Canon i350, i355, i250, i255 Service Manual

i350 / i355

i250 / i255

SIMPLIFIED MANUAL

1. PRODUCT LIST

2. PRODUCT SPECIFICATIONS

3. ERROR DISPLAY

4. SERVICE MODE (test print, EEPROM initialization, destination setting)

5. EXTERNAL VIEW / PARTS LIST

6. TROUBLESHOOTING FLOWCHART (main unit, print head)

7. SERVICE INFORMATION

APPENDIX 1: SHIPMENT INSPECTION PATTERN

APPENDIX 2: i350/i250 SERVICE TOOL

QY8-1389-000

Rev. 00

June 6, 2003

Canon Inc.

1

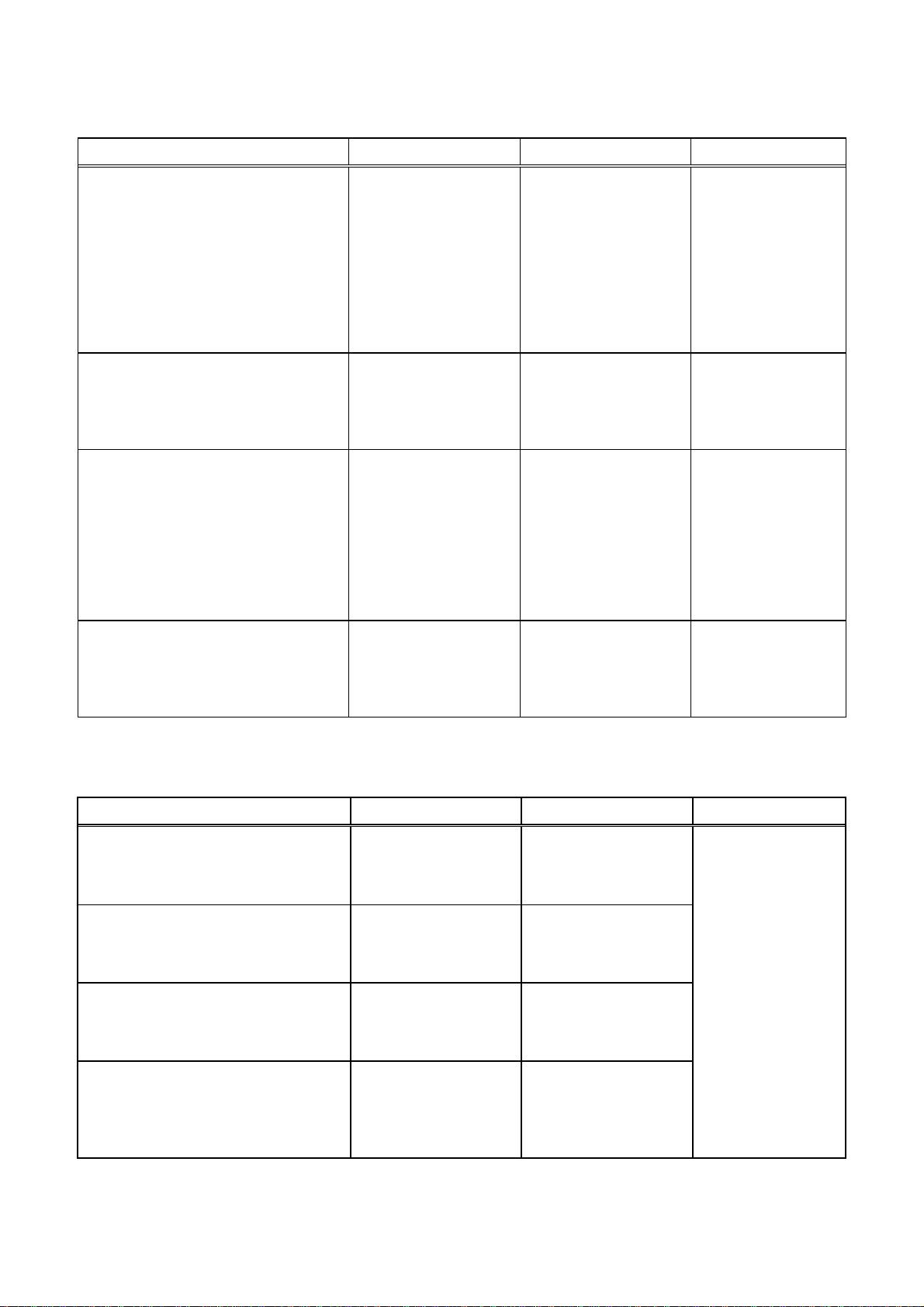

1. PRODUCT LIST

1-1. Main Units

Product name Product code Sales Territory Remarks

Canon Bubble Jet Printer

i350

8549A001AA

8549A002AA

8549A003AA

8549A004AA

8549A005AA

8549A006AA

8549A007AA

8549A009AA

8549A0011AA

US

CA

LAM LVT

LAM HVT

EUR

DE

FR

AU

GB

Canon Bubble Jet Printer

i355

Canon Bubble Jet Printer

i250

Canon Bubble Jet Printer

i255

1-2. Options None

1-3. Consumables

Product name Product code Sales Territory Remarks

Canon Ink Tank

BCI-24 Black

Canon Ink Tank

BCI-24 Color

Canon Ink Tank

BCI-24 Black Twin Pack

Canon Ink Tank

BCI-24 Color Twin Pack

8549A008AA

8549A010AA

8549A013AA

8549A014AA

8549A015AA

8550A001AA

8550A002AA

8550A003AA

8550A004AA

8550A005AA

8550A006AA

8550A007AA

8550A009AA

8550A0011AA

8550A008AA

8550A010AA

8550A013AA

8550A014AA

8550A015AA

6881A001AA

6881A002AA

6881A003AA

6881A004AA

6882A001AA

6882A002AA

6882A003AA

6882A004AA

6881A008AA

6881A009AA

6881A010AA

6881A011AA

6882A008AA

6882A009AA

6882A010AA

6882A011AA

ASA HVT

KR

TW

HK

CN

US

CA

LAM LVT

LAM HVT

EUR

DE

FR

AU

GB

ASA HVT

KR

TW

HK

CN

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

Common with

S200/S200x/S300

/S330/i320/PIXUS

320i

2

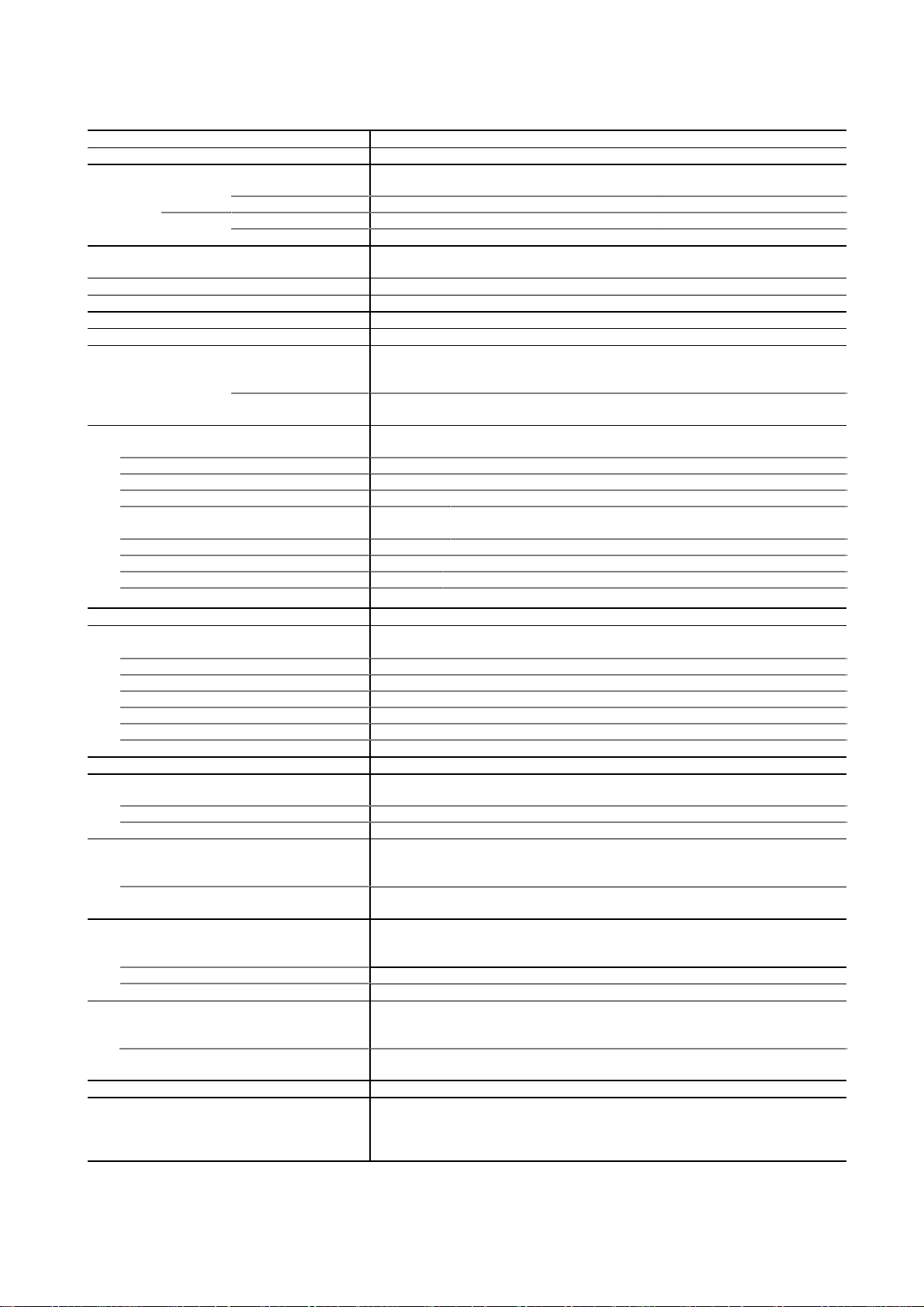

2. PRODUCT SPECIFICATIONS

2-1. Printer Main Unit Specifications

Paper feeding method ASF

Resolution 2,400dpi x 1,200dpi (at the highest resolution)

Printing speed *Measured by new through-put pattern (LowEnd 2003)

HS

CL i350/i355: 4 ppm i250/i255: 3.5 ppm (CL through-put pattern) HQ

BK 11ppm 8 ppm (BK through-put pattern)

CL 11 ppm 9 ppm (CL through-put pattern)

BK 16 ppm 12 ppm (BK through-put pattern)

Printing direction Bi-directional / Uni-directional (automatically switched according to print data

and print mode)

Default mode print duty i350/i250: 50% duty i355/i255: 25% duty

Print width 203.2mm (8 inches)

Interface USB (2.0) *Full Speed only

Supported print head Service part: QY6-0044-000

No. of pages that can be printed

ASF stacking capacity

Paper weight

Plain paper

High resolution paper

Glossy photo paper 10 sheets or less

Professional photo paper / super photo

paper / matte photo paper

Transparency

Envelop

Professional photo card (PC-101)

T-shirt transfer

CL CL: Approx. 170 pages, BK: Approx. 520 pages (SCID No.5 pattern,

default print mode)

BK BK: Approx. 300 pages (1500 character pattern, default print mode)

Max. 10mm (Approx. 100 pages of 75 g/m

64 to 105 g/m

10mm or less

10mm (Approx. 80 sheets) or less

A4/LTR/5x7

4x6

30 sheets or less

10 sheets or less

S(4x6) 20 sheets or less

1 sheet

2

10 sheets or less

20 sheets or less

2

)

Borderless printing 4x6 / 5x7 only

Detection function

Cover open Available

Presence of print head Available

Presence of ink tank Not available

Paper out Available

Paper width Not available

Waste ink full Available

Ink remaining amount Available (Detected by dot counting. Reset by user operation. Default on.)

Head alignment Available (6 types)

Acoustic noise level

Fine (glossy paper / high mode) Approx. 48 dB (Sound pressure level ISO9296)

HQ Approx. 53 dB

HS Approx. 56 dB

Environmental requirements

During operation Temperature

Humidity

Non-operation Temperature

Humidity

5℃ to 35℃ (41 ゚ F to 95 ゚ F)

10% to 90%RH (no condensation)

0℃ to 40℃ (32゚F to 104゚F)

5% to 95%RH (no condensation)

Power supply

Input voltage / Frequency AC 100〜127V

AC 220〜240V

Power consumption During printing Approx. 14 W

Stand-by status Approx. 1 W

External dimensions

With paper feed/delivery tray extended

With paper feed/delivery tray set in i350/i355: Approx. 385(W) X 195(D) X 165(H) mm

i350/i355: Approx. 385(W) X 422(D) X 317(H) mm

i250/i255: Approx. 385(W) X 224(D) X 268(H) mm

i250/i255: Approx. 385(W) X 195(D) X 165(H) mm

50/60Hz

50/60Hz

(LV)

(HV)

Weight Approx. 2.4kg (excluding the print head and ink tanks)

Related standards

RFI, Electrical safety FCC, IC, CE, C-Tick, VCCI, Taiwan EMC, Korean MIC, Gost-R, UL, CUL,

CB Report, GS, FT, Safety Standards, CCC, Korean EK, SASO, SPRING,

TUV (ARG)

*: Blue Angel pending

3

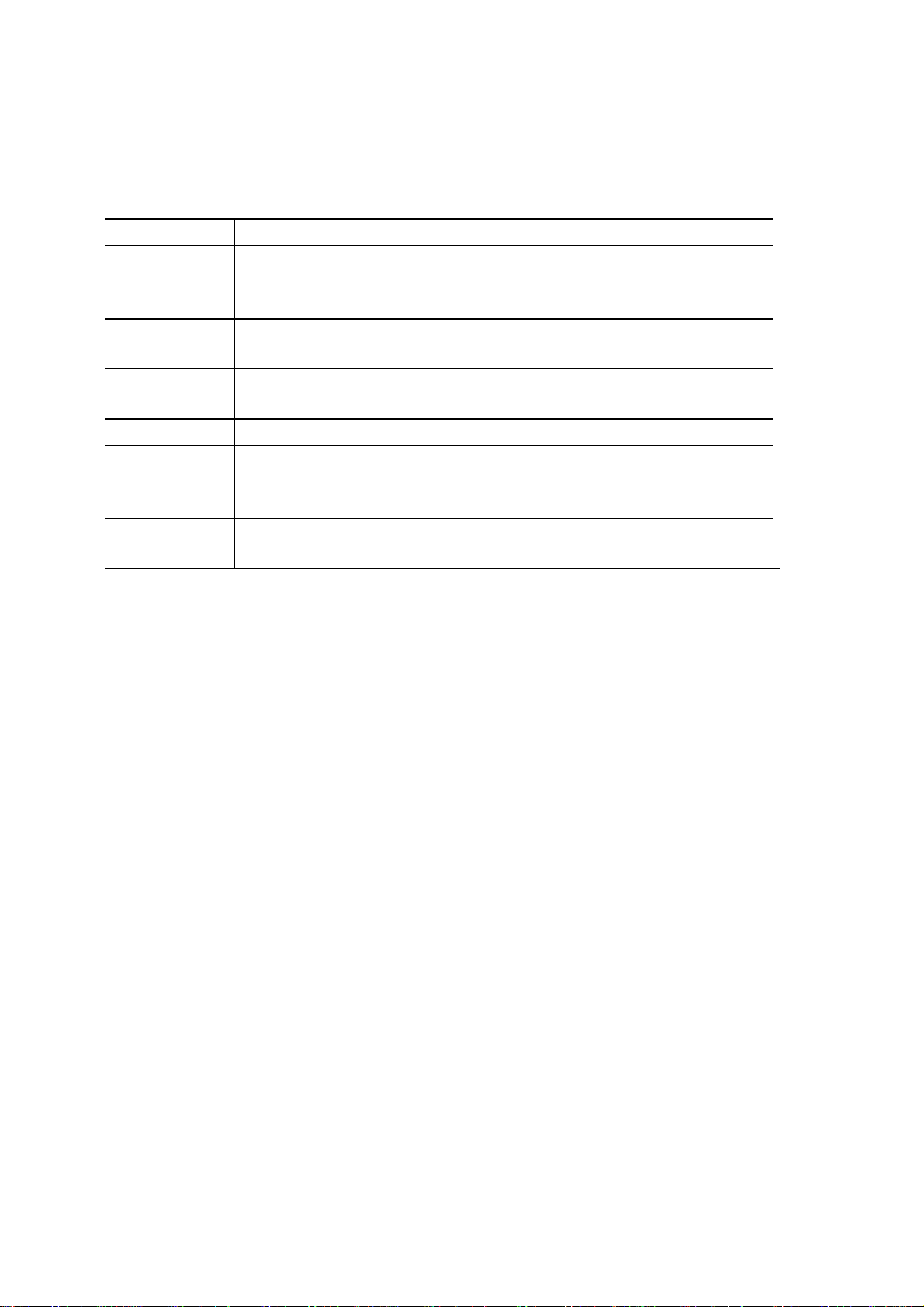

2-2. Product Life

3 years or 4,000 pages (2,500 pages of color printing and 1,500 pages of black printing), whichever

comes first

2-3. Print Head Specifications

Structure 4-color integrated type (ink tank separate type)

Print head Bk: 2 vertical lines, 320 nozzles

Ink colors Bk (new pigment ink)

Ink tank BCI-24 Bk, BCI-24 Color (common parts)

Weight Approx. 60g (excluding ink tanks)

Supply method Service part (excluding ink tanks)

Print head life 4,000 pages (Same as the printer main unit, Cl: 2,500 pages, Bk: 1,500

C/M/Y: 2 vertical lines in each color, 128 nozzles

Ink drop: Bk 30 pl, Col 5pl

Cl: Y, M, C (high brilliance)

(Common with S300/S330/i320)

Part number: QY6-0044-000 (common parts)

Common to the i320, however, not compatible with the S300/S330 series.

pages of black printing

Note: The print head can be physically installed in the old models, however, it is

incompatible with and cannot be used in the old models.

4

3. ERROR DIAPLAY

Errors are displayed by the LEDs, and ink low warnings are displayed by the status monitor.

3-1. Operator Call Error (Orange LED blinking)

LED Display Content Corrective Action

Blinking 2 times Paper out

Blinking 3 times Paper jam

Blinking 4 times Ink tank not installed

Blinking 5 times Print head not installed or failure has

occurred in the print head.

(Not-supported print head (see page 5) is

installed or print head EEPROM data is

abnormal.)

Blinking 8 times Waste ink full or platen waste ink full warning

(Approx. 95% of acceptable amount)

Set paper, and press the RESUME

button to feed the paper.

Remove the jammed paper, and press

the RESUME button.

Re-install the ink tank, and close the

access cover.

Re-install the print head, and close the

access cover. Or confirm the print

head is “QY6-0044-000” and perform

re-installation. If not recovered with the

cartridge installed, power the printer off

and on.

Recoverable by pressing the RESUME

button.

3-2. Service Call Error (Orange and green LEDs blink alternately)

LED Display Content Corrective Action

Blinking 2 times Carriage error Replace the printer as it has failed.

Blinking 6 times Internal temperature abnormal error Replace the printer as it has failed.

Blinking 7 times Waste ink full or platen waste ink full error Replace the printer as it has failed.

Blinking 8 times Abnormal temperature rise Replace the printer as it has failed.

Blinking 9 times EEPROM error Replace the printer as it has failed.

Blinking 10 times No cartridge detected excepting print head

replacement (during printing)

Replace the printer as it has failed.

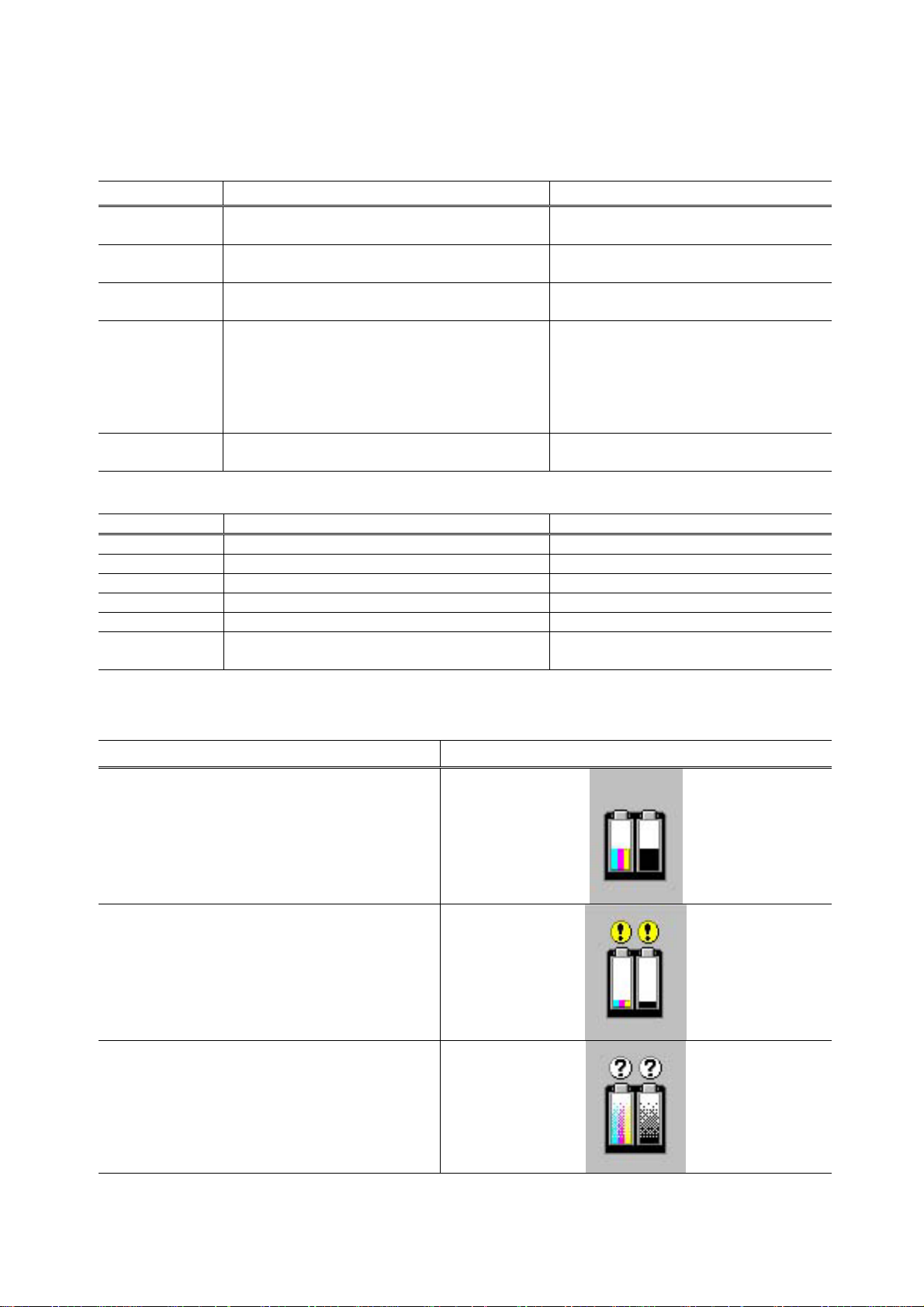

3-3. Ink Low Warning (Ink low warnings are displayed by the status monitor only when the remaining

ink level detection is on, and no status monitor display when off.)

Content Display by status monitor

Ink low warning 1 (approx. half level)

Ink low warning 2 (low remaining ink)

Ink low warning 3 (ink level unknown)

5

4. SERVICE MODE

y

To conduct the following functions, a host computer (Windows98/Me, Win2k/XP), printer driver and

service tool (QY9-0062/63) for the i350 are needed.

Function Procedure Remarks

Print head manual cleaning

< For reference >

Head refreshing (deep cleaning)

Paper feed roller cleaning

Select “Cleaning” from the printer driver utility.

Select “Deep Cleaning” from the printer driver utility.

1. Remove the paper from the ASF.

2. Select “Feed Roller Cleaning“ from the printer driver

Cleaning time: Approx. 40 sec.

Cleaning time: Approx. 70 sec.

Cleaning time: Approx. 2 min.

utility.

3. Following the instruction from the status monitor,

load 3 pages of plain paper in the ASF, and feed

them.

Test printing

1) Nozzle check pattern printing

< For Reference >

Head alignment

2) Shipment pattern printing

- ROM version

- No. of pages fed

- Waste ink amount

EEPROM reset

(Reset of waste ink counter etc.)

Destination setting

(i350/i355/PIXUS 350i/

Select “Nozzle Check“ from the printer driver utility.

1. Select “Print Head Alignment“ from the printer driver

utility.

2. Select the optimal value using the printed head

position adjustment pattern.

Refer to Shipment inspection pattern*

1

below. Refer to Shipment inspection

Refer to EEPROM reset / Destination setting*3 below. Host computer and service tool

Refer to EEPROM reset / Destination setting*

3

below. Host computer and service tool

Nozzle check pattern printing

Significant misalignment can

be adjusted.

pattern sample*

2

below.

Host computer and service tool

are required.

are required.

are required.

i250/i255)

*1 Shipment inspection pattern

a. With the printer powered on, install the print head (QY6-0044-000). (The green lamp lights.)

b. Load A4-sized paper.

c. Connect the printer to the computer, select “USB PORT” using the i350/i250 service tool (QY9-0062/0063). (Refer to

Appendix 2, i350/i250 Service Tool.)

d. Select “TEST PATTERN 1”. The printer starts printing the shipment inspection pattern.

2

Shipment inspection pattern sample

*

EEPROM contents can be confirmed from the shipment inspection pattern printout. (top of the shipment inspection

pattern

Model name

Waste ink amount (%)

ROM Version

i350 P=V X.XX D=XXXXX.X

Page=XXXX PL=XXXX , HR=XXXX , GP=XXXX , CA=XXXX

SettingTime=XXXX / XX / XX XX:XX YY YY YY YY USB= (YYYYYY)

Installation time

No of pages fed:

Page: Total No. of pages fed

PL: Plain paper

PR: PR101, SP101, MP101

CA: Postcard, Ink jet postcard, gloss

postcard

BL: Borderless printing

(Counted separately from other

media)

*3 EEPROM reset / Destination setting

a. With the printer powered on, install the print head (QY6-0044-000). (The green lamp lights.)

b. Connect the printer to the computer, select “USB PORT” using the i350/i250 service tool (QY9-0062/0063). (Refer to

Appendix 2, i350/i250 Service Tool.)

c. <Destination setting>

Destination can be set by clicking each model name in “SET DESTINATION.”

Setting can be changed from the i350 to the i250/i255 (vice versa). Confirm the model name by clicking “GET

DEVICE ID” after setting change. (If incorrect, it can be changed before turning the unit OFF/ON.)

<EEPROM reset>

The EEPROM is reset after the shipment inspection pattern printing when ”EEPROM CLEAR” is checked.

6

Loading...

Loading...