Page 1

95% THERMAL

EFFICIENCY

500, 625, 725,

800 MBH

MULTIPLE

VENTING OPTIONS

UP TO 200

EQUIVALENT FEET

NEGATIVE

PRESSURE

CABINET

5:1 MODULATION

Apex™ Series

STAINLESS STEEL, CONDENSING,

GAS-FIRED COMMERCIAL BOILER

EQUIPPED WITH ABC 2.1

CONTROL SYSTEM

- MULTIPLE BOILER LEAD/LAG

UP TO 8 BOILERS

- LCD TOUCHSCREEN DISPLAY

- INTUITIVE TEXT-BASED MENUS

- OUTDOOR RESET

RELIEF VALVE

UP TO 100PSI

SUB 20PPM NOx

STACKABLE

Low

NOx

Page 2

2

PAG E

Apex Boiler FEATURES

High Performance Commercial Hydronic

and Radiant Heating

Introducing the Apex from Burnham Commercial, a condensing

boiler with thermal eciency ratings of 95%. The Apex utilizes a

stainless steel heat exchanger, designed to extract maximum heat

from the combustion process, along with the Apex Boiler Control

System which is designed to enhance boiler and system eciency

and provide easy installation and servicing. These intelligent

features are wrapped in a sleek, modern appliance-like jacket,

which makes the Apex both attractive and smart.

Stainless Steel Heat Exchanger

The heart of the Apex

boiler is the ASME-certied

stainless steel heat

exchanger. Each heat

exchanger is factory

hydro-tested to ensure

quality and reliability.

• FLEXIBILITY OF VENTING OPTIONS

The ability to vent by using PVC material provides

multiple venting options and enables a greater level

of choice concerning the layout of a boiler room. Apex

boilers can be vented horizontally with a sidewall

penetration, or vertically. In addition to PVC, the Apex

can be vented with concentric polypropylene (500 model

only), AL29-4C stainless steel piping or with single wall

rigid and/or exible polypropylene vent piping.

The Apex Boiler Control System

The Apex Boiler Control System (ABC System) has many features

which maximize the eciency and comfort of a heating system,

while providing unmatched ease of use (for a full description of

these features, please see pages 4–5).

• LCD touchscreen display

• Intuitive menus which provide data in simple text,

not in cryptic codes

• Capable of linking up to eight boilers and three pumps

simultaneously

• Control data logging

• Outdoor reset and warm weather shutdown

• Domestic hot water priority

• Full modulation with 5-to-1 turndown and adaptable

ring rate output

• Built in provision for o-season pump exercising

• Plug and play connections

• Multiple and adjustable pump outputs

• Night setback and unoccupied modes

• 4–20mA and modbus inputs

• EMS Gateway to BacNet, LonWorks®, Modbus (optional)

Page 3

3

PAG E

Apex Boiler FEATURES

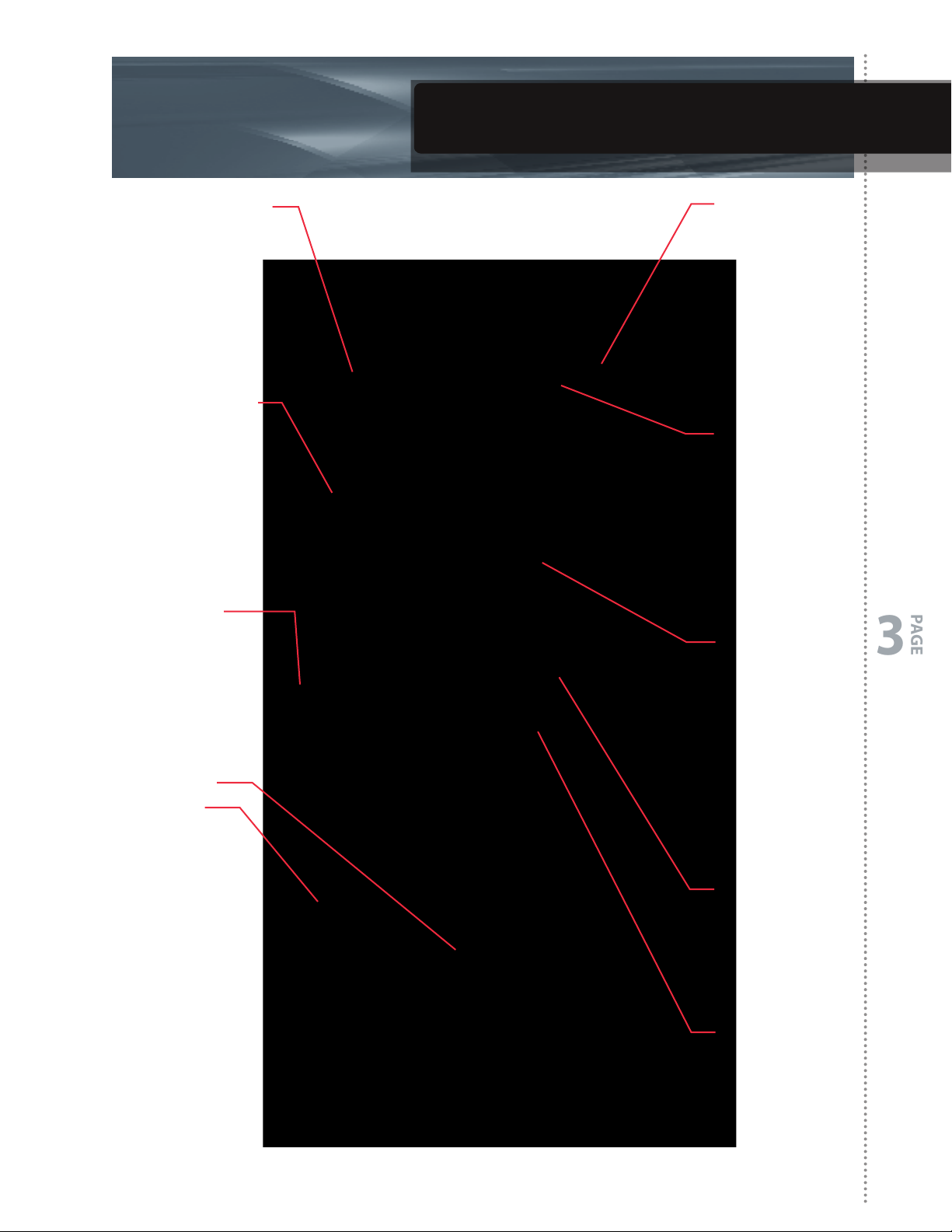

Single Point Power

Boiler pump and DHW

pump are powered

directly from the Apex

Sealed Combustion

with Negative

Cabinet Pressure

Lower portion of the

boiler cabinet operates

under a negative pressure,

creating an additional

layer of safety

Simple

Connections

All gas, water and

electrical connections

are made from the left

side of the boiler

Condensate

Protection

Unique polyproplyene

condensate trap

(patented) stands up to

acidic condensate and

features an integral oat

switch which protects

the heat exchanger from

condensate back-up

Sealed

Top Panel

The sealed top panel

protects boiler controls

from spills or leaks; the

components are also

isolated from the lower

jacket to protect them

from cold or moist

combustion air

Smart Controls

ABC 2.1 control

system oers multiple

boiler lead/lag for up

to eight (8) boilers,

LCD touchscreen

display, intuitive

text-based menus

and outdoor reset

Ecient

Combustion

Air and fuel are

pre-mixed in the

blower assembly

for clean, balanced

combustion, longer

component life

and protection of

mechanical fan

components

Design

Simplicity

Separate spark rod

and ame sensor are

used for longevity

and reliability

Durable,

Ecient

Stainless Steel

Heat Exchanger

Maximizes

heat transfer

Page 4

4

PAG E

Apex Boiler Control FEATURES BEYOND COMPARE

The Apex Boiler Control System is the next generation

of advanced electronic controls designed specically

for condensing boilers. The ABC System was designed

with many features that make the control simple to

understand and use, as well as features that optimize

boiler performance, exibility and overall system

eciency and reliability. The ABC System is simply

the most powerful, versatile and user-friendly boiler

control available.

Touch Screen LCD Display

• Simple setup! Requires only four inputs (boiler

minimum and maximum water temperatures and

outdoor air minimum and maximum temperatures).

• Boiler status, settings and diagnostic information

are all accessible from the display in simple

English text.

• Settings are password protected.

• Built-in diagnostics.

• Display turns red in the event of lockout.

Outdoor Reset

• Adjusts boiler temperature based on the

outdoor temperature.

• Helps to keep the boiler in condensing mode

longer, resulting in higher eciency.

• Improves comfort by reducing overheating

of the zones.

Domestic Priority with

Priority Protection

• Directs boiler output to the indirect water heater.

• Priority Protection is provided to allow the boiler

to continue heating in the event of excessive

domestic hot water demand.

Control Flexibility

• Responds to multiple heating demands, and

features adjustable pump outputs.

• Pump outputs for system, boiler and domestic

hot water pumps.

Warm Weather Shutdown

Control Data Logging

• Can display and recall information from numerous

control parameters.

• Previous ve (5) lock-out events can be recalled

on the display.

• Logs runtime hours for the boiler as well as the

number of cycles for the boiler, the boiler pump,

the DHW pump and the system pump.

• Ideal for commercial installations that maintain

heating loop temperatures year round.

• Fully adjustable.

Freeze Protection

• If possible freezing water temperatures are

detected, the ABC System will operate all pumps

connected to the boiler. If water temperatures

continue to drop, the boiler will re and warm

the system slightly in order to prevent freezing

and damage to the system.

Pump Exercise

• Circulators connected to the ABC System control

that don’t operate for seven (7) days, are activated

to run for ten (10) seconds.

• Reduces the possibility for pumps to seize and fail.

Page 5

5

PAG E

Apex Boiler Control FEATURES BEYOND COMPARE

Staging and Modulation

• The ABC can be connected to external staging controls via a

4–20mA and heat demand contact.

• External controls can modulate the boiler's ring rate in order

to satisfy overall system demand.

• No external relays or adapters are required.

Energy Management System (EMS) Compatible

• Can be connected to a building’s Energy Management System (EMS)

using simple menu selections and wiring a 4–20mA input.

• Connects to EMS using modbus protocol.

• Optional EMS Gateway to BacNet or LonWorks.

• Allows EMS controls to adjust either the ABC central heating

setpoint or the ring rate.

Ease of Connectivity...

Cat 5 Connections

• Enables easy connections between boilers or

between boiler and building management system

• Utilizes ordinary RJ-45 (Cat 5 Ethernet) cord

Line Voltage

Terminal Strip

• 120V AC power,

pump outputs

• Strip slides out and

hooks to boiler for

easy access

“Night Setback” and “Unoccupied”

Control Modes

• EnviraCom™ enabled, allows the boiler to communicate directly

with Honeywell EnviraCom™ thermostats.

• Allows the boiler to further enhance system eciency by reducing

the water temperature during “sleep” and “away” modes.

Reliability

• Built-in brown out protection, with no additional devices such as

“brown out relays” required.

• Internal fuse protection for pump outputs is NOT REQUIRED.

The control is capable of handling up to 15 amps, and does not

require additional relays to switch power to the circulators in

most installations.

Low Voltage

Terminal Strip

• Adds additional

inputs for header

and DHW sensors

Page 6

6

PAG E

Lower Cost HIGHER EFFICIENCY ALTERNATIVE

The Lower Cost, Higher Eciency

Alternative to Single Commercial Boilers

Modular/Multiple Boiler Concept

Modular/multiple boiler systems, such as the Apex put the

eciency, cost and service advantages of compact gas boilers

to work in heating applications where a single commercial

boiler would not be sucient. The systems connect any

number of compact, self-contained gas boilers together and

step-re them to eciently meet heating loads on demand.

Firing to Load Demand Minimizes

Standby Losses

Maximum fuel utilization is achieved during long periods

of full ring at the design temperature for each boiler. In

comparison, a single large boiler would cycle on and o,

more frequently during partial loads, not reaching its rated

eciency. During 90% of the average heating season, less

than 65% of the total heating capacity is required. Step-ring

activates only those boilers needed to meet the load demand

which reduces cycling and increases annual fuel eciency.

Features and Benets of Apex Boilers in

Modular/Multiple Boiler Installations

Choosing a modular or multiple boiler system can have many

benets over a single boiler installation.

• COMPACT DESIGN

• COST SAVINGS

The basic cost of a modular/multiple system is typically

less than that of a single large boiler of equal capacity in

most applications.

• BASE LOADING

The practice of replacing larger boilers with multiple,

smaller modular units can oer numerous benets such as

greatly increased eciencies with reduced standby losses,

cycling and emissions.

Program Outdoor Air Reset

Curve with only four points:

• Minimum boiler water temperature

• Maximum boiler water temperature

• Minimum outdoor air temperature

• Maximum outdoor air temperature

Lighter weight boilers like the Apex are suitable for

installation on any oor, from basement to penthouse.

- Apex boilers are readily portable, and can be brought

through standard doorways using a common hand truck.

- Apex boilers can be installed during any phase

of construction.

- Stackable –boilers mount on top of each other without

the use of a frame. Simply secure with bracket

hardware kit.

- Apex boilers can be interconnected via a common RJ45

ethernet cable (or by alternate three wire connection).

Page 7

7

PAG E

Lower Cost HIGHER EFFICIENCY ALTERNATIVE

TO SYSTEM

FROM SYSTEM

Expansion

TO

System Piping

The Apex is designed to be installed in a variety of congurations. Shown

here are four illustrated examples of how the Apex boiler can be piped into

new or existing heating systems. Examples shown here include heat-only

applications, building heat plus domestic hot water, alternate piping of

heat plus domestic hot water and a multiple boiler installation incorporating

domestic hot water. The Apex provides outstanding exibility by providing

the capability of controlling up to three system pumps. In addition, an indirect

water heater can be placed in either the primary or secondary loop, further

enhancing the boiler’s ability to accommodate a variety of systems.

These illustrations are intended for informational purposes only, and

are not intended for use as near boiler piping diagrams.

For further information on piping requirements, please see the Apex

Installation & Operations Manual.

Circulators / System

Zone Valves

Tank

*

*

*Supply & return lines offset for clarity

HEAT-ONLY APPLICATION

TO SYSTEM

Circulators / System

Zone Valves

Expansion

Tank

Circulator

*Supply & return lines offset for clarity

SYSTEM

*Supply & return lines

FROM SYSTEM

*

*

Expansion

Tank

Circulators

offset for clarity

TO SYSTEM

Expansion

Tank

Circulators / System

Zone Valves

FROM SYSTEM

*

*

*Supply & return lines

offset for clarity

HEAT PLUS INDIRECT (ALTERNATE)HEAT PLUS INDIRECT

FROM

SYSTEM

*

*

*

*

*

*

MODULAR WITH INDIRECT

Page 8

8

PAG E

Low voltage

knockouts

(24V)

F

Gas valve

inlet

H

Supply

tapping

Condensate

trap drain

M

N

O

Line voltage knockouts (115V)

A

B

C

D

E

I

K

L

P

Access panel

Access panel

Apex SPECIFICATIONS & DIMENSIONS

Apex Specications & Ratings

RATINGS

MODEL

MIN.

INPUT

(MBH)

MAX.

INPUT

(MBH)

GROSS

OUTPUT

(MBH)

NET

RATING

(MBH)

THERMAL

EFFICIENCY

GAS

CONNECTION

WATER

CONTENT

(Gal.)

APX500 100 500 475 413 95% 3/4" NPT 4.2 375 50.8 4" 1-1/2" NPT

APX625 125 625 593 516 95% 1" NPT 5.5 430 76.2 6" 2" NPT

APX725 145 725 688 598 95% 1" NPT 5.5 430 76.2 6" 2" NPT

APX800 160 800 760 661 95% 1" NPT 5.0 430 65.3 6" 2" NPT

Apex Dimensions

Model A B C D E F G H

APX500 44-7/8" 22-1/8" 29" 39-11/16" 29-3/8" 3/4" 1-1/2" 1-1/2"

APX625 50-1/4" — 24" 38-7/8" 31-5/8" 1" 2" 2"

APX725 50-1/4" — 24" 38-7/8" 31-5/8" 1" 2" 2"

APX800 54-9/10" 28-3/8" 34-1/4" 48-1/16" 33-3/16" 1" 2" 2"

Model I K L M N O P

APX500 12-1/4" 5" 7-7/16" 35" 17-5/16" 14-29/32" 16-11/16"

APX625 12-1/4" 5" 7-1/2" 35" 17-1/4" 7-1/4" 16-11/16"

APX725 12-1/4" 5" 7-1/2" 35" 17-1/4" 7-1/4" 16-11/16"

APX800 12-1/4" 5" 7-1/2" 35" 17-1/4" 7-1/4" 16-11/16"

APPROX.

SHIPPING

WEIGHT

(Lbs.)

HEAT

TRFR.

AREA

(SQ. FT.)

INTAKE

& VENT

DIA.

SUPPLY &

RETURN

CONNECTIONS

LEFT SIDE

Standard Equipment

ASME stainless steel heat exchanger

Stainless steel mesh burner

Full modulation, 5:1 turndown

Variable speed combustion blower

Negative reduction gas valve

Supply & Return temperature sensors

Flue gas temperature sensor

Sealed control compartment

Negative pressure lower cabinet

Outdoor air temperature sensor

Optional Equipment

Condensate Neutralizer

Header Sensor–1/2NPT required for

multiple burner systems

Header sensor, alternate immersion

(103104-01)

RJ45 Cable Splitter (103192-01)

80 psi relief valve (all models)

©2013 Burnham Commercial • P.O. Box 3939, Lancaster, PA 17604

Front-mounted terminal switch

Low voltage terminal strip

Line voltage junction box

Polypropylene condensate trap

Pressure relief valve, 50 psi for 500

Pressure relief valve, 60 psi for 625, 725, 800

Rear ue outlet

Stacking boiler brackets

Built-in lifting handles

100 psi relief valve (all models)

Tekmar 265-3 boiler modulating control

CSD-1 Kit–Includes high and low gas pressure switches,

manual reset high limit, manual reset low water cuto

and gas valve leak test equipment.

Burnham Commercial Universal Gateway–

LonWorks or BacNet/Metasys/Modbus Compatible

Phone: 888.791.3790 • Fax: 717.293.5803 • www.burnhamcommercial.com

Form No. CCIL02081-4/13-3Mc Printed in the U.S.A.

PVC Vent Kit:

30" CPVC

90° Elbow

(2) Vent-terminals with

rodent screens

FRONT

ABC2.1™ (Apex Boiler Control):

Touch screen display

Built-in diagnostics

Slide out drawer

Multiple boiler lead-lag control

Domestic water priority

Warm weather shut down

4-20 mA inputs for external modulation

Loading...

Loading...