Page 1

Operating and Assembly Instructions

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and

others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

Airless

Paint Sprayers

For questions, parts and accessories: 1-800-626-4401

Models PS250B and PS250E

© 2008 Campbell Hausfeld/Scott Fetzer

Models PS231B, PS260E, PS261C,

and PS260F

For parts, product & service information

visit www.chpower.com

Models PS240C and PS240F

IN424700AV 12/08

Page 2

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spraying Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spray Gun Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Force Feeding Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Description

Airless paint sprayers are capable of spraying a wide variety

of latex, oil-based, and alkyd paints, as well as stains,

preservatives and other non-abrasive finishes.

These sprayers are also powerful and versatile enough to

be used with a variety of options (roller attachment, extra

lengths of hose, etc.) to make it an even more efficient tool.

NOTE: Guns pictured in illustrations may be different than

the one included with your unit.

Application Chart

Coating Can Use Do Not Use Tip Size ** Spray Pressure

Oil Base Stain x .011 - .013” 800 + psi

Wood Sealer x .011 - .013” 800 + psi

Concrete Sealer x .011 - .013” 800 + psi

Enamel x .011 - .013” 1500 + psi

Varnish x .011 - .017” 1500 + psi

Non-Metal Flake Aluminum Paint x .011 - .017” 1500 + psi

Vinyl Latex Paint x .013 - .017” 1700 + psi

Vinyl / Acrylic Latex Paint x .013 - .017” 1700 + psi

Acrylic Latex Paint x .013 - .017” 1700 + psi

Oil Base Paint x .013 - .017” 1700 + psi

Oil and Water Based Primer x .013 - .017” 1700 + psi

V. V/A & A Latex Stain x .013” 1700 + psi

Textured Coatings x N/A

Elastomerics x N/A

Asphalt Coating x N/A

Wood Restorer x N/A

Block Filler x N/A

All Other Materials Not Listed - Call Technical Support at 1-800-626-4401.

**Refer to maximum tip size in the specifications chart (See page 17).

**

www.chpower.com

2

Page 3

Operating Instructions and Assembly Instructions

MANUAL

TEST

RESET

Airless Paint Sprayers

Safety Guidelines

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains information

that is very important to know

and understand. This information

is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, MAY

cause damage to equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service.

Do not operate

unit if damaged

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals, including lead,

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

GENERAL SAFETY

1. SAVE THESE

INSTRUCTIONS - To

reduce the risks of fire

or explosion, electrical

shock, and injury to

persons, read and understand

all instructions included in this

manual. Be thoroughly familiar

with the controls and the proper

use of the equipment.

2. Always wear a mask

or respirator and

eye protection when

painting. Be certain

mask or respirator

will provide necessary protection

against inhalation of harmful

vapors.

3. Keep visitors away and NEVER

allow children or pets in the work

area.

4. Do not smoke or eat when spraying

paint, insecticides, or other

flammable substances.

5. Always work in a clean

environment. To avoid injury and

damage to the workpiece, do not

aim the spray gun at any dust or

debris.

6. When spraying and cleaning,

always follow the instructions and

safety precautions provided by the

material manufacturer (Refer to

MSDS).

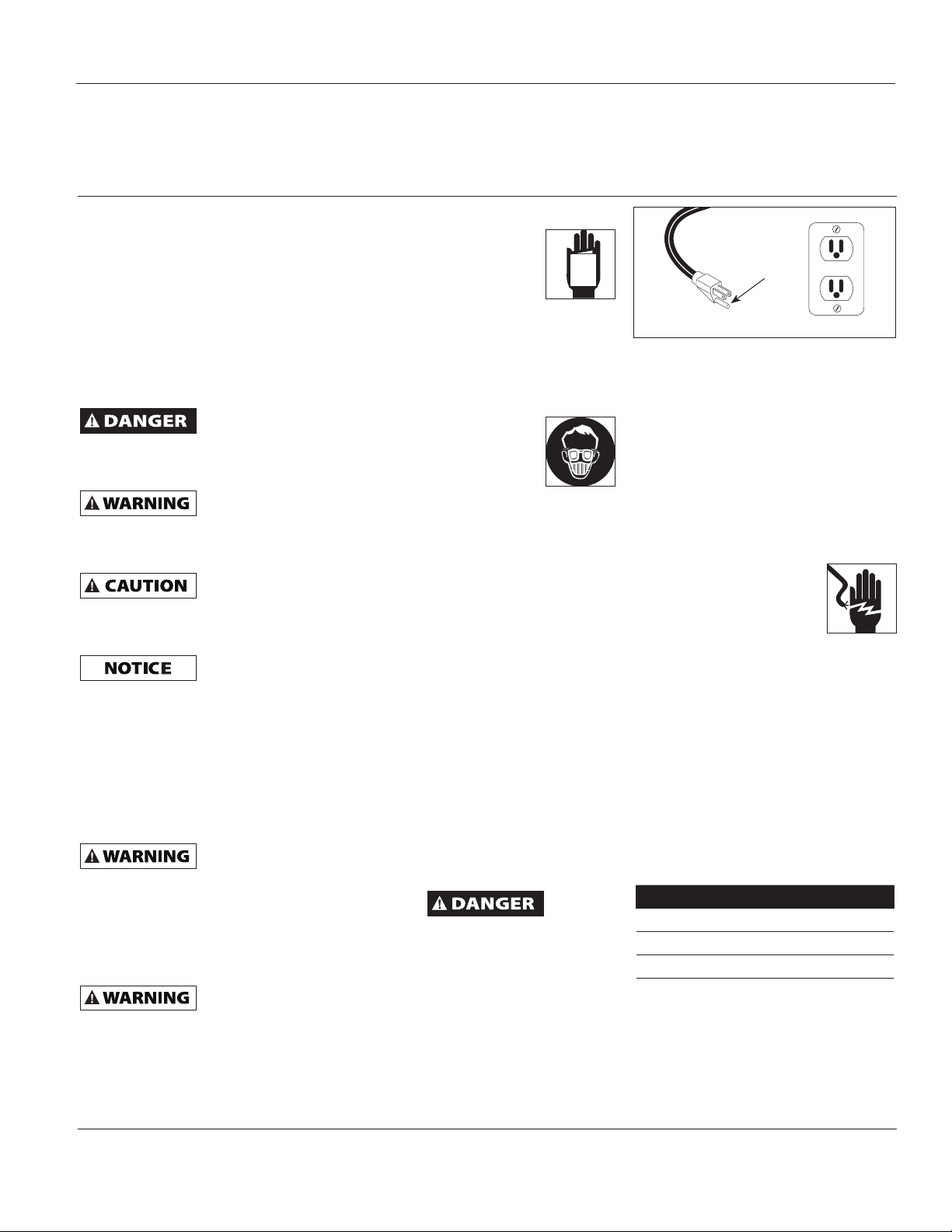

ELECTRICAL SHOCK HAZARD:

● Follow all local electrical and safety

codes, as well as the National

Electrical Code (NEC) and in the

United States, the Occupational

Safety and Health Act (OSHA).

● This product requires a grounded

120V, 15 Amp circuit (See Figure 1).

Grounding

Pin

Figure 1 - Grounding

NOTE: Applies to 120V countries

only.

● If the power receptacles available

will not fit this equipment’s power

cord, then have an appropriate

power receptacle installed by a

certified electrician.

● Only qualified electricians or

service personnel should perform

maintenance on the electrical

components of this equipment.

● Do not modify any of the

electrical components of

this equipment.

● Do not use a power cord

adapter with this equipment.

● If using an extension cord, use only

grounded three wire extension

cords that are in good condition.

● Check with a qualified electrician

or service person if the grounding

instructions are not completely

understood or you are in doubt

as to whether the equipment is

properly grounded.

APPROPRIATE EXTENSION CORD

GAUGE FOR GIVEN LENGTHS

Length of Cord Gauge

25’ 14

25-50’ 12

50-100’ 10

www.chpower.com

3

Page 4

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

SKIN INJECTION HAZARD:

● High pressure spray can inject toxins

into blood stream. If injection

occurs, seek emergency medical

treatment.

Use a face mask/respirator

and protective clothing

when spraying. Always

spray in a well ventilated area to

prevent health and fire hazards. Refer

to Material Safety Data Sheets (MSDS)

of spray material for details.

● Never try to stop leaks with any

part of your body.

● This system is capable of producing

3000 psi (20 500 kPa). Use only

Campbell Hausfeld replacement

parts rated at 3000 psi (20 500 kPa)

or higher.

To reduce the risk of

skin injection:

● Do not aim the

gun at, or spray,

any person or

animal.

● Keep hands and other body parts

away from the discharge. For

example, do not try to stop leaks

with any part of the body.

● Do not clean spray tip while it is

attached to the spray gun. Remove

spray tip from gun to clean tip

guard.

● Always use the nozzle tip guard. Do

not spray without nozzle tip guard

in place.

● Do not remove tip while cleaning

the pump.

● Only use a nozzle tip specified by

the manufacturer.

● Use caution when cleaning and

changing nozzle tips. Before

removing the nozzle tip, follow

the manufacturer’s instructions for

turning off the unit and relieving

the pressure.

● Do not leave the unit energized or

under pressure while unattended.

When not in use turn off the

unit and relieve the pressure in

accordance with the manufacturer’s

instructions.

● High pressure spray is able to inject

toxins into the body and cause

serious bodily injury. In the event

that injection occurs, seek medical

attention immediately.

● Check parts for signs of damage.

Replace any damaged parts.

● This spray gun is rated for 3000 psi

(20 500 kPa). Do not use on systems

designed to produce more than

3000 psi (20 500 kPa).

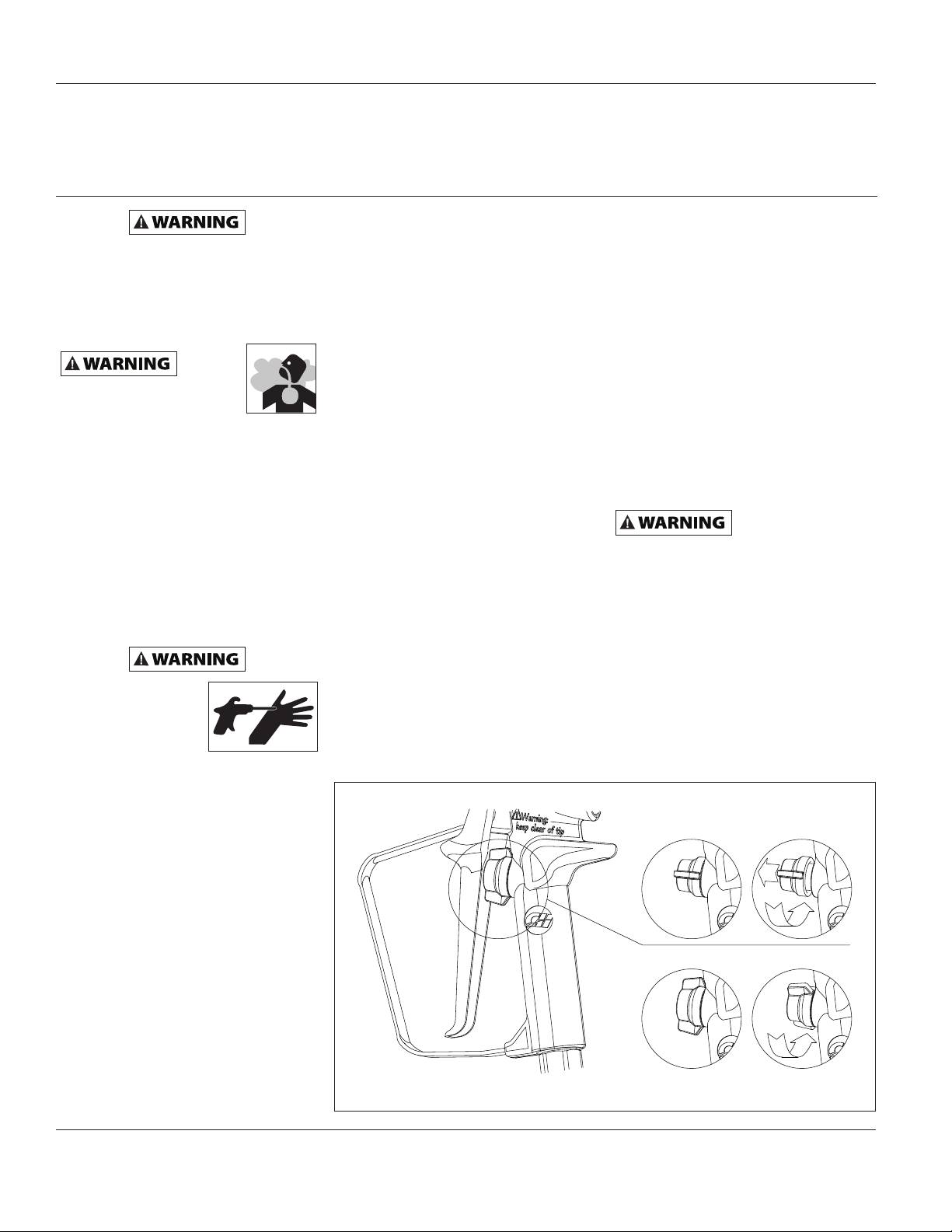

● Always engage the trigger lock

when not spraying. Verify the

trigger lock is functioning properly.

• To lock (engage): rotate tabs on

lock to horizontal position.

• To unlock (disengage) to spray:

rotate tabs on lock to vertical

position.

NOTE: If gun sprays while in the locked

position follow instructions in Spray

Gun Maintenance section for trigger

lock.

● Verify that all connections are

secure before operating. Do not

use pliers to tighten or loosen high

pressure connections.

● Know how to stop your unit

and bleed pressure quickly. Be

thoroughly familiar with the

controls.

● Motor is equipped with an

automatic thermal overload. Motor

will restart without warning, after

cooling.

Never aim or

spray at yourself

or anyone else or serious injury could

occur.

LOCKED TO UNLOCK

UNLOCKED TO LOCK

www.chpower.com

4

Page 5

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Before servicing or resting:

1. Turn the Prime/Spray Control to the

PRIME

position.

2. Turn the pressure control to LOW

PRESSURE/HYDRAULIC BLEEDING

position.

3. Turn power switch to OFF position.

4. With gun pointed in a safe direction,

pull the gun trigger, with the

trigger lock disengaged.

5. Engage trigger lock.

● Simply turning off the pump motor

will not relieve pressure from

system. The above procedure MUST

be followed.

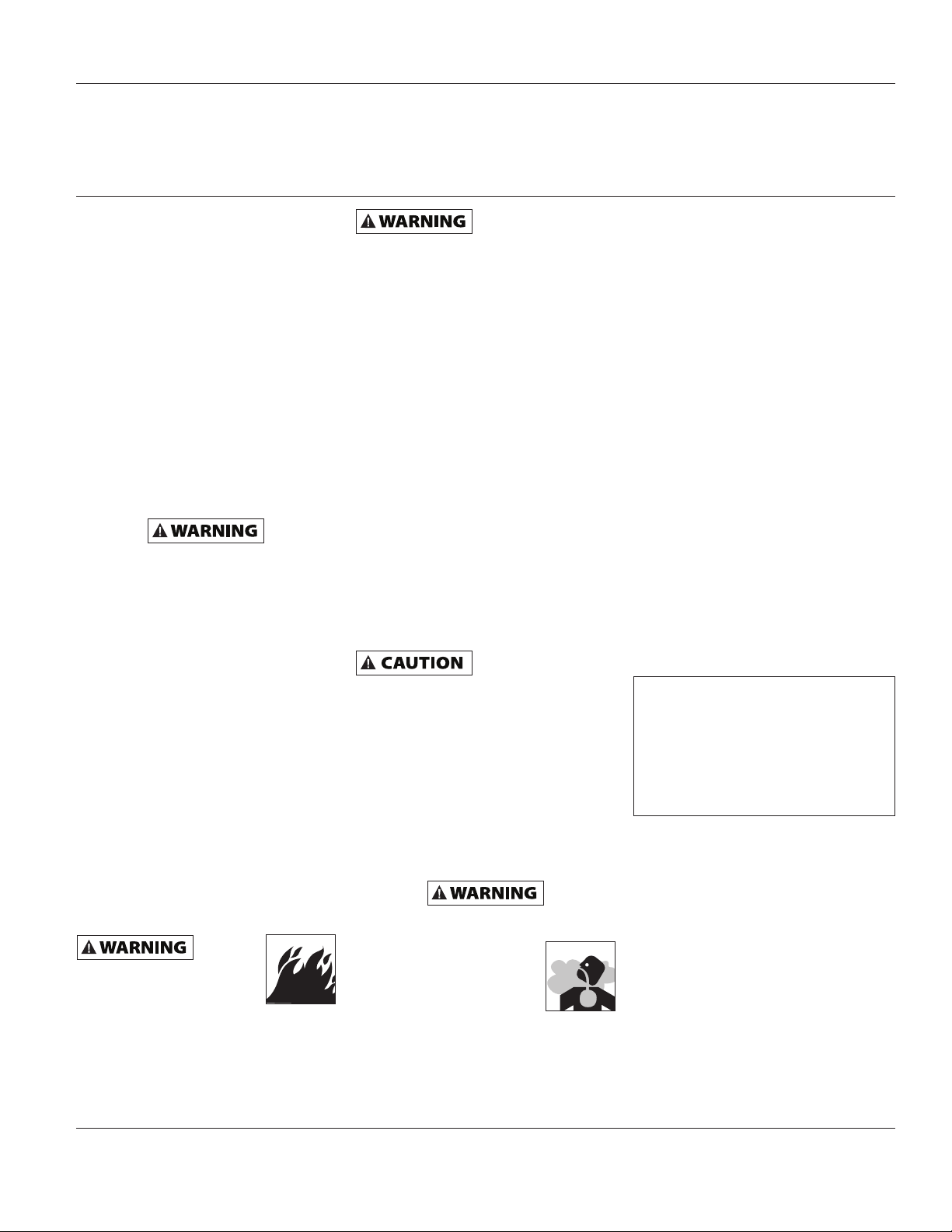

FIRE OR EXPLOSION HAZARD:

● Do not use solvents with flash points

less than 70°F (21°C) to clean this

equipment (examples of acceptable

cleaning solvents are water, mineral

spirits, lacquer thinner, Xylene and

high flash napha. A partial example

list of unacceptable cleaning

solvents are low flash napha, mek,

acetone, alcohol and toluene).

● Use only conductive or grounded

high-pressure airless paint sprayer

hoses specified by the manufacturer.

● Verify that all containers and

collection systems are grounded to

prevent static discharge.

● Do not spray pump assembly.

● Have fire extinguisher equipment

present and working.

Do not spray flammable

materials in vicinity of

open flame or near ignition

sources. Motors, electrical equipment

and controls can cause electrical arcs

that will ignite a flammable gas or

vapor. Never store flammable liquids or

gases in the vicinity of the unit.

Do not spray acids,

corrosive materials,

toxic chemicals, fertilizers or pesticides.

Using these materials could result in

death or serious injury.

● Do not use fuels to clean this

equipment.

● Keep spray area well ventilated.

Keep a good supply of fresh air

moving through the spray area.

● Remove all ignition sources (i.e.

Static electricity, pilot lights,

cigarettes and electrical arcing).

● Airless spraying can cause static

electricity. Always ground the pump

and spraying surface. Always use a

3-wire grounded extension cord and

power receptacle.

● Do not use paints or solvents

containing halogenated

hydrocarbons such as methyl

bromine, carbon tetrachloride, and

ethyl iodine.

Keep hose away

from sharp objects.

Bursting hoses may cause injury.

Examine hoses regularly and replace if

damaged.

● Check hoses for weak or worn

condition before each use, making

certain that all connections are

secure.

● Keep area clean and free of paint or

solvent containers, rags, and other

flammable materials.

TO REDUCE THE RISK OF INJURY:

● Do not spray acids,

corrosive materials, toxic

chemicals, fertilizers, or

pesticides. Using these

materials could result in

death or serious injury.

● Do not kink or over-bend the hose.

● Do not expose the hose to

temperatures or to pressures in

excess of those specified by the

manufacturer.

● Do not use the hose as a strength

member to pull or lift the

equipment.

● Always wear appropriate gloves, eye

protection, and a respirator or mask

when painting.

● Always work in a clean environment.

Do not aim the spray gun at any

dust or debris.

● Do not operate or spray near

children. Keep children, pets, and

visitors away from equipment and

work area at all times.

● Do not over reach or stand on an

unstable support. Keep effective

footing and balance at all times.

● Stay alert and watch what you are

doing.

● Do not operate the equipment when

fatigued or under the influence of

drugs or alcohol.

FAILURE TO FOLLOW

THESE INSTRUCTIONS

CAN RESULT IN

SERIOUS INJURY

INCLUDING DEATH.

www.chpower.com

5

Page 6

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

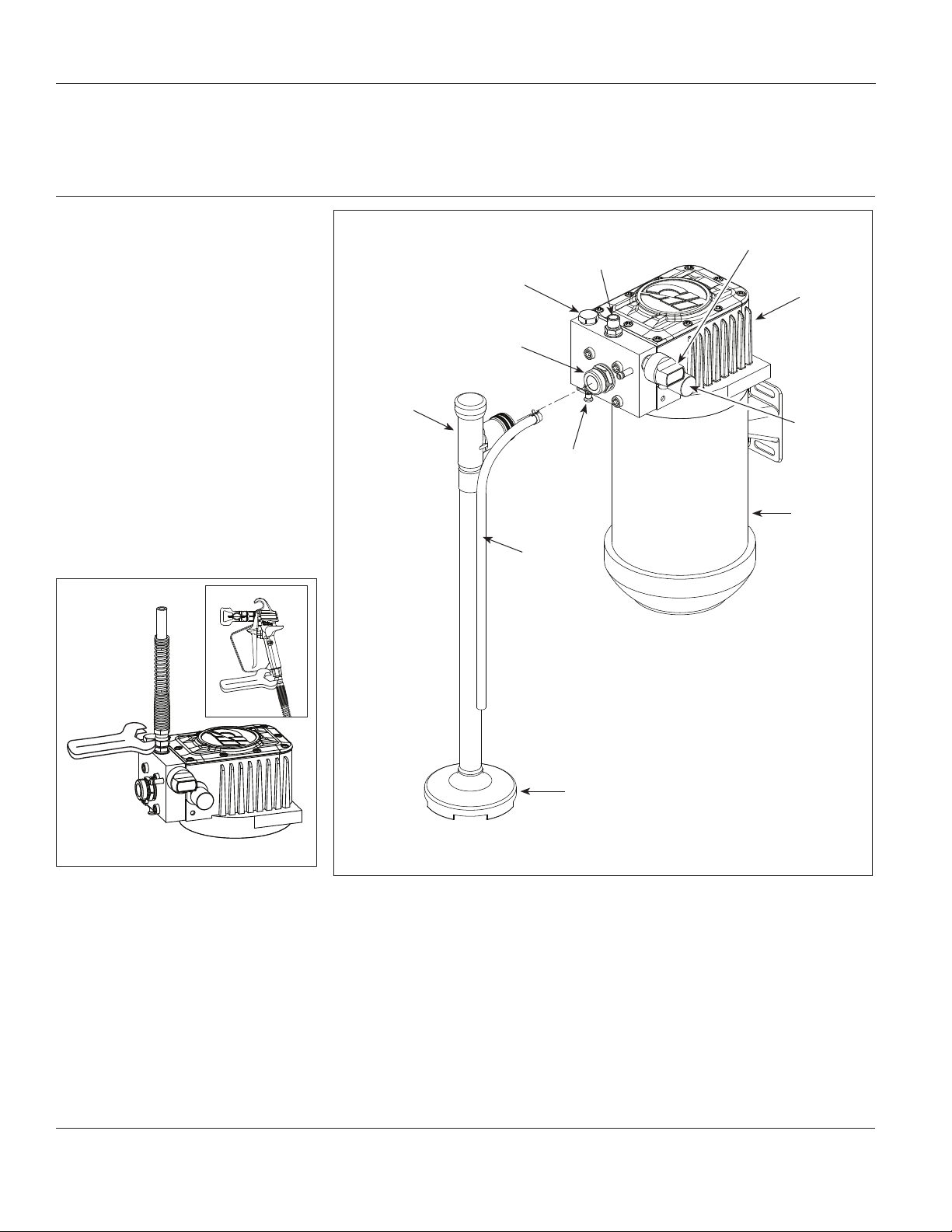

Assembly Instructions

TOOLS REQUIRED:

u 3/4 in. or Adjustable Wrench

u 5/8 in. or Adjustable Wrench

ASSEMBLY

1. Open packaging and check contents.

2. Remove the equipment and all parts

from the carton.

3. If sprayer is on stand, no further

frame assembly is necessary.

If sprayer is on a cart, install handle

in position shown on cover and

tighten knobs.

4. Attach high pressure hose to pump

and spray gun using a 3/4 inch

wrench (See Figure Below). Do not

attach suction assembly at this time.

Pump Assembly

Suction

Assembly

Outlet

Valve

Inlet

Valve

Outlet

Prime

Button

By-pass

Hose

Hose

Adapter

Prime/Spray

Valve

Housing

Pressure

Valve

Motor

FIgure - Attach hose

www.chpower.com

Preparation

Airless painting systems, unlike most

other power tools, require additional

care to ensure proper working order.

Following these instructions will

significantly increase the likelihood

of having a positive paint experience.

It is important that the painting

equipment is flush/tested EACH

time a new job is started. Each

pump is tested at the factory with a

fluid that must be flushed from the

6

Suction

Bell

Assembly

system prior to painting. It is also

required prior to each successive use

to flush the storage lubricant from

the system. Use the solvent which

will be used to clean the equipment.

Refer to the paint manufacturer’s

recommendations for cleaning fluids.

Page 7

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Preparation (Continued)

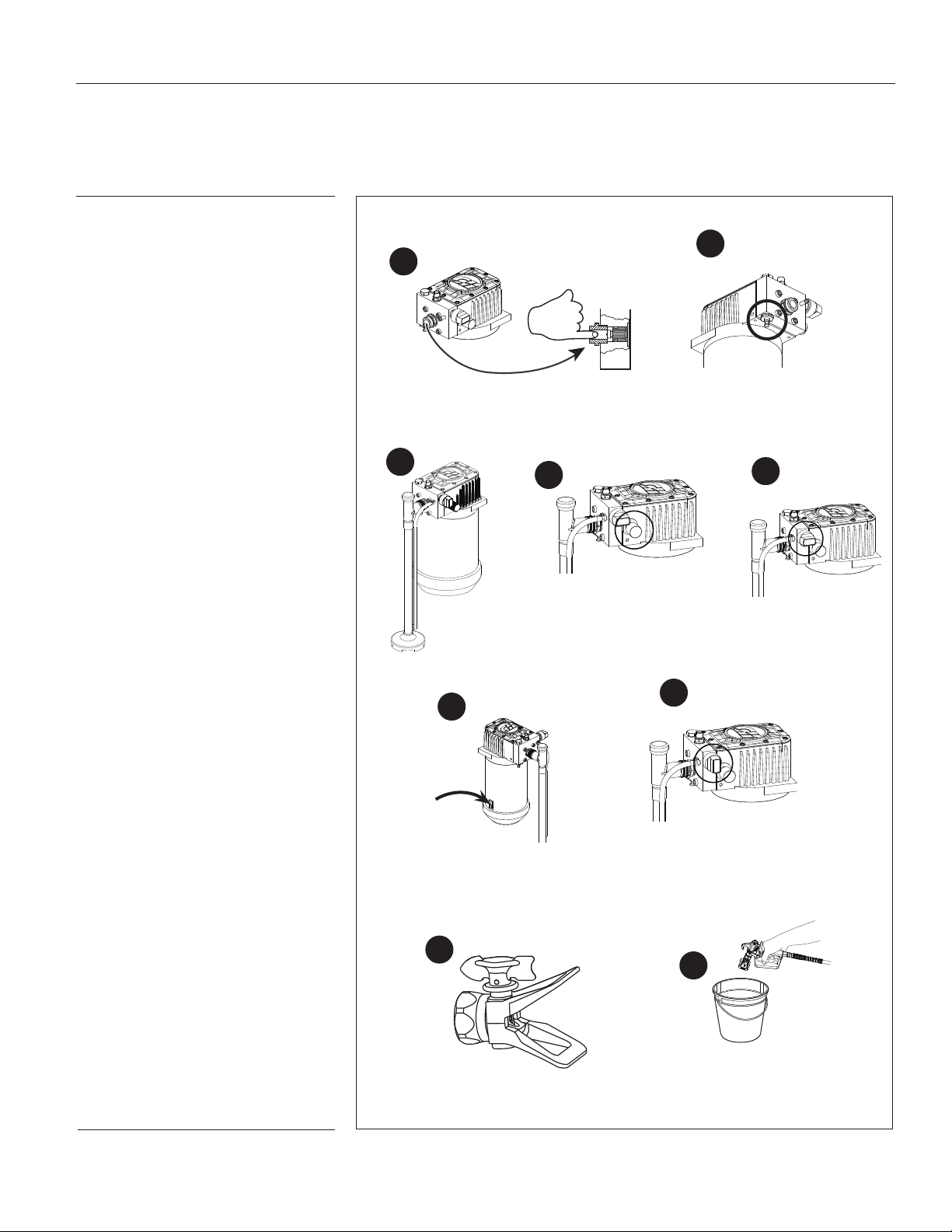

DO NOT ATTACH THE SUCTION

ASSEMBLY UNTIL INSTRUCTED TO DO

SO IN STEP 3.

1. Remove inlet valve cap and with

your smallest finger, push on inlet

valve stem to ensure it moves freely.

2. Push outlet prime button three

times to ensure outlet valve is

moving freely.

3. Attach suction assembly and bypass

tube securely and place both suction

and bypass tubes in cleaning solvent.

4. Turn pressure to HIGH

clockwise).

5. Turn prime/spray control to the

PRIME position.

6. Turn power switch to the

position. In a few seconds, cleaning

solvent will begin to move up

through the tube. Allow the fluid to

circulate for one minute to ensure

all air has been exhausted from the

pump.

7. Turn prime/spray control to SPRAY

position. Watch for any fluid leaks

(See Troubleshooting Chart if leaks

occur).

NOTE: If unit is building pressure

properly, the pump should produce a

knocking sound, which indicates it has

reached its hydraulic relief pressure.

8. When flushing the system with

cleansing fluid (either prior to

use with paint or during cleaning

process) the spray tip can remain in

the CLEAN position.

9. Point spray gun into an empty waste

bucket and pull trigger. To reduce

splashing, direct the fluid stream

along the inside of the bucket wall

and well above the fluid level.

(completely

ON

Starting Instructions

1

Use Finger to

Check Inlet Valve

3

Attach

Suction

Assembly

6

Power Switch

Location

8

4

Turn Pressure

to HIGH

(completely clockwise)

2

Push Outlet

Prime Button

5

Turn Prime/ Spray

Control

to PRIME

(knob is horizontal)

7

Turn Prime/ Spray

Control

to SPRAY

(knob is vertical)

9

Tip in

CLEANING

Position

7

While Pulling Trigger,

Direct Fluid Stream Along

Inside of Bucket

www.chpower.com

Page 8

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Preparation (Continued)

10. After completing the flush/testing

process, purge the pump of fluid.

11. Repeat the preceding steps using

paint instead of cleaning solvent.

NOTE: Strain and thin paint before

using. All paint may have particles that

will clog filter and spray tips. Remove

any skin which may have developed on

Spraying Instructions

Professional looking results can be

obtained by following the spray tips

below.

1. Keep the gun perpendicular to the

surface.

Always hold the gun perpendicular

to the surface with the tip

approximately 12 inches from the

surface. If held at an angle (up

and down or side to side), paint

will build up unevenly, leave the

work splotchy, and cause excessive

overspray (See Figure to the right).

2. Move with a smooth arm stroke.

Move the gun at a steady, even

pace while keeping the gun

perpendicular to the surface (See

Figures to the right). Do not fan

the gun. Fanning the gun will cause

excessive overspray and uneven

coverage (See Figure to the right).

3. Start moving the gun before

triggering.

To get a smooth overlap and prevent

initial paint buildup, start your

stroke movement before pulling the

trigger. Release the trigger before

stopping at the end of the stroke

(See Figure to the right).

NOTE: To assure uniform paint

coverage, overlap each stroke by 20%

- 30% and use two coats with a cross

pattern (one coat horizontal, second

coat vertical).

the paint due to air exposure. Follow

paint manufacturers’ recommendations

on thinning paint.

12. When pure paint appears from

spray tip rotate tip to the SPRAY

position. The system is now ready

for use.

12”

Holding Spray Gun

Thin Coat

Overspray

Heavy

Coat

Thin Coat

Overspray

INCORRECT

Result of Flexing Wrist While Spraying

Approx.

10-12”

Pull

Trigger

Start

Stroke

Proper Way to Trigger Spray Gun

Release

Trigger

End

Stroke

1

CLEAN Position

2

SPRAY Position

Water

Prevent clogged tip

www.chpower.com

8

Page 9

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Spraying Instructions

(Continued)

INTERMITTENT USE

If you are spraying and decide to stop

for several minutes, lock the spray

gun trigger and submerge the tip in

a container of water (See Figure on

page 8). This will prevent paint from

hardening in the tiny spray opening

and clogging the tip. Be sure to release

the pressure in the system and turn the

unit off.

CLEARING CLOGS

REVERSIBLE TIP: (INCLUDED)

1. Rotate the tip to the

(See Figure 1 on page 8).

2. Point gun in a safe direction and

spray. This should clear tip of any

blockage.

3. Rotate the tip back to the

position and continue spraying (See

Figure 2 on page 8).

4. If clogging continues, replace gun

filter and consider straining the

paint prior to use.

Equipment damage

or sharp object is used to clean the tip.

Tungsten carbide is brittle and can be

chipped.

CLEAN position

SPRAY

can occur if a needle

HOW TO CHANGE SPRAY TIPS

It may be necessary to change spray tips

during a paint job. Follow these steps

for safe, easy tip changes.

1. Depressurize and turn off unit per

manufacturer’s instructions.

2. Engage gun trigger lock.

3. Pull red tip insert

out of spray base

and replace with

different tip, fully

inserting tip into base.

HOW TO ATTACH ROLLER ACCESSORY

1. Depressurize and turn off unit per

manufacturer’s instructions.

2. Engage gun trigger lock.

3. Remove spray base, tip, seal and

washer assembly.

4. Attach roller accessory (AL2275

shown) to airless spray gun. If

needed use thread adapter and

washer between roller and spray gun

as shown.

Figure - Attach roller accessory to spray gun

9

www.chpower.com

Page 10

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Cleanup

CLEANUP FOR OVERNIGHT STORAGE

NOTE: Cleaning and maintenance

of the pump are the most important

steps you can take to ensure proper

operation and a long life for your

airless paint sprayer. Please follow the

cleaning instructions carefully and . . .

WEAR ALL NECESSARY

SAFETY GEAR

NECESSARY TOOLS / MATERIALS:

• One (1) bucket

• Water

• Plastic wrap

When reusing the

sprayer with the

SAME PAINT the next day at the SAME

JOB SITE, it is not necessary to flush

the paint from the system. However,

IT IS IMPORTANT TO KEEP AIR FROM

COMING INTO CONTACT WITH THE

PAINT.

NOTE: Do NOT disconnect any hoses.

1. Turn prime/spray control to PRIME

position.

High pressure

hose may still be

pressurized with prime/spray control

in the PRIME position. With the gun

pointed in a safe direction, pull the

gun trigger to relieve any pressure in

the hose.

2. Engage gun trigger lock.

3. Place spray gun in bucket of water.

There should be enough water to

COVER spray tip. This will prevent

paint from drying or clogging tip.

4. Leave suction and bypass tubes in

bucket of paint. Make sure ends

of suction and bypass tubes are

BELOW surface of paint in bucket.

5. Cover bucket and tubes with plastic

wrap or a damp towel to prevent

film forming on paint. Or, if using

latex paint, pour a very thin layer of

water over top of paint. Stir water

into paint the next morning.

Temporary Cleanup

1

Turn Prime/Spray

Control to PRIME

Position

3

Water

Place Gun in

Water

5

PAINT

Cover Bucket

2

To Lock Locked

Engage Trigger Lock

4

Suction and Bypass Tubes

Remain in Bucket with Ends

Below Paint Surface

or

PAINT

www.chpower.com

10

10

Latex Paint: Use Thin Layer of

Water to Cover Paint

Page 11

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

CLEANUP FOR CHANGING PAINTS

OR TEMPORARY STORAGE FOR

MORE THAN ONE NIGHT

WEAR ALL NECESSARY

SAFETY GEAR

NECESSARY TOOLS / MATERIALS:

• Pliers

• Rag

• Gloves

• Two (2) buckets

• At least one (1) gallon of cleaning

fluid

• Cleaning brush

NOTE: Do NOT disconnect any hoses.

NOTE: Refer to coating manufacturer

for recommended cleaning fluid.

1. Turn prime/spray control to PRIME

position.

2. Turn power switch to ON.

High pressure

hose may still be

pressurized with prime/spray control

in the PRIME position. With the gun

pointed in a safe direction, pull the

gun trigger to relieve any pressure in

the hose.

Cleaning Pump

1

Turn Prime/Spray

Control to PRIME

Position

3

2

Turn power switch to ON

(shown in the OFF position)

4

3. Turn pressure to HIGH (completely

clockwise).

4. Tilt unit back, lift suction assembly

above fluid level in bucket.

While holding suction assembly

above paint level, allow pump to

run until empty.

5. Immediately place both suction

assembly and bypass tube in a

bucket containing enough cleaning

fluid to cover suction bell by two

inches. Allow pump to prime and

begin circulating fluid.

6. While fluid is circulating, soak rag

in fluid and wipe exterior of suction

assembly and bypass tube. Remove

suction filter with pliers. Wipe

inside of suction filter housing with

rag removing excess paint buildup.

Clean both sides of suction filter

with rag and reinsert filter into

suction filter housing.

NOTE: Do NOT allow fluid to circulate

for more than 15 minutes.

Turn Pressure to HIGH

(completely clockwise)

5

Suction Assembly and

Bypass Tube in Bucket

of cleaning fluid

Lift Suction Assembly above

Paint Level in Bucket

6

Wipe Exterior of Suction

Assembly and Bypass Tube

11

11

www.chpower.com

Page 12

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

CLEANUP FOR CHANGING PAINTS

OR TEMPORARY STORAGE FOR

MORE THAN ONE NIGHT

Allow the cleaning fluid to continue

circulating for approximately 10

minutes.

7. Turn pressure to HIGH (completely

clockwise).

8. Turn prime/spray control to SPRAY/

ROLL position.

9. If reversible tip is used, rotate spray

tip to CLEAN position.

10. Point spray gun into bucket of

paint and pull trigger.

NOTE: To reduce splashing, direct

fluid stream along inside of bucket

and above the paint level.

11. As soon as cleaning fluid is flowing

from spray gun, release trigger.

NOTE: It should take less than one

minute to clear each 25 feet of high

pressure hose.

12. Engage gun trigger lock.

13. Turn prime/spray control to PRIME

position.

14. Turn pressure control to HIGH.

15. Lift suction assembly above fluid

level in bucket.

NOTE: Allow pump to run until

empty.

16. Repeat process (1 - 15) with

fresh cleaning fluid, to remove

contaminated cleaning fluid from

initial cleaning.

(Continued)

Cleaning Hose and Gun

7

Turn Pressure to HIGH

(completely clockwise).

10

Paint

While Pulling Trigger,

Direct Fluid Stream Along

Inside of Bucket

13

8

9

Turn Prime/ Spray

Control to SPRAY (knob

is vertical)

If Reversible Tip is

Used, Rotate Spray Tip

to CLEAN Position.

12

To Lock Locked

Engage Gun Trigger Lock

15

www.chpower.com

PRIME Position

12

12

14

HIGH PRESSURE

(completely clockwise)

Position

Lift Suction

Assembly

Page 13

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

CLEANUP FOR CHANGING PAINTS OR

TEMPORARY STORAGE FOR MORE

THAN ONE NIGHT

17. Make sure prime/spray control is in

SPRAY position to reduce dribbling.

18. Turn pressure to LOW (completely

counterclockwise).

19. Turn power switch to OFF position.

20. With gun pointed in safe direction

pull trigger with lock released to

relieve any pressure in hose.

21. Engage gun trigger lock.

22. Clean buckets and dispose of any

waste paint and cleaning fluid in

an environmentally responsible

manner.

23. Clean tip guard with cleaning brush

and cleaning fluid.

NOTE: At this point, pump, hose and

spray gun are clean, but still require

further preparation for storage of more

than one day.

(Continued)

Finishing Touches/Shutdown

17

Prime/Spray is

in SPRAY/ROLL

Position

20

18

Turn Pressure to LOW

(completely counterclockwise)

Pull Gun Trigger with

Trigger Lock Released

13

13

21

To Lock Locked

Engage Gun Trigger Lock

www.chpower.com

Page 14

Operating Instructions and Assembly Instructions

Pump

Protector

P L A S T I C W R A P

Airless Paint Sprayers

Storage

SHORT TERM

(LESS THAN ONE WEEK)

WEAR ALL NECESSARY

SAFETY GEAR

NECESSARY TOOLS / MATERIALS:

• Pump Protector Solution

• Plastic Wrap

• 3/4 in. or Adjustable Wrench

OIL OR ALKYD BASED PAINT

If sprayer cleaned with mineral spirits,

simply wrap suction filter housing

in plastic to keep debris out of

suction filter. No other preparation is

necessary.

WATER-BASED PAINT

1. Prepare Pump Protector solution in

bucket as directed on container.

2. Place suction assembly into

solution.

3. Place end of bypass tube into waste

bucket.

4. With prime/spray control in PRIME

position, turn pressure to HIGH

(completely clockwise).

5. Turn power switch ON. Circulate

Pump Protector through bypass

tube until bucket of solution is

EMPTY.

6. Turn pressure to LOW (completely

counterclockwise).

7. Wrap suction filter housing in

plastic to keep debris out of suction

filter.

LONG TERM

(MORE THAN ONE WEEK)

Water Based Paint

1

3

PROTECTION

SOLUTION

Place End of Bypass Tube

into Waste Bucket

6

Prepare Pump

Protector Solution

WASTE

PUMP

BUCKET

2

PUMP

PROTECTION

SOLUTION

Place Suction

Assembly in

Solution

4

PUMP

PROTECTION

SOLUTION

With Prime/Spray

Control in PRIME

Position, Turn

Pressure to HIGH

(completely clockwise)

7

WASTE

BUCKET

WASTE

BUCKET

8. Remove high pressure hose and

drain. Reassemble high pressure

hose to pump.

9. With spray tip attached to spray

gun, wrap tip with plastic to

protect tip.

www.chpower.com

Turn Pressure to LOW

(completely counterclockwise)

14

14

Wrap Suction Filter

Housing in Plastic

Page 15

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Spray Gun Maintenance

Pump damage may

occur if these

instructions are not followed.

Before performing

any maintenance,

make sure to relieve pressure from

system and disconnect power from

sprayer.

• Do not use oil based solvents to

clean equipment after using latex

based coatings. Use only warm soapy

water.

• Always replace clogged gun filters,

do not attempt to clean them.

• Carefully follow cleaning and

storage instructions for your sprayer.

• Do not use metal or other hard

objects to pick dried paint material

from Spray Tip Orifice.

TRIGGER LOCK

Pulling the trigger

must not open the

gun valve when

trigger lock is activated.

You should be able to get the actuator

(#12, page 19) to wiggle slightly with

your finger while holding the trigger

against the trigger lock when it is in the

locked position. If you cannot, adjust

the trigger position by following these

instructions:

1. Place trigger in locked orientation

(tabs horizontal).

2. With one hand holding trigger

lightly against lock, use a 1/4 inch

nut driver to turn nut (#13, page 19)

in until trigger starts to come off the

lock.

3. Reverse the nut (counterclockwise)

1/2 turn.

TIP SEAL AND WASHER

Occasionally, you will need to replace

the silver seal and clear washer located

inside the tip base.

1. To replace seal and washer, first

loosen tip base with adjustable

wrench, and then remove by hand.

2. Remove spray tip.

3. With Phillips screwdriver, push seal

and washer out from front of tip

base.

4. With flat side of seal facing up, place

seal in base. Make sure it lines up

properly with base.

5. Place washer in base. Make sure it

lines up properly with base.

6. Put spray tip back in tip base.

7. Reattach tip base to gun valve.

Make sure spray

tip and tip base fit

snugly in place. A

loose fit can lead to misdirected spray

discharge and a skin injection hazard.

15

15

www.chpower.com

Page 16

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Maintenance Chart

Maintenance User

Item Check Replace Serviceable? Detail Notes

Product safety

labels

Before each use

As required

Yes

See parts listing for location of product safety

labels and related part numbers.

Trigger adjustment

Airless hose

Sealing surfaces

Suction tube

Bypass tube

Suction filter

Gun filter

Roller nap

Prime/spray valve

Push button

Block bolts

Pressure valve

Before each use

Before each use

Before each use

Before each use

Before each use

Before each use

and every 5 gal.

Before each use

Before each use

Before each use

Before each use

Before each use

As required

As required

Every 25 gal. or

more often if

required

Every 25 gal.

As required

Every 1000 gal.

Every 1000 gal.

Do not require

replacement

with normal use

Does not require

replacement

with normal use

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

*SCR

See trigger lock warning under Spray Gun

Maintenance.

Read information on the hang tag attached to the

high pressure hose for instructions on maintenance.

Make sure they are clean.

Check for nicks and cuts.

Check for nicks and cuts.

Do not attempt to clean gun filter, only replace.

3/4” Wrench, torque to 80 in/lbs.

7/8” Socket or wrench, torque to 200 in/lbs.

Block bolts are to be torqued to 275 in/lbs. in an

“X” pattern. These bolts should be checked periodically for correct torque. 1/4” Hex.

5/8” Wrench, torque to 75 in/lbs.

Inlet valve

Outlet valve

Spray tip

Diaphragm

assembly

Oil

Block

Hose connector

* Service Center Recommended

www.chpower.com

Before each use

Before each use

Every 250 gal.

Every 250 gal.

Every 20-75 gal.

Every 1000 gal.

Every 2000 gal.

Does not require

replacement

with normal use

When stripped

or leaking under

pressure

Yes

Yes

Yes

*SCR

Yes

Yes

Yes

16

1-1/16” Wrench, torque to 150 in/lbs.

3/4” Wrench torque to 150 in./lbs.

1” Wrench torque to 135 in/lbs.

This part is only worn out if broken or torn.

H-32 Hydraulic oil CH #AL170200AV.

5/8” - Torque to 350 in/lbs.

Page 17

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Specifications

Operating Pressure Model A - D Power

Ratings

0-3000 psi 115 Volts AC 220 - 240 Volts AC Spray gun trigger lock

60 Hz 50 Hz Spray gun trigger guard

8.5 Amps 4.6 Amps Spray gun pressure diffuser

Model E & F Power

Ratings

Safety Features

Prime/Spray valve over

pressure relief

Weight

Model

PS2###B/E 49 * .42 .26 100 ft. .015 in.

PS2###C/F 55 * .50 .31 150 ft. .017 in.

PS2###D 55 * .60 .43 200 ft. .019 in.

* Weight does not include mounting

Model Motor Kit Housing Kit

PS###B MC014500SV AL133509SV AL125905SV AL116200SV AL131401SV

PS###C MC014502SV AL133509SV AL125906SV AL116201SV AL131401SV

PS###D MC014503SV AL173304SV AL173700SV AL116204SV AL131403SV

PS###E MC014520SV AL133509SV AL125905SV AL116200SV AL131401SV

PS###F MC014521SV AL133509SV AL125906SV AL116201SV AL131401SV

NOTE: All check valve components come with the diaphragm kits.

(lbs.)

Capacity (GPM)

Diaphragm

Kit

Maximum

Hose Length

Eccentric /

Bearing

Maximum

Tip Size@ 0 psi @ 2000 psi

Pressure

Valve Kit

17

www.chpower.com

Page 18

Operating Instructions and Assembly Instructions

For Replacement Parts and Accessories,

Contact Your Local Service Center or Call 1-800-626-4401

Please provide following information: Address parts correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part descriptions and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

4

6

7

17

1

2

3

5

8

13

12

16

15

14

Replacement Parts List

Ref. Part

No. Description No. Qty.

1 Outlet valve assembly AL129600SV 1

2 Hose adapter (Includes washer) AL104700SV 1

3 Diaphragm kit (Check valve See chart

kit included) on page 17 1

4 Piston kit AL131502SV 1

5 Eccentric and See chart

bearing kit on page 17 1

6 Faceplate screws HP007118AV 10

7 Cast faceplate AL045102AV 1

8 Faceplate gasket AL013702AV 1

9 Pressure valve assembly AL131401SV 1

10 Housing kit See chart

(Includes 20,29, & 30) on page 17 1

9

11

10

Ref. Part

No. Description No. Qty.

11 Check valve kit AL163200SV 1

12 Prime/Spray valve assembly AL132100SV 1

13 Pump block (Incl. all washers) AL042413SV 1

14 Outlet prime button kit AL159500SV 1

15 Prime button seal AL162000AV 1

16 Inlet valve assembly AL165400SV 1

17 Block bolts ST070819AV 4

* Shaft seal (motor) AL045503AV 1

* Motor See chart

on page 17 1

* Oil, Hydraulic, 16 oz bottle AL170200AV 1

* Not shown

www.chpower.com

18

Page 19

Operating Instructions and Assembly Instructions

For Replacement Parts and Accessories,

Contact Your Local Service Center or Call 1-800-626-4401

Please provide following information: Address parts correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part descriptions and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

1 or 2

14 (2x)

5

4

21 (4x)

13

12

11 (2x)

3

20

9

8

7

6

22 or 23

15

17

Replacement Parts List

Ref. Part

No. Description No. Qty.

1 Kit, Black Gun Left Grip, Lock

and Guard AL184401SV 1

2 Kit, Pro Gun Left Grip, Lock

and Guard AL184400SV 1

3 Insert, Gun AL179803AG 1

4 Kit, Pro Stem and Diffuser

(includes #7) AL183400SV 1

5 Spring, Gun AL048600AV 1

6 Retainer, Gun Spring AL020201AV 1

7 Seal, Gun AL020300AV 1

8 Washer, Seal AL153801AV 1

9 Washer, Gun Seat Retainer AL005404AV 1

10 Kit, Gun Seal (Includes #7, #8, #9) AL183600SV 1

11 Pin, Gun Actuator AL024102AV 2

12 Actuator, Gun AL182700AV 1

13 Nut, #5-40 Hex Lock ST073804AV 1

14 Kit, Gun Trigger (Trigger, Screws) AL183100SV 1

15 Gun Filters,

100 Mesh (yellow) AL086101AJ 2 pk

50 Mesh (white) AL086100AJ 2 pk

16

19

AL2150 - Black (Std)

14

AL1860 - Metal (Pro)

18

Ref. Part

No. Description No. Qty.

16 Washer, Long Filter MJ105402AV 1

17 Adapter, Long Filter AL072301AV 1

18 Assembly, Pro Gun Swivel

(optional) AL183500AJ 1

19 Guard, Pro Gun Trigger AL184600AV 1

20 O-Ring MJ106511AV 1

21 Screw, #5-40 x 5/16” SHC MJ103804AV 4

22 Grip, Right, Pro Gun AL184302AV 1

23 Grip, Right, Black Gun AL184301AV 1

ADDITIONAL ITEMS AVAILABLE:

Kit, Pro Gun Valve –

Includes #4 - #9, #13 AL183200SV

Kit, Gun Actuator –

Includes #11, #12, #13 AL183700SV

Kit, Pro Gun Insert –

Includes #3 - #9, #16 AL184100SV

Kit, Pro Gun Full Grip –

Includes #2, #19 - #22 AL184500SV

www.chpower.com

19

Page 20

Operating Instructions and Assembly Instructions

For Replacement Parts and Accessories,

Contact Your Local Service Center or Call 1-800-626-4401

Please provide following information: Address parts correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part descriptions and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

1

2

3

15

1

2

3

4

5

12

11

9

6

8

7

10

Replacement Parts List

Ref. Part

No. Description No. Qty.

1 Handle (with hose rack) AL167960AD 1

2 Carriage Bolt MJ103305AV 2

3 Knob PM080900AV 2

4 Washer ST090200AV 2

5 Spacer AL007001AV 2

6 Palnut AL066300AV 2

7 Wheel WA120100AV 2

8 Cart AL167990AD 1

9a By-pass Tube & Clamp AL174300SV 1

9b Option, Solvent Resistant AL174302SV 1

4

16

5

8

13

6

14

Ref. Part

No. Description No. Qty.

10 Suction Bell (with filter) AL111000AJ 1

11a Suction Tube Assembly AL138400SV 1

11b Option, Solvent Resistant AL138404SV 1

12 Bucket Support (with screws) AL168080SV 1

13 Wheel, Pneumatic (optional) WA005620AV 2

14 Cap, Rubber (optional) MJ110300AV 2

15 Bucket Support (w/screws & nuts) AL167953SV 1

16 Stand AL168020AD 1

www.chpower.com

20

Page 21

Operating Instructions and Assembly Instructions

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Motor hums and does not run 1. Unit under pressure 1. Turn Prime/Spray Control to prime position

2. Equipment has been dropped

which caused motor to become

misaligned

3. Supply voltage too low 3. Do not use an extension cord, it is better to add hose length.

Motor does not run or hum 4. Power Switch is in OFF position 4. Flip Power Switch to ON position

5. Bad power connection 5. Check power connections at power receptacle, along extension

6. Circuit breaker or fuse is tripped 6. Correct cause of circuit overload. (Possible causes: Supply

7. Thermal overload protection

activated

Motor runs, but pump does

not prime after being cleaned

after last use. (This problem

can usually be prevented by

following the recommended

cleaning and storage

procedure)

Motor runs, but pump does

not prime even though it was

working just fine a little while

ago. (Usually occurs after

moving or adding more paint

to the paint bucket.)

Pump primes, but does not

build pressure

8. Check valves stuck 8. “Pop” Inlet Valve and Outlet Valves. See Preparation

9. Suction Assembly loose and/or

sealing surfaces are dirty at Inlet

Valve

10. Suction Head not immersed in

paint

11. Prime/Spray Control is in the

spray position and/or the

Pressure Control is in the Low

Pressure/Hydraulic Bleeding

position

12. Hydraulic system contains air 12. Turn Pressure Control to Low Pressure/Hydraulic Bleeding

13. Hydraulic oil level low 13. Add oil so level is within 1/4” of housing edge. (See notes in

14 See Possible Causes 9,10,11,13 14. See Corrective Actions 9,10,11,13

15. Clogged suction filter 15. Remove suction filter and clean. Also, refer to Maintenance

16. Trash caught in valves 16. See “Force Feeding” figure on page 23

17. Paint sediments settled to

bottom of bucket

18. Prime/Spray Control not in Spray

position

19. Pressure Control not set to high

enough pressure

20. Even though Prime/Spray

Control is in Spray position, fluid

still flows from By-Pass Tube.

Prime/Spray Control is worn or

damaged

2. Take to authorized service center to have motor assembly

realigned. Or, call technical support

Use portable generator with a 2400 VA minimum rating

cord and at equipment for looseness or damage

voltage too low, extension cord too long for available supply

voltage, equipment was under pressure while trying to start

motor or motor has been damaged.)

7. Allow motor to cool for approximately 30 minutes, determine

cause and restart motor. (Possible causes: Supply voltage too

low, extension cord too long for available supply voltage,

equipment was under pressure while trying to start motor or

motor has been damaged.)

Instructions

9. Remove Suction Assembly, clean sealing surfaces and

reassemble

10. Add more paint to bucket and/or adjust position of Suction

Assembly

11. Turn the Prime/Spray Control to the Prime position and Pressure

Control fully clockwise

position for 1 minute while motor is running

Maintenance Section on oil leaks.) Turn Pressure Control to Low

Pressure/Hydraulic Bleeding position for 1 minute

section

17. Strain and mix paint thoroughly

18. Turn Prime/Spray Control to Spray position

19. Turn Pressure Control clockwise to desired pressure. Fully

clockwise is maximum pressure

20. Replace with service kit (See replacement parts list) or take

equipment to authorized service center

Continued on next page

21

www.chpower.com

Page 22

Operating Instructions and Assembly Instructions

Troubleshooting Chart (Continued)

Symptom Possible Cause(s) Corrective Action

Pump primes and builds

pressure, however, the

equipment does not spray or

produce a quality spray pattern

Pump primes and builds

pressure, but does not maintain

pressure once trigger is pulled

Gun will not shut-off 28. Trash caught in Gun Valve 28. Clean or replace Gun valve. Also, refer to Gun Maintenance

After moving equipment or

adding paint to bucket, unit

will not prime or spray

Oil in Paint 32. Oil is leaking from between

Fluid leaks other than oil 34. Loose connection 34. Clean sealing surface and reassemble per assembly instructions

Symptoms not listed 37. Possible product quality issue.

21. Clogged gun filter 21. Replace with new filter. Do not attempt to clean gun filters.

22 Clogged Spray Tip 22. See Clearing Clogs section

23 A. Tip is damaged or worn 23. A. Replace tip. Also, refer to Maintenance section

B. Paint requires thinning B. Follow paint manufacturers thinning recommendations.

C. Reversible Spray Tip in

cleaning position

24. Clogged Suction Filter 24. Remove Suction Filter and clean. Also, refer to Maintenance

25. Suction Assembly loose and/or

sealing surfaces are dirty at Inlet

Valve

26. Paint thick due to cold weather.

This problem usually occurs with

Latex based coatings

27. Inlet Valve and/or Outlet Valve

are worn

29. Worn Gun Valve 29. Replace Gun valve. Also, refer to Gun Maintenance section

30. Dried paint under gun actuator 30. Remove 1/4” nut and gun actuator at rear of gun. Remove

31. Suction assembly loose or

damaged

Block and Hydraulic Housing

33. Diaphragm is damaged 33. New diaphragm assembly is needed. (It is recommended that

35. Contaminated sealing surface 35. Consult technical support

36. Damaged component 36. Consult technical support

(We would greatly appreciate

your assistance in continuous

product quality improvement)

Also, refer to Maintenance section

Paint should not typically need to be thinned more than 8

oz. of solvent per gallon

C. Turn Spray Tip to Spray position. See Cleaning section for

details

section

25. Remove Suction Assembly, clean sealing surfaces and

reassemble hand tight

26. Do not paint Latex coatings in temperatures less than 50°F

(10°C). Refer to paint manufactures minimum painting

temperature recommendations

27. Replace valves. Also, refer to Maintenance section

section. This is a very rare occurrence, and will not occur if filters

are properly maintained

dried paint from around needle and back of actuator. Replace

actuator and 1/4” nut. Set gun trigger position with trigger

lock in locked orientation (tabs horizontal) by the following

instructions: With one hand holding trigger softly against

lock, use a 1/4” nut driver to turn nut in until trigger starts to

come off the lock, then back off the nut (counterclockwise) 1/2

turn. Pulling the trigger must not open the gun valve when

trigger lock is activated. You should be able to get the actuator

to wiggle slightly with your finger while holding the trigger

against the locked trigger lock.

31. Tighten suction assembly onto inlet valve. Re-prime sprayer. If

problem is not remedied, consult Technical Support

32. Check hydraulic oil level. Add hydraulic oil if necessary (it is

recommended that this be done by a qualified technician).

Check block bolt torque

this be done by a qualified technician.) Refer to Maintenance

Chart concerning torque settings and type of tools required

to reassemble block onto housing. Refill piston with hydraulic

oil. Correct assembly of internal check valve under diaphragm

assembly is critical to proper operation of the pump – refer to

Parts List or contact technical Support

37. Call technical support at 1-800-626-4401

www.chpower.com

22

Page 23

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

“Force Feeding” Pump

To remove trash that has been caught

in the valves, the unit can be force fed.

With pump on and prime/spray knob

turned to “prime” position, pour the

appropriate solvent into the suction

tube and then fold hose as shown

opposite. While firmly squeezing the

suction tube, slide hand down toward

the pump and repeat until pump

primes.

Notes:

• Weather conditions can cause unsatisfactory results when spraying some coatings.

• High humidity prolongs set, and cure times.

• High temperatures decrease set, and cure times.

• Cold temperatures extend set, and cure times.

• Variations in temperature, and humidity can cause variations in finish quality.

• Coating manufacturers can recommend additives to resolve some of these problems, and should be contacted for assistance

with particular problem resolutions.

www.chpower.com

23

Page 24

Operating Instructions and Assembly Instructions

Airless Paint Sprayers

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Paint Application Systems - 3 years. All Paint Spray Guns and

Paint Application Accessories - 1 year.

2. WHO GIVES THIS WARRANTY (WARRANTOR)

Telephone: 1-800-626-4401.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale or rental) of the Campbell

Hausfeld Product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY

paint application accessories supplied or manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects in material and workmanship which occur within the duration of the warranty

period. Warrantor will also cover normal wear items for a period of thirty days from the date of original purchase against defects in

material and workmanship. These wear items are: HVLP-filters, motor brushes, gun packing, gun canister seal, gun check valve and gun air

flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o-rings.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE

OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If standard duty product is used for commercial or industrial purposes, the

warranty will apply for ninety (90) days from the date of original purchase. If product is used for rental purposes, the warranty will

apply for ninety (90) days from the date of original purchase. Some states do not allow limitation on how long an implied warranty

lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE , OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE,

OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions

provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to operate products in

accordance with instructions shall also include the removal or alteration of any safety devices. If such safety devices are removed or

altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or services that are normally required to maintain the product: HVLP-filters, motor brushes, gun packing, gun canister seal, gun

check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o-rings., or any other expendable

part not specifically listed, will only be covered for thirty days from date of original purchase.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are

defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center. Freight

costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and

serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

: Campbell Hausfeld/A Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030,

: All non-compressor driven paint application systems, HVLP spraying systems, and

This Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other rights which vary from

state to state, or country to country.

www.chpower.com

24

Loading...

Loading...