Canon AJ1 Service Manual

Revision 2.0

Cassette Feeding Unit-AJ1

Service Manual

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the consent of Canon Inc.

Copyright CANON INC. 2016

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

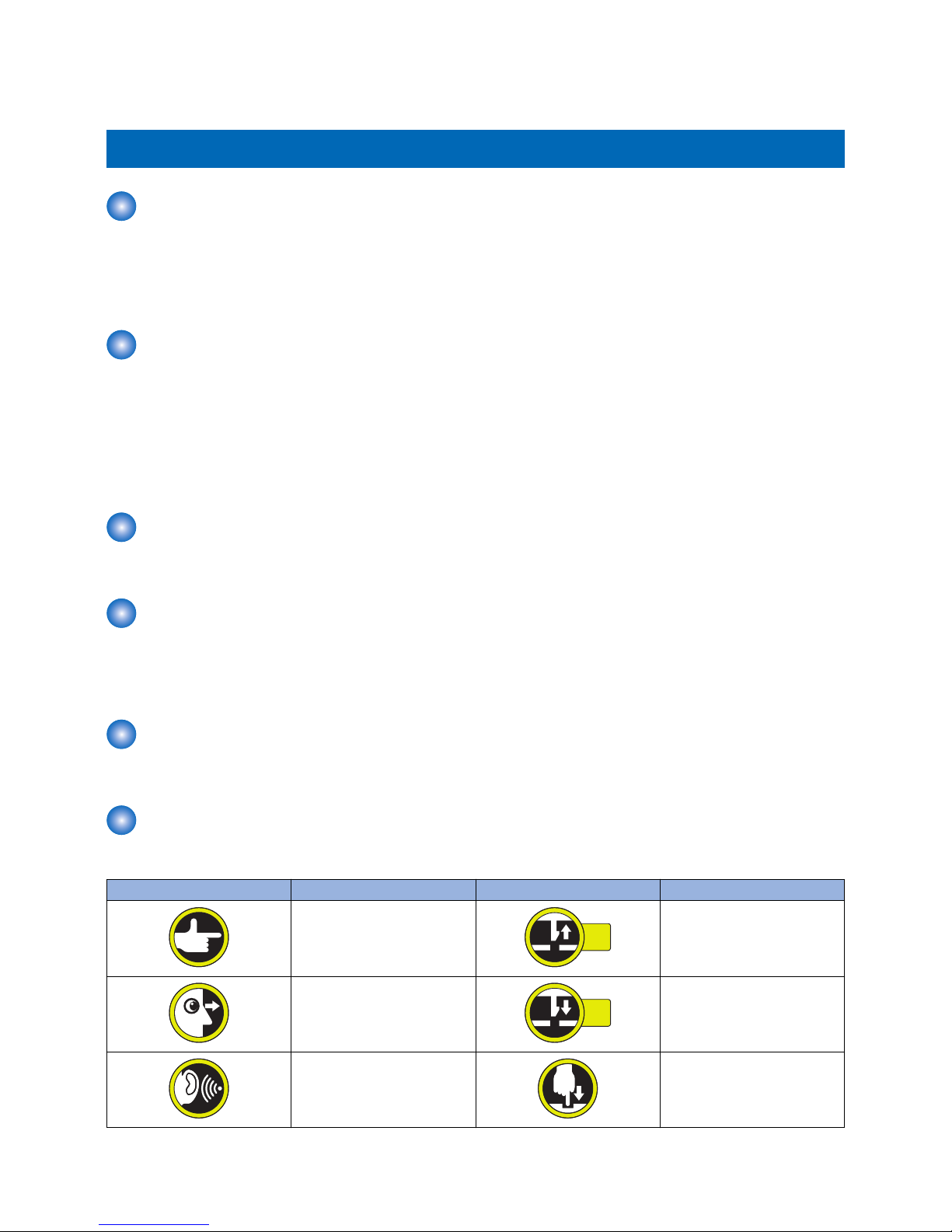

Symbols Explanation Symbols Explanation

Check.

1x

Remove the claw.

Check visually.

1x

Insert the claw.

Check a sound. Push the part.

Introduction

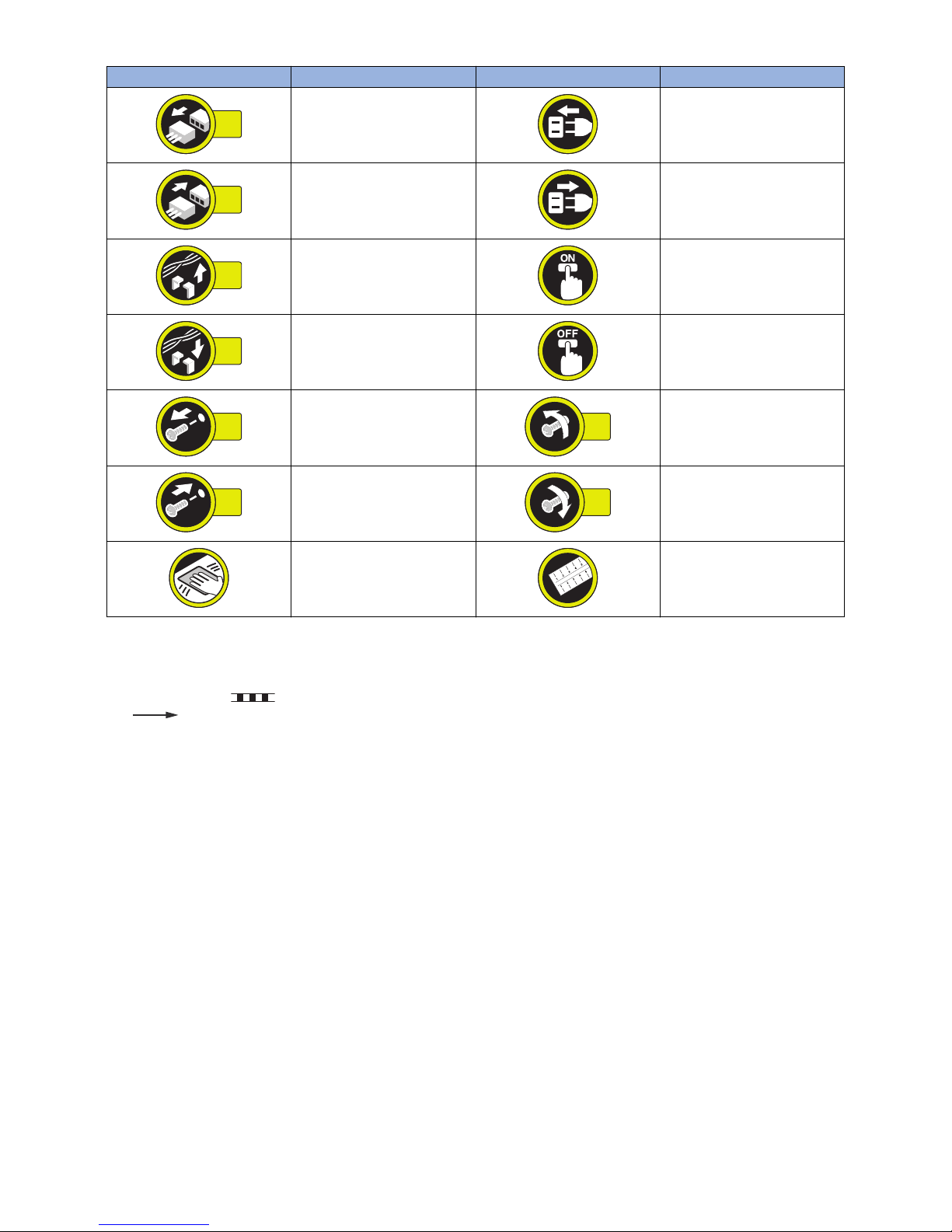

Symbols Explanation Symbols Explanation

1x

Disconnect the connector. Connect the power cable.

1x

Connect the connector. Disconnect the power cable.

1x

Remove the cable/wire from the

cable guide or wire saddle.

Turn on the power.

1x

Install the cable/wire to the cable

guide or wire saddle.

Turn off the power.

1x

Remove the screw.

1x

Loosen the screw.

1x

Install the screw.

1x

Tighten the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Introduction

Contents

Safety Precautions...............................................................................................1

Notes Before it Works Serving............................................................................................................ 2

1. Product Overview.............................................................................................3

Overview............................................................................................................................................. 4

Specification.........................................................................................................................................4

Parts Name.......................................................................................................................................... 4

2. Technical Explanation..................................................................................... 6

Basic Configuration............................................................................................................................. 7

Parts Configuration............................................................................................................................... 7

Paper Path........................................................................................................................................... 9

Controls.............................................................................................................................................10

Paper Size Detection Control............................................................................................................... 10

Paper Level Detection Control..............................................................................................................12

Paper Detection Control...................................................................................................................... 15

Lifter Control.......................................................................................................................................16

Registration Control.............................................................................................................................16

Size Mismatch Detection Control..........................................................................................................17

Jam Detection.....................................................................................................................................17

3. Periodical Service.......................................................................................... 18

List of Periodical Service Works........................................................................................................19

4. Disassembly/Assembly................................................................................. 20

Parts List........................................................................................................................................... 21

External Cover / Internal...................................................................................................................... 21

Major Units......................................................................................................................................... 22

Electrical Components List................................................................................................................23

Sensor............................................................................................................................................... 23

Motor..................................................................................................................................................23

Switch /PCB /Motor /Solenoid.............................................................................................................. 24

List of Connectors............................................................................................................................... 24

Removal from the Connected Equipment ........................................................................................ 26

Procedure...........................................................................................................................................26

External Cover System......................................................................................................................28

Removing the Rear Cover....................................................................................................................28

Removing the Right Cover...................................................................................................................28

Removing the Cassette Receptacle......................................................................................................31

Controller System..............................................................................................................................33

Removing the Cassette Module Controller PCB.................................................................................... 33

Pickup Feed System......................................................................................................................... 34

Removing the Pickup/ Feed/ Separation Roller......................................................................................34

Contents

i

Removing the Auto Close Unit............................................................................................................. 37

Removing the Pickup Unit....................................................................................................................39

Removing the Pullout Motor (M106)..................................................................................................... 40

Removing the Pickup Motor (M102)......................................................................................................40

Removing the Lifter Motor (M104)........................................................................................................ 41

Removing the Pickup Drive Unit...........................................................................................................41

5. Adjustment..................................................................................................... 43

Pickup Feed System......................................................................................................................... 44

Cassette Left Edge Margin Adjustment (1st Side: Mechanical Adjustment)............................................. 44

Cassette Left Edge Margin Adjustment (1st Side: Software Adjustment)................................................. 46

Cassette Left Edge Margin Adjustment (2nd Side: Software Adjustment)................................................ 47

Leading Edge Margin Adjustment (1st Side of Plain Paper)....................................................................47

Leading Edge Margin Adjustment (2nd Side)........................................................................................ 47

APPENDICES......................................................................................................49

Service Tools.....................................................................................................................................50

Special Tools...................................................................................................................................... 50

Solvents and Oils................................................................................................................................ 50

General Circuit Diagram....................................................................................................................51

Contents

ii

Safety Precautions

Notes Before it Works Serving..............2

Notes Before it Works Serving

• At servicing, be sure to turn off the power source according to the specified steps and disconnect the power plug.

• Do not turn off the power switch (of the host machine) when downloading is under way. Turning off the main power switch

while downloading is under way can disable the machine.

Safety Precautions

2

Product Overview

1

Overview............................................... 4

Overview

Specification

Item Description

Paper storage method Front loading method

Pickup method Retard separation method

Paper stack capacity

550 sheets (80 g/m2)

Paper feed reference Center reference

Paper size Width: 98.4 mm to 216.0 mm

Length: 148.0 mm to 355.6 mm

A4-R, A5-R, B5-R, LGL, LTR-R, STMT-R, EXEC-R, 16K

Special standard-size

Paper grammage

60 g/m2 to 163 g/m

2

Paper size switch By the user

Duplexing method Through path

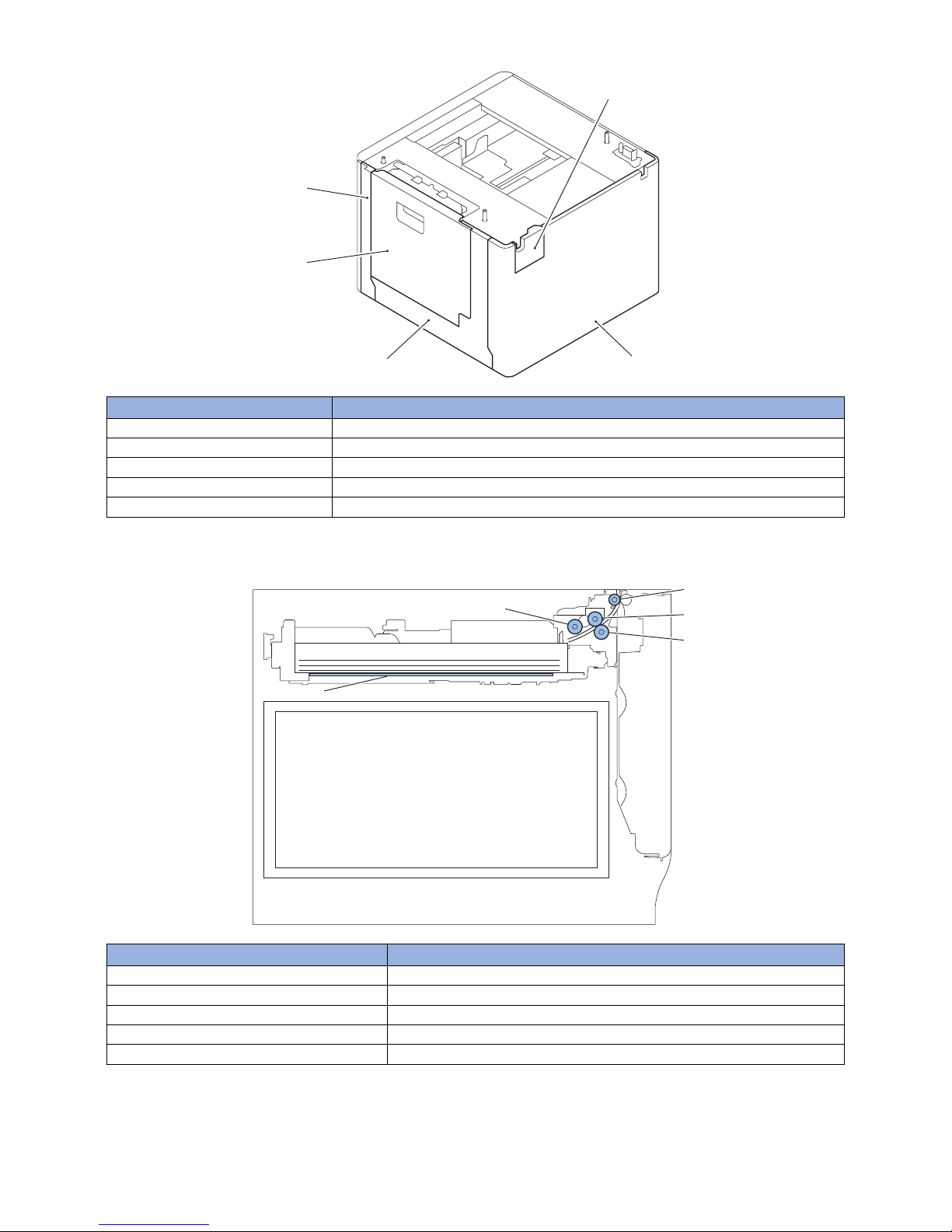

Parts Name

■ External View

[1]

[2]

[3]

[4]

No. Parts Name

[1] Cassette Front Upper Cover

[2] Upper Tray Cover

[3] Lower Tray Cover

[4] Left Cover

1. Product Overview

4

[6]

[7]

[5]

[8]

[9]

No. Parts Name

[5] Connector Cover

[6] Rear Cover

[7] Right Lower Cover

[8] Cassette Right Cover

[9] Right front cover

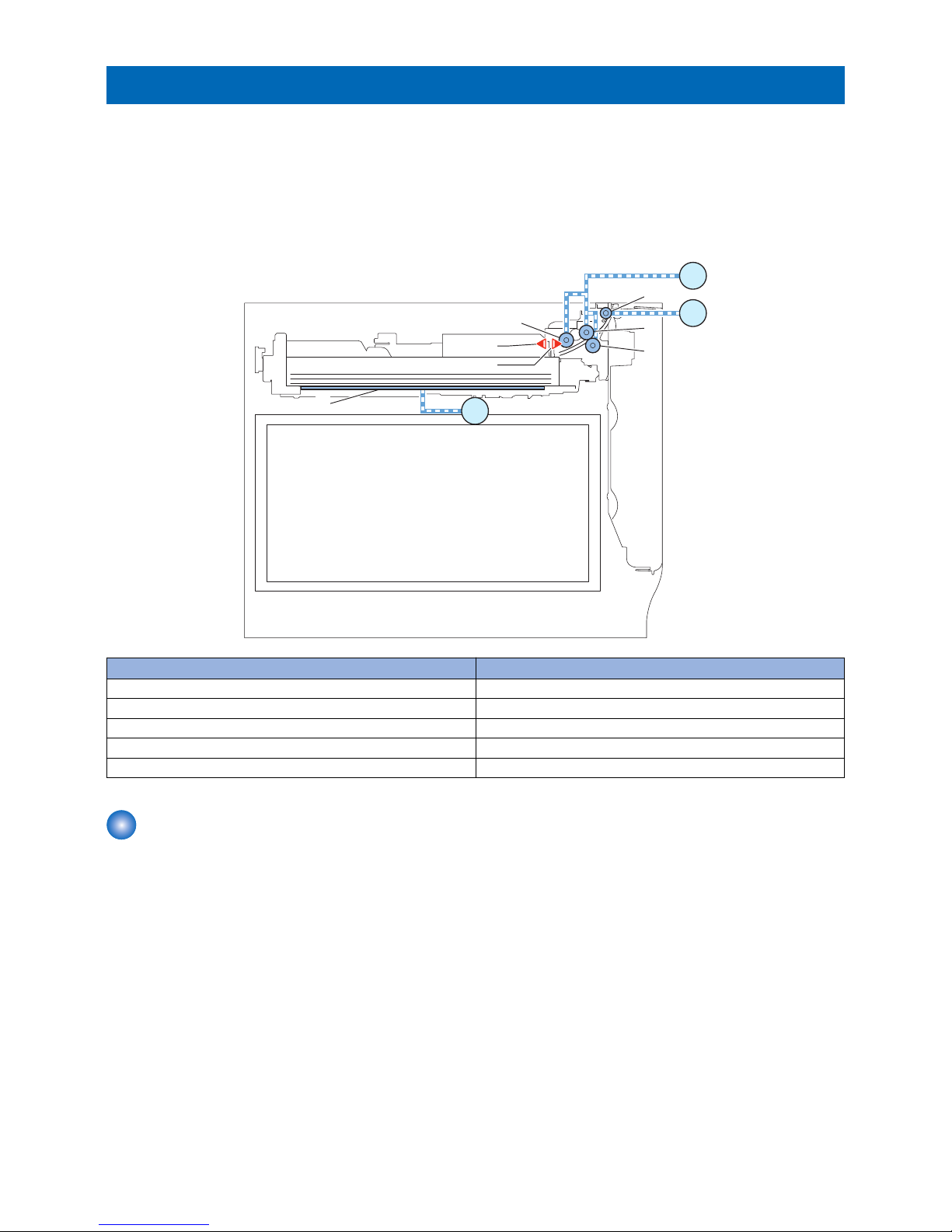

■ Cross-section View

[1]

[2]

[4]

[3]

[5]

No. Parts Name

[1] Cassette 2 pickup Roller

[2] Cassette 2 vertical path Roller

[3] Cassette 2 feed Roller

[4] Cassette 2 separation Roller

[5] Cassette 2 Lifting Plate

1. Product Overview

5

Technical

Explanation

2

Basic Configuration...............................7

Controls...............................................10

Basic Configuration

Parts Configuration

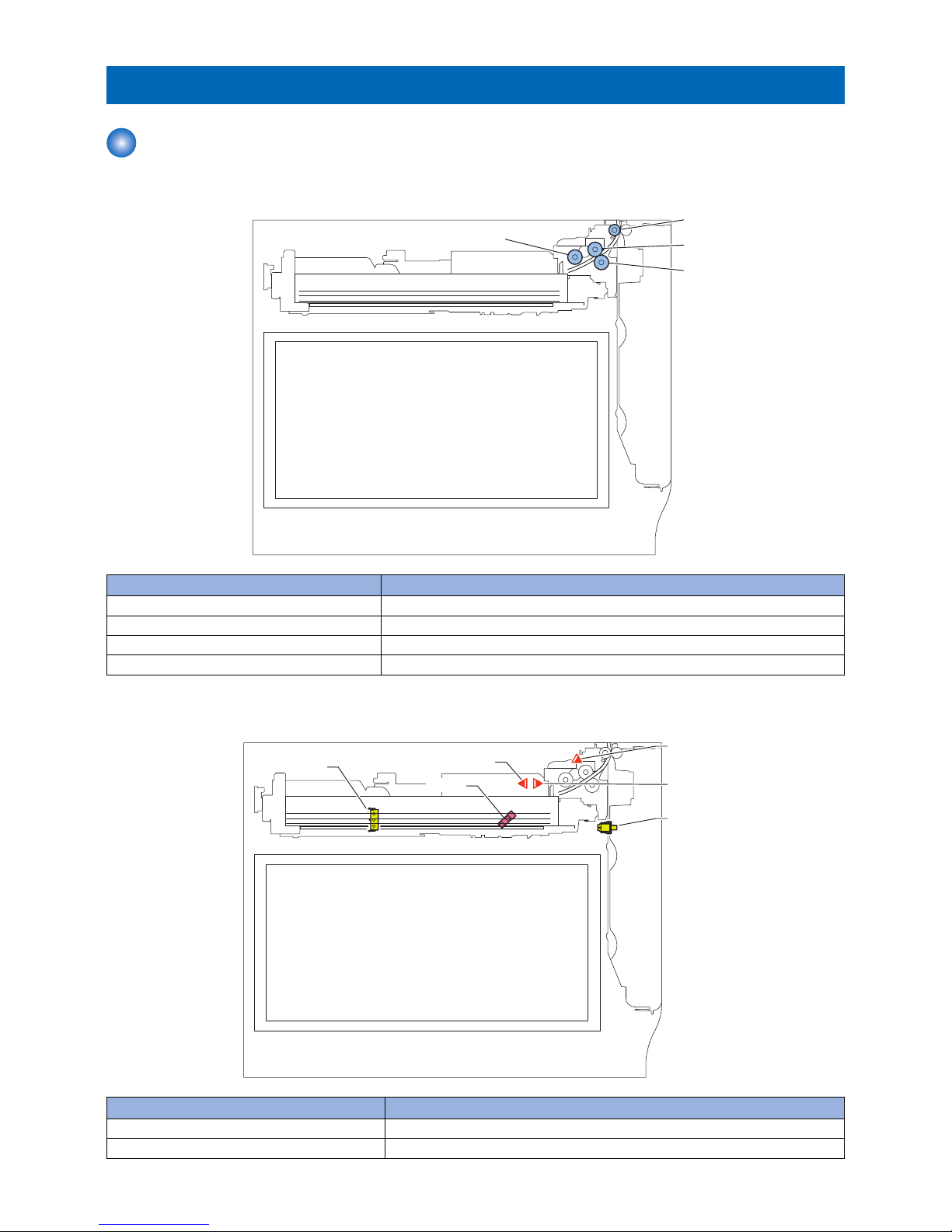

■ Rollers Layout Drawing

[1]

[2]

[4]

[3]

No. Parts Name

[1] Cassette 2 pickup Roller

[2] Cassette 2 vertical path Roller

[3] Cassette 2 feed Roller

[4] Cassette 2 separation Roller

■ Sensors Layout Drawing

PS104

SW101

PS110

SW104

PS101

PS107

No. Parts Name

PS101 Cassette 2 Pullout Sensor

PS104 Cassette 2 Paper Sensor

2. Technical Explanation

7

No. Parts Name

PS107 Cassette 2 Paper Surface Sensor

PS110 Cassette 2 Paper Level Sensor

SW101 Cassette 2 Size Detection Switch

SW104 Cassette Right Door Open/ Close Detection Switch

■ Route of Drive

M102

M106

M104

No. Parts Name

M102 Cassette 2 pickup Motor

M104 Cassette 2 Lifter Motor

M106 Cassette 2 Pullout Motor

2. Technical Explanation

8

Paper Path

Cassette 2

2. Technical Explanation

9

Controls

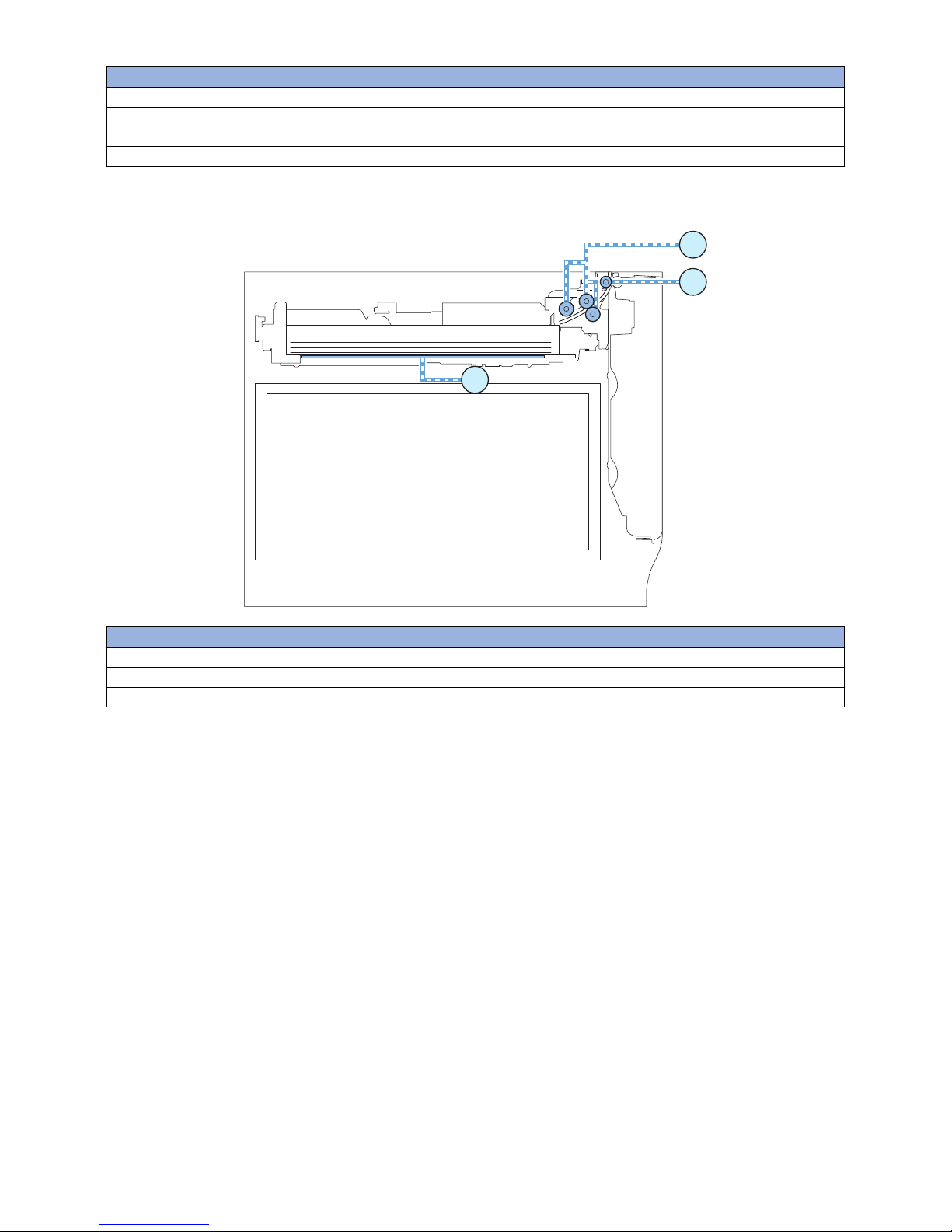

Paper inside a cassette is lifted up by the Lifter Plate.

The Lifter Plate is lifted up by rotating the Cassette 2 Lifter Motor (M104). When the Cassette 2 Pickup Roller comes into contact

with the paper surface, the Cassette 2 Pickup Motor (M102) rotates to pick up the surface layer paper, and the Cassette 2 Feed

Roller and Cassette 2 Separation Roller feed only 1 sheet of paper to the feed path. Then, it is moved to the Pre-registration

Roller by the rotation of the Cassette 2 Pullout Motor (M106).

The Cassette 2 Pickup Roller, Cassette 2 Feed Roller, and Cassette 2 Separation Roller are driven by the Cassette 2 Pickup

Motor (M102) while the Cassette 2 Vertical Path Roller is operated by the rotation of the Cassette 2 Pullout Motor (M106).

M102

M106

M104

[1]

[2]

[4]

[3]

[5]

PS104

PS107

No. Parts name

[1] Cassette 2 Pickup Roller

[2] Cassette 2 Vertical Path Roller

[3] Cassette 2 Feed Roller

[4] Cassette 2 Separation Roller

[5] Cassette 2 Lifter Plate

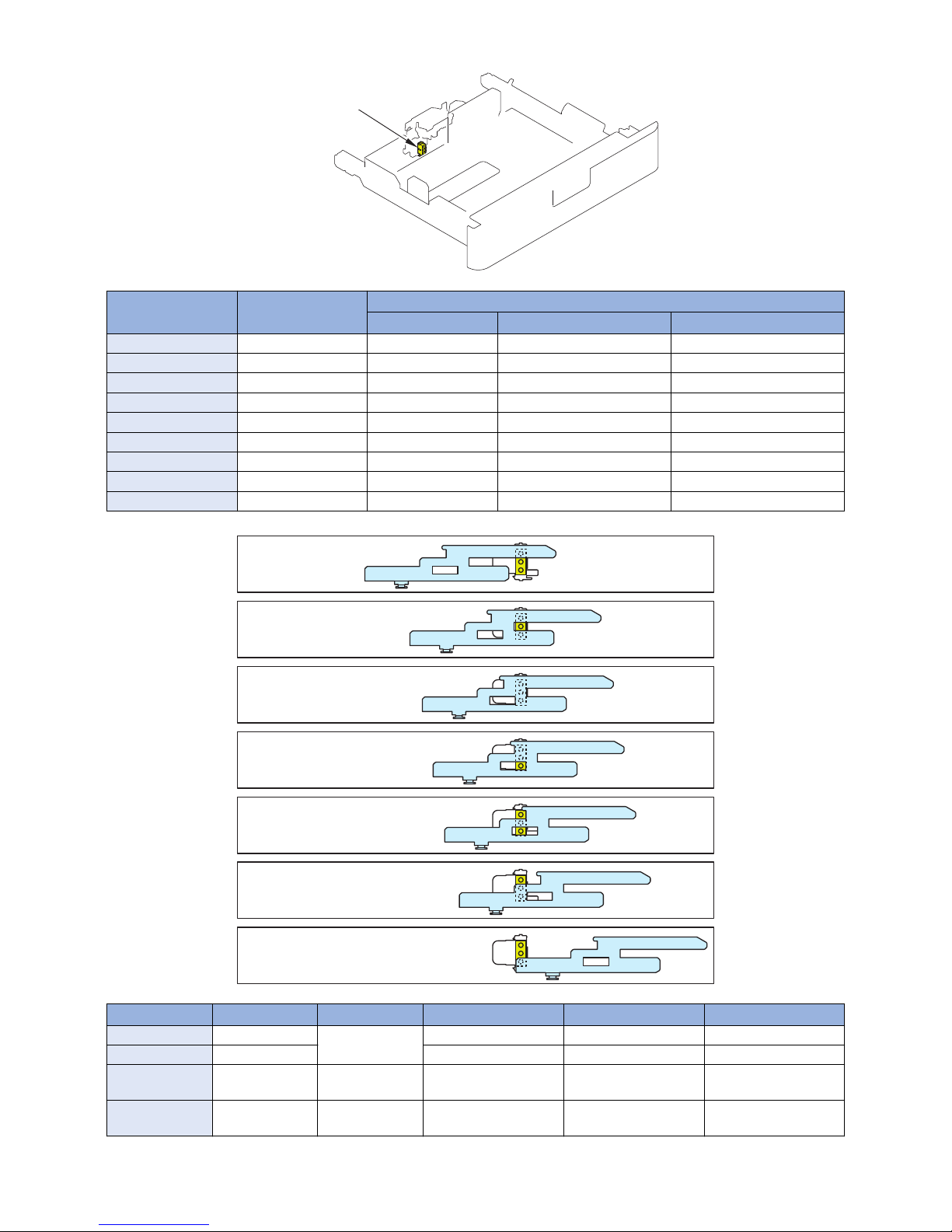

Paper Size Detection Control

The paper size in the cassette is automatically detected by the Cassette 2 Size Detection Switch after the position of the Guide

Plate is adjusted and the cassette is installed in the host machine.

By shifting the Guide Plate, concavo-convex area of the Cassette Size Dial is switched and the Cassette Size Switch at the printer

side is switched. The switch consists of 3 microswitches, and the length is detected in accordance with the combination of

ON/OFF (ON when the switch is pressed). Any standard size paper of AB, inch, or AK configuration can be used. However,

distinction between A5-R and STMT-R (*) should be made manually on the check screen. Distinction between EXEC-R and 16KR and between LTR-R and 16K-R is automatically made according to the country setting.

*: Whether to select A5-R or STMT-R can be registered in the user mode setting.

[Settings/Registration] > [Preferences] > [Paper Settings] > [A5R/STMTP Paper Selection]

Specify A5-R or STMT-R for each cassette.

2. Technical Explanation

10

Cassette Size Switch

Size Length Length Detection

1 2 3

A5-R 210.0 ON OFF OFF

STMT-R 215.9 ON OFF OFF

B5-R 257.0 ON OFF ON

EXEC-R 267.0 ON ON ON

16K-R 270.0 ON ON ON

LTR-R 279.4 ON ON OFF

A4-R 297.0 OFF ON ON

LGL 355.6 OFF OFF ON

(No cassette) - OFF OFF OFF

>@ LGL

>@ A4-R

>@ LTR-R

>@ B5-R

A5-R

>@

STMT-R

EXEC-R

>@

16K-R

16K-R

>@

LTR-R

Paper size *1 Length All modes A/B configuration Inch configuration A/K configuration

A5-R 210.0 [1] [1] - [1]

STMT-R 215.9 - [1] -

B5-R 257.0 [2] [2] Improper loading of pa-

per

Improper loading of paper

EXEC-R 267.0 [3] Improper loading of pa-

per

[3] -

2. Technical Explanation

11

Paper size *1 Length All modes A/B configuration Inch configuration A/K configuration

16K-R 270.0 [3] Improper loading of pa-

per

- [3]

[4] Improper loading of pa-

per

- [4]

LTR-R 279.4 [4] Improper loading of pa-

per

[4] -

[5] Improper loading of pa-

per

[5] Improper loading of pa-

per

A4-R 297.0 [6] [6] Improper loading of pa-

per

[6]

LGL 355.6 [7] Improper loading of pa-

per

[7] Improper loading of pa-

per

(No cassette) - [8] - - -

*1: The paper size can be registered in user mode.

Settings/Registration > Preferences > Paper Settings > Paper Settings

*2: Presence of the cassette is detected when the size switch is pressed.

(When none of the switches are pressed, it is judged as "no cassette".)

Guide Plate

Link Arm

Size Plate

Cassette

Size Switch

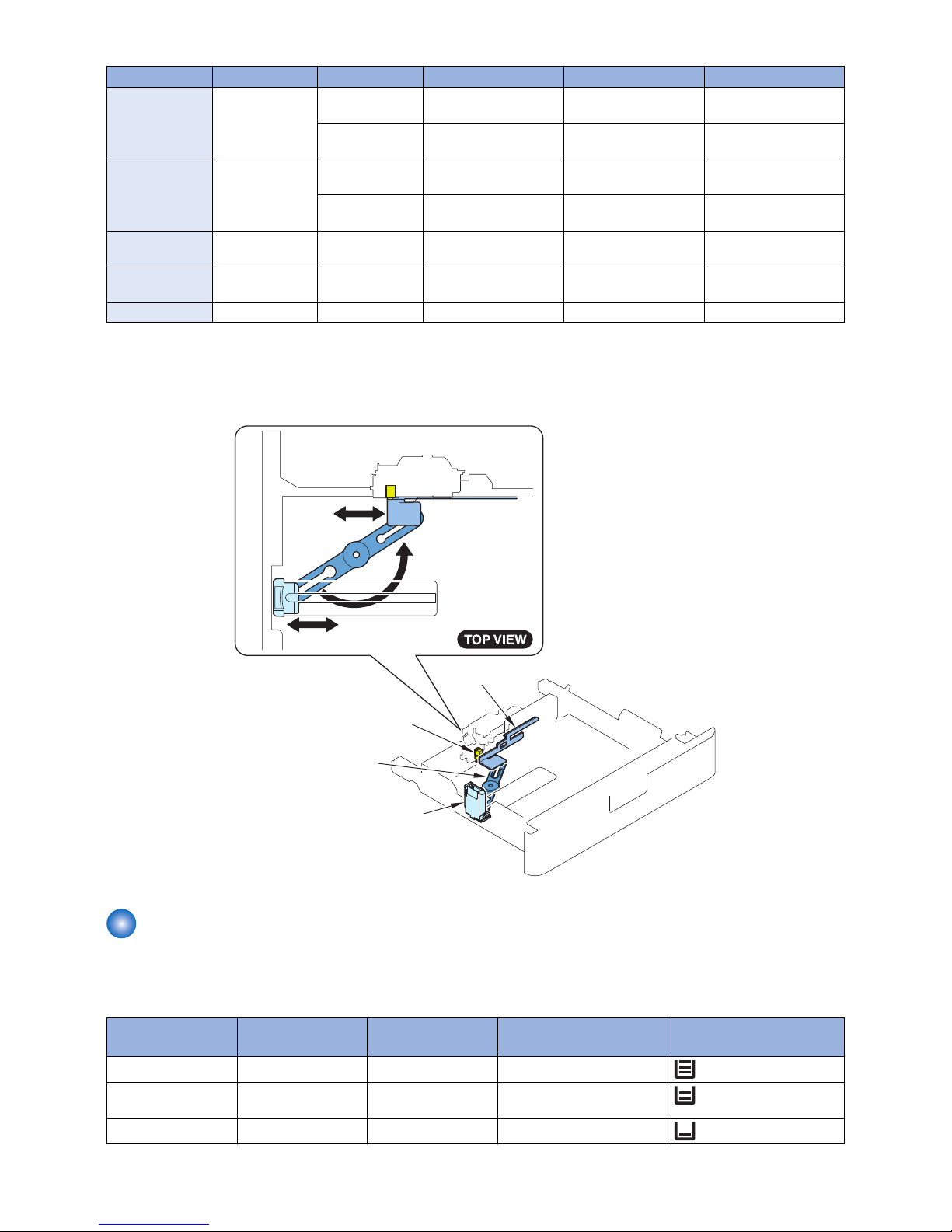

Paper Level Detection Control

Paper level inside the cassette is detected by the sensors shown in the following table.

The level of paper in the cassette is detected by the Cassette 2 Lifter Motor, Cassette 2 Paper Sensor, Cassette 2 Lifter Sensor,

and Cassette 2 Paper Level Sensor.

Cassette 2 Paper

Sensor

Cassette 2 Lifter

Sensor

Cassette 2 Paper

Level Sensor

Paper level Display on the Control

Panel

OFF ON OFF* 100% to 50% of the capacity*

OFF ON OFF Approx. 50% to approx. 50

sheets

OFF ON ON Approx. 50 sheets or less

2. Technical Explanation

12

Loading...

Loading...