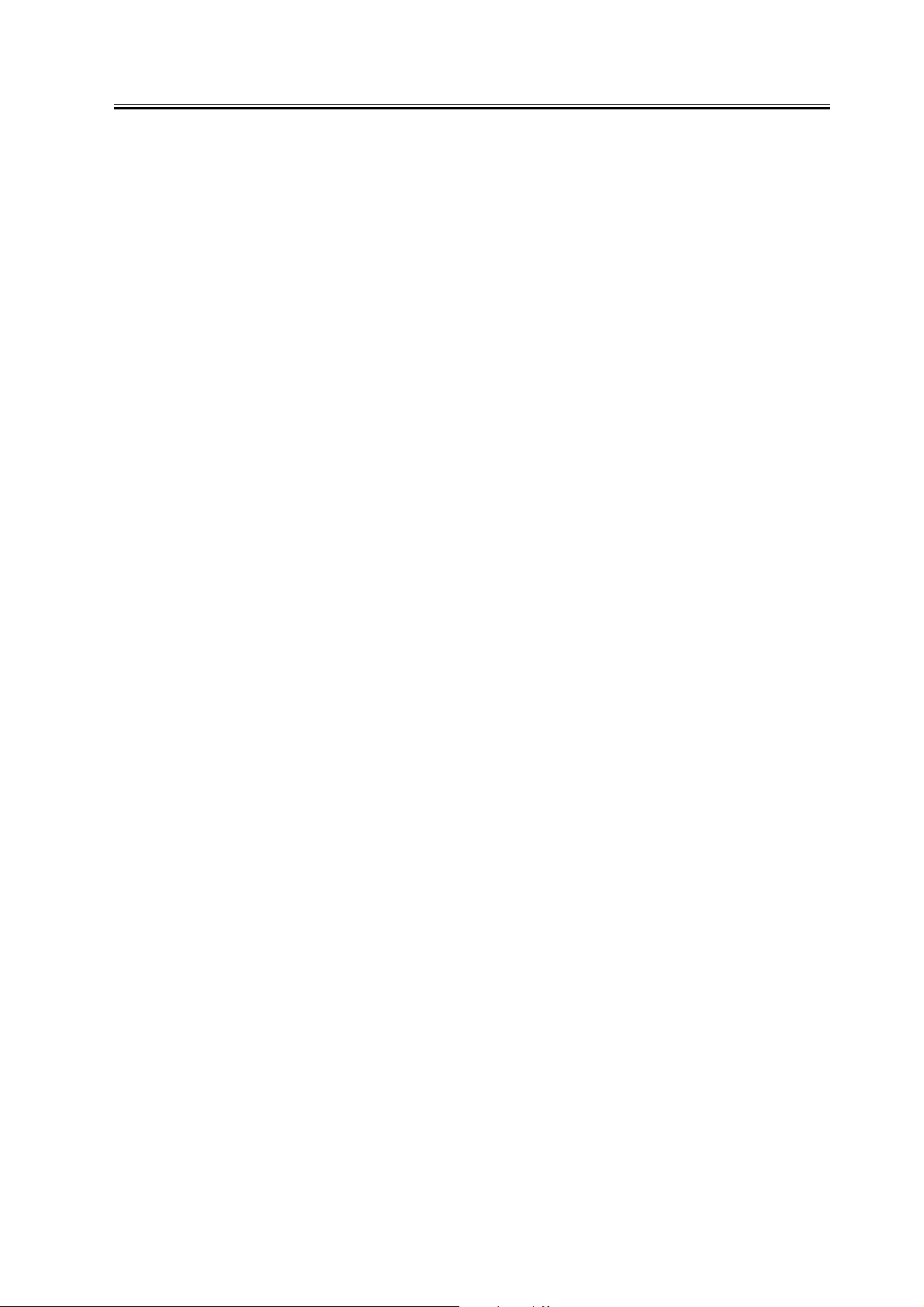

b. Enabling Special Curl Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follow:

2-1

Chapter 2

3) Turn on the host machine.

- When this mode item is enabled, the paper surface

detection mechanism is executed for every sheet of

paper (instead of every 5 sheets) and the timing at

which the delivery tray is moved down is advanced so

that the paper will be stacked properly.

- When this mode item has been enabled, changes in

conditions (e.g., the use of paper with little curl) can

prevent proper stacking. In the light of this, be sure to

check the type of paper most frequently used by the

user before enabling this mode item.

ON

12345678

F-2-4

2.1.3 Downward Curl

Mode

a. Outline

Paper tends to curl downward in certain conditions,

preventing normal delivery/stacking. (See the

following figure.)

0009-2565

to deposit itself normally, try enabling the downward

curl mode item.

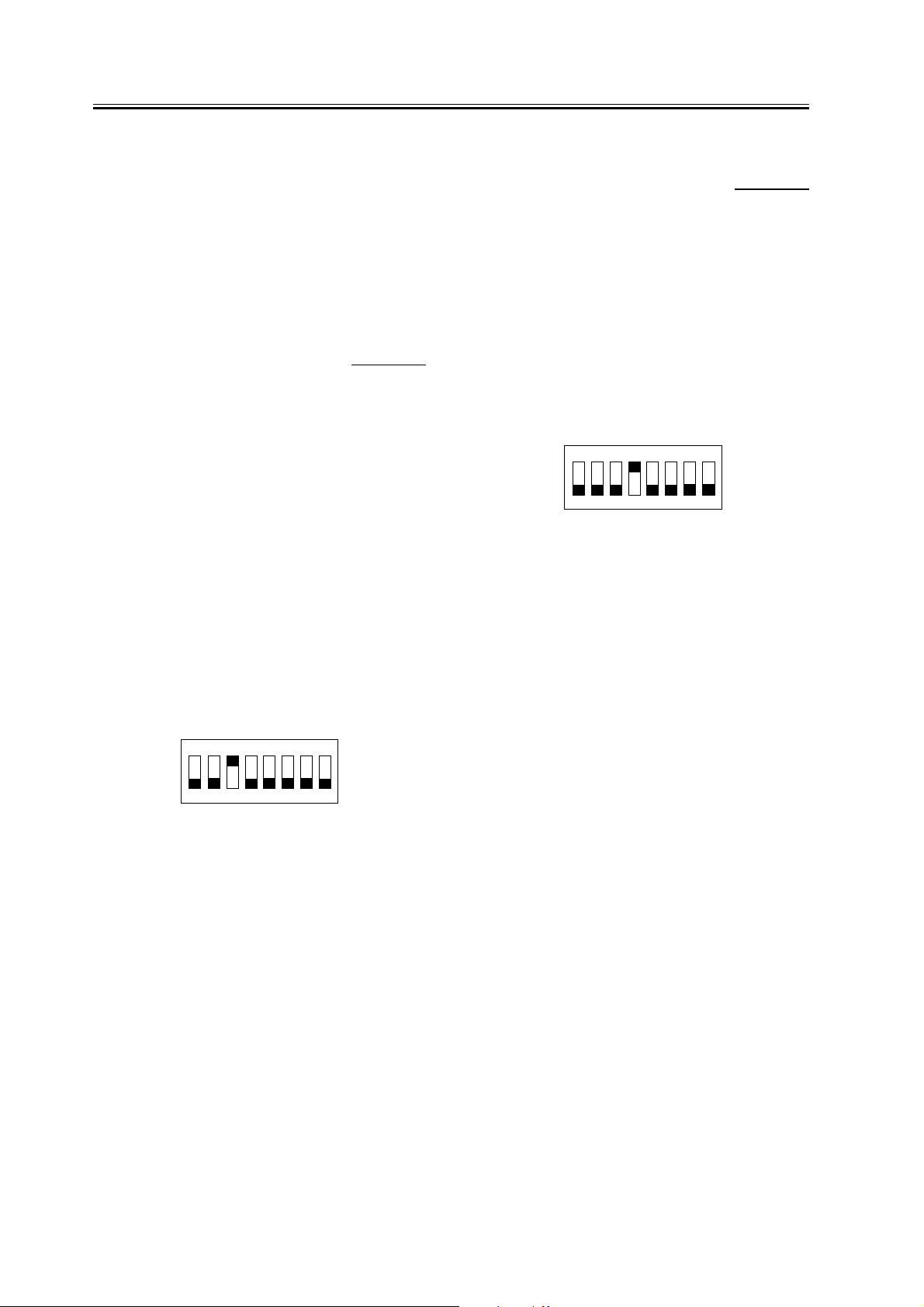

b. Enabling the Downward Curl Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

ON

12345678

F-2-6

3) Turn on the host machine.

- When this mode item is enabled, the machine

changes the speed of its stack delivery roller to ensure

proper stacking.

- When this mode item has been enabled, changes in

conditions (e.g., the use of paper with little curl or

paper with upward curl) can cause improper stacking.

In this regard, it is very important to study the type of

paper that is most often used by the user before

enabling this mode item.

2.1.4 Heavy Paper Upward

Curl Mode

0009-2566

F-2-5

If such is the case,

1) Turn over the stack of paper inside the paper source

(e.g., cassette). If doing so makes the downward

curling worse than before, turn back over the stack. If

the paper still develops downward curl and, thus, fails

2-2

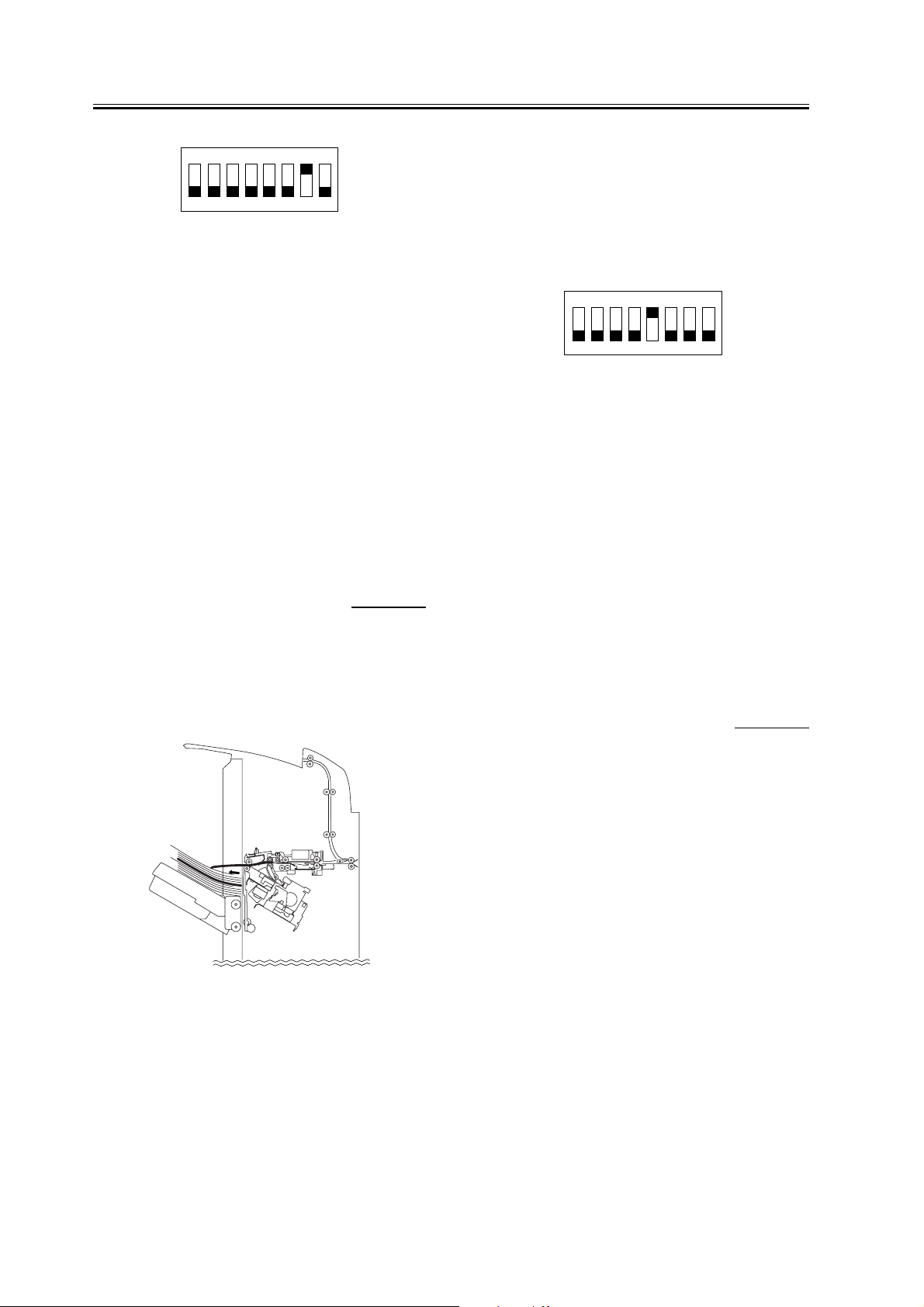

a. Outline

Depending on the selected paper handling mode and

the condition of paper*, upward curl can develop and

prevent the machine from stacking the paper properly.

(See the following figure.)

*For instance, heavy paper cover mode and single-

side binding are selected, and the front/back cover is

LDR and 157 g/m2 or more.

Chapter 2

F-2-7

If this is the case,

1) Turn over the stack of paper in the source (i.e.,

cassette). If doing so has caused the paper to curl more

than before, turn back over the stack. If the curling is

still appreciable and the machine fails to stack the

paper properly, try enabling heavy paper upward curl

mode.

b. Enabling Heavy Paper Upward Curl

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

2.1.5 Stack Delivery Mode

0009-2567

a. Outline

Depending on the selected paper handling mode*,

condition of paper, and environment, the trailing edge

of paper can rain against the stacking wall and prevent

the machine from stacking it correctly (also causing it

to prematurely detect an over-stack condition; see the

following figure).

*For instance, in stack delivery mode other than when

the stack consists of 6 or fewer sheets of small-size

paper.

F-2-9

ON

12345678

F-2-8

3) Turn on the host machine.

- When this mode item is enabled, the machine

changes its operation it executes after the start of stack

edging, thus ensuring that the paper will be stacked

properly.

- When this mode item has been enabled, changes in

conditions (e.g., the use of paper with little curl or

delivery of paper with downward curl) can prevent the

machine from stacking the paper properly. It is

important, therefore, to be sure of the type of paper

used by the user before enabling this mode item.

If this is the case,

1) Turn over the stack of paper inside the source (e.g.,

cassette). If doing so has made upward curling worse

than before, turn back over the stack. If the upward

curling still causes the machine to fail to stack the

paper correctly, try enabling stack delivery mode:

b. Enabling Stack Delivery Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

ON

12345678

F-2-10

3) Turn on the host machine.

- When this mode item is enabled, the machine

changes its operation it executes after stack edging to

2-3

Chapter 2

make sure that the paper will be stacked correctly.

- After this mode items has been enabled, changes in

conditions (e.g., the use of paper with little upward

curl or delivery of paper with downward curl) can

prevent the machine from correctly stacking paper. In

this light, it is very important to check the type of

paper the user most often uses before enabling this

mode item.

2.1.6 Offset Stack Mode

0009-4798

a. Outline

Depending on the paper condition, paper can curl and

the machine can fail to deliver/stack it properly in the

small size offset mode.

If this is the case,

1) Turn over the stack of paper in the source cassette.

If doing so has caused the paper to curl much more

than before, turn back over the stack. If the machine

still fails to stack paper due to large curl, try enabling

the offset stack mode.

b. Enabling the Offset Stack Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

2.1.7 Saddle Delivery Tray

Limitless Mode

a. Outline

The user who uses the saddle mode continuously is

allowed to stack saddles continuously irrespective of

the sheet stacking capacity even if the number of

saddles that can be stacked is exceeded.

b. Enabling the Saddle Delivery Tray Limitless Mode

1) Turn off the host machine.

2) Set the bits of SW104 on the finisher controller

PCB as follows:

ON

12345678

F-2-12

3) Turn on the host machine.

- When this mode has been enabled, stacking can be

continued even after the number of saddles that can be

stacked is exceeded.

0009-4821

ON

12345678

F-2-11

3) Turn on the host machine.

- When this mode has been enabled, the stack delivery

is performed without buffering and the speed of the

stack delivery roller is changed to an appropriate one

to ensure proper stacking.

- If paper with little curl is delivered after this mode

has been enabled, the change in condition can cause

improper stacking. In the light of this, be sure to check

the type of paper that is most frequently used by the

user before enabling this mode.

2-4

Chapter 2

2.2 Adjustment at Time of

Parts Replacement

2.2.1 Adjusting the

Alignment Position

Perform this adjustment after replacing the finisher

controller PCB or when the alignment position must

be changed for some reason.

1) Remove the rear upper cover of the finisher unit.

2) Check that the power of the host machine is off and

set SW104 on the finisher controller PCB as follows

according to the paper used for adjustment.

ON

12345678

A4 paper

ON

12345678

F-2-13

LTR paper

0009-2568

controller PCB or when the staple position must be

changed for some reason. This adjustment adjusts the

front/rear stitches with A4/A4R when the paper used

for adjustment is AB type and with LTR/LTRR when

the paper is INCH type.

1) Remove the rear upper cover of the finisher unit.

2) Check that the host machine power is off and set

SW104 on the finisher controller PCB as follows

according to paper/stitch position used for adjustment.

ON

12345678

A4/front stitch

ON

12345678

A4R/front stitch

ON

12345678

LTR/front stitch

ON

ON

12345678

A4/rear stitch

ON

12345678

A4R/rear stitch

ON

12345678

LTR/rear stitch

ON

3) Turn on the power of the host machine.

4) Press SW103 on the finisher controller PCB.

When SW103 is pressed, the swing guide opens and

the alignment plate moves to prescribed position.

5) Place ten sheets of A4/LTR paper between the

alignment plates and push them against the stopper.

6) Press SW101 or SW102 on the finisher controller

PCB and push the alignment plate against the paper.

When SW101 is pressed, alignment plate moves

0.42 mm forward.

When SW102 is pressed, alignment plate moves

0.42 mm backward.

7) When adjustment is complete, remove paper and

press SW103 on the finisher controller PCB once to

store the adjustment in memory.

8) Turn off all bits of finisher controller PCB SW104.

9) Turn off the power of the host machine and install

the rear upper cover of the finisher unit.

2.2.2 Adjusting the Staple

Position

Perform this adjustment after replacing the finisher

0009-2569

12345678

LTRR/front stitch

12345678

LTRR/rear stitch

F-2-14

3) Turn on the host machine power.

4) Press SW103 on the finisher controller PCB.

When SW103 is pressed, the swing guide opens and

the alignment plate moves to prescribed position.

5) Place a sheet of paper between the alignment plates,

push it against the stopper, and push the rear edge of

the paper against the rear alignment plate.

If the gap between the front alignment plate and front

edge of the paper is 1 mm or greater, end staple

position adjustment and repeat staple position

adjustment after completing alignment plate

adjustment.

6) Press SW103 on the finisher controller PCB once to

staple. However, remove the stapled paper

manually to verify the staple position because it is not

ejected.

7) Press SW103 on the finisher controller PCB once.

8) If the staple position is correct, insert a sheet of

paper between the aligning plates and push it

against the stopper, push the far end edge of the paper

2-5