Canon C9075 Service Manual

imageRUNNER ADVANCE C9075 PRO/9070 PRO/

Periodical Service

Adjustment

Error Code

User Mode

Service Mode

Parts Replacement and Cleaning

Product Overview

Upgrading

9065 PRO/9060 PRO/C7065/7055 Series Rev. 6.0

Service Manual Digest

1

2

3

4

5

6

7

8

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

consent of Canon Inc.

(C) CANON INC. 2013

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check. Remove the claw.

Check visually. Insert the claw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

name accompanies the symbol, the arrow

represents the path of mechanical drive; where a signal

indicates the direction of the

electric signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

Check the noise. Use the bundled part.

Disconnect the connector.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

Push the part.

Turn on the power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

Contents

0 Safety Precautions

CDRH Act -----------------------------------------------------------------------0-2

Laser Safety --------------------------------------------------------------------0-2

Handling of Laser System --------------------------------------------------0-2

Turn power switch ON -------------------------------------------------------0-3

Safety of Toner -----------------------------------------------------------------0-3

About Toner ------------------------------------------------------------------------- 0-3

Toner on Clothing or Skin -------------------------------------------------------- 0-3

Notes When Handling a Lithium Battery --------------------------------0-3

Notes Before it Works Serving ---------------------------------------------0-3

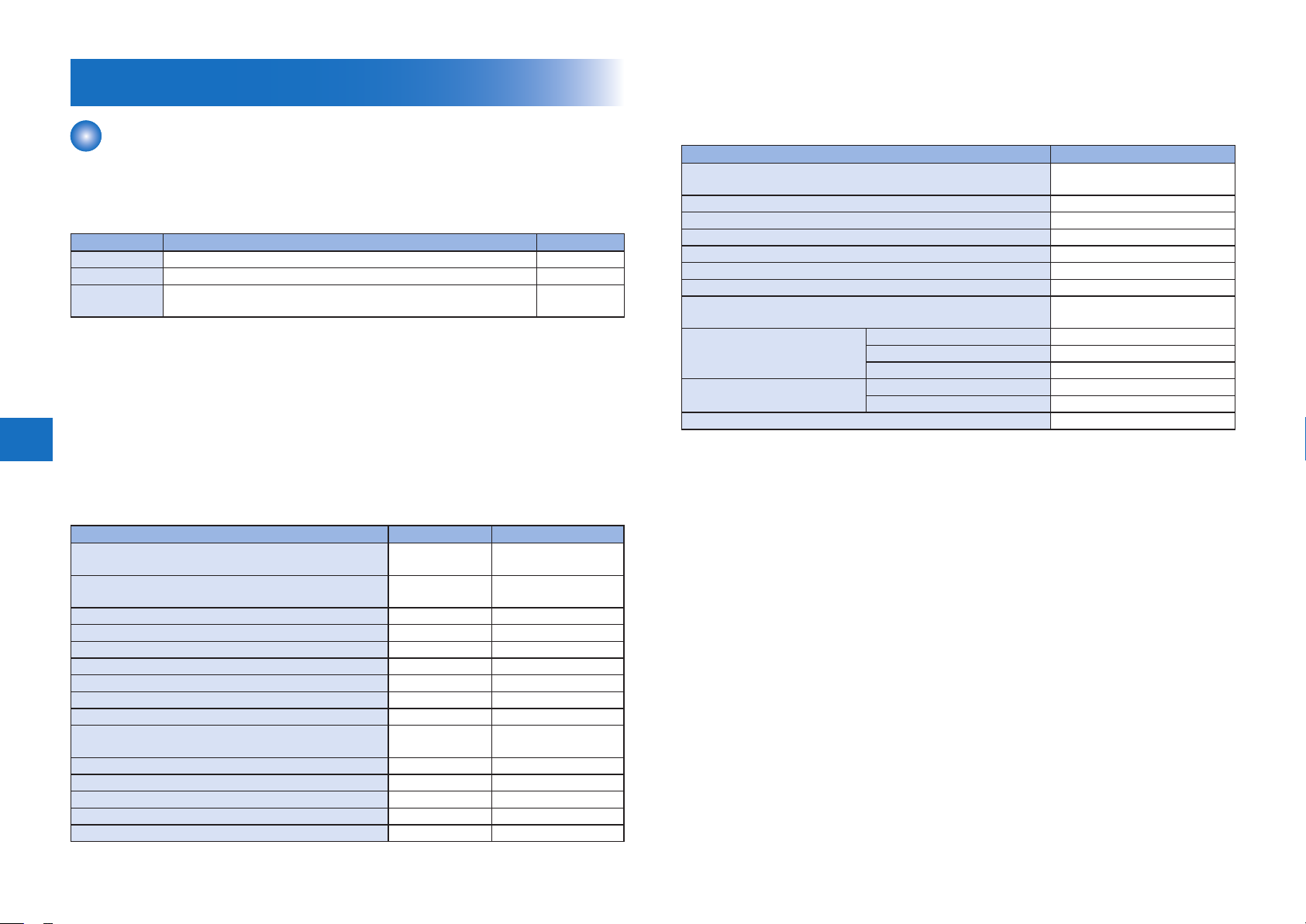

1 Periodical Service

Periodical Service Operation Item ----------------------------------------1-2

2 Adjustment

Overview ------------------------------------------------------------------------2-2

When replacing parts --------------------------------------------------------2-2

Controller System ------------------------------------------------------------------ 2-2

Laser Exposure System ---------------------------------------------------------- 2-6

Image Formation System -------------------------------------------------------- 2-6

When clearing RAM -------------------------------------------------------- 2-14

When clearing RAM --------------------------------------------------------------2-14

3 Error Code

Over View -----------------------------------------------------------------------3-2

Outline -------------------------------------------------------------------------------- 3-2

Error Code ----------------------------------------------------------------------3-3

Error Code Details ----------------------------------------------------------------- 3-3

Jam Code ------------------------------------------------------------------- 3-151

Jam Type -------------------------------------------------------------------------- 3-151

Main Unit -------------------------------------------------------------------------- 3-151

Duplex Color Image Reader-A1 / Color Image Reader-A1----------- 3-154

Paper Deck Unit – A1 ---------------------------------------------------------- 3-155

POD Deck Light – A1 ---------------------------------------------------------- 3-155

Multi-drawer Paper Deck – A1 ----------------------------------------------- 3-156

Buffer Path Unit - F1 ----------------------------------------------------------- 3-157

Insertion Unit -H1 --------------------------------------------------------------- 3-158

Professional Puncher - C1

/Professional Puncher Integration Unit - B1 ------------------------------ 3-159

Insertion Unit -J1 ---------------------------------------------------------------- 3-160

Paper Folding Unit - G1 ------------------------------------------------------- 3-161

Paper Folding Insertion Unit - G1 ------------------------------------------- 3-162

External 2-hole Puncher - A1/External 2/3 Hole Puncher - A1

/External 2/4 Hole Puncher - A1/External 4 Hole Puncher - A1 ----- 3-163

Staple Finisher-A1/Booklet Finisher-A1 ----------------------------------- 3-164

Staple Finisher-B1/Booklet Finisher-B1 ----------------------------------- 3-165

Alarm Code ----------------------------------------------------------------- 3-166

Alarm Code Details ------------------------------------------------------------- 3-166

4 User Mode

List of User Mode -------------------------------------------------------------4-2

Device Information Delivery Settings ----------------------------------------- 4-2

Environment Settings ------------------------------------------------------------- 4-2

Adjustment/Maintenance -------------------------------------------------------- 4-11

Function Settings -----------------------------------------------------------------4-12

Set Destination --------------------------------------------------------------------4-22

Management Settings -----------------------------------------------------------4-23

5 Service Mode

Overview ------------------------------------------------------------------------5-2

Back-up of service mode --------------------------------------------------------- 5-2

COPIER -------------------------------------------------------------------------5-3

DISPLAY ----------------------------------------------------------------------------- 5-3

I/O (I/O display mode) --------------------------------------------------------- 5-140

ADJUST --------------------------------------------------------------------------- 5-186

FUNCTION ----------------------------------------------------------------------- 5-280

OPTION --------------------------------------------------------------------------- 5-325

TEST ------------------------------------------------------------------------------- 5-448

COUNTER ------------------------------------------------------------------------ 5-454

FEEDER --------------------------------------------------------------------- 5-501

DISPLAY -------------------------------------------------------------------------- 5-501

ADJUST --------------------------------------------------------------------------- 5-501

FUNCTION ----------------------------------------------------------------------- 5-503

SORTER -------------------------------------------------------------------- 5-508

ADJUST --------------------------------------------------------------------------- 5-508

FUNCTION ----------------------------------------------------------------------- 5-520

OPTION --------------------------------------------------------------------------- 5-522

BOARD ---------------------------------------------------------------------- 5-536

OPTION --------------------------------------------------------------------------- 5-536

Soft Counter List ---------------------------------------------------------- 5-538

Soft counter specications ---------------------------------------------------- 5-538

Soft Counter List ---------------------------------------------------------------- 5-538

Test Print -------------------------------------------------------------------- 5-546

How to check test print -------------------------------------------------------- 5-546

7 Product Overview

Specications ------------------------------------------------------------------7-2

Specications of main unit ------------------------------------------------------- 7-2

Productivity (print speed) -------------------------------------------------------- 7-3

Paper type --------------------------------------------------------------------------- 7-4

Product lineups ----------------------------------------------------------------7-6

Main unit ----------------------------------------------------------------------------- 7-6

Pickup/delivery options ----------------------------------------------------------- 7-6

Scanning options ------------------------------------------------------------------- 7-9

Expanded-feature options ------------------------------------------------------7-10

Basic Conguration --------------------------------------------------------- 7-11

Functional Conguration -------------------------------------------------------- 7-11

8 Upgrading

Upgrading -----------------------------------------------------------------------8-2

Outline -------------------------------------------------------------------------------- 8-2

6 Parts Replacement and Cleaning

List of Parts ---------------------------------------------------------------------6-2

List of Main Unit -------------------------------------------------------------------- 6-2

List of Clutch / Solenoid ---------------------------------------------------------6-10

List of Motor ------------------------------------------------------------------------6-12

List of Fan ---------------------------------------------------------------------------6-22

List of Sensor ----------------------------------------------------------------------6-25

Lamp / Heater, others ------------------------------------------------------------6-34

List of Switch -----------------------------------------------------------------------6-38

List of PCB --------------------------------------------------------------------------6-41

Connector List ---------------------------------------------------------------------6-52

Safety Precautions

CDRH Act

■

Laser Safety

■

Handling of Laser System

■

Turn power switch ON

■

Points to Note About

■

Turning Off the Main

Power Switch

Safety of Toner

■

Notes When Handling a

■

imageRUNNER ADVANCE

Lithium Battery

Notes Before it Works

■

Serving

C9075 PRO/9070 PRO/9065

PRO/9060 PRO/C7065/7055

Series

CDRH Act

Handling of Laser System

The Center for Devices and Radiological Health of the US Food and Drum Administration put

into force regulations concerning laser products on August 2, 1976. These regulations apply

to laser products manufactured on and after August 1, 1976, and the sale of laser products

not certied under the regulations is banned within the Untied States. The label shown here

indicates compliance with the CDRH regulations, and its attachment is required on all laser

products that are soled in the United States.

F-0-1

A different description may be used for a different product.

When servicing the area around the laser assembly, be sure to turn off the main power.

The machine's covers that can reect laser light are identied by means of a warning label

(Figure). If you must detach a cover showing the label, be sure to take extra caution during

the work.

F-0-2

Laser Safety

Laser beam radiation may pose a danger to the human body. A laser scanner mounted on the

machine is sealed with the protection housing and external cover to prevent the laser beam

from leaking to the outside. The laser beam never leaks out of the scanner as far as users

operate the machine normally.

This product is certicated as a Class 1 laser product under IEC60825-1:2007.

0-2

Turn power switch ON

Safety of Toner

The machine is equipped with 2 power switches: main power switch and control panel power

switch.

The machine goes on when the main power switch is turned on (i.e., other than in low power

mode, sleep mode).

Do not turn off the main power while the progress bar is indicated, during which access

is made to the HDD. If deprived of power, the HDD can suffer a fault (E602).

F-0-3

About Toner

The machine's toner is a non-toxic material made of plastic, iron, and small amounts of dye.

Do not throw toner into re. It may cause explosion.

Toner on Clothing or Skin

• If your clothing or skin has come into contact with toner, wipe it off with tissue; then, wash it

off with water.

• Do not use warm water, which will cause the toner to jell and fuse permanently with the

bers of the cloth.

• Tonner is easy to react with plastic material, avoid contact with plastic.

Notes When Handling a Lithium Battery

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

Notes Before it Works Serving

At servicing, be sure to turn OFF the power source according to the specied steps and

disconnect the power plug.

0-3

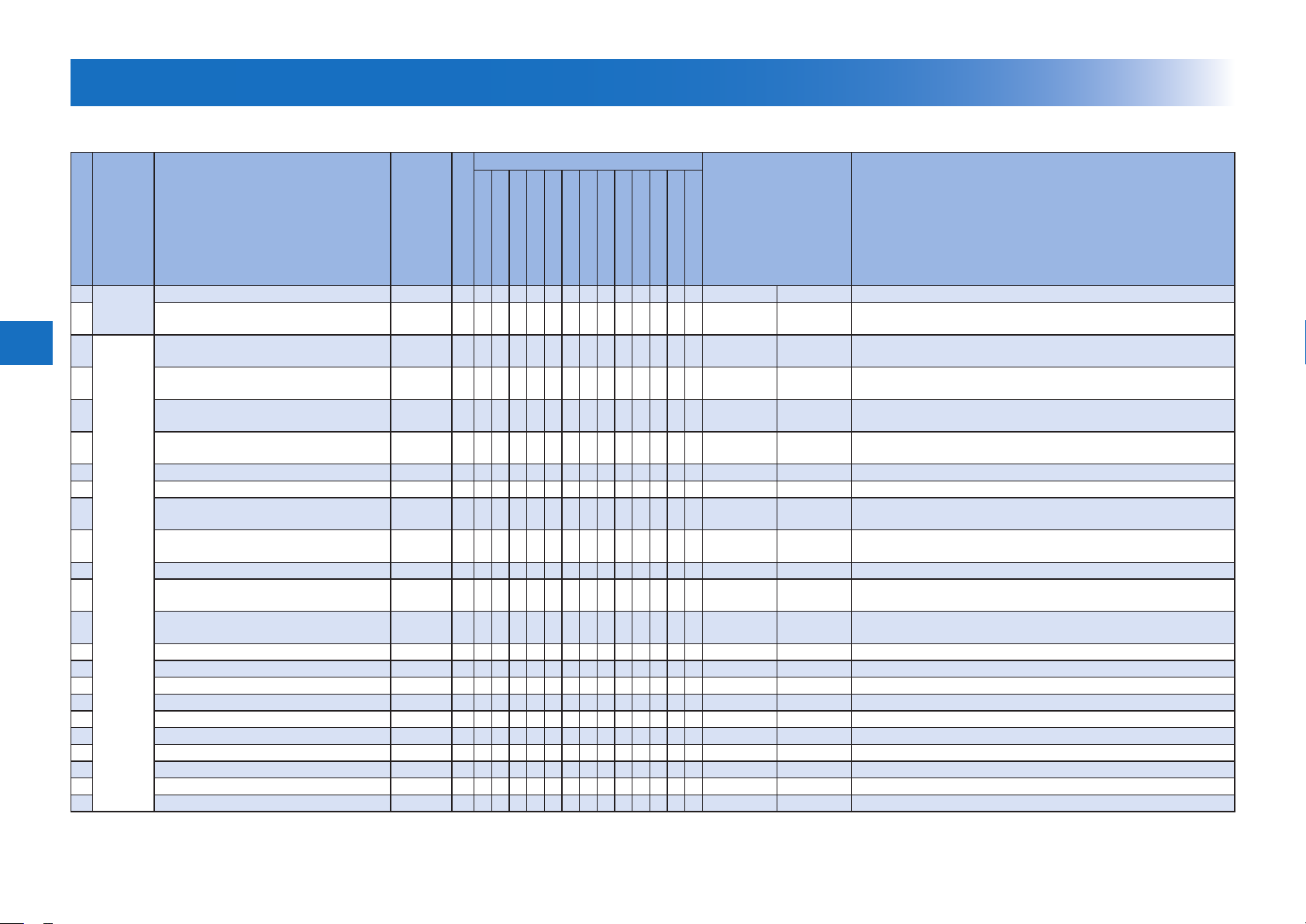

Periodical Service

1

Periodical Service Operation Item

■

1

Periodical Service Operation Item

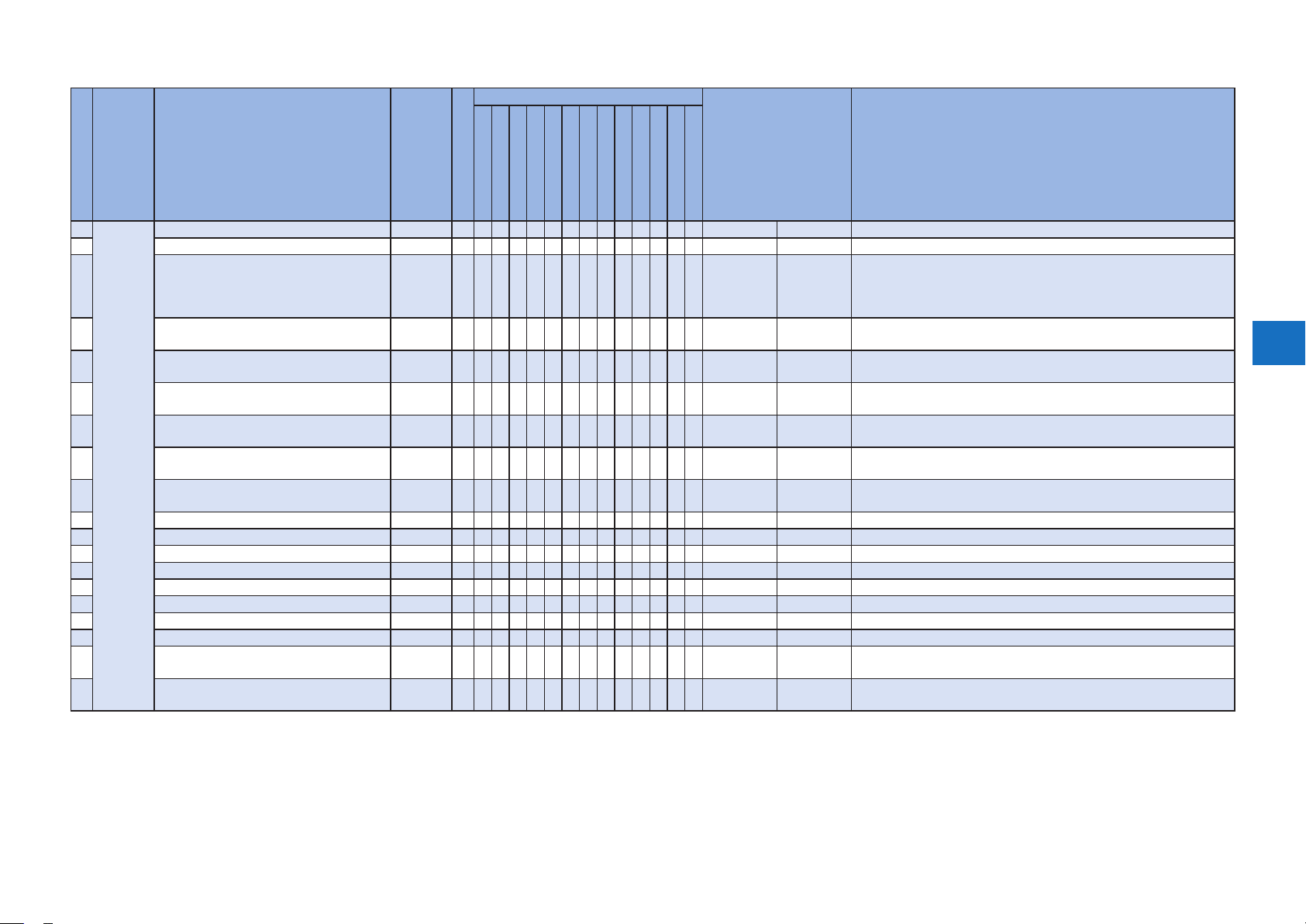

♦: Replacement (Periodical replacement) ●: Replacement (Consumable parts) Δ: Cleaning ×: Lubrication □: Adjustment ■: Inspection

Interva

At installation

No.

Category Part Name Part No

Number

30K

120K

150K

200K

400K

500K

550K

1000K

1400K

1108K

As needed

Others

Counter Remark

1

1

Laser

2 Dustproof Glass Cleaning (color) - 3 Δ - - If dirt appears on the image, clean it with using the attached cleaning

Exposure

3

4 Pre-primary Transfer Charging Assembly FM3-4720 Δ ♦ PRDC-1 PO-UNIT Clean it when replacing the Pre-primary Transfer Charging Wire.

5 Toner Catch Sheet (color) - 3 Δ - - Clean it with alcohol and lint-free paper.

6 Toner Catch Tray (black) - 1 Δ - - Clean it with alcohol and lint-free paper.

7 Toner Blocking Plastic sheet - 4 Δ Clean it with lint-free paper.

8 Primary Charging Wire FL2-8915 1 ♦ PRDC-1 PRM-WIRE

9 Primary Charging Wire Cleaning Pad

10 Primary Charging Wire Cleaning Pad

Process

11 Pre-transfer Charging Wire FL2-8807 1 ♦ PRDC-1 PO-WIRE

12 Pre-transfer Charging Wire Cleaning Pad

13 Pre-transfer Charging Wire Cleaning Pad

14 Grid Plate FC8-2295 1 ♦ PRDC-1 PRM-GRID

15 Grid Cleaning Pad FL3-4090 1 ♦ PRDC-1 GRID-PAD

16 Developing Assembly (Y) FM4-6612 1 ● DRBL-1 DV-UNT-Y

17 Developing Assembly (M) FM4-6613 1 ● DRBL-1 DV-UNT-M

18 Developing Assembly (C) FM4-6614 1 ● DRBL-1 DV-UNT-C

19 Developing Assembly (Bk) FM4-6615 1 ● DRBL-1 DV-UNT-K

20 Drum Cleaning Blade (Bk) FC8-2281 1 ● DRBL-1 CLN-BLD iR ADVANCE C9075PRO/C9070 PRO is 530K

21 Drum Cleaning Scoop-up Sheet (Bk) FL2-8652 1 ● DRBL-1 SU-SHT-K iR ADVANCE C9075PRO/C9070 PRO is 530K

22 Edge Scraper 1 (Bk) FL2-8653 1 ● DRBL-1 EDGE-F-K iR ADVANCE C9075PRO/C9070 PRO is 530K

23 Edge Scraper 2 (Bk) FL2-8654 1 ● DRBL-1 EDGE-F-K iR ADVANCE C9075PRO/C9070 PRO is 530K

Dustproof Glass Cleaning (black) - 1 Δ - - If dirt appears on the image, remove the glass and clean it.

tool.

Primary Charging Assembly FM4-5704 Δ ♦ PRDC-1 PRM-UNIT Clean it when replacing the Primary Charging Wire.

Clean the Shield Plate with lint-free paper.

Clean the Shield Plate with lint-free paper.

Execute this when replacing the Color Drum Unit.

Execute this when replacing the Color Drum Unit.

FL2-0462 1 ♦ PRDC-1 PRM-CLN

Slider

FL2-2720 1 ♦ PRDC-1 PRM-CLN2

Holder

Unit

Slider

Holder

FL2-0462 1 ♦ PRDC-1 PO-CLN

FL2-2720 1 ♦ PRDC-1 PO-CLN2

1-2

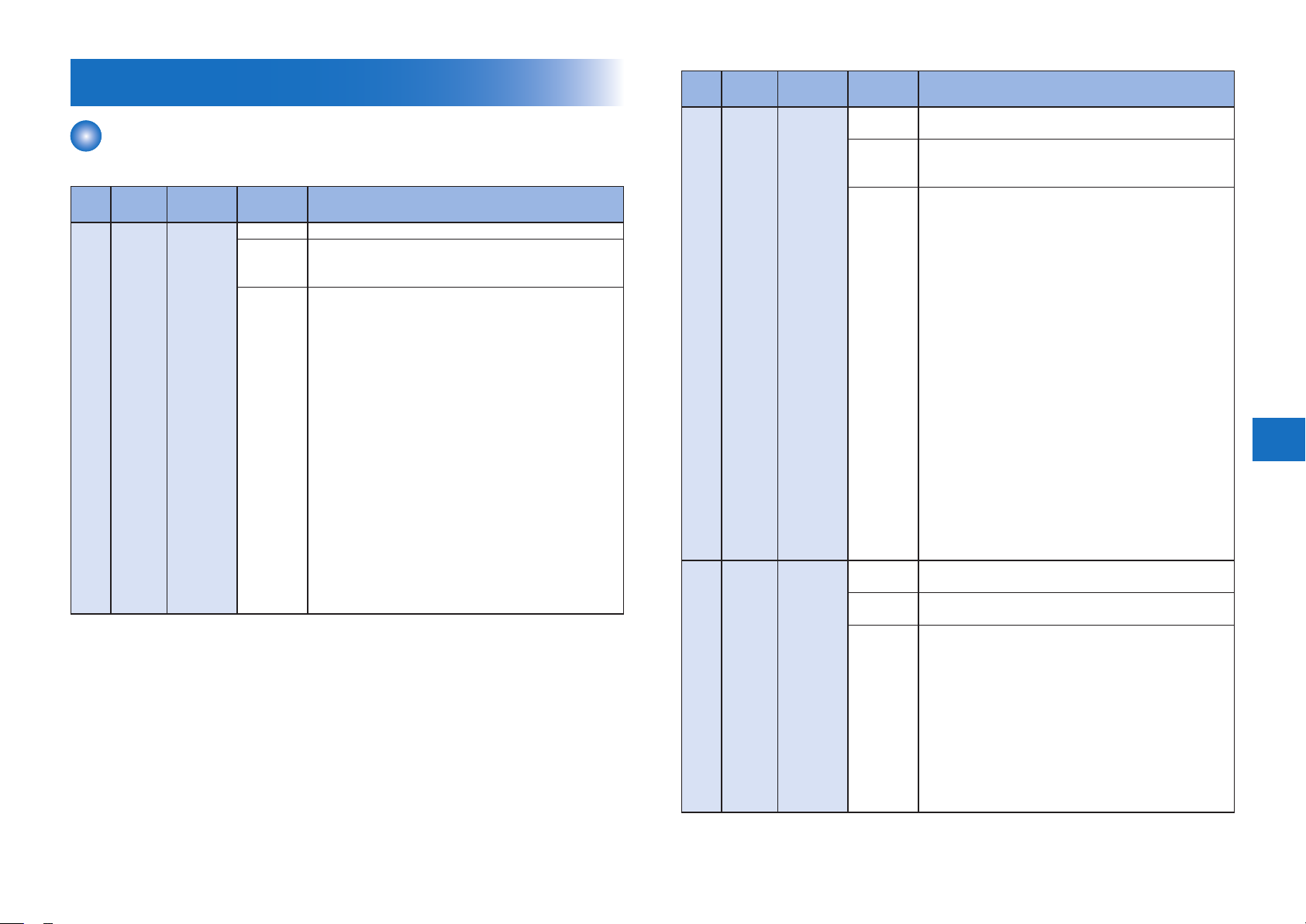

♦: Replacement (Periodical replacement) ●: Replacement (Consumable parts) Δ: Cleaning ×: Lubrication □: Adjustment ■: Inspection

Interva

At installation

No.

Category Part Name Part No

Number

30K

120K

150K

200K

400K

500K

550K

1000K

1400K

1108K

As needed

Others

Counter Remark

24

25 Patch Sensor - 1 Δ - - Clean it with water when replacing the Bk Drum.

26 ITB Unit - 1 □ □ - - When releasing the pressure of ITB Unit, execute the following item.

27 ITB Driver Roller - 1 Δ - - Clean it with alcohol and lint-free paper.

28 ITB Stirring Roller - 1 Δ - - Clean it with alcohol and lint-free paper.

29 ITB Inside Scraper - 1 Δ - - Clean it with alcohol and lint-free paper.

30 ITB HP Sensor - 1 Δ - - Clean it with blower brush.

Image

31 ITB Displacement Sensor - 1 Δ - - Clean it with blower brush.

Formation

System

32 ITB Cleaning Unit - 1 ■ - - Remove the toner piled up on the back of Scoop-up Sheet when

33 ITB FY7-0409 1 ● DRBL-1 TR-BLT

34 ITB Cleaning Blade FC8-1699 1 ● DRBL-1 ITB-BLD1

35 Primary Transfer Roller (Y) FY7-0412 1 ● DRBL-1 1TR-RL-Y

36 Primary Transfer Roller (M) FY7-0412 1 ● DRBL-1 1TR-RL-M

37 Primary Transfer Roller (C) FY7-0412 1 ● DRBL-1 1TR-RL-C

38 Primary Transfer Roller (Bk) FY7-0412 1 ● DRBL-1 1TR-RL-K

39 Secondary Transfer Inner Roller FC7-9325 1 ● DRBL-1 2TR-INRL

40 ITB Inner Scraper Holder FL3-4902 1 ● DRBL-1 WST-TNR

41 Secondary Transfer Outer Roller FC9-0386 1 ● Δ DRBL-1 2TR-ROLL Clean up the paper dust with lint-free paper when replacing the

42 Secondary Transfer Static Eliminator FM3-9841 1 ● Δ DRBL-1 TR-STC-H Clean up the paper dust with lint-free paper when replacing the

Post-secondary Transfer Sensor - 1 Δ Δ - - Use the blower brush. If dirt is obvious, execute cleaning as needed.

- COPIER>FUNCTION>INSTALL>INIT-ITB

- Settings/Registration>Adjustment/Maintenance>Adjust Image

Quality>Auto Correct Color Mismatch

Execute this when replacing the ITB.

Execute this when replacing the ITB.

Execute this when replacing the ITB.

Execute this when replacing the ITB.

Execute this when replacing the ITB.

replacing the ITB Cleaning.

Secondary Transfer Outer Roller.

Secondary Transfer Outer Roller.

1

1-3

♦: Replacement (Periodical replacement) ●: Replacement (Consumable parts) Δ: Cleaning ×: Lubrication □: Adjustment ■: Inspection

Interva

At installation

No.

Category Part Name Part No

Number

30K

120K

150K

200K

400K

500K

550K

1000K

1400K

1108K

As needed

Others

Counter Remark

1

43

44 Pressure Belt Unit Gear - 1 × - - Clean it when replacing the Fixing Belt.

45 Cleaning of oil stain on the Contact Roller

Fixing

46 Fixing Inlet Guide, Sensor Flag - 1 Δ - - When replacing the upper or lower one, clean the dirt on the Inlet

System

47 Pressure Thermistor 1 FK2-7870 1 ♦ PRDC-1 FIX-TH1 iR ADVANCE C9075PRO/C9070 PRO is 1000K

48 Pressure Thermistor 2 FK2-7871 1 ♦ PRDC-1 FIX-TH2 iR ADVANCE C9075PRO/C9070 PRO is 1000K

49 Fixing Belt Unit FM4-5701 1 ● DRBL-1 FX-BLT-U

50 Pressure Belt Unit FM4-5702 1 ● DRBL-1 FX-BLT-L

51

52 Left Deck Pickup Roller FC5-2524 1 ● DRBL-1 C2-PU-RL

53 Right Deck Feed Roller FC5-2526 1 ● DRBL-1 C1-FD-RL

54 Left Deck Feed Roller FC5-2526 1 ● DRBL-1 C2-FD-RL

55 Right Deck Separation Roller FC5-2528 1 ● DRBL-1 C1-SP-RL

56 Left Deck Separation Roller FC5-2528 1 ● DRBL-1 C2-SP-RL

57 Cassette 3 Pickup Roller FC5-2524 1 ● DRBL-1 C3-PU-RL

Pickup/

58 Cassette 4 Pickup Roller FC5-2524 1 ● DRBL-1 C4-PU-RL

Feeding

59 Cassette 3 Feed Roller FC5-2526 1 ● DRBL-1 C3-FD-RL

System

60 Cassette 4 Feed Roller FC5-2526 1 ● DRBL-1 C4-FD-RL

61 Cassette 3 Separation Roller FC5-2528 1 ● DRBL-1 C3-SP-RL

62 Cassette 4 Separation Roller FC5-2528 1 ● DRBL-1 C4-SP-RL

63 Multi-purpose Tray Feed Roller FB1-8581 1 ● DRBL-1 M-FD-RL

64 Multi-purpose Tray Separation Roller FC6-6661 1 ● DRBL-1 M-SP-RL

65 Transparency Sensor - 1 Δ - - Use the blower brush. If dirt is obvious, execute cleaning as needed.

66 Pre-Fixing Feed Belt - 1 Δ Δ - - Use the blower brush. If dirt is obvious, execute cleaning as needed.

67

Filter

68 Primary Charging Dustproof Filter FL2-0439 1 ♦ PRDC-1 OZ-FIL1

69 Fixing Dustproof Filter FL2-8946 1 ♦ PRDC-1 OZ-FIL2

70 Waste Toner Container FM4-5696 1 ● DRBL-1 WST-TNR Replace it when the waste toner full alarm is displayed.

Fixing Belt Unit Gear - 1 × - - Clean it when replacing the Pressure Belt.

Apply the grease by 100mg onto the all circumference of gear teeth.

Apply the grease by 100mg onto the all circumference of gear teeth.

- 1 Δ - - Clean it when replacing the Pressure Belt.

of Pressure Belt Position Sensor and the

lower side of Lower Unit

Guide and the Sensor Flag. Especially clean the back of ag and the

guide contact surface. In case of Upper Unit, interval is 400K and in

case of Lower Unit, interval is 500K.

Right Deck Pickup Roller FC5-2524 1 ● DRBL-1 C1-PU-RL

Ozone Filter FL3-4101 2 ♦ PRDC-1 TN-FIL1

T-1-1

1-4

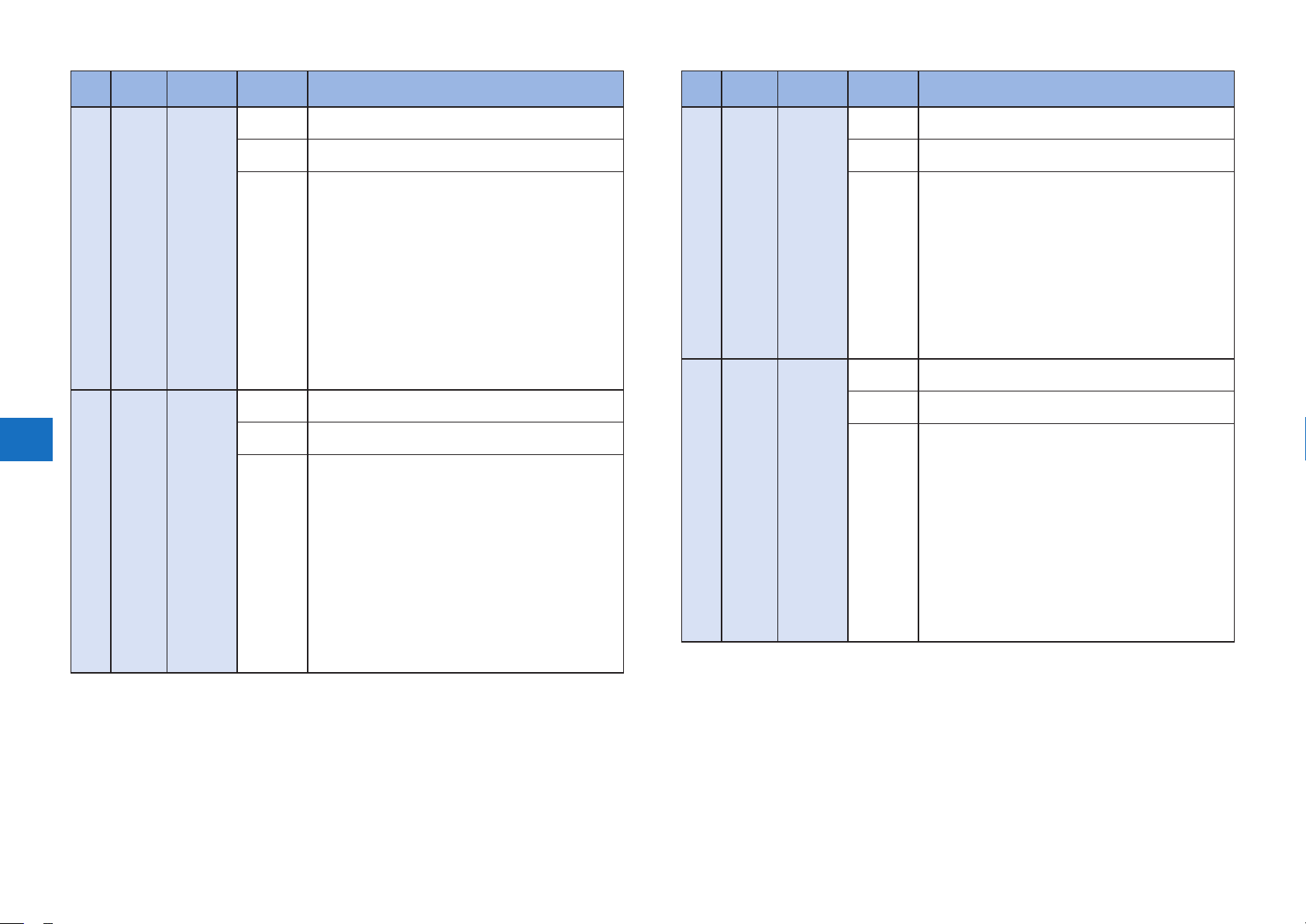

Adjustment

2

Overview

■

When replacing parts

■

When clearing RAM

■

2

Overview

In this chapter, measures of adjustment when replacing parts in servicing operation are

mentioned. Parts to be replaced are categorized into 5 blocks based on their related

technology as shown below.

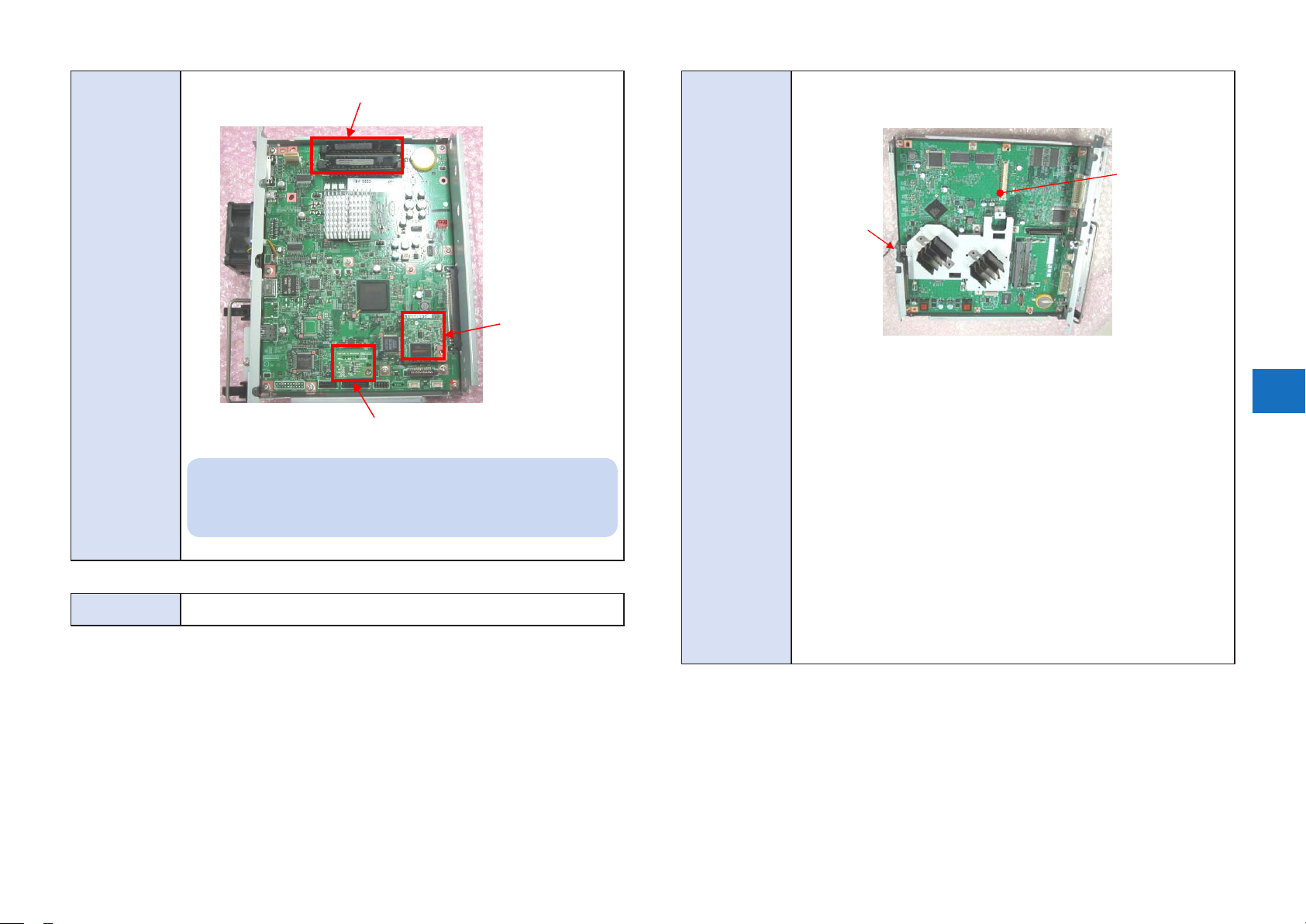

Controller System Main Controller PCB 1 p. 2-2

Main Controller PCB 2 p. 2-3

DC Controller PCB p. 2-4

HDD p. 2-4

TPM PCB p. 2-6

Flash PCB p. 2-6

Riser PCB p. 2-6

Laser Exposure System Laser Scanner Unit p. 2-6

Image Formation System

2

Fixing System

Primary Charging Wire

Grid Plate

Primary Charging Assembly

Pre-Primary Transfer Charging Wire

Pre-Primary Transfer Charging Assembly

Drum Unit

Developing Assembly

Potential Sensor

ITB Cleaning Blade Unit

ITB

Primary Transfer Roller

Patch Sensor Unit

Waste Toner Container

Waste Toner Full Sensor

Fixing belt Unit

Pressure belt Unit

Fixing assembly

p. 2-6

p. 2-6

p. 2-6

p. 2-8

p. 2-8

p. 2-8

p. 2-8

p. 2-9

p. 5-11

p. 2-12

p. 2-12

p. 2-12

p. 2-12

p. 2-12

p. 2-12

p. 2-12

p. 2-13

T-2-1

Procedure of

adjustment

Service part:

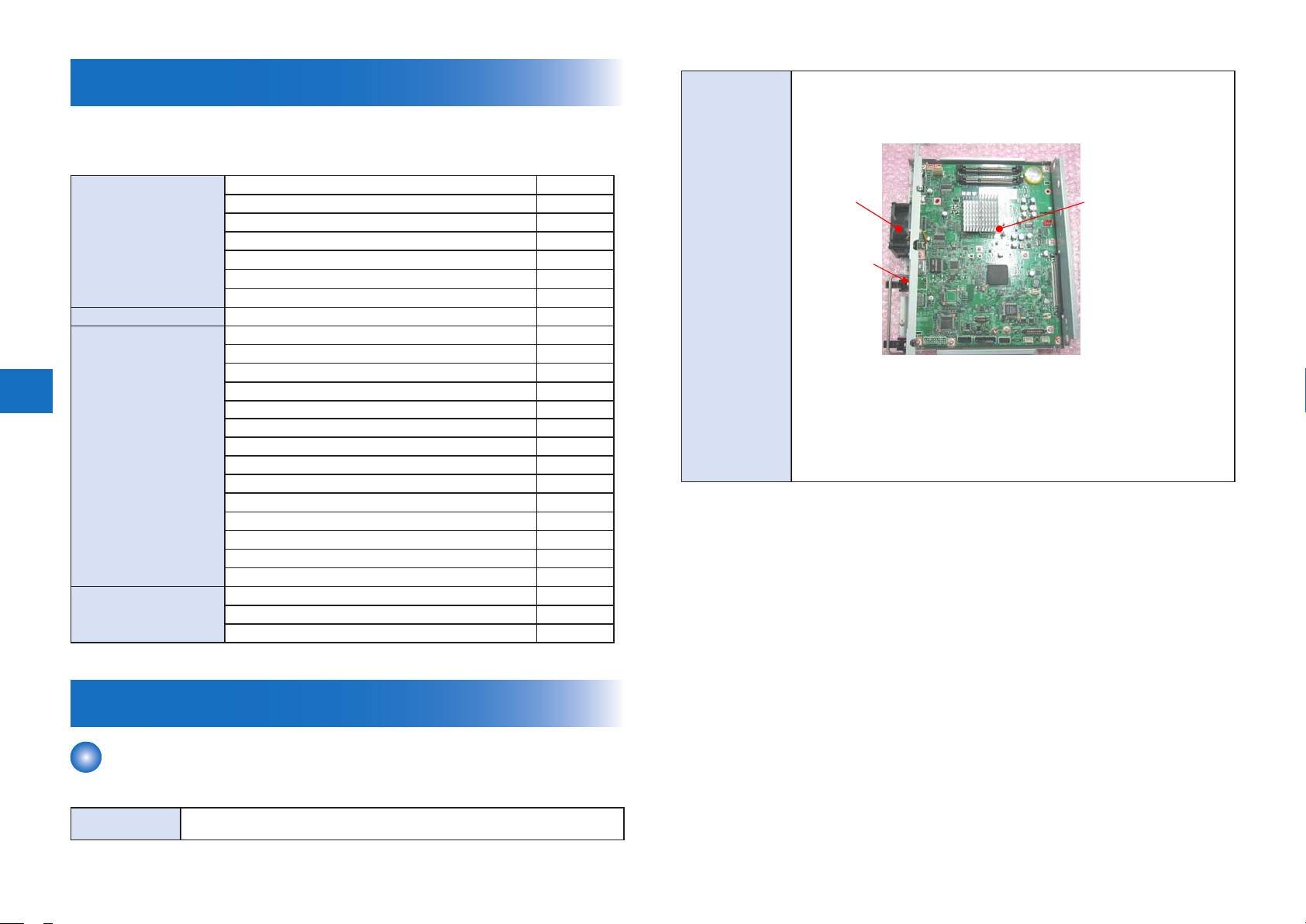

• Setting unit: Main Controller PCB 1 + Controller Box Frame + Cooling Fan

• Parts number differs on a model basis (speed basis).

Cooling Fan

Controller Box

Frame

In order to secure the accuracy of connector connection when slotting in, this

service part is provided with the PCB being installed to the frame.

1) Transferring the parts from old PCB to new PCB

• DDR2-SDRAM (2 pc.)

• Flash PCB

• TPM PCB

Main Controller PCB 1

T-2-2

When replacing parts

Controller System

■Main Controller PCB 1

Procedure of parts

replacement

2-2

Refer to Chapter 4, "Removing the Main Controller PCB 1."

Procedure of

TPM PCB

adjustment

NOTE:

Resetting/registering the data is not necessary after Main

Controller PCB 1 is replaced.

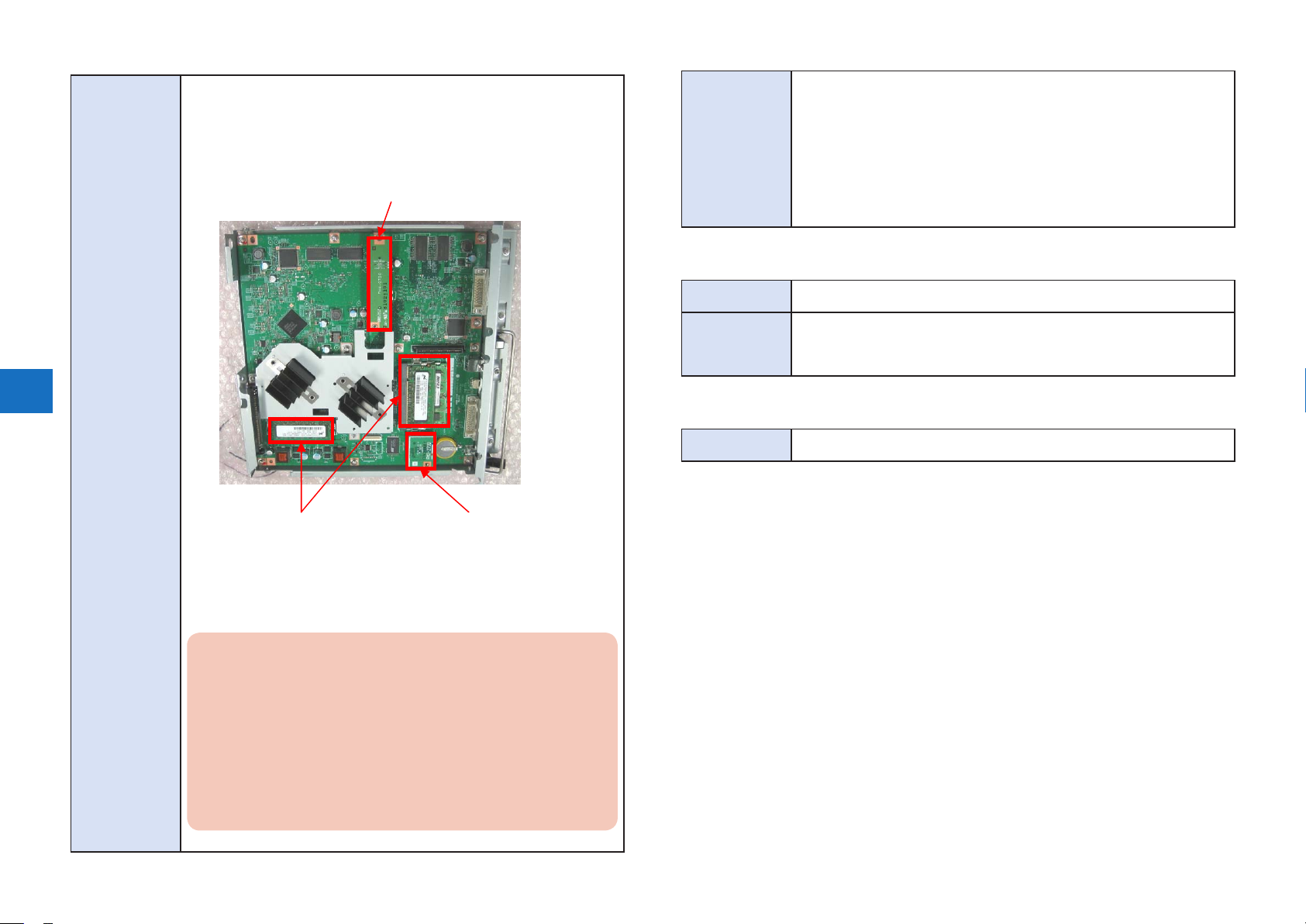

■Main Controller PCB 2

Procedure of parts

replacement

Refer to Chapter 4, "Removing the Main Controller PCB 2."

DDR2-SDRAM (2 pc.)

Flash PCB

T-2-3

Procedure of

adjustment

Service part:

• Setting unit: Main Controller PCB 2 + Controller Box Frame

Main Controller

PCB 2

Controller Box

Frame

In order to secure the accuracy of connector connection when slotting in, this

service part is provided with the PCB being installed to the frame.

1. Before Replacing

Perform the following operations. Be sure to get an approval from the user

beforehand.

1) Backup of the set/registered data

Use the Remote UI.

Management Settings > Data Management > Import/Export

Target data:

• Address List

• Forwarding Settings

• Settings/Registration

• Web Access Favorites

• Printer Settings

• Paper Information

2) Printing the set/registered data

Use the service mode.

(Lv.1) COPIER > FUNCTION > MISC-P > USER-PRT

List of the set/registered data which cannot be backed up is printed.

2

T-2-4

2-3

2

Procedure of

adjustment

2. When Replacing

1) Transferring the parts from old PCB to new PCB

• DDR2-SDRAM (2 pc.) (When option DDR2-SDRAM is installed: 3 pc.)

• Bypass PCB

• Memory PCB

Bypass PCB

Procedure of

adjustment

.

3. After Replacing

■DC Controller PCB

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 4, "Removing the DC Controller PCB."

Before replacing/clearing RAM

COPIER > FUNCTION > SYSTEM > DSRAMBUP

After replacing/clearing RAM:

COPIER > FUNCTION > SYSTEM > DSRAMRES

■HDD

Procedure of parts

replacement

Refer to Chapter 4, "Removing the HDD."

1) After installing the parts, turn ON the main power switch.

2) Restoring the backup data

Use the Remote UI.

Management Settings > Data Management > Import/Export

3) Resetting/registering the data

While referring to the list of set/registered data which was printed out

before replacement, reset/register the data.

4) When the user generates and adds the encryption key, certicate and/

or CA certicate, request the user to generate them again.

T-2-6

T-2-7

2-4

DDR2-SDRAM 3 pc.

Memory PCB

- DDR2-SDRAM (M1)

- DDR2-SDRAM (M0)

- DDR2-SDRAM (P)

Prohibited Operation:

Do not transfer the following parts to another model (which has a

different serial number).

If you fail to do so, the Main Body does not activate normally and

this might cause to fail the restoration.

• Main Controller PCB 1

• Main Controller PCB 2 (with Memory PCB installed)

• Memory PCB

T-2-5

Procedure of

adjustment

1. Before Replacing

Perform the following operations. Be sure to get an approval from the user

beforehand.

1) Backup of the set/registered data

Use the Remote UI.

Management Settings > Data Management > Import/Export

Target data:

• Address List

• Forwarding Settings

• Settings/Registration

• Web Access Favorites

• Printer Settings

• Paper Information

2) Printing the set/registered data

Use the service mode.

(Lv.1) COPIER > FUNCTION > MISC-P > USER-PRT

List of the set/registered data which cannot be backed up is printed.

2. After Replacing

1) HDD format

1-1) Start with the safe mode. (While pressing 2 and 8 keys

simultaneously, turn ON the main power switch.)

1-2) Use SST to format all partitions.

2) Downloading system software

2-1) Use SST to download the system software (System, LANG, RUI

and others).

3) Initializing the key, certicate and CA certicate

(Lv.2) COPIER > FUNCTION > CLEAR > CA-KEY

4) Turning OFF and ON the main power switch

5) Restoring the backup data

Use the Remote UI.

Management Settings > Data Management > Import/Export

6) Resetting/registering the data

While referring to the list of set/registered data which was printed

before replacement, reset/register the data.

7) When the user generates and adds the encryption key, certicate and/

or CA certicate, request the user to generate them again.

8) Executing “Auto Adjust Gradation (Full Adjust)”

Settings/Registration mode: Adjustment/Maintenance > Adjust Image

Quality > Auto Adjust Gradation

T-2-8

Procedure of

adjustment

Caution: When using the Card Reader and imageWARE

Accounting Manager

Card ID used for imageWARE Accounting Manager is stored in

the HDD, so NSA collection control is not enabled after the HDD

replacement. After the HDD is replaced, reinstall the card ID from

imageWARE Accounting Manager using the following procedures.

1) Go to COPIER > FUNCTION> INSTALL > CARD and enter

the numerical value of the leading card which is used for

Department ID. Then, press “OK” button.

(e.g.: If No.1 to No.1000 cards are used for Department ID, enter “1”

of the leading card.)

2) After turning OFF and ON the main power switch, perform the

following operations from Settings/Registration mode.

• In Management Settings > User Management > Department

ID Management > Page Totals, be sure that “ID00000001” to

“ID00001000” are created.

• Set the following: Preferences > Network > TCP / IP Settings

> IPv4 Settings> IP Address Settings > IP Address, Gateway

Address, Subnet Mask

• In Management Settings > User Management> System

Manager Information Settings> System Manager ID and System

PIN, register any number for them. Then, turn OFF and ON the

main power switch.

If “System Manager ID” and “System PIN” are not registered, “card

registration to device” cannot be executed for the imageWARE

Accounting Manager setting operation.

3) Download the card ID from imageWARE Accounting Manager to

the Main Body again.

4) After downloading is completed, go to Management Settings

> User Management > Department ID Management > Page

Totals. Be sure that only the downloaded card ID is displayed.

5) Print using the user card registered from imageWARE

Accounting Manager. Be sure that the card information used

for the target devices of imageWARE Accounting Manager is

collected.

2

T-2-9

2-5

2

Procedure of

adjustment

■TPM PCB

Procedure of parts

replacement

Procedure of

adjustment

■Flash PCB

Procedure of parts

replacement

Procedure of

adjustment

■Riser PCB

Procedure of parts

replacement

Procedure of

adjustment

Caution: Points to Note when Using the System Software-installed

HDD

When using the HDD which was installed the system software of

the other machine (different serial number), be sure to format the

HDD after the installation. If the HDD is not formatted, the operation

cannot be guaranteed.

Refer to Chapter 6, "List of PCB."

When TPM setting is “OFF”

Any operation is not necessary at replacement.

When TPM setting is “ON”

It is necessary to restore the TPM key which was backed up after changing

the setting to “ON”.

1) Removing the network cable

Until the TPM key is restored, information might be leaked due to the

inappropriate access via network, so be sure to perform this operation

appropriately.

2) Connecting the USB Memory after turning ON the main power switch

3) Restoring the TPM key

Management Settings > Data Management >TPM Settings> Restore of TPM

Key

4) Turning OFF and ON the main power switch

Refer to Chapter 6, "List of PCB."

Any operation is not necessary at replacement.

Refer to Chapter 6, "List of PCB."

Any operation is not necessary at replacement.

Setting unit as a service part:

Riser PCB + Frame

T-2-10

T-2-11

T-2-12

T-2-13

Laser Exposure System

■Laser Scanner Unit

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the Laser Scanner Unit."

1) Execute the initial position adjustment of the Skew Correction Motor.

(COPIER > FUNCTION > LASER > LD-ADJ-Y/M/C)

2) Execute the color displacement correction.

(Additional Functions (Setup/Register) > Adjustment/Maintenance > Image

Adjustment > Color Displacement Correction)

Image Formation System

■Primary Charging Wire

Procedure of parts

replacement

Procedure of

adjustment

■Grid Plate

Procedure of parts

replacement

Procedure of

adjustment

■Primary Charging Assembly

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Replacing the Primary Charging Wire."

1) Execute cleaning of the Charging Wire.

(COPIER > FUNCTION > CLEANING > WIRE-EX)

2) Execute the potential control.

(COPIER > FUNCTION > DPC > DPC)

Refer to Chapter 0, "Removing the Grid Plate."

1) Execute cleaning of the Charging Wire.

(COPIERER > FUNCTION > CLEANING > WIR E-EX)

2) Execute the Potential Control.

(COPIER > FUNCTION > DPC > DPC)

Refer to Chapter 0, "Removing the Primary Charging Assembly."

1) Output the Bk halftone image in Service Mode.

(TEST > PG > TYPE: 5)

(TEST > PG > COLOR-Y/M/C: 0)

(TEST > PG > COLOR-K: 1)

2) In the case of density difference between the front and the rear on the test

print image with the dark image on the front side of the test print, go to step

3-1) to make adjustments. With the dark image on the rear side of the test

print, go to step 4-1) to make adjustments. If there is no density unevenness,

execute the work in step 5) and later.

T-2-14

T-2-15

T-2-16

2-6

Procedure of

adjustment

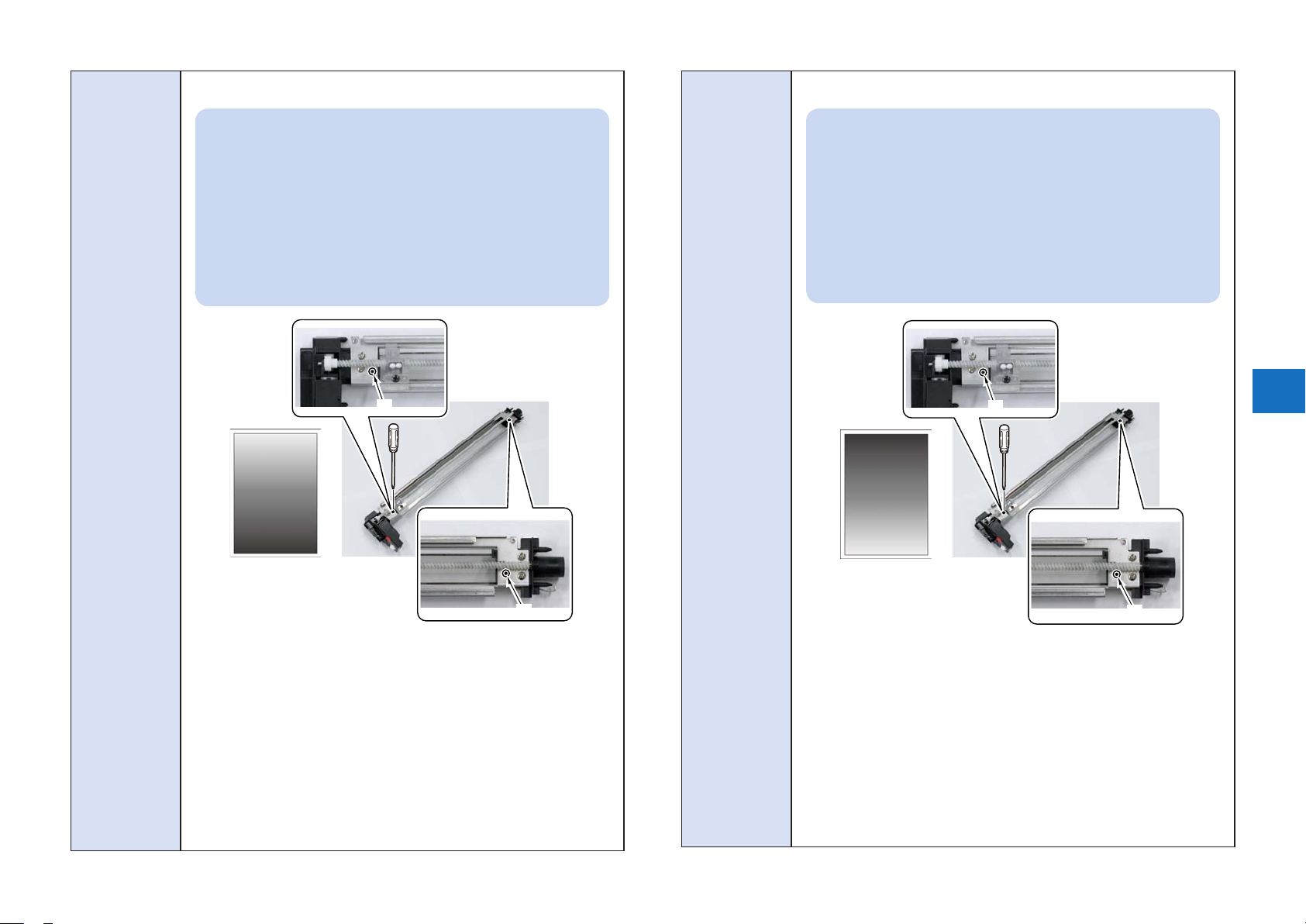

3) Adjust the Primary Charging Assembly (in the case of dark image at the front

side on the test print).

Procedure of

adjustment

4) Adjust the Primary Charging Assembly (in the case of dark image at the rear

side on the test print).

NOTE :

• In the case of dark image at the front side of the test print [1],

execute step 3-1) through 3-3) below until the density gets even.

Then, if there is no density unevenness, execute the work in

step 5) and later.

• Turning the adjustment screw counterclockwise moves down the

Charging Wire (the gap between the grid and the charging wire

gets narrower), resulting in lighter output image density. Turning

the adjustment screw clockwise moves up the Charging Wire

(the gap between the grid and the charging wire gets wider),

resulting in darker output image density.

[1]

[A]

NOTE :

• In the case of dark image at the rear side of the test print [2],

execute step 4-1) through 4-3) below until the density gets even.

Then, if there is no density unevenness, execute the work in

step 5) and later.

• Turning the adjustment screw counterclockwise moves down the

Charging Wire (the gap between the grid and the charging wire

gets narrower), resulting in lighter output image density. Turning

the adjustment screw clockwise moves up the Charging Wire

(the gap between the grid and the charging wire gets wider),

resulting in darker output image density.

[2]

[A]

2

[B]

3-1) Turn the plastic screw [A] counterclockwise to make a full round. Refer to

the replacement procedure of the Primary Charging Assembly to install the

Primary Charging Assembly to the Host Machine, and then output the test

print to check the image.

3-2) If the image at the front side of test print image is still dark, turn the

plastic screw [A] counterclockwise to make another full round. Refer to the

replacement procedure of the Primary Charging Assembly to install the

Primary Charging Assembly to the Host Machine, and then output the test

print to check the image.

3-3) If the image at the front side of the test print is still dark, turn the plastic

screw [B] clockwise to make a half round. Refer to the replacement

procedure of the Primary Charging Assembly to install the Primary Charging

Assembly to the Host Machine, and then output the test print to check the

image.

[B]

4-1) Turn the plastic screw [B] counterclockwise to make a full round. Refer to

the replacement procedure of the Primary Charging Assembly to install the

Primary Charging Assembly to the Host Machine, and then output the test

print to check the image.

4-2) If the image at the rear side of the test print is still dark, turn the plastic

screw [B] counterclockwise to make another full round. Refer to the

replacement procedure of the Primary Charging Assembly to install the

Primary Charging Assembly to the Host Machine, and then output the test

print to check the image.

4-3) If the image at the rear side of the test print is still dark, turn the plastic

screw [A] clockwise to make a half turn. Refer to the replacement procedure

of the Primary Charging Assembly to install the Primary Charging Assembly

to the Host Machine, and then output the test print to check the image.

2-7

2

Procedure of

adjustment

5) Execute cleaning of the Charging wire in Service Mode (FUNCTION >

CLAENING > WIRE-CLN) Duration: approx. 30 sec.

6) Execute the potential control in Service Mode (COPIER > FUNCTION > DPC

> DPC) Duration: approx. 30 sec.

7) Execute the density unevenness correction in User Mode

Execute Density Unevenness Correction ([Setting/Register)] > [Adjustment/

Maintenance] > [Adjust Image Quality] > [Correct shading])

■Pre-Primary Transfer Charging Wire

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Replacing the Pre-Transfer Charging Wire."

1) Execute cleaning of the Charging Wire.

(COPIER > FUNCTION > CLEANING > WIRE-EX)

■Pre-Primary Transfer Charging Assembly

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the Pre-Transfer Charging Assembly."

1) Execute cleaning of the Charging Wire.

(COPIER > FUNCTION > CLEANING > WIRE-EX)

■Drum Unit

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the Drum Unit (Bk)."

Refer to Chapter 0, "Removing the Developing Assembly (Y) / (M) / (C) and the

Drum Unit (Y) / (M) / (C)."

1) Disable (OFF) the warm-up rotation.

(COPIER>FUNCTION>INSTALL>AINR-OFF)

2) Turn OFF the main power switch. (Replace the Drum.)

3) Turn ON the main power switch.

4) Forcible execution of Drum replacement mode

(COPIER>FUNCTION>DPC>DRMRSETY/M/C/K)

5) Enable (ON) the warm-up rotation. (COPIER>FUNCTION>INSTALL>AINROFF)

■Developing Assembly

Procedure of parts

replacement

Refer to Chapter 0, "Removing the Developing Assembly (Bk)."

Refer to Chapter 0, "Removing the Developing Assembly (Y) / (M) / (C) and the

Drum Unit (Y) / (M) / (C)."

T-2-17

T-2-18

T-2-19

T-2-20

Procedure of

adjustment

[Measures before replacing the Developing Assembly.]

1) Disable (OFF) the warm-up rotation.

(COPIER>FUNCTION>INSTALL>AINR-OFF)

2) Turn OFF the main power switch. (Replace the Developing Assembly.)

[Measures after replacing the Developing Assembly.]

1) Turn ON the main power switch.

2) Execution of initial installation mode for Developing Assembly.

(COPIER>FUNCTION>INSTALL>INISET-Y/M/C/K)

3) Execution of setting of Y-toner density.

(COPIER>FUNCTION>INSTALL>TD-AD-Y/M/C/K)

4) Enable (ON) the warm-up rotation.

(COPIER>FUNCTION>INSTALL>AINR-OFF)

5) Settings/Registration mode: Adjustment/Maintenance > Adjust Image Quality

> Auto Adjust Gradation

T-2-21

2-8

■Potential Sensor

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, “After Removing the ITB Cleaning Blade Unit.”

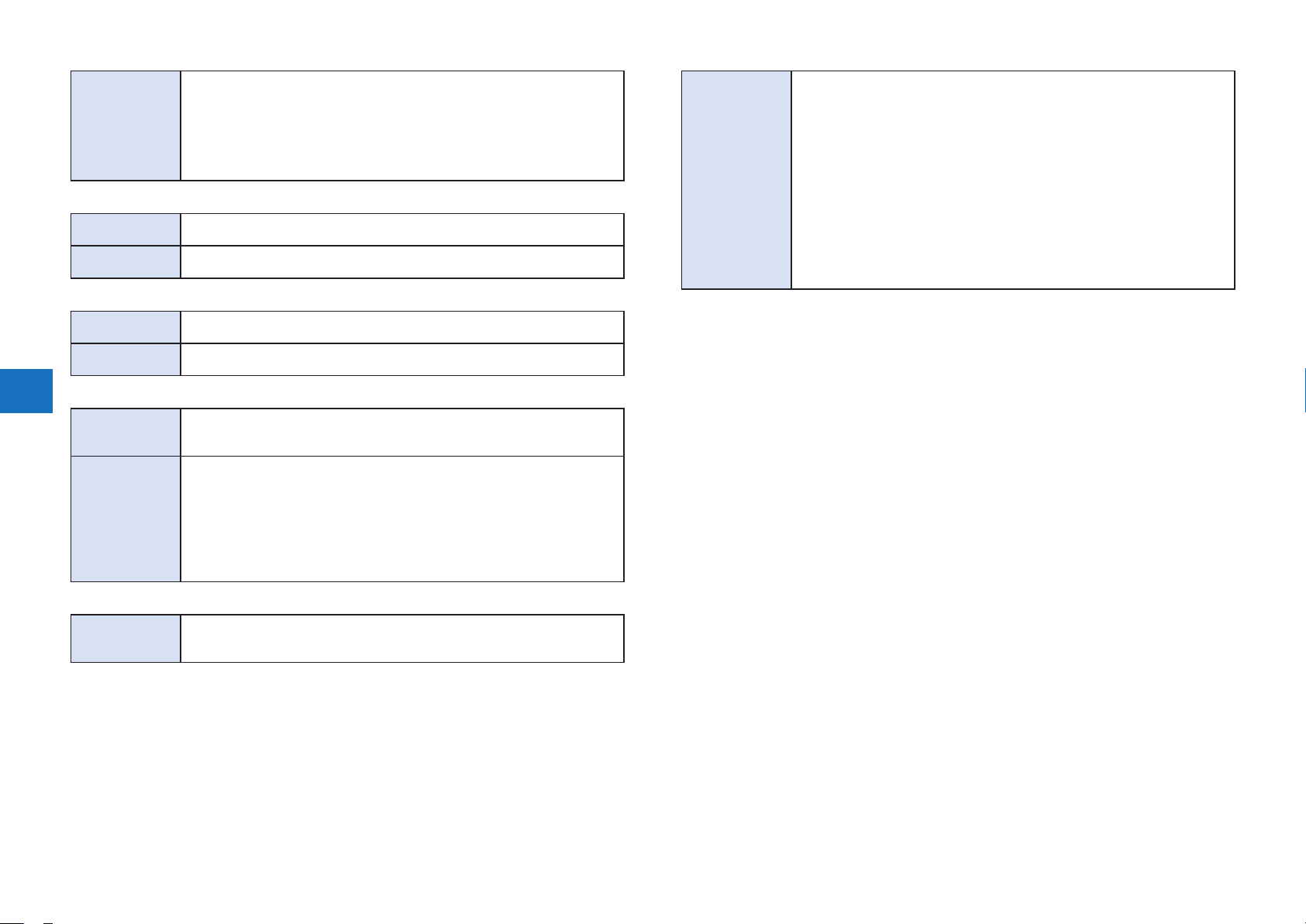

1) Install the Primary Charging Rail, which is in the condition of removing the

Electric Potential Sensor, to the main unit.

• 1 screw

Screw

Procedure of

adjustment

2) Install the ITB Unit to the main unit.

NOTE:

Purpose to remove the ITB Unit in this procedure is to prevent the

ITB from a damage caused by dropping a part.

3) Connect a new cable to the connector on new electric potential sensor.

4) Install the electric potential sensor by aligning with the boss [A] of the

electrode for the potential sensor check

• 1 connector

• 1 screw

Primary Charging Rail

NOTE:

Put the Primary Charging Rail at the angle shown in the gure, and

insert 2 bosses in the boss holes on the main unit.

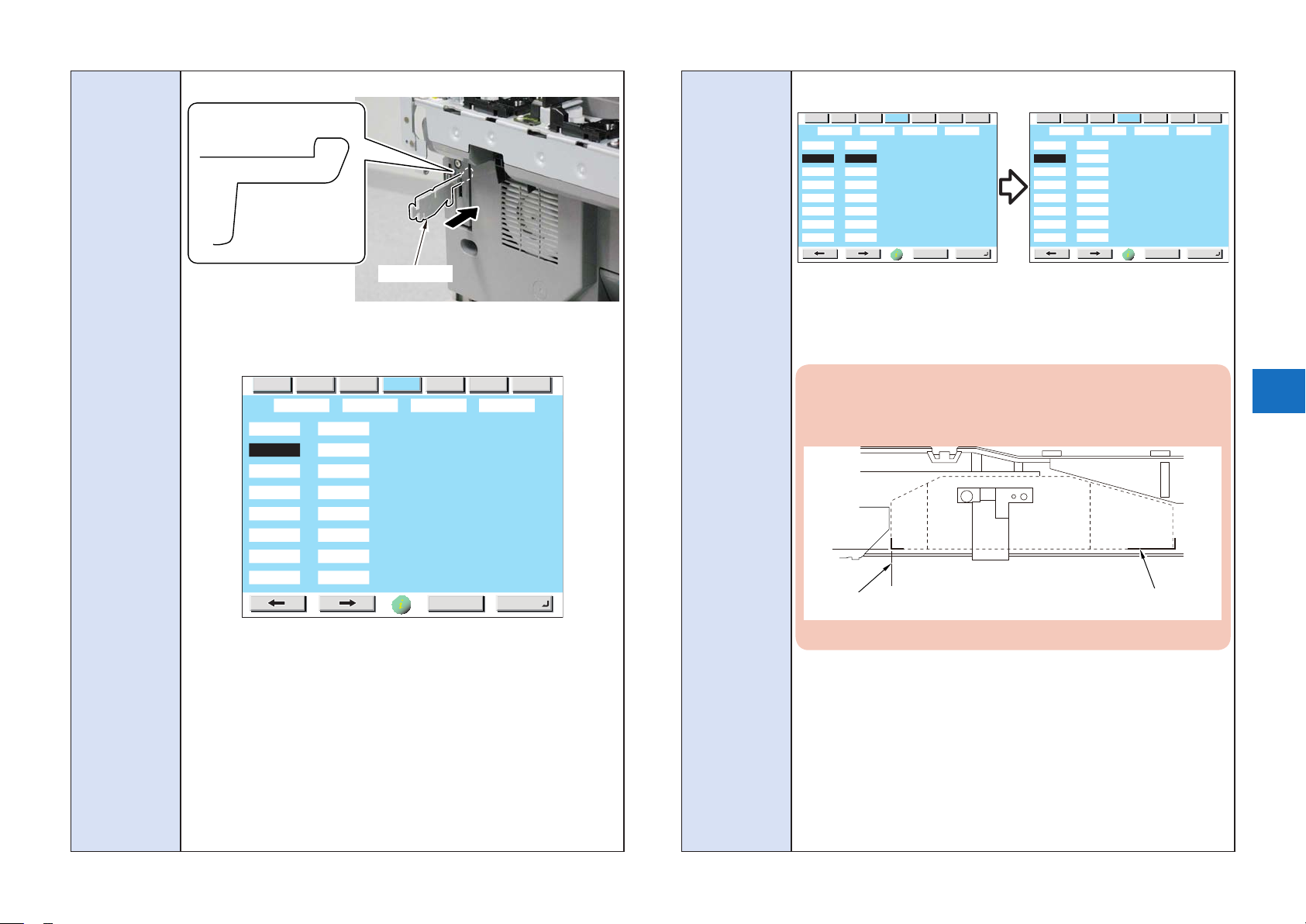

F-2-1

Electric Potential Sensor

[A]

Connector

Screw

[A]

Caution:

Be sure to tighten the screw to prevent the Potential Sensor

coming off.

2

T-2-22

T-2-23

2-9

Procedure of

adjustment

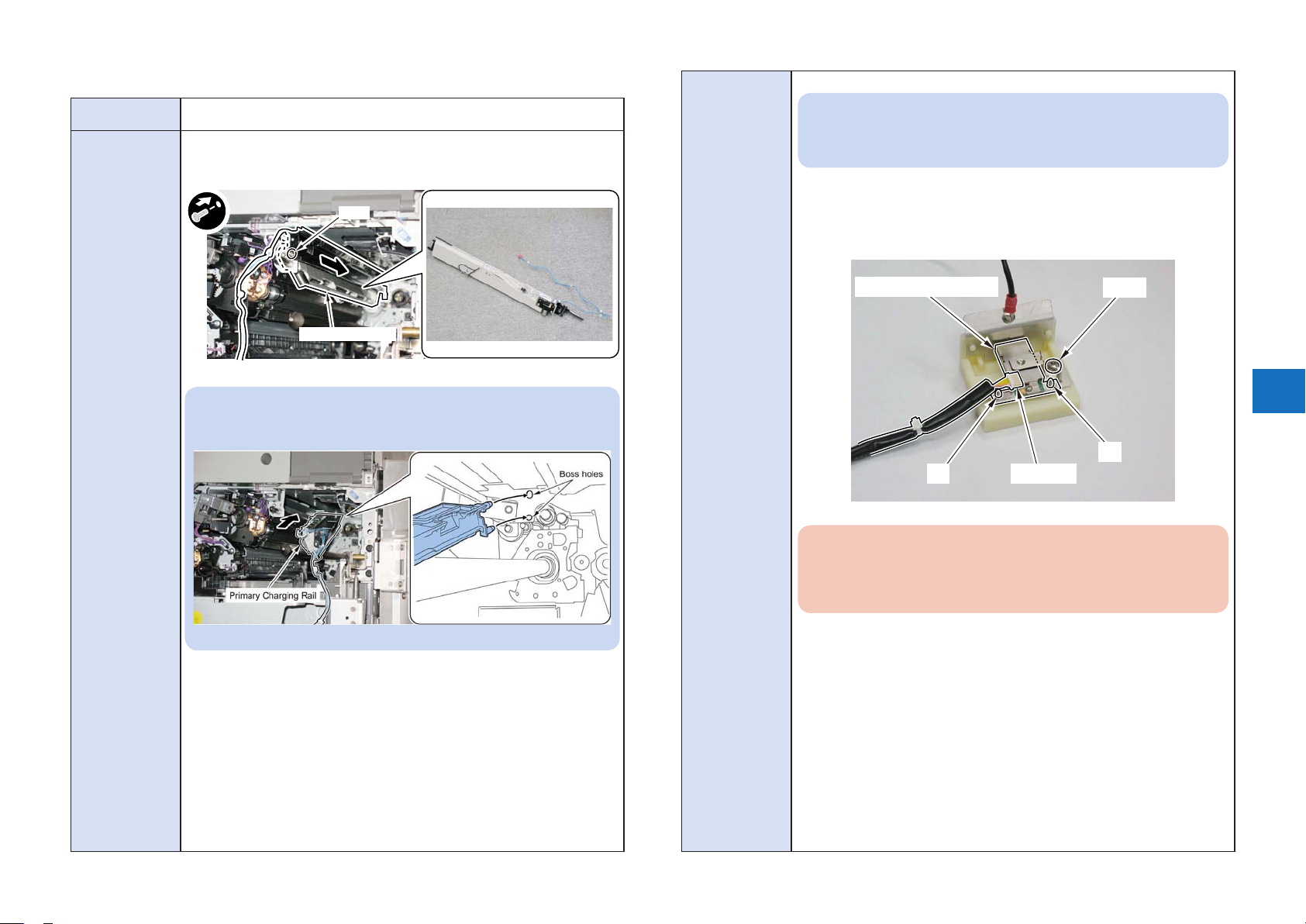

5) Install the new Potential Control PCB.

• 1 screw

• 3 PCB supports

Procedure of

adjustment

7) Place the electrode for electric potential sensor check on the Process Unit

Inner Cover, and clip the metal plate of the hinge area with the clip of the

electrode to connect the grounding.

• 1 ground

2

PCB

Support

PCB

Support

PCB Support

6) Put the wire harnesses of the electrode for the electric potential sensor

check and the Primary Charging Rail into the edge saddle on the right side

plate, and connect a connector.

• 1 edge saddle

• 5 wire saddles

• 2 connectors

Edge Saddle

Wire Saddle

Edge Saddle

Connectors

Connector

Screw

x2

x6

Electrode for

the Potential Sensor Check

Ground

Caution:

Check that the electrode for the Potential Sensor check is secured

in place.

8) Close the multi-door.

Caution:

Do not pinch the cable.

9) Turn the main power switch ON.

10) Disable the pre-rotation with the service mode right after turning the main

power switch ON.

Set to 1 with Service mode > COPIER > FUNCTION > INSTALL > AINROFF.

2-10

T-2-24

T-2-25

Procedure of

adjustment

11) With an exclusive tool, block the front door switch.

Exclusive Tool

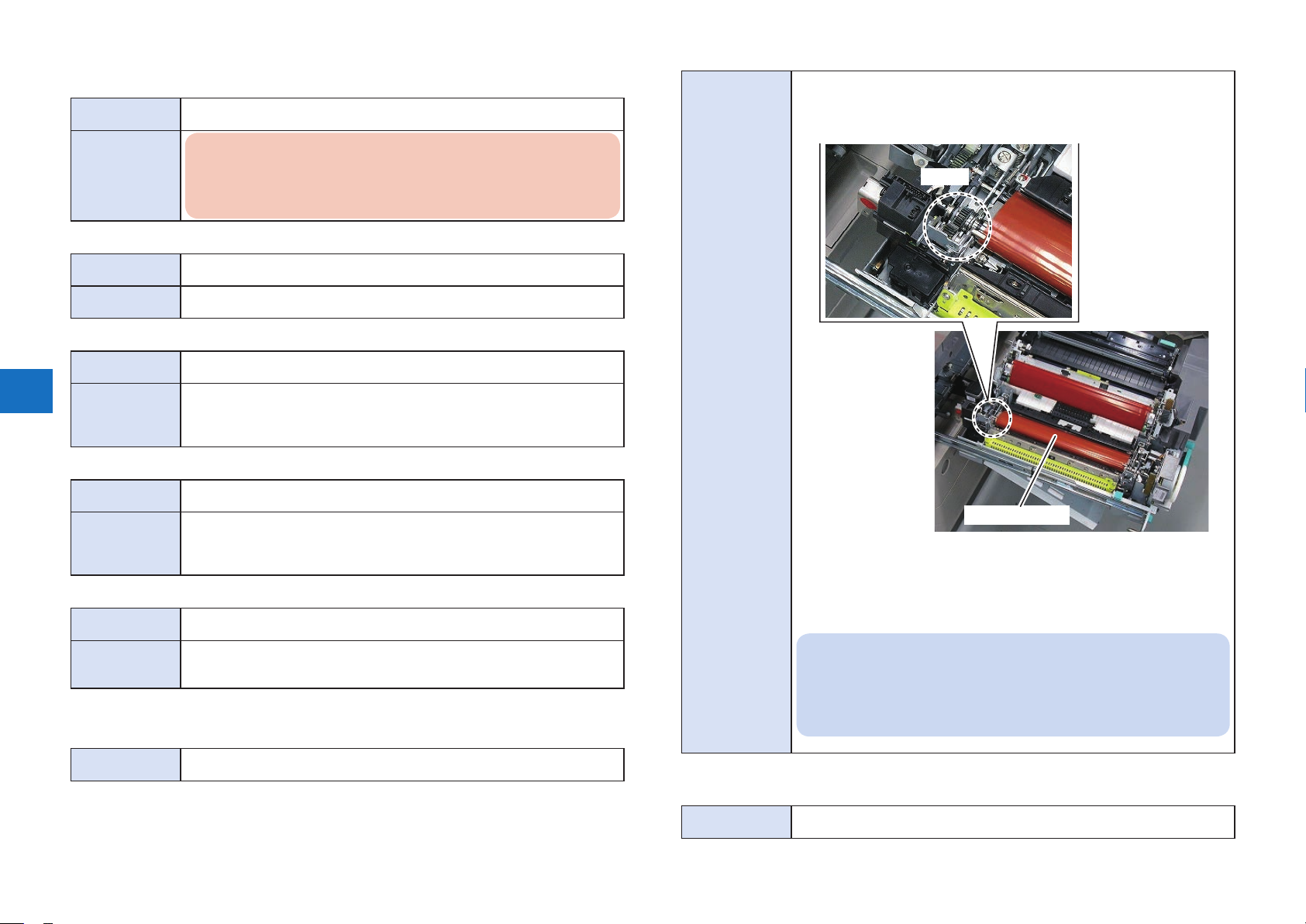

12) If the indication on the screen [A] part becomes [READY] in Service mode,

perform the adjustment of the electric potential sensor.

Service mode > COPIER > FUNCTION > DPC > OFST

CounterTestOptionFunctionAdjustI/ODisplay

< DPC > <READY > <LEVEL 1 >< 1/ 2 >

DPC

OFST

DRM-RSET

OFST-Y

OFST-M

OFST-C

DRMRSETY

DRMRSETM

OK

Procedure of

adjustment

13) When press the [OK] on the display; indication will change from [ACTIVE]

to [OK!].

< DPC > <WAITING > <LEVEL 1 >< 1/ 2 >

DPC

OFST ACTIVE

DRM-RSET

OFST-Y

OFST-M

OFST-C

DRMRSETY

DRMRSETM

CounterTestOptionFunctionAdjustI/ODisplay

< DPC > <READY > <LEVEL 1 >< 1/ 2 >

DPC

OFST OK!

DRM-RSET

OFST-Y

OFST-M

OFST-C

DRMRSETY

DRMRSETM

OK

CounterTestOptionFunctionAdjustI/ODisplay

14) Cancel to disable the pre-rotation with the service mode.

Set to 0 with Service mode> COPIER> FUNCTION> INSTALL> AINR-OFF.

15) Turn the main power switch OFF.

16) Install a new electric potential sensor to the Primary Charging Rail.

17) Attach a new electric potential sensor protection sheet.

Caution:

Peel off the released paper on the electric potential sensor

protection sheet and align it with the engraved line to attach.

Engraved pasting baseline

Gap 0.5 mm or less

Engraved pasting baseline

F-2-2

2

T-2-26

18) Install the Primary Charging Rail to main unit.

19) Install the removed parts in the reverse order of removing.

T-2-27

2-11

■ITB

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the ITB."

Caution:

Be sure to execute “Operation after ITB replacement” when

releasing the ITB pressure.

Procedure of

adjustment

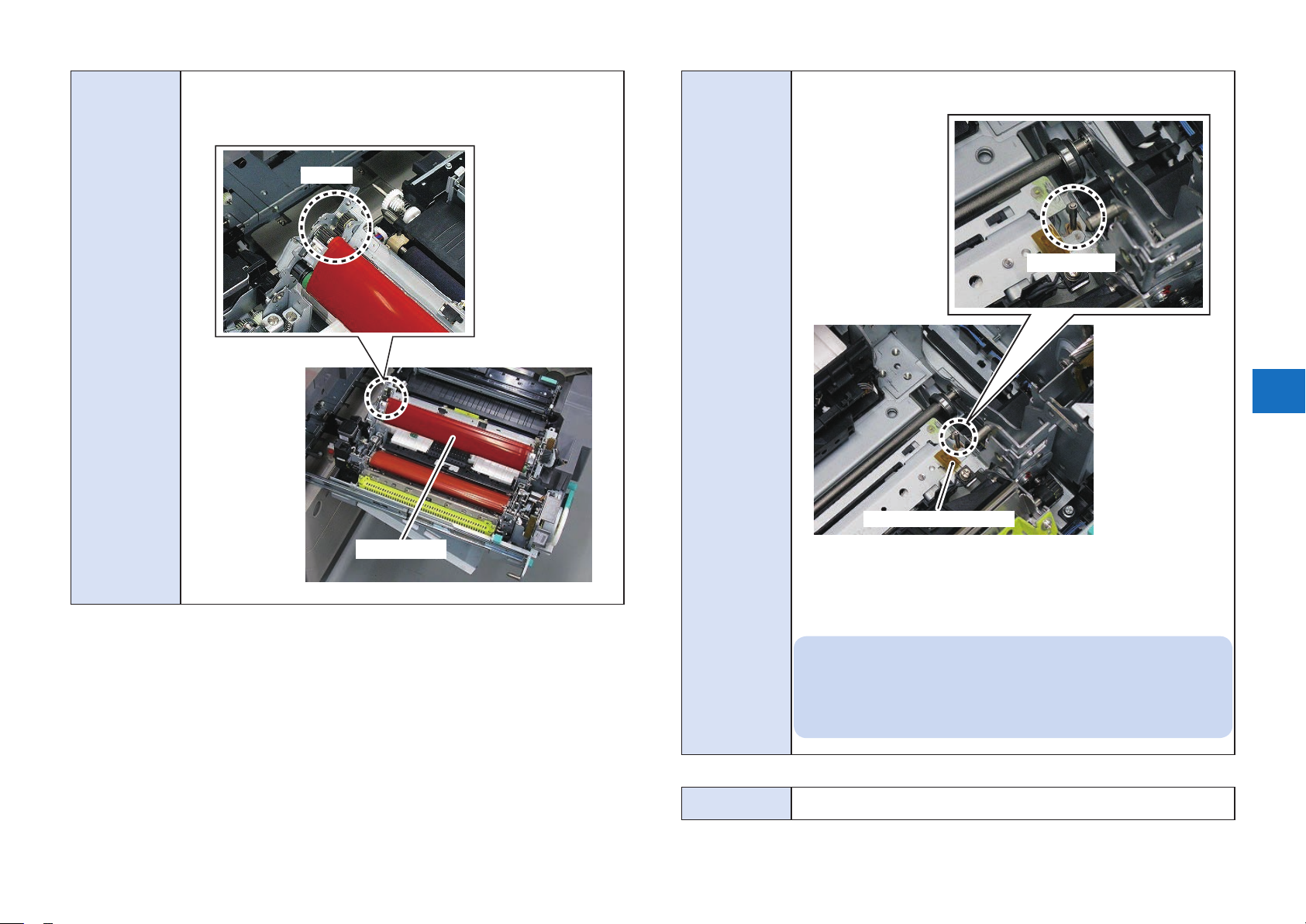

1) When replacing the Fixing Belt Unit, be sure to apply grease (Molykote

PG641) to the 3 gears of the Pressure Belt Unit.

• Application quantity: 100 mg / 1 gear

• Range: whole circumferences of gear tooth surface

3 gears

2

■Primary Transfer Roller

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the Primary Transfer Roller."

1) Execute the Primary Transfer ATVC.

(COPIER > FUNCTION > MISC-P> 1ATVC-EX)

■Patch Sensor Unit

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 4, “Removing the Patch Sensor Unit.”

1) Enter the Patch Sensor Alpha Value.

(COPIER > OPTION > IMG-MCON > P-ALPHA)

2) Adjust the Patch Sensor Light Intensity.

(COPIER > FUNCTION >MISC-P > PT-LPADJ)

■Waste Toner Container

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 0, "Removing the Waste Toner Box."

1) Clear the Waste Toner Counter. (COPIER>FUNCTION>CLEAR>W-TN-CLR)

2) Install a new Waste Toner Container.

3) Execute the offset adjustment of Waste Toner Full Sensor. (COPIER >

FUNCTION > MISC-P > WTN-OFST)

■Waste Toner Full Sensor

Procedure of parts

replacement

Procedure of

adjustment

Refer to Chapter 6, "List of Sensor."

1) Install the Waste Toner Container.

2) Execute the offset adjustment of Waste Toner Full Sensor.

(COPIER > FUNCTION > MISC-P > WTN-OFST)

■Fixing belt Unit

Procedure of parts

replacement

Refer to Chapter 4, "Removing the Fixing Belt Unit."

T-2-28

T-2-29

T-2-30

T-2-31

T-2-32

2) Clean the Inlet Guide and Sensor Flag with lint-free paper moistened with

3) Clear the counter.

■

Pressure belt Unit

Procedure of parts

replacement

Refer to Chapter 4, "Removing the Pressure Belt Unit."

Pressure Belt Unit

alcohol.

COPIER > COUNTER > DRBL-1 > FX-BLT-U

NOTE:

When the foregoing counter clear is executed, the following item is

cleared.

COPIER > DISPLAY > FIXING > FX-U-TM1-8

COPIER > DISPLAY > FIXING > FX-U-STR

T-2-33

2-12

Procedure of

adjustment

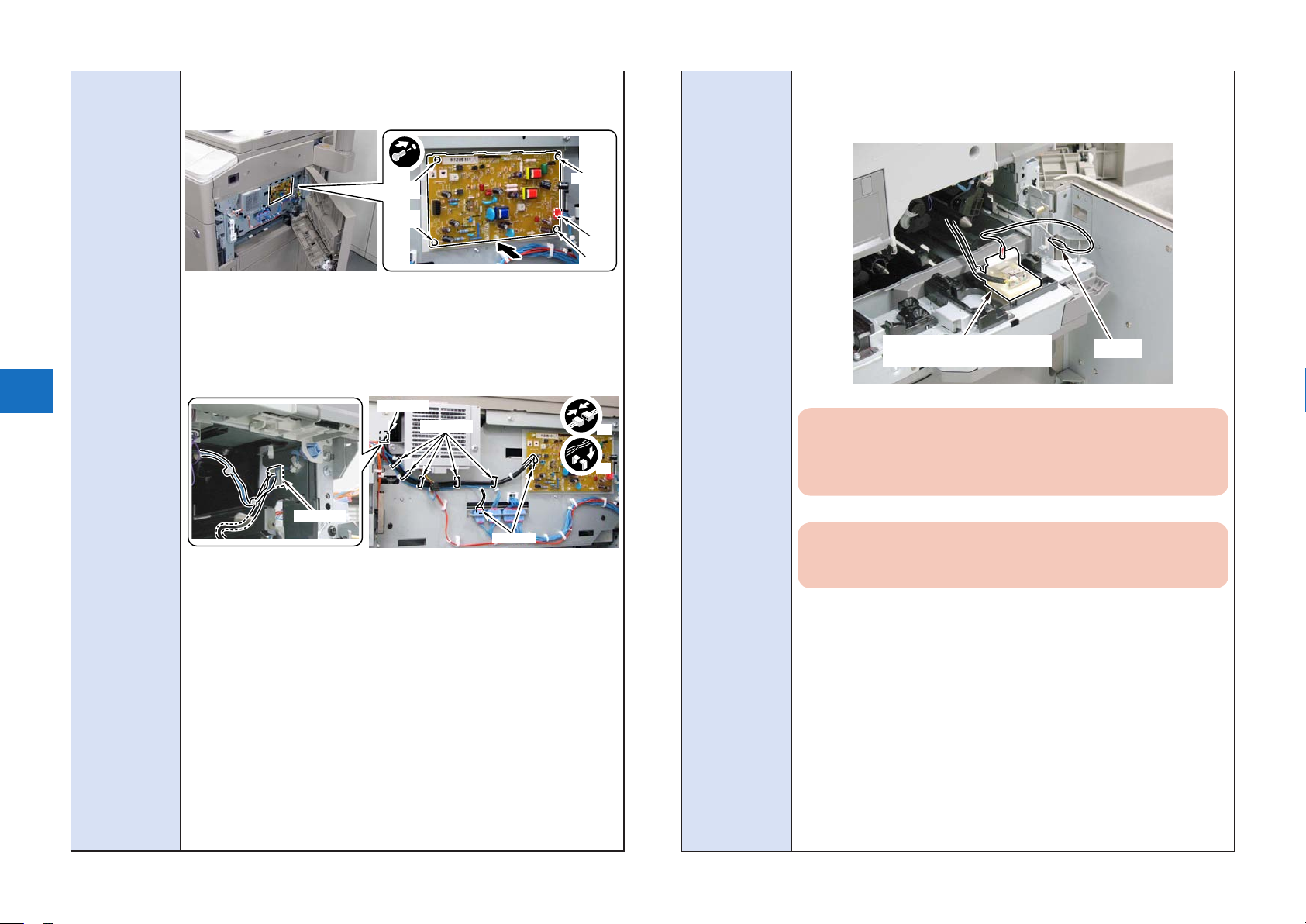

1) When replacing the Pressure Belt Unit, be sure to apply grease (Molykote

PG641) to the 3 gears of the Fixing Belt Unit.

• Application quantity: 100 mg / 1 gear

• Range: whole circumferences of gear tooth surface

3 gears

Procedure of

adjustment

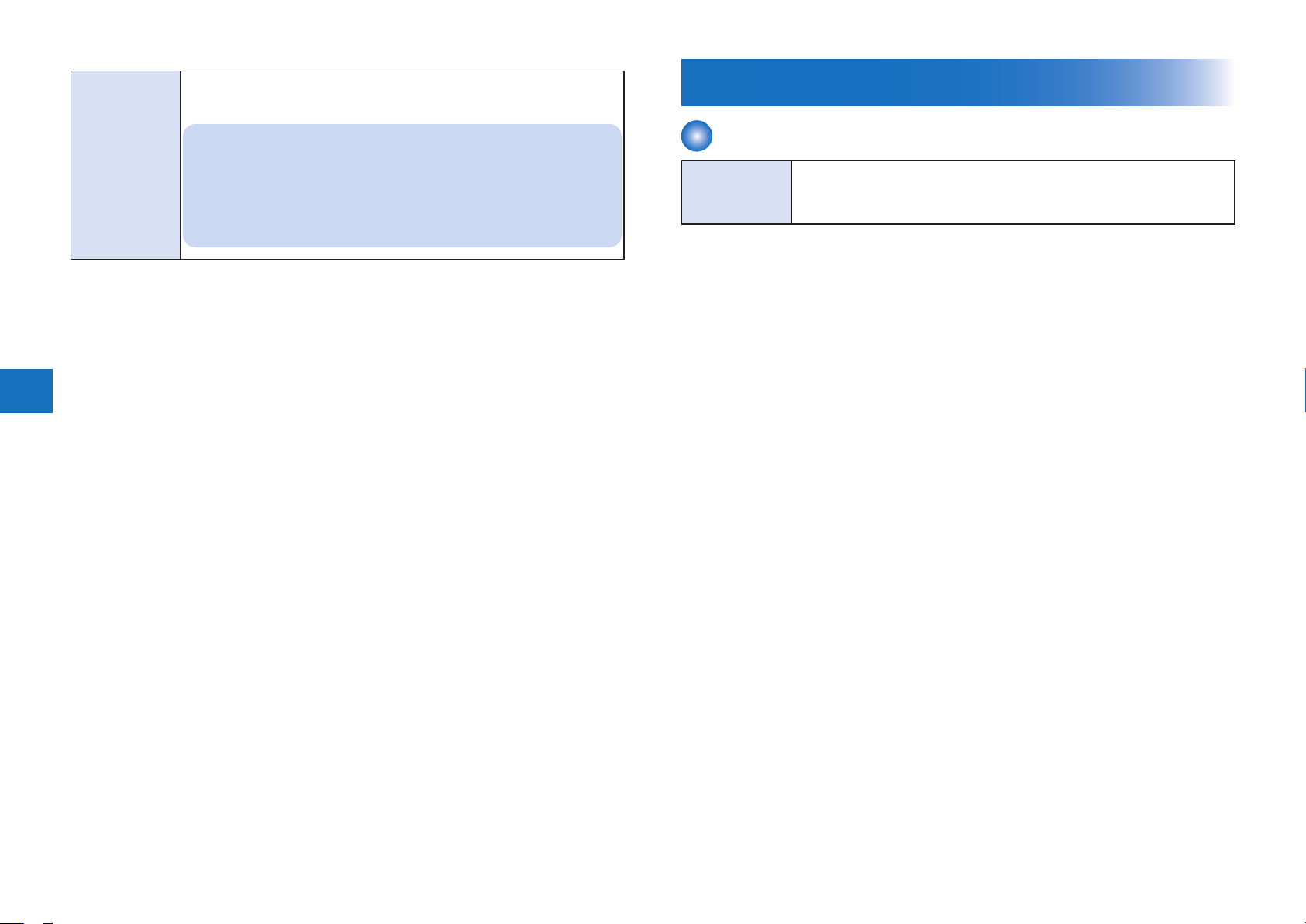

2) Clean the oil on the contact wheel of the Pressure Belt Position Sensor and

the oil spilled from the Pressure Belt with lint-free paper.

Contact Wheel

2

Pressure Sub Thermistor2

Fixing Belt Unit

T-2-34

■

Fixing assembly

Procedure of parts

replacement

3) Clean the Inlet Guide and Sensor Flag with lint-free paper moistened with

alcohol.

4) Clear the counter.

COPIER > COUNTER > DRBL-1 > FX-BLT-L

NOTE:

When the foregoing counter clear is executed, the following item is

cleared.

COPIER > DISPLAY > FIXING > FX-U-TM1-8

COPIER > DISPLAY > FIXING > FX-U-STR 2-8

T-2-35

Refer to Chapter 4, "Removing the Fixing Unit."

2-13

2

Procedure of

adjustment

1) Clear the counter.

COPIER > COUNTER > FIXING > FX-CNT

COPIER > COUNTER > DRBL-1 > FX-BLT-U/FX-BLT-L

NOTE:

When the foregoing counter clear is executed, the following item is

cleared.

COPIER > COUNTER > FIXING > FX-CNT

COPIER > DISPLAY > FIXING > FX-U-TM1-8 / FX-L-TM1-8 / FX-USTR / FX-MTR2-8

T-2-36

When clearing RAM

When clearing RAM

Procedure of

adjustment

Before clearing RAM

COPIER > FUNCTION > SYSTEM > DSRAMBUP

After clearing RAM:

COPIER > FUNCTION > SYSTEM > DSRAMRES

T-2-37

2-14

Error Code

3

Over View

■

Location Code

■

Error Code

■

Jam Code

■

Alarm Code

■

3

3

Over View

Outline

■Outline

This chapter describes various codes which are displayed when a failure occurs on the

product. These are classied into 3 codes as follows.

Code type Explanation Reference

Error code This code is displayed when an error occurs on the machine. p. 3-3

Jam code This code is displayed when a jam occurs inside the machine. p. 3-150

Alarm code This code is displayed when a function of the machine is

malfunctioned.

• Error code notation

An error code is shown in 7-digit [E000XXX] on the display on the operation panel.

However, [000] in 2 to 4 digit is not used. Thus, an error code is described as [EXXX] using

5 to 7 digit in the service manual. (e.g.: E012 = E000012)

■Location Code

Error code and jam code include the location information.

Location information is displayed as 2-digit numbers as follows.

In the jam display screen, the “L” row corresponds to the location code.

Device DISPLAY>JAM DISPLAY>ERR

imageRUNNER ADVANCE C9075 PRO/9065 PRO 00 Main Controller = 00

Printer engine = 05

Color Image Reader Unit - A1(Reader+DADF)

Multi Color Image Reader - A1(Reader+DADF)

POD Deck Light - A1 00 05

Paper Deck Unit - A1 00 05

Multi Deck - A1 00 05

Buffer Path Unit - F1 00 05

Insertion Unit -H1 02 05

Insertion Unit -J1 02 05

Paper Folding Insertion Unit - G1 02 05

Professional Puncher - C1

/ Professional Puncher Integration Unit - B1

Paper Folding Unit - G1 02 05

External 2(2/3,2/4,4)-hole Puncher - A1 02 05

Saddle Finisher - A1/Staple Finisher - A1 02 05

Saddle Finisher - B1/Staple Finisher - B1 02 05

Inner Trimmer - A1 02 05

01 04

02 05

p. 3-165

T-3-1

T-3-2

■Location Code

When jam occurs, pickup location is indicated with the following pickup position code

In the jam display screen, the “P” row corresponds to the pickup position code.

Pickup position Pickup position code

At Finisher jam/At error avoidance jam/At ADF jam without pickup

operation (at SEND, Inbox, etc.)

Right deck 1

Left deck 2

Cassette 3 3

Cassette4 4

Multi-purpose Tray 5

Side Paper Deck 6

Duplex (At duplex printing, jam occurs after paper passes through

the Duplex Paper Sensor (PS24).)

Multi-drawer Paper Deck-A1 Upper deck 11

Middle deck 12

Lower deck 13

Document Insertion Unit Upper tray 2A

Lower tray 2B

Document Insertion / Folding Unit 28

F0

.

0

T-3-3

■Points to Note When Clearing MN-CON

• Execution of clearing MN-COM deletes all data in Address Book, Forwarding Settings,

Settings/Registration (Preferences), Adjustment/Maintenance, Function Settings, Set

Destination, Management Settings, TPM Settings, etc. Before execution of this operation,

ask user to back up the data and get approval for this operation.

• When clearing MN-CON while any login application other than Default Authentication is,

error such as not displayed login screen occurred. In this case, access SMS once and

switch login application to Default Authentication to recover to the normal status.

■Points to Note When Clearing HDD

As a remedy for error codes (E602-XXXX, E611-0000), HDD partition is selected and the

target partition may be cleared.

When clearing partition, be sure to check which data will be deleted by referring Detail of

HDD partition and explain to the user before starting work.

■Measures for E747

There are many detail codes in E747. Since these detail codes are for R&D use, remedy to

be performed in the eld is the same, except for E747-1201 and E747-FF01. Because of that,

errors other than the 2 errors mentioned above are described as E747-XXXX, and common

remedy is described.

3-2

Error Code

Error Code Details

■E000 to E015

E

Detailed

code

E000 -0001 -05 Title Fixing belt temperature rise is insufcient at power ON.

code

Occurance

area

Items Description

Description

of detection

Measures Check if the detection temperature of the thermistor is

Fixing main thermistor (THM1-1) temperature does

not reach 50 degrees Celsius within 120 seconds after

startup of xing belt temperature control.

risen in service mode (COPIER> DISPLAY> ANALOG>

FIX-xx).

A. In case that either one of the thermistor detection

temperature is risen

A-1. Replace the xing belt unit

A-2. Faulty drawer connector -> Clean the drawer

connector or replace the xing drawer cable

B. In case that neither of them are not risen

B-1. Check the connection of the xing thermistor

(to see if the connection of the drawer is

faulty, the connector is physically removed or

disconnected) -> replace the xing belt unit

B-2. Check the connection of the IH power

connector (to see if the connector is physically

removed or disconnected, or the cable is caught)

B-3. Replace the IH power unit

B-4. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

E

Detailed

code

E000 -0101 -05 Title Pressure belt temperature rise is insufcient at power

E001 -0001 -05 Title Abnormal temperature rise of xing main thermistor

code

Occurance

area

Items Description

ON.

Description

of detection

Measures Check if the detection temperature of the thermistor is

Description

of detection

Measures Check the detection temperature of the xing main

Pressure main thermistor (THM2) temperature does

not reach 50 degrees Celsius within 250 seconds after

startup of pressure belt temperature control.

risen in service mode (COPIER> DISPLAY> ANALOG>

FIX-xx).

A. In case that either one of the thermistor detection

temperature is risen

A-1. Check the pressure belt main thermistor

(to see if the thermistor is disconnected, the

harness of the thermistor is disconnected,

foreign substance is in the thermistor, failure of

the thermistor) -> replace the main thermistor or

the pressure stay

A-2. Faulty drawer connector is a possible cause

-> clean the drawer connector or replace the

xing drawer cable

B. In case that neither of them are not risen

B-1. Check the connection of the AC driver

connector (to see if the connector is physically

removed or disconnected, or the cable is caught)

B-2. Replace the AC driver unit

B-3. Replace the DC controller PCB

B-4. Replace the pressure belt unit

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

(circuit failure)

Fixing main thermistor (THM1-1) sensed an abnormal

high temperature. (ASIC detection)

thermistor (THM1-1) in service mode (COPIER>

DISPLAY> ANALOG> FIX-UC).

A. In case that the detection temperature is 250 degC

A-1. The cable of the xing main thermistor is

caught -> replace the xing belt unit

B. In case that the detection temperature is other than

250 degC

B-1. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

3

3-3

3

E

Detailed

code

E001 -0002 -05 Title Abnormal temperature rise of xing subthermistor 1

E001 -0003 -05 Title Abnormal temperature rise of xing subthermistor 2

code

Occurance

area

Items Description

(THM1-2) (circuit failure)

Description

of detection

Measures Check the detection temperature of the xing sub

Description

of detection

Measures Check the detection temperature of the xing sub

Fixing subthermistor 1 (THM1-2) sensed an abnormal

high temperature. (ASIC detection)

thermistor 1 (THM1-2) in service mode (COPIER>

DISPLAY> ANALOG> FIX-UE).

A. In case that the detection temperature is 250 degC

A-1. The cable of the xing sub thermistor 1 is

caught -> replace the xing belt unit

B. In case that the detection temperature is other than

250 degC

B-1. Location of the xing main thermistor is

inappropriate -> replace the xing belt unit

B-2. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

(THM1-3) (circuit failure)

Fixing subthermistor 2 (THM1-3) sensed an abnormal

high temperature. (ASIC detection)

thermistor 2 (THM1-3) in service mode (COPIER>

DISPLAY> ANALOG> FIX-UE2).

A. In case that the detection temperature is 250 degC

A-1. The cable of the xing sub thermistor 2 is

caught -> replace the xing belt unit

B. In case that the detection temperature is other than

250 degC

B-1. Location of the xing main thermistor is

inappropriate -> replace the xing belt unit

B-2. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

E

Detailed

code

E001 -0011 -05 Title Fixing main thermistor abnormal temperature rise (circuit

E001 -0012 -05 Title Fixing sub thermistor 1 (THM1-2) abnormal temperature

code

Occurance

area

Items Description

abnormality)

Description

of detection

Measures Check the detection temperature of the xing main

Description

of detection

Measures Check the detection temperature of the xing sub

Fixing main thermistor (THM1-1) detected abnormal high

temperature. (software detection)

thermistor (THM1-1) in service mode (COPIER>

DISPLAY> ANALOG> FIX-UC).

A. In case that the detection temperature is 250 degC

A-1. The cable of the xing main thermistor is

caught -> replace the xing belt unit

B. In case that the detection temperature is other than

250 degC

B-1. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

rise (circuit abnormality)

Fixing sub thermistor 1 (THM1-2) detected abnormal

high temperature. (software detection)

thermistor 1 (THM1-2) in service mode (COPIER>

DISPLAY> ANALOG> FIX-UE).

A. In case that the detection temperature is 250 degC

A-1. The cable of the xing sub thermistor 1 is

caught -> replace the xing belt unit

B. In case that the detection temperature is other than

250 degC

B-1. Location of the xing main thermistor is

inappropriate -> replace the xing belt unit

B-2. Replace the DC controller PCB

NOTE: After performing the above remedy work, go

through the following to clear the error: COPIER>

FUNCTION> CLEAR> ERR

3-4

Loading...

Loading...