Canon GP-200, GP-215 Service Manual

SERVICE

MANUAL

REVISION 0

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

JULY 1996

FY8-13EE-000

COPYRIGHT © 1996 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN, AND IS

FOR REFERENCE USE ONLY. SPECIFICATIONS AND OTHER INFORMATION CONTAINED

HEREIN MAY VARY SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN

ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146 Japan

This Service Manual provides basic facts and figures needed to service the GP215/GP200 in the field.

The GP215/GP200 is designed to accommodate fax and printer functions in addition to copier functions,

and separate service manuals are available for each function; refer to the appropriate ser vice manual as

necessary.

This Service Manual is organized as follows:

CHAPTER 1, “General Introduction,” shows the GP215/GP200’s features, specifications, and step-bystep instructions on how to operate the copier.

CHAPTER 2, “Copying Processes,” shows how the GP215/GP200 generates copies while discussing

each of the steps involved.

CHAPTER 3, “Operations and Timing,” explains the GP215/GP200’s mechanical system by function

and principles behind its electrical systems in relation to timing of each operation.

CHAPTER 4, “Mechanical System,” explains how to disassemble/assemble and adjust the

GP215/GP200.

CHAPTER 5, “Installation,” provides points to note when selecting the site of installation and instructions on how to install the GP215/GP200.

CHAPTER 6, “Maintenance and Inspection,” provides tables of periodically replaced par ts and consumables/durables as well as a scheduled servicing chart.

APPENDIX contains a general timing chart, general circuit diagrams, and PCB diagrams.

This Service Manual is accompanied by the Service Handbook, which contains information on how to

maintain and inspect the GP215/GP200 through adjustment and troubleshooting work.

Information found in this manual ma y be updated from time to time for product improvement, and major

updates are communicated in the form of Service Information bulletins.

All service persons are expected to be thoroughly familiar with the contents of this Service Manual, the

Service Handbook, and Service Information bulletins and be ready to respond to the needs of the user

promptly.

i

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

■■

System Configuration

The GP200/GP215 Series machine may be configured as follows:

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

ii

ADF-F1 (comes standard with some models)

Projector

RDF-G1 (comes standard with some models)

GP215F (w/ fax function)

GP215 (w/o fax function)

GP200F (w/ fax function, w/o duplexing function)

Multi-Output Tray-C1

Multi-Output Tray-B2

GP200 (w/o fax function, w/o duplexing function)

Handset

Cassette Feeding Unit-L1

Cassette Feeding Unit-M1

CONTENTS

iii

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS.................................1-8

A. External View ...................................1-8

B. Cross Section.................................1-10

C.

Arrangement of Extension Boards....

1-12

IV. OPERATION..........................................1-13

A. Turning On the Power Switches.....1-13

B. Control Panel..................................1-14

C. Basic Operation..............................1-16

D. Extension Mode..............................1-19

E. Costom Common Settings .............1-25

V. ROUTINE WORK BY THE USER.........1-29

VI. SAFETY.................................................1-30

A. Laser Beams..................................1-30

B. Safety of Toner ...............................1-31

CHAPTER 2 COPYING PROCESS

I. IMAGE FORMATION...............................2-1

A. Outline..............................................2-1

B. Latent Image Formation Block.........2-2

C. Pre-Exposure (step 1)......................2-3

D. Primary Charging (step 2)................2-3

E. Laser Exposure (step 3)...................2-4

F. Development (step 4).......................2-4

G. Transfer (step 5) ...............................2-5

H. Separation (step 6)...........................2-6

I. Fixing (step 7)...................................2-7

J. Dram Cleaning .................................2-7

II. AUXILIARY PROCESS............................2-8

CHAPTER 3 OPERATIONS AND TIMING

I. BASIC OPERATION................................3-1

A. Functional Construction....................3-1

B. Outline of the Electrical Circuitry......3-2

C. Inputs to the Major PCBs .................3-6

D. Main Motor Control PCB ................3-16

II. ORIGINAL EXPOSURE SYSTEM.........3-20

A. Outline............................................3-20

B. Varying the Reproduction Ratio .....3-22

C. Sequence of Operations

(original exposure system).............3-22

D. Scanner Motor................................3-23

E. Controlling the Scanning Lamp......3-24

F. Identifying the Size of Originals......3-26

III. IMAGE PROCESSING..........................3-29

A. Outline............................................3-29

B. Analog Image Processing ..............3-31

C. Digital Image Processing ................3-33

IV. LASER EXPOSURE SYSTEM..............3-51

A. Laser Processing Assembly...........3-51

B. Generating the BD Signal ..............3-53

C. Laser Dr iver Circuit.........................3-54

D.

Controlling the Laser Scanner Motor

...3-56

V. IMAGE FORMATION SYSTEM.............3-58

A.

High-Voltage Transformer Circuit

......3-58

B. Controlling the

Primary Charging Roller Bias.........3-60

C. Controlling the

Transfer Charging Roller Bias ........3-63

D. Controlling the Developing Bias.....3-66

E. Controlling the

Separation Static Eliminator Bias...3-68

F.

Controlling the

Transfer Guide/Fixing Roller Bias

...3-69

G. Developing Assemb ly/ Drum Cleaner...3-70

H. Pr imar y Charging Roller

Cleaning Mechanism......................3-73

I. Detecing Errors on the

Composite Power Supply PCB.......3-74

VI. PICK-UP/FEEDING SYSTEM...............3-76

A. Outline............................................3-76

B. Pick-Up from the Cassette .............3-79

C.

Non-Pick Up Operation (standby)

....3-91

D.

Detecting the Level of Copy Paper

...3-93

E.

Detecting the Size of Copy Paper

...3-95

F. Multifeeder ....................................3-100

G. Controlling the

Registration Roller Clutch.............3-103

H. Making Overlay Copies ................3-104

I. Making Two-Sided Copies............3-106

J. Lower Feeding Assembly.............3-108

K. Fixing/Delivery Assembly .............3-118

L. Delivery Assembly........................3-127

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

iv

M. Detecting Jams.............................3-130

VII. FANS ...................................................3-139

A. Functions and Operaitons............3-139

VIII. POWER SUPPLY ................................3-141

A. Outline..........................................3-141

B. SLEEP Mode................................3-145

IX. SYSTEM..............................................3-148

A. Basic Operation............................3-148

B. Diagram of the Function Boards ..3-150

C. Flow of Image Signals..................3-154

X. SERVICE MODE.................................3-158

A. Outline..........................................3-158

B. Using Service Mode.....................3-159

C. Using Adjustment Mode and Settings

Mode.............................................3-160

D. *1* DISPLAY (control displa y mode)...3-161

E. *2* I/O DISPLAY(I/O display mode)....3-178

F. *3* ADJUST (adjustment mode) ..3-197

G. *4* FUNCTION (function mode)...3-208

H. *5* OPTIN (settings mode)...........3-228

I. *6* COUNTER (counter mode)....3-234

J. *7* ACC (accessory mode) ..........3-238

K. Electrical System..........................3-242

XI. SELF DIAGNOSIS...............................3-261

A. Copier...........................................3-261

B. Self Diagnosis of the RDF-G1 ......3-266

C. Self Diagnosis of the ADF-F1 .......3-266

D. Self Diagnosis of the Pedestal.....3-267

E. Self Diagnosis of the

Multi Output Tray -C1 ...................3-267

F. Self Diagnosis of the

Multi Output Tray-12.....................3-268

CHAPTER 4 MECHANICAL SYSTEM

I. BEFORE THE WORK/

POINTS TO NOTE ..................................4-1

A. Main Power Switch and Others........4-1

B. Handling the Harnesses...................4-2

II. EXTERNALS ...........................................4-3

A. External Covers................................4-3

B. Inside Cover.....................................4-4

C. Control Panel....................................4-6

D. Fans..................................................4-7

III. DRIVE ASSEMBLY..................................4-8

A. Scanner Drive Assembly..................4-8

B. Fixing Drive Assembly ....................4-13

C. Duplexing Unit Inlet Motor Mount

Assembly........................................4-14

D. Set-Back Roller Motor Assembly....4-14

E. Pick-Up Drive Assembly .................4-15

IV. PICK-UP ASSEMBLY............................4-18

A. Pick-Up Assembly ..........................4-18

B. Multifeeder Assembly.....................4-20

C. Feeding Assembly..........................4-21

D. Lower Feeding Assembly...............4-23

E. Registration Roller Assembly.........4-23

F. Delivery Assembly..........................4-24

V. EXPOSURE ...........................................4-27

A. Illuminating Assembly.....................4-27

B. CCD Unit ........................................4-28

C. IPU PCB.........................................4-29

D. Laser Scanner Assembly ...............4-30

VI. DEVELOPING SYSTEM .......................4-32

A. Developing Assembly.....................4-32

VII. FIXING SYSTEM ...................................4-34

A. Fixing Assembly.............................4-34

VIII. ELECTRICAL SYSTEM.........................4-37

A. DC Controller PCB.........................4-37

B. Composite Power Supply PCB.......4-37

C. Replacing the ROM DIMM

(image processor PCB)..................4-38

CHAPTER 5 INSTALLATION

I. SELECTING THE SITE...........................5-1

II. UNPACKING AND INSTALLATION .........5-3

A. Unpacking.........................................5-4

B. Supplying Toner ................................5-6

C. Stirr ing the Toner..............................5-8

D. Installing the Drum Car tridge .........5-10

E. Installing the Cassettes..................5-14

F. Installing the Feeder .......................5-16

G. Machine Specifications

Setting Mode (*5*)..........................5-18

H. Fax Settings (for machines equipped

with fax functions)...........................5-19

I. Checking the Copy Images............5-24

III. RELOCATING THE MACHINE ..............5-30

IV.

INSTALLING THE CONTROL CARD V

....5-31

V.

COPY DATA CONTROLLER-A1

..............5-34

CHAPTER 6 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED PARTS......6-1

II. CONSUMABLES AND DURABLES........6-1

III. SCHECULED SERVICING CHART ........6-2

IV. SCHEDULED SERVICING......................6-4

v

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

APPENDIX

A. GENERAL TIMING CHART....................A-1

B. SIGNALS AND ABBREVIATIONS ..........A-2

C. GENERAL CIRCUIT DIAGRAM..............A-3

D. DC CONTROLLER CIRCUIT DIAGRAM...A-7

E. ANALOG PROCESSOR CIRCUIT

DIAGRAM..............................................A-20

F. LASER DRIVER CIRCUIT DIAGRAM..A-24

G. PICK-UP UNIT CIRCUIT DIAGRAM .....A-26

H. CASSETTE SIZE DETECTION

CIRCUIT DIAGRAM ..............................A-27

I. FIXING DRIVER CIRCUIT DIAGRAM..A-28

J. COMPOSITE POWER SUPPLY

CIRCUIT DIAGRAM ..............................A-29

K. LIST OF SPECIAL TOOLS...................A-37

L. SOLVENTS/OILS ..................................A-38

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

I. FEATURES..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS.................................1-8

A. External View ...................................1-8

B. Cross Section.................................1-10

C.

Arrangement of Extension Boards....

1-12

IV. OPERATION..........................................1-13

A. Turning On the Power Switches.....1-13

B. Control Panel..................................1-14

C. Basic Operation..............................1-16

D. Extension Mode..............................1-19

E. Custom Common Settings .............1-25

V. ROUTINE WORK BY THE USER.........1-29

VI. SAFETY.................................................1-30

A. Laser Beams..................................1-30

B. Safety of Toner ...............................1-31

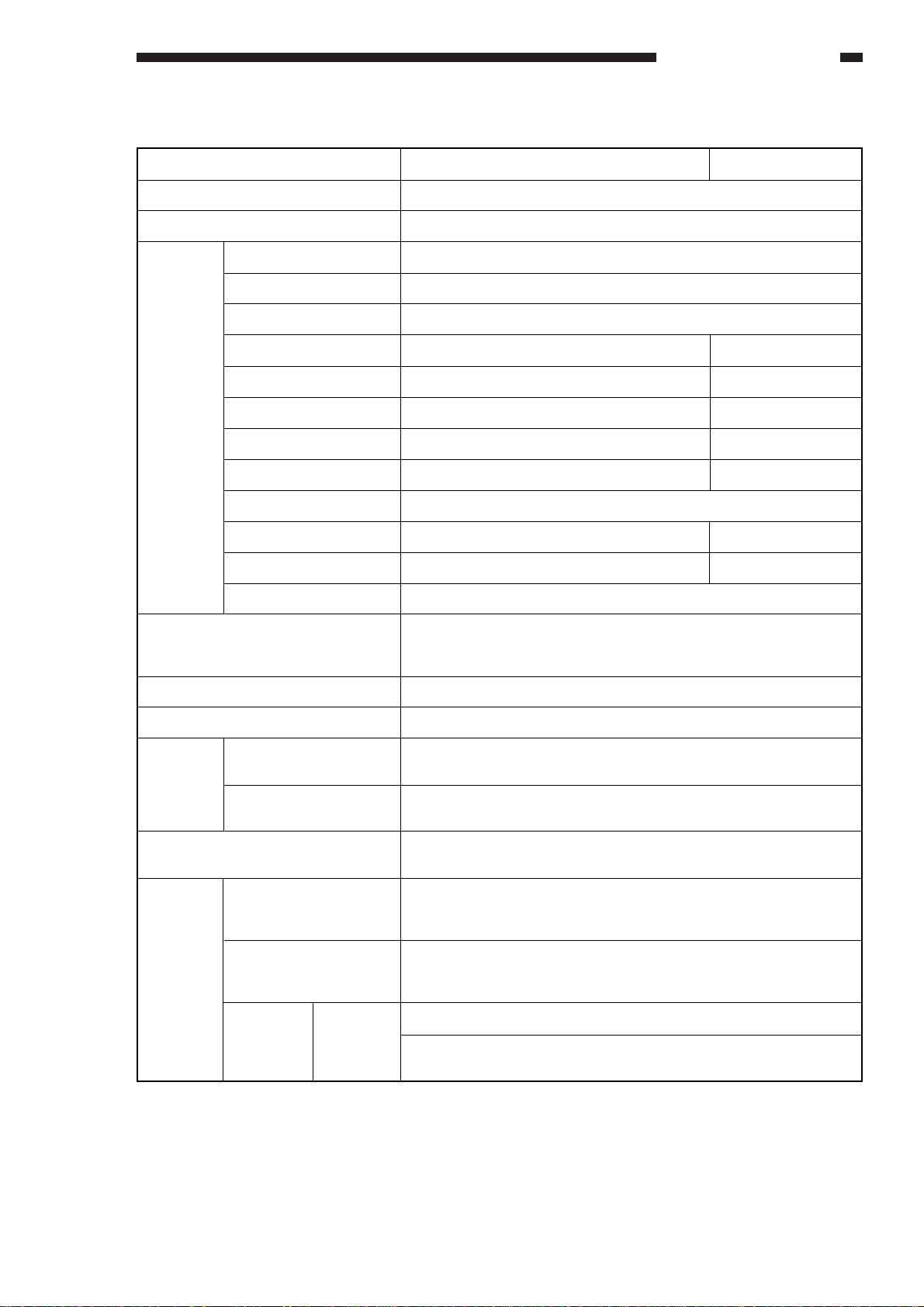

I. FEATURES

1. Establishes a new set of standards for “high-quality imaging” at a resolution of 1200 ××600 dpi

(equivalent), which is the world’s first.

• In copier mode, the resolution is 600 ××600 dpi when reading and 1200 ××600 dpi when writ-

ing.

• In fax reception mode, the resolution is 600 ××600 dpi (hyper genesis smoothing).

• In printer mode, the resolution is 1200 ××600 dpi (new super smoothing technology).

2. Ease of operation and productivity from an integrated design.

• The display is a large LCD touch panel for clear viewing and simple operation. (The display

intensity may be varied.)

• The on-going fax communication status may be indicated while in copier mode.

The display indicates the status (reception/transmission) job number , fax number, party number, and number of processing pages at intervals of 1 sec.

3. P ower -saving, space sa ving, and ozone-less considerations f or the office and the en vir onment.

• The on-demand fixing method warms up the machine quickly so that sleep mode may be

made use of without the risk of wasting time.

• The wait time is 8 sec or less. (at power-on on the control panel; 8.6 sec or less if the main

switch is used)

• The machine is appreciably quieter than the existing models for a better office environment.

• With the help of its power-saving design, the power consumption is 4 W or less* in sleep

mode (about 1/25 of existing Canon models) and 57 W or less** in standby (about 1/4 of existing Canon models).

• The roller charging method has enabled ozone-less operation.

• The width is only 58.5 cm. With the MDC function built into the machine, more space is saved.

All additional copier, fax, printer, and network functions may be built into the machine without affecting the machine size.

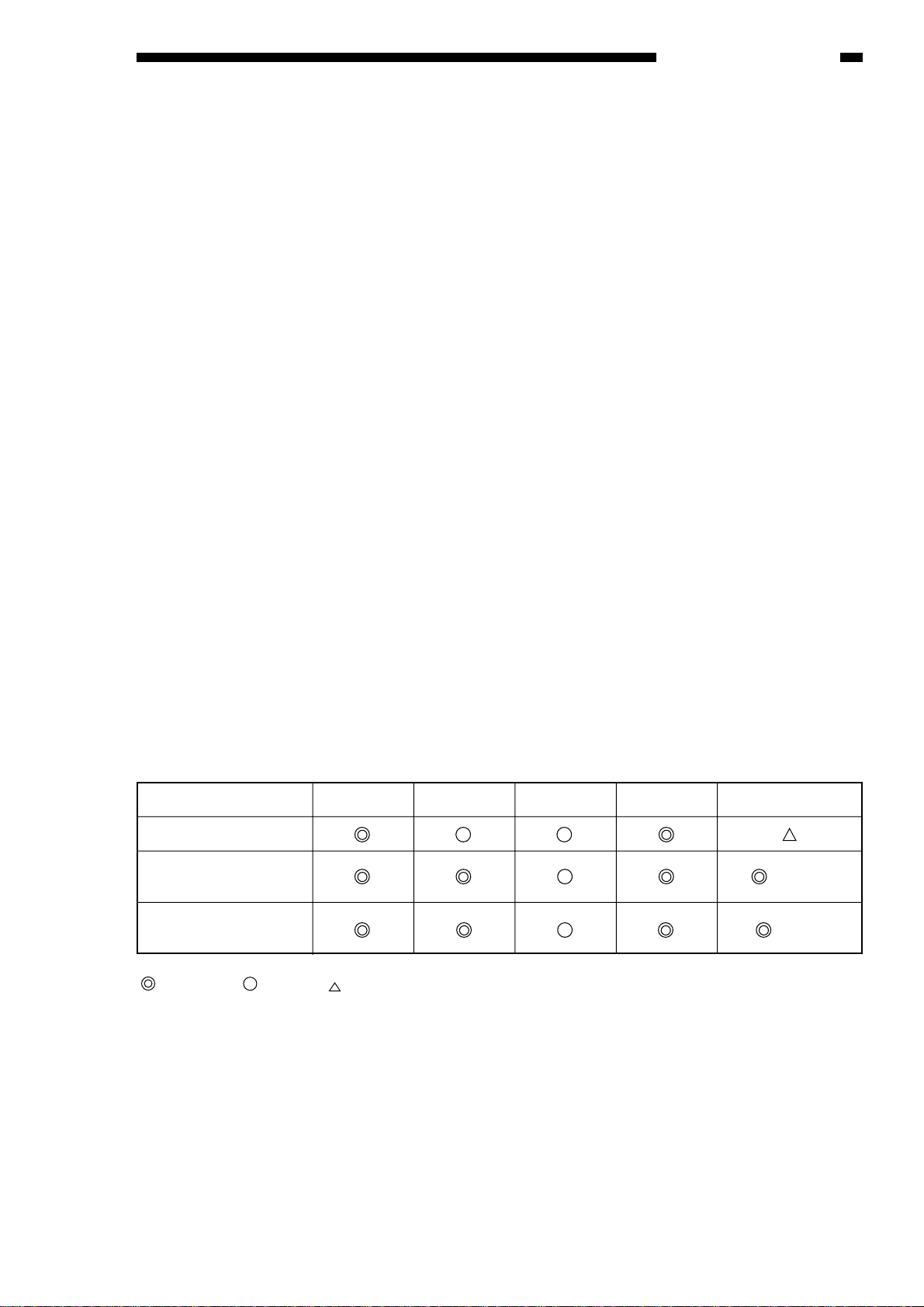

4. GP215 Series with duplexing functions

• As many as four models are available—with combinations of copier, copier/fax, and copi-

er/printer.

• The copier/fax model comes standard with an ADF-F1 or an RDF-G1.

: Standard : Option : Either copyboard cover, ADF-F1, or RDF-G1. (as an option, PostScript Level 2).

* Sleep state is when the main power is OFF. Fax reception is possible. (Not 4 W if a fax transmission

reservation has been made or the printer function has been added.)

** Standby state is when the main power is on. In copier/fax mode, 57 W or less. In copier mode, 50 W

or less.

Copier Fax Printer Duplexing Copyboard

GP215

GP215F ADF

ADF-F1

(GP215FA)

GP215F RF

RF-G1

(GP215FR)

1–1

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

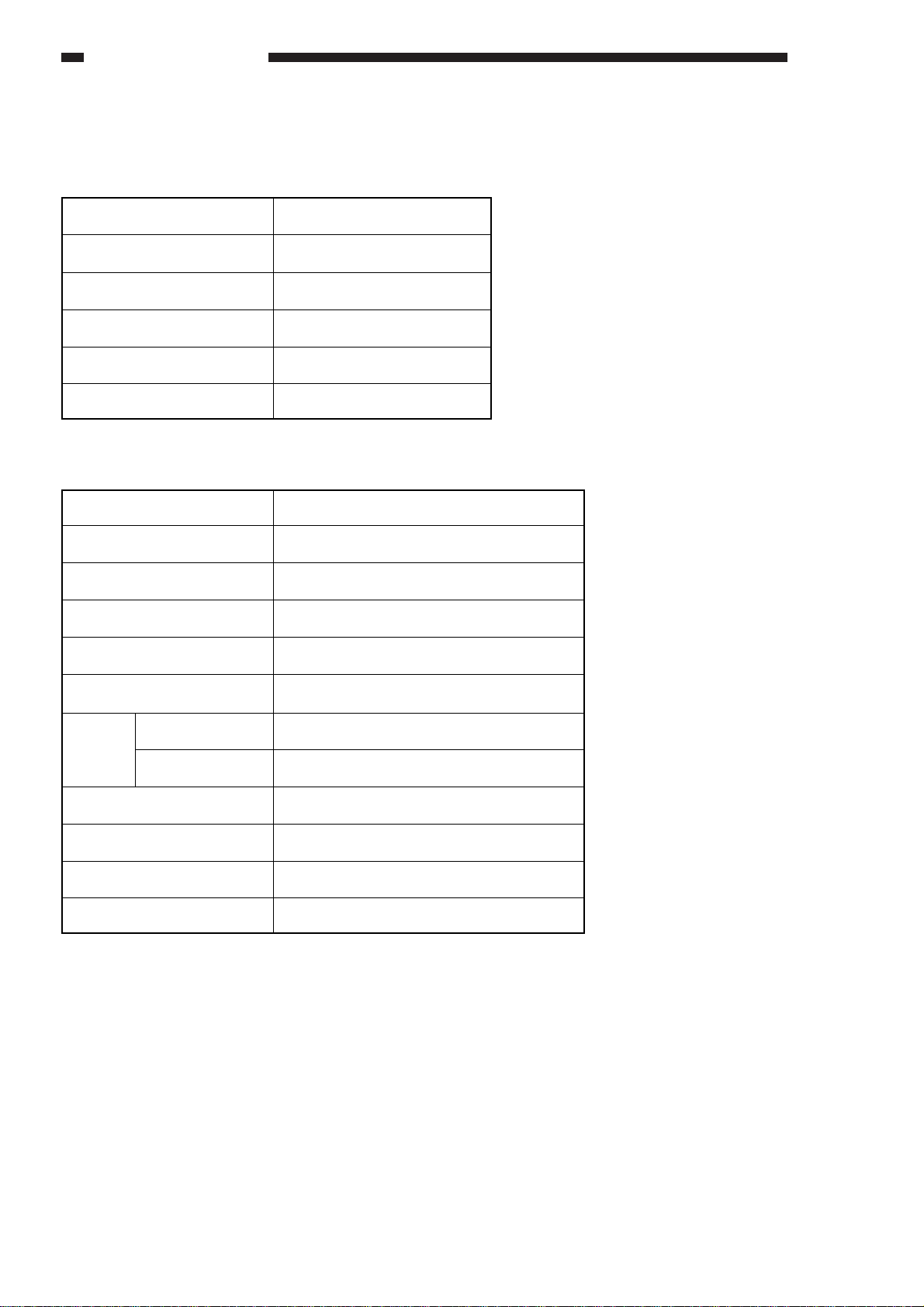

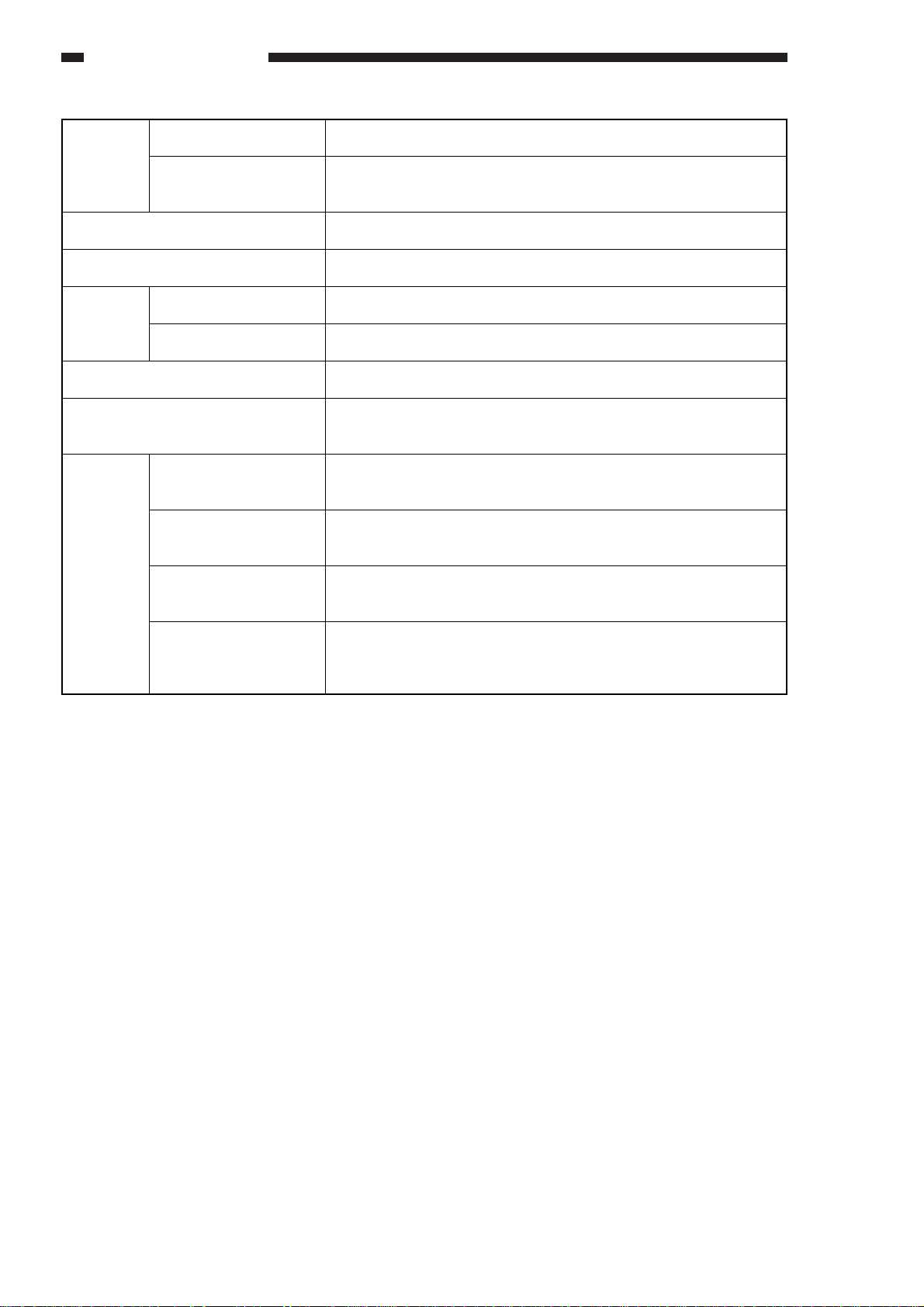

II. SPECIFICATIONS

1. Type

2. System

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–2

1. GENERAL DESCRIPTION

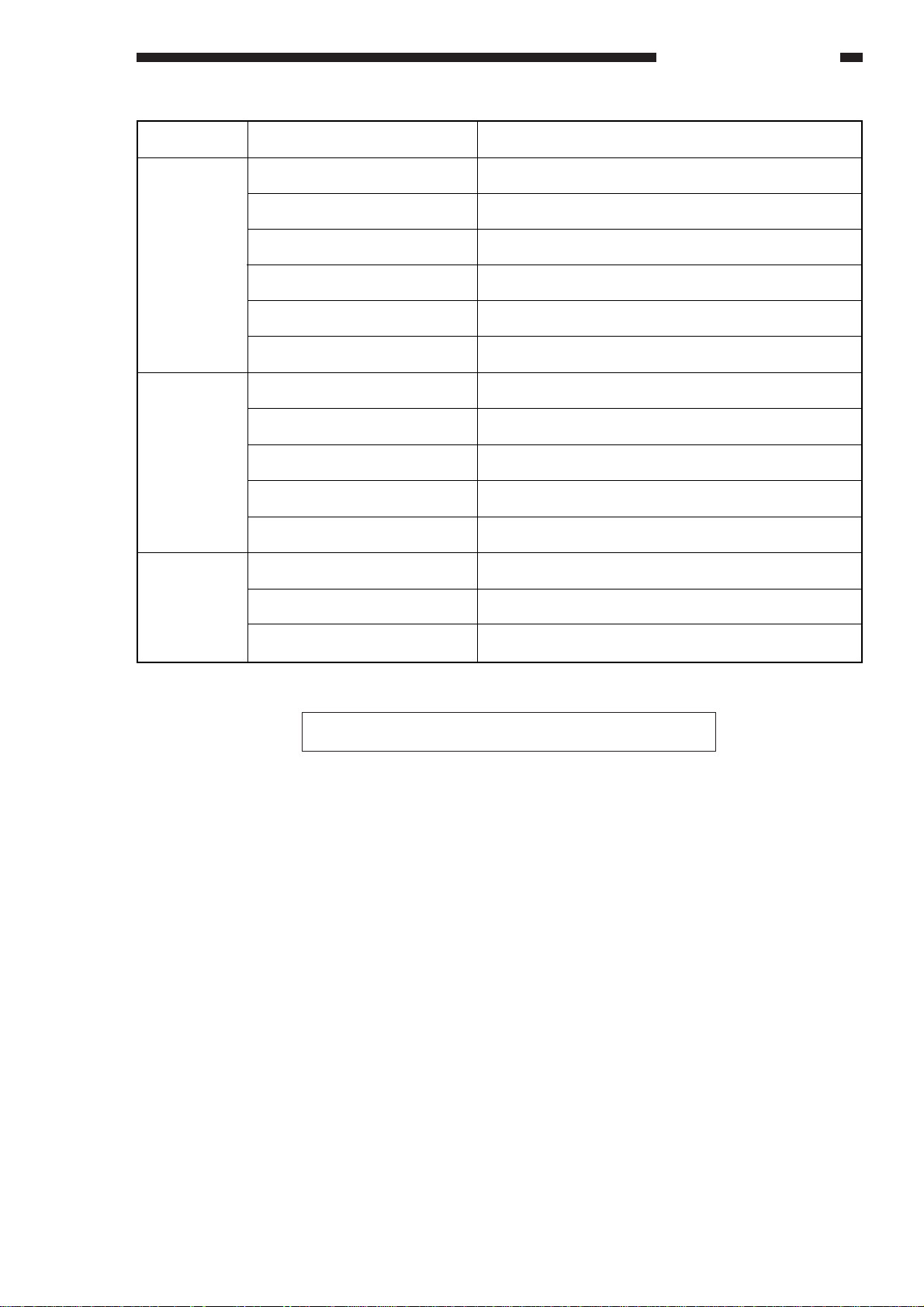

Item Specifications

Body Desktop

Copyboard Fixed

Light source Fluorescent lamp

Lens Lens array

Photosensitive medium OPC

Item Specifications

Copying Indirect electrophotographic

Charging AC roller charging

Exposure Spot laser

Copy density adjustment Automatic or manual

Development Dry, single component toner projection

Automatic 2 cassettes

Pick-up

Manual Multifeeder (about 5 mm deep)

Transfer Roller charging

Separation Static (static eliminator) + cur vature

cleaning Blade

Fixing SURF

3. Performance

*Canon recommended paper.

*May be used but may not feed as expected.

1–3

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

120V 230V

Types of originals Sheet, book, 3-D object (2 kg max.)

Maximum size of original A3, (11 × 17) max.

Direct 1:1±0.5%

Reduce I 1:0.250

Reduce II 1:0.500

Reduce III 1:0.647 –

Reduce IV 1:0.737 –

Reduce V 1:0.786 –

Enlarge I 1:1.214 1:1.414

Enlarge II 1:1.294 –

Enlarge III 1:2.000

Enlarge IV 1:4.000 –

Enlarge V 1:8.000 –

Zoom 1: 0.250 to 8.000 (25% to 800%, in 1% increments)

Wait time • 8.6 sec or less (20°C) from main power-on to star t of copying

• 7.9 sec or less from control panel power-on (sleep) to star t of

copying (fax model)

First copy GP215: 9.2 sec or less (shortest mode)

Continuous copying 100 copies

Copy size Cassette pick-up A3 (297 × 420 mm; max.) / 11”×17” (279×432mm:max)

A5 (STMT; min.)

Multifeeder A3 (297 × 431.8 mm; max.) / 11”×17” (279×432mm:max)

Postcard (A6 vertical)

Paper source 500 sheets in each cassette, 50 sheets in multifeeder

(80 g/m2paper)

Cassette Plain paper (64 to 80 g/m2), tracing paper (SM1, GNT80**),

colored paper*, recycled paper (64 to 80 g/m2), envelope

(COM10, Monarch, DL, C5, B5, No. 4)

Multifeeder Plain paper (64 to 128 g/m2), tracing paper (GNT80**), trans-

parency*, postcard, label sheet, recycled paper (64 to 80

g/m2), envelope

Plain paper (64 to 80 g/m2)

Plain paper (64 to 128 g/m2)

(no overlay copying)

Reprodu

ction

ratio

Types of

copy

paper

Twosided/

overlay

copying

Automatic

Multifeeder

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–4

1. GENERAL DESCRIPTION

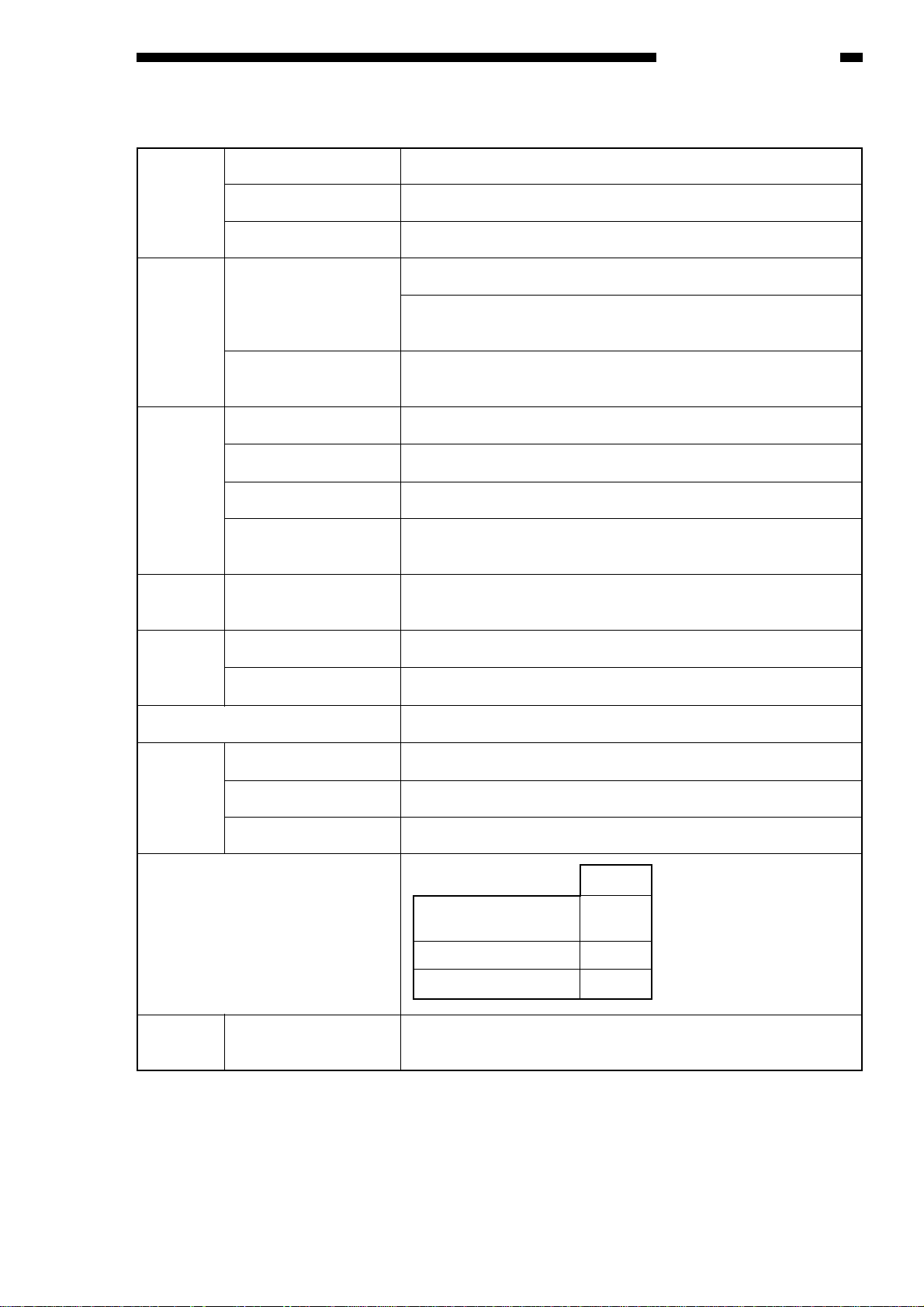

Cassette Claw Non

Regular/universal 55 mm (max.) stacking height (about 500 sheets of 80 g/m

2

paper)

Multifeeder tray 50 sheets (80 g/m2)

Delivery tray 100 sheets (approx.; 80 g/m2)

Leading/trailing edge 2.5 mm in Direct

Left/right 2.5 mm in Direct

Auto clear Provided

Auto shut-off Provided (2-min standard, may be varied between 0 an 9 min

in 1-min increments)

Option Feeder ADF·F1

RF·G1

Sorter Multi-Output Tray -C1

Multi-Output Tray -B2

Pedestal Cassette Feeding Unitl-L1

Cassette Feeding Unitl-M1

Others Handset-A1

Control Card V

Film Projector

Nonimage

width

4. Others

Temperature 7.5° to 32.5°C

Humidity 5% to 85%

Atmospheric pressure 0.8 to 1.0 atm

120 V Serial number

GP200: NFY xxxx

GP200F:NFZ xxxx

GP215:UBY xxxx, QFY xxxx, SFY xxxx, TFY xxxx, UFY xxxx.

GP215F:UBZ xxxx, QFZ xxxx, SFZ xxxx, TFZ xxxx, UFZ xxxx.

Maximum 1.5 kW or less

Standby 0.080 kWh (reference only)

Continuous copying 0.750 kWh (reference only)

0.045 kWh (reference only)

0.003 kWh (reference only)

Noise Copying 66 dB or less (sound power level)

Standby 40 dB or less (sound power level)

Ozone 0.01 ppm or less (average); 0.02 ppm or less (max.)

Width 585 mm (pedestal, copyboard cover)

Depth 700 mm (pedestal, ADF)

Height 571 mm (pedestal, RDF)

Weight

Copy paper Toner Keep copy paper wrapped to protect against humidity.

GP215

Body only 72.4kg

(w/ copyboard cover)

w/ ADV 77.1kg

w/ RDF 84.7kg

1–5

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

Operating environment

Power

supply

Power

consumption

Quick start mode

(SLEEP 1)

Power saving mode

(SLEEP 2)

Dimensions

Consuma

bles

220 / 240V

5. Copying Speed

Table 1-201 Copying Speed (copier only)

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–6

1. GENERAL DESCRIPTION

Reproduction ratio Size Copy paper size Copies/min

Direct A3 (297 × 420mm) A3 12

A4 (210 × 297mm) A4 21

A4R (297 × 210mm) A4R 16

A5 (148.5 × 210mm) A5 22

A5R (210 × 148.5mm) A5R 22

B4 (267 × 364mm) B4 13

B5 (182 × 257mm) B5 22

B5R (257 × 182mm) B5R 18

Reduce II A3 → A5 A5R 20

III A3 → B5 B5R 18

IV A3 → A4 A4R 15

B4 → B5 B5R 18

V B4 → A4 A4R 16

B5 → A5 A5 22

VI A3 → B4 B4 13

A5 → B5 B5 22

Enlarge II A5 → A3 A3 12

III A4 → A3 A3 12

B5 → B4 B4 14

IV A4 → B4 B4 14

A5 → B5 B5 22

V B4 → A3 A3 12

B5 → B4 B4 14

Table 1-202 Copying Speed (copier only)

Specifications subject to change for product improvement.

1–7

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

Ratio Size Copies/min

DIRECT LTR 20

11×17 11

LGL 14

LTRR 17

STMT 22

STMT-R 20

REDUCE LGL

→ LTRR 17

11×17 → LGL 15

11×17 → LTRR 16

11×17 →STMTR 19

11×15 → LTRR 16

ENLARGE LGL → 11×17 12

LTR·R → 11×17 12

STMTR → 11×17 12

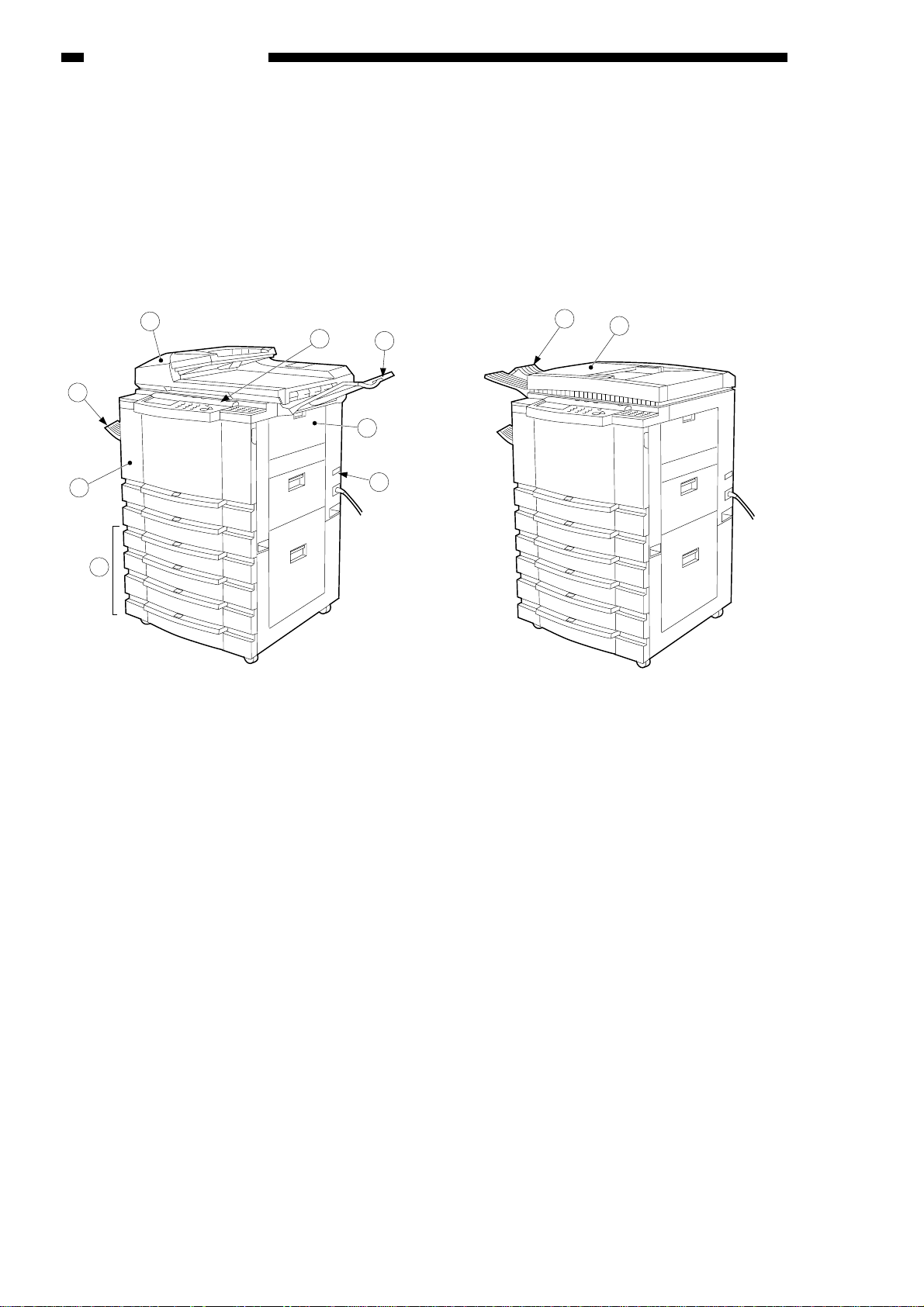

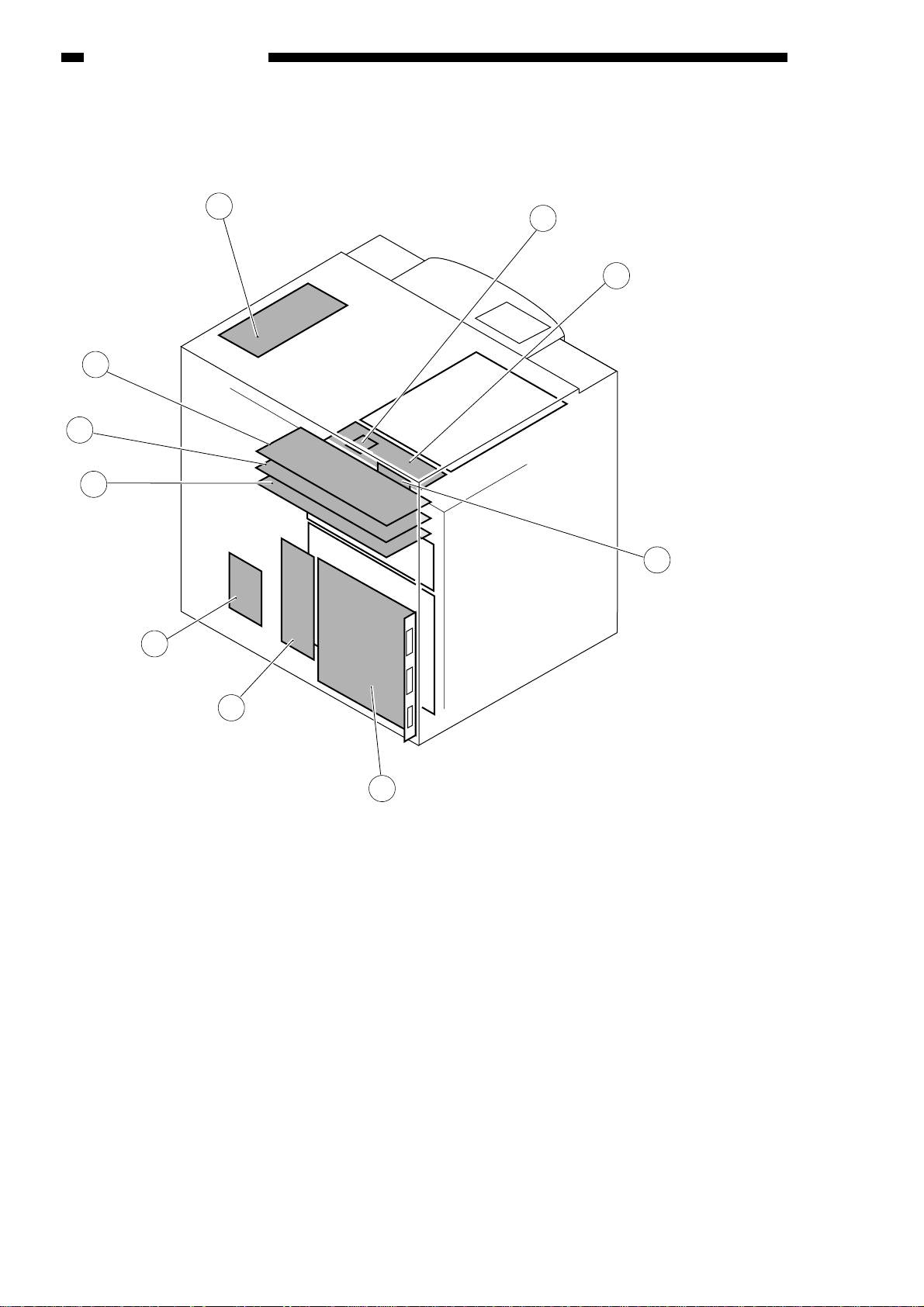

III. NAMES OF PARTS

A. External View

• Model with RDF-G1 as Standard

Figure 1-301

q Deliery tray

w RDF-G1

e Control panel power switch

r Original delivery tray (for RDF)

t Multifeeder

• Model with ADF-F1 as Standard

Figure 1-302

y Main power switch

u Cassette Feeding Unit-L1 (option)

i Front door

o ADF-F1

!0 Original delivery tray (for ADF)

9

10

FIG.1-302

5

2

8

6

3

4

1

7

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–8

1. GENERAL DESCRIPTION

1–9

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

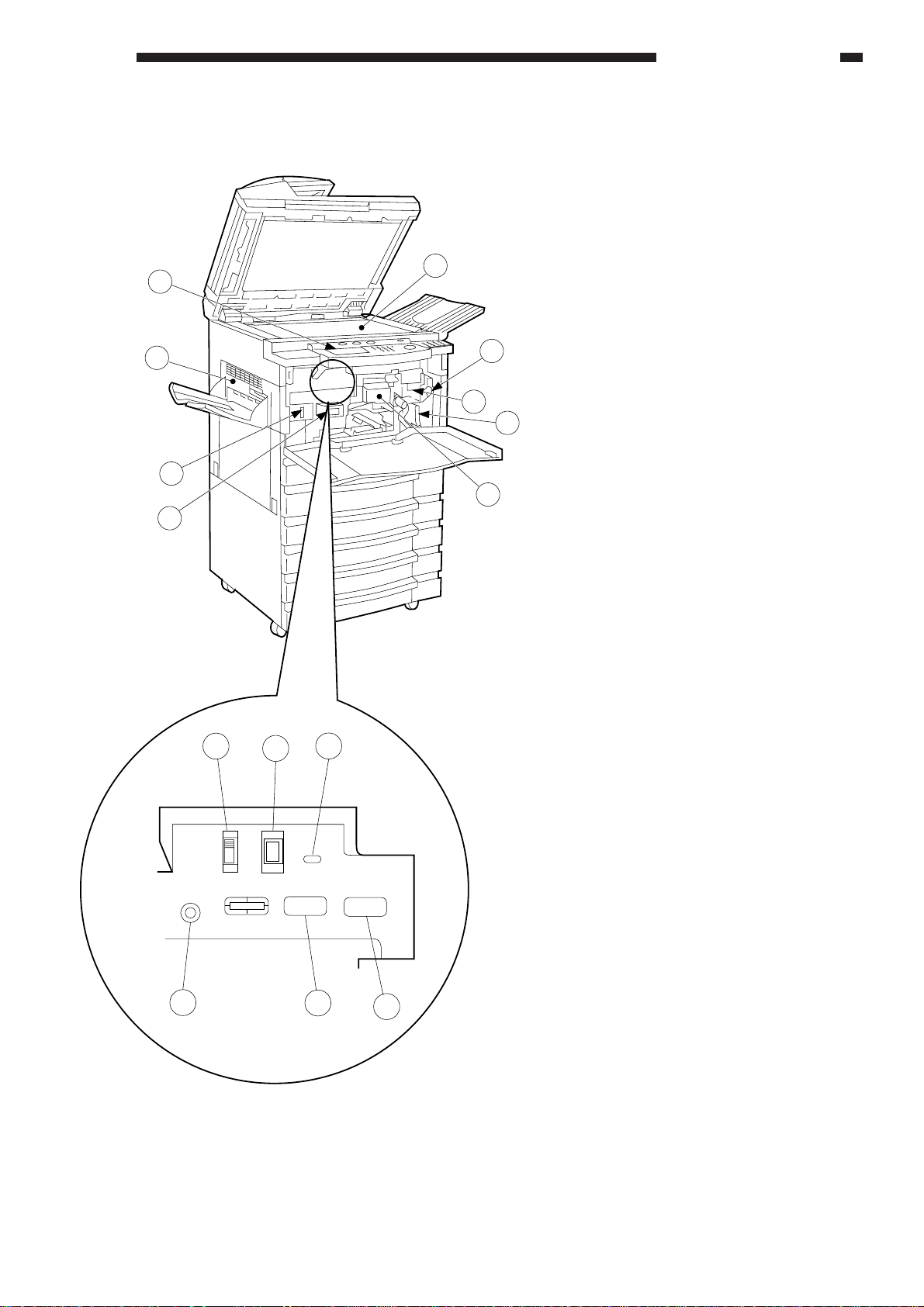

1. GENERAL DESCRIPTION

q Delivery door

w Control panel

e Copyboard glass

r Developing assembly releas-

ing lever

t Developing assembly

y Feeding assembly releasing

lever

u Drum unit

i Fixing assembly releasing

lever opening

o Door switch assembly

!0 Power saving mode switch

• SLEEP 1 (top):

Quick start mode

Anti-condensation function ON

• SLEEP 2 (bottom):

Power saving mode

Anti-condensation function OFF

!1 Cassette heater (option) switch

!2 Service switch

!3 Counter (total)

!4 Counter (printer)

!5 LCD display contrast adjust-

ment

Figure 1-303

2

1

9

8

SLEEP 1

SLEEP 2

10

11

12

3

4

5

7

6

15

14

13

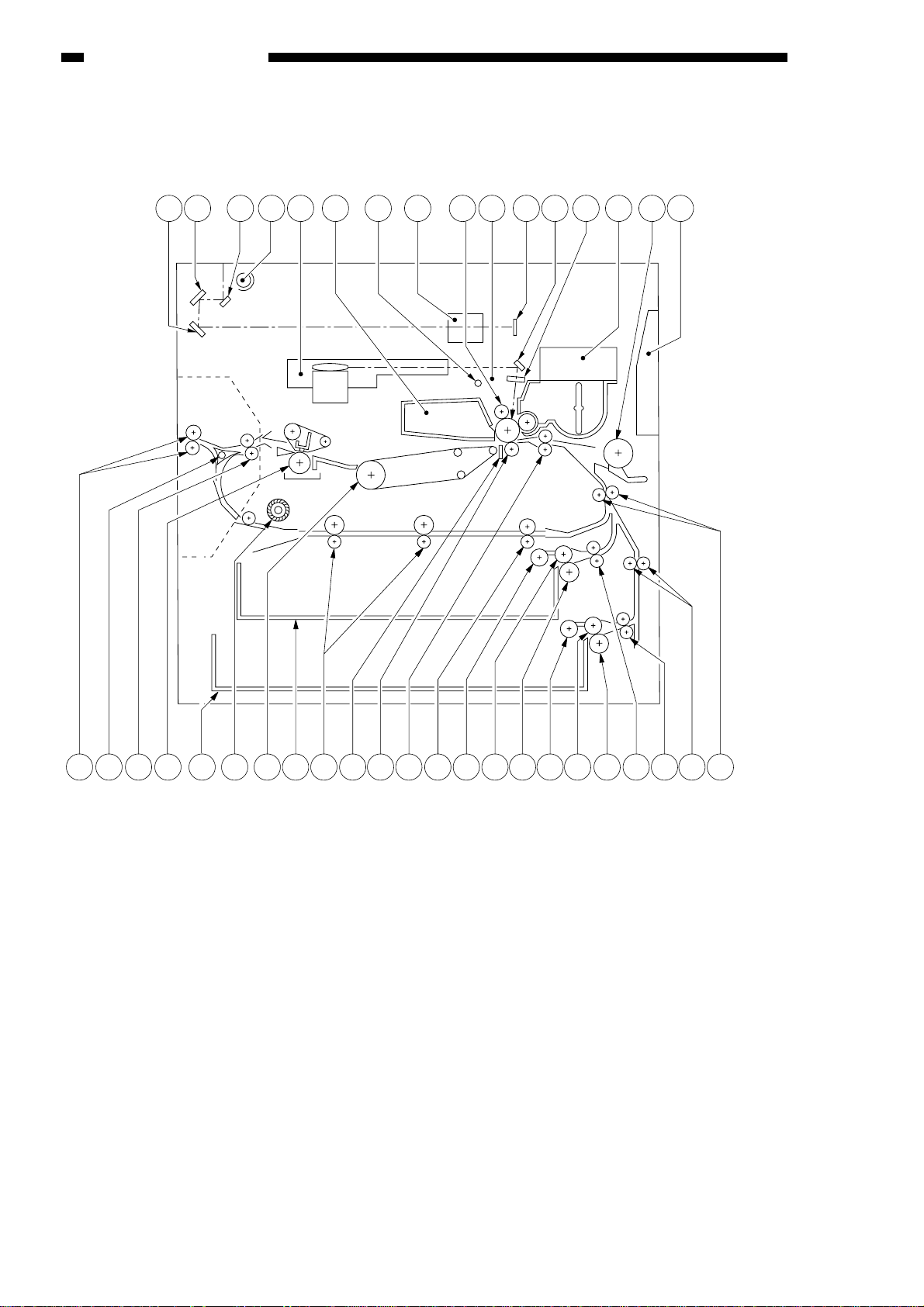

B. Cross Section

1. Cross Section of the GP215

Figure 1-304

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–10

1. GENERAL DESCRIPTION

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

17181921222324252627282930313233 203536373839 34

q No. 3 mirror

w No. 2 mirror

e No. 1 mirror

r Scanning lamp (fluorescent lamp)

t Laser unit

y Drum cleaner assembly

u Pre-exposure lamp

i Lens

o Primary charging roller

!0 Drum unit

!1 CCD

!2 Laser mirror

!3 Dust-proofing glass

!4 Developing assembly

!5 Multifeeder pick-up roller

!6 Multifeeder tray

!7 Vertical path roller 1

!8 Vertical path roller 2

!9 Cassette pick-up feeding (lower)

@0 Cassette pick-up feeding (upper)

@1 Cassette 2 separation roller

@2 Cassette 2 feeding roller

@3 Cassette 2 pick-up roller

@4 Cassette 1 separation roller

@5 Cassette 1 feeding roller

@6 Cassette 1 pick-up roller

@7 Lower feeding assembly outlet roller

@8 Registration roller

@9 Transfer roller

#0 Separation static eliminator

#1 Set-back roller

#2 cassette 1

#3 Feeding assembly

#4 Fan

#5 Cassette 2

#6 Fixing assembly

#7 Delivery roller 1

#8 Paper deflecting plate

#9 Delivery roller 2

1–11

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

C. Arrangement of Extension Boards

1. Arrangement

Figure 1-306

q SCSI Board

w CIST Board

e CORE/IP Board

r FAX Motherboard

t Printer board

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–12

1. GENERAL DESCRIPTION

y System Motherboard

u System Power Supply

i Protocol Controller Board

o Network Interface Board

!0 G3FAX board

1

2

3

10

9

8

4

7

6

5

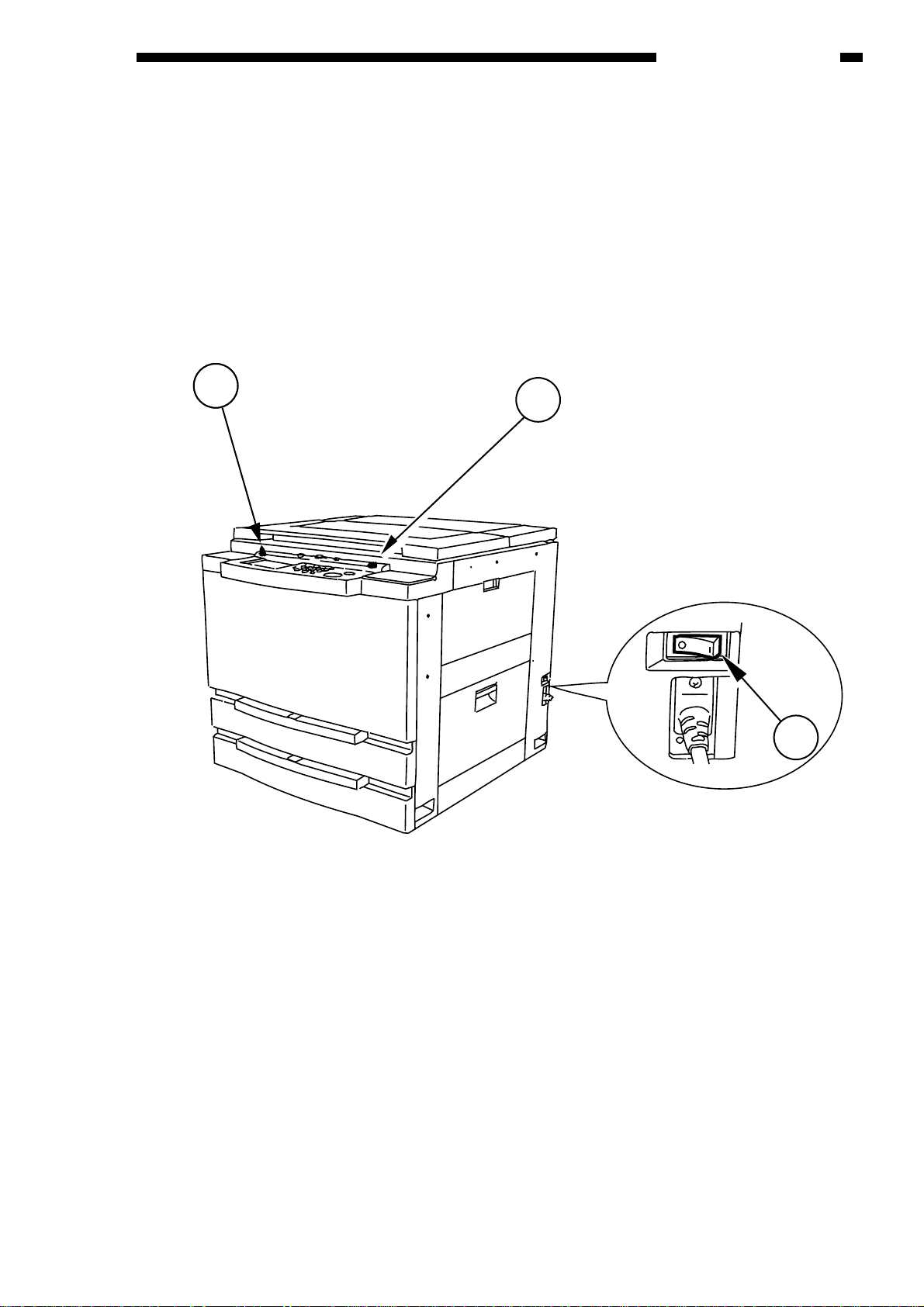

IV. OPERATION

A. Turning On the Power Switches

The machine offers two power switches: main power switch and control panel power switch.

You must first turn on the main power switch and then the control panel switch whenever you are turn-

ing on both switches.

Figure 1-401

q Control panel power switch

w Main power switch

e Main power supply lamp

1–13

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

3

1

2

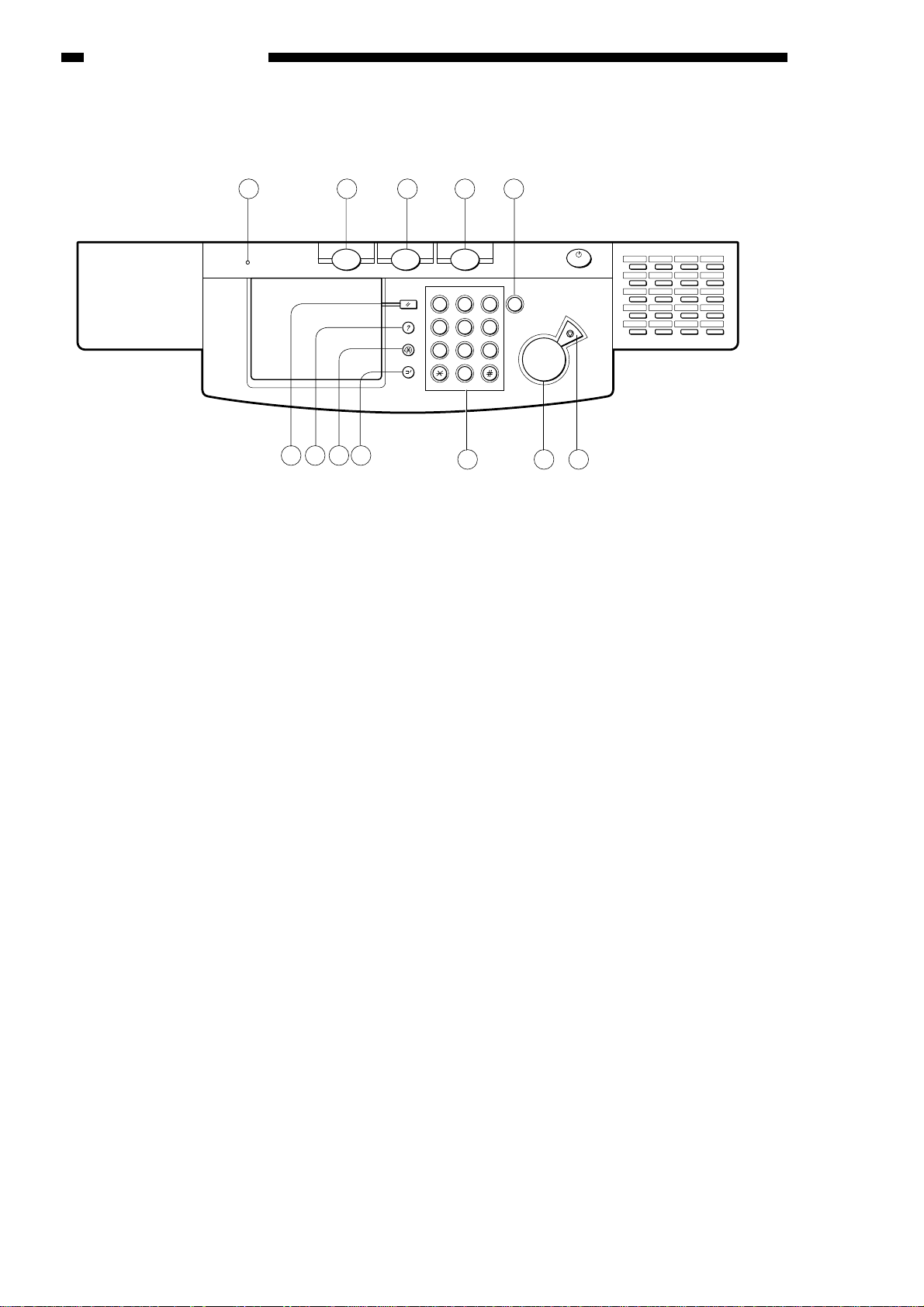

B. Control Panel

Figure 1-402

q Copier key

w Fax key

e Extension key*

r Clean key

t Stop key

y Start key

*If for North America, ‘PRINT I/F’.

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–14

1. GENERAL DESCRIPTION

u Keypad

i Interrupt key

o User mode key

!0 Guide key

!1 Reset key

!2 Power supply lamp

12

11

1

COPY

8910

2

FAX

Reset

Guide

User mode

OPTIONS

1 2 3

4 5 6

7 8 9

3 4

0

7

Clear

C

ON/OFF

Stop

Start

5

6

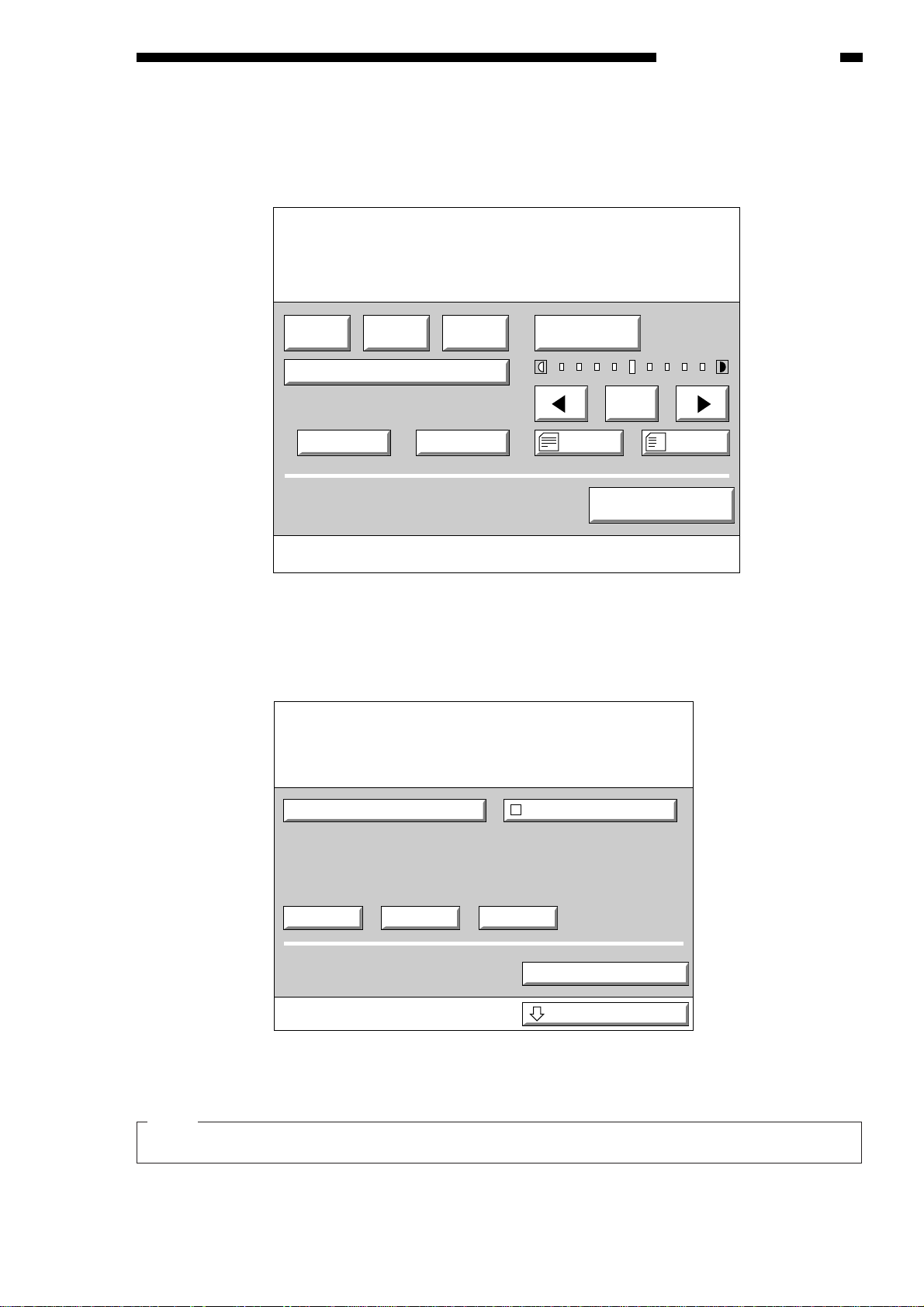

■■

Function Basic Screen of the Touch Panel

1. Copier Basic Screen

Figure 1-403

2. Fax Basic screen

• Press the Fax key to open this screen.

Figure 1-404

Note:

For details, see the Fax Ser vice Manual.

1–15

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

Ready to copy.

100% AUTO

R 1:1 E

ZOOM

SORTER

TWOSIDED

1

PAPER

SELECT

A

A

SPECIAL

FEATURES

Ready to send.

STANDARD STD TEXT AUTO RX

RESOL. DIRECT

CODED

DIALING

DENSITY

ON-HOOK REDIAL

IMAGE

QUALITY

SPECIAL

FEATURES

FAX

MONITOR

00:00

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–16

1. GENERAL DESCRIPTION

SPECIAL

FEATURES

C. Basic Operation

1. Functions Keys

Of the keys on the screen, you may select any of the following on the screen:

R .............120V:78, 73, 64, 50, 25 (%)

230V:50, 25 (%)

E .............120V: 121, 129, 200, 400, 800 (%)

230V:141, 200 (%)

Zoom .............Ratio display, Auto Zoom, +/–, Entire Image, XY Zoom, Zoom Program, Multi-

page Enlarge

SORTER .............Sort, Staple Sort, Group (only if sorting unit is installed)

PAPER .............Auto paper selection, stack bypass, cassette

SELECT

REC., Transp. INTERLVING, SHIFT, MAREGIN, FRAME ERASE, TWO-PAGE

SEPARATION, MODE ,MEMORY, SHARPNESS, IMAGE CREATION, AREA

DESIG., IMAGE COMB., IMAGE SEPARATION, SHEET OVERLAY, DIF. SIZE

ORIGINAL

Note:

1. No next screen exists for Direct, A, text, or text/photo.

2. Using the Preference key, the most frequently used modes may be selected for display. To select,

use ‘custom copy setting’ in user mode.

3. The DEF. SIZE ORIGINAL key is effective only when an RDF is installed.

1–17

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

2. Operations Available during

Copying

q Stopping Copying

To stop continuous copying, press the Stop

key or the Reset key . Copying

will stop after completing the ongoing copying

run.

w Switching from AE Mode to Manual density

Control Mode

You may switch from AE (auto density control)

mode to manual density adjustment mode

during continuous copying.

Howev er , y ou cannot s witch from manual density adjustment mode during continuous copying.

e Interrupting On-Going Copying

To make copies of a different original, press

the Interrupt key to stop the on-going copying.

Note:

The following keys are effective during continuous copying:

a. Stop key

b. Reset key

c. Interrupt key

d. Copy Density key (from AE to manual)

3. Interrupting On-Going Copying

If you want to make copies of a different or iginal while making a large number of copies in continuous copying mode, you can suspend the ongoing copying operation temporarily.

Or, you can suspend fax reception or printer

operation to make copies. (Fax reception or pr inter operation will resume as soon as you end interrupt mode.)

1) Press the Interrupt key to select interrupt

mode.

Available Operations

• Making one-sided copies

• Making 1 to 100 copies

• Selecting non-sort mode

• Selecting manual feed mode

• Selecting a density (darker, lighter, AE)

• Selecting a reproduction ratio (may be

auto)

• Selecting a cassette

• De-selecting ID mode

• De-selecting interrupt mode

You cannot use the document feeder for interrupt mode.

2) Place the original, and press the Start key.

3) To end interrupt mode, press the Interrupt

mode once again.

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–18

1. GENERAL DESCRIPTION

4. Making Two-Sided Copies or

Overlay Copies

Using manual feeding mode, you can make

two-sided copies overlay copies.

Be sure to keep the following in mind when

making two-sided or overlay copying mode:

q Make sure that the side copied and the side to

be copied have the same orientation (i.e., do

not reverse rear and front) when turning over

the copy paper.

w Make sure that the copy paper is not moist.

e Make sure that the copy is not curled.

r After the first copying run, cool the copy paper

sufficiently and remove the curling before

starting the second copying run.

t Use 64 to 128 g/m2paper.

y Remove the curling before the second copy-

ing run for a post card or thick paper (128

g/m2).

5. Using ID Mode

In ID mode, you must enter a 4-digit ID number to make copies. As many as 100 ID numbers

may be stored, and you can check the count

(number of copies made) by number for control of

copying volume by group.

a. Setting the System Control Password

1) Select ‘user mpde’, ‘custom common set-

tings’, and then ‘system settings password

setting’ to set the system control password.

b. Storing ID Numbers

1) Set the system control password.

2) Select ‘custom common settings’ and ‘DEPT.

ID MANAGEMENT’ to enter the system control password.

3) Select ‘yes’ to ‘DEPT. ID MANAGEMENT’,

and store the appropriate group ID and ID

number for ‘STORE DEPT. ID PASSWORD’.

c. Entering an ID Number

1) Press the ‘ID’ icon in the upper right corner of

the Basic screen.

2) Enter the appropriate ‘ID’ and ‘password’.

d. Cleaning the Count (all ID numbers)

1) Select ‘user mode’, ‘custom common set-

tings’, and then ‘DEPT. ID MANAGEMENT’ to

enter the system control password.

2) On the ‘DEPT. ID MANAGEMENT’ screen

select ‘ON’ and then ‘COPY TOTALS’; then,

press ‘CLEAR ALL TOTALS’.

Note:

You cannot clear the counts individually.

D. Extension Mode

■■

Extension Mode Panel (initial screen)

Figure 1-405

1–19

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1. GENERAL DESCRIPTION

TWO-PAGE

SEPARATION

SHEET

OVERLAY

AREA

DESIG.

IMAGE

CREATION

MODE

MEMORY

TRANSP.

INTERLIVING

DIF.SIZE

ORIGINAL

SHARPNESS

REC.

SHIFT

MARGIN

FRAME

ERASE

IMAGE

COMB.

IMAGE

SEPARATION

DONE

■■

SPECIAL FEATURES Screen

COPYRIGHT © 1996 CANON INC. CANON GP215/200 REV.0 JULY 1996 PRINTED IN JAPAN (IMPRIME AU JAPON)

1–20

1. GENERAL DESCRIPTION

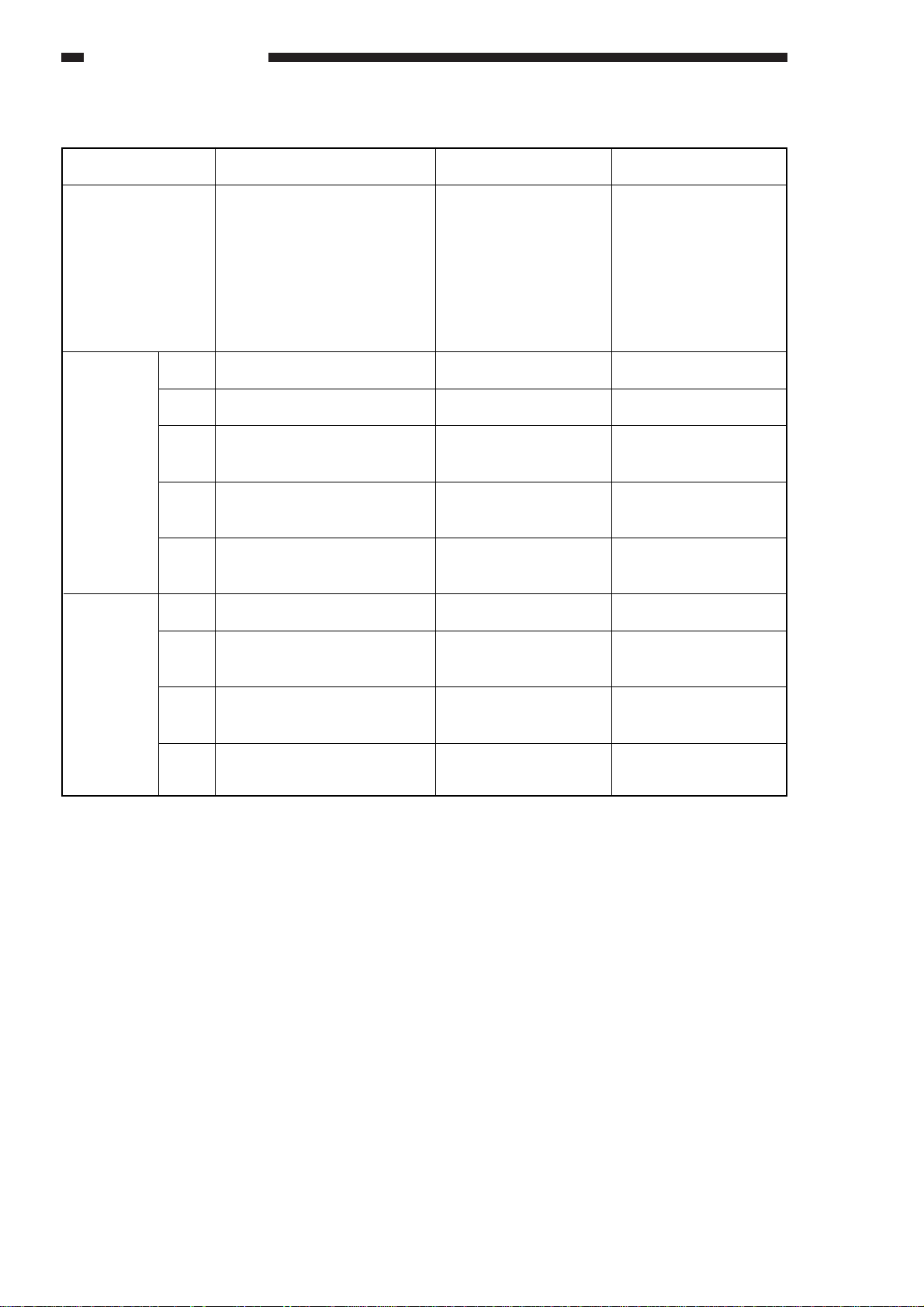

SPECIAL FEATURES screen

TWO-PAGE SEPARATION

TRANSP. INTERLVING

SHIFT

SHEET OVERLAY

DIF. SIZE ORIGINAL/

THIN SHEET ORIGINAL

MARGIN

AREA DESIG.

SHARPNESS

FRAME ERASE

IMAGE CREATION

IMAGE COMB.

PROJECTOR

IMAGE SEPARATION

MODE MEMORY

REC.

Remarks

A4, A4R, LTR, LTRR

Requires a duplexing unit.

Requires an RDF for original

mix size mode and an ADF

for thin paper originals.

Requires an RDF.

Requires a projector.

Requires an RDF.

Next screen

Stack bypass Select

Center Shift, Corner Shift (8 direc-

tions), Keypad Setting

SHEET OVERLAY

BOOK OVERLAY

Left margin, Right margin, Top margin, Bottom margin

Area Desig. (editor or keypad),

Framing, Blanking, Negative/Positive

Reversal

Soft to Hard (9 steps)

Sheet Frame Erasing, Original Frame

Erasing, Book Frame Erase, Binding

Erase

Mirror Image, Image Repeat,

Negative/Positive Reversal, Slant image.

2-on-1, 4-on-1, 2-on-1 Two-Sided

35mm Negative, 35mm Positive, 4 × 5

Negative, 4 × 5 Positive

1-on-2, 1-on-4, 1-on-2 / One-sided, 1-

on-4 / One-Sided

M1 through M5

Most Recent, 2nd Most Recent, 3rd

Most Recent

Loading...

Loading...