Canon iR5000, iR6000 Service Handbook

iR5000/iR6000

SERVICE

HANDBOOK

REVISION 0

JULY 2000

COPYRIGHT

©

2000 CANON INC. CANON iR5000/iR6000 REV.0 JULY 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23BB-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or

changes in products. When changes occur in applicable products or in the contents of this manual,

Canon will release technical information as the need arises. In the event of major changes in the contents

of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with

local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc.

COPYRIGHT © 2000 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of

confidential information.

COPYRIGHT© 2000 CANON INC. CANON iR5000/iR6000 REV.0 JULY 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

Contents

CHAPTER 1 MAINTENANCE AND INSPECTION

1. Periodical Servicing Chart ..............1-1

1.1 Reader Unit................................1-1

1.2 Printer Unit ................................1-1

1.3 Cleaning the photosensitive

drum ........................................... 1-4

2. Periodically Replaced Parts .............. 1-5

2.1 Guide to Timing of

Replacement ............................... 1-5

2.2 Reader Unit ................................ 1-5

2.3 Printer Unit ................................ 1-6

3. Consumables and Durables.............. 1-7

3.1 Guide to Timing of

Replacement ............................... 1-7

3.2 Reader Unit ................................ 1-7

3.3 Printer Unit ................................ 1-8

3.4 Side Paper Deck ......................... 1-9

4. Points to Note for Periodical

Servicing ........................................ 1-10

5. Image Adjustment Basic

Procedure ....................................... 1-11

5.1 Making Pre-Checks ................. 1-11

5.2 Making Checks on the Printer

Unit (1/2) ................................. 1-12

5.3 Making Checks on the Printer

Unit (2/2) ................................. 1-13

5.4 Making Checks on the

Reader Unit .............................. 1-14

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1. Image Adjustments........................... 2-1

1.1 Standards of Image Position ...... 2-1

1.2 Checking the Image Position ..... 2-2

1.3 Adjusting the Left/Right

Image Margin ............................. 2-2

1.3.1 Cassette 3/4 .......................... 2-2

1.3.2 Left/Right Front Deck .......... 2-3

1.3.3 Manual Feed Tray ................ 2-3

1.3.4 Duplex Feeding Unit ............ 2-4

1.3.5 Side Paper Deck ................... 2-4

1.4 Adjusting the Image Leading

Edge Margin............................... 2-5

1.5 Adjusting the Left/Right

Non-Image Width ......................2-5

1.6 Adjusting the Leading Edge

Non-Image Width ....................... 2-6

2. Scanning System .............................. 2-7

2.1 Replacing the Scanner Drive

Cable .......................................... 2-7

2.1.1 Removing the Scanner System

Drive Cable .......................... 2-7

2.1.2 Routing the Scanner

Drive Cable .......................... 2-9

2.2 Adjusting the Position of the

Scanner Mirror Base ................ 2-10

2.3 After Replacing the Scanning

Lamp ........................................ 2-12

3. Image Formation System ................ 2-13

3.1 Routing the Grid Wire of the

Primary Charging Assembly ....2-13

3.2 Routing the Charging Wire of

Charging Assemblies ............... 2-15

3.2.1 Routing the Charging

Wire ................................... 2-15

3.2.2 Adjusting the Heiqht of the

Charging Wire.................... 2-18

3.3 Mounting the Drum Cleaning

Blade ........................................ 2-19

3.3.1 Removing the Cleaning

Blade ..................................2-19

3.3.2 Mounting the Cleaning

Blade ..................................2-20

CONTENTS

3.4 Mounting the Developing

Blade ........................................ 2-22

3.4.1 Removing the Blade Unit ... 2-22

3.4.2 Mounting the Blade ............ 2-22

3.5 Replacing the Potential Sensor/

Potential Control PCB .............. 2-23

3.5.1 Removing the Potential Sensor/

Potential Control PCB ....... 2-23

3.5.2 Adjusting the Potential

Sensor ................................ 2-25

4. Pickup/Feeding System .................. 2-27

4.1 Orientation of the Deck/Cassette

Pickup Roller ...........................2-27

4.2 Orientation of the Deck/Cassette

Separation Roller .....................2-28

4.3 Orientation of the Feeding

Roller of the Deck/Cassette

Pickup Assembly...................... 2-28

4.4 Orientation of the Pickup Roller

of the Side Paper Deck ............. 2-29

4.5 Orientation of the Feeding Roller

of the Side Paper Deck ............. 2-30

4.6 Adjusting the Pressure of the

Separation Roller of the Deck/

Cassette .................................... 2-31

4.7 Adjusting the Pressure of the

Separation Roller of the Manual

Feed Tray ................................. 2-32

4.8 Adjusting the Fixing Inlet

Guide Solenoid (SL1) .............. 2-33

4.9 Adjusting the Position of the

Pickup Solenoid (SL3, SL4)

of the Cassette 3/4 .................... 2-34

4.10 Adjusting the Position of the Deliv-

ery Flapper Solenoid (SL5) .....2-35

4.11 Adjusting the Position of the Right

Deck Pickup Solenoid (SL6) ... 2-35

4.12 Adjusting the Position of the Left

Deck Pickup Solenoid (SL7) ... 2-36

4.13 Adjusting the Position of the

Reversing Flapper Solenoid

(SL8) ........................................ 2-36

4.14 Adjusting the Position of the

Fixing Web Solenoid (SL9) ...... 2-37

4.14.1 New Fixing Web .................. 2-37

4.14.2 Existing Fixing Web ............ 2-37

4.15 Position of the Side Paper

Deck Pickup Roller Releasing

Solenoid ................................... 2-38

4.16 Attaching the Timing Belt of the

Manual Feed Tray Assembly ... 2-38

4.17 Attaching the Drive Belt .......... 2-39

5. Fixing System ................................ 2-40

5.1 Points to Note When Mounting

the Fixing Heater ...................... 2-40

5.2 Position of the Fixing Inlet

Guide ........................................ 2-40

5.3 Adjusting the Lower Roller

Pressure (nip) ........................... 2-41

5.3.1 T aking Measurements ........ 2-41

5.3.2 Standards ........................... 2-41

5.3.3 Making Adjustments .......... 2-41

6. Laser Exposure System .................. 2-42

6.1 When Replacing the Scanner

Unit .......................................... 2-42

7. Electrical Parts ................................ 2-43

7.1 When Replacing the CCD

Unit .......................................... 2-43

7.2 When Replacing the Reader

controller PCB .......................... 2-43

7.3 When Replacing the Main

Controller PCB ......................... 2-44

7.4 When Replacing the HDD

Unit .......................................... 2-44

7.5 When Replacing the DC

Controller PCB ......................... 2-45

7.6 When Replacing the

High-Voltage PCB .................... 2-46

8. Checking the Surface Potential

Control System ............................... 2-47

8.1 Outline ...................................... 2-47

8.2 Disabling the Auto Control

Mechanism ............................... 2-47

8.3 Zero Level Check ..................... 2-48

8.3.1 Method 1 ............................ 2-48

8.3.2 Method 2 ............................ 2-50

8.4 Checking the Potential

System ...................................... 2-53

CONTENTS

8.5 Conv ersion Table for the

Potential Control System .......... 2-55

8.6 Emergency Measures for a

Fault in the Potential Sensor ..... 2-59

9. Checking the Environment Sensor ... 2-60

9.1 Procedure ................................. 2-60

9.2 Emergency Measure for a Fault

in the Environment Sensor ....... 2-60

10. Checking the Photointerrupters....... 2-61

10.1 Using a Meter........................... 2-61

10.2 Using Service Mode................. 2-61

10.3 Check List ................................ 2-61

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS

1.1 Clutches ..................................... 3-1

1.1.1 Reader Unit..........................3-1

1.1.2 Printer Unit .......................... 3-1

1.2 Solenoids and Switches .............3-2

1.2.1 Reader Unit..........................3-3

1.2.2 Printer Unit .......................... 3-3

1.3 Motors ........................................ 3-4

1.3.1 Reader Unit..........................3-5

1.3.2 Printer Unit .......................... 3-5

1.4 Fans ............................................ 3-6

1.4.1 Reader Unit..........................3-7

1.4.2 Printer unit ........................... 3-7

1.5 Sensors ....................................... 3-8

1.5.1 Reader Unit........................3-10

1.5.2 Printer Unit ........................ 3-10

1.6 Lamps, Heaters, and Others ..... 3-12

1.6.1 Reader Unit ........................ 3-13

1.6.2 Printer Unit ........................ 3-13

1.7 PCBs ........................................ 3-14

1.7.1 Reader Unit ........................ 3-15

1.7.2 Printer unit ......................... 3-15

1.8 Variable Resistors (VR), LightEmitting Diodes (LED), and

Check Pins by PCB .................. 3-16

1.8.1 Main Controller PCB ......... 3-16

1.8.2 DC Controller PCB ............ 3-17

1.8.3 Reader Controller PCB ...... 3-18

1.8.4 Power Supply PCB ............ 3-18

1.8.5 HVT PCB .......................... 3-19

1.8.6 Drum Heater Control

PCB ................................... 3-19

CHAPTER 4 SERVICE MODE

1. Organization of Service Mode ......... 4-1

1.1 Outline ....................................... 4-1

1.2 Starting Service Mode and

Making Selections ...................... 4-2

1.3 Ending Service Mode ................. 4-3

1.4 Backing Up Service Mode ......... 4-3

1.5 Basic Operations ........................ 4-4

1.5.1 Initial Screen ........................ 4-4

1.5.2 Level 1/Level 2 Screen ......... 4-4

1.5.3 Level 3 Screen ...................... 4-5

2. DISPLAY (control/display mode) .... 4-6

2.1 COPIER ..................................... 4-6

2.2 FEEDER .................................. 4-19

3. I/O (I/O display mode) ................... 4-20

3.1 DC-CON.................................. 4-21

3.2 R-CON..................................... 4-29

3.3 MN-CON................................. 4-31

3.4 FEEDER .................................. 4-33

3.5 SOR TE R ..................................4-36

4. ADJUST (adjustment mode) .......... 4-44

4.1 COPIER ................................... 4-44

4.2 FEEDER .................................. 4-57

3.5.1 Finisher Block .................... 4-36

3.5.2 Saddle Stitcher Unit ........... 4-41

CONTENTS

4.3 SOR TER ..................................4-58

5. FUNCTION (operation/inspection

mode).............................................. 4-59

5.1 COPIER ................................... 4-59

5.2 FEEDER .................................. 4-75

6. OPTION (settings mode) ...............4-76

6.1 COPIER ................................... 4-76

6.2 FEEDER .................................. 4-92

6.3 SORTER ..................................4-92

6.4 BOARD.................................... 4-93

7. TEST (test print mode) .................. 4-94

8. COUNTER (counter mode) ...........4-98

CHAPTER 5 SELF DIAGNOSIS

1. Error Codes ......................................5-1

1.1 List of Error Codes .................... 5-1

1.2 Self Diagnosis of the ADF ....... 5-13

1.3 Self Diagnosis of the Finisher ... 5-14

1.4 Self Diagnosis of the Saddle

APPENDIX

A. GENERAL TIMING CHART........ A -1

B. LIST OF SIGNALS/ABBREVIA-

TIONS ............................................. A -3

C. General Circuit Diagram .................. A -9

D. PAPER DECK -G1 GENERAL

CIRCUIT DIAGRAM .................. A-11

E. SHIFT TRAY GENERAL

CIRCUIT DIAGRAM .................. A-12

F. SPECIFICATIONS ...................... A-13

1.1 Copier ...................................... A-13

1.1.1 Type .................................. A-13

1.1.2 Method .............................. A-13

1.1.3 Functions .......................... A-14

1.1.4 Others ............................... A-19

1.2 Paper Deck-G1 ....................... A-22

1.3 Shift Tray-B1 .......................... A-23

G. List of Special T ools...................... A-24

H. List of Solvents/Oils ..................... A-26

Stitcher ..................................... 5-18

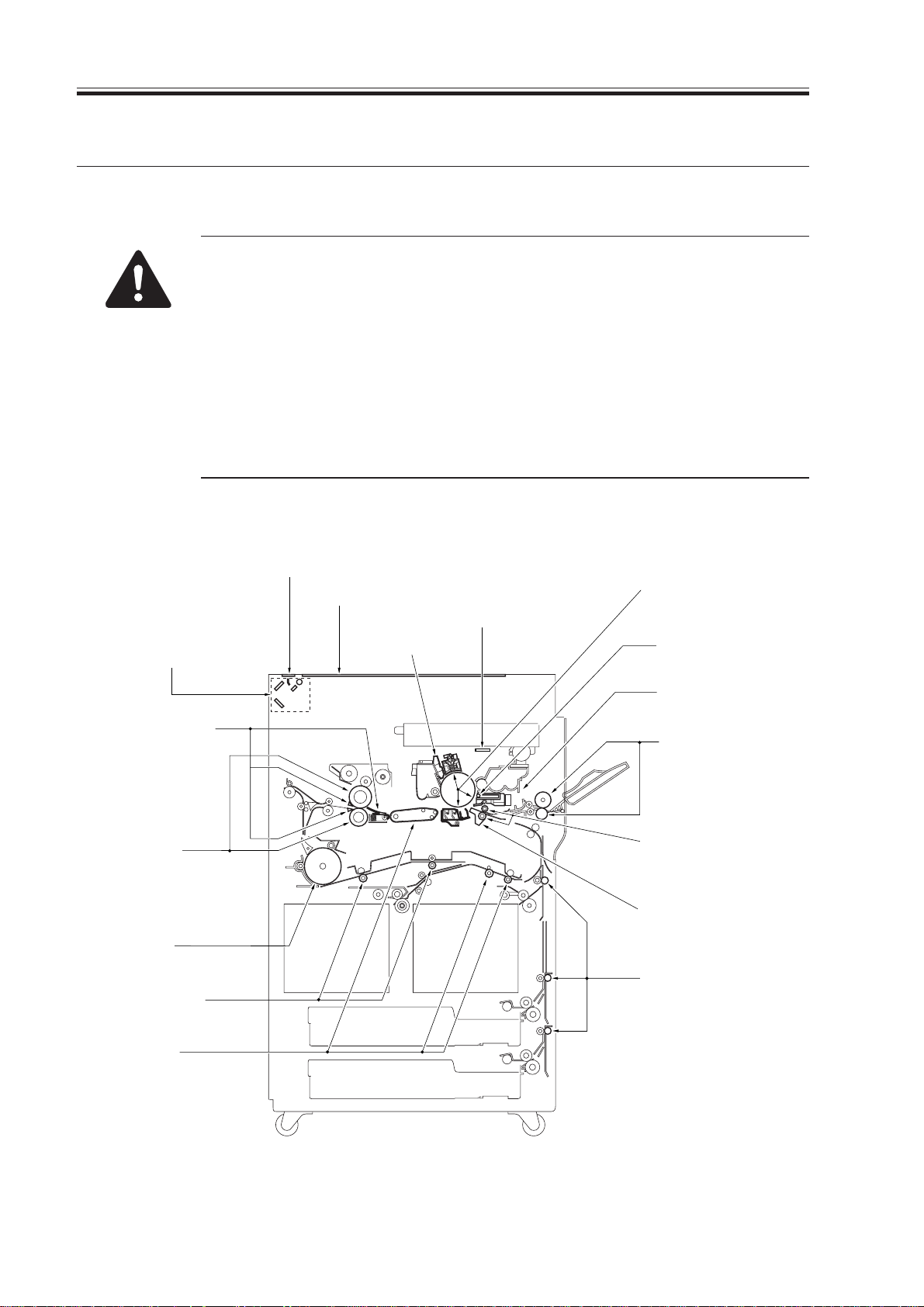

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

1.Periodical Servicing Char t

Do not use solvents or oils other than those indicated.

1.1 Reader Unit

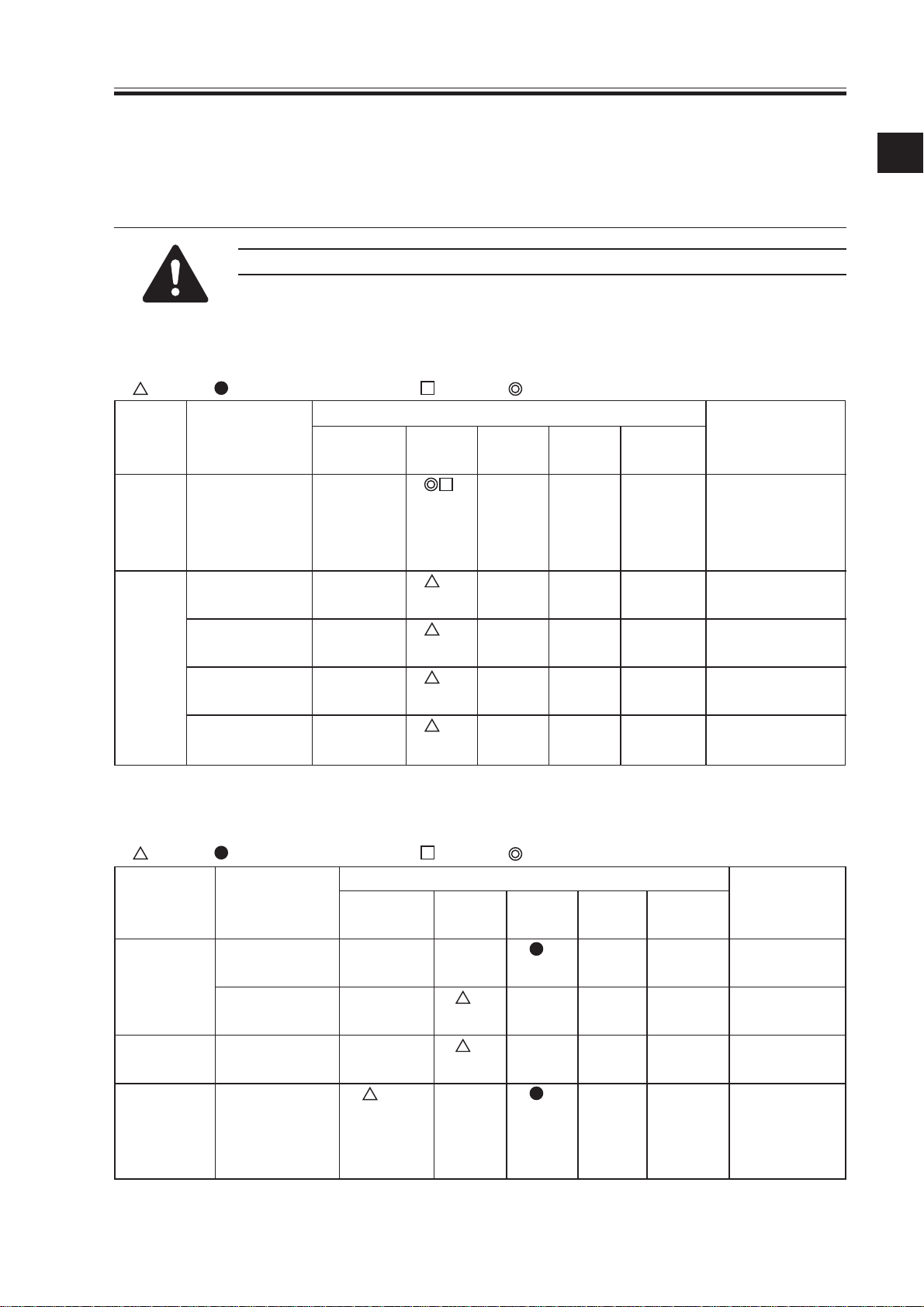

: Clean : Replace ×: Lubricate : Adjust : Inspect

Intervals

Unit Part Upon every every every every Remarks

installation 250,000 500,000 750,000 1,000,000

Scanner Scanner cable

Optical Scanner rail

path (FY9-6011)

Copyboard

glass

No. 1 through

No. 3 mirrors

Scanner

reflecting plate

×

Only at fist

250,000

(inpection/

adjustment).

Silicone oil

1

1.2 Printer Unit

: Clean : Replace ×: Lubricate : Adjust : Inspect

Intervals

Unit Part Upon every every every every Remarks

installation 250,000 500,000 750,0001,000,000

Externals/ Ozone filter

controls (FM3)

Dust-proofing

filter (FM2) from surface.

Laser Dust-proof

optical path glass

Charging Charging wire

assembly (primary, pre- ment, execute

transfer, trans- wire cleaning

fer/separation) 5 times.

Remove dust

After replace-

1-1

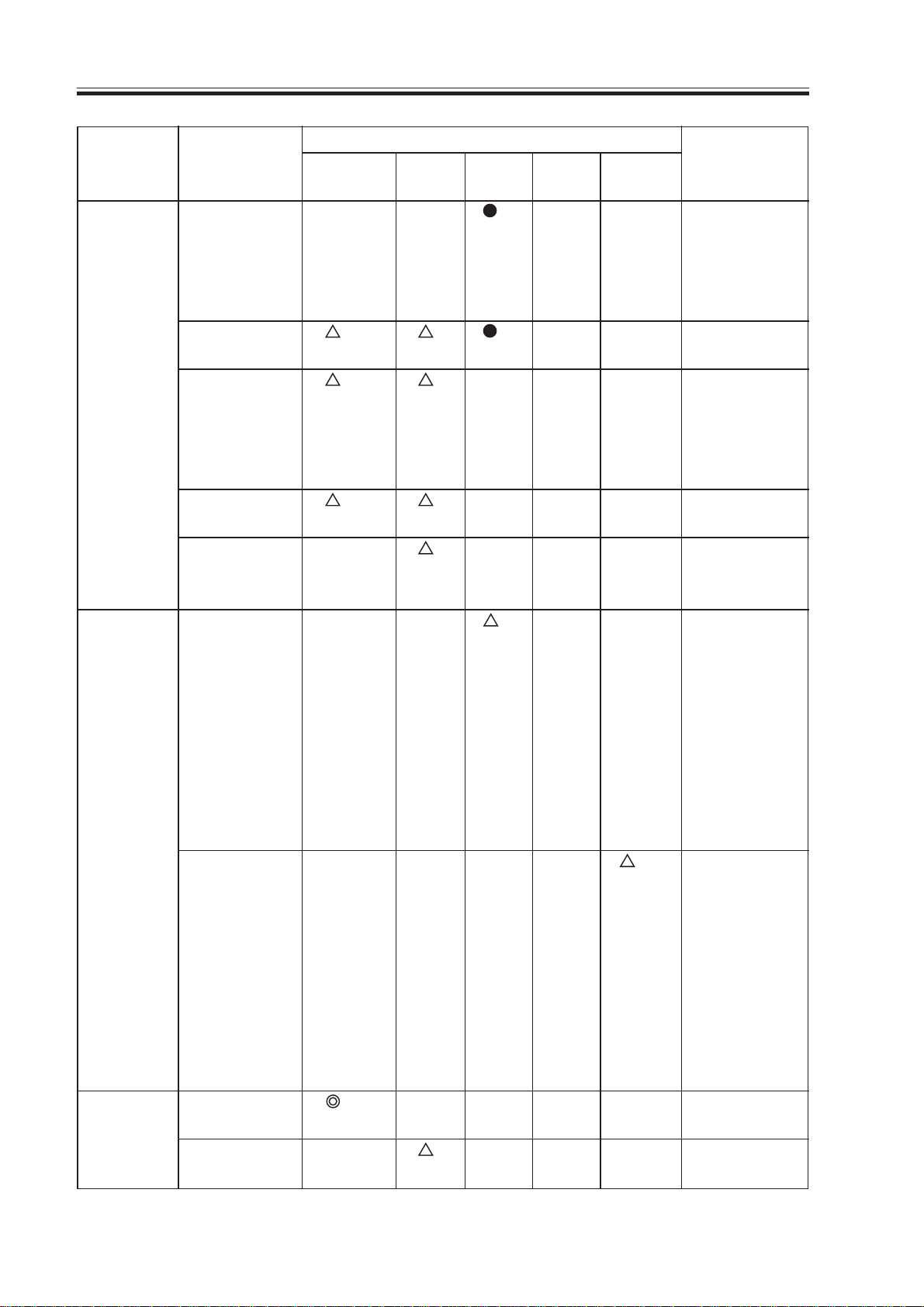

CHAPTER 1 MAINTENANCE AND INSPECTION

Intervals

Unit Part Upon every every every every Remarks

installation 250,000 500,000 750,0001,000,000

Charging Charging wire

assembly cleaner charging wire

(primary, pre- simultatransfer, trans- neously.

fer/separation)

Grid wire

(primary)

Charging

assembly

shielding plate

(each charging

assembly)

Roller

electrode

Primary antistray toner

sheet

Photosensi- Photosensitive

tive drum drum and drum

Electrode (for

slip ring of alcohol;

drum heater) 2) protruding

Developing Developing

assembly cylinder

Developing

assembly roll

×

Replace with

Use alcohol

cleaning powder (CK-

0429); for instructions, see

6. “Cleaning

the Photosensitive

Drum.”

Clean with

1) electrode,

wall of electrode (where

FY9-6008 is

applied).

· Charge col lecting brush

1-2

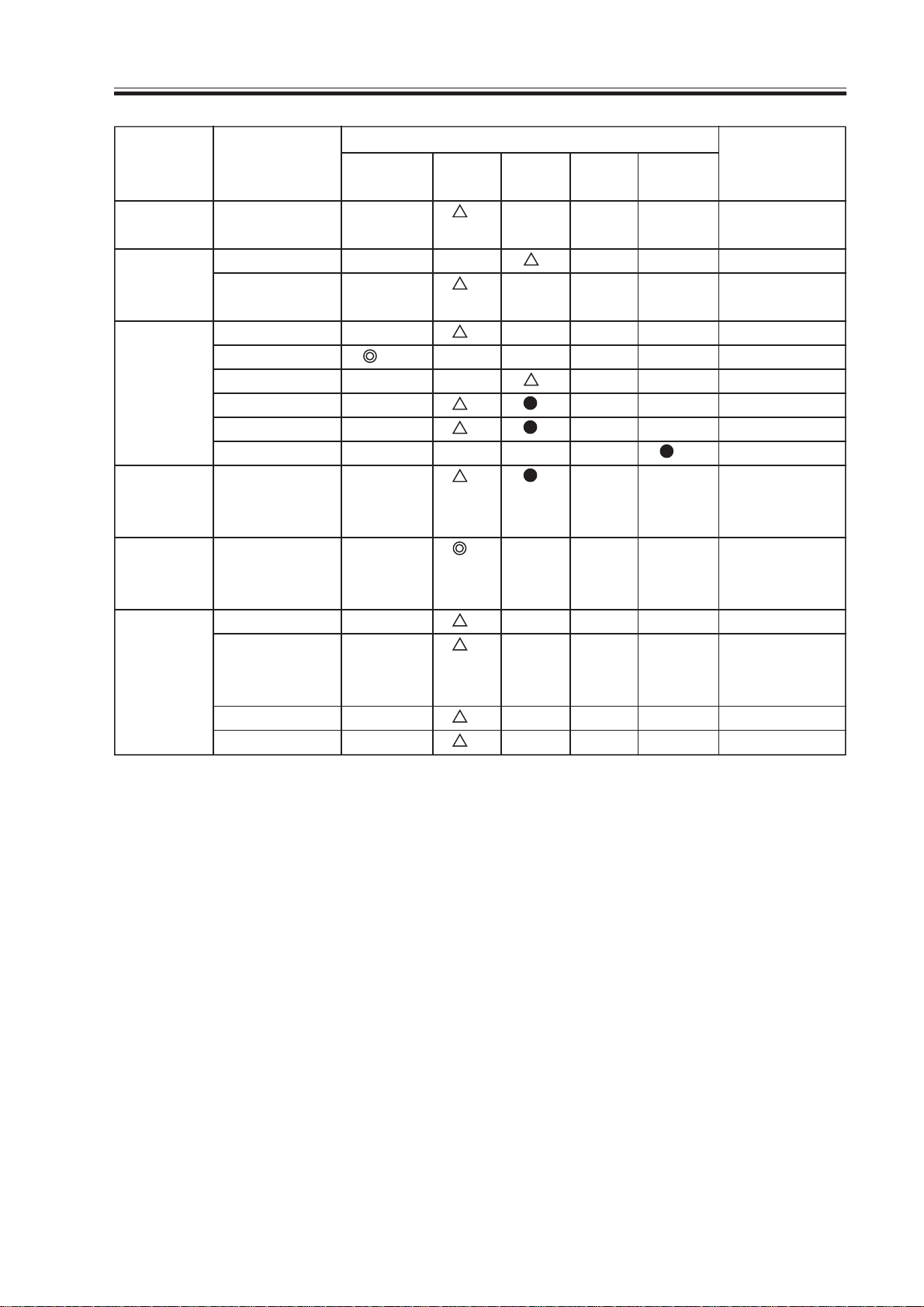

CHAPTER 1 MAINTENANCE AND INSPECTION

Intervals

Unit Part Upon every every every every Remarks

installation 250,000 500,000 750,0001,000,000

Developing Anti strayassembly toner sheet

Cleaner Side scraper

Toner dish

(rear, front)

Fixing Inlet guide

assembly Web

Oil dish

Thermistor

Sub thermistor

Thermal switch

Delivery Separation

assembly claw (upper,

lower)

Waste tonerWaste toner Inspect case,

collection b ox and remove

area toner.

Pickup/ Transfer guide

feeding Registration

assembly roller (upper,

lower)

Feeding belt

Feeding rollers

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

1.3 Cleaning the photosensitive drum

Do not rotate the magnet roll

during work. Otherwise, waste

toner may fall through the

cleaner assembly.

1) Slide out the process unit. (Be sure to

place the drum protective sheet over the

fixing/feeding unit.)

2) Take out the photosensitive drum.

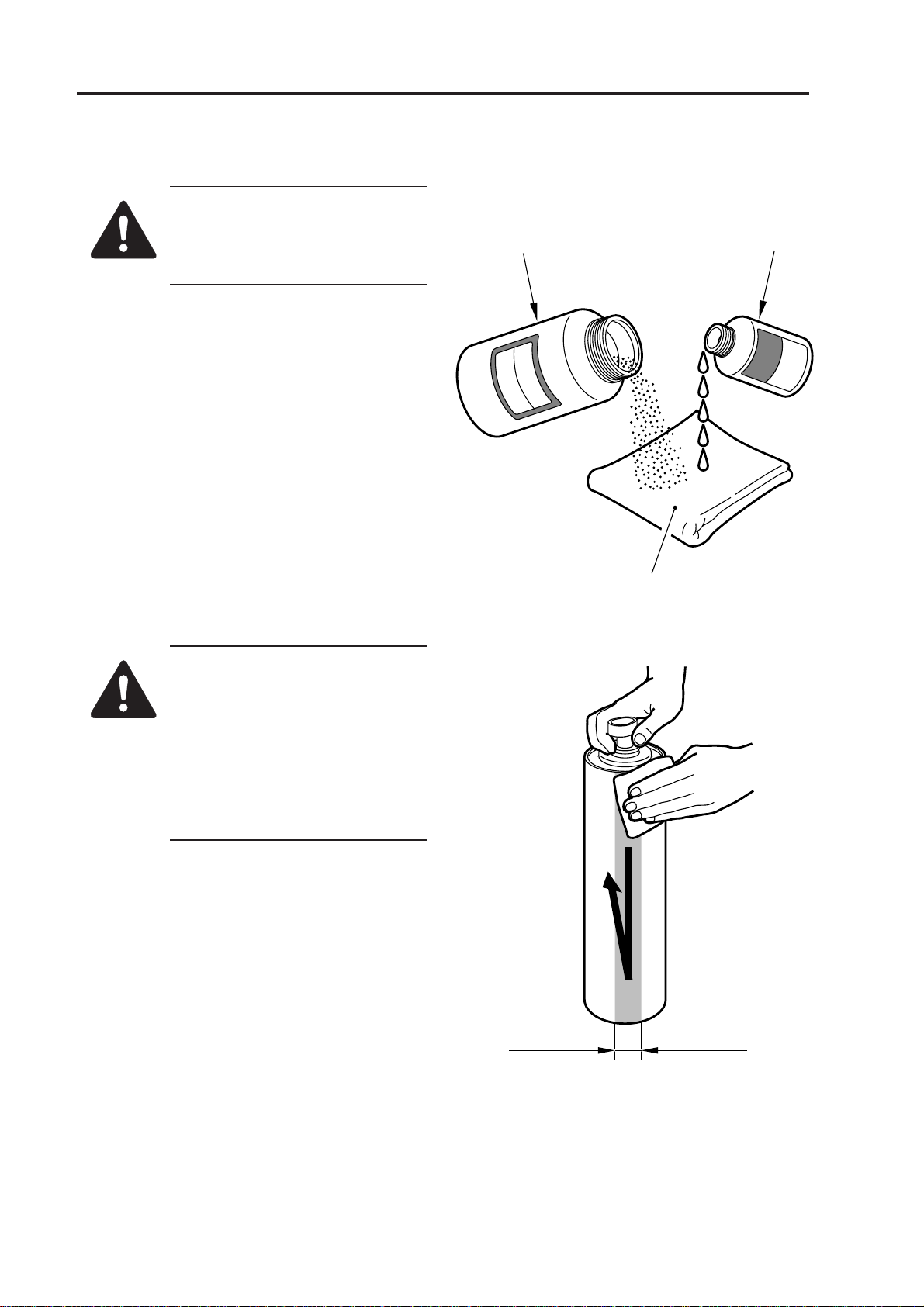

3) Moisten lint-free paper [1] with 5 to 10

cc of alcohol [2]; then, pour 0.2 to 0.3 g

of drum cleaning powder (CK-0429) [3]

on the lint-free paper.

4) While butting the lint-free paper relatively strongly against the photosensitive drum, wipe the surface of the drum

from the front to the rear and from the

rear to the front.

CK-0429

[3]

[2]

[1]

F01-103-01

• Keep the widths of cleaning to

5 to 10 cm in the peripheral

direction of the drum.

• Move the lint-free paper back

and forth 15 to 20 times over a

single area.

Forcing the lint-free paper will

not affect the life of the drum.

5) When the alcohol has evaporated, dry

wipe the surface with lint-free paper. If

the area is uneven, go back to step 4),

and increase the back-and-forth movements.

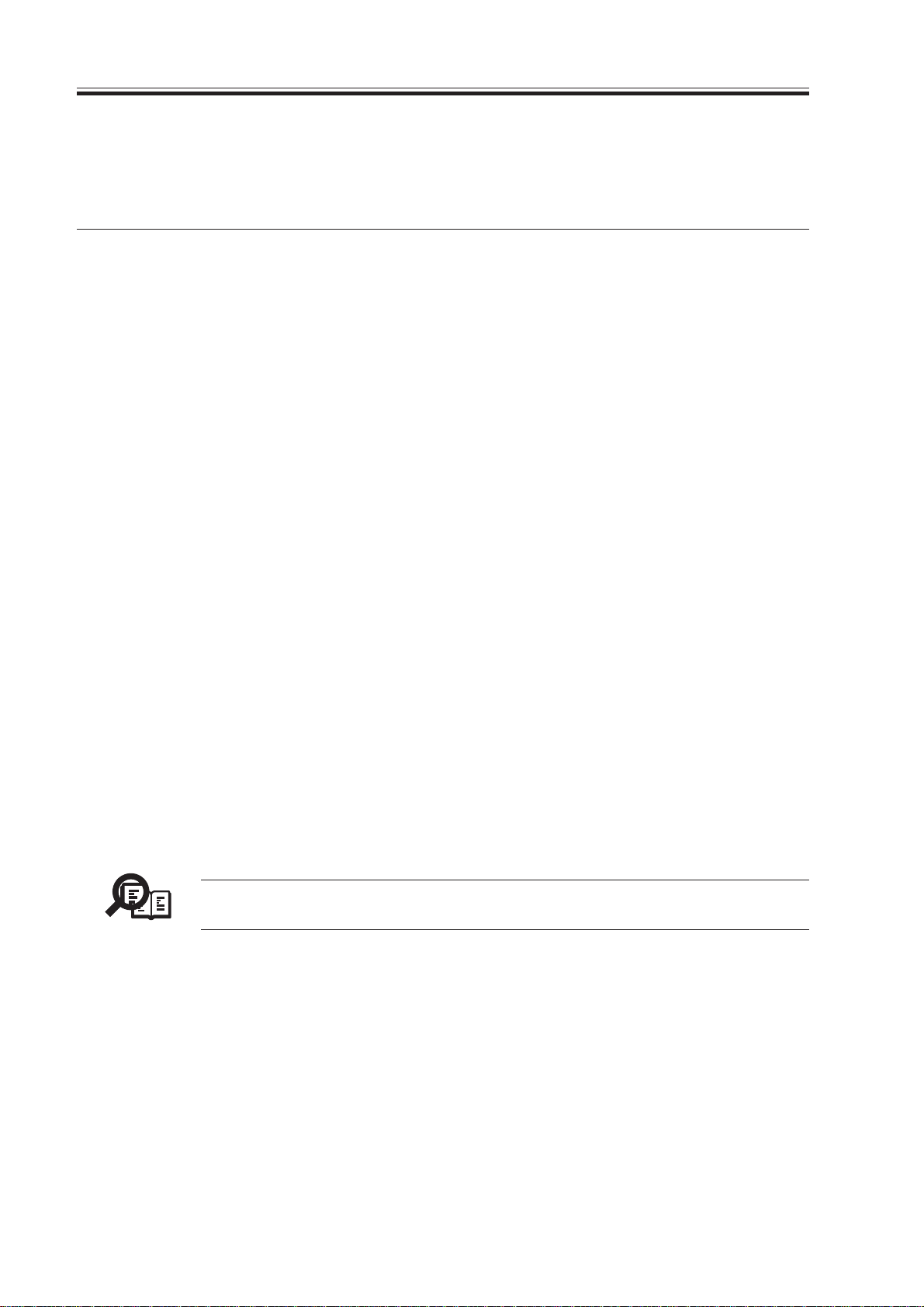

6) Rotate the drum for the width (5 to 10

cm), and repeat steps 3) through 5) until

the entire area of the surface has been

cleaned.

5 to 10cm

1-4

F01-103-02

CHAPTER 1 MAINTENANCE AND INSPECTION

2.Periodically Replaced Par ts

Some parts of the machine must be replaced on a periodical basis to ensure a specific

level of machine performance. (Once they fail, the consequences are likely to be considerable.)

Whenever possible, schedule the replacement to coincide with a scheduled visit to the

user’s.

2.1 Guide to Timing of Replacement

You can check the timing of replacement for periodically replaced parts in service mode:

COPIER>COUNTER>PRDC-1.

2.2 Reader Unit

The reader unit does not have parts that require periodical replacement.

1-5

CHAPTER 1 MAINTENANCE AND INSPECTION

2.3 Printer Unit

As of June 2000

No. Part name Part No. Q’ty Life Remarks

1 Primary, pre-transfer, transfer, FB4-3687 AR 500,000*

separation charging wire

2 Primary grid wire FY1-0883 AR 500,000

3 Primary charging wire FF5-6883 2 500,000 Strengthened polish

cleaner 1 type (blue)

4 Primary charging wire FF2-6884 2 500,000 Strengthened polish

cleaner 2 type (blue)

5 Transfer charging wire FF5-6883 1 500,000 Strengthened polish

cleaner 1 type (blue)

6 Transfer charging wire FF5-6884 1 500,000 Strengthened polish

cleaner 2 type (blue)

7 Separation charging wire FF5-3090 1 500,000

cleaner

8 Pre-transfer charging wire FF5-3090 1 500,000

cleaner

9 Main thermistor FH7-7529 1 500,000

10 Sub thermistor FG5-8812 1 500,000

11 Ozone filter FB5-5570 1 500,000

12 Thermal switch FH7-7154 1 1,000,000

*Do not use the old type (gold plated). After replacement of the charge wire, be sure to

execute wire cleaning in service mode. (COPIER>FUNCTION>CLEANING>WIRECLN)

T01-203-01

The indicated life of each part is for reference only, and is subject to the site

Memo

environment and the conditions of use.

1-6

CHAPTER 1 MAINTENANCE AND INSPECTION

3.Consumables and Durables

Some parts of the machine are likely to require replacement because of wear or damage

once or more over the period of machine warranty. Replace them when they fail.

3.1 Guide to Timing of Replacement

You can check the timing of replacement for durables in service mode:

COPIER>COUNTER>DRBL-1.

3.2 Reader Unit

The reader unit does not have parts that are classified as “consumables” or “durables.”

1-7

CHAPTER 1 MAINTENANCE AND INSPECTION

3.3 Printer Unit

As of June 2000

No. Part name Part No. Q’ty Life Remarks

1 Pickup/feeding roller FB1-8581 1 120,000

(manual feed roller)

2 Separation roller FB5-0873 1 120,000

(manual feed tray)

3 Pickup roller FF5-1220 8 250,000 Each holder uses 2 pc.

4 Pickup/feeding roller FF5-9779 8 250,000 Each holder uses 2 pc.

(deck, cassette)

5 Separation roller FB2-7777 4 250,000

(deck, cassette)

6 Cleaner separation claw FB2-6899 3 500,000

7 Pre-separation charging FA4-1867 1 500,000

assembly scraper

8 Fixing upper roller FB4-3690 1 500,000

9 Fixing lower roller FB5-3619 1 500,000

10 Fixing web FY1-1157 1 500,000

11 Insulating bush (front/rear) FB5-3613 2 500,000 Replace simultaneously

with fixing upper roller.

12 Delivery upper separation claw FB5-3625 6 500,000

13 Delivery lower separation claw FA2-9037 2 1,000,000

14 Developing cylinder FG5-8235 1 1,000,000

15 Developing assembly roll FB2-6933 2 1,000,000

16 Cleaning blade FA4-1827 1 1,000,000 Both edges are used;

each for 500,000; apply

toner upon replacement.

17 Primary corona assembly FG6-5927 1 1,000,000

18 Transfer/separation corona FG6-5911 1 1,000,000

assembly

19 Pre-transfer corona assembly FG6-5045 1 1,000,000

1-8

T01-303-01

CHAPTER 1 MAINTENANCE AND INSPECTION

3.4 Side Paper Deck

As of June 2000

No. Part name Part No. Q’ty Life Remarks

1 Pickup roller (front) FF5-1220 1 250,000

2 Pickup roller (rear) FF5-1221 1 250,000

3 Feeding roller FF5-9779 1 250,000

4 Separation roller FB2-7777-020 1 250,000

T01-304-01

1-9

CHAPTER 1 MAINTENANCE AND INSPECTION

4.Points to Note for Periodical Ser vicing

Unless otherwise instructed, clean with lint-free paper and alcohol.

• Make a thorough check of the block (front, rear) for melting by leakage,

deformation by heat, cracking, discoloration (yellowing). If a fault is

found, replace the part with a new one immediately.

• Check the block (front, rear) including its inside.

• Do not use a cloth on which metal powder is found.

• If you have used solvent, make sure that the part has dried completely

before mounting it back to the machine.

· • Do not use a moist cloth unless specifically indicated.

• Be sure to provide scheduled servicing/replacement at the specified intervals.

Scanning lamp

Dry wipe with lint-free paper.

Reflecting plate

Clean with a blower brush.

No. 1 through No. 3 mirrors

Clean it with a blower brush;

if dirt is excessive, dry wipe

with lint-free paper.

Separation claw, fixing

assembly inlet guide

Clean with solvent

and lint-free paper.

Fixing roller

(upper/lower)

Use cleaning oil and

lint-free paper.

Reversing roller

Duplex Feeding Roller

(right/left)

Reading glass

Copyboard glass

Dust-proofing glass

Dry wipe with lint-free paper.

Pre-exposure glass

Primary/Transfer/Separation/

Pre-transfer charging assembly

Dry wipe with lint-free paper;

then, clean with alcohol.

Dust-collecting roller

Disposing of toner.

Developing assembly base

Clean with a moist

cloth; see Note 1.

Pickup/feeding roller

Registration roller

Transfer guide

Vertical path roller

Feeding assembly

Clean with a moist

cloth; see Note 1.

1-10

Note 1: Do to leave traces of water.

F01-401-01

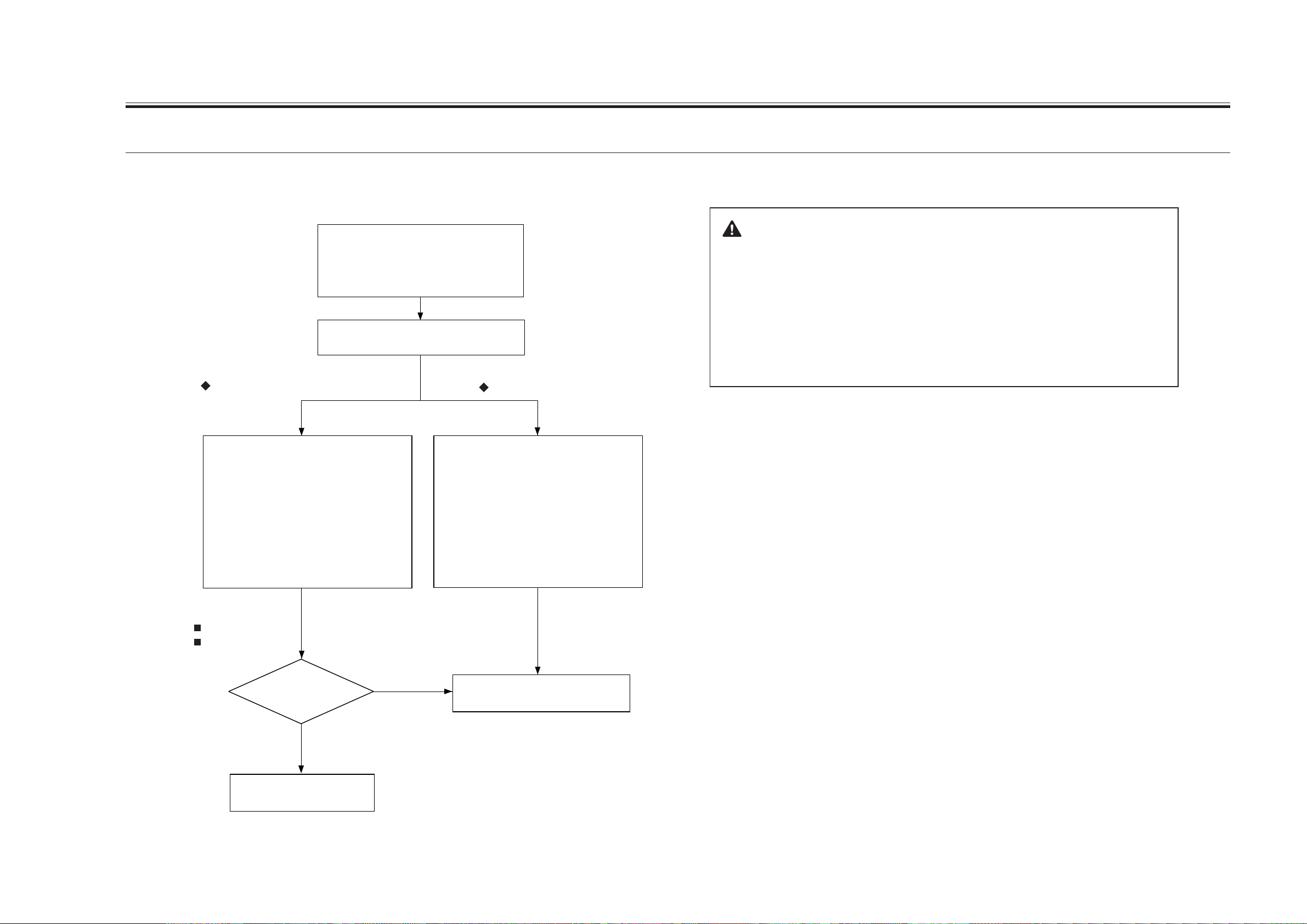

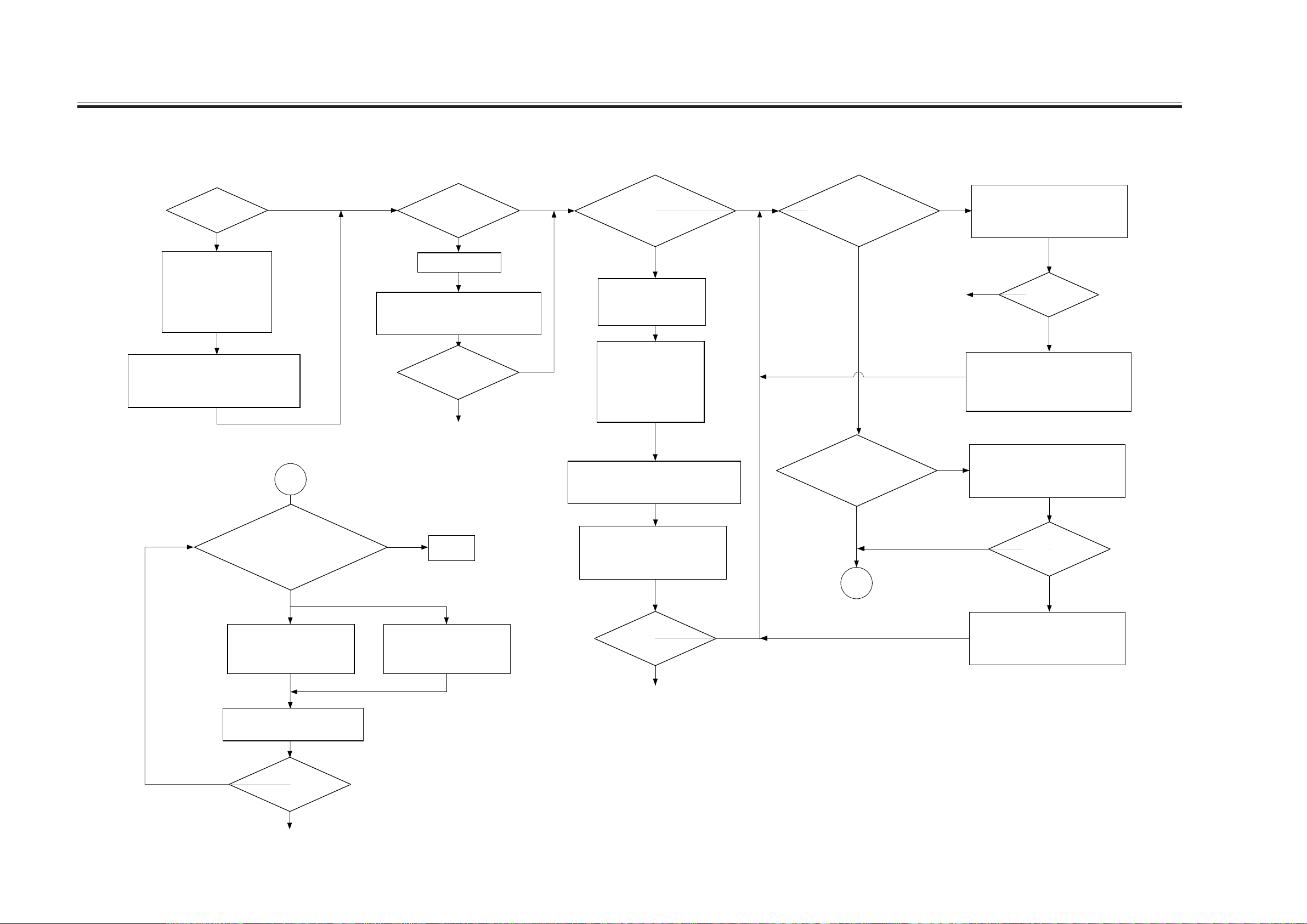

5.Image Adjustment Basic Procedure

5.1 Making Pre-Checks

<Pre-Checks>

CHAPTER 1 IMAGE ADJUSTMENT BASIC PROCEDURE

Clean the following:

1. Primary charging assembly grid wire

2. Primary charging wire

3. Pre-transfer charging wire

4. Transfer charging wire

Check the following:

1. Height of charging wire

If a fault is found on copy images,

Using the NA3 Chart, make two copies each

in the following modes:

1. AE mode

2. Text mode

3. Text/photo mode

Generate several of the following test sheets:

1. 04 (blank)

2. 05 (halftone)

3. 06 (solid black)

Points to Note When Making Checks on the Printer Side

The machine's potential control mechanism is designed for both

copier image output and printer (PDL) image output, and its parameters

for potential control in service mode may be adjusted independently of

each other.

As such, when an image fault occurs, try to find out which side is

causing it, and generate the appropriate images (data) for adjustment of

related parameters.

If a fault is found on printer images,

Generate several each of the following

printer (PDL) images

1. Image with large background

(to check for fogging)

2. Image including solid black

(to check solid black density)

3. Image including halftone

(to check halftone density)

Output Conditions

F value=5

potential control: ON

Are the test

prints normal?

YES

Perform 5.4 “ Making Checks

on the Reader Unit.”

NO

Perform 5.2 “ Making Checks on the

Printer Unit.”

1-11

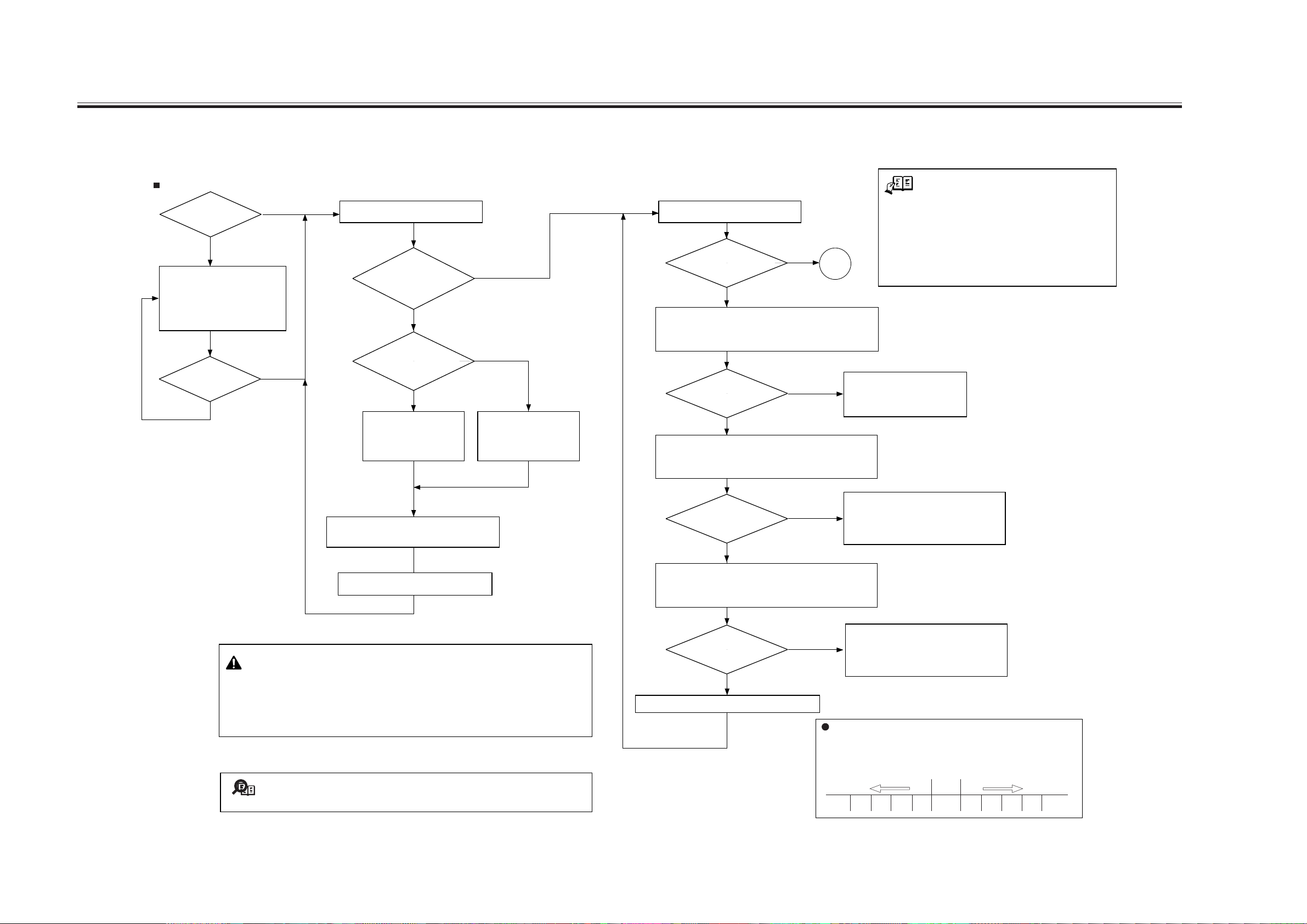

CHAPTER 1 IMAGE ADJUSTMENT BASIC PROCEDURE

5.2 Making Checks on the Printer Unit (1/2)

<Checking Images>

Checking Halftone Images

Are there vertical

lines in the image?

YES

Clean the following; also check

for foreign matter:

1. Dust-proofing glass

2. Charging assemblies

Are there vertical

lines in the image?

NO

YES

NO

<Checking the Density Slope>

Generate a halftone image.

Is there a

difference in density between

front and rear?

YES

Is the rear lighter?

YES

Turn the adjusting screw

found at the front of the

primary charging assembly

clockwise. (2 full turns max.)

NO

NO

Turn the adjusting screw

found at the rear of the

primary charging assembly

clockwise. (2 full turns max.)

<Checking fro Fogging>

Generate a blank print.

Is it foggy?

NO

A

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VDM (for copier image)

COPIER>DISPLAY>DPOT>VDM-P (for printer image)

Are the readings ± 6 V

of the target value?

(*1)

NO

Check the primary charging

system and the potential control

system; if normal, replace the

photosensitive drum.

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VL1M (for copier image)

COPIER>DISPLAY>DPOT>VL1M-P (for printer image)

REF.

*1:VD target value

COPIER >DISPLAY >DPOT >VDT (for copier image)

COPIER >DISPLAY >DPOT >VDT-P (for printer image)

*2:VL1 target value

COPIER >DISPLAY >DPOT >VD1T (for copier image)

COPIER >DISPLAY >DPOT >VD1T-P (for printer image)

Make the selections in service mode, and turn off

and then on the main power switch:

COPIER>FUNCTION>DPC>DPC.

Execute forced

potential control.

Generate one print of a halftone image.

1. If there still is a difference in density after giving the adjusting screw 2 turns (each turn

causing a change of about 0.7 mm), check the scanning lamp and the scanner for soiling.

2. When making a clockwise turn, be sure that the intervals between wire grid runs are not

larger than 9 mm.

When making a counterclockwise turn, be sure that the intervals between wire grid runs

are not smaller than 7.5 mm.

3. The machine will not execute potential control even when the main power switch is

turned off and then on if the temperature of the fixing assembly is 150˚C or higher.

Moving the wire from the photosensitive drum causes the image to be lighter, while

Memo

moving it closer causes the images to be darker.

Are the readings ± 6 V

of the target value?

(*2)

NO

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VL2M (for copier image)

COPIER>DISPLAY>DPOT>VL2M-P (for printer image)

NO

Are the readings 70 ± 15 V?

YES

Adjust the offset value of the VL target potential.

Adjusting the Offset of the VL Target Potential

(DE-OFFSET/DE-OFFSET-P)

Vary the value using the following as a guide:

COPIER>ADJUST>V-CONT>DE-OFST (for copier image)

COPIER>ADJUST>V-CONT>DE-OFST-P (for printer image)

Check the following, and replace them if

necessary:

1. Laser (for output)

2. Potential control system

3. Photosensitive drum

Check the following, and replace them if

necessary.

1. Laser (for output)

2. Potential control system

3. Photosensitive drum

Lighter image Darker image

Default

-50 -40 -30 -20 -10 0 +10 +20 +30 +40 +50

1-12

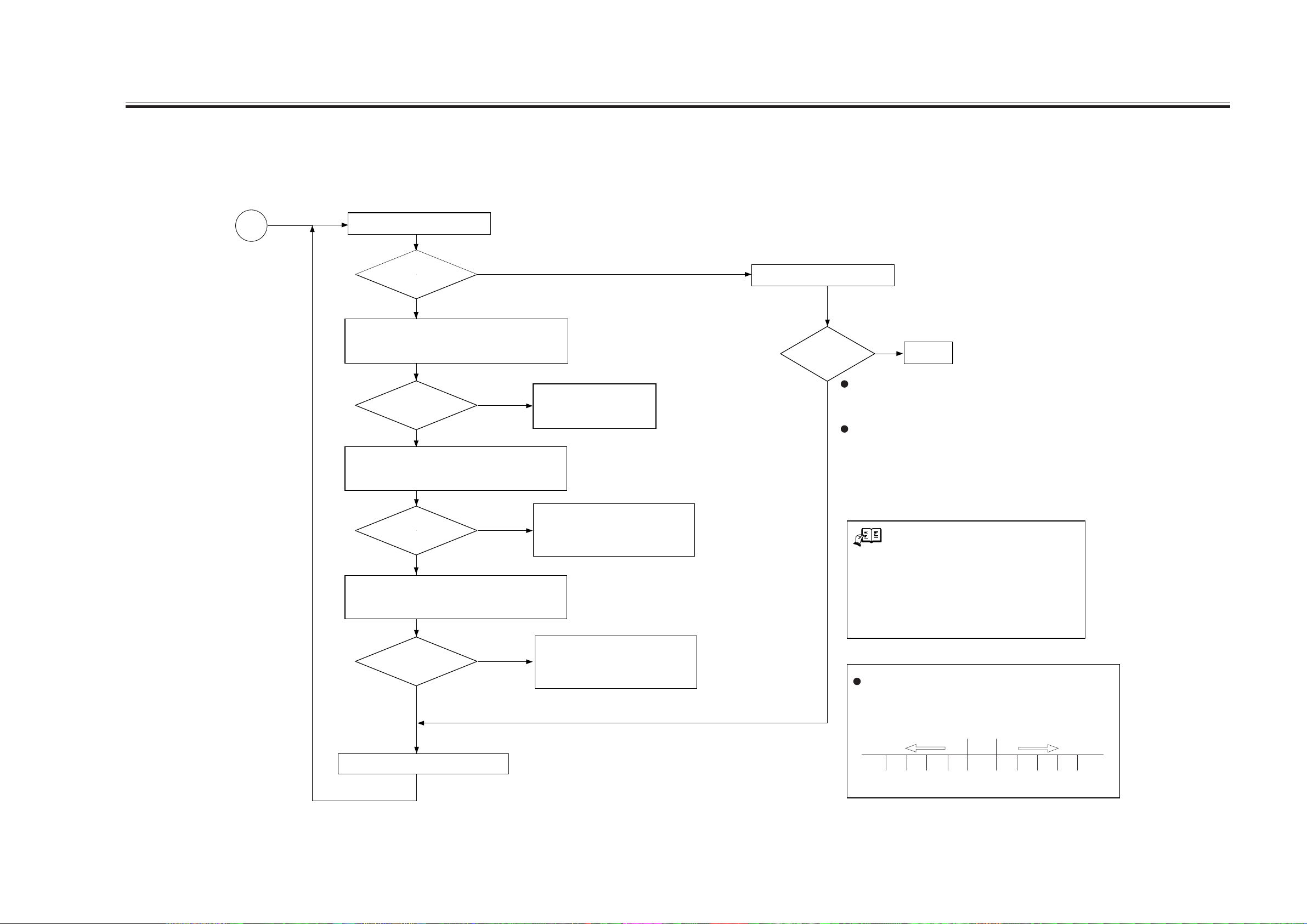

5.3 Making Checks on the Printer Unit (2/2)

<Checking the Solid Black Density>

CHAPTER 1 IMAGE ADJUSTMENT BASIC PROCEDURE

A

Generate a solid black print.

Is the density

too low or too high (too

light or too dark)?

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VDM (for copier image)

COPIER>DISPLAY>DPOT>VDM-P (for printer image)

Are the

readings ± 6 V of the

target value?

(*1)

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VL1M (for copier image)

COPIER>DISPLAY>DPOT>VL1M-P (for printer image)

Are the

readings ± 6 V of the

target value?

(*2)

YES

Check the following readings in service mode:

COPIER>DISPLAY>DPOT>VL2M (for copier image)

COPIER>DISPLAY>DPOT>VL2M-P (for printer image)

Are the readings

70 ± 15 V?

YES

NO

NO

NO

NO

Check the primary charging

system; if normal, replace the

photosensitive drum.

Check the following, and replace them if

necessary:

1. Laser (for output)

2. Potential control system

3. Photosensitive drum

Check the following, and replace them if

necessary:

1. Laser (for output)

2. Potential control system

3. Photosensitive drum

<Checking the Halftone Density>

Generate a halftone image.

Is the halftone

density optimum?

NO

YES

To check a copier image,

See if No. 6 and No. 7 (halftone) of the Test Chart is

reproduced to the more or less the same density.

To check a printer (PDL) image,

See if the density of the halftone area represents the

original data properly.

REF.

*1:VD target value

COPIER >DISPLAY >DPOT >VDT (for copier image)

COPIER >DISPLAY >DPOT >VDT-P (for printer image)

*2:VL1 target value

COPIER >DISPLAY >DPOT >VD1T (for copier image)

COPIER >DISPLAY >DPOT >VD1T-P (for printer image)

Adjusting the Offset Value of the VD Target Potential

(VD-OFFSET/VD-OFFSET-P)

COPIER>ADJUST>V-CONT>VD-OFST (for copier image)

COPIER>ADJUST>V-CONT>VD-VD-OFST-P (for printer image)

End.

Adjust the offset of the VD target potential.

Lighter image Darker image

Default

-5 -4 -3 -2 -1 0 +1 +2 +3 +4 +5

1-13

CHAPTER 1 IMAGE ADJUSTMENT BASIC PROCEDURE

5.4 Making Checks on the Reader Unit

<Making Image Initial Checks> <Checking the Density Slope>

Are there vertical

lines in the images?

YES

Clean the following:

1. Mirrors

2. Lens

3. Standard white plate

(mounted to back of

copyboard glass)

4. Copyboard glass

Execute shading in service mode:

COPIER>FUNCTION>CCD>CCD-ADJ

<Checking Halftone Density>

NO

Execute shading in service mode:

COPIER>FUNCTION>CCD>CCD-ADJ

Is there a difference

in density between

front and rear?

YES

Clean the mirrors.

Is there a

difference in density

between front

and rear?

YES

Perform the instructions under

“ Checking the Density Slope”

for the printer unit.

B

<Checking the Solid Black Density>

NO

NO

Executing Potential Control

Turn off and then on the power switch; then,

make a copy.

Make a copy of

the NA3 Chart in text mode. Is

gray scale No. 1 (solid black)

too light?

YES

Check the life of the

scanning lamp; if it has

reached the end of its

life, replace it.

Clean the following:

1. Mirrors

2. Lens

3. Standard white plate

4. Scanning lamp

5. Reflecting plate

NO

<Checking for Fogging>

Make a copy of

the NA3 Chart in text mode.

Is the white background

foggy?

NO

Perform the instructions

under “nChecking for

Fogging”g on the printer side.

Make a copy of the

NA3 Chart in AE mode. Is the

output foggy?

YES

YES

Execute shading adjustment in service

mode:

COPIER>FUNCTION>CCD>CCD-ADJ.

NO

Increase the white level target value for

shading correction in service mode:

COPIER>ADJUST>CCD>SH-TRGT

(40 max.).

Execute shading adjustment in service

mode:

COPIER>FUNCTION>CCD>CCD-ADJ.

Is the white

background

foggy?

YES

When

the A3 Chart

is copied in text/photo

mode, is the density of No.8 optimum

when compared with Nos.7

through 9?

NO

If it is too light,

Increase the setting of the

following in service mode:

COPIER > ADJUST > DENS

>DENS-ADJ

Make one copy of the A3 Chart in

text/photo mode.

Is the

density of gray scale

YES

No.8 (halftone)

different?

NO

YES

If it is too dark,

Decrease the setting of the

following in service mode:

COPIER > ADJUST > DENS

>DENS-ADJ

End.

Execute shading adjustment in service

mode:

COPIER>FUNCTION>CCD>CCD-ADJ.

Is the density of

gray scale No. 1 (solid black)

too low (light)?

YES

Perform the instructions under

“ Checking the Solid Black Density”

for the printer unit.

NO

NO

B

NO

Decrease the value of AE density

adjustment in service mode:

COPIER>ADJUST>AE>AE-TBL.

Is the white

background

foggy?

YES

1-14

Go to “ Checking the Halftone Density” for the printer side.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1.Image Adjustments

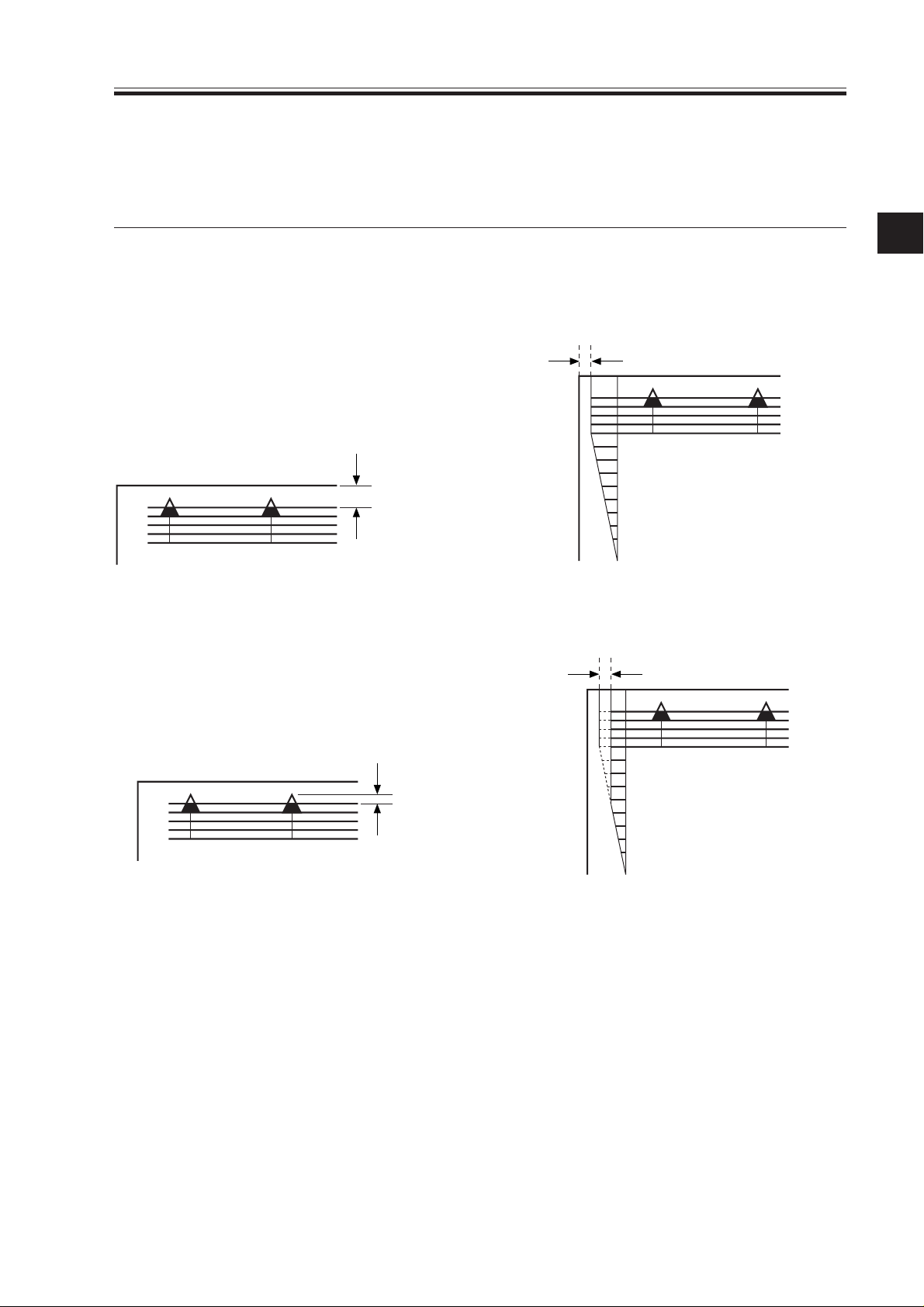

1.1 Standards of Image Position

The image margin/non-image width of a print made in Direct must be as follows:

2.5±1.5mm

0

2

2

4.0

+1.5mm

- 1.0mm

4

6

8

10

F02-101-01 Image Leading Edge Margin F02-101-02 Left/Right Image Margin

2.5mm±1.5

0

2

4

6

+1.5mm

4.0

- 1.0mm

F02-101-03 Leading Edge Non-Image

F02-101-04 Left/Right Non-Image Width

8

10

Width

2-1

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1.2 Checking the Image Position

Make prints using the following as the source of paper (10 prints each), and check to see

that the image margin and the non-image width are as indicated:

• Each cassette

• Front deck (left, right)

• Manual feed tray

• Duplex feeding unit

• Side paper deck

If not as indicated, adjust the image position in the following order:

1. Adjusting the left/right image margin (registration)

2. Adjusting the image leading edge margin (registration)

3. Adjusting the left/right non-image width (CCD read start position)

4. Leading edge non-image width (scanner image leading edge position)

1.3 Adjusting the Left/Right Image Margin

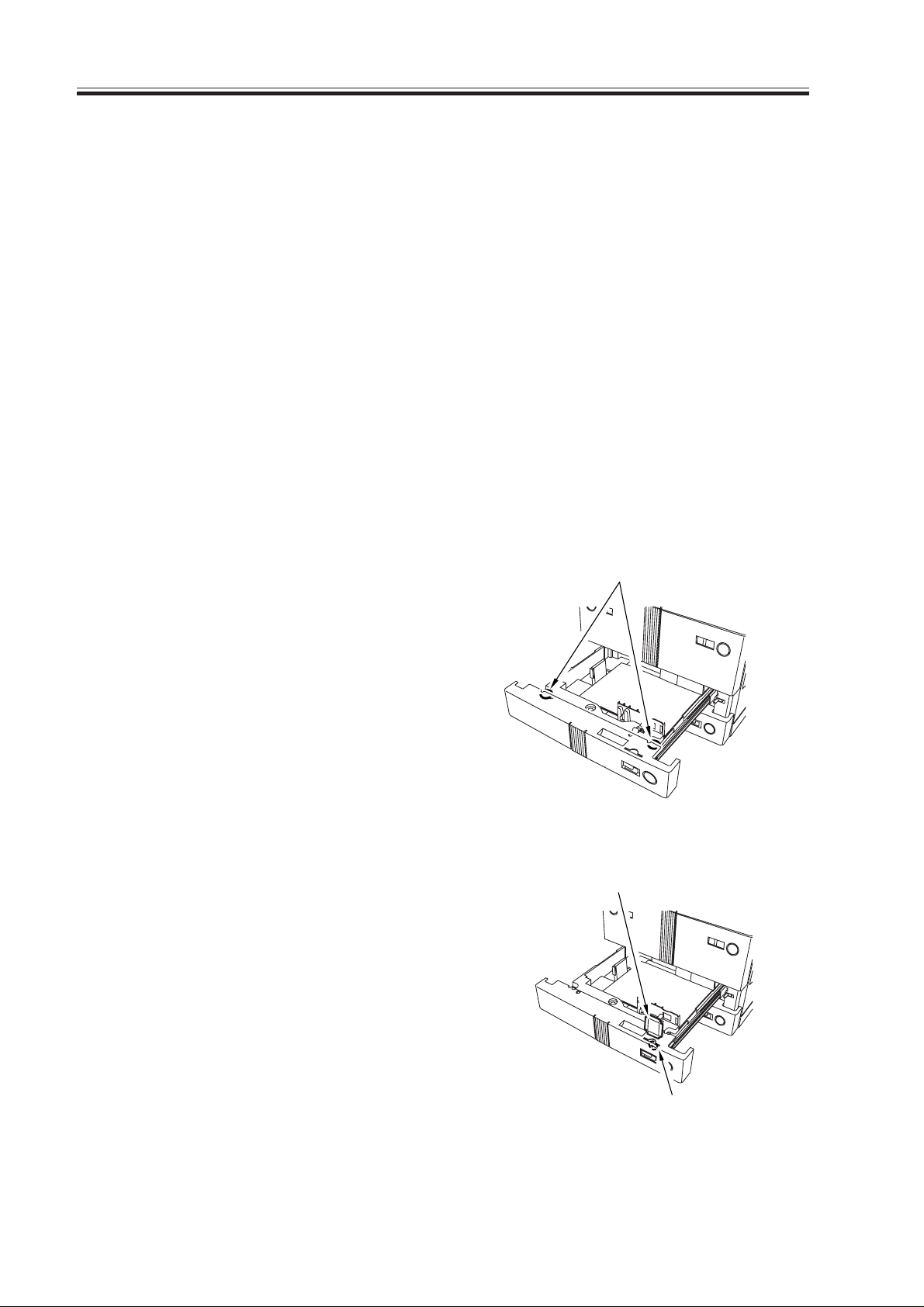

1.3.1 Cassette 3/4

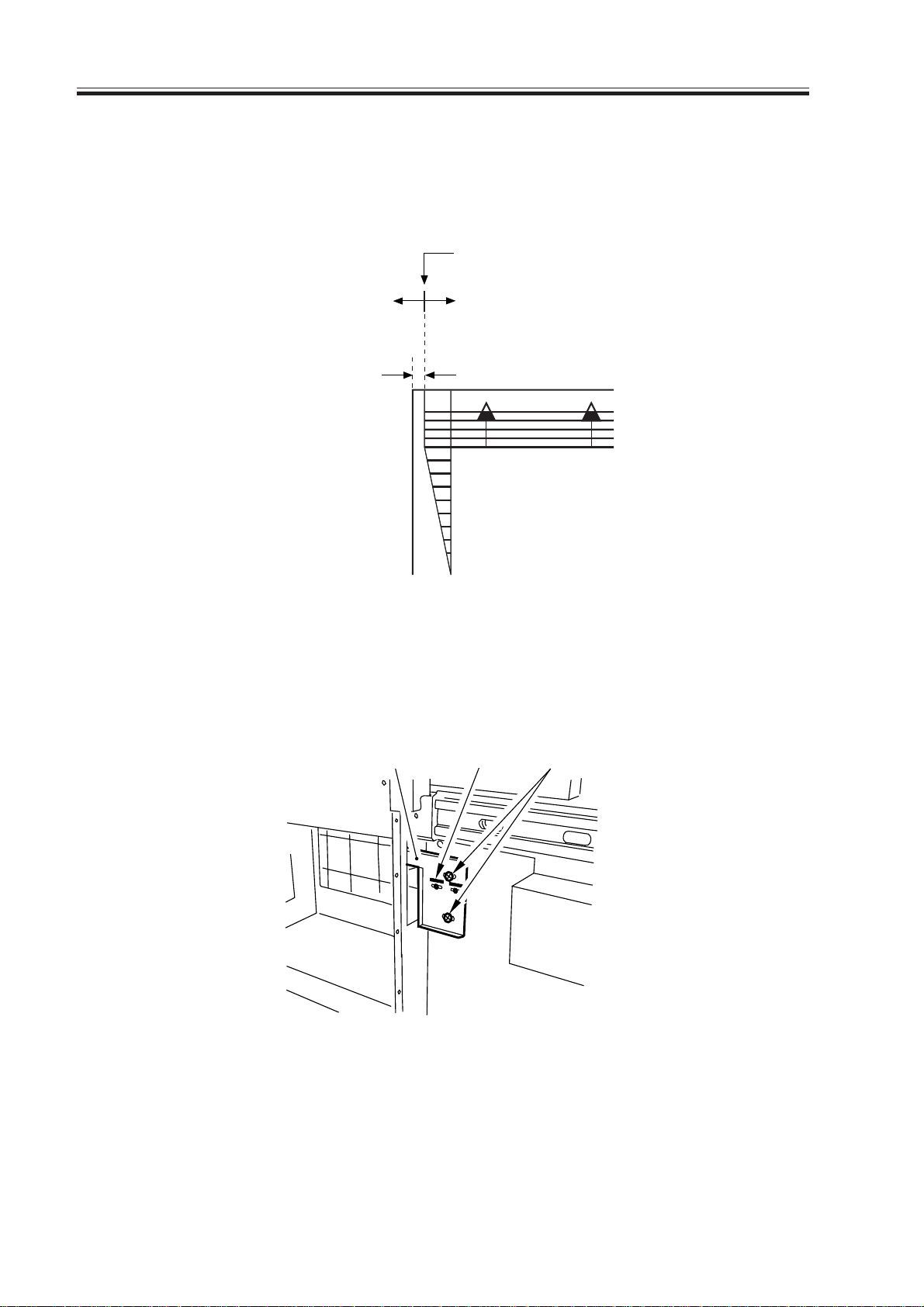

1) Loosen the two fixing screws [1] found

on the left and the right of the cassette.

2) Remove the paper size plate [2], and

turn the adjusting screw [3] found in the

opening of the paper size plate [2] to

adjust the position; then, tighten the two

fixing screws [1].

After making the adjustment, be sure to

execute the following service mode:

COPIER>FUNCTION>CST>C3STMTR/A4R or C4-STMTR/A4R

[1]

F02-103-01

[2]

2-2

[3]

F02-103-02

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1.3.2 Left/Right Front Deck

1) Loosen the four screws [2] and the two

fixing screws [3] of the cassette front

cover [1].

2) Move the cassette guide assembly

(front) [4] to the front or the rear to

make adjustments.

[2]

[3]

[2]

F02-103-03

[4]

[3]

[2]

[1]

1.3.3 Manual Feed Tra y

1) Loosen the two mounting screws [1] of

the manual feed tray, and adjust the position of the manual feed tray.

F02-103-04

[1]

F02-103-05

2-3

CHAPTER 2 STANDARDS AND ADJUSTMENTS

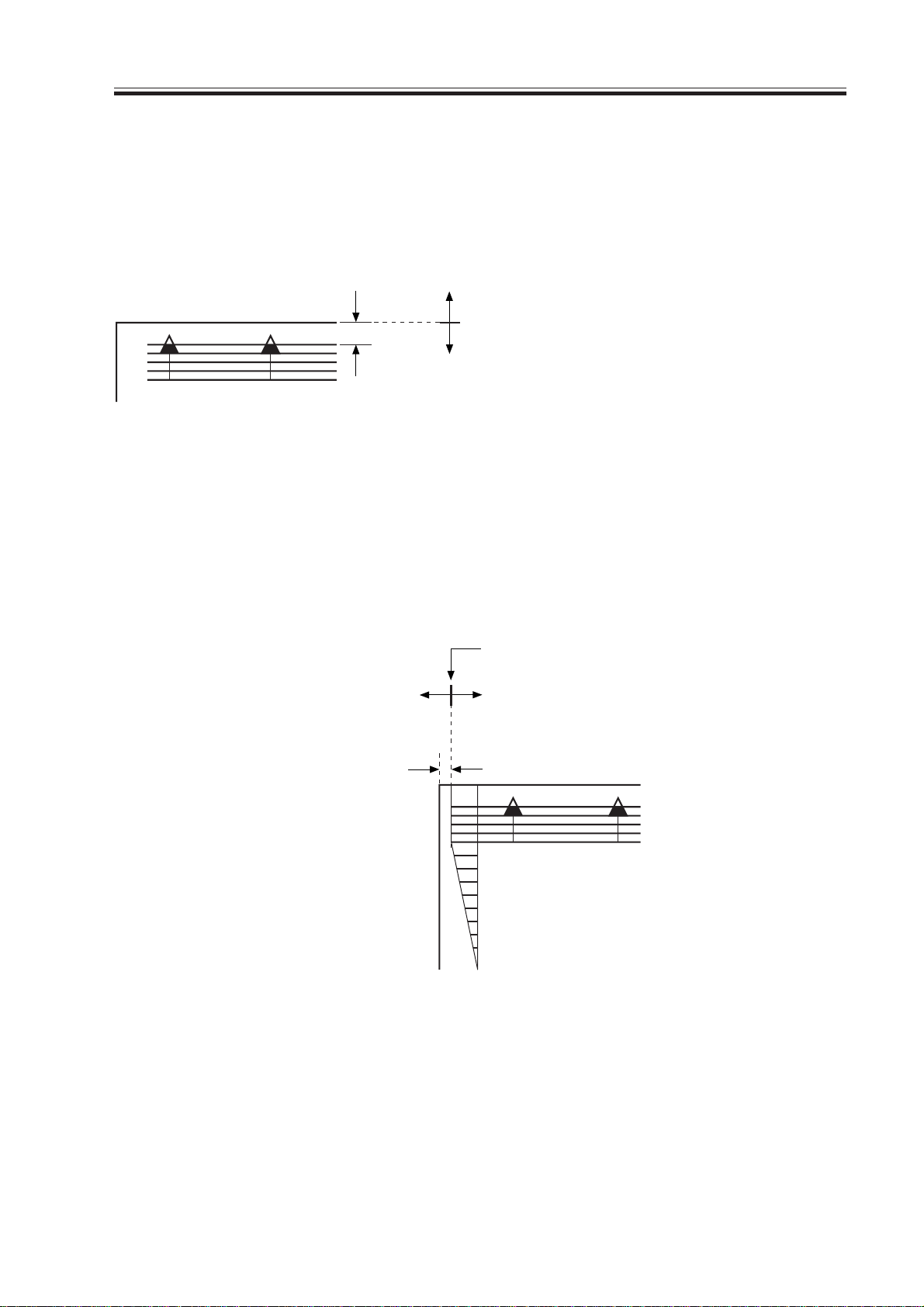

1.3.4 Duplex Feeding Unit

1) Adjust the image margin as indicated using service mode: COPIER>ADJUST>FeedADJ>ADJ-REFE.

Edge of paper

Decreasing the ADF-REFE setting

(A decrease by ‘ 23’ will

ecrease the margin by 1 mm.)

Increasing the ADJ-REFE setting

(An increase by ‘ 23’ will increase

the margin by 1 mm.)

2.5mm±2.0

0

0

2

2

4

4

6

6

8

8

10

10

F02-103-06

1.3.5 Side Paper Deck

1) Slide out the compartment, and turn the two screws to adjust the position of the latch

plate of the deck open solenoid. (At this time, use the index on the latch plate as a

guide.)

Latch plate

Index

Screws

2-4

F02-103-07

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1.4 Adjusting the Image Leading Edge Margin

1) Adjust the image margin in service mode so that it is as indicated:

COPIER>ADJUST>Feed-ADJ>REGIST.

Decreasing the REGIST setting

(A decrease by ‘10’ will increase the margin by 1 mm.)

Edge of paper

Increasing the REGIST setting

(An increase by ‘10’ will decrease the margin by 1 mm.)

F02-104-01

1.5 Adjusting the Left/Right Non-Image Width

1) Adjust the non-image width in service mode so that it is as indicated:

COPIER>ADJUST>ADJ-XY>ADJ-Y.

Edge of image

Decreasing the ADJ-Y setting

(A decrease by ‘12’ will

decrease the margin by 1 mm.)

Increasing the ADJ-Y setting

(An increase by ‘12’ will increase

the non-image width by 1 mm.)

2.5mm±2.0

0

2

4

6

8

10

F02-105-01

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENTS

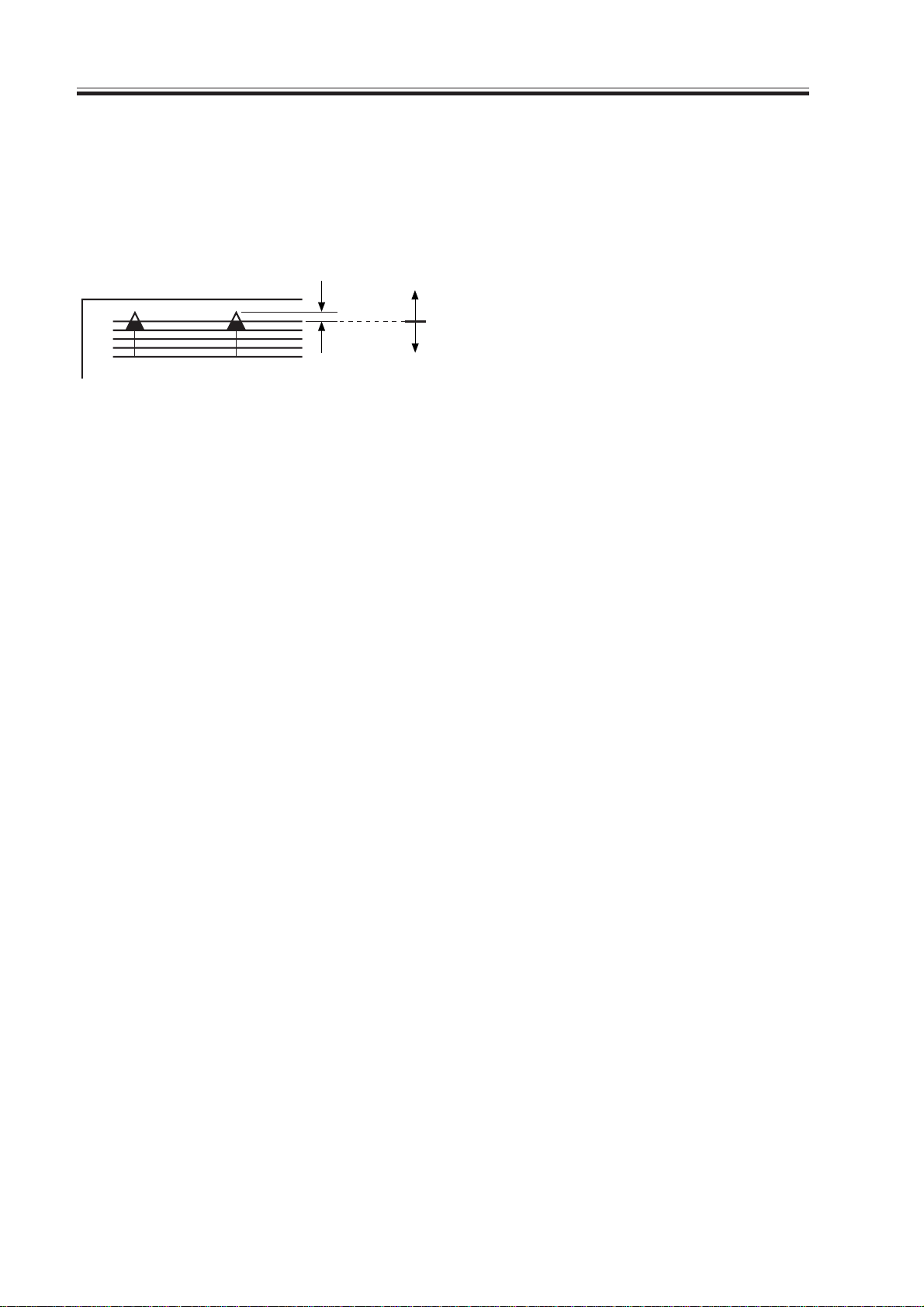

1.6 Adjusting the Leading Edge Non-Image Width

1) Adjust the non-image width in service mode so that it is as indicated:

COPIER>ADJUST>ADJ-XY>ADJ-X.

Decreasing the ADJ-X setting

(A decrease by '12' will decrease the width by 1 mm.)

Image leading edge

Increasing the ADJ-X setting

(An increase by '12' will increase the width by 1 mm.)

F02-106-01

2-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2.Scanning System

2.1 Replacing the Scanner Drive Cable

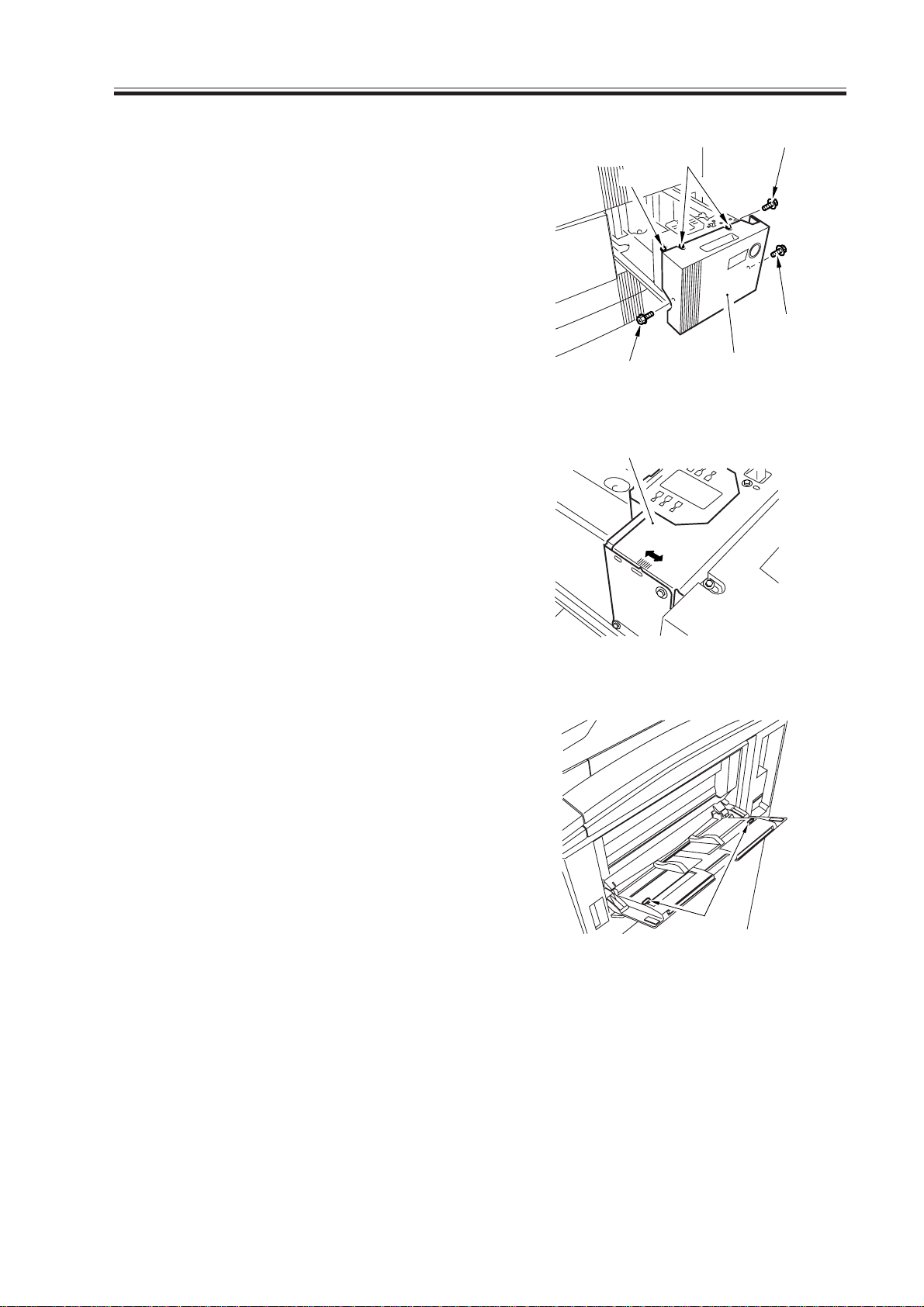

2.1.1 Removing the Scanner System Drive Cable

Obtain the following before starting to replace the scanner drive cable:

• mirror positioning tool (FY9-3040-000)

1) Remove the ADF.

2) Remove the copyboard glass.

3) Remove the reader left cover and the

reader front cover.

4) Remove the motor cover. (See steps 1)

through 4) used to the motor.)

5) Remove the five screws [1], and detach

the PCB base [2].

6) Remove the screw [3], and detach the

ADF base (left) [4]; then, remove the

three screws [5], and detach the

copyboard sensor base [7].

[2]

[1]

F02-201-01

[3] [4]

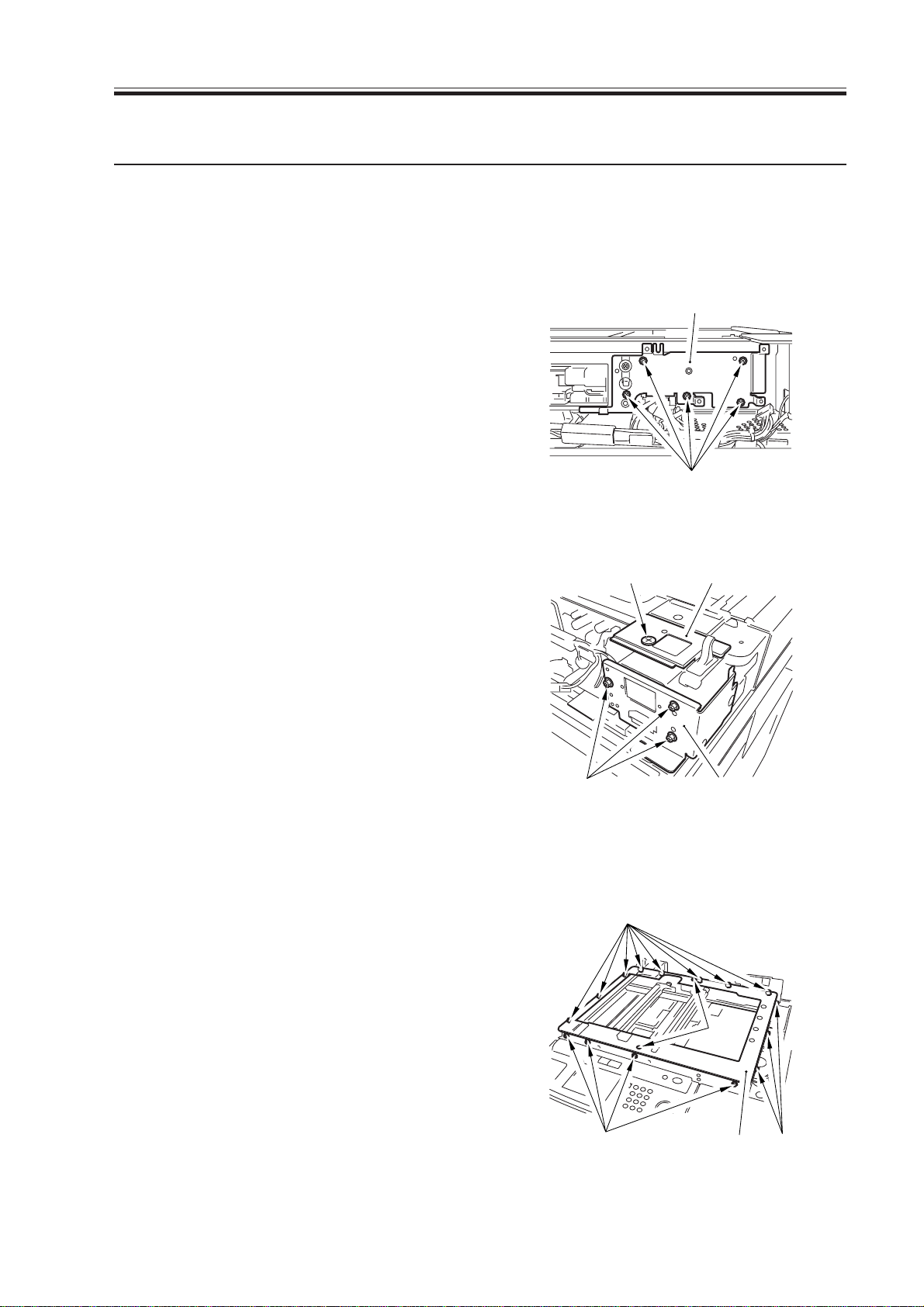

7) Remove the 15 screws [7], and remove

the two screws [8]; then, detach the

reader upper frame [9].

[5]

F02-201-02

[7]

[7]

F02-201-03

[6]

[8]

[9]

[7]

2-7

CHAPTER 2 STANDARDS AND ADJUSTMENTS

8) Remove the two cable fixing screws

[11] of the No. 1 mirror base [10].

9) Remove the two springs [12] used to

secure the cable in place.

10) Remove the cable fixing plate [13] and

each pulley cable.

[11]

[10]

[11]

[12]

[13]

F02-201-04

2-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

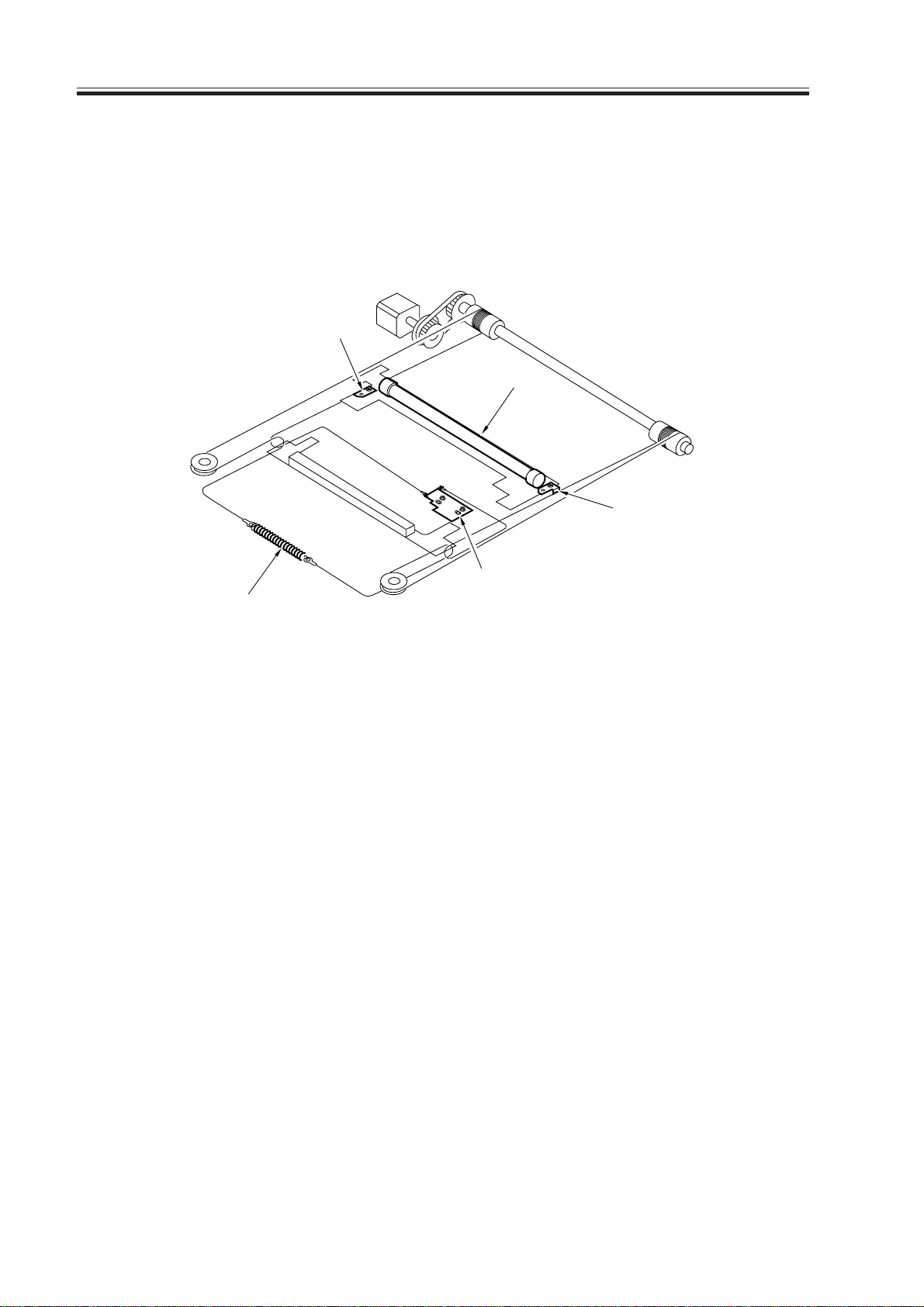

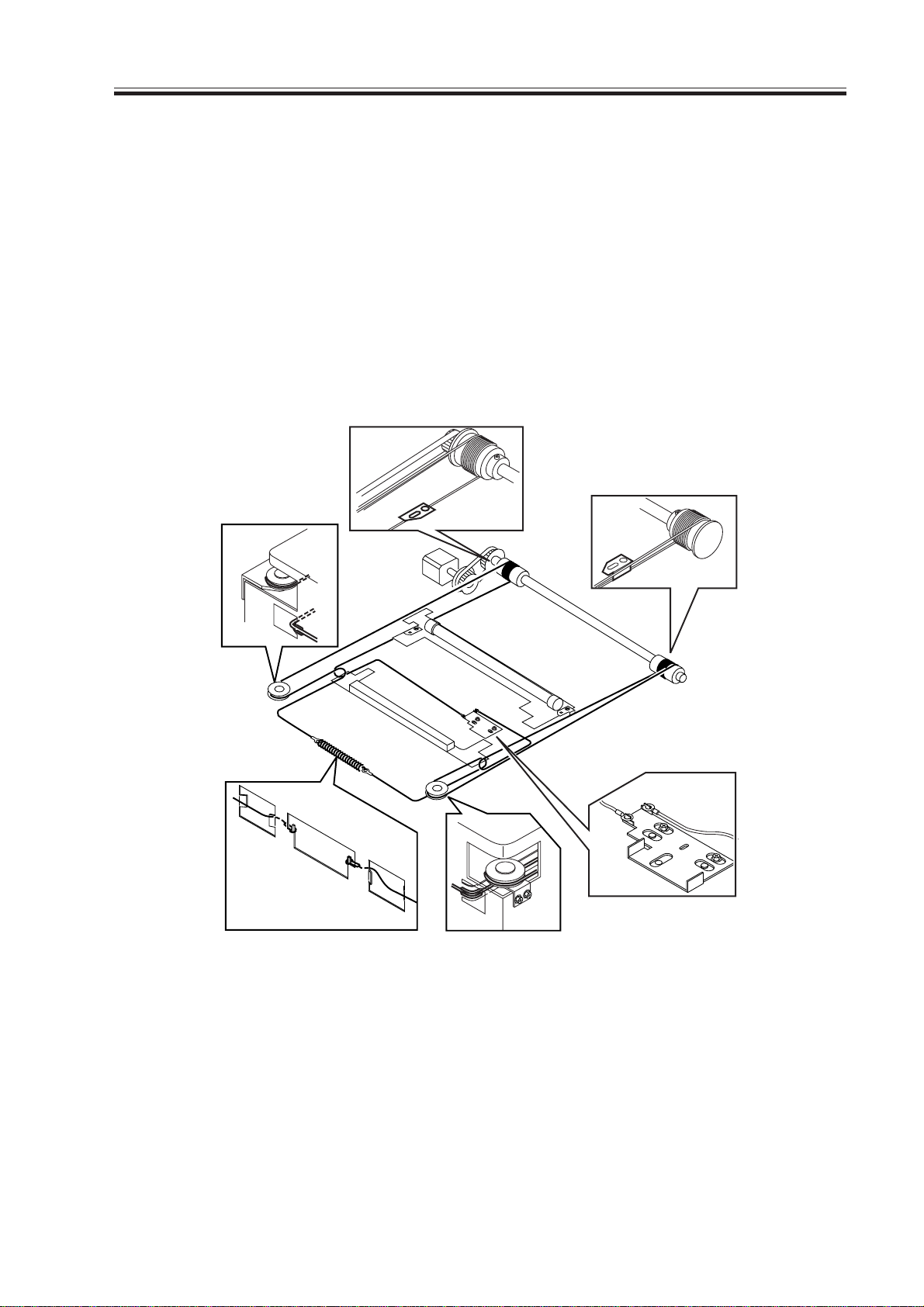

2.1.2 Routing the Scanner Drive Cable

Route the scanner cable to each pulley and hook mirror base in the order indicated:

1) Loosen the screw on the cable fixing plate.

2) Fit the ball of the cable into the hole of the drive pulley, and wind the ca ble (4 times inward, 5 times outward); then, tape it in place. When winding, be sure that the cable

metal fixing is inside.

3) Hook the cable on each pulley, and temporarily fix one end to the cable fixing plate and

the other end to the hook of the reader frame.

4) Temporarily fix the cable metal fixing to the No. 1 mirror base. (Do not fully secure it.)

5) Mount the reader paper frame.

F02-201-05

2-9

CHAPTER 2 STANDARDS AND ADJUSTMENTS

When mounting the reader upper frame, be sure to go through

the following steps:

[2]

1) Fit the eight claws [1] of the reader

[1]

frame correctly into the cut-offs in the

reader upper frame.

2) Secure the positions [2] of the four left/

right claws using screws.

3) Fit the two screws [3] at the end.

[1]

[3]

F02-201-06

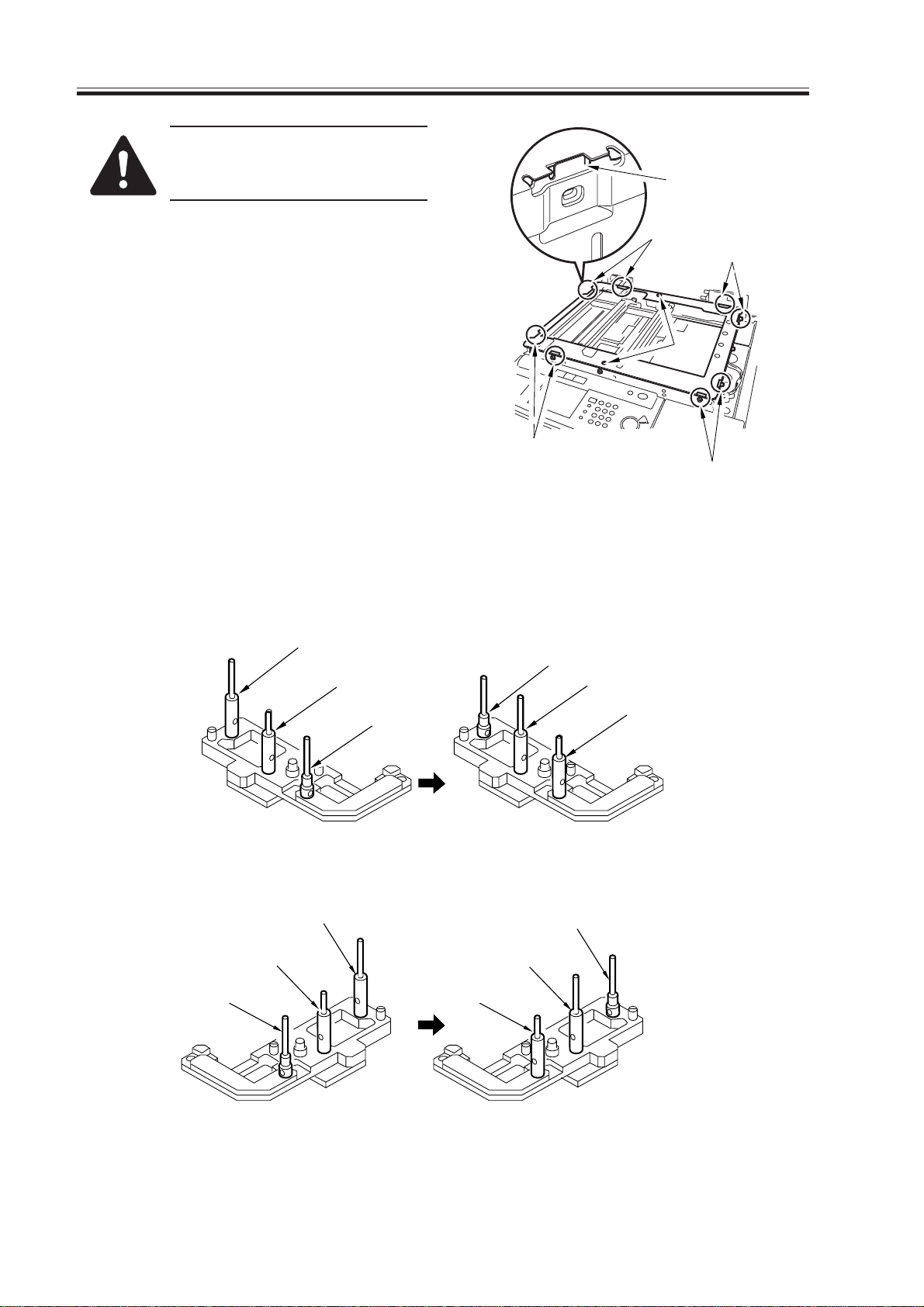

2.2 Adjusting the Position of the Scanner Mirror Base

1) Set the pins of the mirror position tool

as indicated.

[C]

[A]

[B]

[C]

[1]

[1]

[A]

Initial FY9-3009-040 configuration

(for rear)

[C]

[B]

[A]

Initial FY9-3009-040 configuration

(for front)

[B]

Configuration used for the machine

(for rear)

[A]

[C]

[B]

Configuration used for the machine

(for front)

2-10

F02-202-01

Loading...

Loading...