Canon BJC-2000 Service manual

Simplified Manual

for

BJC-2100/2100SP

Part number: QY8-1372-000

1 Product / Option / Comsumable list

2 Specifications

3 Error code list

4 Service mode

(Test print, EEPROM reset....)

5 External view / Parts list

6 H/W troubleshooting flowchart

7 Special Service Information

Attachment

Service Test Print

Rev 01 2000.3/22

(QE-12E-0231)

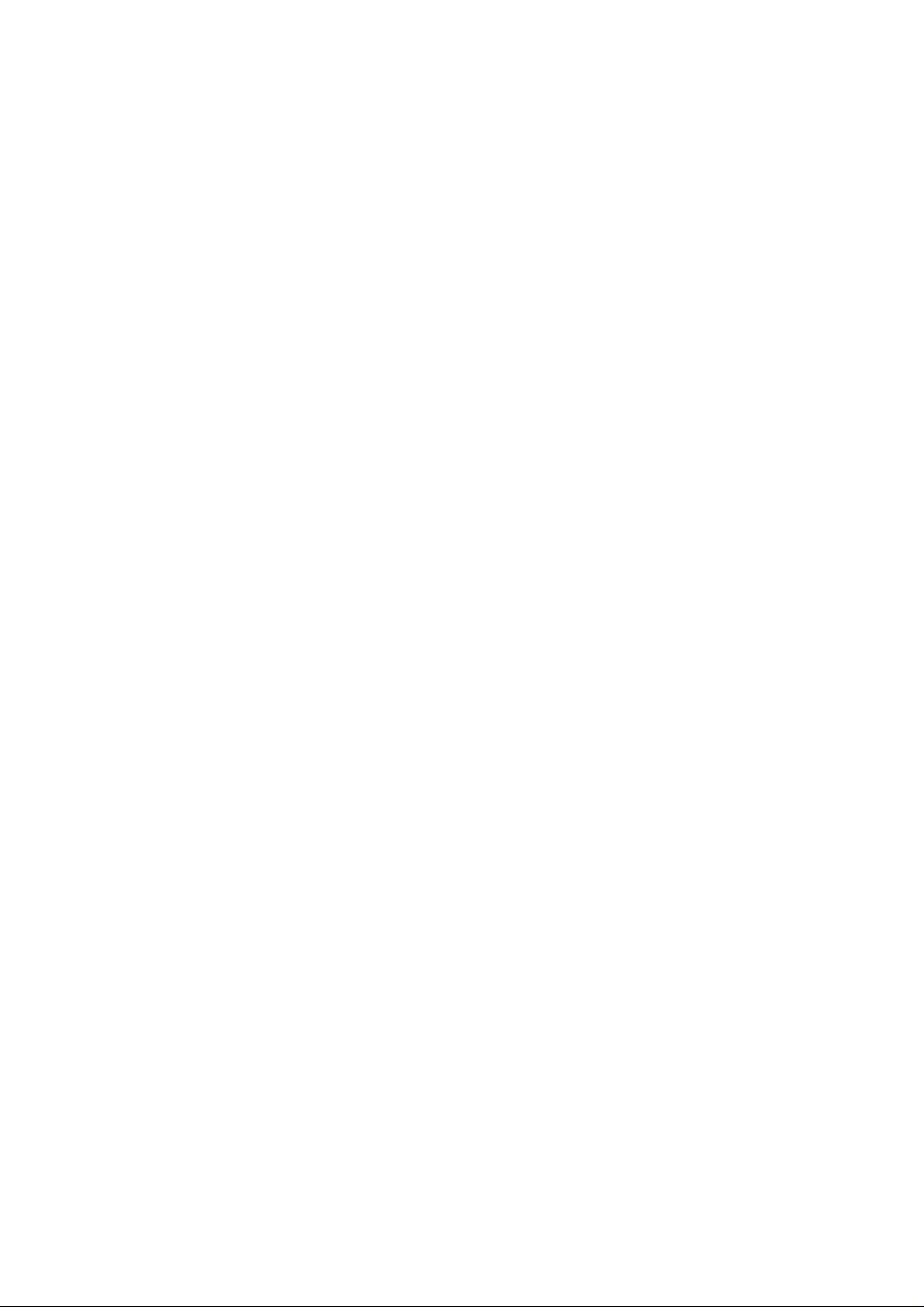

1. Product / Option / Comsumable lists

1.1 Products

Product Name Product Code Sales territory Remarks

Canon Bubble Jet Printer Q30-3330-720 CCSI

BJC-2100 Q30-3330-721 CANADA

Q30-3330-722 LATIN(LV)

Q30-3330-723 LATIN(HV)

Q30-3330-724 ARG

Q30-3330-730 EUROPE

Q30-3330-731 GERMAN

Q30-3330-732 FRANCE

Q30-3330-780 U.K.

Canon Bubble Jet Printer Q30-3331-710 JAPAN

BJ F210

Canon Bubble Jet Printer Q30-3340-740 AUSTRALIA

BJC-2100SP Q30-3340-733 ASIA(HV)

Q30-3340-734 CHN

Q30-3340-750 HK

Q30-3340-760 KRN

Q30-3340-723 TWN

1.2 Options

Product Name Product Code Remarks

Canon BJ Cartridge Container Q70-3130

SB-21

Canon Color Image Scanner Cartridge

IS-22

Canon BJ Scanning Holder Q70-3640

SH-101 A4/LTR

Canon BJ Scanning Holder Q70-3650

SH-101 A3/LDR

1.3 Consumables

Product Name Product Code Remarks

Canon BJ Cartridge F45-0561

BC-20

Canon Color BJ Cartridge F45-1301

BC-21e

Canon Color BJ Cartridge F45-1311

BC-22e Photo

Canon Color BJ Cartridge F45-1101

BC-29F

Canon Ink Cartridge F47-0731

BCI-21 Black

Canon Ink Cartridge F47-0741

BCI-21 Color

Q70-3530

Scanning Holder for IS-22 (A4)

Scanning Holder for IS-22 (A3)

BJ Cartridge (BK)

BJ Cartridge (Regular Color)

BJ Cartridge (Photo Color)

BJ Cartridge (Fluorescent Color)

Ink tank for BC-21e (BK)

Ink Tank for BC-21e (Color)

2. Specifications

(

k (A

2

)

z

t

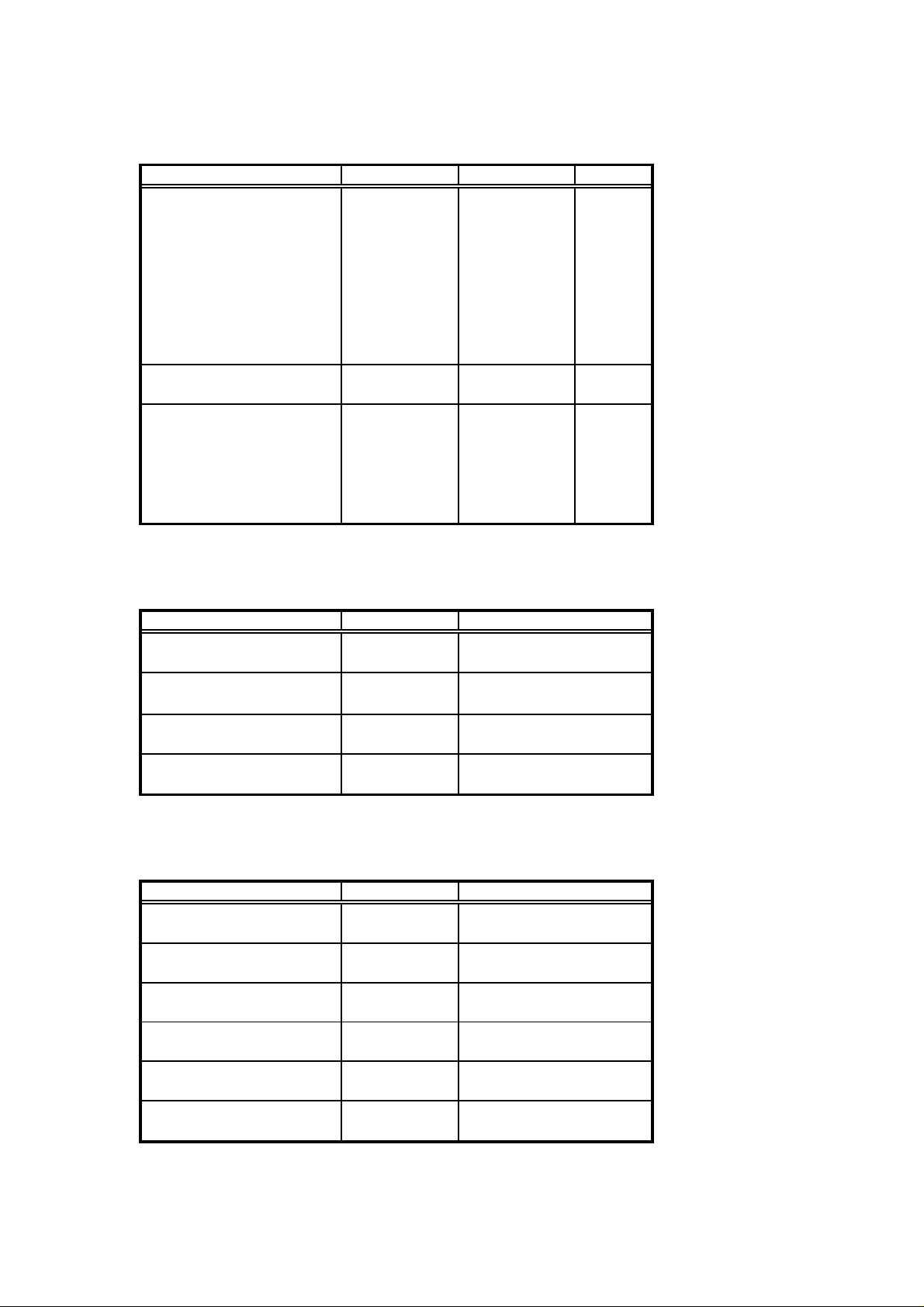

2.1 Specifications

Paper feeding method Auto Sheed Feeding

Resolution 720 dpi X 360 dpi

Printing Speed

HQ Color 1.5ppm (Color throughput pattern)

HS Color 2ppm (Color throughput pattern)

Printing Direction Switching unidirectional

Print width 203.2mm (8inch)

Interface

Stacking Capacity of sheet feeder

Plain paper Max.

Envelopes Max. 5 sheets

Transparencies Max. 20 sheets

Back Print Film Max. 10 sheets

Glossy photo paper Max. 1 sheet

Glossy film Max. 1 sheet

Fabric Max. 1 sheet

T-shirt transfer Max. 1 sheet

Banner paper Max. 1 sheet

Scanning document Max. 1 sheet

Detection functiones

Paper out Available

Paper width None

Waste ink amount Available

Presence of BJ cartridge

Distinction of cartridge Available

Ink out None

Distinction of scanner Available

Mismatch BJ/scanner Available

Noise 45 dB (Sound pressure level ISO9296)

Environmental requirement

During operation Temp. 5 to 35 deg. C (41 to 95 deg. F)

Non operation Temp. 0 to 35 deg. C (32 to 95 deg. F)

Power supply

Input voltage/Frequency

Power consumption 18W

Stand-by status 2W

External dimension

W/O paper tray/suppor

W paper tray/support

Weight 2.4kg (W/O BJ cartridge and option)

Applicable safety standards

Printer

Safety

Note) Difference from the based BJC-2000/2000SP is written in RED

DeskTop serial color bubble jet printer

Mono. 4ppm (Monochrome throughput pattern)

Mono. 5ppm (Monochrome throughput pattern)

( Printing direction automatically changes according to

the print data/ print mode/ installed cartridged type. )

IEEE1284 compatible 8-bit parallel / USB

5mm stac

LGL size Max. 10 sheets

Available

Humidity 10% to 90%RH (no condensation)

Humidity 5% to 90%RH (no condensation)

AC100V/120V 50/60H

AC220/240V 50Hz (HV) Europe,Asia

370(W) X 191(D) X 164(H)

370(W) X 461(D) X 241(H)

FCC,IC,CE Mark,TWN-EMC,C-Tick,VCCI

UL,CUL,CB Report,GS,CE Mark,FIMKO,DENTORI,AS,PSB,CCIB,KRN-DENTORI

pprox. 50 sheets with 75g/m

(LV) Japan,USA,Canada

Product life

2.2

Whichever of the following comes first

-5 years

-Color printing 3000 pages

-Black printing 10000 pages

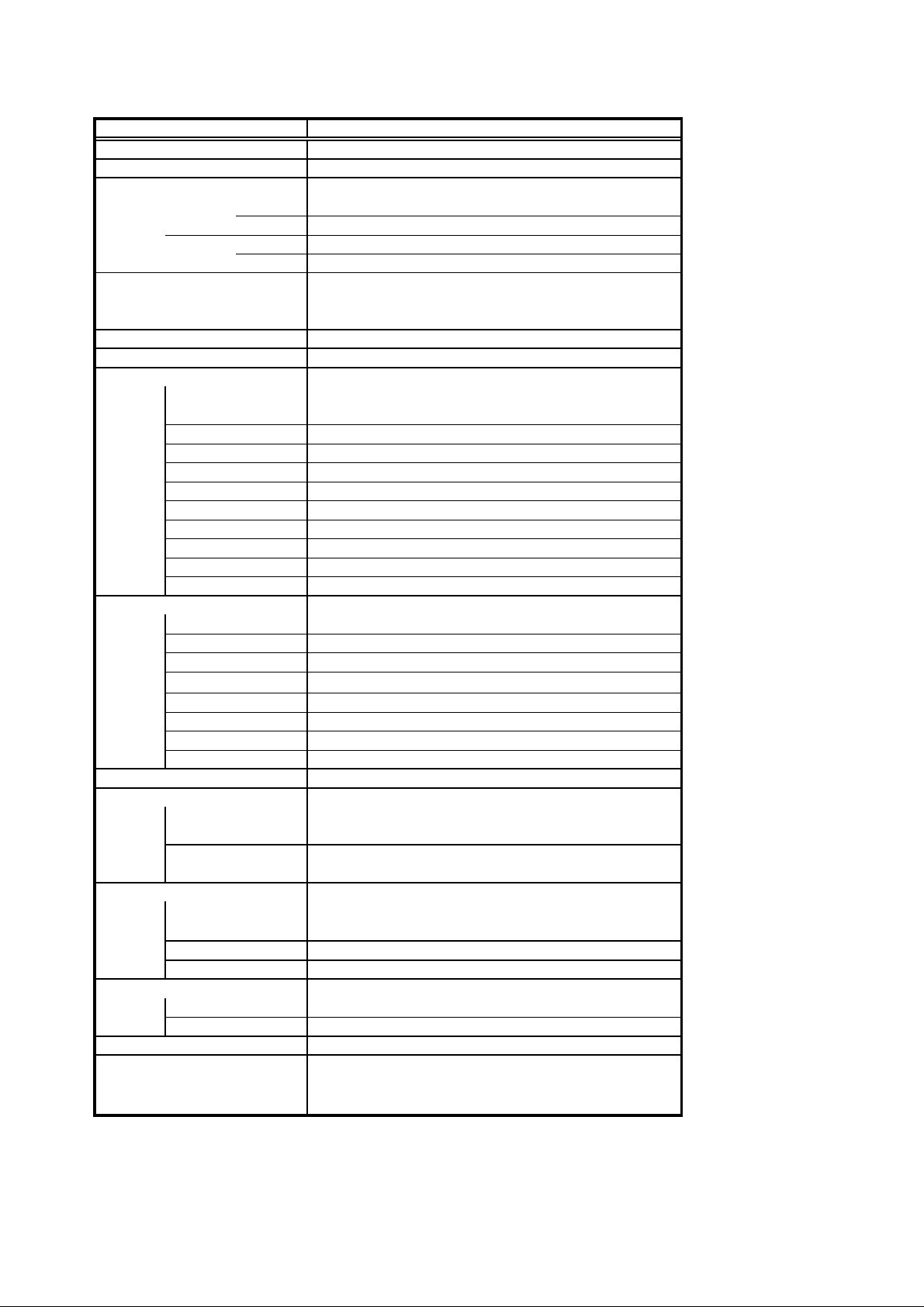

3. Error Code List

Error will be displayed on the host computer monitor.

The host computer should be set to ECP or Nibble mode and use the BJ Status Monitor on Win95.

Error Code

1000 The printer is out of paper. Push the RESET botton to paper feed.

1200 Front cover is opened. Close the front cover.

1300 Paper JAM occurrs. Pull up the paper.

1400 BJ cartridge is not installed. Install the BJ cartridge and close the front cover.

1440 Incorrect cartridge is installed.

5000 Home position error H/W fail Replace the printer.

5100 Carriage control error H/W fail Replace the printer.

5200 Head temperature error H/W fail Replace the BJ cartridge.

5400 Printer temperature error H/W fail Replace the printer.

5600 No cartridge while printing H/W fail Replace the printer.

5B00 Waste ink full H/W fail Replace the printer.

5C00 Purging operation error H/W fail Replace the printer.

6100 ROM error H/W fail Replace the printer.

6300 RAM error H/W fail Replace the printer.

5210 Scanner cartridge error H/W fail Replace the scanner cartridge.

6800 EEPROM error H/W fail Replace the printer.

Error indication Error condition

Install the correct BJ cartridge and close the front cover.

4. Service Mode

O

BC

(black BJ

)

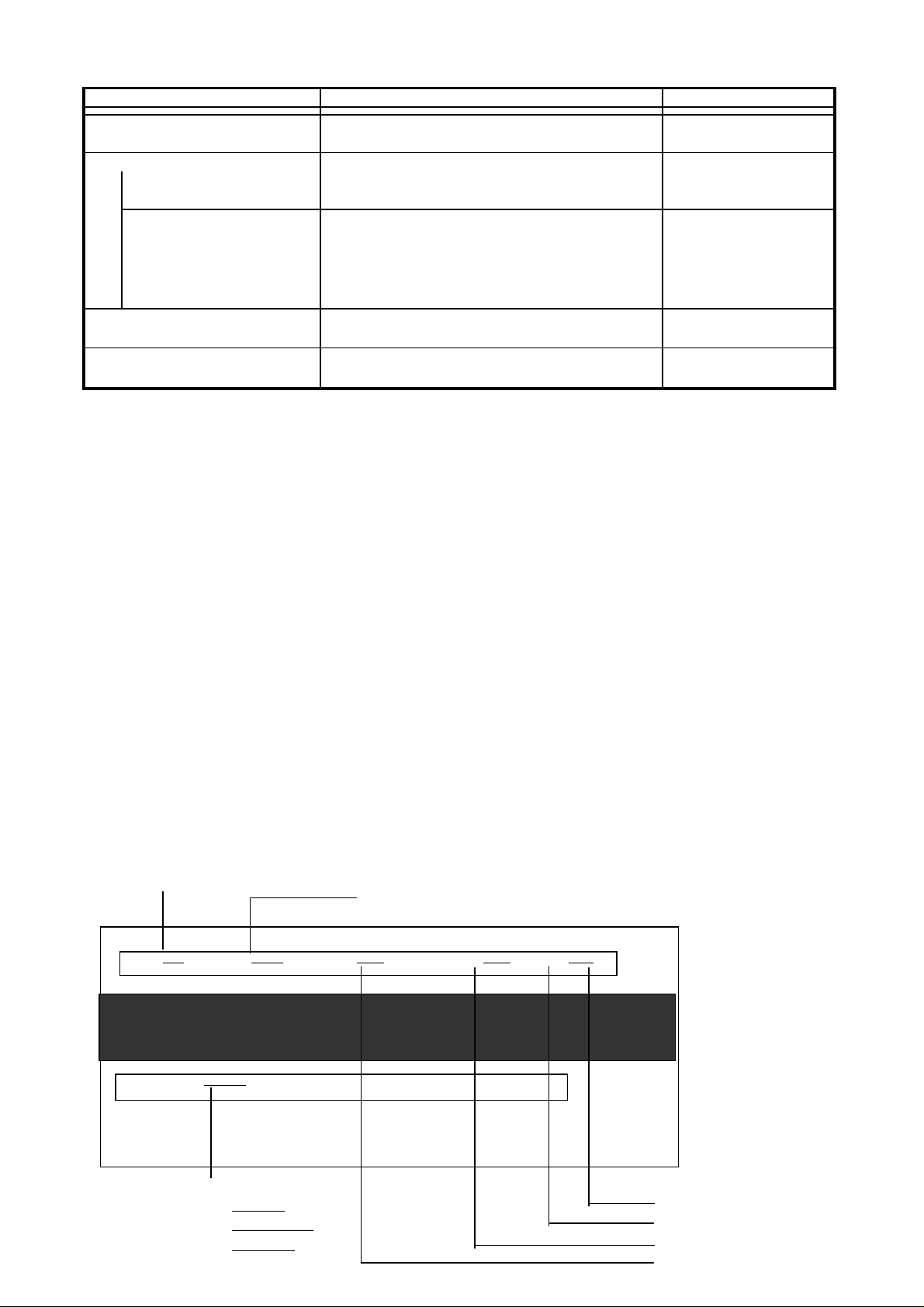

Function Procedure Remarks

Cleaninng the BJ cartridge Cleaning time

Test print Print nozzle check pattern

1) Nozzle pattern Double click the RESET button. BC-20/21e/22e/29F

2) Service test print

Control ROM Version See *1 service test print' Needs BC-20

Pages of each Cartridge Print sample : See *3

Waste ink Amount

Destination setting

EEPROM Reset See *2 EEPROM reset / Destination setting

(Reset waste ink amount)

Destination setting See *2 EEPROM reset / Destination setting

(Japan/SP/Others)

*1 Service test print

-1 Without the cartridge installed, connect the plug of the AC adapter to the AC outlet

while holding down the RESET button.

-2 Release the RESET button, press it down again within 5 seconds and release it.

pen the front cover and install the

-3

-4 Hold down the RESET button for 2 seconds or more and release it.

-5 Close the front cover.

-6 The printer starts service test printing.

Press and hold the RESET botton for 2 seconds or more

( while the AC plug is plugged in) :Approx.20seconds.)

( while the AC plug is plugged in)

-20

cartridge

*2 EEPROM reset / Destination setting

-1 Without the cartridge installed, connect the plug of the AC adapter to the AC outlet

while holding down the RESET button.

-2

Release the RESET button, press it down again within 5 seconds and release it.

-3 Hold down the RESET button for 2 seconds or more and release it.

-4

< EEPROM Reset > < Destination setting >

Hold down the RESET button for 2 secs or more. -Japan Press the RESET button once.

-Others Press the RESET button twice

-SP Press the RESET button 3 times

After the button is pressed, the carriage will move same time

as the number of times the RESET button is pressed.

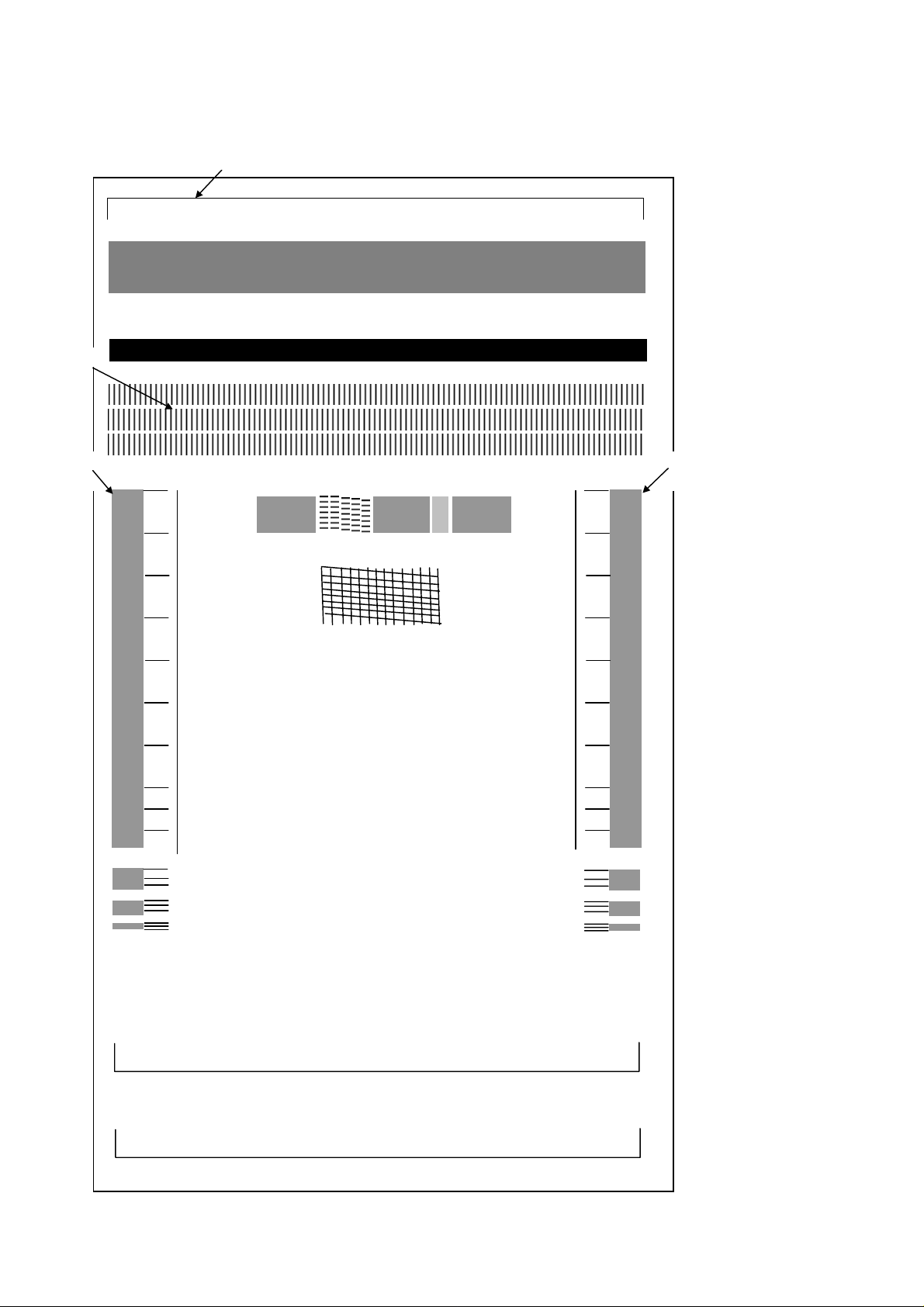

*3 Print sample of 'Service test print'

You can check the EEPROM setting by 'Service test print'.

Control ROM Version

Amount of waste ink

ROM Ver X.XX BC-20 Lost Ink XX.X% Page count-->BK XXXX PB XXXX CL XXXX VC XXXX LD XXXX VL XXXX SC

CG ROM Ver X.XX BJYYYYY Wiping yyyy Manual purge yyyy Dry time : OFF Purge Flag : yyy Door :

close

Destination setting Page counts of

Japan BJ F210

SP BJC-2100SP

Others BJC-2100

SC IS-22(Scanner)

VL BC-22e

VC BC-21e

BK BC-20

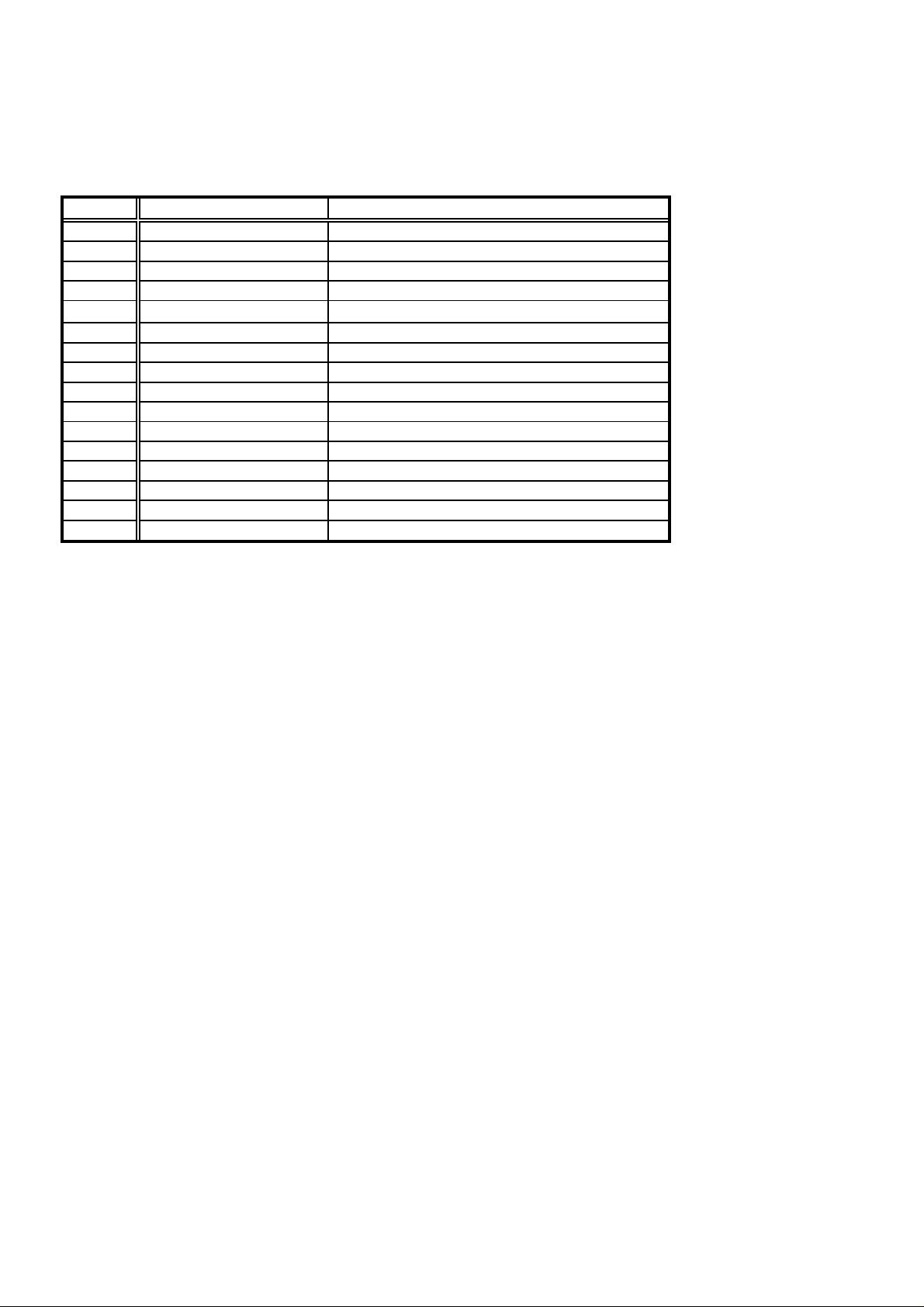

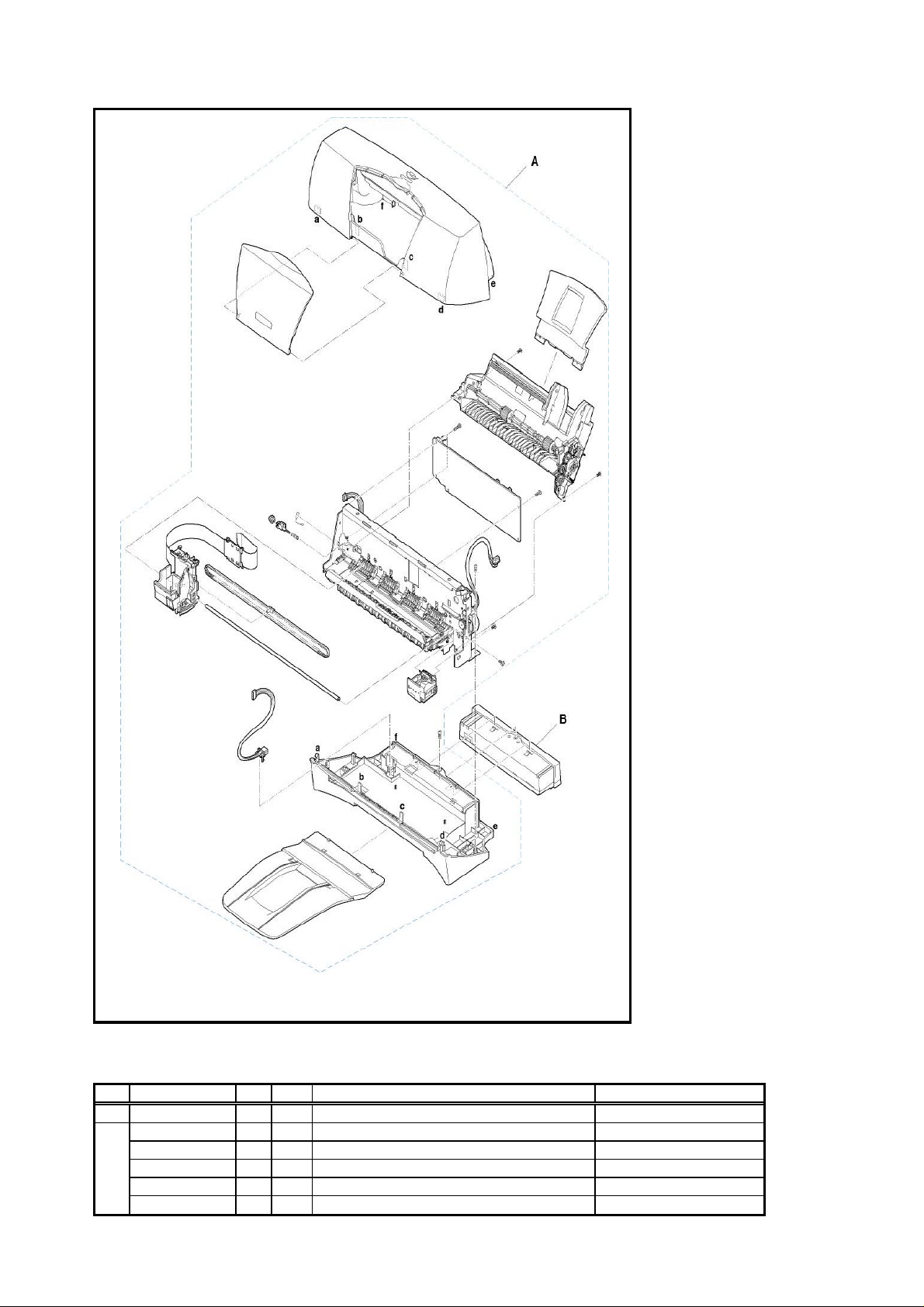

5. External View / Parts List

••••

Parts List

Key Part Number Rank Q'ty Description Remarks

A Q10-1001-710 N 1 WHOLE UNIT, W/O CARTRIDGE CONTAINER

B QH3-3397 1 AC Adapter 100/120V 50/60HZ LV(USA,CANADA,JAPAN)

QH3-3400 1 AC Adapter 100/120V 50/60HZ HV(Europe)

QH3-3403 1 HV(CHN,ASIA,AUS)

QH3-3404 1 LV(KRN)

QH3-3406 1 HV(TWN)

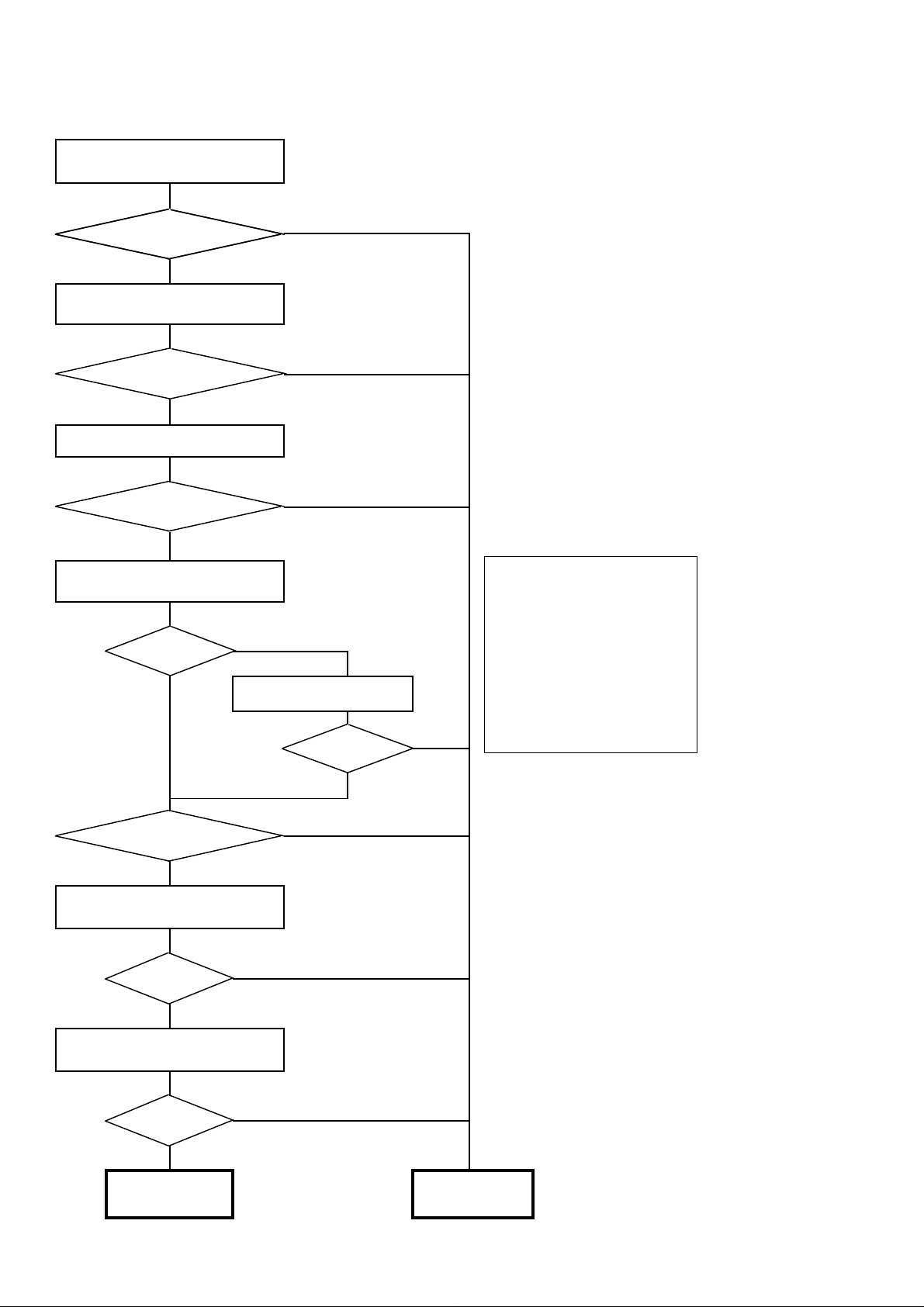

6. H/W Troubleshooting Flowchart

y)

(Confirmation of the printer when refurbishing)

Insert the AC adapter

Doe the CR/LF motor ˝move noisely?

Yes

Open the front cover

Does the CRG move to the

head replacement position?

Yes

Install the print head

Close the front cover

Is purging operation

performed? (Auditoril

Yes

Print the "Service Test Print"

Correct?

Yes

Replace the print-head and

re-print the "service test print".

No

No

No

* Refer to "4.Service Mode"

regarding printing method.

No

Correct ?

<Check items of "Service Test Print">

(Refer to the attached sample)

1) Non ejection of ink

Yes ----------------------------> NG

2) Top margin:

Outside of paper -------------> NG

3) Line

Not connexted ----------------> NG

4) Gray part

If there is black/white line ---> NG

No

No Yes

Is the waste ink capacity

10% or higher ?

Yes

Connect the computer

with the PARALLEL I/F

Possible to

print ?

No

Yes

Connect the computer

with the USB I/F

Possible to

print ?

No

Yes

Normal Defective

7. Service Information

m

Y

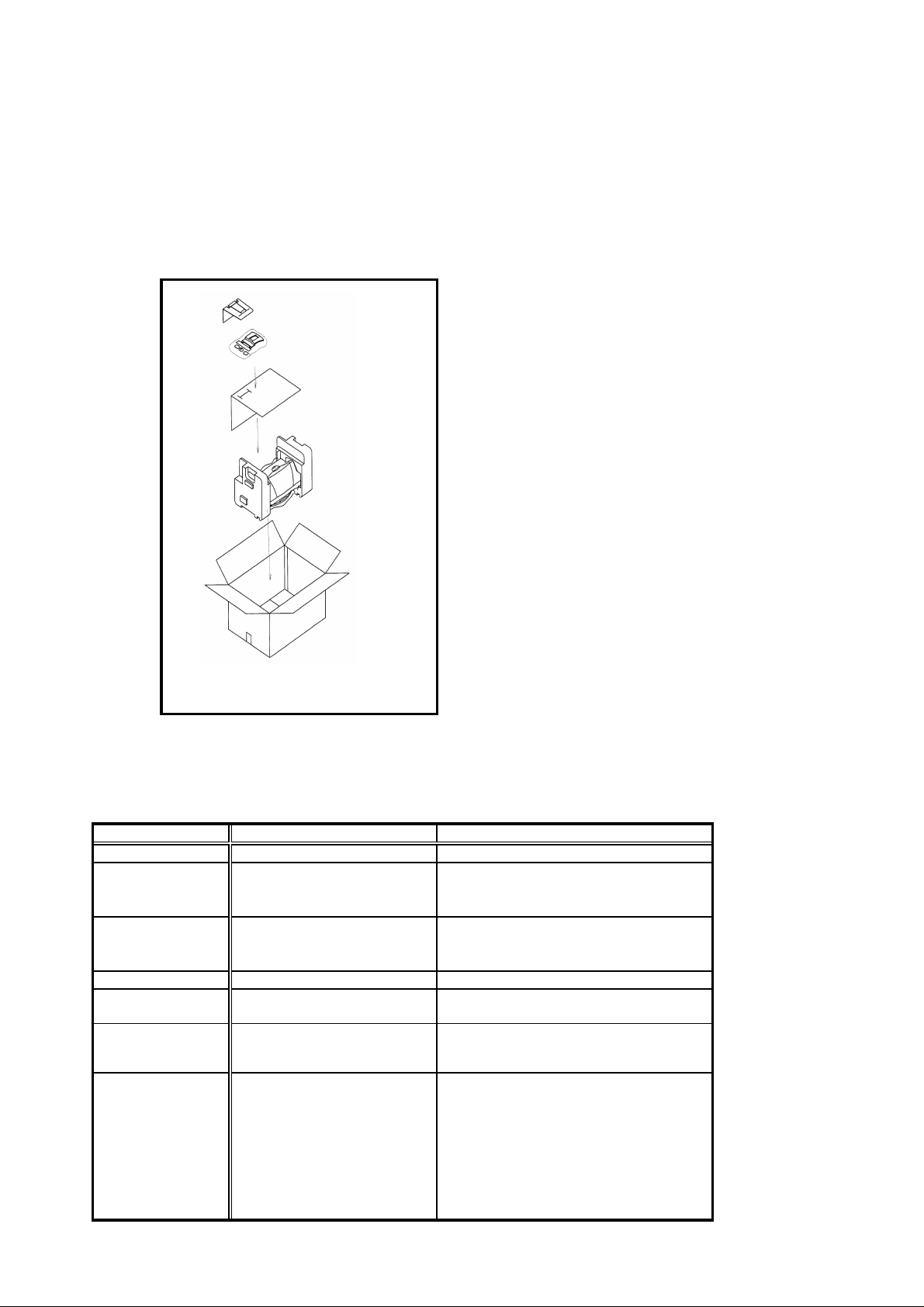

7.1 Replacement using whole unit

Whole Unit (WHOLE UNIT, W/O CARTRIDGE CONTAINER : Q10-1001-710)

1 Remove the AC adapter from the printer returned from the user.

2 Install the removed AC adapter in the whole unit.

3 Affix the product name label. (The label has been packaged with whole unit)

4 Do 'destination setting'. (See "4.Service Mode" for detail)

< Composition of WHOLE UNIT, W/O CARTRIDGE CONTAINER>

Enclosure

•••• Printer unit (No product name label / No AC adapter)

Paper pick-up tray

Paper output tray

Product name labels

Packing material

7.2 Difference from the BJC-2000/2000SP

BJC-2000/2000SP BJC-2100/2100SP

I/F Parallel I/F Only Parallel and USB I/F

External Color One color Two-toned color

Bottom case, Paper output tray

Others

Paper output tray Composed of 3 parts Composed of 2 parts

Elastic Folding

2 flaps No flaps

Spur 13 pcs 7 pcs

Power Supply 30W 18W

Power consumption Max

Product Life Whichever of the following comes first

Auto cleaning

(Auto purge)

Turned On

Replace cartridge

Replace Ink tank

Timer(72Hr)

Print dot count

Cover open 10min

By RESET button

Whichever of the following comes first

Color :6,000 sheets Color :3,000 sheets

Monochro

Yes No

Yes <--

Yes <--

Yes (By internal timer) Yes (By internal timer or time data from P.C.)

Yes <--

Yes <--

es <--

:20,000 sheets Monochrome :10,000 sheets

:Gray

:Current color

Attached Sample (Service Test Print)

Check i

All

tem 1 (Non ejection of ink) :

area of the sample as below

Check item 2 (Top margin)

ROM Ver x.xx BC-20 LostInk xx.x% PageCount -> BK xxxxx PB xxxxx CL xxxxx VC xxxxx LD xxxxx VL xxxxx SC xxxxx

CG Ver 1.00 BJxxxxx Wiping xxxxxxk ManualPurge xxxxx DryTime : OFF PurgeFlag : xxx Door : CLOSE USBSerialNo. Xxxxxx

Check item 3

(Line)

Check item 4 Check item 4

(Gray part) (Gray part)

XX XX XX XX XX XX XX XX XX XX

XX

XX XX XX XX XX XX XX XX XX XX

XX

XX XX XX XX XX XX XX XX XX XX

XX

XX XX XX XX XX XX XX XX XX XX

XX

XX XX XX XX XX XX XX XX XX XX

XX

XX XX XX XX XX XX XX XX XX XX

XX

Paper size :

REVISION 0

QY8-1362-000

OCT. 1998

COPYRIGHT 1998 CANON INC. CANON BJC-2000 1098 SC 0.40-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

1098 SC 0.40-0

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not apply to

your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or

changes in the products. When changes occur in applicable products or in the content of this

manual, Canon will release technical information as the need arises. In the event of major changes in

the contents of this manual over a long or short period, Canon will issue a new editions of this

manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of

the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not

be copied, reproduced or translated into another language, in whole or in part, without the written

consent of Canon Inc., except in the case of internal business use.

Copyright 1998 by Canon Inc.

CANON INC.

BJ Products Technical Support Dept

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 8500/180 personal computer and

Apple LaserWriter 16/600PS-J laser beam printer; final pages were printed on Varityper 5300 with

4000-J RIP. All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I. ABOUT THIS MANUAL

This manual is divided into four sections, and contains information required for servicing

the unit.

Part 1: Saf ety and Precautions

This section tells you how to service the unit safely. It is very important, so please read

it.

Part 2: Product Specifications

This section outlines and specification.

Part 3: Operating Instructions

This section explains how to operate the unit properly. Information required about

installation and service made.

Part 4: Technical Reference

This section outlines the way the unit operates so you can understand it technically.

Part 5: Maintenance

This section explains how to maintain the unit. Descriptions of assembly/disassembly,

adjustment for assembly, troubleshooting procedures, and wiring/circuit diagrams are

given.

Procedures for assembly/disassembly are not given in this manual.

See the illustrations in the separate Parts Catalog.

I

REF.

II. TABLE OF CONTENTS

Page

Part 1: Safety and Precautions

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Ink Stains

1 - 2 1.2.1 Ink path

1 - 3 1.2.2 Ink mist

1 - 4 1.3 BJ Car tridge Heat-Up

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Precautions for Handling BJ Cartridges

1 - 5 2.1.1 Turning the printer ON/OFF

1 - 5 2.1.2 When the printer is not in use

1 - 5 2.1.3 Transpor tation precautions

1 - 5 2.1.4 Ink electroconductivity

1 - 6 2.2 Printer Precautions

1 - 6 2.2.1 Spur deformation prevention

1 - 6 2.2.2 Static electricity damage prevention

1 - 7 3. PRECAUTIONS FOR SERVICE

1 - 7 3.1 EEPROM Data Precautions

1 - 8 3.2 Static Electricity Precautions

1 - 8 3.3 Disassembly and Reassembly Precautions

1 - 8 3.4 Self-Diagnosis

Part 2: Product Specifications

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 3 1.3.1 Color BJ cartridge (Multi-Drop)

2 - 3 1.3.2 Black BJ cartridge

2 - 3 1.3.3 Photo BJ cartridge (Multi-Drop)

2 - 4 1.4 BJ Cartridge Container

2 - 4 1.5 Consumables

2 - 4 1.5.1 BJ cartridges (Color, Black, Photo)

2 - 4 1.5.2 Ink car tridge (Color BJ cartridge)

2 - 5 1.6 Option

2 - 5 1.6.1 Color image scanner cartridge

2 - 5 1.6.2 Scanning holder

2 - 5 1.6.3 White calibration sheet

2 - 6 2. SPECIFICATIONS

2 - 6 2.1 Printer Specifications

2 - 9 2.2 Scanner Cartridge Specifications (Option)

2 -10 2.3 Paper Specifications

2 -10 2.3.1 Paper size

2 -10 2.3.2 Paper type (Recommended)

2 -10 2.3.3 Paper setting

2 -11 2.3.4 Printable area

2 -12 2.4 Interface Specifications

Part 3: Operating Instructions

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Equipment Check

3 - 2 1.2 Printer Dimensions

3 - 3 1.3 Setup Procedure

II

Page

3 - 3 1.3.1 Connecting the interface cable

3 - 3 1.3.2 Turning on the printer

3 - 4 1.3.3 Installing the cartridge

3 - 6 1.3.4 Scanner cartridge precautions

3 - 7 1.3.5 Replacing the ink car tridge

3 - 9 1.3.6 BJ cartridge container

3 -10 1.4 Turning the Printer On/Off

3 -10 1.4.1 Turning the printer on

3 -10 1.4.2 Tur ning the printer off

3 -11 1.5 Paper Settings

3 -11 1.6 Banner Printing

3 -12 1.7 Scanning Precautions

3 -13 1.8 Name of the Parts and Their Functions

3 -15 2. PRINTER SERVICING FUNCTIONS

3 -15 2.1 Error Indications

3 -17 2.2 Cleaning the BJ Cartridge

3 -17 2.3 Self-Test Printout

3 -17 2.3.1 Nozzle check pattern

3 -18 2.3.2 Ser vice test print

3 -19 2.4 EEPROM Reset

3 -19 2.4.1 EEPROM Reset

3 -19 2.4.2 Printing the EEPROM data

Part 4: Technical Reference

4 - 1 1. OVERVIEW

4 - 1 1.1 Printer Diagram

4 - 2 1.2 Print Signal Flow

4 - 3 1.3 Print Drive

4 - 3 1.3.1 Printing drive control

4 - 5 2. FIRMWARE

4 - 5 2.1 720 dpi Printing Feature

4 - 5 2.1.1 Canon extended mode

4 - 6 2.2 Printing Modes

4 - 6 2.2.1 Printing mode

4 - 6 2.2.2 Photo print mode

4 - 6 2.2.3 Multi-drop print mode

4 - 8 2.3 Optimum Printing Direction Control

4 - 8 2.4 Ink Smear Control

4 - 8 2.5 Head Overheating Protection Control

4 - 9 3. PRINTER MECHANICAL SYSTEM

4 - 9 3.1 Overview

4 - 9 3.1.1 Mechanical components

4 -10 3.2 BJ Cartridge

4 -10 3.2.1 Black BJ cartridge structure

4 -11 3.2.2 Color BJ cartridge structure

4 -12 3.2.3 Photo BJ car tridge structure

4 -13 3.2.4 Bubble head unit structure

4 -17 3.3 Purge Unit

4 -17 3.3.1 Purge unit functions

4 -18 3.3.2 Purge unit structure

4 -19 3.4 Carriage

4 -19 3.4.1 Carriage functions

4 -20 3.4.2 Carriage structure

4 -22 3.5 Paper Feed

III

Page

4 -22 3.5.1 Outline of the paper feed

4 -23 3.5.2 Structure of the sheet feeder

4 -24 4. PRINTER ELECTRICAL SYSTEM

4 -24 4.1 Overview

4 -25 4.2 Logic Section

4 -25 4.2.1 Logic section block diagram

4 -26 4.2.2 Logic section components

4 -28 5. SENSOR FUNCTIONS

4 -28 5.1 Pick-Up Roller Sensor

4 -28 5.2 Paper End Sensor

4 -28 5.3 Home Position Sensor (Purge Sensor)

4 -28 5.4 Temperature Sensor

4 -29 5.5 Head Temperature Sensor

4 -29 5.6 Waste Ink Amount Detection

4 -30 6. SCANNER CARTRIDGE

4 -30 6.1 Scanner Cartridge Overview

4 -30 6.1.1 Block diagram

4 -31 6.2 Scanner Cartridge Structure

4 -33 6.3 Signal Contacts

4 -33 6.4 Scan Mode

4 -33 6.5 Calibration

Part 5: Maintenance

5 - 1 1. MAINTENANCE

5 - 1 1.1 Parts for Regular Replacement

5 - 1 1.2 Consumables

5 - 1 1.3 Periodic Maintenance

5 - 2 2. SERVICING TOOLS

5 - 2 2.1 List of Tools

5 - 3 3. GREASE APPLICATION

5 - 4 4. DISASSEMBLY AND REASSEMBLY

5 - 4 4.1 Disassembly and Reassembly

5 - 4 4.2 Disassembly and Reassembly Cautions

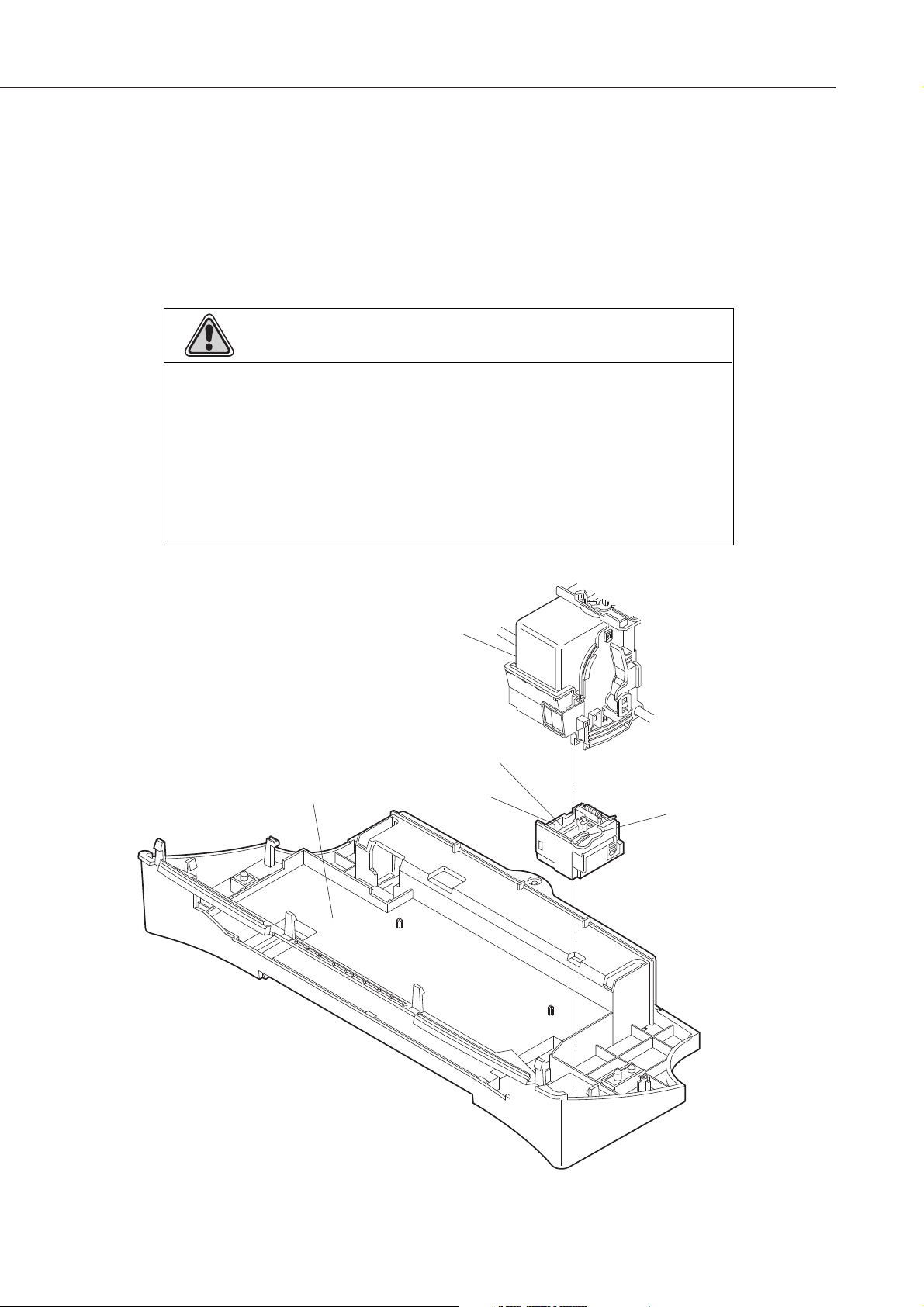

5 - 5 4.3 Logic Board and Bottom Cover Replacement Cautions

5 - 5 4.3.1 Logic board replacement cautions

5 - 5 4.3.2 Cautions after replacing the bottom cover

5 - 6 5. TROUBLESHOOTING

5 - 6 5.1 Troubleshooting

5 - 6 5.1.1 Overview

5 - 6 5.1.2 Troubleshooting cautions

5 - 8 5.2 Error Condition Diagnosis

5 - 8 5.2.1 Initial self check

5 -10 5.2.2 Error recovery

5 -23 6. LOCATION & SIGNAL ASSIGNMENT

5 -23 6.1 Logic Board

5 -25 6.2 Carriage Ribbon Cable

5 -26 6.3 BJ Cartridge & Scanner Cartridge

5 -28 7. CIRCUIT DIAGRAMS

5 -28 7.1 Parts Layout

5 -28 7.1.1 Logic board

IV

III. ILLUSTRATION INDEX

Page

1 - 1 Figure 1- 1 Moving Parts of the Printer

1 - 2 Figure 1- 2 Ink Path

1 - 3 Figure 1- 3 Ink Path of the BJ Cartridge

1 - 3 Figure 1- 4 Ink Mist

1 - 4 Figure 1- 5 BJ Car tridge Aluminum Plate

1 - 6 Figure 1- 6 Spurs and Spur Cleaners

1 - 6 Figure 1- 7 Carriage Ribbon Cable’s Electrical Contacts

1 - 8 Figure 1- 8 Electrical System of Printer

1 - 8 Figure 1- 9 How to Release Plastic Hooks

2 - 1 Figure 2- 1 Printer Exterior

2 - 3 Figure 2- 2 Color BJ Cartridges

2 - 4 Figure 2- 3 BJ Cartridge Container

2 - 4 Figure 2- 4 Ink Car tridges

2 - 5 Figure 2- 5 Scanner Cartridge

2 - 5 Figure 2- 6 Scanning Holder

2 -11 Figure 2- 7 Printing Area

2 -11 Figure 2- 8 Printing Area (Envelope)

2 -11 Figure 2- 9 Printing Area (Banner Paper)

2 -18 Figure 2-10 Timing Chart (Compatible Mode)

2 -19 Figure 2-11 Timing Chart (Nibble Mode)

2 -20 Figure 2-12 Timing Chart (ECP Mode)

3 - 1 Figure 3- 1 Packaging

3 - 2 Figure 3- 2 Printer Dimension

3 - 3 Figure 3- 3 Connecting the Interface Cable

3 - 4 Figure 3- 4 Removing the BJ Cartridge Protectors

3 - 4 Figure 3- 5 BJ Cartridge Handling Precautions

3 - 5 Figure 3- 6 Cartridge Installation

3 - 6 Figure 3- 7 Scanner Car tridge

3 - 7 Figure 3- 8 Removing the Ink Cartridge

3 - 8 Figure 3- 9 Removing the Ink Cartridge Cap

3 - 8 Figure 3-10 Ink Cartridge Protection

3 - 9 Figure 3-11 BJ Cartridge Container

3 -10 Figure 3-12 Never unplug the power cord less than one minute after completing

an operation

3 -11 Figure 3- 13 Banner Printing

3 -12 Figure 3-14 Scanning Holder

3 -13 Figure 3-15 Name of the Parts and Their Functions

3 -14 Figure 3-16 Name of the Parts and Their Functions

3 -14 Figure 3-17 Paper Thickness Lever

3 -17 Figure 3-18 Nozzle Check Pattern

3 -18 Figure 3-19 Service Test Print

4 - 1 Figure 4- 1 Printer Diagram

4 - 2 Figure 4- 2 Printing Signal Flow

4 - 3 Figure 4- 3 Printing Sequence (Black BJ Cartridge/HQ Mode)

4 - 4 Figure 4- 4 Printing Signals

4 - 5 Figure 4- 5 720 dpi Printing Feature

4 - 9 Figure 4- 6 Printer’s Mechanical Configuration

4 -10 Figure 4- 7 Black BJ Cartridge Structure

4 -11 Figure 4- 8 Color BJ Cartridge Structure

4 -12 Figure 4- 9 Photo BJ Cartridge Structure

4 -13 Figure 4-10 Bubble Jet Nozzles (Partial View)

4 -14 Figure 4-11 Nozzle Arrangement

V

Page

4 -14 Figure 4-12 Black BJ Cartridge Block Diagram

4 -15 Figure 4-13 Color (Multi-Drop)/Photo (Multi-Drop) BJ Car tridge Block Diagram

4 -18 Figure 4-14 Purge Unit

4 -19 Figure 4-15 Carriage

4 -20 Figure 4- 16 Paper Thickness Adjustment

4 -21 Figure 4-17 Paper Feed Motor Drive Transmission

4 -22 Figure 4-18 Paper Feed Mechanism

4 -23 Figure 4-19 Paper Pick-Up Mechanism

4 -24 Figure 4-20 Printer Electrical System

4 -25 Figure 4-21 Logic Board Block Diagram

4 -25 Figure 4-22 Printer Block Diagram

4 -28 Figure 4-23 Sensors

4 -30 Figure 4-24 Scanner Cartridge

4 -30 Figure 4- 25 Block Diagram

4 -31 Figure 4-26 Scanner Cartridge

5 - 3 Figure 5- 1 Grease Application Points

5 - 5 Figure 5- 2 Bottom Cover

5 -23 Figure 5- 3 Logic Board

5 -25 Figure 5- 4 Carriage Ribbon Cable

5 -26 Figure 5- 5 Contact Pad

5-28 Figure 5- 6 Logic Board (Top View)

VI

IV. TABLE INDEX

Page

3 -11 TABLE 3- 1 QUICK REFERENCE FOR SETTING

3 -15 TABLE 3- 2 ERROR INDICATIONS

3 -19 TABLE 3- 3 DEFAULT SETTING WHEN RESETTING THE EEPROM

4 - 7 TABLE 4- 1 PRINTING MODES AND HEATING METHODS

4 -16 TABLE 4- 2 HEAD INSTALLATION STATUS AND SIGNAL DETECTION

4 -17 TABLE 4- 3 INK CONSUMPTION DURING CLEANING (AS A STANDARD)

4 -29 TABLE 4- 4 LIST OF SENSOR FUNCTIONS

4 -33 TABLE 4- 5 LIST OF SCAN MODE

VII

This page intentionally left blank

VIII

Page

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Ink Stains

1 - 4 1.3 BJ Cartridge Heat-Up

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Precautions for Handling BJ Cartridges

1 - 6 2.2 Printer Precautions

1 - 7 3. PRECAUTIONS FOR SERVICE

1 - 7 3.1 EEPROM Data Precautions

1 - 8 3.2 Static Electricity Precautions

1 - 8 3.3 Disassembly and Reassembly Precautions

1 - 8 3.4 Self-Diagnosis

Part 1

SAFETY AND

PRECAUTIONS

1. SAFETY PRECAUTIONS

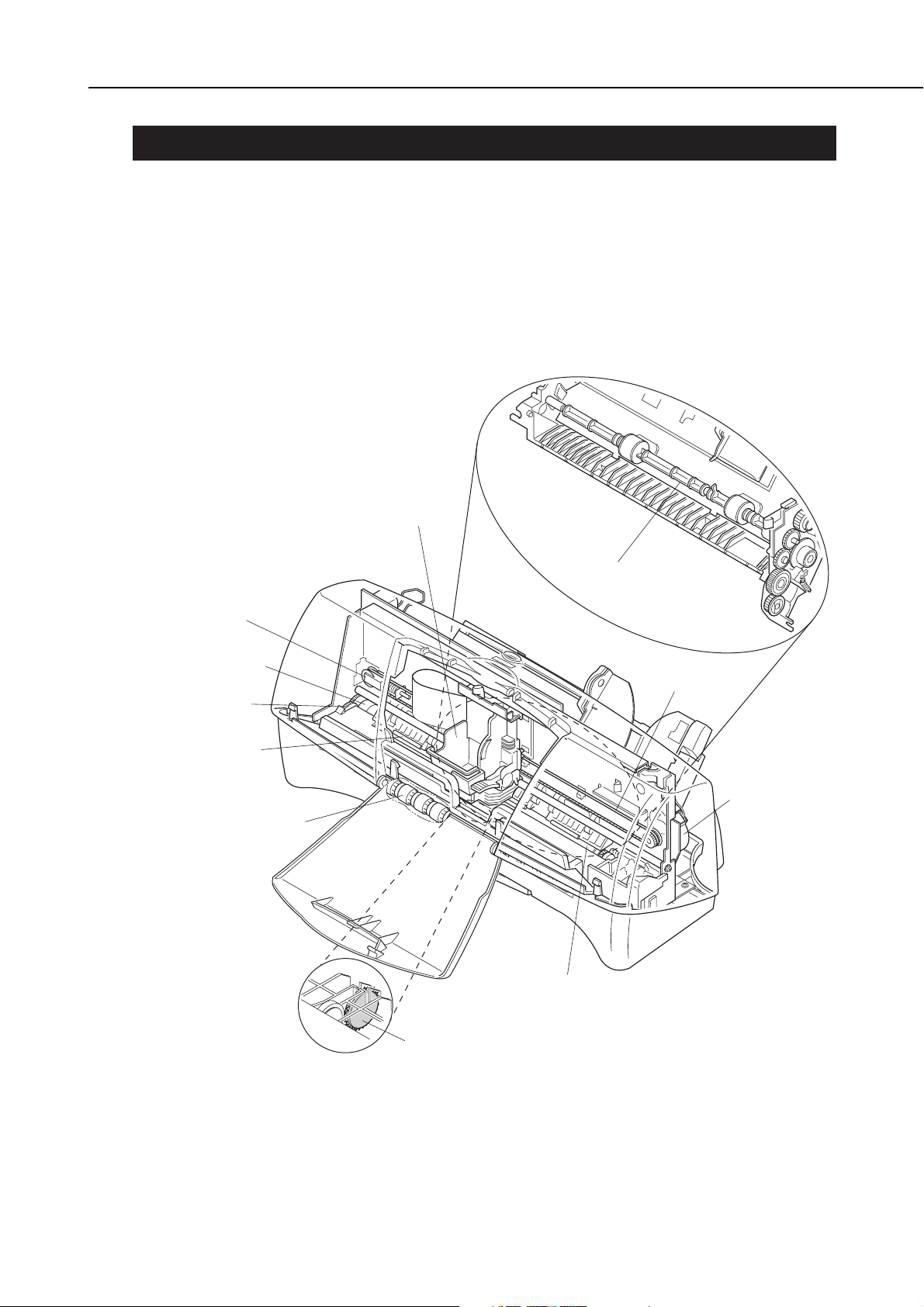

1.1 Moving Parts

The moving parts of the printer are shown below. They include the carriage belt, idler

roller, carriage, slow down gear, paper feed roller, pressure roller, eject roller, spurs,

and pick-up roller. The first three parts above are driven by the carriage motor while

the latter are driven by the paper feed motor. Avoid getting hair, clothing, jewelry, etc.,

caught in these moving parts.

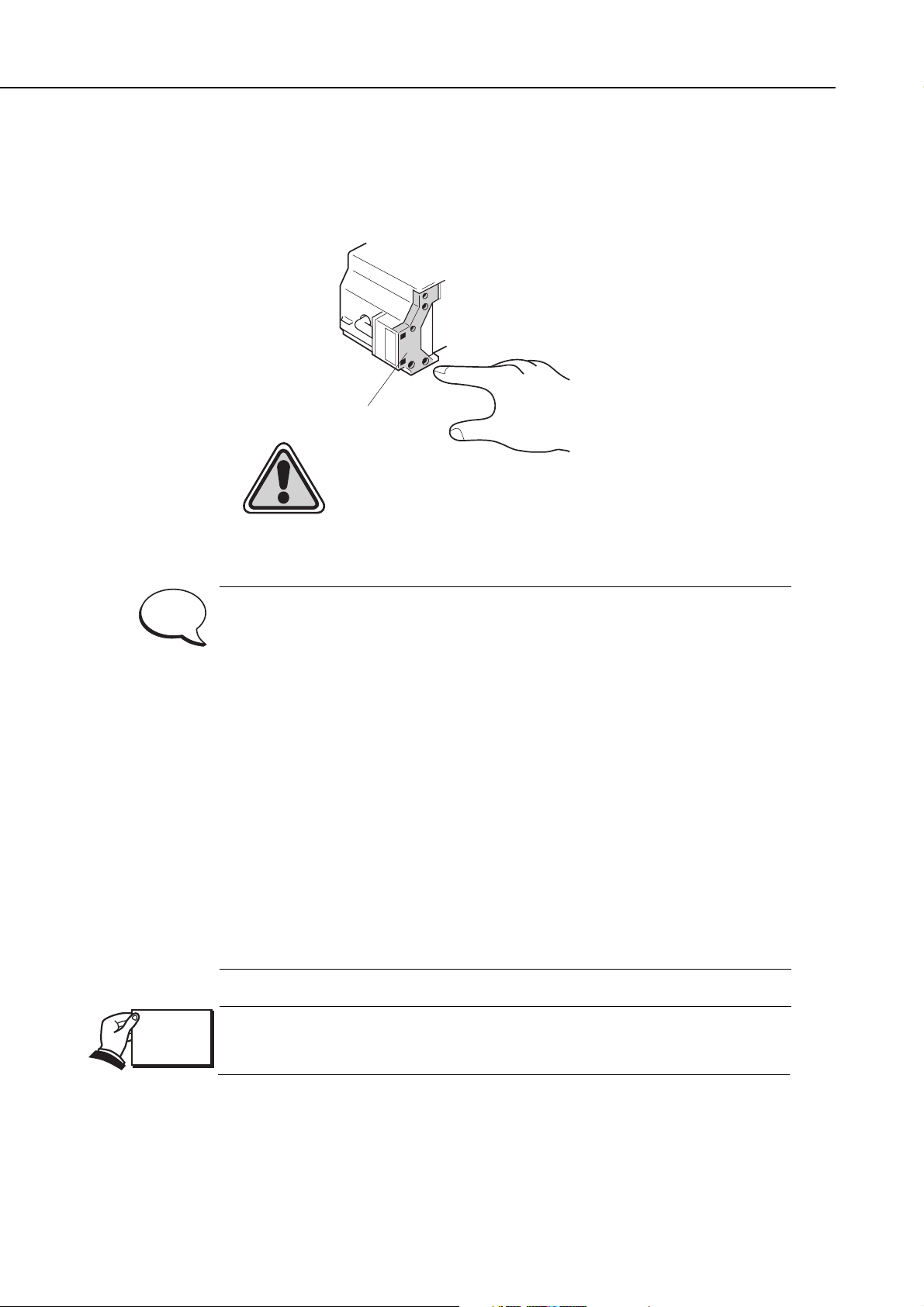

Also note that the spurs are made of metal and have sharp edges. Avoid touching the

spurs with bare hands.

Part 1: Safety and Precautions

BJC-2000

1-1

Figure 1-1 Moving Parts of the Printer

Carriage

Idler Roller

Paper Feed Motor

Slow Down Gear

Pressure Rollers

Eject Roller

Pick-up Roller

Carriage Belt

Carriage Motor

Paper Feed Roller

Spurs

1.2 Ink Stains

1.2.1 Ink path

Do not touch the ink path while servicing as the ink can stain hands, work table,

clothing, etc.

The ink path consists of the BJ cartridge nozzles, head cap, head wiper, maintenance

jet receiving section, and waste ink absorber.

In the case of color BJ cartridges, the cartridge’s ink outlets and joint pipes are also

part of the ink path.

Part 1: Safety and Precautions

BJC-2000

1-2

Figure 1-2 Ink Path

Caution!

Although the ink is non-toxic, it contains organic solvents.

Isopropyl alcohol 67-63-0, glycerin 56-81-5, and ethyleneglycol 107-21-1

in black ink and isopropyl alcohol 67-63-0 in color inks. Do not get ink in

your eyes and mouth. If any ink should get into your eyes, wash with

plenty of water and consult a doctor. If a large amount of the ink is

consumed, consult a doctor immediately.

Give the doctor the information on the BJ cartridge label. Since the ink

contains dyes, any ink stains on clothing, etc., are permanent.

Waste Ink Absorber

BJ Cartridge

Head Wiper

Maintenance Jet

Receiving Section

Head Cap

1.2.2 Ink mist

The BJ cartridge ejects ink onto the paper. During prolonged or heavy-duty use of the

printer, small amounts of ink mist which splatter off paper during printing can

contaminate the inside of the front cover and platen.

Clean any contaminated parts with a soft moist cloth. Ink in such areas can

contaminate the back of the paper and dirty hands and clothing while servicing.

Part 1: Safety and Precautions

BJC-2000

1-3

Figure 1-3 Ink Path of the BJ Cartridge

Figure 1-4 Ink Mist

Black BJ Cartridge Color BJ Cartridge

Color Ink Cartridge

Ink Outlet

Nozzles

Joint Pipe

Nozzles

Joint Pipe

Black Ink Cartridge

Ink Outlet

Platen

Front Cover

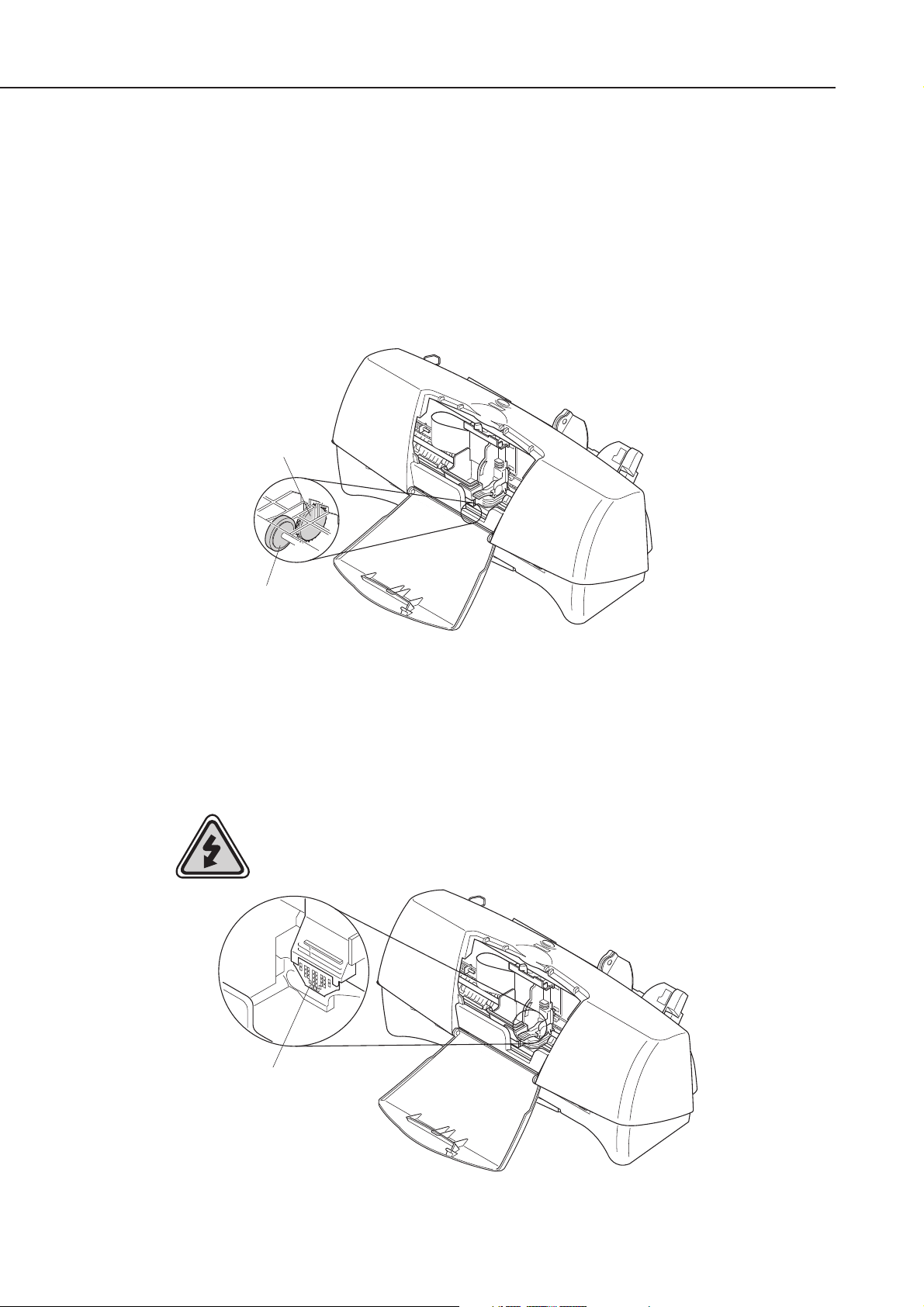

1.3 BJ Cartridge Heat-Up

Do not touch the BJ cartridge’s aluminum plate. The aluminum plate heats up during

printing and becomes particularly hot during prolonged and continuous printing. It can

overheat also if printing is continued even after the cartridge has run out of ink.

The printer has a protective mechanism when the BJ cartridge heats up.

The protective mechanism is activated when the head temperature (diode)

sensor in the BJ cartridge senses a certain temperature.

Protection level 1:

This level prevents the user from touching the bubble jet head’s hot

aluminum plate when the bubble jet head is replaced. For this

purpose, when the front cover is opened, the carriage will not move to

the cartridge replacement position. Close the front cover, leave the

printer inactive for a few minutes to allow it to cool, and then open the

front cover again to perform the required operation.

Protection level 2:

If a high temperature is still detected, the carriage is returned to the

home position for 3.5 seconds to bring down the temperature. After the

resting period, printing will resume. This continues for over 20 seconds

to lower the bubble jet head’s temperature.

Protection level 3:

If the temperature continues to increase, a head temperature error

occurs. This stops the printing operation.

When printing is stopped by a head temperature error or a head

temperature sensor error, follow the troubleshooting procedures in

Part 5:

5.TROUBLESHOOTING (page 5-6).

Part 1: Safety and Precautions

BJC-2000

1-4

Figure 1-5 BJ Cartridge Aluminum Plate

Aluminum Plate

Caution! High Temperature!

NOTE

REF.

2. MACHINE PRECAUTIONS

2.1 Precautions for Handling BJ Cartridges

2.1.1 Turning the printer ON/OFF

The printer will automatically cap the cartridge heads one minute after printing

operations are completed, to prevent the ink from leaking and drying out.

When unplugging the power cord, wait at least one minute after completing an

operation such as printing, feeding paper, cleaning the print head, etc.

If the power cord is accidentally unplugged before one minute has passed, replug the

AC adapter, and wait for more than one minute before unplugging the power cord.

If the nozzles are not capped, the ink may leak and dry out causing the

nozzles to clog.

2.1.2 When the printer is not in use

BJ cartridges should be stored either installed in the printer or in the BJ cartridge

container.

If the BJ cartridge is removed from the printer or BJ Cartridge Container,

the ink may leak and dry out causing the nozzles to clog.

2.1.3 Transportation Precautions

When carrying or transporting the printer, keep the BJ cartridge stored in the BJ

cartridge container.

This prevents the ink from leaking and drying out in the nozzles.

2.1.4 Ink electroconductivity

The ink in the BJ cartridge is electroconductive. If ink leaks into the printer’s

mechanical parts, use a damp paper towel, etc., to wipe clean. If it leaks into the

printer’s electrical components, use tissue paper, etc., to wipe clean completely. If ink

gets into the IC chips on the PCB and it is difficult to clean, replace the PCB.

If ink has leaked inside the printer, do not plug in the power cord. It may

damage the circuitry.

Part 1: Safety and Precautions

BJC-2000

1-5

CAUTION

CAUTION

CAUTION

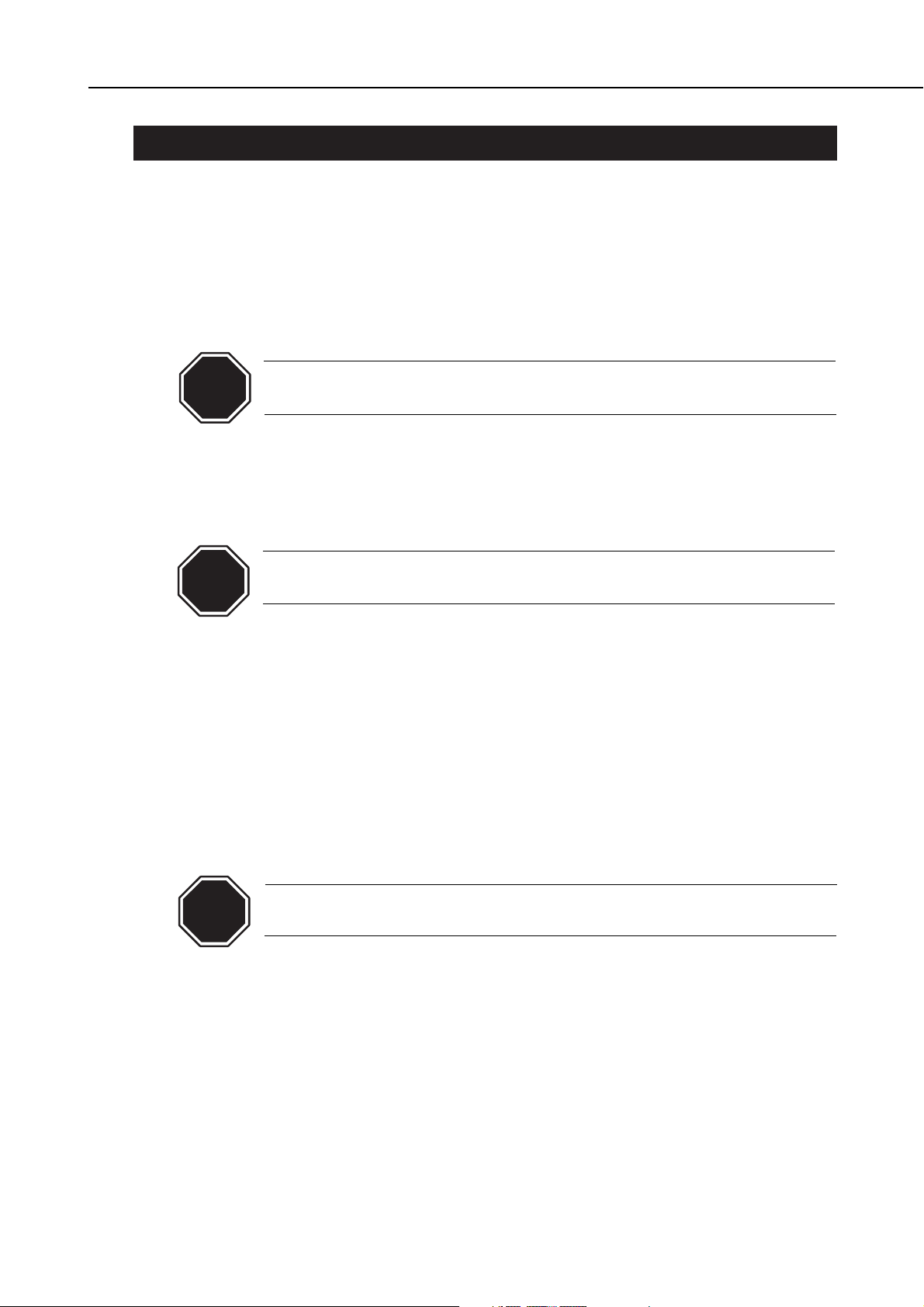

2.2 Printer Precautions

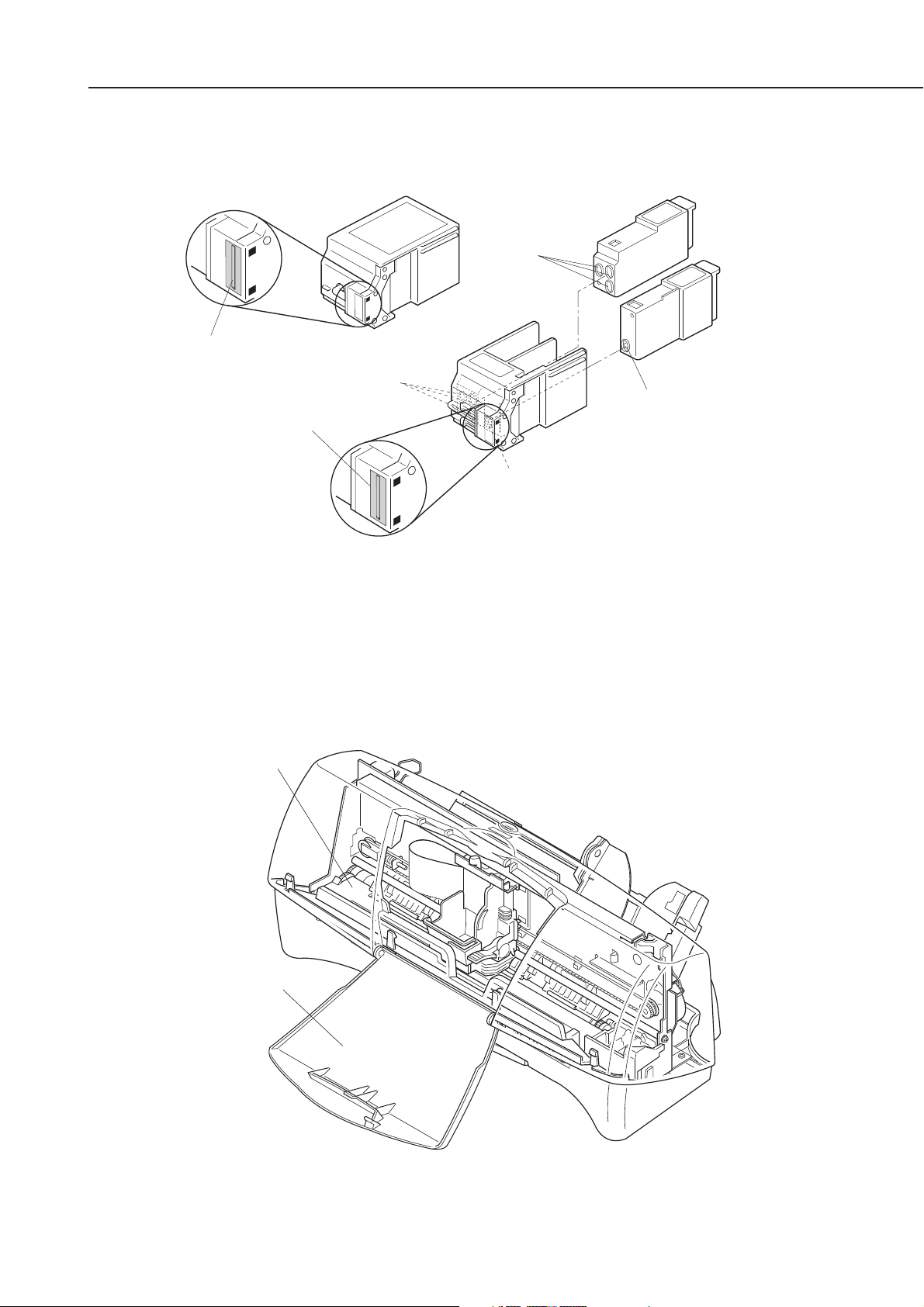

2.2.1 Spur deformation prevention

Do not deform the tips of the spurs.

The spurs come into contact with the paper after printing. As the actual contact

surface is small, any ink adhering to the spurs is minute and wiped off by the spur

cleaners. Therefore any ink on the spurs is not enough to contaminate the paper as it

passes. However, if the spurs become deformed, their contact surface with the paper

increases, causing more ink to adhere to each spur. Since the spur cleaner is unable

to wipe off all the ink, a line of dotted ink may mask the printed paper.

2.2.2 Static electricity damage prevention

The static charge that accumulates from clothing, etc., can damage electrical

components. Therefore, never touch the electrical contacts of the carriage ribbon

cable and BJ cartridge.

Part 1: Safety and Precautions

BJC-2000

1-6

Figure 1-6 Spurs and Spur Cleaners

Figure 1-7 Carriage Ribbon Cable’s Electrical Contacts

Spurs

Spur Cleaners

Electrostatic Discharge!

Contact Points

Part 1: Safety and Precautions

BJC-2000

1-7

3. PRECAUTIONS FOR SERVICE

3.1 EEPROM Data Precautions

The printer keeps track of various settings, the total waste ink amount, and the total

sheets printed with the black, color and photo BJ cartridges. This data is stored in the

EEPROM on the logic board. Note the following precautions during servicing:

1) Before servicing

Check the EEPROM data with a test print. The total sheets printed can give you an

idea of how much the printer has been used.

2) During logic board (EEPROM) replacement

Always visually check the waste ink amount absorbed by the waste ink absorbers

and replace them when necessary as explained in

Part 5: 4.3 Logic Board and Bottom

Cover Replacement Cautions (page 5-5).

If the waste ink absorbers are not visually checked regularly, they may reach or

exceed their full capacity before “waste ink full” is detected. The waste ink may

therefore start leaking.

The memory data for the replacement logic board (EEPROM) is not defined.

Therefore, after replacing the logic board (and EEPROM), reset the total waste ink

amount to zero by clearing the data.

3) After waste ink absorber replacement

After replacing the waste ink absorbers, reset the total waste ink amount to zero by

clearing the EEPROM data.

After the EEPROM is reset, the data it contained cannot be printed out

with a test printout. If you want to check the stored data, be sure to

execute test printout before resetting the EEPROM.

When the stored data is reset, the various settings, the total count of

printed sheets, and the total waste ink amount will all be reset. The total

sheets printed and waste ink amount cannot be input using the operation

panel.

Immediately after the printer is turned on, it keeps track of the estimated

waste ink amount based on the usage conditions. To prevent ink leakage

when the waste ink amount exceeds the waste ink absorption capacity, the

printer stops printing and indicates an error when the waste ink

absorption capacity is close to being full.

For details on checking the EEPROM data with a test printout and for

clearing the data, see

Part 3: 2.4 EEPROM Reset (page 3-19)

.

If the printer stops operating in the case of a waste ink full error, follow the

countermeasures described in

Part 5: 5.1 Troubleshooting (page 5-6)

.

CAUTION

REF.

Loading...

Loading...