Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

IN970400AV 11/00

Operating Instructions & Parts Manual Model WG3013

Wire Feed

Arc Welder

This line of Campbell Hausfeld wire feed

welders is designed to be used on

standard 115V household current. The

welders are equipped with infinite wire

speed control to accurately select the

proper wire feed rate needed for various

welding conditions. Internal components

are thermostatically protected.

These welders are designed for use with

Flux Core Arc Welding (Gasless) or Gas

Metal Arc Welding (Mig) process. As

delivered from the factory, this welder

can weld with .024” (.6 mm) to .035”

(.9 mm) diameter wire. A starter spool

of .035” (.9 mm) flux-cored wire and a

.040 tip are included.

Unpacking

Some welder components may be

found in the wire feed compartment.

When unpacking, inspect carefully for

any damage that may have occurred

during transit. Report any damaged or

missing items by calling (800) 746-5641.

Circuit Requirements

This equipment

requires a dedicated 115 volt circuit. Refer to the

following chart for the correct circuit

breaker or fuse rating. Do not run

other appliances, lights, or tools on

this circuit while operating this

equipment. Extension cords are not

recommended. Blown fuses and tripped

circuit breakers can result from failure

to comply with this recommendation.

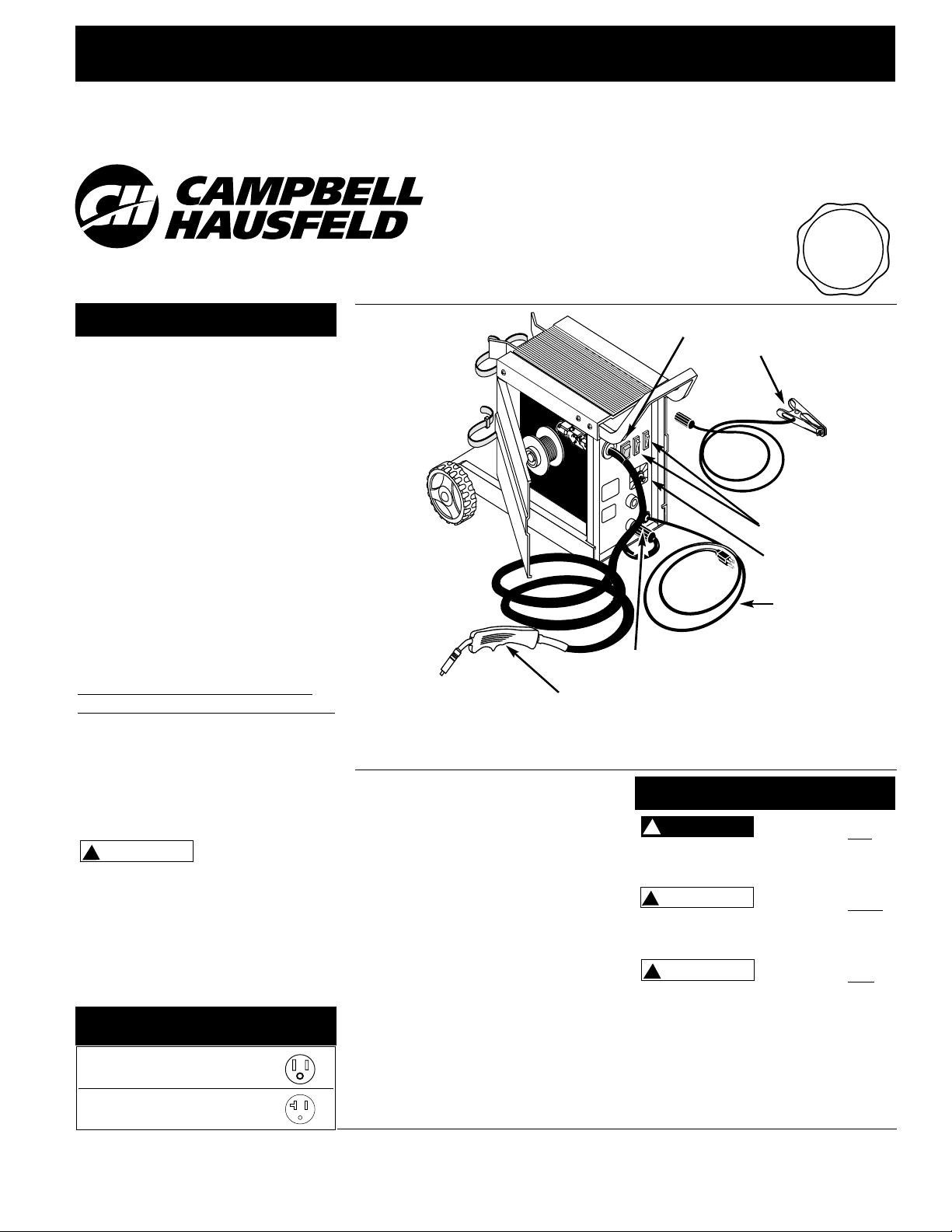

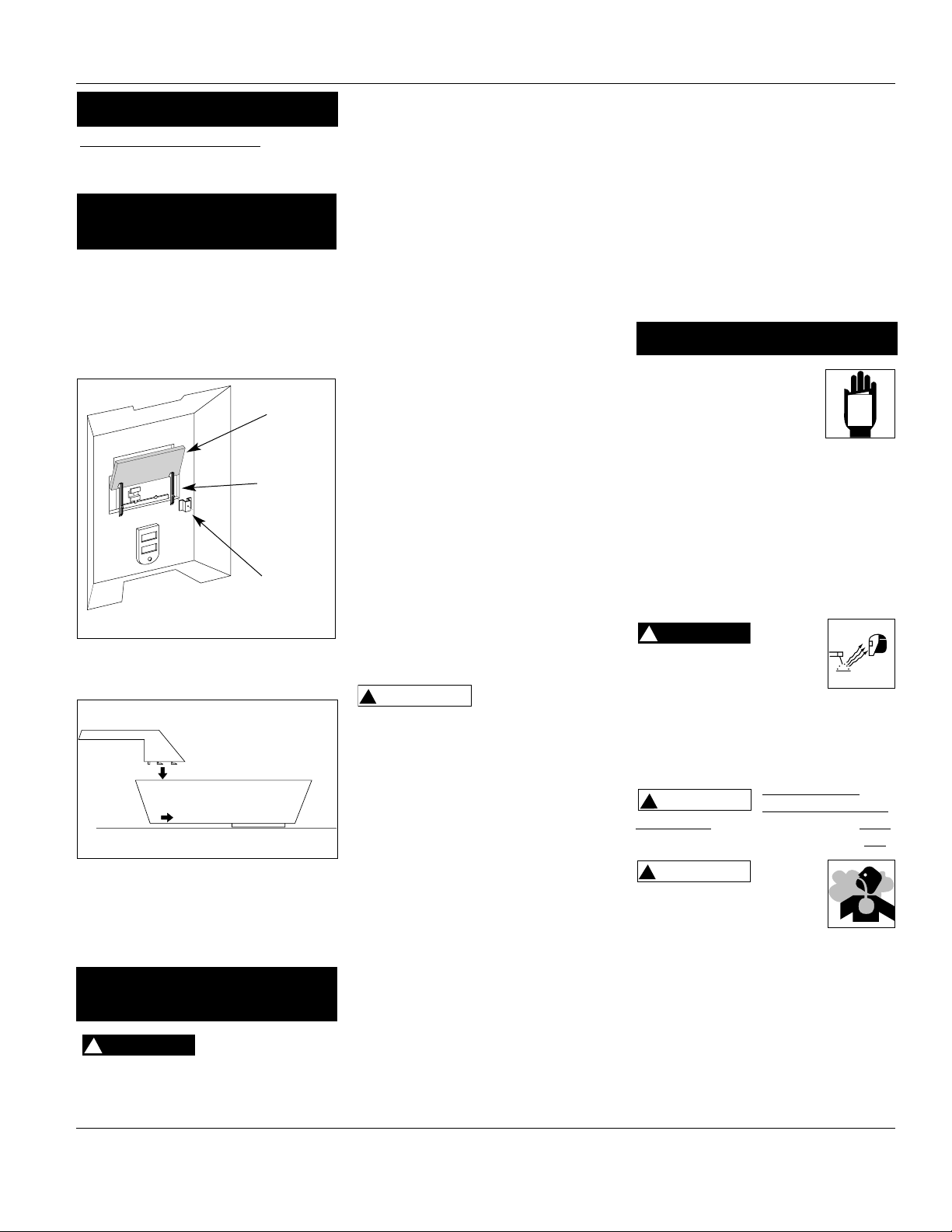

Components and Controls

1. Ground Clamp - connect to work

piece.

2. Wire Feed Gun with .040 tip

3. Power Cord - plug into 115 volt

outlet.

4. On/Off Switch

5. Infinite Wire Speed Control turn clockwise to increase wire

speed and counterclockwise to

decrease wire speed.

6. Heat Selector - Selects welding

power. Four selections are possible

7. Polarity Hook-up - Attach torch

cable to (+) for MIG and (-) for flux

core wire.

Heat Circuit Breaker or

Selector Slow Blow Fuse

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

NOTE: Note means any additional

information pertaining to the product

or its proper usage.

FARMHAND 125

Low 15 amp

High 20 amp

Description

1

2

3

4

5

6

7

Figure 1

General Safety

© 2000 Campbell Hausfeld / Scott Fetzer

For parts, product & service information

visit www.chpower.com

A

N

R

C

U

E

S

S

A

Y

T

I

L

Need

BUILT TO LAST

TM

A

U

Q

Assistance?

Call Us First!

1-800-746-5641

P

R

O

G

R

A

M

!

CAUTION

!

DANGER

!

WARNING

!

CAUTION

Page 2

2

Wire Feed Arc Welder

Torch is “live” (has

current potential)

at all times when machine is turned on.

Always keep a fire

extinguisher accessible while

performing arc welding

operations.

● Before starting or servicing any

electric arc welder, read and

understand all instructions. Failure

to follow safety precautions or

instructions can cause equipment

damage and/or serious personal

injury or death.

● All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper use of electric arc

welders can cause electric

shock, injury, and death!

Take all precautions described in this

manual to reduce the possibility of

electric shock.

● Verify that all components of the

arc welder are clean and in good

condition prior to operating the

welder. Be sure that the insulation

on all cables, wire feed gun, and

power cords is not damaged.

Always repair or replace damaged

components before operating the

welder. Always keep welder panels,

shields, etc. in place when operating

the welder.

● Always wear dry, protective clothing

and welding gloves, and insulated

footwear.

● Always operate the welder in a

clean, dry, well ventilated area. Do

not operate the welder in humid,

wet, rainy, or poorly ventilated

areas.

● Be sure that the work piece is

properly supported and grounded

prior to beginning any electric arc

welding operation.

● Coiled welding cable should be

spread out before use to avoid

overheating and damage to

insulation.

Never immerse the

wire or wire feed

gun in water. If the welder becomes

wet for any reason, be absolutely

certain that it is completely clean and

dry prior to attempting use!

● Always shut the equipment off and

unplug the power prior to moving

the unit.

● Always attach the work lead first.

● Verify that the work piece is

securely grounded.

● Always shut off electric arc welding

equipment when not in use, and cut

off any excess wire from the wire

feed gun.

● Never allow any part of the body to

touch the wire and ground or

grounded work piece at the same

time.

● Awkward welding conditions and

positions can be electrically

hazardous. When crouching,

kneeling or at elevations, be sure to

insulate all conductive parts, wear

appropriate protective clothing, and

take precautions to prevent injury

from falls.

● Never attempt to use this

equipment at current settings or

duty cycles higher than those

specified on the equipment labels.

● Never use an electric arc welder to

thaw frozen pipes.

Flying

sparks and hot metal can

cause injury. As welds cool,

slag can be thrown off. Take

all precautions described in this manual

to reduce the possibility of injury from

flying sparks and hot metal.

● Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

● Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric arc

welding operations produce

intense light and heat and

ultraviolet (UV) rays. This

intense light and UV rays can cause

injury to eyes and skin. Take all

precautions described in this manual to

reduce the possibility of injury to eyes

and skin.

● All persons operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including:

welding helmet or shield with at

least shade 10, flame resistant

clothing, leather welding gloves,

and full foot protection.

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric arc welding

operations cause sparks and

heat metal to temperatures

that can cause severe burns! Use

protective gloves and clothing when

performing any metal working

operation. Take all precautions

described in this manual to reduce the

possibility of skin and clothing burns.

● Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use additional face shields and

flame resistant barriers as needed.

● Never touch work pieces until

completely cooled.

Heat and sparks produced

during electric arc welding

and other metal working

operations can ignite flammable and

explosive materials! Take all

precautions described in this manual to

reduce the possibility of flames and

explosions.

● Remove all flammable materials

within 35 feet (10.7 m) of welding

arc. If removal is not possible,

tightly cover flammable materials

with fire proof covers.

● Do not operate any electric arc

welder in areas where flammable or

explosive vapors may be present.

● Take precautions to be sure that

flying sparks and heat do not cause

flames in hidden areas, cracks,

behind bulkheads, etc.

Fire hazard! Do not weld on

containers or pipes that

contain or have contained

flammable materials or gaseous or

liquid combustibles.

Arc welding closed cylinders

or containers such as tanks

or drums can cause explosion

if not properly vented! Verify that any

cylinder or container to be welded has

an adequate ventilation hole, so that

expanding gases can be released.

General Safety

(Continued)

www.chpower.com

!

WARNING

!

WARNING

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 3

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quicy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face

Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data

Sheets and the manufacturers

instructions for metals, wire, coatings

and cleaners.

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate the welder in

an environment that is clean and

dry. Dust and dirt in the welder

retain moisture and increase wear

of moving parts.

● Place the welder in an area that

provides at least 12” (30,48 cm) of

ventilation space at both the front

and rear of the unit. Keep all

obstructions away from this

ventilation space.

● Store wire in a clean, dry location

with low humidity to preserve the

wire coating.

● The receptacle used for the welder

must be properly grounded and the

welder must be the only load on the

power supply circuit. Refer to the

Circuit Amps chart on page 1 for

correct circuit capacity.

● The use of an extension cord is not

recommended for electric arc

welding machines. The voltage drop

in the extension cord may significantly degrade the performance of

the welder.

Welder components listed below

are in the wire feed compartment.

Open and remove.

HANDLE ASSEMBLY

1. Remove screws from handle. Slide

handle between welder front panel

Do not breathe fumes that

are produced by the arc

welding operation. These

fumes are dangerous. If the welding

area cannot be adequately ventilated,

be sure to use an air supplied

respirator.

● Keep the head and face out of the

welding fumes.

● Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

contain zinc, mercury, or beryllium

without completing the following

precautions:

a. Remove the coating from the

base metal.

b.Make sure that the welding area

is well ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The electromagnetic field

that is generated during arc

welding may interfere with

the operation of various

electrical and electronic devices such as

cardiac pacemakers. Persons using such

devices should consult with their

physician prior to performing any

electric arc welding operations.

● Route the wire gun and work cables

together and secure with tape

when possible.

● Never wrap arc welder cables

around the body.

● Always position the wire gun and

work leads so that they are on the

same side of the body.

● Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

equipment is turned off and excess

wire is cut off. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

Cylinders can explode if

damaged. Shielding gas

3

WG3013

cylinders contain gas under high

pressure. If damaged, a cylinder can

explode. Since gas cylinders are

normally part of the welding process,

be sure to treat them carefully.

● Protect compressed gas cylinders

from excessive heat, mechanical

shocks, and arcs.

● Install and secure cylinders in an

upright position by chaining them

to stationary support or equipment

cylinder rack to prevent falling or

tipping.

● Keep cylinders away from any

welding or other electrical circuits.

● Never allow a welding electrode to

touch any cylinder.

● Use only correct shielding gas

cylinders, regulators, hoses, and

fittings designed for the specific

application; maintain them and

associated parts in good condition.

● Turn face away from valve outlet

when opening cylinder valve.

● Keep protective cap in place over

valve except when cylinder is in use

or connected for use.

● Read and follow instructions on

compressed gas cylinders, associated

equipment, and CGA publication P-1

listed in Safety Standards.

Never use

flammable gasses

with MIG welders. Only inert or nonflammable gasses such as carbon

dioxide, argon, helium, or mixtures of

one or more of these gasses are

suitable for MIG welding.

Never lift cylinders

off the ground by

their valves, caps, or with chains or slings.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents, U.S.

Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

General Safety

(Continued)

Installation

Assembly

www.chpower.com

!

WARNING

!

WARNING

!

WARNING

!

DANGER

!

DANGER

!

WARNING

Page 4

and top cover aligning the holes in

handle with holes in top cover.

2. Fasten screws through top cover and

into handle.

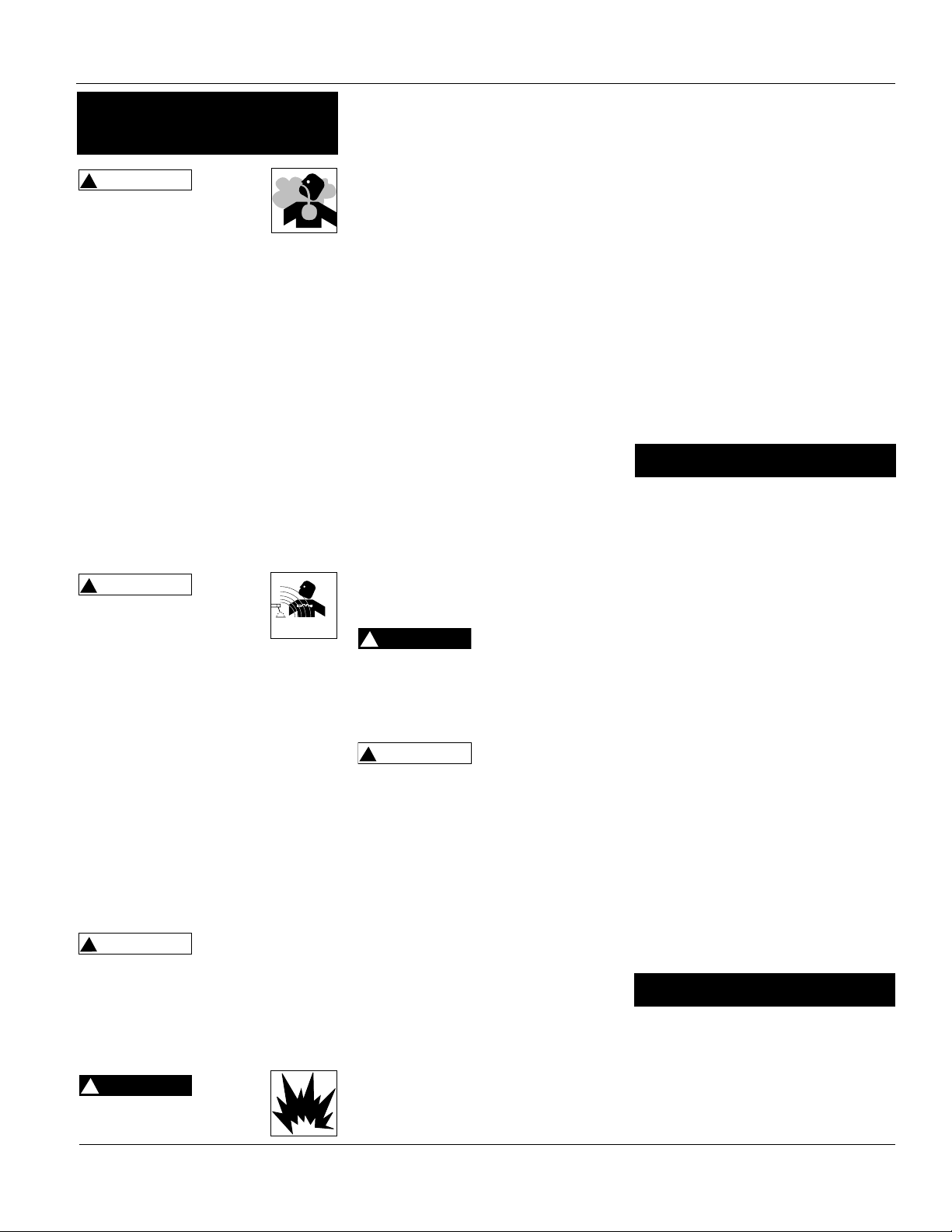

WHEEL AND AXLE ASSEMBLY

1. Insert axle supports into slots in the

welder housing.

2. Insert axle through the axle supports

and firmly push wheels onto axle.

3. Secure wheel with e-clips and wheel

caps.

GAS CYLINDER BRACKET ASSEMBLY

1. Place bracket on welder aligning the

holes in welder housing.

2. Fasten screws through bracket and

into cabinet.

FOOT ASSEMBLY

1. Place foot on welder and align holes

in the welder housing.

2. Fasten screws through foot into

cabinet.

Ground Clamp

1. Loosen hex nut on work clamp.

2. Insert cord through clamp handle and

slide bare wire under the clamp block.

Tighten hex nut making sure bare

wire is clamped securely (Figure 3).

Wire Installation

Welding power

may be applied to

the output terminals, feed roll, work

clamp, gun cable connection and

welding wire even when the the gun

switch is not activated. Do not touch

these parts when the welding machine

is on.

NOTE: Before installing welding wire,

be sure that the diameter of the

welding wire matches the groove in the

drive roller on the wire feed

mechanism and the wire matches the

contact tip in the end of the gun. A

mismatch on any item could cause the

wire to slip or bind.

1. Verify the unit is off and open the

panel on the welder to expose the

wire feed mechanism.

2. Remove the spool quick lock, by

pushing in and rotating 1/4 turn

counterclockwise. The knob, spring,

and spool spacer can now be removed.

NOTE: Spool spacer and spindle spacer

act as an 8” spool spindle adapter.

Purchase of an adapter is not necessary.

* See Figure 4 for assembly.

3. Loosen the wire feed tensioning

screw on the drive mechanism. This

allows initial feeding of the wire into

the gun liner by hand.

4. Install the wire spool onto the

spindle so that the wire can come off

the spool on the end closest to the

wire feed guide tube. Do not cut

the wire loose yet. Install the spool

spacer, spring, and quick lock knob

by pushing in and turning the knob

1/4 rotation clockwise.

5. Hold the wire and cut the wire end

from the spool. Do not allow the wire

to unravel. Be sure that the end of the

wire is straight and free of burrs.

4

Wire Feed Arc Welder

6. Feed the wire through the wire feed

guide tube, over the groove in the

drive roll and into the gun liner.

Tighten the wire feed tensioning screw

so that it is snug. Do not over tighten.

7. Remove the nozzle by turning

counterclockwise. Then unscrew

the contact tip from the end of the

welding torch (See Figure 5). Plug the

welder into the proper power supply

receptacle.

HINT: Keep torch cable straight when

feeding wire.

8. Turn on the welder and set the wire

speed rate to 5. Activate the gun

switch until the wire feeds out past

the torch end. Turn welder off.

9. Carefully slip the contact tip over the

wire and screw it into the torch neck.

Install the nozzle by turning clock-

wise (See Figure 6). Cut the wire off

approximately 1/4” from the end of

the nozzle.

POLARITY

For gas shielded welding, connect the

cable coming out of the torch to the (+)

socket and the ground clamp cable to

the (-) socket on the front panel. For

flux-core (no-gas) welding, connect

torch to (-) and work clamp to (+).

DUTY CYCLE / THERMOSTATIC

PROTECTION

Welder duty cycle is the percentage of

actual weld time that can occur in a ten

minute interval. For example, at a 10%

duty cycle, actual welding can occur for

one minute, then the welder must cool

for nine minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A yellow

lamp is illuminated on the front panel

Assembly (Continued)

Figure 2 - WG3013 Assembly

Clamping

Block

Figure 3 - Work Clamp Assembly

Tension

Screw

Panel

Drive Roller

Spool

Spacer

Guide

Tube

Spindle

4” or 8”

Spool

Spring

Spool

Lock

Figure 4 - Weld Wire Routing

Torch Neck

Contact Tip

Nozzle

Figure 5 - Torch Nozzle

Spindle

Spacer

*Reverse

position and

insert into 8”

spool

Contact Tip Markings

Wire Size mm

.024” or .6

.030” or .8

.035” or .9

.040” or 1.0

www.chpower.com

!

WARNING

Page 5

5

WG3013

if the duty cycle is exceeded. Welding

operations may continue when the

yellow lamp is no longer illuminated.

1. Cut retainer stiffeners and

detachable handle away from shield.

Trim the excess plastic to remove

sharp edges.

2. Insert filter lens.

3. Attach the stiffeners over the pins on

the lens retainers (See Figure 6).

4. To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 7).

NOTE: If you have never welded

before or have little experience, a

full face helmet is recommended.

Both hands are needed to stabilize

and control the angle and arc

length of the torch.

Improper handling

and maintenance

of compressed gas cylinders and

regulators can result in serious injury

or death! Always secure gas cylinders

to the tank bracket kit, a wall or other

fixed support to prevent the cylinder

from falling over. Read, understand,

and follow all the compressed gases

and equipment hazards in the safety

instructions.

NOTE: Shielding gas is not required if

flux-cored welding wire is used.

GAS TYPES

There are 3 types of gas generally used

for gas metal arc welding; 100% argon,

a mixture of 75% argon and 25%

carbon dioxide (C25) or 100% carbon

dioxide. However, 100% carbon

dioxide is not recommended due to

unsatisfactory weld beads. This welder

does not perform well with 100%

carbon dioxide. The 75/25 mixture is

recommended for general steel

welding. For aluminum welding, use

100% argon. Cylinders of either type

gas may be obtained at your local

welding supply outlet. Secure cylinder

in place on your welding machine or

other support to prevent the cylinder

from falling over.

NOTE: Use of incorrect gas may lead to

little or no penetration of welding

bead.

REGULATOR (NOT INCLUDED)

The regulator provides a constant

shielding gas pressure and flow rate

during the welding process.

HOOKUP PROCEDURE

Cylinder gas is

under high

pressure. Point cylinder outlet away

from yourself and any bystanders

before opening.

1. These units fit a 20 cubic ft bottle.

2. With the cylinder securely installed,

remove the cylinder cap, stand to the

side of the cylinder opposite the

outlet, and open the valve slightly,

turning counterclockwise. When gas

is emitted from the cylinder, close the

valve by turning clockwise. This will

blow out dust or dirt that may have

accumulated around the valve seat.

3. Install the regulator onto the

cylinder valve, keeping the face of

the gauges in the vertical position

and tighten the stem nut securely

to the gas valve.

4. Install one end of the gas hose (not

included) to the fitting on the rear

of the welder and the other end to

the fitting on the regulator using

hose clamps (not included) on each

connection. Make sure the gas hose

is not kinked or twisted.

5. Once again, stand opposite the

cylinder outlet and slowly open the

cylinder valve. Inspect for leaks in

the connections.

6. Pull the trigger on the gun to allow

the gas to flow. While the trigger is

pulled and gas is flowing, adjust the

gas regulator to 30-35 cfh (cubic

feet per hour). Release the trigger.

7. Remember to close the gas valve

when finished welding.

1. Be sure to read,

understand, and comply

with all precautions in

the General Safety

Information section. Be

sure to read the entire section

entitled Welding Guidelines prior to

using this equipment.

2. Verify welder is off.

3. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other contaminants. These contaminants make

welding difficult and cause poor

welds.

All persons operating this

equipment or in the area

while equipment is in use

must wear protective welding gear

including: eye protection with proper

shade, flame resistant clothing, leather

welding gloves, and full foot

protection.

WHETHER OR

NOT THE TRIGGER

IS PULLED, the welding wire is LIVE

whenever the welder is turned ON.

If heating, welding, or

cutting materials that are

galvanized, zinc plated, lead,

or cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

4. Connect the work clamp to the

work piece or workbench (if metal).

Make sure the contact is secure.

Avoid surfaces with paint, varnish,

corrosion, or non-metallic materials.

5. Position the Heat Selector on the

front panel to the desired setting.

Assembly

(Continued)

Shielding Gas

Installation

Handshield

Assembly

Figure 6

Lens

Lens

Retainer

Retainer

Stiffener

Figure 7

www.chpower.com

Operation

!

DANGER

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

MANUAL

Page 6

6

Wire Feed Arc Welder

See application decal inside door of

wire feed compartment for proper

heat settings.

NOTE: These settings are general

guidelines only. Heat setting may vary

according to welding conditions and

materials.

6. Rotate the Wire Speed Control to

setting number 5 to start with, then

adjust as needed after test weld.

7. Plug the input cord into a proper

voltage receptacle with proper

circuit capacity (See Chart under

circuit requirements on page 1).

8. Switch the welder ON.

9. Verify that the wire is extended

1/4” from the contact tip. If not,

squeeze the trigger to feed

additional wire, release the trigger,

and cut wire to proper length.

10. Position the wire feed gun near the

work piece, lower the welding

helmet by nodding the head, or

position the hand shield, and

squeeze the gun trigger. Adjust heat

setting and wire speed as needed.

11.When finished welding, turn welder

off and store properly.

Disconnect power

supply and turn

machine off before inspecting or

servicing any components. Keep the

wire compartment cover closed at all

times unless the wire needs

replacement.

Before every use:

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of power cord and

immediately repair or replace any

cord if damaged.

3. Inspect the condition of the gun tip

and nozzle. Remove any weld slag.

Replace gun tip or nozzle if

damaged.

Do not operate this

welding machine

with cracked or missing insulation on

welding cables, wire feed gun, or

power cord.

Every 3 months:

1. Replace any unreadable safety

labels on the welder.

2. Use compressed air to blow all dust

and lint from the ventilation

openings.

3. Clean the wire groove on the drive

roll. Remove wire from the feed

mechanism, remove screws from the

drive roll housing. Use a small wire

brush to clean the drive roll. Replace

if worn or damaged.

Consumer and Wear Parts

The following parts require routine

maintenance:

• Wire feed drive roller

• Gun liner - replace if worn

• Nozzle/contact tips

• Wire - this welder will accept either

4” or 8” diameter spools. Welding wire

is susceptible to moisture and oxidizes

over time, so it is important to select a

spool size that will be used within

approximately 6 months. For mild steel

welding, AWS ER70S6 solid wire or

AWS E71T-GS flux-core wire is

recommended.

• Contact tips - use Campbell Hausfeld,

Tweco

®

, and other compatible tips.

• Nozzle - use Tweco

®

style or compatible

nozzle. Use Campbell Hausfeld nozzle

model WT5021 found at place of

purchase of welder, or use Tweco

®

style

nozzle (or compatible nozzle) found at

local welding supply store.

Changing Wire Sizes

DRIVE ROLLER

There are two grooves in the Drive

Roller. The small groove is for .024” (.6

mm) wire and the other is for .030” .035” (.8 - .9 mm) wire. Remove the

roller cover and flip the drive roll to

choose the correct groove (see Parts

Breakdown).

FLUX CORE WIRE

Due to small inconsistencies in wire

diameter, using one size larger tip is

recommended. For example:

• If wire diameter is .030, use .035 tip.

• If wire diameter is .035, use .040 tip.

This welder is setup for .035 (.9 mm)

wire and has a .040 tip. Since this

welder uses .030 and .035 Flux Core

Wire, the drive roller should be in its

factory pre-set condition.

MIG WIRE

Since MIG wire maintains fair wire

diameter consistency, the contact tip

used should match the wire size used.

When using .024 (.6 mm) wire, use the

small groove on the drive roller. When

using .030 - .035 (.8 - .9 mm) MIG or

Aluminum wire, use the factory set

large groove.

ALUMINUM WIRE

When using Aluminum wire, it is best

to use a larger size tip than the wire

size being used. For example:

• If wire diameter is .030, use .035 tip.

When using .030 - .035 (.8 - .9 mm) MIG

or Aluminum wire, use the factory set

large groove. Aluminum wire is very

weak and should not have the same

tension on the drive roller as Flux Core

or MIG wire should. When tensioning

Aluminum wire down to the Drive

Roller, turn the tension screw three full

turns or until the Drive Roller begins to

grip the wire and feed it through the

torch cable.

Operation

(Continued)

Maintenance

www.chpower.com

MIG

WT5021

Figure 8 - Nozzle

Call (800) 746-5641

for replacement parts.

!

WARNING

!

WARNING

Page 7

7

WG3013

Welding Guidelines

General

This line of welding machines can

utilize the Flux Cored Arc Welding

(Gasless) process or the Gas Metal Arc

Welding (MIG) process. The weld must

be protected (shielded) from

contaminates in the air while it is

molten. The gasless process uses a

tubular wire with a flux material inside.

The flux creates a shielding gas when

melted. The MIG process uses inert gas

to shield the weld while molten.

When current is produced by a

transformer (welding machine) and

flows through the circuit to the weld

wire, an arc is formed between the end

of the weld wire and the work piece.

This arc melts the wire and the work

piece. The melted metal of the weld

wire flows into the molten crater and

forms a bond with the work piece as

shown (Figure 9).

Arc Welding Basics

Five basic techniques affect weld

quality. These are: wire selection, heat

setting, weld angle, wire speed, and

travel speed. An understanding of

these techniques is necessary for

effective welds.

HEAT SETTING

The correct heat involves the adjustment of the welding machine to the

required setting. Heat or voltage is

regulated by a switch on the welder.

The heat setting used depends on the

size (diameter) and type of wire,

position of the weld, and the thickness

of the work piece. Consult specif-

ications listed on the welder. It is

suggested that the welder practice with

scrap metal to adjust settings and

compare welds with Figure 11.

WIRE TYPE AND SIZE

The correct choice of wire type involves

a variety of factors, such as welding

position, work piece material type,

thickness and condition of surface to be

welded. The American Welding Society,

AWS, has set up certain requirements

for each type of wire.

FLUX-CORE WIRE

E - 7

0 T - GS

Weld strength, times

10,000 psi

Welding positions (0

for flat or horizontal,

1 for any position)

Tubular flux core wire

Flux type

AWS E71T-GS or E71T-11 is

recommended for this welder.

SOLID WIRE

ER - 70

S - 6

Weld strength, times

1,000 psi

Solid wire

Wire composition

ER-70S6 is recommended for this

welder.

WELD ANGLE

Weld angle is the angle at which the

nozzle is held during the welding

process. Using the correct angle

ensures proper penetration and bead

formation. As different welding

positions and weld joints become

necessary, nozzle angle becomes an

increasingly important factor in

obtaining a satisfactory weld. Weld

angle involves two positions - travel

angle and work angle.

Travel angle is the angle in the line of

welding and may vary from 5º to 45º

from the vertical, depending on

welding conditions.

Work angle is the angle from hori-

zontal, measured at right angles to the

line of welding. For most applications, a

45º travel angle and 45º work angle is

sufficient. For specific applications,

consult an arc welding handbook.

WIRE SPEED

The wire speed is controlled by the

knob on the front panel. The speed

needs to be “tuned” to the rate at

which the wire is being melted in the

arc. Tuning is one of the most critical

functions in wire feed welding. Tuning

should be performed on a scrap piece

of metal the same type and thickness as

that to be welded. Begin welding with

one hand “dragging” the gun nozzle

across the scrap piece while adjusting

the wire speed with the other hand.

Too slow of speed will cause sputtering

and the wire will burn up into the

contact tip. Too fast a speed will also

cause a sputtering sound and the wire

will push into the plate before melting.

A smooth buzzing sound indicates the

wire speed is properly tuned. For

aluminum, wire speed is typically set

higher (7 - 9 speed range).

NOTE: Repeat the tuning procedure

each time there is a change in heat

setting, wire diameter or type, or work

piece material type or thickness.

TRAVEL SPEED

The travel speed is the rate at which

the torch is moved across the weld

area. Factors such as diameter and type

of weld wire, amperage, position, and

Slag

Weld

Wire

Flux

(Gasless

only)

Work Piece

Shielding

Gas

Contact

Tip

Crater

Nozzle

Figure 9 - Weld Components

www.chpower.com

TRAVEL ANGLE

WORK ANGLE

5º - 45º

5º - 45º

Figure 10 - Weld Angle

Page 8

work piece material thickness all affect

the speed of travel necessary for

completing a good weld (See Fig. 11).

When the speed is too fast, the bead is

narrow and bead ripples are pointed as

shown. When the speed is too slow, the

weld metal piles up and the bead is

high and wide. For aluminum, travel

speed is typically faster.

SLAG REMOVAL (FLUX-CORE WIRE

ONLY)

Wear ANSI

approved safety

glasses (ANSI Standard Z87.1) and

protective clothing when removing

slag. Hot, flying debris can cause

personal injury to anyone in the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the

slag can be removed. Removal is done

with a chipping hammer. Lightly tap

the slag with the hammer and break it

loose from the weld bead. The final

clean-up is done with a wire brush.

NOTE: When making multiple weld

passes, remove the slag before each

pass.

WELDING POSITIONS

Four basic welding positions can be

used; flat, horizontal, vertical, and

8

Wire Feed Arc Welder

Welding Guidelines (Continued)

overhead. Welding in the flat position

is easier than any of the others because

welding speed can be increased, the

molten metal has less tendency to run,

better penetration can be achieved,

and the work is less fatiguing. Welding

is performed with the wire at a 45º

travel angle and 45º work angle.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these

welds.

Overhead welding is the least desirable

position as it is the most difficult and

dangerous. Heat setting and wire

selection will vary depending upon the

position.

All work should be performed in the

flat position if possible. For specific

applications, consult an arc welding

technical manual.

WELD PASSES

Sometimes more then one pass is

necessary to fill the joint. The root pass

is first, followed by filler passes and the

cover pass. If the pieces are thick, it may

be necessary to bevel the edges that

are joined at a 60º angle.

NOTE: Remember to remove the slag

before each pass for gasless process.

www.chpower.com

Normal Heat, Wire Speed, Travel

Speed

Heat Too Low

Heat Too High

Wire Speed Too Fast

Wire Speed Too Slow

Travel Speed Too Slow

Travel Speed Too Fast

Base Metal

Figure 11 - Weld Appearance

Figure 12 - Weld Passes

Cover

Filler

Root

Figure 13 - Multiple Weld Passes

!

WARNING

Page 9

ALUMINUM WELDING

Any aluminum surface to be welded,

must be cleaned thoroughly with a

stainless steel brush to eliminate any

oxides on the weld and grounding

surface. 100% Argon must be used

when welding aluminum. If Argon is not

used, metal penetration is unlikely.

9

WG3013

Welding Guidelines (Continued)

PUSH VS PULL TECHNIQUE

The type and thickness of the work

piece dictates which way to point the

gun nozzle. For thin materials (18 gauge

and up) and all aluminum, the nozzle

should point out in front of the weld

puddle and push the puddle across the

workpiece. For thicker steel, the nozzle

should point into the puddle to increase

weld penetration. This is called

backhand or pull technique

(See Figure 14).

1. Verify that welder is OFF and power

cord disconnected.

2. Remove welder cover to expose the

ON/OFF switch.

3. Disconnect the black and white

power cord wires connected to the

ON/OFF switch.

4. Disconnect the green power cord

wire connected to welder frame.

5. Loosen the cord strain screw(s) and

pull cord out of strain relief.

6. Install new cord in reverse order.

PUSH

PULL

Figure 14

Supply Cable

Replacement

www.chpower.com

Page 10

10

Troubleshooting Chart - Welder

Symptom Possible Cause(s) Corrective Action

1. Duty cycle exceeded

2. Poor ground clamp connection

3. Defective power switch

4. Blown breaker or fuse

1. Wrong size gun tip

2. Gun liner clogged or

damaged

3. Gun tip clogged or damaged

4. Feed roller worn

5. Not enough tension

Slag inside gun nozzle

1. Poor contact

2. Using an extension cord with

excessive length

1. Wire jammed

2. Out of wire

3. Not enough tension

4. Wire liner worn

5. Wire disconnected internally

6. Contact tip clogged

1. Wire speed too slow

2. Travel speed too slow or heat

is too high

For Information About This Product, Call 1-800-746-5641

Bead is intermittently too

thin

Bead is intermittently too

thick

Ragged depressions at

edge of weld

Weld bead does not

penetrate base metal

Wire sputters and sticks

1. Fast and/or inconsistent travel speed

2. Output heat setting too low

1. Slow and/or inconsistent travel speed

2. Output heat setting too high

1. Travel speed too fast

2. Wire speed too fast

3. Output heat setting too high

1. Inconsistent travel speed

2. Output heat setting too low

3. No or low shielding gas

4. Wrong shielding gas (aluminum)

5. Extension cord is too long

6. (Aluminum) Possible oxide buid-up on

surface

1. Damp wire

2. Wire speed too fast

3. Wrong type of wire

4. No or low shielding gas

1. Allow welder to cool until ON/OFF Switch lamp goes out

2. Be sure all connections are secure, and attaching surface is

clean

3. Replace switch

4. Reduce circuit load, reset breaker or replace fuse

1. Use proper size gun tip

2. Clean or replace gun liner

3. Clean or replace gun tip

4. Replace

5. Tighten tensioning screw

Clean slag from gun nozzle

1. Be sure all connections are secure, and attaching surface is

clean

2. Never use an extension cord longer than 20 ft

1. Reload wire

2. Replace wire spool

3. Tighten tensioning screws if wire is slipping

4. Replace liner

5. Call 1-800-746-5641 for assistance

6. Replace contact tip

1. Run speed in 7 - 10 range

2. Increase the travel speed or reduce heat settings

No output

Wire tangles at drive roller

Gun nozzle arcs to work

surface

Ground clamp and/or

cable gets hot

Wire does not feed

(Aluminum) Wire burns back

into tip or (Aluminum) Metal

bubbles or burns through

Troubleshooting Chart - Welds

Symptom Possible Cause(s) Corrective Action

1. Decrease and maintain constant travel speed

2. Increase output heat setting

1. Increase and maintain travel speed

2. Reduce output heat setting

1. Decrease travel speed

2. Decrease wire speed

3. Reduce output heat setting

1. Decrease and maintain constant travel speed

2. Increase output heat setting

3. Use gas for MIG process or refill bottle

4. Use only 100% Argon gas

5. Never use an extension cord longer than 20 ft

6. Clean surface thoroughly with a stainless steel

brush only

1. Use dry wire and store in dry location

2. Reduce wire speed

3. Use flux core wire when not using gas

4. Use gas for MIG process or refill bottle

www.chpower.com

Wire Feed Arc Welder

Page 11

11

Limited 5-3-1 Warranty

1. Duration: The manufacturer warrants that it will repair, at no charge for parts or labor, the Welder, Welding Gun, or Cables, proven defective in material or

workmanship, during the following time period(s) after date of original retail purchase:

For 5 Years: The Welder Transformer and Rectifier

For 3 Years: The Entire Welder (excluding clamps, welding gun, electrode holder, cables, or accessories packed with welder)

For 1 Year: The Welding Clamps, MIG Gun, Electrode Holder, Accessories, and Welding Cables (as applicable)

2. Who Gives This Warranty (Warrantor):

The Campbell Group / A Scott Fetzer Company

100 Production Drive

Harrison, OH 45030

Telephone: (513)-367-4811

3. Who Receives This Warranty (Purchaser): The original purchaser of the Campbell Hausfeld product.

4. What is covered under this warranty: Defects in material and workmanship which occur within the duration of the warranty period. This warranty

extends to the Welder, the Welders Transformer and Rectifier, Welding Gun or Electrode Holder, and cables only.

5. What is not covered under this warranty:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSEARE LIMITED IN DURATION TO THIS EXPRESS

WARRANTY. After this period, all risks of loss, from whatever reason, shall be on the purchaser. Some states do not allow limitations on how long an

implied warranty lasts, so above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT FAILURE OR MALFUNCTION OF

THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow limitations on how long an implied warranty lasts, so above limitations may not apply

to you.

C. This warranty does not apply to any accessory items included with the product which are subject to wear from usage; the repair or replacement of

these items shall be at the expense of the owner. These MIG items include but are not limited to; Contact Tips, Nozzles, Gun Liners, Drive Rollers, Felt

Wire Cleaner. In addition, this warranty does not extend to any damage caused by the untimely replacement or maintenance of any of the previously

listed CONSUMABLE parts.

D. Any failure that results from accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s

manual(s) supplied with the product.

E. Pre-delivery service, i.e. assembly and adjustment.

7. Responsibilities of Warrantor under this warranty: Repair or replace, at Warrantor’s option, products or components which have failed within duration

of the warranty period.

8. Responsibilities of purchaser under this warranty:

A. Deliver or ship the Campbell Hausfeld product or component to Campbell Hausfeld. Freight costs, if any, must be borne by the purchaser.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. When Warrantor will perform repair or replacement under this warranty: Repair or replacement will be scheduled and serviced according to the

normal work flow at the servicing location, and depending on the availability of replacement parts.

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

WG3013

www.chpower.com

Page 12

12

WG3013 Wiring Diagram

Wire Feed Arc Welder

www.chpower.com

+-

WHITE

L2

L1

GREEN

BLACK

ON/OFF

1

4

GROUND

S1

S3

1

2

2

M

FAN

~

5

Y

6

S5 NC

OPENS @ 127˚C

S2

MIN

MAX

T1

S5

~

+

~

S4

GUN

WIRE SPEED

CONTROL BOARD

T2

-

DRIVE

DECK

-

+

M

1243

Page 13

13

WG3013

www.chpower.com

For Replacement Parts, call 1-800-746-5641

Address parts correspondence to:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Please provide following information:

- Model number

- Serial number

- Part description and number as

shown in parts list

MODEL WG3013

2

4

6

8

1

3

5

7

11

12

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27

29

28

30

31

32

33

34

35

36

38

37

39

40

41

42

3

1

40

40

9 & 10

43

** Contact Tip (See chart on Page 15)

45

46

44

13

Page 14

14

Wire Feed Arc Welder

www.chpower.com

1 Torch assembly and hose (Includes Nos. 2-6, 34, and 50-52) WC600700AV 1

2 Torch body, front and back WC600201AV 1

3 Hanger clip WC600003AV 1

4 Nozzle, Tweco®Style WT502100AJ 1

5 Trigger knob WC600202AV 1

6 Torch contact spring WC600203AV 1

7 Work clamp (Cord not included) WC100100AV 1

8 Welding cable 8 AWG (6 ft) ❋ 1

9 Wire speed knob WC400201AV 1

10 Wire speed control board WC402100AV 1

11 Heat selector switch WC400300AV 2

12 On/off switch WC400000AV 1

13 Safety decal DK670100AV 1

14 Handle WC300600AV 1

15 Power cord 14-3 AWG (6 ft) Type SJT ❋ 1

16 Spool spindle WC500300AV 1

17 #10-32 x .5” Pan head sheet metal screw ❋ 2

18 Wire See Chart Below 1

19 Spool adapter WC500200AV 1

20 Spool spring WC500101AV 1

21 Spool locking hub WC500100AV 1

22 Drive deck assembly (Includes Nos. 23-29) WC500000AV 1

23 Tension spring WC500003AV 1

24 Tension screw WC500002AV 1

25 Roller .6-.9mm (.024-.035 in.) WC500001AV 1

26 Roller cover WC500004AV 1

27 #8-36 x 1.5” Pan head screw ❋ 3

28 Swing arm WC500005AV 1

29 Swing arm roller WC500007AV 1

30 Strain relief WC102000AV 1

31 Wheel WC701200AV 2

32 Front foot WC702100AV 1

33 Liner, coated metal WC600208AV 1

34 Gas cylinder bracket WC702200AV 1

35 Axle WC703100AV 1

36 Wheel hub WC703500AV 1

37 Dinse connector WC000200AV 2

38 Dinse socket WC000300AV 2

39 Torch ring WC600009AV 1

40 #10-24 x 1/2” Screw ❋ 9

41 Axle support WC703600AV 2

42 5mm I.D. e-ring ❋ 2

43 Swan neck with Diffuser WC600701AV 1

44 Trumpet liner WC600305AV 1

45 Valve body WC600204AV 1

46 Gas bottle strap WC802000AV 1

❋ Standard hardware item, available at local hardware or welder supply store

Replacement Parts List - Models WG3013

Ref Part Number for Model:

No. Description WG3013 Qty

OPTIONAL WIRE

Part Number Part Number

Type Description (1 pound) (10 pound)

Flux E71T-GS .030” WE200001AV WE201000AV

Flux E71T-GS .035” WE200501AV WE201500AV

MIG ER70S6 .024” WE300001AV WE301500AV

MIG ER70S6 .030” WE300501AV WE302000AV

MIG ER70S6 .035” WE301001AV WE302500AV

Aluminum MIG ER5356 .030” WE303001AV N/A

**OPTIONAL CONTACT TIPS (4/package)

Size

mm in. Part Number

0.6 0.024 WT501200AJ

0.8 0.030 WT501300AJ

0.9 0.035 WT501400AJ

Page 15

15

WG3013

www.chpower.com

Glossary of Welding Terms

AC or Alternating Current - electric

current that reverses direction

periodically. Sixty cycle current travels

in both directions sixty times per

second.

Arc Length - the distance from the

end of the electrode to the point

where the arc makes contact with the

work surface.

Base Metal - the material to be

welded.

Butt Joint - a joint between two

members aligned approximately in the

same plane.

Crater - a pool, or pocket, that is

formed as the arc comes in contact with

the base metal.

DC or Direct Current - electric current

which flows only in one direction. The

polarity (+ or -) determines which

direction the current is flowing.

DC Reverse Polarity - occurs when

the electrode holder is connected to

the positive pole of the welding

machine. Reverse Polarity directs more

heat into melting the electrode rather

then the work piece. It is used on

thinner material.

DC Straight Polarity - occurs when

the electrode holder is connected to

the negative pole of the welding

machine. With straight polarity more

heat is directed to the work piece for

better penetration on thicker material.

Electrode - a coated metal wire having

approximately the same composition as

the material being welded.

Fillet Weld - approximately a triangle

in cross-section, joining two surfaces at

right angles to each other in a lap, T or

corner joint.

Flux - a coating, when heated, that

produces a shielding gas around the

welding area. This gas protects the

parent and filler metals from impurities

in the air.

Flux Cored Arc Welding (FCAW) also called Gasless, is a welding process

used with a wire-feed welding

machine. The weld wire is tubular with

flux material contained inside for

shielding.

Gas Metal Arc Welding (GMAW) also called MIG, is a welding process

used with a wire feed welding

machine. The wire is solid and an inert

gas is used for shielding.

Gas Tungsten Arc Welding (GTAW) also called TIG, is a welding process

used with welding equipment with a

high frequency generator. The arc is

created between a non-consumable

tungsten electrode and the work piece.

Filler metal may or may not be used.

Lap Joint - a joint between two

overlapping members in parallel

planes.

Open Circuit Voltage (OCV) - the

voltage between the electrode and the

work clamp of the welding machine

when no current is flowing (not

welding). The OCV determines how

quickly the arc is struck.

Overlap - occurs when the amperage is

set too low. In this instance, the molten

metal falls from the electrode without

actually fusing into the base metal.

Porosity - gas pockets, or cavities,

formed during weld solidification. They

weaken the weld.

Penetration - the depth into the work

piece that has been heat effected by

the arc during the welding process. A

good weld achieves 100% penetration

meaning that the entire thickness of

the work piece has been heated and

resolidified. The heat effected area

should be easily seen on the opposite

side of the weld.

Shielded Metal Arc Welding

(SMAW) - also called Stick, is a welding

process with uses a consumable

electrode to support the arc. Shielding

is achieved by the melting of the flux

coating on the electrode.

Slag - a layer of flux soot that protects

the weld from oxides and other

contaminants while the weld is

solidifying (cooling). Slag should be

removed after weld has cooled.

Spatter - metal particles thrown from

the weld which cool and harden on the

work surface. Spatter can be minimized

by using a spatter resistant spray on the

work piece before welding.

Tack Weld - weld made to hold parts

in proper alignment until final welds

are made.

Travel Angle - the angle of the

electrode in the line of welding. It

varies from 5º to 45º depending on

welding conditions.

T Joint - made by placing the edge of

one piece of metal on the surface of

the other piece at approximately a 90º

angle.

Undercut - a condition that results

when welding amperage is too high.

The excessive amperage leaves a

groove in the base metal along both

sides of the bead which reduces the

strength of the weld.

Weld Pool or Puddle - a volume of

molten metal in a weld prior to its

solidification as weld metal.

Weld Bead - a narrow layer or layers of

metal deposited on the base metal as

the electrode melts. Weld bead width is

typically twice the diameter of the

electrode.

Work Angle - the angle of the

electrode from horizontal, measured at

right angles to the line of welding.

Page 16

Wire Feed Arc Welder

16

www.chpower.com

Notes

Loading...

Loading...