Page 1

This

product

is specifically designed for

compressed air service

ONLY. Use with any other

material (liquid or gas) is a

misapplication and not permitted. Use

or injection of certain hazardous

liquids or gases in the system (such as

oxygen, alcohol or liquid petroleum

gas) will harm the unit and result in a

combustible condition or hazardous

external leakage. Misapplication will

void all warranties and manufacturer’s

responsibilities.

Installation

Disconnect power and

release all pressure from the

system before attempting to

install, service, relocate or

perform any maintenance.

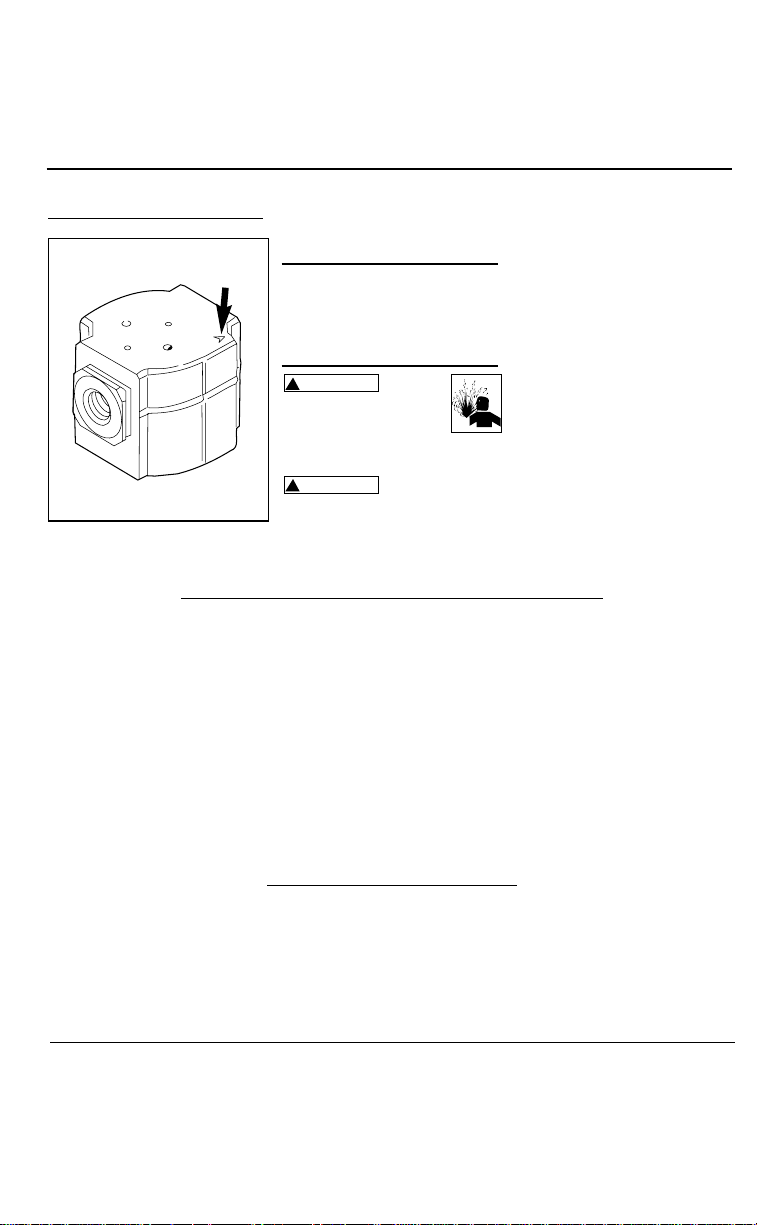

1. Locate the air flow direction arrow

(See Figure 2, detail). This arrow

shows the direction of the air flow,

i.e., it points to the outlet.

2. Securely mount the filter in a

vertical position as close as possible

to air tool connection.

3. Verify the arrow points to the

outlet. (See Figure 2.)

!

WARNING

!

DANGER

General Purpose Filter

Operating Instructions & Parts Manual Model PA212102

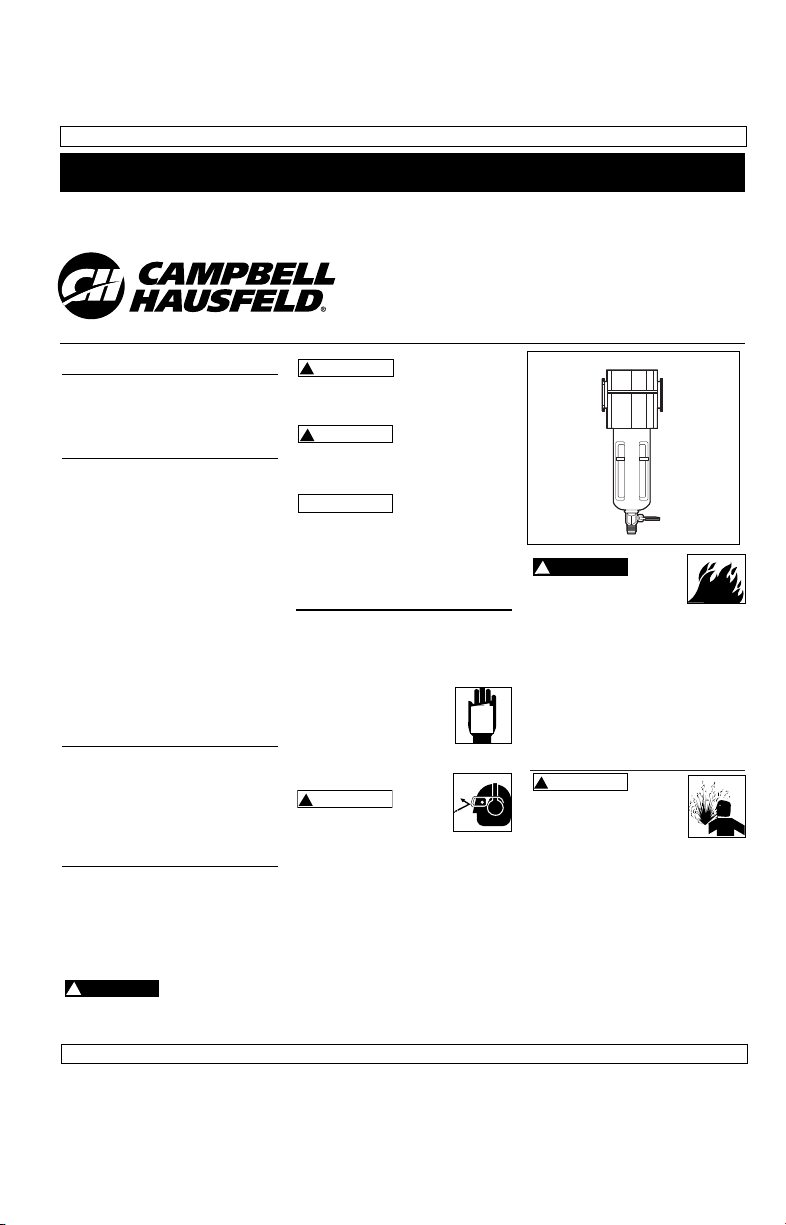

Description

The Campbell Hausfeld general purpose

filter is designed to remove most liquid

and solid particles from the air supply.

Specifications

Average Air Flow . . . . .42.2 SCFM

(Based on 100 psi

inlet pressure with

5 psi drop)

Filter type . . . . . . . . . . . .5 Micron

Body material . . . . . . . .Aluminum

Bowl material . . . . . . . .Polycarbonate

Bowl size . . . . . . . . . . . .100 ml

Max. Temperature . . . .125˚ F (52˚ C)

Max. Pressure . . . . . . . .150 psi

Air Inlet/outlet . . . . . . . .3/8” NPT

Weight . . . . . . . . . . . . . .1.10 lbs

Unpacking

After unpacking the unit, inspect

carefully for any damage that may have

occurred during transit. Make sure to

tighten fittings, bolts, etc., before

putting unit into service.

Safety Guidelines

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following

symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

!

DANGER

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

General Safety

Information

This product is a part of a high pressure

system and the following safety

precautions must be followed at all

times along with any other existing

safety rules.

Read this instruction manual

before installing this device

to the air supply system. Be

thoroughly familiar with

the controls and the proper use of the

equipment.

Safety

glasses

must be worn during

operation.

1. Always work in a well ventilated

area.

2. Do not exceed any pressure rating

of any component in the system.

3. Protect air lines from damage

and/or punctures.

4. Check air hoses for weak or worn

condition before each use. Make

sure all connections are secure.

5. Keep all nuts, bolts and screws tight

and ensure equipment is in safe

working condition.

IN282500AV 11/02

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

For parts, product & service information

visit www.chpower.com

Figure 1

See Warranty on page 4 for important information about commercial use of this product.

© 2002 Campbell Hausfeld/Scott Fetzer

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

BUILT TO LAST

!

WARNING

!

CAUTION

NOTICE

!

WARNING

MANUAL

Page 2

Use Teflon®tape on all threads.

5. Connect the air supply to the inlet

port.

Operation

Before pressurizing system, make

certain the bowl is securely locked in

place by pushing it into the filter body

and turning clockwise to lock.

Maintenance

Release all

pressure before attempting to

install, service, relocate or

perform any maintenance on

the air system. Personal injury

and/or property damage could occur.

Always depress-

urize the unit

before removing the bowl. Personal

injury and/or property damage could

occur. If bowl is difficult to remove, it

may be under pressure.

!

WARNING

!

WARNING

1. Inspect and replace cracked,

damaged or deteriorated seals and

bowls. Wipe bowls with a soft, dry

cloth to clean.

2. Replace or clean filter element

periodically. Remove the filter

element and tap filter on a hard

surface or use an air gun to blow

out residual dirt.

3. Drain bowls at least once per work

shift. To avoid spray or splatter,

cover bottom of filter with a cloth

and turn the manual drain.

4. Before placing the unit in service,

make sure the bowl is reinstalled

and securely locked in place.

Technical Service

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

Installation

(Continued)

4. Install the unit with the same pipe

size as the piping in use. Avoid

using unnecessary fittings,

couplings, etc., that restrict airflow.

2

General Purpose Filter Model PA212102

Atlas "Perma-Guard"

Buna N

Cellulube #150 and #220

Crylex #5 cement

* Eastman 910

Garlock #98403 (polyurethane)

Haskel #568-023

Hilgard Co.'s hil phene

Houghton & Co. oil #1120, #1130 and #1055

Houtosafe 1000

Kano Kroil

Keystone penetrating oil #2

*Loctite 271

*Loctite 290

*Loctite 601

*Loctite Teflon-Sealant

Marvel Mystery Oil

Minn Rubber 366Y

National Compound #N11

"Nylock" VC-3

Parco #1306 Neoprene

*Permabond 910

Petron PD287

Prestone

Pydraul AC

Sears Regular Motor Oil

Sinclair oil "Lily White"

Stauffer Chemical FYRQUEL #150

Stillman #SR 269-75 (polyurethane)

Stillman #SR 513-70 (neoprene)

Tannergas

Telar

Tenneco andrerol #495 & #500 oils

Titon

*Vibra-tite

Zerex

*When in raw liquid form.

Acetaldehyde

Acetic acid (concentrated)

Acetone

Acrylonitrile

Ammonia

Ammonium flouride

Ammonium hydroxide

Ammonium sulfide

Anaerobic adhesives & sealants

Antifreeze

Benzene

Benzoic acid

Benzyl alcohol

Brake fluids

Bromobenzene

Butyric acid

Carbolic acid

Carbon disulfide

Carbon tetrachloride

Caustic potash solution

Caustic soda solution

Chlorobenzene

Chloroform

Cresol

Cyclohexanol

Cylohexanone

Cyclohexene

Dimethyl formamide

Dioxane

Ethane tetrachloride

Ethyl acetate

Ethyl ether

Ethylamine

Ethylene chlorohydrin

Ethylene dichloride

Ethylene glycol

Formic acid (concentrated)

Freon (refrig. & propell.)

Gasoline (high aromatic)

Hydrazine

Hydrochloric acid (concentrated)

Lacquer thinner

Methyl alcohol

Methylene chloride

Methylene salicylate

Mike of lime (CaOH)

Nitric acid (concentrated)

Nitrobenzene

Nitrocellulose lacquer

Phenol

Phosphorous hydroxy chloride

Phosphorous trichloride

Phopionic acid

Pyridine

Sodium hydroxide

Sodium sulfide

Styrene

Sulfuric acid (concentrated)

Sulphural chloride

Tetrahydronaphthalene

Tiophene

Toluene

Turpentine

Xylene

Perchlorethylene and others

MATERIALS THAT ATTACK POLYCARBONATE PLASTIC (PARTIAL LISTING)

TRADE NAMES OF ATTACKING MATERIALS

Flow

direction

arrow

Figure 2 Detail showing location of

flow direction arrow

www.chpower.com

Page 3

General Purpose Filter Model PA212102

For Replacement Parts, call 1-800-543-6400

Address parts correspondence to:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Please provide following information:

- Model number

- Serial Number (if applicable)

- Part description and number as shown

in parts list

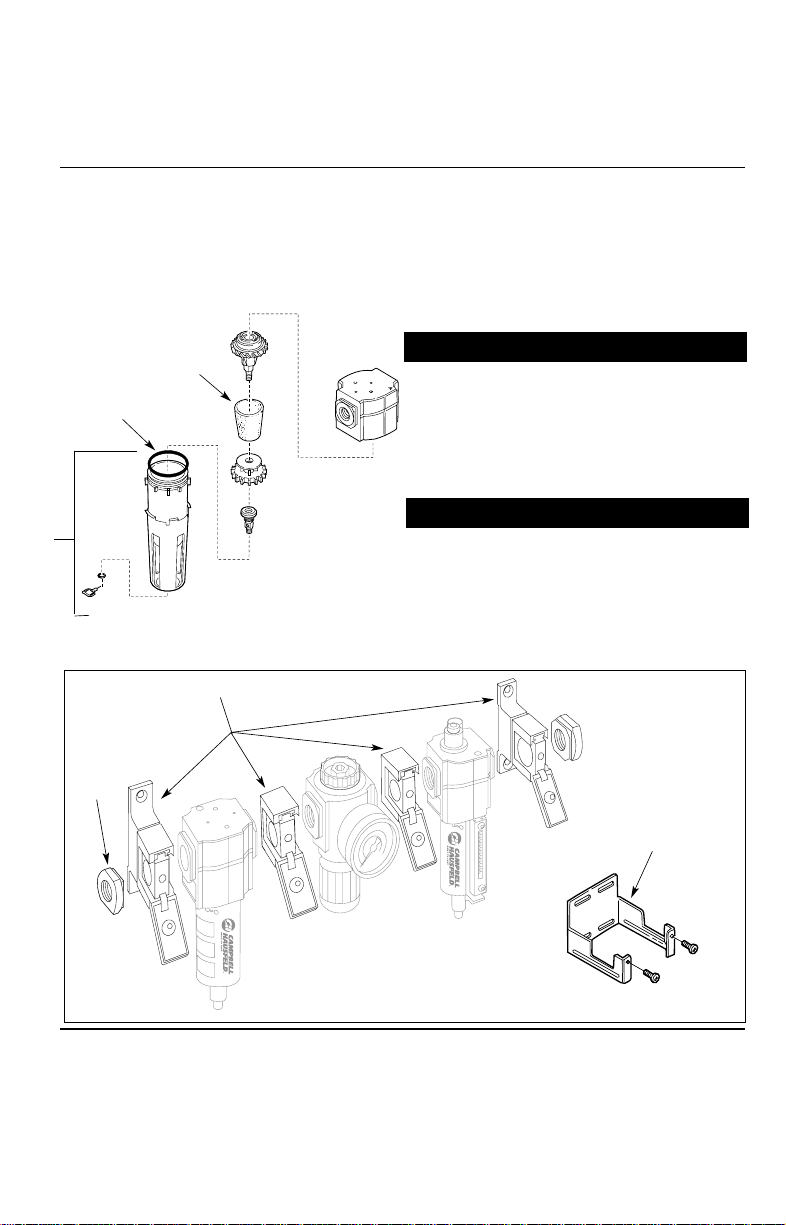

Replacement Parts List

1 Filter element ●, ■ 1

2 Bowl o-ring ■ 1

3 Polycarbonate Bowl SV040800AV 1

■ Filter element kit SX129100AV 1

● Replacement filter elements PA116500AV 2

Ref. Part

No. Description Number Qty.

Figure 3

3

2

3

1

Optional Parts List*

Ref. Part

No. Description Number Qty.

4 Modular Bracket PA117600AV 1

5 Wall Bracket PA117500AV 1

6 Metal Replacement Bowl SV040700AV 1

7 1/4” Modular Pipe Adapter BC411900AV 1

8 3/8” Modular Pipe Adapter BC412000AV 1

9 1/2” Modular Pipe Adapter BC412100AV 1

*Sold separately

7, 8, & 9

4

5

www.chpower.com

Page 4

4

General Purpose Filter Model PA212102

www.chpower.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Products - One Year, Serious

Duty Products - Two Years, Extreme Duty Products - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun,

inflator or air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED

FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial,

industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States

do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance

with instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or

failure to operate products in accordance with instructions shall also include the removal or alteration of any safety

devices. If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shields,

driver blades

, fuses, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants,

material hoses, filter elements, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters,

collets, chucks, rivet jaws, screw driver bits

, sanding pads, back-up pads, impact mechanism, or any other

expendable part not specifically listed. These items will only be covered for ninety (90) days from date of original

purchase. Underlined items are warranted for defects in material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability

of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may

also have other rights which vary from state to state or country to country.

Page 5

5. S’assurer que tous les écrous,

boulons et vis soient bien serrés et

que l’équipement soit en bon état.

Ce produit est fabriqué pour

le service d’air comprimé

SEULEMENT. L’utilisation

avec n’importe quel autre matériel

(liquide ou gaz) est une application

incorrecte interdite. L’utilisation ou

l’injection de certains liquides ou gaz

dans le système (tel que l’oxygène,

l’alcool ou le pétrole) endommagera le

modèle et causera une situation

combustible ou une fuite externe

0hasardeuse. Les applications

incorrectes annuleront toutes garanties

et responsabilités du fabricant.

Installation

non-industrielles.

Débrancher la source de

alimentation et dissiper

toute la pression du système

avant d’essayer de monter, de déplacer

ou de procéder au service ou à

l’entretien.

1. Trouver la flèche indiquant la

direction du débit (Voir Figure 2,

détail). Cette flèche indique la

direction de la circulation d’air donc

elle pointe vers la sortie.

Filtre Tous Usages

Instructions d’Utilisation et Manuel de Pièces de Rechange Modèle PA212102

Description

Le filtre tous usages Campbell Hausfeld

est conçu pour retirer la plupart des

particules solides et liquides de la

source d’alimentation d’air.

Spécifications

Débit d'air moyen . . . .1,2 m3/min

(Basé sur une

pression d'arrivée

de 690 kPa avec

une perte de 34,5

kPa)

Type de filtre . . . . . . . . .5 Microns

Matériel de corps . . . . .Aluminium

Matériel de bol . . . . . . .Polycarbonate

Taille de bol . . . . . . . . . .100 ml

Température Max . . . .52˚ C (125˚ F)

Pression Max . . . . . . . . .1034 kPa

Arrivée/sortie d'air . . . .3/8 po NPT

Poids . . . . . . . . . . . . . . . .49,9 g

Déballage

Lors du déballage du modèle,

l’examiner soigneusement pour

rechercher toute trace de dommage

susceptible de s’être produit en cours

de transport. S’assurer de serrer tous les

raccords, boulons, etc., avant de mettre

le modèle en marche.

Directives de

Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger

indique

un situation hasardeuse imminente qui

RÉSULTERA en perte de vie ou blessures

graves.

Avertissement

indique une situation hasardeuse

potentielle qui PEUT résulter en perte

de vie ou blessures graves.

Attention

indique

une

situation hasardeuse potentielle qui

PEUT résulter en blessures.

Avis

indique

l’information importante pour éviter le

dommage de l’équipement.

Généralités sur la

Sécurité

Ce produit fait partie d’un système de

haute pression. Il est nécessaire de

respecter les précautions de sécurité

suivantes ainsi que tous les règlements

de sécurité en vigueur.

Lire ce manuel d’instructions

avant le montage de cet

appareil au système d’air. Se

familiariser avec toutes les

commandes et avec

l’utilisation correcte de l’équipement.

Des lunettes de sécurité

doivent être utilisées

pendant le fonctionnement.

1. Toujours travaillez dans un endroit

bien ventilé.

2. Ne pas dépasser la classification de

pression de n’importe quelle pièce

détachée du système.

3. Protéger les canalisations d’air

contre le dommage et/ou la

perforation.

4. Vérifier les tuyaux à air pour la

faiblesse ou l’usure avant chaque

usage. S’assurer que tous les

raccords soient bien fixés.

IN282500AV 11/02

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

5 Fr

Figure 1

Voir la Garantie à la page 8 pour de l’information importante sur l’utilisation commercial de ce produit.

© 2002 Campbell Hausfeld/Scott Fetzer

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

BUILT TO LAST

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

AVIS

!

AVERTISSEMENT

MANUEL

!

DANGER

!

AVERTISSEMENT

Page 6

l’utilisation des raccords,

accouplements, etc. inutiles qui

peuvent limiter la circulation d’air.

Utilisez le ruban Teflon

®

pour tous

les filets.

5. Brancher la source d’air à l’orifice

d’arrivée

Fonctionnement

Avant de pressuriser le système ,

s’assurer que le bol est bien verrouillé

en place en le poussant dans le corps

du filtre et en tournant dans le sens des

aiguilles d’une montre pour verrouiller.

Entretien

Dissiper toute la pression

avant d’essayer de monter,

de déplacer ou de procéder

au service ou à l’entretien du système

d’air. Sinon, vous risquerez des

blessures personnelles et/ou dégâts

matériaux.

Toujours

dépressuriser le modèle avant d’enlever le bol

afin d’éviter des blessures personnelles

et/ou dégâts matériaux. Le bol peut

être sous pression s’il est difficile à

enlever.

1. Vérifier et remplacer les joints et

bols fendus, endommagés ou usés.

Essuyer les bols avec un chiffon

propre et sec.

2. Remplacer ou nettoyer la

cartouche filtrante

périodiquement. Enlever la

cartouche filtrante et la frapper

légèrement sur une surface dure

ou utiliser un pistolet à air

comprimé pour y souffler la saleté.

3. Vidanger les bols au moins une fois

par quart de travail. Pour éviter

toute aspersion ou vaporisation,

couvrir le bas du filtre d’un chiffon

et tourner le drain manuel.

4. Installer le bol à nouveau et

s’assurer qu’il soit verrouillé avec

sûreté avant de mettre le modèle

en service.

Service Technique

Pour de l’information concernant le

fonctionnement ou la réparation de ce

produit, s’il vous plaît composer 1-800543-6400.

Installation (Suite)

2. Bien monter le filtre en position

verticale aussi près que possible de

la connexion de l’outil

pneumatique.

3. Vérifier que la flèche pointe vers la

sortie.

(Voir la figure 2.)

4. Utiliser la tuyauterie de même taille

que celle présente pendant

l’installation du modèle. Éviter

6Fr

Filtre Tous Usages Modèle PA212102

Acetaldéhyde

Acide Acétique

(concentré)

Acétone

Acrylonitrile

Ammoniaque

Fluorure d’ammonium

Ammoniaque

Sulfure d’ammonium

Adhésifs et agents

d’étanchéité anaérobie

Antigel

Benzène

Acide Benzoïque

Benzyl alcool

Liquides pour freins

Bromobenzène

Acide Butyrique

Acide Carbolique

Bisulfure de carbone

Tetrachlorure de carbone

Solution de potasse

caustique

Solution de soude

caustique

Chlorobenzène

Chloroforme

Crésol

Cyclohexanol

Cylohexanone

Cyclohexène

Diméthyl formamide

MARQUES DE MATÉRIAUX QUI ATTAQUENT

MATÉRIAUX QUI ATTAQUENT LE PLASTIQUE POLYCARBONATE (LISTE PARTIELLE)

Dioxane

Éthane tetrachloride

Acétate d’Éthyl

Éther d’Éthyl

Éthylamine

Éthylène chlorohydrine

Bichlorure d’Éthylène

Éthylène glycol

Acide Formique

(concentré)

Freon (refrig. & propul.)

Essence (très aromatique)

Hydrazine

Acide Hydrochlorique

(concentré)

Diluant de laque

Alcool méthylique

Chloride de Méthylène

Salicylate de Méthylène

Mike of lime (CaOH)

Acide Nitrique

(concentré)

Nitrobenzène

Laque Nitrocellulose

Phénol

Hydroxy chloride

Phosphoreux

Trichloride Phosphoreux

Acide Phopionic

Pyridine

Hydrate de Soude

Sulfure de Soude

Styrène

Acide Sulfurique

(concentré)

Chloride Sulphureux

Tetrahydronaphthalène

Tiophène

Toluène

Térébenthine

Xylène

Perchloréthylene et autres

Atlas "Perma-Guard"

Buna N

Cellulube #150 et #220

Ciment Crylex #5

* Eastman 910

Garlock #98403

(polyuréthane)

Haskel #568-023

Hilgard Co.'s hil phene

Huile Houghton & Co.

#1120, #1130 et #1055

Houtosafe 1000

Kano Kroil

Huile de décapage

Keystone #2

*Loctite 271

*Loctite 290

*Loctite 601

*Loctite Téflon-Agent

d’étanchéité

Huile Marvel Mystery Oil

Minn Rubber 366Y

National Compound #N11

"Nylock" VC-3

Parco #1306 Neoprene

*Permabond 910

Petron PD287

Prestone

Pydraul AC

Huile Sears Regular

Motor Oil

Huile Sinclair "Lily White"

Stauffer Chemical

FYRQUEL #150

Stillman #SR 269-75 (polyuréthane)

Stillman #SR 513-70

(néoprène)

Tannergas

Telar

Huile Tenneco andrerol

#495 & #500

Titon

*Vibra-tite

Zerex

*Si en forme brut liquide.

Flèche de

débit d’air

Figure 2 Détail illustrant

l’emplacement de la flèche de débit

d’air

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 7

7Fr

Filtre Tous Usages Modèle PA212102

Pour Pièces de Rechange, appeler 1-800-543-6400

Correspondance:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, Ohio 45030 U.S.A.

S’il vous plaît fournir l’information

suivante:

- Numéro de modèle

- Numéro de Série (si présent)

- Description et numéro de la pièce

Liste de Piecès de Rechange

1 Élément du filtre ●, ■ 1

2 Joint torique du bol ■ 1

3 Bol de polycarbonate SV040800AV 1

■ Kit d’élément du filtre SX129100AV 1

● Éléments du filtre de rechange PA116500AV 2

Nº Numéro

Réf. Description de Pièce Qté.

2

3

1

7, 8, & 9

4

5

Figure 3

Liste de Pièces en Option*

4 Fixation modulaire PA117600AV 1

5 Fixation murale PA117500AV 1

6 Bol de métal de rehcange SV040700AV 1

7

Adaptateur modulaire de tuyau 1/4 po

BC411900AV 1

8

Adaptateur modulaire de tuyau 3/8 po

BC412000AV 1

9

Adaptateur modulaire de tuyau1/2 po

BC412100AV 1

*Vendu séparément

Nº Numéro

Réf. Description de Pièce Qté.

Page 8

8Fr

Filtre Tous Usages Modèle PA212102

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Produits À Service Standard (Standard Duty) - Un

An, Produits À Service Sérieux (Serious Duty) - Deux Ans, Produits À Service Extrême (Extreme Duty) - Trois Ans.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio,

45030, Téléphone: (800) 543-6400

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit Campbell

Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tous les outils de fixation (cloueuses et agrafeuses), outils pneumatiques,

pistolets vaporisateurs, gonfleurs ou accessoires pneumatiques Campbell Hausfeld qui sont fournis par ou fabriqués par

le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables qui se révèlent pendant la

période de validité de la garantie.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE

SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce

produit est utilisé pour une fonction commerciale, industrielle ou pour la location, la durée de la garantie sera

quatre-vingt-dix (90) jours à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de

durée pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas

l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou exclusion précédente peut donc ne

pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant

pas les instructions données dans le(s) manuel(s) accompagnant le produit. Un accident, l’utilisation abusive par

l’acheteur, la négligence ou le manque de faire fonctionner les produits selon les instructions comprend aussi

l’enlevage ou la modification de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou

modifiés, la garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

E. Articles ou services qui sont exigés pour l'entretien du produit; Joints torique, ressorts, amortisseurs, écrans de

débris, lames d'entraînement

, fusibles, batteries, joints d'étanchéité, garnitures ou joints, buses de fluide, aiguilles,

buses de sablage

, graisses, tuyaux de matériaux, cartouches filtrantes, pales de moteur, abrasifs, lames, meules de

coupage, burins, fixe-burins, coupeuses, douilles de serrage, mandrins. mâchoires de rivet, lames de tournevis,

tampons de sablage

, tampons de sauvegarde, mécanisme de percussion ou toute pièce qui n’est pas indispensable

et qui n’est pas indiquée. Ces articles seront couverts pour quatre-vingt-dix (90) jours à partir de la date d'achat

original. Les articles soulignés sont garanties pour défauts de matière et de fabrication seulement

.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du Garant, des

produits ou pièces qui se sont révélés défectueux pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Campbell Hausfeld au Centre De Service Autorisé Campbell

Hausfeld. Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE: La réparation

ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la

disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis.

L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

Page 9

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

4. Chequée las mangueras de aire a ver

si están debilitadas o desgastadas

antes de cada uso. Cerciórese de que

todas las condiciones estén bien

apretadas.

5. Mantenga todas las tuercas, pernos y

tornillos bien apretados y cerciórese

de que el equipo esté en buenas

condiciones funcionar.

Este producto está diseñado

específicamente para

sistemas de aire comprimido

SOLAMENTE. El usarlo con otros

materiales (líquidos o gases) no es

adecuado y no está permitido. El uso o

la inyección de ciertos líquidos o gases

peligrosos en el sistema (tales como

oxigeno, alcohol o gas líquido de

petroleo) dañará la unidad y

ocasionará una condición combustible

o fuga externa peligrosa. El uso

inadecuado cancelará todas las

garantías y responsabilidades civiles

del fabricante.

Instalación

Desconecte la unidad y libere

toda la presión del sistema

antes de tratar de instalar,

darle servicio, reubicar o

Filtro de Uso General

Manual de Instrucciones y Lista de Repuestos Modelo PA212102

Descripción

Los filtros de uso general están

diseñados para eliminar la mayoría de

residuos de líquidos y partículas sólidas

de las líneas de suministro de aire a

presiones máximas de 10,34 bar. Este

filtro puede utilizarse también en una

instalación permanente en línea.

Especificaciones

Flujo de aire

promedio . . . . . . . . . . . . . . .1,2 m

3

/min

(En base a una presión

de entrada de 6,90 bar

con una caída de

presión de 0,35 bar)

Tipo de filtro . . . . . . . . . . . .5 Micrones

Material del cuerpo . . . . . .Aluminio

Material del envase . . . . . .Policarbonato

Capacidad del envase . . . .100 ml

Temperatura Máx . . . . . . .52˚ C (125˚ F)

Presión Máx . . . . . . . . . . . . .10,34 bar

Entrada/Salida . . . . . . . . . .9,5 mm (3/8”)

de Aire NPT

Peso . . . . . . . . . . . . . . . . . . . .49,9 g

Desempaque

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Cericiórese de

apretar todas las conexiones, pernos,

etc. antes de comenzar a utilizar la

unidad.

Medidas de Seguridad

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le

indica que hay una situación de peligro

inmediato, que si no la evita, le

ocasionará la muerte o heridas de

gravedad.

Ésto le

indica que

hay una situación, que si no la evita,

podría ocasionará la muerte o heridas

de gravedad.

Ésto le

indica

que hay una situación que podría

ocasionarle heridas no muy graves.

Ésto le

indica una información importante, que

de no seguirla, le podría ocasionará

daños al equipo.

Informaciones

Generales de

Seguridad

Este producto es parte de un sistema de

alta presión y siempre debe seguir las

siguientes medidas de seguridad al

igual que otras medidas de seguridad

establecidas.

Lea este manual de

instrucciones antes de

instalar esta unidad en el

sistema de suministro de

aire. Familiarícese con los

controles y el uso adecuado del equipo.

Siempre debe usar anteojos

de seguridad para operar la

unidad.

1. Siempre trabaje en áreas bien

ventiladas.

2. No exceda la presión indicada para

ninguno de los componentes del

sistema.

3. Proteja todas las líneas de aire contra

daños o rupturas.

IN282500AV 11/02

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

9 Sp

Figura 1

Ver la Garantía en página 12 para información importante sobre el uso comercial de este producto.

© 2002 Campbell Hausfeld/Scott Fetzer

BUILT TO LAST

!

PELIGRO

!

ADVERTENCIA

!

PRECAUCION

AVISO

!

ADVERTENCIA

MANUAL

!

PELIGRO

!

ADVERTENCIA

Page 10

3. Verifique que la flecha apunte

hacia la salida

(Vea Fig. 2).

4. Instale la unidad con tuberías del

mismo tamaño de las usadas. Evite

usar conectores, acopladores, etc

adicionales que pudiesen restringir

el flujo de aire. Use la cinta de

Teflón

®

en todas las roscas.

5. Conecte el suministro de aire al

orificio de entrada.

Funcionamiento

Antes de presurizar el sistema,

asegúrese de que el recipiente esté

trabado con seguridad en su lugar

empujándolo dentro del cuerpo del

filtro y girando hacia la derecha para

trabarlo a la presión deseada.

Mantenimiento

Libere toda la presión del

sistema antes de tratar de

instalar, darle servicio, reubicar

o darle cualquier tipo de

mantenimiento al sistema de aire. De no

hacerlo podría ocasionarle heridas

personales o daños a su propiedad.

Siempre

libere

toda la presión de la unidad antes de

desconectar el envase. De no hacerlo

podría ocasionarle heridas personales o

daños a su propiedad. Si tiene dificultad

para desconectar el envase, éste podría

estar bajo presión.

1. Inspeccione los sellos y envases y

reemplace aquellos que estén rotos,

dañados o deteriorados. Limpie los

envases con un trapo suave y seco.

2. Periódicamente reemplace o limpie

el elemento del filtro. Saque el

elemento del filtro y golpéelo contra

una superficie dura o use una pistola

neumática para eliminar los residuos

de impurezas.

3. Drene los envases por lo menos una

vez durante un turno de trabajo.

Para evitar salpicaduras, cubra el

fondo del filtro con un trapo y gire el

drenaje manual.

4. Antes de comenzar a utilizar la

unidad, cerciórese de que el envase

esté bien instalado y asegurado.

Servicio Técnico

Para mayor información sobre el

funcionamiento o reparación de este

producto, comuníquese al 1-800-543-

6400.

!

Instalación

(Continuación)

darle cualquier tipo de mantenimiento.

1. Ubique la flecha de dirección de

flujo (Vea Figura 2). Esta flecha

muestra la dirección del flujo de

aire, o sea, apunta hacia la salida.

2. Monte en forma segura el filtro en

posición vertical lo más cercano

posible a la conexión de la

herramienta neumática.

10 Sp

Filtro de Uso General Modelo PA212102

MATERIALES DAÑINOS PARA EL PLASTICO POLICARBONATO (LISTA PARCIAL)

MARCAS DE PRODUCTOS DAÑIMOS PARA EL PLASTICO POLICARBONATO*

Acetaldehído

Ácido acético (concentrado)

Acetona

Acrylonitrilo

Amoniaco

Floruro de amonio

Hidróxido de amonio

Sulfuro de amonio

Adhesivos & selladores

anaeróbicos

Anticongelantes

Benceno

Ácido benzoico

Alcohol bencílico

Fluídos para frenos

Bromobenceno

Ácido butírico

Ácido carbólico

Disulfuro de carbón

Tetracloruro de carbón

Solución cáustica de potasa

Solución cáustica de sodio

Clorobenceno

Cloroformo

Creosol

Ciclohexanol

Ciclohexanona

Ciclohexeno

Formamida de dimetila

Dioxano

Tetracloruro de etano

Acetato de etilo

Éter etílico

Etilaminas

Clorhidrina etilénica

Dicloruro etilénico

Etilenoglicol

Ácido fórmico

(concentrado)

Freón (refrig. & propel.)

Gasolina (muy aromática)

Hidracine

Ácido hidroclorhídrico

(concentrado)

Thinner para lacas

Alcohol metílico

Cloruro de metileno

Metileno salicílico

CaOH

Ácido nítrico (concentrado)

Nitrobenceno

Lacas Nitrocelulosas

Fenol

Cloruro hidróxido de

fósforo

Tricloruro de fósforo

Ácido fopiónico

Piridina

Hidróxido de sodio

Sulfuro de sodio

Estireno

Ácido sulfúrico

(concentrado)

Cloruro de azufre

Tetrahidronaftalina

Tiofena

Tolueno

Terpentina

Xileno

Percloretileno y otros

Atlas "Perma-Guard"

Buna N

Cellulube #150 y #220

Cemento Crylex #5

* Eastman 910

Garlock #98403

(poliuretano)

Haskel #568-023

Hilgard Co.'s hil phene

Aceite Houghton & Co.

#1120, #1130 y #1055

Houtosafe 1000

Kano Kroil

Aceite penetrante

Keystone #2

*Loctite 271

*Loctite 290

*Loctite 601

*Sellador de teflón Loctite

Aceite Marvel Mystery

Minn Rubber 366Y

National Compound #N11

"Nylock" VC-3

Parco #1306 Neoprene

*Permabond 910

Petron PD287

Prestone

Pydraul AC

Aceite regular para

motores marca Sears

Sinclair oil "Lily White"

Stauffer Chemical

FYRQUEL #150

Stillman #SR 269-75 (poliuretano)

Stillman #SR 513-70

(neoprene)

Tannergas

Telar

Aceites Tenneco andrerol

#495 & #500

Titon

*Vibra-tite

Zerex

*En forma líquida sin

procesar.

*ESTAS MARCAS DE PRODUCTOS NORTEAMERICANOS TAL VEZ NO ESTEN DISPONIBLES EN PAISES LATINOAMERICANOS

LE RECOMENDAMOS CERCIORARSE DE SI UN QUIMICO ES DAÑINO PARA ESTE FILTRO ANTES DE PONERLO EN CONTACTO.

Flecha de

dirección de flujo

Figura 2 Detalle mostrando

ubicación de la flecha de dirección

de flujo

ADVERTENCIA

!

ADVERTENCIA

Page 11

11 Sp

Filtro de Uso General Modelo PA212102

Para Ordenar Repuestos, Sírvase Llamar al Concesionario

más Cercano a su Domicilio

Lista de Repuestos

1 Elemento del filtro ●, ■ 1

2 Aro tórico del envase ■ 1

3 Recipiente de policarbonato SV040800AV 1

■ Kit del elemento del filtro SX129100AV 1

● Elementos de repuesto del filtro PA116510AV 2

No. de

Ref. Descripción Repuesto Ctd.

Puede escribirnos a:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

Sirvase darnos la siguiente información:

- Número del modelo

- Número de Serie o código con fecha (de haberlo)

- Descripción y número del repuesto según la lista

de repuestos

2

3

1

7, 8, & 9

4

5

Figura 3

Lista de Repuestos Opcionales*

4 Ménsula modular PA117600AV 1

5 Ménsula para pared PA117500AV 1

6 Recipiente de repuesto de metal SV040700AV 1

7 Adaptador modular de tubería de

6,4 mm (1/4”) BC411900AV 1

8 Adaptador modular de tubería de

9,5 mm (3/8”) BC412000AV 1

9 Adaptador modular de tubería de

12,7 mm (1/2”) BC412100AV 1

*Se vende por separado

No. de

Ref. Descripción Repuesto Ctd.

Page 12

!

WARNING

!

DANGER

!

DANGER

Filtro de Uso General Modelo PA212102

Garantía Limitada

1 DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a continuación: Productos

Estándard (Standard Duty) - Un año, Productos Resistentes (Serious Duty) -Dos años, Productos Robustos (Extreme Duty)

- Tres años.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100 Production Drive,

Harrison, Ohio 45030 Teléfono: (800) 543-6400

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor) del producto

Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Cualquier clavadora, grapadora, herramienta neumática, pistola

pulverizadora, inflador o accesorio neumático suministrado o fabricado por el Garante.

5. COBERTURA DE LA GARANTIA: Los defectos substanciales de material y fabricación que ocurran dentro del período de

validez de la garantía.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES PARTICULARES, ESTAN

LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. Si este producto es empleado para uso comercial,

industrial o para renta, la garantía será aplicable por noventa (90) días a partir de la fecha de compra. En algunos

estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos esta

limitación no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE UN DEFECTO,

FALLA O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En algunos estados no se permite la

exclusión o limitación de daños incidentales o consecuentes, por lo tanto, en tales casos esta limitación o exclusión

no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones de

funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al producto. Dichos accidentes, abusos por

parte del comprador, o falta de operar el producto siguiendo las instrucciones del manual de instrucciones

suministrado también debe incluir la desconexión o modificación de los instrumentos de seguridad. Si dichos

instrumentos de seguridad son desconectados, la garantía quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

E. Artículos o servicios normalmente requeridos para el mantenimiento del producto, tales como: anillos en O,

resortes, amortiguadores, defensas, hojas de impulsor

, fusibles, baterías, empaques, almohadillas o sellos, boquillas

de fluído, agujas, boquillas para rociar arena

, lubricantes, mangueras de material, elementos filtrantes, álabes de

motores, abrasivos, hojillas, discos para cortar, cinceles, retenes para cinceles, cortadores, collarines, mandriles,

mordazas para remachadoras, brocas para desarmadores

, almohadillas para lijar, soportes de almohadillas,

mecanismo de impacto

o cualquier otro artículo desgastable que no se haya enumerado específicamente. Estos

artículos sólo estarán cubiertos bajo esta garantía por noventa (90) días a partir de la fecha de compra original. Los

artículos subrayados sólo están garantizados por defectos de material o fabricación.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Reparar o reemplazar, como lo decida el Garante, los

productos o componentes que estén defectuosos, se hayan dañado o hayan dejado de funcionar adecuadamente,

durante el período de validez de la garantía

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Entregar o enviar el producto o componente Campbell Hausfeld al Centro de Servicio autorizado Campbell Hausfeld

más cercano. Los gastos de flete, de haberlos, deben ser pagados por el comprador.

C. Seguir las instrucciones sobre operación y mantenimiento del producto, tal como se indica(n) en el (los) manual(es)

del propietario

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO BAJO ESTA GARANTIA: La reparación o

reemplazo dependerá del flujo normal de trabajo del centro de servicio y de la disponibilidad de repuestos.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos. Usted también

puede tener otros derechos que varían de un Estado a otro. o de un país a otro.

Loading...

Loading...