Page 1

Stationary

Air Compressor

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

1

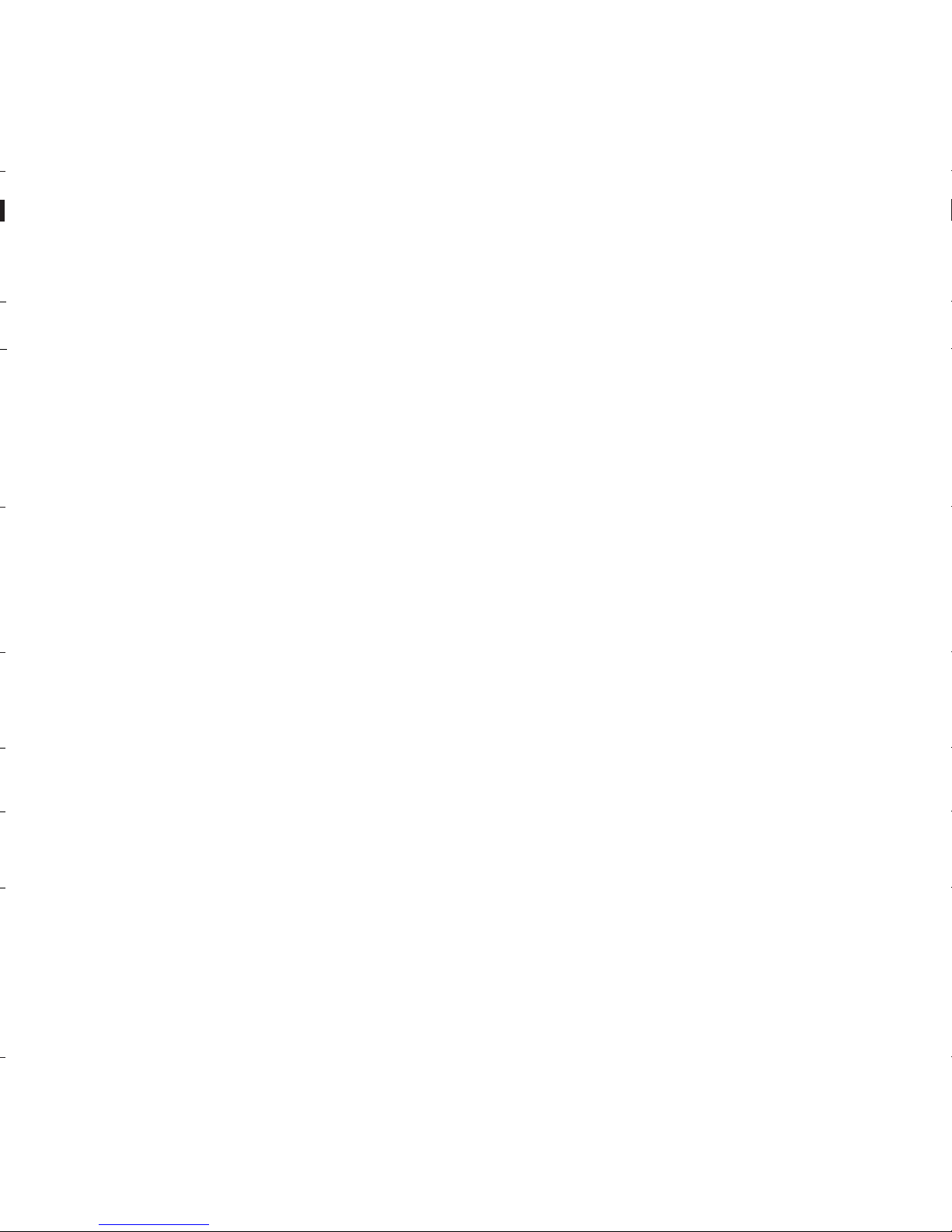

Air compressor units are intended to

provide compressed air to power

pneumatic tools and operate spray guns.

The pumps supplied are oil lubricated. A

small amount of oil carryover is present

in the compressed air stream.

Applications requiring air free of oil or

water should have the appropriate filter

installed. The air compressor unit must

be mounted as described in the

instructions on a solid floor. Any other

use of these units will void the warranty

and the manufacturer will not be

responsible for problems or damages

resulting from such misuse.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may have

occurred during transit. Make sure to

NOTICE

!

CAUTION

!

WARNING

!

DANGER

Operating Instructions

tighten fittings, bolts, etc., before

putting unit into service.

Do not operate

unit if damaged

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

Since the air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses, etc.)

used, make up a high pressure

pumping system, the following safety

precautions must be observed at all

times:

1. Read all manuals

included with this

product carefully. Be

thoroughly familiar

with the controls and

the proper use of the equipment.

2. Follow all local electrical and safety

codes as well as in the United

States, the National Electrical Codes

(NEC) and Occupational Safety and

Health Act (OSHA).

!

WARNING

IN227705AV 12/02

© 2002 Campbell Hausfeld

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be used

“as is” to supply breathing quality

air. For any application of air for

human consumption, you must fit

the air compressor/pump with

suitable in-line safety and alarm

equipment. This additional

equipment is necessary to properly

filter and purify the air to meet

minimal specifications for Grade D

breathing as described in

Compressed Gas Association

Commodity Specification G 7.1 1966, OSHA 29 CFR 1910. 134,

and/or Canadian Standards

Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used

for the purpose of breathing air

application and proper in-line

safety and alarm equipment is not

simultaneously used, existing

warranties are void, and Campbell

Hausfeld disclaims any liability

whatsoever for any loss, personal

injury or damage.

!

DANGER

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and

use hearing protection

when operating the

unit.

6. Do not stand on or use the unit as

a handhold.

7. Before each use, inspect compressed

air system and electrical

components for signs of damage,

MANUAL

Figure 1

Description

General Safety

Page 2

Page 3

PIPING

Never use plastic

(PVC) pipe for

compressed air. Serious injury or death

could result.

Any tube, pipe, or hose used must have

a pressure rating higher then 150 psi.

Minimum recommended pipe size:

- up to 50 feet long use 1/2”

- greater than 50ft. long use 3/4”

Larger diameter pipe is always better.

All wiring and

electrical

connections must be performed by a

qualified electrician. Installations must

be in accordance with local and

national codes.

GROUNDING

This product must be grounded. If the

unit comes with a factory installed

cord, plug the cord into a properly

sized, grounded outlet. For units that

do not have a factory installed cord,

install permanent wiring from the

electrical source to the pressure switch

with a ground conductor connected to

the grounding screw on the pressure

switch. A properly sized cord with a

ground conductor and plug may also

be installed by the user.

Improperly grounded

motors are shock hazards.

Make sure all the

equipment is properly grounded.

WIRING

Local electrical wiring codes differ from

area to area. Source wiring, plug and

protector must be rated for at least the

amperage and voltage indicated on the

motor nameplate, and meet all electrical

codes for this minimum. Use a slow blow

fuse type T or a circuit breaker.

Overheating, short

circuiting and fire

damage will result from inadequate

wiring.

Motor protection should be used when

a motor built-in thermal overload

protection is not provided. Some 3

phase units require a magnetic starter

!

CAUTION

!

DANGER

!

WARNING

!

WARNING

(Part number MP3445 available

separately). Do not draw bolts tight.

Allow the pads to absorb vibrations. A

flexible coupling should be installed

between the tank and service piping.

This compressor is

extremely top

heavy. The unit must be bolted to the

floor with isolation pads or secured

with the wall cable (if provided)

before operating to prevent

equipment damage, injury or death.

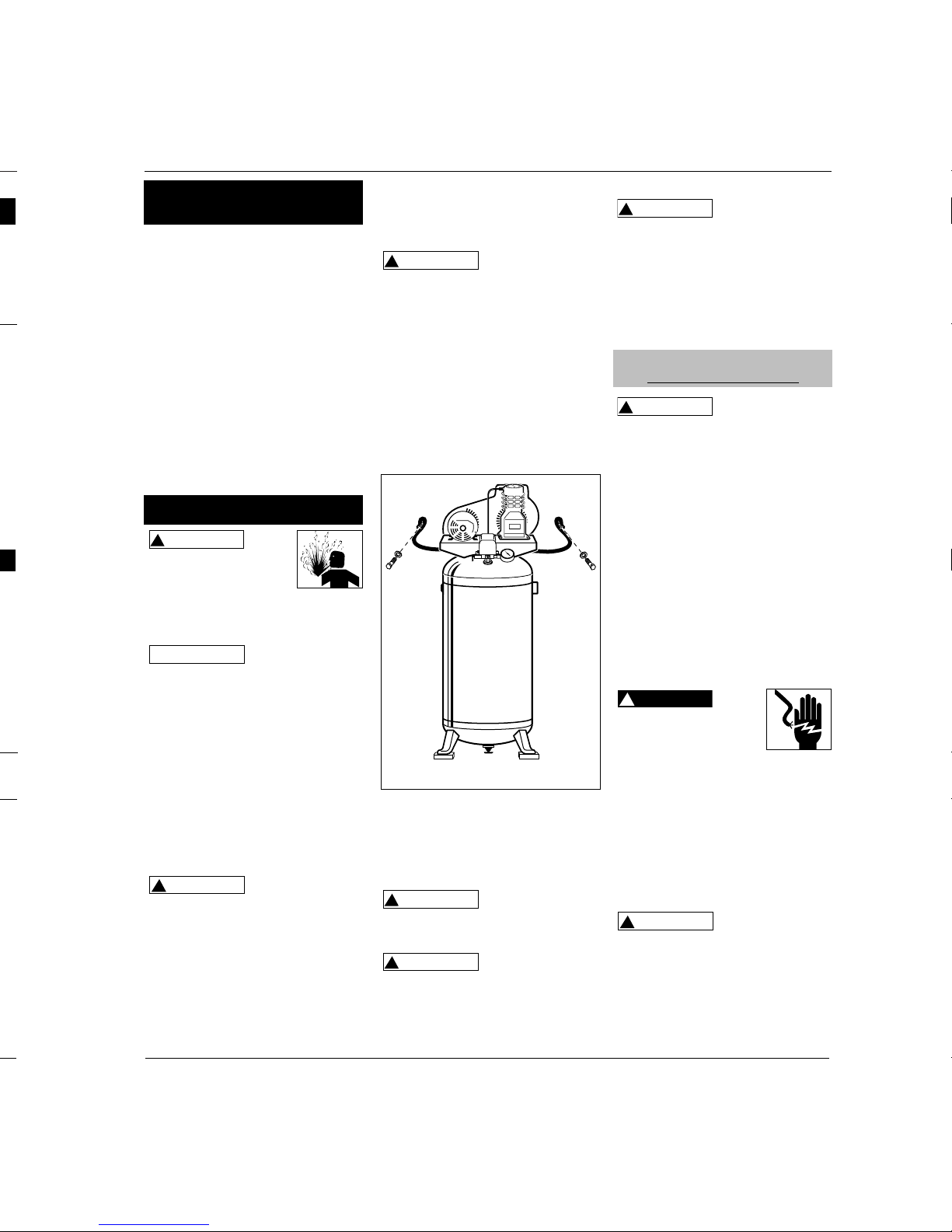

WALL CABLE INSTALLATION

(Provided on some 30 gallon models)

Included with the safety cable are two

lag screws and washers.

1. Place an isolation pad beneath each

foot of the compressor to minimize

vibration.

2. Position the cable through the

baseplate as shown in Figure 3.

3. Place the screws through the

washers then through looped ends

of cable.

4. Secure the screws to a stud within a

framed wall. Use anchors if the wall

is concrete.

Do not secure the

compressor with

toggle bolts into drywall. Drywall

sheeting or plaster will not support

the weight of the compressor.

Never install a

shut-off valve

between the compressor pump and the

tank. Personal injury and/or equipment

damage may occur.

!

WARNING

!

WARNING

!

WARNING

Vertical Models

3

Operating Instructions

hot during use. To avoid the risk of

severe burns, never touch the

discharge tube.

Check valve - One-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump.

Belt Guard - Covers the belt, motor

pulley and flywheel.

Tank Drain Valve - This valve is

located on the bottom of the tank. Use

this valve to drain moisture from the

tank daily to reduce the risk of

corrosion.

Reduce tank pressure below 10 psi,

then drain moisture from tank daily to

avoid tank corrosion. Drain moisture

from tank(s) by opening the drain

valve located underneath the tank.

Disconnect, tag and lock

out power source, then

release all pressure from

the system before

attempting to install, service, relocate

or perform any maintenance.

LOCATION

This compressor is

not intended for

outdoor installation.

It is extremely important to install the

compressor in a clean, well ventilated

area where the surrounding air

temperature will not be more than 100°F.

Provide a minimum clearance of 18

inches between the compressor

flywheel or fan to the wall and ensure

clear access to the drain cock to

facilitate condensate drainage.

Do not locate the compressor air inlet

near steam, paint spray, sandblast areas

or any other source of contamination.

MOUNTING

Never use the

wood shipping

skids for mounting the compressor.

FLOOR MOUNTING

(All Units)

On some 30 gallon models a wall cable

is provided and should be installed. If

the unit is not secured with the wall

cable, the compressor feet MUST be

bolted to a flat, even, concrete floor or

separate concrete foundation.

Vibration isolators must be used

between the tank leg and the floor

!

CAUTION

NOTICE

!

WARNING

Figure 3 - Wall Cable Installation

Electrical Installation

HARD WIRED UNITS ONLY

Installation

Introduction

(Continued)

Page 4

Page 5

extension. Screw the cap onto one end of

the extension. Remove the oil drain plug

from the base of the pump and install the

oil drain extension (See Figure 6).

Vertical Models

5

Operating Instructions

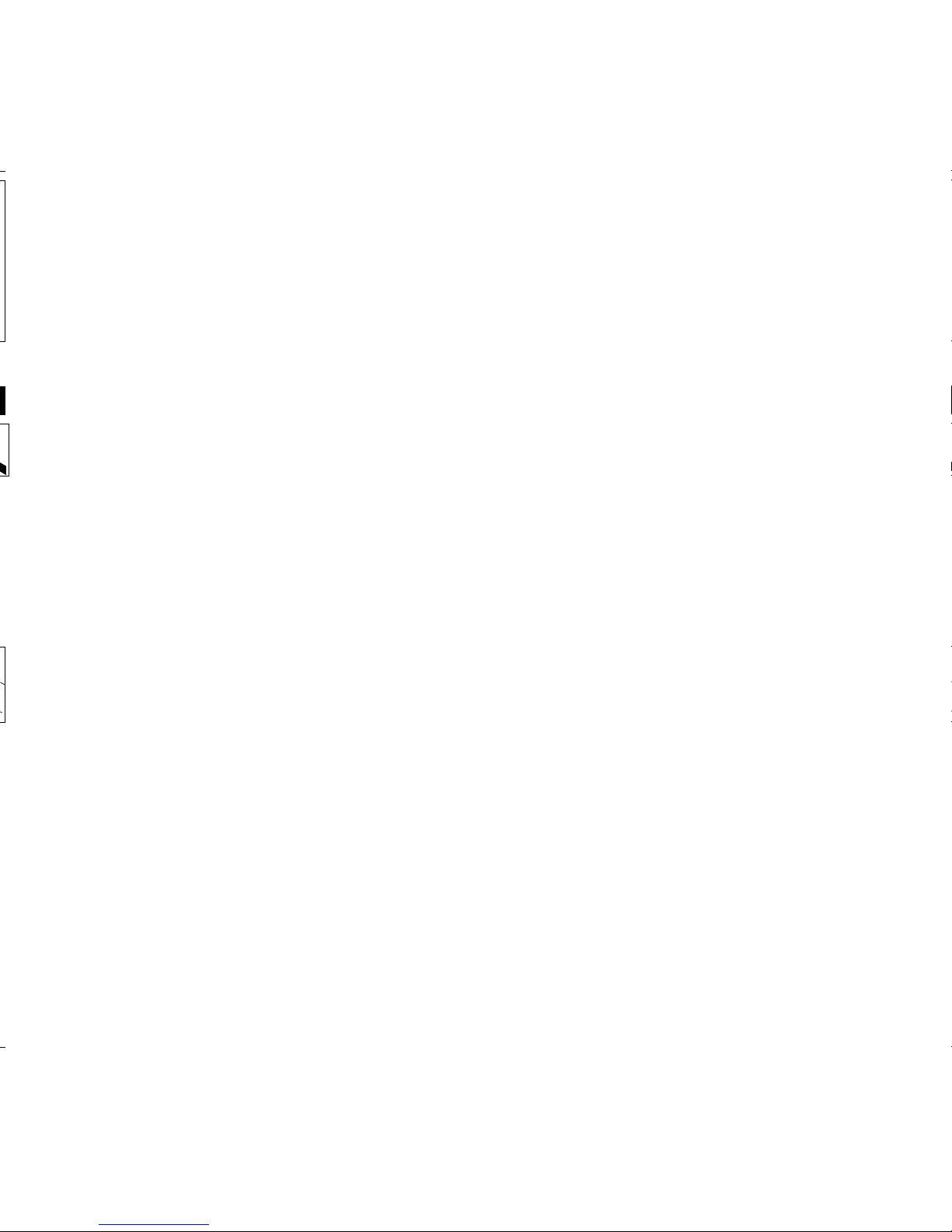

LUBRICATION

THIS UNIT IS

SHIPPED WITHOUT

OIL! Follow lubrication instructions

before operating compressor.

Ensure oil drain extension and cap has

been installed (if included) then remove

the dipstick breather (See Fig. 6) and fill

pump oil according to the chart.

See specification label on air tank for

pump model number and refer to the

chart for the proper oil capacity. Use

SAE 30 industrial grade air compressor

oil or full synthetic motor oil like Mobil

1 10W30. Do not use regular

automotive oil such as 10W-30.

Additives in motor oil can cause valve

deposits and reduce pump life. For

maximum pump life, drain and replace

oil after the first hour of run time.

Proper oil fill level is illustrated in

Figure 6.

START-UP

Do not attach air

tools to open end

of the hose until start-up is completed

and the unit checks OK.

!

CAUTION

!

CAUTION

Never disconnect

threaded joints

with pressure in tank!

1. Remove the breather and fill pump

to the proper oil level. See

lubrication section.

2. Open the tank drain valve. Turn

outlet valve to open air flow.

3. Move pressure switch lever or knob

to the OFF position and plug in

power cord. Move pressure switch

to the AUTO position to run the

unit.

4. Run the unit for 30 minutes, under

no load, to break in pump parts.

5. Move the pressure switch lever or

knob to OFF and turn tank drain

valve to shut off air flow. The

compressor is now ready for use.

Disconnect, tag and lock

out power source, then

release all pressure from

the system before attempting to install,

service, relocate or perform any

maintenance.

All repairs should be performed by an

authorized service representative.

FOR EFFICIENT OPERATION:

Perform the following test to verify free

operation of the safety valve weekly

and follow maintenance schedule.

!

WARNING

!

WARNING

Model Approx. Oil Capacity

VS260000KB 6 oz

VT470200KB 11.5 oz

VT470000KB 12 oz

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form

into droplets as it comes from an air

compressor pump. When humidity is

high or when a compressor is in

continuous use for an extended period

of time, this moisture will collect in the

tank. When using a paint spray or

sandblast gun, this water will be carried

from the tank through the hose, and out

of the gun as droplets mixed with the

spray material.

IMPORTANT: This condensation will

cause water spots in a paint job,

especially when spraying other than

water based paints. If sandblasting, it

will cause the sand to cake and clog the

gun, rendering it ineffective.

A filter in the air line, located as near to

the gun as possible, will help eliminate

this moisture.

1. Pull ring on safety valve and allow

the ring to snap back to normal

position (See Figure 8). This valve

automatically releases air if the tank

pressure exceeds the preset

maximum.

Do not attempt to

tamper with this

valve. This valve should be checked

occasionally. If air leaks after the ring

has been released, or the valve is stuck

and cannot be actuated by the ring, the

safety valve must be replaced.

A large amount of

fast moving air will

be released if this valve is actuated

with pressure in the tank.

2. With motor OFF and unplugged,

clean debris from motor, flywheel,

tank, air lines and pump cooling fins.

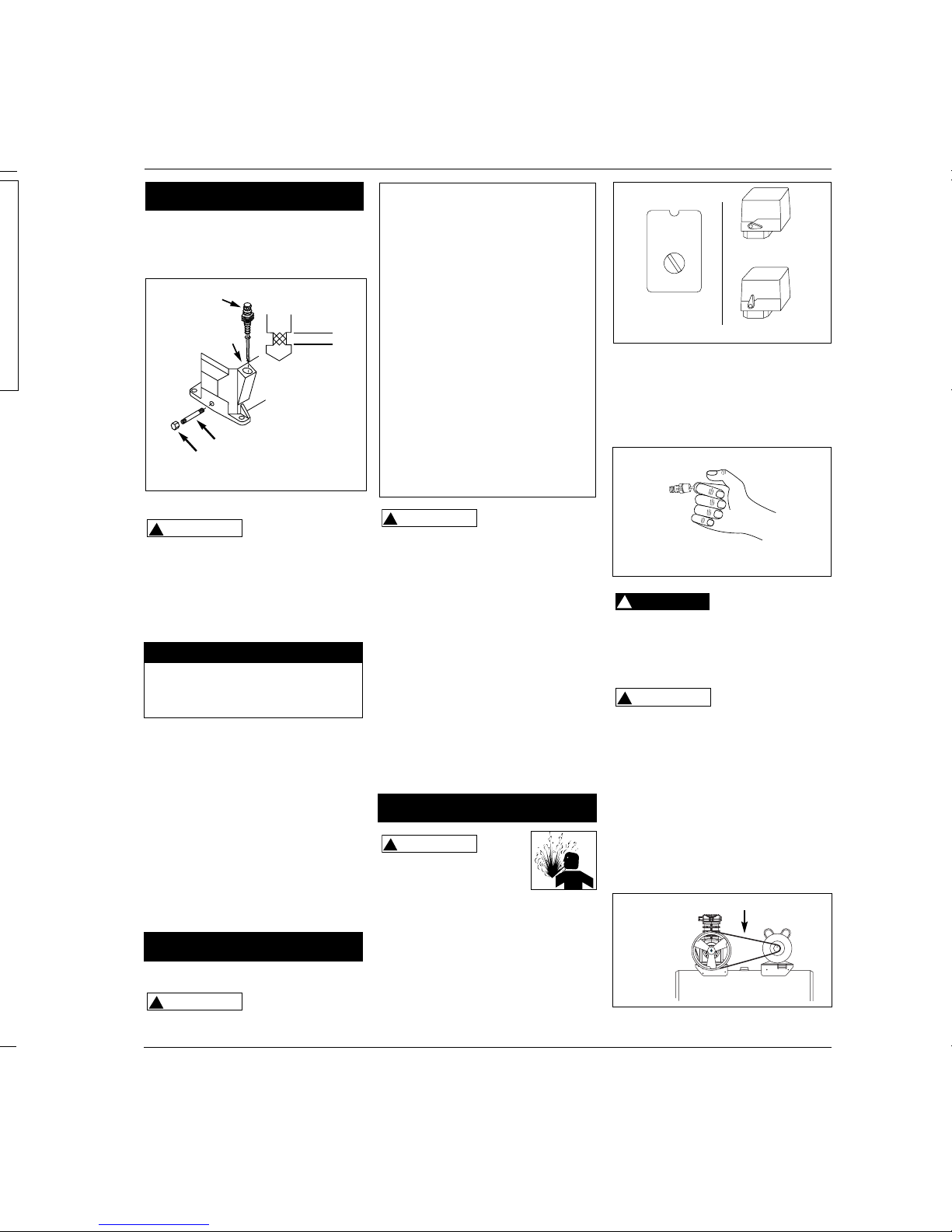

DRIVE BELT

Belts will stretch in normal use. Properly

adjusted, a 5-pound force applied to

the belt between the motor pulley and

the pump will deflect the belt about

1/2”(See Figure 9).

!

CAUTION

!

DANGER

Dipstick

Breather

Full

Add

Add Oil

Oil Drain Extension

Cap

Low

Max

Figure 6

Operation

Assembly (Con’t)

Figure 8

Maintenance

A

U

T

O

/

O

F

F

Figure 7

Lever - Off

Lever - Auto

Knob

Auto/Off

1/2” Deflection

Figure 9

Page 6

Page 7

Vertical Models

7

Operating Instructions

Symptom Possible Cause(s) Corrective Action

Excessive noise

(knocking)

Continued

Large quanity of oil in the

discharge air

NOTE: In an oil

lubricated compressor there

will always be a small

amount of oil in the air

stream.

Water in discharge air/tank

Motor hums and runs slowly

or not at all

Reset mechanism cuts out

repeatedly or fuses blow

repeatedly

Tank does not hold pressure

when compressors off and

the shut off valve is closed

Pressure switch

continuously blows air out

the unloader valve

Pressure switch does not

release air when the unit

shuts off

Excessive vibration

6. Noisy check valve in

compressor system

1. Worn piston rings

2. Compressor air intake

restricted

3. Excessive oil in

compressor

4. Wrong oil viscosity

1. Normal operation. The

amount of water

increases with humid

weather

1. Use of extension cord

2. Malfunctioning check

valve or unloader valve

3. Low voltage

4. Malfunctioning pressure

switch - contacts will not

close

1. Too many devices on

same circuit

2. Incorrect fuse size or

circuit breaker

3. Malfunctioning check

valve

4. Pressure switch set too

high

5. Loose wiring

6. Malfunctioning motor

1. Worn check valve

2. Check all connections and

fittings for leaks

3. Check tank for cracks or

pin holes

1. Malfunctioning check

valve

1. Malfunctioning unloader

valve on pressure switch

1. Loose fasteners

2. Belt needs replaced

3. Belt alignment

6. Replace.

Do not disassemble check valve with

air pressure in tank

1. Replace with new rings. Maintain oil level and change oil

more frequently.

2. Clean filter. Check for other restrictions in the intake system.

3. Drain down to full level.

4. Use Mobil 1®10W-30

1. Drain tank more often. At least daily.

2. Add a filter to reduce the amount of water in the air line.

1. Do not use an extension cord. Use longer air hose with

larger diameter.

2. Replace check valve, unloader valve or pressure switch.

Do not disassemble check valve with

air pressure in tank

3. Check with voltmeter, check reset switch on motor. If reset

switch trips repeatedly, find and correct the cause. See next

item.

4. Repair or replace pressure switch.

1. Limit the circuit to the use of only the air compressor.

2. Be sure that fuses or circuit breakers are rated properly.

3. Replace check valve.

Do not disassemble check valve with

air pressure in tank

4. Adjust or replace.

5. Check all electrical connections.

6. Replace motor.

1. Replace check valve.

Do not disassemble check valve with

air pressure in tank

2. Tighten.

3. Replace tank. Never repair a damaged tank.

1. Replace the check valve if the unloader valve bleeds off

constantly.

Do not disassemble check valve with

air pressure in tank

1. Replace the pressure switch if it does not release the

pressure for a short period of time when the unit shuts off.

Do not disassemble pressure switch with

air pressure in tank

1. Tighten.

2. Replace with correct size.

3. Align flywhell and pulley.

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

Troubleshooting Chart (Continued)

Page 8

Page 9

Compresseur D’Air

Stationnaire

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

9Fr

Les modèles de compresseurs d’air sont

conçus pour fournir de l’air comprimé

aux outils pneumatiques et pour faire

fonctionner les pistolets vaporistateurs.

Les pompes fournies sont graissées à

l’huile. Un peu d’huile résiduelle est

présent dans le débit d’air comprimé.

Installer les filtres appropriés pour les

applications qui requièrent de l’air libre

d’huile ou d’eau. Le compresseur d’air

doit être monté selon les instructions,

sur un plancher solide. Autres usages

de ces modèles nieront la garantie et le

fabricant ne sera pas responsable pour

les problèmes ou dommages résultant

de l’usage incorrect.

Directives De Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger

indique

une situation hasardeuse imminente

qui RÉSULTERA en perte de vie ou

blessures graves.

Avertis-

sement

indique une situation hasardeuse

potentielle qui PEUT résulter en perte

de vie ou blessures graves.

Attention

indique

une situation hasardeuse potentielle

qui PEUT résulter en blessures.

Avis

indique

l’information importante pour éviter le

dommage de l’équipement.

Déballage

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de s’être

produit en cours de transport. Serrer

tous raccords, boulons, etc., avant

d’utiliser le modèle.

AVIS

!

ATTENTION

!

AVERTISSEMENT

!

DANGER

Instructions D’Utilisation

Ne pas

faire

fonctionner un modèle qui a été

endommagé pendant le transport, la

manipulation ou l’utilisation. Le

dommage peut résulter en éclatement

et peut causer des blessures ou dégâts

matériels.

Puisque le compresseur d’air et les

autres pièces détachées (pompe,

pistolets, filtres, graisseurs, tuyaux, etc.)

font partie d’un système de haute

pression, il est nécessaire de suivre les

précautions suivantes.

1. Lire attentivement tous

manuels compris avec

ce produit. Bien se

familiariser avec ce

produit, ses

commandes et son utilisation.

2. Suivre tous les codes de sécurité et

d’électricité locaux ainsi qu’aux

États-Unis les National Electrical

Codes (NEC) et Occupational Safety

and Health Act (OSHA).

3. Seules les personnes bien

familiarisées avec ces règlements

!

AVERTISSEMENT

IN227705AV 12/02

© 2002 Campbell Hausfeld

Avertissement D’Air Respirable

Ce compresseur/pompe N’EST PAS

équipé pour et NE DEVRAIT PAS être

utilisé “comme soi” pour fournir de

l’air respirable. En cas

d’applications d’air pour la

consommation humaine, le

compresseur d’air/pompe doit être

équipé avec de l’équipement de

sécurité en canalisation et

d’alarme. Cet équipement

additionnel est nécessaire pour

filtrer et purifier l’air afin

d’atteindre les spécifications

minimales pour la respiration Grade

D décrites dans le Compressed Gas

Association Commodity

Specification G 7.1 - 1966, OSHA 29

CFR 1910. 134, et/ou Canadian

Standards Associations (CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour

les applications d’air respirable et

l’équipement de sécurité en

canalisation et d’alarme n’est pas

utilisé simultanément, les garanties

en existance seront annulées, et

Campbell Hausfeld nie toute

responsabilité pour n’importe

quelle perte, blessure ou dommage.

!

DANGER

d’utilisation doivent être autorisées

à se servir du compresseur.

4. Garder les visiteurs à l’écart de/et NE

JAMAIS permettre les enfants dans

l’endroit de travail.

5. Utiliser des lunettes de

sécurité et la

protection auditive

pendant l’utilisation du

modèle.

6. Ne pas se tenir debout sur/ni utiliser

le modèle comme une prise à main.

7. Inspecter le système d’air comprimé

et pièces détachées électriques pour

toute indication de dommage,

détérioration, faiblesse ou fuites

MANUEL

Figure 1

Description

Généralités sur la

Sécurité

Page 10

Page 11

Tous tubes, conduits, ou tuyaux utilisés

doivent avoir une classification de

pression au delà de 1034 kPa. Taille de

tuyau minimum recommandée:

- jusqu’à 15,24 m, 12,7 mm (1/2 po)

- plus que 15,24 m, 19,1 mm (3/4 po)

Un tuyau de diamètre plus large est

idéal.

Un

électricien qualifié doit effectuer

l’installation et les raccordements

électriques en respectant tous les

codes électriques locaux et nationaux.

MISE À LA TERRE

Ce produit doit être mis à la terre. Si le

modèle est livré avec un cordon installé

à l’usine, brancher le cordon dans une

prise de courant de taille correcte mise

à la terre. Pour les modèles qui n’ont

pas de cordon installé à l’usine,

installer des fils permanents de la

source d’électricité au manostat avec

un fil de terre branché à la vis de terre

sur le manostat. Vous pouvez aussi

installer un cordon de taille correcte

avec un fil de terre et une fiche.

Les moteurs qui ne sont pas

correctement mis à la terre

tiennent le risque de secousse

électrique. S’assurer que tout équipement

soit correctement mis à la terre.

INSTALLATION DE FILS

Les codes locaux concernant

!

DANGER

!

AVERTISSEMENT

MONTAGE

Ne jamais

utiliser

les palettes en bois d’expédition pour

le montage du compresseur.

MONTAGE AU PLANCHER

(Tous les modèles)

Un câble de mur est fourni et devrait

être installé pour quelques modèles de

30 gallons (114 L). Si le modèle n’est

pas fixé avec le câble de mur, les pieds

du compresseur DOIVENT être fixés à

un plancher en béton plat et égal ou

sur une fondation en béton séparée.

Les isolateurs de vibration doivent

être utilisés entre la jambe du réservoir

et le plancher (Numéro de pièce

MP3445, disponible séparément). Ne

pas trop serrer les boulons afin de

permettre que les tampons absorbent

les vibrations. Un accouplement

flexible devrait être installé entre le

réservoir et la tuyauterie de service.

Ce

compresseur est très lourd du haut. Le modèle

doit être boulonné au plancher avec

des tampons isolateurs ou fixé au

câble de mur (si fourni) avant son

utilisation pour éviter le dommage à

l’équipement, les blessures ou la mort.

MONTAGE DU CÂBLE DE MUR

(Fourni avec quelques modèles de

113,6 Litres)

Le câble de sécurité comprend deux vis

à tête carrée et rondelles.

1. Placer un tampon sous chaque pied

du compresseur pour réduire la

vibration.

2. Placer le câble à travers la plaque de

base tel qu’indiqué sur la Figure 3.

3. Placer les vis à travers les rondelles et

en suite à travers les bouts bouclés

du câble.

4. Fixer les vis à un poteau dans un mur

encadré. Utiliser des ancres sur les

murs en béton.

Ne pas

fixer le

compresseur avec des boulons à écrou

articulés dans le placoplâtre. Les murs

en placoplâtre ou en plâtre ne peuvent

pas soutenir le poids du compresseur.

Ne jamais

installer

une soupape d’arrêt entre la pompe du

compresseur et le réservoir. Blessures

et/ou dégâts matériels peuvent se

présenter.

TUYAUTERIE

Ne jamais

utiliser

les tuyaux en plastique (CPV) pour l’air

comprimé. Ceci peut causer des

blessures graves ou la mort.

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

ATTENTION

Modèles Verticaux

11 Fr

Instructions D’Utilisation

soulage les démarrages du moteur sous

charge.

Régulateur - Le régulateur contrôle la

quantité de pression d’air échappée à

la sortie de tuyau (Vendu séparément).

Soupape de Sûreté ASME - Cette

soupape laisse échapper l’air

automatiquement si la pression du

réservoir dépasse la pression maximum

réglée d’avance.

Tuyau de Décharge - Ce tuyau

transporte l’air comprimé de la pompe

au clapet. Ce tuyau devient très chaud

pendant son utilisation. Ne jamais

toucher le tuyau de décharge afin

d’éviter des brûlures sévères.

Clapet - Une soupape à sens unique qui

permet à l’air d’entrer le réservoir mais

qui empêche que l’air du réservoir

retourne dans la pompe du compresseur.

Carter de Courroie - Couvre la

courroie, la poulie de moteur et le

volant.

Robinet de Purge de Réservoir Cette soupape est située au fond du

réservoir. Utiliser cette soupape pour

purger l’humidité du réservoir

quotidiennement afin de réduire le

risque de corrosion.

Réduire la pression du réservoir sous

68,95 kPa, et ensuite purger l’humidité

du réservoir quotidiennement afin

d’éviter la corrosion. Purger l’humidité

du(des) réservoir(s) en ouvrant le robinet

de purge situé sous le réservoir.

Débrancher, étiquetter et

verrouiller la source de

puissance, ensuite dissiper toute la

pression du système avant d’installer,

réparer, déplacer ou de procéder à

l’entretien du modèle.

ENDROIT

Ce

compresseur n’est pas conçu pour l’utilisation à

l’extérieur.

Il est très important d’installer le

compresseur dans un endroit propre et

bien aéré, où la température de l’air ne

dépassera pas 38,1˚ C.

Une distance minimum de 45,7 cm est

requise entre le volant du compresseur

ou un évantail et un mur afin d’assurer

l’accès au robinet de purge.

Ne pas situer l’arrivée d’air du

compresseur près de la vapeur, peinture

pulvérisée, endroits de décapage au

sable et autres sources de contamination.

AVIS

!

AVERTISSEMENT

Introduction (Suite)

Figure 3 - Installation du Câble de Mur

Installation Électrique

INSTALLATION DE FILS DIRECTE

SEULEMENT

Installation

Page 12

Page 13

terre de la fiche et au corps métallique

du manostat.

QUINCAILLERIE ADDITIONNELLE

EXIGÉE

Acheter des tuyaux, un régulateur et

une soupape d’arrêt ayant une

classification minimum de 1034 kPa et

qui dépasse la pression de service

maximum du compresseur.

RALLONGE DE VIDANGE D’HUILE

Un rallonge de vidange d’huile et un

bouchon sont compris avec quelques

modèles (situés avec le manuel

d’utilisation). Installer le rallonge de

vidange d’huile et le bouchon avant

d’ajouter l’huile à la pompe. Utiliser

du ruban Teflon

®

ou du mastique sur

les filets à chaque bout du rallonge de

vidange d’huile pour éviter les fuites.

Visser le bouchon sur un bout du

rallonge. Enlever le bouchon de

vidange d’huile de la base de la pompe

et installer le rallonge de vidange

d’huile (Voir Figure 6).

GRAISSAGE

CE

MODÈLE

EST EXPÉDIÉ SANS HUILE! Suivre les

instructions de graissage avant

d’utiliser le compresseur.

S’assurer que le rallonge de vidange

d’huile et le bouchon soient installés (si

compris). Enlever le reniflard de la

réglette-jauge (Voir Fig. 6) et remplir la

pompe d’huile selon le tableau.

Se référer à la décalcomanie de

spécifications sur le réservoir pour le

numéro de la pompe et se référer au

tableau pour la capacité d’huile correcte.

Utiliser l’huile pour compresseur d’air

industrielle SAE 30 ou l’huile

complètement synthétique pour moteurs

!

ATTENTION

Modèles Verticaux

13 Fr

Instructions D’Utilisation

telle que Mobil 1 10W-30. Ne pas

utiliser l’huile pour automobile

ordinaire

telle que 10W-30. Les additifs

dans l’huile de moteur peuvent causer de

l’encrassement dans les soupapes et

peuvent diminuer la vie de la pompe.

Pour assurer la durée maximum de la

pompe, purger et remplacer l’huile après

la première heure de fonctionnement. Le

niveau d’huile correct est illustré sur la

Figure 6.

DÉMARRAGE

Ne pas

brancher

les outils pneumatiques au bout ouvert

du tuyau avant que le démarrage soit

complet et que le modèle fonctionne

correctement.

Ne jamais

débrancher les raccords filetés si le réservoir

est pressurisé!

1. Enlever le reniflard et remplir la

pompe d’huile jusqu’au niveau correct.

Se référer à la section de graissage.

2. Ouvrir le robinet de purge de

réservoir. Tourner la soupape de

sortie afin d’ouvrir la circulation d’air.

3. Mettre le levier ou le bouton du

manostat à la position OFF et brancher

!

AVERTISSEMENT

!

ATTENTION

le cordon d’alimentation. Mettre le

levier du manostat à la position AUTO

pour faire fonctionner le modèle.

4. Faire fonctionner le modèle pour 30

minutes, sans charge afin d’effectuer

le rôdage des pièces de la pompe.

5. Mettre le levier ou bouton du

manostat à la position OFF et

tourner le robinet de purge de

réservoir afin de couper la circulation

d’air. Le compresseur est prêt à

utiliser.

Débrancher, étiquetter et

verrouiller la source de

puissance et dissiper la

pression du système avant de monter,

réparer, déplacer ou de procéder à

l’entretien du modèle.

Toutes réparations doivent être

performées par un représentant de

service authorisé.

POUR LE FONCTIONNEMENT

EFFICACE:

Faire l’essaie de la soupape de sûreté

chaque semaine pour s’assurer qu’elle

fonctionne librement et respecter

l’horaire d’entretien.

1.Tirer sur l’anneau

de la soupape de

sûreté et la laisser

revenir à sa

position normale

(Voir Figure 8). Cette soupape

relâche l’air automatiquement

lorsque la pression du réservoir

dépasse le maximum réglé d’avance.

Ne pas

trifouiller

avec cette soupape. Vérifier cette

soupape de temps en temps. S’il y a

des fuites d’air après que l’anneau soir

relâché, ou si la soupape est prise et ne

peut pas être actionnée par l’anneau, la

soupape de sûreté doit être remplacée.

Une

large

!

ATTENTION

!

DANGER

!

AVERTISSEMENT

Dipstick

Breather

Full

Add

Add Oil

Oil Drain Extension

Cap

Low

Max

Figure 6

Fonctionnement

Reniflard de la

reglette-jauge

Ajoutez l’huile

Plein

Ajoutez

Rallonge de vidange d’huile

Bouchon

Bas

VS260000KB 0,18 L

VT470200KB 0,34 L

VT470000KB 0,35 L

Modèle Capacité d’huile approx.

HUMIDITÉ DANS L’AIR COMPRIMÉ

L’humidité dans l’air comprimé forme des

gouttelettes en arrivant de la pompe du

compresseur d’air. Si l’humidité est

élevée, ou si le compresseur est utilisé

continuellement, cette humidité

s’accumulera dans le réservoir. Pendant

l’utilisation d’un pistolet à peinture ou

d’un pistolet pour le décapage au sable,

cette eau sera transportée du réservoir par

moyen du tuyau, et en forme de

gouttelettes, mélangée avec le matériel

utilisé.

IMPORTANT: Cette condensation peut

causer des taches d’eau sur votre travail de

peinture, surtout pendant la pulvérisation

de peinture qui n’est pas à base d’eau.

Pendant le décapage au sable, cette eau

servira à tenir le sable ensemble et causera

une obstruction dans le pistolet.

Un filtre à air en canalisation situé aussi

près du pistolet que possible aidera à

éliminer cette humidité.

Montage

Installation (Suite)

A

U

T

O

/

O

F

F

Figure 7

Levier - Off

Levier - Auto

Bouton

Auto/Off

Entretien

Figure 8

Page 14

Page 15

Modèles Verticaux

15 Fr

Instructions D’Utilisation

Symptôme Cause(s) Possible(s) Mesure Corrective

Bruit excessif

(cognement)

Suite

Large quantité d’huile dans

l’air de décharge

REMARQUE: Il y aura

toujours un peu d’huile dans

le jet d’air avec un

compresseur graissé par

l’huile.

Eau dans l’air de

débit/réservoir

Le moteur ronronne et

fonctionne lentement ou

pas du tout

Le mécanisme de

réenclenchement se

déclenche à maintes reprises

ou les fusibles sautent à

maintes reprises

Le réservoir ne conserve pas

la pression quand le

compresseur est hors circuit

et la soupape d’arrêt est

fermée

Le manostat laisse souffler

de l’air continuellement à

travers de la soupape de

déchargement

Le manostat ne relâche pas

l’air lorsque le modèle se

coupe (off)

Vibration excessive

6. Clapet bruyant dans le système de

compresseur

1. Segments de piston usés

2. Arrivée d’air du compresseur

limité

3. Huile excessive dans le

compresseur

4. Viscosité d’huile incorrecte

1. Fonctionnement normal. La

quantité d’eau augmente avec le

temps humide

1. Cordon prolongateur utilisé

2. Fonctionnement défectueux du

clapet ou de la soupape de

déchargement

3. Basse tension

4. Panne de manostat - contacts ne

ferment pas

1. Trop d’appareils sur le même

circuit

2. Taille de fusible ou de disjoncteur

incorrecte

3. Fonctionnement défectueux du

clapet

4. Manostat réglé trop haut

5. Fils désserrés

6. Fonctionnement défectueux du

moteur

1. Clapet usé

2. Inspecter tous branchements et

raccordements pour des fuites

3. Inspecter le réservoir pour des

fentes ou des trous d’épingles

1. Fonctionnement défectueux du

clapet

1. Fonctionnement défectueux de la

soupape de déchargement sur le

manostat

1. Attaches désserrés

2. Changement de la courroie exigé

3. Redressage de la courroie

la partie supérieure du piston. Remplacer la culasse et la plaque de

soupape et utiliser un nouveau joint d’étanchéité. Voir la section de

Graissage pour l’huile recommandée.

6. Remplacer.

Ne pas démonter le clapet

si le réservoir est pressurisé

1. Remplacer les segments de piston. Entretenir le niveau d’huile

correct et changer l’huile plus souvent.

2. Nettoyer le filtre. Vérifier le système d’arrivée pour autres

restrictions.

3. Vidanger jusqu’au niveau plein.

4. Utiliser l’huile Mobil 1

®

10W-30

1. Purger le réservoir plus souvent, au moins quotidiennement.

2. Ajouter un filtre pour diminuer la quantité d’eau dans la

canalisation d’air.

1. N’utilisez pas un cordon prolongateur. Utilisez un tuyau d’air plus

long avec un diamètre plus large.

2. Remplacer le clapet, la soupape de déchargement ou le manostat.

Ne pas démonter le clapet

si le réservoir est pressurisé

3. Vérifier avec un voltmètre, inspecter le disjoncteur de

réenclenchement du moteur. Si le disjoncteur de réenclenchement

se déclenche à maintes reprises, rechercher et corriger la cause. Voir

l’article suivant.

4. Réparer ou remplacer le manostat.

1. Limiter l’usage du circuit au compresseur d’air seulement.

2. Vérifier la classification des fusibles et des disjoncteurs.

3. Remplacer le clapet.

Ne pas démonter le clapet

si le réservoir est pressurisé

4. Régler ou remplacer.

5. Inspecter tous les branchements électriques.

6. Remplacer le moteur.

1. Remplacer le clapet.

Ne pas démonter le clapet

si le réservoir est pressurisé

2. Serrer.

3. Remplacer le réservoir. Ne jamais réparer un réservoir endommagé.

1. Remplacer le clapet si la soupape de déchargement a une fuite d’air

continue.

Ne pas démonter le clapet

si le réservoir est pressurisé

1. Remplacer le manostat si la pression n’est pas dissipé pendant une

courte durée quand le modèle se coupe.

Ne pas démonter le

manostat si le réservoir est

pressurisé

1. Serrer.

2. Remplacer avec une courroie de taille correcte.

3. Aligner le volant et la poulie.

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

Guide De Dépannage (Suite)

Page 16

Page 17

Compresores de

Aire Estacionarios

Sírvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

17 Sp

Estos compresores de aire están

diseñados para suministrarle aire

comprimido a herramientas neumáticas

y operar pistolas pulverizadoras. Los

cabezales suministrados con estas

unidades están lubricados con aceite. El

aire comprimido suministrado contiene

residuos de aceite. Para utilizarlo en

aplicaciones que requieran el

suministro de aire sin residuos de aceite

o agua, le debe instalar un filtro

adecuado. El compresor de aire se debe

colocar sobre un piso sólido según las

instrucciones suministradas. Cualquier

otro uso de estas unidades cancelaría la

garantía y el fabricante no sería

responsable por los problemas o daños

ocasionados por dichos usos.

Medidas De Seguridad

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe

reconocer los siguientes símbolos.

Ésto le

indica que

hay una situación inmediata que LE

OCASIONARIA la muerte o heridas de

gravedad.

Ésto le

indica

que hay una situación que PODRIA

ocasionarle la muerte o heridas de

gravedad.

Ésto le

indica

que hay una situación que PODRIA

ocasionarle heridas no muy graves.

Ésto le

indica

una información importante, que de no

seguirla, le podría ocasionar daños al

equipo.

AVISO

!

PRECAUCION

!

ADVERTENCIA

!

PELIGRO

Manual de Instrucciones

Para desempacar

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Igualmente,

cerciórese de apretar todos los pernos,

tuercas y conexiones, antes de usarlo.

No debe

utilizar la

unidad si se ha dañado durante el

envío, manejo o uso. Los daños podrían

ocasionar una explosión y ocasionarle

heridas o daños a su propiedad.

Como el compresor de aire y otros

componentes usados (bomba de

material, pistolas pulverizadoras,

filtros, lubricadores, mangueras, etc.)

intengran un sistema de alta presión,

en todo momento deberá seguir las

siguientes medidas de seguridad:

1. Lea con cuidado todos

los manuales incluídos

con este producto.

Familiarícese con los

controles y el uso

adecuado del equipo.

!

ADVERTENCIA

IN227705AV 12/02

© 2002 Campbell Hausfeld

Advertencia sobre

el aire respirable

Este compresor/cabezal no viene listo

de fábrica para suministrarle aire

respirable. Antes de utilizarlos con

este fin, deberá instalarle un sistema

de seguridad y alarma incorporado a

la línea. Este sistema adicional es

necesario para filtrar y purificar el

aire adecuadamente, para cumplir con

las especificaciones mínimas sobre

aire respirable de Grado D descritas

en la Especificación de Productos G

7.1 - 1966 de la Asociación de Aire

Comprimido.Igualmente, deberá

cumplir los requisitos establecidos

por el Artículo 29 CFR 1910. 134 de la

Organización norteamericana OSHA

y/o la Canadian Standards

Associations (CSA).

RENUNCIA A LAS GARANTIAS

Si el compresor se utiliza para producir

aire respirable SIN haberle instalado el

sistema de seguridad y alarma, todas

la garantías se anularán y la compañia

Campbell Hausfeld. no asumirá

NINGUNA responsabilidad por

pérdidas, heridas personales o daños.

!

PELIGRO

2. Siga todos los códigos de seguridad

laboral y electricidad establecidos

en su país, por ejemplo, los de la

NEC y OSHA en EUA.

3. Sólo personas bien familiarizadas

con estas medidas de seguridad

deben utilizar el compresor.

4. Mantenga a los visitantes alejados y

NUNCA permita la presencia de

niños en el área de trabajo.

5. Use anteojos de

seguridad y protéjase

los oídos para operar la

unidad.

6. No se encarame sobre la unidad ni

la use para sostenerse.

7. Antes de cada uso, revise el sistema

de aire comprimido y los

MANUAL

Figura 1

Descripción

Generales Seguridad

Page 18

Page 19

No use

tornillos

de fiador para fijar el compresor a

muros en seco. Éstos no son lo

suficientemente resistentes para

sostener el peso del compresor.

Nunca

instale la

válvula de cierre entre el cabezal y el

tanque. Ésto podría ocasionarle

heridas y/o daños a su propiedad.

TUBERIAS

Nunca

use

tuberías de plástico (PVC) en sistemas

de aire comprimido. El hacerlo podría

ocasionarle heridas o daños a su

propiedad.

Todo tubo o manguera empleado debe

estar capacitado para presiones de más

de 150 psi. Tamaño mínimo

recomandado para tubos:

- hasta 50 pies de largo: use 1/2”

- más de 50 pies: use 3/4”

Es siempre aconsejable usar diámetros

mayores.

Todos

los

trabajos de alambrado y conexiones

eléctricas las debe hacer un electricista

calificado. Las instalaciones eléctricas

se deben hacer según los códigos

locales y nacionales.

CONEXION A TIERRA

Este aparto debe estar conectado a

tierra. Si la unidad trae un cordón

instalado de fábrica, enchúfelo en una

toma de tamaño apropiado y conectada

a tierra. Para las unidades que no traen

cordón instalado de fábrica, instale un

alabrado permanenete desde la fuente

de energía hasta el presostato, con un

cable de tierra conectado al tornillo de

tierra del presostato. El usuario puede

también instalar un cordón de tamaño

apropiado con enchufe y cable de tierra.

Los artefactos eléctricos

conectados a tierra

incorrectamente constituyen

un riesgo de electrocutamiento.

Cerciórese de que todas las conexiones

a tierra estén hechas adecuadamente.

ALAMBRADO

Los códigos locales de eléctricidad

varian de un área a otra. El sistema de

alambrado, los enchufes y protectores

deben cumplir con el voltaje y amperaje

indicado en la placa del motor.

Igualmente, éstos deben cumplir con los

códigos locales de eléctricidad. Use un

fusible tipo T de acción retardada.

!

PELIGRO

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

En algunos modelos de 30 galones se

proporciona un cable de pared el cual

debe ser instalado. Si la unidad no se

asegura a la pared con un cable,

DEBERA atornillar las patas a una

superficie plana y nivelada, tal como un

piso de concreto o una base de concreto

aparte. Debe usar almohadillas

aislantes entre las patas del tanque y el

piso. No apriete los pernos

excesivamente. (Parte núm. MP3445,

disponible por separado). Permita que

las almohadillas absorban la vibración.

Deberá instalar conexiones flexibles

entre el tanque y las tuberías.

La parte

superior

de este compresor es sumamente

pesada. La unidad se atornillar al piso

y colocarle almohadillas aislantes o se

debe asegurar a la pared con el cable

(si se incluye) antes de utilizarla para

evitar daños, heridas o la muerte.

INSTALACION DEL CABLE PARA

SOSTENERLO A LA PARED

(Suministrado con algunos modelos de

113,6 Litros)

Con el cable de seguridad se incluyen

dos tornillos de fiador y arandelas.

1. Coloque una almohadilla aislante

debajo de cada pata del compresor

para minimizar la vibración.

2. Coloque el cable en la base tal como

se le indica en la Figura 3.

3. Colóquele las arandelas a los

tornillos e introdúzcalos en los aros

de los extremos del cable.

4. Si es una pared de entramado, los

tornillos se deben fijar al montante.

Use una trabilla si la pared es de

concreto.

!

ADVERTENCIA

Modelos Verticales

19 Sp

Manual de Instrucciones

Válvula de Seguridad ASME - Esta

válvula libera el aire automáticamente

si la presión del tanque excede el nivel

máximo fijado.

Tubo de Descarga - Este tubo

transporta el aire comprimido del

cabezal a la válvula de chequeo. Este

tubo se calienta mucho durante el uso.

Para evitar el riesgo de sufrir

quemaduras severas, nunca toque el

tubo de descarga.

Válvula de Chequeo - Esta válvula de

un solo sentido permite la entrada de

aire al tanque, pero evita que se

regrese al cabezal.

Tapa de las Bandas - Cubre la banda,

la polea del motor y el volante.

Válvula de drenaje del tanque - Esta

válvula está ubicada en la parte inferior

del tanque. Úsela para drenar la

humedad del tanque diariamente para

reducir el riesgo de que el tanque se

oxide.

Reduzca la presión del tanque a menos

de 0,69 bar, después drene la humedad

del tanque para eviotar que se oxide.

Drene la humedad del/de los tanque(s)

abriendo la válvula de drenaje ubicada

debajo del tanque.

Desconecte el cordón

eléctrico y amárrelo y

después libere toda la presión del

sistema antes de tratar de instalarlo,

darle servicio o darle cualquier tipo de

mantenimiento.

UBICACION

Este

compresor no está diseñado para instalarse a

la intemperie.

Es sumamente importante que instale el

compresor en un área limpia y bien

ventilada donde la temperatura

ambiental no exceda los 38,1˚ C.

La distancia mínima entre el volante del

compresor o ventilador y la pared debe

ser de 45,7 cm (18”) para tener acceso a

la llave de drenaje sin incovenientes.

No coloque la entrada de aire del

compresor en un área donde haya vapor,

se rocíe pintura o arena o haya ningún

otro tipo de contaminación.

INSTALACION

Nunca

instale el

compresor sobre las bases de madera

usadas para transportarlo.

INSTALACION EN EL PISO

(Todas las Unidades)

!

PRECAUCION

AVISO

!

ADVERTENCIA

Figura 3 - Instalación del cable para

sostenerlo a la pared

Instalaciones Eléctricas

SOLO LAS UNIDADES CON

CONEXIONES PERMANENTES

Instalación

Introducción (Con’t)

Page 20

Page 21

ACCESORIOS ADICIONALES

NECESARIOS

Compre una manguera, un regulador y

una válvula de cierre diseñados para

presiones mínimas de 10,3 bar y que

excedan las presiones máximas de

trabajo del compresor.

EXTENSION PARA DRENAR EL

ACEITE

Algunos modelos traen una extensión

para el sistema de drenaje de aceite y

una tapa (anexos al manual de

instrucciones). Instale la extensión y la

tapa antes de añadirle aceite al

cabezal. Para evitar fugas de aceite,es

muy recomendable que le aplique cinta

pegante de Teflón

®

o un sello en pasta a

las roscas en cada uno de los extremos

de la extensión. Atornille la tapa en uno

de los extremos de la extensión, quítele

el tapón a la base del cabezal e instálele

la extensión (Vea la Figura 6).

LUBRICACION

ESTA

UNIDAD

VIENE DE FABRICA SIN ACEITE. Siga las

instrucciones de lubricación antes de

utilizar el compresor.

Cerciórese de haberle instalado la

extensión para drenar el aceite y la tapa

(si se incluyen), sáquele la varilla al

respiradero (Vea la Fig. 6) y llénelo de

aceite según se le indica en la tabla.

La etiqueta en el tanque de aire

especifica el modelo del cabezal y la

tabla en este manual le indica la

capacidad de aceite para cada modelo.

Use aceite SAE 30 de calidad industrial

para compresores de aire o un sintético

!

PRECAUCION

Modelos Verticales

21 Sp

Manual de Instrucciones

tipo Mobil 1 10W30. No use aceite

normal para vehículos tipo 10W-30.

Los aditivos en los aceites para motores

pueden ocasionar depósitos de residuos

en las válvulas y reducir la duración del

cabezal. Para lograr la máxima

duración del cabezal, drene el aceite y

cámbielo después de la primera hora de

funcionamiento. La Figura 6 le indica el

nivel adecuado de aceite.

PREPARACION PARA EL USO

No co-

necte las

herramientas neumáticas al extremo de

la manguera hasta terminar el proceso

de preparación para el uso y se haya

cerciorado de que la unidad está lista

para funcionar.

¡Nunca

desconecte las conexiones con roscas antes

de liberar la presión del tanque!

1. Sáquele el respiradero y llene el

cabezal de aceite hasta alcanzar el

nivel adecuado. Vea la sección de

lubricación.

2. Abra la válvula de drenaje del

tanque. Abra la llave de salida para

permitir el flujo de aire.

3. Mueva la palanca o perilla del

presostato a la posición OFF y

enchufe el cordón de alimentación.

Coloque la palanca del presostato en

AUTO para encender la unidad.

4. Deje que la unidad funcione por 30

minutos, sin carga, para que las

piezas del cabezal se fijen.

5. Mueva la palanca o perilla del

presostato a la posición OFF y gire la

válvula de drenaje del tanque para

!

ADVERTENCIA

!

PRECAUCION

HUMEDAD EN EL AIRE COMPRIMIDO

La humedad que se acumula en el aire

comprimido se convierte en gotas a

mediada que sale del cabezal. Cuando el

nivel de humedad es muy alto o cuando

el compresor ha estado en uso

continuop por mucho tiempo, esta

humedad se acumulará en el tanque.

Cuando esté pintando o rociando arena,

la humedad saldrá del tanque mezclada

con el material que esté rociando.

IMPORTANTE: Esta condensación

ocasionará manchas en la pintura,

especialmente cuando esté pintando con

pinturas que no sean a base de agua. Si

está rociando arena, la humedad hará

que la arena se aglutine y obstruya la

pistola.

Instale un filtro de línea, ubicado lo más

cerca posible de la pistola, para tratar de

eliminar este problema.

cortar el flujo de aire. El compresor

estará listo para funcionar.

Desconecte el cordón

eléctrico y amárrelo y

después libere toda la

presión del sistema antes de tratar de

instalarlo, darle servicio o darle

cualquier tipo de mantenimiento.

Todos los trabajos de reparación los

debe hacer un técnico autorizado.

PARA EL FUNCIONAMIENTO

EFICIENTE:

Semanalmente haga la siguiente prueba

para verificar el funcionamiento

adecuado de la válvula de seguridad y

déle el mantenimiento necesario

indicado en la tabla de mantenimiento.

1. Hále el anillo de

la válvula de

seguridad y

déjelo que

regrese a su

posición normal

(Vea la Figura 8). Esta válvula libera el

aire automáticamente si la presión del

tanque excede el nivel máximo fijado.

Nunca

trate de

modificar esta válvula. Esta válvula se

debe chequear ocasionalmente. Si hay

fugas de aire después de soltar el

anillo, o si la válvula está atascada y no

la puede activar con el anillo, deberá

reemplazarla.

Si la

válvula de

seguridad se hace funcionar con presión

de aire en el tanque, se liberará una gran

cantidad de aire que se encuentra en

movimiento a gran velocidad.

2. Con el motor APAGADO y

desconectado, limpie el motor, el

volante, el tanque, las líneas de aire y

las aletas de enfriamiento del cabezal.

BANDAS

Las bandas se estiran con el uso normal.

Cuano están bien ajustadas la deflexión

!

PRECAUCION

!

PELIGRO

!

ADVERTENCIA

Ensamblaje

Dipstick

Breather

Full

Add

Add Oil

Oil Drain Extension

Cap

Low

Max

Extensión del sistema

de drenaje de aceite

Tapa

Para añadirle

el aceite

Varilla del

respiradero

Lleno

Añádale

aceite

Figura 6

Modelo Cap. Aprox. de Aceite

VS260000KB 0,18 L

VT470200KB 0,34 L

VT470000KB 0,35 L

Funcionamiento

Bajo

A

U

T

O

/

O

F

F

Figure 7

Palanca - Apagado

Palanca -

Automático

Perilla Auto/

Apagado

Mantenimiento

Figura 8

Page 22

Page 23

Modelos Verticales

23 Sp

Manual de Instrucciones

Problema Posible(s) Causa(s) Acción a Tomar

Aceite excesivo en el aire

de descarga. NOTA: En un

compresor lubricado con

aceite siempre hay una

pequeña cantidad de aceite

en el flujo de aire.

Agua en el aire de salida o

en el tanque

El motor zumba y funciona

lentamente o no funciona

en lo absoluto

El mecanismo de reajuste

interrumpe el

funcionamiento

constantemente o los

fusibles se funden con

frecuencia

El tanque no mantiene la

presión cuando el

compresor está apagado y

la válvula de cierre está

cerrada

El interruptor de presión

tira continuamente aire por

la válvula de descarga

El interruptor de presión no

libera el aire cuando la

unidad de apaga

Vibración excesiva

1. Aros del émbolo desgastados

2. La entrada de aire del compresor

está restringida

3. Demasiado aceite en el compresor

4. Viscosidad del aceite equivocada

1. Operación normal. La cantidad

de agua aumenta con el clima

húmedo

1. Utiliza un cordón de extensión

2. Malfuncionamiento de la válvula

de verificación o de la válvula de

descarga

3. Voltaje bajo

4. Malfuncionamiento del

interruptor presión, los contactos

no se cierran

1. Demasiados aparatos en el mismo

circuito

2. Tamaño incorrecto del fusible o

del disyuntor

3. Malfuncionamiento de la válvula

de verificación

4. Interruptor de presión fijado

demasiado alto

5. Cableado flojo

6. Malfuncionamiento del motor

1. Válvula desgastada

2. Verifique todas las conexiones y

los accesorios para detectar fugas

3. Revise el tanque para detectar

fisuras o perforaciones

1. Malfuncionamiento de la

válvula

1. Malfuncionamiento de la válvula

de descarga en el interruptor de

presión

1. Ajustadores flojos

2. La correa necesita ser reemplazada

3. Alineación de la correa

1. Reemplácelos con aros nuevos. Mantenga el nivel de aceite y

cambie el aceite con más frecuencia.

2. Limpie el filtro. Verifique otras restricciones en el sistema de entrada.

3. Escúrralo hasta que alcance el nivel de lleno.

4. Use Mobil 1® 10W-30.

1. Drene el tanque con más frecuencia. Al menos diariamente.

2. Agregue un filtro

1. No utilice un cordón de extensión. Utilice una manguera de aire

más larga con un diámetro mayor.

2. Reemplace la válvula de verificación, la válvula de descarga o el

interruptor de presión.

No desarme la válvula con

presión de aire en el tanque.

3. Verifique con un voltímetro, revise el interruptor de reajuste del

motor. Si este se dispara varias veces, busque la causa y corríjala.

Consulte el siguiente punto.

4. Repare o reemplace el interruptor de presión.

1. Use sólo el compresor de aire en el circuito.

2. Asegúrese de que los fusibles o los disyuntores sean del tamaño

adecuado.

3. Reemplace la válvula de verificación

No desarme la válvula con

presión de aire en el tanque.

4. Ajuste o reemplace el interruptor.

5. Verifique todas las conexiones eléctricas

6. Reemplace el motor.

1. Reemplace la válvula.

No desarme la válvula con

presión de aire en el tanque

.

2. Apriete.

3. Reemplace el tanque. Nunca repare un tanque dañado

1. Reemplace la válvula de verificación si la válvula de descarga tiene

perdidas constantemente.

No desarme la válvula con

presión de aire en el tanque.

1. Reemplace el interruptor de presión si éste no libera la presión por

un breve período de tiempo cuando se apaga la unidad.

No desarme el interruptor de

presión si hay presión en el

tanque.

1. Ajústelos.

2. Reemplace la correa con otra del tamaño adecuado.

3. Alinee el volante y la polea.

!

PELIGRO

!

PELIGRO

!

PELIGRO

!

PELIGRO

!

PELIGRO

Guía de Diagnóstico de Averías (Continuación)

Page 24

Loading...

Loading...