Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

IN952501AV 4/01

Operating Instructions

Welder/Generator

These units are powered by air-cooled

four cycle engines and designed to run

at maximum RPM and give a

continuous wattage as rated. On

certain models, a low-oil level shutoff

is provided to protect the engine. This

feature is usually associated with

extended run models. The alternator is

thermostatically protected. To operate

this unit as a generator or welder, set

the switch on the front panel

accordingly

When unpacking, inspect carefully for

any damage that may have occurred

during transit. Make sure any loose

fittings, bolts, etc., are tightened

before putting unit into service. Report

any missing items by calling 1-800-746-

5641.

Danger alerts you

to a hazard that

WILL result in death or serious injury

Warning alerts you

to a hazard that

COULD result in death or serious

injury.

Caution alerts you

to a hazard that

MAY result in minor injury.

Notice alerts you

to important

information that will help you prevent

damage to equipment.

● Before starting or

servicing any

welder/generator, read

and understand all

instructions. Failure to

follow safety precautions or

instructions can cause equipment

damage and or serious personal

injury or death. Engine instructions

for these units are contained in a

separate manual. Retain all manuals

for future reference.

● Never use this welder/generator for

any application other than that

specified by the manufacturer.

Never operate this welder/generator

under conditions not approved by

the manufacturer. Never attempt to

modify this welder/generator to

perform in any manner not

intended by the manufacturer.

● For maintenance and repairs, use

only products and parts

recommended by the manufacturer.

● Be sure that the welder/generator is

properly grounded to an external

ground path prior to operation.

Refer to the section entitled

"Grounding Instructions" for proper

grounding procedures.

● Be sure that the welder/generator is

operated only by persons who have

read and understand these

instructions.

● Be sure that the welder/generator is

placed on a flat level surface prior

to and during operation. The

welder/generator must not slide or

shift during operation.

● Keep all persons away from the

welder/generator during operation.

● Do not allow persons wearing loose

clothing or jewelry to start or

operate the welder/generator.

Loose clothing or jewelry may

become entangled in moving

components, causing equipment

damage and or personal injury.

● Keep all persons away from parts

that move or become hot during

operation.

● Be sure all powered devices are shut

off prior to connecting them to the

welder/generator.

● Keep the welder/generator clean

and well maintained at all times.

Never operate this

welder/generator in an

explosive or flammable

atmosphere or poorly ventilated area.

● Be sure that all tools and appliances

are in good repair and are properly

grounded. Use devices that have

three prong power cords. If an

extension cord is used, be sure that

it has three prongs for proper

grounding.

Do not operate this

welder/generator

on wet surfaces or in the rain.

Shut off the

engine and

disconnect the spark plug wire before

performing any service or maintenance

to the unit.

● Use only unleaded fuel. Do not refill

the fuel tank while the engine is

running. Use precautions to prevent

fuel spillage during refills. Be sure

the fuel tank cap is securely in place

before starting the engine. Clean up

any spilled fuel before starting the

engine. Allow engine to cool for at

least two minutes before refueling.

● This welder/generator may be used

for emergency stand-by service. In

such cases, a manual transfer switch

must be installed between the

electric utilities meter and the

electrical distribution box. This

switch should be installed by a

licensed electrician.

Never mix oil with

gasoline for this

engine. This is a four cycle engine

designed to run on pure gasoline. Oil is

used for engine lubrication purposes

only.

Always keep a fire

extinguisher accessible while

performing arc welding

operations.

© 2001 Campbell Hausfeld

For parts, product & service information

visit www.chpower.com or call 1-800-746-5641

Description

Unpacking

General Safety

BUILT TO LAST

TM

!

DANGER

!

WARNING

!

CAUTION

NOTICE

MANUAL

!

WARNING

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

Page 2

2

Operating Instructions

● All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper use of electric

arc welders can cause

electric shock, injury, and

death! Take all precautions

described in this manual to reduce the

possibility of electric shock.

● Verify that all components of the

arc welder are clean and in good

condition prior to operating the

welder. Be sure that the insulation

on all cables, electrode holders, and

power cords is not damaged.

Always repair or replace damaged

components before operating the

welder. Always keep welder panels,

shields, etc. in place when operating

the welder.

● Always wear dry protective clothing

and welding gloves, and insulated

footwear.

● Always operate the welder in a

clean, dry, well ventilated area. Do

not operate the welder in humid,

wet, rainy, or poorly ventilated

areas.

● Be sure that the work piece is

properly supported and grounded

prior to beginning any electric arc

welding operation.

● Coiled welding cable should be spread

out before use to avoid overheating

and damage to insulation.

Never immerse the

electrode or

electrode holder in water. If the welder

becomes wet for any reason, be

absolutely certain that it is completely

clean and dry prior to attempting use!

● Always shut the equipment off prior

to moving the unit.

● Always attach the work lead first.

● Verify that the work piece is

securely grounded.

● Always shut off electric arc welding

equipment when not in use and

remove the electrode from the holder.

● Never allow any part of the body to

touch the electrode and ground or

grounded work piece at the same time.

● Awkward welding conditions and

positions can be electrically hazardous.

When crouching, kneeling or at

elevations, be sure to insulate all

conductive parts, wear appropriate

protective clothing, and take

precautions to prevent injury from falls.

● Never attempt to use this

equipment at current settings or

duty cycles higher than those

specified on the equipment labels.

● Never use an electric arc welder to

thaw frozen pipes.

Flying sparks and hot metal

can cause injury. As welds

cool, slag can be thrown

off. Take all precautions described in

this manual to reduce the possibility of

injury from flying sparks and hot metal.

● Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

● Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric arc welding

operations produce intense

light and heat and

ultraviolet (UV) rays. This

intense light and UV rays can cause

injury to eyes and skin. Take all

precautions described in this manual to

reduce the possibility of injury to eyes

and skin.

● All persons operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including:

welding helmet or shield with at

least shade 10, flame resistant

clothing, leather welding gloves,

and full foot protection.

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric arc welding

operations cause sparks

and heat metal to

temperatures that can cause severe

burns! Use protective gloves and

clothing when performing any metal

working operation. Take all precautions

described in this manual to reduce the

possibility of skin and clothing burns.

● Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use additional face shields and

flame resistant barriers as needed.

● Never touch work pieces until

completely cooled.

Heat and sparks produced

during electric arc welding

and other metal working

operations can ignite

flammable and explosive materials!

Take all precautions described in this

manual to reduce the possibility of

flames and explosions.

● Remove all flammable materials

within 35 feet (10.7 meters) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

● Take precautions to be sure that

flying sparks and heat do not cause

flames in hidden areas, cracks,

behind bulkheads, etc.

Fire hazard! Do not weld on

containers or pipes that

contain or have contained

flammable materials or

gaseous or liquid combustibles.

Arc welding closed

cylinders or containers such

as tanks or drums can cause

explosion if not properly

vented! Verify that any cylinder or

container to be welded has an

adequate ventilation hole, so that

expanding gases can be released.

Do not breathe fumes that

are produced by the arc

welding operation. These

fumes are dangerous. If the welding

area cannot be adequately ventilated,

be sure to use an air-supplied

respirator.

● Keep the head and face out of the

welding fumes.

● Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

contain zinc, mercury, or beryllium

without completing the following

precautions:

General Safety

(Continued)

www.chpower.com

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 3

3

a. Remove the coating from the

base metal.

b. Make sure that the welding area

is well ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The electromagnetic field

that is generated during

arc welding may interfere

with the operation of

various electrical and electronic devices

such as cardiac pacemakers. Persons

using such devices should consult with

their physician prior to performing any

electric arc welding operations.

● Route the electrode and work

cables together and secure with

tape when possible.

● Never wrap arc welder cables

around the body.

● Always position the electrode and

work leads so that they are on the

same side of the body.

● Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

equipment is turned off and electrode

is removed. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents, U.S.

Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed

Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA

22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quicy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data

Sheets and the manufacturers

instructions for metals, electrodes,

coatings and cleaners.

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate the

welder/generator in an

environment that is clean and dry.

Dust and dirt in the unit retain

moisture and increase wear of

moving parts.

● Store electrodes in a clean, dry

location with low humidity to

preserve the flux coating.

PRE-OPERATION

1. Check engine oil level. Oil is NOT

mixed with the gasoline, however

adequate oil supply is necessary for

proper engine lubrication. Refer to

the Engine Manual for SAE, API and

fill quantity specifications. Unit is

shipped without oil in engine.

2. Use of a Ground Fault Interrupter

(GFI) is strongly recommended.

Ground Fault Interrupters can

significantly reduce the possibility of

injury if an electrical short occurs. In

order to install a GFI, the

welder/generator neutral wire must

be internally grounded to the

welder/generator frame, and the

frame must be properly grounded

to the earth.

A Ground Fault

Interrupter may

not be effective if used on a

welder/generator that is not grounded!

Refer to the section entitled Grounding

for proper steps to ground the

welder/generator.

3. When installing a GFI, be sure to

follow all national and local

regulations. If not sure of

regulations or procedures, obtain

assistance from a qualified (licensed

or certified) electrical technician.

GROUNDING

1. Use the ground terminal and wing

nut on the welder/generator frame

to connect the unit to a suitable

ground source. Securely fasten the

end terminal of the ground wire to

the ground terminal on the

welder/generator frame. Tighten

the washer and wing nut on top of

the ground wire end terminal.

2. The ground wire should be made of

#8 gauge wire. Do not use wire with

a higher gauge number. Higher

gauge numbers indicate thinner

wire, which may not provide an

adequate ground path.

3. The other end of the ground wire

must be securely fastened to an

approved ground source.

The following are ground sources

approved by the National Electric Code.

Other ground sources may be

acceptable. Refer to the National Electric

Code and local regulations for further

ground source information. If not sure

of regulations or procedures, obtain

assistance from a qualified (licensed or

certified) electrical technician.

a. An underground water pipe at

least ten feet in length

b. A non-corrosive underground

pipe at least eight feet in length

and 3/4 inch diameter

c. A steel or iron underground rod

at least eight feet in length and

5/8 inch diameter

d. A non-ferrous rod at least eight

feet in length, 1/2 inch in

diameter, and approved for

grounding purposes

Any rod or pipe used for grounding must

be driven to eight feet deep or buried in

the deepest possible trench.

STARTING

1. Remove all electrical loads from the

welder/generator.

General Operations

General Safety

(Continued)

Welder/Generator

www.chpower.com

!

WARNING

!

WARNING

!

WARNING

Page 4

4

Operating Instructions

2. Rotate fuel shut-off valve counter

clockwise to enable fuel flow.

3. Rotate the engine switch to the ON

position.

4. Adjust the choke lever as follows:

a. For cold engine, move the choke

lever as far as possible to the left,

choke fully ON, position.

b. For warm/hot engine, move the

choke lever midway between the

choke and run positions.

5. Pull the starter rope with a brisk,

smooth motion.

NOTE: Some models may be equipped

with an electric starter. For models

equipped with an electric starter, turn

the key.

6. After each start up, allow the engine

to run for 2-3 minutes with no load.

7. As the engine warms up and

stabilizes, adjust the choke lever to

the right, until the lever is positioned

at the RUN label.

Engine speed is

preset to provide

proper output voltage. Never attempt to

modify or adjust engine speed or output

voltage.

ENGINE BREAK-IN

After initial start-up, the engine should

be broken in according to the

manufacturer's instructions. Refer to the

engine manual for the proper break-in

procedure.

SHUT OFF

1. Shut off and remove all electrical

load devices from the welder/

generator.

2. Allow the engine to run for 2-3

minutes with no electrical loads.

3. Rotate the engine switch to the OFF

position.

4. Verify that the welder/generator has

completely stopped.

5. Close the fuel supply valve.

6. Allow the unit to cool before

installing any covers.

LOW OIL SHUTDOWN

A low oil shutdown switch is provided to

protect the engine and welder/generator

on most extended run models. When

engine oil level drops too low for proper

engine operation, the low oil shutdown

switch causes the engine to shut off. If oil

level is low when attempting to start the

welder/generator engine, the low oil

level shutdown switch prevents the

engine from starting. If engine does not

start, check oil level.

NOTE: It is important to keep the

welder/generator unit on a level surface.

The oil level shutdown switch can

prevent the engine from starting even if

oil level is sufficient, when the

welder/generator unit is placed on an

uneven surface.

(FRONT PANEL SWITCH MUST BE SET

TO GENERATOR)

LOAD DEVICES

1. All load devices and extension cords

should use three prong terminals.

Refer to Table 2 for extension cord

and cable size requirements.

2. Allow the engine to run for 2-3

minutes before applying any

electrical loads.

3. The 120 volt receptacles are rated

for 20 amps and may be used in any

combination of 120 volt loads and

also with 240 volt loads through the

240 volt receptacles.

The 240 volt receptacles, found

on some units, are rated for 20

amps and may be used in any

combination of 240 volt loads and

also with 120 volt loads through the

120 volt receptacles.

The 120/240 volt twist lock

receptacle, found on some units, is

rated for 20 amps and may be used

in any combination of 120 volt and

240 volt loads.

4. Individual receptacles should not be

loaded beyond the amperage

rating.

5. Total combined load through any

combination of receptacle must not

exceed the rated load limits of the

welder/generator. Refer to the

identification plate on the

welder/generator for amp and

wattage specifications.

6. Always shut off and remove loads

before starting or shutting off the

welder/generator engine.

7. When plugging multiple electrical

load devices into the

welder/generator receptacles, be

sure to connect and activate the

highest power draw item first.

Allow the welder/generator engine

to stabilize, then connect and

activate the next highest power

draw device. The smallest power

draw device should be connected to

the receptacle and activated last.

Radio 50-200

Refrigerator 190-2000

Skillet 1200

Space heater 600-4800

Sump pump 400-3000

Television 200-500

Toaster 900-1700

Vacuum cleaner 200-300

Water pump 1000-3000

Water heater 1000-5000

Small hand saw 1000-2000

Large hand saw 1500-2500

Air conditioner 2000-3000

Automatic washer 150-1500

Brooder 100+

Clothes dryer 5000-10,000

Coffee maker 400-700

Electric drill (small) 225-1000

Electric drill (large) 500-1000

Fan 40-200

Freezer 300-500

Hot plate 330-1100

Iron 500-1500

Light bulb As Rated

Load Device Watts Load Device Watts

TABLE 1 - ESTIMATED POWER USAGE (WATTS)

General Operations

(Continued)

Generator Operations

www.chpower.com

!

CAUTION

Page 5

5

2.5 300 600 1000 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 50

15 1800 3600 150 100 65

20 2400 4800 175 125 75 50

25 3000 6000 150 100 60

30 3600 7200 125 65

40 4800 9600 90

Amps Watts Watts #8 #10 #12 #14 #16

120 V 240 V Wire Wire Wire Wire Wire

TABLE 2 - EXTENSION CORDS

MAXIMUM RECOMMENDED LENGTHS (IN FEET)

NOTE: Power draw can be calculated

by multiplying volts and amps. The

resulting number is wattage.

Never exceed the posted maximum

wattage for the welder/generator or any

individual receptacle. Refer to owner's

manuals and product tags to determine

the wattage of all electrical load devices.

If actual watt ratings are not available,

the Power Usage Chart, see Table 1,

may be used as a general guideline.

Remember that devices which generate

heat during operation such as heaters,

incandescent light bulbs, motors and

hair dryers have a higher power draw

than devices which generate little heat

during operation such as florescent

bulbs, radios, and clocks.

Long power cords and extension cords

also draw additional power. Keep cords

at minimum possible length.

Refer to Table 2 for maximum limits for

lengths of extension cords.

8. Circuit protection is provided by a

circuit breaker. The circuit breaker

opens when the welder/generator

load exceeds its maximum capacity or

a short circuit occurs. If the circuit

breaker opens, perform the following

procedures to correct the problem:

a. Shut off and disconnect all

electrical loads.

b. Attempt to determine the cause

of the electrical problem overloading or short circuit.

c. Do not use any devices that have

short circuits. Avoid overloading

the welder/generator.

d. Press the circuit breaker

pushbutton to reset the circuit

breaker.

Repeated cycling

of the circuit

breaker indicates a problem and may

cause damage to the welder/generator

or load devices. Do not operate the

welder/generator if repeated cycling of

the circuit breaker occurs.

Installation for Stand-by Use

Precautions must be taken to prevent

electrical back feeding into utility

systems. This requires isolation of the

electrical system. To isolate the

electrical system, perform the following

procedures:

1. Turn off the main electrical system

switch prior to connecting the

welder/generator.

2. In accordance with national and

local standards, a double throw

transfer switch must be installed in

the system.

Always shut off

main power prior

to temporary connection of the

welder/generator to a building

electrical system.

Installation of the

welder/generator

as a backup electrical source must be

performed by a qualified (licensed or

certified) electrical technician.

(FRONT PANEL SWITCH MUST BE SET

TO THE WELDING POSITION)

Welding Lead Assemblies

Welding leads assemblies are not

included with all units. Use copper

welding cables in the size specified in

Table 3.

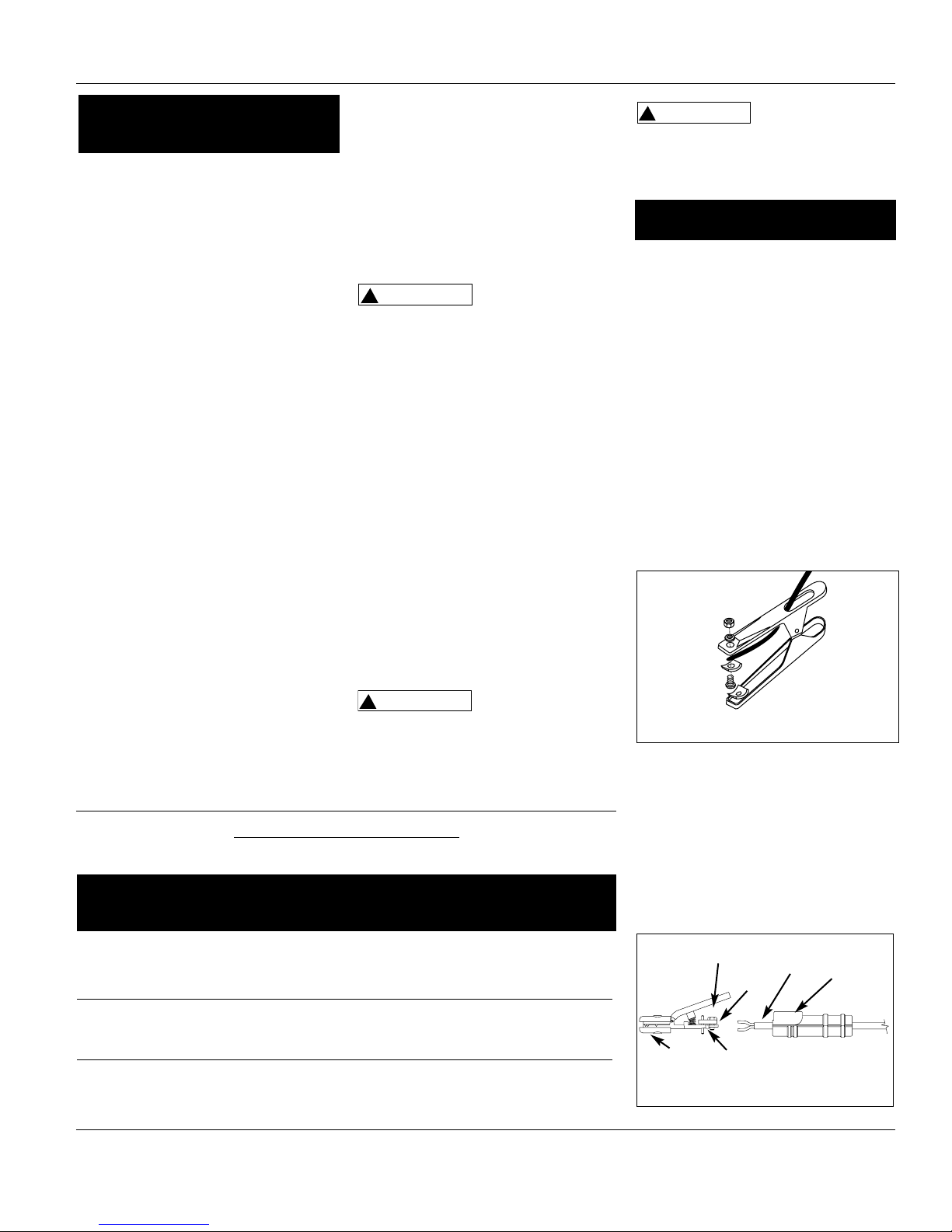

GROUND CLAMP (SEE FIGURE 1)

1. Strip 1/2” of insulation from the end

of one of the welding cables.

2. Loosen hex nuts on work clamp.

3. Insert the end of the welding cable

through clamp handle and slide the

bare wire under the clamp block.

4. Tighten the hex nuts, securing the

cable in place.

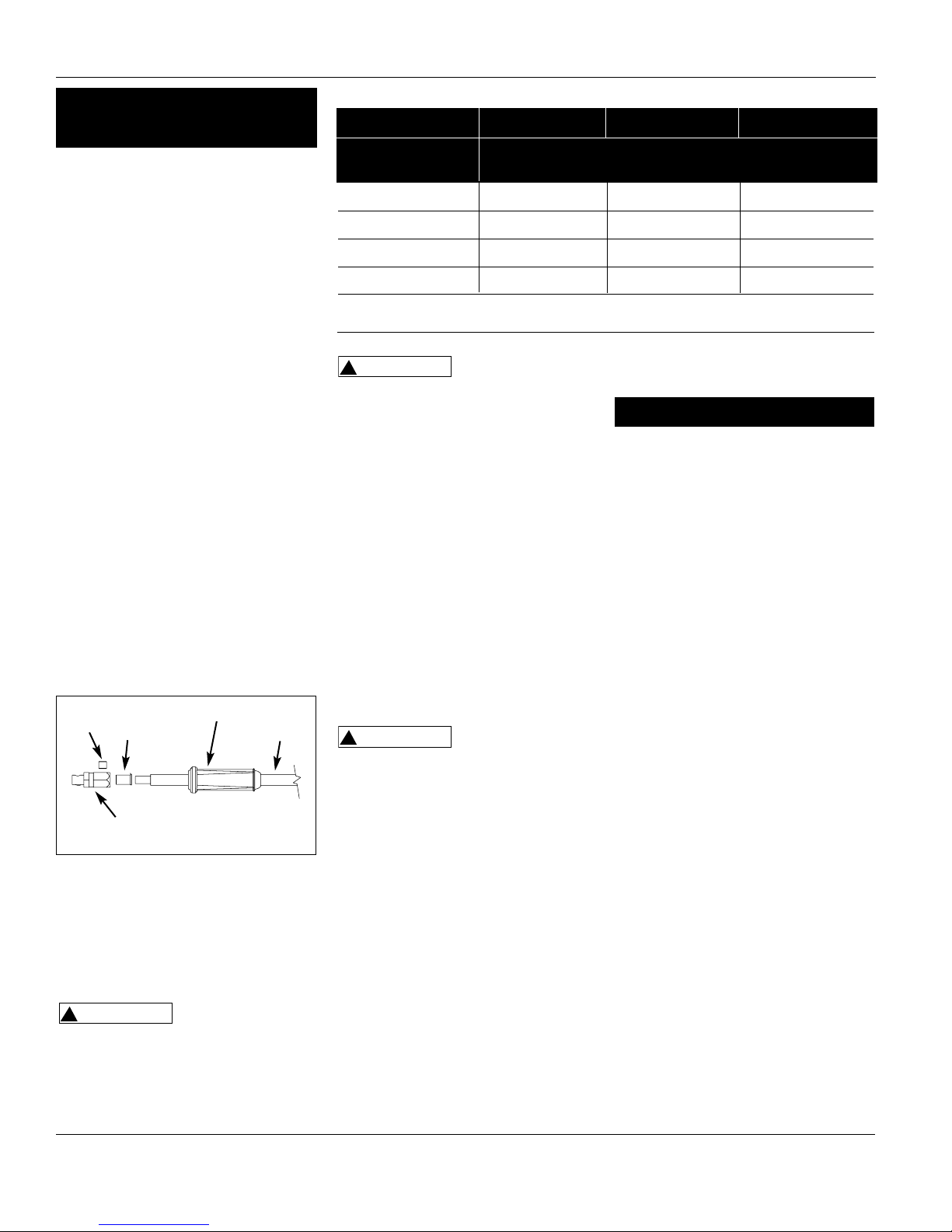

ELECTRODE HOLDER (SEE FIGURE 2)

1. Strip 1” of insulation from the end

of the other welding cable.

Separate the strands of the cable

into two sections and twist.

2. Loosen the setscrew a few turns. Do

not remove it completely. Pull

the insulated handle off of the

electrode holder, and slide it over

the welding cable.

Generator Operations

(Continued)

Welder Operations

Welder/Generator

Figure 1 - Work Clamp Assembly

Figure 2 - Electrode Holder Assembly

Shim

Cable Bolt

Welding

Cable

Electrode

Holder

Set Screw

Handle

www.chpower.com

!

CAUTION

!

WARNING

!

WARNING

Page 6

Total Cable Length* 0-20 ft (0-6 m) 20-40 ft (6-12 m) 40-60 ft (12-18 m)

Maximum Welding

Current Recommended Sizes of Copper Welding Cables

6

3. Loosen the bolt on the top of the

electrode holder.

4. Slide the bare wires from the cable

between the shim and the brass

body of the electrode holder.

5. Tighten the bolt to secure the cable

in place.

6. Slide the insulated handle onto the

electrode holder and tighten the

setscrew. Do not overtighten the

setscrew. Overtightening will

damage the insulated handle.

DINSE PLUGS (SEE FIGURE 3)

1. Strip 1/2” of insulation from the

opposite end of the welding cable.

2. Insert this end of the welding cable

through the dinse plug boot and

slide the bare wire into the wire

sleeve.

3. Insert the welding cable/wire sleeve

assembly into the back of the dinse

plug.

4. Tighten the set screw, securing the

cable in place.

5. Slide the boot over the hex portion

of the dinse plug.

6. Repeat for the other lead.

Welding

1. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other

contaminants. These contaminants

make welding difficult and cause

poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear protective

welding gear including: eye protection

with proper shade (minimum shade 10),

flame resistant clothing, leather welding

gloves, and full foot protection.

If heating, welding,

or cutting materials

that are galvanized, zinc plated, lead, or

cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

2. Connect the work clamp to the

work piece. Make sure the contact is

on bare metal and not obstructed

by paint, varnish, corrosion, or nonmetallic materials.

3. Insert the exposed part of the

electrode (the end with no flux) into

the jaws of the electrode holder.

4. Set the amperage adjustment knob

to the proper amperage for the

electrode diameter. Refer to the

chart on the front panel for proper

electrode current settings.

The electrode

holder and rod are

electrically “live” (current potential)

when the engine is running.

5. Position the electrode to begin

weld, lower the welding helmet or

position the hand shield, and strike

an arc. Adjust weld amperage as

needed.

6. When finished welding, turn engine

off and store unit properly.

DUTY CYCLE/THERMOSTATIC

PROTECTION

Welder duty cycle is the percentage of

actual weld time that can occur in a ten

minute interval. For example, at a 10%

duty cycle, actual welding can occur for

one minute, then the welder must cool

for nine minutes.

Internal components of this welder are

Welder Operations

(Continued)

100 A 6 AWG (15 mm2) 6 AWG (15 mm2) 4 AWG (20 mm2)

150 A 6 AWG (15 mm2) 3 AWG (25 mm2) 2 AWG (35 mm2)

200 A 4 AWG (20 mm2) 2 AWG (35 mm2) 1 AWG (40 mm2)

250 A 3 AWG (25 mm2) 2 AWG (35 mm2) 1/0 AWG (55 mm2)

* Total cable length is the sum of the ground and electrode cable lengths

protected from overheating with an

automatic thermal switch.

INFREQUENT USAGE

If the welder/generator is used

infrequently, starting difficulty may

occur. To help prevent this, the

welder/generator should be run for

approximately 30 minutes per week.

STORAGE

If the welder/generator is not to be

used for extended periods of time, the

following pre-storage procedures

should be performed:

1. Make sure engine oil is filled to the

proper level.

2. Drain all fuel from the tank, lines,

carburetor and fuel valve.

3. Remove the spark plug, and pour

approximately one teaspoon of oil

into the spark plug hole.

4. Pull the starter cord several times to

spread the oil throughout the

cylinder.

5. Slowly pull the starter cord, until

resistance is felt. This indicates that

the piston is moving upward on the

compression cycle, and the intake

and exhaust valves are closed. (The

piston pushes a small amount of air

from the spark plug hole on

compression.)

6. Use of fuel stabilizers or antigumming agents in the fuel system

can help prevent the build up of

gum and varnish.

Whenever the welder/generator is

stored, be sure that the fuel shut-off

Operating Instructions

Figure 3 - Dinse Plug Assembly

Set

Screw

Boot

Welding

Cable

Wire

Sleeve

Dinse Plug

TABLE 3 - WELDING CABLES

www.chpower.com

Maintenance

!

WARNING

!

WARNING

!

WARNING

Page 7

7

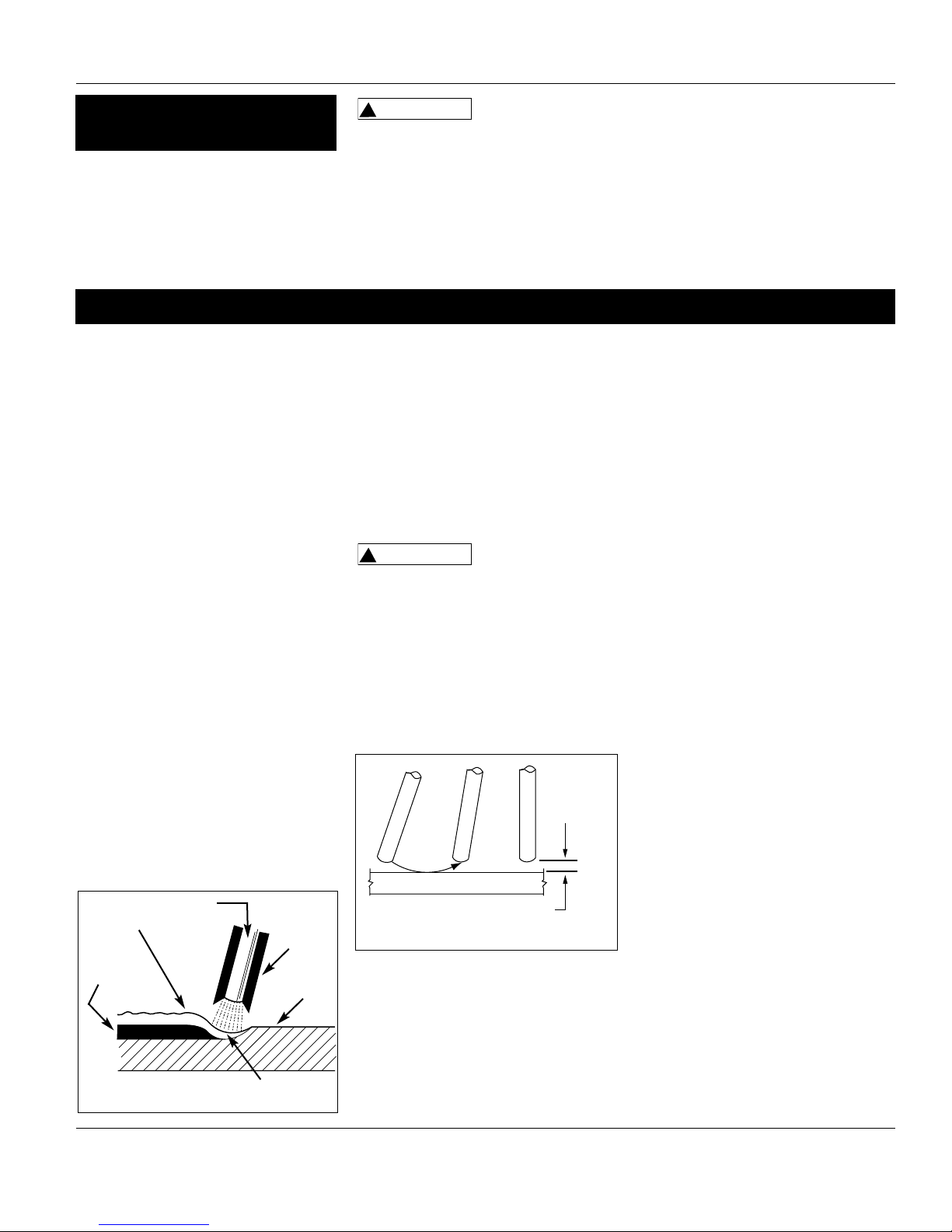

General

This line of welding machines utilizes a

process known as Shielded Metal-Arc

Welding (SMAW). This process is used to

bond metals by heating them with an

electric arc created between the

electrode and the work piece.

Electrodes used for shielded metal arc

welding have two parts. The inner core is

a metal rod or wire that should be similar

in composition to the base metal. The

outer coating is called flux. Various types

of flux exist. Each coating is used for a

particular welding situation.

While the metal is molten, it can be

contaminated by elements in the air. This

contamination could weaken the weld.

The flux coating creates a protective

barrier called slag that protects the

molten metal from contaminants.

When current (amperage) flows through

the circuit to the electrode, an arc is

formed between the end of the electrode

and the work piece. The arc melts the

electrode and the work piece. The melted

metal of the electrode flows into the

molten crater and forms a bond with the

work piece as shown in Figure 4.

NOTE: Discontinue using and discard

electrodes that burn down to 1 to 2

inches from the electrode holder.

STRIKING AN ARC

Place the bare end of the electrode in the

holder. Grip the holder lightly to reduce

tiring of the hand and arm.

NOTE: Always keep the jaws of the

holder clean to insure good electrical

contact with the electrode.

Be careful not to

touch the work

piece or welding bench with the

electrode as this causes arc flashes.

The best method of striking an arc is the

scratching method. Drag the electrode at

an angle along the surface much like

striking a match. Upon contact with the

plate, lift the electrode approximately

1/16” off the surface or it will stick (See

Figure 5).

NOTE: Should the electrode stick to the

work piece, break it loose by quickly

twisting or bending at the holder while

pulling upward. If the electrode does not

break loose, disengage the electrode by

releasing it from the holder.

ELECTRODE TYPE AND SIZE

Four types of electrodes are

recommended for this welder. The

electrodes are commonly known by the

AWS (American Welding Society)

designation as follows:

1. E-6011 DEEP PENETRATING

• Flat bead with deep penetrating arc.

• For rusted or dirty mild steel general

repair work.

2. E-6013 GENERAL PURPOSE

• All position, smooth deposit rod with

low spatter.

• For all mild steel and general purpose

work.

3. E-7014 FAST FILL

• Smooth bead and fast deposition

• Ideal for joints with poor fitup and

general repair work.

4. E-7018-AC HIGH STRENGTH

• Ideal for pipes and structural

applications.

• Low hydrogen reduces porosity for a

strong weld.

NOTE: Only the E-7018-AC electrode is

recommended for use with these

welders. Other E-7018 electrodes are

designed for use with higher open

circuit voltages than these welders are

capable of producing. Recommended

electrode diameter is 3/32” or 1/8”.

Arc Welding Basics

Four basic techniques affect weld

quality. These are: amperage setting,

weld angle, arc length, and travel

speed. Proper use of these techniques is

necessary for good weld quality.

Slag

Weld

Wire

Flux

Work

Piece

Crater

Figure 4 - Weld Components

Same as Electrode Diameter

Figure 5 - Scratching Method

Welding Guidelines

Welder/Generator

Maintenance

(Continued)

valve is in the closed position.

Refer to the engine manual that

accompanies this unit for instructions

regarding maintenance of engine

components.

Never tamper with

engine speed

settings or welder/generator frequency

settings. Any governor adjustments

should be made by qualified personnel

only.

WELD CABLES

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of electrode holder

insulating pieces and immediately

replace cracked or missing parts.

Every 3 months:

Replace any unreadable labels on the

welder. Use compressed air to blow all

dust and lint from the ventilation

openings.

www.chpower.com

!

WARNING

!

WARNING

1/16"

Page 8

8

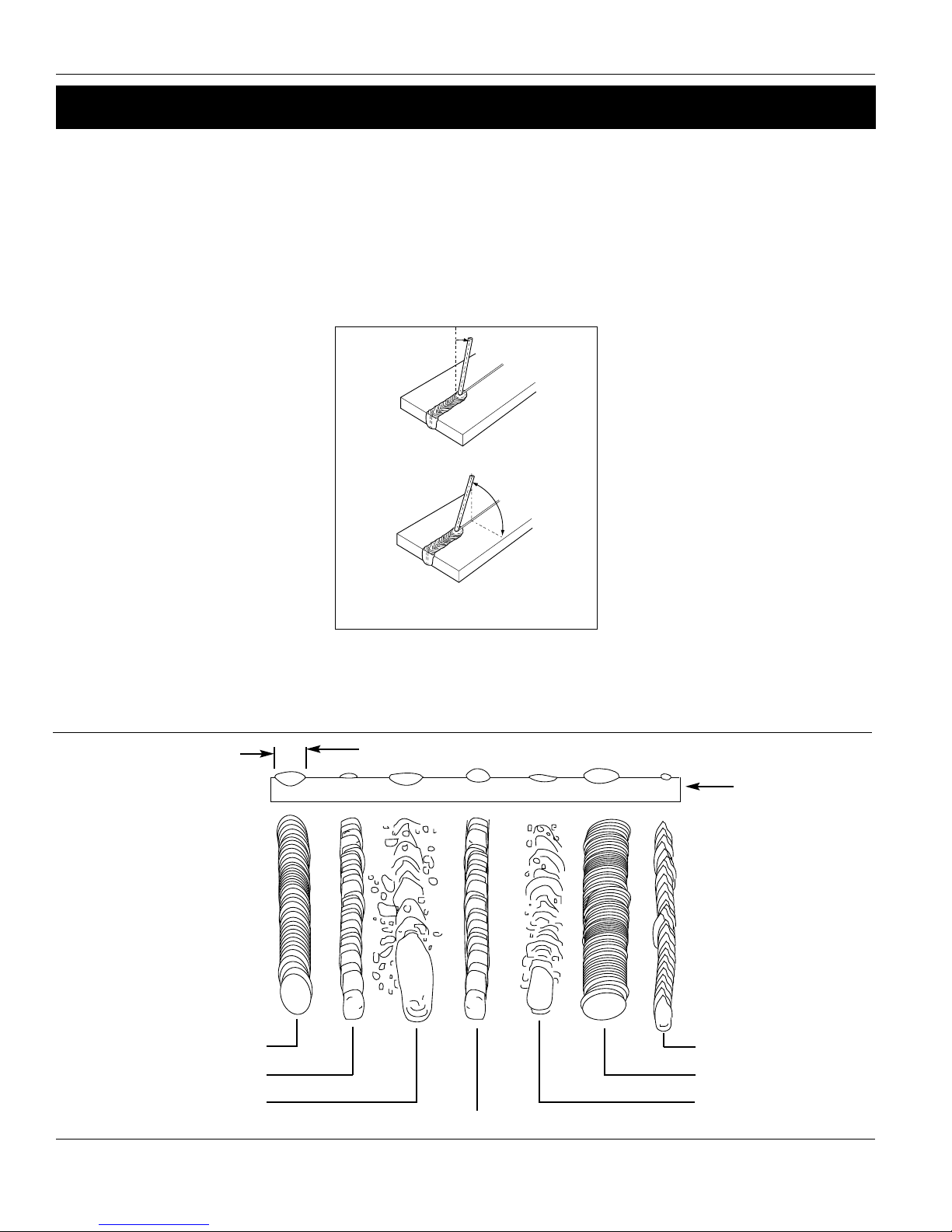

Normal Amps, Arc Length, Speed

Amperage Too Low

Amperage Too High

Arc Length Too Short

Arc Length Too Long

Speed Too Slow

Speed Too Fast

Workpiece

NOTE: Weld bead width (W)

should be approximately

twice the diameter for the

electrode rod used.

W

Figure 7 - Weld Appearance

AMPERAGE SETTING

The correct amperage involves the

adjustment of the welding machine to

the required amp setting. This is

regulated by a knob on the welder. The

amperage required depends on the size

(diameter) of electrode used and the

thickness of the work piece.

Consult specifications listed on the

welder. Excessive amps burn through

light metals and the weld bead is flat

and porous (See Figure 7). The bead

appears high and irregular if the

amperage is too low.

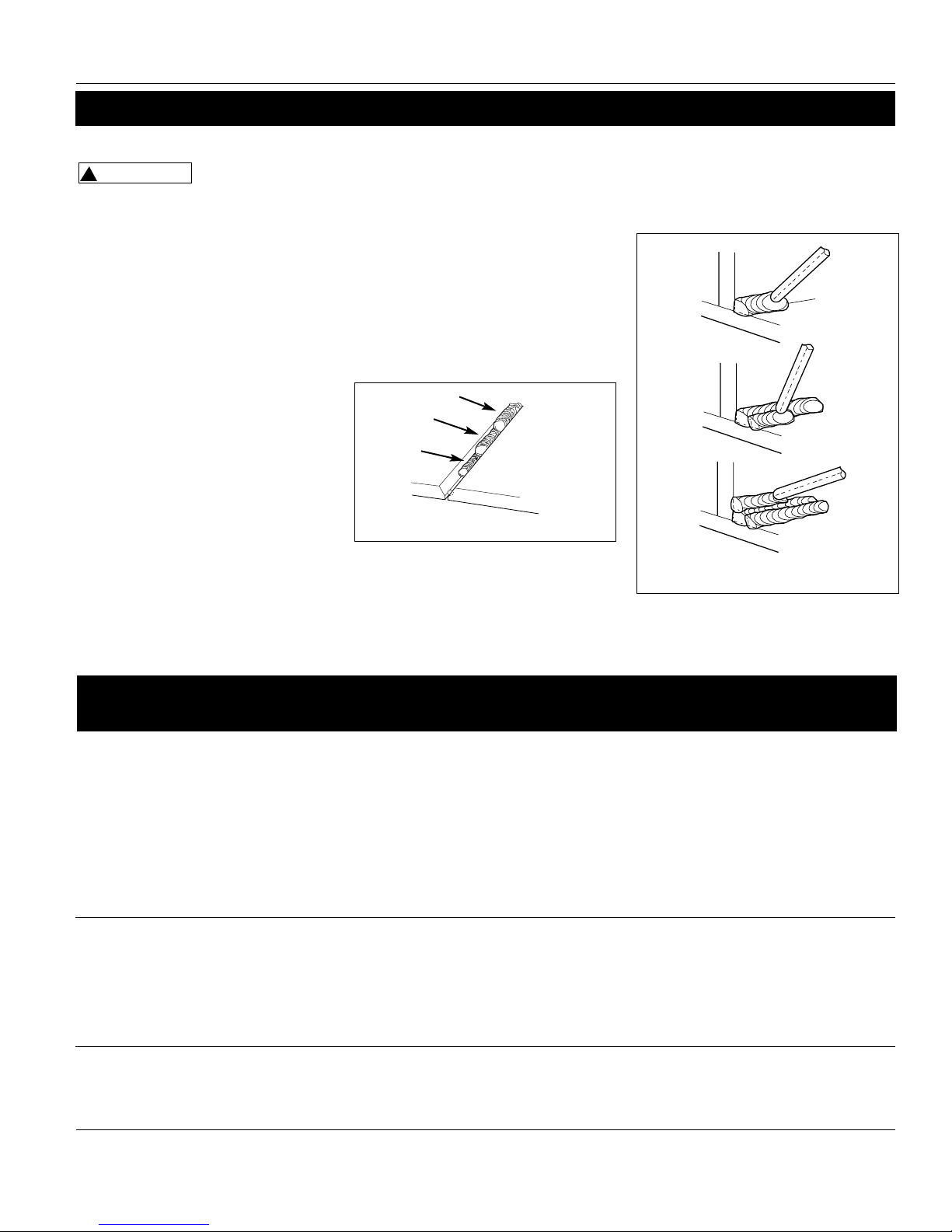

WELD ANGLE

Weld angle is the angle at which the

electrode is held during the welding

process. Using the correct angle ensures

proper penetration and bead

formation. Electrode angle involves

two positions - travel angle and work

angle (See Figure 6).

Travel angle is the angle in the line of

welding and may vary from 5º to 45º

from the vertical, depending on

welding conditions.

Work angle is the angle from

horizontal, measured at right angles to

the line of welding.

For most applications, a 45º travel

angle and 45º work angle is sufficient.

For specific applications, consult an arc

welding handbook.

NOTE: Right handed welders should

weld from left to right. Left handed

welders should weld from right to left.

The electrode should always point into

the weld puddle as shown.

ARC LENGTH

Arc length is the distance from the

work piece to the tip of the electrode,

the distance which the arc must travel.

A proper arc length is essential to

generate the heat needed for welding

(See Figure 7). An arc that is too long

produces an unstable arc, reduces

penetration, increases spatter, and

causes flat and wide beads. Too short

an arc does not create enough heat to

melt the work piece, the electrode has

a tendency to stick, penetration will be

poor, and uneven beads with irregular

ripples result. A proper arc should be

no longer than the diameter of the rod.

The sound of a proper arc is a steady,

crisp sizzle, similar to bacon frying.

TRAVEL SPEED

The travel speed is the rate at which

the electrode is moved across the weld

area (See Figure 7). When the speed is

too fast, the bead is narrow and bead

ripples are pointed as shown. When the

speed is to slow, the weld metal piles

up and the bead is high and wide. To

control travel speed, watch the width

of the weld bead (not the arc) when

welding. The weld bead is the orange,

molten metal behind the arc. The width

should be approximately twice the

diameter of the welding rod. Control

travel speed to obtain a consistent

bead width.

Welding Guidelines (Continued)

Operating Instructions

Figure 6 - Weld Angle

5o - 45

o

Travel Angle

Work Angle

www.chpower.com

Page 9

9

SLAG REMOVAL

Wear ANSI

approved safety

glasses (ANSI Standard Z87.1) and

protective clothing when removing

slag. Hot, flying debris can cause

personal injury to anyone in the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the

slag can be removed. Removal is done

with a chipping hammer. Lightly tap

the slag with the hammer and break it

loose from the weld bead. The final

clean-up is done with a wire brush.

When making multiple weld passes,

remove the slag before each pass.

WELDING POSITIONS

Four basic welding positions can be used;

flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than

any of the others because welding speed

can be increased, the molten metal has

Figure 9 - Multiple Weld Passes

Welding Guidelines (Continued)

Welder/Generator

less tendency to run, better penetration

can be achieved, and the work is less

fatiguing.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these welds.

All work should be performed in the

flat position if possible. For specific

applications, consult an arc welding

handbook.

WELD PASSES

Sometimes more then one pass is

necessary to fill the joint. The root pass

is first, followed by filler passes and the

cover pass (See Figures 8 & 9). If the

Figure 8 - Weld Passes

Cover

Filler

Root

pieces are thick, it may be necessary to

bevel the edges that are joined at a 60º

angle. Remember to remove the slag

before each pass.

No output voltage

Low output voltage

with no load

High output voltage

with no load

1. Engine speed is too slow

2. Open, shorted, or incorrect wiring

3. Faulty capacitor

4. Open or shorted field windings

5. Open diodes

6. Front panel switch set incorrectly

7. Circuit breaker tripped

1. Engine speed is too slow

2. Open diodes

3. Faulty capacitor

4. Open or shorted field windings

5. Voltage setting on front panel incorrect

1. Faulty capacitor

2. Engine speed is too fast

3. Voltage setting on front panel incorrect

1. Adjust engine speed ✽

2. Referring to the wiring diagram, clean and

reconnect all wiring ✽

3. Replace capacitor ✽

4. Test winding resistance, replace field

winding if necessary ✽

5. Test diodes, replace if necessary ✽

6. Set front panel switch to generator

7. Reset circuit breaker

1. Adjust engine speed ✽

2. Test diodes, replace if necessary ✽

3. Replace capacitor ✽

4. Test winding resistance, replace field

winding if necessary ✽

5. Adjust setting on front panel

1. Replace capacitor ✽

2. Adjust engine speed ✽

3. Adjust setting on front panel

Troubleshooting Chart - Generator

Symptom Possible Cause(s) Corrective Action

www.chpower.com

!

WARNING

Page 10

10

Operating Instructions

✽ These diagnostic and repair procedures should be performed by an authorized service center.

Troubleshooting Chart - Generator (Continued)

Symptom Possible Cause(s) Corrective Action

Low output voltage

under load

Erratic output voltage

Noisy operation

1. Open diode

2. Engine speed too slow at full load

3. Excessive load applied

4. Voltage setting on front panel incorrect

1. Unbalanced engine

2. Dirty, corroded, or loose wiring

connection

3. Unstable load applied

1. Loose welder/generator or engine bolt

2. Short circuit in welder/generator field or

load

3. Faulty bearing

1. Test diodes, replace if necessary ✽

2. Adjust engine speed ✽

3. Reduce the applied load

4. Adjust setting on front panel

1. Refer to engine manual

2. Referring to the wiring diagram, clean and

reconnect all wiring ✽

3. Remove all loads, then apply each one

individually to determine which one is

causing erratic function

1. Tighten all mountings

2. Test winding resistance, replace field

winding if necessary ✽

Test load devices for shorts. Replace

defective load device.

3. Replace bearing

1. Check work clamp, cable and connection to work

piece. Check electrode cable and clamp

2. Check all welder external connections

3. Set front panel switch to weld

4. Referring to the wiring diagram, clean and

reconnect all wiring ✽

5. Replace capacitor ✽

6. Test winding resistance, replace field winding if

necessary ✽

7. Test diodes, replace if necessary ✽

1.Avoid contact with work piece

2. Make sure clothing and work area are dry

1. Verify that electrode is for alternating current (AC)

2. Use smaller diameter electrode

3. Verify proper grounding. (No paint, varnish or

corrosion)

4. Adjust engine speed

Troubleshooting Chart - Welder

Symptom Possible Cause(s) Corrective Action

1. Inadequate current at electrode

2. Poor connections at welder

3. Front panel switch set incorrectly

4. Open, shorted, or incorrect wiring

5. Faulty capacitor

6. Open or shorted field windings

7. Open diodes

1. Accidental contact with work

piece

2. Current leakage caused by moist

clothing or work area

1. Wrong type of electrode.

2. Electrode diameter too large

3. Work piece not properly

grounded

4. Engine speed is too slow

Welder runs but does not

weld

Welder gives trickle

shocks

Arc difficult to strike

✽ These diagnostic and repair procedures should be performed by an authorized service center.

www.chpower.com

Page 11

11

Troubleshooting Chart - Welds

Symptom Possible Cause(s) Corrective Action

Bead is intermittently

too thin or too thick

Ragged depressions

at edge of weld

Weld bead does not

penetrate base metal

Electrode sticks to

workpiece

Electrodes sputter

and stick

1. Inconsistent travel speed

2. Output amp setting incorrect

1. Travel speed too fast

2. Arc length too short

3. Output amp setting too high

1. Inconsistent travel speed

2. Output amp setting too low

3. Electrode diameter too large

1. Arc length short

2. Amp setting low

3. Incorrect electrode

Damp electrodes

1. Carefully watch and control the width of the molten weld

bead

2. Adjust output amp setting or change to smaller diameter

electrode

1. Watch orange molten weld puddle and control bead width

2. Practice running electrode across workpiece with welder OFF

3. Reduce output amp setting

1. Decrease and maintain constant travel speed

2. Increase output amp setting

3. Change to smaller diameter electrode

1. Lift electrode to correct arc length as soon as arc is struck

2. Increase amp setting or change to smaller diameter

electrode

3. Verify electrode is suitable for 62.5 V open circuit voltage

Use dry electrodes and store in dry location

Welder/Generator

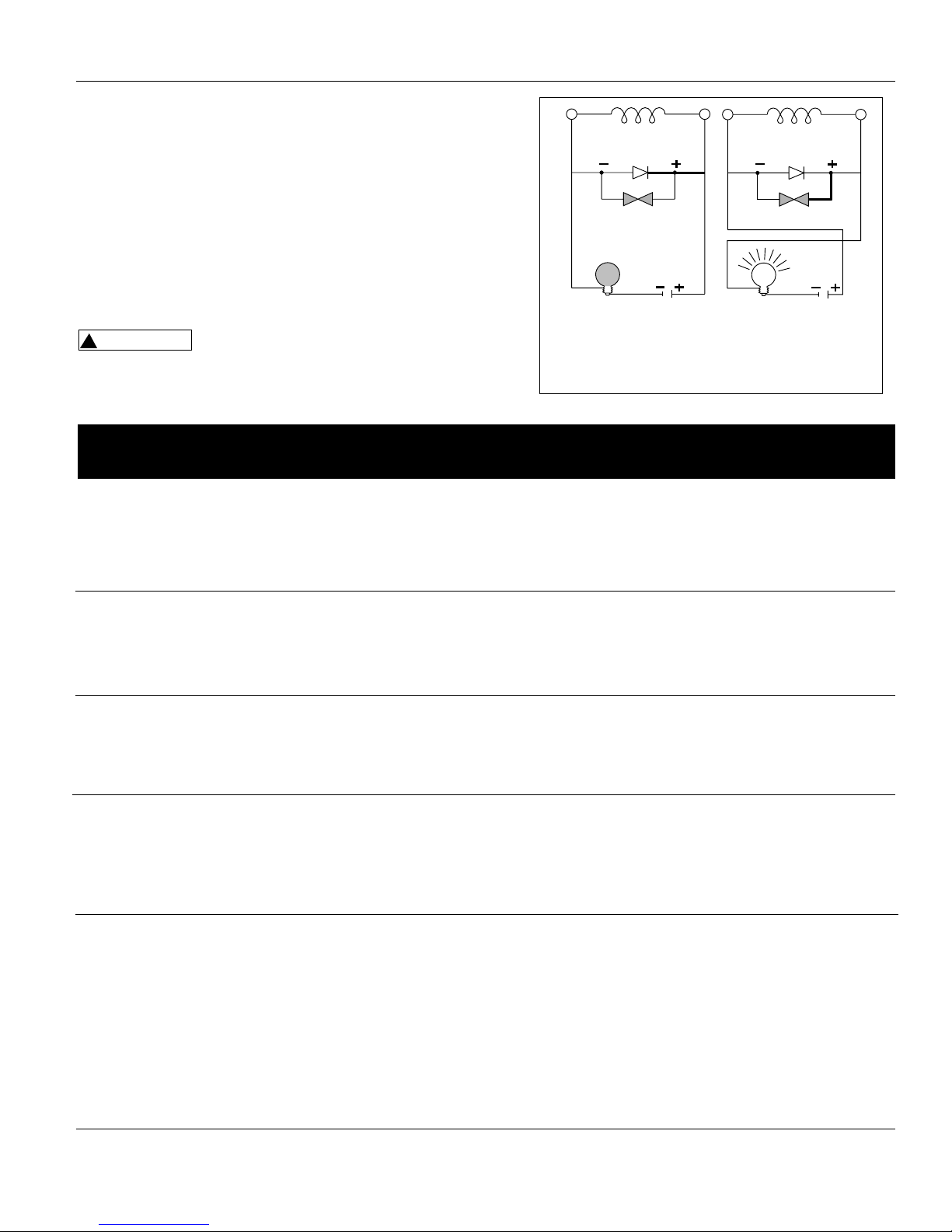

TESTING WELDER/GENERATOR DIODES

The following method eliminates the need to disconnect the diodes

from the welder/generator wiring.

1. Use a 12 Volt battery and automotive lamp (Type 5001) to test

the diodes in the welder/generator.

2. Connect the battery and lamp as shown in Figure 10.

3. If the diodes are operating properly, the lamp illuminates

brightly when the battery polarity is correct, and goes dim when

battery polarity is reversed.

4. If there is no change in lamp brightness when polarity is

reversed, the diodes must be replaced.

For testing of rotor, stator, or field windings,

consult an authorized service center.

Figure 10 - Diode Test Procedure

www.chpower.com

!

WARNING

Lamp Off

Lamp On

Page 12

12

AC or Alternating Current - electric

current that reverses direction

periodically. Sixty cycle current travels in

both directions sixty times per second.

Arc Length - the distance from the end

of the electrode to the point where the

arc makes contact with the work surface.

Base Metal - the material to be welded.

Butt Joint - a joint between two

members aligned approximately in the

same plane.

Crater - a pool, or pocket, that is formed

as the arc comes in contact with the base

metal.

DC or Direct Current - electric current

which flows only in one direction. The

polarity (+ or -) determines which

direction the current is flowing.

DC Reverse Polarity - occurs when the

electrode holder is connected to the

positive pole of the welding machine.

Reverse Polarity directs more heat into

melting the electrode rather than the

work piece. It is used on thinner

material.

DC Straight Polarity - occurs when the

electrode holder is connected to the

negative pole of the welding machine.

With straight polarity more heat is

directed to the work piece for better

penetration on thicker material.

Electrode - a coated metal wire having

approximately the same composition as

the material being welded.

Fillet Weld - approximately a triangle in

cross-section, joining two surfaces at

right angles to each other in a lap, T or

corner joint.

Flux - a coating, when heated, that

produces a shielding gas around the

welding area. This gas protects the

parent and filler metals from impurities

in the air.

Flux Cored Arc Welding (FCAW) - also

called Gasless, is a welding process used

with a wire-feed welding machine. The

weld wire is tubular with flux material

contained inside for shielding.

Gas Metal Arc Welding (GMAW) also called MIG, is a welding process

used with a wire feed welding machine.

The wire is solid and an inert gas is used

for shielding.

Gas Tungsten Arc Welding (GTAW) also called TIG, is a welding process used

with welding equipment with a high

frequency generator. The arc is created

between a non-consumable tungsten

electrode and the work piece. Filler

metal may or may not be used.

Lap Joint - a joint between two

overlapping members in parallel planes.

Open Circuit Voltage (OCV) - the

voltage between the electrode and the

work clamp of the welding machine

when no current is flowing (not

welding). The OCV determines how

quickly the arc is struck.

Overlap - occurs when the amperage is

set too low. In this instance, the molten

metal falls from the electrode without

actually fusing into the base metal.

Porosity - gas pockets, or cavities,

formed during weld solidification. They

weaken the weld.

Penetration - the depth into the work

piece that has been heat effected by the

arc during the welding process. A good

weld achieves 100% penetration

meaning that the entire thickness of the

work piece has been heated and

resolidified. The heat effected area

should be easily seen on the opposite

side of the weld.

Shielded Metal Arc Welding (SMAW)

- also called Stick, is a welding process

that uses a consumable electrode to

support the arc. Shielding is achieved by

the melting of the flux coating on the

electrode.

Slag - a layer of flux soot that protects

the weld from oxides and other

contaminants while the weld is

solidifying (cooling). Slag should be

removed after weld has cooled.

Spatter - metal particles thrown from

the weld which cool and harden on the

work surface. Spatter can be minimized

by using a spatter resistant spray on the

work piece before welding.

Tack Weld - weld made to hold parts in

proper alignment until final welds are

made.

Travel Angle - the angle of the

electrode in the line of welding. It varies

from 5º to 45º depending on welding

conditions.

T Joint - made by placing the edge of

one piece of metal on the surface of the

other piece at approximately a 90º

angle.

Undercut - a condition that results

when welding amperage is too high.

The excessive amperage leaves a groove

in the base metal along both sides of the

bead which reduces the strength of the

weld.

Weld Pool or Puddle - a volume of

molten metal in a weld prior to its

solidification as weld metal.

Weld Bead - a narrow layer or layers of

metal deposited on the base metal as

the electrode melts. Weld bead width is

typically twice the diameter of the

electrode.

Work Angle - the angle of the electrode

from horizontal, measured at right

angles to the line of welding.

Glossary of Welding Terms

www.chpower.com

Operating Instructions

Page 13

13

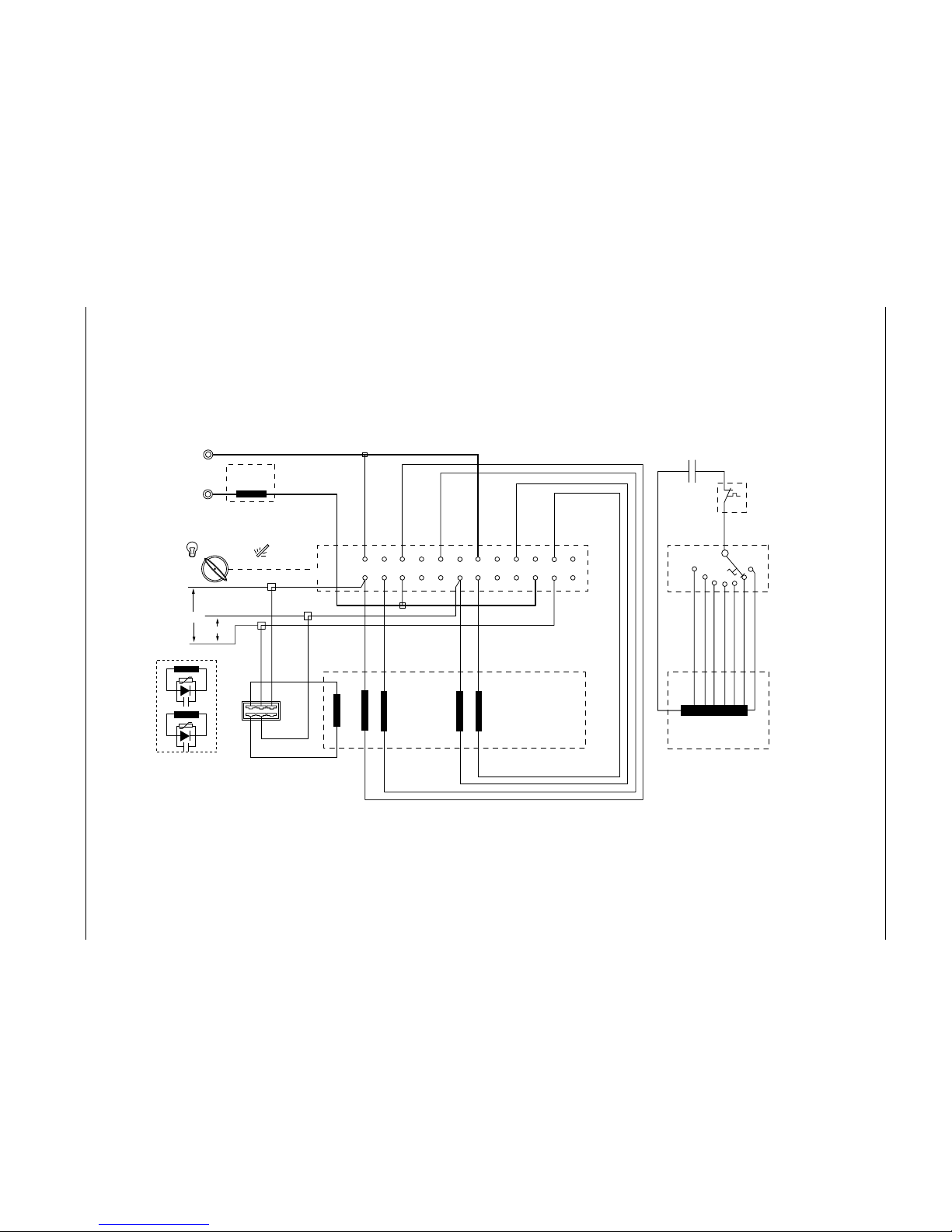

Welding

Impedance

Gen. Weld.

Rotor

Red

White

Brown

Battery Charger

12V AC

Blue

Brown

GreyRed

BlackWhite

Yellow

Green

Main Winding

Brown

Red

White

Green

Generator/Welder

Power Switch

2 4 6 8 10 12 14 16 18 20 22 24

135 7911131517192123

Capacitor

Thermal Trip

(Fitted Inside

the Windings)

Violet

Black

Blue

Grey

Red

Brown

Yellow

Orange

Auxiliary Winding

Welding Current

and Generator

Voltage Selector

R/L1

White

Orange

115V

230V

Blue

Electrode

Holder

Ground

Clamp

1

2

7

6

3

4

5

Adjustable

Figure 11 - Wiring Diagram - AC Welder/Generator

www.chpower.com

Welder/Generator

Page 14

Operating Instructions

Limited Warranty

1. DURATION: One year from the date of purchase by the original purchaser. Units used for rental or commercial purposes are

warranted for 90 days from date of purchase.

2. WHO GIVES THIS WARRANTY (WARRANTOR):

The Campbell Group / A Scott Fetzer Company

100 Production Drive

Harrison, Ohio, 45030

Telephone: (513) 367-4811.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld portable welder/generator supplied or

manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects on material and workmanship which occur within the duration of the

warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO ONE YEAR

FROM THE DATE OF ORIGINAL PURCHASE. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product.

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment.

E. Normal adjustments which are explained in the owner’s manual(s) provided with the product, i.e. belts, pressure switch.

F. Items or service that are normally required to maintain the product, i.e. lubricants, filters and gaskets.

G. Electric motor and gasoline engine components are expressly excluded from coverage under this limited warranty. Such

components should be returned by the purchaser to the original manufacturer or to its authorized repair stations for service.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which have failed within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center.

Freight costs, if any, must be borne by the purchaser.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A. Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and

depending on the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact the

Campbell Hausfeld Product Service Department (see paragraph 2).

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

www.chpower.com

Page 15

IN952500AV 3/01

Instructions D’Utilisation

Soudeur/Génératrice

Ces modèles sont alimentés par des

moteurs à quatre temps à

refroidissement par air et conçus pour

fonctionner à un tr/min maximum et

donner une puissance en watts

continue tel qu’indiquée. Sur certains

modèles, un indicateur d’huile bas est

fourni pour protéger le moteur. Cette

caractéristique est d’habitude

attribuée avec des modèles à

fonctionnement prolongé.

L’alternateur a un protecteur

thermique. Pour faire fonctionner ce

modèle comme soudeur ou

génératrice, positionner l’interrupteur

sur le panneau avant en conséquence.

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de

s’être produit en cours de transport.

Serrer tous raccords, boulons, etc.,

avant de faire fonctionner le modèle.

Composer le 1-800-746-5641 s’il y a des

pièces qui manquent.

Danger

vous

avertis d’un danger qui RÉSULTERA en

blessure grave ou la mort.

Avertissement vous avertis d’un

danger qui POURRA résulter en

blessure grave ou la mort.

Attention

vous avertis d’un danger qui POURRA

résulter en blessure.

Avis

vous

avertis d’informations importantes qui

aidera à empêcher le dommage à

l’équipement.

● Avant de démarrer ou

d’entretenir le modèle

soudeur/génératrice, lire

et comprendre toutes les instructions.

Manque de respecter les précautions

de sécurité ou les instructions peut

résulter en panne d’équipement

et/ou en blessures personnelles

graves ou en mort. Les instructions

de moteur de ces modèles sont dans

un manuel séparé. Conserver tous les

manuels comme référence.

● Ne jamais utiliser ce modèle

soudeur/génératrice pour une

application autre que celle spécifiée

par le fabricant. Ne jamais faire

fonctionner ce modèle

soudeur/génératrice dans des

conditions qui ne sont pas

approuvées par le fabricant. Ne

jamais essayer de modifier ce modèle

soudeur/génératrice afin de

performer d’une façon autre que

celle conçue par le fabricant.

● Pour l’entretien et la réparation,

utiliser seulement les produits et les

pièces recommandées par le

fabricant.

● S’assurer que le modèle

soudeur/génératrice soit mis à la terre

correctement à une source externe

avant le fonctionnement Se référer à

la section “Instructions de Mise à la

Terre” pour la marche à suivre

correcte concernant la mise à la terre.

● S’assurer que le modèle

soudeur/génératrice soit utilisé

seulement par des personnes qui ont

lus et compris ces instructions.

● S’assurer que le modèle

soudeur/génératrice soit placé sur

une surface plate avant et pendant le

fonctionnement. Le

soudeur/génératrice ne doit pas

glisser ni se déplacer pendant le

fonctionnement.

● Garder toutes personnes à l’écart du

modèle soudeur/génératrice pendant

le fonctionnment.

● Ne pas permettre que les personnes

qui portent des vêtements et de la

bijouterie démarrent ou fassent

fonctionner le modèle

soudeur/génératrice. Les vêtements

flottants et la bijouterie peuvent se

prendre dans les pièces mouvantes,

endommageant l’équipement et/ou

causant des blessures personnelles.

● Garder toutes personnes à l’écart des

pièces mouvantes ou qui se

réchauffent pendant le

fonctionnement.

● S’assurer que tous les appareils

alimentés soient hors circuit avant de

les brancher au modèle

soudeur/génératrice.

● Garder le modèle

soudeur/génératrice propre et en bon

état de marche à tout temps.

Ne jamais faire fonctionner

ce modèle soudeur/

génératrice dans un endroit

explosif, inflammable ou mal-aéré.

● S’assurer que tous les outils et

appareils soient en bon état de

marche et mis à la terre

correctement. Utiliser des appareils

qui ont un cordon d’alimentation à

trois broches. Si vous utilisez un

cordon prolongateur, s’assurer qu’il

ait trois broches pour la mise à la

terre correcte.

Ne pas

faire

fonctionner ce modèle soudeur/

génératrice sur une surface trempe ni

dans la pluie.

Couper

le moteur

et déconnecter le fil de la bougie

d’allumage avant de procéder à

l’entretien du modèle.

● Utiliser seulement de l’essence sans

plomb. Ne jamais faire le plein

d’essence pendant que le moteur

fonctionne. Faire attention de ne

pas renverser pendant que vous

faites le plein d’essence. S’assurer

que le capuchon du réservoir à

essence soit bien placé avant de

démarrer le moteur. Nettoyer les

déversements avant de démarrer le

moteur. Permettre que le moteur

se refroidisse pendant au moins

deux minutes avant de faire le plein

d’essence.

© 2001 Campbell Hausfeld

Description

Déballage

Généralités Sur La Sécurité

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

BUILT TO LAST

TM

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

AVIS

MANUEL

!

AVERTISSEMENT

!

AVERTISSEMENT

!

DANGER

Page 16

16 Fr

Instructions D’Utilisation

● Ce modèle soudeur/génératrice

peut être utilisé comme source

alternative en cas d’urgence. Dans

ce cas, un inverseur manuel doit

être installé entre le compteur

d’électricité et la boîte de

dispersion. Cet interrupteur devrait

être installé par un électricien

autorisé.

Ne jamais

mélanger

de l’huile avec de l’essence pour ce

moteur. Ceci est un moteur à quatre

temps conçu pour fonctionner

uniquement avec de l’essence. L’huile

est utilisé seulement pour graisser le

moteur.

Toujours garder un

extincteur d’incendie à la

portée pendant le soudage à

l’arc.

● Seules des personnes qualifiées

doivent performer l’installation,

l’entretien, la réparation et le

fonctionnement de cet équipement

en conformément aux codes locaux,

provinciaux et nationaux.

L’utilisation incorrecte des

soudeurs à l’arc électriques

peut causer des secousses électriques,

des blessures et la mort! Respecter

toutes les précautions décrites dans ce

manuel pour réduire le risque de

secousse électrique.

● Vérifier que les pièces détachées du

soudeur à l’arc soient propres et en

bon état de marche avant de faire

fonctionner le soudeur. S’assurer

que l’isolation sur les câbles, porteélectrodes et cordons

d’alimentation ne soient pas

endommagés. Toujours réparer ou

remplacer des pièces endommagées

ou usées avant de faire fonctionner

le soudeur. Toujours garder les

panneaux de soudage, les écrans

etc. en place pendant le

fonctionnement du soudeur.

● Toujours porter des vêtements

protecteurs secs, des gants de

soudage et des chaussures isolées.

● Toujours faire fonctionner le

soudeur dans un endroit propre, sec

en bien aéré. Ne pas faire

fonctionner le soudeur dans un

endroit humide, trempe, pluvieux

ou mal-aéré.

● S’assurer que l’objet de travail soit

bien supporté et mis à la terre avant

de commencer le soudage à l’arc.

● Étendre le câble à soudage enroulé

pour empêcher le surchauffage et

d’endommager l’isolation.

Ne

jamais

immerger l’électrode ou le porteélectrode dans l’eau. Si le soudeur

se mouille, s’assurer qu’il soit

complètement propre et sec avant

d’essayer de l’utiliser!

● Toujours mettre l’équipement hors

circuit avant de le déplacer.

● Toujours fixer le conducteur de

travail en premier.

● Vérifier que l’objet de travail soit

bien mis à la terre.

● Toujours mettre l’équipement de

soudage à l’arc hors circuit (off)

lorsqu’il est au repos et enlever

l’électrode du porte-électrode.

● Ne jamais permettre que les parties du

corps touchent l’électrode et la pièce

de terre ou l’objet de travail mis à la

terre en même temps.

● Les positions et conditions de

soudage difficiles peuvent poser des

dangers électriques. Lorsque vous

êtes accroupis, à genou ou élevés,

s’assurer d’isoler toutes pièces

conductives, porter les vêtements

protecteurs appropriés et prendre des

précautions pour s’empêcher de

tomber.

● Ne jamais essayer d’utiliser cet

équipement aux réglages de

courant ou aux facteurs d’utilisation

supérieurs à ceux spécifiés sur les

étiquettes de l’équipement.

● Ne jamais utiliser un soudeur à l’arc

pour dégeler des tuyaux gelés.

Des étincelles volantes et le

métal chaud peuvent causer

des blessures. Pendant le

refroidissement des soudures, la scorie

peut être dégagée. Prendre toutes les

précautions décrites dans ce manuel

pour diminuer le risque de blessures

causées par les étincelles volantes et le

métal chaud.

● Porter un écran facial approuvé par

ANSI ou des lunettes de sécurité

avec des écrans latéraux pendant le

burinage ou le meulage des pièces

en métal.

● Porter des bouchons d’oreilles lors

du soudage aérien afin d’empêcher

que la scorie ou que les

éclaboussures tombent dans les

oreilles.

Les opérations de soudage à

l’arc électrique produisent

une lumière et une chaleur

intense ainsi que des rayons

ultraviolets. (UV). Cette lumière

intense et les rayons UV peuvent causer

des blessures aux yeux et à la peau.

Prenez toutes les précautions décrites

dans le manuel pour diminuter la

possibilité de blessures aux yeux et à la

peau.

● Toutes personnes qui font

fonctionner cet équipement ou qui

sont dans l’endroit lorsque

l’équipement est en marche doivent

porter des vêtements de soudage

protecteurs, y compris un casque ou

un écran avec au moins une

puissance de 10, des vêtements

résistant aux flammes, des gants de

soudage en cuir, et de la pleine

protection pour les pieds.

Ne

jamais

regarder aux opérations de soudage

à l’arc sans protection oculaire telle

que décrite ci-dessus. Ne jamais

utiliser une lentille filtrante ombrée

qui est fêlée, cassée ou classifiée

moins que 10. Avertir les autres

autours de ne pas regarder à l’arc.

Les opérations de soudage à

l’arc peuvent causer des

étincelles et chauffer le

métal à des températures qui

peuvent causer des brûlures

graves! Utiliser des gants et des

vêtements protecteurs lors des

opérations métallurgiques. Prenez

toutes les précautions décrites dans le

manuel afin de diminuer le risque de

brûler la peau et les vêtements.

● S’assurer que toutes les personnes

dans l’endroit de soudage soient

protégées de la chaleur, des

étincelles et des rayons ultraviolets.

Utiliser d’autres écrans faciales et

barrières résistantes aux flammes au

besoin.

● Ne jamais toucher les objets de

travail avant qu’ils ne soient

complètement refroidis.

La chaleur et les étincelles

produites lors du soudage à

l’arc électrique et autres

opérations métallurgiques peuvent

allumer les substances inflammables et

matériaux explosifs! Prenez toutes les

précautions décrites dans le manuel

pour diminuer la possibilité de flammes

ou d’explosion.

● Enlever tous matériaux

inflammables jusqu’à 35 pi (10.7

mètres) de l’arc de soudage. S’il

n’est pas possible, bien recouvrir les

Généralités Sur La

Sécurité (Suite)

!

ATTENTION

!

AVERTISSEMENT

!

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 17

17 Fr

matériaux inflammables avec des

covercles ingnifugés.

● Prenez les précautions pour

s’assurer que les étincelles volantes

et la chaleur ne causent pas de

flammes dans des endroits cachés,

fissures, derrière les cloisons, etc.

Risque d’incendie! Ne pas

souder les boîtes ou pipes qui

contiennent ou qui ont déjà

contenu des matériaux inflammables,

ou des gaz ou liquides combustibles.

Le soudage à l’arc des boîtes

ou des cylindres fermés tels

que les réservoirs ou les

cylindres peuvent causer une explosion

s’ils ne sont pas bien aérés! Vérifier

que tous les cylindres ou boîtes qui

doivent être soudés aient un trou

suffisament grand pour aérer afin que

les gaz en expansion peuvent être

relâchés.

Ne pas respirer les vapeurs

produites lors du soudage à

l’arc. Les vapeurs sont

dangereuses. Si l’endroit de soudage

ne peut pas être bien aéré, s’assurer

dutiliser un respirateur qui vous fournit

de l’air.

● Garder la tête et le visage hors des

vapeurs de soudage.

● Ne pas performer du soudage à l’arc

électrique sur des métaux galvanisés

ou plaqués de cadmium, qui

contiennent du zinc, du mercure ou

du berylium sans suivre les

précautions suivantes:

a. Enlever l’enrobement du métal de

base.

b. S’assurer que l’endroit de

soudage soit bien aéré.

c. Utiliser un respirateur pour vous

fournir de l’air.

Des vapeurs extrêmement toxiques

sont crées lorsque ces métaux sont

chauffés.

Le champ électromagnétique

qui est crée pendant le

soudage à l’arc peut entrer en conflit

avec le fonctionnement de plusieurs

appareils électriques tels que les

stimulateurs cardiaques. Les personnes

qui utilisent ces appareils devraient

consulter leur médecin avant de

performer le soudage à l’arc.

● Faire passer l’électrode et les câbles

de service ensembles et fixer avec

du ruban là où possible.

● Ne jamais s’envelopper les câbles de

soudage autour du corps.

● Toujours positionner l’électrode et

les conducteurs de travail afin qu’ils

soient du même côté du corps.

● S’exposer aux champs

électromagnétiques pendant le

soudage peut avoir d’autres

conséquences inconnues reliées à la

santé.

Toujours

s’assurer

que l’endroit de travail soit sécure et

libre d’hasards (étincelles, flammes,

métal incandescent ou scorie) avant

de partir. S’assurer que l’équipement

soit hors circuit et que l’électrode

soit enlevé. S’assurer que les câbles

soit enroulés et hors portée.

S’assurer que tout métal et scorie

soit refroidit.

NORMES DE SÉCURITÉ ADDITIONNELLES

Norme ANSI Z49.1 de l’ American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

(Normes de Sécurité et de Santé)

OSHA 29 CFR 1910, du Superintendent

of Documents, U.S. Government

Printing Office, Washington, D.C. 20402

National Electrical Code (Code

Électrique National)

Norme NFPA 70, du National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders (Manipulation Sûr des

Gaz Comprimés en Cylindres)

CGA Pamphlet P-1, du Compressed Gas

Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA

22202

Code for Safety in Welding and

Cutting (Code de Sécurité pour le

Soudage et le Coupage)

Norme CSA W117.2, du Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

(Procédés de Coupage et de

Soudage)

Norme NFPA 51B, du National Fire

Protection Association, Batterymarch

Park, Quicy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face

Protection (Règlements

Professionnels et D’Éducation de

Sécurité pour la Protection des

Yeux et du Visage)

Norme ANSI Z87.1, de l’American

National Standards Institute, 1430

Broadway, New York, NY 10018

Se référer aux Material Safety Data

Sheets (Données De Sécurité) et les

instructions du fabricant pour métaux,

électrodes, enduits et produits pour le

nettoyage.

EMPLACEMENT

Un bon emplacement peut augmenter

la performance, la fiabilité et

l’espérance de vie du soudeur à l’arc

d’une façon significante.

● Pour les meilleurs résultats, placer le

modèle soudeur/génératrice dans

un environnement propre et sec. La

poussière et le débris dans le

modèle absorbent l’humidité et

augmentent l’usure des pièces

mouvantes.

● Entreposer les électrodes dans un

endroit propre et sec avec une

humidité basse afin de préserver

l’enrobement de flux.

PRÉ-FONCTIONNEMENT

1. Vérifier le niveau d’huile du moteur.

L’huile N’EST PAS mélangée avec de

l’essence, par contre une source

adéquate d’huile est nécessaire pour

le graissage correct du moteur. Se

référer au Manuel du Moteur pour le

SAE, API et les spécifications de

remplissage. Le modèle est livré sans

huile dans le moteur.

2. Utiliser un interrupteur pour protéger

contre un dérangement due à une

mise à la terre accidentelle (DDFT)

L’usage d’une DDFT est fortement

encouragé. Ces interrupteurs

peuvent diminuer de façon

spectaculaire le risque de blessures

dans le cas de secousse électrique.

Pour installer un DDFT, le fil neutre du

modèle soudeur/génératrice doit être

mis à la terre de façon interne au bâti