Page 1

Supplemental Instructions

Modular Installation

Alpine™ Series Gas Boiler

These instructions supplement information contained in Installation, Operating and Service Instructions for Alpine™ Gas-Fired

Boiler (IO&S), Part No. 101602-01. Follow Supplemental Instructions and details outlined below until directed otherwise.

WARNING

Prior to attempting any service on this boiler, read, understand and follow all instructions as outlined in

this supplement and also the Installation, Operating and Service Instructions which was provided with the

boiler.

GENERAL INFORMATION

These instructions contain supplemental information related only to Modular Installations on the Alpine™ boiler.

This information is also found in the IO&S manual furnished with the boiler. Refer to IO&S manual for all nonmodular related installation instructions. Where applicable, substitute these instructions, paragraph for paragraph,

for the information outlined in the IO&S manual..

Modular Installation

A. General Guidelines

1. Read and follow all venting, combustion air,

water piping, gas piping and electrical instructions

contained in the Installation, Operating and Service

Instructions unless otherwise instructed in this

section.

2. Consult Local Building Codes or National Fuel Gas

Code, NFPA 54/ANSI Z222.3 for restrictions and

instructions on modular boiler installations.

B. Venting

1. Each boiler must have an individual vent pipe.

Refer to Venting Section of the Installation,

Operating and Service Instructions for venting

guidelines and options.

WARNING

Do not manifold vent pipes together.

2. The maximum vent length for each boiler is sixty

(60) equivalent feet.

3. The minimum horizontal distance between vent

terminations is one (1) foot. Additional horizontal

distance is desirable to avoid frost damage to the

building. Vent terminations must be at least twelve

(12) inches above the ground plus the expected

snow accumulation.

102170-01-6/08

CAUTION

Installing multiple vent terminations close

together promotes frost buildup on buildings. To

minimize this possibility, extend the distance from

the building to the end of the vent termination

and increase the horizontal distance between

terminations.

4. Multiple vertical vent pipes may be piped through

a common conduit or chase so that one roof

penetration may be made. Each vent termination

must be one (1) foot from other terminations.

C. Air Intake Piping

1. Each boiler must have an individual air intake

pipe, refer to Venting Section of the Installation,

Operating and Service Instructions for Air Intake

Guidelines and Options.

2. The maximum air intake length for each boiler is

sixty (60) equivalent feet.

3. Locate air intake termination on the same wall as

the vent termination if possible, to prevent nuisance

boiler shutdowns. However, boiler may be installed

with vertical venting and sidewall combustion air

inlet (or visa versa) if installation conditions do not

allow alternate arrangement.

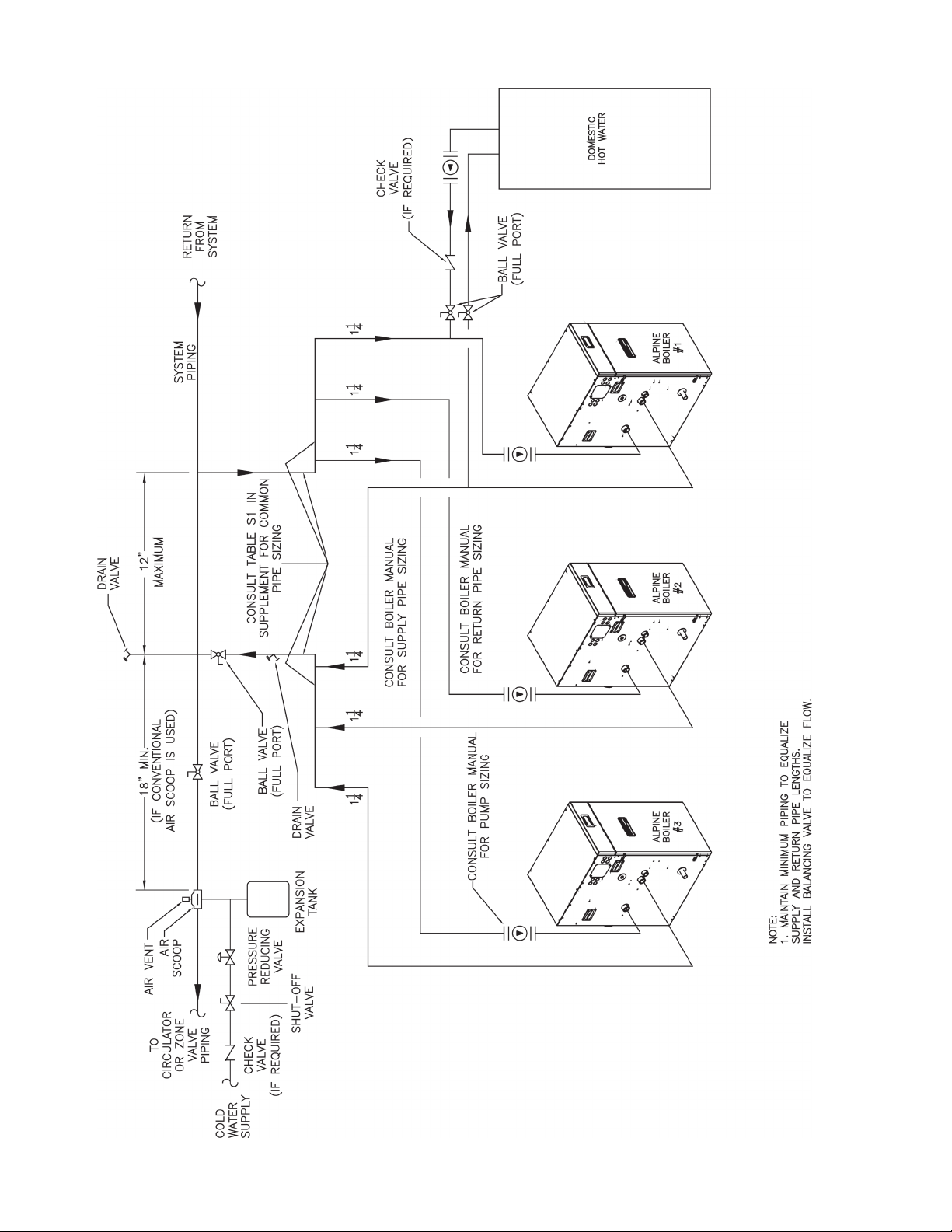

D. Water Piping (See Table S1)

Installing a low water cutoff in the system piping of

modular systems is strongly recommended and may be

required by Local Codes.

1

Page 2

Figure S1: Modular Boiler Water Piping

2

Page 3

TABLE S1: MODULAR BOILER WATER MANIFOLD SIZING

Boiler

Model

ALP080 1¼” 1½” 2” 2½” 2½” 2½” 2½”

ALP105 1½” 2” 2” 2½” 2½” 2½” 3”

ALP150 2” 2” 2½” 2½” 2½” 3” 3½”

ALP210 2” 2½” 3” 3” 3½” 4” 4”

ALP285 2½” 2½” 3” 3½” 3½” 4” 5”

ALP399 2½” 3” 3 4” 4” 5” 5”

2 3 4 5 6 7 8

Recommended Minimum Common Water Manifold Size (NPT)

E. Gas Piping

1. Refer to National Fuel Gas Code, Local Codes and

Tables 12A and 13 of the Installation, Operating and

Service Instructions for gas pipe sizing.

2. Each boiler must be piped as shown in Figure 26 of

the Installation, Operating and Service Instructions.

WARNING

If gas pressure in the building is above ½ psig,

an additional gas pressure regulator is required.

Using one additional regulator for multiple

boilers may result in unsafe boiler operation.

The additional regulator must be able to properly

regulate gas pressure at the input of the smallest

boiler. If the regulator cannot do this, two or

more additional regulators are required. Consult

regulator manufacturer and/or local gas supplier

for instructions and equipment ratings.

Number of Units

F. Electrical

1. Each boiler must be provided with a fused

disconnect and service switch.

2. Install wiring in accordance with requirements of

authority having jurisdiction. In the absence of such

requirements, follow the National Electric Code,

NFPA 70 and/or CSA C22.1 Electric Code.

G. Modular Boiler Control Systems

Contact a controls manufacturer such as Honeywell or

Tekmar to properly apply a modular control system.

Common systems may use outdoor temperature, return

water temperature or both to stage the boilers.

3

Loading...

Loading...