Campbell Hausfeld LIGHT DUTY CART Airless Paint Sprayers, PS###A, PS###B, PS###C, PS###D Assembly Instructions And Parts List

...Page 1

Airless Paint

Sprayers

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Assembly Instructions and Parts List

Airless Paint Sprayers

IN421000AV 3/02

Assembly Instructions

LIGHT DUTY CART MODELS

Tools required:

7/16” Wrench or

adjustable

11/16” Wrench or

adjustable

Hammer

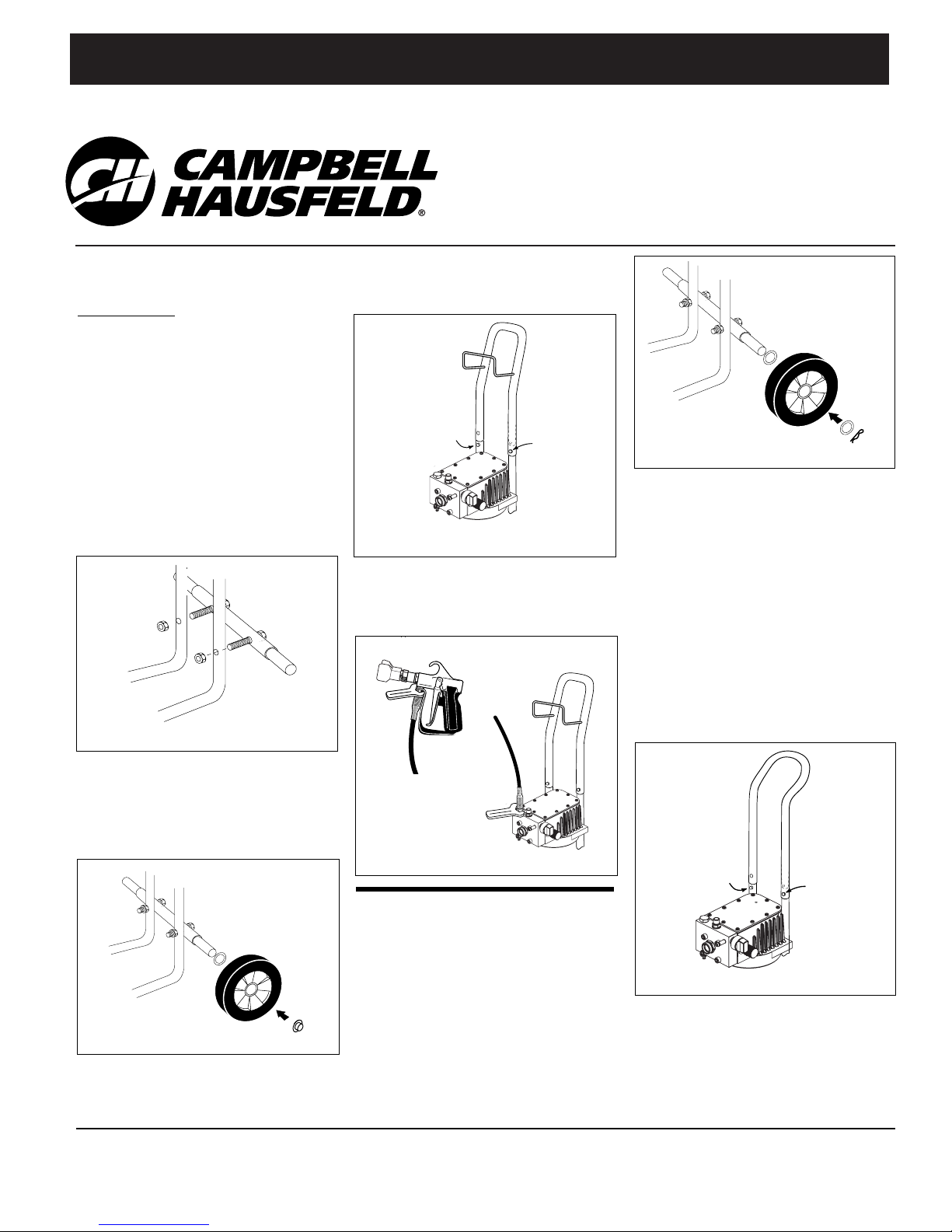

1. Open packaging and check contents

against packing list on hardware pack.

2. Stand pump upright and hold steady.

Attach axle to cart legs by inserting

pre-assembled bolts into holes in cart

legs. Secure with one 1/4” - 20 nut on

each bolt. Use 7/16” wrench to tighten (See Figure 1).

3. Slide one 5/8” I.D. washer and wheel

on to each end of the axle. Using a

hammer, tap a pal nut onto each end

of the axle to retain the wheels (See

Figure 2).

4. Slide handle on to cart by depressing

the retaining snaps while pushing

handle in place. Be sure to check that

the retaining snaps lock into holes in

handle. Hose rack should be facing

the pump (See Figure 3).

5. Attach high pressure hose to pump

and spray gun using a 11/16” wrench

(See Figure 4). Do not attach suction

assembly at this time.

Assembly Instructions

HEAVY DUTY CART MODELS

1. Place washer from parts pack onto

axle.

2. Place wheel onto axle with side with

the longest hub going on first.

3. Place another washer on the axle.

4. Place cotter pin through hole in the

end of the axle.

5. Repeat for the other side (See

Figure 5).

6. Slide the two ends of the handle

over the two ends of the bottom

frame. The bend in the handle

should be away from the unit.

7. Stand behind the unit and reach

over the handle to grip the ends at

the bottom of the handle. Using

your thumb and forefinger, depress

the Valco Snaps and gently push

down on the handle until it starts

over the snaps. Then move your

hands to the top of the handle and

push it the rest of the way down

(See Figure 6).

8. When the handle is all the way

down the snaps will “click” into

place. If all four snaps do not pop

through, grasp the handle and twist

it right to left until the remaining

snap pops through.

Figure 1 - Attach Axle

Figure 2 - Attach Wheels

Figure 3 - Attach Handle

Figure 5 - Attach Wheels

Figure 4 - Attach Hose

Figure 6 - Attach Handle

Push

Lock

Push

Lock

For parts, product & service information

visit www.chpower.com

© 2002 Campbell Hausfeld/Scott Fetzer

BUILT TO LAST

D

L

E

L

L

E

B

P

F

S

U

A

H

M

A

C

Page 2

2

Assembly Instructions and Parts List

Assembly (Continued)

9. Place bucket hook over top of frame

with the hook to the outside of the

frame.

10. Line up the two holes in the bucket

hook with the two holes in the top

of the frame (See Figure 7).

If using a power

tool to drive the

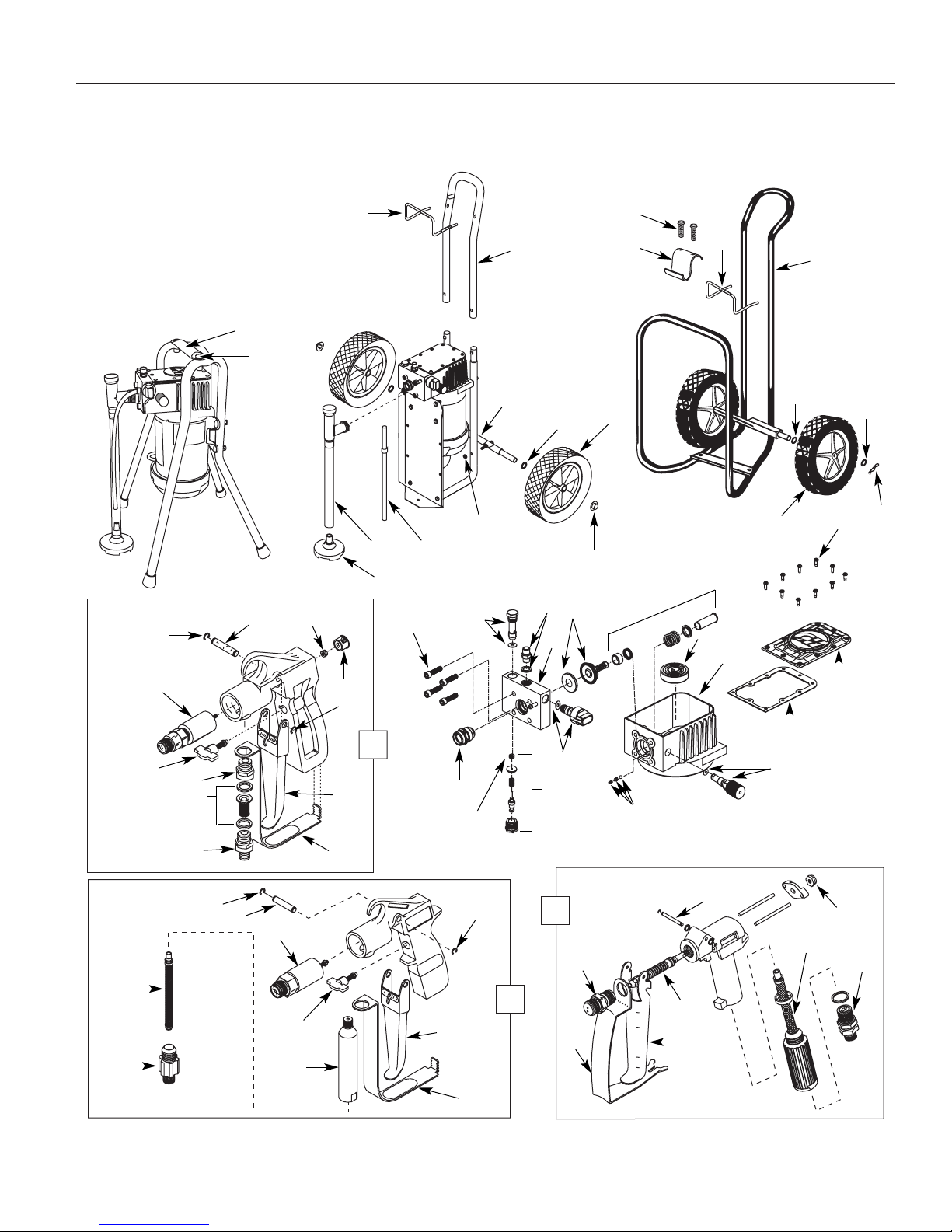

1 Stand handle AL172304AV 1

2 Handle bolt AL152201AV 2

3 Hose rack AL066101AV 1

4 Handle (Includes hose rack) AL066021SV 1

5 Axle (Includes bolts) AL066030SV 1

6 Washer ST090200AV 2

7 Wheel WA002601AV 2

8 Pal nut AL066300AV 2

9 Nut AL060000AV 2

10 By-Pass tube and clamp AL174302SV 1

11 Suction tube assembly AL138404SV 1

(Includes tube and connectors)

12 Suction bell assy. (Includes filter) AL111000SV 1

13 Bucket hook AL136200AD 1

14 Screws HP007117AV 4

15 Handle (Includes hose rack) AL139200SV 1

16 Washer AL136000AV 4

17 Cotter pin AL149700AV 2

18 Wheel WA002602AV 2

19 Faceplate screws HP007118AV 1

20 Piston kit AL131502SV 1

21 Diaphragm kit (Check valve

kit included) See chart 1

22 Hose adapter (Includes washer) AL104700SV 1

23 Outlet valve assembly AL129600SV 1

24 Pump block (Incl. all washers) AL042413SV 1

25 Inlet valve assembly AL165400SV 1

26 Pushbutton seal AL162000AV 1

27 Outlet push/pull assy. AL159500SV 1

28 Prime/Spray valve assembly AL132100SV 1

29 Check valve kit AL163200SV 1

30 Pressure valve assembly AL131401SV 1

31 Housing kit

(Includes 20,29, & 30) See chart 1

32 Eccentric and bearing kit See chart 1

33 Faceplate gasket AL013702AV 1

34 Cast faceplate AL045102AV 1

35 Valve stem nut (3 pack) AL083300AV 1

36 Gun swivel AL081300AV 1

37 Gun filter (100 mesh) (2pack) AL086101AJ 1

38 Trigger pin AL085800AV 1

39 Ball, valve & plunger assy AL083800AV 1

40 Trigger AL083900AV 1

41 Trigger guard AL083700AV 1

42 Gun diffuser AL083000AV 1

43 Pro gun (with .015 tip) AL3104 1

44 Semi pro gun (Includes .015 tip)

(Metal) AL2140 1

(Plastic) AL2130 1

45 Retaining ring ST002500AV 2

46 Trigger AL023600AD 1

47 Handle with screw AL023703SV 1

48 ■ Long filter housing AL139002SV 1

49 Safety lock AL117800SV 1

50 Gun valve AL138700SV 1

51 Trigger pin AL024100AD 1

52 ■ Gun filter (100 mesh) (2 pk.) AL086101AJ 1

53 ■ Hose adapter AL072302SV 1

54 Gun ass’y w/o tip (Consumer) AL126100SV 1

55 Hose adapter AL072300AV 1

56 100 Mesh filter (3 pk.) AL126301AJ 1

57 Filter housing adapter AL072400AV 1

58 Stop nut ST073804AV 1

59 Plug ST073706AV 1

60 Block bolts MJ103910AV 4

* Shaft seal AL045503AV 1

* Motor See chart 1

Panel & decal AL162200SV 1

■ Long filter housing assembly AL139000SV 1

(Includes 48, 52 & 53)

* Not shown

OPTIONAL METAL GUN FILTERS AVAILABLE (Twin pack)

30 Mesh filter AL086103AJ

50 Mesh filter AL086100AJ

200 Mesh filter AL086102AJ

screws, do not apply too much torque.

These are self-tapping screws and will

strip out the frame if too much torque

is applied.

11. Drive the two screws provided

through the bucket hook and into

the frame with a straight screwdriver or a 5/16” nut driver.

Do not attach the suction assembly

at this time.

Figure 7 - Install Bucket Hook

Replacement Parts List

Ref. Part

No. Description Number Qty.

Ref. Part

No. Description Number Qty.

www.chpower.com

NOTICE

Page 3

3

Assembly Instructions and Parts List

RISK OF INJECTION.

WA

RNIN

G:

NE

V

ER

A

I

M

G

U

N

A

T

PERSON OR

A

N

Y

P

A

RT OF

BO

D

Y

.

MAX. 205

BAR

For Replacement Parts and Accessories,

Contact Your Local Service Center or Call 1-800-626-4401

CONSUMER

GUN

PROFESSIONAL

GUN

Please provide the following

information:

- Model number

- Serial number

- Part description and number

as shown in parts list

Address parts correspondence:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

SEMI-PRO

GUN

1

2

3

4

5

6

7

8

9

1011

12

13

14

3

15

16

16

17

18

54

47

46

45

59

58

51

45

50

49

57

56

55

53

52

45

51

50

49

48

47

46

45

44

43

42

39

41

40

38

37

36

35

www.chpower.com

19

34

33

30

29

28

27

25

23

22

21

20

32

60

24

26

31

Page 4

Assembly Instructions and Parts List

0-2800 psi 115 Volts AC Spray gun trigger lock

60 Hz Spray gun trigger guard

15Amps Spray gun pressure diffuser

Min. circuit Prime/Spray valve over pressure relief

Operating Power Safety

Pressure Requirements Features

Weight Capacity (GPM) Maximum Maximum

Model (lbs.) @ 0 PSI @ 2000 PSI Hose Length Tip Size

.40 GPM 49 * .40 .24 75’ .015”

.42 GPM 49 * .42 .26 100’ .015”

.48 - .50 GPM 55 * .50 .31 150’ .017”

.60 GPM 55 * .60 .43 200’ .019”

* Weight does not include mounting

Specifications

4

www.chpower.com

Eccentric/ Pressure

Model Motor Kit Diaphragm Kit Bearing Valve Kit

PS###A MC014304SV AL125904SV AL116203SV AL174201SV

PS###B MC014300SV AL125905SV AL116200SV AL174200SV

PS###C MC014301SV AL125906SV AL116201SV AL174200SV

PS###D MC014303SV AL173700SV AL116204SV AL131403SV

PS###E MC014401SV AL125905SV AL116200SV AL174200SV

PS###F MC014402SV AL125906SV AL116201SV AL174200SV

NOTE: All check valve kits come with the diaphragms.

Page 5

Pulverizadores de

Tintas Sem Ar

Leia e guarde estas instruções. Antes de tentar montar, instalar, operar ou executar qualquer serviço de manutenção no produto descrito, leia

estas instruções cuidadosamente. Proteja-se a si próprio e terceiros, pelo cumprimento de toda a informação de segurança. A falta de cumprimento destas instruções, poderá resultar em acidentes pessoais e/ou danos materiais! Guarde estas instruções para consultas futuras.

Instruções de Montagem e Listas de Peças Pulverizadores de Tintas Sem Ar

IN421000AV 3/02

Instruções de Montagem

MODELOS DE CARROS PARA

SERVIÇO LEVE

Ferramentas necessárias:

Chave de bocas 7/16"ou ajustável

Chave de bocas 11/16" ou ajustável

Martelo

1. Abrir a embalagem e conferir o conteúdo

segundo a lista de embalagem.

2. Colocar o suporte da bomba direito e

manter firme. Montar o eixo das rodas

nas pernas do carro, inserindo os parafusos nos furos. Segurar com uma porca

1/4" – 20 em cada parafuso. Usar uma

chave 7/16" para apertar (ver Figura 1)

3. Colocar uma anilha de D.I. 5/8" e uma

roda em cada extremo do eixo. Usando

um martelo, bater uma porca em cada

extremo do eixo para fixar as rodas (ver

Figura 2).

4. Montar a pega no carro carregando nos

pinos de fixação para colocar a pega na

sua posição. Assegurar que os pinos de

fixação entram nos furos da pega.

O suporte da mangueira deverá ficar virado para a bomba (ver Figura 3).

5. Montar a mangueira de alta pressão e

pistola de pulverização à bomba usando

uma chave de 11/16" (ver Figura 4). Não

montar nesta altura, o conjunto de

aspiração.

Instruções de Montagem

MODELOS DE CARROS PARA SERVIÇO

PESADO

1. Colocar uma anilha no eixo.

2. Colocar uma roda no eixo, primeir do

lado com o cubo mais comprido.

3. Colocar outra anilha no eixo.

4. Colocar o pino de fixação através do

furo do extremo do eixo.

5. Repetir do outro lado (ver Figura 5).

6. Deslizar os dois extremos d pega sobre

os dois extremos da estrutura inferior. A

curvatura da pega deverá ficar virada

para trás.

7. Colocar-se por trás da unidade e inclinar-se por cima da pega para alcançar os

extremos inferiores da pega. Usando os

dedos polegar e indicador, pressionar os

pinos Valco e empurrar suavemente a

pega até esta passar os pinos. Mudar

então as mãos para o topo da pega e

empurrar a mesma o resto do curso (ver

Figura 6).

8. Quando a pega tiver encaixado completamente ouvir-se-á um clique e a peça

estará no seu sítio certo. Se nem todos

os quatro pinos tiverem ficado correctamente encravados, forçar a pega para a

direita e para a esquerda até todos os

pinos estarem bem encravados.

Figura 1 - Montar o eixo

Figura 2 – Montar a roda

Figura 3 – Montar a pega

Figura 5 – Montar a roda

Figura 4 – Montar a mangueira

Figura 6 – Montar a pega

Empurrar

Encravar

Empurrar

Encravar

PORTUGUÊS

© 2002 Campbell Hausfeld/Scott Fetzer

BUILT TO LAST

D

L

E

L

L

E

B

P

F

S

U

A

H

M

A

C

Page 6

2PG

Instruções de Montagem e Listas de Peças

Montagem (continuação)

9. Colocar o gancho do balde no topo da

estrutura, virado para fora.

10. Alinhar os dois furos do gancho do

balde com os dois furos do topo da

estrutura (ver Figura 7)

.

Se usar uma

ferramenta eléctrica

para apertar os parafusos, não aplicar

binário em demasia. Estes parafusos são

auto roscantes e ficarão danificados se se

aplicar binário demasiado.

1 Pega da estrutura de suporte AL172304AV 1

2 Parafuso da pega AL152201AV 2

3 Suporte de mangueira AL066101AV 1

4 Pega (Inclui o suporte da mangueira) AL066021SV 1

5 Eixo (Inclui pernos) AL066030SV 1

6 Anilha ST090200AV 2

7 Roda WA002601AV 2

8 Porca de acoplamento AL066300AV 2

9 Porca AL060000AV 2

10 Tubo de bypass e braçadeira

AL174302SV

1

11 Conjunto de tubo de aspiração

AL138404SV

1

(Inclui tubo e ligadores)

12 Conjunto da campânula de aspiração

(Inclui filtro) AL111000SV 1

13 Gancho para balde AL136200AD 1

14 Parafusos HP007117AV 4

15 Pega (Inclui suporte de mangueira) AL139200SV 1

16 Anilha AL136000AV 4

17 Pino de chaveta AL149700AV 2

18 Roda WA002602AV 2

19 Parafusos do prato HP007118AV 1

20 Kit pistão AL131502SV 1

21 Conjunto diafragma (Conjunto

válvula de controle incluído) Ver esquema 1

22 Adaptador de mangueira

(Inclui anilha) AL104700SV 1

23 Conjunto da válvula de saída AL129600SV 1

24 Bloco da bomba (Incl. todas as anilhas)AL042413SV 1

25 Conjunto da válvula de entrada AL165400SV 1

26 Anel retentor do botão AL162000AV 1

27 Conjunto empurrar/puxar da saída AL159500SV 1

28 Conjunto da válvula

de Escorval/Pulverizar AL132100SV 1

29 Kit válvula de controle AL163200SV 1

30 Conjunto da válvula de pressão

AL131401SV

1

31 Conjunto cárter

(Inclui 20,29, & 30) Ver esquema 1

32 Conjunto excêntrico e chumaceira Ver esquema 1

33 Gaxeto do prato AL013702AV 1

34 Prato fundido AL045102AV 1

35 Porca do veio da válvula (pacote de 3) AL083300AV 1

36 Articulação giratória da pistola AL081300AV 1

37 Filtro da pistola

(100 mesh) (pacote de 2) AL086101AJ 1

38 Pino de gatilho AL085800AV 1

39 Conjunto esfera, válvula & êmbolo AL083800AV 1

40 Gatilho AL083900AV 1

41 Guarda do gatilho AL083700AV 1

42 Difusor de pistola AL083000AV 1

43 Pistola profissional (com ponta .015) AL3104 1

44 Pistola semi profissional (Inclui ponta de .015)

(Metal)

AL2140

1

(Plástico)

AL2130

1

45 Anel retentor ST002500AV 2

46 Gatilho AL023600AD 1

47 Pega com parafuso AL023703SV 1

48 ■ Alojamento de filtro grande AL139002SV 1

49 Encravamento de segurança AL117800SV 1

50 Válvula da pistola AL138700SV 1

51 Pino do gatilho AL024100AD 1

52 ■ Filtro de pistola (100 malhas) (p.2) AL086101AJ 1

53 ■ Adaptador de mangueira AL072302SV 1

54 Conjunto da pistola s/ ponta AL126100SV 1

(consumível)

55 Adaptador de mangueira AL072300AV 1

56 Filtro de 100 malhas (p. 3) AL126301AJ 1

57 Adaptador do alojamento do filtro AL072400AV 1

58 Porca de paragem ST073804AV 1

59 Bujão ST073706AV 1

60 Parafusos do bloco MJ103910AV 4

* Anel retentor do eixo AL045503AV 1

* Motor Ver esquema

1

Painel & decalque AL162200SV 1

■ Conjunto de alojamento de filtro

grande (Inclui

48, 52 e 53

) AL139000SV 1

* Não mostrado

FILTROS DE PISTOLA METÁLICOS OPCIONAIS DISPONÍVEIS

(Pacote duplo)

Filtro de 30 malhas AL086103AJ

Filtro de 50 malhas AL086100AJ

Filtro de 200 malhas AL086102AJ

11. Apertar os dois parafusos fornecidos

através do gancho de balde com uma

chave de fendas ou com uma chave de

porcas de 5/16”.

Não montar nesta altura o conjunto

de aspiração.

Figura 7 – Instalar o gancho para o balde

Lista de Peças de Substituição

Ref.

No. Descrição Número da Peça Quant.

Ref.

No. Descrição Número da Peça Quant.

!

AVISO

Page 7

RISK OF INJECTION.

WA

RNIN

G:

NE

V

ER

A

I

M

G

U

N

A

T

PERSON OR

A

N

Y

P

A

RT OF

BO

D

Y

.

MAX. 205

BAR

CONSUMER

GUN

PROFESSIONAL

GUN

SEMI-PRO

GUN

1

2

3

4

5

6

7

8

9

1011

12

13

14

3

15

16

16

17

18

54

47

46

45

59

58

51

45

50

49

57

56

55

53

52

45

51

50

49

48

47

46

45

44

43

42

39

41

40

38

37

36

35

19

34

33

30

29

28

27

25

23

22

21

20

32

3PG

Instruções de Montagem e Lista de Peças

Para Peças de Substituçao e Acessórios,

Contactar o seu Centro de Serviço Local, ou Telefonar para: 1-800-626-4401

PISTOLA DE

CONSUMIDOR

PISTOLA

PROFISSIONAL

É favor fornecer a seguinte informação:

- Número do Modelo

- Número de Série

- Descrição da peça e número tal como

apresentado na lista de peças

Endereço para correspondência:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

PISTOLA

SEMI-

PROFISSIONAL

60

24

26

31

Page 8

Instruções de Montagem e Lista de Peças

0-193 bar 115 Volts AC Segurança do gatilho da pistola

60 Hz

Guarda do gatilho da pistola de pulverização

15 Amps

Difusor de pressão da pistola de pulverização

Circuito Mín. Segurança por sobrepressão da

válvula de Escorva/Pulverização

Pressão Requisitos Características

de funcionamento de alimentação de Segurança

Comprimento Tamanho máx.

Peso Capacidade (l/min.) máx. da ponta

Modelo (kg) @ 0 bar @ 138 bar de mangueira de pulverização

.40 GPM 22 * 1,5 0,9 23 m 0,015"

.42 GPM 22 * 1,6 1,0 30 m 0,015"

.48 - .50 GPM 25 * 1,9 1,2 46 m 0,017"

.60 GPM 25 * 2,3 1,6 61 m 0,019"

* O peso não inclui montagem

Especificações

4PG

PS###A MC014304SV AL125904SV AL116203SV AL174201SV

PS###B MC014300SV AL125905SV AL116200SV AL174200SV

PS###C MC014301SV AL125906SV AL116201SV AL174200SV

PS###D MC014303SV AL173700SV AL116204SV AL131403SV

PS###E MC014401SV AL125905SV AL116200SV AL174200SV

PS###F MC014402SV AL125906SV AL116201SV AL174200SV

NOTA: Todos os conjuntos de válvulas vêm com os diafragmas.

Conjunto Conjunto Excêntrico/ Conjunto Válvula

Modelo Motor diafragma Chumaceira de Pressão

Page 9

Pulverizadores de

Pintura Sin Aire

Por favor, lea y guarde estas instrucciones. Lea las instrucciones cuidadosamente antes de intentar montar, instalar, poner en funcionamiento o

realizar el mantenimiento del producto que se describe. Protéjase usted mismo a los demás cumpliendo toda la información sobre seguridad.

¡No cumplir con las instrucciones podría provocar daños personales y/o materiales! Conserve las instrucciones para su consulta futura.

Instrucciones de Montaje y Lista de Piezas

Pulverizadores de Pintura Sin Aire

IN421000AV 3/02

Instrucciones de Montaje

MODELOS DE CARRO LIGERO

Herramientas necesarias:

Llave de 7/16 pulg. o ajustable

Llave de 11/16 pulg. o ajustable

Martillo

1.

Abra el embalaje y compruebe el contenido

según la lista de embalaje en el paquete.

2.

Ponga la bomba hacia arriba y sujétela firme-

mente. Fije el eje a las patas del carro insertando los pernos pre-montados en los orificios

de las patas del carro. Asegure con una tuerca

de1/4 pulg. – 20 en cada perno. Use una llave

de 7/16 para apretar (vea la Figura 1).

3.

Deslice una arandela de 5/8 pulg. de diámetro interno y la rueda a cada extremo del

eje. Usando un martillo, dé golpes a una

tuerca compañera en cada extremo del eje

para retener las ruedas (vea la Figura 2).

4.

Deslice el mango en el carro oprimiendo los

retenedores mientras empuja el mango en

su sitio. Asegúrese de comprobar que los

cierres de retención se bloquean en los orificios del mango. El soporte de manguera

debe estar de cara a la bomba (vea Fig. 3).

5.

Conecte la manguera de alta presión a la

bomba y a la pistola utilizando una llave

de 11/16 pulg. (vea Fig. 4). No conecte el

conjunto de succión en este momento.

Instrucciones de Montaje

MODELOS DE CARRO DE ALTA

RESISTENCIA

1.

Coloque la arandela del paquete de

piezas en el eje.

2. Coloque la rueda en el eje, poniendo el

lado del cubo más largo primero.

3. Coloque otra arandela en el eje.

4. Coloque la chaveta a través del orificio

en el extremo del eje.

5.

Repita la operación para el otro lado (Fig. 5).

6. Deslice los dos extremos del mango sobre

los dos extremos de la parte inferior del

soporte. La curvatura en el mango debe

estar alejada del equipo.

7. Póngase detrás del equipo y extiéndase

sobre el mango para sujetar los extremos

en la parte inferior del mango. Usando el

dedo pulgar y el dedo índice, oprima los

cierres autoblocantes Valco Snaps y

empuje hacia abajo con cuidado en el

mango hasta que empiece a estar sobre

los automáticos. Después, mueva las

manos hasta la parte superior del mango

y empújelo hacia abajo, hasta que llegue

a su posición final (vea la Figura 6).

8. Cuando el mango haya llegado hasta

abajo, los cierres autoblocantes harán

“clic” indicando que están en su sitio.

Si no se bloquean los cuatro cierres,

sujete el mango y tuérzalo de derecha a

izquierda hasta que todos los cierres se

hayan asentado.

Figura 1 – Fije el eje

Figura 2 – Fijación de las ruedas

Figura 3 – Sujeción del mango

Figura 5 – Colocación de las ruedas

Figura 4 – Conexión de la manguera

Figura 6 – Colocación del mango

Empuje

Bloquee

Empuje

Bloquee

ESPAÑOL

© 2002 Campbell Hausfeld/Scott Fetzer

BUILT TO LAST

D

L

E

L

L

E

B

P

F

S

U

A

H

M

A

C

Page 10

2ES

Instrucciones de Montaje y Lista de Piezas

Montaje (continuación)

9. Coloque el gancho para el cubo sobre la

parte superior del bastidor con el gancho

hacia la parte externa del bastidor.

10. Alinee los dos orificios en el gancho para

el cubo con los dos orificios de la parte

superior del bastidor (vea la Figura 7).

Si utiliza una

herramienta motori-

zada para los tornillos, no aplique demasia-

1 Mango de posición AL172304AV 1

2 Perno de mango AL152201AV 2

3 Soporte de manguera AL066101AV 1

4 Mango

(incluye soporte manguera) AL066021SV 1

5 Eje (incluye pernos) AL066030SV 1

6 Arandela ST090200AV 2

7 Rueda WA002601AV 2

8 Tuerca compañera AL066300AV 2

9 Tuerca AL060000AV 2

10 Tubo derivación y abrazadera

AL174302SV

1

11 Conjunto de tubo de succión

AL138404SV

1

(incluye tubo y conectores)

12 Conjunto de campana de succión

(incluye filtro) AL111000SV 1

13 Gancho para cubo AL136200AD 1

14 Tornillos HP007117AV 4

15 Mango

(incluye soporte de manguera) AL139200SV 1

16 Arandela AL136000AV 4

17 Chaveta AL149700AV 2

18 Rueda WA002602AV 2

19 Tornillos de la placa

de recubrimiento HP007118AV 1

20 Conjunto del pistón AL131502SV 1

21 Conjunto del diafragma (Conjunto

de válvula de retención incluido) Ver esquema 1

22 Adaptador de manguera

(incluye arandela) AL104700SV 1

23 Conjunto de válvula de salida AL129600SV 1

24 Bloque de bomba

(incluye todas las arandelas) AL042413SV 1

25 Conjunto de válvula de entrada AL165400SV 1

26 Sello del interruptor de botón AL162000AV 1

27 Conjunto de salida de empujar/tirar AL159500SV 1

28 Conjunto de válvula para cebar/

pulverizar AL132100SV 1

29 Conjunto de válvula de retención AL163200SV 1

30 Conjunto de válvula de presión

AL131401SV

1

31 Conjunto de la caja

(Incluye 20, 29 y 30) Ver esquema 1

32 Conjunto de excéntrica y

rodamiento Ver esquema 1

33 Junta de la placa de recubrimiento AL013702AV 1

34 Placa de recubrimiento fundida AL045102AV 1

35 Tuerca de vástago de bomba

(paquete de 3) AL083300AV 1

36 Dispositivo giratorio de pistola AL081300AV 1

37 Filtro de la pistola

(malla 100) (paquete de 2) AL086101AJ 1

38 Pasador de gatillo AL085800AV 1

39 Conjunto de bola, válvula y émbolo AL083800AV 1

40 Gatillo AL083900AV 1

41 Protección de gatillo AL083700AV 1

42 Difusor de pistola AL083000AV 1

43 Pistola profesional

(con punta de 0,015) AL3104 1

44 Pistola semi-profesional

(incluye punta de 0,015)

(Metal)

AL2140

1

(Plástico)

AL2130

1

45 Anillo de retención ST002500AV 2

46 Gatillo AL023600AD 1

47 Mango con tornillo AL023703SV 1

48 ■ Alojamiento largo de filtro AL139002SV 1

49 Seguro AL117800SV 1

50 Válvula de pistola AL138700SV 1

51 Pasador de gatillo AL024100AD 1

52 ■ Filtro de pistola (100 mesh)

(paquete de 2) AL086101AJ 1

53 ■ Adaptador de manguera AL072302SV 1

54 Conjunto de pistola sin punta

(consumible) AL126100SV 1

55 Adaptador de manguera AL072300AV 1

56 Filtro 100 Mesh (3 paquetes) AL126301AJ 1

57 Adaptador de alojamiento de filtro AL072400AV 1

58 Tuerca de tope ST073804AV 1

59 Tapón ST073706AV 1

60 Pernos del bloque MJ103910AV 4

* Sello del eje AL045503AV 1

* Motor Ver esquema 1

Panel y pegatina AL162200SV 1

■ Conjunto de alojamiento de filtro

largo (incluye

48, 52 y 53

) AL139000SV 1

* No se muestra

FILTROS OPCIONALES DE PISTOLA DE METAL DISPONIBLES

(paquete doble)

Filtro 30 Mesh AL086103AJ

Filtro 50 Mesh AL086100AJ

Filtro 200 Mesh AL086102AJ

do par de fuerzas. Estos tornillos son de

autobloqueo y se saldrían del bastidor si se

usa demasiado par de fuerzas.

11. Atornille los dos tornillos que se suministran a través del gancho para cubo y en

el bastidor con un destornillador recto o

con una llave de tuercas de 5/16 pulg.

No conecte el conjunto de succión

en este momento.

Figura 7 – Instalación del gancho para el cubo

Lista de Piezas de Repuesto

Ref. Nº

No. Descripción de pieza Cant.

Ref.

No. Descripción Nº de pieza Cant.

!

AVISO

Page 11

RISK OF INJECTION.

WA

RNIN

G:

NE

V

ER

A

I

M

G

U

N

A

T

PERSON OR

A

N

Y

P

A

RT OF

BO

D

Y

.

MAX. 205

BAR

1

2

3

4

5

6

7

8

9

1011

12

13

14

3

15

16

16

17

18

54

47

46

45

59

58

51

45

50

49

57

56

55

53

52

45

51

50

49

48

47

46

45

44

43

42

39

41

40

38

37

36

35

19

34

33

30

29

28

27

25

23

22

20

32

3ES

Instrucciones de Montaje y Lista de Piezas

Para piezas de repuesto y accesorios, póngase en contacto

con su Centro de Servicio Local o llame al 1-800-626-4401

PISTOLA

DOMÉSTICA

Por favor, proporcione la

siguiente información:

- Número de modelo

- Número de serie

- Descripción y número de la

pieza tal y como se muestra

en la lista de piezas

Dirección para correspondencia

sobre piezas:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

PISTOLA

SEMI

PROFESIONAL

PISTOLA

PROFESIONAL

60

24

26

31

21

Page 12

Instrucciones de Montaje y Lista de Piezas

0-193 bar 115 Volts CA Seguro de gatillo de pistola

60 Hz Protección de gatillo de pistola

15 Amperios Difusor de presión de pistola

Circuito min. Válvula de cebado/pulverización

sobre alivio de presión

Presión Requisitos Características

de funcionamiento de energía de seguridad

Peso Capacidad(l/min.) Longitud máx. Tamaño máx.

Modelo (kg) @ 0 bar @ 138 bar de manguera de la punta

.40 GPM 22 * 1,5 0,9 23 m 0,015”

.42 GPM 22 * 1,6 1,0 30 m 0,015”

.48 - .50 GPM 25 * 1,9 1,2 46 m 0,017”

.60 GPM 25 * 2,3 1,6 61 m 0,019”

*El peso no incluye soporte

Especificaciones

4ES

Conjunto Conjunto Excéntrica/ Conjunto de

Modelo del motor del diafragma Rodamiento válvula de presión

PS###A MC014304SV AL125904SV AL116203SV AL174201SV

PS###B MC014300SV AL125905SV AL116200SV AL174200SV

PS###C MC014301SV AL125906SV AL116201SV AL174200SV

PS###D MC014303SV AL173700SV AL116204SV AL131403SV

PS###E MC014401SV AL125905SV AL116200SV AL174200SV

PS###F MC014402SV AL125906SV AL116201SV AL174200SV

NOTA: Todos los conjuntos de válvula de retención vienen con el diafragma

Loading...

Loading...