Burnham 8B Series, 805B, 806B, 810B, 807B Installation, Operating And Servicing Instructions

...

SEIRESB8

RELIOBDERIF-SAG

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

,reliobnonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp

rebmuNledoMrelioBrebmuNlaireSrelioBetaDnoitallatsnI

____-_____8________6

rotcartnoCgnitaeH rebmuNenohP

sserddA

8141602R13-7/03

1

Price - $5.00

IMPORTANT INFORMATION - PLEASE READ THIS PAGE CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local

regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local

regulations.

This Series 8B Boiler has been approved by the Massachusetts Board of Plumbers and Gas Fitters:

Approval No. G1-0202-11A.

The Commonwealth of Massachusetts requires this product to be installed by a licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

REGNAD

noitautissuodrazahyltnenimminasetacidnI

,htaednitluserlliw,dediovatonfi,hcihw

ytreporplaitnatsbusroyrujnisuoires

.egamad

.egamad

GNINRAW

noitautissuodrazahyllaitnetopasetacidnI

,htaednitluserdluoc,dediovatonfi,hcihw

ytreporplaitnatsbusroyrujnisuoires

.egamad

NOITUAC

noitautissuodrazahyllaitnetopasetacidnI

nitluseryam,dediovatonfi,hcihw

ytreporproyrujnironimroetaredom

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sdrazahyrujnilanosrep

REGNAD

rosihtfoytinicivehtnisdiuqilrosropavelbammalfrehtoroenilosagesuroerotsTONOD

.ecnailpparehtoyna

lacirtceleynahcuotTONOD-ecnailppaynaetarepootyrtTONOD,sropavsagllemsuoyfI

yletomeramorfreilppussagehtllac,yletaidemmI.gnidliubehtnienohpynaesurohctiws

,elbaliavanusireilppusehtfirosnoitcurtsnis'reilppussagehtwolloF.enohpdetacol

.tnemtrapederifehttcatnoc

elbitsubmocrevoetercnoc,teprac,gniroolfelbitsubmocnoreliobsihtllatsniTONOD

rognipipcitsalpsahcuslairetamdetceffataehynarevoetercnocnoron,doowrogniroolf

.dleihsroolfelbitsubmocdellatsniylreporpatuohtiwgniriw

2

GNINRAW

ehtwolloF.ylefasetarepootecivresdnaecnanetniamralugerseriuqerreliobsihT

.launamsihtnideniatnocsnoitcurtsni

ytreporpesuacnacecnanetniamroecivres,noitaretla,tnemtsujda,noitallatsnireporpmI

erofeblaunameritneehtdnatsrednudnadaeR.efilfossolroyrujnilanosrep,egamad

ebtsumecivresdnanoitallatsnI.ecivresro,noitarepopu-trats,noitallatsnignitpmetta

.ycnegaecivresrorellatsnidelliksdna,decneirepxe,elbaegdelwonkaybylnodemrofrep

.detnevylreporpebtsumreliobsihT

snoisivorperaerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenreliobsihT

.rianoitalitnevdnanoitsubmocetauqedarof

ehtfotratsehterofebdenaelcdnadetcepsniebtsummetsysgnitnevehtforoiretniehT

rofnosaesgnitaehehttuohguorhtyllacidoirepdetcepsniebdluohsdnanosaesgnitaeh

suoixonwollaotyrassecensimetsystnevdetcurtsbonudnanaelcA.snoitcurtsboyna

drawotetubirtnoclliwdnaylefastnevotefilfossolroyrujniesuacdluoctahtsemuf

.ycneiciffes'reliobehtgniniatniam

gnippatehtotnidellatsnisievlavfeilererusserpasselnuetelpmoctonsinoitallatsnI

roflaunamsihtfonoitceSmirTdnagnipiPretaWehteeS-reliobfopotehtnodetacol

.sliated

dnanwodtuhsotreliobehtesuacyamhcihwsecivedytefashtiwdeilppussireliobsihT

gnitaeheht,ytilibissopasisepipnezorfoteudegamadfI.ecivrestuohtiwtrats-erton

dnasdraugefasetairporpparo;rehtaewdlocnidednettanutfelebtondluohsmetsys

sireliobehtfiegamadtneverpotmetsysgnitaehehtnodellatsniebdluohssmrala

.evitareponi

sgnittifepipynawercsnutonoD.erusserphgihrednuretawtohyrevsniatnocreliobsihT

ehtgnirussaylevitisoptuohtiwreliobsihtfostnenopmocynatcennocsidottpmettaron

nehwtnempiuqednagnihtolcevitcetorpraewsyawlA.erusserponsahdnaloocsiretaw

ehtnoylertonoD.seirujnidlacstneverpotreliobsihtgnicivresropugnitrats,gnillatsni

.reliobehtfoerusserpdnaerutarepmetehtenimretedotseguagerutarepmetdnaerusserp

oD.gnitareposireliobehtnehwtohyrevemocebhcihwstnenopmocsniatnocreliobsihT

.loocerayehtsselnustnenopmocynahcuotton

,animulaniatnocleufehtdnanoitsubmocfostcudorp,noitcurtsnocfoslairetamrelioB

rocixotrehtoro/dnasedyhedla,sedixonegortin,edixonomnobrac,slatemyvaeh,acilis

ehtotnwonkerahcihwdnayrujnisuoiresrohtaedesuacnachcihwsecnatsbuslufmrah

esusyawlA.mrahevitcudorperrehtodnastcefedhtrib,recnacesuacotainrofilaCfoetats

ehtybraengnikrowrognicivresnehwtnempiuqednasrotaripser,gnihtolcytefasreporp

.ecnailppa

.htaedroyrujnilanosrepesuacnacredroreporpehtnisnoitcurtsnillawollofoteruliaF

slaunamsrerutcafunamtnenopmocnideniatnocesohtllagnidulcni,snoitcurtsnilladaeR

rogniniatniam,gnitarepo,pugnitrats,gnillatsnierofebreliobehthtiwdedivorperahcihw

.gnicivres

elbammalfrehtodnaenilosag,slairetamelbitsubmocmorfeerfdnaraelcaerareliobpeeK

.sdiuqilrosropav

.retawottcejbusneebsahhcihwlortnochtiwreliobetarepotonoD

.semitllataecalpniebtsumsdraugdnaserusolcne,setalprevocllA

ECITON

.launamsihtfokcabehtnodetnirpsihcihwfoypoca,ytnarrawdetimilasahreliobsihT

yltcerroceraslortnocllatahteesotrotcartnocgnillatsniehtfoytilibisnopserehtsitI

.etelpmocsinoitallatsniehtnehwylreporpgnitarepoeradnadellatsni

evahlevelaesevobateef000,2nahtretaergsedutitlatanoitallatsniroftliubsreliobASU

replevelaesevobateef000,1reptnecrep4etartupnisagecuderotdecifiroyllaicepsneeb

naidanaC.FxidneppAdna2.1.8noitceS,1.322ZISNA/45APFN,edoCsaGleuFlanoitaNeht

.lebalgnitarehtnodetacidnisignizisecifiro'sreliob

3

Table of Contents

I. Pre-Installation ................................................ 6

II. Boiler Assembly ................................................ 8

III. Gas Control System Assembly ....................... 15

(Knockdown Boilers)

IV. Water Trim and Piping .................................... 27

V. Gas Piping ....................................................... 31

VI. Venting ............................................................33

VII. Electrical .......................................................... 36

VIII. System Start-up ............................................... 59

IX. Service ............................................................. 68

X. Repair Parts ..................................................... 75

4

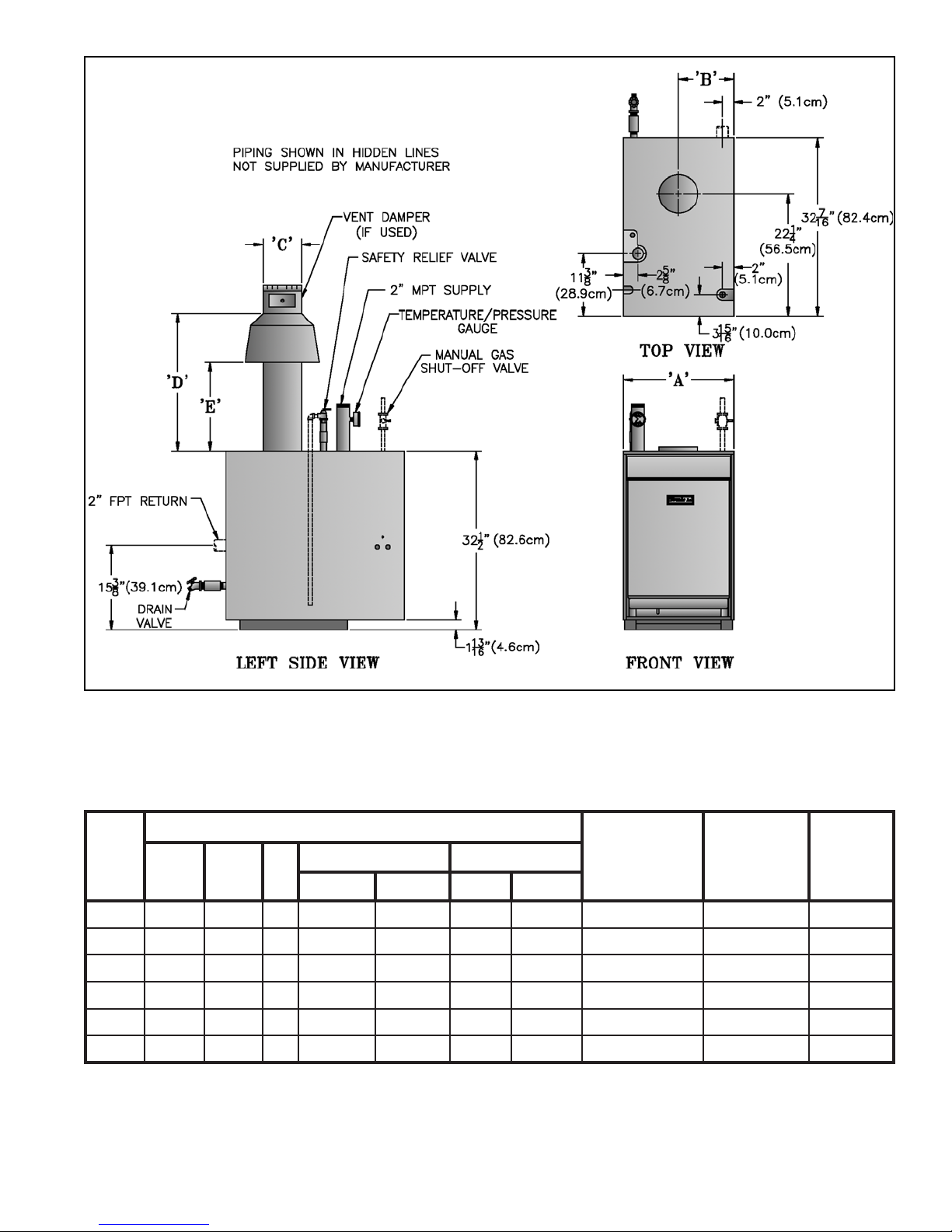

Table 1: Dimensional Data

Figure 1: Dimensional Data

relioB

ledoM

ABC

.oN

B50802017 61/31-4261/31-428/1-618/1-61.tf51x.aid"79.11096

B6084/3-328/7-118 61/31-724/3-528161.tf51x.aid"89.31077

B7082/1-724/3-319 61/31-824/3-528161.tf51x.aid"99.51578

B8084/1-138/5-519 61/31-0361/11-620261.tf51x.aid"99.71089

B908532/1-71012/1-3361/7-622251.tf51x.aid"019.910801

B0184/3-838/3-91012/1-3361/7-622251.tf51x.aid"019.120021

)1(

.)"4/1-73silenap

)2(

)3(

)4(

)sehcnI(snoisnemiD

DE

ASUadanaCASUadanaC

TPN1:ezisnoitcennocsaG

)ylnOretaW(isp05:erusserPgnikroWelbawollAmumixaM

.rellatsniybdeilppussenilneddihninwohssmetI

5

dednemmoceR

eziSyenmihC

)dnuoR(

retaW

tnetnoC

)snollaG(

.xorppA

gnippihS

thgieW

)BL(

pottekcajotroolf(thgiehreliobot"4/3-4sdda;gniroolfelbitsubmocnosnoitallatsnirofderiuqeresablaicepS

I. Pre-Installation

GNINRAW

erofebsnoitcurtsnilladaerylluferaC

llawollofoteruliaF.reliobgnillatsni

esuacnacredroreporpnisnoitcurtsni

.htaedroyrujnilanosrep

A. Inspect shipment carefully for any signs of damage.

All equipment is carefully manufactured, inspected and

packed. Our responsibility ceases upon delivery of

boiler to carrier in good condition. Any claim for

damage or shortage in shipment must be filed

immediately against carrier by consignee. No claims

for variances or shortages will be allowed by Boiler

Manufacturer, unless presented within sixty (60) days

after receipt of equipment.

B. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to the

National Fuel Gas Code, NFPA 54/ANSI Z223.1 and/

or CAN/CGA B149 Installation Codes. Where

required by the authority having jurisdiction, the

installation must conform to the Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME No. CSD-1.

C. Provide clearance between combustible material

and boiler jacket (following clearances are minimums):

1. USA, 805B-807B: listed for Alcove installation

a. Front: 18"

b. Top: 36"

c. Draft hood, rear, sides and flue connector: 6"

2. USA, 808B-810B: for installation in room which is

large in comparison with size of boiler.

a. Front: 18"

b. Top: 51½"

c. Draft hood, rear, sides, and flue connector: 6"

3. Canada, 805B-810B:

a. Top and front: 18" (45.7cm)

b. Flue, rear and sides: 6" (15.2cm)

D. Provide clearance for servicing and proper operation

(following clearances are recommended and may be

reduced to minimum clearances shown above):

1. Single boiler, 805B-807B, Front/Top: 24" (61cm)

2. Single boiler, 808B-810B, Front/Top: 48" (122cm)

3. Multiple/modular boiler, USA/Canada, Sides:

1" (2.5cm)

E. Install boiler on level floor as close to chimney as

possible. For basement installation provide a solid base

such as concrete or masonry construction if floor is not

level or if water may be encountered on floor around

boiler.

F. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, control

replacement, etc.).

GNINRAW

noitallatsnirofdeifitrecngisedsiecnailppA

roF.ylnogniroolfelbitsubmocnonno

ylnogniroolfelbitsubmocnonoitallatsni

elbaTnidetsilesablaicepsnodellatsninehw

.gnitepracnodellatsniebtontsumrelioB.2

sihcihwetercnocnodellatsnisireliobnehW

gnitlemottcejbussitahtlairetamarevo

laicepseht,).cte,gnibuttnaidarXEP,CVP(

tonsidapetercnocA.desuebtsumesab

.gniroolfelbitsubmoctcetorpottneiciffus

Table 2: Special Base Required for Installation on

Combustible Flooring

.oNledoMrelioBrebmuNtraPesaBlaicepS

B50855061816

B60856061816

B70857061816

B80858061816

B90859061816

B01850161816

G. Provide combustion and ventilation air in

accordance with applicable provisions of local building

codes, or the National Fuel Gas Code, NFPA 54/ANSI

Z223.1, Section 5.3, Air for Combustion and

Ventilation; or CAN/CGA B149 Installation Codes,

Part 5, Venting Systems and Air Supply for

Appliances.

GNINRAW

rianoitalitnevdnanoitsubmocetauqedA

reporperussaotdedivorpebtsum

.noitsubmoc

The following guideline is based on the National Fuel

Gas Code, NFPA 54/ANSI Z223.1.

1. Determine volume of space (boiler room). Rooms

communicating directly with space (through

permanent openings not furnished with doors) are

considered part of space.

Volume [ft³] = Length [ft] x Width [ft] x Height [ft]

2. Determine Total Input of all appliances in space.

Round result to nearest 1,000 Btu per hour (Btuh).

3. Determine type of space. Divide Volume by Total

Input.

6

a. If result is greater than or equal to 50 ft³ per 1,000

Btuh, space is considered an unconfined space.

b. If result is less than 50 ft³ per 1,000 Btuh, space is

considered a confined space.

4. Determine building type. A building of unusually

tight construction has the following characteristics:

a. Walls and ceiling exposed to outside atmosphere

have a continuous water vapor retarder with a

rating of 1 perm or less with openings gasketed

and sealed, and

b. Weather-stripping has been added on openable

windows and doors, and

c. Caulking or sealants applied in joints around

window and door frames, between sole plates

and floors, between wall-ceiling joints, between

wall panels, at plumbing and electrical

penetrations, and at other openings.

5. For boiler located in an unconfined space in a

building of other than unusually tight construction,

adequate combustion and ventilation air is normally

provided by fresh air infiltration through cracks

around windows and doors.

6. For boiler located in an unconfined space in a

building of unusually tight construction or in a

confined space, provide outdoor air through

permanent opening(s) which communicate directly

or by duct with the outdoors or spaces (crawl or

attic) freely communicating with the outdoors.

Minimum dimension of air opening(s) is 3" (7.6cm).

a. Two permanent openings: Locate one opening

within 12 " (30.5cm) of top of space. Locate

remaining opening within 12" (30.5cm) of bottom

of space. Size each opening per following:

i. Minimum free area of 1 square inch per 3,000

Btu per hour input of all equipment in space.

ii. Free area shall not be less than the sum of

the areas of all vent connectors in the

confined space.

Alternate method for boiler located within confined

space. Use indoor air if two permanent openings

communicate directly with additional space(s) of

sufficient volume such that combined volume of all

spaces meet criteria for unconfined space. Size each

opening for minimum free area of 1 square inch per

1,000 Btu per hour input of all equipment in

spaces, but not less than 100 square inches.

7. Ventilation Duct Louvers and Grilles. Equip

outside openings with louvers to prevent entrance

of rain and snow, and screens to prevent entrance of

insects and rodents. Louvers and grilles must be

fixed in open position or interlocked with

equipment to open automatically before burner

operation. Screens must not be smaller than ¼ inch

mesh.

Consider the blocking effect of louvers, grilles and

screens when calculating the opening size to

provide the required free area. If free area of louver

or grille is not known, assume wood louvers have

20-25 percent free area and metal louvers and

grilles have 60-75 percent free area.

8. For Specially Engineered Installations. The above

requirements shall be permitted to be waived where

special engineering, consistent with good

engineering practice and approved by the authority

having jurisdiction, provides an adequate supply of

air for combustion, ventilation, and dilution of flue

gases.

i. Direct communication with outdoors.

Minimum free area of each opening must be

1 square inch per 4,000 Btu per hour input

of all equipment in space.

ii. Vertical ducts. Minimum free area of each

opening must be 1 square inch per 4,000

Btu per hour input of all equipment in

space. Duct cross-sectional area shall be

same as opening free area.

iii. Horizontal ducts. Minimum free area of

each opening must be 1 square inch per

2,000 Btu per hour input of all equipment

in space. Duct cross-sectional area shall be

same as opening free area.

b. One permanent opening shall be permitted where

the boiler has clearances of at least 1" (2.5cm)

from the sides and rear and 6" (15.2cm) from the

front. Locate the opening within 12 " (30.5cm) of

top of space. Size opening per following:

GNINRAW

rehtoroenilosagerehwreliobllatsnitonoD

fosecruosro,sdiuqilrosropavelbammalf

,srenaelc,sehcaelb.e.i(snobracordyh

cirbaf,srevomertniap,syarps,slacimehc

.derotsrodesuera).cte,srenetfos

ECITON

ehtotdragerhtiwreliobehtfognizis-siM

evissecxenitluserlliwdaolmetsysgnitaeh

tnenopmocdetareleccadnagnilcycreliob

tnarrawTONSEODmahnruB.eruliaf

reliobdezis-simybdesuacseruliaf

otreliobehtezisrevoTONOD.snoitacilppa

yltaergsreliobelpitlum/raludoM.metsyseht

.gnizisrevoreliobfodoohilekilehtecuder

7

II. Boiler Assembly

A. Remove Crate (Semi-Pak and Packaged Only)

1. Remove all fasteners at crate skid.

2. Lift outside container and remove with all other

inside protective spacers and bracing.

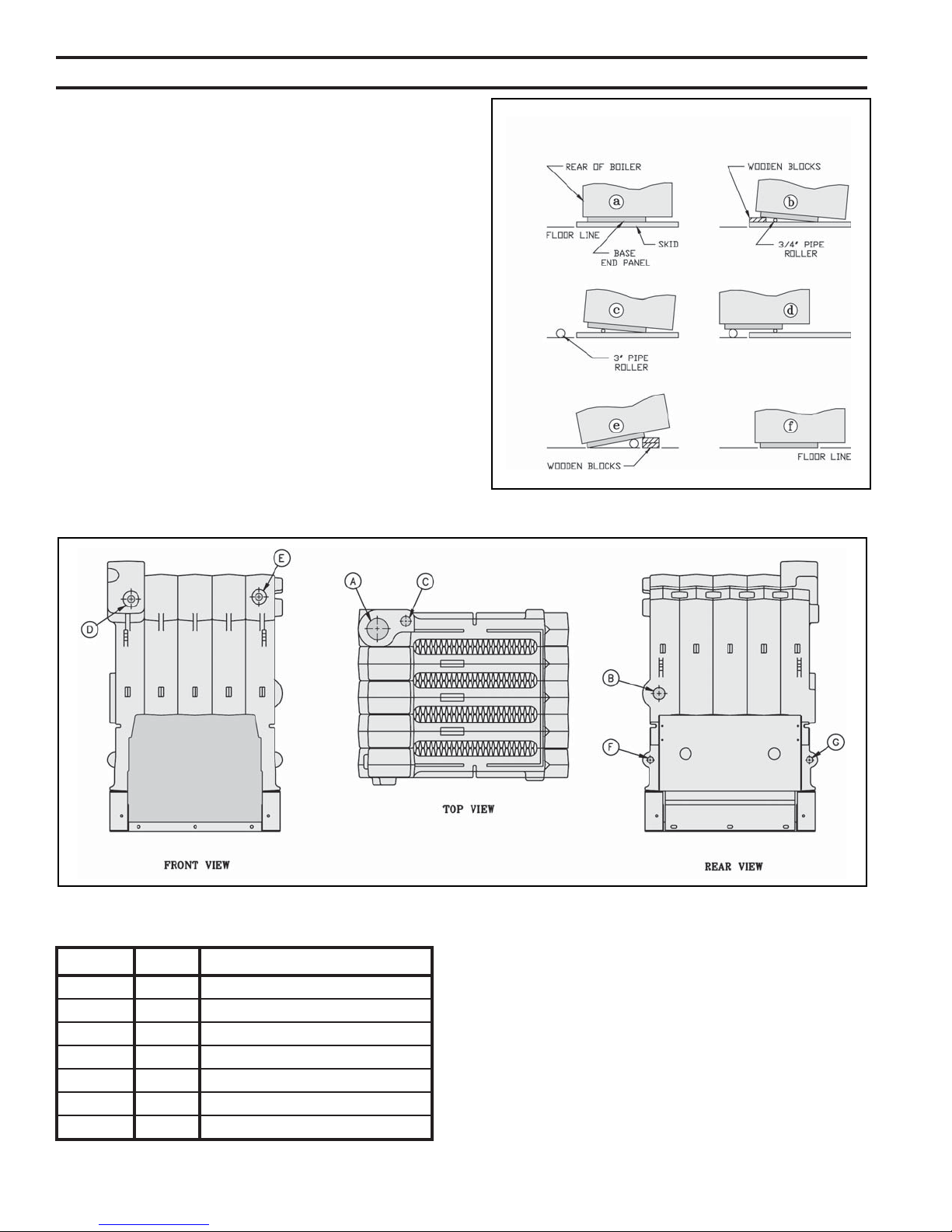

B. Remove boiler from skid. See Figure 2. Exercise care

to avoid dropping boiler.

1. Place boiler in approximate location. Refer to

Section I: Pre-Installation. Remove base hold down

bolts.

2. Using pry bar under rear corner of Base End Panel,

raise boiler and install 1½" wood blocks under rear

corners. Install ¾" pipe roller between Base and

skid.

3. Remove 1½" wood blocks. Place 3" pipe roller on

floor behind skid.

4. Roll boiler off skid. Move skid out of way.

Figure 2: Skid Removal

Table 3: Purpose of Tappings

gnippaTeziSesopruP

A"2ylppuS

B"2nruteR

C"¾evlaVfeileR

D"¾timiL

E"¾timiLyrailixuA

F"¾tuohsaW

G"¾niarD

Figure 3: Tapping Locations

8

5. Roll boiler until 3" roller is located as shown. Use

pry bar to install wood blocks under front corners of

base. Remove 3" roller.

6. Lift boiler with pry bar. Remove wood blocks.

Lower boiler.

C. For Packaged Boiler only, proceed to Paragraph E.

D. Test Section Assembly for leaks before connecting to

system and installing controls, trim and jacket. Refer

to Figure 3 and Table 3.

1. Plug Tappings C & E (¾ NPT) and Return Tapping

B (2 NPT).

2. Insert ¾" NPT x ¼" NPT bushing in Tapping D.

Install pressure gauge capable of indicating 50 psi.

3. Insert 2" NPT x ¾" NPT bushing in Supply

Tapping A. Install purge valve with a hose that

runs to a drain.

4. Connect fill valve and piping to Drain Tapping G.

GNINRAW

.reliobtsetkaelotriaesutonoD

5. Fill boiler completely with water by venting air

through purge valve. Close purge valve and apply

water pressure of at least 10 psi but less than 50 psi

gauge pressure.

6. Examine boiler for leaks or damage due to

shipment or handling.

7. Remove plugs from Return Tapping B, Tapping C,

and Tapping E (if second limit or operating control

is used). Also remove fill valve and piping, purge

valve and piping, and pressure gauge.

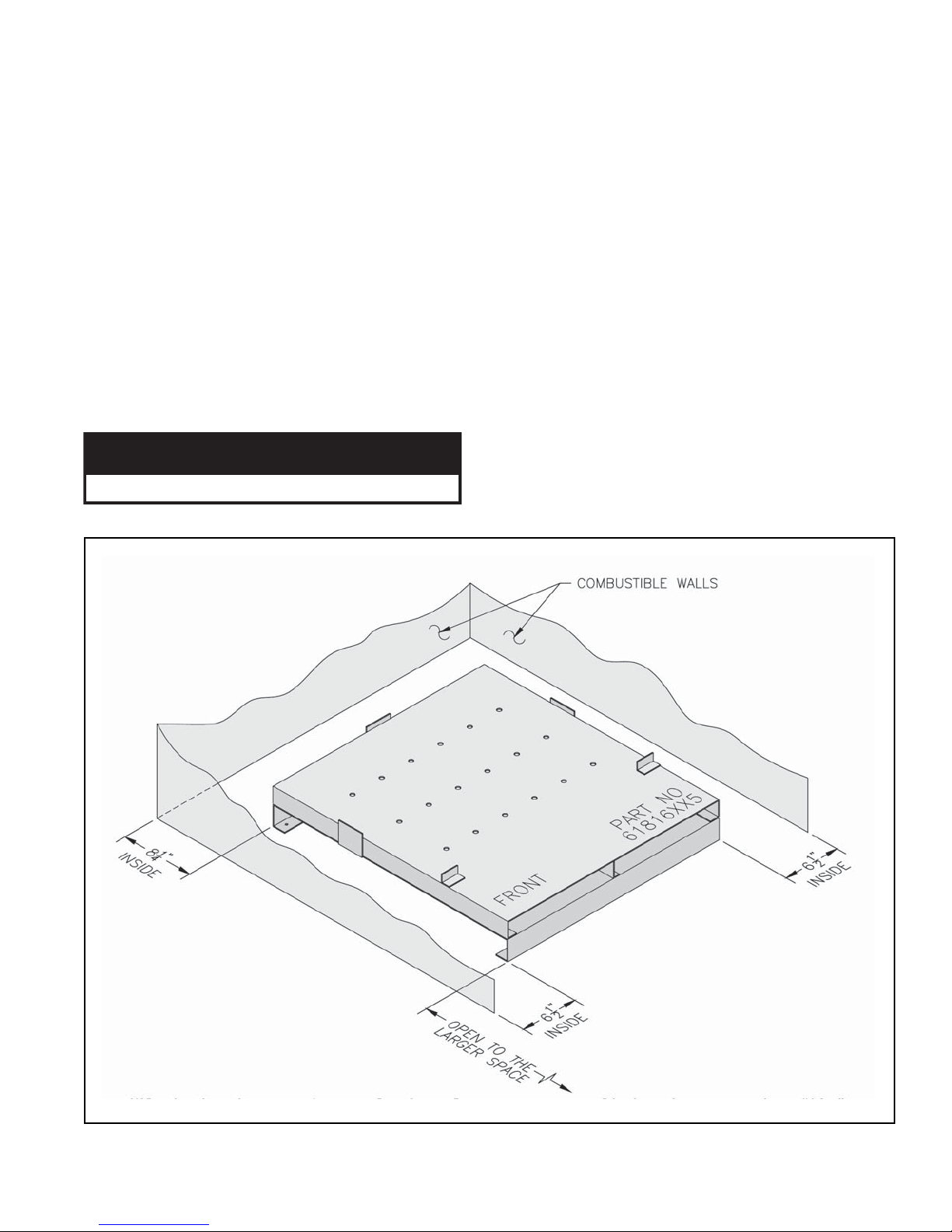

E. Install special base if installation is on combustible

flooring. See Figure 4. Floor shield adds 4¾" to boiler

height.

1. Place special base on combustible floor with surface

marked "FRONT" in upward position.

2. Locate special base with spacing to combustible

materials as shown in Figure 4.

3. Place boiler on special base. Boiler must rest inside

locating brackets. Boiler jacket panels will

overhang special base.

4. Do not enclose boiler (including special base) on all

four sides. Models 805B - 807B may be enclosed

Figure 4: Installation of Special Base for Combustible Flooring

9

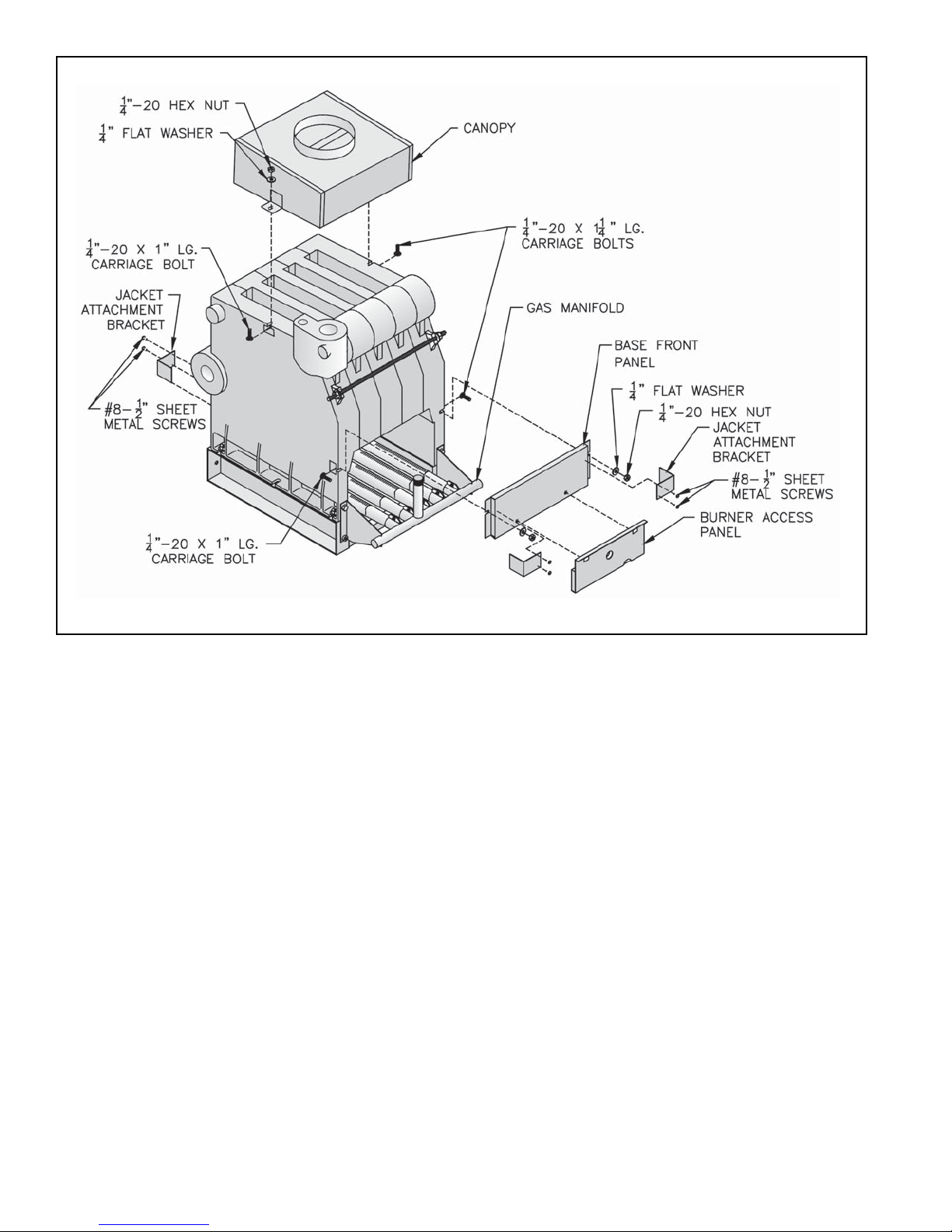

Figure 5: General Assembly (Knockdown Boilers)

on three sides (alcove) while maintaining

clearances shown in Figure 4.

F. Move boiler to permanent location by sliding or

walking. DO NOT DROP.

For Packaged Boiler proceed to Section IV: Trim and

Piping.

G. Install Canopy on section assembly. See Figure 5.

Canopy and hardware are located in Combination

Boiler Parts and Control Carton.

1. Position Canopy on top of Section Assembly.

Locate between end sections and sealing ledge on

front and back of each section.

2. Fasten each end with ¼" - 20 x 1" carriage bolts,

washers and nuts.

3. Seal between Canopy and Section Assembly with

furnace cement.

H. Inspect joints between sections. They were factory

sealed. If any openings resulted during shipment or

handling, reseal with furnace cement. Confirm tie rods

are only hand tight to allow for thermal expansion.

I. Install Base Front Panel. See Figure 5. Panel and

hardware located in Combination Boiler Parts and

Control Carton.

1. Attach Base Front Panel to Section Assembly using

¼" - 20 x 1¼" carriage bolts, washers and nuts.

2. Seal between top of Base Front Panel and Section

Assembly with furnace cement (shipped in

Combination Boiler Parts and Control Carton).

3. Seal between top of Base Rear Panel and Section

Assembly with furnace cement.

J. Install Pilot/Main Burner Assembly. See Figure 7.

Assembly is located in Combination Boiler Parts and

Control Carton. Verify assembly is properly located on

support bracket in Base Rear Panel, seated on Main

Burner Orifice, and secured with hitch pin clip.

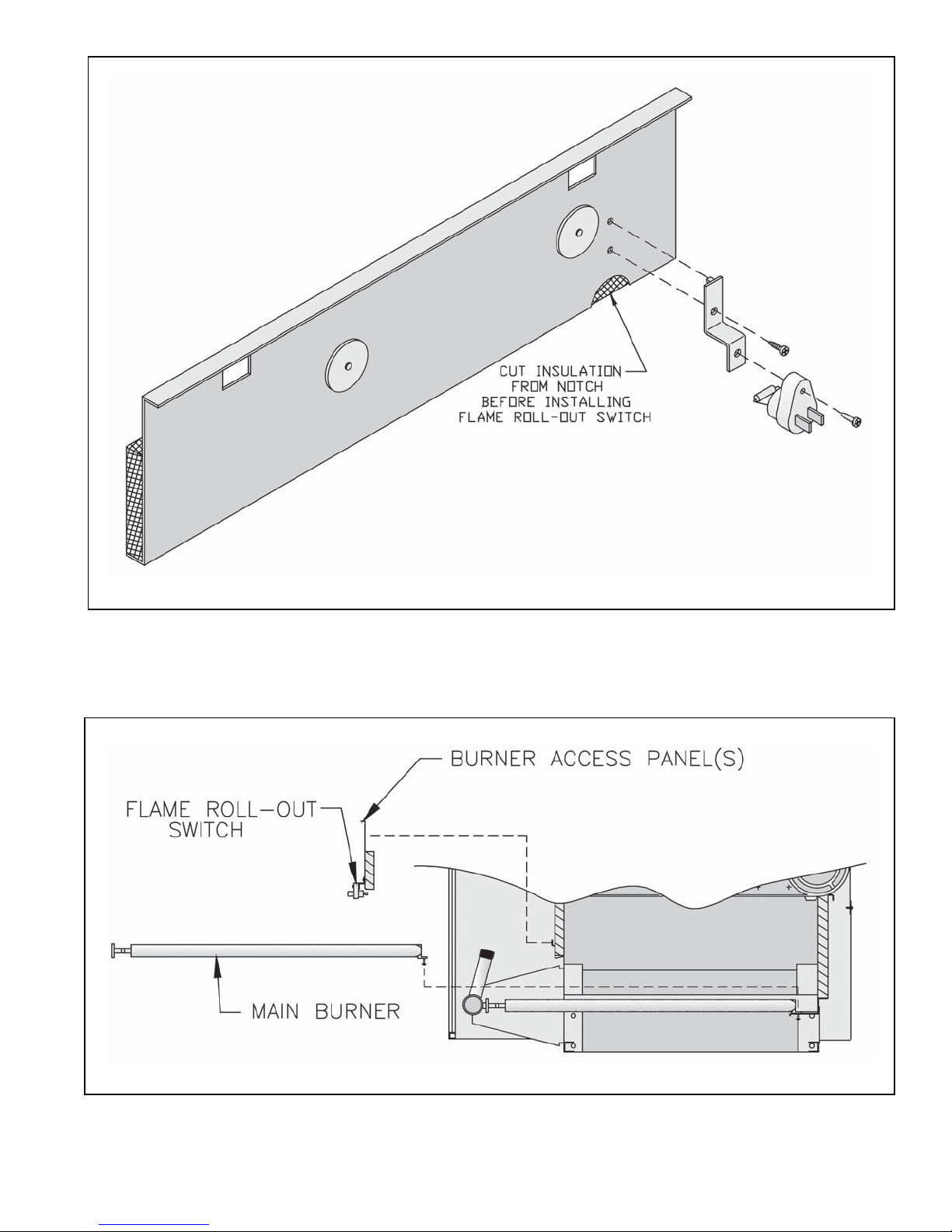

K. Attach Flame Roll-out Switch to Burner Access

Panel. See Figure 6. Flame Roll-out Switch and

hardware are located in Combination Boiler Parts and

Control Carton. Flame Roll-out Switch is a single use

device - do not test with heat - switch cannot be reset.

10

Figure 6: Flame Roll-out Switch Installation

Figure 7: Burner/Burner Access Panel Installation

11

1. Cut insulation from semicircular notch at right end of

the burner access panel. Models 808B - 810B have

two (2) burner access panels. Remove insulation

from notch of right side burner access panel only.

2. Attach Flame Roll-out Switch Mounting Bracket to

burner access panel with (1) #8 x ½" lg. sheet metal

screw.

3. Attach Flame Roll-out Switch to mounting bracket

with (1) #8 x ¾" lg. sheet metal screw.

L. Install Burner Access Panel(s). Locate Burner

Access Panel(s) in Combination Boiler Parts and

Control Carton. Engage Burner Access Panel holes

with projections on Base Front Panel. See Figure 6.

M. Install Immersion Well(s).

1. Remove Immersion Well(s) from Combination

Boiler Parts and Control Carton..

2. Insert Immersion Well in Tapping D. See Figure 3.

3. If second limit or operating control is used, insert

immersion well in Tapping E. If vertical gas

piping is to be installed inside of boiler jacket, it is

recommended that second limit be installed in

system piping.

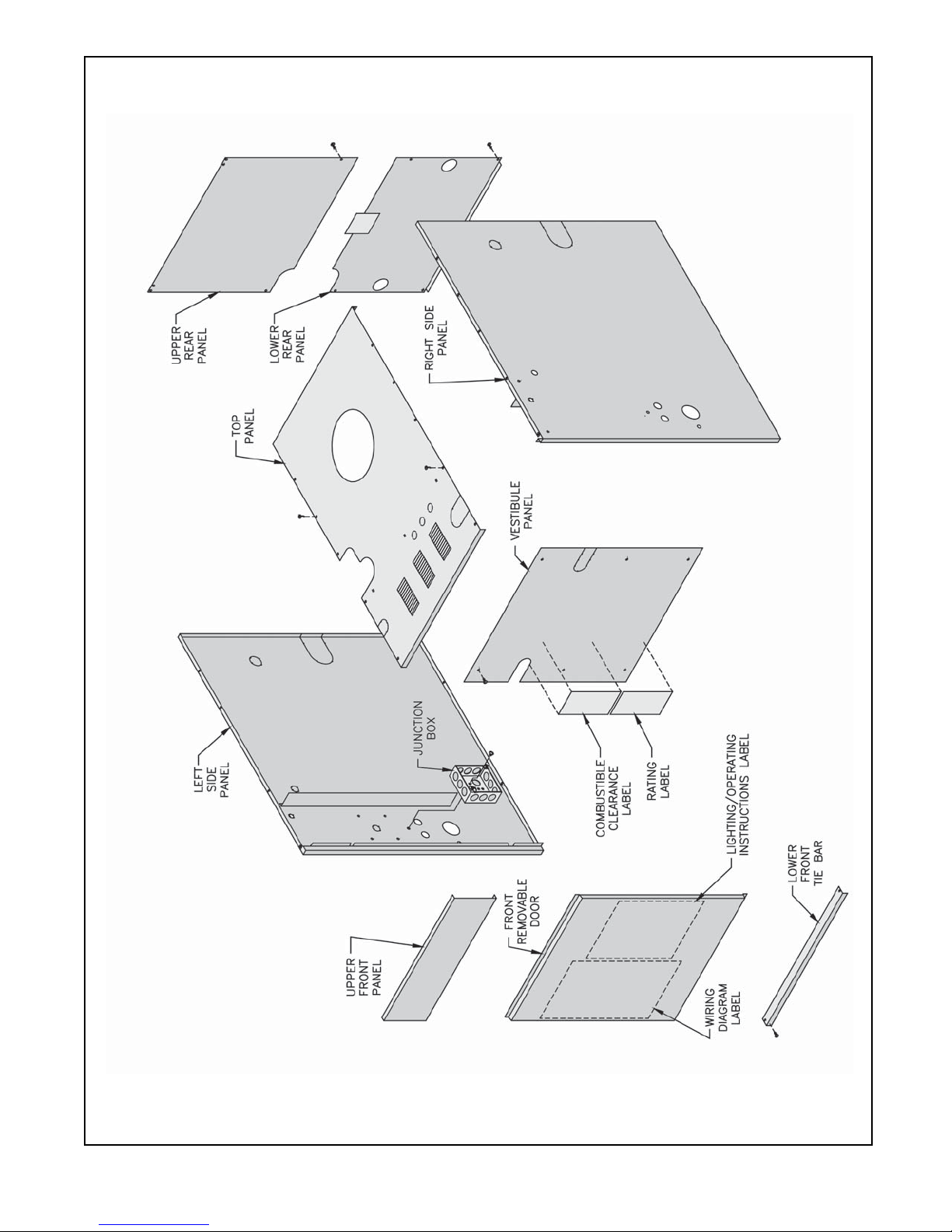

7. Attach Lower Front Tie Bar to Left Side and Right

Side Panels.

8. Engage Upper Front Panel in slots on Left Side and

Right Side Panels. Place Top Panel in position.

Attach Top Panel to Left Side, Right Side and

Upper Rear Panels.

9. Tighten all jacket screws.

10. Affix Lighting/Operating Instructions Label and

Wiring Diagram Label to inside of Front

Removable Door. Labels are located in

Combination Boiler Parts and Control Carton.

O. Install Junction Box. See Figure 8. Attach junction

box to inside of Left Side Panel with ¼" - 20 x ¼" lg.

machine screw (located in Combination Boiler Parts

and Control Carton).

P. Install Limit Control. Locate limit in Combination

Boiler Parts and Control Carton. Insert limit probe into

left immersion well as far as possible. Tighten set

screw.

Q. Install Auxiliary Limit or operating control (if used).

Insert control probe into right immersion well as far as

possible. Tighten set screw.

N. Install Jacket. See Figure 8.

1. Locate four (4) Jacket Attachment Brackets in

Combination Boiler Parts and Control Carton.

Attach to Front Base Panel and Rear Base Panels

with #8 sheet metal screws. See Figure 5.

2. Hang Left Side Panel and Right Side Panel onto

Jacket Attachment Brackets.

3. Attach Lower Rear Panel to Left and Right Side

Panels. Do not tighten sheet metal screws.

4. Attach Upper Rear Panel to Lower Rear Panel. Do

not install three (3) upper screws.

5. Remove Rating Label and Combustible Clearance

Label from Combination Boiler Parts and Control

Carton. Attach to Vestibule Panel in locations

shown.

6. Attach Vestibule Panel to Left Side and Right Side

Panels.

R. Install Gas Control Assembly. Refer to Section III,

Gas Control System Assembly (Knockdown Boilers).

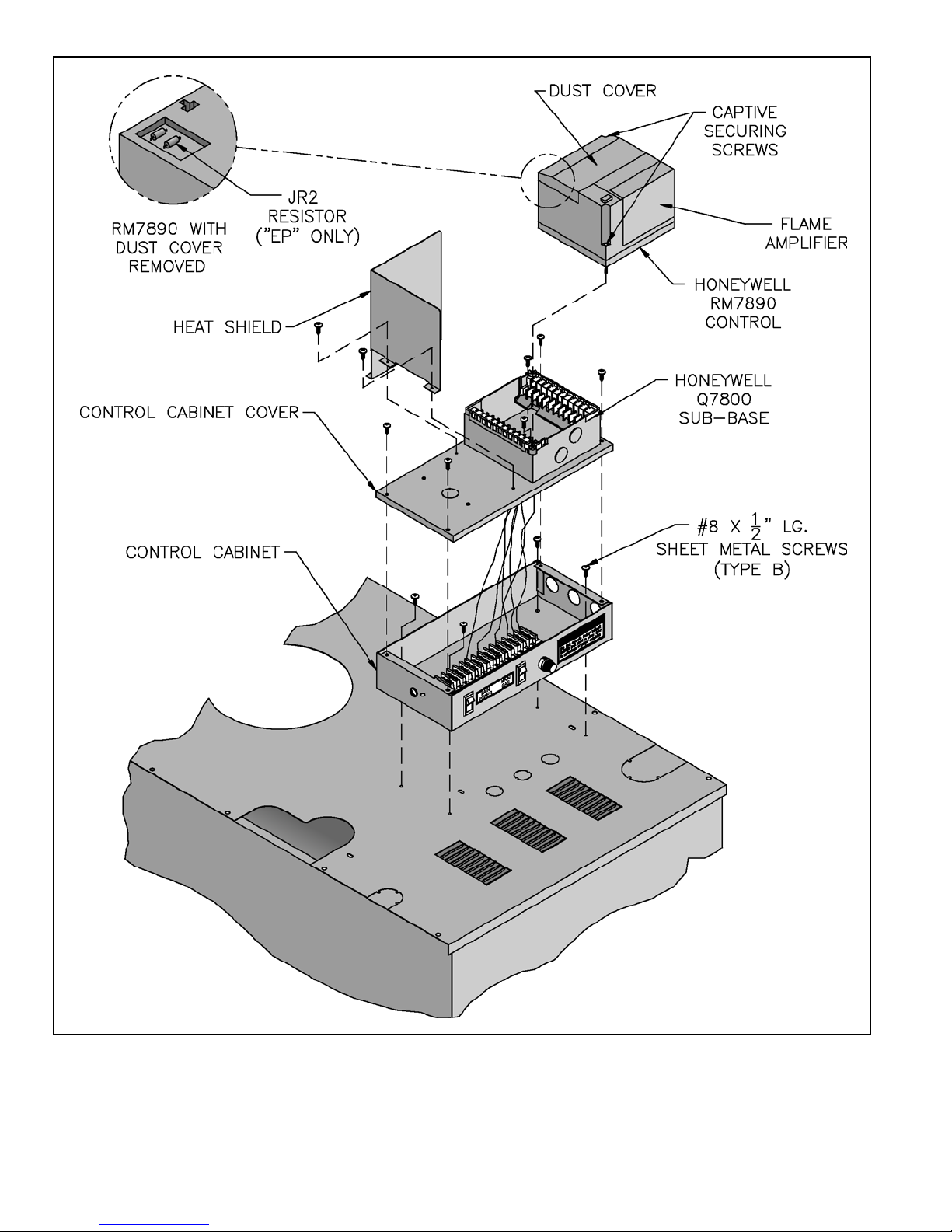

S. EP and OP System: See Figure 9.

1. Install pre-wired EP/OP Control Cabinet Assembly

to right front corner of jacket top panel.

2. Install Honeywell RM7890 Control (located in

RM7890 Control Carton).

3. EP Only: Remove RM7890's Dust Cover. With a

pair of side cutters, carefully snip both wire leads to

the brown resistor labelled "JR2" and discard it.

Replace Dust Cover.

4. Install Honeywell R7847 Flame Amplifier.

5. Install heat shield.

12

Figure 8: Jacket Assembly

13

Figure 9: EP/OP Control Installation

14

III. Gas Control System Assembly (Knockdown Boilers)

A. 24V Standing Pilot Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

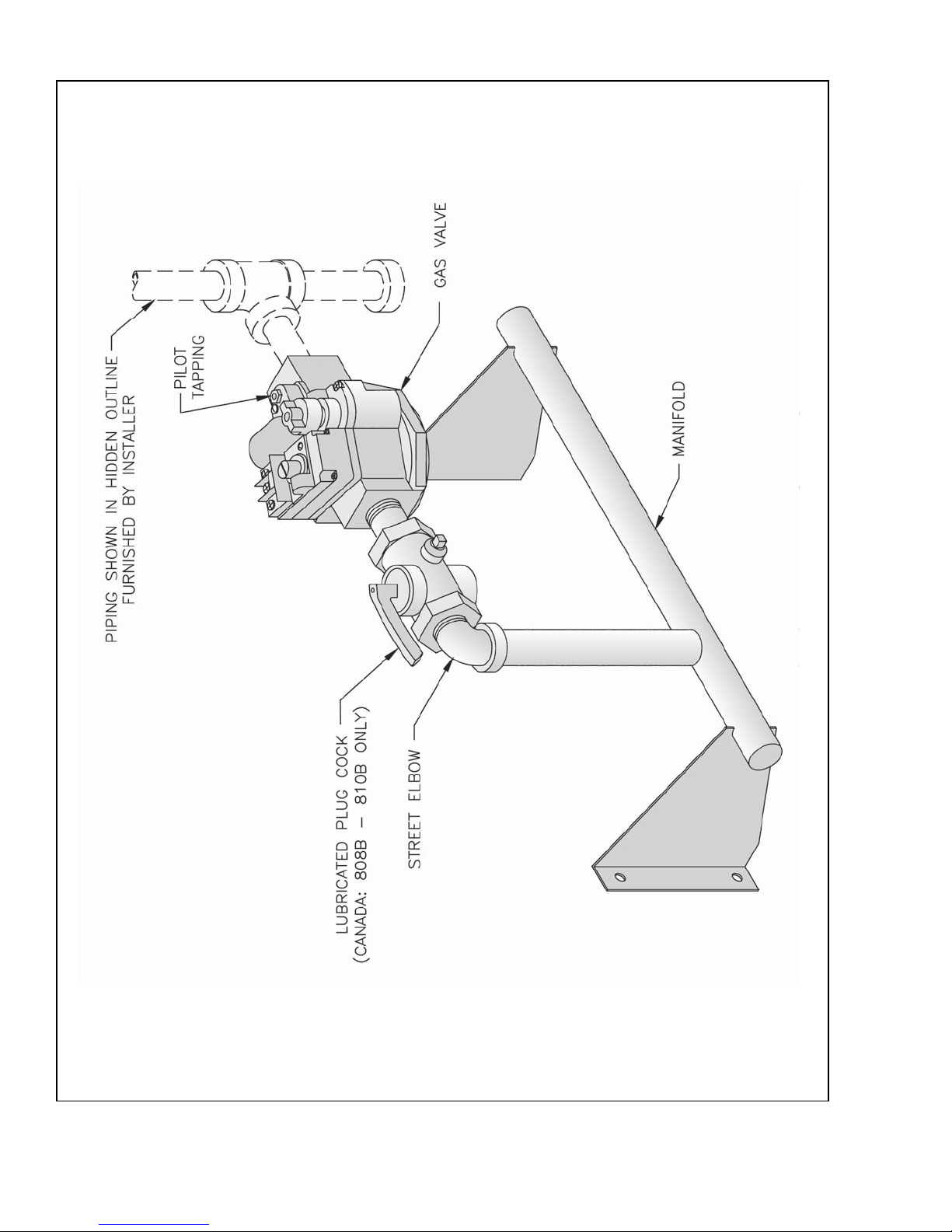

1. Install Gas Control Assembly on Manifold. See

Figure 10. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls. See Figure

10.

3. Connect Thermocouple Lead to Gas Valve.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

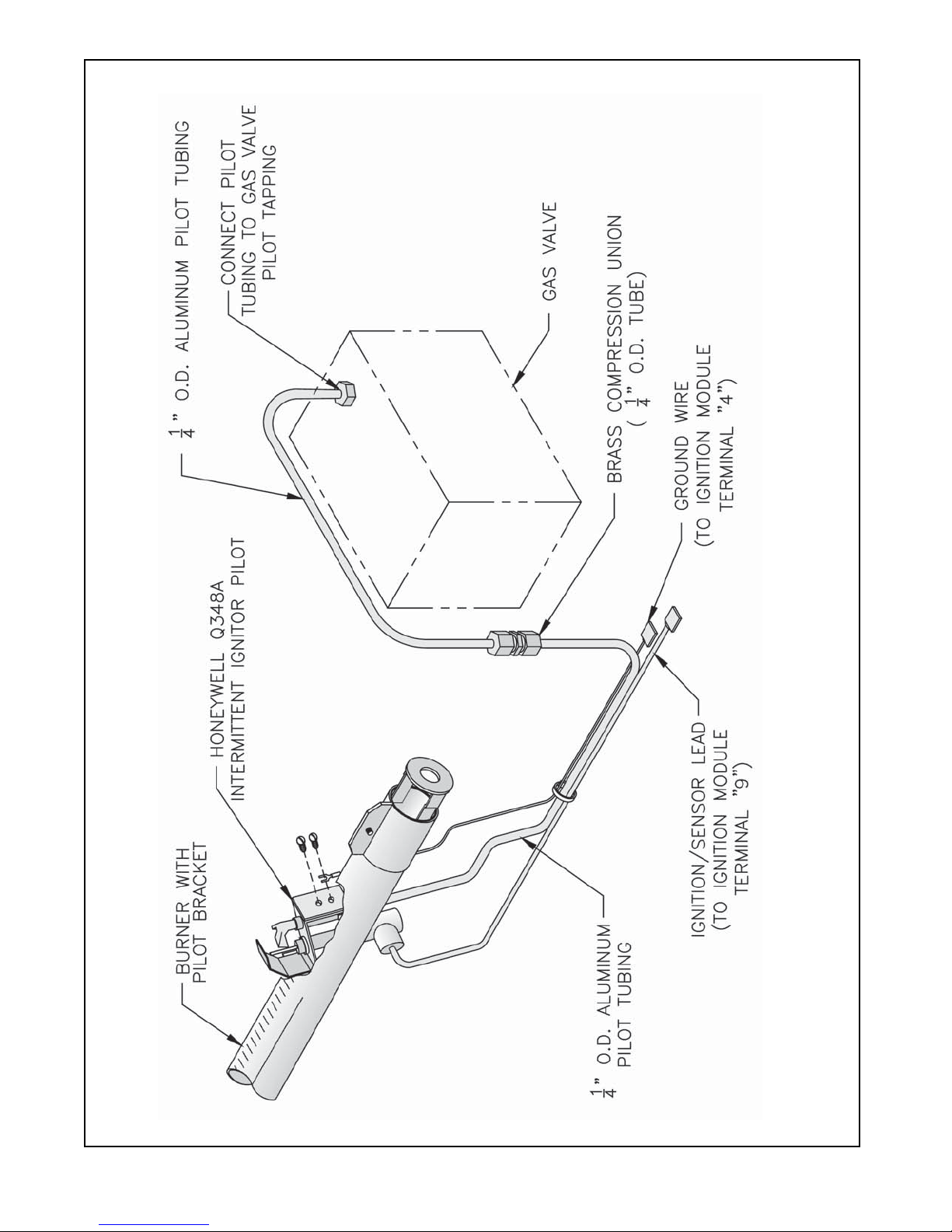

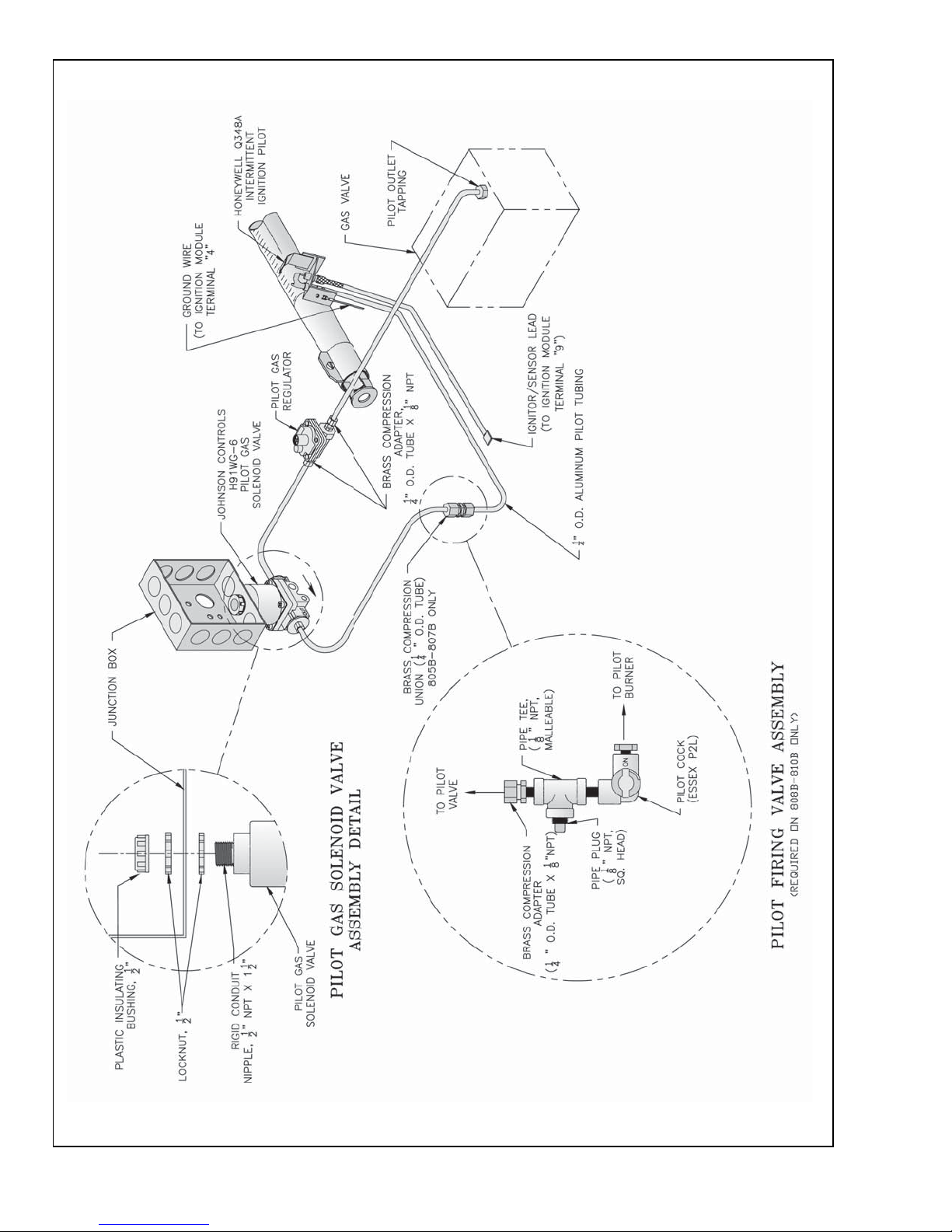

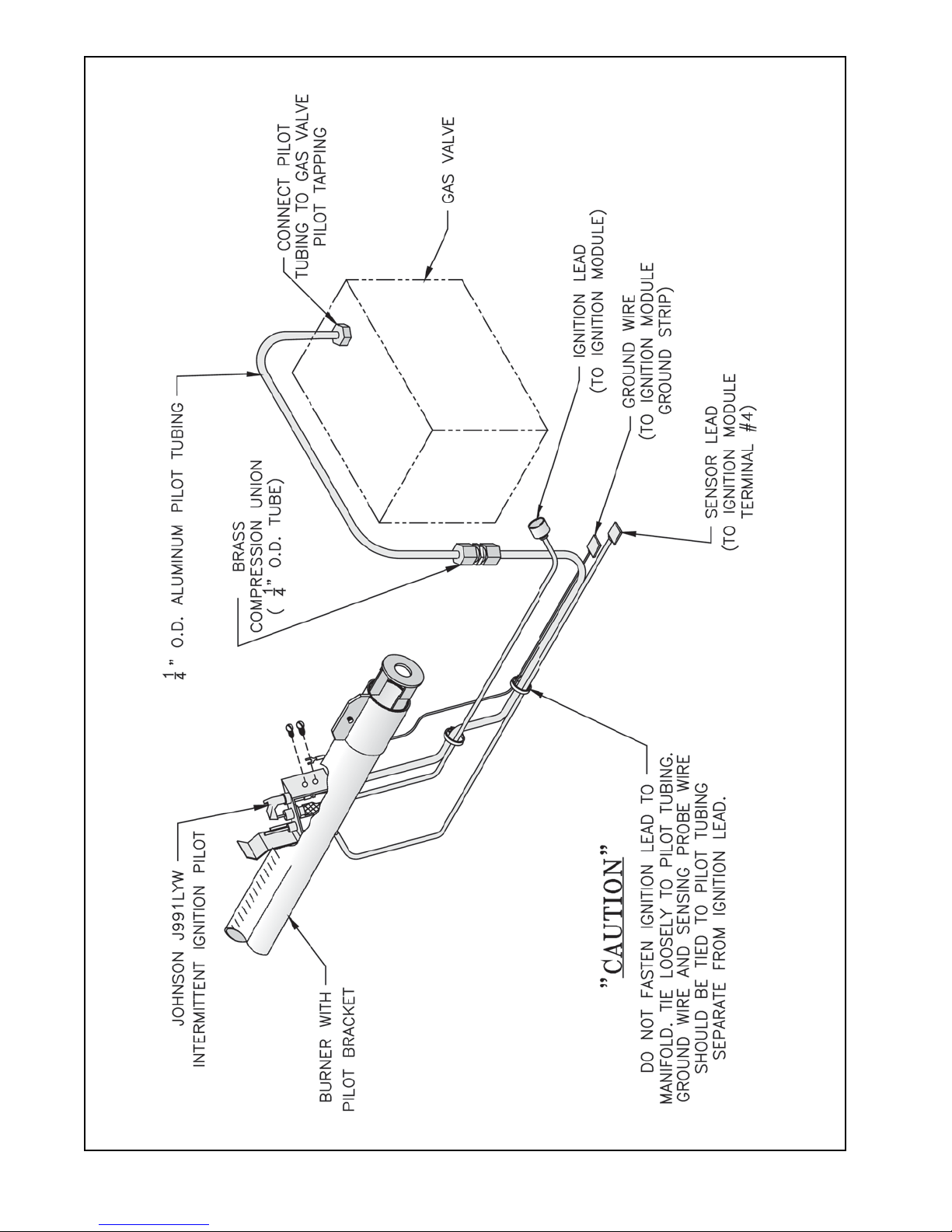

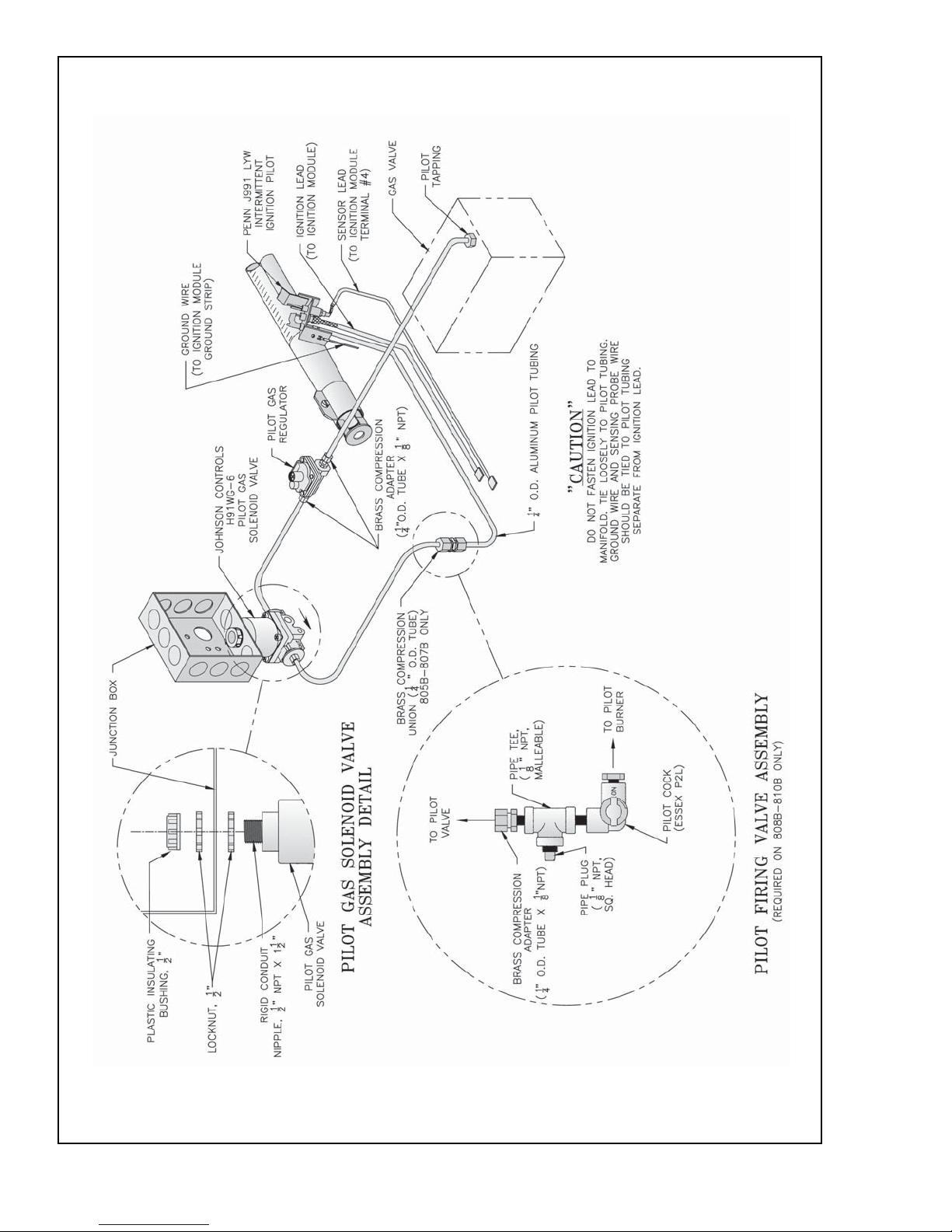

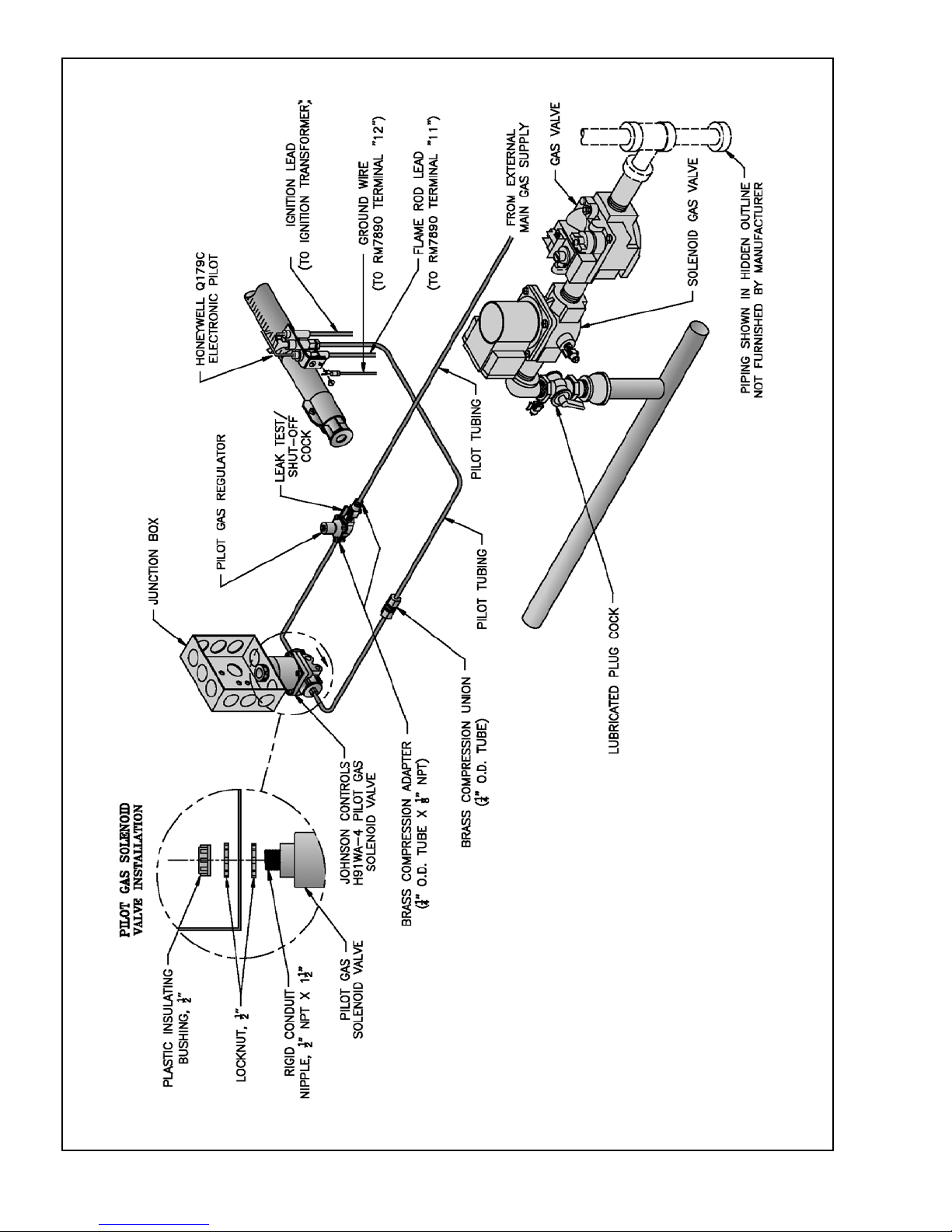

B. EI (Intermittent Ignition)

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 11. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls.

a. Honeywell EI

i. USA - See Figure 12.

ii. Canada - See Figure 13.

b. Johnson EI

i. USA - See Figure 14.

ii. Canada - See Figure 15.

3. Install Ignition Module.

a. Attach Ignition Control Mounting Bracket to

Jacket Vestibule Panel using two (2) #8 x ½"

sheet metal screws.

b. Attach Johnson Ignition Module to Mounting

Bracket using two (2) #6 x ¾" sheet metal screws

or attach Honeywell Ignition Module to

Mounting Bracket using two (2) #8 x ½" sheet

metal screws.

c. Connect pilot ground wire and ignitor/sensor

lead(s) to ignition module. Refer to "Section VII:

Electrical" for connection details.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box. See Figure 8.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

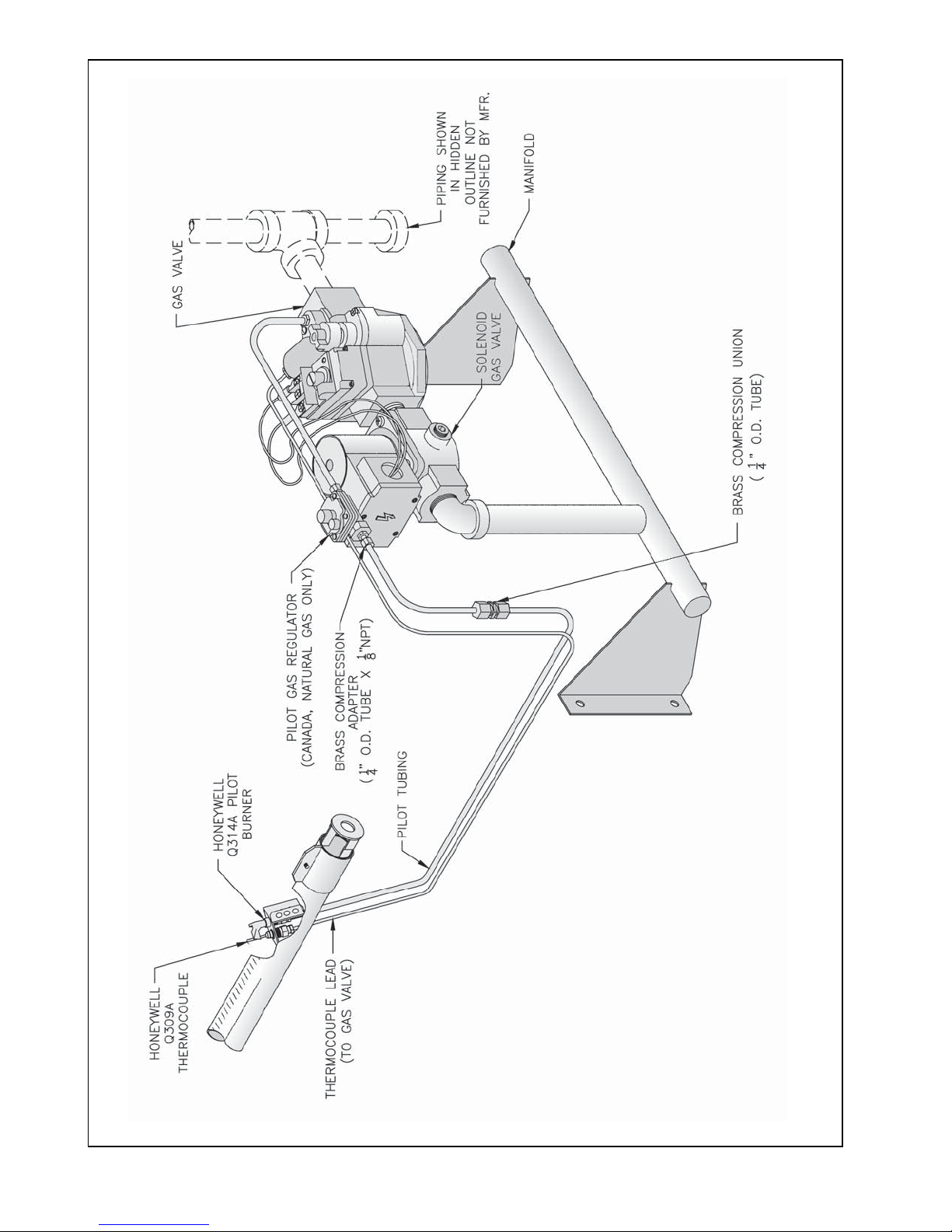

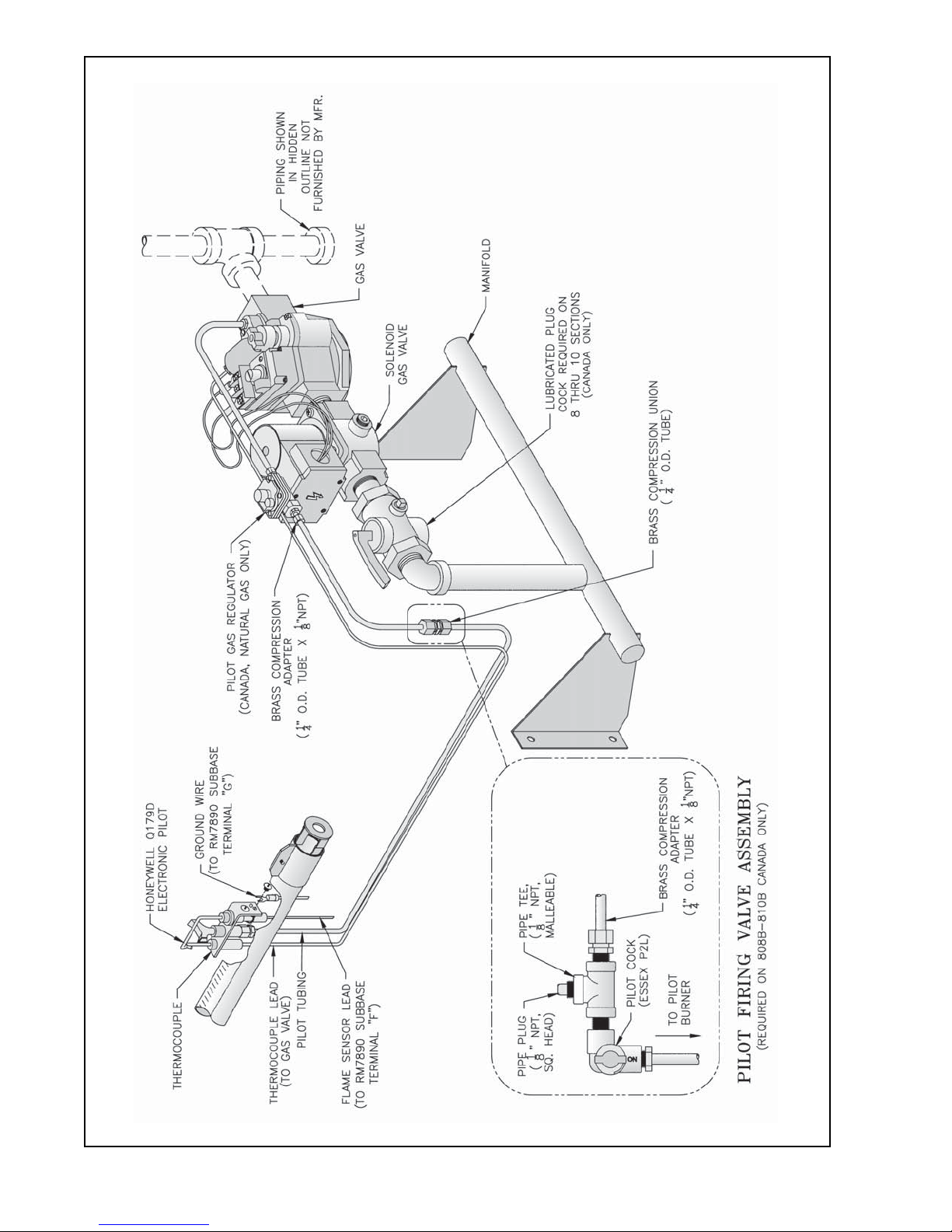

C. OP Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 16. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls. See Figure

16.

3. Connect Thermocouple Lead to Gas Valve.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

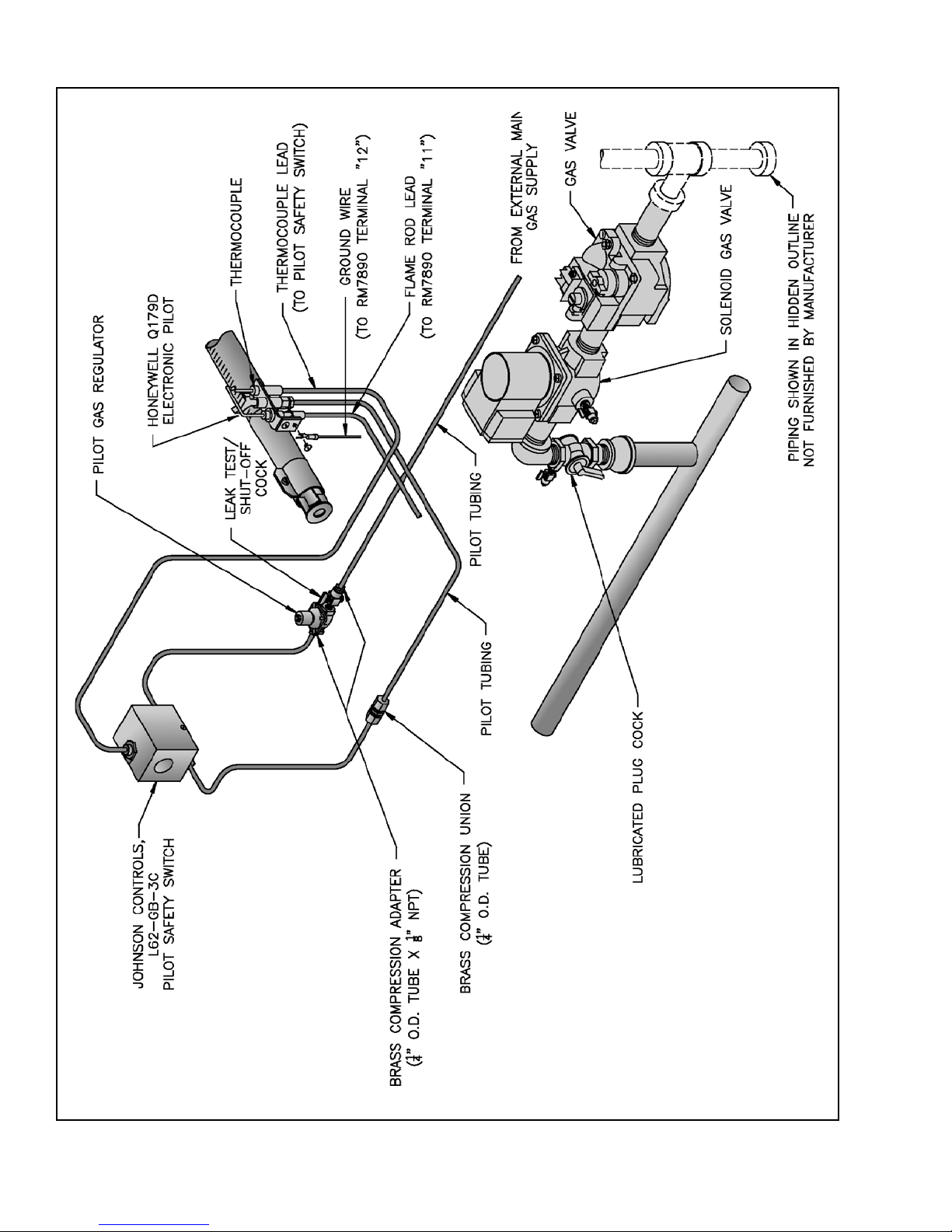

D. OP-CSD-1 Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 17. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Mount pilot switch.

3. Install pilot burner piping and controls. See Figure

17.

4. Connect Thermocouple lead to pilot switch.

5. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

6. Attach transformer/control center to junction box.

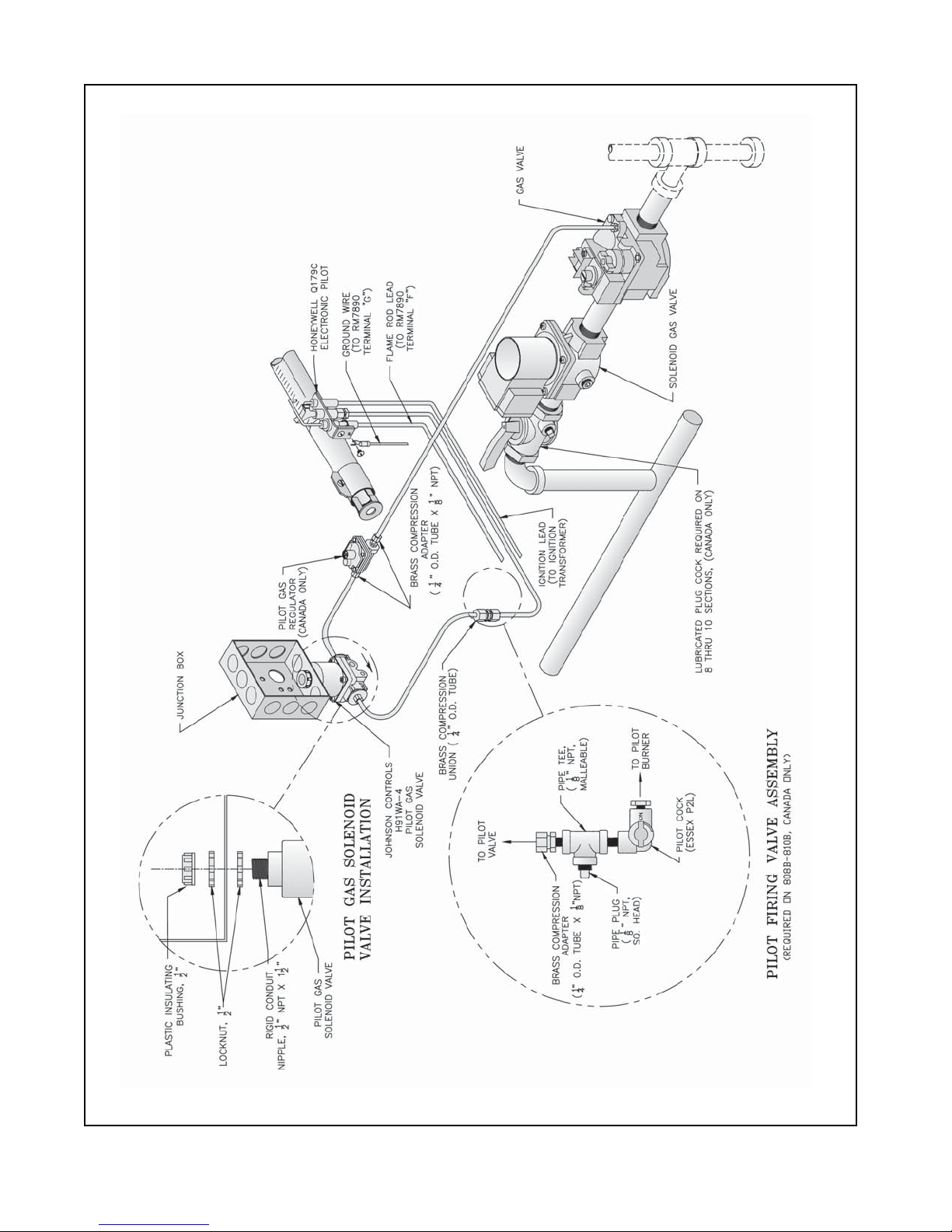

E. EP Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 18.

2. Install pilot burner piping and controls. See Figure

18.

3. Install Ignition Transformer.

a. Attach Ignition Transformer to Jacket Vestibule

Panel using four (4) #8 x ½" lg. sheet metal

screws.

b. Connect Ignition Lead from Pilot to Ignition

Transformer.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

15

b. Attach transformer/control center to junction

box.

Panel using four (4) #8 x ½" lg. sheet metal

screws.

F. EP-CSD-1 Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 19.

2. Install pilot burner piping and controls. See Figure

19.

3. Install Ignition Transformer.

a. Attach Ignition Transformer to Jacket Vestibule

b. Connect Ignition Lead from Pilot to Ignition

Transformer.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

16

Figure 10: Schematic Gas Piping, 24V Standing Pilot, 806B & 807B

17

Figure 11: Main Gas Piping, Intermittent Ignition (EI)

18

Figure 12: Schematic Pilot Piping (Honeywell EI), USA

19

Figure 13: Schematic Pilot Piping (Honeywell EI)

Canada: Natural Gas, 805B - 810B; LP Gas, 806B - 807B

20

Figure 14: Schematic Pilot Piping (Johnson EI), USA

21

Figure 15: Schematic Pilot Piping (Johnson EI)

Canada: Natural Gas, 805B - 810B; LP Gas, 806B - 807B

22

Figure 16: Schematic Gas Piping, OP Control System, 806B - 810B

23

Figure 17: Schematic Gas Piping, OP-CSD-1 Control System, 808B - 810B

24

Figure 18: Schematic Gas Piping, EP Control System (Natural Gas Only), 806B - 810B

25

Figure 19: Schematic Gas Piping, EP-CSD-1 Control System, 808B - 810B

26

IV. Water Trim and Piping

.erutcurts

.retawfonoitidda

GNINRAW

roreliobotegamaddnanoitareporeporpminitluseryamreliobepipylreporpoteruliaF

reliobleetsdnanorifonoisorrocesuaclliwretawreliobfonoitanimatnocnegyxO

smelborprevoctonseodytnarraWs'mahnruB.eruliafreliobotdaelnacdna,stnenopmoc

tneuqerfybdesuacpu-dliub)emil(elacsroretawreliobfonoitanimatnocnegyxoybdesuac

A. Design and install boiler and system piping to prevent

oxygen contamination of boiler water and frequent water

additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fittings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fittings which allow

oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

f. Use properly designed and operating air

elimination devices in water piping.

B. Design system to obtain a 20°F temperature rise through

the boiler (see Table 4). If a temperature rise greater

than 40°F is desired, consult Burnham.

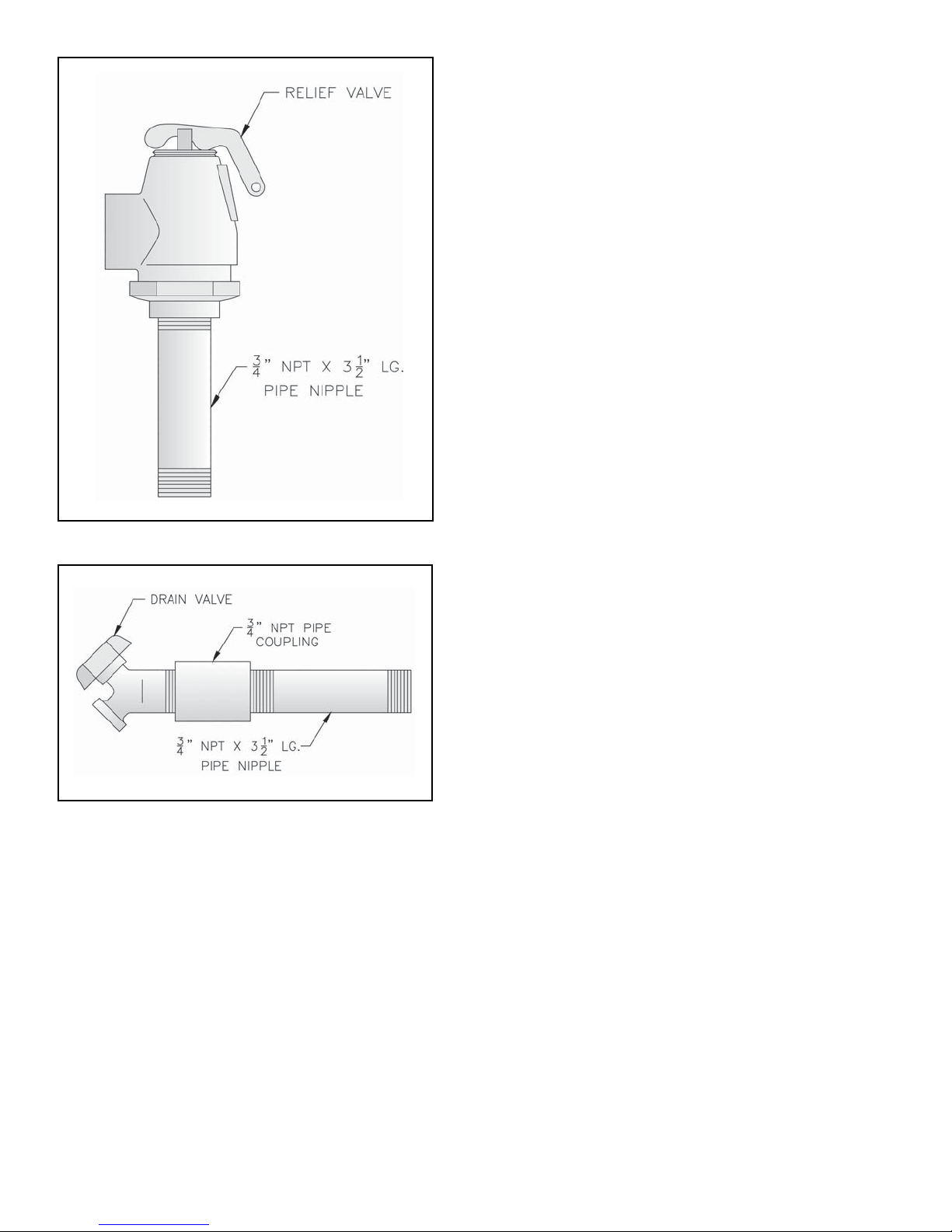

C. Install Safety Relief Valve. See Figure 20. Components

are located in Water Trim Carton. Safety Relief Valve

must be installed with spindle in vertical position.

1. Install ¾" NPT x 3½" lg. nipple in tapping "C". See

Figure 3.

2. Install safety relief valve on ¾" NPT nipple.

GNINRAW

.tnemegnarragnipip

Table 4: Flow Rate, Temperature Rise, and

Pressure Drop

RELIOB

EZIS

B508

B608

B708

B808

B908

B018

WOLF

ETAR

)MPG(

12

41

01

62

71

31

13

12

51

73

42

81

24

82

12

74

13

32

.PMET

ESIR

URHT

RELIOB

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

.NIM

RELIOB

GNIPIP

)TPN(

"½1

"¼1

"¼1

"½1

"½1

"¼1

"2

"½1

"¼1

"2

"½1

"½1

"2

"2

"½1

"2

"2

"½1

tsumgnipipegrahcsidevlavfeilererusserP

erevesfolaitnetopehttahthcusdepipeb

ynaniepipTONOD.detanimilesisnrub

TONOD.ruccodluocgnizeerferehwaera

.spacrosgulp,sevlavffotuhsynallatsni

egrahcsidreporprofsedoClacoLtlusnoC

RELIOB

ERUSSERP

PORD

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

27

Figure 20: Safety Relief Valve Installation

Figure 21: Drain Piping Installation

b. Insert Temperature-Pressure Gauge. Tighten by

applying pressure to square shank on back of

gauge. DO NOT APPLY PRESSURE ON GAUGE

CASE since this may ruin gauge calibration.

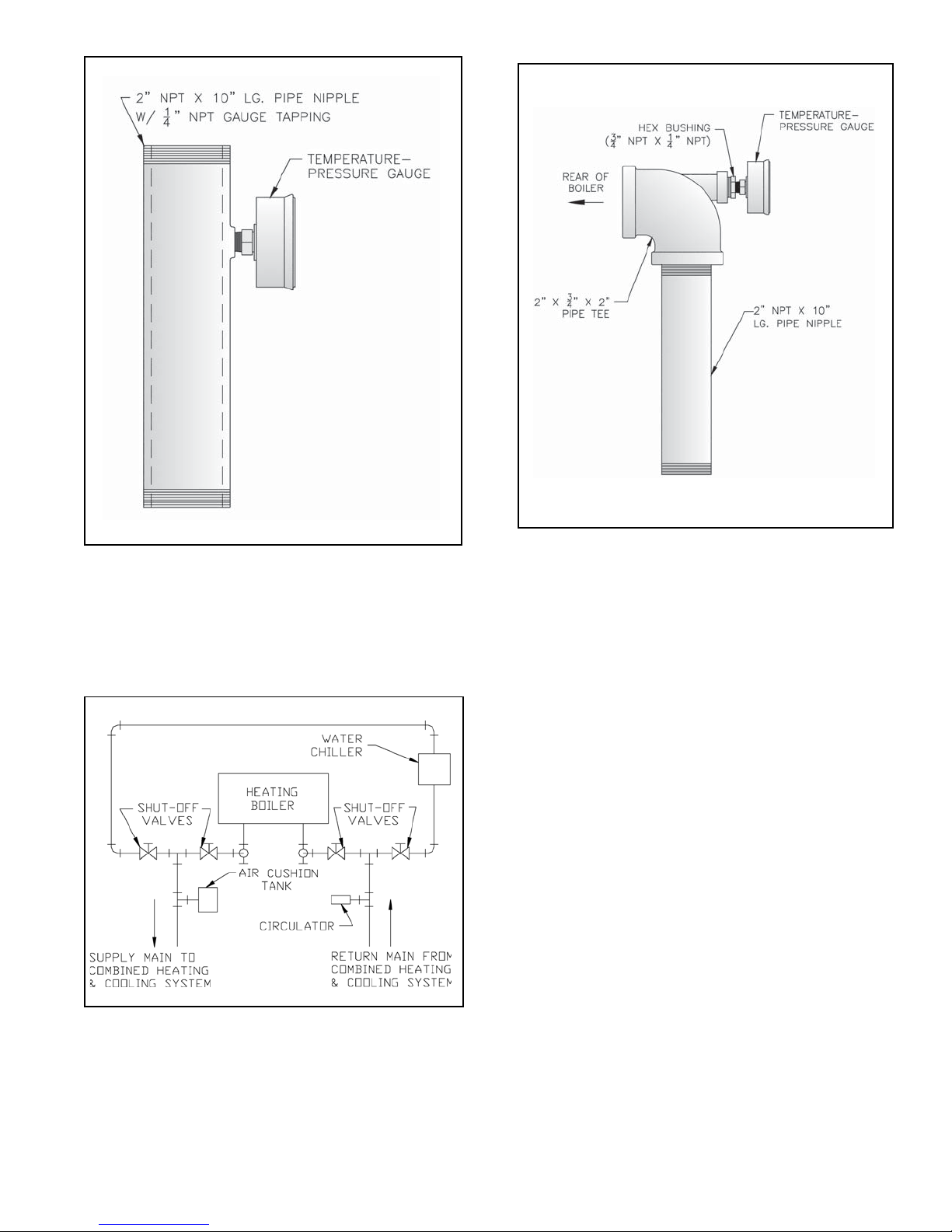

2. Alternate Temperature-Pressure Gauge Piping. See

Figure 23.

a. Install 2 NPT x 10" Nipple into Supply Tapping

"A". See Figure 3.

b. Install 2 NPT x ¾ NPT x 2 NPT Tee (provided) or

2 NPT x 2 NPT x ¾ NPT Tee (installer furnished).

¾" NPT leg should face forward.

c. Install ¾ NPT x ¼ NPT Bushing.

d. Insert Temperature-Pressure Gauge. Tighten by

applying pressure to square shank on back of

gauge. DO NOT APPLY PRESSURE ON GAUGE

CASE since this may ruin gauge calibration.

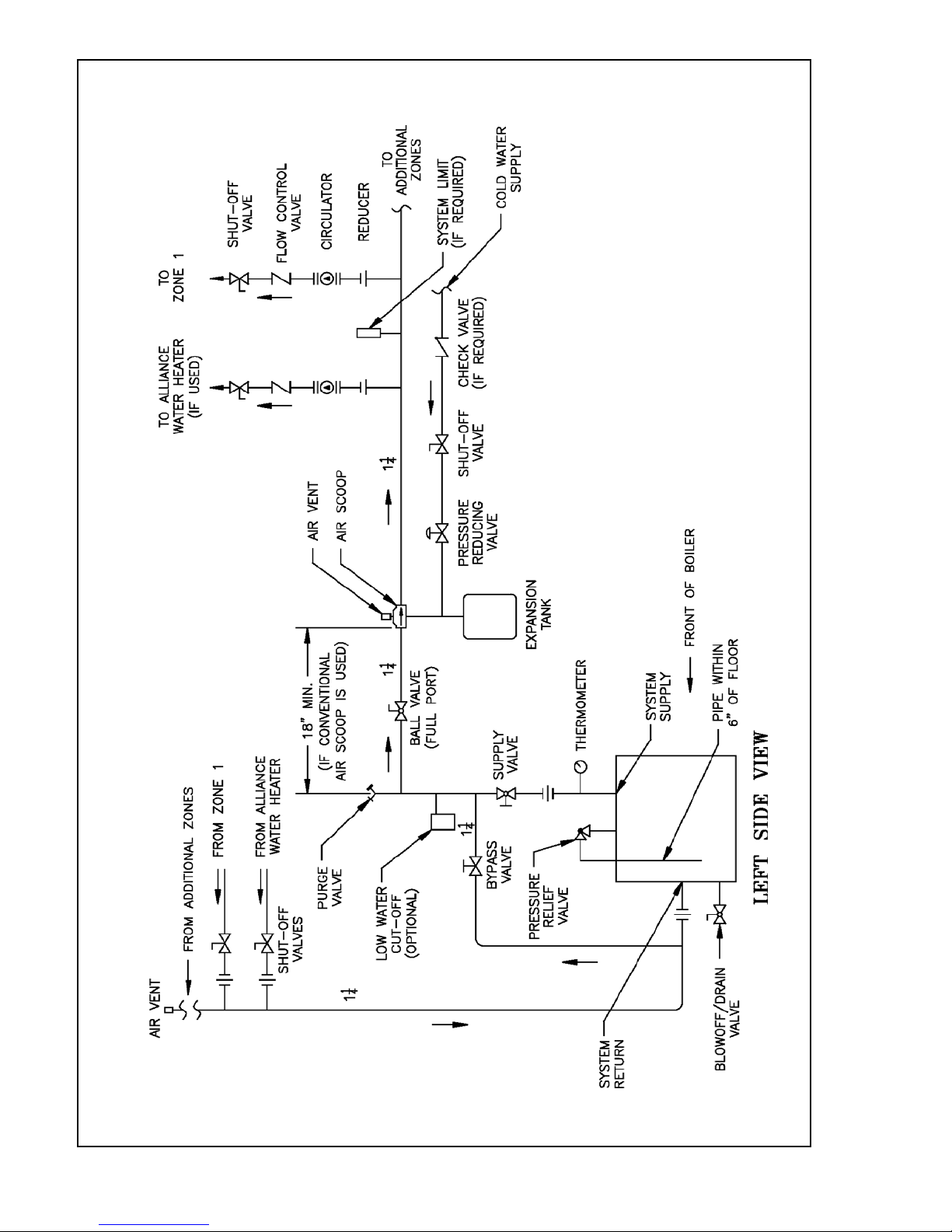

F. Connect system supply and return piping to boiler. See

Figure 25. Also consult I=B=R Installation and Piping

Guides. Maintain minimum ½ inch clearance from hot

water piping to combustible materials.

1. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled medium

piped in parallel with heating boiler using

appropriate valves to prevent chilled medium from

entering boiler. See Figure 24. Also consult I=B=R

Installation and Piping Guides.

2. If boiler is connected to heating coils located in air

handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

flow control valves to prevent gravity circulation of

boiler water during cooling system operation.

3. Use boiler bypass if boiler is operated in system

which has a large volume or excessive radiation

where low boiler water temperatures may be

encountered (i.e. converted gravity circulation

system, etc.). See Figure 25.

4. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of installation.

D. Install Drain Valve in rear of Left End Section, Tapping

"G". See Figure 21. Components are located in Water

Trim Carton.

E. Install Temperature-Pressure Gauge. Components are

located in Water Trim Carton.

1. Standard Temperature - Pressure Gauge Piping. See

Figure 22.

a. Install 2" NPT x 10" lg. nipple with gauge tapping

into Supply Tapping "A". See Figure 3. Gauge

tapping should face forward.

5. A start-up strainer is recommended for practically all

modular installations (new and replacement alike) to

prevent system debris and sediment from ending up

in the boilers where it will inhibit heat transfer and

may eventually cause a cast iron section to crack

from overheating.

G. Alliance Water Heater (if used). Refer to Alliance

Installation, Operating and Service Instructions for

additional information. Install in same manner as space

heating zone.

28

Figure 22: Temperature-Pressure Gauge

Installation

Figure 23: Alternate Temperature-Pressure

Gauge Installation

Figure 24: Recommended Piping for Combination

Heating & Cooling (Refrigeration) System

29

Figure 25: Recommended Boiler Piping for Circulator Zoned Heating Systems

30

Loading...

Loading...