Page 1

MOD. OVG505/2N

MOD. OVG505/2W

MOD. OVG505/2X

USE AND MAINTENANCE INSTRUCTIONS

FOR BUIL-IN GAS OVENS

Page 2

Page 3

Table of contents

Instructions for the user

Technical

I

nstallation

C

onnection

G

as

Oven functions

S

witching

S

witching

K

nob

C

leaning

Removing the oven door

Cle

Replacing the bul

T

roubleshooting

characteristics

to the gas supply

regulation

guard installation

aning the side rails

on the oven

the gas grill on

and maintenance

b

guide

C

ustomer

technical service

Page 4

Page 5

User instructions

Thank you for choosing one of our products. We hope you will get the very best

performance from this appliance.

Therefore we would ask you

to carefully comply with the the suggestions and

instructions in this manual for proper use of our products.

The manufacturer shall not be held liable for damage to persons and property

which is due to poor or incorrect installation of the appliance.

The

manufacturer reserves the right to modify its products as deemed fit without

prior

notice.

Technical characteristics

This appliance complies with circular EEC concerning limitation of radio and

electrical disturbances For the parts that will come in

to contact with food

products, this appliance is compliant with 89/109/EEC.

Before the first use

Once having unpacked and installed the appliance, take out all the internal

accessories and bring the oven to the maximum temperature for a 20 minutes

time, in order to eliminate any remains of manufacturing grease , oil or resins

that can produce unpleasant smells during cooking.

Ventilate the room while doing this operation..

Wash drips and trays with appropriate

detergents.

IMPORTANT: accessible parts will become hot when in use.

To avoid burns and scalds children should be kept away.

During the first minutes of working of the appliance it is possible to find some

water droplets on the front side, which do not compromise the correct functioning

of the appliance.

WARNING: IN CASE OF DISASSEMBLY, MAINTENANCE AND CLEANING

OF THE APPLIANCE, BE CAREFUL SOME PARTS COULD BE SHARP.

PLEASE USE SUITABLE PREVENTION AND PROTECTION EQUIPMENT

(GLOVES, ETC.).

For maintenance, moving, installation and cleaning of the appliance use suitable

prevention and protection equipment (gloves, etc.).

Lifting and moving of appliances weighing more than 25 kg must be carried out

using proper equipment, or by two persons, in order to avoid risks or injuries.

Page 6

BEFORE USING THE OVEN PRECAUTIONS AND GENERAL S

UGGESTIONS

Unplug the appliances before performing any maintenance and/or cleaning.

Any repairs or other work on the appliances must be carried out by qualified

technicians only.

Make sure that the electrical cables of other appliances used near the cookt

or oven do not touch the hot parts or get stuck in the oven door.

Keep children away from the oven during and immediately after use.

Use oven gloves to remove pots and accessories when the oven is hot.

Do not cover the bottom of the oven with aluminium

foil.

Do not place flammable material inside the oven. If the appliance is turned on

accidentally, it could catch on fire.

After using the oven, make sure that the pointer of the knob is in the 'off'

position and close the tap of the gas pipeline or cylind

er.

Do not store flammable materials inside the oven cavity.

The oven is equipped with a fan to cool the internal parts, the components of

the oven and create a slight air flow that exits from the slot under the control

panel.

This cooling fan turns on imm

ediately and shuts down 10-30 minutes after the

oven is switched off (depending on oven temperature).

If the fan does not work, do not use the oven and call the service centre.

If there is a power failure, do not use the appliance;

if a power failure occur

s while the appliance is operating, turn off the appliance

and do not use it again until power is restored.

In the grill function, the cooling fan starts immediately with the door open or

closed and stops as in the preceding function.

op

Page 7

During use, the inter

nal glass of the oven door may steam up.

The accessible parts of the oven may become hot during use. It is advised to

keep toddlers, children and differently-abled persons away from the oven

during and immediately after use. If this is not possible, an adult must be

present during the entire oven operation and cooling period.

Do not place heavy objects on the door in order to avoid damaging the oven

cavity or door hinges.

Do not block the cooling or exhaust openings or slots.

If the oven burner knob becomes

increasingly difficult to turn, call the service

centre to replace the tap.

Attention:

to reduce consumption and avoid overheating, the oven door should

be kept closed unless specifically required otherwise.

Technical characteristics

This appliance complies with circular EEC concerning limitation of radio and

electrical disturbances For the parts that will come in

to contact with food

products, this appliance is compliant with 89/109/EEC.

Dimensions:

Height: 591 mm

Width: 597 mm

Depth: 445 mm

Power supply voltage:

Volume: 58 L

230V a.c. - 50hz

Page 8

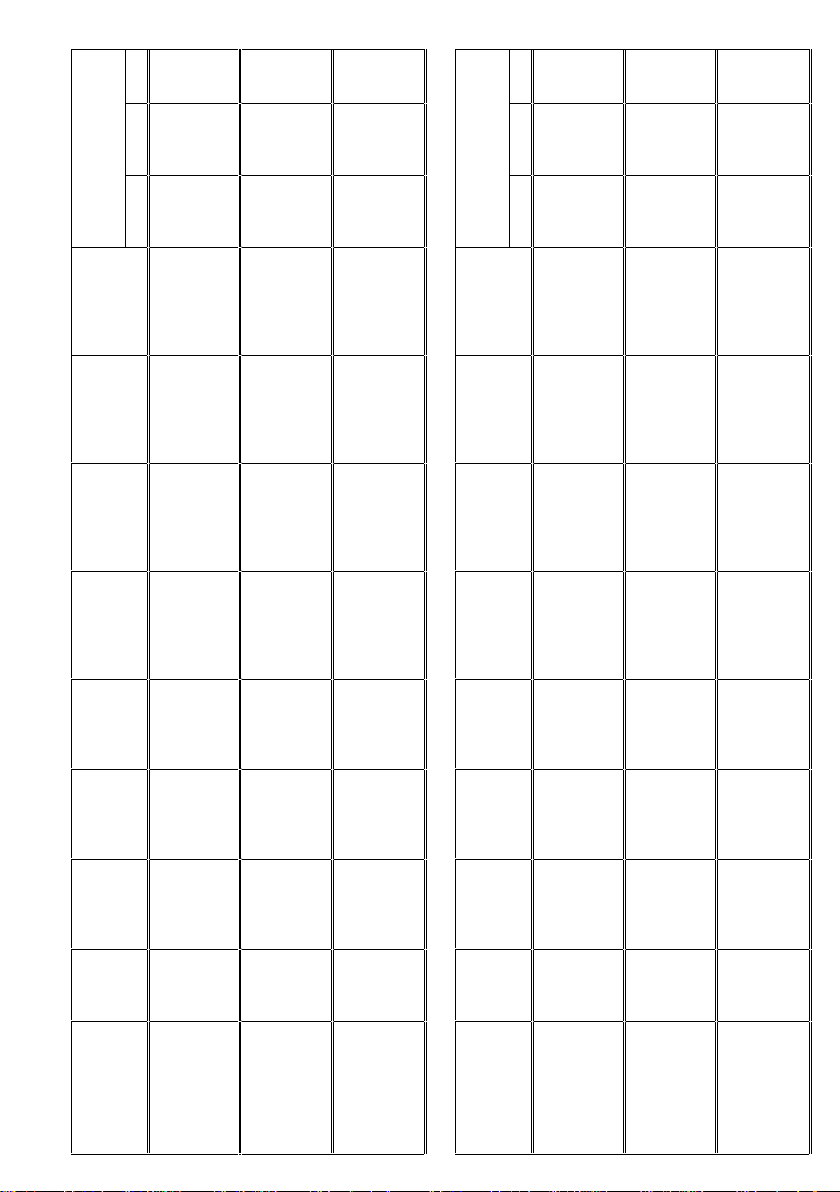

3+

35

max.

30

28

45

37

25

20

35

max.

30

28

45

37

25

20

nominal

CATEGORY II2H

UK

min.

Gas pressure (mbar)

(kW)

Reduced

nominal heat

capacity

Air necessary

for

combustion

m³/h

Nominal

consumption

Nominal heat

capacity (kW)

Injector

marking

(100/mm)

pass

By

marking

(100/mm)

20

0,80

5,4

196 g/h

2,70

80

48

25

0,80

5,4

193 g/h

2,70

80

48

17

0,80

5,4

257 l/h

2,70

115

48 adjusted

nominal

20

min.

Gas pressure (mbar)

al heat

Reduced

nomin

capacity (kW)

4,8

Air necessary

for

combustion

m³/h

Nominal

consumption

Nominal heat

capacity (kW)

Injector

marking

(100/mm)

pass

By

marking

(100/mm)

175 g/h

2,40

80

-

25

4,8

172 g/h

2,40

80

-

17

4,8

229 l/h

2,40

115

-

Open

Air setting

Dest.

Type of

burner

INJECTOR TABLES

Type of gas used

Oven

LIQUEFIED

PETROLEUM

GAS (Butane)

G30

Open

Oven

G31

LIQUEFIED

PETROLEUM

GAS (Propane)

Open

Air setting

Oven

G20

NATURAL GAS

(Methane)

Type of

Type of gas used

burner

Open

Grill

G30

LIQUEFIED

PETROLEUM

GAS (Butane)

Open

Grill

G31

LIQUEFIED

PETROLEUM

GAS (Propane)

Open

Grill

AS

G20

NATURAL G

(Methane)

Page 9

INSTALLATION

ATTENTION: This appliance can be installed and operated only in rooms that

are continuously ventilated according to UNI 7129/UNI 7131.

IMPORTANT: The installation must be carried out by professionally qualified

personnel following the manufacturer's instructions. Any maintenance on the

appliance must be performed with the appliance disconnected from the electrical

power supply and with the gas supply tap closed. The installation must be carried

out in compliance with the current regulations in the country in which the

appliance will be used.

Gas connection

For the connection of the appliance to the gas distribution system or a gas

cylinder, use the rigid metal pipe in copper or steel with relative fittings

compliant with the standard UNIwith continuous wall compliant with standard UNI-CIG 9891. The pressure

regulators used must be compliant with the standard UNI-CIG 7432.

CIG 7129 or the flexible hose in stainless steel

Electrical connection

The electrical connection must be carried o

to the manufacturer's instructions and in compliance with current local standards.

Make sure the voltage matches the value indicated on the technical data plate

visible, with the door open, on one of the side edges of the cavity. If the plug is

not easily accessible, the installer must provide an omni-polar switch with a

contact opening distance of at least 3 mm. The appliance is supplied with a

plugless cable. A normalized plug must be used, taking into consideration that:

ut by a qualified technician according

yellow- green = earth

blue = neutral

brown = phase

The appliance is required by law to have an earth connection.

Do not use multiple sockets or extension cords.

Page 10

Installation room (fig. 1)

For proper operation of the gas appliance, it is essential that the room has a

natural air flow from openings on the external walls providing sufficient air for

combustion of the gas. These openings must have a free air-flow cross-section of

at least 100 cm2 (realized with one or more openings).

The exhaust of the combustion residual products must occur through hoods

connected to chimney flues or directly to the outdoors. If it is not possible to

install a hood, an electric fan must be applied to the external wall or window of

the room provided that the ro

current standards. This electric fan must have a capacity that guarantees, for a

kitchen, an hourly air renewal of 3-5 times its volume.

om has the required air inlet openings according to

Fig. 1

Page 11

Insertion into the furniture unit:

The appliance can be inserted either under a worktop or into a column. In either case

comply with the dimensions shown in figures 1 and 2.

For column instal

lation, in order to ensure proper ventilation, it is very important to

provide an opening of at least 85-90mm as shown in figure 1.

The oven is secured to the furniture unit by four screws located in the holes of

the perimeter frame (see fig. 1).

Do notuse the door as a lever when installing the oven.

Do not place excessive pressure on the oven door when it is open.

Fig. 2.1

Page 12

Fig. 2.2

Page 13

CONNECTION TO THE GAS SUPPLY

The supply system must be

compliant with the current

standards in the country of

use. The type of gas for which the oven has been regulated is indicated on the serial

number plate located on one o

f the side edges of the cavity (visible with the door

open) and on the packaging. Before carrying out the connection, the oven must be

adapted to the type of gas that will be used.

L

ink

the

male cylindrical threaded pipe-fitting

side of the appliance to the supply, by using

fittings

O

which are

therwise

compliant with the current standards.

you can use a flexible metallic pipe entirely

½"G,

which

is placed on the back

a

non-flexible metallic pipe

fixed to the wall

and pipe

and pipe

-

fittings which are compliant with the current standards; the length of the pipe cannot

be

over

2000 mm

, in compliance with the current standards.

Check that the pipe cannot come in contact with movable parts that could damage it.

Place the seal (fig. 3)

with the appliance.

I

mportant: to connect the appliance to a LPG supply, place a pressure regulator

which is

Attention:

compliant with the current standards

when finished, check that there are no gas leaks.

Use soap and water or special liquids to

DO NOT USE OPEN FLAMES WHEN SEARCHING FOR GAS LEAKS.

between the pipe-fitting and the pipe. The

between the pipe and the gas tank.

make sure that there are no gas leaks.

seal is provided

Warning: the use of a rubber flexible hose fastened with hose clamps is prohibited

because it cannot be inspected.

Fig. 3

Ramp (pipe-fitting) Seal Gas pipe

______

______

______

Page 14

Adaptation to the gas in use

Other types of gas can be used by changing the burner s

1)

Make sure that the oven is not connected to the electrical mains.

2)

Open the oven door completely.

3)

Extract the bottom of the oven after having removed the retaining screws (fig.

etting as follows:

4).

4)

Take off the burner by unscrewing the screw.

5)

Unscrew the injector and replace it according to the injector table provided

separately. Reassemble the burner and the bottom of the oven, following the

above steps in the reverse order.

Flame adjustment (if applicable) - (fig. 5 and 6)

To adjust the flame, proceed

as follows:

loosen the screw C and turn the ring nut D to position N for natural or methane gas, and

position

fixed pointer on the burner. An adjusted flame is obtained in this man

GPL

for cylinder gas, aligning the movable pointer on the ring nut with the

ner.

Fig. 4 Fig. 5

Fig. 6

EXCESS AIR REGULAR FLAME LACK OF AIR

Page 15

Setting of the minimum (fig. 7a-7b)

The oven thermostat is equipped with a by-pass for the minimum; when changing the

type of gas it is also necessary to adjust the setting in the following manner:

Remove the thermostat knob;

If the front panel is in glass, remove it by unscrewing the two locking ring nuts

located under the ot

her two knobs (fig. 7a);

If the control panel is in metal, the adjustment can be made through the

opening located on the left side of the thermostat knob housing (fig. 7b);

Turn on the oven and let it operate at maximum with the door closed for at

least 30

minutes;

Move the oven thermostat knob to the minimum and set the by-pass to the

minimum so as to obtain a reduced but stabilized flame.

Perform this operation

with the oven door closed;

Use a screwdriver to operate on the notch of the by-pass screw. A fe

w turns of

the by-pass screw is sufficient to adjust the minimum when passing from

liquid gas to methane gas;

fig. 7a fig. 7b

IMPORTANT:

check that the flame remains lit at the minimum.

If the flame goes out, adjust the byFor operation with G30/G31, the adjustment screw of the by-pass must be screwed in

completely.

When these operations are finished (injector replacement, air adjustment and minimum

setting), turn off the oven and replace the data plate with the new data plate indicating

the operating gas.

after having adjusted the burner, open and close the oven door to

pass setting.

Page 16

OVEN FUNCTIONS (fig. 8)

60' Timer Oven light Green light Selector knob

Fig. 8

Green light

Th

e green light turns on when the selector knob is in any position different from

switched off.

S

elector knob

It allows to choose between the different cooking functions and set the desired temperature

of the oven burner.

Oven light

The oven internal light is turned on by switching the knob in a clockwise direction.

60' Timer

The regulating knob must be turned in a clockwise direction until it reaches the 60 minutes

position and then turned to the desired time by turning the knob in a counter clockwise

direction. The oven will not be turned off automatically.

A minute counter ringing will advise that the cooking time is over.

Page 17

SWITCHING ON THE OVEN

oven is equipped with electric ignition. To turn on the oven, open the door

The

pletely. If the door is just partially open, a safety system blocks the automatic

com

ignition of burners.

Press the thermostat knob and turn it counter-clockwise.

Keep the knob pressed for a few seconds to trigger the electric ignition.

H

owever, do not activate the device for more than 15 seconds.

If the burner does not light in 15 seconds, keep the door completely open and wait at

least 1 minute before trying again.

When the oven is turned on, choose your favorite cooking temperature between Min.

and Max.

NOTE: when the oven is turned on for the first time, it is normal to have to repeat the

operation several times due to the presence of air in the gas supply line. Once the flame

is lit, keep the thermostat knob pressed for a few seconds to activate the safety

thermocouple that would otherwise block the

of the burner through the slots located in the front part of the oven plate; if it is not lit,

repeat the operation.

The proper operation of the burner should be checked with the oven door closed.

Notes:

The oven burner has a safety valve which block the gas flow in the following cases:

- if the selector knob is accidentally turned with immediate gas flow.

- if the burner flame is accidentally cut off.

- in the case of lack of gas depending by the gas provider.

gas supply. Check the successful lighting

DURING OPERATIO

Keeping the door closed, check that the cooling fan is operating properly.

does not work, proceed as follows:

1.

check the power supply; if there is a power failure stop baking, turn off the

appliance and wait for power to be restored.

2.

if there

is no power failure, do not use the oven and contact the service centre.

If the oven door is opened during use, the fan stops to prevent the flow of hot air in the

direction of the user; once the door is closed again the fan resumes operation; if this

doe

s not occur, perform the checks listed in points 1 and 2.

N

If the fan

Page 18

SWITCHING THE GAS GRILL ON

The grill has an electronic ignition.

To switch the gas grill on, proceed as follows:

open the oven door;

press the knob slightly and turn it clockwise to the grill position;

the cooling fan starts;

press the knob right in to trigger the electric ignition.

Please note that the electric ignition does not have to be pressed more than

15 seconds. If the burner does not start in 15 seconds, keep the oven door open

and wait for at least 1 minute before trying again the electric ignition.

Note: when doing the electric ignition for the first time, it is quite normal

having to try many times the electric ignition, because of the air inside the gas pipe.

During grill operation:

The oven door must be kept open and the knob protection fitted.

Keeping the door open, check the correct working of the cooling fan.

If the cooling fan doesn't start, operate in this way:

1 Check there has been no interruption in the electricity supply; if so, stop cooking,

switch off the grill and wait for the electricity to come.

2 If there has not been any interruption in the electricity supply, do not use the oven

and call the After-sales Service.

WARNING:

The accessible parts of the oven can be very hot when using the grill:

keep away the children.

Always use oven gloves when moving food in or out of the oven cavity.

Page 19

How to use the grill

Foods to be grilled

Cuts of thin meat 6 4

Cuts of normal meat 8 5

Fish (e.g. trout, salmon)

Sausages

Toast

Depending on the type of food (e.g. meats, fish, poultry, etc.), you will need to turn

the

food to expose both sides to the infrared rays.

The data provided above is approximate. Cooking times vary based on the

experience of the person using th

The cooking times do not include pre-heating. It is advisable to pre-heat the oven

for about 15 min.

With the ventilated grill function, do not select a temperature of more than 190°C.

e oven and the amount and quality of the foods.

Cooking time in minutes

Over

15 12

12 10

52

Under

ATTENTION:

The accessible parts of the oven may become hot during use. It is advised to keep

toddlers, children and differently-abled persons away from the oven duri

ng and

immediately after use.

If this is not possible, an adult must be present during the entire oven operation and

cooling period.

Page 20

INSTRUCTIONS FOR INSTALLING KNOB GUARD

OPEN OVEN DOOR

INSTALL KNOB GUARD

IN SLOTS OF FRONT

MAKE SURE THE KNOB GUARD IS ATTACHED

BY PULLING IT OUTWARDS

FASTEN KNOB GUARD ONTO FRONT

BY MOVING IT TO THE RIGHT

CLOSE OVEN DOOR

ATTENTION:

During operation the knob guard gets very hot.

Use kitchen gloves.

Page 21

CLEANING AND MAINTENANCE OF

THE OVEN

Important:

or

disconnect the power supply via the omni-polar switch of the electrical system.

Before performing any maintenance, you must either unplug the oven

Cleaning the oven:

Let the oven cool after each use

and clean it to keep burnt on

residues

from being repeatedly heated.

For tough dirt, use a product specifically for oven cleaning. Follow the

instructions on the container of the product.

Clean the outside with a sponge dampened in lukewarm water.

Do not use abrasive produ

cts, steel wool pads, electrical or steam cleaners, or

flammable products.

Do not use abrasive substances or materials to clean the glass as they may

damage it.

Wash accessories in a dishwasher or by hand using a product for oven

cleaning.

ATTENTION:

use

protective gloves for the following tasks.

Page 22

How to remove the oven door (fig. 9)

To make it easier to clean the oven, it is possible to remove the door from the hinges

as follows:

The hinges A are equipped with 2 mobile UWhen the U-bolts B are

After this, lift the door up and pull it outwards, holding the door on both sides

near the hinges.

To re-install the door:

Slide the hinges into the grooves and open the door all the way.

Turn the mo

again.

Fig. 9

lifted, the hinges are disconnected from their housing.

bile U-bolts to their starting position before closing the door

bolts B.

ATTENTION:

Please ensure that you do not remove the hinge locking system when you remove the

door. The hinge mechanism has a very strong spring. Never immerse the door in

water.

Page 23

Cleaning the side rails -

Fig. 10

The side rails are to be hooked onto the wall of the oven. Slide the racks and tray

provided into the side rails.

To remove the side rails press on part A as shown

Fig. 10

.

Replac

ement of oven lamp (fig. 11)

Disconnect the oven from the electrical power supply.

Use a screwdriver to remove the light cover.

Replace the lamp

Put the light cover back

Restore the power supply

N.B. : use only lamps that are 25W 230V, type E

technical service.

Fig

. 11

-

14, T 300°C,

available from our

Page 24

TROUBLESHOOTING GUIDE

The burner does not light

Is the gas supply tap open?

I

s the gas supply obstructed?

Is the gas cylinder empty?

Are the burner openings blocked?

The burner does not stay lit

Repeat the ignition operation positioning the knob on the symbol representing

the maximum temperature.

The electric ignition doesn't wor

k

Is there a power failure?

The cooling system doesn't work

Is there a power failure?

Is the oven door open?

CUSTOMER TECHNICAL SERVICE

Before contacting technical service

If the product does not work, we suggest the following:

check that the plug is firmly in the socket;

If you cannot identify the reason for the

turn the appliance off, do not tamper with it and contact technical services department.

This household appliance is marked in compliance with European Directive 2002/96/EC

on waste from electrical and electronic equipment (WEEE). If you make sure this product

is disposed of properly, you will help to prevent possible negative consequences for the

environment and for people's health, which otherwise might occur due to incorrect

treatment of this product at the end of its life cycle.

The symbol

normal domestic waste. In fact, it must be taken to the nearest collection point for the

recycling of electrical and electronic waste. It must be disposed of in accordance with

current environmental regulations on waste disposal. For more information about

treatment, salvage and recycling of this product, please contact the nearest local

authorities, the organization that collects waste at home, or the shop where it was

purchased.

on the product indicates that this appliance may not be handled as

malfunction:

Page 25

Page 26

Page 27

Page 28

12300089000

Loading...

Loading...